Page 1

USER INSTRUCTIONS

Limitorque PT Series

FCD LMENM2001-00 – 01/10

Installation

Operation

Maintenance

Experience In Motion

Page 2

Limitorque PT Series Worm Gear Operator FCD LMENIM2001-00 – 01/10

Contents

1 Introduction

1.1 Purpose 4

1.2 User Safety 4

2 Inspection, Installation, and Mounting Procedures 5

2.1 Initial Inspection and Storage Instructions 6

2.2 Inspection and Recording 6

2.3 Storage Procedure 6

2.4 General Mounting Instructions 7

2.5 Setting Position Limit Stops for PT 12, 14, 30, 40, 50, 75 8

2.6 Setting Position Limit Stops PT60 9

2.7 Setting Position Limit Stops for PT 65, 120, 150 10

2.8 Setting Position Limit Stops for PT 250, 500, 1000 11

3 Lubrication 12

4 Disassembly and Reassembly Instructions 13

4.1 Safety Precautions 13

4.2 Safety Practices 14

4.3 PT 12, 14, 30, 40 14

4.4 PT 50, 75 18

4.5 PT 60 21

4.6 PT 65, 120, 150 25

4.7 PT 250, 500, 1000 28

4.8 Spur Gear Attachments - PT 14, 30, 40 31

4.9 Spur Gear Attachments - PT 60 34

4.10 Spur Gear Attachments - PT 65, 120, 150 37

4.11 Spur Gear Attachments - PT 250, 500, 1000 39

5 How to Order Parts 42

Figures

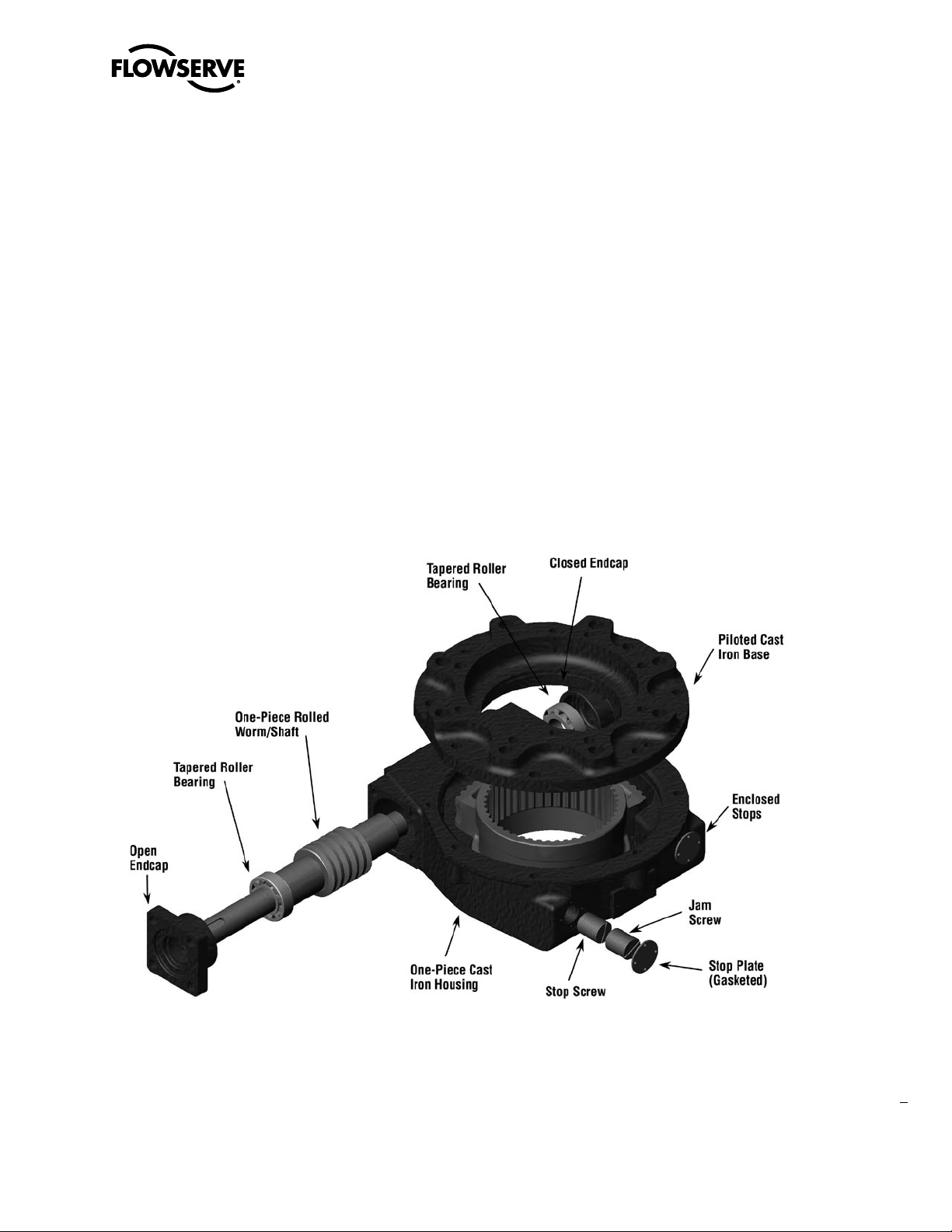

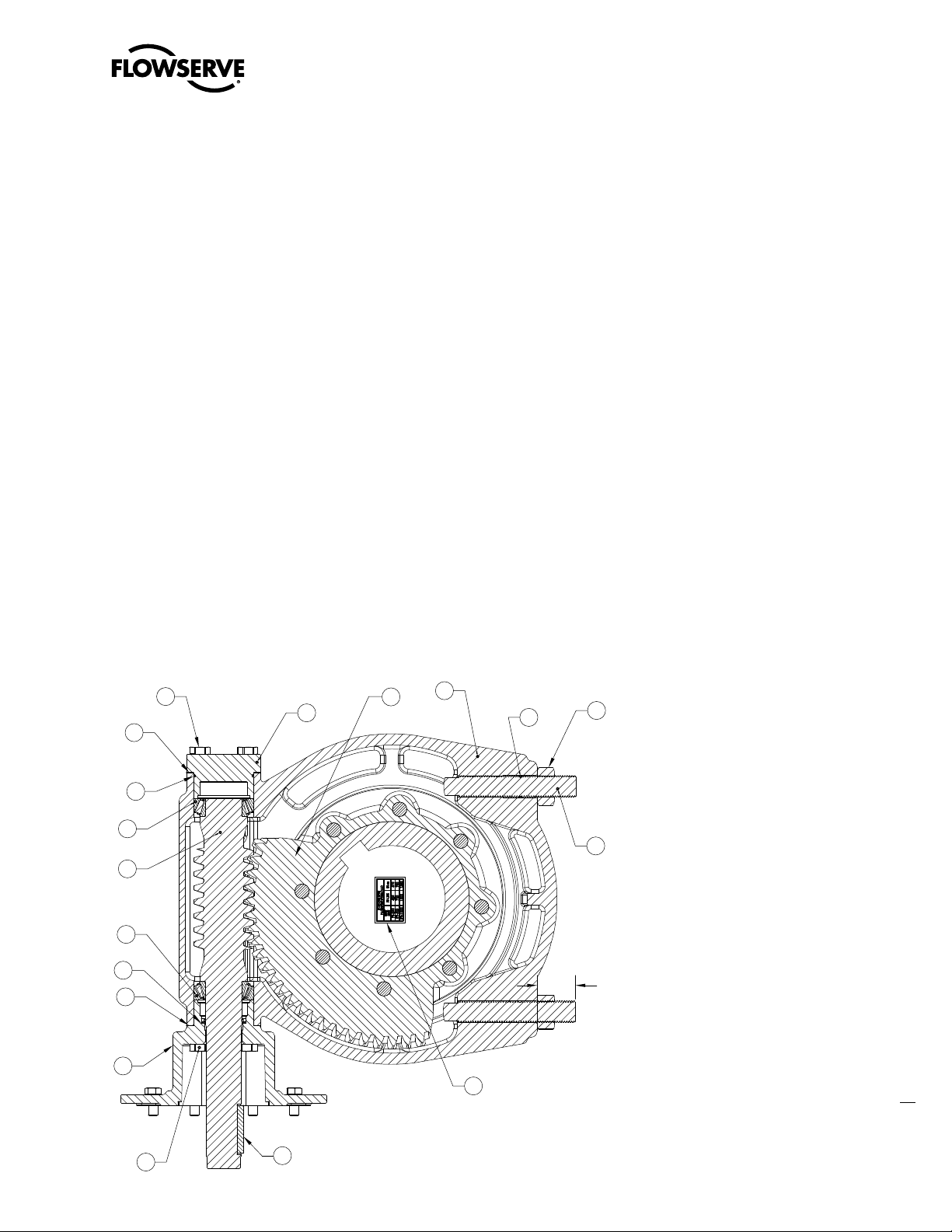

Figure 2.1 – Typical PT Exploded View 5

Figure 2.2 – Setting Position Limit Stops – PT12, 14, 30, 40, 50, 75 8

Figure 2.3 – Setting Position Limit Stops – PT60 9

Figure 2.4 – Setting Position Limit Stops – PT65, 120, 150 10

Figure 2.5 – Setting Position Limit Stops – PT250, 500, 1000 11

Figure 4.1-2 – PT12, 14, 30, 40 Disassembly & Reassembly 16

Figure 4.3-5 – PT50, 75 Disassembly & Reassembly 20

Figure 4.6-7 – PT60 Disassembly & Reassembly 23

Figure 4.8-11 – PT65, 120, 150 Disassembly & Reassembly 26-27

Figure 4.12-13 – PT250, 500, 1000 Disassembly & Reassembly 30

Figure 4.14 – PT14, 30, 40 SGA Disassembly & Reassembly 33

Figure 4.15-17 – PT60 SGA Disassembly & Reassembly 35-36

Figure 4.18-20 – PT65, 120, 150 SGA Disassembly & Reassembly 37-38

2

Figure 4.21-22 – PT250, 500, 1000 SGA Disassembly & Reassembly 40-41

Page 3

Limitorque PT Series Worm Gear Operator FCD LMENIM2001-00 – 01/10

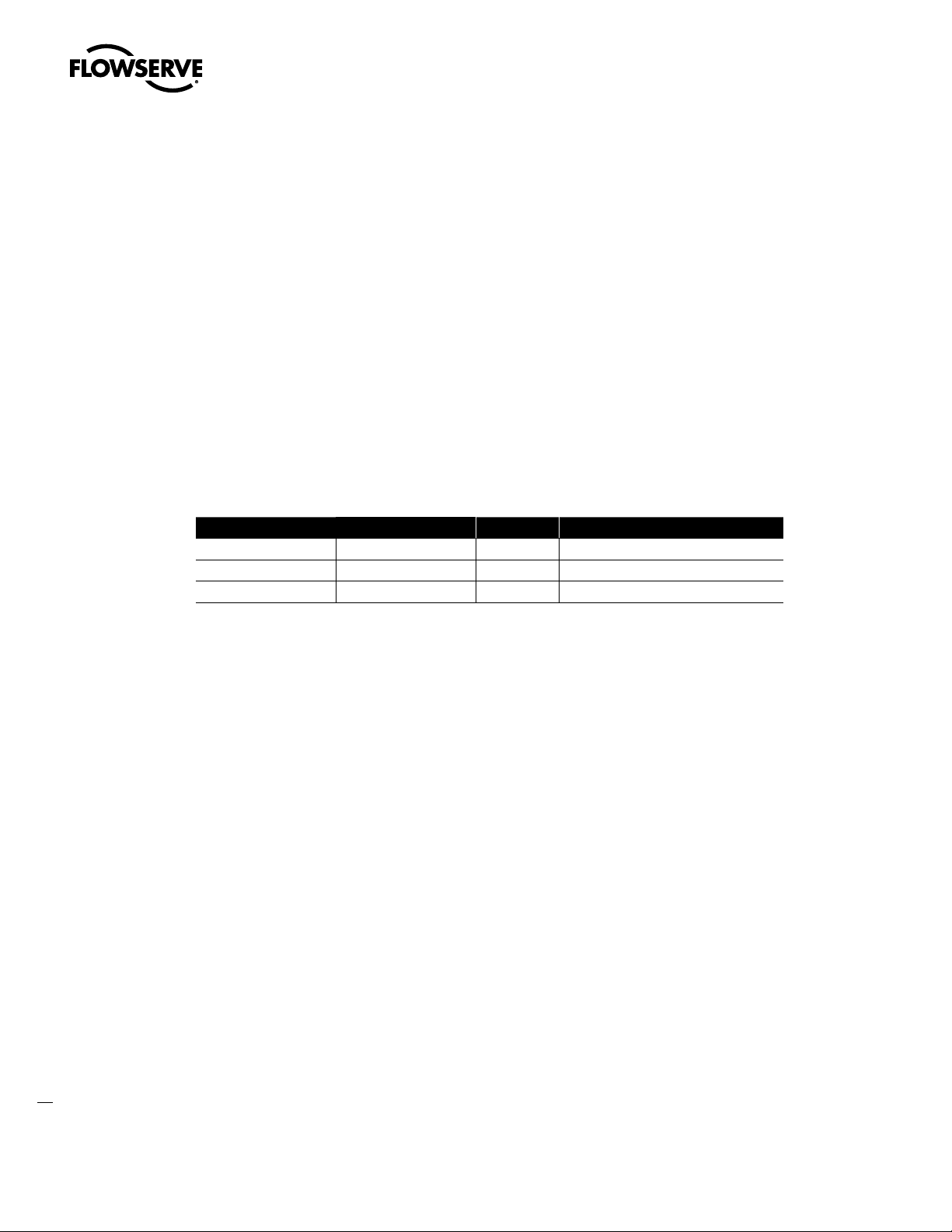

Tables

Table 2.1 – Stem Adapter Bolt Torques 7

Table 3.1 – Lubricants 12

Table 4.1 – Parts List – PT12, 14, 30, 40 17

Table 4.2 – Parts List – PT50, 75 21

Table 4.3 – Parts List – PT60 24

Table 4.4 – Parts List – PT65, 120, 150 28

Table 4.5 – Parts List – PT250, 500, 1000 31

Table 4.6 – Parts List – Spur Gear Attachment – PT14, 30, 40 33

Table 4.7 – Parts List – Spur Gear Attachment – PT60 36

Table 4.8 – Parts List – Spur Gear Attachment – PT65, 120, 150 39

Table 4.9 – Parts List – Spur Gear Attachment – PT250, 500, 1000 41

flowserve.com

3

Page 4

1

Limitorque PT Series Worm Gear Operator FCD LMENIM2001-00 – 01/10

Introduction

1.1 Purpose

The installation and maintenance manual (IOM) explains how to install and maintain the Flowserve Limitorque PT

operator. Information on installation, disassembly, reassembly, lubrication, and spare parts is provided.

1.2 User Safety

Safety notices in this manual detail precautions the user must take to reduce the risk of personal injury and damage

to the equipment. The user must read and be familiar with these instructions before attempting installation, operation,

or maintenance. Failure to observe these precautions could result in serious bodily injury, damage to the equipment.

