Estes 2110 User Manual

COUNTDOWN AND LAUNCH

8" (20 cm)

LAUNCH SUPPLIES (Sold Separately)

• Porta Pad® II Launch Pad

• Electron Beam® Launch Controller

• Recovery Wadding

• Igniters (with Engines)

• Igniter Plugs (with Engines)

• Recommended Estes® Engines:

B4-2, B6-2, C6-3

www.estesrockets.com

ESTES INDUSTRIES

1295 H Street

Penrose, CO 81240

PRINTED IN CHINA

EST 2110

FLYING MODEL ROCKET KIT INSTRUCTIONS

KEEP FOR FUTURE REFERENCE

KEY ALWAYS OUT UNTIL

FINAL COUNTDOWN!

1...

1...

Masking

Tape

2...

2...

SLIDE ROCKET

DOWN OVER

LAUNCH ROD.

5...

5...

3...

3...

4... 3... 2... 1...

15 FT. (5 M)

4...

4...

INSERT KEY.

PUSH DOWN

AND HOLD.

KEY

ASSEMBLY TIP: Read all instructions

before beginning work on your model. Make

sure you have all parts and supplies.

TEST FIT ALL PARTS TOGETHER

BEFORE APPLYING ANY GLUE!

If any parts don't fit properly, sand as

required for precision assembly.

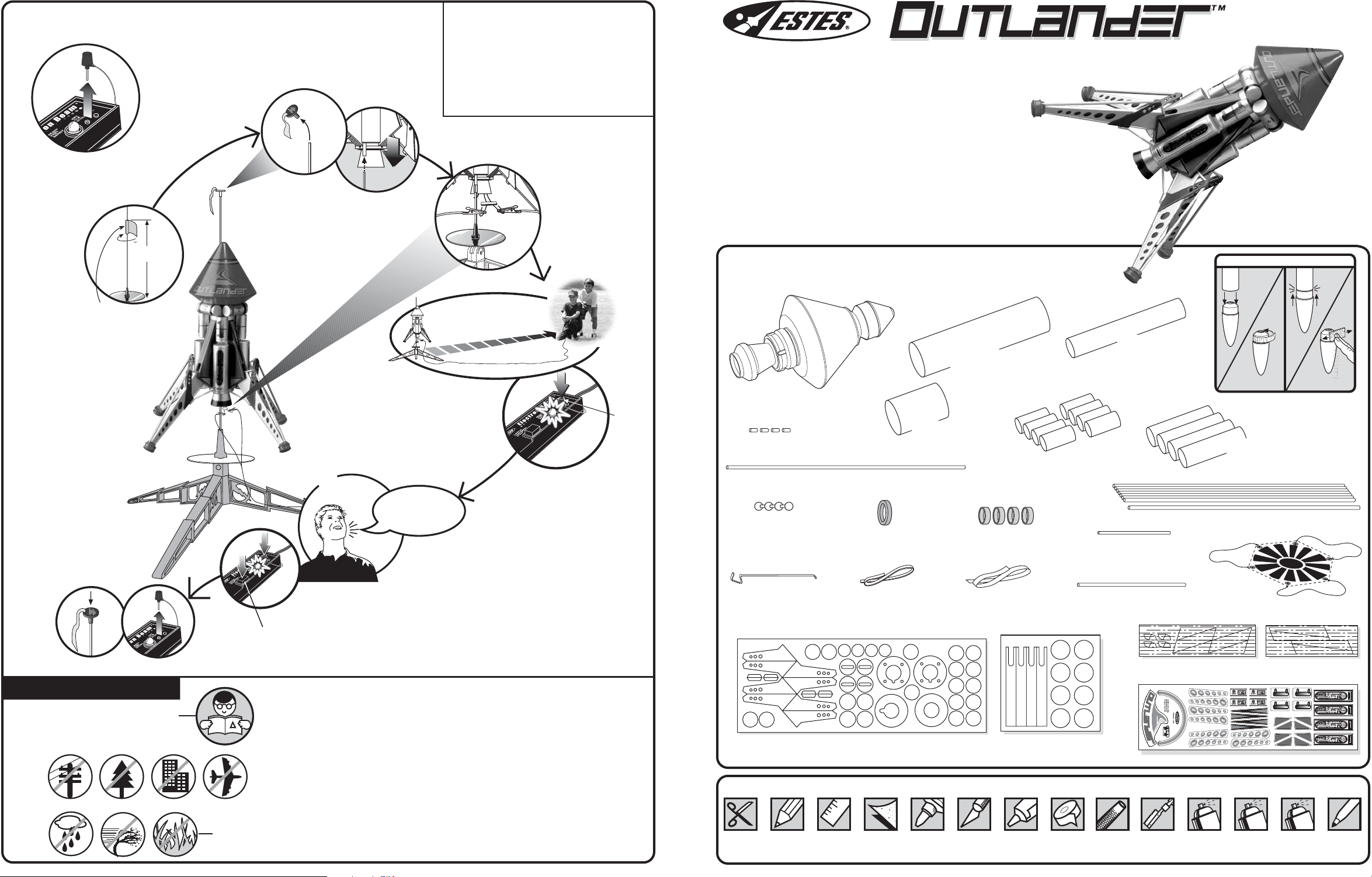

PARTS

Locate the parts shown below and lay them out on the table in front of

you. DO NOT USE THIS DRAWING TO ASSSEMBLE YOUR ROCKET.

