Page 1

7169Fr4Hqa2ECQqEpRfd63ND/4NVqYNEFOTqTAv7RCUlwWzsC+2wd68VWEg==

FANUC Series 16+/160+/160+s-MODEL B

FANUC Series 18+/180+/180+s-MODEL B

FANUC Series 21+/210+/210+s-MODEL B

CONNECTION MANUAL (HARDWARE)

B-63523EN/03

© MyFANUC 19C934977F3A4E20A8A35A328E753C6E

Page 2

• The appearance and specifications of this product are subject to change without notice.

Foreign Exchange and

the government of Japan. Other models in this manual may also be subject to export

vernment of

Should you wish to export or re-export these products, please contact FANUC for advice.

er, a very large number of operations that must not or cannot be

being possible are "not possible".

which are registered trademarks of respective owners. However, these names are not

followed by or in the main body.

7169Fr4Hqa2ECQqEpRfd63ND/4NVqYNEFOTqTAv7RCUlwWzsC+2wd68VWEg==

• No part of this manual may be reproduced in any form.

The products in this manual are controlled based on Japan’s “

Foreign Trade Law”. The export of Series 16i from Japan is subject to an export license by

controls.

Further, re-export to another country may be subject to the license of the go

the country from where the product is re-exported. Furthermore, the product may also be

controlled by re-export regulations of the United States government.

In this manual, we endeavor to include all pertinent matters.

There are, howev

performed, and if the manual contained them all, it would be enormous in volume.

It is, therefore, requested to assume that any operations that are not explicitly described as

This manual contains the program names or device names of other companies, some of

© MyFANUC 19C934977F3A4E20A8A35A328E753C6E

Page 3

7169Fr4Hqa2ECQqEpRfd63ND/4NVqYNEFOTqTAv7RCUlwWzsC+2wd68VWEg==

B–63523EN/03

DEFINITION OF WARNING, CAUTION, AND NOTE

DEFINITION OF WARNING, CAUTION, AND NOTE

This manual includes safety precautions for protecting the user and preventing damage to the

machine. Precautions are classified into W arning and Caution according to their bearing on safety.

Also, supplementary information is described as a Note. Read the Warning, Caution, and Note

thoroughly before attempting to use the machine.

WARNING

Applied when there is a danger of the user being injured or when there is a danger of both the user

being injured and the equipment being damaged if the approved procedure is not observed.

CAUTION

Applied when there is a danger of the equipment being damaged, if the approved procedure is not

observed.

NOTE

The Note is used to indicate supplementary information other than Warning and Caution.

` Read this manual carefully, and store it in a safe place.

s–1

© MyFANUC 19C934977F3A4E20A8A35A328E753C6E

Page 4

7169Fr4Hqa2ECQqEpRfd63ND/4NVqYNEFOTqTAv7RCUlwWzsC+2wd68VWEg==

© MyFANUC 19C934977F3A4E20A8A35A328E753C6E

Page 5

7169Fr4Hqa2ECQqEpRfd63ND/4NVqYNEFOTqTAv7RCUlwWzsC+2wd68VWEg==

B–63523EN/03

PREFACE

PREFACE

This manual describes the electrical and structural specifications required

for connecting the CNC control unit to a machine tool. The manual

outlines the components commonly used for F ANUC CNC control units,

as shown in the configuration diagram in Chapter 2, and supplies

additional information on using these components. The manual outlines

the I/O unit, servo, spindle, and other components common to FANUC

CNC control units, and supplies additional information on using these

components in this CNC control unit. For detailed specifications, refer

to the manuals of these components.

For options not covered in this manual, also refer to the manuals of these

components.

Applicable models

The models covered by this manual, and their abbreviations, are :

Product Name Abbreviations

FANUC Series 16i–TB 16i–TB

FANUC Series 16i–MB 16i–MB

FANUC Series 18i–TB 18i–TB

FANUC Series 18i–MB5 18i–MB5

FANUC Series 18i–MB 18i–MB

FANUC Series 21i–TB 21i–TB

FANUC Series 21i–MB 21i–MB

FANUC Series 160i–TB 160i–TB

FANUC Series 160i–MB 160i–MB

FANUC Series 180i–TB 180i–TB

FANUC Series 180i–MB5 180i–MB5

FANUC Series 180i–MB 180i–MB

FANUC Series 210i–TB 210i–TB

FANUC Series 210i–MB 210i–MB

Series 16i

Series 18i

Series 21i

Series 160i

Series 180i

Series 210i

FANUC Series 160is–TB 160is–TB

FANUC Series 160is–MB 160is–MB

FANUC Series 180is–TB 180is–TB

FANUC Series 180is–MB5 180is–MB5

FANUC Series 180is–MB 180is–MB

FANUC Series 210is–TB 210is–TB

FANUC Series 210is–MB 210is–MB

p–1

© MyFANUC 19C934977F3A4E20A8A35A328E753C6E

Series 160is

Series 180is

Series 210is

Page 6

7169Fr4Hqa2ECQqEpRfd63ND/4NVqYNEFOTqTAv7RCUlwWzsC+2wd68VWEg==

PREFACE

Organization of this

manuals

Chapter and title Contents

Chapter 1

CONFIGURATION

Chapter 2

TOT AL CONNECTION DAIGRAMS

Chapter 3

INSTALLATION

Chapter 4

POWER SUPPLAY CONNECTION

Chapter 5

CONNECTION TO CNC PERIOHERALS

B–63523EN/03

This manual consists of chapters 1 to 15 and appendixes at the end of the

book.

Provides general information related to the connection of the i Series CNC, as well as an

introduction to detailed information.

Describes how to connect peripheral units to the i Series CNC.

Describes the installation requirements for using the i Series CNC.

1) Required power supply capacity

2) Heat output

3) Locations of connectors on the control unit

4) Action against noise

Describes how to make connections related to the power supply of the i Series CNC.

Describes how to connect the following peripheral devices to the i Series CNC:

1) MDI unit

2) I/O device (RS–232–C)

3) High–speed skip (HDI)

4) Built–in ethernet

Chapter 6

SPINDLE CONNECTION

Chapter 7

SERVO INTERF ACE

Chapter 8

CNC DISPLA Y UNIT WITH PC

FUNCTIONS

Chapter 9

CONNECTION TO FANUC I/O Link

Chapter 10

EMERGENCY STOP SIGNAL

Chapter 11

REMOTE BUFFER INTERFACE

(INCLUDING F ANUC DNC1 AND DNC2)

Chapter 12

HIGH–SPEED SERIAL BUS (HSSB)

Chapter 13

CONNECTION TO OTHER

NET–WORKS

Chapter 14

CONNECTION FOR Series

160is/180is/210is

Describes how to connect spindle–related units to the i Series CNC.

Describes how to connect servo–related units to the i Series CNC.

Describes how to connect a CNC display unit with PC functions to the i Series CNC.

Describes how to connect machine interface I/O with the FANUC I/O Link.

Describes how to handle the emergency stop signal.

Be sure to read this chapter.

Describes the remote buffer, DNC1, and DNC2 interfaces that can be used with the i Series CNC.

Describes the high–speed serial bus (HSSB) that can be used with the i Series CNC.