voiding of the warranty, or operational difficulty.

Safety notice are presented in this manual in three forms:

c WARNING: Refers to personal safety. Alerts the user to potential danger. Failure to follow warning notices

could result in personal injury or death.

a CAUTION: Directs the user’s attention to general precautions that, if not followed, could result in personal injury

and/or equipment damage.

NOTE: Highlights information critical to the user’s understanding of the operator’s installation and operation.

4

Page 5

Limitorque PT Series Worm Gear Operator FCD LMENIM2001-00 – 01/10

Inspection,

2

Installation, and

Mounting Procedures

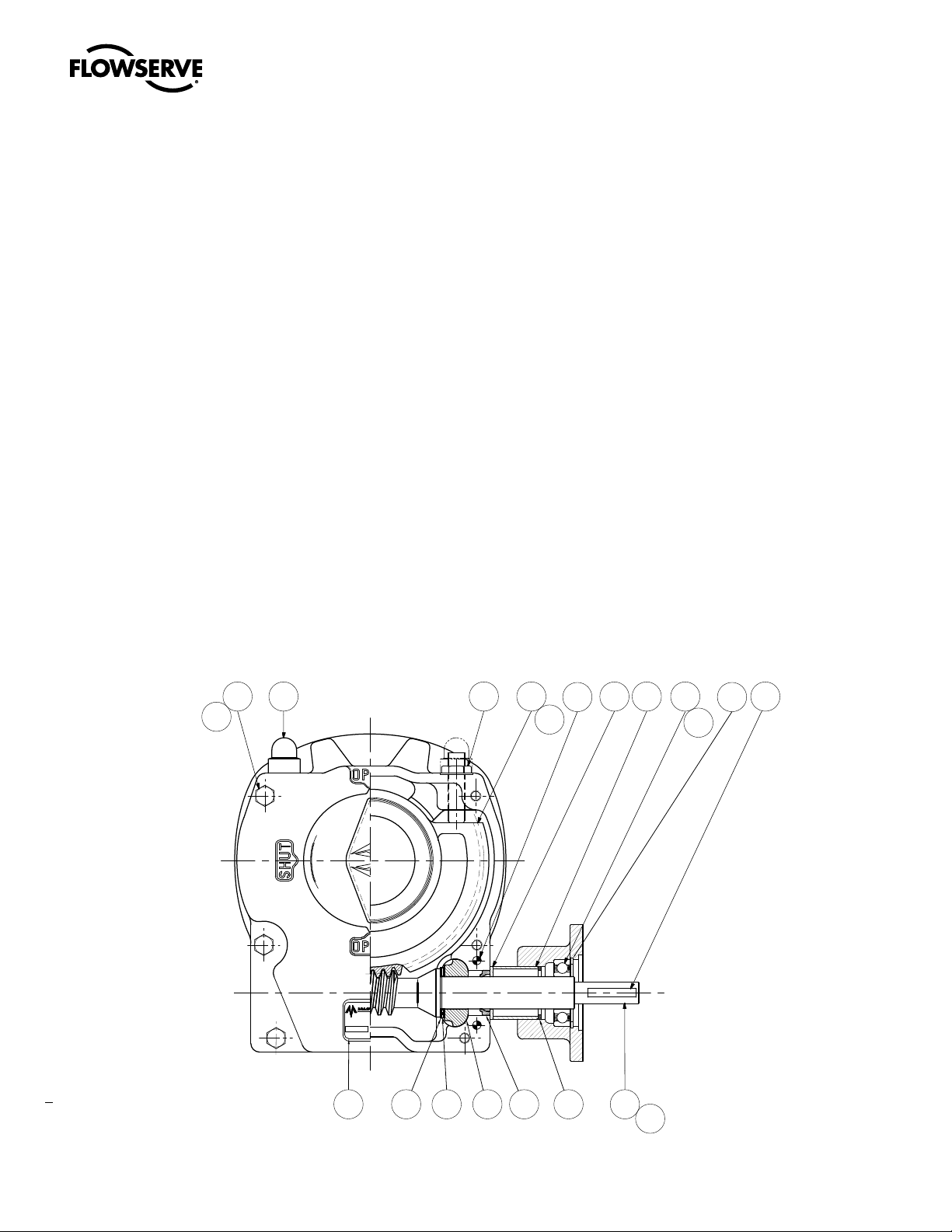

Figure 2.1 – Typical PT Exploded View

trical operation

c WARNING: Do not manually operate the PT operator with devices other than the installed handwheel or wrench

nut. Using additive force devices (cheater bars, wheel wrenches, pipe wrenches, or other devices of this nature)

on the operator handwheel or wrench or wrench nut may cause serious personal injury and/or damage to the

operator or valve.

5

flowserve.com

Page 6

Limitorque PT Series Worm Gear Operator FCD LMENIM2001-00 – 01/10

2.1 Initial Inspection and Storage Instructions

c WARNING: Read this installation and maintenance manual carefully and completely before attempting to

store the operator. If an electric actuator is attached to the PT manual operator, be aware of the electrical

hazards. Consult the electric actuator installation and maintenance manual for guidance.

2.2 Inspection and Recording

Upon receipt of the operator, inspect the condition of the equipment, and record nameplate information.

1. Carefully remove operator from shipping carton or skid. Thoroughly examine the equipment for any physical

damage that may have occurred during shipment. If damaged, immediately report the damage to the transport

company.

2. A nameplate is attached to each operator with the following information:

• Operator size

• Assembly position

• Order Number

• Serial number

• Customer tagging

Record this information for future reference, i.e. ordering parts, obtaining further information.

2.3 Storage Procedure

NOTE: The following is the recommended storage procedure to retain maximum product integrity during storage.

Failure to comply with recommended procedure will void the warranty.

Storage (less than 1 year)

Store operators on wooden skids to protect the machined mounting flange. Place the wooden skids containing the

operators in a clean, dry, protected warehouse. If the operators must be stored outside, they must be covered in

polyethylene protection with silica get crystals to absorb moisture. If an electric actuator is attached to the PT, refer to

the storage procedures in its respective manual for appropriate storage procedures. Rotate input shafts every three

months to mix the lubricant.

6

Page 7

Limitorque PT Series Worm Gear Operator FCD LMENIM2001-00 – 01/10

2.4 General Mounting Instructions

a CAUTION: To avoid the potential for disengaging the worm gear segment, ensure that the pointer cap pointer is

oriented to the mid-point of the 90º valve travel. Full stroke rotation of the quadrant should not move the pointer

past the corresponding Open or Close ID marks on the housing cover.

