Page 1

Worcester Controls

07334-F

Modular Accessory System (Series 90)

Installation, Operation and Maintenance Instructions

I. INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

II. INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

A. Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

B. Air Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

III. ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

A. Housing Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

1. Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

2. Base . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

3. Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

NOTE: Installation instructions pertaining to specific options, which may or may not be combined with this Installation,

Operation, and Maintenance Manual, depending on which options are being used, are as follows:

Solenoid Block Options – Part number 18460

Switch Options – Part number 18472

Feedback Options – Part number 18430

Positioner/Controller Options – Part Number 18478

Heater Option – Part Number 09258

Page 2

2 Modular Accessory System (Series 90) 07334-F

I. INTRODUCTION

The MODULAR ACCESSORY SYSTEM SERIES 90 (OR 90 M.A.S.) is

designed to provide a wide choice of valve position feedback and

pneumatic valve actuator control functions. Applications range from

simple end-of-travel limit switch indication to automated control using

feedback from a system parameter sensor (temperature, flow rate,

etc.). Maximum ambient temperature is 110°F for models with

solenoid and 160°F for models with electronics and no solenoid.

The concept behind the unit is flexibility, allowing the user to

customize a M.A.S. for a particular application. For this reason, only

individual installation instruction sheets pertaining to the specific

options being used are combined with this Installation, Operation

and Maintenance Manual. Please note – this unit is a complex

device and not all options can be accommodated simultaneously. A

table summarizing the available options follows. Note that the

presence of the POSITIONER or CONTROLLER options changes the

list of available options. Certain options also require the addition of

a second terminal block which will be provided in the M.A.S. unit or

kit when required.

a WARNING: The series 90 M.A.S. is an electromechanical device

subject to normal wear and tear. Its life is dependent upon

application and environmental conditions. Breather/Drain fittings

are recommended for humid environments when moisture may

condense inside the sealed M.A.S. housing.

CAUTION: Flowserve recommends that all product that must be

stored prior to installation be stored indoors, in an environment

suitable for human occupancy. Do not store product in areas where

exposure to relative humidity above 85%, acid or alkali fumes,

radiation above normal background, ultraviolet light, or

temperature above 120°F or blow 40°F may occur. Do not store

within 50 feet of any source of ozone.

M.A.S. MODEL: The M.A.S. product code per the appropriate options is

marked on the name plate as the M.A.S. model

number, with the exception of the voltage rating (if

any) and product revision level (R#). Voltage rating and

R# are marked in separate locations on the nameplate.

The Product Code is Composed of:

Size . . . . . . . . . . . . . . . . Size of actuator (10, 15, 20, etc.) to which

the M.A.S. will be mounted. Will be blank if

unknown.

Product Options . . . . . . See below.

Product Series . . . . . . . . 90

Action . . . . . . . . . . . . . . blank – if no solenoid

S – single-acting solenoid

D – double-acting solenoid

Direction . . . . . . . . . . . . blank – if standard

R – if reverse-acting

Switch Options . . . . . . . See below.

Circuit Board . . . . . . . . . P – Positioner

C – Controller

Blank if none

Input Signal . . . . . . . . . 1 – 1-5 mA

(If P or C is used) 4 – 4-20 mA

10 – 10-50 mA

13 – 0-135 ohms

1K – 0-1000 ohms

Setpoint . . . . . . . . . . . . . 4 – 4-20 mA

(If Controller) K – 0-1000 ohms

Custom Product No. . . . P, T, C, or similar number

(If special)

Product Code Examples: 20 H 90 D M2 C 4 K

10 90 S P6 T3293

Flow Control Division

Worcester Controls

Available Options

Non-Positioner/Controller Units Positioner/Controller Units

Order Codes and Descriptions Order Codes and Descriptions

B – Breather/Drain Fitting

H – Heater

D – Dual-Feedback Potentiometer

P – Single-Feedback Potentiometer

4 – 4 to 20 Milliamp Feedback

S – Single-Acting Solenoid Block

(One Three-Way Solenoid)

D – Double-Acting Solenoid Block

(One Four-Way Solenoid)

