Page 1

Installation, Operation, and Maintenance

Breaking the Barriers

Flowserve TX2

Triple Offset Butterfly Valves

FCD-DVENIM0400-00

Page 2

Flow Control Division

TABLE OF CONTENTS

SECTION

TITLE

PAGE

FOREWORD

2

I

THEORY OF OPERATION

3

II

PRELIMINARY PRECAUTIONS

3

III

INSPECTION

4

IV

TOOL REQUIREMENT

4

V

STORAGE

5

VI

INSTALLATION

5

VII

STEPS OF INSTALLATION

5

VIII

FLANGE CONNECTING AND BOLTING

7

IX

REMOVAL PROCEDURE

8

X

LUBRICATION SCHEDULE

8

XI

STUFFING BOX MAINTENANCE PROCEDURE

8

XII

CHANGE OF DISC AND BODY SEAT

11

XIII

CHANGE OF GASKET

14

XIV

ASSEMBLY AND DISASSEMBLY

14

XV

PARTS AND SERVICE

16

XVI

TROUBLESHOOTING GUIDE

17

XVII

CAUTIONS

18

XVIII

PARTS LIST AND MARKINGS

21

FOREWORD

Flowserve Corporation, Flow Control Division, has established this Installation, Operating and

maintenance Manual to facilitate field installation, operation and repair of Flowserve TX2 Triple

Offset Butterfly Valves

It is recommended that questions or concerns involving the processes described in this manual be

directed to the local Sales Representative of Flowserve Corporation. Only Flowserve

replacement repair parts should be used. Part numbers referenced in the following sections are

available from Flowserve Corporation, Flow Control Division.

2

Page 3

Flow Control Division

Preferred

direction of flow

SECTION I

THEORY OF OPERATION

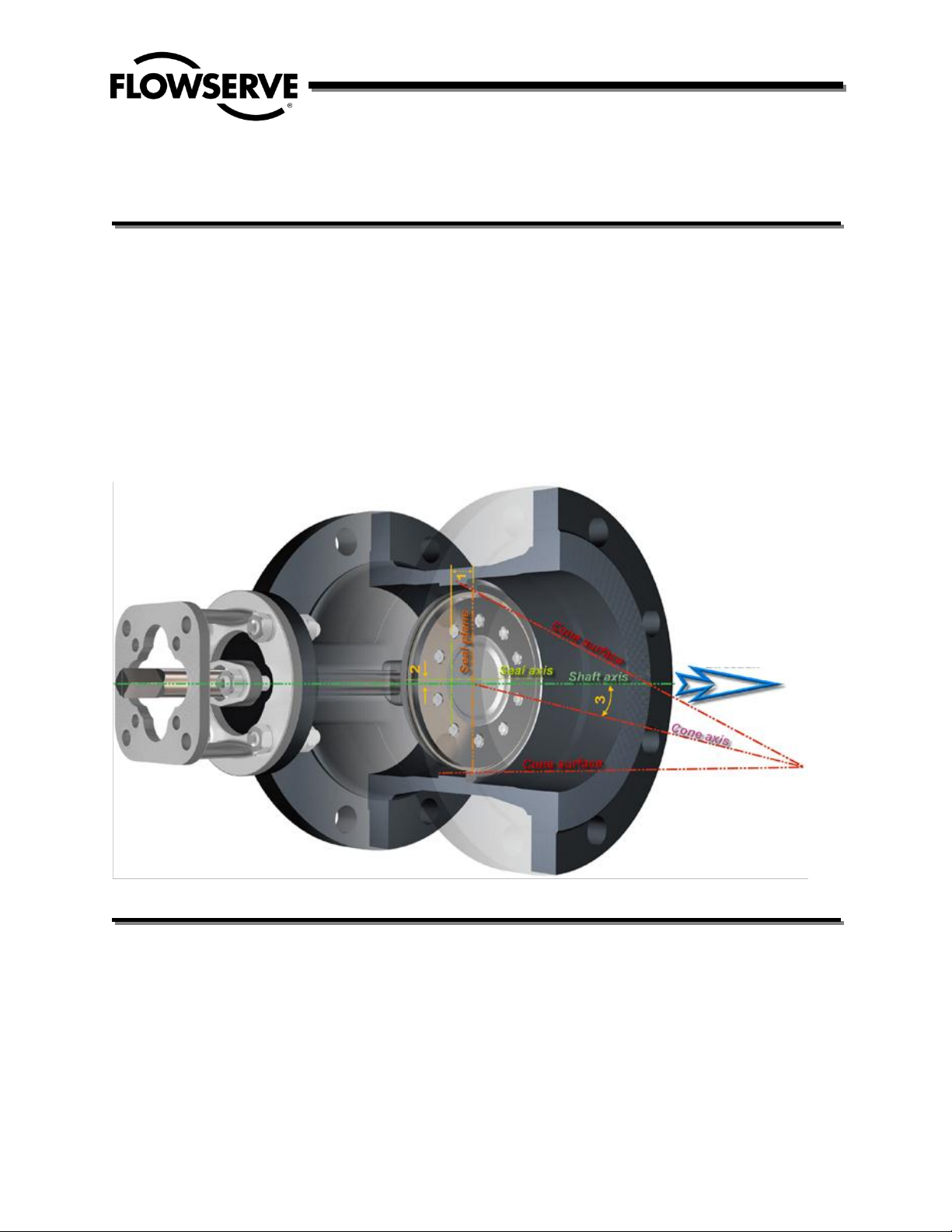

The valve design is based on a double eccentric geometry of the disc rotating center, utilizing a floating

radius machined seal ring, in conjunction with an inclined cone seating surface of body. This design

makes the disc cam back and away from body seat, eliminating wear between the seat and seal ring. It

also compensates for deviations of the geometry caused by temperature or tolerance changes. (Fig. 1)

The disc seal of valve deflects from its regularly circular shape to an elliptic form when it reaches the

closed position. This matches the inclined cone of body seat geometry, creating the sealing between disc

seal and body seat. Dimension changes due to temperature fluctuations cause the seal ring to adjust its

seating position within the inclined cone geometry, thus maintaining a positive seal as usual.

Due to the unique conical surface of the valve, there is a “preferred” and “non-preferred” flow direction.

The preferred flow direction would be with the shaft upstream and the direction is marked on the body

with a directional arrow. The shaft side is referred to as the high pressure side of the valve.

