Estes 2189 User Manual

GLUE

GLUE

6. INSTALL SHOCK CORD MOUNT

GLUE

3

MOUNT

SHOCK CORD

SECTION

2

SECTION

1

SECTION

A. Cut out Shock

Cord Mount from

BACK PAGE.

3

B. Apply glue.

Fold forward.

1

2

SHOCK CORD

3

C. Apply glue.

Fold forward.

7. ATTACH PARACHUTE & SHOCK CORD

A. Remove excess

flash and clean

the eyelet of the

nose cone.

CAUTION:

Do not cut

off eyelet.

B. Form loop in Shroud

Lines and push

through hole in Nose

Cone.

C. Pass 'Chute

through loop.

D. Squeeze tightly

and hold for

one minute.

D.

Tie Shock Cord

to Nose Cone

using a double

knot.

1.5

(3.8 cm)

E. Glue mount 1.5” (3.8 cm) inside upper Body

Tube. Hold until glue sets. Let dry.

HELPFUL HINT:

DOUBLE KNOT

IF NOSE CONE/COUPLER FIT IS. . .

TOO

LOOSE

ADD

MASKING TAPE.

TOO

TIGHT

SAND FOR FIT.

NO

COUNTDOWN AND LAUNCH

KEY ALWAYS

OUT UNTIL

FINAL

COUNTDOWN!

1...

1...

Masking

Tape

Use 3/16” (5 mm)

Maxi™ Rod

4" (10.1 cm)

2...

2...

3...

3...

15 FT. (5 M)

4...

4...

SHOCK CORD

SECTION

SECTION

SECTION

CUT OUT AND USE

FOR STEP 6.