1. Place valve in full closed position.

2. Remove the pointer cap from the PT operator. Refer to Section 4 for removal/replacement instructions for the

pointer cap.

3. PT12/14/30/40/50/60/75/120/150 – Slide the splined adapter onto the valve shaft and insert the key. Splined

adapters include machining for a setscrew to eliminate movement of the splined adapter on the valve shaft.

4. Confirm operator stop alignment before engaging splines. Mount operator on valve and bolt securely.

5. PT65/120/150 – Remove the splined adapter from the PT and mount the PT to the valve. Align the valve shaft with

the bore and key of the splined adapter. Using either the PT or electric actuator handwheel, rotate the PT drive

sleeve to align the drive sleeve’s splines with the splined adapter. Slide the splined adapter down onto the valve

stem and into the drive sleeve of the PT.

NOTE: Blank splined adapters are not machines for set screws.

6. PT250/500/1000 – Stem adapters are bolted into place from the top of the PT. Remove the torque nut and align

the valve drive stem with the bore and key of the torque nut. Slide the torque nut onto the valve stem. Using either

the PT or electric actuator handwheel, rotate the PT drive sleeve to align the drive sleeve’s threaded holes with the

torque nut’s through holes. Bolt the torque nut into position. Preload properly class 8.8 fasteners, securing torque

nut as follows at installation. (Preload is not set at factory.)

Table 2.1 – Stem Adapter Bolt Torques

Unit Size ft-lb N m

PT250 475 640

PT500 700 950

PT1000 1,200 1,620

Fasteners that are stainless steel or other than property class 8.8 require different preload torque than listed above.

Consult factory.

7. Turn PT operator input shaft to full closed position. The stops are preset for 90º travel. Be certain of correct direction of rotation.

flowserve.com

7

Page 8

Limitorque PT Series Worm Gear Operator FCD LMENIM2001-00 – 01/10

11

-

5

5

0

C

0

3

-

0

0

1

10

09

04

05

06

0208

07

SERIAL No:

FULLY GREASE

DIVISION OF

12

13

02B

16

17

18

09B

14

12A

15

03

16B

2.5 Setting Position Limit Stops - PT12, 14, 30, 40, 50, 75

Refer to Figure 2.2.

1. Remove the two Stop Screw Caps (pc# 10) (if supplied) to expose the Stop Screws (pc# 11).

2. Loosen the Stop Adjusting Nut on the Stop Screw and adjust the screw by turning it counterclockwise to back the

screw away from the Worm Gear Quadrant (pc# 12)

3. Place the valve disk in the full closed position

4. Turn the Stop Screw (pc# 11) in the clockwise direction until the end of the screw contacts the Worm Gear

Quadrant (pc# 12)

5. Tighten the Stop Adjusting Nut to secure the closed set position

6. Move the valve disk to the full open position

7. Follow steps 2 through 5

a CAUTION: If the valve is operated with an electric actuator/gear operator combination, and the valve is position-

seated, set the actuator limit switches to trip prior to engagement of the PT Drive Sleeve/Worm Gear with the

Stop Screws. Damage to the operator could result from the Drive Sleeve/Worm Gear contacting the Stop Screw

under motorized operation.

Note: The stops are adjustable to +/- 5º of total travel to allow for proper positioning of the worm gear quadrant.

Figure 2.2 – Setting Position Limit Stops – PT12, 14, 30, 40, 50, 75

8

Page 9

Limitorque PT Series Worm Gear Operator FCD LMENIM2001-00 – 01/10

7

8

11

10

12

6

2

18

19

4

15

17

3

20

1

9

21

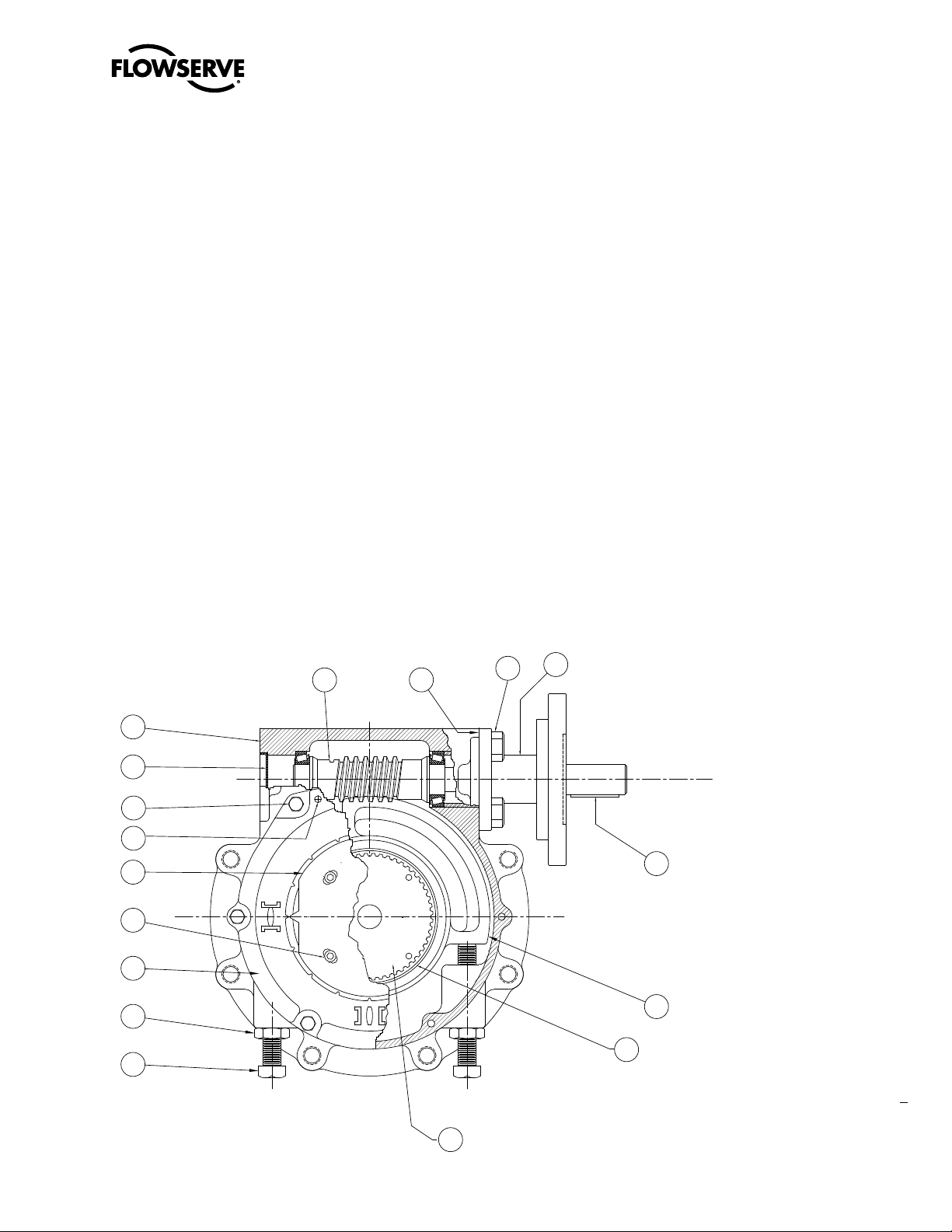

2.6 Setting Position Limit Stops - PT60

Refer to Figure 2.3.

1. Loosen the Stop Adjusting Nut (pc# 8)

2. Turn the Stop Adjusting Screw (pc# 7) counterclockwise to back the screw away from the Worm Gear (pc# 19)

3. Place the valve disk in the full closed position (pointer will point to the full closed marking on the Gear Housing,

pc# 2)

4. Turn the Stop Adjusting Screw in the clockwise direction until the end of the screw contacts the Worm Gear

5. Tighten the Stop Adjusting Nut to secure the closed set position

6. Move the valve disk to the full open position

7. Follow steps 1 through 5

a CAUTION: If the valve is operated with an electric actuator/gear operator combination, and the valve is

position-seated, set the actuator limit switches to trip prior to engagement of the PT Worm Gear with the Stop

Screws. Damage to the operator could result from the Worm Gear contacting the Stop Screw under motorized

operation.

Note: The stops are adjustable to +/- 5º of total travel to allow for proper positioning of the worm gear quadrant.

Figure 2.3 – Setting Position Limit Stops – PT60

9

flowserve.com

Page 10

Limitorque PT Series Worm Gear Operator FCD LMENIM2001-00 – 01/10

5

19

8

23

2

1

7

9

10

20

6

11

18

3

21

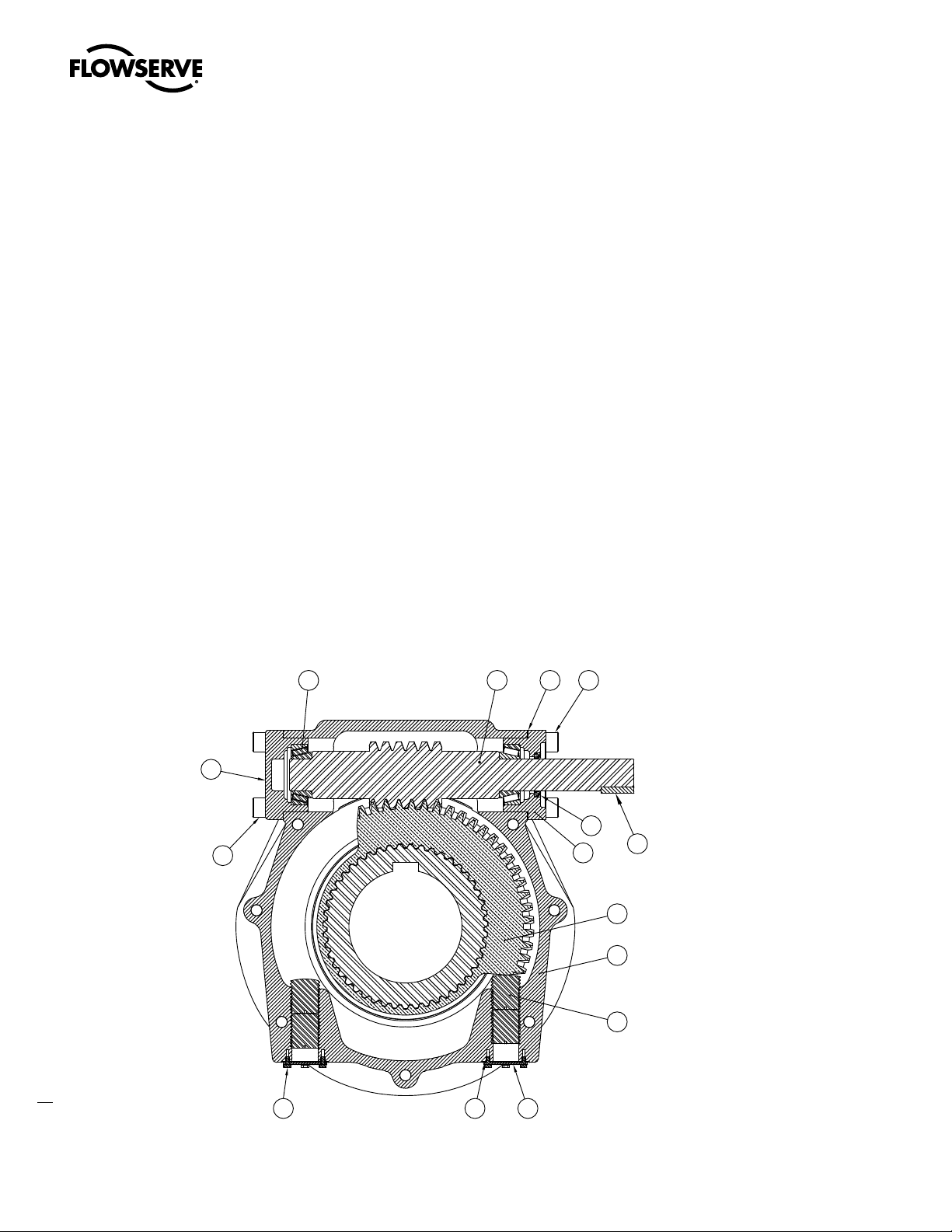

2.7 Setting Position Limit Stops - PT65, 120, 150

Refer to Figure 2.4.