SECTION II

PRELIMINARY PRECAUTIONS

FOR SAFETY, FOLLOW THESE CAUTIONS BEFORE INSTALLING, REMOVING OR

DISASSEMBLING YOUR VALVE.

1. MUST KNOW WHAT MEDIA IS IN THE PIPELINE.

2. MAKE SURE THE LINE IS DEPRESSURIZED.

3. USE PROTECTIVE CLOTHING AND EQUIPMENT TO AVOID INJURY. KEEP HANDS AND

OTHER BODY PARTS OUT OF THE VALVE.

4. ALWAYS ENSURE THE VALVE IS IN THE FULLY CLOSED POSITION BEFORE

INSTALLATION, REMOVAL OR DISASSEMBLY.

5. ENSURE THAT FLANGE FACES ARE CLEAN BEFORE INSTALLATION IN PIPELINE.

3

Page 4

Fig. 2

SECTION III

INSPECTION

1. Before installation of the valve into the piping system, visually inspect the valve to determine

if any damage has occurred during shipping. Particularly, inspect the actuator, shaft, valve

interior, valve body and flanges. For proper operation of the valves, the seat and disc seal

must be undamaged and free of foreign material. If other than superficial damage is

discovered, contact Flowserve immediately, indicating the location and extent of the damage

found.

2. If it is necessary to clean the valve, use a soft cloth and mineral spirits, or an equivalent

solvent. All rust preventive should be removed before installing your valve.

SECTION IV

TOOL REQUIREMENT

Flow Control Division

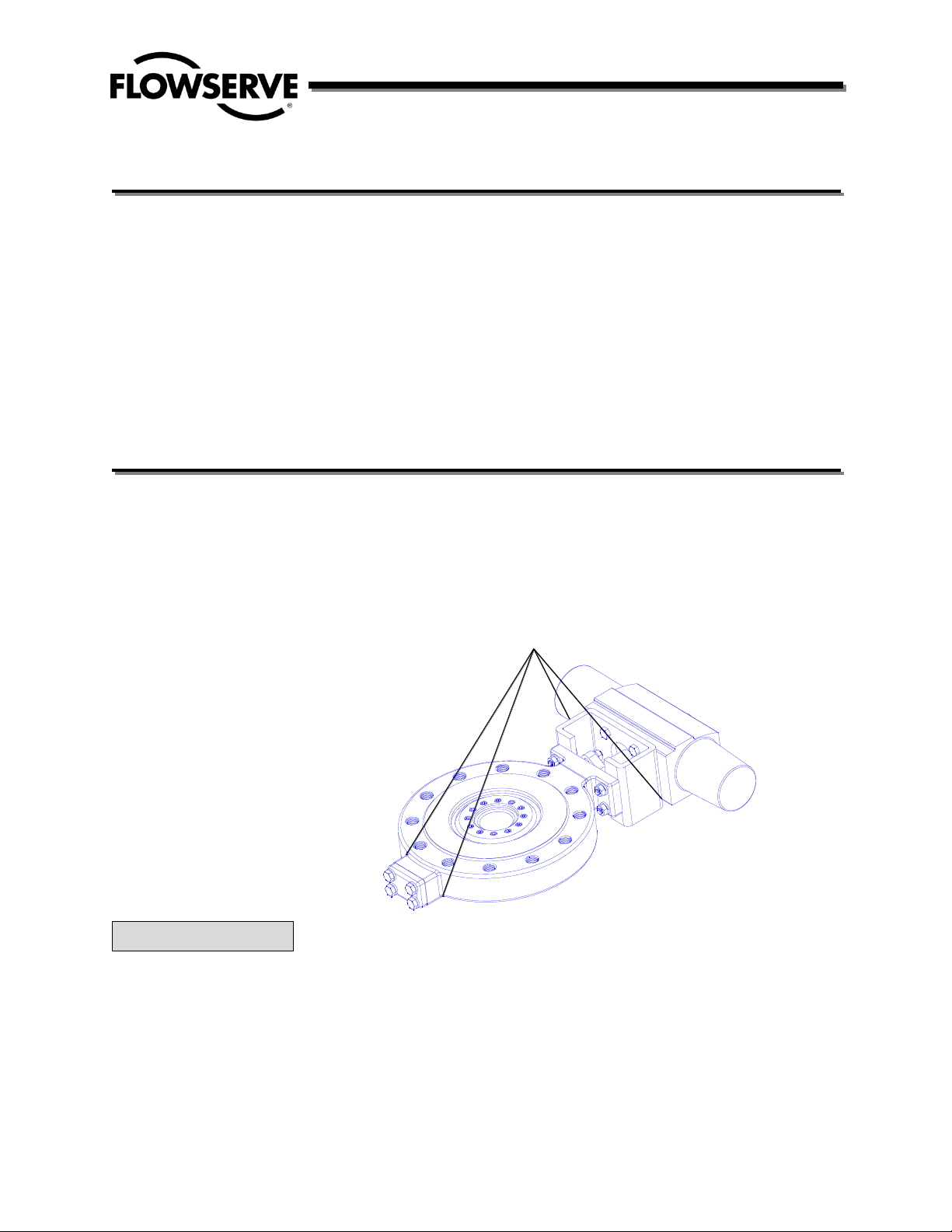

There are no special tools required for installation and maintenance that are not commercially available.

Any lifting devices used to move the valve into a desired position shall be of sufficient size to support the

weight of the valve and actuator assembly. Nylon slings secured around the valve bearing areas are

recommended to reduce the possibility of mechanical damage occurring to the valve body and actuator.

The assembly should never be lifted by the actuator. (Fig.2)

WARNING

NEVER pass a lifting device through the valve port or severe damage may

occur.

4

Page 5

Flow Control Division

Fig 3

Fig 4

SECTION V

STORAGE

When the valve is not put into immediate service, it is required that the valve be stored in a heated building that is

fire resistant, weather tight and well ventilated. Storage area shall be situated and constructed so that it will not be

subject to flooding or the presence of any corrosive chemicals. Flowserve recommends that all valve actuators be

cycled approximately every 60 days or as required by the manufacturer of the actuation system. Any spare parts for

the valve shall be stored in the original packaging and under the same conditions as the valve will be stored. For

storage greater than 4 months, the storage container should be inspected every four (4) months to ensure it is in good

condition, and any additional protective coverings or materials are in working order. Ensure all parts are plugged,

and bare metal is covered with a suitable rust inhibitor.