Describes how to connect the i Series CNC to networks.

Describes connection for Series 160is/180is/210is

APPENDIX A) EXTERNAL DIMENSIONS OF EACH UNIT

B) 20–PIN INTERFACE CONNECTORS AND CABLES

C) CONNECTION CABLE (SUPPLIED FROM US)

D) OPTICAL FIBER CABLE

E) LIQUID CRYST AL DISPLA Y (LCD)

F) MEMORY CARD INTERF ACE

p–2

© MyFANUC 19C934977F3A4E20A8A35A328E753C6E

Page 7

7169Fr4Hqa2ECQqEpRfd63ND/4NVqYNEFOTqTAv7RCUlwWzsC+2wd68VWEg==

B–63523EN/03

Related manuals of

Series 16i/18i/21i/160i/

180i/210i/160is/ 180is/

210is–MODEL B

PREFACE

The following table lists the manuals related to Series 16i, Series 18i,

Series 21i, Series 160i, Series 180i, Series 210i, Series 160is, Series

180is, Series 210is–MODEL B. This manual is indicated by an

asterisk(*).

Manual name

DESCRIPTIONS B–63522EN

CONNECTION MANUAL (HARDWARE) B–63523EN *

CONNECTION MANUAL (FUNCTION) B–63523EN–1

Series 16i/18i/160i/180i/160is/180is–TB

OPERATOR’S MANUAL

Series 16i/160i/160is–MB, Series 18i/180i/180is–MB5,

Series 18i/180i/180is–MB OPERATOR’S MANUAL

Series 21i/210i/210is–TB OPERATOR’S MANUAL B–63604EN

Series 21i/210i/210is–MB OPERATOR’S MANUAL B–63614EN

MAINTENANCE MANUAL B–63525EN

Specification

number

B–63524EN

B–63534EN

Series 16i/18i/160i/180i/160is/180is–MODEL B

P ARAMETER MANUAL

Series 21i/210i/210is–MODEL B PARAMETER MANUAL B–63610EN

PROGRAMMING MANUAL

Macro Compiler/Macro Executor

PROGRAMMING MANUAL

FAPT MACRO COMPILER (For Personal Computer)

PROGRAMMING MANUAL

C Language Executor PROGRAMMING MANUAL B–62443EN–3

CAP (T series)

FANUC Super CAPi T OPERAT ORS MANUAL B–63284EN

FANUC Symbol CAPi T OPERAT OR’S MANUAL B–63304EN

MANUAL GUIDE For Lathe PROGRAMMING MANUAL B–63343EN

MANUAL GUIDE For Lathe OPERA T OR’S MANUAL B–63344EN

CAP (M series)

FANUC Super CAPi M OPERAT OR’S MANUAL B–63294EN

B–63530EN

B–61803E–1

B–66102E

MANUAL GUIDE For Milling PROGRAMMING MANUAL B–63423EN

MANUAL GUIDE For Milling OPERA T OR’S MANUAL B–63424EN

PMC

PMC Ladder Language PROGRAMMING MANUAL B–61863E

PMC C Language PROGRAMMING MANUAL B–61863E–1

p–3

© MyFANUC 19C934977F3A4E20A8A35A328E753C6E

Page 8

7169Fr4Hqa2ECQqEpRfd63ND/4NVqYNEFOTqTAv7RCUlwWzsC+2wd68VWEg==

PREFACE

Related manuals of

SERVO MOTOR αi series

B–63523EN/03

Manual name

Network

FANUC I/O Link–II CONNECTION MANUAL B–62714EN

Profibus–DP Board OPERA T OR’S MANUAL B–62924EN

Ethernet Board/DA T A SERVER Board

OPERATOR’S MANUAL

FAST Ethernet Board/FAST DA TA SERVER

OPERATOR’S MANUAL

DeviceNet Board OPERA T OR ’S MANUAL B–63404EN

PC function

Screen Display Function OPERA TOR’S MANUAL B–63164EN

Specification

number

B–63354EN

B–63644EN

The following table lists the manuals related to SER VO MOTOR ai series

Manual name

AC SERVO MOTOR αi series DESCRIPTIONS B–65262EN

Specification

number

Related manuals of

SERVO MOTOR α series

AC SERVO MOTOR αi series P ARAMETER MANUAL B–65270EN

AC SPINDLE MOTOR αi series DESCRIPTIONS B–65272EN

AC SPINDLE MOTOR αi series PARAMETER MANUAL B–65280EN

SERVO AMPLIFIER αi series DESCRIPTIONS B–65282EN

SERVO MOTOR αi series MAINTENANCE MANUAL B–65285EN

The following table lists the manuals related to SER VO MOTOR a series

Manual name

FANUC AC SER VO MOTOR α series DESCRIPTIONS B–65142

FANUC AC SER VO MOTOR α series

P ARAMETER MANUAL

FANUC AC SPINDLE MOT OR α series DESCRIPTIONS B–65152

FANUC AC SPINDLE MOT OR α series

P ARAMETER MANUAL

FANUC SER VO AMPLIFIER α series DESCRIPTIONS B–65162

FANUC SER VO MOT OR α series

MAINTENANCE MANUAL

Specification

number

B–65150

B–65160

B–65165

Either of the following servo motors and the corresponding spindle can

be connected to the CNC covered in this manual.

D FANUC SERVO MOTOR ai series

D FANUC SERVO MOTOR a series

This manual mainly assumes that the FANUC SER VO MOTOR ai series

of servo motor is used. For servo motor and spindle information, refer to

the manuals for the servo motor and spindle that are actually connected.

p–4

© MyFANUC 19C934977F3A4E20A8A35A328E753C6E

Page 9

7169Fr4Hqa2ECQqEpRfd63ND/4NVqYNEFOTqTAv7RCUlwWzsC+2wd68VWEg==

B–63523EN/03

Table of Contents

DEFINITION OF WARNING, CAUTION, AND NOTE s–1. . . . . . . . . . . . . . . . . . . . . . . . . .

PREFACE p–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1. CONFIGURATION 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 CONTROL UNIT CONFIGURATION AND COMPONENT NAMES 2. . . . . . . . . . . . . . . . . . . . . .

1.1.1 Configurations of LCD–mounted Type Control Units 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1.2 Configurations of Stand–alone T ype Control Units 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 HARDWARE OVERVIEW 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2. TOTAL CONNECTION DIAGRAMS 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3. INSTALLATION 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 ENVIRONMENTAL REQUIREMENTS OUTSIDE THE CABINET 29. . . . . . . . . . . . . . . . . . . . . . .

3.2 POWER SUPPLY CAPACITY 30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.1 Power Supply Capacities of CNC–related Units 30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3 DESIGN AND INSTALLATION CONDITIONS OF THE MACHINE TOOL

MAGNETIC CABINET 33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4 THERMAL DESIGN OF THE CABINET 35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4.1 T emperature Rise within the Cabinet 35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4.2 Heat Output of Each Unit 36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4.3 Thermal Design of Operator’s Panel 39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5 ACTION AGAINST NOISE 41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5.1 Separating Signal Lines 41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5.2 Ground 43. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5.3 Connecting the Signal Ground (SG) of the Control Unit 45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5.4 Noise Suppressor 47. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5.5 Cable Clamp and Shield Processing 48. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5.6 Measures Against Surges due to Lightning 51. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.6 CONTROL UNIT 53. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.6.1 Installation of the Control Unit 53. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.6.2 Installing the Stand–alone T ype Control Unit 54. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.7 CABLING DIAGRAM 55. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.8 DUSTPROOF MEASURES FOR CABINETS AND PENDANT BOXES 55. . . . . . . . . . . . . . . . . . . .

