Page 1

GESTRA Steam Systems

PA 46

PA 47

MPA 46

MPA 47

Installation Instructions 81844700

RapidAction Intermittent Valve for Removing Boiler Sludge

PA 46, PA 47, MPA 46, MPA 47

1

Page 2

2

Contents

Page

Important Notes

Usage for the intended purpose ..............................................................................................................4

Safety note .............................................................................................................................................4

Danger ...................................................................................................................................................4

Classification pursuant to Article 9 of the Pressure Equipment Directive (PED) 97/23/EC .........................

Classification pursuant to Annex 1 of ATEX Directive 94/9/EC ..................................................................5

Explanatory Notes

Scope of supply ......................................................................................................................................6

Description .............................................................................................................................................7

Function .................................................................................................................................................7

Technical Data

End connection .......................................................................................................................................8

Pressure ratings .....................................................................................................................................8

Materials ................................................................................................................................................8

Pressure & temperature ratings ..............................................................................................................8

Corrosion resistance ...............................................................................................................................9

Sizing .....................................................................................................................................................9

Name plate/ marking ..............................................................................................................................9

Capacity chart PA 46, PA 47, MPA 46, MPA 47 ......................................................................................10

Control pressure chart MPA 46, MPA 47 ................................................................................................11

5

Design

PA 46, PA 47 .........................................................................................................................................12

MPA 46, MPA 47 ...................................................................................................................................13

Key .......................................................................................................................................................14

Installation

PA 46, PA 47, MPA 46, MPA 47 .............................................................................................................15

Flanged design .....................................................................................................................................15

Socketweld design ..............................................................................................................................15

Buttweld design .................................................................................................................................16

Heat treatment of welds .......................................................................................................................16

Mounting of hand lever ........................................................................................................................16

Commissioning

PA 46, PA 47, MPA 46, MPA 47 ............................................................................................................16

Operation

Duration and frequency of intermittent boiler blowdown .......................................................................17

Page 3

Contents continued

Page

Emergency operation MPA 46, MPA 47

Danger .................................................................................................................................................17

Fit hand lever for emergency operation .................................................................................................17

Maintenance

Danger .................................................................................................................................................17

Replacing stuffing box PA 46, PA 47 ......................................................................................................18

Replacing stuffing box, valve seat and valve plug PA 46, PA 47 .............................................................19

Replacing stuffing box MPA 46, MPA 47 ................................................................................................20

Replacing stuffing box, valve seat and valve plug MPA 46, MPA 47 .......................................................21

Retightening stuffing box ......................................................................................................................22

Replacing control membrane in diaphragm actuator MPA 46, MPA 47 ...................................................22

Torques ................................................................................................................................................23

Tools .....................................................................................................................................................23

Single parts of stuffing box, valve plug, valve seat .................................................................................24

Mounting/removing valve seat ..............................................................................................................25

Mounting/removing control membrane .................................................................................................26

Key .......................................................................................................................................................27

Retrofitting

Danger .................................................................................................................................................27

Mounting diaphragm actuator ...............................................................................................................27

Mounting forkhead................................................................................................................................28

Tools .....................................................................................................................................................28

Torques ................................................................................................................................................28

Spare Parts

Spare parts list .....................................................................................................................................29

Parts for retrofitting

List of parts for retrofitting ....................................................................................................................30

Decommissioning

Danger .................................................................................................................................................30

Disposal................................................................................................................................................30

Annex

Declaration of Conformity .....................................................................................................................31

3

Page 4

4

Important Notes

Usage for the intended purpose

PA 46, PA 47, MPA 46, MPA 47:

Use the rapid-action intermittent valves*) only for removing boiler water containing accumulated

nonmetallic sediments from steam boilers within the admissible pressure und temperature ratings.

Use only compressed air (at room temperature) or pressurized water (at room temperature) as control

fluid for the GESTRA diaphragm actuator in accordance with the specified pressure/temperature

ratings.

Application in potentially explosive atmospheres as classified according to Annex I of ATEX Directive

94/9/EC.

*) Please note:

In British English an intermittent valve for removing boiler sludge is referred to as “(intermittent)

bottom blowdown valve”.

In American English the term “(intermittently operating) blowoff valve” is used, but only in

conjunction with a slowopening valve (ASME code).

Safety Note

The equipment must only be installed and commissioned by qualified and competent staff.

Retrofitting and maintenance work must only be performed by qualified staff

who – through adequate training – have achieved a recognised level of competence.

Danger

The valve is under pressure during operation.

When loosening flanged connections, sealing plugs or stuffing boxes, hot water and

steam may escape.

Before carrying out installation and maintenance work make sure the system is

depressurized.

Isolate the valve from both upstream and downstream pressure.

Depressurize control lines!

The valve becomes hot during operation.

This presents the risk of severe burns to hands and arms.

Before carrying out installation and maintenance work make sure that the valve is cold.

Risk of severe burns and scalds to the whole body!

Before carrying out any maintenance work on the valve or loosening flanged

connections, stuffing box unions or sealing plugs make sure that all connected lines

are depressurized (zero bar) and cooled down to room temperature (20 °C).

During operation moving internals can pinch one’s hands or fingers, causing severe

injuries. Do not touch the valve during operation! The intermittent valves for removing

boiler sludge MPA 46, MPA 47 are time controlled and can open and close abruptly.

Sharp edges on internals present a danger of cuts to hands. Always wear industrial

gloves when replacing the packing, valve seat or valve plug!

