Flowserve Limitorque MX-40, Limitorque MX-140, Limitorque MX-150, Limitorque MX-10, Limitorque MX-05 User Instructions

...Page 1

USER INSTRUCTIONS

Swanson Flo | 800-288-7926 | www.swansonflo.com

Limitorque MX

Electronic Actuator

FCD LMENIM2314-00 – 07/08

Maintenance

and Spare Parts

Experience In Motion

Page 2

Swanson Flo | 800-288-7926 | www.swansonflo.com

Page 3

Limitorque MX Maintenance and Spare Parts FCD LMENIM2314-00 – 07/08

Swanson Flo | 800-288-7926 | www.swansonflo.com

Contents

1 Introduction 1

1.1 Premise 1

1.2 Procedure Emphasis 1

1.3 Important Notes and Warning Statements 1

1.4 Reference Documents 2

2 MX Actuator Subassembly 3

2.1 MX Actuator Subassembly Components 4

2.1.1 Product Description 4

2.1.2 Storage 4

2.1.3 Unit Weights 5

2.2 Product Identification 5

2.2.1 Initial Inspection and Recording Suggestions 5

2.3 Maintenance 6

2.3.1 Recommended Maintenance 6

2.3.2 Unit Lubrication 6

2.3.3 O-Ring and Lubrication 8

2.4 Subassembly Removal and Remounting Procedures 8

2.5 How to Order Replacement Subassemblies 9

2.5.1 Replacement Parts 9

2.5.2 Return Procedure 9

3 Remove Actuator from Mounting Adapter 11

3.1 Actuator Removal with Type B1/B4/B4E Base (Torque) 11

3.1.1 Removal (Type B1/B4/B4E Base) 11

3.1.2 Remounting (Type B1/B4/B4E Base) 12

3.2 Actuator Removal with Type A1/A1E Base (Thrust) 14

3.2.1 Removal (Type A1/A1E Base) Actuator Removal Separate from Thrust Base 14

3.2.2 Remounting (Type A1/A1E Base) Actuator Remounting Separate from Thrust Base 15

3.2.3 Removal (Type A1/A1E Base) Actuator and Thrust Base as a Unit 17

3.2.4 Remounting (Type A1/A1E Base) Actuator and Thrust Base as a Unit 18

4 Mechanical Assemblies 19

4.1 Motor 19

4.1.1 Removal 20

4.1.2 Remounting 21

4.1.3 Removal and mounting of MX-140 motor (40 RPM and greater) 22

4.1.4 Remounting 23

4.1.5 Mounting of MX-150 motor 23

4.2 Declutch 25

4.2.1 Removal 27

4.2.2 Remounting 29

4.3 Top-Mounted Handwheel (MX-05, -10, -20, and -40) 32

4.3.1 Removal 33

4.3.2 Remounting 33

4.4 Side-Mounted Handwheel Without Spur Gear Attachment (MX-10, -20, -85, -140, and -150) 35

4.4.1 Side-Mounted Handwheel Without Spur Gear Attachment (MX-85, -140, and -150) 36

4.4.2 Removal of Side-Mounted Handwheel (MX-10, -20, -85, -140, and -150) 37

4.4.3 Removal 37

4.4.4 Remounting 39

i

flowserve.com

Page 4

Limitorque MX Maintenance and Spare Parts FCD LMENIM2314-00 – 07/08

Swanson Flo | 800-288-7926 | www.swansonflo.com

4.5 Side-Mounted Handwheel With Spur Gear Attachment (MX-40, -85, -140, and -150) 40

4.5.1 MX-85, -140, and -150 Handwheel with SGA 41

4.5.2 Removal of Handwheel 42

4.5.3 Removal 42

4.5.4 Remounting 45

4.6 Converting Top-Mounted Handwheel to Side-Mounted Handwheel (MX-10, -20, and -40) 50

4.6.1 Removing Top-Mounted Handwheel 50

4.6.2 Installing Side-Mounted Handwheel 51

4.7 Thrust Base Type A1/A1E 53

4.7.1 Removal 56

4.7.2 Remounting 56

4.8 Torque Base Type B1 57

4.8.1 Removal 58

4.8.2 Remounting 58

4.9 Baseplate Type B4 59

4.9.1 Removal 60

4.9.2 Remounting 62

4.10 Worm Shaft 63

4.10.1 Removal 64

4.10.2 Remounting 65

4.11 Drive Sleeve (MX-05 and -10) 67

4.11.1 Removal 68

4.11.2 Remounting 69

4.12 Drive Sleeve (MX-20, -40, -85, -140, and -150) 70

4.12.1 Removal 71

4.12.2 Remounting 73

4.12.3 MX-85, -140, and -150 Optional Drive Sleeve and Baseplate Removal 74

4.12.4 MX-85, -140, and -150 Optional Drive Sleeve and Baseplate Remounting 76

4.13 Handwheel Adapter (MX-05) 77

4.13.1 Removal 78

4.13.2 Remounting 79

4.14 Handwheel Adapter (MX-10, -20 and -40)/Handwheel Worm Gear (MX-10, -20, -40, -85, -140, and -150) 81

4.14.1 Removal 83

4.14.2 Remounting 84

4.15 Clutch and Clutch Ring Components (MX-20, -40, -85, -140, and -150) 87

4.15.1 Removal 88

4.15.2 Remounting 89

5 Electronic Assemblies 93

5.1 Control Panel (CP) 93

5.2 Control Module 94

5.2.1 Removal 95

5.2.2 Remounting 98

5.2.3 Fuse Replacement 101

5.2.4 Control Module Return Options 102

5.2.5 EPROM Care and Replacement 102

ii

Page 5

Limitorque MX Maintenance and Spare Parts FCD LMENIM2314-00 – 07/08

Swanson Flo | 800-288-7926 | www.swansonflo.com

5.3 Installation and Removal of SMT Controls

(most units supplied after September 2003 and before September 2007) 105

5.3.1 Installation 105

5.3.2 Removal 108

5.3.3 Fuse Replacement 108

5.3.4 Control Module Return Options 108

5.4 Mounting of SMT Controls with 54-point terminal block and four LED configuration

(some units supplied from December 2006 with majority after September 2007) 109

5.4.1 Installation 109

5.4.2 Removal 110

5.5 Mounting of Standard and Optional Controls with 54-point terminal block and four LED configuration 111

5.5.1 Installation 111

5.5.2 Removal 114

5.6 Adding Electronic Options to Your MX Actuator(Most Supplied After September 2007) 114

5.7 Restoring Power to Actuator with New Control Module 115

5.8 Terminal Block (prior to March 2007) 115

5.8.1 Removal 116

5.8.2 Remounting 118

5.9 MX Terminal Block (Supplied With Most Actuators Since March 2007) 120

5.9.1 Terminal Block Shield Installation 120

5.10 Control Module-Contactor Assembly (Not required for most actuators shipped after September 2007.

Please see Section 5.4 for power board installation with contactor.) 121

5.10.1 Removal 122

5.10.2 Remounting 123

5.11 Replacing 19 Amp Reverser on the MX-140 and -150 (Not for most actuators shipped after September 2007) 125

5.12 19 Amp Power Assembly for Units Shipped After September 2007 128

5.13 Encoder (Through hole and surface mount technology, most units prior to September 2007) 129

5.13.1 Removal 130

5.13.2 Remounting 132

5.14 Encoder Drive Cartridge (Most units prior to September 2007) 133

5.14.1 Removal 134

5.14.2 Remounting 135

5.15 Removal and Replacement of MX Encoder (Supplied With Most Actuators Since September 2007) 136

5.15.1 Removal 137

5.15.2 Remounting 137

5.16 Encoder Drive Cartridge (Supplied With Most Actuators Since September 2007) 138

5.16.1 Removal 139

5.16.2 Remounting 140

5.17 Motor Lead Harness (MX-85, -140, and -150) 141

5.17.1 Removal 141

5.17.2 Remounting 142

5.18 Solid State Motor Reverser Upgrade Instructions (Most units prior to September 2007) 143

5.18.1 Disassembly Procedure 144

5.18.2 Assembly Procedure 145

5.19 Mounting of SSMR (Solid State Motor Reverser) in units shipped after February 2008 147

5.20 Complete Conversion to SMT Controls 149

iii

flowserve.com

Page 6

Limitorque MX Maintenance and Spare Parts FCD LMENIM2314-00 – 07/08

Swanson Flo | 800-288-7926 | www.swansonflo.com

6 Spare and Replacement Parts 150

6.1 Guidelines for Recommended Spare Parts 150

6.1.1 Wear Components 150

6.1.2 Bearings, O-rings, and Seals 150

6.1.3 Critical Components 151

6.2 Recommended Spare Parts for MX Actuators 151

6.2.1 Commissioning and Startup 151

6.2.2 Short-Term Duty 151

6.2.3 Long-Term Duty 151

6.2.4 Severe Duty 152

6.3 Other Concerns 152

7 Regulatory Information 154

7.1 Declaration of Conformity 154

Figures

Figure 2.1 – Typical MX Actuator 3

Figure 2.2 – MX Nameplate 5

Figure 2.3 – Oil Fill/Plug Locations (MX-05 through -40) 7

Figure 2.4 – Oil Fill and Drain Locations (MX-85, -140, and -150) 7

Figure 4.1 – Motor (MX-05, -10, -20, and -40) 19

Figure 4.3 – Motor, Support Plate and Adapter (MX-150) 24

Figure 4.4 – Declutch (MX-05 and -10) 25

Figure 4.5 – Declutch (MX-20 and -40) 26

Figure 4.6 – Declutch (MX-85, -140, and -150) 27

Figure 4.7 – Top-Mounted Handwheel (MX-05, -10, -20, and -40) 32

Figure 4.8 – Side-Mounted Handwheel (MX-10 and -20) 35

Figure 4.9 – Side-Mounted Handwheel (MX-85, -140, and -150) 36

Figure 4.10 – Side-Mounted Handwheel with SGA (MX-40) 40

Figure 4.11 – Side-Mounted Handwheel With SGA (MX-85, -140, and -150) 41

Figure 4.12 – Type A1 Thrust Base (MX-05, -10, -20, and -40) 53

Figure 4.13 – Type A1 Thrust Base (MX-85) - F16 Flange 54

Figure 4.14 – Type A1 Thrust Base (MX-85, -140, and -150) - F25 Flange 55

Figure 4.15 – Type B1 Torque Base (MX-05, -10, -20, and -40) 57

Figure 4.16 – Type B4 Baseplate (MX-05, -10, -20, and -40) 59

Figure 4.17 – Type B4 Baseplate (MX-85, -140, and -150) 60

Figure 4.18 – Worm Shaft (MX-05, -10, -20, and -40) 63

Figure 4.19 – Drive Sleeve (MX-05 and -10) 67

Figure 4.20 – MX-20 and -40 Drive Sleeve 70

Figure 4.21 – MX-85, -140, and -150 10:1 and 13:1 ratios 71

Figure 4.22 – Handwheel Adapter (MX-05) 77

iv

Figure 4.23 – Handwheel (MX-05) 77

Figure 4.24 – Handwheel Adapter Assembly 81

Figure 4.25 – Handwheel Worm Gear Assembly 82

Figure 4.26 – MX-20 and -40 Clutch and Ring Components 87

Figure 4.27 – MX-85, -140, and -150 Clutch and Ring Components 87

Page 7

Limitorque MX Maintenance and Spare Parts FCD LMENIM2314-00 – 07/08

Swanson Flo | 800-288-7926 | www.swansonflo.com

Figure 4.28 – MX-85, -140, and -150 Clutch Ring 90

Figure 5.1 – Control Panel 93

Figure 5.2 – Control Module 94

Figure 5.3 – Location of Fuses and Voltage Jumper 101

Figure 5.4 – LCS Board 102

Figure 5.5 – Main CPU Board 102

Figure 5.6 – Power Board 103

Figure 5.7 – DDC Board 103

Figure 5.8 – Location of Fuses and Voltage Jumper 108

Figure 5.9 – SMT Controls with four LEDs 109

Figure 5.10 – Option Board Assembly 113

Figure 5.11 – Restoring Power to Actuator with New Control Module 115

Figure 5.12 – Terminal Block 116

Figure 5.13 – Terminal Block 120

Figure 5.14 – Terminal Block Shield 120

Figure 5.15 – Control Module - Contactor Assembly and Wiring Diagrams 121

Figure 5.15 – (continued) 122

Figure 5.16 – Encoder 130

Figure 5.17 – Encoder Drive Cartridge 133

Figure 5.18 – Encoder 136

Figure 5.19 – Encoder Drive Cartridge 138

Figure 5.20 – Motor Lead Assembly 141

Figure 5.21 – Cutaway View of SSMR Controls Area 143

Figure 5.22 – Disassembly Procedure 144

Figure 5.23 – Solid State Reverser and Fuse Block Assembly Installation 145

Figure 5.24 – Control module reinstallation 146

Figure 5.25 – SSMR (Solid State Motor Reverser) 148

Tables

Table 2.1 – MX Actuator Subassembly Components 4

Table 2.2 – Unit weights 5

Table 2.3 – MX-05 and -10 Oil Capacities when using Oil Fill/Plug Ports 8

Table 4.1 – Motor Parts List 19

Table 4.2 – Motor Parts List 22

Figure 4.2 – Motor and Adapter (MX-140) 22

Table 4.3 – Motor Parts List 23

Table 4.4 – Declutch Parts List (MX-05 and -10) 25

Table 4.5 – Declutch Parts List (MX-20 and -40) 26

Table 4.6 – Declutch Parts List (MX-85, -140, and -150) 27

Table 4.7 – Top-Mounted Handwheel Parts List (MX-05, -10, -20, and -40) 32

Table 4.8 – Side-Mounted Handwheel Parts List (MX-10 and -20) 35

Table 4.9 – Side-Mounted Handwheel without Spur Gear Attachment Parts List (MX-85, -140, and -150) 36

Table 4.10 – Side-Mounted Handwheel Parts List (MX-40) 40

Table 4.11 – Side-Mounted Handwheel Parts List (MX-85, -140, and -150) 41

Table 4.12 – Type A1 Thrust Base Parts List (MX-05, 10, -20, and -40) 53

v

flowserve.com

Page 8

Limitorque MX Maintenance and Spare Parts FCD LMENIM2314-00 – 07/08

Swanson Flo | 800-288-7926 | www.swansonflo.com

Table 4.13 – Type A1 Thrust Base Parts List (MX-85) 54

Table 4.14 – Type A1 Thrust Base Parts List (MX-85, -140, and -150) - F25 Flange 55

Table 4.15 – Type B1 Torque Base Parts List (MX-05, -10, -20, and -40) 57

Table 4.16 – Type B4 Baseplate Parts List 59

Table 4.17 – Worm Shaft Parts List 63

Table 4.18 – Drive Sleeve Parts List (MX-05 and -10) 67

Table 4.19 – Drive Sleeve Parts List (MX-20, -40, -85, -140, and -150) 70

Table 4.20 – Handwheel Adapter Parts List (MX-05) 77

Table 4.21 – Handwheel Adapter Assembly Parts List 81

Table 4.22 – Handwheel Worm Gear Assembly Parts List 82

Table 4.23 – Clutch and Clutch Ring Components Parts List 87

Table 4.24 – Clutch Ring Assembly Parts List 90

Table 5.1 – Control Panel Parts List 93

Table 5.2 – Control Module Parts List 94

Table 5.3 - Voltage Jumper Positions 109

Table 5.4 - Control Board Connectors 112

Table 5.5 - Screw Part Numbers 113

Table 5.5 – Terminal Block Parts List 115

Table 5.7 – Terminal Block Parts List 120

Table 5.8 – Control Module-Contactor Assembly Parts List 121

Table 5.9 – 19 Amp Power Assembly 128

Table 5.10 – Encoder Parts List 129

Table 5.11 – Encoder Drive Sleeve Speed (RPM) 130

Table 5.12 – Encoder Drive Cartridge Parts List 133

Table 5.13 – Encoder Drive Cartridge Drive Sleeve Speed 133

Table 5.14 – Encoder Parts List 136

Table 5.15 – Encoder Drive Sleeve Speed (RPM) 136

Table 5.16 – Encoder Drive Cartridge Parts List 138

Table 5.17 – SSMR Upgrade Kit Parts List 143

Table 5.18 – SSMR Motor Fuse Table 145

Table 5.19 - SSMR Parts List 147

vi

Page 9

1

Swanson Flo | 800-288-7926 | www.swansonflo.com

Limitorque MX Maintenance and Spare Parts FCD LMENIM2314-00 – 07/08

Introduction

1.1 Premise

The Flowserve Limitorque MX actuator components are separated into subassembly groupings. This

manual covers the removal and remounting procedures for each subassembly group. Use these instructions when disassembly is required for service, maintenance, or parts replacement.

1.2 Procedure Emphasis

Please refer to the following methods used to emphasize text throughout this manual. Safety warnings,

cautions, and notes present material that is important to user safety. Be sure to read any safety notices

you see, as they could prevent equipment damage, personal injury, or even death to you or a co-worker.

Safety notices are presented in this manual in three forms:

WARNING: Refers to personal safety. Alerts the user to potential danger. Failure to follow

c

warning notices could result in personal injury or death.

CAUTION: Directs the user’s attention to general precautions that, if not followed, could result in

a

personal injury and/or equipment damage.

NOTE: Highlights information critical to the user’s understanding of the procedure.

Bold text stresses attention to the details of the procedure.

1.3 Important Notes and Warning Statements

Please read this Maintenance and Spare Parts Manual carefully and completely before attempting to

store or perform maintenance on your MX valve actuator. Further installation, setup, and operation

instructions are available in the Installation and Operation manual (LMENIM2306) located in the actuator

terminal compartment at shipment.

1

flowserve.com

Page 10

Limitorque MX Maintenance and Spare Parts FCD LMENIM2314-00 – 07/08

Swanson Flo | 800-288-7926 | www.swansonflo.com

WARNING: Be aware of electrical hazards within the actuator and high-pressure hazards of

c

the attached valve or other actuated device when installing or performing maintenance on

your MX actuator. Failure to observe these precautions could result in serious bodily injury,

damage to the equipment, or operational difficulty.

