Page 1

FANUC Series 30+-MODEL B

FANUC Series 31+-MODEL B

FANUC Series 32+-MODEL B

PARAMETER MANUAL

B-64490EN/05

Page 2

• No part of this manual may be reproduced in any form.

• All specifications and designs are subject to change without notice.

The products in this manual are controlled based on Japan’s “Foreign Exchange and

Foreign Trade Law”. The export of Series 30i-B, Series 31i-B5 from Japan is subject to an

export license by the government of Japan. Other models in this manual may also be

subject to export controls.

Further, re-export to another country may be subject to the license of the government of

the country from where the product is re-exported. Furthermore, the product may also be

controlled by re-export regulations of the United States government.

Should you wish to export or re-export these products, please contact FANUC for advice.

In this manual we have tried as much as possible to describe all the various matters.

However, we cannot describe all the matters which must not be done, or which cannot be

done, because there are so many possibilities.

Therefore, matters which are not especially described as possible in this manual should be

regarded as ”impossible”.

Page 3

B-64490EN/05 DEFINITION OF WARNING, CAUTION, AND NOTE

DEFINITION OF WARNING, CAUTION, AND NOTE

This manual includes safety precautions for protecting the user and preventing damage to the machine.

Precautions are classified into Warning and Caution according to their bearing on safety. Also,

supplementary information is described as a Note. Read the Warning, Caution, and Note thoroughly

before attempting to use the machine.

WARNING

Applied when there is a danger of the user being injured or when there is a

danger of both the user being injured and the equipment being damaged if the

approved procedure is not observed.

CAUTION

Applied when there is a danger of the equipment being damaged, if the

approved procedure is not observed.

NOTE

The Note is used to indicate supplementary information other than Warning and

Caution.

• Read this manual carefully, and store it in a safe place.

s-1

Page 4

Page 5

B-64490EN/05 PREFACE

PREFACE

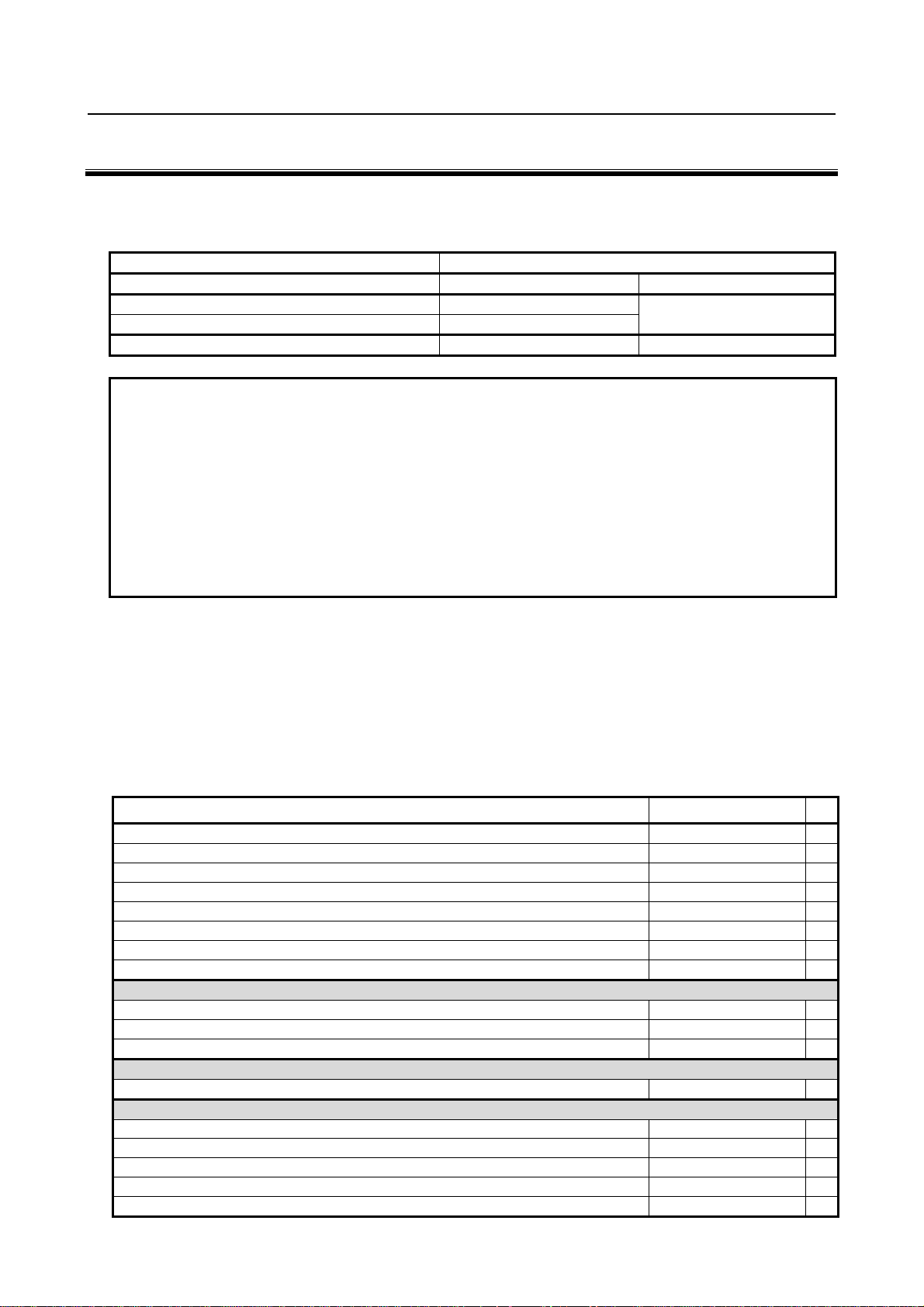

Applicable models

The models covered by this manual, and their abbreviations are :

Model name Abbreviation

FANUC Series 30i–B 30i –B Series 30i

FANUC Series 31i–B 31i –B

FANUC Series 31i–B5 31i –B5

FANUC Series 32i–B 32i –B Series 32i

NOTE

1 For an explanatory purpose, the following descriptions may be used according to

the types of path control used:

- T series: For the lathe system

- M series: For the machining center system

2 Unless otherwise noted, the model names 31i-B, 31i-B5, and 32i-B are

collectively referred to as 30i. However, this convention is not necessarily

observed when item 3 below is applicable.

3 Some functions described in this manual may not be applied to some products.

For details, refer to the DESCRIPTIONS (B-64482EN).

Related manuals of

Series 30i- MODEL B

Series 31i- MODEL B

Series 32i- MODEL B

The following table lists the manuals related to Series 30i-B, Series 31i-B, Series 32i-B. This manual is

indicated by an asterisk(*).

Table 1 Related manuals

Manual name Specification number

DESCRIPTIONS B-64482EN

CONNECTION MANUAL (HARDWARE) B-64483EN

CONNECTION MANUAL (FUNCTION) B-64483EN-1

OPERATOR’S MANUAL (Common to Lathe System/Machining Center System) B-64484EN

OPERATOR’S MANUAL (For Lathe System) B-64484EN-1

OPERATOR’S MANUAL (For Machining Center System) B-64484EN-2

MAINTENANCE MANUAL B-64485EN

PARAMETER MANUAL B-64490EN *

Programming

Macro Executor PROGRAMMING MANUAL B-63943EN-2

Macro Compiler PROGRAMMING MANUAL B-66263EN

C Language Executor PROGRAMMING MANUAL B-63943EN-3

PMC

PMC PROGRAMMING MANUAL B-64513EN

Network

PROFIBUS-DP Board CONNECTION MANUAL B-63993EN

Industrial Ethernet CONNECTION MANUAL B-64013EN

Fast Ethernet / Fast Data Server OPERATOR’S MANUAL B-64014EN

DeviceNet Board CONNECTION MANUAL B-64043EN

FL-net Board CONNECTION MANUAL B-64163EN

p-1

Series 31i

Page 6

PREFACE B-64490EN/05

Manual name Specification number

CC-Link Board CONNECTION MANUAL B-64463EN

Operation guidance function

MANUAL GUIDE i

(Common to Lathe System/Machining Center System) OPERATOR’S MANUAL

MANUAL GUIDE i (For Machining Center System) OPERATOR’S MANUAL

MANUAL GUIDE i (Set-up Guidance Functions) OPERATOR’S MANUAL

Dual Check Safety

Dual Check Safety CONNECTION MANUAL B-64483EN-2

B-63874EN

B-63874EN-2

B-63874EN-1

Related manuals of SERVO MOTOR αi/βi series

The following table lists the manuals related to SERVO MOTOR αi/βi series

Table 2 Related manuals

Manual name Specification number

FANUC AC SERVO MOTOR αi series DESCRIPTIONS

FANUC AC SERVO MOTOR αi series / FANUC AC SERVO MOTOR βi series /

FANUC LINEAR MOTOR LiS series /

FANUC SYNCHRONOUS BUILT-IN SERVO MOTOR DiS series

PARAMETER MANUAL

FANUC AC SPINDLE MOTOR αi series DESCRIPTIONS

FANUC AC SPINDLE MOTOR αi/βi series, BUILT-IN SPINDLE MOTOR Bi series

PARAMETER MANUAL

FANUC SERVO AMPLIFIER αi series DESCRIPTIONS

FANUC AC SERVO MOTOR αi series / FANUC AC SPINDLE MOTOR αi series /

FANUC SERVO AMPLIFIER αi series MAINTENANCE MANUAL

CNCs that are described in this manual can be connected to following servo motors and spindle motors.

This manual mainly assumes that the FANUC SERVO MOTOR αi series of servo motor is used. For

servo motor and spindle information, refer to the manuals for the servo motor and spindle that are actually

connected.

B-65262EN

B-65270EN

B-65272EN

B-65280EN

B-65282EN

B-65285EN

p-2

Page 7

B-64490EN/05 TABLE OF CONTENTS

TABLE OF CONTENTS

DEFINITION OF WARNING, CAUTION, AND NOTE................................. s-1

PREFACE....................................................................................................p-1

1 DISPLAYING PARAMETERS.................................................................1

2 SETTING PARAMETERS FROM MDI....................................................2

3 INPUTTING AND OUTPUTTING PARAMETERS THROUGH THE

RS232C INTERFACE..............................................................................4

3.1 OUTPUTTING PARAMETERS THROUGH THE RS232C INTERFACE.......4

3.2 INPUTTING PARAMETERS THROUGH THE RS232C INTERFACE...........5

3.3 I/O FORMATS ...............................................................................................6

3.3.1 Keywords .................................................................................................................6

3.3.2 Inch/Metric Switching..............................................................................................7

3.3.3 Bit Format.................................................................................................................7

3.3.4 Bit Machine Group Format ......................................................................................7

3.3.5 Bit Path Format ........................................................................................................8

3.3.6 Bit Axis Format........................................................................................................8

3.3.7 Bit Spindle Format ...................................................................................................9

3.3.8 Byte/Word/Two-Word Format.................................................................................9

3.3.9 Byte/Word/Two-Word Machine Group Format.......................................................9

3.3.10 Byte/Word/Two-Word Path Format.......................................................................10

3.3.11 Byte/Word/Two-Word Axis Format ......................................................................10

3.3.12 Byte/Word/Two-Word Spindle Format..................................................................11

3.3.13 Real Number Format..............................................................................................11

3.3.14 Real Number Machine Group Format....................................................................12

3.3.15 Real Number Path Format......................................................................................12

3.3.16 Real Number Axis Format......................................................................................13

3.3.17 Real Number Spindle Format.................................................................................13

3.3.18 Start and End of a Record.......................................................................................14

