Page 1

UC Series 3

FANUC Series 30+-MODEL B

FANUC Series 31+-MODEL B

FAN

2+-MODEL B

OPERATION AND MAINTENANCE

HANDBOOK

B-64487EN/03

Page 2

• No part of this manual may be reproduced in any form.

• All specifications and designs are subject to change without

The products in this manual are controlled based on Japan’s

“Foreign Exchange and Foreign Trade Law”. The export of Series

30i-B, Series 31i-B5 from Japan is subject to an export license by

the government of Japan. Other models in this manual may also

be subject to export controls.

Further, re-export to another country may be subject to the

license of the government of the country from where the product

is re-exported. Furthermore, the product may also be controlled

by re-export regulations of the United States government.

Should you wish to export or re-export these products, please

contact FANUC for advice.

The products in this manual are manufactured under strict quality

control. However, when some serious accidents or losses are

predicted due to a failure of the product, make adequate

consideration for safety.

In this manual we have tried as much as possible to describe all

the various matters.

However, we cannot describe all the matters which must not be

done, or which cannot be done, because there are so many

possibilities.

Therefore, matters which are not especially described as possible

in this manual should be regarded as ”impossible”.

This manual contains the program names or device names of

other companies, some of which are registered trademarks of

respective owners. However, these names are not followed by ®

or ™ in the main body.

notice.

Page 3

SAFETY PRECAUTIONS

This section describes the safety precautions related to the use of CNC

units.

It is essential that these precautions be observed by users to ensure the

safe operation of machines equipped with a CNC unit (all descriptions in

this section assume this configuration). Note that some precautions are

related only to specific functions, and thus may not be applicable to

certain CNC units.

Users must also observe the safety precautions related to the machine,

as described in the relevant manual supplied by the machine tool builder.

Before attempting to operate the machine or create a program to control

the operation of the machine, the operator must become fully familiar

with the contents of this manual and relevant manual supplied by the

machine tool builder.

DEFINITION OF WARNING, CAUTION, AND NOTE

This manual includes safety precautions for protecting the user and

preventing damage to the machine. Precautions are classified into

Warning and Caution according to their bearing on safety. Also,

supplementary information is described as a Note. Read the Warning,

Caution, and Note thoroughly before attempting to use the machine.

WARNING

Applied when there is a danger of the user being injured or when there is a

danger of both the user being injured and the equipment being damaged if

the approved procedure is not observed.

CAUTION

Applied when there is a danger of the equipment being damaged, if the

approved procedure is not observed.

NOTE

The Note is used to indicate supplementary information other than

Warning and Caution.

• Read this manual carefully, and store it in a safe place.

GENERAL WARNINGS AND CAUTIONS

WARNING

1 Never attempt to machine a workpiece without first checking the operation

of the machine. Before starting a production run, ensure that the machine

is operating correctly by performing a trial run using, for example, the

single block, feedrate override, or machine lock function or by operating

the machine with neither a tool nor workpiece mounted. Failure to confirm

the correct operation of the machine may result in the machine behaving

unexpectedly, possibly causing damage to the workpiece and/or machine

itself, or injury to the user.

2 Before operating the machine, thoroughly check the entered data.

Operating the machine with incorrectly specified data may result in the

machine behaving unexpectedly, possibly causing damage to the

workpiece and/or machine itself, or injury to the user.

3 Ensure that the specified feedrate is appropriate for the intended

operation. Generally, for each machine, there is a maximum allowable

feedrate. The appropriate feedrate varies with the intended operation.

Refer to the manual provided with the machine to determine the maximum

allowable feedrate.

If a machine is run at other than the correct speed, it may behave

unexpectedly, possibly causing damage to the workpiece and/or machine

itself, or injury to the user.

4 When using a tool compensation function, thoroughly check the direction

and amount of compensation. Operating the machine with incorrectly

specified data may result in the machine behaving unexpectedly, possibly

causing damage to the workpiece and/or machine itself, or injury to the

user.

s-1

Page 4

SAFETY PRECAUTIONS

WARNING

5 The parameters for the CNC and PMC are factory-set. Usually, there is not

need to change them. When, however, there is not alternative other than

to change a parameter, ensure that you fully understand the function of the

parameter before making any change.

Failure to set a parameter correctly may result in the machine behaving

unexpectedly, possibly causing damage to the workpiece and/or machine

itself, or injury to the user.

CAUTION

1 Immediately after switching on the power, do not touch any of the keys on

the MDI panel until the position display or alarm screen appears on the

CNC unit.

Some of the keys on the MDI panel are dedicated to maintenance or other

special operations. Pressing any of these keys may place the CNC unit in

other than its normal state. Starting the machine in this state may cause it

to behave unexpectedly.

2 The User’s Manual and programming manual supplied with a CNC unit

provide an overall description of the machine's functions, including any

optional functions. Note that the optional functions will vary from one

machine model to another. Therefore, some functions described in the

manuals may not actually be available for a particular model. Check the

specification of the machine if in doubt.

3 Some functions may have been implemented at the request of the

machine-tool builder. When using such functions, refer to the manual

supplied by the machine-tool builder for details of their use and any related

cautions.

4 The liquid-crystal display is manufactured with very precise fabrication

technology. Some pixels may not be turned on or may remain on. This

phenomenon is a common attribute of LCDs and is not a defect.

NOTE

Programs, parameters, and macro variables are stored in nonvolatile

memory in the CNC unit. Usually, they are retained even if the power is

turned off. Such data may be deleted inadvertently, however, or it may

prove necessary to delete all data from nonvolatile memory as part of error

recovery. To guard against the occurrence of the above, and assure quick

restoration of deleted data, backup all vital data, and keep the backup

copy in a safe place.

WARNINGS AND CAUTIONS RELATED TO PROGRAMMING

This section covers the major safety precautions related to programming.

Before attempting to perform programming, read the supplied User’s

Manual carefully such that you are fully familiar with their contents.

WARNING

1 Coordinate system setting

If a coordinate system is established incorrectly, the machine may behave

unexpectedly as a result of the program issuing an otherwise valid move

command. Such an unexpected operation may damage the tool, the

machine itself, the workpiece, or cause injury to the user.

2 Positioning by nonlinear interpolation

When performing positioning by nonlinear interpolation (positioning by

nonlinear movement between the start and end points), the tool path must

be carefully confirmed before performing programming. Positioning

involves rapid traverse. If the tool collides with the workpiece, it may

damage the tool, the machine itself, the workpiece, or cause injury to the

user.

s-2

Page 5

WARNING

3 Function involving a rotary axis

When programming polar coordinate interpolation or normal-direction

(perpendicular) control, pay careful attention to the speed of the rotary

axis. Incorrect programming may result in the rotary axis speed becoming

excessively high, such that centrifugal force causes the chuck to lose its

grip on the workpiece if the latter is not mounted securely. Such mishap is

likely to damage the tool, the machine itself, the workpiece, or cause injury

to the user.

4 Inch/metric conversion

Switching between inch and metric inputs does not convert the

measurement units of data such as the workpiece origin offset, parameter,

and current position. Before starting the machine, therefore, determine

which measurement units are being used. Attempting to perform an

operation with invalid data specified may damage the tool, the machine

itself, the workpiece, or cause injury to the user.

5 Constant surface speed control

When an axis subject to constant surface speed control approaches the

origin of the workpiece coordinate system, the spindle speed may become

excessively high. Therefore, it is necessary to specify a maximum

allowable speed. Specifying the maximum allowable speed incorrectly

may damage the tool, the machine itself, the workpiece, or cause injury to

the user.

6 Stroke check

After switching on the power, perform a manual reference position return

as required. Stroke check is not possible before manual reference position

return is performed. Note that when stroke check is disabled, an alarm is

not issued even if a stroke limit is exceeded, possibly damaging the tool,

the machine itself, the workpiece, or causing injury to the user.

7 Tool post interference check

A tool post interference check is performed based on the tool data

specified during automatic operation. If the tool specification does not

match the tool actually being used, the interference check cannot be made

correctly, possibly damaging the tool or the machine itself, or causing

injury to the user. After switching on the power, or after selecting a tool

post manually, always start automatic operation and specify the tool

number of the tool to be used.

CAUTION

1 Absolute/incremental mode

If a program created with absolute values is run in incremental mode, or

vice versa, the machine may behave unexpectedly.

2 Plane selection

If an incorrect plane is specified for circular interpolation, helical

interpolation, or a canned cycle, the machine may behave unexpectedly.

Refer to the descriptions of the respective functions for details.

3 Torque limit skip

Before attempting a torque limit skip, apply the torque limit. If a torque limit

skip is specified without the torque limit actually being applied, a move

command will be executed without performing a skip.

4 Programmable mirror image

Note that programmed operations vary considerably when a

programmable mirror image is enabled.

5 Compensation function

If a command based on the machine coordinate system or a reference

position return command is issued in compensation function mode,

compensation is temporarily canceled, resulting in the unexpected

behavior of the machine.

Before issuing any of the above commands, therefore, always cancel

compensation function mode.

B-64487EN/03

s-3

Page 6

SAFETY PRECAUTIONS

WARNINGS AND CAUTIONS RELATED TO HANDLING

This section presents safety precautions related to the handling of

machine tools. Before attempting to operate your machine, read the

supplied User’s Manual carefully, such that you are fully familiar with

their contents.

