Page 1

The Pulsair III is a digital positioner designed primarily for

controlling adjustable valves. The positioner can be used with single

or double action 39 series actuators.

The Pulsair III Watertight Positioner (L93W) can be equipped with

modules for feedback, limit switches, sensors, and a pressure

gauge block.

The Pulsair III Hazardous Location Positioner (4L93Z) does not

allow for switch/sensor options. However, the feedback (4–20 mA

output) option is included as standard.

For the L93W, modules can be factory assembled before delivery or

fitted later.

The modules for feedback (4–20 mA output) and limit

switches/sensors can contain the following:

Feedback (4–20 mA output) and/or one of the following functions:

• Two mechanical switches (code M2)

• Two proximity (reed) switches (code R2)

• Two Namur sensors (code P2)

Storage Instructions

PULSAIR III positioners are precision instruments which should be

stored and handled accordingly to avoid problems or damage.

Electro-pneumatic positioners contain electronic components which

can be damaged by exposure to excessive water. Appropriate

precautions should be taken to protect units while in storage.

Warehouse Storage

Stored in original shipping containers, units should be stored in an

environmentally controlled area, i.e., clean, cool (15–26°C, 60–80°F)

and dry, out of direct sunlight or weather exposure.

Field Storage

NOTE: Once the air supply to the positioner is connected and turned

on, internal air bleed will prevent the ingress of moisture and protect

the unit from corrosion. It is recommended that the air supply be

left on at all times.

• If units are installed immediately, turn, and leave on,

the air supply.

• If positioners must be stored outdoors, tighten all

covers which may have loosened in shipment and

make sure all open enclosure points are sealed.

Positioners should be wrapped and sealed, air and watertight with

desiccant inside the plastic, units should be securely covered with an

opaque cover and not exposed to direct sunlight, rain or snow.

Units should have all ports sealed and be protected from direct

exposure to weather. For long term storage (>1 month) or overseas

shipment, units should be protected with plastic and desiccant.

Potential Damage to Mechanism

When units are stored in hot, humid climates, the daily

heating/cooling cycle will cause air to expand/contract and be drawn

in and out of the positioner housing. Dependent on the local

temperature variations, humidity, dew points and time in storage,

condensation could occur and accumulate inside causing erratic

operation or failure due to water and corrosion. The potential for

condensation damage is especially high in southern climates and

aggravated if units are exposed to direct sunlight.

For further assistance, please contact you nearest Worcester

distributor.

Worcester Controls

19860-C

Series 93 PULSAIR III

Digital Electronic Positioner

Installation, Operation and Maintenance Instructions

Page 2

2 Series 93 PULSAIR III Digital Electronic Positioner Installation, Operation and Maintenance 19860-C

Flow Control Division

Worcester Controls

Installation

If Positioner is not already mounted to the 39 Series Actuator, mount

per part 1:

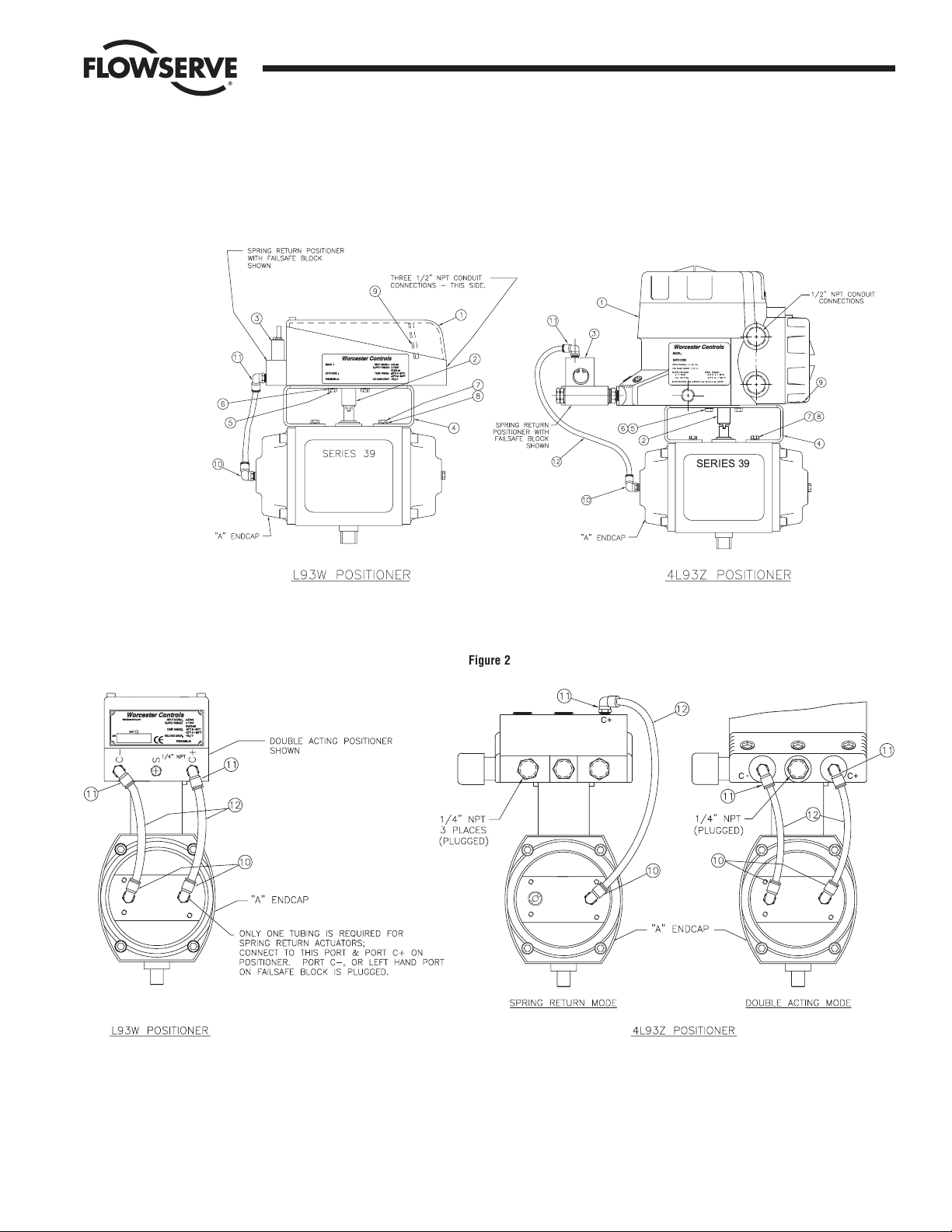

1. Attaching the Positioner to the 39 Series Actuator

(refer to Figure 1)

Remove positioner (1) from the box. Coupling (spindle adapter)

(2), and failsafe block (3) (used with spring return only) are

loose inside the box.

Insert the round end of the coupling (2) into the bottom of the

positioner making sure that the spline seats properly, and that

the coupling is firmly seated in the positioner shaft. There is a

spring loaded ring on the coupling which must fit into a groove

inside the positioner shaft.

Install the mounting bracket (4) onto the bottom of the

positioner using four M6 X 12 mm screws (5) and lock washers

(6) included in the bracket kit. Align the bracket with the

positioner.

Rotate the coupling to align the coupling tang with the slot in

the output shaft on top of the actuator. Attach the

positioner/bracket/ coupling assembly to the actuator using

four M5 x 12 mm screws (7) and lock washers (8). The air

inlet porting on the positioner must be on the same end as the

“A” endcap (air inlet end) of the actuator.

Using an indelible marker, mark the 39 actuator model number

and output torque (as found on 39 actuator nameplate) on the

white mylar label supplied with the positioner and attach it to the

side of the actuator opposite the nameplate side.

2. If not already attached, attach the Failsafe Block to the Positioner

(for spring return only)

Refer to figure 1.

Install three O-rings (for L93W only) into the failsafe block (3).

Mount the failsafe block (3) to the end of the positioner (1) with

the ‘C+’ port to the right using the two screws provided with the

L93W, or three each of fittings and bushings and six grommets

with the 4L93Z.

3. Air Connections (Refer to Figures 1 and 2)

IMPORTANT: Use industrial air (or other non-flammable gas), Which

must be dry and oil free. See PULSAIR III Technical Reference

Manual (Part No. 19990) for other air supply requirements and

technical data.