4 DESCRIPTION OF PARAMETERS......................................................15

4.1 INPUT TYPE................................................................................................15

4.2 DATA TYPE.................................................................................................15

4.3 REPRESENTATION OF PARAMETERS ....................................................16

4.4 STANDARD PARAMETER SETTING TABLES...........................................17

4.5 PARAMETERS OF SETTING......................................................................20

4.6 PARAMETERS OF RS232C INTERFACE ..................................................22

4.6.1 Parameters Common to All Channels ....................................................................23

4.6.2 Parameters of Channel 1 (I/O CHANNEL=0) .......................................................27

4.6.3 Parameters of Channel 1 (I/O CHANNEL=1) .......................................................28

4.6.4 Parameters of Channel 2 (I/O CHANNEL=2) .......................................................29

4.7 PARAMETERS OF CNC SCREEN DISPLAY FUNCTIONS........................30

4.8 PARAMETERS OF ETHERNET/DATA SERVER FUNCTIONS..................30

4.9 PARAMETERS OF POWER MATE CNC....................................................34

4.10 PARAMETERS OF ETHERNET/ INDUSTRIAL ETHERNET FUNCTIONS.35

4.11 PARAMETERS OF SYSTEM CONFIGURATION .......................................37

c-1

Page 8

TABLE OF CONTENTS B-64490EN/05

4.12 PARAMETERS OF AXIS CONTROL/INCREMENT SYSTEM (1 OF 3) ......39

4.13 PARAMETERS OF COORDINATE SYSTEM (1 OF 2)...............................50

4.14 PARAMETERS OF STORED STROKE CHECK.........................................57

4.15 PARAMETERS OF THE CHUCK AND TAIL STOCK BARRIER.................64

4.16 PARAMETERS OF FEEDRATE..................................................................68

4.17 PARAMETERS OF ACCELERATION/DECELERATION CONTROL..........82

4.18 PARAMETERS OF SERVO (1 OF 2)..........................................................97

4.19 PARAMETERS OF DI/DO (1 OF 2)...........................................................133

4.20 PARAMETERS OF DISPLAY AND EDIT (1 OF 6)....................................145

4.21 PARAMETERS OF PROGRAMS (1 OF 4)................................................178

4.22 PARAMETERS OF PITCH ERROR COMPENSATION ............................194

4.23 PARAMETERS OF SPINDLE CONTROL .................................................202

4.24 PARAMETERS OF TOOL COMPENSATION (1 OF 3).............................247

4.25 PARAMETERS OF CANNED CYCLES .....................................................270

4.25.1 Parameters of Canned Cycle for Drilling (1 of 2)................................................270

4.25.2 Parameters of Thread Cutting Cycle ....................................................................278

4.25.3 Parameters of Multiple Repetitive Canned Cycle ................................................279

4.25.4 Parameters of Canned Cycle for Drilling (2 of 2)................................................283

4.25.5 Parameters of Canned Cycle for Grinding (for Grinding Machine) (1 of 2)........288

4.26 PARAMETERS OF RIGID TAPPING ........................................................291

4.27 PARAMETERS OF SCALING/COORDINATE ROTATION.......................305

4.28 PARAMETERS OF SINGLE DIRECTION POSITIONING.........................307

4.29 PARAMETERS OF POLAR COORDINATE INTERPOLATION ................308

4.30 PARAMETERS OF NORMAL DIRECTION CONTROL.............................309

4.31 PARAMETERS OF INDEX TABLE INDEXING..........................................311

4.32 PARAMETERS OF INVOLUTE INTERPOLATION ...................................314

4.33 PARAMETERS OF EXPONENTIAL INTERPOLATION ............................315

4.34 PARAMETERS OF FLEXIBLE SYNCHRONIZATION CONTROL

(1 OF 2).....................................................................................................316

4.35 PARAMETERS OF STRAIGHTNESS COMPENSATION (1 OF 2)...........319

4.36 PARAMETERS OF INCLINATION COMPENSATION ..............................322

4.37 PARAMETERS OF CUSTOM MACROS...................................................324

4.38 PARAMETERS OF PATTERN DATA INPUT............................................346

4.39 PARAMETERS OF POSITIONING BY OPTIMUM ACCELERATION.......347

4.40 PARAMETERS OF SKIP FUNCTION .......................................................349

4.41 PARAMETERS OF EXTERNAL DATA INPUT/OUTPUT ..........................360

4.42 PARAMETERS OF FINE TORQUE SENSING..........................................362

4.43 PARAMETERS OF MANUAL HANDLE RETRACE (1 OF 2) ....................363

4.44 PARAMETERS OF GRAPHIC DISPLAY (1 OF 4) ....................................369

4.45 PARAMETERS OF SCREEN DISPLAY COLORS (1 OF 2)......................371

4.46 PARAMETERS OF RUN HOUR AND PARTS COUNT DISPLAY.............372

4.47 PARAMETERS OF TOOL MANAGEMENT FUNCTIONS (1 OF 2)...........375

4.48 PARAMETERS OF TOOL LIFE MANAGEMENT (1 OF 2)........................376

4.49 PARAMETERS OF POSITION SWITCH FUNCTIONS.............................384

4.50 PARAMETERS OF MANUAL OPERATION AND AUTOMATIC

OPERATION (1 OF 2)...............................................................................387

4.51 PARAMETERS OF MANUAL HANDLE (1 OF 2) ......................................390

c-2

Page 9

B-64490EN/05 TABLE OF CONTENTS

4.52 PARAMETERS OF REFERENCE POINT WITH MECHANICAL

STOPPER .................................................................................................395

4.53 PARAMETERS OF SOFTWARE OPERATOR'S PANEL..........................397

4.54 PARAMETERS OF PROGRAM RESTART (1 OF 2).................................400

4.55 PARAMETERS OF HIGH-SPEED CYCLE CUTTING...............................403

4.56 PARAMETERS OF ROTARY TABLE DYNAMIC FIXTURE OFFSET.......411

4.57 PARAMETERS OF POLYGON TURNING................................................413

4.58 PARAMETERS OF THE ELECTRONIC GEAR BOX (EGB) .....................421

4.59 PARAMETERS OF PMC AXIS CONTROL (1 OF 4).................................431

4.60 PARAMETERS OF MULTI-PATH CONTROL...........................................441

4.61 PARAMETERS OF INTERFERENCE CHECK BETWEEN PATHS ..........444

4.62 PARAMETERS OF SYNCHRONOUS/COMPOSITE CONTROL AND

SUPERIMPOSED CONTROL (1 OF 3).....................................................448

4.63 PARAMETERS OF ANGULAR AXIS CONTROL......................................462

4.64 PARAMETERS OF AXIS SYNCHRONOUS CONTROL ...........................465

4.65 PARAMETERS OF SEQUENCE NUMBER COMPARISON AND STOP..474

4.66 PARAMETERS OF CHOPPING/HIGH PRECISION OSCILLATION

FUNCTION................................................................................................475

4.67 PARAMETERS OF AI CONTOUR CONTROL (1 OF 2)............................477

4.68 PARAMETERS OF HIGH-SPEED POSITION SWITCH (1 OF 2) .............480

4.69 OTHER PARAMETERS ............................................................................484

4.70 PARAMETERS OF MAINTENANCE.........................................................489

4.71 PARAMETERS OF THE INCORRECT OPERATION PREVENTION

FUNCTION................................................................................................493

4.72 PARAMETERS OF AUTOMATIC DATA BACKUP....................................501

4.73 PARAMETERS OF AXIS CONTROL ........................................................502

4.74 PARAMETERS OF PARALLEL AXIS CONTROL .....................................504

4.75 PARAMETERS OF AXIS SWITCHING .....................................................505

4.76 PARAMETERS OF PMC AXIS CONTROL (2 OF 4).................................506

4.77 PARAMETERS OF CANNED CYCLE FOR GRINDING (FOR GRINDING

MACHINE) (2 OF 2)...................................................................................506

4.78 PARAMETERS OF SCREEN DISPLAY COLORS (2 OF 2)......................506

4.79 PARAMETERS OF MANUAL OPERATION AND AUTOMATIC

OPERATION (2 OF 2)...............................................................................507

4.80 PARAMETERS OF HIGH-SPEED SMOOTH TCP (1 OF 2)......................508

4.81 PARAMETERS OF DUAL CHECK SAFETY (1 OF 2)...............................509

4.82 PARAMETERS OF WAVEFORM DIAGNOSIS.........................................509

4.83 PARAMETERS OF TROUBLE DIAGNOSIS FUNCTION..........................510

4.84 LATHE/MACHINING CENTER G CODE SYSTEM SWITCHING

FUNCTION (1 OF 2)..................................................................................510

4.85 PARAMETERS OF THREE-DIMENSIONAL ROTARY ERROR

COMPENSATION......................................................................................510

4.86 PARAMETERS OF 3-DIMENSIONAL ERROR COMPENSATION ...........515

4.87 PARAMETERS OF 3-DIMENSIONAL MACHINE POSITION

COMPENSATION......................................................................................517

c-3

Page 10

TABLE OF CONTENTS B-64490EN/05