WARNING

1 Manual operation

When operating the machine manually, determine the current position of

the tool and workpiece, and ensure that the movement axis, direction, and

feedrate have been specified correctly. Incorrect operation of the machine

may damage the tool, the machine itself, the workpiece, or cause injury to

the operator.

2 Manual reference position return

After switching on the power, perform manual reference position return as

required.

If the machine is operated without first performing manual reference

position return, it may behave unexpectedly. Stroke check is not possible

before manual reference position return is performed.

An unexpected operation of the machine may damage the tool, the

machine itself, the workpiece, or cause injury to the user.

3 Manual numeric command

When issuing a manual numeric command, determine the current position

of the tool and workpiece, and ensure that the movement axis, direction,

and command have been specified correctly, and that the entered values

are valid.

Attempting to operate the machine with an invalid command specified may

damage the tool, the machine itself, the workpiece, or cause injury to the

operator.

4 Manual handle feed

In manual handle feed, rotating the handle with a large scale factor, such

as 100, applied causes the tool and table to move rapidly. Careless

handling may damage the tool and/or machine, or cause injury to the user.

5 Disabled override

If override is disabled (according to the specification in a macro variable)

during threading, rigid tapping, or other tapping, the speed cannot be

predicted, possibly damaging the tool, the machine itself, the workpiece, or

causing injury to the operator.

6 Origin/preset operation

Basically, never attempt an origin/preset operation when the machine is

operating under the control of a program. Otherwise, the machine may

behave unexpectedly, possibly damaging the tool, the machine itself, the

tool, or causing injury to the user.

7 Workpiece coordinate system shift

Manual intervention, machine lock, or mirror imaging may shift the

workpiece coordinate system. Before attempting to operate the machine

under the control of a program, confirm the coordinate system carefully.

If the machine is operated under the control of a program without making

allowances for any shift in the workpiece coordinate system, the machine

may behave unexpectedly, possibly damaging the tool, the machine itself,

the workpiece, or causing injury to the operator.

8 Software operator's panel and menu switches

Using the software operator's panel and menu switches, in combination

with the MDI panel, it is possible to specify operations not supported by the

machine operator's panel, such as mode change, override value change,

and jog feed commands.

Note, however, that if the MDI panel keys are operated inadvertently, the

machine may behave unexpectedly, possibly damaging the tool, the

machine itself, the workpiece, or causing injury to the user.

s-4

Page 7

WARNING

9 RESET key

Pressing the RESET key stops the currently running program. As a result,

the servo axes are stopped. However, the RESET key may fail to function

for reasons such as an MDI panel problem. So, when the motors must be

stopped, use the emergency stop button instead of the RESET key to

ensure security.

CAUTION

1 Manual intervention

If manual intervention is performed during programmed operation of the

machine, the tool path may vary when the machine is restarted. Before

restarting the machine after manual intervention, therefore, confirm the

settings of the manual absolute switches, parameters, and

absolute/incremental command mode.

2 Feed hold, override, and single block

The feed hold, feedrate override, and single block functions can be

disabled using custom macro system variable #3004. Be careful when

operating the machine in this case.

3 Dry run

Usually, a dry run is used to confirm the operation of the machine. During a

dry run, the machine operates at dry run speed, which differs from the

corresponding programmed feedrate. Note that the dry run speed may

sometimes be higher than the programmed feed rate.

4 Tool radius and tool nose radius compensation in MDI mode

Pay careful attention to a tool path specified by a command in MDI mode,

because tool radius or tool nose radius compensation is not applied. When

a command is entered from the MDI to interrupt in automatic operation in

tool radius or tool nose radius compensation mode, pay particular attention

to the tool path when automatic operation is subsequently resumed. Refer

to the descriptions of the corresponding functions for details.

5 Program editing

If the machine is stopped, after which the machining program is edited

(modification, insertion, or deletion), the machine may behave

unexpectedly if machining is resumed under the control of that program.

Basically, do not modify, insert, or delete commands from a machining

program while it is in use.

B-64487EN/03

WARNINGS RELATED TO DAILY MAINTENANCE

WARNING

1 Memory backup battery replacement

When replacing the memory backup batteries, keep the power to the

machine (CNC) turned on, and apply an emergency stop to the machine.

Because this work is performed with the power on and the cabinet open,

only those personnel who have received approved safety and

maintenance training may perform this work.

When replacing the batteries, be careful not to touch the high-voltage

circuits (marked

Touching the uncovered high-voltage circuits presents an extremely

dangerous electric shock hazard.

NOTE

The CNC uses batteries to preserve the contents of its memory, because it

must retain data such as programs, offsets, and parameters even while

external power is not applied.

If the battery voltage drops, a low battery voltage alarm is displayed on the

machine operator's panel or screen.

When a low battery voltage alarm is displayed, replace the batteries within

a week. Otherwise, the contents of the CNC's memory will be lost.

Refer to the Section “Method of replacing battery” of the Part IV,

“Maintenance” in the User’s Manual (Common to T/M series) for details of

the battery replacement procedure.

and fitted with an insulating cover).

s-5

Page 8

SAFETY PRECAUTIONS

WARNING

2 Absolute Pulsecoder battery replacement

When replacing the memory backup batteries, keep the power to the

machine (CNC) turned on, and apply an emergency stop to the machine.

Because this work is performed with the power on and the cabinet open,

only those personnel who have received approved safety and

maintenance training may perform this work.

When replacing the batteries, be careful not to touch the high-voltage

circuits (marked

Touching the uncovered high-voltage circuits presents an extremely

dangerous electric shock hazard.

NOTE

The absolute Pulsecoder uses batteries to preserve its absolute position.

If the battery voltage drops, a low battery voltage alarm is displayed on the

machine operator's panel or screen.

When a low battery voltage alarm is displayed, replace the batteries within

a week. Otherwise, the absolute position data held by the Pulsecoder will

be lost.

Refer to the FANUC SERVO MOTOR αi series Maintenance Manual for

details of the battery replacement procedure.

WARNING

3 Fuse replacement

Before replacing a blown fuse, however, it is necessary to locate and

remove the cause of the blown fuse.

For this reason, only those personnel who have received approved safety

and maintenance training may perform this work.

When replacing a fuse with the cabinet open, be careful not to touch the

high-voltage circuits (marked

Touching an uncovered high-voltage circuit presents an extremely

dangerous electric shock hazard.

and fitted with an insulating cover).

and fitted with an insulating cover).

s-6

Page 9

Page 10

PREFACE

The Operation and Maintenance Handbook is for persons who are

familiar with NC programs and operations. It is used to refer to

necessary information quickly in operating or maintaining NC machine

tools at a work site.

The Handbook only contains reference information. It does not contain

other types of information, such as essential information or notes. Read

the following manuals first.

The Handbook assumes that the reader is familiar with the information in

the following manuals.

For information on safety precautions, be sure to read "SAFETY

PRECAUTIONS" described on the first page of the manual.

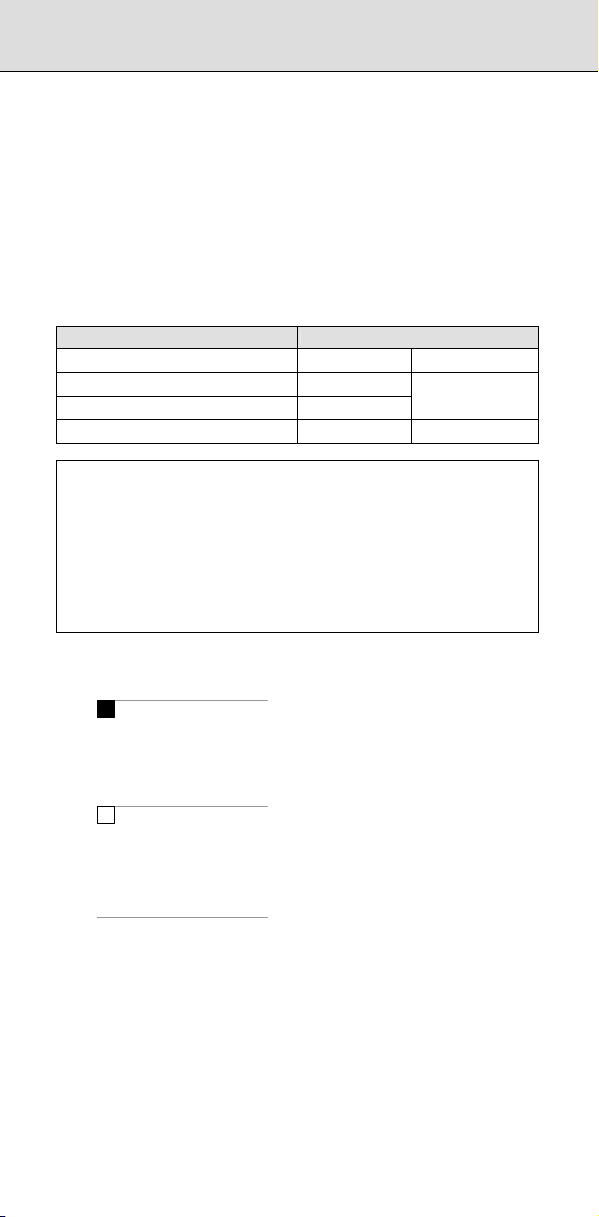

(1) Applicable models

This manual describes the models indicated in the table below.