Page 5

Important Notes continued

Classification pursuant to Article 9 of the Pressure Equipment Directive (PED) 97/23/EC

Type

Fluid Gas, steam Liquid Gas, steam Liquid

Fluid group 1 2 1 2 1 2 1 2

Application no yes no yes no yes no yes

Type

MPA 46 CL 150 20, 25, 32, 40, 50

MPA 46 CL 300 20, 25, 32 40, 50

MPA 46 PN 40 20, 25, 32 40, 50

MPA 47 CL 400 25 40, 50

MPA 47 PN 63 25 40, 50

PA 46 CL 150 20, 25, 32, 40, 50

PA 46 CL 300 20, 25, 32 40, 50

PA 46 PN 40 20, 25, 32 40, 50

PA 47 CL 400 25 40, 50

PA 47 PN 63 25 40, 50

PN CLASS

CE Marking no

PA 46, PA 47 MPA 46, MPA 47

Nominal size DN

Exception pursuant to article 3.3 Category I

0525

Classification pursuant to Annex 1 of ATEX Directive 94/9/EC

Type

Equipment group II II

Equipment category 2 2

Potentially explosive atmosphere (1999/92/EC) 1, 2, 21, 22 1, 2, 21, 22

CE Marking / EX Marking

Marking “X”

PA 46, PA 47 MPA 46, MPA 47

II 2 G/D c X

The equipment itself does not generate inadmissibly high

surface temperatures. The user must make sure that the

operating fluid does not generate inadmissibly high surface

temperatures.

II 2 G/D c X

5

Page 6

6

Explanatory Notes

Scope of supply

PA 46

1 Intermittent valve for removing boiler sludge PA 46

1 Hand lever

1 Installation manual

PA 47

1 Intermittent valve for removing boiler sludge PA 47

1 Hand lever

1 Installation manual

MPA 46

1 Intermittent valve for removing boiler sludge MPA 46

1 Installation manual

MPA 47

1 Intermittent valve for removing boiler sludge MPA 47

1 Installation manual

Retrofitting kit for PA 46, PA 47

1 Diaphragm actuator

1 Spacer disc

1 Installation manual

Hand lever for emergency operation

1 Hand lever for emergency operation

1 Forkhead G 10 x 20, DIN 71752

1 Hexagonhead cap screw

Spare Parts

1 Kit according to spare parts list (see page 29)

Page 7

Explanatory Notes continued

Description

Intermittent valves for manual or automatic and programmecontrolled removing of boiler sludge from

land or marine installations, particularly if these installations are operated without constant supervision

in accordance with TRD 604. Sludge sediments, which are accumulated precipitates from boiler water

that settle at the bottom of the boiler, will be removed from the steam boiler with the the aid of valves

PA and MPA. These valves give the boiler a short blow at regular intervals, thereby discharging

accumulated sludge and sediments.

■ PA 46 and PA 47 are designed for manual operation (diaphragm actuator can be retrofitted).

■ MPA 46 and MPA 47 feature a diaphragm actuator for compressed air or pressurized water.

Function

The intermittent valves for removing boiler sludge PA 46 and PA 47 are openend by means of a hand

lever. A pressure pin forces the springloaded valve plug out of the valve seat. The large cross

sectional area of the orifice creates a suction effect, giving a shortterm high water flow which will

discharge the precipitated sludge and sediments and if installed move them to a mixing cooler

(= blowdown receiver). The intermittent valve for removing boiler sludge must be completely opened

for about 2 seconds with the aid of the hand lever in order to give the boiler a short and highly

effective blow.

The intermittent valves for removing boiler sludge MPA 46 and MPA 47 are openend by the diaphragm

actuator. The guide pin of the diaphragm actuator acts upon the pressure pin, which in turn forces the

springloaded valve plug out of the valve seat. The large crosssectional area of the orifice creates a

suction effect, giving a shortterm high water flow which will discharge the precipitated sludge and

sediments and if installed move them to a mixing cooler (= blowdown receiver). Compressed air

(at room temperature) or pressurized water (at room temperature) can be used as control fluid for the

diaphragm actuator in accordance with the specified pressure and temperature ratings (see diagram

on page 11).

The duration of the bottom blowdown, i. e. the time when the valve is open, should be approx.

2 seconds. The time period when the valve remains closed and hence the frequency of the bottom

blowdown must be established as a function of the size and capacity of the steam boiler. We

recommend that approx. 10 per cent of the total amount of boiler water to be removed is discharged

via the intermittent valve for removing boiler sludge.

The duration and frequency of the bottom blowdown must be established individually by the user

as a function of the size and capacity of the steam boiler, the boiler water quality and the

corresponding load.

7

Page 8

8

Technical Data

Connections

Type

(M)PA 46 Flanges to DIN, PN 40

(M)PA 47 Flanges to DIN, PN 63

Pressure Ratings

(M)PA 46 EN – PN 40 Class 150, 300

(M)PA 47 EN – PN 63 Class 400

Materials

Designation DIN EN DIN ASTM

Body *) PA..., MPA... P250GH (1.0460) C 22.8 (1.0460) A 105

Stuffing box union *) P250GH (1.0460) C 22.8 (1.0460) A 105

Sealing plug *) 42CrMo4 (1.7225) A193 B7

Gasket X5CrNi1810 (1.4301) X 5 CrNi 18 10 (1.4301)

Seat, hardened X46Cr13 (1.4034) X 46Cr 13 (1.4034)

Valve cone, hardened X39CrMo171 (1.4122) X 35 CrMo 17 (1.4122)

Disk springs 51CrV4 (1.8159) 50 CrV 4 (1.8159)

Compression springs DIN EN 102701SH DIN 17223C

Diaphragm actuator StW 23 (1.0334)

Packing PTFEsilk

Control membrane EPDM

Standard On request

Flanges to Class 150, 300

Buttweld ends for DIN and ASME pipes

Socketweld ends for DIN and ASME pipes

Flanges to Class 400

Buttweld ends for DIN and ASME pipes

Socketweld ends for DIN and ASME pipes

Pressure / Temperature Ratings

Acc. to EN 10921 for 1.0460 acc. to PED and AD 2000 or A 105 acc. to PED

max. pressure [bar] at t = Control Control

100 °C 200 °C 300 °C ts/p max fluid pressure

40 37.9 33.5 246/36

(M)PA 46

(M)PA 47

Ratings according to

PN 40 1.0460 EN 10921 37.3 30.2 25.8 234/29

PN 40 A105 EN 10921

Class 150 A105 ASME B16.34 17.7 14.0 10.2 198/14

Class 300 A105 ASME B16.34 46.4 43.9 38.9 254/41

PN 63 1.0460 EN 10921 58.8 47.6 40.6 257/44

PN 63 A105 EN 10921 63 59.6 52.7 271/55

Class 400 A105 ASME B16.34 61.8 58.4 51.7 270/54

Water

or

com

pressed

air

Max.