4.88 PARAMETERS OF INTERFERENCE CHECK FOR ROTARY AREA

(1 OF 2).....................................................................................................520

4.89 PARAMETERS OF BUILT-IN 3D INTERFERENCE CHECK ....................524

4.90 PARAMETERS OF SPINDLE CONTROL WITH SERVO MOTOR

(1 OF 2).....................................................................................................558

4.91 PARAMETERS OF PATH TABLE OPERATION.......................................566

4.92 PARAMETERS OF WORKPIECE SETTING ERROR COMPENSATION

(1 OF 2).....................................................................................................569

4.93 PARAMETERS OF LINEAR INCLINATION COMPENSATION

FUNCTION................................................................................................571

4.94 PARAMETERS OF TILTED WORKING PLANE INDEXING COMMAND .572

4.95 PARAMETERS OF AXIS CONTROL/INCREMENT SYSTEM (2 OF 3) ....573

4.96 PARAMETERS OF DI/DO (2 OF 2)...........................................................574

4.97 PARAMETERS OF FEEDRATE CONTROL AND

ACCELERATION/DECELERATION CONTROL........................................575

4.98 PARAMETERS OF PROGRAM RESTART (2 OF 2).................................576

4.99 PARAMETERS OF TOOL CENTER POINT CONTROL...........................577

4.100 PARAMETERS OF MACHINE CONFIGURATION SELECTING

FUNCTION................................................................................................579

4.101 PARAMETERS OF COORDINATE SYSTEM (2 OF 2).............................581

4.102 PARAMETERS OF SYNCHRONOUS/COMPOSITE CONTROL AND

SUPERIMPOSED CONTROL (2 OF 3).....................................................584

4.103 PARAMETERS OF PROGRAMS (2 OF 4)................................................585

4.104 PARAMETERS OF DISPLAY AND EDIT (2 OF 6)....................................585

4.105 PARAMETERS OF EMBEDDED MACRO (1 OF 2)..................................592

4.106 PARAMETERS OF DISPLAY AND EDIT (3 OF 6)....................................592

4.107 PARAMETERS OF GRAPHIC DISPLAY (2 OF 4) ....................................596

4.108 PARAMETERS OF DISPLAY AND EDIT (4 OF 6)....................................600

4.109 PARAMETERS OF TOOL COMPENSATION (2 OF 3).............................616

4.110 PARAMETERS OF OPTIMUM TORQUE

ACCELERATION/DECELERATION FOR RIGID TAPPING......................619

4.111 PARAMETERS OF ARBITRARY SPEED THREADING............................622

4.112 PARAMETERS OF PROGRAMS (3 OF 4)................................................625

4.113 PARAMETERS OF MACHINING QUALITY LEVEL ADJUSTMENT.........642

4.114 PARAMETERS OF WORKPIECE SETTING ERROR COMPENSATION

(2 OF 2).....................................................................................................643

4.115 PARAMETERS OF HIGH-SPEED SMOOTH TCP (2 OF 2)......................645

4.116 PARAMETERS OF SERVO (2 OF 2)........................................................646

4.117 PARAMETERS OF PMC AXIS CONTROL (3 OF 4).................................649

4.118 PARAMETERS OF PMC...........................................................................655

4.119 PARAMETERS OF EMBEDDED MACRO (2 OF 2)..................................669

4.120 PARAMETERS OF HIGH-SPEED POSITION SWITCH (2 OF 2) .............671

4.121 PARAMETERS OF MALFUNCTION PROTECTION.................................672

4.122 PARAMETERS OF MANUAL HANDLE (2 OF 2) ......................................672

4.123 PARAMETERS OF SYNCHRONOUS/COMPOSITE CONTROL AND

SUPERIMPOSED CONTROL (3 OF 3).....................................................680

c-4

Page 11

B-64490EN/05 TABLE OF CONTENTS

4.124 PARAMETERS OF PMC AXIS CONTROL (4 OF 4).................................680

4.125 PARAMETERS OF EXTERNAL DECELERATION POSITIONS

EXPANSION..............................................................................................681

4.126 PARAMETERS OF DISPLAY AND EDIT (5 OF 6)....................................684

4.127 PARAMETERS OF TOOL MANAGEMENT FUNCTIONS (2 OF 2)...........693

4.128 PARAMETERS OF TOOL LIFE MANAGEMENT (2 OF 2)........................704

4.129 PARAMETERS OF HYPOTHETICAL LINEAR AXIS CONTROL..............705

4.130 PARAMETERS OF STRAIGHTNESS COMPENSATION (2 OF 2)...........708

4.131 PARAMETERS OF FLEXIBLE SYNCHRONIZATION CONTROL

(2 OF 2).....................................................................................................710

4.132 PARAMETERS OF PROGRAMS (4 OF 4)................................................713

4.133 PARAMETERS OF MANUAL LINER/CIRCULAR INTERPOLATION........714

4.134 PARAMETERS OF CANNED CYCLES FOR DRILLING M CODE

OUTPUT IMPROVEMENT ........................................................................715

4.135 PARAMETERS OF THE MACHINING CONDITION SELECTION

FUNCTION................................................................................................716

4.136 PARAMETERS OF PARAMETER CHECK SUM FUNCTION...................721

4.137 PARAMETERS OF DUAL CHECK SAFETY (2 OF 2)...............................723

4.138 PARAMETERS OF SAFETY FUNCTION BY FL-net.................................724

4.139 PARAMETERS OF AXIS CONTROL/INCREMENT SYSTEM (3 OF 3) ....725

4.140 PARAMETERS OF LINEAR SCALE WITH ABSOLUTE ADDRESS

REFERENCE POSITION ..........................................................................725

4.141 PARAMETERS OF PIVOT AXIS CONTROL.............................................726

4.142 PARAMETERS OF FSSB (1 OF 2) ...........................................................729

4.143 PARAMETERS OF SERVO GUIDE Mate.................................................729

4.144 PARAMETERS OF GRAPHIC DISPLAY (3 OF 4) ....................................730

4.145 PARAMETERS OF EMBEDDED ETHERNET...........................................731

4.146 PARAMETERS OF INTERFERENCE CHECK FOR ROTARY AREA

(2 OF 2).....................................................................................................734

4.147 PARAMETERS OF PERIODICAL SECONDARY PITCH

COMPENSATION......................................................................................751

4.148 PARAMETERS OF MANUAL HANDLE RETRACE (2 OF 2) ....................754

4.149 PARAMETERS OF AI CONTOUR CONTROL (2 OF 2)............................756

4.150 PARAMETERS OF CYLINDRICAL INTERPOLATION..............................758

4.151 PARAMETERS OF OPTIMAL TORQUE

ACCELERATION/DECELERATION..........................................................759

4.152 PARAMETERS OF NANO SMOOTHING..................................................762

4.153 PARAMETERS OF TOOL COMPENSATION (3 OF 3).............................764

4.154 PARAMETERS OF 5-AXIS MACHINING FUNCTION...............................771

4.155 PARAMETERS OF FSSB (2 OF 2) ...........................................................791

4.156 PARAMETERS OF DISPLAY AND EDIT (6 OF 6)....................................799

4.157 LATHE/MACHINING CENTER G CODE SYSTEM SWITCHING

FUNCTION (2 OF 2)..................................................................................810

4.158 PARAMETERS OF HIGH PRECISION OSCILLATION FUNCTION .........813

4.159 PARAMETERS OF SPINDLE CONTROL WITH SERVO MOTOR

(2 OF 2).....................................................................................................815

c-5

Page 12

TABLE OF CONTENTS B-64490EN/05

4.160 PARAMETERS OF SPINDLE UNIT COMPENSATION AND NUTATING

ROTARY HEAD TOOL LENGTH COMPENSATION.................................817

4.161 PARAMETERS OF GRAPHIC DISPLAY (4 OF 4) ....................................819

APPENDIX

A CHARACTER CODE LIST..................................................................837

c-6

Page 13

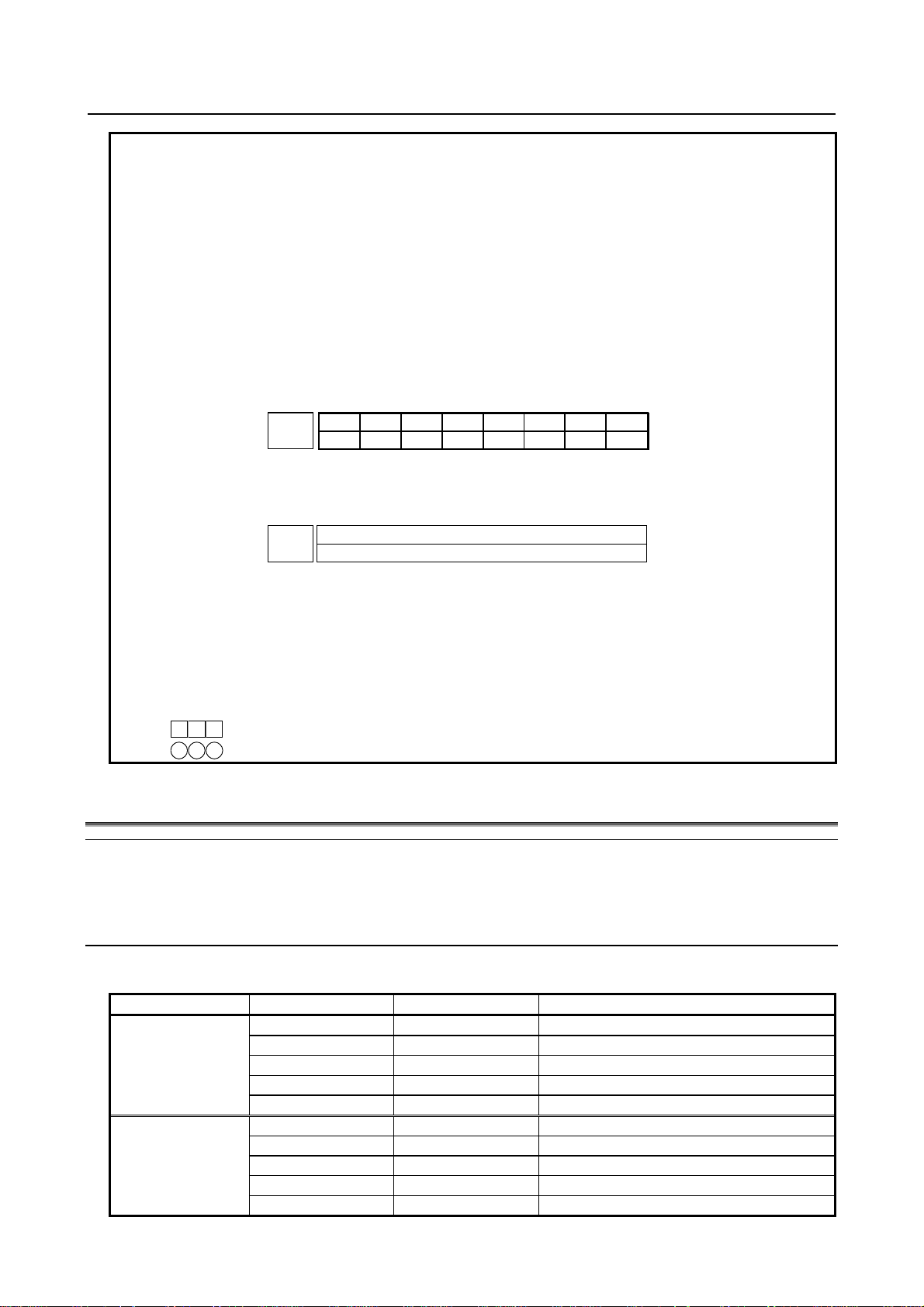

B-64490EN/05 1.DISPLAYING PARAMETERS

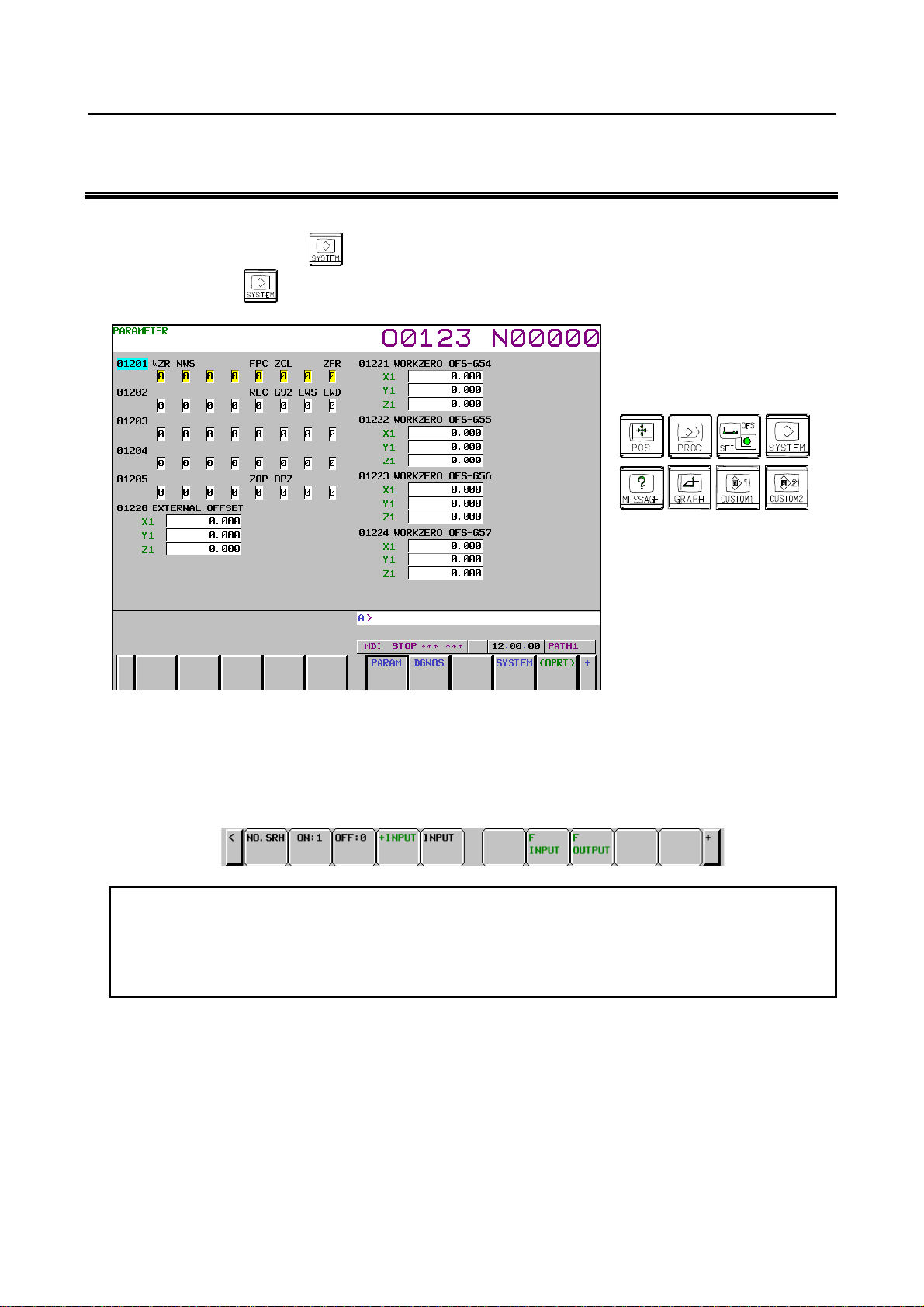

1 DISPLAYING PARAMETERS

Follow the procedure below to display parameters.

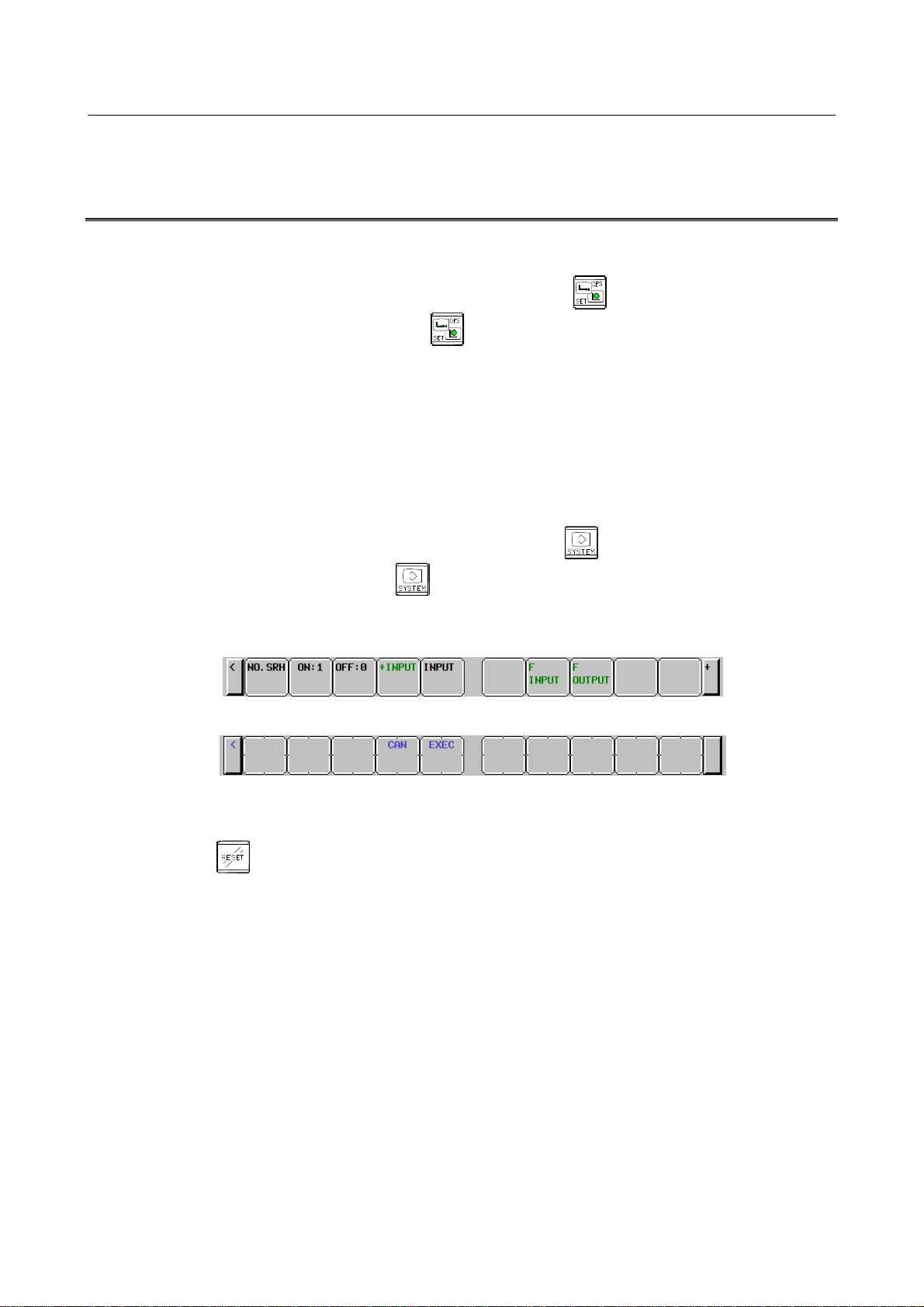

1 Press the function key

function key

then selected.

2 The parameter screen consists of multiple pages. Use step (a) or (b) to display the page that contains

the parameter you want to display.

(a) Use the page change keys or the cursor keys to display the desired page.

(b) Enter the data number of the parameter you want to display from the keyboard, then press the

soft key [NO.SRH]. The parameter page containing the specified data number appears with the

cursor positioned at the data number. (The data is displayed in reverse video.)

once, then the chapter selection soft key [PARAM]. The parameter screen is

on the MDI unit as many times as required, or alternatively, press the

Function keys

NOTE

If key entry is started with the chapter selection soft keys displayed, they are

replaced automatically by operation selection soft keys including [NO.SRH].

Pressing the soft key [(OPRT)] can also cause the operation selection soft keys

to be displayed.

- 1 -

Page 14

2.SETTING PARAMETERS FROM MDI B-64490EN/05

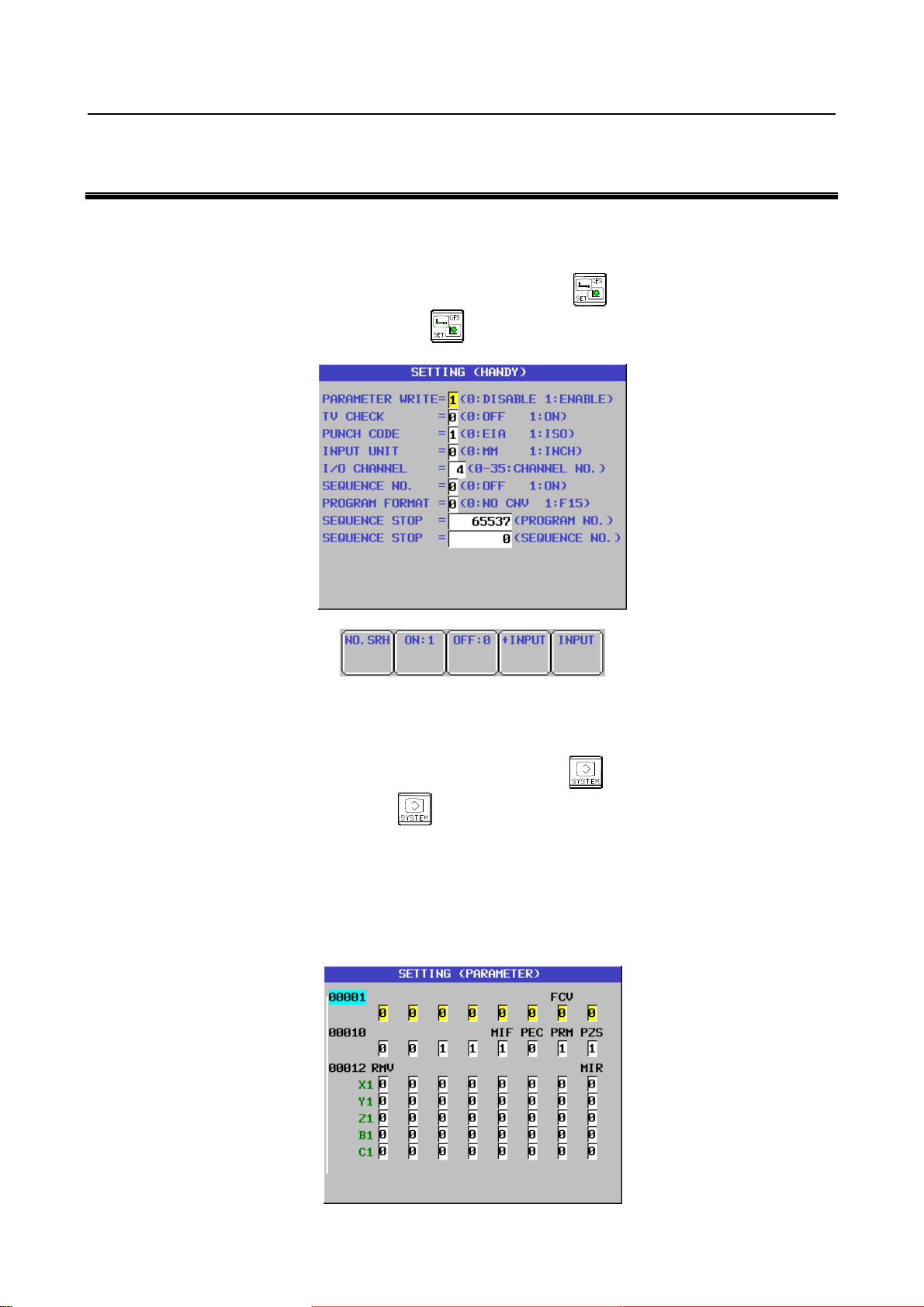

2 SETTING PARAMETERS FROM MDI

Follow the procedure below to set parameters.

