Page 1

682 Seal Cooler

Experience In Motion

New generation seal cooler to meet and

exceed the seal cooler requirements stated

in the 4th Edition of API Standard 682

Installation

Operation

Maintenance

Page 2

Description

The 682 Seal Cooler was designed as a new generation seal cooler to meet and

exceed the seal cooler requirements stated in the First Edition of API Standard

682. These requirements address the primary specications of the seal coolers that should be used in conjunction with mechanical seals. A secondary goal

was to eliminate the fouling and corrosion problems inherent with typical seal

cooler designs. With release of the Fourth Edition of API Standard 682, the

requirements for this size of seal cooler are basically the same except that the

cooling coil material must now be 316 instead of 304. The standard material has

been upgraded to 316, allowing the 682 Seal Cooler to continue meeting the

requirements of API Standard 682. The following is a brief summary of the major

requirements specied for Fourth Edition “Seal Flush Coolers”:

• Seal ush coolers should not be sized for less than a 8 l / min (2 gpm)

ush ow per seal.

• The seal ush uid should be on the tube side and the cooling water on

the shell side.

• When required, seal ush coolers should be designed, fabricated, and

inspected according to ASME B31.3 using piping components.

• The tubes should be ¾ inch diameter with 0.095 inch minimum wall

thickness.

• The tubes should be 316 austenitic stainless steel and the shell should

be carbon steel.

• The seal cooler should allow complete draining and venting of both the

water and process sides.

• Meets and exceeds API Standard 682 design requirements.