UPPER BODY TUBE

BT-60 (5 11/16")

(30402)

ASCENT MODULE/

NOSE CONE

(60542)

LOWER BODY

LAUNCH LUG (1/4") (4)

(38176)

LAUNCH LUG (9 1/16")

PLASTIC HINGE

BALL STRAND

(60543)

(38185)

GREEN CENTERING RING

AR-2050 (30164-2)

TUBE BT-60 (2")

(30411)

YELLOW FOOT PAD RING (4)

EB-20B (30171-4)

SMALL TANK

BT-20 (1 1/2") (8)

(30319)

WOODEN DOWEL 1/12 x 2

ENGINE MOUNT

TUBE BT-20 (5")

(30310)

(32058)

HELPFUL HINT:

LARGE TANK

WOODEN DOWEL (1/8" x 9") (8)

IF NOSE CONE/COUPLER FIT IS. . .

TOO

LOOSE

ADD

MASKING TAPE.

BT-50 (3") (4)

(30412)

(32054)

TOO

TIGHT

SAND FOR FIT.

PRECAUTIONS

NAR Safety Code

12

LAUNCH

BUTTON

NO DRY GRASS

OR WEEDS

HOLD KEY DOWN AND

PRESS LAUNCH BUTTON

UNTIL LIFT-OFF!

FLYING YOUR ROCKET

Choose a large field (500 ft. [152 m] square) free of dry weeds and

brown grass. The larger the launch area, the better the chance of

recovering your rocket. Football fields and playgrounds are great.

Launch only with little or no wind and good visibility.

Always follow the National Association of Rocketry (NAR)

Safety Code.

MISFIRES

TAKE THE KEY OUT OF THE CONTROLLER. WAIT ONE MINUTE

BEFORE GOING NEAR THE ROCKET! Disconnect the igniter clips and

remove the engine. Take the plug and igniter out of the engine. If the igniter

has burned, it worked but did not ignite the engine because it was not

touching the propellant inside the engine. Put a new igniter all the way

inside the engine without bending it. Push the plug in place. Repeat the

steps under Countdown and Launch.

© 2003 Estes-Cox Corp. All rights reserved.

P/N 60545 (9-03)

ENGINE HOOK

(35021)

SHOCK CORD (1/4" x 24")

(38383)

DIE-CUT CARD

(32436)

ELASTIC CORD

(38224)

DIE-CUT CARD

(32435)

SUPPLIES In addition to the parts included in the kit you will also need:

SCISSORS PENCIL RULER FINE

SANDPAPER

(#400-600 GRIT)

CARPENTER'S

GLUE

MODELING

KNIFE

PLASTIC

CEMENT

MASKING

SILICONE HINGE TUBE (1/8" x 4")

TAPE

(60544)

ROUND

FILE

DIE-CUT BALSA SHEET

RAZOR

SAW

ASSEMBLED

PARACHUTE

18" (45 cm)

(35802)

(32214)

DECAL SHEET (60550)

SPRAY PAINT:

SPRAY

PRIMER

WHITE

BLUE, RED,

SILVER, BLACK

DIE-CUT BALSA SHEET

(32215)

SPRAY

CLEAR

COAT

PAINT

PEN

G

LU

E

1

(25 mm)

G

L

U

E

G

L

U

E

PAINTING GUDE

NOTE: In order to paint the model like you see it on the package, it will be necessary to

paint some parts before final assembly. This guide can be used for reference

to paint as you build.

LEGS: Sand, primer and paint.

STRUTS: Midnight Blue

NOSE CONE, NOZZLE: Sand, primer and paint.

NOSE CONE: Midnight Blue

NOZZLE: Silver

INSTALL SHOCK CORD MOUNT

RD

O

C

NT

3

U

CK

N

O

O

IO

M

T

C

SH

E

2

S

N

IO

T

C

E

1

S

N

IO

T

C

E

S

A. Cut out Shock Cord

Mount from WOOD

DOWEL CUTTING

GUIDE.

3

B. Apply glue.

Fold forward.

1

2

SHOCK CORD

3

C. Apply glue.

Fold forward.

D. Squeeze tightly

and hold for one

.

minute

E. Glue mount at least 1” (25 mm) inside

Ascent Module. Hold until glue sets.

Let dry.

