Page 1

Worcester Controls

Worcester Controls Series 72 actuators are electro-hydraulic quarterturn valve actuators. The design utilizes a double-rack, single-pinion

concept, with each rack integrally cast to a piston. Both pistons are

supported and centered by large, stainless steel guide rods.

Standard units feature an extended top shaft for manual override

capabilities and a completely modular design which allows simple

attachment of a variety of accessories. All units feature a normally

open solenoid valve which returns the actuator to its initial position

when power is lost to the actuator.

a WARNING: Series 72 actuators are electro-mechanical devices

subject to normal wear and tear. Actuator life is dependent upon

application and environmental conditions. If applied in hazardous

services such as, but not limited to, media temperature extremes,

toxins, flammables, or other services where improper or incomplete

operation could produce a safety hazard, it is incumbent upon the

system designer and the user to provide proper warning devices such

as temperature sensors, oxygen sensors and flow sensors.

CAUTION: Flowserve recommends that all products which must be

stored prior to installation be stored indoors, in an environment

suitable for human occupancy. Do not store product in areas where

exposure to relative humidity above 85%, acid or alkali fumes,

radiation above normal background, ultraviolet light, or temperatures

above 120°F or below 40°F may occur. Do not store within 50 feet of

any source of ozone.

INSTALLATION

NOTE: The Series 72 actuator is normally installed with its major axis

parallel to the pipe line (this is mandatory when mounting actuator to

90° V1 diverter/Three-Way (D44 & T44) valves and CPT valves). The

actuator can be oriented above, beside or beneath the valve without

affecting its operation.

Actuators come with an ISO locating ring used for optional ISO

mounting.

A. Determine mode of operation desired (normally open or normally

closed) of the valve.

B. Determine desired quadrant for bracket attachment and direction

of mounting of actuator (in-line or cross-line).

C. Attach mounting bracket to actuator using four (4) cap screws

and lockwashers provided in mounting kit. To avoid any damage

to the Series 72 actuator body, ONLY the proper length screws

supplied with the mounting kit should be used. For small topmount style valves, attach bracket such that bracket nameplate

will be to side of valve. For mounting to 818/828 Series valves,

insert ISO locating ring into groove on bottom of actuator before

attaching to bracket. Note: Ring can be permanently held in

groove by applying Loctite to ring before inserting in groove.

D. Attach bracket/actuator assembly to valve as follows:

CAUTION: Ball valves can trap pressurized media in the cavity. If it

is necessary to remove any valve body bolts, stem nuts or remove

valve from the line, and if the valve is or has been in operation,

make sure there is NO pressure to or in the valve and operate valve

one full cycle.

1. Valve Models Top-Mount 44 (

1

/

4"–2"), 45 (2

1

/

2"–4"), 51/52

(

1

/

2"–4"), 151/301 (3"–4"), Top Mount 59 (

1

/

4"–3"), WK70, WK74

and H71 (

1

/

2"–2"), 818/828 (2"–3"), 82/83 (

1

/

2"–3"), 94 (

1

/

2"–4"):

NOTE: For above listed valves, it is not necessary to remove

any valve body bolts or remove valve from line in order to

mount actuator.

a. Rotate valve ball and stem to position necessary to

achieve desired operation. If any valve information is

marked on stop plate or handle, it will be necessary to

transfer this information to the bracket nameplate.

WCAIM2049

(Part 18960)

Series 72 “Electri-SAFE”

On/Off Operation Including CLC Option

Installation, Operation and Maintenance Instructions

Page 2

2 Series 72 “Electric-SAFE” On/Off Operation Including CLC Option WCAIM2049

Flow Control Division

Worcester Controls

b. For

1

/

4"–2" 44,

1

/

2"–2" WK70 & WK74,

1

/

4"–1

1

/

2" 59 and

1

/

2"–1

1

/

2" H71 series top-mount style valves and

1

/

2"–2"

51/52 and

1

/

2"–1

1

/

2" 82/83 Series valves with high-cycle

stem packing as standard, remove handle nut,

lockwasher, handle, separate stop plate (if any), retaining

nut and stop pin(s). Add the two additional Belleville

washers with their larger diameter sides touching each

other. Add the self-locking nut to the stem and tighten

while holding the stem flats with wrench. Tighten until

Belleville washers are flat, the nut will "bottom", and then

back nut off

1

/

3 of a turn. The two additional Belleville

washers and the self-locking nut are included in the

mounting kit.