In the text, the abbreviations indicated below may be used.

Model name Abbreviation

FANUC Series 30i-MODEL B 30i-B Series 30i

FANUC Series 31i-MODEL B5 31i-B5

FANUC Series 31i-MODEL B 31i-B

FANUC Series 32i-MODEL B 32i-B Series 32i

NOTE

1 For an explanatory purpose, the following descriptions may be used

according to the types of path control used:

• T series: For the lathe system

• M series: For the machining center system

2 Unless otherwise noted, the model names 31i-B, 31i-B5, and 32i-B are

collectively referred to as 30i. However, this convention is not necessarily

observed when item 3 below is applicable.

3 Some functions described in this manual may not be applied to some

products. For details, refer to the DESCRIPTIONS (B-64482EN).

(2) Special symbols

This manual uses the following symbols:

M

-

Indicates a description that is valid only for the machine center system

set as system control type (in parameter No. 0983).

In a general description of the method of machining, a machining center

system operation is identified by a phase such as "for milling machining".

T

-

Indicates a description that is valid only for the lathe system set as

system control type (in parameter No. 0983).

In a general description of the method of machining, a lathe system

operation is identified by a phrase such as "for lathe cutting".

-

Indicates the end of a description of a system control type.

When a system control type mark mentioned above is not followed by

this mark, the description of the system control type is assumed to

continue until the next item or paragraph begins. In this case, the next

item or paragraph provides a description common to the control types.

Series 31i

p-1

Page 11

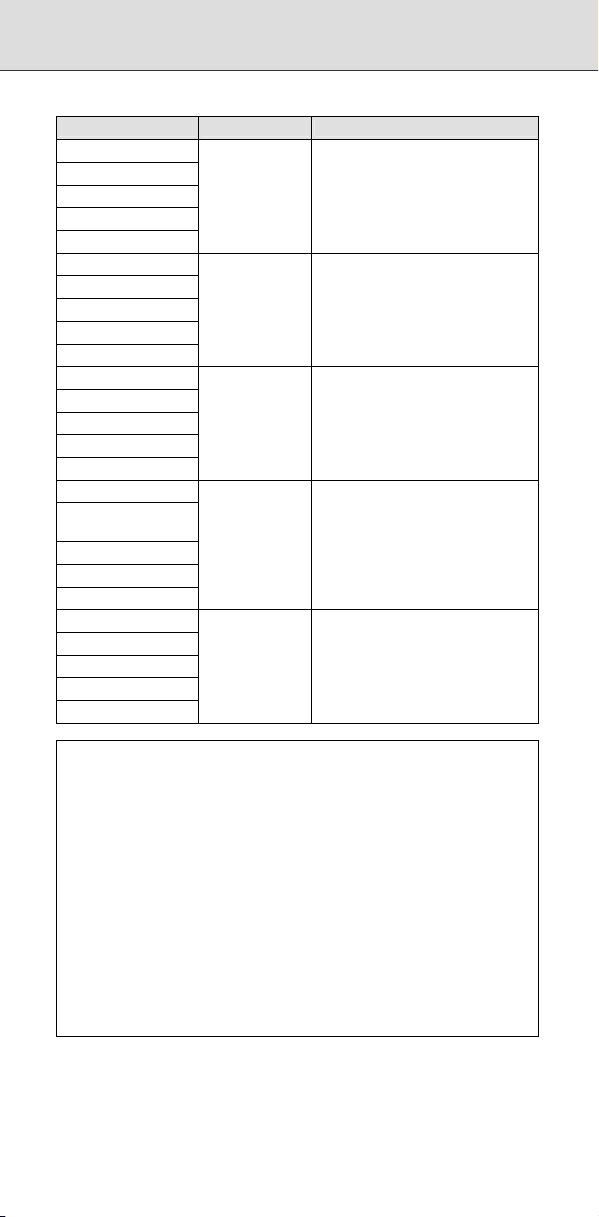

(3) Description of parameters

Parameters are classified by data type as follows:

Data type Valid data range Remarks

Bit

Bit machine group

Bit path

Bit axis

Bit spindle

Byte

Byte machine group

Byte path

Byte axis

Byte spindle

Word

Word machine group

Word path

Word axis

Word spindle

2-word

2-word machine

group

2-word path

2-word axis

2-word spindle

Real

Real machine group

Real path

Real axis

Real spindle

NOTE

1 Each of the parameters of the bit, bit machine group, bit path, bit axis, and

bit spindle types consists of 8 bits for one data number (parameters with

eight different meanings).

2 For machine group types, parameters corresponding to the maximum

number of machine groups are present, so that independent data can be

set for each machine group.

3 For path types, parameters corresponding to the maximum number of

paths are present, so that independent data can be set for each path.

4 For axis types, parameters corresponding to the maximum number of

control axes are present, so that independent data can be set for each

control axis.

5 For spindle types, parameters corresponding to the maximum number of

spindles are present, so that independent data can be set for each spindle

axis.

6 The valid data range for each data type indicates a general range. The

range varies according to the parameters. For the valid data range of a

specific parameter, see the explanation of the parameter.

0 or 1

-128 to 127

-32768 to 32767

0 to ±999999999

See the standard

parameter

setting tables.

Some parameters handle these

types of data as unsigned data.

Some parameters handle these

types of data as unsigned data.

Some parameters handle these

types of data as unsigned data.

B-64487EN/03

p-2

Page 12

PREFACE

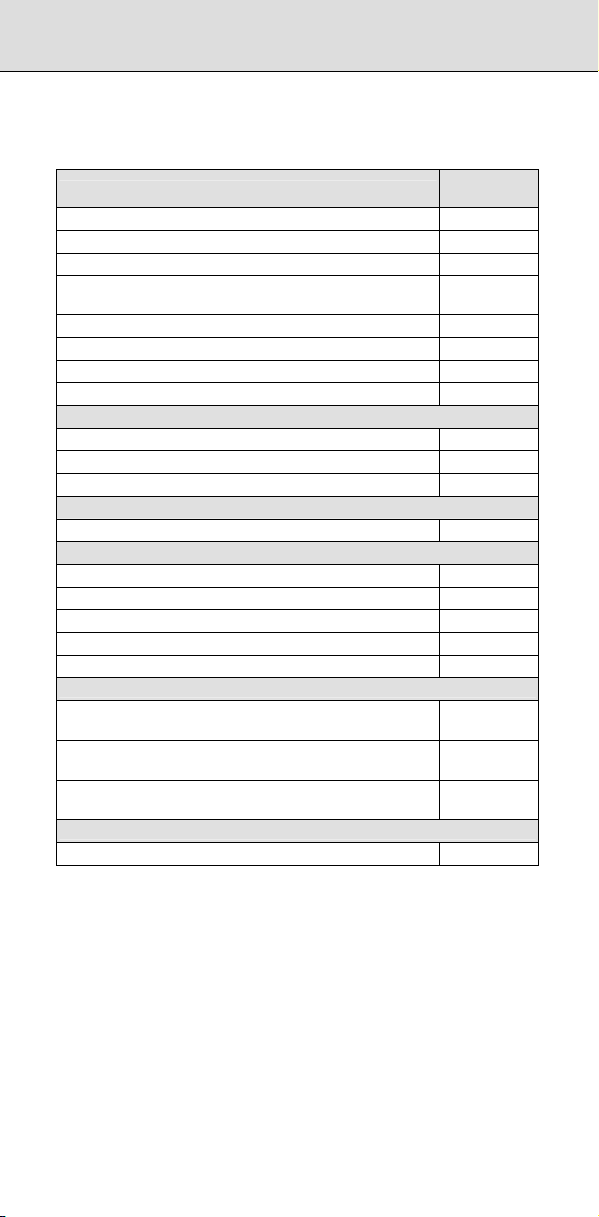

(4) Related manuals of Series 30i-MODEL B, Series 31i-MODEL B5,

Series 31i-MODEL B, Series 32i-MODEL B

The following table lists the manuals related to Series 30i-B, Series

31i-B, Series 31i-B5, Series 32i-B. This manual is indicated by an

asterisk (*).