1 Place the NC in the MDI mode or the emergency stop state.

2 Follow the substeps below to enable writing of parameters.

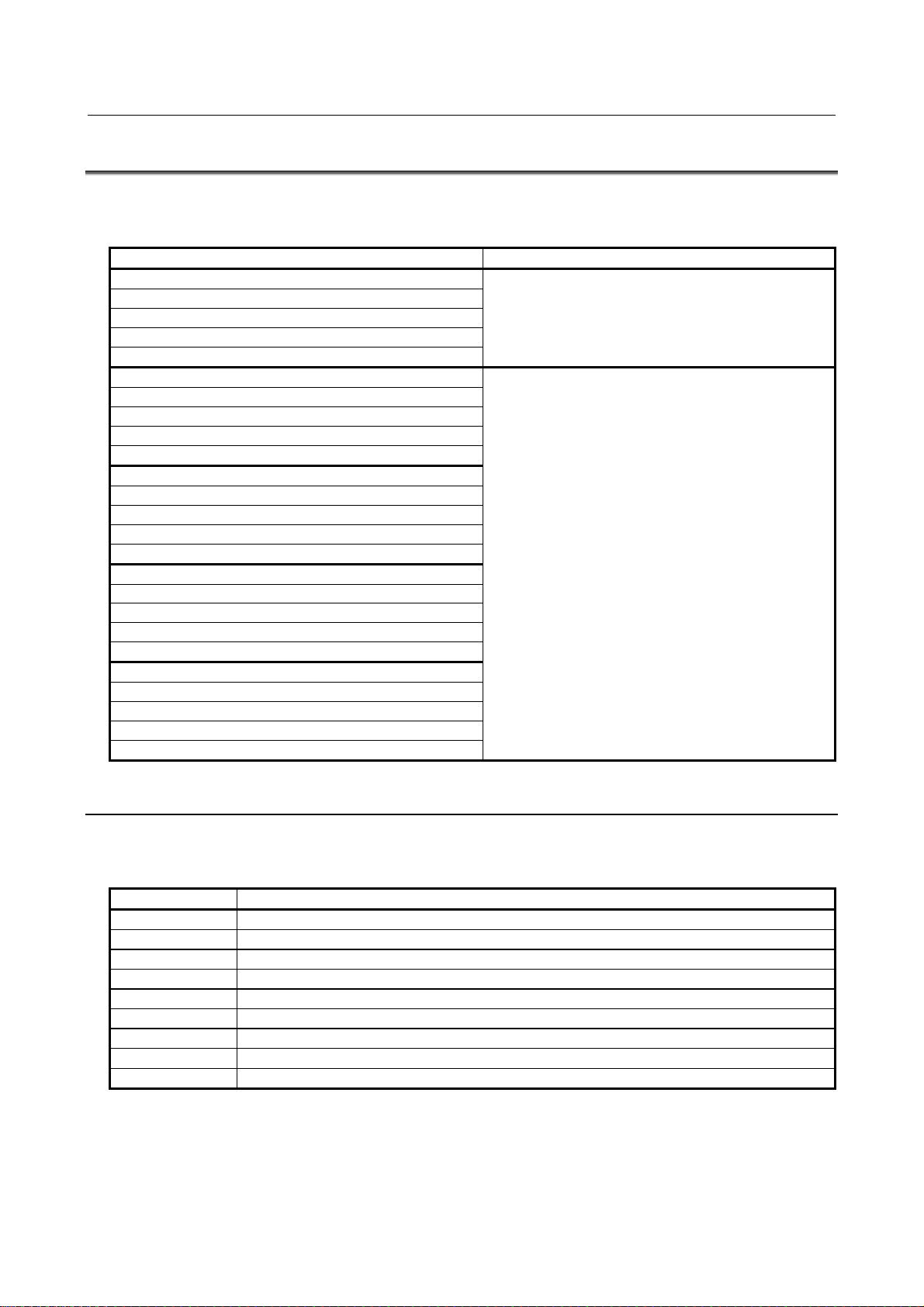

2-1 To display the setting screen, press the function key

alternatively press the function key

(The first page of the setting screen appears.)

2-2 Position the cursor on "PARAMETER WRITE" using the cursor keys.

2-3 Press the soft key [(OPRT)] to display operation selection soft keys.

2-4 To set "PARAMETER WRITE=" to 1, press the soft key [ON:1], or alternatively enter 1 and

press the soft key [INPUT]. From now on, the parameters can be set. At the same time an alarm

SW0100, “PARAMETER WRITE ENABLE” occurs in the CNC.

once, then the chapter selection soft key [SETTING].

as many times as required, or

3 To display the parameter screen, press the function key

alternatively press the function key

Chapter 1, "DISPLAYING PARAMETERS.")

4 Display the page containing the parameter you want to set, and position the cursor on the parameter.

(See Chapter 1, "DISPLAYING PARAMETERS.")

5 Enter data, then press the soft key [INPUT]. The parameter indicated by the cursor is set to the

entered data.

[Example] 12000 [INPUT]

once, then the chapter selection soft key [PARAM]. (See

as many times as required, or

- 2 -

Page 15

B-64490EN/05 2.SETTING PARAMETERS FROM MDI

Data can be entered continuously for parameters, starting at the selected parameter, by separating

each data item with a semicolon (;).

[Example]

Entering 10;20;30;40 and pressing the soft key [INPUT] assigns values 10, 20, 30, and 40 to

parameters in order starting at the parameter indicated by the cursor.

6 Repeat steps 4 and 5 as required.

7 If parameter setting is complete, set "PARAMETER WRITE=" to 0 on the setting screen to disable

further parameter setting.

8 Reset the NC to release the alarm SW0100.

If an alarm PW0000, “POWER MUST BE OFF” occurs in the NC, turn it off before continuing

operation.

- 3 -

Page 16

3. INPUTTING AND OUTPUTTING PARAMETERS

THROUGH THE READER/PUNCHER INTERFACE

B-64490EN/05

3 INPUTTING AND OUTPUTTING

PARAMETERS THROUGH THE RS232C

INTERFACE

This section explains the parameter input/output procedures for input/output devices connected to the

RS232C interface.

The following description assumes the input/output devices are ready for input/output. It also assumes

parameters peculiar to the input/output devices, such as the baud rate and the number of stop bits, have

been set in advance. (See Section 4.5, “PARAMETERS OF RS232C INTERFACE.”)

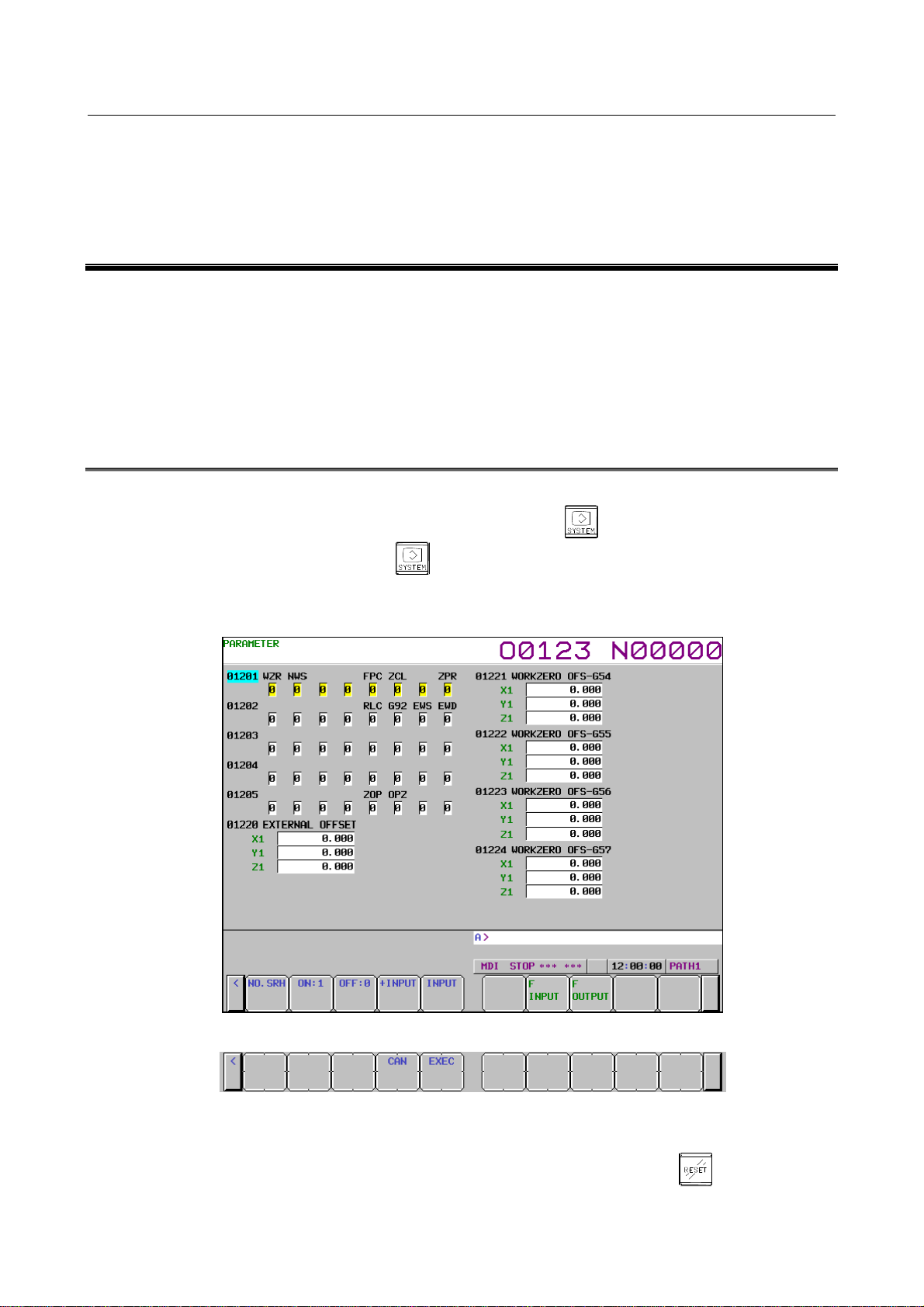

3.1 OUTPUTTING PARAMETERS THROUGH THE RS232C

INTERFACE

1 Select the EDIT mode or set to Emergency stop.

2 To select the parameter screen, press the function key

alternatively press the function key

3 Press the soft key [(OPRT)] to display operation selection soft keys, then press the continuous menu

key located at the right-hand side of the soft keys to display another set of operation selection keys

including [F OUTPUT].

once, then the chapter selection soft key [PARAM].

as many times as required, or

4 Pressing the soft key [F OUTPUT] changes the soft key display as shown below:

5 Press the soft key [EXEC] to start parameter output. When parameters are being output, "OUTPUT"

blinks in the state display field on the lower part of the screen.

6 When parameter output terminates, "OUTPUT" stops blinking. Press the

parameter output.

- 4 -

key to interrupt

Page 17

3. INPUTTING AND OUTPUTTING PARAMETERS

B-64490EN/05

THROUGH THE RS232C INTERFACE

3.2 INPUTTING PARAMETERS THROUGH THE RS232C

INTERFACE

1 Place the NC in the emergency stop state.

2 Enable parameter writing.

2-1 To display the setting screen, press the function key

alternatively press the function key

The first page of the setting screen appears.

2-2 Position the cursor on "PARAMETER WRITE" using the cursor keys.

2-3 Press the soft key [(OPRT)] to display operation selection soft keys.

2-4 To set "PARAMETER WRITE=" to 1, press the soft key [ON:1], or alternatively enter 1, then

press the soft key [INPUT]. From now on, parameters can be set.

At the same time an alarm SW0100, “PARAMETER WRITE ENABLE” occurs in the NC.

3 To select the parameter screen, press the function key

alternatively press the function key

4 Press the soft key [(OPRT)] to display operation selection keys, then press the continuous menu key

located at the right-hand side of the soft keys to display another set of operation selection soft keys

including [F INPUT].

5 Pressing the soft key [F INPUT] changes the soft key display as shown below:

once, then the chapter selection soft key [SETTING].

once, then soft key [PARAM].

as many times as required, or

as many times as required, or

6 Press the soft key [EXEC] to start inputting parameters from the input/output device. When

parameters are being input, "INPUT" blinks in the state display field on the lower part of the screen.

Press the

7 When parameter read terminates, "INPUT" stops blinking, and an alarm PW0100 occurs in the NC.

Turn it off before continuing operation.

key to interrupt parameter input.

- 5 -

Page 18

3. INPUTTING AND OUTPUTTING PARAMETERS

THROUGH THE READER/PUNCHER INTERFACE

B-64490EN/05

3.3 I/O FORMATS

This section describes the I/O formats of parameters.

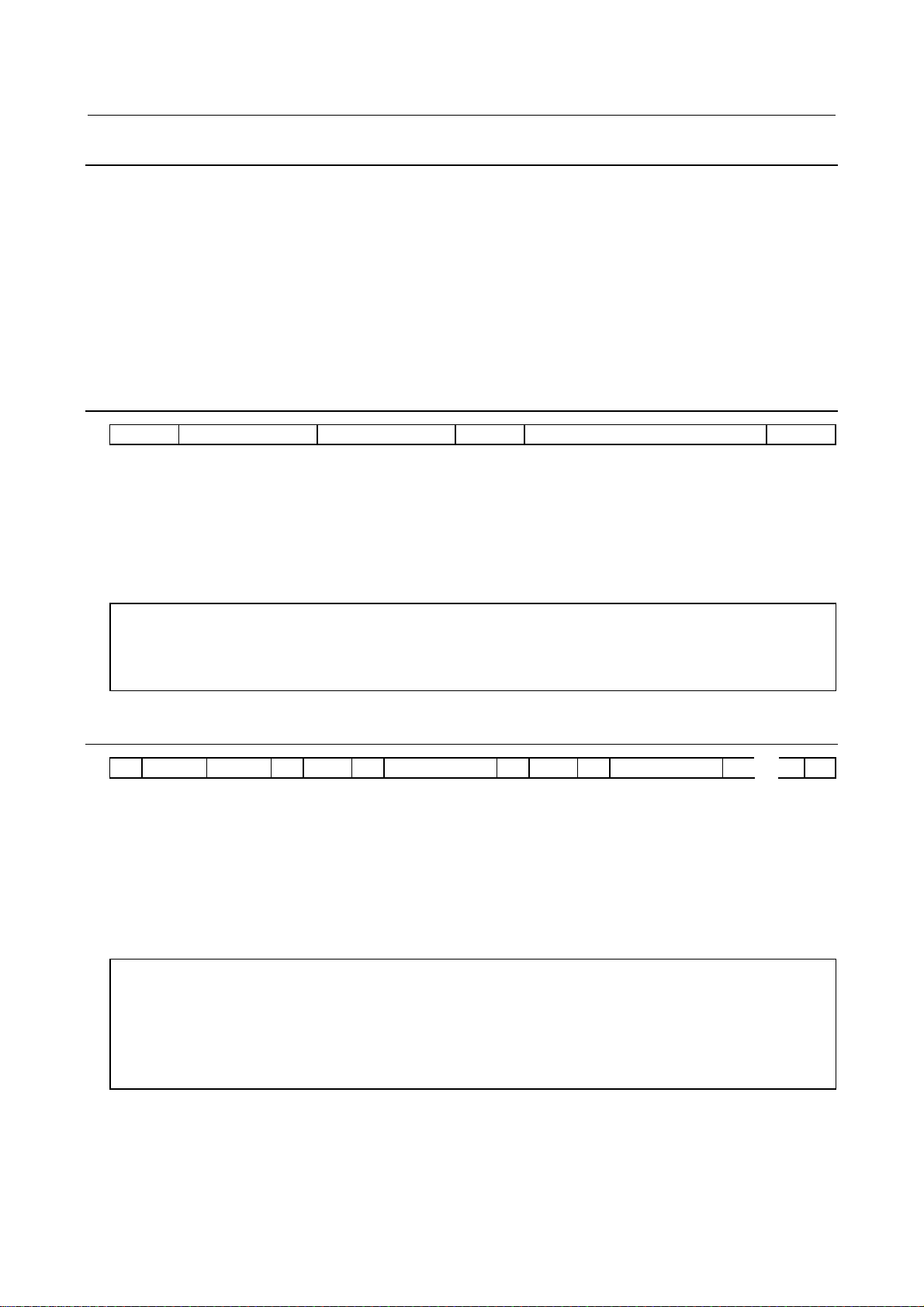

Parameters are classified by data format as follows:

Data format Remarks

Bit

Bit machine group

Bit path

Bit axis

Bit spindle

Byte

Byte machine group

Byte path

Byte axis

Byte spindle

Word

Word machine group

Word path

Word axis

Word spindle

2-word

2-word machine group

2-word path

2-word axis

2-word spindle

Real

Real machine group

Real path

Real axis

Real spindle

Data of these formats is represented by an 8-digit

binary number, with each digit corresponding to a bit.