SECTION VI

INSTALLATION

The valve must be installed so that pipeline stresses are not transmitted to the valve body. Despite its solid

manufacture, such stress may affect valve operation. If pipeline stresses are severe, they should be cushioned by

expansion joints or compensators. If supports are necessary for the valve, they should only support the dead weight

of the valve and should not serve as base points for the pipeline.

SECTION VII

STEPS OF INSTALLATION

7.1. All valve s must be in full closed position during installation or removal. It is not necessary to torque

seat the valve, but the disc travel must be restricted to prevent damage.

7.2. Please be sure there is no foreign material and that it is clean inside of the pipe and valve.

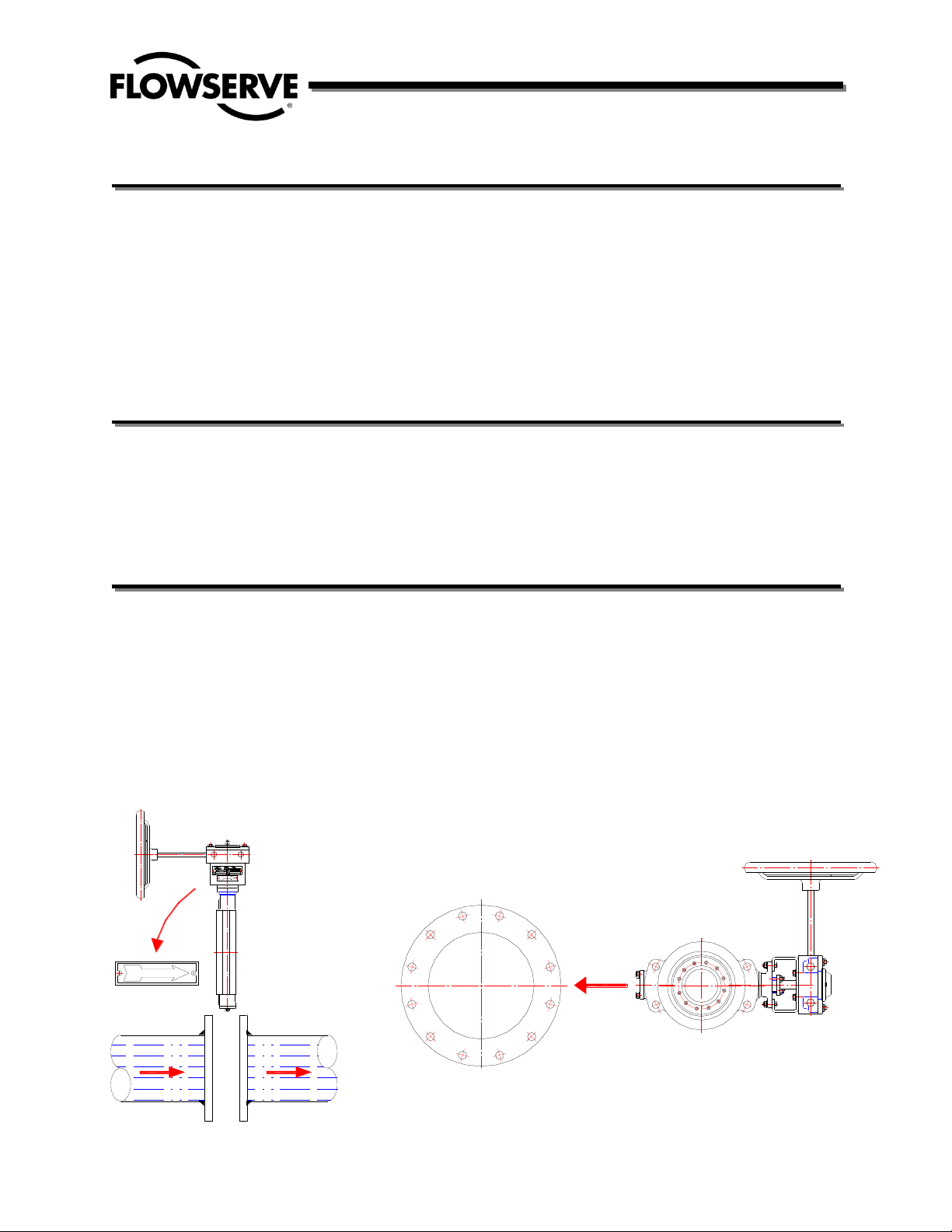

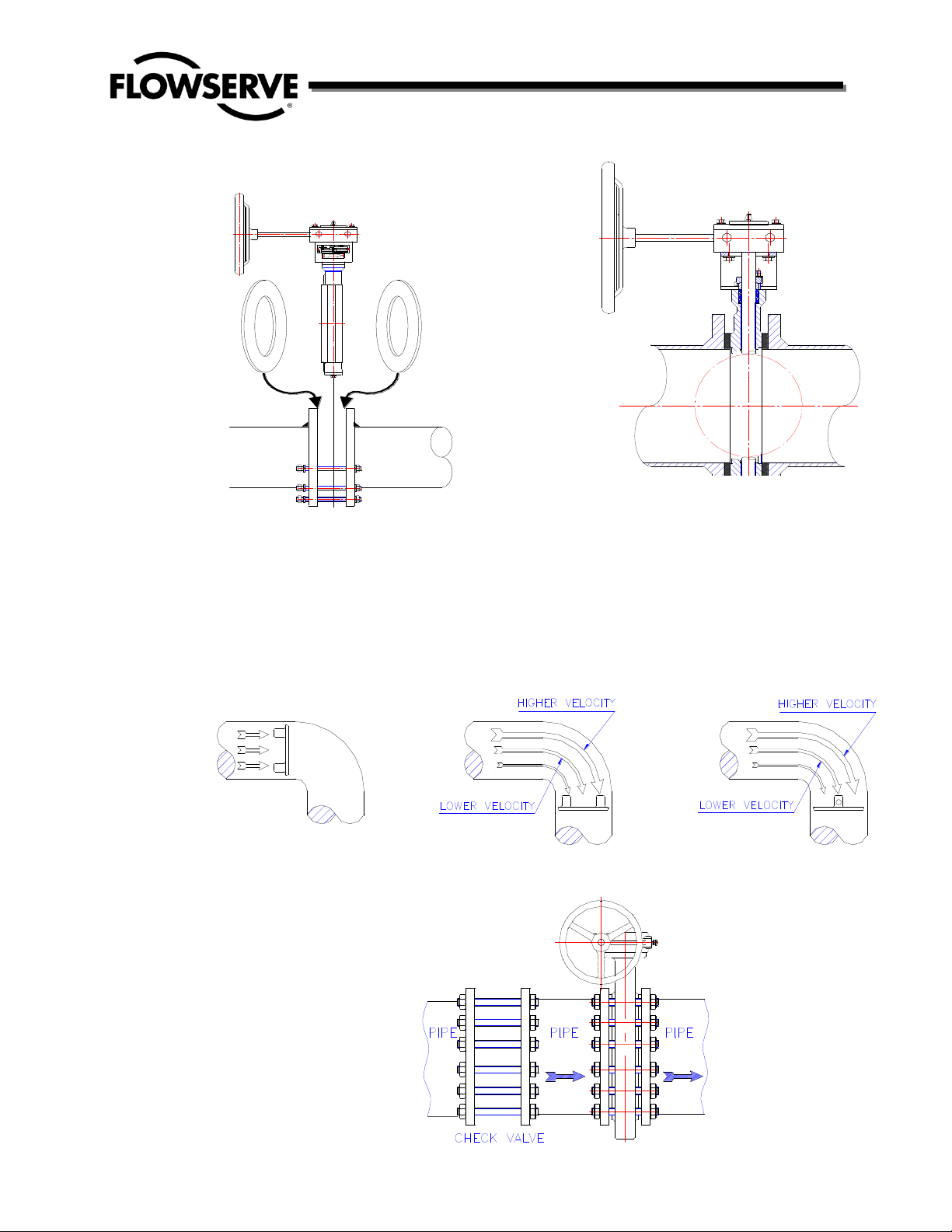

7.3. The shaft side of the disc is considered the high-pressure side of the valve, (as indicated on the

drawings by a flow arrow) meaning the best closure performance is obtained on this side of the valve, and a

determination as to the best installation should be made, to utilize this feature. This may not necessarily be

the normal flow direction of the system. (Fig.3).

7.4. Please install the valve stem horizontally as (Fig.4), thus could prevent sand and some chips from