WARNING: Do not manually operate actuator with devices other than installed handwheel

c

and declutch lever. Using additive force devices (cheater bars, wheel wrenches, pipe

wrenches, or other devices of this nature) on the actuator handwheel or declutch lever may

cause serious personal injury and/or damage to the actuator or valve.

1.4 Reference Documents

• Protection, Control and Monitoring features of MX Electric Actuators (Bulletin LMENTB2300)

• MX Control, Performance and Value in Multi-turn Electric Valve Actuators (Bulletin LMENBR2302)

• MX Installation Manual (Bulletin LMENIM2306)

The latest revisions to these documents are available on-line from Flowserve Limitorque’s website,

www.flowserve.com or at www.limitorque.com

2

Page 11

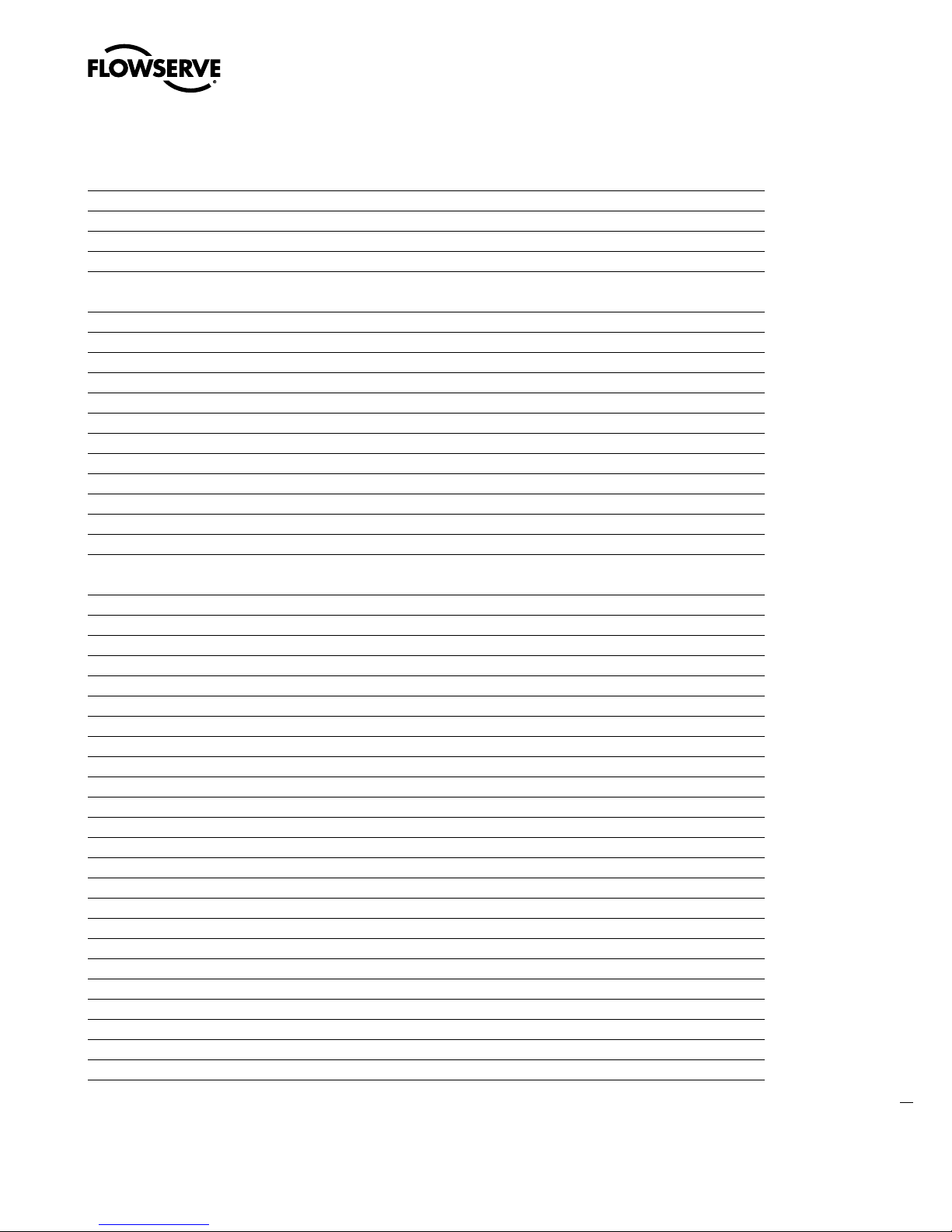

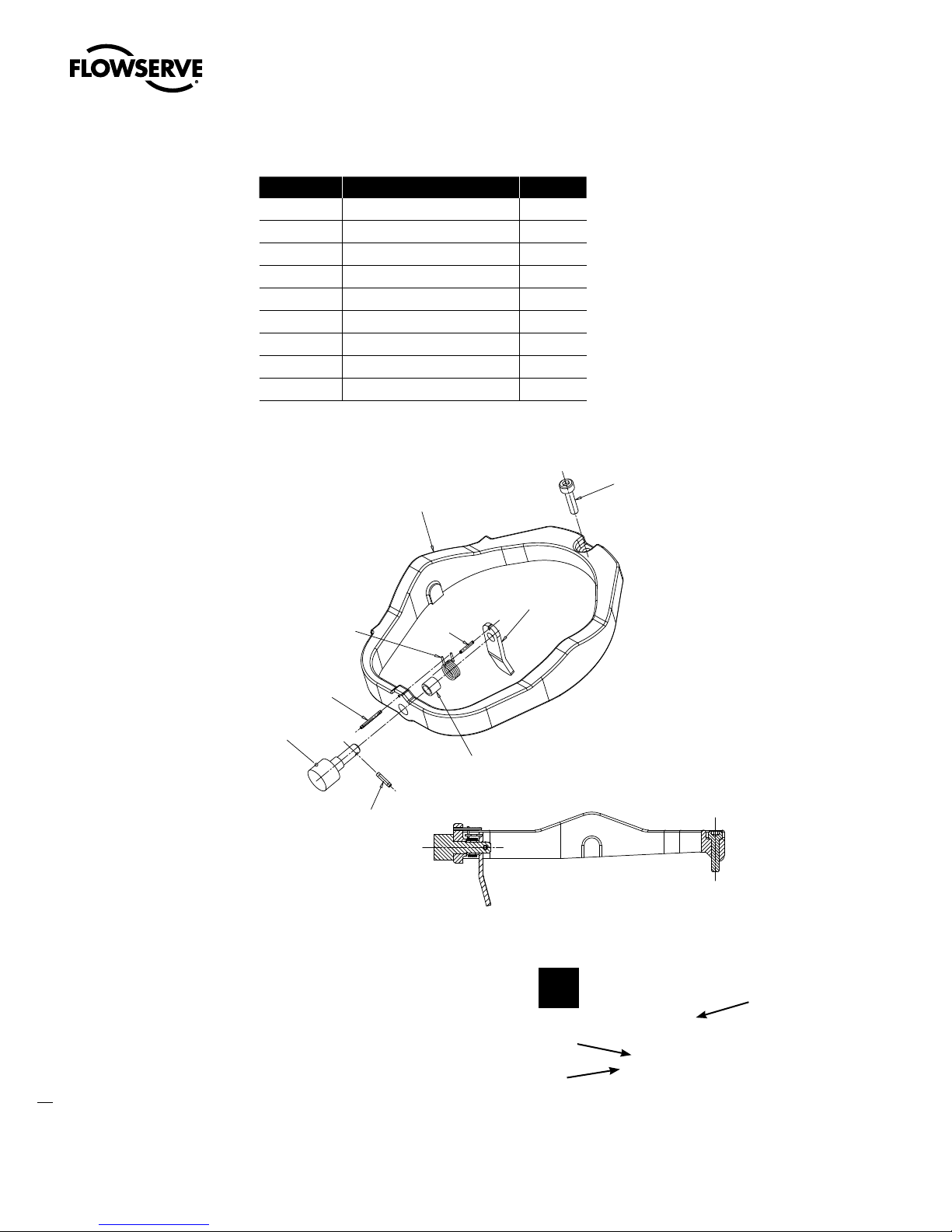

2

1

3

4

14

9

10

13

8

7

6

5

2

11

Swanson Flo | 800-288-7926 | www.swansonflo.com

Limitorque MX Maintenance and Spare Parts FCD LMENIM2314-00 – 07/08

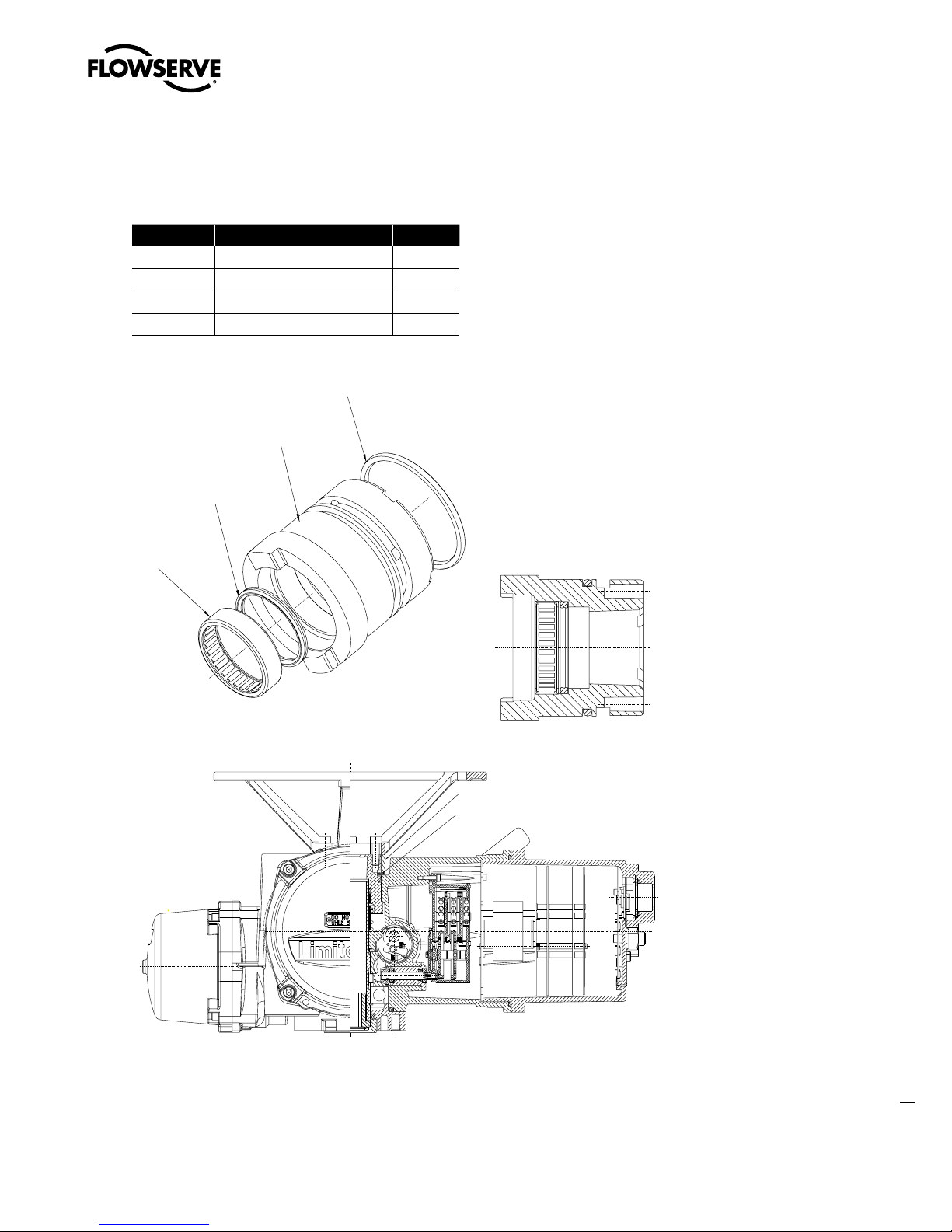

MX Actuator Subassembly

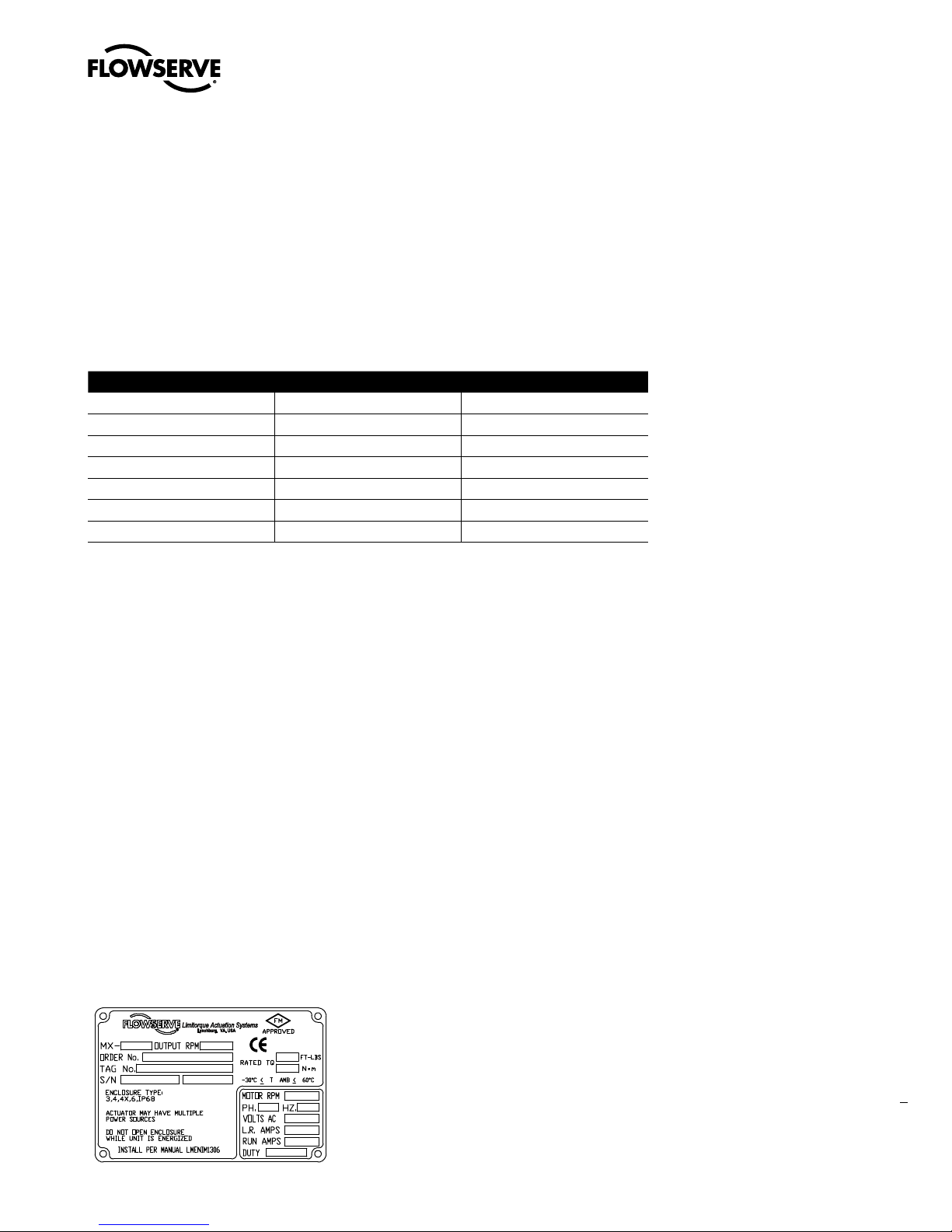

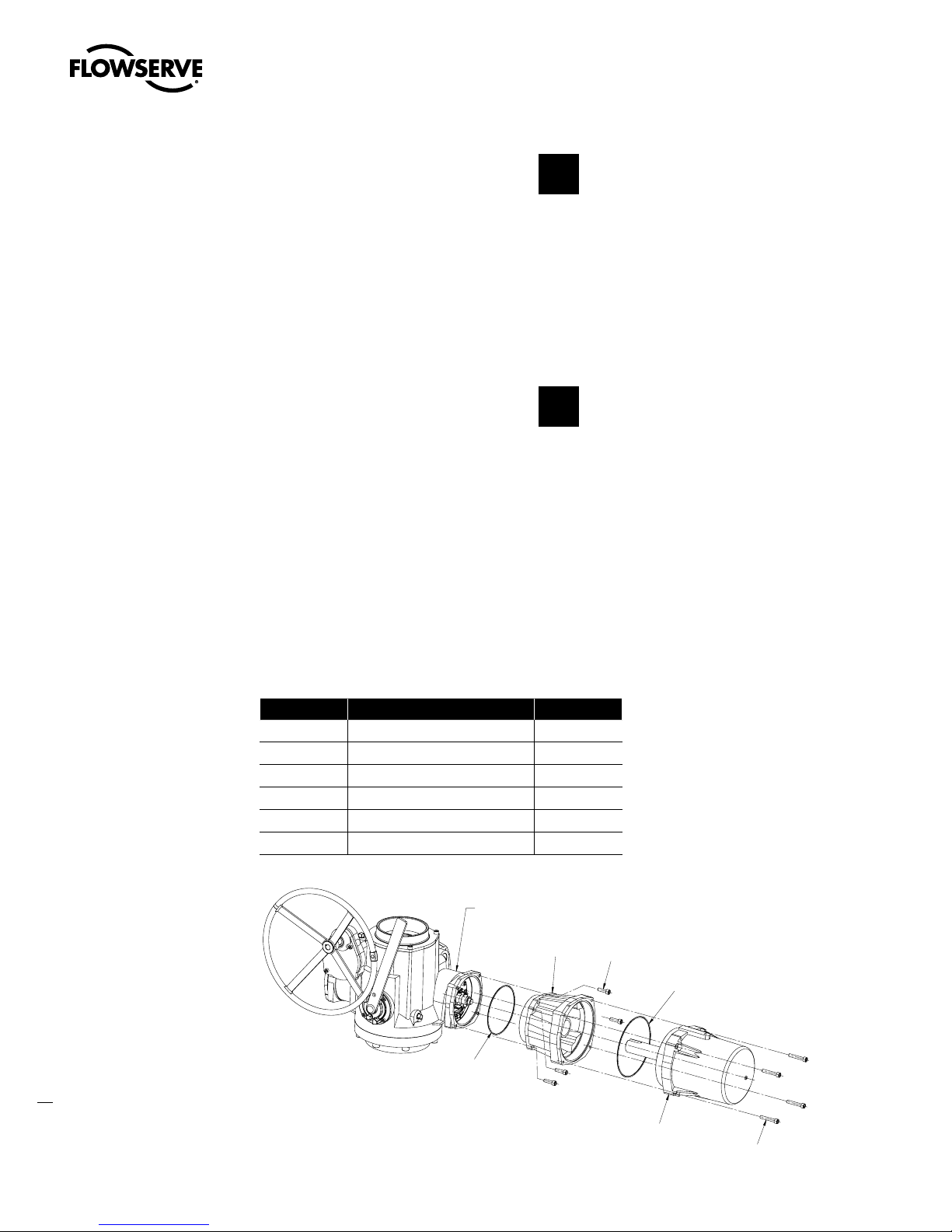

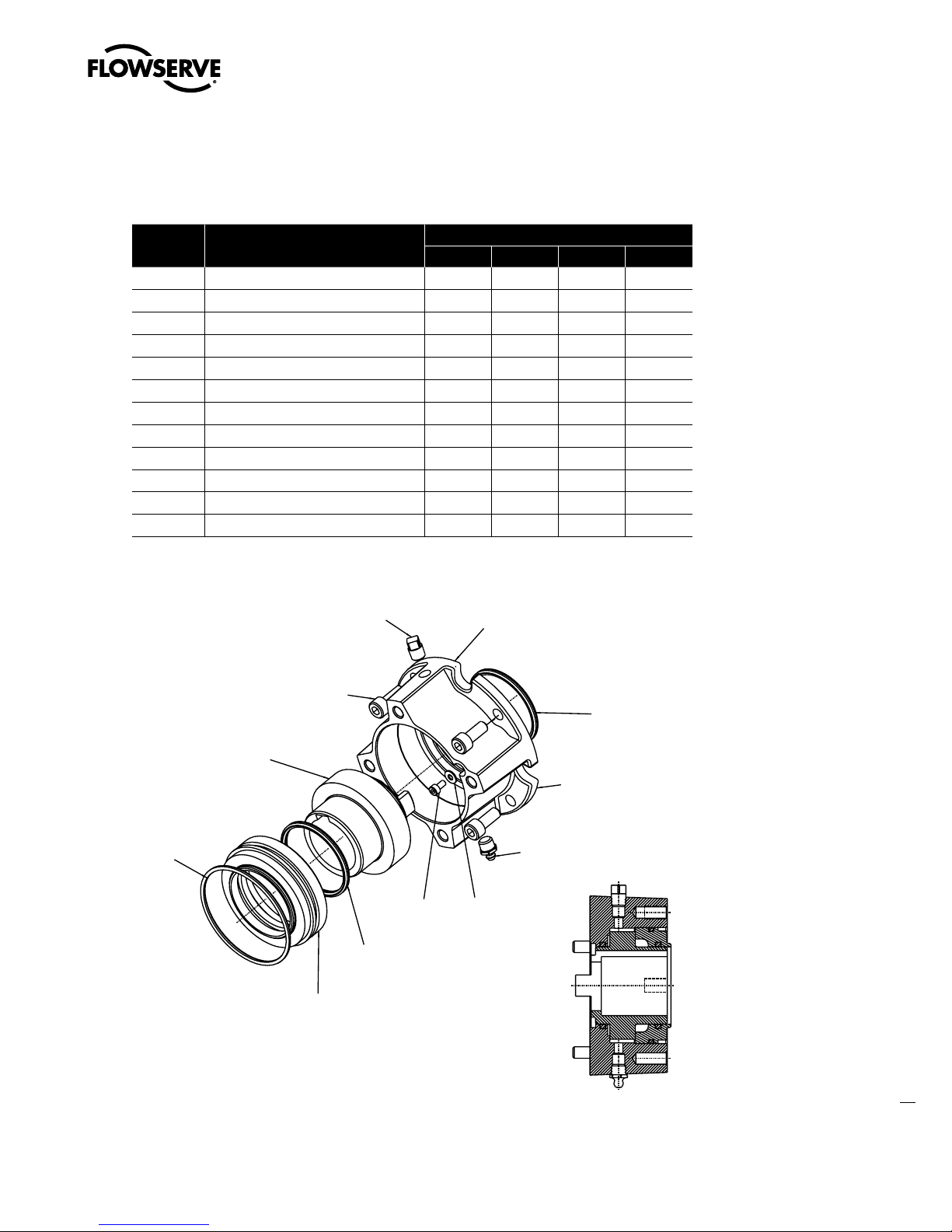

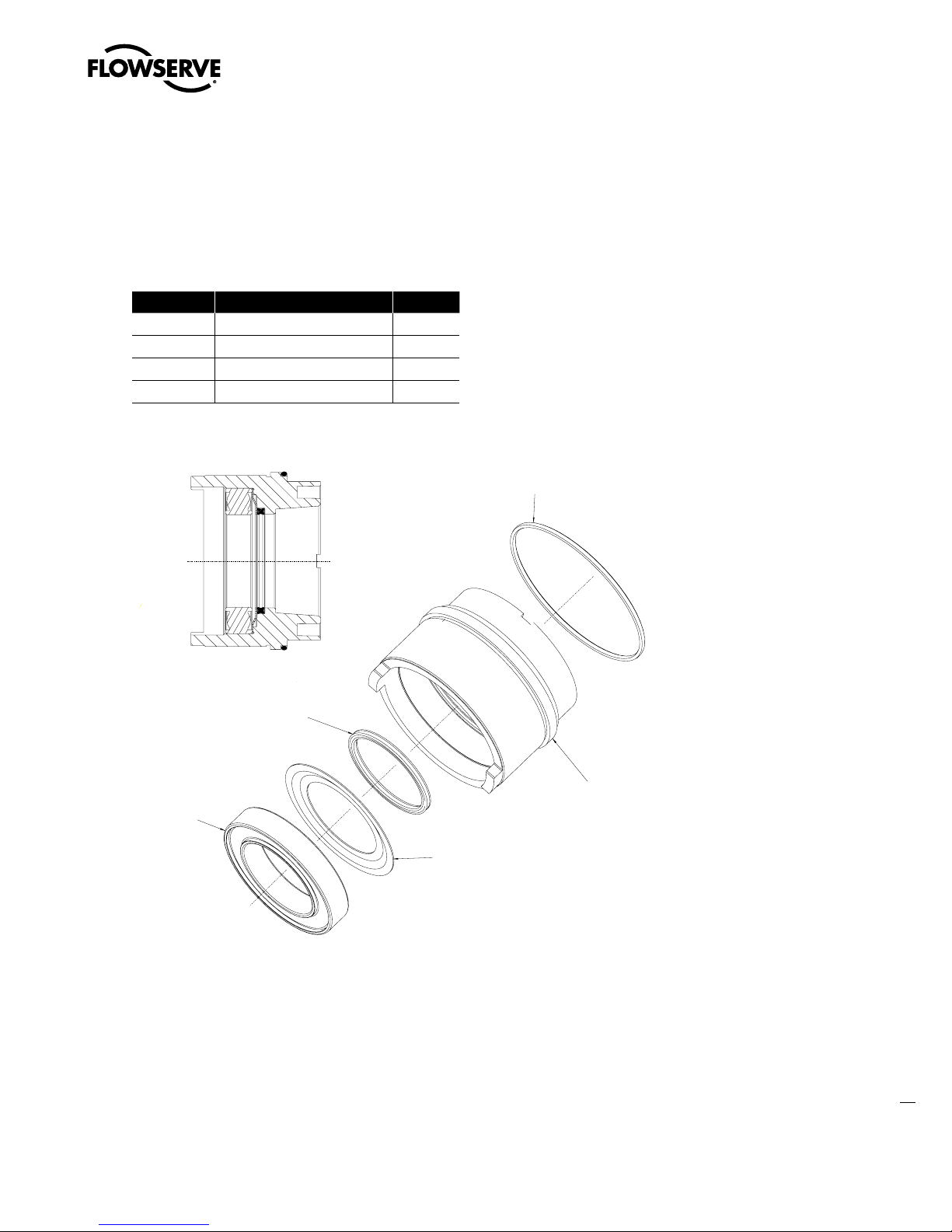

Figure 2.1 – Typical MX Actuator

NOTE: MX-05 with B4 base shown

3

flowserve.com

Page 12

Limitorque MX Maintenance and Spare Parts FCD LMENIM2314-00 – 07/08

Swanson Flo | 800-288-7926 | www.swansonflo.com

2.1 MX Actuator Subassembly Components

Table 2.1 – MX Actuator Subassembly Components

No. Description

1

Top-mounted handwheel

2

Drive sleeve

3

Worm shaft

4

Motor

5

Declutch lever

6

Encoder

7

Control panel (CP)

8

Control module

9

Optional bases

Thrust base type

• A1 = Standard thrust base

• A1E = Extended-reach thrust base

10

Baseplate-type B4 with stem nut options type:

• B4 = stem nut with variable bore and key

• B4E = extended-reach stem nut with variable bore and key

• BL = splined stem nut (SAE or Involute)

11

Handwheel adapter/handwheel worm gear

12

Side-mounted handwheel (not shown, but available for the MX-10, -20,-85, -140, and -150)

13

Encoder drive cartridge

14

Terminal block

2.1.1 Product Description

Your MX actuator controls the opening and closing travel of valves and other actuated devices. OPEN

and CLOSED limits are protected by an absolute encoder that provides optical sensing of valve position

and measures valve position in both motor and handwheel operation. No battery or backup power

supply is required. Output torque is derived from motor speed, temperature, and voltage. If the preset

torque is exceeded, the motor shuts off. As a result of this reliable and advanced protection technology,

all valve and other actuated devices are protected from potential damage from overload, improper

seating, and foreign obstructions.

A range of control and network options is available and can be easily added to the control capabilities

already available on a standard actuator. Contact your local Limitorque distributor or Limitorque sales

office for further information.

2.1.2 Storage

Storage Recommendations

Your MX actuator is double-sealed and weatherproof as shipped, providing all compartment covers and

cable entry plugs are left intact. Actuators should be stored in a clean, dry, protected warehouse until

4

ready for installation. If actuators must be stored outdoors, they should be stored off the ground, high

enough to prevent being immersed in water or buried in snow.

Page 13

Limitorque MX Maintenance and Spare Parts FCD LMENIM2314-00 – 07/08