8 bar

Page 9

Technical Data continued

Corrosion resistance

If the unit is used for the intended purpose, its safety is not impaired by corrosion.

Sizing

The housing must not be subjected to sharp increases in pressure. The dimensional allowances for

corrosion reflect the latest state of technology.

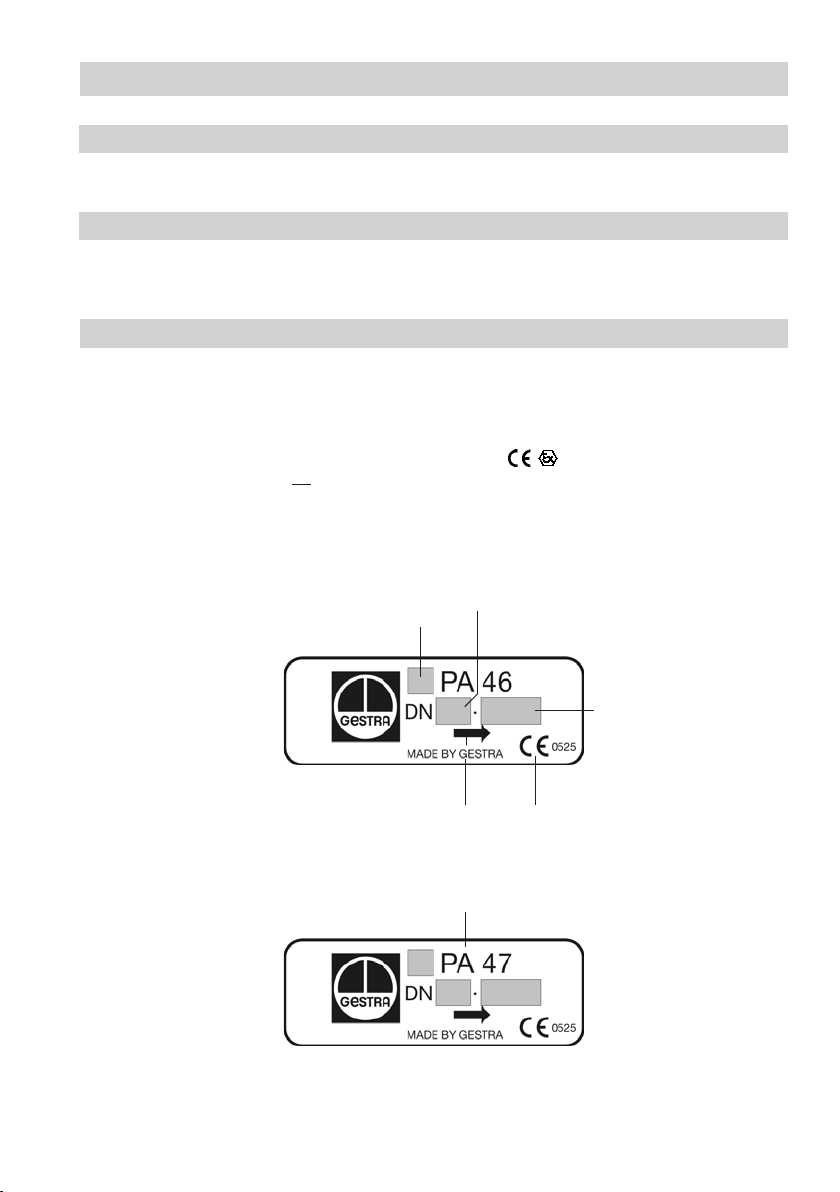

Name plate / Marking

According to EN 19 the name plate and the housing indicate the valve type and design:

■ Type designation PA 46, PA 47: Design with hand lever

MPA 46, MPA 47: Design with diaphragm actuator

■ Marking according to ATEX: Marking: II 2G/D c X

■ Stamp on valve body, e. g. indicates term and year of production

(Example: 4th quarter 2004)