Series 93 PULSAIR III mounting kits contain two elbow fittings

for actuator, two elbow and two straight fittings for positioner,

and one length of

1

/

4

" O.D. tubing. The length of tubing will be cut

to suit the assembly.

Note: Pipe thread sealant may be used on the threads of the fittings

(do not allow thread sealant to contaminate the internal air passages

of the positioner). Fluoropolymer tape thread sealant should not be

used.

If not already plumbed, plumb the Positioner to the Actuator

Connect the elbow air fitting(s) (10) to the actuator “A” end cap.

Connect

1

/

4" NPT straight or elbow air fitting(s) (11) into the

positioner.

For spring return, use ‘C+’ port on the failsafe block, and make

sure that there is a plug in the unidentified port on the failsafe

block (far left position).

For double acting actuator, use the ‘C+’ and ‘C-’ ports on the

positioner. Note that no failsafe block is necessary.

Cut the tubing (12) provided to as short a length as possible that

will still reach comfortably from the positioner to the actuator.

Connect the tube(s) to their respective actuator and positioner

port fittings.

4. Connect 80 psig Supply Air to Positioner (Refer to Figure 2)

Remove plastic plug from the positioner (or failsafe block) port

‘S’ and discard.

Connect an air supply line to the

1

/

4" NPT ‘S’ port.

5. Installation of M2, R2, or P2 Switch/Sensor and/or 4-20 mA

Output Options (for L93W Positioner only)

1. If not already installed, install optional switches/sensors

and/or 4–20 mA output into the positioner (if applicable):

2. The option kit includes a circuit board with switches

mounted, two mounting screws, and a cam assembly with

two mounting screws installed.

3. Refer to the PULSAIR III Technical Reference Manual (Part

No. 19990) for assembly illustrations.

4. Remove the outside positioner cover.

5. Remove the plastic, yellow and black, position indicator. The

indicator is a press fit and can be removed by prying up

using fingers or small screwdrivers.

6. Remove the two inside cover attachment screws located at

the terminal strip end of the inside positioner cover.

7. Carefully lift the inside cover to clear the yellow push button

switches, and slide the inside cover towards the terminal

strip to remove. The inside cover has a lip which is under

the clear filter cover.

8. Install the circuit board over the positioning shaft, and align

the board socket with the twelve pins on the positioner

motherboard. Press firmly to seat the contacts.

9. Install the two mounting screws to hold the circuit board to

the positioner motherboard.

ACTUATOR SIZE PORT THREAD (NPT)

10–20

1

/

8"

25–42

1

/

4"

Page 3

19860-C Series 93 PULSAIR III Digital Electronic Positioner Installation, Operation and Maintenance 3

Flow Control Division

Worcester Controls

Figure 1

! !"#

$

% &'( ) % &

% '( ) %

*

Figure 2

C+

-

C

C+

Page 4

4 Series 93 PULSAIR III Digital Electronic Positioner Installation, Operation and Maintenance 19860-C

Flow Control Division

Worcester Controls

10. Install the cam assembly with the lobes oriented towards the

terminal strip end of the positioner, over the positioner shaft.

Move the switch contact arms (M2 mechanical switches

only) aside so that the cam assembly can sit all the way

down on the shaft.

NOTE: Cam assembly does not have to be installed, if switches are

not going to be used and only the 4–20 mA output is to be utilized.

CAUTION: For m2 mechanical switches, Do not force the CAM

assembly down without moving the contact arms, as damage to

the limit switch may result.

11. Rotate the cam assembly to line up the cam assembly

attachment screws and tighten the screws finger tight. You

should still be able

to move the cams for alignment before final tightening of the

attachment screws.

6. Electrical Connections

See wiring diagram (9) on inside of cover (refer to Figure 1 for

wiring label location) or Figure 3 below.

a WARNING: In a hazardous environment where there is a risk of

explosion, electrical connections must comply with the relevant

regulations.

Remove the positioner cover (if not already done) for connecting

signal source and for optional board wiring. NOTE: For 4L93Z

units there are separate covers for programming and electrical

connections.

Connect a 4–20 mA signal source to terminal locations 1

(positive lead) and 2 (negative lead).

Adjust the signal source to between 8 and 20 mA.

For 4–20 mA output module option

(for L93W & 4L93Z Positioners)

Connect a 10-28 volt DC source to terminal locations 11

(positive) and 12 (negative return from load).