CAUTION: The self-locking stem nut is difficult to

tighten, and must fully flatten Belleville washers before

backing off.

For 2" 59, H71, 82/83 and 2

1

/

2" 45, 82/83 valves, and

valves 3" and larger with square stem, remove handle

assembly, retaining nut, stop and stop screws. Replace

with valve stem spacer or, if valve has graphite stem

packing, with two Belleville washers, and replace

retaining nut.

NOTE: Belleville washers are installed with their larger

diameter sides touching each other. Do not use stem

spacer when Belleville washers are used. Using a wrench

to prevent stem from turning, tighten retaining nut until

stem packing is fully compressed or Bellevilles, if used,

are fully flattened, then back off nut

1

/

6 turn. Excessive

tightening causes higher torque and shorter seal life.

Large valves with V51 high-cycle stem packing option

installed, (identified by two Belleville washers installed

and handle assembly, stop, and stop screws removed),

and 818/828 Series valves do not require stem area

disassembly.

For

1

/

2"–2" 94 valves, remove handle (if any). Do not

remove gland plate or gland bolts.

For 3"–4" 94 & 2"–3" E818/828 valves, remove handle

assembly, stop, and spacer (if any). Do not remove gland

plate or gland bolts.

For 2"–3" 818/828 valves, remove handle assembly,

locking plates and hardware, and stop screw (if any).

Do not remove stop plate.

c. Center coupling on valve stem.

d. Lower mounting bracket/actuator assembly over coupling

and onto valve, making sure that male actuator shaft

engages slot in coupling.

e. Secure bracket to valve using cap screws and

lockwashers, or bolts and nuts provided in mounting kit.

Tighten securely. For small top-mount style valves,

bracket nameplate will be to side of valve.

Install set screws (if any) in the coupling and tighten

securely.

f. Determine if mode of operation is as desired; if not:

Fail-Safe Actuators - The normal method of mounting is

to have the actuator in-line with the pipe line and the

valve and actuator in the “FAIL-CLOSED” position.

For “FAIL-CLOSED” cross-line operation, invert actuator

and cross-line mount actuator to pipe line.

For “FAIL-OPEN” in-line operation, invert actuator. (NOTE:

If in-line coupling is used, actuator does not need to be

inverted.) Rotate the valve ball and stem 90°, so coupling

lines up with actuator shaft. Mount actuator in-line with

the pipe line.

For “FAIL-OPEN” cross-line operation, rotate the valve ball

and stem 90°, so coupling lines up with actuator shaft.

Mount actuator cross-line to pipe line.

g. Determine position indication. Buttons on position

indicator are set up to show valve closed on in-line

mounting, i.e., pistons together on actuator. If different

indication is required:

1. Check which visual indication is required.

2. Check that indicator, when located on actuator shaft,

will show correct indication.

3. To change indication, push out (remove) red and

white buttons and reassemble in opposite positions.

4. Locate indicator on actuator shaft flats. Press firmly

until location nibs snap into recess on actuator shaft.