4

04

Code letter “M” for

diaphragm actuator

Direction of flow

Nominal size

PN /CL

CE marking if required

Type of

equipment

9

Page 10

10

Technical Data continued

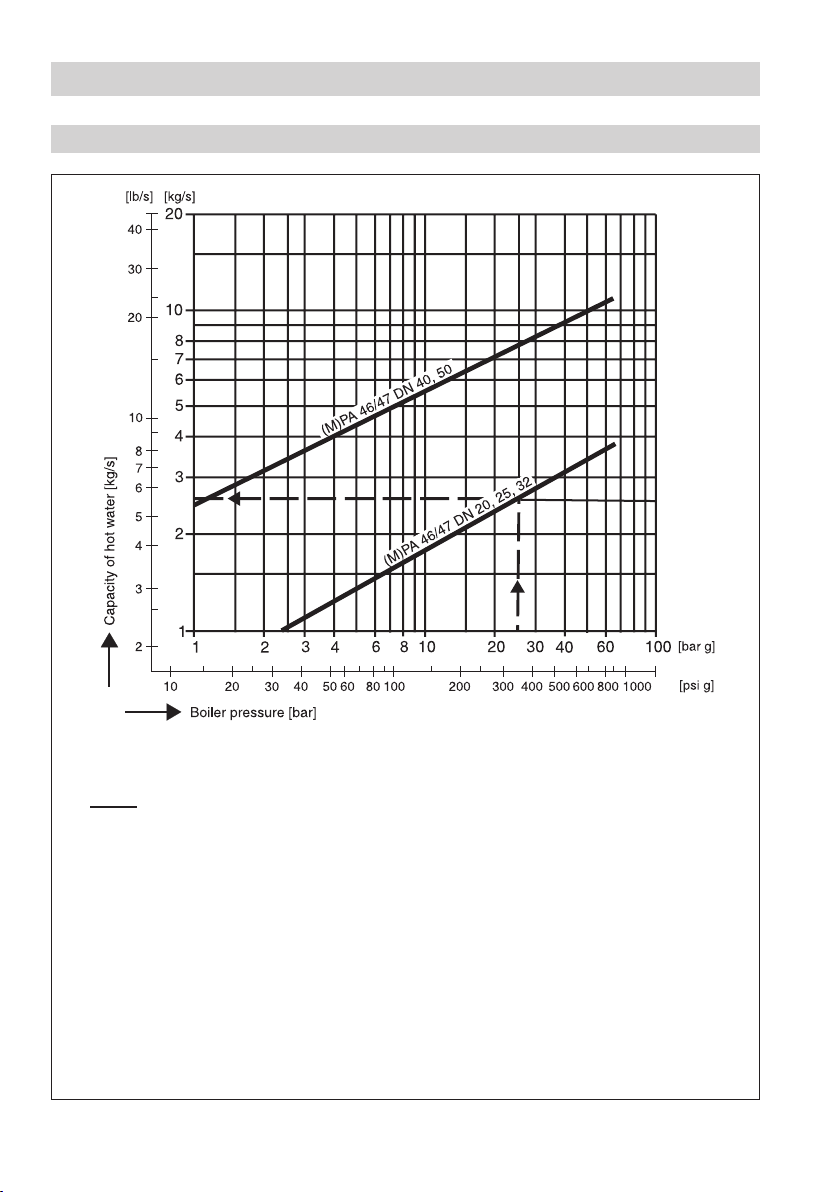

Capacity chart PA 46, PA 47, MPA 46, MPA 47

Calculation of the amount of boiler water to be discharged

according to the following formula:

Q · S

A =

K – S

Conductivity of

feedwater: S [µS/cm]

Admissible conductivity

of boiler water: K [µS/cm]

Boiler capacity: Q [kg/h]

Amount of boiler water

to be discharged: A [kg/h]

Fig. 1

Example

Conductivity of

feedwater: S = 20 µS/cm

Admissible conductivity

of boiler water: K = 4000 µS/cm

Boiler capacity: Q = 2000 kg/h

Amount of boiler water

to be discharged: A ≈ 10 kg/h

How to read chart fig. 1

Boiler pressure: 25 bar

Nominal size of intermittent valve for removing boiler

sludge DN 32

Capacity: 2.5 kg/s

Page 11

Technical Data continued

Control pressure chart MPA 46, MPA 47

Fig. 2

Boiler pressure [bar]

Control pressure [bar]

11

Page 12

12

Design PA 46, PA 47

W

V

U

3

T

S

R

Q

P

O

N

M

L

K

J

1

A

B

C

D

Fig. 3

I

H

E

F

G

Page 13

Design MPA 46, MPA 47

Y

X

V

4

3

T

Z

W

B

Fig. 4

2

S

R

Q

P

O

N

M

L

K

J

I

H

C

D

E

F

G

13

Page 14

14

Key

Locking lever

A

Mounting bracket

B

Check hole

C

Valve plug

D

Name plate

E

Gasket D 38 x 44 (DN 2032), D 52 x 60 (DN 4050)

F

Sealing plug

G

Valve seat

H

Valve body

I

Base bushing

J

Packing ring 14 x 28 x 7

K

Wiper ring

L

Pressure ring

M

Disc springs (15 pcs.)

N

Union nut

O

Compression spring

P

Check pin

Q

Pressure pin

R

Split pin 2.5 x 40, ISO 1234

S

Forkhead G 10 x 20, DIN 71752

T

Centering screw

U

Pressure plate

V

Hexagonhead cap screw M10 x 200, ISO 4014

W

Spacer disc

X

GESTRA Diaphragm actuator

Y

Screwed connection (3/8") for control fluid

Z

Hand lever for PA 46, PA 47

1

Hand lever for emergency operation MPA 46, MPA 47

2

Retaining piece for hand lever

3

Hexagonhead cap screw for forkhead M 10 x 25, ISO 4017

4

Page 15

Installation

Danger

Risk of death, severe injuries, physical damage or destruction caused by explosive

mixtures!

If the equipment is electrically insulated and installed between pipe flanges, electrostatic

charges may build up.

When using the equipment in explosionrisk areas make sure that static electricity will

be discharged (earthing).

PA 46, PA 47, MPA 46, MPA 47

The intermittent valve for removing boiler sludge can be installed in horizontal or vertical pipes.

The hand lever of the PA 46, PA 47 and the hand lever for the emergency operation of MPA 46, MPA 47

must be freely movable.

Attention

■ To avoid waterhammer lay the pipe downstream of the intermittent valve in such a way

that it has a slight fall, or evacuate the pipe before carrying out the boiler blowdown.

■ The length of the pipe between the steam boiler and the intermittent valve for removing

boiler sludge must not exceed two metres!

Flanged design

1. Observe position of installation. The hand lever

(MPA...) must be freely movable.

2. Observe the direction of flow. The arrow indicating the flow direction is specified on the name

plate E.

3. Consider space required for opening the valve. When the intermittent valve for removing boiler

sludge is installed, a minimum space of at least

the actuator!

4. Remove plastic plugs. They are only used as transit protection.

5. Clean seating surfaces of both flange faces.

6. Install intermittent valve for removing boiler sludge.

Socketweld design

1. Observe position of installation. The hand lever

(MPA...) must be freely movable.

2. Observe the direction of flow. The arrow indicating the flow direction is specified on the name

plate E.

3. Consider space required for opening the valve. When the intermittent valve for removing boiler

sludge is installed a minimum space of at least

the actuator!

4. Remove plastic plugs. They are only used as transit protection.

5. Clean socketweld ends.

Arc weld trap only manually (welding processes 111 and 141 in accordance with ISO 4063).

6.

1 or the hand lever for emergency operation 2

150 mm is required for removing or retrofitting

1 or the hand lever for emergency operation 2

150 mm is required for removing or retrofitting

15

Page 16

16

Installation continued

Buttweld design

1. Observe position of installation. The hand lever 1 or the hand lever for emergency operation 2

(MPA...) must be freely movable.

2. Observe the direction of flow. The arrow indicating the flow direction is specified on the name

plate E.

3. Consider space required for opening the valve. When the intermittent valve for removing boiler

sludge is installed a minimum space of at least

the actuator!

4. Remove plastic plugs. They are only used as transit protection.

5. Arcweld trap only manually (welding processes 111 and 141 in accordance with ISO 4063)

or use gas welding process (welding process 3 in accordance with ISO 4063).