The setting range of data varies from one parameter

to another.

For details, refer to the description of each parameter.

3.3.1 Keywords

The alphabetic characters listed below are used as keywords.

A numeric value after each keyword has the following meaning:

Keyword Meaning of a numeric value that follows

N Parameter number

Q Data identifier (1: Parameter data, 0: Pitch error compensation data)

T

L

A Controlled axis number (1 and up) of an axis type parameter

S Spindle number (1 and up) of a spindle type parameter

P Value of a parameter independent of inch/metric switching

M Metric input value of a parameter dependent on inch/metric switching

I Inch input value of a parameter dependent on inch/metric switching

Machine group number (1 and up) of a machine group type parameter

Path number (1 and up) of a path type parameter

- 6 -

Page 19

3. INPUTTING AND OUTPUTTING PARAMETERS

B-64490EN/05

THROUGH THE RS232C INTERFACE

3.3.2 Inch/Metric Switching

For parameters dependent on inch/metric switching such as those for length and feedrate, whether data is

inch data or metric data is specified by the input mode in the case of input from the MDI panel, or by the

keyword I or M prefixed to the data in the case of input from an external I/O device. The keyword I or M

is added also when data is output to an external I/O device.

If the input mode or keyword differs from the actually used mode as in a case where data input in the inch

mode is used in the metric mode, the CNC performs automatic data conversion. So, data need not be

converted according to a mode change. Moreover, when parameter data is displayed, the data is converted

according to the display mode. However, when data is output to an external I/O device, the original data

is output according to the original keyword.

3.3.3 Bit Format

N ***** Q1 P ******** ;

A numeric value after N represents a parameter number.

Q1 indicates that the data is parameter data.

An 8-digit binary number after P represents the bit values (0/1) of a parameter, with the first digit

corresponding to bit 0 and the eighth digit corresponding to bit 7.

Leading zeros may not be omitted.

A semicolon (;) marks the end of a block. (LF is used for the ISO code, and CR is used for the EIA code.)

Example

N00010Q1P00000001;

Parameter No. 10

Parameter value Bit 0 is set to 1, and the other bits are set to 0.

3.3.4 Bit Machine Group Format

N ***** Q1 T ** P ******** T ** P ********

A numeric value after N represents a parameter number.

Q1 indicates that the data is parameter data.

A numeric value after T represents a machine group number (1 and up).

An 8-digit binary number after P represents the bit values (0/1) of a parameter for each machine group,

with the first digit corresponding to bit 0 and the eighth digit corresponding to bit 7.

Leading zeros may not be omitted.

A semicolon (;) marks the end of a block. (LF is used for the ISO code, and CR is used for the EIA code.)

Example

N01005Q1T1P10000001T2P10000001 ;

Parameter No. 1005

Parameter value

1st machine group: Bits 0 and 7 are set to 1, and the other bits are set to 0.

2nd machine group: Bits 0 and 7 are set to 1, and the other bits are set to 0.

・ ・ ・

;

- 7 -

Page 20

3. INPUTTING AND OUTPUTTING PARAMETERS

THROUGH THE READER/PUNCHER INTERFACE

B-64490EN/05

3.3.5 Bit Path Format

N ***** Q1 L ** P ******** L ** P ********

A numeric value after N represents a parameter number.

Q1 indicates that the data is parameter data.

A numeric value after L represents a path number (1 and up).

An 8-digit binary number after P represents the bit values (0/1) of a parameter for each path, with the first

digit corresponding to bit 0 and the eighth digit corresponding to bit 7.

Leading zeros may not be omitted.

A semicolon (;) marks the end of a block. (LF is used for the ISO code, and CR is used for the EIA code.)

・ ・ ・

Example

N01005Q1L1P10000001L2P10000001.......;

Parameter No. 1005

Parameter value

Path 1: Bits 0 and 7 are set to 1, and the other bits are set to 0.

Path 2: Bits 0 and 7 are set to 1, and the other bits are set to 0.

3.3.6 Bit Axis Format

N ***** Q1 A ** P ******** A ** P ********

A numeric value after N represents a parameter number.

Q1 indicates that the data is parameter data.

A numeric value after A represents a controlled axis number (1 and up).

An 8-digit binary number after P represents the bit values (0/1) of a parameter for each controlled axis,

with the first digit corresponding to bit 0 and the eighth digit corresponding to bit 7.

Leading zeros may not be omitted.

A semicolon (;) marks the end of a block. (LF is used for the ISO code, and CR is used for the EIA code.)

Example

N01005Q1A1P10000001A2P10000001A3P10000001.......;

Parameter No. 1005

Parameter value

1st axis: Bits 0 and 7 are set to 1, and the other bits are set to 0.

2nd axis: Bits 0 and 7 are set to 1, and the other bits are set to 0.

3rd axis: Bits 0 and 7 are set to 1, and the other bits are set to 0.

▪

・ ・ ・

;

;

- 8 -

Page 21

3. INPUTTING AND OUTPUTTING PARAMETERS

B-64490EN/05

THROUGH THE RS232C INTERFACE

3.3.7 Bit Spindle Format

N ***** Q1 S ** P ******** S ** P ********

A numeric value after N represents a parameter number.

Q1 indicates that the data is parameter data.

A numeric value after S represents a spindle number (1 and up).

An 8-digit binary number after P represents the bit values (0/1) of a parameter for each spindle, with the

first digit corresponding to bit 0 and the eighth digit corresponding to bit 7.

Leading zeros may not be omitted.

A semicolon (;) marks the end of a block. (LF is used for the ISO code, and CR is used for the EIA code.)

・ ・ ・

Example

N05603Q1S1P00001000S2P00001000S3P00000000;

Parameter No. 5603

Parameter value

1st spindle: Bit 3 is set to 1, and the other bits are set to 0.

2nd spindle: Bit 3 is set to 1, and the other bits are set to 0.

3rd spindle: All bits are set to 0.

3.3.8 Byte/Word/Two-Word Format

N ***** Q1 P ******** ;

A numeric value after N represents a parameter number.

Q1 indicates that the data is parameter data.

A numeric value after P represents a parameter value (integer).

A semicolon (;) marks the end of a block. (LF is used for the ISO code, and CR is used for the EIA code.)

Example

N00100Q1P31515;

Parameter No. 100

Parameter value 31515

;

3.3.9 Byte/Word/Two-Word Machine Group Format

N ***** Q1 T ** P ****** T ** P ******

A numeric value after N represents a parameter number.

Q1 indicates that the data is parameter data.

A numeric value after T represents a machine group number (1 and up).

A numeric value after P represents the value (integer) of a parameter for each machine group.

A semicolon (;) marks the end of a block. (LF is used for the ISO code, and CR is used for the EIA code.)

Example

N01020Q1T1P88T2P89......;

Parameter No. 1020

Parameter value 1st machine group: 88

2nd machine group: 89

▪

- 9 -

・ ・ ・

;

Page 22

3. INPUTTING AND OUTPUTTING PARAMETERS

THROUGH THE READER/PUNCHER INTERFACE

B-64490EN/05

3.3.10 Byte/Word/Two-Word Path Format

N ***** Q1 L ** P ****** L ** P ******

A numeric value after N represents a parameter number.

Q1 indicates that the data is parameter data.

A numeric value after L represents a path number (1 and up).

A numeric value after P represents the value (integer) of a parameter for each path.

A semicolon (;) marks the end of a block. (LF is used for the ISO code, and CR is used for the EIA code.)

・ ・ ・

Example

N01020Q1L1P88L2P89L3P90......;

Parameter No. 1020

Parameter value Path 1: 88

Path 2: 89

Path 3: 90

▪

3.3.11 Byte/Word/Two-Word Axis Format

N ***** Q1 A ** P ****** A ** P ******

A numeric value after N represents a parameter number.

Q1 indicates that the data is parameter data.

A numeric value after A represents a controlled axis number (1 and up).

A numeric value after P represents the value (integer) of a parameter for each controlled axis.

A semicolon (;) marks the end of a block. (LF is used for the ISO code, and CR is used for the EIA code.)

Example

N01020Q1A1P88A2P89A3P90A4P66......;

Parameter No. 1020

Parameter value 1st axis: 88

2nd axis: 89

3rd axis: 90

4th axis: 66

▪

・ ・ ・

;

;

- 10 -

Page 23

3. INPUTTING AND OUTPUTTING PARAMETERS

B-64490EN/05

THROUGH THE RS232C INTERFACE

3.3.12 Byte/Word/Two-Word Spindle Format

N ***** Q1 S ** P ****** S ** P ******

A numeric value after N represents a parameter number.

Q1 indicates that the data is parameter data.

A numeric value after S represents a spindle number (1 and up).

A numeric value after P represents the value (integer) of a parameter for each spindle.

A semicolon (;) marks the end of a block. (LF is used for the ISO code, and CR is used for the EIA code.)

・ ・ ・

Example

N05680Q1S1P19S2P19S3P0S4P0;

Parameter No. 5680

Parameter value 1st spindle: 19

2nd spindle: 19

3rd spindle: 0

4th spindle: 0

3.3.13 Real Number Format

N ***** Q1 P ****** ;

N ***** Q1 M ****** ;

N ***** Q1 I ****** ;

A numeric value after N represents a parameter number.

Q1 indicates that the data is parameter data.

A numeric value after each of P, M, and I represents the value (real number) of a parameter.

A semicolon (;) marks the end of a block. (LF is used for the ISO code, and CR is used for the EIA code.)

Example

N01451Q1P5000.0;

Parameter No. 1451

Parameter value 5000.0

;

- 11 -

Page 24

3. INPUTTING AND OUTPUTTING PARAMETERS

THROUGH THE READER/PUNCHER INTERFACE

B-64490EN/05

3.3.14 Real Number Machine Group Format

N ***** Q1 T ** P ****** T ** P ******

N ***** Q1 T ** M ****** T ** M ******

N ***** Q1 T ** I ****** T ** I ******

・ ・ ・

・ ・ ・

・ ・ ・

A numeric value after N represents a parameter number.

Q1 indicates that the data is parameter data.

A numeric value after T represents a machine group number (1 and up).

A numeric value after each of P, M, and I represents the value (real number) of a parameter for each

machine group.

A semicolon (;) marks the end of a block. (LF is used for the ISO code, and CR is used for the EIA code.)

Example

N01220Q1T1M50.0T2M60.0........;

Parameter No. 1220

Parameter value 1st machine group: 50.0

2nd machine group: 60.0

▪

3.3.15 Real Number Path Format

;

;

;

N ***** Q1 L ** P ****** L ** P ******

N ***** Q1 L ** M ****** L ** M ******

N ***** Q1 L ** I ****** L ** I ******

・ ・ ・

・ ・ ・

・ ・ ・

;

;

;

A numeric value after N represents a parameter number.

Q1 indicates that the data is parameter data.

A numeric value after L represents a path number (1 and up).

A numeric value after each of P, M, and I represents the value (real number) of a parameter for each path.

A semicolon (;) marks the end of a block. (LF is used for the ISO code, and CR is used for the EIA code.)

Example

N01220Q1L1M50.0L2M60.0L3M70.0 ;

Parameter No. 1220

Parameter value Path 1: 50.0

Path 2: 60.0

Path 3: 70.0

- 12 -

Page 25

3. INPUTTING AND OUTPUTTING PARAMETERS

B-64490EN/05

THROUGH THE RS232C INTERFACE

3.3.16 Real Number Axis Format

N ***** Q1 A ** P ****** A ** P ******

N ***** Q1 A ** M ****** A ** M ******

N ***** Q1 A ** I ****** A ** I ******

・ ・ ・

・ ・ ・

・ ・ ・

;

;

;

A numeric value after N represents a parameter number.

Q1 indicates that the data is parameter data.

A numeric value after A represents a controlled axis number (1 and up).

A numeric value after each of P, M, and I represents the value (real number) of a parameter for each

controlled axis.

A semicolon (;) marks the end of a block. (LF is used for the ISO code, and CR is used for the EIA code.)

Example

N01220Q1A1M50.0A2M60.0A3M70.0A4M0.0A5M0.0 ........;

Parameter No. 1220

Parameter value 1st axis: 50.0

2nd axis: 60.0

3rd axis: 70.0

4th axis: 0.0

5th axis: 0.0

▪

3.3.17 Real Number Spindle Format

N ***** Q1 S ** P ****** S ** P ******

N ***** Q1 S ** M ****** S ** M ******

N ***** Q1 S ** I ****** S ** I ******

A numeric value after N represents a parameter number.

Q1 indicates that the data is parameter data.

A numeric value after S represents a spindle number (1 and up).

A numeric value after each of P, M, and I represents the value (real number) of a parameter for each

spindle.

A semicolon (;) marks the end of a block. (LF is used for the ISO code, and CR is used for the EIA code.)

Example

N05898Q1S1P30.0S2P30.0S3P0.0S4P0.0;

Parameter No. 5898

Parameter value 1st spindle: 30.0

2nd spindle: 30.0

3rd spindle: 0.0

4th spindle: 0.0

・ ・ ・

・ ・ ・

・ ・ ・

;

;

;

- 13 -

Page 26

3. INPUTTING AND OUTPUTTING PARAMETERS

THROUGH THE READER/PUNCHER INTERFACE

B-64490EN/05

3.3.18 Start and End of a Record

A parameter record starts with "%" and ends with "%".

Example

%; ......................................... Start of record

N00000Q1P00001100;

N00002Q1P00000000;

▪

▪

N09162Q1P00000000;

N09163Q1P00000000;

% .......................................... End of record

When parameters and pitch error compensation data are included in a single file, the file starts with "%"

and ends with "%".

- 14 -

Page 27

B-64490EN/05 4.DESCRIPTION OF PARAMETERS

4 DESCRIPTION OF PARAMETERS

4.1 INPUT TYPE

There are two input types for parameters depending on their usage.

Setting input

These parameters are set depending on NC programs or machining usage.

When the memory protection signal KEY is “1”, they can be input on SETTING screen.

They can also be input on PARAMETER screen.

Parameter input

These parameters are adjusted and set depending on each machine.

They can be input on PARAMETER screen.

NOTE

To make input on PARAMETER screen enable, it is needed that PARAMETER

WRITE on SETTING screen is 1 or that parameter PWE (No.8900#0) is 1.