Swanson Flo | 800-288-7926 | www.swansonflo.com

If your unit incorporates a rising stem application, it may be shipped with a plastic cap over the drive

sleeve. If so, install a pipe plug or protective stem cover to protect the drive sleeve from possible

corrosion.

Preferred Storage Orientation

Your MX actuator should be stored with the motor and terminal compartment in the horizontal position

to obtain optimum service life.

2.1.3 Unit Weights

Table 2.2 – Unit weights

Unit lb. kg

MX-05 52 24

MX-10 65 29

MX-20 109 49

MX-40 133 60

MX-85 259 117

MX-140 300 136

MX-150 410 186

NOTE: Weights include stem nut and lubricant.

2.2 Product Identification

2.2.1 Initial Inspection and Recording Suggestions

Upon receipt of the actuator, several steps should be initially followed to ensure condition of equipment

and to establish proper record keeping.

1. After removing the actuator from the shipping carton or skid, thoroughly examine it for any physical

damage which may have occurred during shipment. If you note any damage, immediately report the

damage to the transport company and call Limitorque for further assistance.

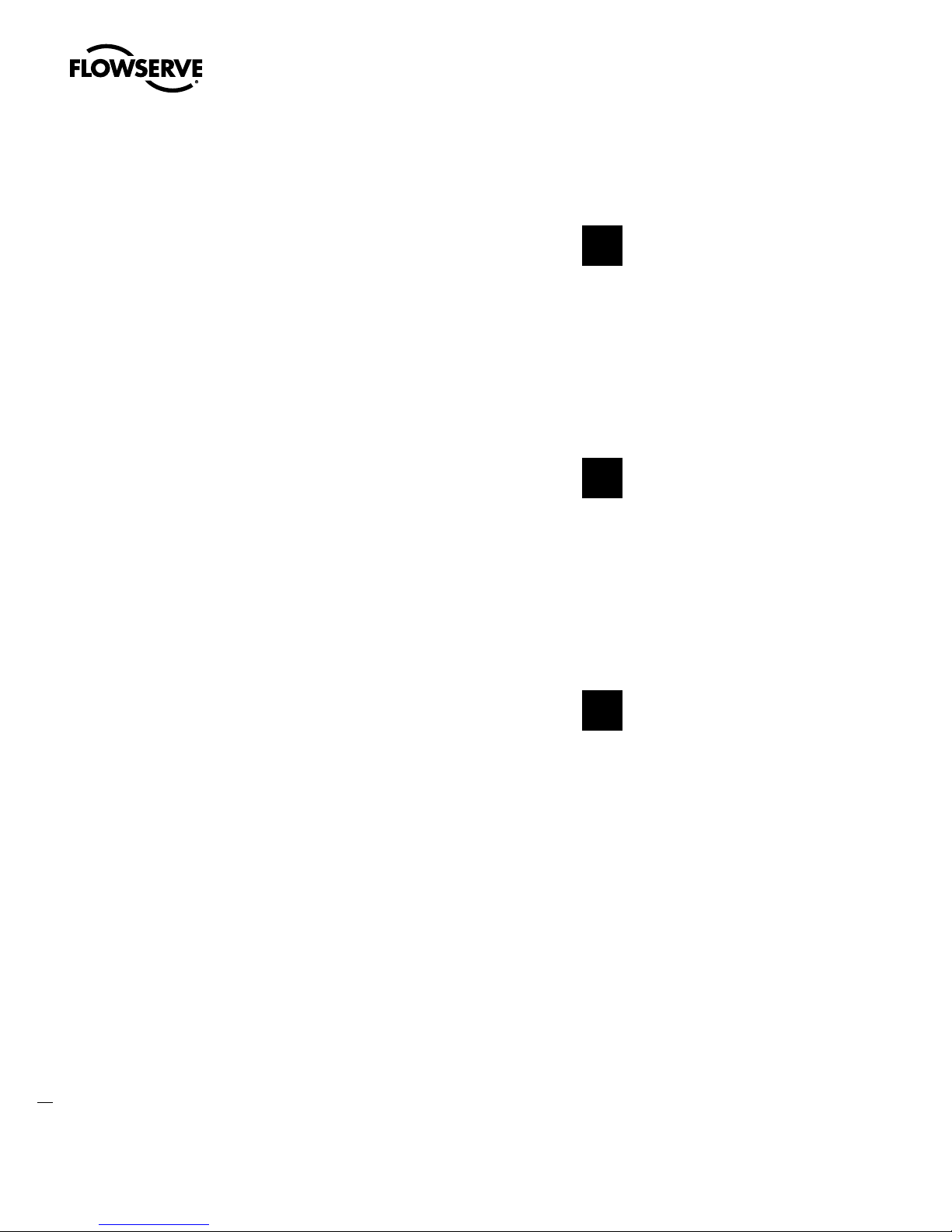

2. A nameplate with important information is attached to each actuator. Record the following information for use when you need to contact Limitorque with any questions about your actuator:

• Unit type/size

• Flowserve Limitorque order number

• Serial number

Figure 2.2 – MX Nameplate

5

flowserve.com

Page 14

Limitorque MX Maintenance and Spare Parts FCD LMENIM2314-00 – 07/08

Swanson Flo | 800-288-7926 | www.swansonflo.com

2.3 Maintenance

2.3.1 Recommended Maintenance

Under normal operating conditions, the MX is a maintenance-free actuator. Therefore, for normal

applications, no formal actuator maintenance is required although visual inspection for oil leakage and

excessive noise is recommended every 1 million drive sleeve turns or every 3000 cycles. When conditions are severe due to frequent operation or high temperatures, inspect the oil level and oil quality more

often. Replace any seals that permit oil leakage or water ingress. When installing pipe plugs, use PTFE

tape or paste to achieve a proper seal.

2.3.2 Unit Lubrication

Check for proper oil level every 1 million drive sleeve turns (reference Installation and Operation Manual

- Diagnostics Section to learn how to view drive sleeve turns data). Change oil every 6000 unit cycles or

if water or other foreign material is found during oil inspection.

Oil Level Inspection and Fill Criteria

(Reference Table 2.3 for oil capacities when mounted in varying positions)

• Actuator viewed in upright position (top-mounted handwheel up)

Oil level should be approximately 1 inch (25.4 mm) below the outer surface of the housing at the oil fill

port.

NOTE: Do not overfill with oil because oil will expand during actuator operation. Actuators are shipped

with an oil volume suitable for any mounting position. When checking the factory-supplied oil level,

excess oil may drain from the highest oil fill port due to the various mounting orientations of each

application.

• Actuator viewed in side-mounted position (terminal compartment up). Oil level should be up to the

bottom of the oil fill plug.

• Actuator viewed in all other positions than described previously should have the oil capacities

maintained. Fill through the highest oil fill port until the oil is at a level that will contact the bottom of

the pipe plug when installed in oil fill port.