collecting around bottom bushing and seat. Such reside could damage the valve.

Fog 4

Fig 4

5

Page 6

Fig 6

4.5. Install valve and gaskets into pipeline as (Fig.5).

Flow Control Division

Fig 5

4.6. Make sure that the valve is installed concentrically between the flanges in order to could

prevent the disc from being damaged by interference with the flange and pipeline (Fig.6)

4.7. The typical installation for a butterfly valve connected to an elbow would be to align the

shaft axis to allow equal flow on each side of the shaft, minimizing dynamic torque requirements

for the valve. (Fig.7)

Excellent Good Not recommended

Fig 7

4.8. Always use an extension tube between wafer check valve and butterfly valve. Never

connect them directly. (Fig.8)

Fig 8

6

Page 7

Flow Control Division

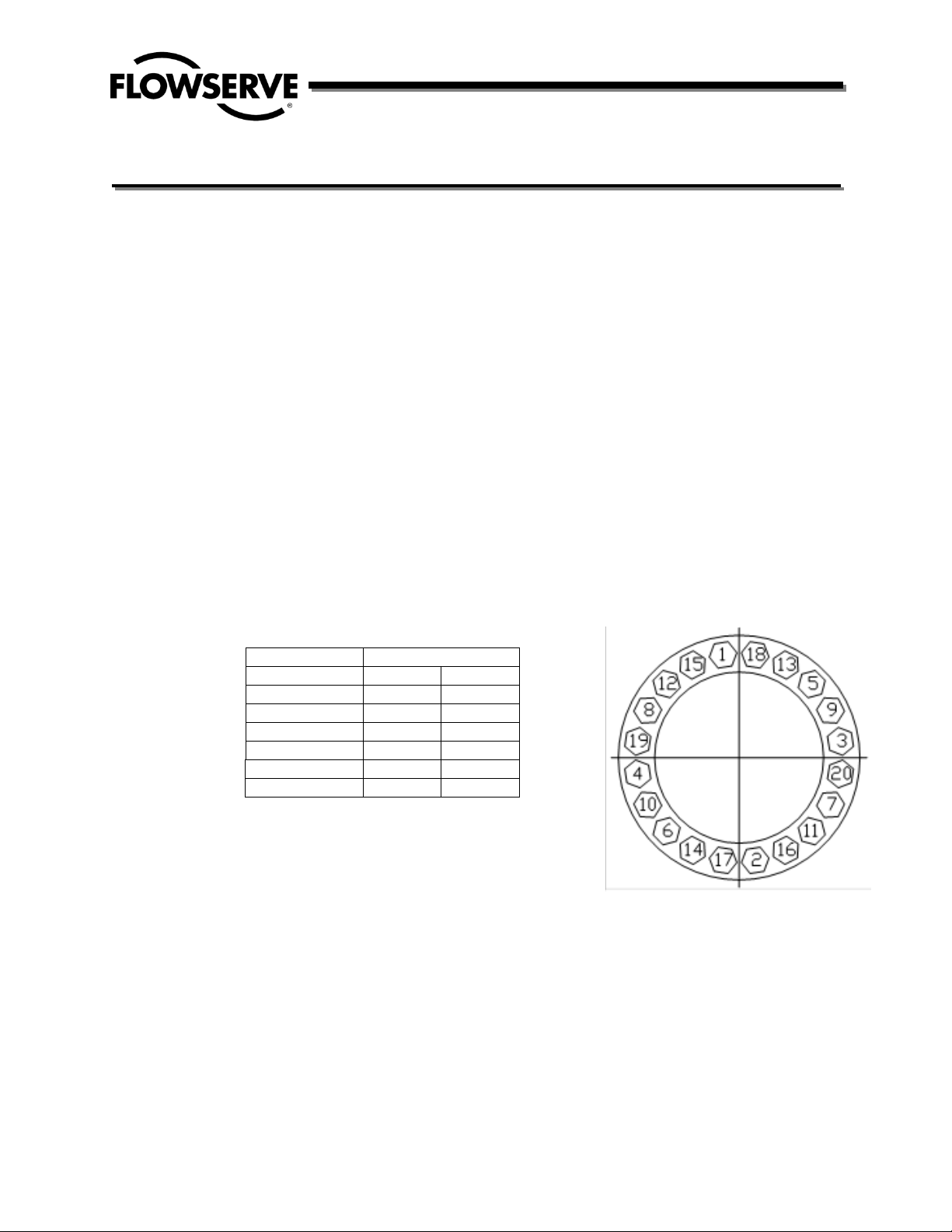

Bolt size

Torque

(ft-lb)

(Nm)

5/8” (M16)

110

150

3/4” (M20)

200

270

7/8” (M22)

320

434

1” (M26)

480

650

1-1/8”(M28)

600

815

1-1/4”(M32)

840

1140

SECTION VIII

FLANGE CONNECTING & BOLTING

8.1. Keep valve protection boards until installation.

8.2. Make sure the material and size of gaskets could be suitable for the service. Ensure that the faces of flange and

valve are smooth and flat. Sandpaper the faces if there are any defects.