For M2 Limit or R2 proximity switch option

(for L93W Positioner only)

M2- Connect 125 VAC- 3 amp maximum, or 30 VDC - 2 amp

maximum wiring to terminal locations as follows:

R2 - Connect 125 VAC or 30 VDC - 250 mA maximum wring to

terminal locations as follows:

Terminal Locations:

3 Clockwise switch, normally open - Switch #1

4 Clockwise switch, normally closed - Switch #1

5 Clockwise switch, common - Switch #1

6 Counter-Clockwise switch, normally open - Switch #2

7 Counter-Clockwise switch, normally closed - Switch #2

8 Counter-Clockwise switch, common - Switch #2

For P2 Namur Sensor Option

(for L93W Positioner only)

Connect appropriate Namur amplifier (rated for 5–25 VDC

output) wiring to terminal locations as follows:

Terminal Locations:

3 Clockwise Sensor, negative - Sensor #1

4 Clockwise Sensor, positive - Sensor #1

6 Counter-Clockwise Sensor, negative - Sensor #2

7 Counter-Clockwise Sensor, positive - Sensor #2

For open collector alarm output

Connect 8–28 VDC wiring to terminal location 13 (positive) and

14 (negative).

Menus and Pushbuttons

The positioner is controlled using the five pushbuttons and the

display, which are accessible when the positioner cover is removed.

For normal functioning, the display shows the current position value.

Press the ESC button for two seconds to display the main menu.

Figure 3

Page 5

19860-C Series 93 PULSAIR III Digital Electronic Positioner Installation, Operation and Maintenance 5

Flow Control Division

Worcester Controls

Use the UP and DOWN pushbuttons to browse through the main

menu and the sub-menus.

The main menu is divided up into a basic menu, and a full menu.

Other functions:

ESC - Exit the menu without making any changes (as long as any

changes have not been confirmed with OK).

FUNC - To select function and change parameters.

OK - To confirm selection or change of parameters.

MENU INDICATOR - Displays the location of the current menu

row in the menu.

IN SERVICE - The positioner is following the input signal. This is

the normal status when the positioner is working.

OUT OF SERVICE - The positioner is not following the input

signal. Critical parameters can be changed.

MANUAL- The positioner can be adjusted manually using the

push buttons.

UNPROTECTED- Most of the parameters can be changed when

the positioner is in the ‘Unprotected’ mode. However, critical

parameters are locked when the positioner is in the ‘In Service’

mode.

MENU STATUS INDICATORS - On the left side of the display there

are indicators that mean the following:

Top Left (on and flashing) - OUT OF SERVICE

Middle Left (on and flashing) - MANUAL MODE

Bottom Left (on) - UNPROTECTED MODE

Calibration

The following steps are used to calibrate the unit for verification of

installation. Specific programming and advanced features are

explained in the Technical Reference Manual (Part No. 19990).

1. Apply 80 psig air to the supply ‘S’ port of the positioner.

2. Set the input signal source to 10–12 milliamps.

3. Look at the display- it should read “BASIC MENU” over

“CALIBRATE”

4. Momentarily depress the pushbuttons in the following sequence

to begin the auto-calibration routine.

FUNC, FUNC, OK, OK, OK, OK, OK

5. At this point, the positioner will begin it’s auto-calibration

routine.

Note: If the display reads ‘increase C+ damper’, there is too much air

volume flowing to the actuator (speed is too high). Adjust the

damper by turning the C+ damper screw clockwise

1

/

2 turn and press

the ‘ok’ button. Refer to the inside electrical cover for location of the

C+ damper screw. Adjust until the unit performs the auto-calibration

routine without getting the ‘increase C+ damper’ message.

6. For double acting actuators, both the ‘C+’ and ‘C-’ damper

screws may need adjusting. Follow the display instructions

accordingly.

7. At the end of the auto-calibration routine, press and hold the OK

pushbutton for three seconds to place the unit back to ‘IN

SERVICE’.

8. If an internal leak is detected during the auto-calibration

routine, the display will show ‘AIR LEAK DETECTED’. The next

screen will show ‘ESC=ABORT’ and ‘OK=GO ON’. Press the ESC

to stop the calibration routine or OK to allow you to continue

the calibration and ignore the leak.