4. POWER SUPPLY CONNECTION 56. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 GENERAL 57. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 TURNING ON AND OFF THE POWER TO THE CONTROL UNIT 58. . . . . . . . . . . . . . . . . . . . . . .

4.2.1 Power Supply for the Control Unit 58. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2.2 +24V Input Power Specifications 60. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2.3 Power–on Sequence 63. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2.4 Power–off Sequence 64. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3 CABLE FOR POWER SUPPLY TO CONTROL UNIT 65. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4 BATTERIES 66. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.1 Battery for Memory Backup (3VDC) 66. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.2 Batteries for CNC Display Unit with PC Functions (3VDC) 71. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.3 Battery for Separate Absolute Pulse Coders (6VDC) 72. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.4 Battery for Absolute Pulse Coder Built into the Motor (6VDC) 73. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5. CONNECTION TO CNC PERIPHERALS 74. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

c–1

© MyFANUC 19C934977F3A4E20A8A35A328E753C6E

Page 10

7169Fr4Hqa2ECQqEpRfd63ND/4NVqYNEFOTqTAv7RCUlwWzsC+2wd68VWEg==

Table of Contents

B–63523EN/03

5.1 CONNECTION OF MDI UNIT (LCD–MOUNTED TYPE) 75. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1.1 General 75. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1.2 Connection to the MDI Unit (LCD–mounted Type) 76. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1.3 Connection with the Standard MDI Unit 77. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1.4 Key Layout of Separate–type MDI 78. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1.5 61–Key MDI Unit 82. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2 CONNECTION WITH THE DISPLAY/MDI UNITS

(FOR THE STAND–ALONE TYPE i SERIES CNC) 83. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.1 Overview 83. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.2 Connection with the 10.4I/9.5I LCD Unit 84. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.3 Connection with the 7.2I LCD Unit Via the Display Link 87. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.4 Connecting to the 7.2I LCD Unit by the Display Link (Multiple Connection) 91. . . . . . . . . . . . . . . . . . .

5.2.5 Connection of the Detachable 7.2I LCD/MDI Unit Via the Display Link 96. . . . . . . . . . . . . . . . . . . . . .

5.2.6 Connection with an CNC Display Unit with PC Functions 102. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3 CONNECTION WITH INPUT/OUTPUT DEVICES 104. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3.1 Overview 104. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3.2 Connecting I/O Devices 106. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3.3 RS–232–C Serial Port 107. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3.4 RS–232–C Interface Specification 109. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3.5 F ANUC Handy File Connection 118. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.4 CONNECTING THE HIGH–SPEED SKIP (HDI) 119. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.4.1 General 119. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.4.2 Connection to the High–speed Skip (HDI) 120. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.4.3 Input Signal Rules for the High–speed Skip (HDI) 122. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.5 LINKING THE EMBEDDED ETHERNET INTERFACE 123. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.5.1 Connection to the Ethernet Interface 123. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.5.2 Specification of T wisted–Pair Cable 125. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.5.3 Anti–Noise Measure 127. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.5.4 Network Installation 127. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6. SPINDLE CONNECTION 129. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1 SERIAL SPINDLE 134. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1.1 Connection of One to Two Serial Spindles 134. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1.2 Connecting One to Four Serial Spindles 136. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2 ANALOG SPINDLE INTERFACE 144. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3 POSITION CODER INTERFACE 145. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7. SERVO INTERFACE 146. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1 CONNECTION TO THE SERVO AMPLIFIERS 147. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1.1 General 148. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1.2 Interface to the Servo Amplifiers 148. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1.2.1 Interface to the servo amplifiers 148. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1.2.2 Interfacing with servo amplifiers (for high–speed HR V function) 148. . . . . . . . . . . . . . . . . . . . . .

7.1.3 Separate Detector Interface 150. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1.4 Separate Detector Interface Unit Specification 152. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1.5 Connection of Power Supply 152. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1.6 Linear Scale Interface 153. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1.7 Stand–alone Type Pulse Coder Interface 154. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1.8 Input Signal Requirements 157. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1.9 Connection of Battery for Separate Absolute Detector 159. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1.10 Connection Between the Basic Unit and Expansion Unit 161. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1.11 Connector Locations 162. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1.12 Installation 163. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

c–2

© MyFANUC 19C934977F3A4E20A8A35A328E753C6E

Page 11

7169Fr4Hqa2ECQqEpRfd63ND/4NVqYNEFOTqTAv7RCUlwWzsC+2wd68VWEg==

B–63523EN/03

7.1.13 Notes on Installing a Separate Detector Interface Unit 164. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1.14 Connecting the Servo Check Adapter 166. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table of Contents

8. CNC DISPLAY UNIT WITH PC FUNCTIONS 168. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.1 OVERVIEW 169. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2 CAUTIONS 169. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.3 CONNECTION 170. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.4 GENERAL CONNECTION DIAGRAMS 171. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.4.1 CNC Display Unit with PC Functions Having Neither Soft Keys nor a T ouch Panel 171. . . . . . . . . . . . . .

8.4.2 CNC Display Unit with PC Functions Having Soft Keys but No T ouch Panel 173. . . . . . . . . . . . . . . . . . .

8.4.3 CNC Display Unit with PC Functions Having a T ouch Panel but No Soft Key 174. . . . . . . . . . . . . . . . . .

8.4.4 CNC Display Unit with PC Functions Having a T ouch Panel and Soft Key 175. . . . . . . . . . . . . . . . . . . . .

8.5 SPECIFICATIONS 176. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.5.1 Installation Environmental Conditions 176. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.5.2 Power Supply Specification 177. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.5.3 Shutdown 178. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.6 INSTALLATION SPACE 179. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.6.1 Basic Unit 10.4I LCD Type 179. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.6.2 Basic Unit 12.1I LCD T ype 180. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.6.3 Basic Unit 15.0I LCD T ype 180. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.6.4 HDD Unit 181. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.7 PERIPHERAL EQUIPMENT AND CONNECTION 182. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.7.1 Connector Layout Diagram 182. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.7.2 Main Power Supply Input 183. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.7.3 Floppy Disk Drive (Signal and Power Supply) 184. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.7.3.1 Operating environment 186. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.7.3.2 Handling precautions 186. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.7.4 High–speed Serial Bus (HSSB) 187. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.7.5 Typewriter–style Keyboard 188. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.7.6 Mouse 190. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.7.7 Centronics Parallel Port 191. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.7.8 Serial Port 2 + USB 192. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.7.9 Serial Port 1 194. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.7.10 Soft Keys 195. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.7.11 PCMCIA Card 196. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.7.12 Hard Disk Unit 197. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.8 PCI EXPANSION BOARD 198. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.8.1 Installation Method 198. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9. CONNECTION TO FANUC I/O Link 200. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.1 GENERAL 201. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.2 CONNECTION 202. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.2.1 Connection of FANUC I/O Link by Electric Cable 204. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.2.2 Connection of FANUC I/O Link Optical Fiber Cable 205. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.2.3 Connection when Two Channels of F ANUC I/O Links are Used 209. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.3 UNITS THAT CAN BE CONNECTED USING FANUC I/O LINK 213. . . . . . . . . . . . . . . . . . . . . . . . .