8.3. Check that all the bolts and nuts are in good condition.

8.4. Apply lubricant such as Molybdenum to all the bolts and nuts before fixing them.

8.5. The pipe support(s) may now be required to be partially disengaged. A determination as to pipe flange

alignment and space between the pipe flange and the valve face must be made at this time. The optimum spacing

would be such as to only allow the flange gasket to be installed, at the maximum, and the flange bolt holes would be

concentric.

8.6. The opposite connecting pipe flange face may not be more than 1/4 inch away from the valve flange face.

Alternate methods of alignment, other than using the flange bolts, must be utilized to conform with this requirement.

8.7. Install all studs, maintaining uniform clearance between the studs and the mating bolt holes. Additionally the

studs spanning the valve assembly should not contact the valve body.

8.8. Seat the flange by alternate tightening of four equally-spaced flange bolts no more than 1/4 turn per bolt, until

the flange faces seat. During this operation, it is advisable to continually check the relative distance between the

flange faces. Torque the bolts to approximately 25% of the final torque value (see table 1).

8.9. Inspect the remaining bolts and assure correct alignment. Tighten to the same level as the first four bolts.

8.10. Complete the tightening of all flange bolting in a minimum of four increments to the final determined torque

value.

8.11. Test cycle the valve to be sure that there is no interference or binding.

12. Maximum Torque of Flange Bolt

Table 1.

※Actual torque shall depend on gasket

type, consult gasket manufacturer.

BOLT TIGHTENING SEQUENCE (Fig.9)

7

Page 8

Flow Control Division

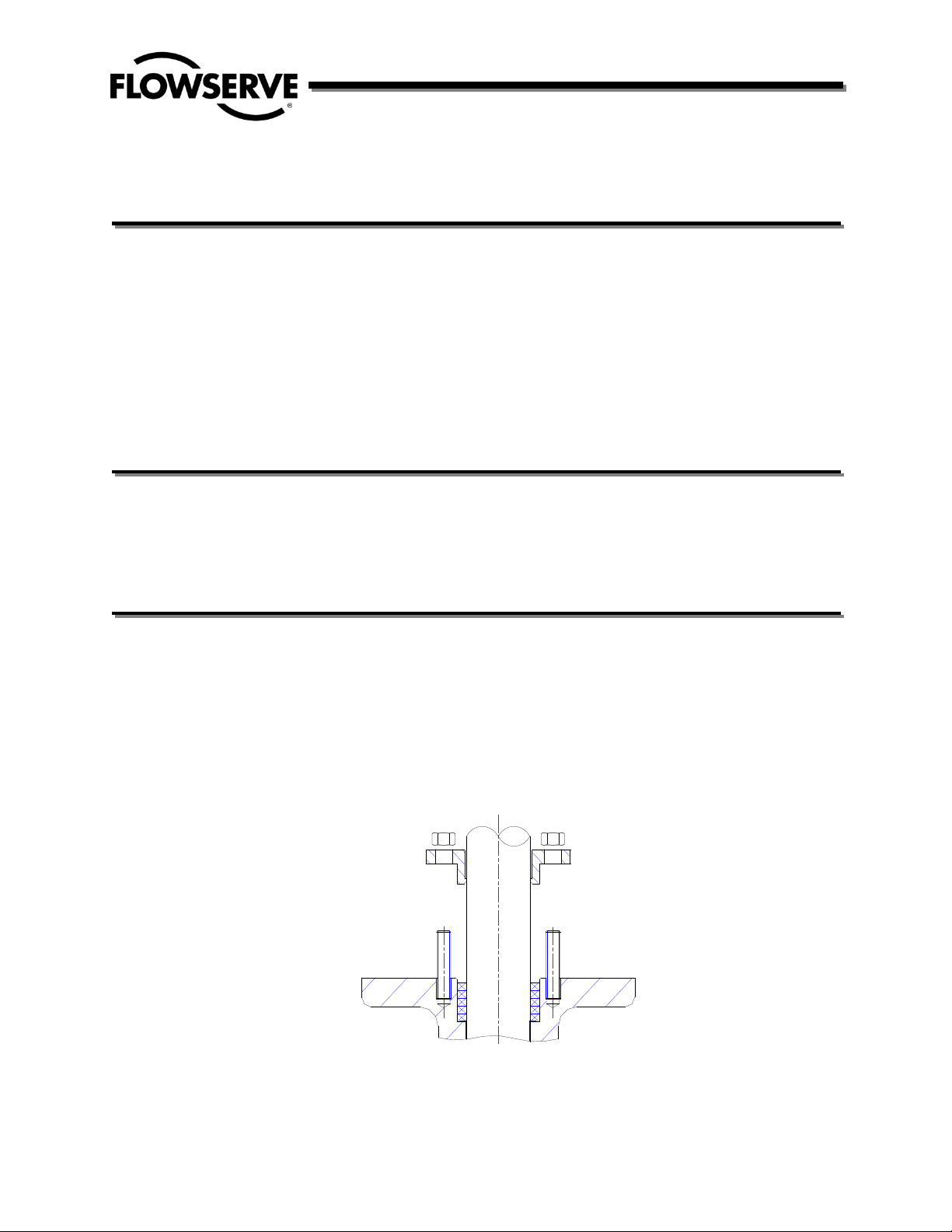

Fig 10

SECTION IX

REMOVAL PROCEDURE

To remove your valve from the pipeline, please follow these simple steps:

Ensure that the valve is in the closed position.

Ensure that the line is depressurized.

Use protective clothing and equipment to prevent injury.

If your valve is equipped with a fail-open actuator, manually close the valve or disconnect the actuator then close

the valve before removal.

Attach nylon slings to the body shoulders of the valve and around the body of the actuator.

Remove the bolts holding the valve to the pipeline flanges.