6

Page 15

Figure 2.3 – Oil Fill/Plug Locations (MX-05 through -40)

t.9UPQNPVOUFE

IBOEXIFFMPJMDIFDLPJMmMM

t.9TJEFNPVOUFE

IBOEXIFFMPJMDIFDLPJMmMM

t0JMESBJOBMMVOJUT

t.9UPQNPVOUFE

IBOEXIFFMPJMDIFDLPJMmMM

t.9TJEFNPVOUFE

IBOEXIFFMPJMDIFDLPJMmMM

0JM1MVH

0JM1MVH

0JM1MVH

0JM1MVH

0JM1MVH

0JM1MVH

Swanson Flo | 800-288-7926 | www.swansonflo.com

Limitorque MX Maintenance and Spare Parts FCD LMENIM2314-00 – 07/08

Figure 2.4 – Oil Fill and Drain Locations (MX-85, -140, and -150)

Lubrication Data

• Oil Specifications: MX actuators are oil-filled using Mobil SHC-632, which is a synthetic oil suitable for

ambient temperatures of -22°F to 250°F (-30°C to 120°C). For extreme low temperature conditions,

alternative lubricants are available - consult factory for further information.

Table 2.3 – MX-05 and -10 Oil Capacities when using Oil Fill/Plug Ports

Nominal Oil Capacities oz. liters

MX-05

MX-10

MX-20

Top-mounted handwheel with handwheel up 38 1.1

Top-mounted handwheel with terminal compartment up 47 1.4

Side-mounted handwheel with terminal compartment up 43 1.3

10 0.3

16 .05

7

flowserve.com

Page 16

Limitorque MX Maintenance and Spare Parts FCD LMENIM2314-00 – 07/08

Swanson Flo | 800-288-7926 | www.swansonflo.com

MX-40

Top and side-mounted handwheel with handwheel up 40 1.2

Top-mounted handwheel with terminal compartment up 53 1.6

Side-mounted handwheel with terminal compartment up 53 1.6

MX-85, -140, and -150

All Configurations 192 5.7

2.3.3 O-Ring and Lubrication

O-rings and seals should be replaced any time an actuator is disassembled. Lubricate with a substance

that is compatible with Buna N seals.

2.4 Subassembly Removal

and Remounting Procedures

This manual divides each MX actuator subassembly into a Removal and Remounting procedure. Use

the following procedures to remove subassemblies for inspection, repair or replacement. Some subassemblies require prior subassembly removal before allowing the desired subassembly removal. Note

the First Remove instructions at the beginning of each subassembly removal procedure. Remove these

subassemblies first, and then remove the desired subassembly according to the instructions. Once

removed, evaluate subassembly components to determine requirement for a new subassembly. If a new

subassembly is required, see Section 2.5. Once components have been identified and replaced, remount

following the appropriate Remounting procedures.

2.5 How to Order Replacement Subassemblies

2.5.1 Replacement Parts

Replacement parts are sold in modular subassemblies; therefore, when part replacement is required,

order parts at the subassembly levels as shown in this manual. Parts may be ordered from your local

Limitorque representative (see www.flowserve.com) or direct from the factory:

Telephone: 1-434-528-4400

Fax: 1-434-845-9736

8

Page 17

Limitorque MX Maintenance and Spare Parts FCD LMENIM2314-00 – 07/08

Swanson Flo | 800-288-7926 | www.swansonflo.com

Please have the following information, found on the actuator nameplate, available to help us facilitate

your order:

• Unit type/size

• Limitorque order number

• Serial number

2.5.2 Return Procedure

When parts are identified for warranty or other component replacement, a Return Material Authorization

(RMA) must be obtained from Flowserve. Contact factory for a RMA number (see contact information in

section 2.5.1). All returned parts must be accompanied by documentation with the following information

to obtain credit for returned goods:

• Return Material Authorization (RMA)

• Unit type/size

• Flowserve Limitorque order number

• Serial number

Return parts to the address listed below:

Limitorque Actuation Systems

5114 Woodall Road

Lynchburg, VA 24502

9

flowserve.com

Page 18

This page is intentionally blank.

Swanson Flo | 800-288-7926 | www.swansonflo.com

Limitorque MX Maintenance and Spare Parts FCD LMENIM2314-00 – 07/08

10

Page 19

Limitorque MX Maintenance and Spare Parts FCD LMENIM2314-00 – 07/08

Swanson Flo | 800-288-7926 | www.swansonflo.com

Remove Actuator

3

from Mounting Adapter

3.1 Actuator Removal with Type B1/B4/B4E Base (Torque)

3.1.1 Removal (Type B1/B4/B4E Base)

STEP 1

WARNING: Hazardous Voltage! Turn off all power sources to actuator before

c

removing actuator from mounting plate. Power sources may include main power or

control power. If necessary, disconnect incoming power leads L1, L2, L3, and control

wiring from the terminal block.

Remove the bolts that secure the actuator

to the mounting adapter. If type B1 or B4E

base is used in addition to the standard type

B4 or B4E baseplate, you may leave the B1

base attached to the mounting adapter and

remove the actuator only. Or if required, you

may remove the bolts that mount type B1 base

to mounting adapter. This will allow actuator

removal along with optional B1 base.

1

11

flowserve.com

Page 20

Limitorque MX Maintenance and Spare Parts FCD LMENIM2314-00 – 07/08

Swanson Flo | 800-288-7926 | www.swansonflo.com

STEP 2

WARNING: Potential high-pressure vessel! Before disassembling your actuator,

c

ensure that the valve or other actuated device is isolated and is not under pressure.

Lift actuator from mounting adapter.

2

3.1.2 Remounting (Type B1/B4/B4E Base)

STEP 3

Ensure stem nut (#1-22) is secured inside

actuator drive sleeve with retaining ring

(#1-23). Lower the actuator onto the mating

component, making sure to align stem nut key

and keyway with mating component.

STEP 4

Ensure that the actuator and mounting adapter

flange mating holes are aligned correctly.

3

1-22

1-23

4

12

Page 21

Limitorque MX Maintenance and Spare Parts FCD LMENIM2314-00 – 07/08

Swanson Flo | 800-288-7926 | www.swansonflo.com

STEP 5

WARNING: Hazardous Voltage! Turn off all power sources before rewiring incoming

c

power leads L1, L2, L3, and control wiring in the terminal block.

Secure the actuator to the mounting adapter

with mounting bolts.

STEP 6

5

Reconnect incoming power leads L1, L2, L3, and control wiring to the terminal block. Restore

power source when ready for operation.

13

flowserve.com

Page 22

Limitorque MX Maintenance and Spare Parts FCD LMENIM2314-00 – 07/08

Swanson Flo | 800-288-7926 | www.swansonflo.com

3.2 Actuator Removal with Type A1/A1E

Base (Thrust)

NOTE: Two procedure options are available for removing the actuator and thrust base:

1. Remove actuator from thrust base, leaving thrust base mounted to mounting flange or removing

thrust base separately.

2. Remove actuator and thrust base as a unit from mounting flange.

3.2.1 Removal (Type A1/A1E Base)

Actuator Removal Separate from Thrust Base

STEP 1

WARNING: Hazardous Voltage! Turn off all power sources to actuator before

c

removing actuator from mounting plate. Power sources may include main power or

control power. If necessary, disconnect incoming power leads L1, L2, L3, and control

wiring from the terminal block.

Remove the bolts (#10-10) that secure the

actuator to the thrust base assembly (#10).

STEP 2

WARNING: Potential high-pressure vessel! Before disassembling your actuator,

c

ensure that the valve or other actuated device is isolated and is not under pressure.

Lift actuator from thrust base assembly (#10).

1

10-10

10

2

14

10

Page 23

Limitorque MX Maintenance and Spare Parts FCD LMENIM2314-00 – 07/08

Swanson Flo | 800-288-7926 | www.swansonflo.com

STEP 3

WARNING: Potential for actuated device to change position! The thrust base will

c

maintain position only if non-backdriving thread lead is used. Ensure proper thread

lead is used in your application before allowing thrust base to be used for maintaining position when actuator is removed.

Thrust base removal (if required)

The valve position will be maintained if a

locking thread lead is used on the valve stem.

If thrust base removal is required, use the

following removal procedure.

Remove the bolts that secure the thrust base

to the mounting adapter.

3

STEP 4

4

Rotate the thrust base (#10) until it feeds off

the threaded stem.

3.2.2 Remounting (Type A1/A1E Base)

Actuator Remounting Separate from Thrust Base

STEP 5

5

Thrust base remounting (if required)

Ensure the thrust base stem nut has the two

lugs positioned upward to engage with the

drive sleeve slots when actuator is reinstalled

onto thrust base. Thread thrust base back

onto mounting adapter.

10

15

flowserve.com

Page 24

Limitorque MX Maintenance and Spare Parts FCD LMENIM2314-00 – 07/08

Swanson Flo | 800-288-7926 | www.swansonflo.com

STEP 6

Secure thrust base to mounting adapter with

mounting bolts.

STEP 7

Actuator remounting

Lower the actuator onto the thrust base,

making sure thrust nut lugs align and properly

engage with drive sleeve slots.

6

7

STEP 8

8

Install bolts (#10-10) to secure the actuator to

the thrust base assembly (#10).

STEP 9

WARNING: Hazardous Voltage! Turn off all power sources before rewiring incoming

c

power leads L1, L2, L3, and control wiring in the terminal block.

Reconnect incoming power leads L1, L2, L3, and control wiring to the terminal block. Restore

power source when ready for operation.

16

Page 25

Limitorque MX Maintenance and Spare Parts FCD LMENIM2314-00 – 07/08

Swanson Flo | 800-288-7926 | www.swansonflo.com

3.2.3 Removal (Type A1/A1E Base)

Actuator and Thrust Base as a Unit

STEP 1

WARNING: Hazardous Voltage! Turn off all power sources to actuator before

c

removing actuator from mounting plate. Power sources may include main power or

control power. If necessary, disconnect incoming power leads L1, L2, L3, and control

wiring from the terminal block.

Actuator and thrust base removal

Remove the bolts that secure the actuator and

thrust base (#10) to the mounting adapter.

1

STEP 2

WARNING: Potential high-pressure vessel! Before disassembling your actuator,

c

ensure that the valve or other actuated device is isolated and is not under pressure.

Declutch the actuator to manual mode.

2

STEP 3

3

Rotate the handwheel until the actuator lifts

off the threaded stem.

17

flowserve.com

Page 26

Limitorque MX Maintenance and Spare Parts FCD LMENIM2314-00 – 07/08

Swanson Flo | 800-288-7926 | www.swansonflo.com

3.2.4 Remounting (Type A1/A1E Base)

Actuator and Thrust Base as a Unit

STEP 4

4

Actuator and thrust base remounting

Declutch the actuator to manual mode. Lift

actuator up to the threaded stem and carefully

align threads with thrust base threaded stem

nut.

STEP 5

5

Rotate the handwheel to lower the actuator

along the threaded stem and onto the

mounting adapter plate.

18

STEP 6

6

Install the mounting bolts to secure the

actuator and thrust base (#10) to the

mounting adapter.

STEP 7

WARNING: Hazardous Voltage! Turn off all power sources before rewiring incoming

c

power leads L1, L2, L3, and control wiring in the terminal block.

Reconnect incoming power leads L1, L2, L3, and control wiring to the terminal block. Restore

power source when ready for operation.

Page 27

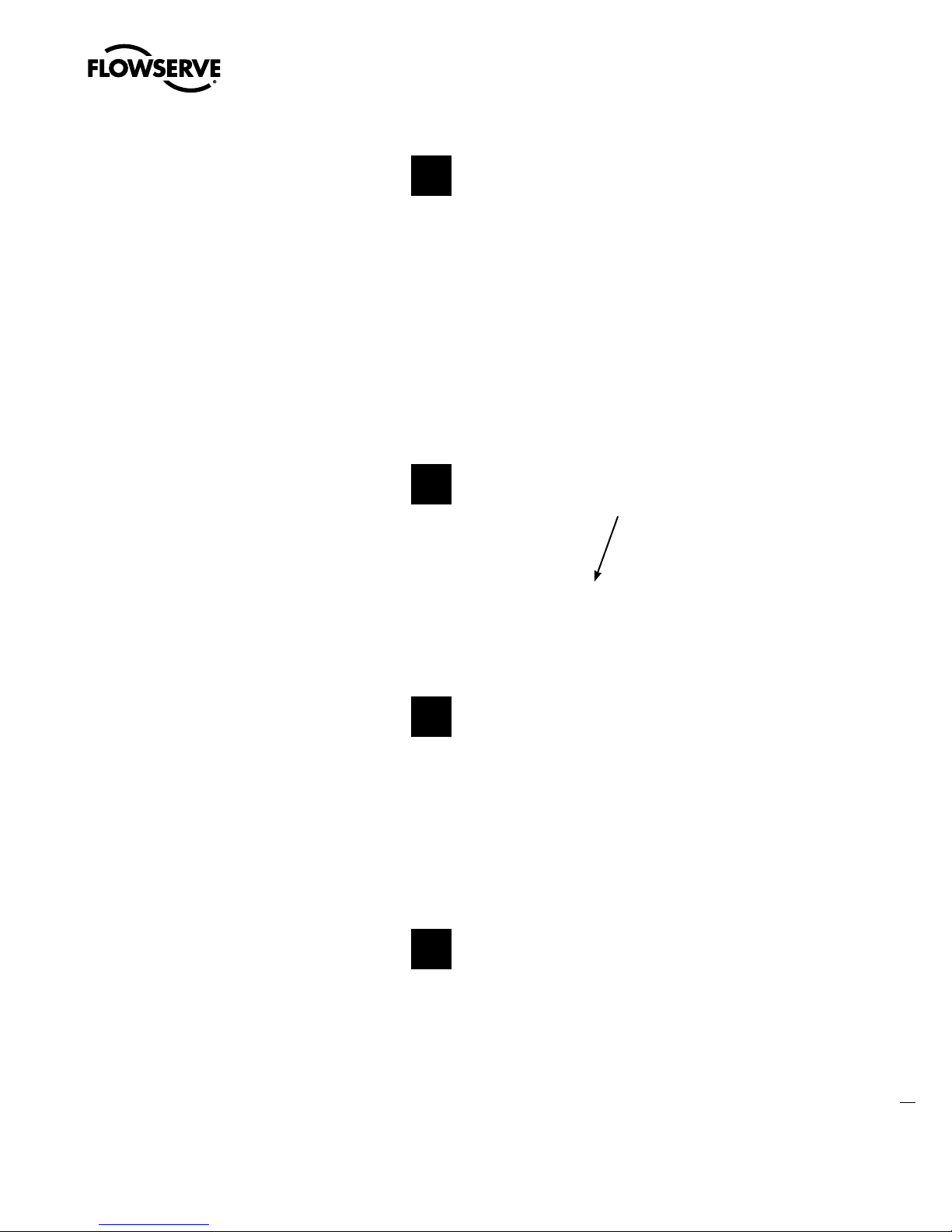

4

A

A

4- 1

4- 2

4- 3

4- 4

Motor

leads

4- 8

4- 9

A ssembly must have

rotation of rotor as shown.

Phase connections are:

T1-Phase 'A '

T2-Phase 'B '

T3-Phase 'C '

View A-A

Swanson Flo | 800-288-7926 | www.swansonflo.com

Limitorque MX Maintenance and Spare Parts FCD LMENIM2314-00 – 07/08

Mechanical Assemblies

4.1 Motor

NOTE: Proper motor testing is required when replacing motor. Consult your Limitorque representative

or the Limitorque factory to replace with correct motor.