Attention

■ Only qualified welders certified e. g. according to DIN EN 2871 may weld the valve into

pressurized lines.

Heat treatment of welds

A subsequent heat treatment of the welds is not required.

Mounting hand lever PA 46, PA 47

1. Release retaining piece for hand lever 3 and pull it out of the forkhead T.

2. Apply lubricant (e. g. WINIX 5000) to the retaining piece, forkhead and hole for attaching the

hand lever.

3. Push hand lever

1 through mounting bracket B into the forkhead T and fix it in place by

means of the retaining piece 3.

150 mm is required for removing or retrofitting

Commissioning

PA 46, PA 47, MPA 46, MPA 47

The flanged connections of the PA 46, PA 47, MPA 46, MPA 47 must be permanently bolted and

leakproof.

After starting up the steam boiler or pressure vessel, the intermittent valve for removing boiler sludge

should be completely opened and closed once. The valve must close automatically, ensuring tight

shutoff.

The stuffing box must be leakproof! Inspect the check hole C in order to detect any fluid leakage.

If the equipment is mounted in a new and unpurged installation increase the blowdown frequency

a little at the beginning.

®

WINIX

5000 is a registered trademark of WINIX GmbH, Norderstedt

Page 17

Operation

Duration and frequency of intermittent boiler blowdown

When the GESTRA intermittent valve opens, a localized lowpressure area forms around the blowoff

opening and the boiler sludge rushes out at high velocity, giving the steam boiler a short blow. The

discharge of sludge and precipitated solids (valve fully open) takes approx. 2 seconds. In order to

ascertain the blowdown frequency, the operating data of the installation have to be taken into account:

Use formula of fig. 1 to calculate the amount of boiler water in [kg/h] that must be discharged so that

1.

the admissible conductivity value of the boiler water will not be exceeded. Example: 10 kg/h

Use the capacity chart to determine the discharge capacity in [kg/h] of the existing intermittent

2.

valve or of the intermittent valve that has been selected according to the size of the boiler standpipe.

Example: 2.5 kg/s

3. The results of item 1) and 2) give a blowdown duration of 4 seconds.

For an effective blowdown the valve must only be open for 2 seconds, which means that according to the

above calculation 2 cycles per hour are required.

The time period between blowdowns (valve closed) is therefore 30 minutes.

The GESTRA automatic intermittent blowdown control TA.... features the following settings: Blowdown

duration (valve open) usually 2 seconds. Blowdown frequency (time between blowdowns valve closed)

adjustable, e. g. 30 minutes. It is possible to reduce the intermittent blowdown frequency if continuous

(top) boiler blowdown is performed instead (see installation instructions BA.../ BAE...).

Emergency operation MPA 46, MPA 47

Danger

Risk of severe injuries to the whole body. Make sure that the line for the control fluid of

the diaphragm actuator is depressurized (zero bar) and isolated during the emergency

operation of the MPA 46, MPA 47.

Insert the hand lever for emergency operation only to operate the valve and remove it

immediately after operation.

Fit hand lever for emergency operation

1. Fit hand lever for emergency operation

2. Remove hand lever for emergency operation 2 immediately after operation.

2, operate intermittent valve for removing boiler sludge.

Maintenance

GESTRA intermittent valves for removing boiler sludge PA 46, PA 47, MPA 46 and MPA 47 are usually

free of maintenance.

After starting up the steam boiler or pressure vessel, the intermittent valve for removing boiler sludge

should be completely opened and closed once. The valve must close automatically, ensuring tight

shutoff.

The stuffing box must be leakproof! Inspect the check hole C in order to detect any fluid leakage.

17

Page 18

18

Maintenance continued

Danger

Risk of severe burns and scalds to the whole body!

Before carrying out any maintenance work on the valve or loosening flanged connections,

stuffing box unions or sealing plugs make sure that all connected lines are depressurized

(zero bar) and cooled down to room temperature (20

Replacing stuffing box PA 46, PA 47

°C).

1. Undo retaining piece

3 for forkhead T and pull out hand lever 1. Fig. 3

2. Unscrew hexagonhead cap screws W and remove locking lever A.

3. Remove pressure plate

4. Pull out split pin

V and mounting bracket B.

S.

5. Use openend spanner A. F. 28 mm to unscrew the pressure pin R from the valve plug D.

6. Remove compression spring P.

7. Use openend spanner A. F. 32 mm to unscrew the union nut O.

8. Unscrew sealing plug

9. Pull out valve plug

G and remove gasket F.

D.

10. Take out internal parts N M L K L J of stuffing box.

11. Clean stuffing box, valve body and valve plug.

12. Reinsert valve plug D and use abrasive paste type TETRABOR® F400 for polish grinding.

13. Insert new gasket

14. Reinsert internal parts of stuffing box according to order as specified on page 24.

F and screw in sealing plug G. Tighten with a torque of 350 Nm.

Fig. 5, Fig. 6

15. Apply heatresistance lubricant to stuffing box thread (use e.g. WINIX® 2150).

16. Align valve plug D such that the hole for the split pin S is perpendicular to the flow direction of the

intermittent valve.

17. Use openend spanner A. F. 32 mm to screw in union nut O and tighten at room temperature with a

torque of 55 Nm.

18. Apply heatresistant lubricant to both sides of the compression spring P (use e. g. WINIX® 2150)

and place it onto the union nut O.

19. Use openend spanner A. F. 28 mm to screw the pressure pin R onto the valve plug D until the

holes for the split pin S in the valve plug and the pressure pin overlap.

20. Insert split pin S.

21. Reinsert mounting bracket B and pressure plate V. Align check hole C to the right.

22. Insert and screw in hexagonhead cap screws W and locking lever A and tighten them in

diagonally opposite pairs, applying a torque of 20 Nm.

23. Insert hand lever 1 and fix it to the forkhead T by means of retaining piece 3.

24. Operate valve once (open it until it hits the stop).

WINIX® 2150 is a registered trademark of WINIX GmbH, Norderstedt

TETRABOR® is a registered trademark of WackerChemie GmbH, Kempten

Page 19

Maintenance continued

Replacing stuffing box, valve seat and valve plug PA 46, PA 47

1. Undo retaining piece for forkhead

2. Unscrew hexagonhead cap screws

3. Remove pressure plate

4. Pull out split pin

V and mounting bracket B.