Manual name

DESCRIPTIONS B-64482EN

CONNECTION MANUAL (HARDWARE) B-64483EN

CONNECTION MANUAL (FUNCTION) B-64483EN-1

OPERATOR’S MANUAL

(Common to Lathe System/Machining Center System)

OPERATOR’S MANUAL (For Lathe System) B-64484EN-1

OPERATOR’S MANUAL (For Machining Center System) B-64484EN-2

MAINTENANCE MANUAL B-64485EN

PARAMETER MANUAL B-64490EN

Programming

Macro Executor PROGRAMMING MANUAL B-63943EN-2

Macro Compiler PROGRAMMING MANUAL B-66263EN

C Language Executor PROGRAMMING MANUAL B-63943EN-3

PMC

PMC PROGRAMMING MANUAL B-64513EN

Network

PROFIBUS-DP Board CONNECTION MANUAL B-63993EN

Fast Ethernet / Fast Data Server OPERATOR’S MANUAL B-64014EN

DeviceNet Board CONNECTION MANUAL B-64043EN

FL-net Board CONNECTION MANUAL B-64163EN

CC-Link Board CONNECTION MANUAL B-64463EN

Operation guidance function

MANUAL GUIDE i (Common to Lathe System/Machining

Center System) OPERATOR’S MANUAL

MANUAL GUIDE i (For Machining Center System)

OPERATOR’S MANUAL

MANUAL GUIDE i Set-up Guidance

OPERATOR’S MANUAL

Dual Check Safety

Dual Check Safety CONNECTION MANUAL B-64483EN-2

Specification

number

B-64484EN

B-63874EN

B-63874EN-2

B-63874EN-1

p-3

Page 13

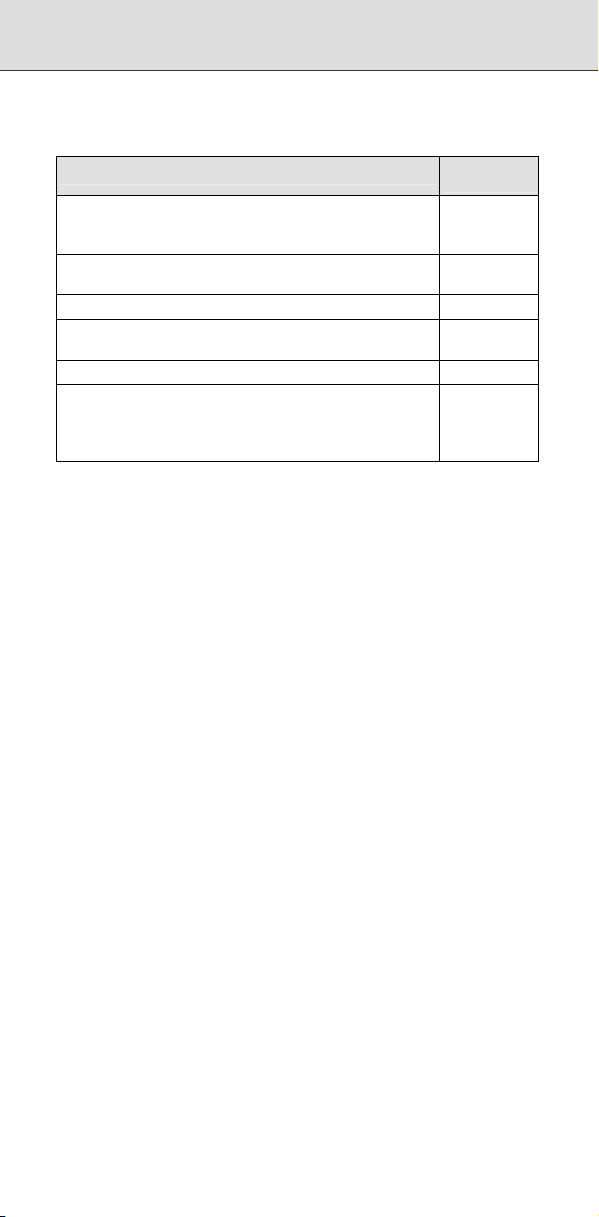

(5) Related manuals of SERVO MOTOR αi series, SPINDLE MOTOR αi

series, SERVO AMPLIFIER αi series

The following table lists the manuals related to SERVO MOTOR αi

series, SPINDLE MOTOR αi series, and SERVO AMPLIFIER αi series.

Manual name

FANUC AC SERVO MOTOR αis series

FANUC AC SERVO MOTOR αi series

DESCRIPTIONS

FANUC AC SERVO MOTOR αiS/αiF/βiS series

PARAMETER MANUAL

FANUC AC SPINDLE MOTOR αi series DESCRIPTIONS B-65272EN

FANUC AC SPINDLE MOTOR αi/βi series

PARAMETER MANUAL

FANUC SERVO AMPLIFIER αi series DESCRIPTIONS B-65282EN

FANUC AC SERVO MOTOR αis/αi series

FANUC AC SPINDLE MOTOR αi series

FANUC SERVO AMPLIFIER αi series

MAINTENANCE MANUAL

Either of the following servo motors and the corresponding spindle can

be connected to the CNC covered in this manual.

This manual mainly assumes that the FANUC SERVO MOTOR αi series

of servo motor is used. For servo motor and spindle information, refer to

the manuals for the servo motor and spindle that are actually connected.

B-64487EN/03

Specification

number

B-65262EN

B-65270EN

B-65280EN

B-65285EN

p-4

Page 14

Page 15

Table of Contents

1 SCREEN DISPLAY AND OPERATION ................................... 1

1

2 OPERATION LIST ................................................................. 55

3 G CODE ................................................................................. 65

4 PROGRAM FORMAT ............................................................ 79

5 CUSTOM MACRO ................................................................. 99

6 HARDWARE ........................................................................ 129

7 PARAMETERS .................................................................... 193

8 ALARM LIST........................................................................ 401

9 SIGNAL LIST (X/Y, G/F) ...................................................... 523

10 PMC...................................................................................... 597

11 ETHERNET .......................................................................... 679

12 POWER MATE CNC MANAGER FUNCTION ..................... 721

13 DIAGNOSIS INFORMATION ............................................... 727

14 HISTORY FUNCTION .......................................................... 765

15 WAVEFORM DIAGNOSIS ................................................... 777

16 DIGITAL SERVO.................................................................. 783

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17 AC SPINDLE........................................................................ 811