SECTION X

LUBRICATION SCHEDULE

Flowserverecommends that your valve be inspected at least every three months to determine lubrication and other

maintenance requirements dependign upon your specific service conditions.

SECTION XI

STUFFING BOX MAINTENANCE PROCEDURE

Routine maintenance of the stuffing box consists of tightening the packing gland periodically. If leakage around the

stuffing box is discovered, first tighten the hex-nuts on the gland follower (more than 2/3 compression) as this may

reduce packing life. If the leakage still persists, replace the packing according to the following procedure. (For

clarity, the actuator and bracket are not shown in the following diagrams. It is not necessary to remove the actuator

or bracket before performing this procedure).

11.1 In order to gain access to the packing, remove the gland follower and slide it up to the actuator. See the diagram

below:

8

Page 9

Flow Control Division

11.2 Remove all of the packing in the stuffing box using a flexible screw hook. For stuffing boxes that

contain a lantern ring, use a puller with 10-32 threads to remove the lantern ring. Save the lantern ring for

reuse, but discard the other packing material. Please replace all the gland packing no matter the gland

packing is made of Graphite. (Fig.11)

Fig.11

11.3 Inspect the drive shaft, bore of the stuffing box, and the gland follower. These surfaces should be relatively

scratch free. If there is any damage, polish the surface to 32 rms finish (Fig.13). If any part has severe damage,

contact your Flowserve representative..

Fig.13

9

Page 10

Flow Control Division

Graphite Packing

Screw Size

Max. Torque

M8

110

Kg-cm

M10

120

Kg-cm

M12

140

Kg-cm

M16

450

Kg-cm

M20

650

Kg-cm

11.4 Install each new ring of packing, use the gland

follower to push each ring of packing evenly into

position after starting it in the stuffing box bore.

Stagger the splice-joints of each packing ring so they

are as far as possible from each other (see example

above). Usually, rotating each ring until the splice is

at 90° from the previous splice is sufficient. (Fig.14)

Fig 14

11.5 Install the gland follower and tighten it to firmly seat the packing. DO NOT compress the gland follower too

much. Over-tightening may dramatically reduce the life of the packing and may make it more difficult to operate the

valve. The maximum torque of the gland screw as below,

10

Page 11

Flow Control Division

Fig 15

SECTION XII

CHANGE OF DISC AND BODY SEAT

12.1 To facilitate reassembly, mark the positon of the operator, yoke and body mounting flange

before disassembling (Fig. 15)

12.2 For reassembly, make a mark on the retainer and disc before disassembling.

12.3 Turn the stem counterclockwise around 180° (Fig. 16in order to make it easier to loosen and remove the bolts

and take off the retainer, gasket and disc seat.

Fig.16

12.4 Loosen all bolts from the retainer by hexagonal wrench.

12.5 Take off the retainer, disc seat and gasket (seal-3) in sequence.

12.6 The replacement of body seat is available for Class 300 and 600 valves Class 150 valve bodies

have a one piece design.

12.7 To make a mark for reassemble on the body and body seat before replacing the body seat.

11

Page 12

SEAL-4

The inclined side of body

seat on the right side

The straight side of

body seat on the left

12.8 Loosen all bolts from body seat by hexagonal wrench.

12.9 Remove the body seat and gasket (seal-4) in sequence.

12.10 Clean the body seat and all components of body, disc and retainer.

12.11 Put a new gasket (seal-4) into the groove of the body seat. (Fig. 17)

Flow Control Division

Fig.17

12.12 Please refer to Fig.18 for assembling the body seat.

Fig.18

12.13 Screw the bolts into the holes of body seat and tighten the bolts in a diagonal sequence

12

Page 13

SEAL-3

The inclined side of

disc seat and

retainer on the right

side

The straight side of

disc seat and

retainer on the left

12.14 Please refer to Fig.19 for putting new gasket (seal-3) into the disc groove.

Flow Control Division

Fig.19

12.15 Please refer to Fig. 20 for assembling the retainer and disc seat. Firstly, put back the bolts

into the holes of retainer and tighten the bolts slightly. After turning the disc clockwise towards

the closing direction, turn around the valve and tighten the bolts in a diagonal sequence.

Fig 20

13

Page 14

Flow Control Division

SEAL-2

SECTION XIII

CHANGE OF GASKET

13.1 Loosen and remove the bolts from the body bottom cover and take off the bottom cover and

gasket (seal-2). (Fig. 21)

13.2 Replace the gasket (seal-2) with a new one, put back the bottom cover and the bolts, and

tighten the bolts in a diagonal sequence.

Fig.21

SECTION XIV

ASSEMBLY AND DISASSEMBLY

14.1 Assembly

14.1.1. Clean all valve components and make sure that they are free of oil, grease and dust.

14.1.2. Inspect all components for damage before starting to assemble. Look especially for

damage to the disc seal ring and body seat surface, and wear in the bearing areas of the body and

drive shaft.

14.1.3. Insert the disc into the body inner diameter, holding it at the open position. The disc is

double eccentric and closes clockwise. Ensure the eccentricities of the disc and body will be in

the same position when closed.

14.1.4. Insert the drive shaft bearing and bottom shaft bearing into the body.

14.1.5. Open the disc nearly 180°. In this position it is possible to assemble the seal o-ring, the

seal ring and the seal ring retainer.

14

Page 15

Flow Control Division

14.1.6. Position the seal o-ring on the disc, then place the seal ring onto the disc with the larger

diameter of the outer radius edge on the side of the disc hub.

14.1.7. Place the seal ring retainer onto the disc. Insert the lock washers and hex-socket cap

screws into the seal ring retainer and lightly tighten them.

14.1.8. Turn the disc clockwise into the closed position, then tighten the hex-socket cap screws

fully.

14.1.9. Insert the packing retainer and packing rings into the drive side packing gland.

14.1.10. Insert the studs into the threaded holes in the drive side packing gland.

14.1.11. Install the packing follower and tighten it into position with the hex nuts. Do not tighten

one hex nut further than the other.

14.1.12. Install the blind flange with gasket and tighten it into position with the hex-socket cap

screws.

14.1.13. The valve is now ready for actuator mounting. The disc is held quite securely in

position, so the actuator may be pushed onto the shaft then moved to the desired fail position.

Please consult the actuator’s literature for further details.

14.2. Disassembly

14.2.1. Place the valve on a bench or other suitable working surface with the drive shaft side of

the valve up. Remove the actuator and actuator bracket from the valve.