MASK OFF

NO PAINT

SILVER

UPPER BODY TUBE: Sand, primer and paint.

UPPER BODY TUBE: Silver (all)

GEAR BOX ASSEMBLY: Sand, primer and paint.

GEAR BOX ASSEMBLY: Midnight Blue (all)

FEET: Bright Red

MASK OFF

NO PAINT

Black

SMALL AND LARGE TANKS: Sand, primer, paint.

SMALL TANKS: Silver (all) LARGE TANKS: Silver (all)

ASCENT MODULE: Sand, primer and paint.

ATTACHING PARACHUTE & SHOCK CORD

A. Form loop in Shroud

Lines and push through

hole in Nose Cone.

B. Pass 'Chute

through loop.

PREPARE PARACHUTE FOR FLIGHT

NOTE: Use Estes

Wadding (EST

A.

Insert 6-7 squares

of loosely crumpled

recovery wadding

into rocket.

302274) Only.

B.

Spike.

C.

Fold.

C.

D.

Pull tight.

Roll.

D.

Tie Shock

Cord on with

double knot.

E.

Wrap lines loosely. Insert ‘Chute,

Shock Cord and Nose Cone into

Body Tube.

ENGINE PREP

Midnight BlueBright Red

Separate igniter and igniter plug.

NOTE: On areas where surfaces are to be glued,

TIP MUST

TOUCH

PROPELLANT!

mask off prior to painting or remove paint

before gluing.

2 11

PREPARE YOUR ENGINE

ONLY WHEN YOU ARE

OUTSIDE AT THE LAUNCH SITE

PREPARING TO LAUNCH!

Hold engine

upright, drop in

igniter. Igniter must

touch propellant.

Insert igniter

plug.

Firmly push all

the way in.

Bend igniter

wires back.

Insert engine.

20. ATTACH ASCENT MODULE

A. Apply plastic

cement to

body tube.

B. Align launch lug with

hole and slide Ascent

Module over body tube.

TOP OF ASCENT

MODULE SHOULD

BE FLUSH WITH TOP

OF LAUNCH LUG

1. CUT WOOD DOWELS

Refer to the Wooden Dowel Cutting Guide and carefully cut all the dowels needed for the leg assemblies. Lightly sand ends smooth.

2. PREPARE HINGE ASSEMBLY

(Four needed for assembly)

A. Separate plastic

Hinge Balls (4)

from strand.

1"

(25 m

)

m

B. Cut Silicone Hinge

Tube into four equal

pieces of 1" (25.4 mm).

C. Insert a hinge ball half

way into each of the

four Silicon Hinge

Tubes.

D. Collect four 1 3/4" (4.4 cm) wood dowels

(Section "D" of template). Insert one into

each hinge until it touches hinge ball.

FINISHING YOUR ROCKET

If you have chosen not to paint your parts before final assembly, now you can sand, prime and paint. The easiest way to get good results is to

spray paint the entire rocket all one color. You may also paint the Ascent Module a different color than the body. When completely dry, proceed

to decal placement.

If you have already painted your parts prior to assembly, proceed to decal placement.

DECAL PLACEMENT

Remove decals from backing one at a time and refer to the drawing below or to the

picture on the front of the package.

A (wrap)

B

C (four)

D (four)

E (four)

F

D

G

C

E

3. LANDING FOOT ASSEMBLY

(Four needed for assembly)

A. Remove die-cut discs shown in gray

from card. Remove the outside nubs

with sandpaper.

4. LEG ASSEMBLY

(Four needed for assembly)

B. Carefully remove the die-cut pieces

using a modeling knife.

A. Sand smooth the die-cut balsa sheet.

YELLOW FOOT

PAD RING

B. Glue the discs and yellow Foot Pad

Ring together as shown.

TOP

C. Collect the four 6 3/4" (17.1 cm) dowels (Section "C" of

template). Match the angled cut to the foot end. Glue as

shown. Repeat for all four legs and let dry.

COMPLETED FOOT PAD

C. Repeat for other three. Let dry.

FOOT

ANGLE CUT

10

F (four)

G (eight-right and left)

H (eight-right and left)

MATCH ANGLE

D. Collect the four 2 3/16" (8.1 cm) dowels with angle cuts

at both ends (Section "A" of template). Glue as shown.

H

Make sure angles match. Repeat for all four legs. Let dry.

E. Remove Support Struts

from die-cut card. Sand

the nubs smooth.

F. Glue Support Strut to assembly as

shown. Make sure strut is flush with

ends of dowel. Repeat for all four

legs. Let dry.

A

B

G. Collect the four 5 5/8" (14.3 cm) dowels (section "B" of template).

Glue as shown. Make sure dowel is flush with end of leg and

butts up to end of top dowel. Repeat for all four legs. Let dry.

H. Glue remaining struts to opposite sides

for all four leg assemblies. Let dry.

…Continued Page 4

3

Loading...

Loading...