18 MAINTENANCE INFORMATION......................................... 827

19 MAINTENANCE FUNCTION ............................................... 853

c-1

17

18

19

Page 16

Table of Contents

SAFETY PRECAUTIONS ............................................................. s-1

DEFINITION OF WARNING, CAUTION, AND NOTE......................... s-1

GENERAL WARNINGS AND CAUTIONS.......................................... s-1

WARNINGS AND CAUTIONS RELATED TO PROGRAMMING ........s-2

WARNINGS AND CAUTIONS RELATED TO HANDLING.................. s-4

WARNINGS RELATED TO DAILY MAINTENANCE........................... s-5

PREFACE .....................................................................................p-1

1 SCREEN DISPLAY AND OPERATION ................................... 1

1.1 SETTING AND DISPLAY UNITS................................................. 1

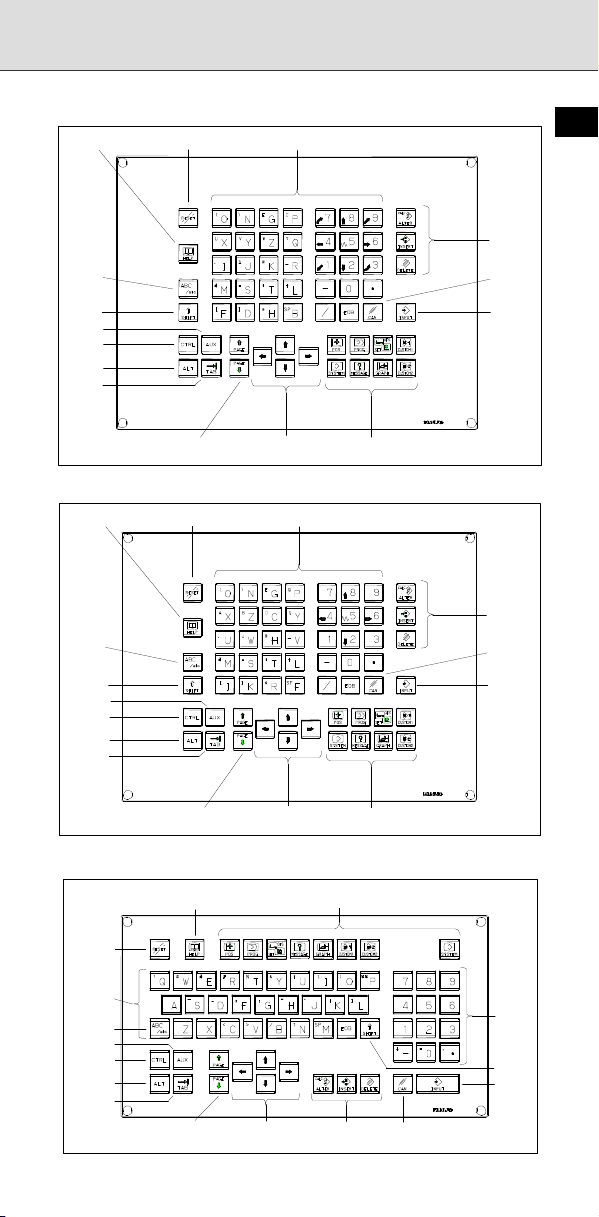

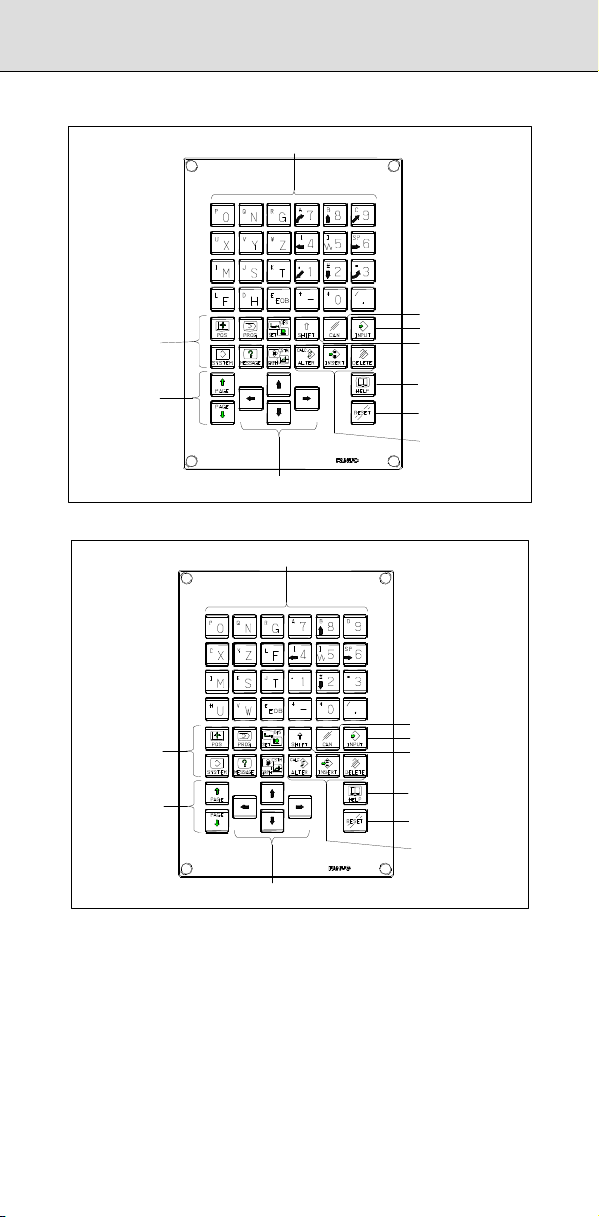

1.1.1 Standard MDI Unit (ONG Key) ......................................2

1.1.2 Standard MDI Unit (QWERTY Key)............................... 2

1.1.3 Small MDI Unit (ONG Key)............................................ 3

1.1.4 Explanation of the MDI Keyboard.................................. 4

1.2 FUNCTION KEYS AND SOFT KEYS ..........................................6

1.2.1 General Screen Operations........................................... 6

1.3 SCREENS DISPLAYED BY FUNCTION KEY

1.3.1 Position Display in the Workpiece Coordinate System 13

1.3.2 Position Display in the Relative Coordinate System .... 15

1.3.3 Overall Position Display ..............................................17

1.3.4 Handle Interrupt Display.............................................. 18

1.3.5 Operating Monitor Display........................................... 19

1.4 SCREENS DISPLAYED BY FUNCTION KEY

MODE) ......................................................................................21

1.4.1 Program Contents Display...........................................21

1.4.2 Program Check Screen............................................... 22

1.4.3 Next Block Display Screen .......................................... 23

1.5 SCREENS DISPLAYED BY FUNCTION KEY

MODE) ......................................................................................24

1.5.1 Editing a Program........................................................ 24

1.5.2 Program Folder Screen ............................................... 26

1.6 SCREENS DISPLAYED BY FUNCTION KEY

1.6.1 Setting and Displaying the Tool Offset Value .............. 27

1.6.2 Displaying and Entering Setting Data.......................... 30

1.6.3 Displaying and Setting the Workpiece Origin Offset

Value........................................................................... 32

1.6.4 Direct Input of Workpiece Origin Offset Value

Measured .................................................................... 33

1.6.5 Displaying and Setting Custom Macro Common

Variables ..................................................................... 34

1.6.6 Displaying and Setting the Software Operator's Panel 35

1.6.7 Character-to-Codes Correspondence Table................ 37

1.7 SCREENS DISPLAYED BY FUNCTION KEY

1.7.1 Displaying and Setting Parameters .............................38

1.7.2 Checking by Self-Diagnosis Screen ............................ 39

1.7.3 Coordinate System on Part Drawing and Coordinate

System Specified by CNC - Coordinate System.......... 40

1.7.4 Displaying and Setting Pitch Error Compensation

Data ............................................................................44

1.8 SCREENS DISPLAYED BY FUNCTION KEY

1.8.1 Alarm Display.............................................................. 47

1.8.2 Alarm History Display.................................................. 49

1.9 HELP FUNCTION...................................................................... 50

1.9.1 Initial Menu Screen...................................................... 50

1.9.2 Alarm Detail Screen ....................................................51

1.9.3 Operation Method Screen ...........................................53

1.9.4 Parameter Table Screen .............................................54

.................. 13

(MEM

(EDIT

.................. 27

.................. 38

.................. 47

2 OPERATION LIST ................................................................. 55

3 G CODE ................................................................................. 65

3.1 G CODE LIST IN THE MACHINING CENTER SYSTEM........... 67

c-2

Page 17

3.2 G CODE LIST IN THE LATHE SYSTEM ................................... 72

B-64487EN/03

4 PROGRAM FORMAT ............................................................ 79

5 CUSTOM MACRO ................................................................. 99

5.1 TYPES OF VARIABLES ............................................................ 99

5.2 SYSTEM VARIABLE .................................................................99

5.3 ARGUMENT SPECIFICATION I/II........................................... 118

5.4 ARITHMETIC AND LOGIC OPERATION ................................ 118

5.5 CONTROL COMMAND ........................................................... 119

5.6 MACRO CALL ......................................................................... 120

5.6.1 Simple Call (G65)...................................................... 120

5.6.2 Modal Call: Call After the Move Command (G66)...... 120

5.6.3 Modal Call: Each Block Call (G66.1) .........................121

5.6.4 Macro Call Using a G Code....................................... 121

5.6.5 Macro Call Using a G Code (Specification of Multiple

Definitions) ................................................................ 121

5.6.6 Macro Call Using a G Code with a Decimal Point

(Specification of Multiple Definitions)......................... 121

5.6.7 Macro Call Using an M Code..................................... 122

5.6.8 Macro Call Using an M Code (Specification of Multiple

Definitions) ................................................................ 122

5.6.9 Subprogram Call Using an M Code........................... 122

5.6.10 Subprogram Call Using an M Code (Specification of

Multiple Definitions)................................................... 122

5.6.11 Subprogram Calls Using a T Code............................ 123

5.6.12 Subprogram Calls Using an S Code.......................... 123

5.6.13 Subprogram Calls Using a Secondary Auxiliary

Function .................................................................... 123