ELECTRICAL INSTALLATION

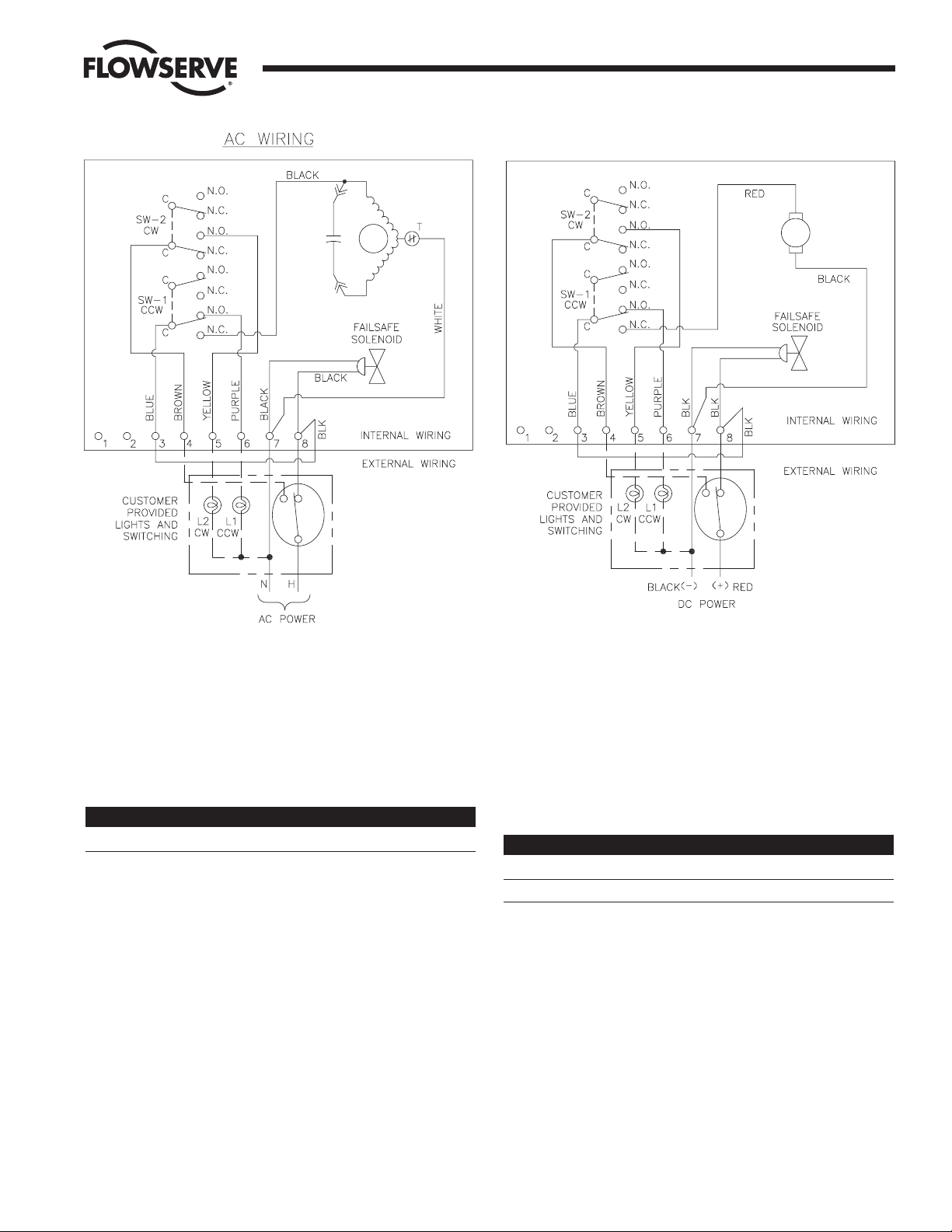

AC Electrical Supply (on/off models with one integral solenoid):

With assembly complete to this point, it is convenient to make

conduit connections and bring wiring through enclosure. It should be

noted that the successful use of this device in hazardous atmospheres

or other detrimental environments depends on proper conduit

construction techniques.

The solenoid coil wattage and required amperage is as follows:

Voltage Holding Amps* Watts

120 VAC 50/60 HZ .2 10

240 VAC 50/60 HZ .1 10

*Inrush is 80% greater than Holding values on AC solenoids.

A. Remove limit switch cover and gasket.

B. Attach power supply wires to terminal strip locations 7 and 8 per

the wiring diagram shown below and also located on the inside of

the limit switch cover.

NOTE: All wiring to terminal strip should be inserted only to midpoint of strip.

C. Attach the ground wire to the customer’s green grounding screw

located on the limit switch casting flange face.