9. When the unit is back ‘IN SERVICE’, the positioner should

respond to the 4–20 mA input signal with 4 mA= Full CW and 20

mA=Full CCW positions.

4–20 mA Output Option Calibration

Attach a current meter (4–20 mA range) in line with the positive

meter lead connected to terminal strip position 12, the negative

meter lead connects to the negative power supply (10–28 volts DC)

lead, and the positive power supply lead connects to terminal strip

position 11.

1. Turn on the ammeter and power supply.

2. Press and hold the ESC pushbutton for three seconds to get the

display back to the root menu. Display should show ‘BASIC

MENU’ over ‘MAN/AUTO’.

3. Press the DOWN button twice and display should read ‘BASIC

MENU’ over ‘SHIFT MENU’.

4. Press the FUNC button once and display should read ‘Full menu’

over ‘no’.

5. Press the DOWN button and display should read ‘Full menu’

over ‘yes’.

6. Press the OK button and display should read ‘FULL MENU’ over

‘SHIFT MENU’.

7. Press the DOWN button four (4) times and display should read

‘FULL MENU’ over ‘TUNING’.

8. Press the FUNC button and the display should read ‘TUNING’

over ‘Close time’.

9. Press the DOWN button three (3) times and display should read

‘TUNING’ over ‘Expert’.

10. Press the FUNC button once and the display should read ‘Expert’

over ‘togglestep’.

11. Press the DOWN button three (3) times and the display should

read ‘Expert’ over ‘Ref Cal’.

12. Press the FUNC button once and the display should read ‘Ref

Cal’ over ‘Set point’.

13. Press the DOWN button four (4) times and the display should

read ‘Ref Cal’ over ‘Transm’.

Page 6

6 Series 93 PULSAIR III Digital Electronic Positioner Installation, Operation and Maintenance 19860-C

Flow Control Division

Worcester Controls

14. Press the FUNC button once and the display should read

‘Transm’ over ‘Transm low’.

15. Press the FUNC button once and display should read ‘Transm

low’ over ‘LO=4.0 mA’.

16. Press the UP or DOWN button as necessary to adjust the output

signal to read 4.0 mA, or as close to 4.0 as is possible.

17. Press the OK button to accept the setting. The display should

read ‘Transm low’ over ‘UPDATED’ for a brief moment.

18. Press ESC and display should read ‘Transm’ over ‘Transm low’.

19. Press DOWN once and display should read ‘transm’ over

‘Transm hi’.

20. Press FUNC button once and the display should read ‘Transm hi’

over ‘HI=20.0 mA’.

21. Press the UP or DOWN button as necessary to adjust the output

signal to read 20.0 mA, or as close to 20.0 as is possible.

22. Press the OK button to accept the setting. The display should

read ‘Transm hi’ over ‘UPDATED’ for a brief moment.

23. Press the ESC button for 2-3 seconds and the display will return

to the ‘FULL MENU’ over ‘MAN/AUTO’ screen.

24. Disconnect the calibration ammeter from terminal positions 11

and 12, and attach your readout leads to terminal position 11

(positive) and 12 (negative).

Limit (M2) and Proximity (R2) Switch Cam Adjustment

(for L93W Positioner only)

1. Connect an ohmmeter to terminal position 3 (switch 1 normally open) and terminal position 5 (switch 1 - common).

2. Input a 4.2 mA signal so that the positioner is in the clockwise

position.

3. Using a screwdriver or similar tool, use the notch on the lower

cam and rotate the cam counter-clockwise away from the

switch and then clockwise until switch 1 closes. The ohmmeter

indication changes from infinite to a low reading that indicates

continuity through the switch.

4. Input a 19.8 mA signal so that the positioner is in the counterclockwise position.

5. Connect the ohmmeter leads to terminal position 6 (switch 2 normally open), and terminal position 8 (switch 2 - common).

6. Using a screwdriver or similar tool, use the notch on the upper

cam and rotate the cam clockwise away from the switch, and

then counter-clockwise as necessary until switch 2 closes. The

ohmmeter indication changes from infinite to a low reading that

indicates continuity through the switch.

7. Tighten the 2 mounting screws on the cam assembly to lock the

cam positions in place.