5.6.14 Subprogram Call Using a Specific Address............... 124

5.7 INTERRUPTION TYPE CUSTOM MACRO ............................. 125

5.8 EXTERNAL OUTPUT COMMANDS........................................ 126

5.9 COMMAND RANGE................................................................ 127

6 HARDWARE ........................................................................ 129

6.1 LCD-MOUNTED TYPE CONTROL UNIT HARDWARE........... 129

6.1.1 LCD-mounted Type Control Unit (8.4” LCD Unit and

10.4” LCD Unit A)...................................................... 129

6.1.2 LCD-mounted Type Control Unit (10.4” LCD Unit B

6.2 LCD-MOUNTED TYPE CONTROL UNIT (WITH PERSONAL

6.3 STAND-ALONE TYPE CONTROL UNIT HARDWARE............ 152

6.4 HARDWARE COMMON TO LCD-MOUNTED TYPE AND

and 15” LCD Unit) ..................................................... 137

COMPUTER FUNCTION WITH Windows®CE) HARDWARE . 144

6.2.1 Inverter Board and Fan Adapter Board...................... 149

6.2.2 Backup Unit............................................................... 151

6.3.1 Stand-Alone Type Control Unit.................................. 152

6.3.2 Display Unit for Stand-Alone Type Control Unit......... 156

6.3.2.1 Display unit (10.4” LCD unit A) .................. 156

6.3.2.2 Display unit (10.4” LCD unit B and

15” LCD unit)............................................. 159

6.3.2.3 Display unit for automotive manufacturers. 163

6.3.3 Display Unit for Stand-Alone Type Control Unit (with

Personal Computer Function with Windows®CE)...... 168

6.3.3.1 Inverter Board and Fan adapter Board ...... 171

6.3.3.2 Backup unit................................................ 173

STAND-ALONE TYPE CONTROL UNITS............................... 174

6.4.1 Optional Board .......................................................... 174

6.4.1.1 Fast Ethernet board................................... 174

6.4.1.2 Additional axis board ................................. 177

6.4.1.3 HSSB interface board................................ 177

6.4.1.4 PROFIBUS-DP board................................ 178

6.4.1.5 DeviceNet board........................................ 181

6.4.1.6 CC-Link board ........................................... 188

6.4.2 Other Units................................................................ 190

6.4.2.1 Separate detector interface unit................. 190

6.4.2.2 Analog input separate detector interface

unit ............................................................191

c-3

Page 18

Table of Contents

7 PARAMETERS .................................................................... 193

7.1 HOW TO ENTER THE PARAMETERS ................................... 193

7.2 PARAMETER LIST.................................................................. 195

7.2.1 Setting....................................................................... 198

7.2.2 Reader/Puncher Interface ......................................... 198

7.2.3 CNC Screen Display .................................................200

7.2.4 Ethernet / Data Server Function ................................ 200

7.2.5 Power Mate CNC Manager .......................................201

7.2.6 System Configuration................................................ 201

7.2.7 Axis Control / Increment System ...............................202

7.2.8 Coordinate System 1................................................. 204

7.2.9 Stroke Limit Check .................................................... 205

7.2.10 Chuck and Tail Stock Barrier..................................... 207

7.2.11 Feedrate.................................................................... 207

7.2.12 Acceleration/Deceleration Control............................. 210

7.2.13 Servo......................................................................... 212

7.2.14 DI/DO 1..................................................................... 228

7.2.15 Display and Edit 1 .....................................................229

7.2.16 Programs 1................................................................ 238

7.2.17 Pitch Error Compensation .........................................242

7.2.18 Spindle Control.......................................................... 243

7.2.19 Serial Spindle............................................................ 249

7.2.20 Spindle Control 2....................................................... 266

7.2.21 Tool Compensation 1 ................................................ 267

7.2.22 Canned Cycle............................................................ 272

7.2.23 Rigid Tapping............................................................ 275

7.2.24 Scaling/Coordinate Rotation...................................... 278

7.2.25 Single Direction Positioning....................................... 279

7.2.26 Polar Coordinate Interpolation................................... 279

7.2.27 Normal Direction Control ........................................... 279

7.2.28 Index T

7.2.29 Involute Interpolation................................................. 280

7.2.30 Exponential Interpolation........................................... 280

7.2.31 Flexible Synchronous Control 1................................. 280

7.2.32 Straightness Compensation ...................................... 282

7.2.33 Inclination Compensation.......................................... 283

7.2.34 Custom Macros......................................................... 283

7.2.35 Patter Data Input ....................................................... 288

7.2.36 Positioning by Optimum Acceleration........................ 288

7.2.37 Skip Functions........................................................... 289

7.2.38 External Data Input....................................................293

7.2.39 Fine Torque Sensing................................................. 294

7.2.40 Manual Handle Retrace 1.......................................... 294

7.2.41 Graphic Display 1...................................................... 297

7.2.42 Screen Display Colors............................................... 297

7.2.43 Run Hour and Parts Count Display............................ 297

7.2.44 Tool Life Management 1............................................ 298

7.2.45 Position Switch.......................................................... 300

7.2.46 Manual/Automatic Operation Functions..................... 301

7.2.47 Manual Handle.......................................................... 302

7.2.48 Manual Linear/Circular Interpolation.......................... 303

7.2.49 Reference Position with Mechanical Stopper ............303

7.2.50 Software Operator's Panel ........................................303

7.2.51 Program Restart 1..................................................... 304

7.2.52 Software Operator's Panel 2...................................... 305

7.2.53 High-speed Cutting....................................................305

7.2.54 Fixture Offset............................................................. 306

7.2.55 Polygon Turning ........................................................ 307

7.2.56 Electric Gear Box

7.2.57 Axis Control by PMC 1 .............................................. 310

7.2.58 Multi-path ..................................................................312

7.2.59 Interference Check for Each Path..............................312

7.2.60 Synchronous/Composite Control and Superimposed

7.2.61 Angular Axis Control.................................................. 316

7.2.62 Axis Synchronous Control ......................................... 317

able ...............................................................280

(EGB)............................................ 308

Control 1 ...................................................................313

c-4

Page 19

7.2.63 Sequence Number Comparison and Stop ................. 319

7.2.64 Chopping/ High precision oscillation function ............319

7.2.65 AI Contour Control..................................................... 319

7.2.66 High-speed Position Switch....................................... 320

7.2.67 Others ....................................................................... 322

7.2.68 Maintenance.............................................................. 323

7.2.69 Macro Executor ......................................................... 323

7.2.70 Wrong Operation Prevention Function ...................... 326

7.2.71 Automatic Data Backup............................................. 327

7.2.72 Axis Control............................................................... 328

7.2.73 Parallel Axis Control.................................................. 328

7.2.74 Axis Switching........................................................... 328

7.2.75 Tool Retract and Recover..........................................328

7.2.76 Screen Display Colors 2............................................ 328

7.2.77 High-speed Smooth TCP 1........................................ 329

7.2.78 Dual Check Safety..................................................... 329

7.2.79 Diagnosis ..................................................................329

7.2.80 Three-dimensional Rotary Error Compensation.........329

7.2.81 Three-dimensional Error Compensation.................... 330

7.2.82 3-dimensional Machine Position Compensation........ 331

7.2.83 Rotation Area Interference Check ............................. 332

7.2.84 Built-in 3D Interference Check................................... 332

7.2.85 Spindle Control Based on Servo Motor/Cs Contour

Control 1 ...................................................................347

7.2.86 Path Table Operation ................................................ 349

7.2.87 Workpiece Setting Error Compensation 1..................349

7.2.88 Linear Inclination Compensation ...............................350

7.2.89 Tilted Working Plane Indexing................................... 350

7.2.90 Axis Control / Increment System 2 ............................ 350

7.2.91 DI/DO 2..................................................................... 351

7.2.92 Feedrate Control and Acceleration/Deceleration

Control ......................................................................351

7.2.93 Program R

7.2.94 Tool Center Point Control.......................................... 351

7.2.95 Coordinate System 2................................................. 352

7.2.96 Synchronous/Composite Control and Superimposed

Control 2 ...................................................................352

7.2.97 Programs 2................................................................ 353

7.2.98 Display and Edit 2 .....................................................353

7.2.99 Embedded Macro 1................................................... 355

7.2.100 Display and Edit 3 ..................................................... 355

7.2.101 Graphic Display 2...................................................... 355

7.2.102 Display and Edit 4 ..................................................... 356

7.2.103 Tool Compensation 2................................................ 358

7.2.104 Optimum Torque Acceleration/Deceleration For Rigid

Tapping ..................................................................... 359

7.2.105 Arbitrary Speed Threading ........................................ 360

7.2.106 Programs 3................................................................ 360

7.2.107 Machining Quality Level Adjustment.......................... 363

7.2.108 Workpiece Setting Error Compensation 2.................. 363

7.2.109 High-speed Smooth TCP 2........................................ 363

7.2.110 Servo 2...................................................................... 363

7.2.111 Axis Control by PMC 2 .............................................. 364

7.2.112 PMC .......................................................................... 364

7.2.113 Dual Check Safety 2..................................................365

7.2.114 Embedded Macro Functions 2................................... 365

7.2.115 High-speed Position Switch 2.................................... 366

7.2.116 Malfunction Protection............................................... 366

7.2.117 Manual Handle 2....................................................... 366

7.2.118 Synchronous/Composite Control and Superimposed

Control 3 ...................................................................369

7.2.119 Axis Control by PMC 3 .............................................. 369

7.2.120 External Deceleration Positions Expansion ...............370

7.2.121 Display and Edit 5 ..................................................... 370

7.2.122 Tool Management Functions..................................... 373

7.2.123 Tool Life M

estart 2..................................................... 351

anagement 2............................................ 375

B-64487EN/03

c-5

Page 20

Table of Contents

7.2.124 Straightness Compensation 2 ................................... 376

7.2.125 Flexible Synchronous Control 2................................. 377

7.2.126 Programs 4................................................................ 378

7.2.127 Tool Management ..................................................... 378

7.2.128 Manual Liner/Circular Interpolation............................ 378

7.2.129 Canned Cycles for Drilling M Code Output

Improvement ............................................................. 379

7.2.130 Tool Management ..................................................... 379

7.2.131 Machining Condition Selection Functions .................. 379

7.2.132 Dual Check Safety 3..................................................380

7.2.133 FSSB 1...................................................................... 381

7.2.134 Linear Scale with Absolute Address Reference

Position ..................................................................... 381