M2 – 2 SPDT Mechanical Switches

M4– 4 SPDT Mechanical Switches

D2 – 2 DPDT Mechanical Switches

P6 – 2 AC Proximity Switches

P8 – 2 DC Proximity Switches

120A – 120 Volt AC Solenoid

12D – 12 Volt DC Solenoid

24D – 24 Volt DC Solenoid

B – Breather/Drain Fitting

H - Heater

P – Single-Feedback Potentiometer

4 – 4 to 20 Milliamp Feedback

S – Single-Acting Solenoid Block

(Two Three-Way Solenoids)

D – Double-Acting Solenoid Block

(Two Three-Way Solenoids)

M2 – 2 SPDT Mechanical Switches

P6 – 2 AC Proximity Switches

P8 – 2 DC Proximity Switches

120A – 120 Volt AC Solenoids

12D – 12 Volt DC Solenoids

24D – 24 Volt DC Solenoids

P – Positioner Circuit Board

(Various Input Signal Options)

C – Controller Circuit Board

(Various Input Signal and Set Point Options)

Page 3

II. INSTALLATION

A. Mounting Instructions

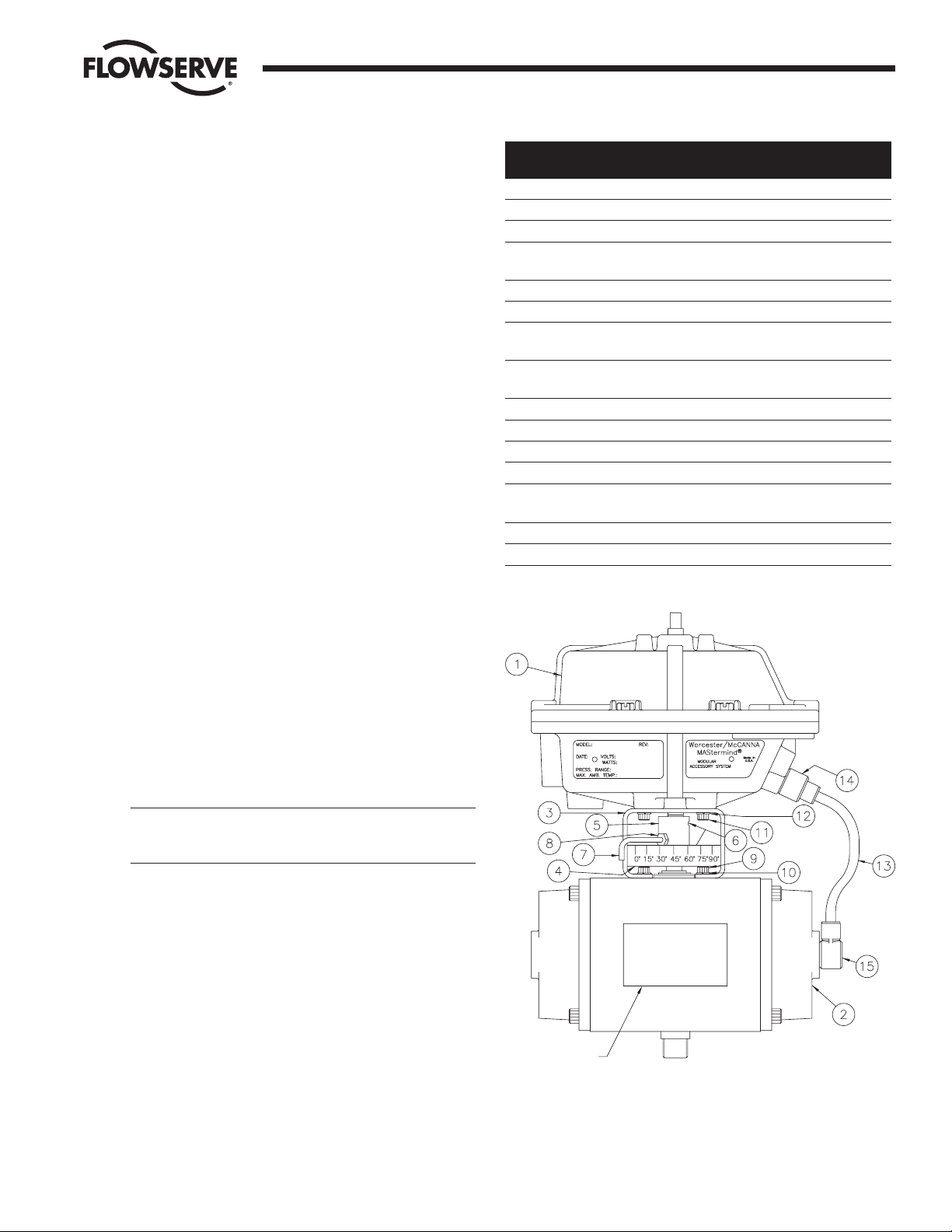

1. Refer to Figure 1. The series 90 is designed to be mounted

in-line with the major axis of the actuator. The air connections

for the series 90 should be on the same end as the air

connections for the actuator. The standard 39 actuator has its

air connections on the right-hand end cap (with the exception

of the line 0539 which has its air connections on the back) as

you face the actuator nameplate. The Series 90 nameplate will

be on the same side as the actuator nameplate.

2. If the actuator is double-acting, rotate the actuator shaft to its

clockwise position. Spring-return actuators will be in this

position already.

3. Place the mounting bracket on the actuator. Brackets to be

used with Series 90 positioner or controller packages may

have an optional indicating scale. This scale can be oriented

on either side of the actuator (depending on customer’s

preference), but normally will be located on the same side as

the actuator nameplate. Secure the mounting bracket with the

four (4) screws and lockwashers supplied in the kit.

4. Place the coupling over the actuator shaft. (Note: For the 05

and 1039 actuators only, shallow slot is placed over the

actuator shaft). Sizes 10-40 couplings have four (4) threaded

holes; two are ¹₄-20 thread for set screws and the other two

are #10-32 (located 45 degrees off the center line of the

coupling). The two #10-32 threaded holes must be on the

same side as the indicator scale (if any) on the bracket. The