KEY

MOUNT

3

2

1

Space Transport Corporation

www.estesrockets.com

ESTES INDUSTRIES

1295 H Street

Penrose, CO 81240

PRINTED IN CHINA

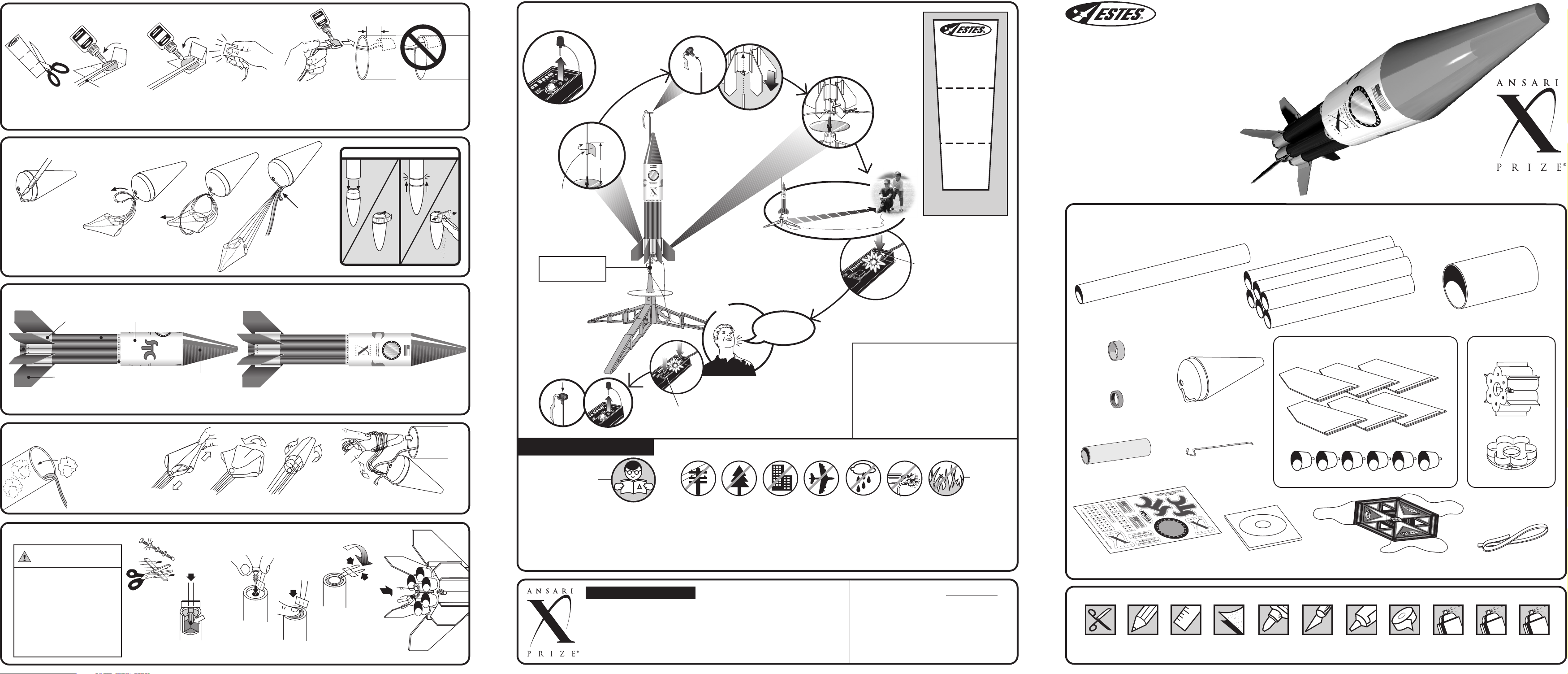

ASSEMBLY TIP: Read all instructions before

beginning work on your model. Make sure you

have all parts and supplies.

TEST FIT ALL PARTS TOGETHER

BEFORE APPLYING ANY GLUE!

If any parts don't fit properly, sand as required

for precision assembly.

PARTS

Locate the parts shown below and lay them out on the table in front of

you. DO NOT USE THIS DRAWING TO ASSEMBLE YOUR ROCKET.

RUBICON

FLYING MODEL ROCKET KIT INSTRUCTIONS

KEEP FOR FUTURE REFERENCE

#2189

X PRIZE is a registered trademark of the

X PRIZE Foundation and is used by permission.

8. FINISHING YOUR ROCKET

SILVER GRAY

GRAY

ORANGE

WHITE

SILVER

First spray rocket with white primer, except for internal tube. Let dry and sand.

Repeat until rocket is smooth. FOLLOW THE PAINT SCHEME ON THE PACKAGE.

ORANGE

When paint is dry, peel decals one at a time from backing

sheet and apply where shown. Rub down to remove bubbles.

PREPARE PARACHUTE FOR FLIGHT

A.

Insert 6-8 squares of

loosely crumpled

recovery wadding

into rocket.

NOTE: Only Estes

Wadding (302274)

Recommended.

B.

Spike Parachute.

PREPARE ENGINE

WARNING: FLAMMABLE

To avoid serious injury, read

instructions & NAR Safety Code

included with engines.

PREPARE YOUR ENGINE

ONLY WHEN YOU ARE

OUTSIDE AT THE LAUNCH

SITE PREPARING TO

If you do not use your prepared

engine, remove the igniter before

LAUNCH!

storing your engine.

A.

Separate

igniter and

plug.

B.

Insert igniter.

C.

Tip must

touch

propellant!

OPTIONAL: Spray a clear coat on entire rocket after paint

dries and after decal placement.

E.

Fold.

C.

Insert

plug.

D.

Roll.

D.

Push down.

Wrap lines loosely. Insert ‘Chute, Shock

Cord and Nose Cone into Body Tube.

E.

Gently bend

igniter wires

to form leads

as shown.

F. Insert

Engine.

Engine Mount Tube BT-50L (1)

30480

AR2050 (30164-2)

(30366)

Nose Cone PNC-321 (1)

(60893)

White Tank Tubes BT-50A (6)

PLASTIC PARTS SET 1 (1)

(30456)

(60833)

Fins (6)

Body Tube BT-321 (1)

(30457)

PLASTIC PARTS SET 2 (1)

(60834)

Fin Mount (1)

LAUNCH

BUTTON

5...