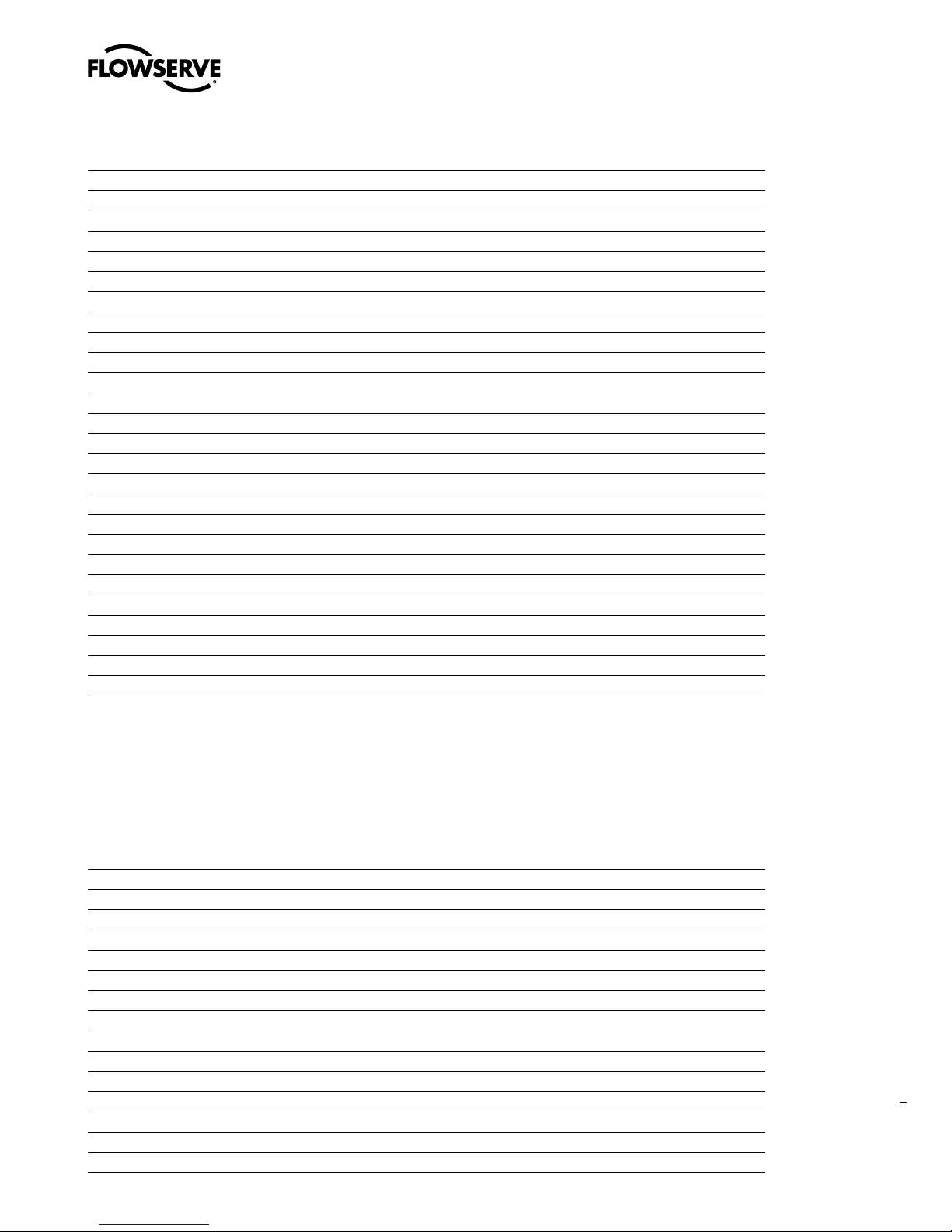

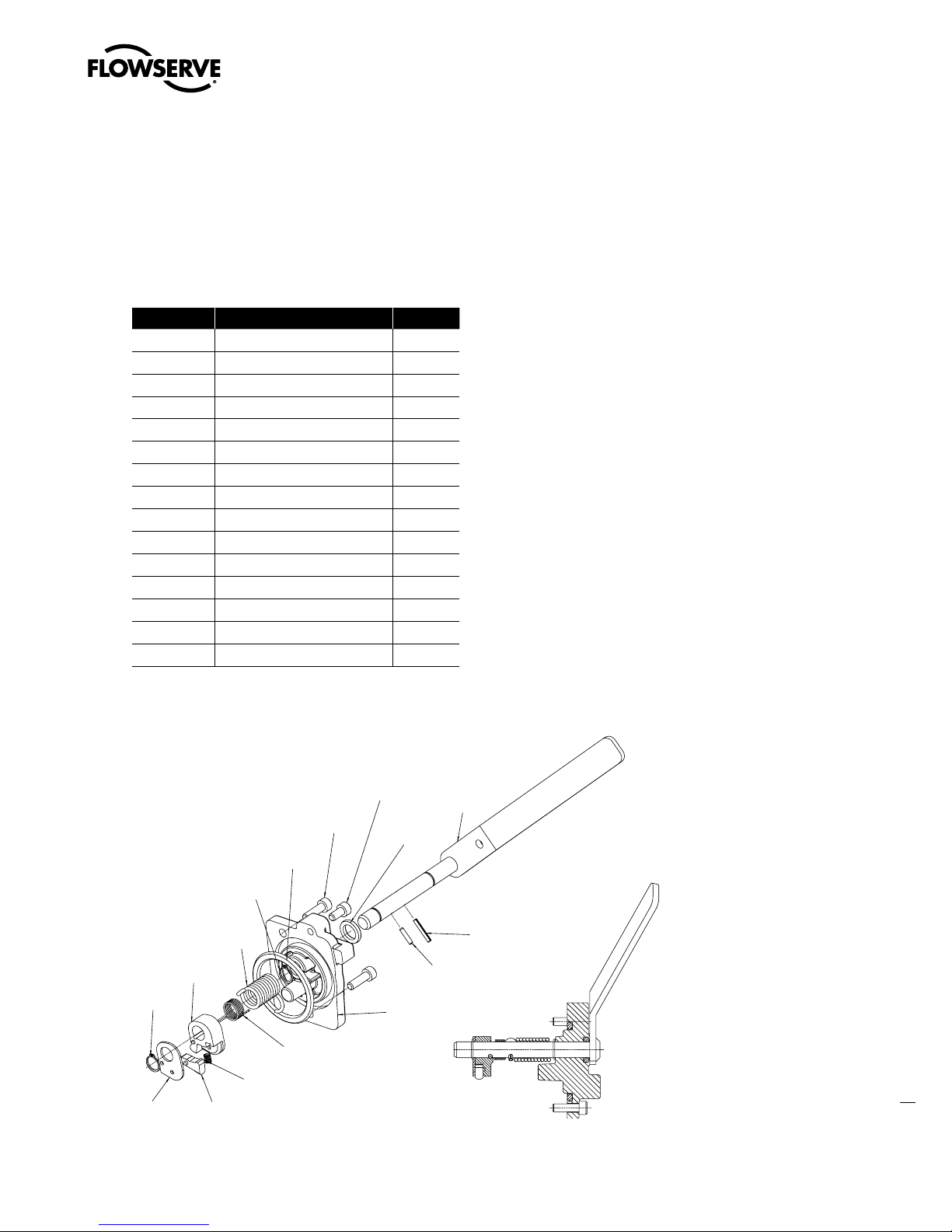

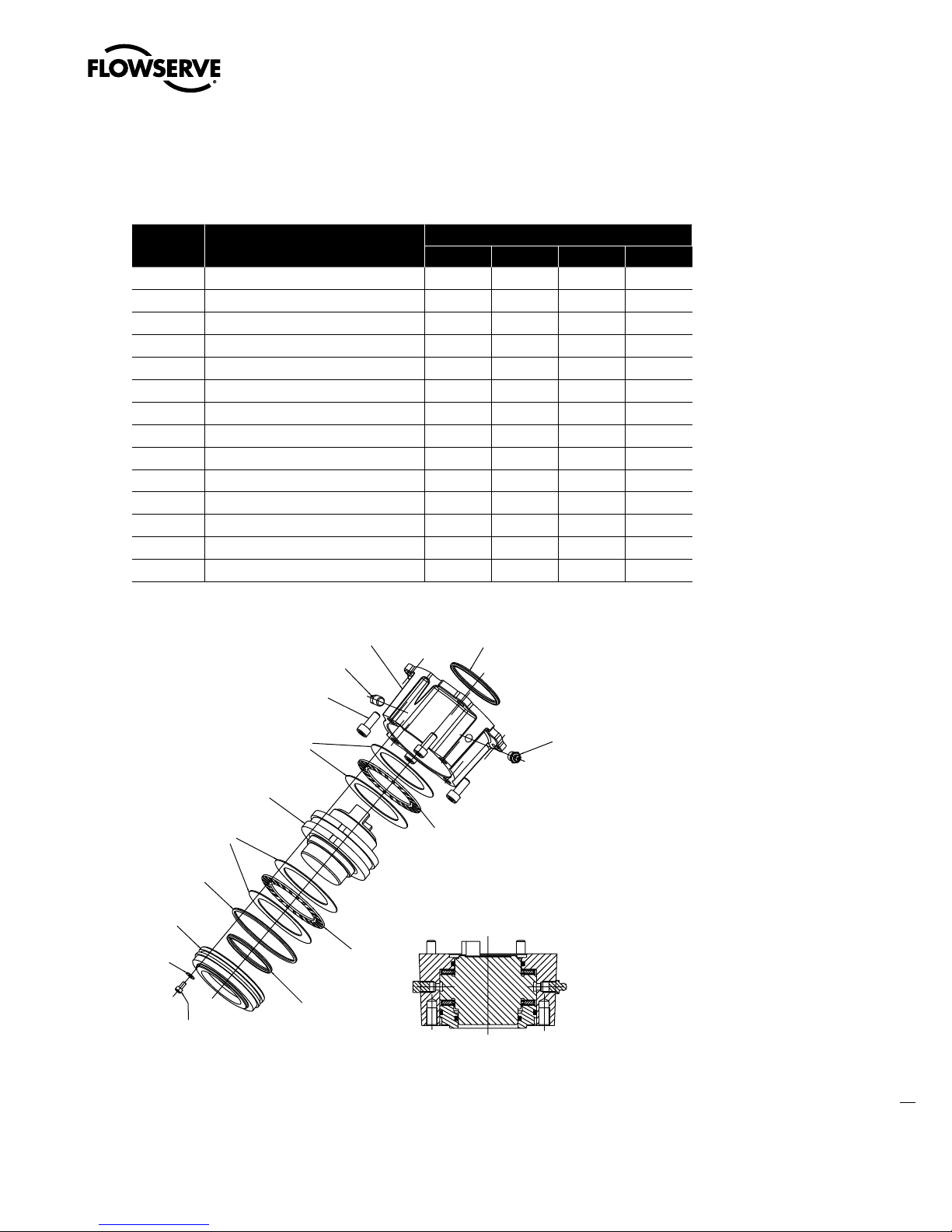

Table 4.1 – Motor Parts List

Part Number Description Qty.

4-1 Motor cover 1

4-2 Stator 1

4-3 Rotor assembly 1

4-4 Bearing 1

4-8 Bearing preload spring 1

4-9 Setscrew 1

Figure 4.1 – Motor (MX-05, -10, -20, and -40)

flowserve.com

19

Page 28

Limitorque MX Maintenance and Spare Parts FCD LMENIM2314-00 – 07/08

Swanson Flo | 800-288-7926 | www.swansonflo.com

4.1.1 Removal

STEP 1

WARNING: Hazardous Voltage! Turn off all power sources to actuator before removing

c

motor assembly. Power sources may include main power or control power.

Using an M6 hex key, remove the four M8

screws (#1-14) that mount the motor assembly

to the MX-05 through MX-40 actuator.

MX-85 requires an M8 hex key and uses an

M10 screw.

1

1-14

STEP 2

CAUTION: The rotor is not connected to the motor housing; when removing the motor,

a

ensure the rotor is carefully removed and not dropped from the motor housing.

Withdraw the complete motor (subassembly

#4), including the rotor (#4-3), until the wiring

harness is accessible. Note the O-ring (#1-15)

on the spigot/pilot of the motor assembly;

replace at remounting.

STEP 3

2

1-15

3

Disconnect the motor power plug from the

motor power socket connector.

4-3

20

Page 29

Limitorque MX Maintenance and Spare Parts FCD LMENIM2314-00 – 07/08

Swanson Flo | 800-288-7926 | www.swansonflo.com

4.1.2 Remounting

STEP 4

WARNING: Hazardous Voltage! Turn off all power sources to actuator before removing

c

motor assembly. Power sources may include main power or control power.

Lightly lubricate the O-ring (#1-15) that

is installed around the motor spigot/pilot

(subassembly #4).

4

1-15

STEP 5

Hold the motor assembly (housing/stator/rotor)

close to the actuator housing and reconnect the

motor power plug to the motor power socket

connector.

STEP 6

Coil the spiral-wrapped motor power wiring

inside the motor cavity and around the motor

bearing housing to ensure that it does not

come into contact with the rotor shaft.

MX-05 through -40 motor wiring will wrap

around about 360°. MX-85/140/150 motor

wiring will wrap around about 180°.

5

6

Motor Power

Socket

Connector

Motor Power

Plug

21

flowserve.com

Page 30

Limitorque MX Maintenance and Spare Parts FCD LMENIM2314-00 – 07/08

MAIN UNIT ASSEMBLY

4-8

1-14

4-10

1-15

4-7

4-9

Swanson Flo | 800-288-7926 | www.swansonflo.com

STEP 7

Push the rotor shaft onto the protruding

worm shaft, aligning the rotor shaft slots with

the worm shaft pin. Slide the motor housing

spigot/pilot into the actuator housing.

STEP 8

Fit the four screws (#1-14) into the motor

subassembly mounting holes and tighten.

7

8

1-14

4.1.3 Removal and mounting of MX-140 motor

(40 RPM and greater)

Table 4.2 – Motor Parts List

Part Number Description Qty.

1-14 Socket head cap screw 4

1-15 O-ring 1

4-7 Motor 1

4-8 Adapter, motor 1

4-9 Socket head cap screw 4

4-10 O-ring 1

Figure 4.2 – Motor and Adapter (MX-140)

22

Page 31

Limitorque MX Maintenance and Spare Parts FCD LMENIM2314-00 – 07/08

Swanson Flo | 800-288-7926 | www.swansonflo.com

STEP 1

Remove the four (4) socket head cap screws (#4-9) from the motor. Exercise caution as the motor is

heavy and the motor leads may be compromised during disassembly.

STEP 2

Remove the motor leads plug from the motor contactor seal assembly.

STEP 3

Remove the four (4) socket head cap screws (#1-15) from the motor adapter. Ensure the motor leads

have been previously disconnected.

4.1.4 Remounting

Follow steps in Section 4.1.3 in reverse order. Ensure O-rings were not damaged in disassembly. If

necessary, replace.

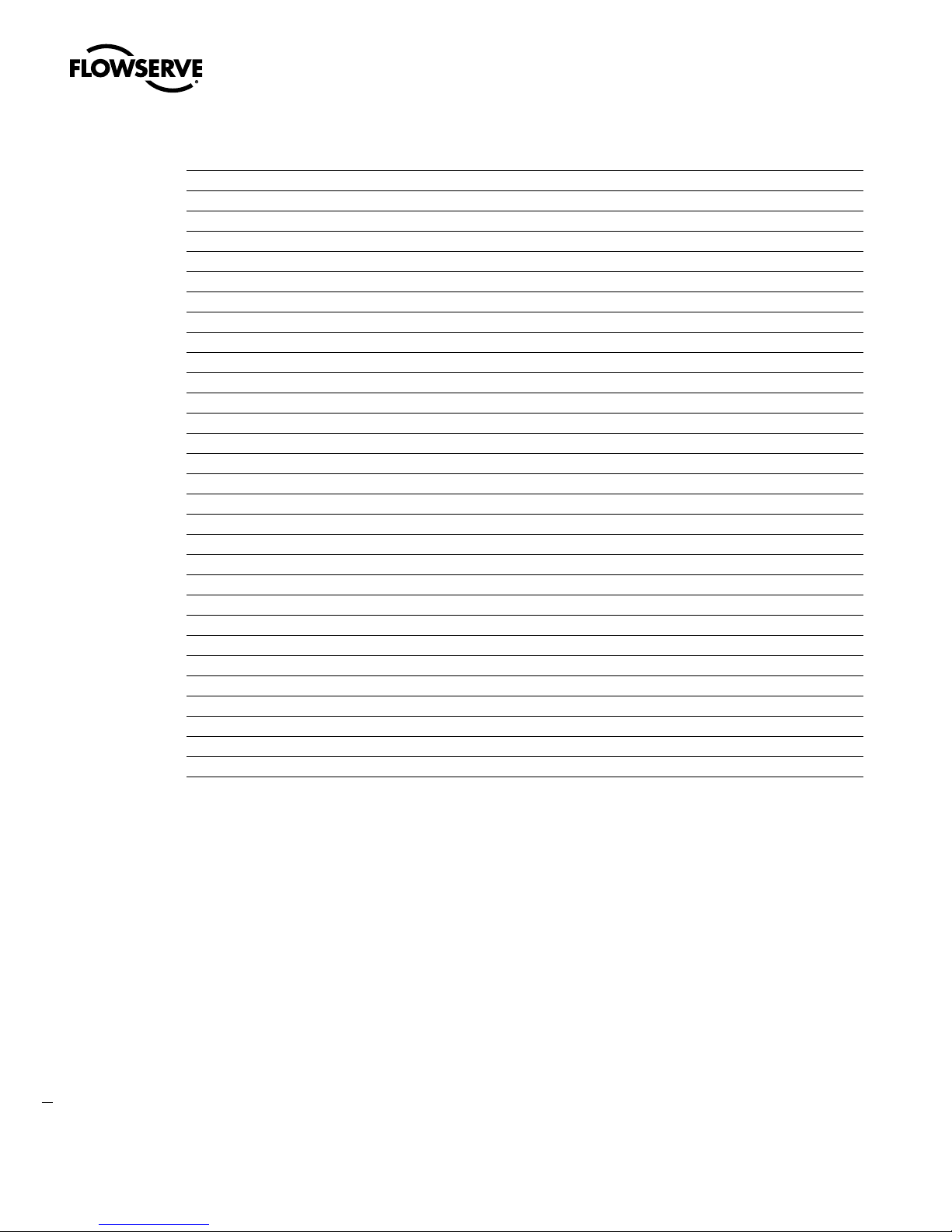

4.1.5 Mounting of MX-150 motor

The assembly of the MX-150 motor is a two-phase process. Phase 1 includes the mounting of the

motor support plate (#4-17), motor adapter (#4-8), and selection of a quantity of shims required to

offset any gap between the motor support plate and the motor support. Phase two includes removal

of the motor support plate, reinstallation with the shims in place and final tightening of all mounting

screws.