9.4 CONNECTION OF CONNECTOR PANEL I/O MODULE 214. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.4.1 Configuration 214. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.4.2 Connection Diagram 215. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.4.3 Module Specifications 216. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.4.4 DI/DO Connector Pin Assignment 218. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.4.5 DI (Input Signal) Connection 219. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

c–3

© MyFANUC 19C934977F3A4E20A8A35A328E753C6E

Page 12

7169Fr4Hqa2ECQqEpRfd63ND/4NVqYNEFOTqTAv7RCUlwWzsC+2wd68VWEg==

Table of Contents

9.4.6 DO (Output Signal) Connection 221. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.4.7 DI/DO Signal Specifications 222. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.4.8 2A Output Connector Pin Allocation 224. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.4.9 2A DO (Output Signal) Connection 225. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.4.10 2A Output DO Signal Specifications 226. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.4.11 Analog Input Connector Pin Allocation 227. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.4.12 Analog Input Signal Connections 228. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.4.13 Analog Input Signal Specifications 230. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.4.14 Analog Input Specifications 231. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.4.15 Manual Pulse Generator Connection 233. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.4.16 Cable Length for Manual Pulse Generator 234. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.4.17 Connection of Basic and Extension Modules 235. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.4.18 Module Installation 236. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.4.19 Other Notes 241. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.4.20 Distribution I/O Setting 244. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B–63523EN/03

9.5 CONNECTION OF OPERATOR’S PANEL I/O MODULE (FOR MATRIX INPUT) 247. . . . . . . . . . .

9.5.1 Overall Connection Diagram 247. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.5.2 Power Connection 248. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.5.3 DI/DO Connector Pin Arrangement 249. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.5.4 DI (General–purpose Input Signal) Connection 250. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.5.5 DI (Matrix Input Signal) Connection 252. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.5.6 DO (Output Signal) Connection 253. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.5.7 Manual Pulse Generator Connection 256. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.5.8 External View 257. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.5.9 Specifications 258. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.5.10 Other Notes 261. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.6 CONNECTION OF OPERATOR’S PANEL I/O MODULE AND

POWER MAGNETICS CABINET I/O MODULE 265. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.6.1 Overall Connection Diagram 265. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.6.2 Power Connection 267. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.6.3 DI/DO Connector Pin Arrangement 268. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.6.4 DI (General–purpose Input Signal) Connection 269. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.6.5 DO (Output Signal) Connection 273. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.6.6 Manual Pulse Generator Connection 275. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.6.7 External View 275. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.6.8 Specifications 276. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.6.9 Other Notes 278. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.7 CONNECTION OF MACHINE OPERATOR’S PANEL INTERFACE UNIT 282. . . . . . . . . . . . . . . . .

9.7.1 Function Overview 282. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.7.2 System Configuration 284. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.7.3 Signal Assignment 285. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.7.4 Interface 287. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.7.5 PMC Addresses 298. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.7.6 Major Connection Precautions 299. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.7.7 State of the LEDs on the Machine Operator’s Panel Interface Unit 299. . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.7.8 Connector (on the Cable Side) Specifications 300. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.7.9 Machine Operator’s Panel Interface Unit Dimension Diagram (Including Connector Locations) 301. . . . .

9.7.10 Machine Operator’s Panel Interface Unit Mounting Dimension Diagram 302. . . . . . . . . . . . . . . . . . . . . . .

9.7.11 Fuse Mounting Position 304. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.8 CONNECTION OF OPERATOR’S PANEL CONNECTION UNIT 305. . . . . . . . . . . . . . . . . . . . . . . . .

9.8.1 Input Signal Regulations for Operator’s Panel Connection Unit 306. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.8.2 Output Signal Regulations for Operator’s Panel Connection Unit 308. . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.8.3 Connector Layout for Operator’s Panel Connection Unit 309. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.8.4 External View of Operator’s Panel Connection Unit 311. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.9 CONNECTION OF SOURCE OUTPUT TYPE CONNECTION UNIT 312. . . . . . . . . . . . . . . . . . . . . .

9.9.1 Input Signal Specifications for Source Output T ype Connection Unit 313. . . . . . . . . . . . . . . . . . . . . . . . .

c–4

© MyFANUC 19C934977F3A4E20A8A35A328E753C6E

Page 13

7169Fr4Hqa2ECQqEpRfd63ND/4NVqYNEFOTqTAv7RCUlwWzsC+2wd68VWEg==

B–63523EN/03

9.10 FANUC I/O LINK CONNECTION UNIT 322. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.11 CONNECTING THE FANUC SERVO UNIT b SERIES WITH I/O LINK 329. . . . . . . . . . . . . . . . . . .

9.12 CONNECTION OF THE DISTRIBUTION I/O MACHINE OPERATOR’S PANEL 332. . . . . . . . . . .

9.13 CONNECTION TO MACHINE OPERATOR’S PANEL 364. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table of Contents

9.9.2 Output Signal Specifications for Source Output T ype Connection Unit 314. . . . . . . . . . . . . . . . . . . . . . . .

9.9.3 Connector Pin Layout for Source Output T ype Connection Unit 318. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.9.4 Dimensions of Source Output T ype Connection Unit 321. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.10.1 Overview 322. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.10.2 Specification 323. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.10.3 Connection 326. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.10.3.1 I/O Link interface 326. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.11.1 Overview 329. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.11.2 Connection 330. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.11.3 Maximum Number of Units that can be Connected 331. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.11.4 Address Assignment by Ladder 331. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.12.1 Differences between the FS0 Standard Machine Operator’s Panel and