1. Remove the Stop Plates (pc# 9) and Stop Plate Gaskets (pc# 10) to expose the Stop Screws (pc# 7)

2. Remove the outboard Stop Screws

3. Turn the inboard Stop Screw counterclockwise to back the screw away from the Drive Sleeve/Worm Gear

4. Place the valve disk in the full closed position (pointer will point to the full closed marking on the Gear Housing)

5. Turn the Stop Screw in the clockwise direction until the end of the screw contacts the Drive Sleeve/Worm Gear

6. Install the outboard Stop Screw and tighten firmly against the inboard Stop Screw to secure the closed set position

7. Move the valve disk to the full open position

8. Follow steps 3 through 6

a CAUTION: If the valve is operated with an electric actuator/gear operator combination, and the valve is position-

seated, set the actuator limit switches to trip prior to engagement of the PT Drive Sleeve/Worm Gear with the

Stop Screws. Damage to the operator could result from the Drive Sleeve/Worm Gear contacting the Stop Screw

under motorized operation.

Note: The stops are adjustable to +/- 5º of total travel to allow for proper positioning of the worm gear quadrant.

Figure 2.4 – Setting Position Limit Stops – PT65, 120, 150

10

Page 11

Limitorque PT Series Worm Gear Operator FCD LMENIM2001-00 – 01/10

2X 2.29

ASSEMBLE STOPS

TO THIS DIMENSION

Wormshaft & Stops

Scale 1 : 3

25

15

7

15

8

9

6

2

6

21

45

17

1

3

11

10

12

22

2.8 Setting Position Limit Stops – PT250, 500, 1000

Refer to Figure 2.5.

1. Loosen the Stop Adjusting Nut (pc# 11)

2. Turn the Stop Adjusting Screw (pc# 10) counterclockwise to back the screw away from the Drive Sleeve/Worm

Gear (pc# 3)

3. Place the valve disk in the full closed position (pointer will point to the full closed marking on the Gear Housing, pc# 1)

4. Turn the Stop Adjusting Screw in the clockwise direction until the end of the screw contacts the Drive Sleeve/Worm

Gear

5. Tighten the Stop Adjusting Nut to secure the closed set position

6. Move the valve disk to the full open position

7. Follow steps 1 through 5

a CAUTION: If the valve is operated with an electric actuator/gear operator combination, and the valve is

position-seated, set the actuator limit switches to trip prior to engagement of the PT Worm Gear with the

Stop Screws. Damage to the operator could result from the Worm Gear contacting the Stop Screw under

motorized operation.

Note: The stops are adjustable to +/- 5º of total travel to allow for proper positioning of the worm gear quadrant.

Figure 2.5 – Setting Position Limit Stops – PT250, 500, 1000

11

flowserve.com

Page 12

Limitorque PT Series Worm Gear Operator FCD LMENIM2001-00 – 01/10

Lubrication

3

Flowserve Limitorque PT operators are shipped with the following lubricants:

Table 3.1 –

Product Lubricant Soap Base Temperature Range

PT 12, 14, 30, 40, 50, 75 Premium MC 2092SW Calcium -65ºF to 225ºF (-54ºC to 107ºC)

PT 60 Esso Unirex EP-2 Lithium -22ºF to 176ºF (-30ºC to 80ºC)

PT 65, 120 through 1000 Conoco Dynalife-L-EPO Lithium 0ºF to 225ºF (-18ºC to 107ºC)

NOTE: The lubricant should be checked every 18 months for manual operators.

a CAUTION: Do not add a different lubricant to a Flowserve Limitorque operator unless it is of the same soap base

Quantity

Limitorque operators are built to operate on the partial immersion principle. The primary concern regarding the amount

of lubricant is whether the “worm” is totally immersed in grease. This can be verified by the use of one or more of the

“ll” and “drain” plugs provided on the operator housing in most sizes.

Quality

When removing a “fill” or “drain” plug to inspect the lubricant level, remove a small amount and ensure that it is clean

and free of any contaminant including water. Should dirt, water, or other foreign matter be found, the operators should

be flushed with a commercial degreaser/cleaner like Exxon VARSOL #1 or #3, which is non-corrosive and does not

affect seal materials such as Buna-N or Viton. Repack operator with fresh lubricant.

Lubricants

as the existing lubricant, or you have received the approval of lubricant manufacturer.

12

Consistency

The main gear box lubricant should be slightly uid, approximating a standard NLGI-0 grade consistency or less.

Alternate lubricants may be used in place of the standard lubricants supplied by Flowserve provided they are of a

formulation similar to those listed above for the respective product.

Page 13

Limitorque PT Series Worm Gear Operator FCD LMENIM2001-00 – 01/10

Disassembly and

4

Reassembly Instructions

4.1 Safety Precautions

c WARNING: Read this Installation, Operation and Maintenance Manual carefully and completely before attempting

to install, operate, or troubleshoot the Limitorque operator.

c WARNING: Potential HIGH PRESSURE vessel — be aware of high-pressure hazards associated with the attached

valve or other actuated device when installing or performing maintenance on the operator. Do not remove the

operator mounting bolts from the valve or actuated device unless the valve or device stem is secured or there is

no pressure in the line.

c WARNING: For maintenance and/or disassembly of the operator while installed on the valve, ensure that the

operator is not under thrust or torque load. If the valve must be left in service, the valve stem must be locked in

such a way as to prevent any movement of the valve stem.

c WARNING: Do not manually operate the operator with devices other than the installed handwheel. Using force

beyond the ratings of the operator and/or using additive force devices such as cheater bars, wheel wrenches, pipe

wrenches, or other devices on the operator handwheel may cause serious personal injury and/or damage to the

operator and valve.

c WARNING: Do not exceed any design limitations or make modifications to this equipment without first consulting

Limitorque.

c WARNING: Use of this product must be suspended any time it fails to operate properly.

a CAUTION: If a motor actuator is driving the manual operator, do not operate the valve under motor operation

without first checking and setting the limit switch and checking for correct motor rotation.

a CAUTION: Do not use replacement parts that are not genuine Flowserve Limitorque parts, as serious personal

injury and/or damage to the operator and valve may result.

13

flowserve.com

Page 14

Limitorque PT Series Worm Gear Operator FCD LMENIM2001-00 – 01/10

4.2 Safety Practices

The following check points should be performed to maintain safe operation of the PT gear operator:

• Set up a periodic operating schedule on infrequently used valves.

• Ensure that the limit and/or torque switches on any electric actuator tted to the PT worm gear operator are

correctly and appropriately adjusted.

4.3 PT12, 14, 30, 40

Refer to Figures 4.1, 4.2 and Table 4.1.

1. Remove the Key (pc# 18) from the Worm Shaft (pc# 2) assembly.

2. Remove the plastic Indicator Cap (pc# 19) by applying equal pressure underneath the cap, on opposite sides of the

cap, and prying upward.

Note: The metal Indicator Cap is removed by removing the two screws that attach the Indicator Cap to the Quadrant.

3. Remove the Flange Cover Hex Head Screws (pc# 9)

4. Turn the operator onto its side and tap on the Quadrant (pc# 12) and flange of the Cover (pc# 1) to separate the

Cover, Worm Shaft (pc# 2) assembly, and Quadrant from the Gearcase (pc# 21).

Caution: Use a soft-headed mallet to prevent damage to the Quadrant bore and keyways.

Caution: Care should be taken to prevent the Quadrant and Worm Shaft assembly from completely disengaging from

the Gearcase.

Note: The Flange Cover will not separate from the Gearcase without adequate force to overcome and clear the dowel

pin connections between the Flange Cover and Gearcase.

5. Return the operator to the upright position.

6. With the Quadrant free from the base of the Gearcase, lift the Cover, Quadrant, and Worm Shaft assembly from the

Gearcase and slide the Worm Shaft assembly away from the Quadrant.

7. Remove the Quadrant from the Gearcase.

8. Slide the Worm Shaft assembly out of the Flange Cover.

Note: If additional disassembly is required, please follow the steps below:

9. Remove the Snap Ring (pc# 17) and tap out the Input Bearing (pc# 16) from the Cover.

Note: The Smalley Retaining Ring (pc# 3) and Protection Sleeve (pc# 15) can be removed if required. Remove the

Protection Sleeve by tapping it out of the Flange Cover.

14

10. Remove Thrust Washers (pc# 7), Thrust Bearings (pc# 6), Worm Shaft Bearings (pc# 5), and Oil Seal (pc# 4) as

required.

Page 15

Limitorque PT Series Worm Gear Operator FCD LMENIM2001-00 – 01/10

Reassembly Instructions:

1. Tap the Dowel pins (pc# 13) flush with the Flange Cover (pc# 1).

2. If the Worm Shaft components have been removed, reassemble the Worm Shaft (pc# 2) with the Thrust Washers

(pc# 7), Thrust Bearings (pc# 6), Worm Shaft Bearings (pc# 5), and Oil Seal (pc# 4).

Note: The Oil Seal should be located near the end of the Worm Shaft to facilitate installing the assembly into the

Gearcase (pc# 21).

3. Lower the Quadrant (pc# 12), with the wording up, and the Worm Shaft (pc# 2) assembly, with the dashes on the

Worm Shaft Bearings facing up, into the Gearcase simultaneously.