size 05 coupling has two (2) ¹₄-20 threaded holes for set

screws only. DO NOT tighten the set screws at this time.

5. If the mounting kit is for a positioner or controller, an optional

indicating arm and locknut for the coupling may be provided.

If so, install this arm into the coupling and secure with the

locknut. The arm will point down and extend outside the

indicating scale mounted on the bracket.

CAUTION: The actuator is in its clockwise position (per step

#2). The indicating arm must be installed to allow rotation

of the actuator shaft in the counter-clockwise direction.

6. Place the Series 90 unit on the bracket while inserting the

shaft into the coupling slot. Be certain the holes in the bracket

and 90 housing are aligned and secure with the four (4) #1032 socket head screws and lockwashers provided.

7. The coupling set screws can be tightened after the actuator

has been cycled 90 degrees.

Item

No. Qty Description

1 1 Series 90 – M.A.S.

2 1 Series 39 Actuator

3 1 Mounting Bracket

4 1 Indicating Scale – Optional

(Positioner/Controller Only)

5 2 Coupling

6 2 Set Screw

7 1 Indicating Arm – Optional

(Positioner/Controller Only)

8 1 Locking Unit – Optional

(Positioner/Controller Only)

9 4 Actuator Mounting Screw

10 4 Actuator Mounting Lockwasher

11 4 M.A.S. Mounting Screw

12 4 M.A.S. Mounting Lockwasher

13 1 ¹₄" O.D. X 31" Tubing

(Cut by User)

14 2 Straight Screw

15 2 Elbow Fitting

07334-F Modular Accessory System (Series 90) 3

Flow Control Division

Worcester Controls

Figure 1

Nameplate

Page 4

4 Modular Accessory System (Series 90) 07334-F

B. Air Connections

1. Series 90 mounting kits contain two (2) elbow “quick”

fittings, two (2) straight “quick” fittings, and one (1) length of

¹⁄₄" O.D. tubing. Single-acting or spring-return assembles will

use one elbow and one straight fitting. Double-acting

assemblies will use two elbow and two straight fittings. The

length of tubing will be cut to suit the assembly (one piece for

spring-return, two pieces for double-acting).

2. Refer to Figure 2. Assemble the elbow fitting(s) to the

actuator. Pipe thread sealant may be used on the threads (do

not allow thread sealant to contaminate the internal air

passages of the M.A.S.). Fluoropolymer tape thread sealant

should not be used.