Distribution I/O Machine Operator Panel 332. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.12.2 Overall Connection Diagram 334. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.12.3 Connector Mounting Diagram 335. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.12.4 Power Supply Connection 336. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.12.5 Emergency Stop Signal Connection 337. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.12.6 General–purpose DI Signal Connection 338. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.12.7 General–purpose DO Signal Connection 342. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.12.8 Manual Pulse Generator Connection 343. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.12.9 Relay T erminal Connection 343. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.12.10 Keyboard Addresses 344. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.12.11 Other Signal Addresses 346. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.12.12 Allocation 347. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.12.13 Specifications 349. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.12.14 Other Notes 352. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.12.15 Operator’s Panel 355. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.13.1 Overview 364. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.13.2 T otal Connection Diagram 366. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.13.3 Each Connections 367. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.13.3.1 Pin assignment 367. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.13.3.2 Power supply connection 369. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.13.3.3 MDI connection 370. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.13.3.4 I/O link connection 371. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.13.3.5 Emergency stop signal connection 372. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.13.3.6 Power ON/OFF control signal connection 372. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.13.3.7 DI (input signal) connection 373. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.13.3.8 DO (output signal) connection 376. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.13.3.9 Manual pulse generator connection 376. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.13.3.10Connector (on the cable side) specifications. 380. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.13.4 DI/DO Address 381. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.13.4.1 Keyboard of main panel 381. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.13.4.2 Override signals 382. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.13.5 DI/DO Mapping 383. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.13.6 Outline 385. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.13.6.1 Outline of main panel A 385. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.13.6.2 Outline of main panel B 387. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.13.6.3 Outline of sub panel A 388. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

c–5

© MyFANUC 19C934977F3A4E20A8A35A328E753C6E

Page 14

7169Fr4Hqa2ECQqEpRfd63ND/4NVqYNEFOTqTAv7RCUlwWzsC+2wd68VWEg==

Table of Contents

9.13.6.4 Outline of sub panel B 389. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.13.6.5 Outline of sub panel C 390. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.13.6.6 Connector locations of main panel A/A1 391. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.13.6.7 Connector locations of main panel B/B1 392. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.13.6.8 Outline of sub panel B1 393. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.13.6.9 Outline of main panel A1 394. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.13.6.10Outline of main panel B1 395. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.13.6.11Outline of sub panel C1 396. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.13.7 Specifications 397. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.13.7.1 Environmental requirement 397. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.13.7.2 Order specification 397. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.13.7.3 Main panel A/B/A1/B1 specification 398. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.13.7.4 Sub panel A/B/B1/C/C1 specification 398. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.13.7.5 Power supply specification 398. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.13.7.6 General–purpose DI signal definition 398. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.13.7.7 General–purpose DO signal definition 399. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.13.8 Key Symbol Indication on Machine Operators Panel 400. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.13.8.1 Meaning of key symbols 400. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.13.8.2 Detachable key top 402. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.13.9 Others 403. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.13.10 Maintenance Parts 406. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B–63523EN/03

10.EMERGENCY STOP SIGNAL 407. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1 1.REMOTE BUFFER INTERFACE (INCLUDING FANUC DNC1 AND DNC2) 410. . . .

11.1 GENERAL 411. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.2 REMOTE BUFFER INTERFACE (RS–232–C) 413. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.3 REMOTE BUFFER INTERFACE (RS–422) 415. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.4 DNC2 INTERFACE (RS–232–C) 417. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.5 DNC1 INTERFACE 418. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.5.1 Multipoint Connection 418. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.5.2 Point–to–point Connection 419. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.HIGH–SPEED SERIAL BUS (HSSB) 420. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.1 OVERVIEW 421. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.2 CAUTIONS 421. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.3 CONNECTION DIAGRAM 422. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.4 PERSONAL COMPUTER SPECIFICATION 423. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.4.1 Specification of Personal Computer in Case that the Interface Board of ISA Type are Used 423. . . . . . . . .

12.4.2 Specification of Personal Computer in Case that the Interface Board of PCI T ype are Used 423. . . . . . . . .

12.5 INSTALLATION ENVIRONMENT 424. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.6 PROCEDURE FOR INSTALLING PERSONAL COMPUTER INTERFACE BOARDS 425. . . . . . . .

12.7 HANDLING PRECAUTIONS 427. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.8 RECOMMENDED CABLES 428. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.CONNECTION TO OTHER NETWORKS 429. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

c–6

© MyFANUC 19C934977F3A4E20A8A35A328E753C6E

Page 15

7169Fr4Hqa2ECQqEpRfd63ND/4NVqYNEFOTqTAv7RCUlwWzsC+2wd68VWEg==

B–63523EN/03

Table of Contents

14.CONNECTION FOR Series 160is/180is/210is 430. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.1 TOTAL CONNECTION DIAGRAMS 431. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.1.1 LCD–Mounted Type Series 160is/180is/210is Control Unit 431. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.1.2 CNC Display Unit for Windows (Stand–Alone Type) 432. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.2 INSTALLATION 433. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.2.1 Connector Names and Connector Layout 433. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.2.1.1 LCD–mounted Series 160is/180is/210is 433. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.2.1.2 CNC display unit for Windows 435. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.2.2 External Dimensions of the Units 436. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.2.3 Environmental Conditions for Control Units 437. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.2.4 Power Supply Capacity 437. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.3 CONNECTION TO CNC PERIPHERALS 438. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.3.1 Main Power Input 438. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.3.2 Backup Unit 439. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.3.3 Ethernet Interface (10BASE–T/100BASE–TX) 442. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.3.4 Serial Port/USB Port 450. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.3.4.1 Serial port 450. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.3.4.2 USB port 452. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.3.5 F A Full–Keyboard 453. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.3.6 High–Speed Serial Bus (HSSB) (HSSB) [For Stand–Alone T ype] 455. . . . . . . . . . . . . . . . . . . . . . . . . . . .

APPENDIX

A. EXTERNAL DIMENSIONS OF EACH UNIT 459. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B. 20–PIN INTERFACE CONNECTORS AND CABLES 531. . . . . . . . . . . . . . . . . . . . . . .

B.1 OVERVIEW 532. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B.2 ADDITIONAL TARGET MODEL 532. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B.3 BOARD–MOUNTED CONNECTORS 532. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B.3.1 Vertical–type Connectors 532. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B.3.2 Straight and Right–angled Connectors (for Spring and Screw–fixing Connector Housings) 532. . . . . . . .

B.4 CABLE CONNECTORS 533. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B.5 RECOMMENDED CONNECTORS, APPLICABLE HOUSINGS, AND CABLES 536. . . . . . . . . . . .

C. CONNECTION CABLE (SUPPLIED FROM US) 547. . . . . . . . . . . . . . . . . . . . . . . . . . . .

D. OPTICAL FIBER CABLE 551. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

E. LIQUID CRYSTAL DISPLAY (LCD) 563. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

F. MEMORY CARD INTERFACE 566. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

c–7

© MyFANUC 19C934977F3A4E20A8A35A328E753C6E

Page 16

7169Fr4Hqa2ECQqEpRfd63ND/4NVqYNEFOTqTAv7RCUlwWzsC+2wd68VWEg==

© MyFANUC 19C934977F3A4E20A8A35A328E753C6E

Page 17

7169Fr4Hqa2ECQqEpRfd63ND/4NVqYNEFOTqTAv7RCUlwWzsC+2wd68VWEg==

B–63523EN/03

1

1. CONFIGURATION

CONFIGURATION

1

© MyFANUC 19C934977F3A4E20A8A35A328E753C6E

Page 18

7169Fr4Hqa2ECQqEpRfd63ND/4NVqYNEFOTqTAv7RCUlwWzsC+2wd68VWEg==

1. CONFIGURATION

1.1

CONTROL UNIT CONFIGURATION AND COMPONENT NAMES

1.1.1

Configurations of

LCD–mounted T ype

Control Units

B–63523EN/03

The i series control units are divided into two types: the LCD–mounted

type and stand–alone type.

LCD–mounted type control units have a built–in display. Stand–alone

type control units have a separate display unit. In the following sections,

the LCD–mounted type is also referred to as the LCD–mounted type, and

the stand–alone type is also referred to as the stand–alone type.