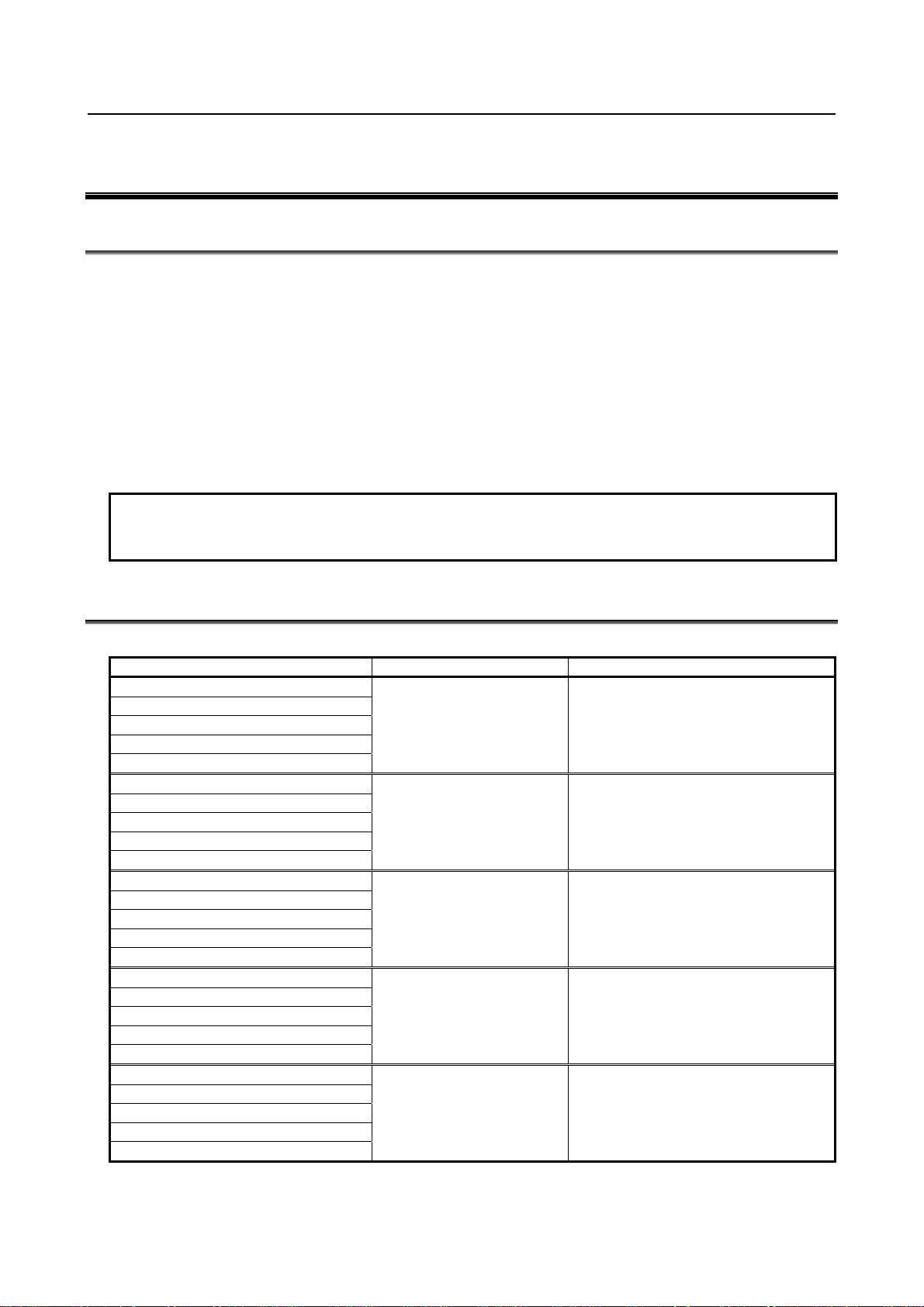

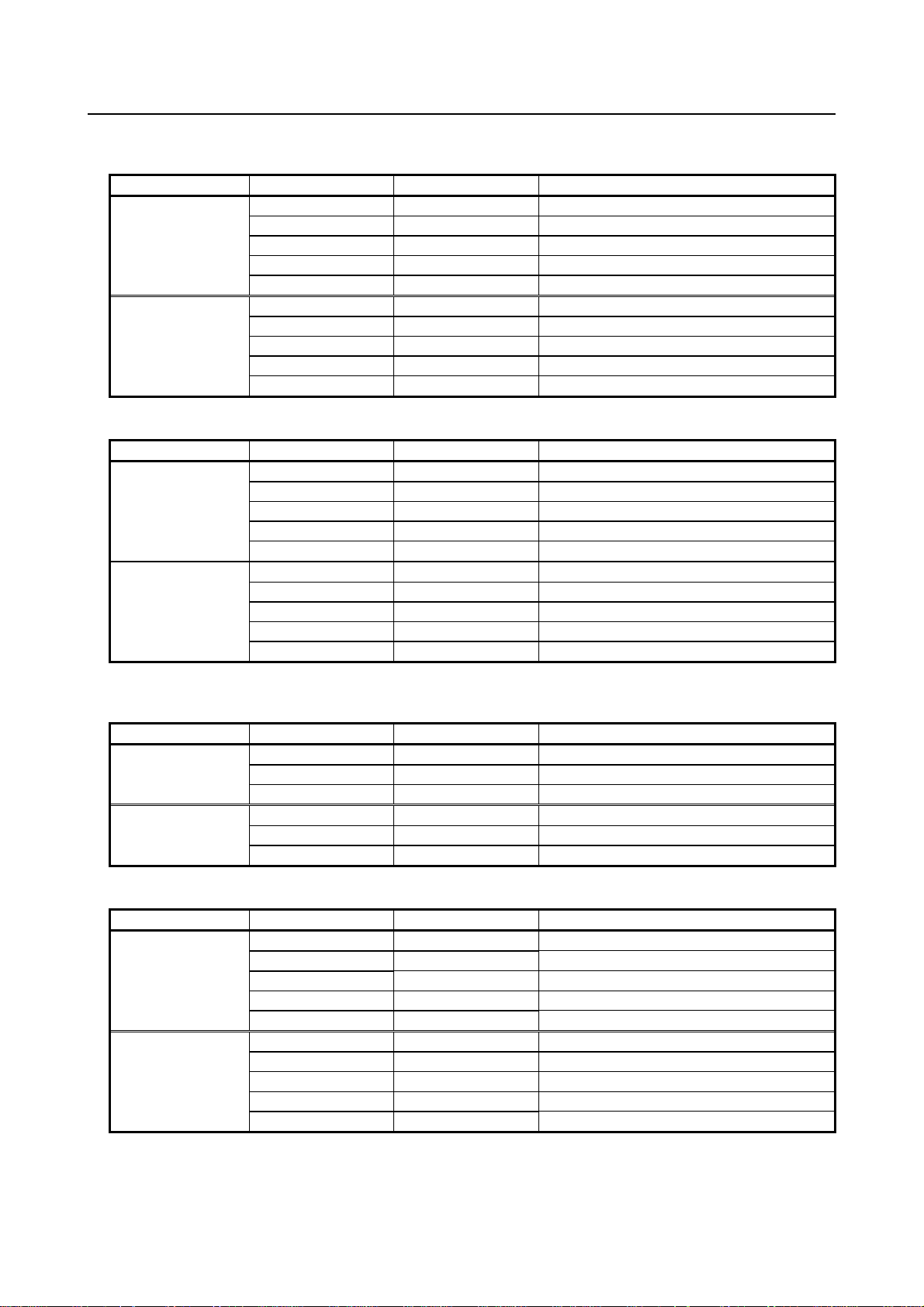

4.2 DATA TYPE

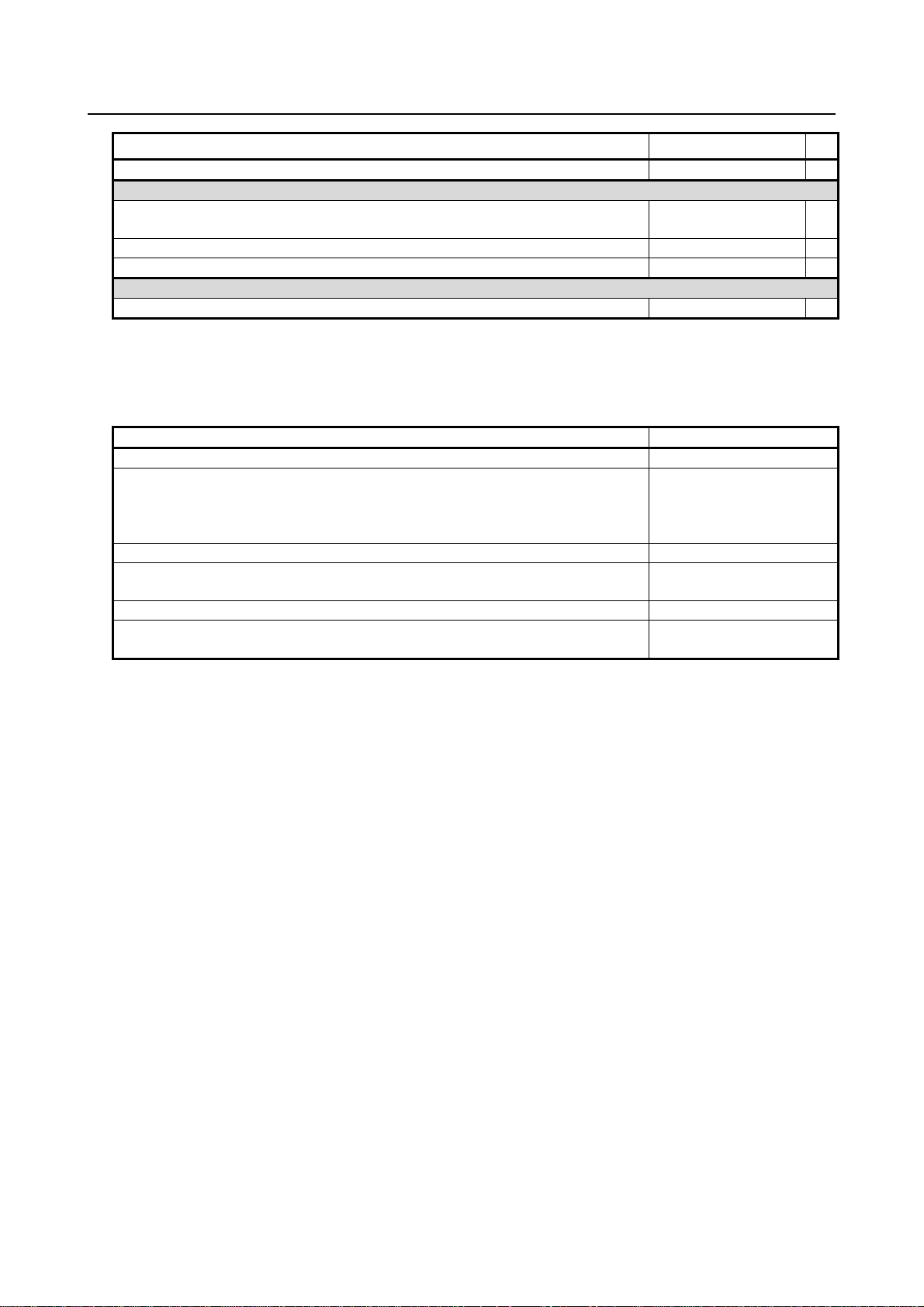

Parameters are classified by data type as follows:

Data type Valid data range Remarks

Bit

Bit machine group

Bit path

Bit axis

Bit spindle

Byte

Byte machine group

Byte path

Byte axis

Byte spindle

Word

Word machine group

Word path

Word axis

Word spindle

2-word

2-word machine group

2-word path

2-word axis

2-word spindle

Real

Real machine group

Real path

Real axis

Real spindle

See the Standard Parameter

0 or 1

-128 to 127

0 to 255

-32768 to 32767

0 to 65535

0 to ±999999999

Setting Tables.

Some parameters handle these types of

data as unsigned data.

Some parameters handle these types of

data as unsigned data.

Some parameters handle these types of

data as unsigned data.

- 15 -

Page 28

4.DESCRIPTION OF PARAMETERS B-64490EN/05

NOTE

1 Each of the parameters of the bit, bit machine group, bit path, bit axis, and bit

spindle types consists of 8 bits for one data number (parameters with eight

different meanings).

2 For machine group types, parameters corresponding to the maximum number of

machine groups are present, so that independent data can be set for each

machine group.

3 For path types, parameters corresponding to the maximum number of paths are

present, so that independent data can be set for each path.

4 For axis types, parameters corresponding to the maximum number of control

axes are present, so that independent data can be set for each control axis.

5 For spindle types, parameters corresponding to the maximum number of

spindles are present, so that independent data can be set for each spindle axis.

6 The valid data range for each data type indicates a general range. The range

varies according to the parameters. For the valid data range of a specific

parameter, see the explanation of the parameter.