Caution: The O-Ring (pc# 22) on the lower Quadrant journal seals the Gearcase / Quadrant interface. Check the condi-

tion of the O-Ring. If damaged, replace it.

4. Mesh the gearing on the Quadrant with the Worm on the Worm Shaft and slide into the Gearcase.

5. Repack the gearing area with lubricant, thoroughly immersing the Worm/Worm Gear interface and Bearings.

6. Apply Loctite 574 or equivalent around the Oil Seal and slide the Oil Seal down the Worm Shaft and into the

Gearcase.

7. Apply a bead of Loctite 574 or equivalent on the machined surface and around the bolt holes of the Gearcase, being

careful to avoid applying Loctite into the bolt holes.

8. Prior to installing the Flange Cover (pc# 1), place the Protective Sleeve Seal (pc# 14) against the Oil Seal.

9. Slide the Cover over the Worm Shaft and place onto the Gearcase.

10. Tap down the Dowel pins (pc# 13) in the two holes that are not tapped so that they are flush with the Flange Cover.

11. Install the Flange Cover screws.

12. Attach the Indicator Cap (pc# 19) to the Quadrant (pc# 12) noting the location of the nub on the inside of the plastic

Indicator Cap that sets in one of the drilled holes in the Quadrant.

Note: The cast iron Indicator Cap is attached with two screws.

Caution: Check that the Indicator Cap is installed to correctly reflect the position of the Quadrant relative to valve

position.

13. Ensure that the Protection Sleeve (pc# 15) is against the Protection Sleeve Seal. Use the Smalley Retaining Ring

(pc# 3) to push the Protection Sleeve against the Protection Sleeve Seal if needed.

14. Place the Input Bearing (pc# 16) and Snap Ring (pc# 17) over the Worm Shaft and into the Motor Flange of the

Cover.

15. Re-insert the Key in the Worm Shaft.

16. Check the operator for proper operation. The Worm Shaft should be capable of operation by hand. Stroke through a

complete open-close cycle.

flowserve.com

15

Page 16

Limitorque PT Series Worm Gear Operator FCD LMENIM2001-00 – 01/10

11

-

5

5

0

C

0

3

-

0

0

1

10

09

04

05

06

0208

07

SERIAL No:

FULLY GREASE

DIVISION OF

12

13

02B

16

17

18

09B

14

12A

15

03

16B

22

01

20

19

21

Figure 4.1 – PT12, 14, 30, 40 Disassembly & Reassembly

16

Figure 4.2 – PT12, 14, 30, 40 Disassembly & Reassembly

Page 17

Table 4.1 – Parts List – PT12, 14, 30, 40

Piece # Description

1 Cover

2 Motorized Worm Shaft

3 Smalley Retaining Ring

4 Oil Seal

5 Worm Shaft Bearing

6 Thrust Bearing

7 Thrust Washer

9 Hex Head Screw

10 Stop Screw Cap

11 Stop Screw Kit

12 Quadrant

13 Dowel

14 Protection Sleeve Seal

15 Protection Sleeve

16 Input Bearing

17 Snap Ring

18 Key

19 Indicator Cap

20 Indicator Cap O-Ring

21 Gearcase

22 Quadrant O-Ring

23 Hex Head Screw (not shown)

24 Lockwasher (not shown)

25 Splined Adapter (not shown)

Limitorque PT Series Worm Gear Operator FCD LMENIM2001-00 – 01/10

flowserve.com

17

Page 18

Limitorque PT Series Worm Gear Operator FCD LMENIM2001-00 – 01/10

4.4 PT50, 75

Refer to Figure 4.3, 4.4, 4.5 and Table 4.2

1. Remove the Key (pc# 6) from the Motorized Pinion (pc# 8).

2. Remove the plastic Indicator Cap (pc# 12) by applying equal pressure underneath the cap, on opposite sides of the

cap, and prying upward.

Note: The metal Indicator Cap is removed by removing the two screws that attach the Indicator Cap to the Quadrant

(pc# 9).

3. Remove the Cover Screws (pc# 13)

4. Turn the operator onto its side and tap on the Quadrant (pc# 9) to separate the Flanged Cover (pc# 14) from the

Gearcase (pc# 2).

Caution: Use a soft-headed mallet to prevent damage to the Quadrant bore and keyways.

Note: The Flanged Cover will not separate from the Gearcase without adequate force to overcome the Dowels (pc# 18)

connecting the Flanged Cover and Gearcase.

5. Return the operator to the upright position

6. Remove the Flanged Cover (pc# 14) with Motorized Pinion (pc# 6) and Bearings.

7. With the Quadrant free from the base of the Gearcase, lift the Quadrant and Worm Shaft assembly from the

Gearcase and slide the Worm Shaft assembly away from the Quadrant and out of the Gearcase.

8. Remove the Quadrant from the Gearcase.

Note: If additional disassembly is required, please follow the steps below:

9. Slide the Motorized Pinion and Pinion Shaft Bearings (pc# 7) assembly out of the Flanged Cover by lifting the rear

bearing until it clears the bearing recess and tapping on the outboard end of the pinion shaft. .

10. Remove the Circlip (pc# 22) and tap out the Bearing from the inboard side of the Flanged Cover.

Note: The Smalley Retaining Ring (pc# 23) and Protection Sleeve (pc# 24) can be removed from the Flanged Cover if

required. Remove the Protection Sleeve by tapping it out of the Flanged Cover.

11. Remove the Circlip (pc# 20) from the Worm Shaft

12. Remove the Spur Wheel

Note: The Worm Shaft Bearings (pc# 17) are press-fitted to the Worm Shaft. Removal will require a gear puller or

similar device.

18

Reassembly Instructions:

1. If the Worm Shaft (pc# 16) components have been removed, reassemble the Worm Shaft with the Worm Shaft

Bearings (pc# 17), Spur Wheel (pc# 19), and Circlip (pc# 20).

2. Lower the Quadrant (pc# 9), with the wording up, and the Worm Shaft assembly, into the Gearcase simultaneously.

Caution: The O-Ring (pc# 1) on the lower Quadrant journal seals the Gearcase / Quadrant interface. Check the condi-

tion of the O-Ring. If damaged, replace it.

3. Mesh the gearing on the Quadrant with the Worm on the Worm Shaft and slide into the Gearcase.

Page 19

Limitorque PT Series Worm Gear Operator FCD LMENIM2001-00 – 01/10

4. Mount the Motorized Pinion (pc# 8) and Bearing assembly into the Gearcase.

Note: The Oil Seal should be located near the end of the Motorized Pinion (pc# 8) to facilitate installing the assembly

into the Gearcase (pc# 2).

5. Repack the gearing area with lubricant, thoroughly immersing the Worm/Worm Gear, Worm Shaft Bearings, and

Spur Wheel/Motorized Pinion.

6. Apply Loctite 574 or equivalent around the Oil Seal and slide the Oil Seal down the Motorized Pinion (pc# 8) and

into the Gearcase.

7. Apply a bead of Loctite 574 or equivalent on the machined surface and around the bolt holes of the Gearcase, being

careful to avoid applying Loctite into the bolt holes.

8. Reinstall the Flanged Cover Bearing by seating it into the Flanged Cover from the outboard end of the Cover.

9. Install the Circlip (pc# 22).

10. Prior to installing the Flanged Cover place the Protection Sleeve Seal (pc# 25) against the Oil Seal.

11. Slide the Flanged Cover over the Worm Shaft and place onto the Gearcase.

12. Tap down the Cover Dowels (pc# 18), in the two holes in the Gearcase that are not tapped so that they are flush

with the Flanged Cover.

13. Install the Flanged Cover screws.

14. Attach the Indicator Cap (pc# 12) to the Quadrant (pc# 9) noting the location of the nub on the inside of the plastic

Indicator Cap that sets in one of the drilled holes in the Quadrant.

Caution: Check the condition of the o-ring in the Indicator Cap. If worn or damaged, replace it.

Caution: Check that the Indicator Cap is installed to correctly reflect the position of the Quadrant relative to the valve

position.

Note: The cast iron Indicator Cap is attached with two screws.

15. Ensure that the Protection Sleeve (pc# 24) is against the Protection Sleeve Seal (pc# 25). Use the Smalley Retaining

Ring (pc# 23) to push the Protection Sleeve against the Protection Sleeve Seal if needed.

16. Place the Flanged Cover Bearing and Snap Ring (pc# 17) over the Motorized Pinion (pc# 8) and into the Flanged

Cover.

17. Re-insert the Key (pc# 6) in the Motorized Pinion (pc# 8).

18. Check the operator for proper operation. The Worm Shaft should be capable of operation by hand. Stroke through a

complete open-close cycle.

flowserve.com

19

Page 20

Limitorque PT Series Worm Gear Operator FCD LMENIM2001-00 – 01/10

16

0

0

-

1

-

0

3

2

0

5

C

17

19

18

20 21

07

08

10

1112

13

15

14

09

09A

06

13B

05 04 03

02

01

05B

24

22

23

25

Figure 4.3 – PT50, 75 Disassembly & Reassembly

Figure 4.4 – PT50, 75 Disassembly & Reassembly

Figure 4.5 – PT50, 75 Disassembly & Reassembly

20

Page 21

Table 4.2 – Parts List – PT50, 75

Piece # Description

1 Quadrant O-Ring

2 Gearcase

3 Protection Cap

4 Indicator O-Ring

5 Oil Seal

6 Shaft Key

7 Pinion Shaft Bearing

8 Motorized Pinion

9 Quadrant

10 Socket Set Screw

11 Jam Nut

12 Indicator Cap

13 Cover Screw

14 Flanged Cover

15 Nameplate

16 Worm Shaft

17 Worm Shaft Bearing

18 Cover Dowel

19 Spur Wheel

20 Wheel Circlip

21 Spur Wheel Key

22 Snap Ring

23 Smalley Retaining Ring

24 Protection Sleeve

25 Protection Sleeve Seal

Limitorque PT Series Worm Gear Operator FCD LMENIM2001-00 – 01/10

4.5 PT60

Refer to Figure 4.6, 4.7 and Table 4.3

1. Remove the Valve Position Indicator (pc# 12) by removing the Indicator Bolts and Lockwashers (pc# 11).

2. Remove the Worm Cover (pc# 10).

3. Replace the Valve Position Indicator so that the center hub and the Segment Gear (pc# 19) maintain their orientation, or scribe a mark across the spline teeth for reassembly later.

4. Remove the Motor Flange (pc# 14) with Bearing Spacer (pc# 9) by removing the Thrust Spacer Bolts (pc# 20).

5. Remove the Thrust Spacer Shims.

Note: Retain the Shims as they will be required for reassembly.