7.2.135 Pivot Axis Control ...................................................... 381

7.2.136 FSSB 2...................................................................... 381

7.2.137 SERVO GUIDE Mate ................................................ 382

7.2.138 Graphic Display 3...................................................... 382

7.2.139 Embedded Ethernet .................................................. 382

7.2.140 Rotation Area Interference Check 2 ..........................383

7.2.141 Periodical Secondary Pitch Compensation................ 385

7.2.142 Manual Handle Retrace 2.......................................... 386

7.2.143 AI Contour Control 2..................................................386

7.2.144 Cylindrical Interpolation .............................................387

7.2.145 Optimum Torque Acceleration/Deceleration.............. 387

7.2.146 Nano Smoothing .......................................................388

7.2.147 Tool Compensation 3................................................ 388

7.2.148 5-axis Machining Function......................................... 391

7.2.149 FSSB 3...................................................................... 393

7.2.150 Display and Edit 6 ..................................................... 395

7.2.151 High precision oscillation function.............................. 395

7.2.152 Spindle Control Based on Servo Motor/Cs Contour

Control 2 ...................................................................396

7.2.153 Spindle Unit Compensation and Nutating Rotary

H

7.2.154 Graphic Display 4...................................................... 398

ead Tool Length Compensation.............................. 397

8 ALARM LIST........................................................................ 401

8.1 ALARM LIST (CNC)................................................................. 401

8.1.1 Alarms on Program and Operation (PS Alarm),

Background Edit Alarms (BG Alarm), Communication

Alarms (SR Alarm) ....................................................401

8.1.2 Parameter Writing Alarm (SW Alarm)........................ 452

8.1.3 Servo Alarms (SV Alarm) ..........................................452

8.1.4 Overtravel Alarms (OT Alarm)................................... 463

8.1.5 Memory File Alarms (IO Alarm) ................................. 464

8.1.6 Alarms Requiring Power to be Turned Off

(PW Alarm)................................................................ 464

8.1.7 Spindle Alarms (SP Alarm)........................................ 467

8.1.8 Overheat Alarms (OH Alarm) ....................................470

8.1.9 Other Alarms (DS Alarm)........................................... 470

8.1.10 Malfunction Prevention Function Alarms (IE Alarm) ..475

8.2 ALARM LIST (SERIAL SPINDLE) ...........................................477

8.3 SYSTEM ALARMS .................................................................. 495

8.3.1 Overview ................................................................... 495

8.3.2 Operations on the System Alarm Screen................... 496

8.3.3 System Alarms Detected by Hardware...................... 499

8.3.4 System Alarms 114 to 160 (Alarms on the FSSB)..... 500

8.4 SYSTEM ALARMS RELATED TO THE PMC AND I/O LINK... 504

8.5 PMC ALARM MESSAGES ......................................................509

8.6 POWER MATE CNC MANAGER FUNCTION .........................519

8.7 ERROR DISPLAY ON THE SPINDLE AMPLIFIER ................. 520

9 SIGNAL LIST (X/Y, G/F) ...................................................... 523

9.1 LIST OF SIGNALS .................................................................. 525

9.1.1 List of Signals (in Order of Symbols) ......................... 525

9.1.2 List of Signals (in Order of Addresses) ...................... 546

9.2 LIST OF ADDRESSES ............................................................ 567

c-6

Page 21

B-64487EN/03

10 PMC...................................................................................... 597

10.1 OPERATING THE PMC SCREEN........................................... 597

10.1.1 Transition of the PMC Screens.................................. 598

10.2 PMC DIAGNOSIS/MAINTENANCE SCREEN

([PMC MAINTE])...................................................................... 599

10.2.1 Monitoring PMC Signal Status ([STATUS] Screen) ... 599

10.2.2 Checking PMC Alarms ([PMC ALARM] Screen)........ 600

10.2.3 Setting and Displaying Variable Timers ([TIMER]

Screen) .....................................................................600

10.2.4 Setting and Displaying Counter Values ([COUNTR]

Screen) .....................................................................602

10.2.5 Setting and Displaying Keep Relays ([KEEP RELAY]

Screen) .....................................................................603

10.2.6 Setting and Displaying Data Tables ([DATA] Screen) 608

10.2.7 Data Input/Output ([I/O] Screen)................................ 611

10.2.8 Displaying the I/O Device Connection Status

([I/O DEVICE] Screen) ..............................................613

10.2.9 Signal Trace Function ([TRACE] Screen).................. 615

10.2.10 Setting of Trace Parameter ([TRACE SETING]

Screen) .....................................................................615

10.2.11 Execution of Trace .................................................... 617

10.2.12 Monitoring the Network Communication Status and

10.3 LADDER DIAGRAM MONITOR AND EDITOR SCREENS

10.4 PMC CONFIGURATION DATA SETTING SCREENS ([PMC

the PMC Signal Status ([I/O DGN] Screen) ...............619

([PMC LADDER])..................................................................... 620

10.3.1 Displaying a Program List ([LIST] Screen)................. 621

10.3.2 Monitoring Ladder Diagrams ([LADDER] Screen) .....622

10.3.3 Collective Monitor Function ....................................... 623

10.3.4 Editing Ladder Programs........................................... 625

10.3.5 NET EDITOR Screen ................................................ 626

10.3.6 PROGRAM LIST EDITOR Screen............................. 627

10.3.7 Duplicate Coil Check Function ..................................628

CONFIG]) ................................................................................ 629

10.4.1 Displaying and Editing Title Data ([TITLE] Screens).. 630

10.4.1.1 PMC title data display screen.................... 630

10.4.1.2 Title (message) data display screen ..........630

10.4.2 Displaying and Editing Symbol and Comment Data

([SYMBOL] Screens)................................................. 631

10.4.2.1 SYMBOL & COMMENT DATA VIEWER

10.4.2.2 SYMBOL & COMMENT DATA VIEWER

10.4.3 Displaying and Editing Message Data ([MESAGE]

Screens).................................................................... 632

10.4.4 Displaying and Editing I/O Module Allocation Data

([MODULE] Screens) ................................................632

10.4.4.1 I/O MODULE VIEWER screen...................632

10.4.5 Displaying and Editing PMC Settings ([SETING]

Screens).................................................................... 633

10.4.6 Displaying the Status of PMCs and Changing

the Target PMC ([PMC STATUS] Screens)............... 636

10.4.7 Displaying and Setting Parameters for the Online

Function ([ONLINE] Screen)...................................... 636

10.4.8 Displaying and Setting System Parameters

([SYSTEM PARAM] Screens) ...................................637

10.4.9 Displaying and Setting Configuration Parameters

([CONFIG PARAM] Screens) .................................... 639

10.4.9.1 MENU screen............................................ 639

10.4.9.2 CNC-PMC INTERFACE screen................. 639

10.4.9.3 MACHINE SIGNAL INTERFACE screen ... 640

10.4.9.4 LADDER EXECUTION screen...................641

10.4.9.5 PMC MEMORY SETTING screen ............. 642

10.4.10 Displaying and Editing I/O Link i Assignment Data

([I/O LINK I] Screen).................................................. 642

screen (basic f

screen (extended format)........................... 631

ormat)................................. 631

c-7

Page 22

Table of Contents

10.4.10.1 Displaying group information of I/O Link i

10.4.10.2 Displaying slot information of I/O Link i

10.4.10.3 Displaying title information of I/O Link i

10.4.10.4 Setting enabled groups of I/O Link i

10.5 FUNCTIONAL INSTRUCTIONS.............................................. 646

10.5.1 List of Functional Instructions.................................... 646

10.5.2 Details of Functional Instructions............................... 650

10.5.2.1 Timer......................................................... 650

10.5.2.2 Counter ..................................................... 650

10.5.2.3 Data transfer.............................................. 651

10.5.2.4 Table data .................................................653

10.5.2.5 Comparison............................................... 655

10.5.2.6 Bit operation .............................................. 657

10.5.2.7 Code conversion........................................663

10.5.2.8 Operation instruction .................................665

10.5.2.9 CNC functions ...........................................668

10.5.2.10 Program control......................................... 669

10.5.2.11 Rotation control ......................................... 671

10.5.3 Functional Instructions (Arranged in Sequence of

SUB No.)................................................................... 671

10.6 I/O MODULE ASSIGNMENT NAMES (I/O Link) ...................... 676

assignment data ........................................ 643

assignment data ........................................ 644

assignment data ........................................ 644

assignment data (assignment selection

function)..................................................... 645

11 ETHERNET .......................................................................... 679

11.1 OVERVIEW ............................................................................. 679

11.2 ETHERNET MOUNTING LOCATIONS ................................... 679

11.3 LIST OF ETHERNET-RELATED SCREENS ...........................679

11.3.1 Setting and Maintenance (SYSTEM key) .................. 679

11.3.2 File Operation (PROG Key)....................................... 680

11.3.3 Error Message (MESSAGE Key)............................... 680

11.4 EMBEDDED ETHERNET ........................................................681

11.4.1 Parameter Setting Screen ......................................... 681

11.4.2 FTP File Transfer Operation Screen.......................... 685

11.4.3 Maintenance Screen for Embedded Ethernet

Function .................................................................... 686