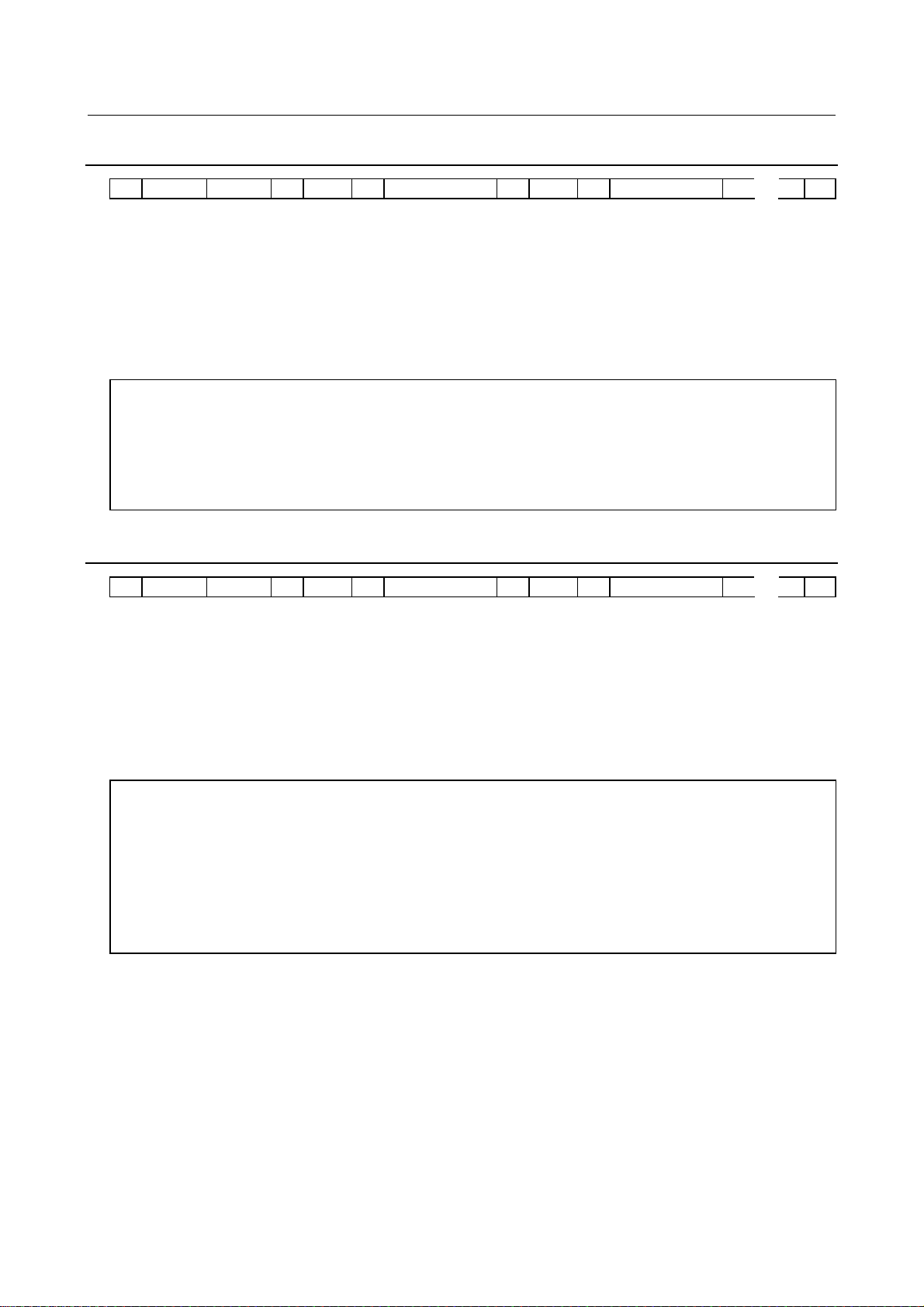

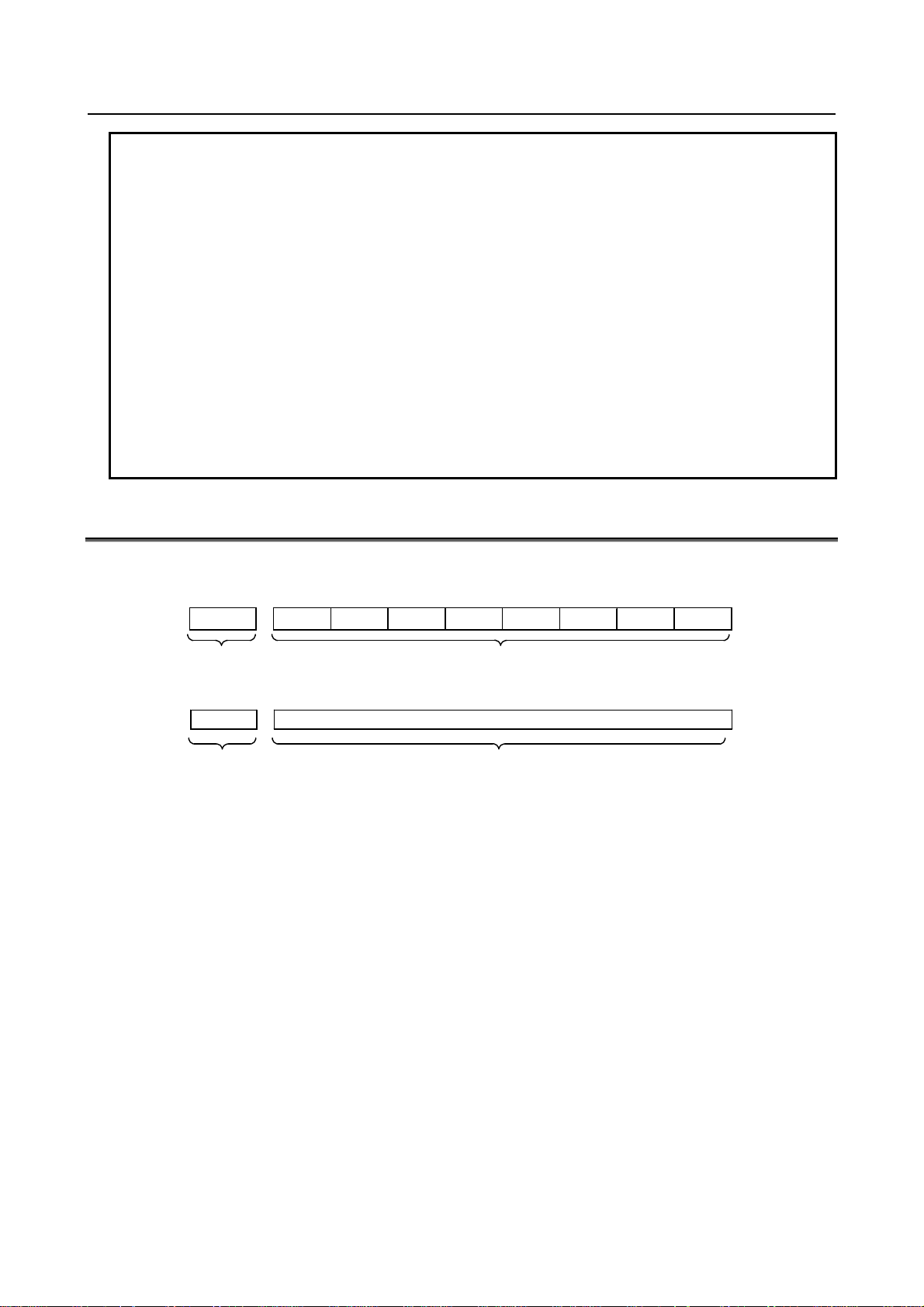

4.3 REPRESENTATION OF PARAMETERS

Parameters of the bit type, bit machine group type, bit path type, bit axis type,

and bit spindle type

Parameters other than the bit-type parameters above

#7 #6 #5 #4 #3 #2 #1 #0

0000 EIA NCR ISP CTV TVC

Data No. Data (Data #0 to #7 are bit positions.)

1023 Number of the servo axis for each axis

Data No. Data

- 16 -

Page 29

B-64490EN/05 4.DESCRIPTION OF PARAMETERS

NOTE

1 The bits left blank in Chapter 4, “DESCRIPTION OF PARAMETERS” and

parameter numbers that appear on the display but are not found in the

parameter list are reserved for future expansion. They must always be 0.

2 A parameter usable with only one path control type, namely, the lathe system (T

series) or the machining center system (M series), is indicated using two rows as

shown below. When a row is blank, the parameter is not usable with the

corresponding series.

[Example 1]

Parameter HTG is a parameter common to the M and T series, but

Parameters RTV and ROC are parameters valid only for the T series.

1403

#7 #6

RTV

#5 #4 #3 #2 #1 #0

ROC

HTG

HTG

T series

M series

[Example 2]

The following parameter is provided only for the M series.

1411

Cutting feedrate

T series

M series

3 When "to" is inserted between two parameter numbers, there are parameters

with successive numbers between the two starting and ending parameter

numbers, but those intermediate parameter numbers are omitted for

convenience.

4 The lower-case letter "x" or "s" following the name of a bit-type parameter

indicates the following:

- ” x” : Bit axis type parameters

- ” s” : Bit spindle type parameters

4.4 STANDARD PARAMETER SETTING TABLES

Overview

This section defines the standard minimum data units and valid data ranges of the CNC parameters of the

real type, real machine group type, real path type, real axis type, and real spindle type. The data type and

unit of data of each parameter conform to the specifications of each function.

Explanation

(A) Length and angle parameters (type 1)

Unit of data Increment system Minimum data unit Valid data range

IS-A 0.01 -999999.99 to +999999.99

mm

deg.

inch

IS-B 0.001 -999999.999 to +999999.999

IS-C 0.0001 -99999.9999 to +99999.9999

IS-D 0.00001 -9999.99999 to +9999.99999

IS-E 0.000001 -999.999999 to +999.999999

IS-A 0.001 -99999.999 to +99999.999

IS-B 0.0001 -99999.9999 to +99999.9999

IS-C 0.00001 -9999.99999 to +9999.99999

IS-D 0.000001 -999.999999 to +999.999999

IS-E 0.0000001 -99.9999999 to +99.9999999

- 17 -

Page 30

4.DESCRIPTION OF PARAMETERS B-64490EN/05

(B) Length and angle parameters (type 2)

Unit of data Increment system Minimum data unit Valid data range

IS-A 0.01 0.00 to +999999.99

mm

deg.

inch

IS-B 0.001 0.000 to +999999.999

IS-C 0.0001 0.0000 to +99999.9999

IS-D 0.00001 0.00000 to +9999.99999

IS-E 0.000001 0.000000 to +999.999999

IS-A 0.001 0.000 to +99999.999

IS-B 0.0001 0.0000 to +99999.9999

IS-C 0.00001 0.00000 to +9999.99999

IS-D 0.000001 0.000000 to +999.999999

IS-E 0.0000001 0.0000000 to +99.9999999

(C) Velocity and angular velocity parameters

Unit of data Increment system Minimum data unit Valid data range

IS-A 0.01 0.00 to +999000.00

mm/min

degree/min

inch/min

IS-B 0.001 0.000 to +999000.000

IS-C 0.0001 0.0000 to +99999.9999

IS-D 0.00001 0.00000 to +9999.99999

IS-E 0.000001 0.000000 to +999.999999

IS-A 0.001 0.000 to +96000.000

IS-B 0.0001 0.0000 to +9600.0000

IS-C 0.00001 0.00000 to +4000.00000

IS-D 0.000001 0.000000 to +400.000000

IS-E 0.0000001 0.0000000 to +40.0000000

If bit 7 (IESP) of parameter No. 1013 is set to 1, the valid data ranges for IS-C, IS-D, and IS-E are

extended as follows:

Unit of data Increment system Minimum data unit Valid data range

mm/min

degree/min

inch/min

IS-C 0.001 0.000 to +999000.000

IS-D 0.0001 0.0000 to +99999.9999

IS-E 0.0001 0.0000 to +99999.9999

IS-C 0.0001 0.0000 to +9600.0000

IS-D 0.00001 0.00000 to +4000.00000

IS-E 0.00001 0.00000 to +4000.00000

(D)Acceleration and angular acceleration parameters

Unit of data Increment system Minimum data unit Valid data range

IS-A 0.01 0.00 to +999999.99

IS-B 0.001 0.000 to +999999.999

IS-C 0.0001 0.0000 to +99999.9999

IS-D 0.00001 0.00000 to +9999.99999

IS-E 0.000001 0.000000 to +999.999999

IS-A 0.001 0.000 to +99999.999

IS-B 0.0001 0.0000 to +99999.9999

IS-C 0.00001 0.00000 to +9999.99999

IS-D 0.000001 0.000000 to +999.999999

IS-E 0.0000001 0.0000000 to +99.9999999

mm/sec2

deg./sec

inch/sec2

2

- 18 -

Page 31

B-64490EN/05 4.DESCRIPTION OF PARAMETERS

If bit 7 (IESP) of parameter No. 1013 is set to 1, the valid data ranges for IS-C, IS-D, and IS-E are

extended as follows:

Unit of data Increment system Minimum data unit Valid data range

mm/min

degree/min

inch/min

IS-C 0.001 0.000 to +999999.999

IS-D 0.0001 0.0000 to +99999.9999

IS-E 0.0001 0.0000 to +99999.9999

IS-C 0.0001 0.0000 to +99999.9999

IS-D 0.00001 0.00000 to +9999.99999

IS-E 0.00001 0.00000 to +9999.99999

Notes

(1) Values are rounded up or down to the nearest multiples of the minimum data unit.

(2) A valid data range means data input limits, and may differ from values representing actual

performance.

(3) For information on the ranges of commands to the CNC, refer to Appendix D, "RANGE OF

COMMAND VALUE" in the "OPERATOR’S MANUAL" (B-64484EN).

- 19 -

Page 32

4.DESCRIPTION OF PARAMETERS B-64490EN/05

4.5 PARAMETERS OF SETTING

#7 #6 #5 #4 #3 #2 #1 #0

0000 SEQ INI ISO TVC

[Input type] Setting input

[Data type] Bit path

#0 TVC TV check

0: Not performed

1: Performed

#1 ISO Code used for data output

0: EIA code

1: ISO code

NOTE

1 The I/O setting of a memory card is made by bit 0 (ISO) of

parameter No. 0139.

2 The I/O setting of an USB memory is made by bit 0 (ISU) of

parameter No. 11505.

3 The I/O setting of a data server is made by bit 0 (ISO) of parameter

No. 0908.

4 When EIA code is used for data output (ISO = 0), set bit 3 (ASI) of

parameter No.101 and 111 and 121 to 0.

#2 INI Unit of input

0: In metrics

1: In inches

#5 SEQ Automatic insertion of sequence numbers

0: Not performed

1: Performed

#7 #6 #5 #4 #3 #2 #1 #0

0001 FCV

[Input type] Setting input

[Data type] Bit path

#1 FCV Program format

0: Series 16 standard format

1: Series 15 format

- 20 -

Page 33

B-64490EN/05 4.DESCRIPTION OF PARAMETERS

NOTE

1 Programs created in the Series 15 program format can be used for

operation on the following functions:

1 Subprogram call M98

2 Thread cutting with equal leads G32 (T series)

3 Canned cycle G90, G92, G94 (T series)

4 Multiple repetitive canned cycle

G71 to G76 (T series) / G71.7 to G71.6 (M series)

5 Drilling canned cycle

G83.1, G80 to G89 (T series) / G73, G74, G76, G80 to G89 (M

series)

2 When the program format used in the Series 15 is used for this

CNC, some limits may add. Refer to the Operator’s Manual.

#7 #6 #5 #4 #3 #2 #1 #0

0002 SJZ

[Input type] Setting input

[Data type] Bit

#7 SJZ On an axis for which bit 3 (HJZx) of parameter No. 1005 is set:

0: If a reference position is not established yet, reference position return is performed

with deceleration dogs.

If a reference position is already established, reference position return is performed

at a parameter-set feedrate without using deceleration dogs.

1: Reference position return is performed with deceleration dogs at all times.

NOTE

SJZ is valid for an axis for which bit 3 (HJZx) of parameter No.

1005 is set to 1. When bit 1 (DLZx) of parameter No. 1005 is set to

1, however, manual reference position return after a reference

position is set is performed at a parameter-set feedrate, regardless

of the setting of SJZ.

#7 #6 #5 #4 #3 #2 #1 #0

0010 PEC PRM PZS

[Input type] Setting input

[Data type] Bit path

#0 PZS When a part program is output, the O number is:

0: Not zero-suppressed.

1: Zero-suppressed.

#1 PRM When parameters are output, the parameters whose values are 0 are:

0: Output.

1: Not output.

#2 PEC When pitch error compensation data is output, the data whose value is 0 is:

0: Output.

1: Not output.