14.2.2. Separate the packing follower by removing the hex-nuts from the studs, then remove the

studs.

14.2.3. Remove the packing using a flexible screw-hook.

14.2.4. Remove the packing retainer, being careful not to damage the finish of the packing gland

bore or the drive shaft.

14.2.5. Open disc at 90°, then separate the seal ring retainer, seal ring, and o-ring from the disc.

14.2.6. Close the disc, and support the opposite side of the disc to prevent damage to the shafts

while drilling out the pins.

14.2.7. Pull out the stem and remove the disc from the body. Disassembly is now complete.

15

Page 16

Flow Control Division

TX2 Spare Parts

No.

Name

Remark

Materials

QTY

Select

8

SEAL-2

-

GRAPHITE

1

12

GLAND

PACKING

-

GRAPHITE

1

17

SEAL-3

-

GRAPHITE

1

18

DISC SEAT

Metal Seat

(1)

A182 Gr. F6a

1

A240 Gr. 304

A240 Gr. 316

UNS S32205

INCO 718

Laminated

A240 Gr. 304

1

A240 Gr. 316

UNS S32205

INCO 718

21

SEAL-4

(2)

Class 300 and class

600 only

GRAPHITE

1

22

BODY SEAT

(2)

A240 Gr. 304

1

Class 300 and Class

600 only

A240 Gr. 316

Remark:

1. (18)DISC SEAT: A182 Gr. F6a is only available on valves with solid

metal seats

2. (21)SEAL-4、(22)BODY SEAT are only available for Class 300

and 600; Class 150 BODY SEAT and body is in one piece design.

SECTION XV

PARTS AND SERVICE

15.1. Parts and service kits for most valve components are readily available. For parts or service

information, contact your Flowserve representative, stating the complete data from the valve

identification plate and specify what is required.

16

Page 17

Flow Control Division

16.2

16.3

20

19

17

23

22

21

16.4

SECTION XVI

TROUBLESHOOTING GUIDE

In the event of valve difficulties you may try the following procedures before contacting Flowserve. If your

valve doesn’t operate properly before or after trying these trouble- shooting ideas, you may contact your

Flowserve representative for assistance

.

16.1 LEAKAGE FROM STUFFING BOX

If leakage around the stuffing box is discovered, first tighten the nuts on the gland follower to stop the

leakage. Do not over tighten the gland follower (more than 2/3 compression) as this may reduce packing

life. If the leakage still persists, replace the packing according to the procedure in the “ Stuffing Box

Maintenance Procedure” section.

16.2 LEAKAGE BETWEEN SEAL RING AND SEAT

Inspect Seal Ring for damage or excessive wear. If necessary, the Seal Ring may be lightly hand

polished using wet 400grit sandpaper. If leakage persists, or if not damage is evident, open and close the

valve 4 to 5 times, shutting it TIGHTLY each time. Re-check for leakage. If the valve still leaks in this

area, strike the back of the disc near the perimeter with a lead bar (or similar soft headed instrument to

prevent damaging the disc) to firmly seat the disc. Be sure to apply the force in a direction that will assist

in closing, not opening the disc. If leakage in this area persists, check the Seal Ring for roundness. If the

Seal Ring is out of round greater than its diameter times 1.00 x 10-3 (D x 0.001), orient the seal ring with

the longest dimension perpendicular to the valve shaft, and re-test for leakage. If leakage still preexists,

contact Flowserve for repair. (Fig.22)

16.3. LEAKAGE BETWEEN SEAL RING RETAINER AND SEAL RING (19) OR DISC

Firstly, ensure the bolts of retainer (20) were tightened in a diagonal sequence. If leakage persists, please

disassemble the retainer (19) and inspect the gasket (17). If found to be damaged, please replace the

gasket. (Fig. 22)

Fig.22

16.4. LEAKAGE BETWEEN BODY SEAT AND BODY (LOCKED DESIGN).

Firstly, ensure the bolts of body seat (22) were tightened in a diagonal sequence. If leakage persists, please

disassemble the body seat (23) and inspect the gasket (21). If found the damage, please replace the gasket. (Fig. 22)

17

Page 18

Flow Control Division

X

SECTION XVII

CAUTIONS

17.1. Application:

17.1.1. The valves are not suitable for a flows containing metal chips, which could hurt the valve seats.

17.1.2. Be sure the valve materials are suitable for the process fluid, especially if the fluid is corrosive.

17.1.3. Be sure the valves are suitable for the pressure and temperature ratings of the connecting

flanges.

17.1.4. The valve service temperature range:-196 ~ 760℃. (-321~1400°F)

17.1.5. Maximum working pressure can not be higher than the design pressure of the valve.

17.2. Installation:

17.2.1 You must know what media is in the pipeline.

17.2.2 Make sure the line is depressurized.

17.2.3 Be sure the Arrow direction of the valve follows the flow direction of the process flow.

17.2.4 Use protective clothing and equipment to avoid injury. Keep hands and other body parts out of the

valve.

17.2.5. ALWAYS ENSURE THE VALVE IS IN THE FULLY CLOSED POSITION BEFORE

INSTALLATION, REMOVAL OR DISASSEMBLY.

17.2.6. Before installation of the valve into the piping system visually inspect the valve to determine if any

damage has occurred during shipping. Particularly, inspect the actuator, shaft, valve interior, valve body

and flanges. For proper operation of the valves, the seat and disc seal must be undamaged. If other than

superficial damage is discovered, contact Flowserve. immediately, indicating the location and extent of

the damage found.

17.2.7 When re-installing a valve, a new gasket should always be used. .

17.2.8 After installing the valve in the pipeline, check leakage of flange connecting faces by using

compressed air. (Fig.27)

17.2.9 Make sure the faces of valve, gaskets and flanges are clean before installation.

Fig.27 Fig.28

18

Page 19

Flow Control Division

X

Fig. 30

17.3. On Service:

17.3.1 Do not touch the valve body when it is on service.

17.3.2 Do not loosen flange bolts, valve bolts when valve is on service. (Fig.28)

17.3.3 The valve must be supported when there is pipeline vibration, so that pipeline stresses are not

transmitted to the valve and actuator.