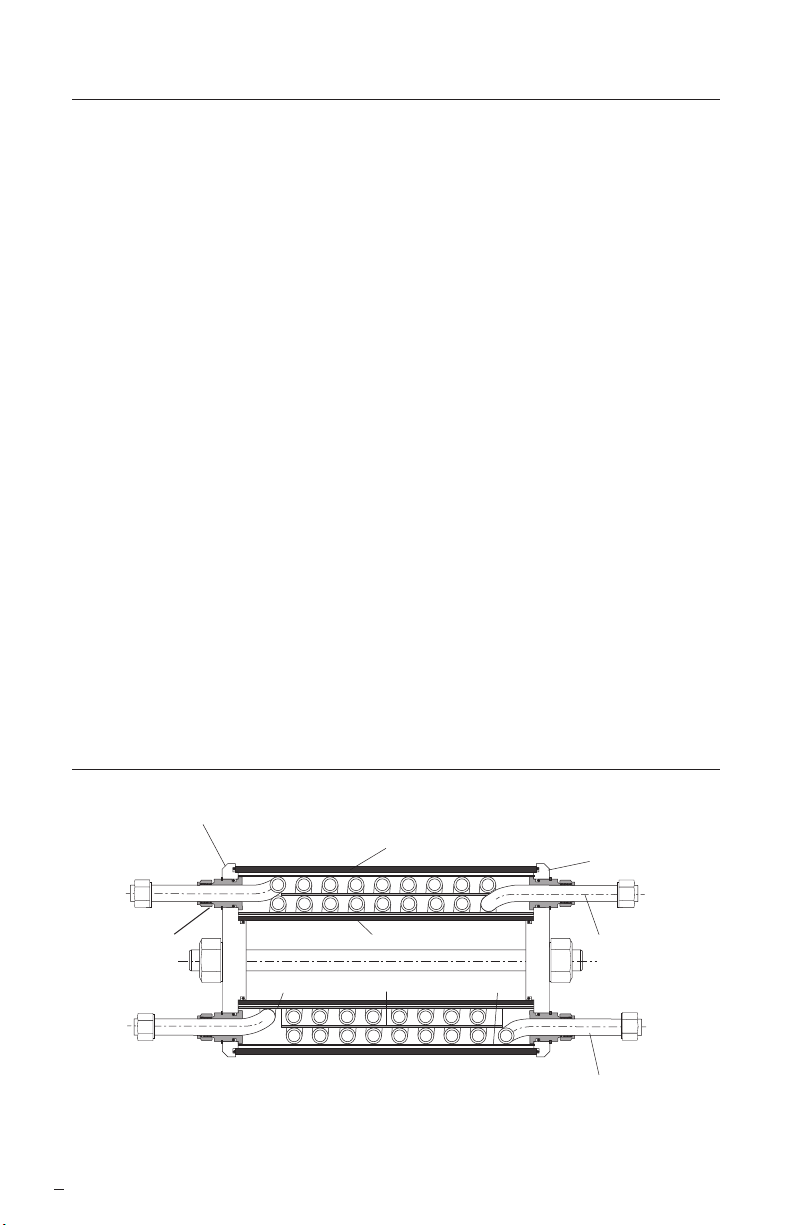

Design Features Figure 1

cover

outer shell

tting

The images of parts shown in these instructions may differ visually from the actual

2

parts due to manufacturing processes that do not affect the part function or quality.

inner shell

bafebafebafe

cover

inner cooling

coil tubing

outer cooling

coil tubing

Page 3

• Contains 300 Series Stainless Steel for all wetted parts to provide superior

corrosion resistance.

• Disassembles Easily without damaging the cooling coils for cleaning to

prevent scaling and cooler fouling from reducing operating efciencies.

• Contains Seamless Cooling Coil Tubing separated by bafes that channel

the cooling water ow to prevent it from bypassing any of the cooling coils

and to provide the highest efciency.

• Allows Complete Drainage and Venting of both the tube and shell side uids

to prevent vapor lock conditions and ensure the highest efciency.

• Can be congured for Series or Parallel Tube Flow to provide the cooling

characteristics needed.

• Available with an ASME Section VIII, Division 1 “U” Stamp for applications

where the equipment must be rated and veried as meeting the ASME

design requirements for pressure vessels.

• Provides Explosion Resistance through a pressure relief feature that

prevents the internal pressure from exceeding the allowable working

pressure of the inner and outer shells.

Product Specications

Standard Materials:

• O-rings Fluoroelastomer

• Tubing 316 Stainless Steel

• Fittings 316 Stainless Steel

• Shell and Covers 304 Stainless Steel

Technical Data:

• Cooling Coil Tube OD 19 mm (0.750 inch)

• Cooling Coil Tube Wall Thickness 2.4 mm (0.095 inch)

• Effective Cooling Area 0.51 m 2 (5.50 ft 2)

• Shell (Coolant) Flow Rate 24.6 to 75.7 l / min (6.5 to 20 gpm)

• Tube (Product) Flow Rate 7.6 to 37.9 l / min (2 to 10 gpm)

• Unit Weight (Empty) 62.1 kg (137 lbs)

• Maximum Temperature (Tube Side) 371°C (700°F )

• Maximum Temperature (Shell Side) 93°C (200°F), Canada 65°C (200°F)

• Max. Working Pressure (Tube Side) 255 Bar @ 371°C

(3,700 psig @ 700°F)

• Max. Working Pressure ( Shell Side ) 14.5 Bar @ 93°C (210 psig @ 200°F)

3

Page 4

Standard Model Numbers:

• Series Tube Flow: A2R21431-01 (Base) / A2R21431-06

• Parallel Tube Flow: A2R23812-01 (Base) / A2R23812-06

1 Installation

1.1 Primary Piping Plans

Plan 21 - Seal Flush Plan 21 provides cooling to the seal with high ush

ow rate capabilities by recirculating pump discharge uid

through a ow control orice and a seal cooler before it enters

the seal chamber. Because the circulated uid returns to the

pump suction and must be re-pumped to discharge on each

pass, the seal cooler is typically piped for Series or Multiple

Pass Tube Flow to maximize heat transfer capability for

continually removing both process uid and seal generated

heat. This piping plan is targeted for clean high temperature

uids and hot water under 80°C (176°F) to improve vapor

margins, meet secondary seal element temperature limits,

reduce coking and polymerizing, and/or improve uid lubricity.

Plan 23 - Seal Flush Plan 23 cools the seal chamber uid by using a

pumping device to circulate the seal chamber uid out through

a seal cooler and back to the seal chamber. With the need to

minimize head loss or pressure drop through this recirculation

system, the seal cooler is typically piped for Parallel or Single

Pass Tube Flow. The circulated uid is isolated from the pump

impeller area by a throat bushing so that the seal cooler

needs to cool only the seal chamber uid heated by seal

generated heat and heat soak from the process side.