5...

4... 3... 2... 1...

HOLD KEY DOWN AND

PRESS LAUNCH BUTTON

UNTIL

LIFT-OFF!

INSERT KEY.

PUSH DOWN

AND HOLD.

ESTES LAUNCH SUPPLIES

(Sold Separately)

• Porta Pad® II Launch Pad (Requires 3/16”

[5 mm] Maxi™ Rod - sold separately).

• Electron Beam® Launch Controller

• Recovery Wadding

• Igniters (with Engines)

• Igniter Plugs (with Engines)

• Recommended Engines: D12-3, D12-5

Engine Hook Retainer Ring (1)

Green Engine Block (1)

PRECAUTIONS

NO DRY

NAR Safety Code

FLYING YOUR ROCKET

Choose a large field (500 ft. [152 m] square) free of dry weeds and

brown grass. The larger the launch area, the better the chance of

recovering your rocket. Football fields and playgrounds are great.

Launch only with little or no wind and good visibility.

Always follow the National Association of Rocketry (NAR)

Safety Code.

TEAM OVERVIEW

One of the newest entrants to the ANSARI X PRIZE race, Space Transport Corporation was

founded in August of 2002 by Eric Meier and Philip Storm, former engineers for Aerojet. The

company was founded with the vision of maximizing efficiency in development, production,

and administration to provide inexpensive space access. The company operates from a 3,500

square foot office/shops in Forks, WA. The community in the beautiful Forks area is founded

on a pioneering spirit and STC is proud to be a part of a new generation of pioneers in the

region. STC has launched several unmanned sounding rockets, one to a height of 150,000

feet, and has successfully tested the engines that will be used on its manned ANSARI X PRIZE

vehicle, the Rubicon.

5

6

Space Transport Corporation

MISFIRES

TAKE THE KEY OUT OF THE CONTROLLER. WAIT ONE MINUTE

BEFORE GOING NEAR THE ROCKET! Disconnect the igniter clips and

remove the engine. Take the plug and igniter out of the engine. If the igniter

has burned, it worked but did not ignite the engine because it was not

touching the propellant inside the engine. Put a new igniter all the way

inside the engine without bending it. Push the plug in place. Repeat the

steps under Countdown and Launch.

TEAM SPECIFICATIONS:

Name: Space Transport Cor poration. Website: www.space-transport.com

Country of Origin: Forks, Washington, USA

VEHICLE SPECIFICATIONS:

Name: Rubicon

Length: 22 feet (6.7 m). Diameter: 38 inches (96.5 cm). GTOW: 5,000 (2,268 KG).

DRY WT: 1,500 lb (680 KG). Engines: Seven. Total Thrust: 20,000 lb. (88,964 N).

Payload Capacity: 595 lbs (270 kg). Crew Environment: Pressurized cabin.

MISSION SPECIFICATIONS:

Launch Method: Ver tical Take-off from ground. Max Accel. Force on Ascent: 7 G’s.

Max Speed: 3,000 mph (1,341 m/s). Max. Altitude: ~68 miles (110 km). Time in

Weightless Conditions: ~3 minutes. Landing Method: Ocean splashdown via

parachute. Total Flight Duration: ~25 minutes.

© 2004-2005 Estes-Cox Corp. All rights reserved.