Page 3

WCAIM2049 Series 72 “Electric-SAFE” On/Off Operation Including CLC Option 3

DC Electrical Supply (on/off models with one integral solenoid):

With assembly complete to this point, it is convenient to make

conduit connections and bring wiring through enclosure. It should be

noted that the successful use of this device in hazardous atmospheres

or other detrimental environments depends on proper conduit

construction techniques.

The solenoid coil wattage and required amperage is as follows:

Voltage Holding Amps Watts

24 VDC .45 10

A. Remove limit switch cover and gasket.

B. Attach power supply wires to terminal strip locations 7 and 8 per

the wiring diagram shown on previous page and also located on

the inside of the limit switch cover.

NOTE: All wiring to terminal strip should be inserted only to midpoint of strip.

C. Attach the ground wire to the customer’s green grounding screw

located on the limit switch casting flange face.

AC Electrical Supply (CLC models with two integral solenoids):

With assembly complete to this point, it is convenient to make

conduit connections and bring wiring through enclosure. It should be

noted that the successful use of this device in hazardous atmospheres

or other detrimental environments depends on proper conduit

construction techniques.

Control solenoid wattage for 120 VAC and 240 VAC is 6 watts.

The failsafe solenoid coil wattage and required amperage is as follows:

Voltage Holding Amps* Watts

120 VAC 50/60 Hz .2 10

240 VAC 50/60 Hz .1 10

*Inrush is 80% greater than Holding values on AC solenoids.

A. Remove limit switch cover and gasket.

B. Attach power supply wires to terminal strip locations 7 and 8 per

the wiring diagram shown below and also located on the inside of

the limit switch cover.

NOTE: All wiring to terminal strip should be inserted only to midpoint of strip.

C. Attach the ground wire to the customer’s green grounding screw

located on the limit switch casting flange face.

Flow Control Division

Worcester Controls

DC Wiring

Page 4

4 Series 72 “Electric-SAFE” On/Off Operation Including CLC Option WCAIM2049

INSTALLATION OF ACCESSORIES

For details on installation of accessories, refer to the installation

instructions contained in respective accessory kit.

OPERATION

The Series 72 Actuator opens when power is applied. The hydraulic

pump/motor is turned off when the actuator reaches its full open

position by the limit switch SW-1. Power is maintained to the

normally open solenoid to keep the actuator in the open position.

A. Basic Actuator

The Series 72 actuator drive shaft rotates through a full 90°

segment with approximately 2° overtravel at each end of travel.

Rotation is accomplished by pumping hydraulic fluid into the

center chamber, forcing the two opposing pistons apart, resulting

in a counter-clockwise rotation of the drive shaft to the "open"

position. Closure is accomplished by means of springs contained

within the end caps which force the pistons together when the

power to the solenoid has been interrupted.

If rotation opposite to that described above is required, refer to

the section on Installation for the proper procedure to reverse

the rotation.

B. Stroke Times

On/Off Version:

Standard stroke times of the Series 72 actuator are shown in the

following table. Times shown represent average times under 50%

load conditions at 72 degrees Fahrenheit environmental

temperature. Opening and closing speeds will increase as the

environmental temperature goes down. Actuator temperature can

be controlled through the use of heater elements, heating bands,

insulation, and other typical means for hydraulic equipment

temperature control.

The figures shown below are meant as an indication of obtainable

speeds only. Faster or slower speeds are obtainable, if required,

by using additional control equipment.

Actuator Size 1572 2072

Opening @ 72°F 6 sec. 10 sec.

Closing @ 72°F 1 sec. 3 sec.

CLC Version:

The Series 72 equipped with the CLC option can attain the same

speeds as the On/Off Version, or be adjusted to attain slower

opening or closing speeds. Control of the actuator’s cycle time is

achieved by breaking up the power applied to the actuator into a

series of pulses. Opening and closing speeds will increase as the

environmental temperature goes down. Actuator temperature can

be controlled through the use of heater elements, heating bands,

insulation, and other typical means for hydraulic equipment

temperature control.

The length of time a power pulse is applied is controlled by the

“ON” adjustable control. The interval between pulses is controlled

by the “OFF” adjustable control.