6. Pull on the Worm Shaft/Bearing assembly (pc# 3) to move the tapered roller bearing cup forward.

Note: The Segment Gear (pc# 19) should be in the mid travel position in the Worm Housing (pc# 2). If the Worm

Shaft/Bearing assembly comes forward about 1 inch it will be possible to lift out the Segment Gear. If the Worm

Shaft does not come forward, remove the Frost Plug (pc# 17) from the other end of the Gear Housing and tap on

the Worm Shaft to release it from the Worm Housing.

21

flowserve.com

Page 22

Limitorque PT Series Worm Gear Operator FCD LMENIM2001-00 – 01/10

7. Remove the Segment Gear from the Worm Housing

8. Remove the Worm Shaft/Bearing assembly from the Worm Housing.

9. Remove Worm Shaft Bearings (pc# 3) from the Worm Shaft/Bearing assembly, if required, with a gear puller or

similar device.

Reassembly Instructions:

1. Check the condition of the Motor Flange Bushing (pc# 22), Segment Gear O-Ring (pc# 5), and Face Groove O-Ring

(pc# 4). Replace as required.

2. Grease the tapered roller bearings on the Worm Shaft/Bearing assembly (pc# 3) and place the Worm Shaft/Bearing

assembly into the Worm Housing (pc# 2) bore, stopping short of engaging the back Roller Bearing Cone.

3. Offset the Worm Shaft/Bearing assembly toward the outside of the Worm Housing so that it is away from the center

hub bore.

4. Grease the center hub bore and install the Segment Gear into the Worm Housing.

Note: Push the Segment Gear straight into the Worm Housing to avoid cutting the Segment Gear O-Ring (pc# 5).

Note: The Segment Gear should be seated on the shoulder in the base of the Worm Housing for PT60 operators with

one-piece segments. For operators with a removable bushing, be sure the Valve Position Indicator plate is

installed on the Segment Gear until the Worm Cover (pc# 10) is installed so that the valve position is maintained

upon reinstallation.

5. Engage the Worm Shaft/Bearing assembly with the Segment Gear and move it inward to engage the Roller Bearing

Cone.

6. Slide the other Roller Bearing Cone into the bearing bore and push it forward using the Bearing Spacer (pc# 9). The

Worm should now be engaged properly with the Segment Gear.

Note: Ensure that the Worm Shaft/Bearing assembly rotates with minimal play. Remove shims until the Worm Shaft/

Bearing assembly is tight, then add back one shim to obtain the proper fit.

7. Install the Thrust Spacer Shims (pc# 18) on the Bearing Spacer (pc# 9), engage in the housing bore, and fasten

with the Thrust Spacer Bolts (pc# 20).

Note: For operators with spur gear attachments, there will be a 1/8 inch gap from the outside of the Worm Housing

(pc# 2) to the Bearing Spacer when the Bearing Cone engages. For operators without spur gear attachments, the

Thrust Spacer length is built into the Bearing Spacer (pc# 9).

8. Re-lubricate the Worm Housing, focusing on the Worm/Segment Gear interface, while rotating the Worm Shaft/

Bearing assembly (pc# 3). Lubricate the top hub of the Segment Gear.

9. Run a bead of silicone around the top edge of the Worm Housing (pc# 2).

22

10. Place the Worm Cover on the hub and push down straight and even. Install the Worm Cover Bolts (pc# 6) and

tighten.

11. Mount the Valve Position Indicator (pc# 12) in the appropriate position relative to the Segment Gear.

12. Check rotation to ensure proper operation. The Worm Shaft/Bearing assembly should be capable of operation by

hand. Stroke through a complete open-close cycle.

Page 23

Figure 4.6 – PT60 Disassembly & Reassembly

7

8

11

10

12

6

2

18

19

4

15

17

3

20

1

9

21

13

5

14

16

22

Limitorque PT Series Worm Gear Operator FCD LMENIM2001-00 – 01/10

Figure 4.7 – PT60 Disassembly & Reassembly

23

flowserve.com

Page 24

Limitorque PT Series Worm Gear Operator FCD LMENIM2001-00 – 01/10

Table 4.3 – Spur Gear Attachment Parts List - PT60

Piece # Description

1 Insert Bushing

2 Worm Housing

3 Worm Shaft/Bearing Assembly

4 Face Groove O-Ring

5 Segment Gear O-Ring

6 Worm Cover Bolts

7 Stop Adjusting Screw

8 Adjustment Screw Jam Nut

9 Bearing Spacer

10 Worm Cover

11 Indicator Bolt, Lockwasher, Seal Kit

12 Valve Position Indicator

13 Worm Gasket

14 Motor Flange

15 Worm Cover Locating Pins

16 Insert Bushing O-Ring

17 Frost Plug

18 Thrust Spacer Shims

19 Segment Gear

20 Thrust Spacer Bolts

21 Input Key

22 Motor Flange Bushing

24

Page 25

Limitorque PT Series Worm Gear Operator FCD LMENIM2001-00 – 01/10

4.6 PT65, 120 and 150

Refer to Figures 4.8, 4.9, 4.10, 4.11 and Table 4.4.

1. Remove the Pointer Cap (pc# 14) and Gasket (pc# 15).

2. Turn the operator upside down and remove the Base (pc# 4).

3. Rotate the Base slightly to lift it from the Housing (pc# 1). Use jack-bolt holes if necessary.

4. Remove the Open End Cap (pc# 5) and Oil Seal (pc# 19) over the Worm Shaft (pc# 3).

5. Rotate the Worm Shaft until the Worm is disengaged from the one-piece Drive Sleeve/Worm Gear (pc# 2).

6. Remove the Closed End Cap (pc# 6) and Gasket (pc# 23).

7. Remove the Worm Shaft assembly from the Housing.

8. Remove the one-piece Drive Sleeve/Worm Gear from the Housing.

9. Remove worm shaft Tapered Roller Bearings (pc# 18) from the Worm Shaft assembly if required.

Reassembly Instructions:

1. Install the one-piece Drive Sleeve/Worm Gear (pc# 2) into the Housing.

2. Install the Worm Shaft assembly (pc# 3) into the Housing (pc# 1).

3. Install the Closed End Cap (pc# 6) and End Cap Gasket (pc# 23) with the tapered roller bearing cup inserted in the

End Cap.

4. Rotate the Worm Shaft (pc# 3) to re-engage the Worm with the Drive Sleeve/Worm Gear (pc# 2).

5. Install the Oil Seal (pc# 19) and the Open End Cap (pc# 5) with the tapered roller bearing cup inserted into the End

Cap.

Note: The Oil Seal must be properly lubricated.

Note: A series of gaskets are supplied in order to properly shim the Open End Cap (pc# 5). Start the assembly with

three (3) gaskets under the Open End Cap and install onto the Housing (pc# 1). Once installed, push/pull the

Worm Shaft (pc# 3) along its axis. If there is any movement, remove the Open End Cap and remove one gasket.

Reinstall and check the Worm Shaft movement again. No axial movement is allowed.

6. Install the Open End Cap.

7. Position the center of the Drive Sleeve/Worm Gear at approximately 45 degrees on the Worm Shaft.

8. Re-lubricate the housing to replace lubricant lost during disassembly.

9. Install the Base (pc# 4), ensuring that both O-Rings (pc# 12) have been replaced. Lubricate the O-Rings for easier

installation.

10. Tighten the Base socket head cap screws.

11. Return the operator to the upright position and install the Pointer Cap (pc# 14) and Pointer Cap Gasket (pc# 15).

12. Check for proper operation by stroking the operator through a complete open-close cycle.

25

flowserve.com

Page 26

Limitorque PT Series Worm Gear Operator FCD LMENIM2001-00 – 01/10

A

A

11

16

17

5

19

8

23

2

1

7

9

10

20

6

11

18

3

21

Figure 4.8 – PT65, 120, 150 Disassembly & Reassembly

Figure 4.9 – PT65, 120, 150 Disassembly & Reassembly

26

Page 27

Figure 4.10 – PT65, 120, 150 Disassembly & Reassembly

4

24

12

13

15

14

12

B

B

22

Limitorque PT Series Worm Gear Operator FCD LMENIM2001-00 – 01/10

Figure 4.11 – PT65, 120, 150 Disassembly & Reassembly

27

flowserve.com

Page 28

Limitorque PT Series Worm Gear Operator FCD LMENIM2001-00 – 01/10

Table 4.4 – Parts List – PT65, 120, 150

Piece # Description

1 Housing

2 Drive Sleeve

3 Worm Shaft

4 Base

5 Open End Cap

6 Closed End Cap

7 Stop Screw

8 Key

9 Stop Plate

10 Stop Plate Gasket

11A Hex Head Cap Screw

11B Lockwasher

12A O-Ring

12B O-Ring

13 O-Ring

14 Pointer Cap

15 Pointer Cap Gasket

16 Nameplate

17 Drive Screw

18 Tapered Roller Bearing

19 Oil Seal

20 Socket Head Cap Screw

21 Socket Head Cap Screw

22 Socket Head Cap Screw

23 End Cap Gasket

24 Splined Adapter

25 Motorized Adapter (not shown)

26 Hex Head Cap Screw (not shown)

27 Lockwasher (not shown)

28

4.7 PT250, 500, 1000

Refer to Figures 4.12, 4.13 and Table 4.5.

1. Remove the Pointer Cap (pc# 19).

2. Remove the hex head cap screws that secure the Stem Nut (pc# 18) to the Drive Sleeve/Gear (pc# 3).

3. Attach two eye bolts to the Stem Nut and remove the Stem Nut from the Drive Sleeve/Gear.

4. Remove the blind End Cap (pc# 7) and Worm Shaft Shim Set (pc# 9) from the Housing (pc# 1).

5. Turn the operator upside down and remove the screws from the Base Plate (pc# 13).

6. Insert two eye bolts into the threaded holes in the Base Plate and remove the Base Plate.

7. Remove the open End Cap and Worm Shaft Gasket (pc# 17).

Page 29

Limitorque PT Series Worm Gear Operator FCD LMENIM2001-00 – 01/10

8. Remove the Tapered Roller Bearing (pc# 6) from the open worm bore.

9. Remove the Tapered Roller Bearing (pc# 6) from the blind worm bore.

10. Attach two eye bolts to the Drive Sleeve/Gear (pc# 3) and remove.

11. Remove the Worm Shaft (pc# 2) from the Housing (pc# 1).

12. Remove the Hex Nut (pc# 11) from the Drive Sleeve Stops (pc# 10) and remove the Stops from the Housing.

Reassembly Instructions:

1. Install the Drive Sleeve Stops (pc# 10) into the Housing (pc# 1) and reattach the Hex Nuts (pc# 11).

2. Insert the Worm Shaft (pc# 2) into the Housing.

3. Attach two eye bolts to the Drive Sleeve/Gear (pc# 3) and install into the Housing.

Note: Replace the upper O-Ring (pc# 4) and lower O-Ring (pc# 5) on the Drive Sleeve/Gear (pc# 3). Lubricate the

O-Rings for easier installation.