Actuator Size Port Thread (NPT)

05 – 20 ¹⁄₈"

25 – 40 ¹⁄₄"

3. Refer to Figure 3. Assemble the straight fitting(s) to the

Series 90 housing as shown in Figure 3. The thread sizes are

labeled for reference in the figure. Pipe sealant may be used

on the threads (do not allow thread sealant to contaminate the

internal air passages of the M.A.S.). Fluoropolymer tape

thread sealant should not be used.

4. Cut the tubing provided to as short a length as possible that

will still reach comfortably from the Series 90 unit to the

actuator. On double-acting versions, the tubes run parallel to

each other and do not cross. The operation of the actuator

can be reversed by reversing the location of the tubes at the

actuator. Connect the tubes to their respective actuator and

series 90 ports (ref. Figures 2, 3 and 4).

5. Refer to Figure 4 for a diagram of the Series 90 air

connections in each of its four (4) configurations.

a. Connect the supply air for the actuator (80 psi

nominal/100 psi maximum) to the location labeled

“SUPPLY” in the appropriate sketch.

b. Locations labeled “VENT” may be fitted with a porous

muffler (or other fitting if desired) to reduce exhaust noise.

Air must be allowed to flow freely from these ports. “VENT”

locations must not be plugged under any circumstances.

c. Ports labeled “NOT USED” must remain plugged with the

stainless steel pipe plugs provided.

Flow Control Division

Worcester Controls

Figure 2 – Actuator Fitting Locations Figure 3 – M.A.S. Fitting Locations

Figure 4 – Air Connections for All M.A.S. Configurations

Page 5

07334-F Modular Accessory System (Series 90) 5

III. ASSEMBLY

A. Housing Assembly

The housing consists of the base, cover, shaft, baseplate, and

associated hardware. The housing is assembled as received from

Flowserve. For ease of maintenance, assembly instructions will be

provided here.

1. Cover

CAUTION: Use care to avoid damaging the machined flange

surface of the cover.

a. Apply a light coat of Cindal 2321 lubricant (or other

bearing grease) to the shaft hole.

b. Assemble the captive type cover screws through the

flange holes. The screws must be turned through approx.

¹⁄₄" of thread until they reach the clearance diameter and

remain loose in the cover. Use caution to avoid crossthreading these screws. Refer to Figure 5.

c. Check to see that the shaft seal has been installed as

shown in Figure 6.

CAUTION: When assembling cover to base, be sure

wires are away from any rotating parts and are not

pinched between cover and base flanges.

Relubricate the shaft hole anytime cover is removed

and replaced.

To avoid damaging the cover hole finish and binding the

shaft to cover, check the top of the shaft for burrs or

impact damage before installing or removing cover.

2. Base

CAUTION: Use care to avoid damaging the machined flange

surface of the base.

a. Check to see that the shaft seal and bearing have been

installed as shown in Figure 6.

b. Apply a light coat of bearing lubricant to the shaft hole.

c. Insert the shaft through the shaft hole in the base from

the inside. The shaft fits through this hole with minimal

clearance — care must be taken to avoid damaging the

bearing surfaces or causing the shaft to gall.

d. Place one of the nylon thrust washers onto the shaft end

protruding outside the base. Assemble one of the snap

rings to the shaft in the groove below this thrust washer

(rounded side towards thrust washer – see detail).

e. Place a second nylon thrust washer over the shaft and

into place against the shaft boss on the inside of the

base. Secure the shaft in place with a second snap ring in

the groove adjacent to the second thrust washer (rounded

side towards thrust washer – see detail).

f. Place the third snap ring into the upper groove as shown

in Figure 6.

g. If the base is machined to accept a Breather/Drain fitting

as shown in Figure 7, then the boss on the bottom of the

base near the electrical conduit connection bosses will be

tapped with ³₈" NPT threads. If this boss is tapped, the

Breather/Drain fitting must be installed. The use of

fluoropolymer tape or other thread sealant is

recommended prior to installing this fitting into the boss.

h. Plug the ³₄" NPT conduit connection on the end of the

base temporarily with the threaded plastic plug provided.

This plug will be removed and discarded when the unit is

installed.

i. Plug the (4) ¹₄" NPT and (1) ¹₈" NPT air connection ports

with the stainless steel pipe plugs provided. Thread

sealant is not recommended prior to installing these

plugs. The residue left by a thread sealing compound

could foul the solenoid valve air passages. If a solenoid

valve option is to be installed in the unit, some of these

plugs will not be used – refer to the Solenoid Block

Installation Instructions to determine which plugs can be

left out.

