Page 1

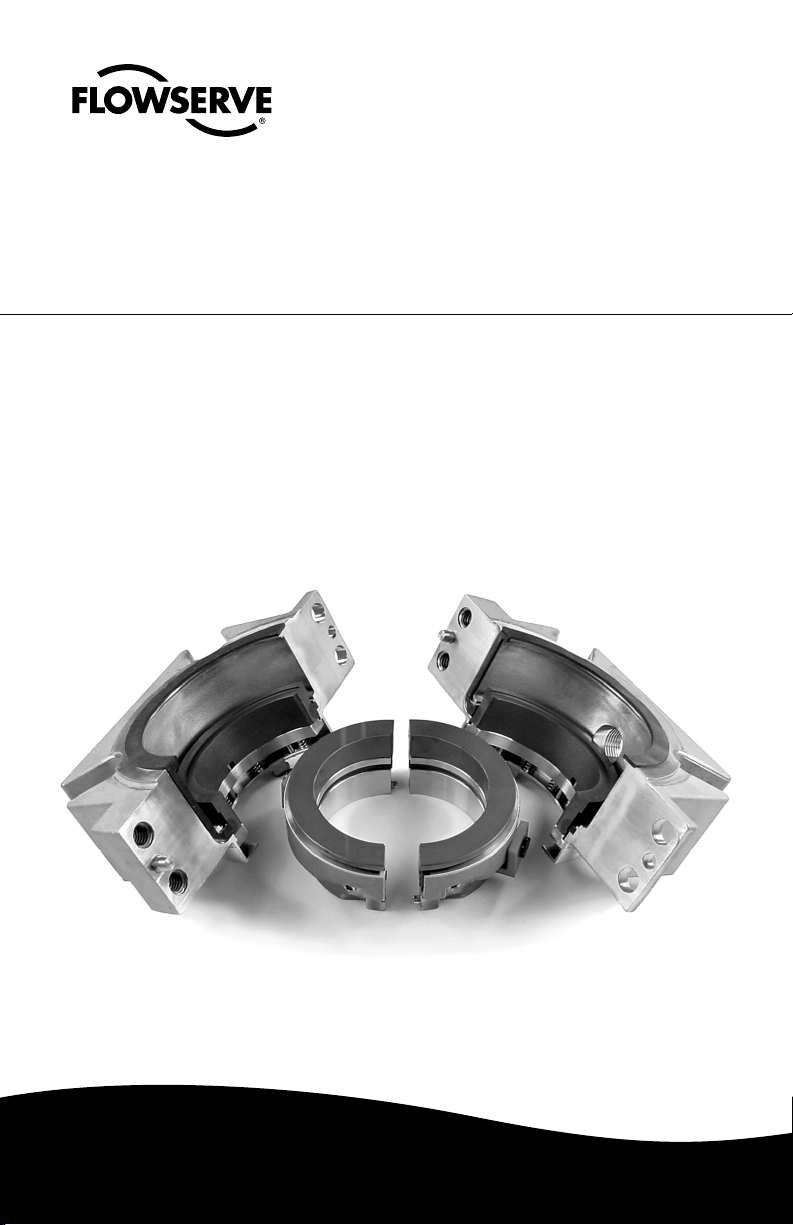

Supplementary PSS II and III

For Goulds 3410 Pumps

Installation

Instructions

Experience In Motion

Page 2

Installation of a PSS II and III on a Goulds 3410 Pump can be simplified

by following the supplemental instructions below. These instructions

should be used in conjunction with the standard PSS II and III Installation

Instructions.

1. After making the appropriate checks and prior to installing the seal,

remove the slingers on the 3410 S and L models (reference Table 1).

If a labyrinth is used on the bearing frame, the seal will not fit. Check

the minimum distance required for PSS II and III installation in Table 1.

Table 1

Pump Model 3410 S 3410 M 3410 L 3410 XL

Sleeve Diameter 1.750" 2.125" 2.750" 3.000"

and Seal Size

Must Slinger Be Yes No Yes No

Removed?