4. Install the Tapered Roller Bearing (pc# 6) and bearing cone for the blind worm bore.

5. Install the Tapered Roller Bearing (pc# 6) and bearing cone for the open End Cap.

6. Install the open End Cap and Worm Shaft Gasket (pc# 17).

7. Re-lubricate the housing to replace lubricant lost during disassembly.

8. Insert two eye bolts into the Base Plate (pc# 13) and install the Base Plate (pc# 13) to the Housing (pc# 1).

Note: Ensure that the O-Ring is securely positioned into the groove on the bottom of the Base Plate. Lubricate the

O-Ring for easier installation

9. Turn the operator right side up and install the blind Worm Cap (pc# 7) and Worm Shaft Shim Set (pc# 9) on the

Housing.

Note: Add or subtract shims until there is no excessive play in the Worm Shaft (pc# 2) and the Worm Shaft turns

freely.

10. Attach two eye bolts to the Stem Nut (pc# 18) and install into the Drive Sleeve/Gear

11. Install the Pointer Cap.

12. Check the rotation of the Drive Sleeve/Gear through one complete open-close cycle to ensure proper operation.

flowserve.com

29

Page 30

Limitorque PT Series Worm Gear Operator FCD LMENIM2001-00 – 01/10

SECTION A-A

Drivesleeve

SCALE 1 : 3

19

15

3

13

18

4

5

14

20

2X 2.29

ASSEMBLE STOPS

TO THIS DIMENSION

Wormshaft & Stops

Scale 1 : 3

25

15

7

15

8

9

6

2

6

21

45

17

1

11

10

12

22

Figure 4.12 – PT250, 500, 1000 Disassembly & Reassembly

Figure 4.13 – PT250, 500, 1000 Disassembly & Reassembly

30

Page 31

Limitorque PT Series Worm Gear Operator FCD LMENIM2001-00 – 01/10

Table 4.5 – Parts List – PT250, 500, 1000

Piece # Description Piece # Description

1 Housing 26 SGA Housing

2 Worm Shaft 27 Gear

3 Drive Sleeve/Gear 28 Ball Bearing

4 O-Ring 29 Ball Bearing

5 O-Ring 30 Not used with double SGA

6 Tapered Roller Bearing 31 Drive Pinion

7 End Cap 32 Key

8 O-Ring 33 SGA Gear

9 Worm Shaft Shim Set 34 Ball Bearing

10 Drive Sleeve Stop 35 SGA Pinion

11 Hex Nut 36 SGA Cover Gasket

12 O-Ring 37 Dowel Pin

13 Base Plate 38 SGA Cover

14 O-Ring 39A Hex Head Cap Screw

15 Hex Head Cap Screw 39B Hex Head Cap Screw

16 Square Head Pipe Plug 40 Not used with double SGA

17 Worm Shaft Gasket 41 Oil Seal

18 Stem Nut 42 SGA Adapter Gasket

19 Pointer Cap 43 Unit Adapter

20 Machined Hex Head Cap Screw 44 Key

21 Oil Seal 45 Not used with double SGA

22 Screw Preload Sticker 46 Hex Head Cap Screw

23 Nameplate 46A Lockwasher

24 Type U Drive Screw

25 Key

4.8 Spur Gear Attachments - PT14, 30, 40

Refer to Figure 4.14 and Table 4.6

1. Remove Hex Head Screws (pc# 12) from the spur Cover (pc# 1).

2. Remove spur Cover and Input Pinion (pc# 4).

3. Remove Key from Input Pinion.

4. Remove Circlip (pc# 11)

5. Pull Input Pinion out of Cover

6. Remove Circlip (pc# 10)

7. Tap out Sealed Bearings (pc# 6) from Cover

8. Remove the Hex Full Nuts (pc# 15) and Lockwashers (pc# 16) from the Mounting Studs (pc# 14) that attach the

spur Gearcase (pc# 2) to the Flanged Cover of the operator.

9. Remove Circlip (pc# 9) from spur Gearcase.

10. Remove the Spur Gear from the spur Gearcase (pc# 2).

31

flowserve.com

Page 32

Limitorque PT Series Worm Gear Operator FCD LMENIM2001-00 – 01/10

11. Remove Circlip (pc# 8)

12. Tap out Sealed Bearing (pc# 5)

Reassembly Instructions:

1. If the Sealed Bearing (pc# 5) has been removed from the spur Gearcase (pc# 2), reinstall the bearing and Circlip

(pc# 8).

2. Insert the Spur Gear (pc# 3) into the spur Gearcase.

3. Mount the spur Gearcase to the Flanged Cover of the operator, using the Hex Full Nuts and Lockwashers, aligning

the key slot with the key slot in the operator Worm Shaft.

Caution: The Worm Shaft Key should remain in the Worm Shaft when the Spur Gear and spur Gearcase are removed

from the operator. Be sure the Key is in place prior to installing the spur Gearcase and Spur Gear.

4. Reinstall the two Sealed Bearings (pc# 6) if they were removed from the spur Cover (pc# 1) and install the Circlip

(pc# 10).

5. Install the Input Pinion (pc# 4) into the spur Cover (pc# 1) and install the Circlip (pc# 11) to retain the Input Pinion

in the spur Cover.

6. Re-lubricate the housing to replace lubricant lost during disassembly.

7. Apply a bead of Loctite 574 or equivalent on the machined surface and around the bolt holes of the spur Gearcase,

being careful to avoid applying Loctite into the bolt holes.

8. Install the spur Cover (pc# 1) with Input Pinion (pc# 4), meshing the pinion gear with the Spur Gear.

Note: Rotate the input pinion slightly if the pinion gear does not properly mesh with the Spur Gear.

9. Secure the Cover with Hex Head Screws.

10. Install the Pinion Shaft Key.

32

Page 33

Limitorque PT Series Worm Gear Operator FCD LMENIM2001-00 – 01/10

5

9

8

15

16

4

6

12

13

10

11

18

STORAGE AND

TRANSPORT ONLY

6

3

14

2

1

STUDS TO BE FITTED WITH

A PROJECTION DIMENSION

OF 24.0/25.0 AND SECURED

USING LOCTITE 242

Figure 4.14 – PT14, 30, 40 Spur Gear Attachment Disassembly & Reassembly

Table 4.6 – Parts List – Spur Gear Attachment PT14, 30, 40

Piece # Description

1 Cover

2 Gearcase

3 Spur Gear

4 Input Pinion

5 Sealed Bearing

6 Sealed Bearing

7 Bearing

8 Circlip

9 Circlip

10 Circlip

11 Circlip

12 Hex Head Screw

13 Dowel (H&G)

14 Mounting Stud

15 Hex Full Nut

16 Spring Washer

17 Grease

18 Plug, black PVC

33

flowserve.com

Page 34

Limitorque PT Series Worm Gear Operator FCD LMENIM2001-00 – 01/10

4.9 Spur Gear Attachments - PT60

Refer to Figure 4.15, 4.16, 4.17 and Table 4.7

1. Remove the Motor Flange (pc# 14)

2. Remove the Spur Cover (pc# 20) and Spur Cover Seal (pc# 16) from the Spur Housing (pc#19)

Note: The cover has a Locating Pin (pc# 23). Use a prying device such as a screwdriver along the edge to free the Spur

Housing Cover from the Spur Housing.

3. Remove the Input Shaft (pc# 4) with O-Rings (pc# 1)

4. Remove Spur Gear (pc# 10) and Spur Gear Key (pc# 11)

5. Remove the Spur Housing (pc# 19) and Spur Housing Gaskets (pc# 18)

6. If disassembly of the PT is required, please see section 4.4

Reassembly Instructions:

1. Install all Spur Housing Gaskets (pc# 18) and Spur Housing (pc# 19) with two bolts opposite each other in order to

hold the assembly in place against the PT Housing.

Caution: The Spur Housing Gaskets between the Spur Housing and the PT Housing act as shims to set the bearing

preload for the tapered roller bearings on the Worm Shaft/Bearing Assembly (pc# 3). The Assembly should

have minimum play up and down and end to end. It should also rotate easily.

2. Remove one gasket at a time until the shaft pinches and will not rotate. Add back one gasket to obtain the

correct fit.

3. Lightly lubricate the keyed end of the Worm Shaft/Bearing Assembly, (pc# 3) and install the Spur Gear Key

(pc# 11)

4. Install the Spur Gear (pc# 10) into the Spur Housing (pc# 19), avoiding pushing it to the bottom of the housing.

5. Lubricate the journal bore for the Input Shaft (pc# 4)

6. Lubricate the Input Shaft and slide it into the journal bore in the Spur Cover (pc# 20). Be sure that the O-Rings

(pc# 1) and Input Shaft Washers (pc# 7 & 8) are in place.

7. Ensure that the Spur Cover Locating Pins (pc# 23) in the Spur Cover (pc# 20) are flush with the mating surface of

the Spur Cover.

8. Relubricate the Spur Housing (pc# 19) but do not fill completely.

9. Run a bead of silicone sealant around the mating surface of the Spur Housing and Spur Cover.

10. Apply the small end journal washer to the Input Shaft (pc# 4).

11. Install the Spur Cover (pc# 20) with Locating Pins (pc# 23), Spur Cover Gasket (pc# 33), and Input Shaft onto the

Spur Housing and aim the small journal of the Input Shaft for the mating bore in the Spur Housing.

34

12. With the Spur Cover in place and properly seated, drive in the Spur Cover Locating Pins (pc# 23) and install the

Cover bolts.

13. Lightly lubricate the bore of the Motor Flange (pc# 14) and bolt the Flange in place.

14. Check the rotation of the Worm Gear through at least one half of the travel of the Gear.

Note: Replace any worn or damaged O-Rings or Gaskets to ensure proper sealing.