S.

5. Use openend spanner A. F. 28 mm to unscrew the pressure pin

6. Remove compression spring

7. Use openend spanner A. F. 32 mm to unscrew the union nut

8. Unscrew sealing plug

9. Pull out valve plug

10. Take out internal parts

G and remove gasket F.

D.

N M L K L J of stuffing box.

11. Use steel punch to knock the valve seat

T and pull out hand lever 1. Fig. 3

W and remove locking lever A.

R from the valve plug D.

P.

O.

H out of the valve body I. Fig. 7

12. Clean stuffing box and valve body.

13. Insert new valve seat

H such that two opposite holes are in the flow direction of the intermittent

valve.

14. Use punch made of CuZn to fix the valve seat in the valve body.

15. Reinsert valve plug

16. Insert new gasket

D and use abrasive paste type TETRABOR® F400 for polish grinding.

F and screw in sealing plug G. Tighten with a torque of 350 Nm.

Fig. 8

17. Reinsert internal parts of stuffing box according to order as specified on page 24.

®

18. Apply heatresistance lubricant to stuffing box thread (use e.g. WINIX

19. Align valve plug

D such that the hole for the split pin S is perpendicular to the flow direction of the

2150).

intermittent valve.

20. Use openend spanner A. F. 32 mm to screw in union nut

a torque of

55 Nm.

21. Apply heatresistant lubricant to both sides of the compression spring

and place it onto the union nut

O.

22. Use openend spanner A. F. 28 mm to screw the pressure pin

holes for the split pin

23. Insert split pin

24. Put mounting bracket

25. Insert and screw in hexagonhead cap screws

diagonally opposite pairs, applying a torque of

26. Insert hand lever

S in the valve plug and the pressure pin overlap.

S.

B and pressure plate V in place. Align check hole C to the right.

W and locking lever A and tighten them in

20 Nm.

1 and fix it to the forkhead T by means of retaining piece 3.

O and tighten at room temperature with

P (use e. g. WINIX® 2150)

R onto the valve plug D until the

27. Operate valve once (open it until it hits the stop).

Fig. 5, Fig. 6

WINIX® 2150 is a registered trademark of WINIX GmbH, Norderstedt

TETRABOR® is a registered trademark of WackerChemie GmbH, Kempten

19

Page 20

20

Maintenance continued

Replacing stuffing box MPA 46, MPA 47

1. Detach pressure line for the control fluid of the diaphragm actuator from the screwed socket

2. Remove diaphragm actuator

3. Remove spacer disk

4. Unscrew hexagonhead cap screws

5. Remove pressure plate

6. Pull out split pin

S.

7. Use openend spanner A. F. 28 mm to unscrew the pressure pin

8. Remove compression spring

9. Use openend spanner A. F. 32 mm to unscrew the union nut

10. Unscrew sealing plug

11. Pull out valve plug

D.

12. Take out internal parts

Y. Fig. 4

X and pressure plate V.

W.

V and mounting bracket B.

R from the valve plug D.

P.

O.

G and remove gasket F.

N M L K L J of stuffing box.

13. Clean stuffing box, valve body and valve plug.

14. Reinsert valve plug

15. Insert new gasket

16. Reinsert internal parts of stuffing box according to order as specified on page 24.

17. Apply heatresistance lubricant to stuffing box thread (use e.g. WINIX

18. Align valve plug

D and use abrasive paste type TETRABOR® F400 for polish grinding.

F and screw in sealing plug G. Tighten with a torque of 350 Nm.

Fig. 5, Fig. 6

®

2150).

D such that the hole for the split pin S is perpendicular to the flow direction of the

intermittent valve.

19. Use openend spanner A. F. 32 mm to screw in union nut

O and tighten at room temperature with

a torque of 55 Nm.

20. Apply heatresistant lubricant to both sides of the compression spring

P (use e. g. WINIX® 2150) and

place it onto the union nut O.

21. Use openend spanner A. F. 28 mm to screw the pressure pin

R onto the valve plug D until the

holes for the split pin S in the valve plug and the pressure pin overlap.

22. Insert split pin

23. Reinsert mounting bracket

24. Insert hexagonhead cap screws

S.

B and pressure plate V. Align check hole C to the right.

W and tighten them in diagonally opposite pairs with a torque

of 20 Nm.

25. Put spacer disk

26. Screw on diaphragm actuator

X onto pressure plate V.

Y with a torque of 120 Nm.

27. Attach pressure line for the control fluid of the diaphragm actuator.

28. Operate the valve once.

Z.

WINIX® 2150 is a registered trademark of WINIX GmbH, Norderstedt

TETRABOR® is a registered trademark of WackerChemie GmbH, Kempten

Page 21

Maintenance continued

Replacing stuffing box, valve seat and valve plug MPA 46, MPA 47

1. Detach pressure line for the control fluid of the diaphragm actuator from the screwed socket

Z.

2. Remove diaphragm actuator Y. Fig. 4

3. Remove spacer disk X and pressure plate V.

4. Unscrew hexagonhead cap screws W.

5. Remove pressure plate V and mounting bracket B.

6. Pull out split pin S.

7. Use openend spanner A. F. 28 mm to unscrew the pressure pin R from the valve plug D.

8. Remove compression spring P.

9. Use openend spanner A. F. 32 mm to unscrew the union nut O.

10. Unscrew sealing plug G and remove gasket F.

11. Pull out valve plug D.

12. Take out internal parts N M L K L J of stuffing box.

13. Use steel punch to knock the valve seat H out of the valve body I. Fig. 7

14. Clean stuffing box, valve body and valve plug.

15. Insert new valve seat H such that two opposite holes are in the flow direction of the intermittent

valve.

16. Use punch made of CuZn to fix the valve seat in the valve body. Fig. 8

17. Insert valve plug D and apply abrasive paste type TETRABOR® F400 for polish grinding.

18. Insert new gasket F and screw in sealing plug G. Tighten with a torque of 350 Nm.

19. Reinsert internal parts of stuffing box according to order as specified on page 24. Fig. 5, Fig. 6

20. Apply heatresistance lubricant to stuffing box thread (use e. g. WINIX® 2150).

21. Align valve plug D such that the hole for the split pin S is perpendicular to the flow direction of the

intermittent valve.