GRASS

OR

WEEDS

P/N 60839 (2-05)

Yellow Spacer Tool (1)

(35004)

Decal Sheet (1)

(60840)

SUPPLIES In addition to the parts included in the kit you will also need:

SCISSORS PENCIL RULER FINE

Engine Hook EH-2 (1)

(35021)

Die Cut Centering Ring (1)

SANDPAPER

(#400-600 GRIT)

(32437)

CARPENTER'S

GLUE

MODELING

KNIFE

Nozzles (6)

Assembled Parachute 18" (46 cm) (1)

TUBE-TYPE

PLASTIC

CEMENT

(35802)

MASKING

TAPE

SPRAY

PRIMER

WHITE

Cap (1)

Rubber Shock Cord (1/4" x 30")

WHITE, SILVER,

ORANGE, GRAY

(1) (38369)

SPRAY PAINT:

SPRAY

CLEAR

COAT

GLUE

GLUE

GLUE

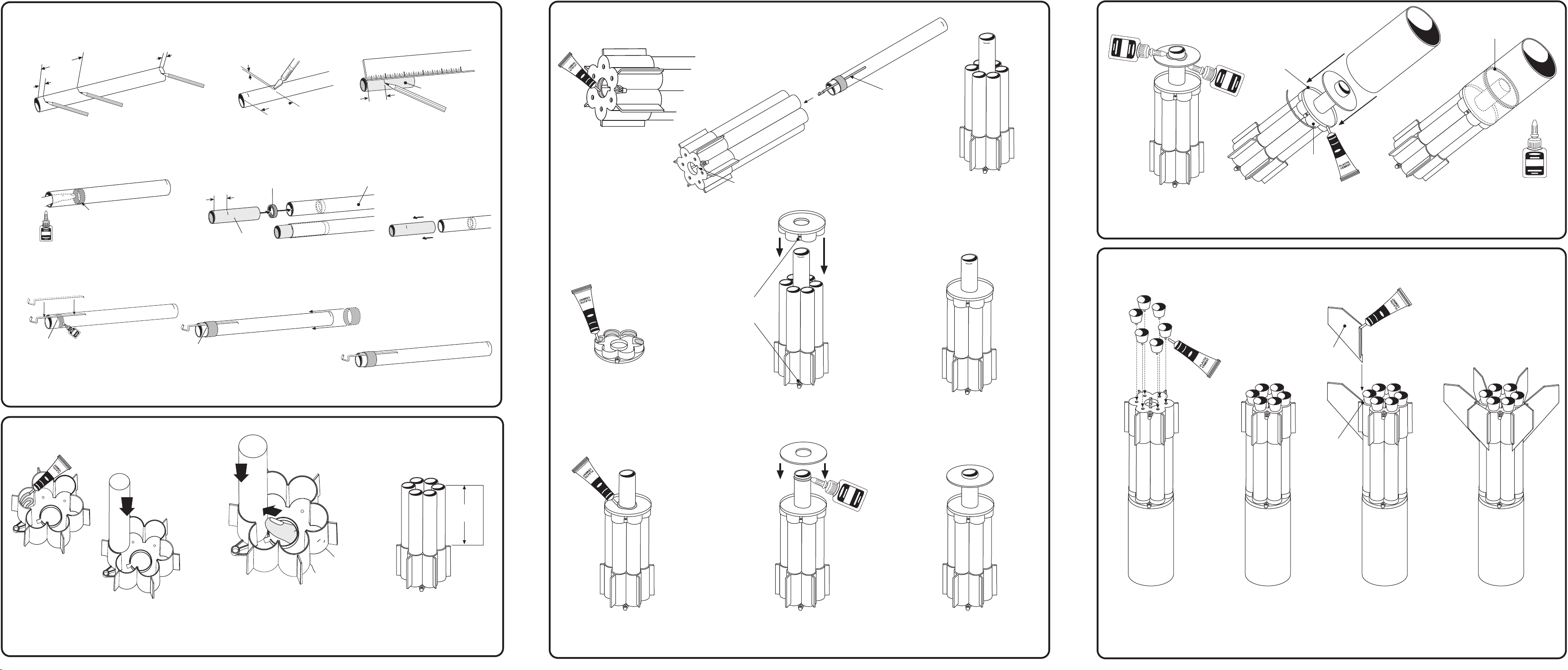

1. ASSEMBLE ENGINE MOUNT

GLUE

INCHES

1

2

3

4

5

GLUE

GLUE

1/8

(3 mm)