Page 35

Figure 4.15 – PT60 SGA Disassembly & Reassembly

14

17

3

SECTION A-A

12

16

24

11

3

9

6

10

785

A

21

22

28

29

27

30

2

18 23

A

25

19

33

15

160 INS BUSHING, ORDER SEPARATELY

FLOWSERVE # 65-240-0057-2

Limitorque PT Series Worm Gear Operator FCD LMENIM2001-00 – 01/10

Figure 4.16 – PT60 SGA Disassembly & Reassembly

35

flowserve.com

Page 36

Limitorque PT Series Worm Gear Operator FCD LMENIM2001-00 – 01/10

31

26

14

32

13

20

34

Figure 4.17 – PT60 SGA Disassembly & Reassembly

36

Table 4.7 – Parts List – Spur Gear Attachment – PT60

Piece # Description Piece # Description

1 Input Shaft O-Ring 18 Spur Housing Gasket

2 Worm Housing 19 Spur Housing

3 Worm Shaft/Bearing Assembly 20 Spur Cover

4 Input Shaft 21 Stop Adjusting Screw

5 Input Shaft Bearing 22 Stop Adjusting Nut

6 Input Shaft Flanged Bushing 23 Spur Cover Locating Pin

7 Input Shaft Flanged Bushing Washer 24 Spur Cover Worm Shaft Bearing

8 Input Shaft Spur Cover Washer 25 Segment Gear

9 Bearing Spacer 26 Segment O-Ring

10 Spur Gear 27 Valve Position Indicator

11 Spur Gear Key 28 Indicator Bolt, Lockwasher, and Seal Kit

12 Spur Housing Bolt 29 Worm Cover

13 Spur Cover Bolt 30 Worm Cover Bolt

14 Motor Flange 31 Worm Cover Gasket

15 Worm Cover Locating Pins 32 Motor Flange Bolts

16 Spur Cover Seal 33 Face Groove O-Ring

17 Frost Plug 34 Insert Bushing O-Ring

Page 37

Limitorque PT Series Worm Gear Operator FCD LMENIM2001-00 – 01/10

9

12

3

4.10 Spur Gear Attachments - PT65, 120, 150

Refer to Figure 4.18, 4.19, 4.20 and Table 4.8

1. Remove the Socket Head Cap Screws (pc# 9) that secure the Spur Gear Attachment (SGA) Cover (pc# 2) to the

SGA Housing (pc# 1)

2. Remove the SGA Cover, Input Pinion (pc# 3) and SGA Cover Gasket

3. Remove the Intermediate Gear (pc# 4)

4. Remove the Output Gear (pc# 5) from the Worm Shaft

5. Remove the SGA Housing (pc# 1) and SGA Housing Gasket (pc# 13)

6. If the PT requires disassembly, please see section 4.5

Reassembly Instructions:

1. Install the SGA Housing (pc# 1) and SGA Housing Gasket (pc# 13)

2. Insert the Output Gear (pc# 5) onto the PT Worm Shaft

3. Install the Intermediate Gear (pc# 4)

4. Re-lubricate thoroughly the Oil Seal (pc# 10) in the SGA Cover (pc# 2)

5. Re-lubricate the SGA Housing to replace lubricant lost during disassembly

6. Install the SGA Housing Cover (pc# 2) with Input Pinion (pc# 3) and SGA Cover Gasket.

Note: Replace any worn or damaged O-rings or gaskets to ensure proper sealing.

Figure 4.18 – PT65, 120, 150 SGA Disassembly & Reassembly

37

flowserve.com

Page 38

Limitorque PT Series Worm Gear Operator FCD LMENIM2001-00 – 01/10

A

A

8

11

SECTION A-A

2

1

4

6

7

5

10

13

3

Figure 4.19 – PT65, 120, 150 SGA Disassembly & Reassembly

Figure 4.20 – PT65, 120, 150 SGA Disassembly & Reassembly

38

Page 39

Limitorque PT Series Worm Gear Operator FCD LMENIM2001-00 – 01/10

Table 4.8 – Parts List – Spur Gear Attachment – PT65, 120, 150

Piece # Description

1 SGA Housing

2 SGA Cover

3 Input Pinion

4 Intermediate Gears

5 Output Gear

6 Needle Roller Bearing

7 Radial Ball Bearing

8 Dowel Pin

9 Socket Head Cap Screw

10 Lip Seal

11 Pipe Plug

12 Key

13 SGA Housing Gasket

4.11 Spur Gear Attachments - PT250, 500, 1000

Refer to Figure 4.21, 4.22 and Table 4.9

1. Remove the hex head cap screws from the Unit Adapter (pc# 43) and remove the Unit Adapter from the SGA

(Spur Gear Attachment) Cover (pc# 38).

2. Remove all traces of the SGA Adapter Gasket (pc# 42).

3. Remove the SGA Pinion (pc# 35)

4. Remove the Ball Bearing (pc# 29) from the SGA Cover.

5. Remove the hex head cap screws that attach the SGA Cover to the SGA Housing (pc# 26) and remove

the SGA Cover.

6. Remove the Spur Gear (pc# 33) from the Drive Pinion (pc# 31)

7. Remove the Drive Pinion

8. Remove the SGA Cover Gasket (pc# 36) from the SGA Cover surface

9. Remove the Ball Bearing (pc# 28) from the Worm Shaft (pc# 2)

10. Remove the SGA Input Gear (pc# 27) from the Worm Shaft

11. Remove the SGA Housing (pc# 26) from the PT Housing (pc#1)

12. If disassembly of the PT is required, please see section 4.6

39

flowserve.com

Page 40

Limitorque PT Series Worm Gear Operator FCD LMENIM2001-00 – 01/10

43

46

44

SECTION C-C

Single SGA

Scale = 1:3

38

29

37

42

30

40

28

29

36

39B

26

27

39A

21

46A

Reassembly Instructions:

1. Install the SGA Housing (pc# 26) to the PT Housing (pc# 1)

2. Install the SGA Input Gear (pc# 27) onto the Worm Shaft (pc# 2)

3. Install the Ball Bearing (pc# 28) onto the Worm Shaft

4. Replace the SGA Cover Gasket (pc# 36)

5. Install the Drive Pinion (pc# 31)

6. Install the Spur Gear (pc# 33) onto the Drive Pinion

7. Re-lubricate the housing to replace lubricant lost during disassembly.

8. Replace the SGA Cover Gasket (pc# 36) and install the SGA Cover (pc# 38)

9. Relubricate the Oil Seal (pc# 41) in the SGA Cover

10. Insert the Ball Bearing (pc# 29) into the SGA Cover

11. Install the SGA Pinion (pc# 35)

12. Replace the SGA Adapter Gasket (pc# 42)

13. Attach the Unit Adapter (pc# 43)

Note: Replace any worn or damaged O-Rings or Gaskets to ensure proper sealing and operation.

Figure 4.21 – PT250, 500, 1000 SGA Disassembly & Reassembly

40

Page 41

Limitorque PT Series Worm Gear Operator FCD LMENIM2001-00 – 01/10

SECTION D-D

SCALE = 1:3

41

35

31

32

34

43

16

2X

33

Double SGA

Figure 4.22 – PT250, 500, 1000 SGA Disassembly & Reassembly

Table 4.9 – Parts List – Spur Gear Attachment – PT250, 500, 1000

Piece # Description Piece # Description

1 Housing 36 SGA Cover Gasket

2 Worm Shaft 37 Dowel Pin

16 Square Head Pipe Plug 38 SGA Cover

21 Oil Seal 39A Hex Head Cap Screw

26 SGA Housing 39B Hex Head Cap Screw

27 Gear 40 Not used with double SGA

28 Ball Bearing 41 Oil Seal

29 Ball Bearing 42 SGA Adapter Gasket

30 Input Pinion 43 Unit Adapter

31 Drive Pinion 44 Key

32 Key 45 Unit Adapter

33 SGA Gear 46 Hex Head Cap Screw

34 Ball Bearing 46A Lockwasher

35 SGA Pinion

41

flowserve.com

Page 42

5

To order parts or obtain further information about your Limitorque PT valve operator,

contact your local Limitorque distributor sales office, www.limitorque.com, or:

Flowserve Limitorque

5114 Woodall Road

Lynchburg, VA 24502

Telephone: 434-528-4400

Fax 434-845-9736

Limitorque PT Series Worm Gear Operator FCD LMENIM2001-00 – 01/10

How to Order Parts

All inquiries or orders must be accompanied by the following information, which is

located on the nameplate:

1. Operator size

2. Order number

3. Serial number

42

Page 43

This page intentionally left blank.

Limitorque PT Series Worm Gear Operator FCD LMENIM2001-00 – 01/10

flowserve.com

43

Page 44

To find your local Flowserve representative,

visit www.flowserve.com, www.limitorque.com

or call USA 1 800 225 6989

Flowserve Corporation

Flow Control

United States

Flowserve Limitorque

5114 Woodall Road,

P.O. Box 11318

Lynchburg, VA 24506-1318

Phone: 434-528-4400

Facsimile: 434-845-9736

England

Flowserve Limitorque

Euro House

Abex Road

Newbury

Berkshire, RG14 5EY

United Kingdom

Phone: 44-1-635-46999

Facsimile: 44-1-635-36034

Japan

Limitorque – Nippon Gear Co., Ltd.

Asahi-Seimei Bldg. 4th Floor

1-11-11 Kita-Saiwai, Nishi-Ku

Yokohama-Shi, (220-0004)

Japan

Phone: 81-45-326-2065

Facsimile: 81-45-320-5962

Canada

Flowserve Limitorque

120 Vinyl Court

Woodbridge, Ontario L4L 4A3

Canada

Phone 905-856-4565

Fax 905-856-7905

FCD LMENIM2001-00 Printed in USA. 01/10

Flowserve Corporation has established industry leadership in the design and manufacture of its products. When properly selected, this Flowserve product is designed to perform its intended

function safely during its useful life. However, the purchaser or user of Flowserve products should be aware that Flowserve products might be used in numerous applications under a

wide variety of industrial service conditions. Although Flowserve can (and often does) provide general guidelines, it cannot provide specific data and warnings for all possible applications.

The purchaser/user must therefore assume the ultimate responsibility for the proper sizing and selection, installation, operation, and maintenance of Flowserve products. The purchaser/

user should read and understand the Installation Operation Maintenance (IOM) instructions included with the product, and train its employees and contractors in the safe use of Flowserve

products in connection with the specific application.

While the information and specifications contained in this literature are believed to be accurate, they are supplied for informative purposes only and should not be considered certified or as

a guarantee of satisfactory results by reliance thereon. Nothing contained herein is to be construed as a warranty or guarantee, express or implied, regarding any matter with respect to this

product. Because Flowserve is continually improving and upgrading its product design, the specifications, dimensions and information contained herein are subject to change without notice.

Should any question arise concerning these provisions, the purchaser/user should contact Flowserve Corporation at any one of its worldwide operations or offices.

© 2010 Flowserve Corporation, Irving, Texas, USA. Flowserve is a registered trademark of Flowserve Corporation.

flowserve.com

Singapore

Limitorque Asia, Pte., Ltd.

12, Tuas Avenue 20

Singapore 638824

Phone: 65-6868-4628

Facsimile: 65-6862-4940

China

Limitorque Beijing, Pte., Ltd.

RM A1/A2

22/F, East Area, Hanwei Plaza

No. 7 Guanghua Road, Chaoyang District

Beijing 100004, Peoples Republic of China

Phone: 86-10-5921-0606

Facsimile: 86-10-6561-2702

India

Flowserve Limitorque

No.10-12, THE OVAL, Third floor

Venkatnarayana Road

T. Nagar, Chennai 600 017

Phone: 91-44-2432-8755

& 91-44-2432-4801

Facsimile: 91-44-2432-8754

Loading...

Loading...