17.3.4 Do not use a “F” wrench to operate the hand wheel of gear box. (Fig.29)

Fig.29 Fig.30

If there are any problems could not be eliminated during service,please contact your Flowserve

representative for further assistance. (Fig.30)

19

Page 20

Flow Control Division

17.1 Maintenance

17.4.1 Maintenance personnel should be trained before doing the repair.

17.4.2. Do not replace the gaskets when the pipeline is in operation or is pressurized.

17.4.3. Repaint the valve when it rusts.

17.4.4. If finding the parts of valve has been corroded, please replace with a new one.

17.4.5. If valve body has corroded please measure the thickness of the body to determine if the

body is still workable. Please see table below.

17.4.6. Pay examine any the abrasion of stem, disc and seats to determine if theses parts are still

workable.

17.4.7. Very clearly mark and show protection procedure when the flow medium is poisonous.

17.4.8 Before removing the valves please make sure that the piping is under no pressure and the

temperature is lower than 100℉.

Minimum Wall Thickness

20

Page 21

SECTION XVIII

PARTS LIST AND MARKINGS

Parts for Wafer and Lug Designs

Flow Control Division

21

Page 22

No.

Name

Materials

Spare

parts

No.

Name

Materials

Spare

parts

1

BODY

A216 Gr. WCB

15

SPRING WASHER

A240 Gr. 304

A351 Gr. CF8M

16

NUT

A194 Gr. 8

2 BEARING

A182 Gr. F316

17

GASKET

GRAPHITE

* 3 BEARING

A182 Gr. F316

18

SOLID SEAL RING

A240 Gr. 316

*

4

DUST-PROOF SEAL

GRAPHITE

INCO 718

5

DISC

A216 Gr. WCB

LAMINATED SEAL RING

UNS S32205

A351 Gr. CF8M

INCO 718

6

SHAFT

A182 Gr. F6a

19

SEAL RING RETAINER

A351 Gr. CF8

A479 XM-19

A351 Gr. CF8M

UNS 32205

20

SOCKET HEAD CAP

BOLT

A913 Gr. B8

7

THRUST RING

A240 Gr. 316

21

GASKET

GRAPHITE

*

(1)

8

BOTTOM COVER

GASKET

GRAPHITE

*

22

BODY SEAT

A240 Gr.

304+Stellite hard

face

*

(1)

9

BOTTOM COVER

A216 Gr. WCB

A240 Gr.

316+Stellite hard

face

A351 Gr. CF8M

23

SOCKET HEAD CAP

BOLT

A913 Gr. B8

10

SPRING WASHER

A240 Gr. 304

24

YOKE

A536 65-45-12

*

(2)

11

BOLT

A913 Gr. B8

A216 Gr. WCB

12

GLAND PACKING

GRAPHITE

*

25

PIN

A182 Gr. F316

26

DUST-PROOF SEAL

GRAPHITE

13

GLAND

A351 Gr. CF8

27

BEARING

A182 Gr. F316

A351 Gr. CF8M

28

LOCK PLATE

PTFE+316SS

14

STUD

A913 Gr. B8

Notes:

1. Part numbers 21, 22, 23 are only available for model Class 300 and 600 designs

Class150 valve bodies are one-piece design.

2. For part No. 24, A216 Gr. WCB is used on the following ISO 5211 sizes: F07/F05, F10/F07, 12/F10, F14/F12, F16/F14

A536 65-45-12 is used on the following sizes: F16, F25, F30, F35, F40.

3. We can supply different materials of construction to suit specific customer requirements

Parts List for Wafer and Lug Designs

Flow Control Division

22

Page 23

Parts for Flanged Designs

Flow Control Division

23

Page 24

No.

Name

Materials

Spare parts

No.

Name

Materials

Spare parts

1

BODY

A216 Gr. WCB

15

SPRING WASHER

A240 Gr. 304

A351 Gr. CF8M

16

NUT

A194 Gr. 8

2

BEARING

A182 Gr. F316

17

GASKET

GRAPHITE

*

3

BEARING

A182 Gr. F316

18

SOLID SEAL RING

A240 Gr. 316

*

4

DUST-PROOF SEAL

GRAPHITE

INCO 718

5

DISC

A216 Gr. WCB

LAMINATED SEAL RING

UNS S32205

A351 Gr. CF8M

INCO 718

6

SHAFT

A182 Gr. F6a

19

SEAL RING RETAINER

A351 Gr. CF8

A479 XM-19

A351 Gr. CF8M

UNS 32205

20

SOCKET HEAD CAP

BOLT

A913 Gr. B8

7

THRUST RING

A240 Gr. 316

21

GASKET

GRAPHITE

*

(1)

8

BOTTOM COVER

GASKET

GRAPHITE

*

22

BODY SEAT

A240 Gr.

304+Stellite hard

face

*

(1)

9

BOTTOM COVER

A216 Gr. WCB

A240 Gr.

316+Stellite hard

face

A351 Gr. CF8M

23

SOCKET HEAD CAP

BOLT

A913 Gr. B8

10

SPRING WASHER

A240 Gr. 304

24

YOKE

A536 65-45-12

*

(2)

11

BOLT

A913 Gr. B8

A216 Gr. WCB

12

GLAND PACKING

GRAPHITE

*

25

PIN

A182 Gr. F316

26

DUST-PROOF SEAL

GRAPHITE

13

GLAND

A351 Gr. CF8

27

BEARING

A182 Gr. F316

A351 Gr. CF8M

28

LOCK PLATE

PTFE+316SS

14

STUD

A913 Gr. B8

29

BODY RETAINER

A351 Gr. CF8

A351 Gr. CF8M

Notes:

1. Part numbers 21, 22, 23 are only available for model Class 300 and 600 designs

Class150 valve bodies are one-piece design.

2. For part No. 24, A216 Gr. WCB is used on the following ISO 5211 sizes: F07/F05, F10/F07, 12/F10, F14/F12, F16/F14

A536 65-45-12 is used on the following sizes: F16, F25, F30, F35, F40.

3. We can supply different materials of construction to suit specific customer requirements.

Parts List for Flanged Designs

Flow Control Division

24

Page 25

Fig. 24

Fig.23

Each valve will be marked with an arrow to show

Recommended direction of flow

Each valve will have a casting mark as shown in Fig 24

Each valve will have the following information

in the casting as shown in Fig 25 and 26

Series Number : 870

Size: 20

Material

Heat number

Flow Control Division

Fig. 25 Fig. 26

25

Page 26

Flow Control Division

Printed in U.S.A.

July 2010

© Flowserve Corporation

Flowserve Pte. Ltd.

12 Tuas Avenue 20

Republic of Singapore 638824

Phone 65 6879 8900

Fax 65 6862 4940

26

Loading...

Loading...