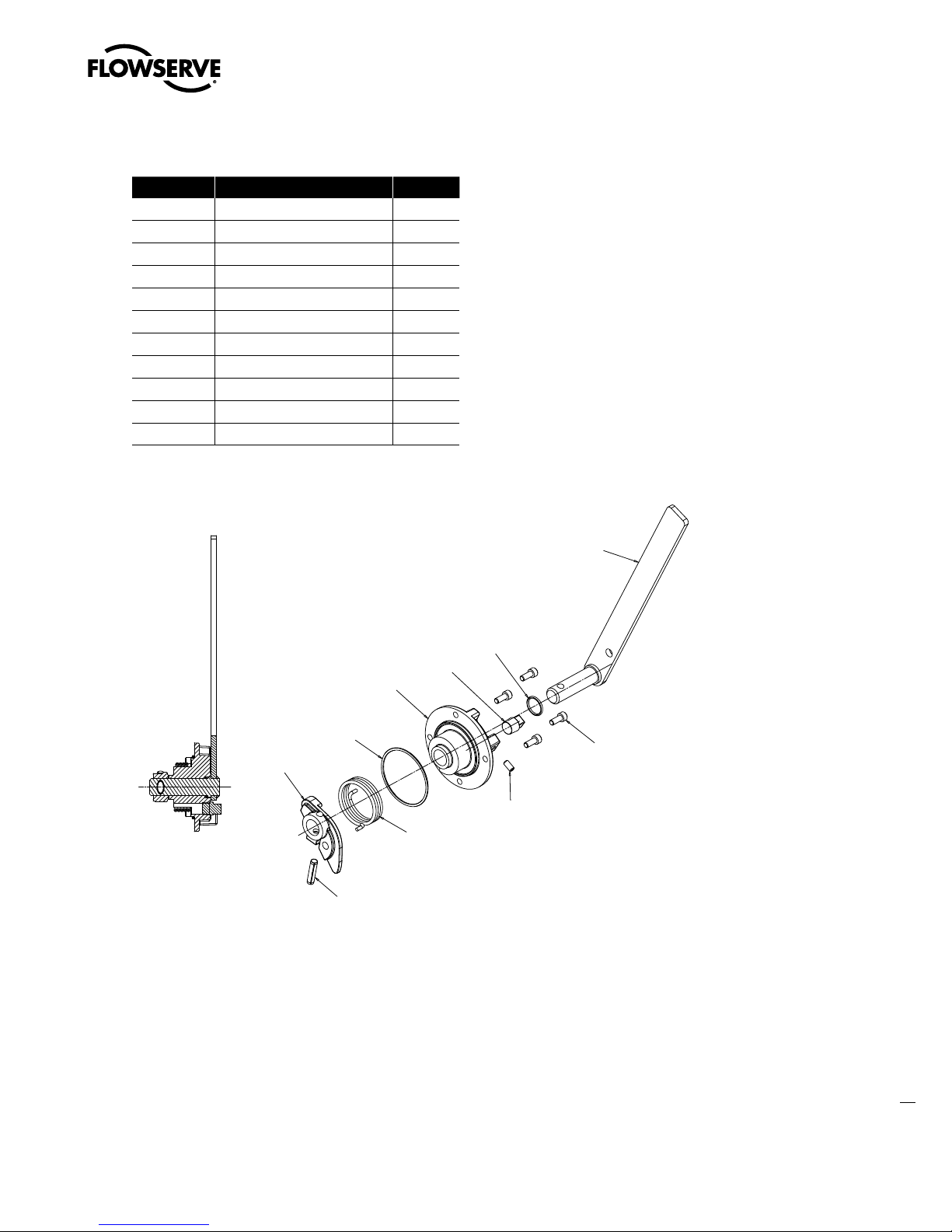

Table 4.3 – Motor Parts List

Part Number Description Qty.

1-15 O-ring 1

4-7 Motor 1

4-8 Motor adapter 1

4-9 Socket head cap screws 4

4-10 O-ring 1

4-11 Sheilded ball bearing 1

4-13 Plate, wiring sheild 1

4-14 Socket head cap screws 3

4-15 Socket head cap screws 4

4-16 Pipe plug 6

4-17 Plate, motor support 1

4-18 Shims AS REQ’D

4-19 Socket head cap screws 4

4-20 Socket head cap screws 4

23

flowserve.com

Page 32

Limitorque MX Maintenance and Spare Parts FCD LMENIM2314-00 – 07/08

UNIT HOUSING

1-15

4-8

4-13

4-15

4-7

4-9

4-16

4-10

4-14

4-11

4-18

4-17

4-19

4-20

4-20

UNIT BASEPLATE

UNIT BASEPLATE

MOUNT ADAPTER (PC-4-8) TO UNIT HOUSING

BEFORE MOUNTING MOTOR (PC-4-7)

Swanson Flo | 800-288-7926 | www.swansonflo.com

Figure 4.3 – Motor, Support Plate and Adapter (MX-150)

STEP 1

Install support plate (4-17) to unit base plate using socket head cap screws (#4-20).

STEP 2

Place the lead seal connector through the slot in the adapter (#4-8). Install the adapter loosely to unit

housing using screws (#4-15). Rotate adapter until gap is uniform with plate (#4-17). Tighten screws

(#4-15).

STEP 3

Measure gap and select the shim (#4-18) total thickness to be at least the gap plus up to .1mm (.004

inch). Shims are .1mm (.004 inch) each.

STEP 4

Remove plate (#4-17), install shims (#4-18), reinstall plate to base of unit, tighten screws (#4-20). Then

install and tighten screws (#4-19) with shims in place.

NOTES:

1. Pipe plugs (#4-16) must be installed with tape or pipe sealant over the four (4) mounting screws

(#4-15) and the two (2) jacking tap holes.

2. When mounting motor (#4-7) leads must be placed behind plate (#4-13).

24

Page 33

Limitorque MX Maintenance and Spare Parts FCD LMENIM2314-00 – 07/08

Swanson Flo | 800-288-7926 | www.swansonflo.com

3. Take care not to damage either the O.D. on adapter to I.D on housing and the O.D. on motor to I.D. on

adapter to protect flame path for hazardous certifications.

4.2 Declutch

Table 4.4 – Declutch Parts List (MX-05 and -10)

Part Number Description Qty.

5-1 Declutch cover 1

5-2 Declutch shaft 1

5-3 Declutch cam 1

5-4 Declutch spring 1

5-5 Cam spring 1

5-6 Declutch latch 1

5-7 Latch spring 1

5-8 Cam plate 1

5-9 Retaining ring 2

5-10 Socket head cap screw 1

5-11 O-ring 1

5-12 Socket head cap screw 2

5-13 Dowel pin 1

5-14 Roll pin 1

5-15 O-ring 1

Figure 4.4 – Declutch (MX-05 and -10)

25

flowserve.com

Page 34

Limitorque MX Maintenance and Spare Parts FCD LMENIM2314-00 – 07/08

PC. NO. 5-5

Spring,

Declutch

cam

PC. NO. 5- 4

Spring, Declutch shaft

5- 2

5-14

5-13

5-12

5-10

5-11

5- 1

5-15

5- 9

5- 4

5- 5

5- 7

5- 6

5-16

5- 9

5- 3

Swanson Flo | 800-288-7926 | www.swansonflo.com

Table 4.5 – Declutch Parts List (MX-20 and -40)

Part Number Description Qty.

5-1 Declutch cover 1

5-2 Declutch shaft 1

5-3 Declutch cam 1

5-4 Declutch spring 1

5-5 Cam spring 1

5-6 Declutch latch 1

5-7 Latch spring 1

5-8 Cam plate 1

5-9 Retaining ring 2

5-10 Socket head cap screw 1

5-11 O-ring 1

5-12 Socket head cap screw 2

5-13 Dowel pin 1

5-14 Roll pin 1

5-15 O-ring 1

5-16 Dowel pin 1

Figure 4.5 – Declutch (MX-20 and -40)

26

Page 35

Limitorque MX Maintenance and Spare Parts FCD LMENIM2314-00 – 07/08

Swanson Flo | 800-288-7926 | www.swansonflo.com

Table 4.6 – Declutch Parts List (MX-85, -140, and -150)

Part Number Description Qty.

5-1 Declutch cover 1

5-2 Declutch shaft 1

5-3 Declutch cam 1

5-4 Declutch spring 1

5-9 Retaining ring 2

5-10 Socket head set screw 1

5-11 O-ring 1

5-12 Socket head set screw 2

5-13 Spiral pin 1

5-15 O-ring 1

5-16 Pipe plug 1

Figure 4.6 – Declutch (MX-85, -140, and -150)

4.2.1 Removal

NOTE: The MX-05, -10, -85, -140, and -150 declutch assembly may be removed and remounted without

other subassembly removal.

NOTE: The MX-20 and -40 declutch assembly may be removed without other subassembly removal, but

remounting requires removing the following subassemblies:

1. Handwheel (Subassembly #13)

2. Handwheel adapter (Subassembly #12)

3. Clutch and clutch ring (Subassembly #16)

27

flowserve.com

Page 36

Limitorque MX Maintenance and Spare Parts FCD LMENIM2314-00 – 07/08

X

Swanson Flo | 800-288-7926 | www.swansonflo.com

STEP 1

WARNING: Potential to operate while dangerous mechanical parts are exposed during

c

subassembly removal. To prevent injury, turn off all power sources to actuator before

removing side-mounted and top-mounted handwheel assembly. Power sources may

include main power or control power.

NOTE: Oil removal is not necessary on MX-05, -10, -85, -140, and -150 if actuator is mounted with

declutch lever up.

Drain oil from actuator using the lowest of three

plugs in your application mounting orientation.

STEP 2

WARNING: Potential to operate while dangerous mechanical parts are exposed during

c

subassembly removal. To prevent injury, turn off all power sources to actuator before

removing declutch assembly. Power sources may include main power or control power.

Using a 5 mm (MX-05 and -10) or 6 mm

(MX-20, -40, -85, -140, and -150) hex key,

remove the two M6 (MX-05 and -10) screws

(#5-12), M8 (MX-20 and -40) or the four M8

(MX-85, -140, and -150) screws that retain the

declutch assembly cover (#5-1) on the actuator

housing.

1

2

Oil Plug Drains

5-12

5-1

28

Page 37

STEP 3

Swanson Flo | 800-288-7926 | www.swansonflo.com

Withdraw the complete declutch assembly,

slightly twisting if necessary, to remove. Note

the O-ring (#5-15) with the declutch assembly

cover (#5-1). Replace at remounting.

Picture 3a is typical MX-05 through -40. Picture

3b is typical MX-85/140/150.

Limitorque MX Maintenance and Spare Parts FCD LMENIM2314-00 – 07/08

3a

5-15

3b

4.2.2 Remounting

STEP 4

(MX-20 and -40 only) Remove the following

subassemblies before remounting the declutch

assembly. (See corresponding referenced

sections for removal information.)

1. Handwheel (subassembly #13). (See

Section 4.3.1.)

2. Handwheel adapter (subassembly #12).

(See Section 4.13.1.)

3. Clutch and clutch ring (subassembly #16).

(See Section 4.15.1.)

Lightly lubricate the O-ring (#5-15) and fit it to

the inner race of the declutch cover (#5-1).

4

5-15

29

flowserve.com

Page 38

Limitorque MX Maintenance and Spare Parts FCD LMENIM2314-00 – 07/08

Swanson Flo | 800-288-7926 | www.swansonflo.com

STEP 5

CAUTION: (MX-20 and -40 only) To create proper mating between the cam latch (#5-6)

a

and the shoulder on the worm gear, ensure cam latch is positioned below the worm gear

shoulder (see Picture 5a).

TIP: (MX-20 and -40 only) - Picture 5a shows

proper alignment between the cam latch (#5-6)

and the shoulder on the worm gear.

TIP: (MX-20 and -40 only) - Picture 5b shows

improper alignment between the cam latch

(#5-6) and the shoulder on the worm gear.

Improper alignment could cause the cam latch

to be broken off by the worm gear lug.

TIP: (MX-85, -140, and -150 only) - Picture 5c

shows proper alignment between the cam and

the clutch ring roller.

Fit the complete declutch assembly into the

actuator housing, slightly twisting if necessary,

to remount into actuator. See picture 5d.

5a

Cam Latch and

Worm Gear

Shoulder Proper

Alignment

5b

Cam latch and

worm gear shoulder

improper alignment

30

5c

5d

Page 39

Limitorque MX Maintenance and Spare Parts FCD LMENIM2314-00 – 07/08

Swanson Flo | 800-288-7926 | www.swansonflo.com

STEP 6 (MX-85, -140, AND -150 ONLY)

Set screw adjustment. Install drive sleeve, baseplate, clutching and handwheel worm gear components. Assure the clutch lugs are fully engaged to the motor worm gear lugs before the adjustment.

With declutch lever resting on cap pad (not the set screw) place declutch cap assembly (1-4) into

housing without mounting screws. Rotate cap assembly clockwise until declutch cam is resisted

by the roller, clutch ring and clutch combination. Holding the declutch lever, rotate the set screw

clockwise through declutch cap, (this will rotate the cap counterclockwise) until the cap mounting

holes are inline with the taps in the housing. Install declutch assembly mounting screws. Then

rotate set screw counterclockwise ¼ turn, plus or minus

STEP 7

Fit the two M6 (MX-05 and -10) screws

(#5-12), M8 (MX-20 and -40) screws to retain

the declutch assembly cover (#5-1) on the

housing. Tighten using a 5 mm (MX-05 and

-10) or 6 mm (MX-20, -40 and -85) hex key.

Picture 7a shows the two screws for the MX-20

and -40. Picture 7b shows the four screws for

the MX-85.

1

⁄8 turn. Adjustment is complete.

7a

See picture 7a for MX-05, -10, -20 and -40. See

picture 7b for MX-85, -140, and -150.

STEP 8 (MX-20 AND -40 ONLY)

Remount the following subassemblies after remounting the declutch assembly.

(See corresponding referenced sections for remounting information.)

1. Handwheel (subassembly #13). (See Section 4.3.2.)

2. Handwheel adapter (subassembly #12). (See Section 4.4.2, 4.4.3, and 4.5.3.)

3. Clutch and clutch ring (subassembly #16). (See Section 4.15.2.)

7b

31

flowserve.com

Page 40

Limitorque MX Maintenance and Spare Parts FCD LMENIM2314-00 – 07/08

1-9 (MX-05 only) Handwheel spacer (1)

1-10 Wave spring (1)

1-8 Handwheel (1)

1-11 Socket head cap screw (4)

Swanson Flo | 800-288-7926 | www.swansonflo.com

4.3 Top-Mounted Handwheel

(MX-05, -10, -20, and -40)

Table 4.7 – Top-Mounted Handwheel Parts List (MX-05, -10,

-20, and -40)

Part Number Description Qty.

1-8 Handwheel 1

1-9 Handwheel Spacer (MX-05 only) 1

1-10 Wave Spring 1

1-11 Socket head cap screw 4

Figure 4.7 – Top-Mounted Handwheel (MX-05, -10, -20, and -40)

32

WARNING: Do not manually operate the actuator with devices other than the installed

c

handwheel and declutch lever. Using force beyond the ratings of the actuator and/or additive

forces such as cheater bars, wheel wrenches, pipe wrenches, or other devices on the actuator

handwheel or declutch lever may cause serious personal injury and/or damage to the actuator

and valve.

Page 41

Limitorque MX Maintenance and Spare Parts FCD LMENIM2314-00 – 07/08

Swanson Flo | 800-288-7926 | www.swansonflo.com

4.3.1 Removal

STEP 1

WARNING: Potential to operate while dangerous mechanical parts are exposed during

c

subassembly removal. To prevent injury, turn off all power sources to actuator before

removing top-mounted handwheel assembly. Power sources may include main power

or control power.

Using a 6 mm (MX-05 and -10) hex key or

8 mm (MX-20 and -40) hex key, remove the

four screws (#1-11) that secure the handwheel

(#1-8) to the handwheel adapter assembly

(#1-1).

1

STEP 2

Lift the handwheel (#1-8) off the handwheel

adapter (#1-1).

4.3.2 Remounting

STEP 3

Install handwheel (#1-8) onto handwheel

adapter assembly (#1-1).

1-8

11-1

2

3

1-1

1-8

33

flowserve.com

Page 42

Limitorque MX Maintenance and Spare Parts FCD LMENIM2314-00 – 07/08

Swanson Flo | 800-288-7926 | www.swansonflo.com

STEP 4

Align the handwheel slots with the mounting

holes. Fit the four screws (#1-11) in handwheel

mounting holes and tighten.

4

34

Page 43

Limitorque MX Maintenance and Spare Parts FCD LMENIM2314-00 – 07/08

Swanson Flo | 800-288-7926 | www.swansonflo.com

4.4 Side-Mounted Handwheel Without Spur Gear

Attachment (MX-10, -20, -85, -140, and -150)

Table 4.8 – Side-Mounted Handwheel Parts List (MX-10 and -20)

Part Number Description Qty.

13-1 Handwheel wormshaft 1

13-2 Handwheel worm cap 1

13-3 Ball bearing 1

13-4 Quad ring 1

13-5 Seal retainer 1

13-6 O-ring 1

13-7 Roll pin 1

13-8 Ball bearing 1

13-9 Socket head cap screw 2 (MX-10), 4 (MX-20)

13-10 Side-Mounted handwheel 1

Figure 4.8 – Side-Mounted Handwheel (MX-10 and -20)

WARNING: Do not manually operate the actuator with devices other than the installed

c

handwheel and declutch lever. Using force beyond the ratings of the actuator and/or additive

forces such as cheater bars, wheel wrenches, pipe wrenches, or other devices on the actuator

handwheel or declutch lever may cause serious personal injury and/or damage to the actuator

and valve.

35

flowserve.com

Page 44

Limitorque MX Maintenance and Spare Parts FCD LMENIM2314-00 – 07/08

4&$5*0/""

Swanson Flo | 800-288-7926 | www.swansonflo.com

4.4.1 Side-Mounted Handwheel Without Spur Gear Attachment

(MX-85, -140, and -150)

Table 4.9 – Side-Mounted Handwheel without Spur Gear

Attachment Parts List (MX-85, -140, and -150)

Part Number Description Qty.

13-1 Handwheel wormshaft 1

13-2 Handwheel worm cap 1

13-3 Ball bearing 1

13-4 Quad ring 1

13-5 Roll pin 1

13-6 O-ring 1

13-7 Key 1

13-8 Needle bearing 1

13-9 Socket head cap screw 4

13-10 Side-Mounted handwheel 1

13-18 Socket head set screw 1

WARNING: Do not manually

c

operate the actuator with

devices other than the installed

handwheel and declutch lever.

Using force beyond the ratings

of the actuator and/or additive

forces such as cheater bars,

wheel wrenches, pipe wrenches,

or other devices on the actuator

handwheel or declutch lever may

cause serious personal injury

and/or damage to the actuator

and valve.

Figure 4.9 – Side-Mounted Handwheel (MX-85, -140, and -150)

36

Page 45

Limitorque MX Maintenance and Spare Parts FCD LMENIM2314-00 – 07/08

Swanson Flo | 800-288-7926 | www.swansonflo.com

4.4.2 Removal of Side-Mounted Handwheel

(MX-10, -20, -85, -140, and -150)

NOTES: The MX-10 and -20 handwheel is

mounted with a roll pin (13-7). If removal of the

handwheel from the worm shaft is necessary,

remove the handwheel and worm shaft

assembly from unit before removing roll pin.

Removing the roll pin before disassembly of

worm shaft will damage the ball bearing (13-3).