22. Use openend spanner A. F. 32 mm to screw in union nut O and tighten at room temperature with

a torque of 55 Nm.

23. Apply heatresistant lubricant to both sides of the compression spring P (use e.g. WINIX® 2150) and

place it onto the union nut O.

24. Use openend spanner A. F. 28 mm to screw the pressure pin R onto the valve plug D until the

holes for the split pin S in the valve plug and the pressure pin overlap.

25. Insert split pin S.

26. Reinsert mounting bracket B and pressure plate V.

27. Insert hexagonhead cap screws W and tighten them in diagonally opposite pairs with a torque

of 20 Nm.

28. Put spacer disk X onto pressure plate V.

29. Screw on diaphragm actuator Y with a torque of 120 Nm.

30. Attach pressure line for the control fluid of the diaphragm actuator.

31. Operate the valve once.

WINIX® 2150 is a registered trademark of WINIX GmbH, Norderstedt

TETRABOR® is a registered trademark of WackerChemie GmbH, Kempten

21

Page 22

22

Maintenance continued

Retightening stuffing box

If fluid leaks out of the control hole C, retighten the stuffing box with the union nut O.

Insert pin punch through opening of the mounting bracket B and push it into one of the holes of the

1.

union nut O. Carefully tighten union nut clockwise until the fluid stops leaking out of the control

hole C.

2. Operate valve once the valve must close automatically, ensuring tight shutoff.

Attention

■ If the stuffing box cannot be tightened further by means of the union nut O all internal

parts of the stuffing box must be replaced!

■ If the force of the spring does not close the valve automatically loosen the union nut

O a little. If fluid leaks out of the control hole the internals of the stuffing box must be

replaced.

Replacing control membrane in diaphragm actuator MPA 46, MPA 47

1. Detach pressure line for the control fluid of the diaphragm actuator.

2. Unscrew hexagonhead bolts

3. Remove and clean upper part

4. Take out old control membrane

5. Insert new control membrane

6. Put upper part

6 on top and align its holes with the holes of the control membrane and the

lower part.

7. Insert hexagonhead bolts

opposite pairs to a torque of 5 Nm.

8. Attach pressure line for the control fluid of the diaphragm actuator.

9. Check tightness. If necessary retighten hexagonhead bolts

10. To grease the guide plate pin

diaphragm actuator (use e. g. WINIX 5000).

5 and hexagon nuts. Fig. 9

6 of the diaphragm actuator.

7. Clean lower part 8.

7, aligning its holes with the holes of the lower part.

5 and tighten them with the respective hexagon nuts in diagonally

5 carefully in diagonally opposite pairs.

9 apply lubricant to the grease nipple in the connecting socket of the

Attention

■ The torque for tightening the hexagonhead cap screws 5 must not exceed 5 Nm

because higher torques could damage the control membrane!

WINIX® 5000 is a registered trademark of WINIX GmbH, Norderstedt

Page 23

Maintenance continued

Torques

Item

G

O

W

U

Y

5

All torques indicated in the table are based at a room temperature of 20 °C.

Intermittent valves for removing boiler sludge Torques [Nm]

PA 46, PA 47, MPA 46, MPA 47 350

PA 46, PA 47, MPA 46, MPA 47 55

PA 46, PA 47, MPA 46, MPA 47 20

PA 46, PA 47 60

MPA 46, MPA 47 120

MPA 46, MPA 47 5

Tools

■ Spanner A. F. 13 mm, DIN 3113, Form B

■ Spanner A. F. 17 mm, DIN 3113, Form B

■ Spanner A. F. 28 mm, DIN 3113, Form B

■ Spanner A. F. 32 mm, DIN 3113, Form B

■ Spanner A. F. 36 mm, DIN 3113, Form B

■ Spanner A. F. 41 mm, DIN 3113, Form B

■ Torque spanner 1 12 Nm, ISO 6789

■ Torque spanner 20 120 Nm, ISO 6789

■ Torque spanner 80 400 Nm, ISO 6789

■ Socket spanner 13 x 250, DIN 3112

■ Punch 20 x 200, made of steel

■ Punch 20 x 200, made of CuZn (brass)

■ Pin punch 8 x 150, DIN 6450 C

■ Grease gun (for valve plug)

23

Page 24

24

Maintenance continued

Single parts of stuffing box, valve plug, valve seat

N

M

L

K

L

J

H

Fig. 5

Fig. 6

D

Page 25

Maintenance continued

Mounting/removing valve seat

Fig. 7

Fig. 8

25

Page 26

26

Maintenance continued

Mounting/removing control membrane

6

7

5

8

9

Fig. 9

Page 27

Key

Hexagonhead bolt M8 with hexagon nut M8

5

Upper part of the diaphragm actuator

6

Control membrane

7

Lower part of the diaphragm actuator with connector socket

8

Guide pin with plate

9

Retrofitting

GESTRA intermittent valves PA 46 and PA 47 can be retrofitted with a GESTRA diaphragm actuator

(MPA 46, MPA 47).

Danger

Risk of severe burns and scalds to the whole body!

Before carrying out any retrofitting work on the valve or loosening flanged connections,

stuffing box unions or sealing plugs make sure that all connected lines are depressurized

(zero bar) and cooled down to room temperature (20

Insert the hand lever for emergency operation 2 only to operate the valve and remove it

immediately after operation.

Mounting diaphragm actuator

°C).

1. Undo centering screw U. Fig. 3

2. Undo retaining piece

Note that the hand lever must not be mounted again!

3. Snap retaining piece

4. Unscrew hexagonhead cap screws

5. Insert hexagonhead cap screws

6. Put spacer disk

7. Apply heatresistant lubricant to the connector socket of the diaphragm actuator

(use e.g. WINIX® 2150).

8. Screw on diaphragm actuator

9. Attach pressure line (

10. Operate the valve once.

3 for forkhead T and pull out hand lever 1.

3 on forkhead T.

W and remove locking lever A.