IMPORTANT: If no solenoid is to be used, all of the ports

must be plugged. Refer to Figure 7.

j. The M.A.S. uses a standard O-ring to achieve both

Watertight (TYPE 4) and Explosion-proof – (TYPE 7)

ratings. Refer to Figure 8.

Flow Control Division

Worcester Controls

Figure 5

Figure 6

Page 6

6 Modular Accessory System (Series 90) 07334-F

k. Refer to Figure 9. The baseplate contains one factory-

assembled terminal strip located in the “primary” (side)

location on the baseplate. A second terminal strip is

required with some M.A.S. options, outlined below. The

extra terminal strip will be provided with the appropriate

options. Attach it to the baseplate with four #4 x ³₈" selftapping screws provided in the “secondary” (end)

location.

l. Assemble the baseplate into the base using the four

#6 – 32 screws provided. Use care when tightening these

screws as the baseplate is plastic and could be damaged

if over-tightened.

If options such as Switches, Potentiometer kit, etc. are to

be installed, they can be assembled to the baseplate prior

to installing baseplate into base.

CAUTION: Avoid contacting baseplate with solvents –

damage may result.

Options Requiring

Second Terminal Strip *

Feedback Potentiometers – P, D, 4

Switches – M4, D2

Positioner – All

Controller – All

* Included with option or kit if required.

m. The base is provided with an alignment pin pressed into

the flange that will allow the cover to be assembled in

only one orientation (See Figures 9 and10). Be certain the

cover is correctly positioned prior to tightening bolts, or

damage may result.

n. M.A.S. options are supplied with wiring diagrams that

should be affixed to the inside of the cover as shown in

Figure 10. Note the orientation of the terminal strips on

the wiring diagrams and their location in the cover.

Flow Control Division

Worcester Controls

Figure 7

Figure 8

Figure 10

Figure 9

Page 7

07334-F Modular Accessory System (Series 90) 7

3. Troubleshooting

Problem Possible Cause Solution

Shaft binds Cover not Loosen cover screws

centered and allow cover to

center on shaft.

Retighten cover screws.

Inadequate Remove cover and

lubrication lubricate shaft hole with

bearing grease, such as

Cindol 2321. If excessive

wear or galling is

present, shaft and

affected part of housing.

Flow Control Division

Worcester Controls

Page 8

Flow Control Division

Worcester Controls

Flowserve Corporation has established industry leadership in the design and manufacture of its products. When properly selected, this Flowserve product is designed to perform its intended function

safely during its useful life. However, the purchaser or user of Flowserve products should be aware that Flowserve products might be used in numerous applications under a wide variety of industrial

service conditions. Although Flowserve can (and often does) provide general guidelines, it cannot provide specific data and warnings for all possible applications. The purchaser/user must therefore

assume the ultimate responsibility for the proper sizing and selection, installation, operation, and maintenance of Flowserve products. The purchaser/user should read and understand the Installation

Operation Maintenance (IOM) instructions included with the product, and train its employees and contractors in the safe use of Flowserve products in connection with the specific application.

While the information and specifications contained in this literature are believed to be accurate, they are supplied for informative purposes only and should not be considered certified or as a guarantee of

satisfactory results by reliance thereon. Nothing contained herein is to be construed as a warranty or guarantee, express or implied, regarding any matter with respect to this product. Because Flowserve

is continually improving and upgrading its product design, the specifications, dimensions and information contained herein are subject to change without notice. Should any question arise concerning

these provisions, the purchaser/user should contact Flowserve Corporation at any one of its worldwide operations or offices.

For more information about Flowserve Corporation, contact www.flowserve.com or call USA 1-800-225-6989.

FLOWSERVE CORPORATION

FLOW CONTROL DIVISION

1978 Foreman Drive

Cookeville, Tennessee 38501 USA

Phone: 931 432 4021

Facsimile: 931 432 3105

www.flowserve.com

© 2003 Flowserve Corporation, Irving, Texas, USA. Flowserve and Worcester Controls are registered trademarks of Flowserve Corporation. 07334-F 9/03 Printed in USA

Loading...

Loading...