The MX-85, -140, and -150 handwheel is

mounted with a key (13-7) and a set screw

(13-18). See pictures a and b.

a

b

4.4.3 Removal

STEP 1

WARNING: Potential to operate while dangerous mechanical parts are exposed during

c

subassembly removal. To prevent injury, turn off all power sources to actuator before

removing side-mounted handwheel assembly. Power sources may include main power

or control power.

Drain oil from actuator using the lowest of three

plugs in your application mounting orientation.

NOTE: Oil removal is not necessary if the

actuator is mounted on valve or other device

with the drive sleeve in a vertical position.

1

Oil Plug Drains

37

flowserve.com

Page 46

Limitorque MX Maintenance and Spare Parts FCD LMENIM2314-00 – 07/08

Swanson Flo | 800-288-7926 | www.swansonflo.com

STEP 2 (MX-10 AND -20)

CAUTION: Be aware of inner bearing (#13-8) when removing the side-mounted hand-

a

wheel. It may stay in the actuator housing or come out with the side-mounted handwheel

assembly. Ensure it is inserted back in actuator housing before remounting side-mounted

handwheel assembly.

TIP: (MX-85, -140, and -150 only) Needle bearing (#13-8) is pressed into housing.

Using a 6 mm hex key, remove the M8 screws

(#13-9) from the handwheel worm shaft cap

(#13-2).

2

13-9

13-2

STEP 3

Rotate the handwheel assembly clockwise

(CW) to withdraw the complete subassembly

(#13) from the actuator housing.

3

38

Page 47

4.4.4 Remounting

Swanson Flo | 800-288-7926 | www.swansonflo.com

STEP 4

Check that bearing (#13-8) is correctly in place

in the actuator housing.

The MX-10 and -20 is a slip fit (4a).

The MX-85, -140, and -150 is a press fit (4b).

Limitorque MX Maintenance and Spare Parts FCD LMENIM2314-00 – 07/08

4a

13-8

4b

STEP 5

Insert the complete subassembly into the

actuator housing, rotating counterclockwise

(CCW) to properly mesh the gearing. Ensure

the end of the worm shaft is seated in the inner

bearing (#13-8).

STEP 6

Position the worm shaft cap (#13-2) back on

the actuator housing. Using a 6 mm hex key, fit

the (#13-9) screws onto the worm shaft cap to

secure side-mounted assembly to the actuator

housing.

5

6

39

flowserve.com

Page 48

Limitorque MX Maintenance and Spare Parts FCD LMENIM2314-00 – 07/08

Swanson Flo | 800-288-7926 | www.swansonflo.com

4.5 Side-Mounted Handwheel With Spur Gear

Attachment (MX-40, -85, -140, and -150)

Table 4.10 – Side-Mounted Handwheel Parts List (MX-40)

Part Number Description Qty.

13-1 Handwheel worm shaft 1

13-2 Spur adapter plate 1

13-3 Ball bearing 1

13-6 O-ring 1

13-7 Roll pin 1

13-8 Ball bearing 1

13-9 Socket head cap screw M8x25 4

13-10 Side-Mounted handwheel 1

13-11 Needle bearing 3

13-12 Handwheel input gear 1

13-13 Spur adapter cap 1

13-14 Handwheel input pinion 1

13-15 Quad ring 1

13-16 O-ring spacer 1

13-17 Dowel pin 1

13-18 Roll pin 1

13-19 O-ring 1

13-20 Socket head cap screw M8x20 4

WARNING: Do not manu-

c

ally operate the actuator

with devices other than

the installed handwheel

and declutch lever. Using

force beyond the ratings

of the actuator and/

or additive forces such

as cheater bars, wheel

wrenches, pipe wrenches,

or other devices on the

actuator handwheel or

declutch lever may cause

serious personal injury

and/or damage to the

actuator and valve.

40

Figure 4.10 – Side-Mounted Handwheel with SGA (MX-40)

Page 49

Limitorque MX Maintenance and Spare Parts FCD LMENIM2314-00 – 07/08

13-10

13-18

13-17

13-19

13-9

13-6

13-5

13-1

13-8

13-24

13-24

13-3

13-28

13-2

13-17

13-14

13-7

13-23

13-15

13-11

13-12

13-22

13-13

Swanson Flo | 800-288-7926 | www.swansonflo.com

4.5.1 MX-85, -140, and -150 Handwheel with SGA

Table 4.11 – Side-Mounted Handwheel Parts List (MX-85, -140,

and -150)

Part Number Description Qty.

13-1 Handwheel worm shaft 1

13-2 Spur adapter plate 1

13-3 Ball bearing 1

13-5 Spiral pin 1

13-6 Gasket 1

13-7 Key 1

13-8 Needle bearing 1

13-9 Socket head cap screw M8x25 4

13-10 Side-Mounted handwheel 1

13-11 Ball bearing 1

13-12 Handwheel input gear 1

13-13 Spur adapter cap 1

13-14 Handwheel input pinion 1

13-15 Oil seal 1

13-17 Dowel pin 1

13-18 Set screw 1

13-19 Gasket 1

13-20 Socket head cap screw M8x20 4

13-22 Ball bearing 1

13-23 Ball bearing 1

13-24 Key 2

13-28 Retaining ring 1

WARNING: Do not manually

c

operate the actuator w/ devices

other than the installed handwheel and declutch lever. Using

force beyond the ratings of the

actuator and/or additive forces

such as cheater bars, wheel

wrenches, pipe wrenches, or

other devices on the actuator

handwheel or declutch lever

may cause serious personal

injury and/or damage to the

actuator and valve.

Figure 4.11 – Side-Mounted Handwheel With SGA (MX-85, -140, and -150)

41

flowserve.com

Page 50

Limitorque MX Maintenance and Spare Parts FCD LMENIM2314-00 – 07/08

Swanson Flo | 800-288-7926 | www.swansonflo.com

4.5.2 Removal of Handwheel

NOTES: The MX-40 handwheel is mounted with

a roll pin (#13-7). If removal of the handwheel

from the worm shaft is necessary, remove the

handwheel and worm shaft assembly from unit

before removing roll pin. Removing the roll pin

before disassembly of worm shaft will damage

the ball bearing (#13-3).

The MX-85, -140, and -150 handwheel is

mounted with a key (#13-7) and a set screw

(#13-18). See pictures a and b.

a

b

42

STEP 4

Remove the four M6 screws (#13-9) from the worm shaft plate (#13-2).

4.5.3 Removal

STEP 1

WARNING: Potential to operate while dangerous mechanical parts are exposed during

c

subassembly removal. To prevent injury, turn off all power sources to actuator before

removing side-mounted handwheel assembly. Power sources may include main power

or control power.

NOTE: Oil removal is not necessary if the actuator is mounted on valve or other device with the

drive sleeve in a vertical position.

Drain oil from actuator using the lowest of three

plugs in your application orientation.

1

Oil Plug Drains

Page 51

Limitorque MX Maintenance and Spare Parts FCD LMENIM2314-00 – 07/08

Swanson Flo | 800-288-7926 | www.swansonflo.com

STEP 2

CAUTION: Be aware of inner bearing (#13-8) when removing the side-mounted hand-

a

wheel. It may stay in the actuator housing or come out with the side-mounted handwheel

assembly. Ensure it is inserted back in actuator housing before remounting side-mounted

handwheel assembly.

Remove the four screws (#13-20) from the

handwheel spur gear cap (#13-13).

2

13-20

STEP 3

Remove handwheel spur gear cap assembly.

Note when assembly is removed, the spur gear

(#13-12) is loose in spur gear cap. Remove

spur gear.

3a

13-12

MX-40

3b

13-12

MX-85/140/150

43

flowserve.com

Page 52

Limitorque MX Maintenance and Spare Parts FCD LMENIM2314-00 – 07/08

Swanson Flo | 800-288-7926 | www.swansonflo.com

STEP 4

Remove the four M6 screws (#13-9) from the

worm shaft plate (#13-2).

4a

13-9

13-2

MX-40

4b

STEP 5

Removing worm shaft assembly.

MX-40: Remove adapter plate and worm

assembly together (5a).

MX-85/140/150: Remove adapter plate, then

remove worm assembly (5b).

NOTE: When removing the side-mounted

handwheel, the inner bearing (#13-8) should

remain in place in the housing.

Rotate the handwheel assembly clockwise

(CW) to withdraw the complete worm shaft

plate subassembly.

MX-85/140/150

5a

MX-40

5b

44

MX-85/140/150

Page 53

STEP 6

Swanson Flo | 800-288-7926 | www.swansonflo.com

If needed, remove the handwheel worm gear

assembly (#12-1). (See Section 4.14.1 for

removal procedure.)

4.5.4 Remounting

STEP 7

Check that bearing (#13-8) is correctly in place

in the actuator housing.

MX-40 is slip fit in housing (7a).

Limitorque MX Maintenance and Spare Parts FCD LMENIM2314-00 – 07/08

6

Handwheel Worm Gear Adapter (12-1)

7a

MX-85 is press fit in housing (7b).

STEP 8

If previously removed, install handwheel worm

gear assembly (#12-1). (See Section 4.14.2 for

remounting procedure.)

13-8

7b

8

Handwheel Worm Gear Adapter (12-1)

45

flowserve.com

Page 54

Limitorque MX Maintenance and Spare Parts FCD LMENIM2314-00 – 07/08

Swanson Flo | 800-288-7926 | www.swansonflo.com

STEP 9

Ensure O-ring (MX-40) (#13-6) is in place on

worm shaft plate.

MX-40, -85, -140, and -150: Insert worm

shaft assembly into actuator housing. Rotate

assembly in counterclockwise (CCW) direction

to properly mate with handwheel worm gear

assembly (#12-1)(9b).

9a

13-6

9b

13-2

STEP 10A - MX-40

Secure with four M8 screws (#13-9) to secure

the adapter plate (#13-2).

10a

13-9

13-2

46

Page 55

STEP 10A AND B - MX-85, -140, AND -150

Swanson Flo | 800-288-7926 | www.swansonflo.com

Ensure gasket (#13-6) is placed on adapter

(#13-2) and install adapter to housing and

secure with four M8 screws (#13-9).

Limitorque MX Maintenance and Spare Parts FCD LMENIM2314-00 – 07/08

10b

10c

47

flowserve.com

Page 56

Limitorque MX Maintenance and Spare Parts FCD LMENIM2314-00 – 07/08

Swanson Flo | 800-288-7926 | www.swansonflo.com

STEP 11

MX-40 (11a)

Fit gear (#13-12) onto end of worm shaft

(#13-1). Ensure gear slot is fitted into pin

(#13-7).

11a

13-1

13-7

MX-85, -140, and -150 (11b and 11c)

Fit gear (#13-12) onto end of worm shaft.

Ensure both keys (#13-24) are in place in worm

shaft.

13-12

11b

13-24

11c

13-12

48

Page 57

STEP 12A - MX-40

Swanson Flo | 800-288-7926 | www.swansonflo.com

Ensure O-ring (#13-19) is in place on worm

shaft plate (#13-2).

STEP 12B - MX-85, -140, AND -150

Ensure gasket (#13-19) is in place on adapter

(#13-2).

Limitorque MX Maintenance and Spare Parts FCD LMENIM2314-00 – 07/08

12a

13-19

13-2

12b

STEP 13A - MX-40

Check that quad ring (#13-15), spacer (#13-16)

and needle bearing (#13-11) are correctly

placed in plate (#13-2) and cap (#13-13).

Install handwheel spur cap assembly, secure

with screws (#13-20).

STEP 13B - MX-85, -140, AND -150

Check that seal (#13-15), and ball bearings

(#13-11, 13-22, and 13-23) are correctly placed

in adapter (#13-2) and cap (#13-13).

Install handwheel spur cap assembly. Secure

with screws (#13-20). Remount handwheel

(#13-10) if removed with key (#13-7) and set

screw (#13-18).

13a

13b

49

flowserve.com

Page 58

Limitorque MX Maintenance and Spare Parts FCD LMENIM2314-00 – 07/08

Swanson Flo | 800-288-7926 | www.swansonflo.com

4.6 Converting Top-Mounted Handwheel

to Side-Mounted Handwheel

(MX-10, -20, and -40)

4.6.1 Removing Top-Mounted Handwheel

WARNING: Do not manually operate the actuator with devices other than the installed

c

handwheel and declutch lever. Using force beyond the ratings of the actuator and/or additive

forces such as cheater bars, wheel wrenches, pipe wrenches, or other devices on the actuator

handwheel or declutch lever may cause serious personal injury and/or damage to the actuator

and valve.

STEP 1

WARNING: Potential to operate while dangerous mechanical parts are exposed during

c

subassembly removal. To prevent injury, turn off all power sources to actuator before

removing side-mounted and top-mounted handwheel assembly. Power sources may

include main power or control power.

Drain oil from actuator using the lowest of three

plugs in your application mounting orientation.

NOTE: Oil removal is not necessary if actuator

is mounted on valve or other device with the

drive sleeve in a vertical position.

NOTE: MX-10 shown.

1

Oil Plug

Drains

50

Page 59

STEP 2

Swanson Flo | 800-288-7926 | www.swansonflo.com

Remove top-mounted handwheel assembly

(#1) and handwheel adapter assembly (#12-1)

using disassembly instructions detailed in

Sections 4.3.1 and 4.13.1 respectively.

Limitorque MX Maintenance and Spare Parts FCD LMENIM2314-00 – 07/08

2a

2b

12

STEP 3

Using a 6 mm hex key, remove the M8 screws

(#13-9) from the handwheel worm shaft cap

(#13-2).

3

13-9

4.6.2 Installing Side-Mounted Handwheel

STEP 4

Install bearing (#13-8) from side-mounted

handwheel adapter kit into the actuator

housing.

MX-10, -20 and -40: the bearing is a slip fit into

the housing.

MX-85, -140, and -150: the bearing is a press

fit into the housing.

4

13-2

13-8

51

flowserve.com

Page 60

Limitorque MX Maintenance and Spare Parts FCD LMENIM2314-00 – 07/08

Swanson Flo | 800-288-7926 | www.swansonflo.com

STEP 5

Replace the handwheel adapter (#12-5) with

the handwheel worm gear (#12-1) that is

included in the side-mounted handwheel

adapter kit.

STEP 6 (MX-20 AND -40 ONLY)

Place the O-ring (#12-4) around the handwheel

adapter; pressing the O-ring into the slot

between the handwheel worm gear adapter

assembly (#12-1) and the actuator housing

(approximately every 15° to 30° until O-ring

seats into slot).

5

12

6

12-4

STEP 7

Place the retainer plate (#1-32) on the top of

the actuator housing. Align the mounting taps

and secure with screws (#1-33).

STEP 8

Complete the remounting procedure for side-mounted handwheel assembly #13A (MX-10 and -20)

or #13B (MX-40) as detailed in Section 4.4.3 or Section 4.5.3.