To adjust, start with both controls at midpoint. To reduce cycle

time on 120 VAC units, turn “ON” control in CW direction and

“OFF” control in CCW direction. To increase cycle time turn “ON”

control in CCW direction and “OFF” in CW direction. To reduce

cycle time on 240 VAC units, turn “ON” control in CCW direction

and “OFF” control in CW direction. To increase cycle time turn

“ON” control in CW direction and “OFF” control in CCW direction.

Flow Control Division

Worcester Controls

DC Wiring

CCW/CW (OPEN/CLOSE) CW (CLOSE) CCW (OPEN)

Page 5

IMPORTANT: If “ON” time adjustable control is at minimum and/or

“OFF” time adjustable control is at maximum, the actuator will not

rotate. The minimum “ON” pulse must allow the actuator to move

a closed valve out of its seat. Verify proper CLC operation by

opening a fully closed valve.

C. Manual Operation

In the event of power failure, the Series 72 actuator will cycle to

the fail position, but can be cycled manually. This is accomplished

by applying a wrench to the exposed top shaft of the actuator and

turning it in the desired direction. Note that the actuator will not

remain in the open position until power is restored to the fail-safe,

normally open, solenoid.

a WARNING: CARE MUST BE TAKEN TO ENSURE THAT THE

ACTUATOR IS NOT OPERATED ELECTRICALLY WHILE MANUAL

OPERATION IS BEING PERFORMED.

D. Limit Switches

The “standard” mounting configuration of the 72 Actuator to the

valve is in-line, fail-closed. In this configuration, SW-1, as

described in the wiring diagram (shown in electrical installation

section and also located inside the limit switch cover) and shown

in illustration below, will give indication when the actuator is in

the open position, or CCW limit of rotation. SW-2 gives indication

of the closed position, or CW limit of rotation.

Actuator failure position may be changed by either inverting the

actuator or mounting cross-line. In these cases, the limit switch

must be mounted the same as described above, but SW-1 and

SW-2 indication will be reversed from that above. If there is

question as to which switch is going to indicate a given position,

the actuator should be operated, and SW-1 and SW-2 checked to

verify which switch will give the desired indication.

CAUTION: Switches have been factory adjusted but should be

rechecked after installation. Adjustment is as follows:

1. With actuator mounted in "standard" configuration, set

actuator in closed position with the adjustment screw near its

loose limit, adjust closed position switch SW-2 (see

illustration) by tightening the adjusting screw until switch

contacts click. Tighten the adjustment screw an additional

1

/

4 turn.

2. Change actuator to its full open position and adjust open

position switch SW-1.

a) If the actuator does not open fully, back the adjusting

screw out

1

/

2 turn and cycle the actuator.

b) If the actuator opens fully, and the motor continues to

run, tighten the adjusting screw until the switch contacts

click and tighten again by an additional

1

/

4 turn.

c) Cycle the actuator to verify the settings are correct. The

limit switch SW-1 should stop the pump motor when the

actuator is fully open.

3. Make electrical connections for the limit switches to the

terminal strip, if applicable, in accordance with the wiring

diagram inside the limit switch cover.

4. Install the limit switch cover.

WCAIM2049 Series 72 “Electric-SAFE” On/Off Operation Including CLC Option 5

Flow Control Division

Worcester Controls

Page 6

6 Series 72 “Electric-SAFE” On/Off Operation Including CLC Option WCAIM2049

MAINTENANCE AND

TROUBLESHOOTING

CAUTION: THE ACTUATOR MUST BE ISOLATED ELECTRICALLY

BEFORE ANY MAINTENANCE ACTIVITY OR COVER REMOVAL IS

BEGUN.

I. MAINTENANCE:

Periodic checks should be performed to make certain that all

mounting fasteners remain tight.

II. TROUBLESHOOTING

Any visible oil leakage is cause to replace the actuator. The

actuator cannot be repaired and refilled with oil in the field.

A. If actuator does not function, check to make sure:

1. That valve is free to rotate. This can be done as described

in Manual Operation.