The configuration and component names of each type are shown in the

figures given below. This manual explains how to attach the connectors

shown in these figures to devices. The numbers in parentheses () in the

figures are keyed to the item numbers of the descriptions in this manual.

The numbers in brackets [] in the figures are connector numbers.

Series 16i/18i/21i LCD–mounted type control units (A circle in the table

denotes that a unit is available.)

Display

Expansion

slot

Soft key 16i 18i 21i

8.4″ TFT color

LCD

10.4″ TFT color

LCD

10.4″ TFT color

LCD (with touch

panel)

7.2″ STN

monochrome LCD

None 5+2 f f f

2 5+2 f f f

3 5+2 f f

4 5+2 f f

None 10+2 f f f

2 10+2 f f f

3 10+2 f f

4 10+2 f f

None None f f f

2 None f f f

3 None f f

4 None f f

None 5+2 f f f

2 5+2 f f f

3 5+2 f f

4 5+2 f f

9.5″ STN

monochrome LCD

2

© MyFANUC 19C934977F3A4E20A8A35A328E753C6E

None 10+2 f f f

2 10+2 f f f

3 10+2 f f

4 10+2 f f

Page 19

10.4 TFT

7169Fr4Hqa2ECQqEpRfd63ND/4NVqYNEFOTqTAv7RCUlwWzsC+2wd68VWEg==

B–63523EN/03

1. CONFIGURATION

Series 160is/180is/210is LCD–mounted type control units (A circle in

the table denotes that a unit is available.)

Display

10.4″ TFT

color LCD

Expan-

sion slot

None

2

3

Soft key

10+2 None f f f

None Provided f f f

10+2 Provided f f f

10+2 None f f f

None Provided f f f

10+2 Provided f f f

10+2 None f f f

None Provided f f f

10+2 Provided f f f

10+2 None f f f

Touch

panel

160is 180is 210is

4

None Provided f f f

10+2 Provided f f f

3

© MyFANUC 19C934977F3A4E20A8A35A328E753C6E

Page 20

7169Fr4Hqa2ECQqEpRfd63ND/4NVqYNEFOTqTAv7RCUlwWzsC+2wd68VWEg==

1. CONFIGURATION

LCD–mounted type control unit

Liquid–crystal

display

Memory card

interface

B–63523EN/03

Soft key switch

NOTE

This figure is a front view of the Series 16i/18i/21i

LCD–mounted type control unit with an 8.4″ TFT color

liquid–crystal display. The configurations of other control

units are basically the same as that shown above.

The numbers in parentheses () in the figures are keyed to

the item numbers of the descriptions in this manual. The

numbers in brackets [] in the figures are connector numbers.

4

© MyFANUC 19C934977F3A4E20A8A35A328E753C6E

Page 21

7169Fr4Hqa2ECQqEpRfd63ND/4NVqYNEFOTqTAv7RCUlwWzsC+2wd68VWEg==

B–63523EN/03

LCD–mounted type control unit

1. CONFIGURATION

Fan unit

Battery

Unit rear panel

Ethernet connector

[CD38A] (5.5)

Servo unit connector

[COP10A–1] (left) (7)

[COP10A–2] (right) (7)

Soft key

MDI connector

[CA55] (5.1)

Servo check board

connector

[CA69]

Power supply

module

Fuse

Serial spindle or

position coder connector

[JA41] (6)

I/O–Link connector

[JD44A]

Analog spindle or

high–speed skip

connector [JA40] (6.2, 5.4)

I/O unit interface

connector (5.3) [JD36A (left)

and JD36B (right)]

Power supply

connector [CP1]

NOTE

This figure is a rear view of the Series 16i/18i/21i LCD–mounted type control unit without option

slots. The configurations of the other control units of the Series 16i/18i/21i are basically the

same as that shown above.

The numbers in parentheses () in the figures are keyed to the item numbers of the descriptions

in this manual. The numbers in brackets [] in the figures are connector numbers.

5

© MyFANUC 19C934977F3A4E20A8A35A328E753C6E

Page 22

7169Fr4Hqa2ECQqEpRfd63ND/4NVqYNEFOTqTAv7RCUlwWzsC+2wd68VWEg==

1. CONFIGURATION

LCD–mounted type control unit

B–63523EN/03

Rear of unit

Option board

For remote buf fer, DNC1, or DNC2

RS–422

connector (11)

[JD6A]

RS–232C

connector (11)

[JD28A]

Rear of unit

Option board

For HSSB board

HSSB optical

connector (12)

[COP7]

6

© MyFANUC 19C934977F3A4E20A8A35A328E753C6E

Page 23

7169Fr4Hqa2ECQqEpRfd63ND/4NVqYNEFOTqTAv7RCUlwWzsC+2wd68VWEg==

B–63523EN/03

1. CONFIGURATION

NOTE

1 The above figures are rear views of a LCD–mounted type

control unit with option slots. The configurations of the

option slot portions of other LCD–mounted type control

units are the same as in the above figures.

2 When a loader control board is used, refer to the loader

control connection manual.

3 The optional functions shown below use option boards.

These option boards do not have connectors for connecting

external devices.

D C language

D Symbol CAPi T

D RISC

The numbers in parentheses () in the figures are keyed to

the item numbers of the descriptions in this manual. The

numbers in brackets [] in the figures are connector numbers.

7

© MyFANUC 19C934977F3A4E20A8A35A328E753C6E

Page 24

7169Fr4Hqa2ECQqEpRfd63ND/4NVqYNEFOTqTAv7RCUlwWzsC+2wd68VWEg==

1. CONFIGURATION

LCD–mounted type control unit

Servo unit

connector (FSSB)

(7) [CP10A–1] (left)

[CP10A–2] (right)

(Near side) (Far side)

Rear side of unit

Option board

For sub–CPU card

Servo check

board connector

B–63523EN/03

Analog output

connector (6)

[JA40]

Connector for

serial spindle/

position coder (6)

[JA41]

(7) [CA54]

Rear side of unit

Option board

For data server board

ATA card

Ethernet (5)

[CD33]

NOTE

The above figures are rear views of a LCD–mounted type

control unit with option slots. The configurations of the

option slot portions of other LCD–mounted type control

units are the same as in the above figures.

The numbers in parentheses () in the figures are keyed to

the item numbers of the descriptions in this manual. The

numbers in brackets [] in the figures are connector numbers.

8

© MyFANUC 19C934977F3A4E20A8A35A328E753C6E

Page 25

7169Fr4Hqa2ECQqEpRfd63ND/4NVqYNEFOTqTAv7RCUlwWzsC+2wd68VWEg==

B–63523EN/03

LCD–mounted type control unit

1. CONFIGURATION

Rear of unit

Option board

Profibus board

Connector for

master board

[JN1]

Connector for

slave board

[JN2]

Rear side of unit

Option board

I/O Link–II interface board

I/O LINK–II

terminal unit

[TB1]

NOTE

The above figures are rear views of a LCD–mounted type

control unit with option slots. The configurations of the

option slot portions of other LCD–mounted type control

units are the same as in the above figures.