7

1-32

52

Page 61

Limitorque MX Maintenance and Spare Parts FCD LMENIM2314-00 – 07/08

10-2

10-15

10-13

10-3

10-6

10-7

10-16

10-12

10-12

10-13

10-10

10-1

10-8

10-11

10-17

MX-40 gasket

and quad ring

not shown

10-14

Swanson Flo | 800-288-7926 | www.swansonflo.com

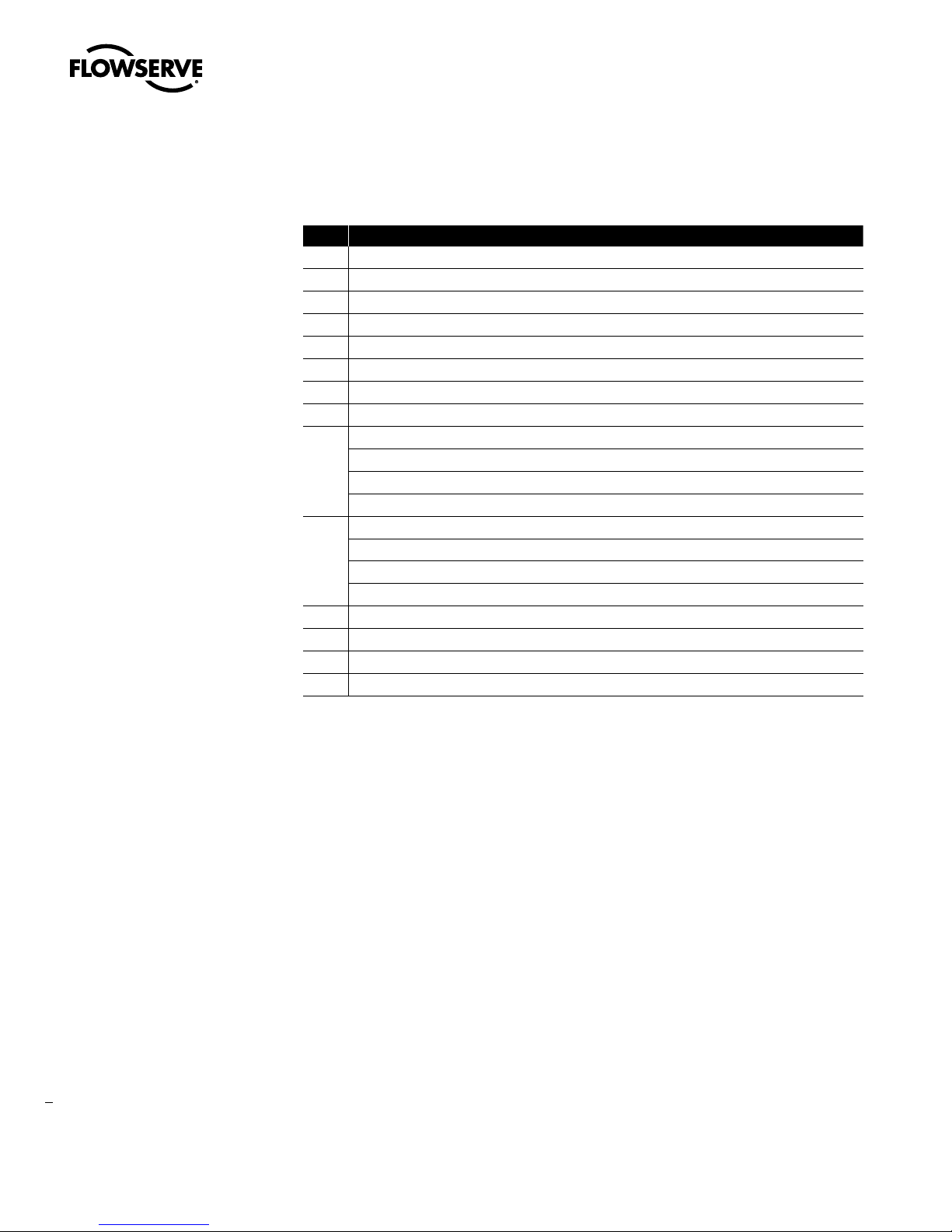

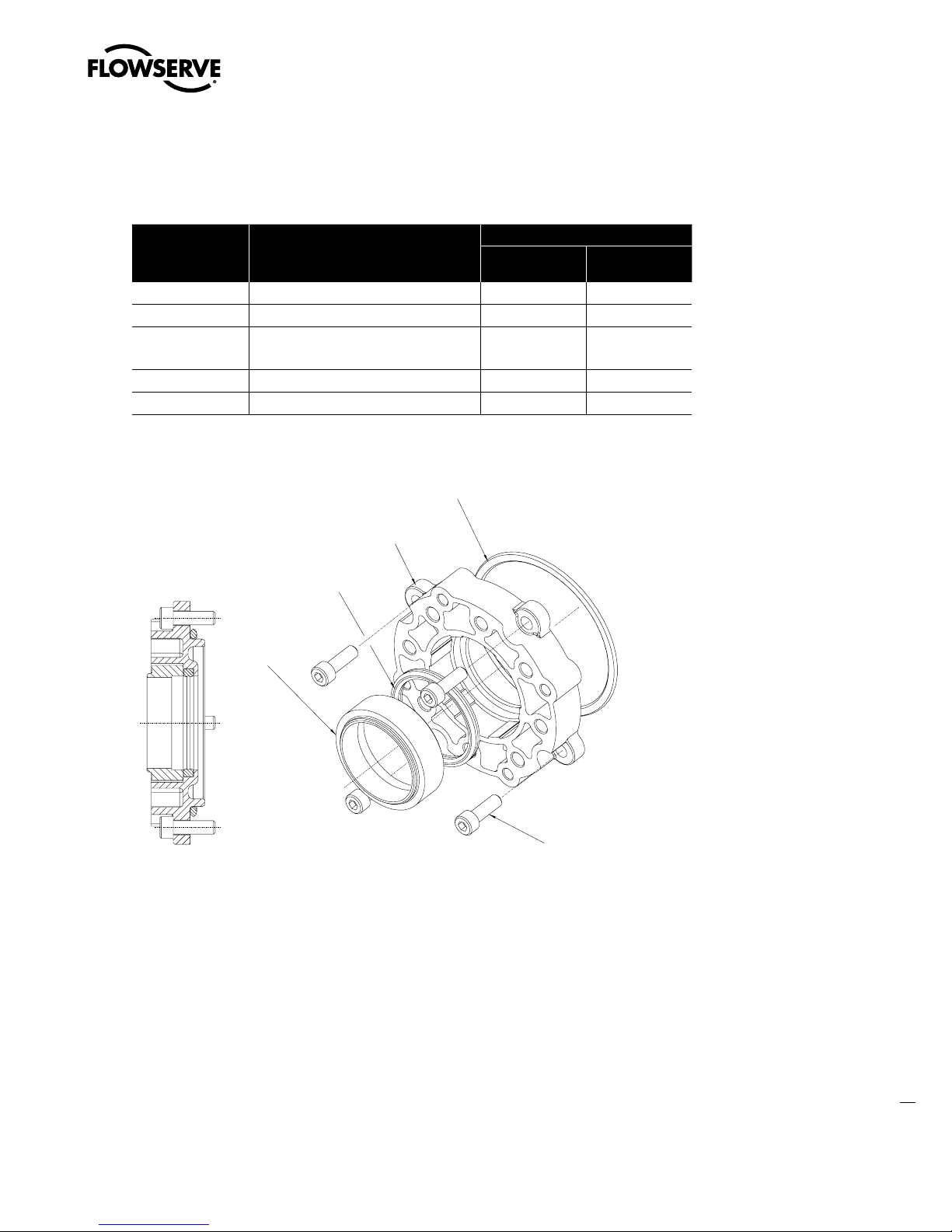

4.7 Thrust Base Type A1/A1E

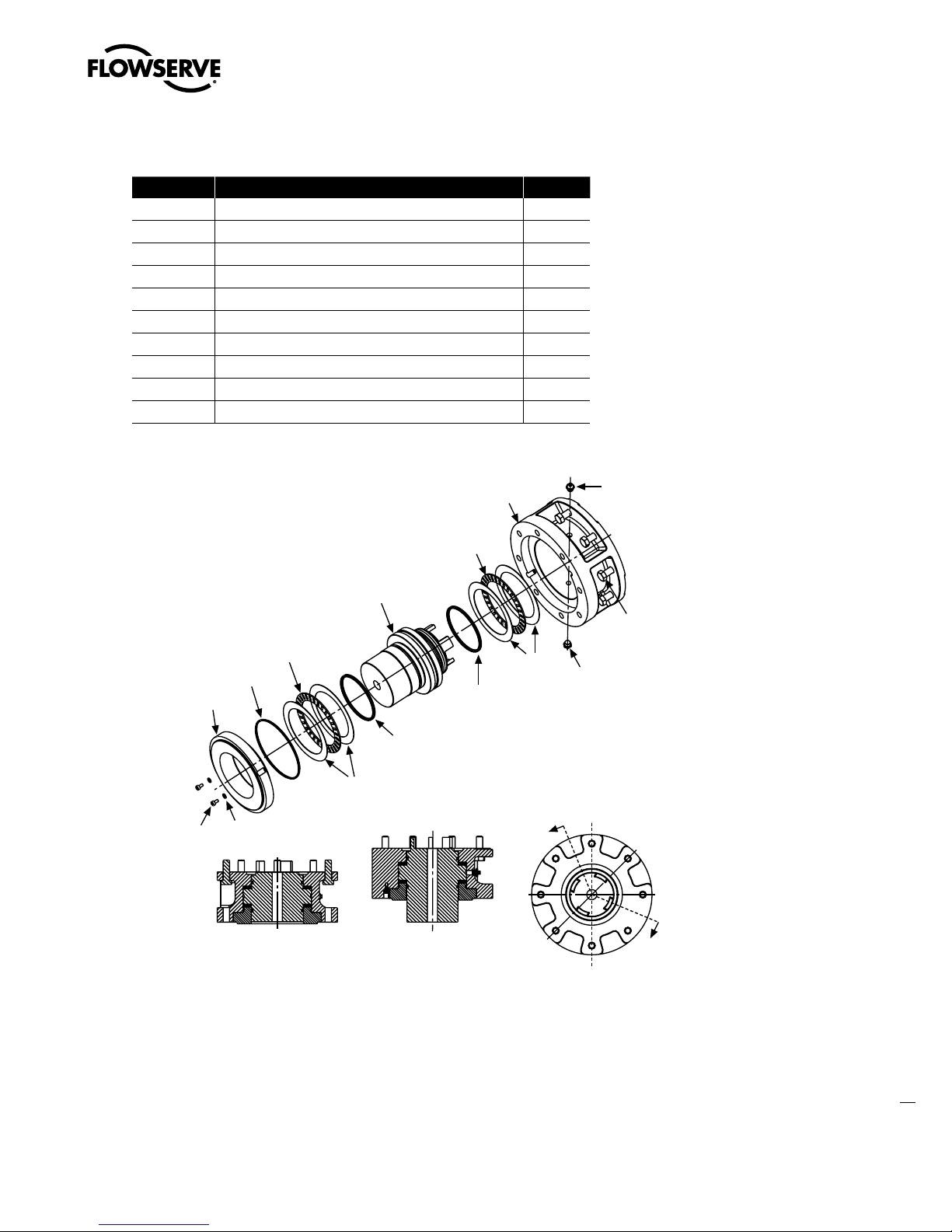

Table 4.12 – Type A1 Thrust Base Parts List (MX-05, 10, -20, and -40)

Part No. Description

10-1 Thrust base housing 1 1 1 1

10-2 Thrust pilot (Threaded on MX-40) 1 1 1 1

10-3 Thrust nut (A1 or A1E) 1 1 1 1

10-6 Socket head cap screw 1 1 1 N/A

10-7 Washer 1 1 1 N/A

10-8 Pipe plug 1 1 N/A N/A

10-10 Socket head cap screw 4 4 4 4

10-11 Grease fitting 1 1 1 1

10-12 Thrust bearing 2 2 2 2

10-13 Thrust washer 4 4 4 4

10-14 Quad ring 1 1 1 N/A

10-15 O-ring 1 1 1 1

10-16 Quad ring 1 1 1 1

10-17 Gasket N/A N/A N/A 1

(MX-05) (MX-10) (MX-20) (MX-40)

Quantity

Figure 4.12 – Type A1 Thrust Base (MX-05, -10, -20, and -40)

CAUTION: The MX-05 through -40 A1/A1E thrust base contains lubrication. Ensure that a

a

quality Lithium-based lubricant is used when reassembling the thrust base.

53

flowserve.com

Page 62

Limitorque MX Maintenance and Spare Parts FCD LMENIM2314-00 – 07/08

10-17

10-2

10-13

10-12

10-14

10-3

10-14

10-12

10-10

10-1

10-13

10-11

10-15

SECTION A-A

VIEW SHOWN WITH

STANDARD NUT

SECTION A-A

VIEW SHOWN WITH

EXTENDED NUT

Swanson Flo | 800-288-7926 | www.swansonflo.com

Table 4.13 – Type A1 Thrust Base Parts List (MX-85)

Part Number Description Qty.

10-1 Thrust base housing 1

10-2 Thrust base mounting flange 1

10-3 Thrust nut (A1 or A1E) 1

10-10 Socket head cap screw 4

10-11 Grease fitting 1

10-12 Thrust bearing 2

10-13 Thrust washer 4

10-14 Quad ring 2

10-15 O-ring 1

10-17 Socket head cap screw 6

Figure 4.13 – Type A1 Thrust Base (MX-85) - F16 Flange

54

Page 63

Limitorque MX Maintenance and Spare Parts FCD LMENIM2314-00 – 07/08

4PDLFU

IFBEDBQ

TDSFXT

)PVTJOH

5ISVTU

CFBSJOH

2VBESJOH

5ISVTUOVU

5ISVTU

XBTIFS

5ISVTU

CFBSJOH

0SJOH

4PDLFUIFBE

DBQTDSFXT

8BTIFS

5ISVTU

QJMPU

1JQFQMVH

1JQFQMVH

4FDUJPO""

7JFXTIPXOXJUI

TUBOEBSEOVU

4FDUJPO##

7JFXTIPXOXJUI

FYUFOEFEOVU

"

#

#

"

2VBESJOH

5ISVTU

XBTIFS

Swanson Flo | 800-288-7926 | www.swansonflo.com

Table 4.14 – Type A1 Thrust Base Parts List (MX-85, -140, and -150) - F25 Flange

Part Number Description Qty.

10-1 Thrust Base Housing 1

10-2 Thrust Base Plate 1

10-3 Thrust Nut 1

10-10 Socket Head Cap Screws 4

10-11 Pipe Plug 1

10-12 Thrust Bearing 2

10-13 Thrust Washer 4

10-14 Quad Ring 2

10-15 O-ring 1

10-17 Socket Head Cap Screws 6

Figure 4.14 – Type A1 Thrust Base (MX-85, -140, and -150) - F25 Flange

55

flowserve.com

Page 64

Limitorque MX Maintenance and Spare Parts FCD LMENIM2314-00 – 07/08

Swanson Flo | 800-288-7926 | www.swansonflo.com

4.7.1 Removal

First Remove

1. Remove actuator from mounting adapter.

STEP 1

WARNING: Potential to operate while dangerous mechanical parts are exposed during

c

subassembly removal. To prevent injury, turn off all power sources to actuator before

removing thrust base assembly. Power sources may include main power or control

power.

Remove the four screws (#10-10) and pull the

thrust base assembly off the actuator.

1

4.7.2 Remounting

STEP 2

Secure the thrust base with the four screws

(#10-10).

2

56

Page 65

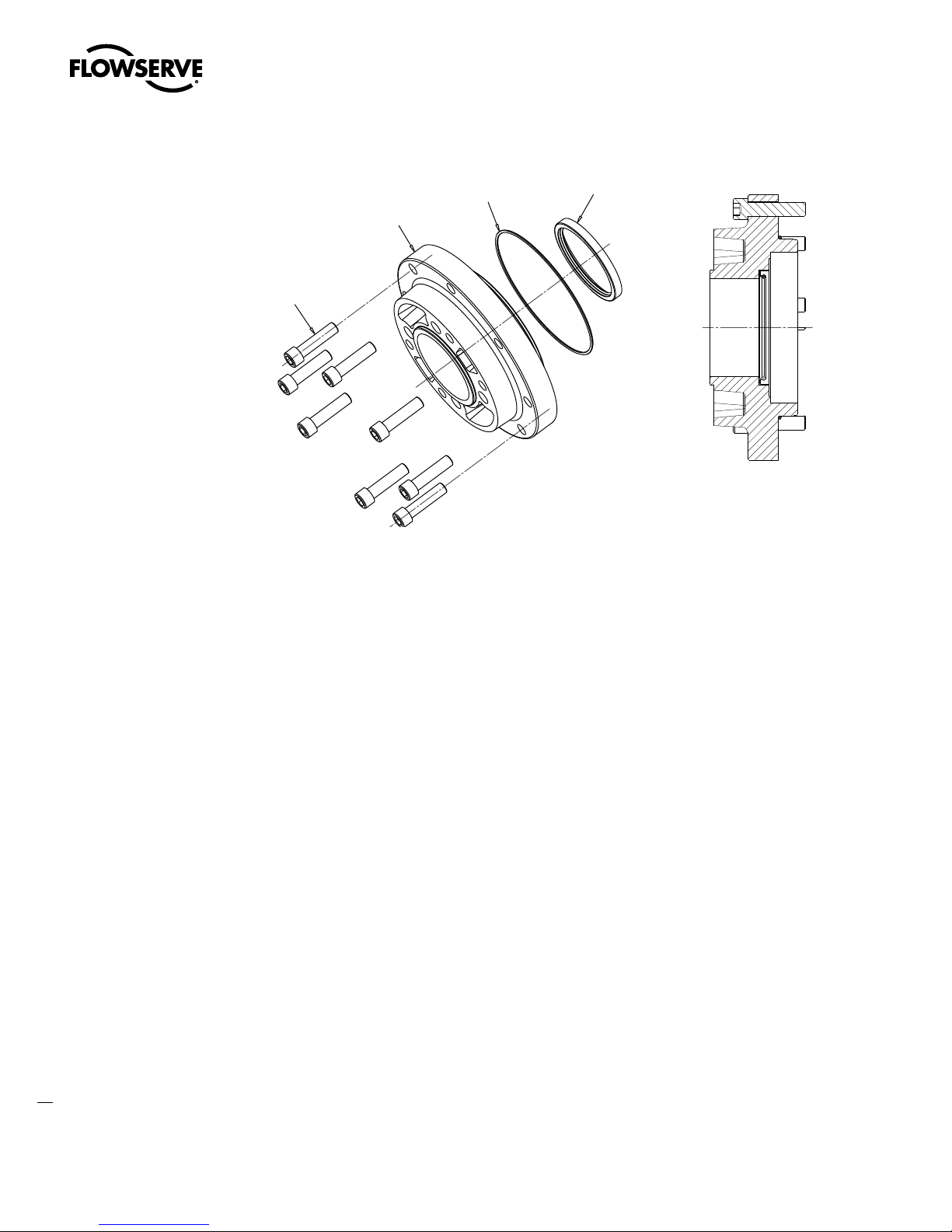

Limitorque MX Maintenance and Spare Parts FCD LMENIM2314-00 – 07/08

10-1

10-2

10-3

10-14

10-14 (MX-05 & 10)

10-16 (MX-20 & 40)

10-15

10-11

10-8

10-6

10-7

10-10

10-17 (MX-40 only)

gasket not shown

Swanson Flo | 800-288-7926 | www.swansonflo.com

4.8 Torque Base Type B1

Table 4.15 – Type B1 Torque Base Parts List (MX-05, -10, -20, and -40)

Part

Number

10-1 Torque housing 1 1 1 1

10-2 Torque/thrust pilot 1 1 1 1

10-3 Torque nut (B1) 1 1 1 1

10-6 Socket head cap screw 1 1 1 N/A

10-7 Washer 1 1 1 N/A

10-8 Pipe plug 2 2 N/A N/A

10-10 Socket head cap screw 4 4 4 4

10-11 Grease fitting 1 1 1 1

10-14 O-ring 2 2 1 N/A

10-15 O-ring 1 1 1 1

10-16 O-ring N/A N/A 1 1

10-17 Gasket N/A N/A N/A 1

Description

MX-05 MX-10 MX-20 MX-40

Quantity

Figure 4.15 – Type B1 Torque Base (MX-05, -10, -20, and -40)

57

flowserve.com

Page 66

Limitorque MX Maintenance and Spare Parts FCD LMENIM2314-00 – 07/08

Swanson Flo | 800-288-7926 | www.swansonflo.com

4.8.1 Removal

First Remove

1. Remove actuator from mounting adapter.

STEP 1

WARNING: Potential to operate while dangerous mechanical parts are exposed during

c

subassembly removal. To prevent injury, turn off all power sources to actuator before

removing torque base assembly. Power sources may include main power or control

power.

Remove the four screws (#10-1) and pull the

torque base assembly off the actuator.

1

4.8.2 Remounting

STEP 2

Secure the torque base with the four screws

(#10-1).

2