- 21 -

Page 34

4.DESCRIPTION OF PARAMETERS B-64490EN/05

#7 #6 #5 #4 #3 #2 #1 #0

0012 RMVx MIRx

[Input type] Setting input

[Data type] Bit axis

#0 MIRx Mirror image for each axis

0: Mirror image is off. (Normal)

1: Mirror image is on. (Mirror)

#7 RMVx Releasing the assignment of the control axis for each axis

0: Not released

1: Released

(Equivalent to the control axis detachment signals DTCH1, DTCH2, and so forth

<G0124>)

NOTE

1 RMVx is valid when bit 7 (RMBx) of parameter No. 1005 is set to 1.

2 Switch RMVx while the axis is stopping.

When switching while the axis is moving, the control axis is

detached after the movement of the axis is completed.

4.6 PARAMETERS OF RS232C INTERFACE

To transfer data (programs, parameters, and so forth) to and from an external input/output device through

the I/O device interface (RS-232-C serial interface), the parameters described below need to be set.

The input/output device connected to a channel (such as RS-232-C serial port 1 and RS-232-C serial port

2) can be selected by setting I/O CHANNEL (parameter No. 0020). The specifications (input/output

specification number, baud rate, and the number of stop bits) of an input/output device connected to each

channel must be set in the parameters corresponding to each channel beforehand.

For channel 1, two combinations of parameters to specify the input/output device data are provided.

The following shows the interrelation between the input/output device interface parameters for the

channels.

- 22 -

Page 35

B-64490EN/05 4.DESCRIPTION OF PARAMETERS

I /O CHA NNEL

0020

or foreground input

Set channels to be used

for data input/output.

I/O CHANNEL (0 to 5)

=0 : Channel 1

=1 : Channel 1

=2 : Channel 2

=3 : Channel 3

:

:

:

Input/output to and from the memory card

interfac e, etc. is also possible.

When IO4 is set

0021

Foreground output

0022

Background input

0023

Background output

The channel setting is the same as No.0020.

Input/output channel number (parameter No.0020)

↓

0101 Stop bit an d ot her data

I/O C HANNEL=0 0102 Number spec ified for t he i nput/output dev ice

(Channel 1)

I/O C HANNEL=1 0112 Nu mber specified for the input/ou tput device

(Channel 1)

I/O C HANNEL=2 0122 Number spec ified for t he i nput/output dev ice

(Channel 2)

:

:

:

I/O C HANNEL=5

0103 B aud rate

0111 Stop b it a nd other data

0113 B aud rate

0121 Stop bit an d ot her data

0123 B aud rate

4.6.1 Parameters Common to All Channels

0020 I/O CHANNEL : Input/output device selection, or interface number for a foreground input device

0021 Foreground output device setting

0022 Background input device setting

0023 Background output device setting

[Input type] Setting input

[Data type] Byte

[Valid data range] 0 to 17

The CNC has the following interfaces for transferring data to and from an external

input/output device and the host computer:

Input/output device interface (RS-232-C serial ports 1 and 2)

Memory card interface

Data server interface

Embedded Ethernet interface

USB memory interface

By setting bit 0 (IO4) of parameter No. 0110, data input/output can be controlled

separately. When IO4 is not set, data input/output is performed using the channel set in

parameter No. 0020. When IO4 is set, a channel can be assigned to each of foreground

input, foreground output, background input, and background output.

In these parameters, specify the interface connected to each input/output device to and

from which data is to be transferred. See the table below for these settings.

Correspondence between settings and input/output devices

Setting Description

0,1 RS-232-C serial port 1

2 RS-232-C serial port 2

- 23 -

Page 36

4.DESCRIPTION OF PARAMETERS B-64490EN/05

Correspondence between settings and input/output devices

Setting Description

Memory card interface of CNC

4

5 Data server interface

9 Embedded Ethernet interface

17 USB memory interface

Memory card/USB interface in the secondary display unit for Ethernet

connection or the shared display unit for Ethernet connection

0024

Setting of communication with the ladder development tool (FANUC LADDER-III, ladder editing

package)

[Input type] Setting input

[Data type] Word

[Valid data range] 0 to 255

This parameter is used to enable or disable the PMC online connection function.

By specifying this parameter, the PMC online connection function can be enabled or

disabled without displaying the PMC online setting screen.

Setting RS-232-C High-speed interface

0 The setting on the PMC online setting screen is not altered.

1 To be used (channel 1) Not to be used

2 To be used (channel 2) Not to be used

10 Not to be used To be used

11 To be used (channel 1) To be used

12 To be used (channel 2) To be used

255 Communication is terminated forcibly (as with the [FORCED STOP] soft key).

NOTE

1 The setting of this parameter becomes valid when the power is

turned on or this parameter is modified. After this parameter is set,

the power need not be turned off then back on.

2 A setting modification made on the PMC online setting screen is

not reflected in this parameter.

3 The communication settings of a baud rate and so forth for using

RS-232-C made on the PMC online setting screen are valid. When

no modification is ever made to the settings on the PMC online

setting screen, the baud rate is 9600, parity is not used, and the

number of stops bits is 2.

4 If you set this parameter to 1, 2, 11, or 12, the PMC online monitor

occupies the specified RS232-C communications port. To use the

communications port for the Handy File, for example, set the

parameter to 255 to prevent the RS232-C port from being used by

the PMC online monitor.

#7 #6 #5 #4 #3 #2 #1 #0

0100 ENS IOP NCR CRF CTV

[Input type] Setting input

[Data type] Bit

#1 CTV Character counting for TV check in the comment section of a program.

0: Performed

1: Not performed

- 24 -

Page 37

B-64490EN/05 4.DESCRIPTION OF PARAMETERS

#2 CRF Output of the end of block (EOB) in ISO code

0: Depends on the setting of bit 3 (NCR) of parameter No. 0100.

1: CR, LF are output.

#3 NCR Output of the end of block (EOB) in ISO code

0: LF, CR, CR are output.

1: Only LF is output.

#6 IOP Stopping a program output or input operation by a reset is:

0: Enabled

1: Disabled

(Stopping a program input/output operation with the soft key [STOP] is enabled at all

times.)

#7 ENS Action taken when a NULL code is found during read of EIA code

0: An alarm is generated.

1: The NULL code is ignored.

#7 #6 #5 #4 #3 #2 #1 #0

0110 IO4

[Input type] Parameter input

[Data type] Bit

NOTE

When this parameter is set, the power must be turned off before

operation is continued.

#0 IO4 Separate control of I/O channel numbers is:

0: Not performed.

1: Performed.

If the I/O channels are not separately controlled, set the input/output device in parameter

No. 0020.

If the I/O channels are separately controlled, set the input device and output device in the

foreground and the input device and output device in the background in parameters No.

0020 to No. 0023 respectively.

Separate control of I/O channels makes it possible to perform background editing,

program input/output, and the like during the DNC operation.

#7 #6 #5 #4 #3 #2 #1 #0

0138 MNC MDP

[Input type] Parameter input

[Data type] Bit

#0 MDP To the extensions of input/output files, a path number is:

0: Not added.

1: Added.

NOTE

If a file name is specified by setting F, this parameter is ignored, and

a path number is not added to the extension.

- 25 -

Page 38

4.DESCRIPTION OF PARAMETERS B-64490EN/05

#7 MNC DNC operation from the memory card and external device subprogram call from the

memory card are:

0: Not performed.

1: Performed.

#7 #6 #5 #4 #3 #2 #1 #0

0139 ISO

[Input type] Setting input

[Data type] Bit

#0 ISO When a memory card is selected as an I/O device, data input/output is performed using

0: ASCII codes.

1: ISO codes.

NOTE

See Appendix J, "ISO/ASCII code conversion tool" in the

"OPERATOR’S MANUAL" (B-64484EN) for conversion between

ISO and ASCII code.

WARNING

1 Unless data is input using ASCII codes, set this parameter to 1 to

input or output data using ISO codes.

2 Data input/output with ASCII codes is dangerous because parity

information is not included and a data error during the data

input/output is not detected.

3 DNC operation from a memory card also must set the parameter to

1, and execute DNC operation by ISO code. ASCII code is

dangerous because parity information is not included and a data

error during the data input is not detected.

#7 #6 #5 #4 #3 #2 #1 #0

0313 TFO BOP

[Input type] Parameter input

[Data type] Bit

#0 BOP NC data output function is:

0: Disabled.

1: Enabled.

NOTE

If a file with the same name already exists in the external I/O device,

the file is overwritten. It is recommended to clear the external I/O

device before using this function.

#1 TFO On NC data output function, text data (such as parameter, program) is:

0: Output.

1: Not output.

- 26 -

Page 39

B-64490EN/05 4.DESCRIPTION OF PARAMETERS

#7 #6 #5 #4 #3 #2 #1 #0

0908 ISO

[Input type] Setting input

[Data type] Bit

#0 ISO When a data server is selected as an I/O device, data input/output is performed using

0: ASCII codes.

1: ISO codes.

NOTE

See Appendix J, "ISO/ASCII code conversion tool" in the

"OPERATOR’S MANUAL" (B-64484EN) for conversion between

ISO and ASCII code.

WARNING

1 Unless data is input using ASCII codes, set this parameter to 1 to

input or output data using ISO codes.

2 Data input/output with ASCII codes is dangerous because parity

information is not included and a data error during the data

input/output is not detected.

3 DNC operation from a data server also must set the parameter to

1, and execute DNC operation by ISO code. ASCII code is

dangerous because parity information is not included and a data

error during the data input is not detected.

4.6.2 Parameters of Channel 1 (I/O CHANNEL=0)

#7 #6 #5 #4 #3 #2 #1 #0

0101 NFD ASI SB2

[Input type] Parameter input

[Data type] Bit

#0 SB2 The number of stop bits

0: 1

1: 2

#3 ASI Code used at data input/output

0: EIA or ISO code (input: automatically distinguished/output: decided by the setting

parameter of bit 1 (ISO) of parameter No.0000)

1: ASCII code

NOTE

When ASCII code is used for data input/output (ASI = 1), set bit 1

(ISO) of parameter No.0000 to 1.

#7 NFD Feed before and after the data at data output

0: Output

1: Not output

When input/output devices other than the FANUC PPR are used, set NFD to 1.

- 27 -

Page 40

4.DESCRIPTION OF PARAMETERS B-64490EN/05

0102 Number specified for the input/output device (when the I/O CHANNEL is set to 0)

[Input type] Parameter input

[Data type] Byte

[Valid data range] 0 to 6

Set the specification number of the input/output device corresponding to I/O

CHANNEL=0.

The following table lists the specification numbers and corresponding input/output device

specifications.

Specification numbers and corresponding input/output device specifications

Specification number Input/output device specification

0 RS-232-C (control codes DC1 to DC4 are used)

1 FANUC CASSETTE ADAPTOR 1(FANUC CASSETTE B1/B2)

2 FANUC CASSETTE ADAPTOR 3(FANUC CASSETTE F1)

3

4 RS-232-C (control codes DC1 to DC4 are not used)

5 Portable tape reader

6 FANUC PPR

0103 Baud rate (when I/O CHANNEL is set to 0)

[Input type] Parameter input

[Data type] Byte

[Valid data range] 1 to 12

Set the baud rate of the input/output device corresponding to I/O CHANNEL=0.

When setting this parameter, see the following table:

Setting Baud rate (bps) Setting Baud rate (bps)

1 50 8 1200

3 110 9 2400

4 150 10 4800

6 300 11 9600

7 600 12 19200

FANUC PROGRAM FILE Mate、FANUC FA Card Adaptor,

FANUC FLOPPY CASSETTE ADAPTOR, FANUC Handy File

FANUC SYSTEM P-MODEL H

FANUC SYSTEM P-MODEL G, FANUC SYSTEM P-MODEL H

Baud rates and corresponding settings

4.6.3 Parameters of Channel 1 (I/O CHANNEL=1)

#7 #6 #5 #4 #3 #2 #1 #0

0111 NFD ASI SB2

[Input type] Parameter input

[Data type] Bit

#0 SB2 The number of stop bits

0: 1

1: 2

- 28 -

Page 41

B-64490EN/05 4.DESCRIPTION OF PARAMETERS

#3 ASI Code used at data input/output

0: EIA or ISO code (input: automatically distinguished/output: decided by the setting

parameter of bit 1 (ISO) of parameter No.0000)

1: ASCII code

NOTE

When ASCII code is used for data input/output (ASI = 1), set bit 1

(ISO) of parameter No.0000 to 1.

#7 NFD Feed before and after the data at data output

0: Output

1: Not output

When input/output devices other than the FANUC PPR are used, set NFD to 1.

0112 Number specified for the input/output device (when the I/O CHANNEL is set to 1)

[Input type] Parameter input

[Data type] Byte

[Valid data range] 0 to 6

Set the specification number of the input/output device corresponding to I/O

CHANNEL=1.

0113 Baud rate (when I/O CHANNEL is set to 1)

[Input type] Parameter input

[Data type] Byte

[Valid data range] 1 to 12

Set the baud rate of the input/output device corresponding to I/O CHANNEL=1.

4.6.4 Parameters of Channel 2 (I/O CHANNEL=2)

#7 #6 #5 #4 #3 #2 #1 #0

0121 NFD ASI SB2

[Input type] Parameter input

[Data type] Bit

#0 SB2 The number of stop bits

0: 1

1: 2

#3 ASI Code used at data input/output

0: EIA or ISO code (input: automatically distinguished/output: decided by the setting

parameter of bit 1 (ISO) of parameter No.0000)

1: ASCII code

NOTE

When ASCII code is used for data input/output (ASI = 1), set bit 1

(ISO) of parameter No.0000 to 1.

#7 NFD Feed before and after the data at data output

0: Output

1: Not output

- 29 -

Page 42

4.DESCRIPTION OF PARAMETERS B-64490EN/05

0122 Number specified for the input/output device (when the I/O CHANNEL is set to 2)

[Input type] Parameter input

[Data type] Byte

[Valid data range] 0 to 6

Set the specification number of the input/output device corresponding to I/O

CHANNEL=2.

0123 Baud rate (when I/O CHANNEL is set to 2)

[Input type] Parameter input

[Data type] Byte

[Valid data range] 1 to 12

Set the baud rate of the input/output device corresponding to I/O CHANNEL=2.

4.7 PARAMETERS OF CNC SCREEN DISPLAY FUNCTIONS

#7 #6 #5 #4 #3 #2 #1 #0

0300 PCM

[Input type] Setting input

[Data type] Bit

#0 PCM If the CNC main unit has a memory card interface or if the FS30i /31i /32i is in use and

connected to a PC via the HSSB or Ethernet interface, when the CNC screen display

function is started:

0: The memory card interface on the CNC side is used.

1: The memory card interface on the PC side is used.

When the CNC screen dual display function is active, the data input source and

output destination are linked to a key entry choice.

If the CNC main unit has no memory card interface, the memory card interface on the PC

side is used regardless of the setting of this parameter. This parameter is valid only while

the CNC screen display function is active.

4.8 PARAMETERS OF ETHERNET/DATA SERVER

FUNCTIONS

#7 #6 #5 #4 #3 #2 #1 #0

0901 EFT

[Input type] Parameter input

[Data type] Bit Path

#1 EFT The FTP file transfer function by the Ethernet function is:

0: Not used.

1: Used.

NOTE

In a multi-path system, the setting of the parameter for path 1 is

used throughout the system.

- 30 -

Page 43

B-64490EN/05 4.DESCRIPTION OF PARAMETERS

#7 #6 #5 #4 #3 #2 #1 #0