W and tighten them with a torque of 20 Nm.

X onto pressure plate V.

3

Y with a torque of 120 Nm.

/8") for the control fluid of the diaphragm actuator.

27

Page 28

28

Retrofitting continued

Mounting the forkhead (hand lever for emergency operation)

1. Align and fit forkhead

the hexagonhead cap screw

2. Fit hand lever for emergency operation

3. Remove hand lever for emergency operation

Tools

■ Spanner A. F. 16 mm, DIN 3113, Form B

■ Spanner A. F. 17 mm, DIN 3113, Form B

■ Spanner A. F. 41 mm, DIN 3113, Form B

■ Torque spanner 20 120 Nm, ISO 6789

Torques

Item

Y

4

W

All torques indicated in the table are based at a room temperature of 20 °C.

T together with hexagonhead cap screw 4 to the pressure plate V. Tighten

2 with a torque of 20 Nm. Fig. 4

2, operate intermittent valve for removing boiler sludge.

Intermittent valves for removing boiler sludge Torques [Nm]

MPA 46, MPA 47 120

MPA 46, MPA 47 20

PA 46, PA 47, MPA 46, MPA 47 20

2 immediately after operation.

Page 29

Spare Parts

Spare parts list

Item Designation

J K

L M

N F

D H

J K

L M

N F

D H

J K

L M

N F

7

2 3 4 T

9

N F

Internal parts of stuffing box, DN 20 to DN 50:

Base bushing, wiper ring,

Packing ring 14 x 28 x 7, pressure ring,

disk springs (15 pcs.),

Gasket D 38 x 44, D 52 x 60

Valve plug, valve seat and internal parts

of stuffing box, DN 20, DN 25, DN 32:

Base bushing, wiper ring,

Packing ring 14 x 28 x 7, pressure ring,

disk springs (15 pcs.),

Gasket D 38 x 44

Valve plug, valve seat and internal parts

of stuffing box, DN 40, DN 50:

Base bushing, wiper ring,

Packing ring 14 x 28 x 7, pressure ring,

disk springs (15 pcs.),

Gasket D 52 x 60

Control membrane for diaphragm actuator 335 131

Hand lever for emergency operation with forkhead 335 060

Guide pin with plate 335 130

Diaphragm actuator with spacer disk 335 093

Stock code Stock code

PA 46, PA 47 MPA 46, MPA 47

335 064 335 064

335 063 335 063

335 065 335 065

29

Page 30

30

Parts for retrofitting

List of parts for retrofitting

Item Designation

Y X

2 3 4 T

Diaphragm actuator with spacer disk 335 093

Hand lever for emergency operation with forkhead 335 060

Stock code Stock code

PA 46, PA 47 MPA 46, MPA 47

Decommissioning

Danger

Risk of severe burns and scalds to the whole body!

Before loosening flanged connections, stuffing box unions or sealing plugs make sure

that all connected lines are depressurized (zero bar) and cooled down to room

temperature (20

Disposal

Dismantle the valve and separate the waste materials, using the material specifications in the table

„Materials“ on page 8 as a reference.

For the disposal of the valve observe the pertinent legal regulations concerning waste disposal.

°C).

Page 31

Annex

Declaration of Conformity

We hereby declare that the pressure equipment PA 46, PA 47, MPA 46 and MPA 47 conform to the

following European Directives:

■ Pressure Equipment Directive 97/23/EC of 29 May 1997 for equipment of category 1 according to

the table “Pressure Equipment Directive” on page 5.

■ ATEX Directive 94/9/EC of 23 March 1994.

Applied conformity assessment procedure according to 97/23/EC: Annex III, Module H, verified by the

Notified Body 0525.

Applied conformity assessment procedure according to 94/9/EC: Annex VIII.

This declaration is no longer valid if modifications are made to the equipment without consulation with us.

Bremen, 8th March 2004

GESTRA AG

Dipl.Ing. Uwe Bledschun

(Academically qualified engineer)

Head of the Design Dept.

Dipl.Ing. Lars Bohl

(Academically qualified engineer)

Quality Assurance Manager

31

Page 32

32

www.gestra.de

81844700/1205cm · © 2004 GESTRA AG · Bremen · Printed in Germany

GESTRA

Agencies all over the world:

Great Britain

Flowserve Flow Control (UK) Ltd.

Burrel Road, Haywards Heath

West Sussex RH 16 1TL

Tel. 00 44 14 44 / 31 44 00

Fax 00 44 14 44 / 31 45 57

Email: gestraukinfo@fl owserve.com

Italia

Flowserve S.p.A.

Flow Control Division

Via Prealpi, 30

l20032 Cormano (MI)

Tel. 00 39 02 / 66 32 51

Fax 00 39 02 / 66 32 55 60

Email: infoitaly@fl owserve.com

GESTRA ESPAÑOLA S.A.

Luis Cabrera, 8688

E28002 Madrid

Tel. 00 34 91 / 5 15 20 32

Fax 00 34 91 / 4 13 67 47; 5 15 20 36

Email: aromero@fl owserve.com

España

Flowserve DALCO Steam Products

2601 Grassland Drive

Louisville, KY 40299

Tel.: 00 15 02 / 4 95 01 54, 4 95 17 88

Fax: 00 15 02 / 4 95 16 08

Email: dgoodwin@fl owserve.com

USA

Portugal

Flowserve Portuguesa, Lda.

Av. Dr. Antunes Guimarães, 1159

Porto 4100082

Tel. 0 03 51 22 / 6 19 87 70

Fax 0 03 51 22 / 6 10 75 75

Email: jtavares@fl owserve.com

Polska

GESTRA POLONIA Spolka z.o.o.

Ul. Schuberta 104

PL 80172 Gdansk

Tel. 00 48 58 / 3 06 10 02 od 10

Fax 00 48 58 / 3 06 33 00

Email: gestra@gestra.pl

GESTRA AG

P. O. Box 10 54 60, D28054 Bremen

Münchener Str. 77, D28215 Bremen

Telephone +49 (0) 421 35 03 0

Fax +49 (0) 421 35 03 393

EMail gestra.ag@fl owserve.com

Internet www.gestra.de

Loading...

Loading...