The numbers in parentheses () in the figures are keyed to

the item numbers of the descriptions in this manual. The

numbers in brackets [] in the figures are connector numbers.

9

© MyFANUC 19C934977F3A4E20A8A35A328E753C6E

Page 26

9.5 STN

7169Fr4Hqa2ECQqEpRfd63ND/4NVqYNEFOTqTAv7RCUlwWzsC+2wd68VWEg==

1. CONFIGURATION

1.1.2

Configurations of

Stand–alone T ype

Control Units

B–63523EN/03

Series 16i/18i/21i stand–alone type control units (A circle in the table

denotes that a unit is available.)

Slot rack name

Single–slot rack None 2 f f f (*NOTE)

3–slot rack 2 4 f f f (*NOTE)

Expansion

slot

Mini

slot

16i 18i 21i

Re-

marks

Series 16i/18i/21i display units (A circle in the table denotes that a unit

is available.)

Display

10.4″ TFT color LCD 10+2 Provided f f f

10.4″ TFT color LCD

(with touch panel)

9.5″ STN

monochrome LCD

Soft

key

None Provided f f f

10+2 Provided f f f

10+2 None f f f

Graphic

display

160i 180i 210i

Re-

marks

Series 160i/180i/210i display units (CNC display unit with PC functions)

(A circle denotes that a unit is available.)

Display

″

10.4″ TFT color LCD

″

12.1″ TFT color LCD

″

15.0″ TFT color LCD

Soft

key

None None f f f

10+2 Provided f f f

None Provided f f f

10+2 Provided f f f

None None f f f

10+2 None f f f

None Provided f f f

10+2 Provided f f f

None None f f f

10+2 None f f f

None Provided f f f

10+2 Provided f f f

Touch

panel

160i 180i 210i

Re-

marks

10

© MyFANUC 19C934977F3A4E20A8A35A328E753C6E

Page 27

7169Fr4Hqa2ECQqEpRfd63ND/4NVqYNEFOTqTAv7RCUlwWzsC+2wd68VWEg==

B–63523EN/03

1. CONFIGURATION

Series 160is/180is/210is display units (CNC display unit with PC

functions) (A circle denotes that a unit is available.)

Display

10.4″ TFT color LCD

Soft

key

10+2 None f f f

None Provided f f f

10+2 Provided f f f

Touch

panel

160is 180is 210is

Re-

marks

11

© MyFANUC 19C934977F3A4E20A8A35A328E753C6E

Page 28

7169Fr4Hqa2ECQqEpRfd63ND/4NVqYNEFOTqTAv7RCUlwWzsC+2wd68VWEg==

1. CONFIGURATION

Stand–alone type control unit

Battery

(4.4)

Memory card

interface

LCD connector (5)

[COP20A]

B–63523EN/03

Battery

(4.4)

Status display LED

I/O unit interface

connector (5.2)

[JD5A, JD5B]

I/O Link

connector (9)

[JD44A]

Slot 3 Slot 2

Connector for analog

spindle or high–speed

skip (6) (5.3) [JA40]

Connector for serial

spindle or position

coder (6) [JA41]

Mini slot

Slot 12

Mini slot

Slot 11

Mini slot

Slot 10

Mini slot

Slot 9

Servo unit (FSSB)

connector (7)

[COP10A–1(lower)]

[COP10A–2(upper)]

Connector for

CRT link and MDI (5)

[JD45]

LED for maintenance

Servo check board

connector (7) [CA69A]

Power supply

connector (4)

[CP1(right)]

[CP2(left)]

Rotary switch for

maintenance (upper),

Push switch for

maintenance (lower)

GND

connection terminal

Connector for ethernet

[CD38A]

NOTE

The numbers in parentheses () in the figures are keyed to

the item numbers of the descriptions in this manual. The

numbers in brackets [] in the figures are connector numbers.

12

© MyFANUC 19C934977F3A4E20A8A35A328E753C6E

Page 29

7169Fr4Hqa2ECQqEpRfd63ND/4NVqYNEFOTqTAv7RCUlwWzsC+2wd68VWEg==

B–63523EN/03

Stand–alone type control unit

Connector for analog

spindle or high–speed

skip (6) (5.3) [JA40]

Connector for

serial spindle or position

coder (6) [JA41]

1. CONFIGURATION

Sub–CPU board

Mini slot

Servo unit

(FSSB) connector (7)

[COP10A–1(lower)]

[COP10A–2(upper)]

Servo check board

connector (7) [CA69B]

NOTE

The numbers in parentheses () in the figures are keyed to

the item numbers of the descriptions in this manual. The

numbers in brackets [] in the figures are connector numbers.

13

© MyFANUC 19C934977F3A4E20A8A35A328E753C6E

Page 30

7169Fr4Hqa2ECQqEpRfd63ND/4NVqYNEFOTqTAv7RCUlwWzsC+2wd68VWEg==

1. CONFIGURATION

Stand–alone type control unit (mini slots)

HSSB board

C board

B–63523EN/03

HSSB optical

connector (12)

The C board has

no connector.

Remote buf fer , DNC2 board

Remote buf fer , DNC2 board

DNC1 board

RS–232–C

connector (11)

RS–422

connector (11)

RS–485

connector (11)

NOTE

The numbers in parentheses () in the figures are keyed to

the item numbers of the descriptions in this manual. The

numbers in brackets [] in the figures are connector numbers.

14

© MyFANUC 19C934977F3A4E20A8A35A328E753C6E

Page 31

7169Fr4Hqa2ECQqEpRfd63ND/4NVqYNEFOTqTAv7RCUlwWzsC+2wd68VWEg==

B–63523EN/03

Stand–alone type control unit (mini slots)

Ethernet board

DeviceNet board

1. CONFIGURATION

Ethernet board

connector (13)

DeviceNet board

connector (13)

PROFIBUS board

FL–net board

I/O Link–II board

PROFIBUS board

connector (13)

FL–net board

connector (13)

I/O Link–II board

connector (13)

NOTE

The numbers in parentheses () in the figures are keyed to

the item numbers of the descriptions in this manual. The

numbers in brackets [] in the figures are connector numbers.

15

© MyFANUC 19C934977F3A4E20A8A35A328E753C6E

Page 32

7169Fr4Hqa2ECQqEpRfd63ND/4NVqYNEFOTqTAv7RCUlwWzsC+2wd68VWEg==

1. CONFIGURATION

LCD unit for stand–alone type control unit

Liquid–crystal

display

Memory card

interface

Soft key switch

B–63523EN/03

Connector for

MDI connection (5)

[CA55]

I/O unit interface

connector (5)

[JD36A]

LCD connector (5)

[COP20B]

© MyFANUC 19C934977F3A4E20A8A35A328E753C6E

Fuse

Power supply

connector(5)

[CPIA (right)]

[CPIB (left)]

GND

connection terminal

NOTE

The numbers in parentheses () in the figures are keyed to

the item numbers of the descriptions in this manual. The

numbers in brackets [] in the figures are connector numbers.