8. Adjust the input signal to 15 mA, and return to 20 mA to verify

that the cam contacts or trips the switch, and the ohm reading

changes from infinite to a low reading.

9. Remove the ohmmeter leads from terminal positions 6 and 8,

and attach them to terminal positions 3 and 5.

10. Adjust the input signal to 4 mA and verify that the cam contacts

or trips the switch and the ohm reading changes from infinite to

a low reading.

11. If the ohm reading does not change, and continues to show an

infinite reading, loosen the cam assembly mounting screws and

adjust the cam as necessary.

12. Repeat the adjustment and set procedure until you can supply a

4 mA and a 20 mA signal and have the switches close.

Namur Sensor (P2) Cam Adjustment (for L93W Positioner only)

Refer to diagram below:

1. Connect a milliammeter positive lead to terminal position 3

(sensor 1 - negative), and a 24 VDC power supply positive lead

to terminal position 4 (sensor 1 - positive). Connect the

millammeter negative lead to the 24 VDC power supply negative

terminal.

2. Input a 4.2 mA signal so that the positioner is in the clockwise

position.

3. Using a screwdriver or similar tool, use the notch on the lower

cam and rotate the cam counter-clockwise away from the sensor

Page 7

19860-C Series 93 PULSAIR III Digital Electronic Positioner Installation, Operation and Maintenance 7

Flow Control Division

Worcester Controls

and then clockwise until sensor 1 trips. The milliammeter

indication changes from ≥ 3 mA to a ≤ 1 mA reading.

4. Tighten the two mounting scrrews to 15 mA, and return to 20

mA to verify that the cam trips the sensor, and the milliammeter

reading changes from a ≥ 3 mA to a ≤ 1 mA.

5. Remove the milliammeter and power supply leads from termianl

positions 6 and 7, and attach them to termianl positions 3 and 4.

6. Adjust the input signal to 4 mA and verify that the cam trips the

sensor and the milliammeter reading changes from a ≥ 3 mA to

a ≤ 1 mA reading.

7. If the milliammeter reading does not change, and continues to

show an ≥ 3 mA reading, loosen the cam assembly mounting

screws and adjust the cam as necessary.

8. Repeat the adjustment and set procedure until you can supply a

4 mA or a 20 mA signal and have the appropriate sensor trip.

Operation and Maintenance

Refer to Technical Reference Manual (Part No. 19990) for detailed

operation and maintenance information.

Page 8

Flow Control Division

Worcester Controls

Flowserve Corporation has established industry leadership in the design and manufacture of its products. When properly selected, this Flowserve product is designed to perform its intended function

safely during its useful life. However, the purchaser or user of Flowserve products should be aware that Flowserve products might be used in numerous applications under a wide variety of industrial

service conditions. Although Flowserve can (and often does) provide general guidelines, it cannot provide specific data and warnings for all possible applications. The purchaser/user must therefore

assume the ultimate responsibility for the proper sizing and selection, installation, operation, and maintenance of Flowserve products. The purchaser/user should read and understand the Installation

Operation Maintenance (IOM) instructions included with the product, and train its employees and contractors in the safe use of Flowserve products in connection with the specific application.

While the information and specifications contained in this literature are believed to be accurate, they are supplied for informative purposes only and should not be considered certified or as a guarantee of

satisfactory results by reliance thereon. Nothing contained herein is to be construed as a warranty or guarantee, express or implied, regarding any matter with respect to this product. Because Flowserve

is continually improving and upgrading its product design, the specifications, dimensions and information contained herein are subject to change without notice. Should any question arise concerning

these provisions, the purchaser/user should contact Flowserve Corporation at any one of its worldwide operations or offices.

For more information about Flowserve Corporation, contact www.flowserve.com or call USA 1-800-225-6989.

FLOWSERVE CORPORATION

FLOW CONTROL DIVISION

1978 Foreman Drive

Cookeville, Tennessee 38501 USA

Phone: 931 432 4021

Facsimile: 931 432 3105

www.flowserve.com

© 2003 Flowserve Corporation, Irving, Texas, USA. Flowserve and Worcester Controls are registered trademarks of Flowserve Corporation. 19860-C 8/03 Printed in USA

Loading...

Loading...