11.4.4 Log Screen of the Embedded Ethernet Function....... 690

11.5 ETHERNET OPTIONAL BOARD............................................. 695

11.5.1 Parameter Setting Screen ......................................... 695

11.5.2 Fast Data Server Operation Screen .......................... 702

11.5.3 Machine Remote Diagnosis Operation Screens........ 705

11.5.4 Maintenance Screen (for Data Server Function)........708

11.5.5 Maintenance Screen ................................................. 709

11.5.6 Error Message Screen ..............................................712

11.6 TROUBLESHOOTING............................................................. 718

11.6.1 Confirmation of Connection with the Hub Unit........... 718

11.6.2 Confirmation of Each Parameter Setting ................... 718

11.6.3 Confirmation of Communications Based on the Ping

Command.................................................................. 718

12 POWER MATE CNC MANAGER FUNCTION ..................... 721

12.1 SCREEN DISPLAY.................................................................. 721

12.2 PARAMETERS........................................................................ 725

12.3 WARNING............................................................................... 726

13 DIAGNOSIS INFORMATION ............................................... 727

13.1 DIAGNOSIS FUNCTION ......................................................... 727

13.1.1 Displaying Diagnosis Screen..................................... 727

13.2 LIST OF DIAGNOSIS INFORMATION (DGN) ......................... 727

13.2.1 Display of Causes of Instructions not Functioning ..... 727

13.2.2 State of TH Alarm...................................................... 727

13.2.3 Details of Serial Pulsecoder ......................................728

13.2.4 Details of Separate Serial Pulsecoder Alarms........... 729

c-8

Page 23

13.2.5 Details of Invalid Servo Parameter Alarms (on

the CNC Side) ........................................................... 729

13.2.6 Position Error Amount ............................................... 730

13.2.7 Machine Position....................................................... 730

13.2.8 Distance from the end of the deceleration dog to

the first grid point....................................................... 730

13.2.9 Reference Counter.................................................... 730

13.2.10 Machine Coordinates on the Angular/Cartesian Axes730

13.2.11 Servo Motor Temperature Information....................... 730

13.2.12 Cause that Sets Parameter APZ (No. 1815#4) to 0... 731

13.2.13 Details of Invalid Servo Parameter Setting Alarms

(on the Servo Side) ...................................................731

13.2.14 Detailed Descriptions about Invalid Servo Parameter

Setting Alarms........................................................... 732

13.2.15 Diagnosis Data Related to the Inductosyn Absolute

Position Detector....................................................... 740

13.2.16 Diagnosis Data Related to the Serial Spindles .......... 740

13.2.17 Diagnosis Data Related to Rigid Tapping.................. 741

13.2.18 Diagnosis Data Related to the Small-hole Peck

Drilling Cycle ............................................................. 742

13.2.19 Diagnosis Data Related to the Dual Position

Feedback Function.................................................... 743

13.2.20 Automatic Alteration of Tool Position Compensation. 743

13.2.21 Data for Adjusting the Compensation of the Start

Position of Thread Cutting when the Spindle Speed

Is Changed................................................................ 744

13.2.22 State of High-speed HRV Current Control................. 744

13.2.23 Thermal Growth Compensation along Tool Vector.... 744

13.2.24 Spindle Error and Warning States .............................744

13.2.25 Digital Servo (2) ........................................................ 745

13.2.26 Automatic Data Backup ............................................. 745

13.2.27 Fan Rotation Speed .................................................. 746

13.2.28 Custom Macro / Execution Macro / Auxiliary Macro ..746

13.2.29 Spindle Revolution Number History Function ............746

13.2.30 Servo Leakage Detection Function............................ 746

13.2.31 Spindle Leakage Detection Function ......................... 747

13.2.32 Internal cooling fan for the servo amplifier................. 748

13.2.33 Radiator cooling fan for servo amplifier ..................... 748

13.2.34 Internal cooling fan for common power supply........... 748

13.2.35 Radiator cooling fan for common power supply......... 749

13.2.36 Internal cooling fan

13.2.37 Radiator cooling fan for spindle amplifier................... 750

13.2.38 Internal cooling fan for common power supply........... 750

13.2.39 Radiator cooling fan for common power supply......... 750

13.2.40 Tool offset conversion (G44.1) ..................................751

13.2.41 Built-in 3D Interference Check................................... 753

13.2.42 Detector battery exhaustion....................................... 753

13.2.43 Diagnosis Data Related to Axis Synchronous

Control ......................................................................753

13.2.44 Diagnosis Data Related to Synchronous/Composite

Control ......................................................................753

13.2.45 Diagnosis Data Related to Axis Synchronous

Control 2 ...................................................................754

13.2.46 Detailed Descriptions about Invalid FSSB Setting

Alarms....................................................................... 754

13.2.47 Absolute Position Detection....................................... 758

13.2.48 Diagnosis Data Related to Linear Scale with

Absolute Address Reference Marks.......................... 758

13.2.49 Wrong Operation Prevention Function ...................... 759

13.2.50 Flexible Path Axis Assignment Information................ 759

13.2.51 Total Current Actual Power Consumption of All

Servo/Spindle............................................................ 760

13.2.52 Chopping................................................................... 761

13.2.53 Communication ......................................................... 761

13.2.54 Total Current Actual Power Consumption of All

Servo/Spindle............................................................ 762

for spindle amplifier ....................749

B-64487EN/03

c-9

Page 24

Table of Contents

13.2.55 Current Actual Power Consumption of Each Servo ... 762

13.2.56 Current Actual Power Consumption of Each Spindle. 762

13.2.57 Cumulative Values of Total Power Consumption of

All Servo/Spindle....................................................... 762

13.2.58 Cumulative Power Consumption of Each Servo........ 763

13.2.59 Cumulative Power Consumption of Each Spindle...... 763

13.2.60 Interpolation State..................................................... 763

13.2.61 3-dimensional Machine Position Compensation ........ 763

13.2.62 Automatic Phase Synchronization for Flexible

Synchronous Control................................................. 764

14 HISTORY FUNCTION .......................................................... 765

14.1 OVERVIEW OF HISTORY FUNCTION ................................... 765

14.2 ALARM HISTORY ................................................................... 765

14.2.1 Screen Display .......................................................... 765

14.2.2 Erasing History Data from the ALARM HISTORY

Screen....................................................................... 766

14.2.3 External/Macro Alarm Display................................... 766

14.3 EXTERNAL OPERATOR MESSAGE HISTORY ..................... 767

14.3.1 Screen Display .......................................................... 767

14.3.2 Erasing History Data from the External Operator

Message History Screen ........................................... 767

14.3.3 Parameter Setting ..................................................... 768

14.4 OPERATION HISTORY........................................................... 768

14.4.1 Parameter Setting ..................................................... 768

14.4.2 Screen Display .......................................................... 770

14.4.3 Inputting and Outputting Operation History Data ....... 772

14.4.3.1 Outputting operation history data............... 772

14.4.4 History Data Not Displayed on the Screen ................ 772

14.4.5 Erasing History Data from the Operation History

14.5 SELECTING OPERATION HISTORY SIGNALS .....................773

14.6 OUTPUTTING ALL HISTORY DATA....................................... 775

Screen....................................................................... 773

15 WAVEFORM DIAGNOSIS ................................................... 777

15.1 WAVEFORM DIAGNOSIS PARAMETER SCREEN................ 777

15.1.1 Tracing Data..............................................................778

15.1.2 Outputting Data......................................................... 779

16 DIGITAL SERVO.................................................................. 783

16.1 INITIAL SETTING SERVO PARAMETERS............................. 783

16.2 FSSB SETTING SCREEN ....................................................... 793

16.2.1 FSSB Display and Setting Screen............................. 793

16.3 SERVO TUNING SCREEN...................................................... 801

16.3.1 Parameter Setting ..................................................... 801

16.3.2 Displaying Servo Tuning Screen ...............................801

16.4 αi SERVO INFORMATION SCREEN ...................................... 801

16.5 αi SERVO WARNING INTERFACE ........................................ 805

16.6 ADJUSTING REFERENCE POSITION (DOG METHOD)........ 806

16.7 REFERENCE POSITION SETTING WITHOUT DOGS ........... 808

17 AC SPINDLE........................................................................ 811

17.1 SERIAL INTERFACE AC SPINDLE......................................... 811

17.1.1 Overview of Spindle Control...................................... 811

17.1.1.1 Method A of gear change for M series

17.1.1.2 Method B of gear change for M series

17.1.1.3 T series .....................................................812

17.1.2 Automatic Setting of Standard Parameters................812

17.1.3 Spindle Setting and Tuning Screen ........................... 814

17.1.3.1 Display method.......................................... 814

17.1.3.2 Spindle setting screen ............................... 814

17.1.3.3 Spindle tuning screen................................ 815

17.1.3.4 Spindle monitor screen.............................. 817

17.1.3.5 Correspondence between operation mode

17.1.4 Warning Interface...................................................... 821

(parameter SGB (No. 3705#2)=0) .............811

(bit 2 (SGB) of parameter No. 3705 is 1) ... 812

and parameters on spindle tuning screen.. 819

c-10

Page 25

17.1.5 Spindle Information Screen ....................................... 823

B-64487EN/03

18 MAINTENANCE INFORMATION......................................... 827

18.1 SCREEN DISPLAY AT POWER ON ....................................... 827

18.1.1 Display until the CNC Starts...................................... 827

18.1.2 IPL Display................................................................ 827

18.1.3 System Label Check Error......................................... 828

18.2 SYSTEM CONFIGURATION SCREEN DISPLAY ...................828

18.2.1 Hardware Configuration Screen ................................829

18.2.2 Software Configuration Screen.................................. 830

18.3 CNC STATE DISPLAY ............................................................833

18.4 PERIODICAL MAINTENANCE SCREEN ................................835

18.4.1 Overview ................................................................... 835

18.4.1.1 Screen configuration.................................. 835

18.4.1.2 Procedure.................................................. 836

18.4.2 Screen Display and Setting ....................................... 836

18.4.2.1 Status screen display and setting.............. 836

18.4.2.2 Setting screen display and setting .............841

18.4.3 Registered Data Input/Output.................................... 844

18.4.3.1 Data output................................................ 844

18.4.3.2 Data input.................................................. 845

18.4.4 Parameter ................................................................. 845

18.4.5 Warning..................................................................... 845

18.5 MAINTENANCE INFORMATION SCREEN............................. 846

18.5.1 Overview ................................................................... 846

18.5.2 Screen Display and Operation................................... 846

18.5.2.1 Screen display........................................... 846

18.5.2.2 Edit operation ............................................ 847

18.5.2.3 Operation of soft keys................................ 848

18.5.2.4 Input/output of maintenance information.... 849

18.5.2.5 Half-size kana input................................... 850

18.5.3 Parameter ................................................................. 851

18.5.4 Warning..................................................................... 852

19 MAINTENANCE FUNCTION ............................................... 853

19.1 INPUT AND OUTPUT OF DATA .............................................853