2. That actuator is the correct size.

3. That correct voltage is supplied to actuator.

4. That the motor is running, but the actuator does not

move. If so, then replacement of the actuator may be

required.

B. If proper voltage has been verified and valve is free, proceed

as follows:

1. Shut off power to the actuator and remove the limit

switch cover.

2. Inspect all connections to the terminal strip and check for

loose wires.

3. Turn on power to the actuator.

a WARNING: EXPOSED ELECTRICAL CONNECTIONS

CAN CAUSE SEVERE SHOCK. CARE MUST BE TAKEN TO

PREVENT SHORT CIRCUIT CONNECTIONS FROM

FINGERS, SCREWDRIVERS, AND TOOLS.

4. Check to see that the limit switch adjustment screws are

set properly. If screws are tightened too much, the limit

switch SW-1 will not allow the motor to run and the

actuator will not operate. See “OPERATION, Section D”

for adjustment procedure. Limit switch SW-2 does not

affect the operation of the actuator.

5. If the motor still does not operate, turn off power to the

actuator and replace the motor capacitor. If the motor still

does not operate, replace the actuator.

6. Replace the cover gasket and cover, tightening all of the

cover screws.

C. If the actuator opens, but drifts closed and reopens in a

cyclical operation:

1. Cycle the actuator a few times to see if the ball check

valve will reseat.

2. If not, replace the actuator. The problem lies internal to

the fluid passageway check valve and cannot be fixed in

the field.

D. If the actuator does not open, but the motor is running:

1. Remove the cover on the solenoid end of the actuator

opposite the limit switch end.

2. Check the normally open solenoid to make sure the coil

has voltage.

3. Replace the coil on the normally open solenoid if

necessary.

NOTE: When removing the solenoid, attach a chase string

or wire to the coil wires as you pull the coil wires through

the actuator. This will make feeding the new coil wires

much easier.

4. If the solenoid coil has voltage and is operating properly,

replace the actuator. Solenoid valve replacement cannot

be done in the field without introducing air into the

hydraulic system, and should be done at the factory.

Flow Control Division

Worcester Controls

Page 7

WCAIM2049 Series 72 “Electric-SAFE” On/Off Operation Including CLC Option 7

Flow Control Division

Worcester Controls

This page intentionally left blank.

Page 8

Flow Control Division

Worcester Controls

Flowserve Corporation has established industry leadership in the design and manufacture of its products. When properly selected, this Flowserve product is designed to perform its intended function

safely during its useful life. However, the purchaser or user of Flowserve products should be aware that Flowserve products might be used in numerous applications under a wide variety of industrial

service conditions. Although Flowserve can (and often does) provide general guidelines, it cannot provide specific data and warnings for all possible applications. The purchaser/user must therefore

assume the ultimate responsibility for the proper sizing and selection, installation, operation, and maintenance of Flowserve products. The purchaser/user should read and understand the Installation

Operation Maintenance (IOM) instructions included with the product, and train its employees and contractors in the safe use of Flowserve products in connection with the specific application.

While the information and specifications contained in this literature are believed to be accurate, they are supplied for informative purposes only and should not be considered certified or as a guarantee of

satisfactory results by reliance thereon. Nothing contained herein is to be construed as a warranty or guarantee, express or implied, regarding any matter with respect to this product. Because Flowserve

is continually improving and upgrading its product design, the specifications, dimensions and information contained herein are subject to change without notice. Should any question arise concerning

these provisions, the purchaser/user should contact Flowserve Corporation at any one of its worldwide operations or offices.

For more information about Flowserve Corporation, contact www.flowserve.com or call USA 1-800-225-6989.

FLOWSERVE CORPORATION

FLOW CONTROL DIVISION

1978 Foreman Drive

Cookeville, Tennessee 38501 USA

Phone: 931 432 4021

Facsimile: 931 432 3105

www.flowserve.com

© 2003 Flowserve Corporation, Irving, Texas, USA. Flowserve and Worcester Controls are registered trademarks of Flowserve Corporation. WCAIM2049 10/03 Printed in USA

Loading...

Loading...