Must Centering Yes Yes Yes No

Devices Be Removed?

1

Bolt Size and Length

Recommended long long long long

Number of Bolts 2 2 2 2

Distance from Stuffing 2.38" 2.69" 2.55" 2.94"

Box to Slinger

Distance from Stuffing 2.54" 2.74" 2.70" 3.09"

Box to Bearing Frame*

Distance from Stuffing - 2.44" 2.18" -

Box to Labyrinth

Minimum Distance 2.40" 2.62" 2.62" 2.62"

Required For

PSS II and III Installation* *

*This is an approximate dimension which varies from pump to pump.

**Assumes that the centering devices are removed.

/2" x 2"

1

/2" x 21/4"1/2" x 21/4"1/2" x 21/4"

2. If there is no drain hole in the bottom of the cradle, drill one.

3. Install the seal drive, rotating face, and stationary face per the

standard instructions. Reference FIS145eng, PSS II Installation

Instructions and FIS175eng, PSS III Installation Instructions.

4. Prior to gland installation, remove the gland centering devices from

seals being installed in the 3410 S, M, and L models (reference Table 1).

© Copyright 2005 Flowserve Corporation

2

Page 3

Bearing Housing Bolts

Figure 1

Figure 2

5. Assemble the gland

halves around the

seal but do not yet bolt

the gland to the pump.

6. Remove the bolts

holding the bearing

housing, Figure 1.

7. Install both gland

bolts. Install the lower

bolt by rotating the

bearing housing 90

degrees for easier

access. See Figure 2.

Tighten the bolts

evenly with the gland

visually centered. Use

a crow foot-wrench to

tighten the lower bolt.

See Figures 3 and 4.

Draw the bolts up

evenly. Finger tight

plus one half turn is

usually adequate.

Figure 3

Figure 4

8. Reinstall the bearing

housing bolts and

complete the PSS II

or III installation per

the standard installation instructions.

3

Page 4

TO REORDER REFER TO

B/M #

.

F.O

USA and Canada

Flowserve Corporation

Flow Solutions

Kalamazoo, Michigan USA

Telephone: 1 269 381 2650

Telefax: 1 269 382 8726

FIS146eng REV 06-05 Printed in USA

To find your local Flowserve representative

and find out more about Flowserve Corporation,

visit www.flowserve.com

Flowserve Corporation has established industry leadership in the design and manufacture of its products. When properly

selected, this Flowserve product is designed to perform its intended function safely during its useful life. However, the

purchaser or user of Flowserve products should be aware that Flowserve products might be used in numerous applications

under a wide variety of industrial service conditions. Although Flowserve can provide general guidelines, it cannot

provide specific data and warnings for all possible applications. The purchaser/user must therefore assume the ultimate

responsibility for the proper sizing and selection, installation, operation, and maintenance of Flowserve products. The

purchaser/user should read and understand the Installation Instructions included with the product, and train its employees

and contractors in the safe use of Flowserve products in connection with the specific application.

While the information and specifications contained in this literature are believed to be accurate, they are supplied for informative

purposes only and should not be considered certified or as a guarantee of satisfactory results by reliance thereon. Nothing

contained herein is to be construed as a warranty or guarantee, express or implied, regarding any matter with respect to this

product. Because Flowserve is continually improving and upgrading its product design, the specifications, dimensions and

information contained herein are subject to change without notice. Should any question arise concerning these provisions, the

purchaser/user should contact Flowserve Corporation at any one of its worldwide operations or offices.

flowserve.com

Europe, Middle East, Africa

Flowserve Corporation

Flow Solutions

Roosendaal, The Netherlands

Telephone: 31 165 581400

Telefax: 31 165 552622

Asia Pacific

Flowserve Corporation

Flow Solutions

Singapore

Telephone: 65 684 65100

Telefax: 65 674 71963

Latin America

Flowserve Corporation

Flow Solutions

Mexico City

Telephone: 52 55 5567 7170

Telefax: 52 55 5567 4224

Loading...

Loading...