This piping arrangement is the plan of choice for clean hot

water services, particularly above 80°C (176°F) where water

has low lubricity, and many clean hot hydrocarbons to improve

vapor margins.

4

Page 5

A 682 Seal Cooler piped for series tube ow is shown in Figure 2 and a 682 Seal

Cooler piped for parallel tube ow is shown in Figure 3. Both Figure 2 and Figure

3 show the 682 Seal Cooler mounted either vertically as preferred or horizontally

as may be required by some applications.

Series Tube Flow Piping Figure 2

Vertical Mount

(preferred)

cooling

water out

cooling

product

drain

cooling

water in

cooling

water in

Horizontal Mount

product

drain

product

vent

cooling

water out

product

vent

0.45 to 0.60 m

(1.5 to 2.0 feet)

0.9 m (3.0 feet)

Maximum

Parallel Tube Flow Piping Figure 3

cooling

water out

Vertical Mount

(preferred)

product

vent

cooling

water out

Horizontal Mount

product

drain

product

vent

cooling

water in

0.45 to 0.60 m

(1.5 to 2.0 feet)

0.9 m (3.0 feet)

Maximum

cooling

product

drain

cooling

water in

5

Page 6

1.2 Vertical or Horizontal Mounting

Even though the 682 Seal Cooler can provide cooling capabilities when it

is mounted horizontally, it is much more advantageous to mount this seal

cooler vertically. In a vertical position, the cooling coil tubing winds gradually downward and upward for optimum uid drainage and gas/air venting.

Vertical

tube side

gas vents

in shell

Horizontal

trapped gas

in tubing

tube

side uid

drains

shell side

gas vents

(in cover)

tube side

gas vent

cooling

water

drains

(in cover)

trapped gas

tube side

uid drains

In a horizontal position, it is much more difcult to totally drain both the

sealing and cooling uids. The sealing uid becomes trapped within the

lower turns of the cooling coil and the shell side cooling water becomes

trapped below the lowest drainage point. The seal cooler would need to

be removed and positioned vertically to achieve total drainage. It is also

much more difcult to vent gas/air from a horizontal installation because

the gas/air can become trapped within the upper turns of the cooling coil.

A series of ush and bleed steps might be necessary in order to remove

these trapped gases.

The presence of trapped gas/air is more critical when using a Plan 23

seal ush. Trapped gases that become entrained in the sealing uid can

reduce the seal cooler efciency and ow in the seal ush circuit. This can

ultimately cause the seal to overheat and fail due to a lack of lubrication. A

vertically mounted seal cooler provides the advantage of a thermosyphon

effect which is lacking with horizontal installations to help alleviate these

potentially detrimental conditions.

6

Page 7

It is strongly recommended that the 682 Seal Cooler be mounted in a

vertical position whenever possible for a Plan 23 to ensure proper cooling

efciencies and simplify maintenance requirements. For applications that

must conform to API Standard 682 requirements, the API Standard 682

species that the seal cooler must be mounted to allow complete draining

and venting of both the cooling water and the process uid. Vertical

installations achieve this capability but horizontal mountings do not.

2 Operation

2.1 When installing and again before start-up, ensure that the seal cooler,

piping, and vent locations provide complete venting of gas/air from both

the tube and shell systems. This requires the vents to be located at the

highest point in each system.

2.2 Before start-up, ensure that all the gas/air is vented from both the tube

and shell systems to provide the system efciencies expected and prevent

a vapor lock condition.

2.3 When installing and again before start-up, ensure that the seal cooler,

piping, and drain locations allow for drainage of uid from both the tube

and shell systems. This requires the drains to be located at the lowest

point in each system. A drain valve (not just a plug) should be mounted

in the shell system.

2.4 If the tube and shell systems can not be congured for both proper venting

and proper draining, as with a horizontal installation, it is more important

for proper venting be achieved.

2.5 Before start-up, ensure that all piping is properly attached to the appropri-

ate connections for both the tube and shell systems to prevent uid leaks

and achieve expected cooler efciencies.

2.6 At start-up, ensure that the ush uid ow and cooling uid ow are set

and stabilized at the prescribed ow rates determined for the application.