REAR

2

(5.1 cm)

1/2

(13 mm)

FRONT

(3 mm)

1/8

”

2

(5.1 cm)

3/4

(19 mm)

YELLOW SPACER

TOOL

3. INSTALL ENGINE MOUNT, CAP AND CENTERING RING

ENGINE

HOOK

4. INSTALL BODY TUBE

GLUE

FILLET

RIDGE

A. Measure and mark Engine Mount Tube.

REAR

1 3/4

(4.4 cm)

GLUE INSIDE

D. Smear glue 1-3/4” (4.4 cm) inside

Engine Mount Tube.

1/2

(13 mm)

MARK

F. Apply glue around tube just ahead

of the 1/2” (13 mm) mark. Position

Engine Hook. Insert Engine Hook

into slit as shown.

3/4

(19 mm)

YELLOW SPACER

B. Cut 1/8” (3 mm) slit at

2” (5.1 cm) mark.

GREEN ENGINE

BLOCK

TOOL

C. Mark Yellow Spacer Tool 3/4”

(19 mm) from end.

ENGINE MOUNT

TUBE

E. Push Engine Block into Engine Mount Tube with Spacer Tool up to mark.

Remove Spacer Tool immediately. Let dry.

1/2

(13 mm)

MARK

G. Slide Engine Hook Retainer

Ring onto Engine Mount

Tube up to 1/2” (13 mm)

mark. Let dry.

COMPLETED ASSEMBLY

A. Apply tube type plastic

cement around inside

surface of Fin Mount

where shown.

B. Insert Engine Mount assembly

and align Engine Hook with

SLOT

slot in Fin Mount.

Note: Launch

Lugs must be

in line.

D. Apply tube type plastic

cement to inside of Cap

where shown. E. Turn Cap over, align Launch Lugs and slide

over Engine Mount Tube and onto Tank Tubes.

Let dry completely.

C. Push Engine Mount into

place with end of the tube

stopping on the shoulder

of the Fin Mount. Let dry.

COMPLETED ASSEMBLY

A. Apply a glue fillet around both

B Apply tube type plastic cement

sides of Centering Ring at

Tube/Ring joint. Let dry

completely.

5. ATTACH NOZZLES AND FINS

CAP

around outside of ridge on Cap.

Slide Body Tube down onto Cap.

Must be flush. Wipe off any

excess glue. Let dry completely.

FLAT

SIDE

C. Apply a glue fillet to inside Tube/

Ring joint. Let dry completely.

2.

INSTALL TANK TUBES

A.

Apply tube type plastic cement into one

cavity. Insert one Tank Tube into the cavity.

2

B.

Gently press the base of the Tank Tube until it

slips down past lip on inside of fin mount, so

that bottom of tube rests on bottom of base.

Repeat for remaining tubes.

C.

All tubes must be

even at top.

TOP OF

TANK TUBES

7 1/2

(19.1 cm)

TOP OF

FIN BASE

F. Apply tube type plastic cement to

Tube/Cap joint. Let dry completely.

G. Apply Carpenter’s glue around tube at the

1/8” (3 mm) mark. Slide Centering Ring onto

Tube, even with mark. Let dry completely.

COMPLETED ASSEMBLY

FINS MUST

BE

FLUSH WITH

BOTTOM

OF FIN

MOUNT

A. Apply tube type plastic

cement to narrow ends of

COMPLETED ASSEMBLY COMPLETED ASSEMBLY

Nozzles. Insert into

mounting holes in Fin

Mount. Let dry completely.

3

4

B. Apply tube type plastic cement

to flat side of a Fin. Attach to Fin

Tab. Fin must be flush with

bottom. Let dry completely before

proceeding onto remaining fins.

Loading...

Loading...