16

Page 33

7169Fr4Hqa2ECQqEpRfd63ND/4NVqYNEFOTqTAv7RCUlwWzsC+2wd68VWEg==

B–63523EN/03

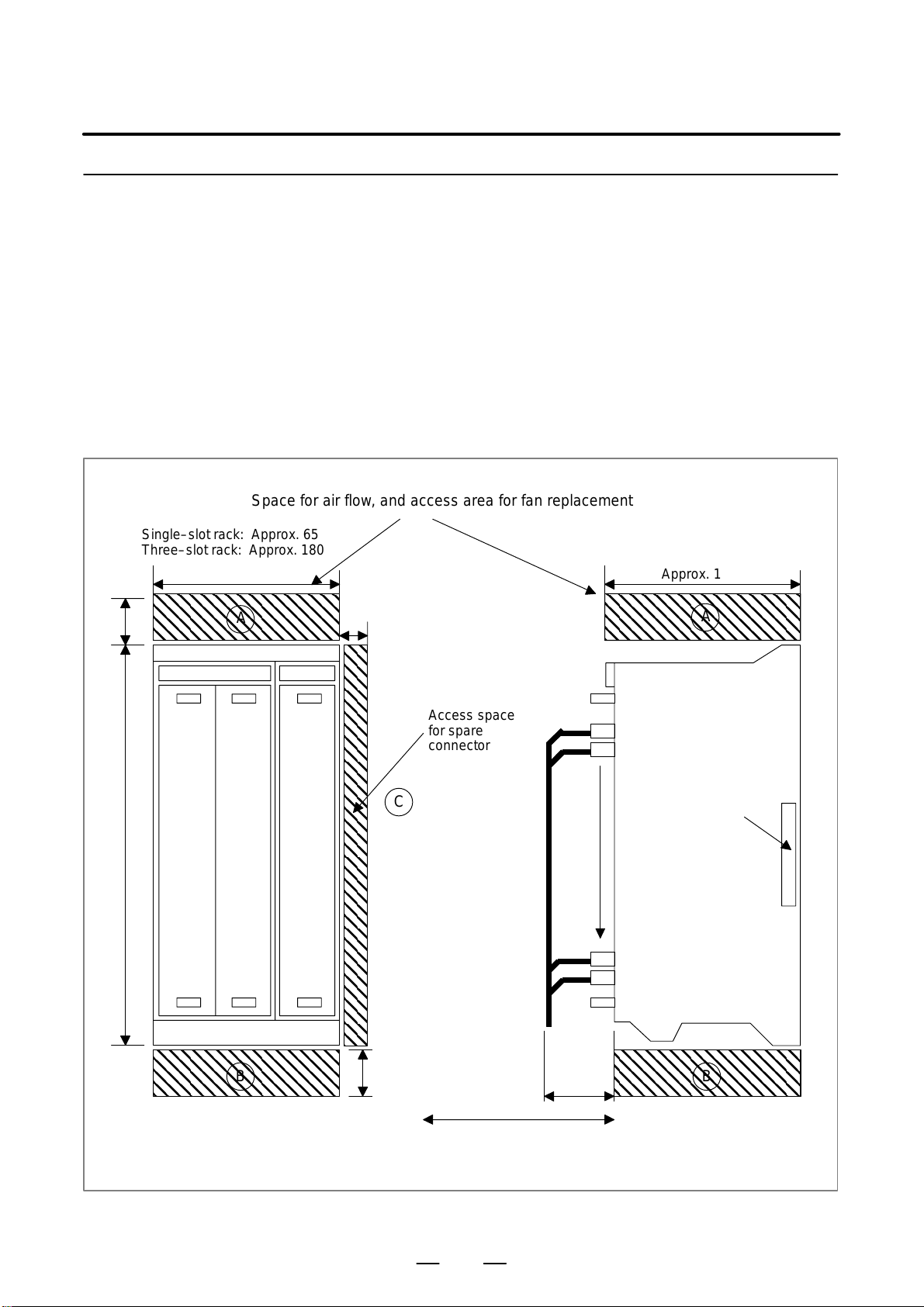

1.2

HARDWARE OVERVIEW

Serial communication board

Remote buffer/

DNC1/DNC2/HDLC

Sub–CPU board

Sub–CPU for 2–path control

· 2–axis to 8–axis control

· Spindle interface

· Analog output

C board

C functions for PMC

Loader control board

Loader control function

· 2–/4–axis control

Data server board

Data server function

RISC board

High–precision contour control

function

HSSB interface board

1. CONFIGURATION

Mother board

CPU for controlling CNC

· Power supply

· 2–axis to 8–axis control

· Spindle interface

· LCD/MDI

· I/O link

· PMC–SB7

· Analog output/high–

speed DI

· RS–232C × 2

· Memory card interface

Basic system

Symbol CAPi T

Conversational

automatic

programming

function

The following types of units are

available:

D Unit without option slots

D Unit having two option slots

D Unit having three option slots

D Unit having four option slots

High–speed serial bus

interface

Network board

· I/O Link–II board

· Ethernet board

· Profibus–DP board

· DeviceNet board

Options

On a unit with option slots, as many option boards as the number of option slots can be mounted. (However, the

option board must satisfy the mounting conditions. See the mounting conditions for additional options.)

Fig. 1.2 (a) Configuration of the LCD–mounted type control unit (Series 16i/160is)

17

© MyFANUC 19C934977F3A4E20A8A35A328E753C6E

Page 34

7169Fr4Hqa2ECQqEpRfd63ND/4NVqYNEFOTqTAv7RCUlwWzsC+2wd68VWEg==

1. CONFIGURATION

Serial communication board

Remote buffer/

DNC1/DNC2/HDLC

Sub–CPU board

Sub–CPU for 2–path control

· 2–axis to 6–axis control

· Spindle interface

· Analog output

C board

C functions for PMC

Symbol CAPi T

Conversational

automatic

programming

function

Loader control board

Loader control function

· 2–/4–axis control

Data server board

Data server function

HSSB interface board

High–speed serial bus

interface

B–63523EN/03

Mother board

CPU for controlling CNC

· Power supply

· 2–axis to 6–axis control

· Spindle interface

· LCD/MDI

· I/O link

· PMC–SB7

· Analog output/high–

speed DI

· RS–232C × 2

· Memory card interface

Basic system

· I/O Link–II board

· Ethernet board

· Profibus–DP board

· DeviceNet board

The following types of units are available:

D Unit without option slots

D Unit having two option slots

D Unit having three option slots

D Unit having four option slots

Network board

Options

On a unit with option slots, as many option boards as the number of option slots can be mounted. (However,

the option board must satisfy the mounting conditions. See the mounting conditions for additional options.)

Fig. 1.2 (b) Configuration of the LCD–mounted type control unit (Series 18i/180is)

18

© MyFANUC 19C934977F3A4E20A8A35A328E753C6E

Page 35

7169Fr4Hqa2ECQqEpRfd63ND/4NVqYNEFOTqTAv7RCUlwWzsC+2wd68VWEg==

B–63523EN/03

Serial communication board

Remote buffer/

DNC1/DNC2/HDLC

C board

C functions for PMC

Network board

· I/O Link–II board

· Ethernet board

· Profibus–DP board

· DeviceNet board

Symbol CAPi T

Conversational

automatic

programming