2.7 Do not allow the shell system cooling uid ow rate to be operated below

24.6 L / min (6.5 gpm). Lower ow rates will encourage fouling which

reduces the seal cooler heat transfer capabilities.

2.8 Cooler performance should be monitored periodically. Baseline tempera-

tures should be gathered soon after equipment commissioning. Target

shell side base line temperature differential should be 20°F or lower.

Exceeding this temperature could result in a loss of efciency and possibly

result in shell side fouling.

2.9 Periodically shell and tube side temperature differential should be

monitored. With no change in process temperature tube side

temperatures should be not exceed 10-20°F rise from base line.

Shell side differential exceeding 20°F or signicant variation from base

line indicates loss of efciency. Shell side fouling could be a cause and

cooler cleaning should be considered.

7

Page 8

TO REORDER REFER TO

flowserve.com

B/M #

F.O .

3 Maintenance

3.0 Remove the seal cooler from service.

3.1 Remove all end ttings connected to the lengths of tubing protruding from each end

of the cooler. Fitting ferrules and nuts cannot be removed from the primary lengths

of protruding tube and should be remain in place. Do not remove the ttings directly

adjacent to the tube cover. Be sure to retain all ttings and mark them appropriately.

This will minimize the likelihood of tting leaks upon reassembly.

3.2 Remove the center bolt.

3.3 Remove each of the four snap rings located near each tube to end cover tting.

3.4 Carefully pry each end cover from the main cooler body. A short piece of pipe

(6 or 8 inch) screwed into the shell side inlet or outlet offers an adequate amount of

leverage. Take care not to use too much force, which can result in coil stretch. The

outer and inner shells can now be removed, which will expose the coiled tubing.

3.5 Remove the sheet metal bafes located at the tube body OD and ID. Orientation is

important and should be recorded.

3.6 Clean the shell and coils taking care not to damage either.

3.7 Inspect all components for damage or corrosion and replace as needed. Secondary

sealing components such as O-rings should always be replaced.

3.8 Reassemble the unit in reverse of disassembly. Center bolt torque required is

100 to 150 ft-lbf. All ttings should be reassembled to the manufacturer’s specications.

3.9 Leak testing is recommended after assembly. Refer to end user specications or

procedures. Alternately, individual units can be returned to Flowserve for

refurbishment and testing.

FIS221eng ORG 10/13 Printed in USA

To find your local Flowserve representative

and find out more about Flowserve Corporation,

visit www.flowserve.com

Flowserve Corporation has established industry leadership in the design and manufacture of its products. When properly

selected, this Flowserve product is designed to perform its intended function safely during its useful life. However,

the purchaser or user of Flowserve products should be aware that Flowserve products might be used in numerous

applications under a wide variety of industrial service conditions. Although Flowserve can provide general guidelines,

it cannot provide specific data and warnings for all possible applications. The purchaser/user must therefore assume

the ultimate responsibility for the proper sizing and selection, installation, operation, and maintenance of Flowserve

products. The purchaser/user should read and understand the Installation Instructions included with the product, and

train its employees and contractors in the safe use of Flowserve products in connection with the specific application.

While the information and specifications contained in this literature are believed to be accurate, they are supplied for

informative purposes only and should not be considered certified or as a guarantee of satisfactory results by reliance

thereon. Nothing contained herein is to be construed as a warranty or guarantee, express or implied, regarding any

matter with respect to this product. Because Flowserve is continually improving and upgrading its product design,

the specifications, dimensions and information contained herein are subject to change without notice. Should any

question arise concerning these provisions, the purchaser/user should contact Flowserve Corporation at any one of

its worldwide operations or offices.

© 2013 Flowserve Corporation

USA and Canada

Kalamazoo, Michigan USA

Telephone: 1 269 381 2650

Telefax: 1 269 382 8726

Europe, Middle East, Africa

Roosendaal, the Netherlands

Telephone: 31 165 581400

Telefax: 31 165 554590

Asia Pacific

Singapore

Telephone: 65 6544 6800

Telefax: 65 6214 0541

Latin America

Mexico City

Telephone: 52 55 5567 7170

Telefax: 52 55 5567 4224

Loading...

Loading...