Page 1

SERVICE MANUAL

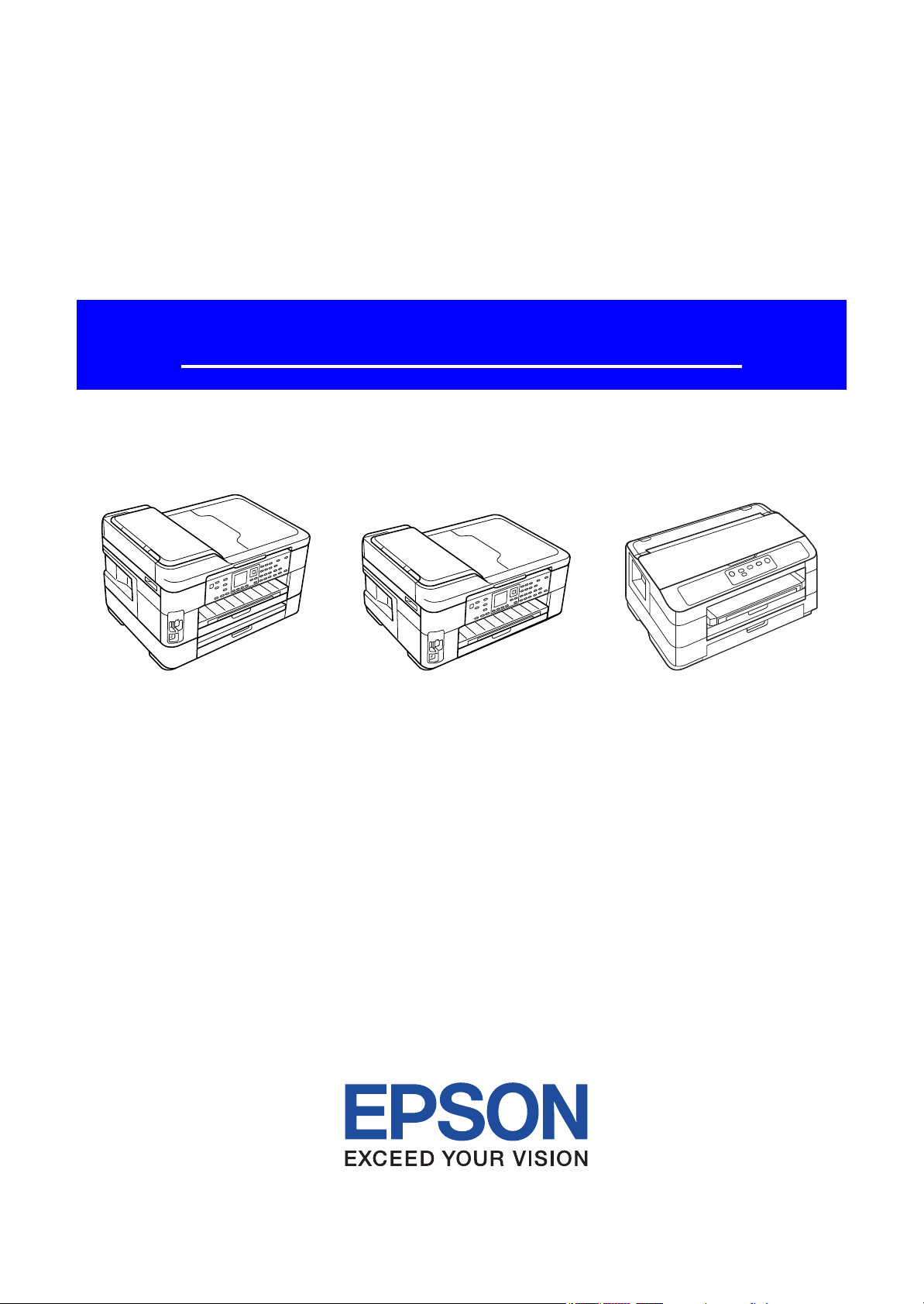

Color Inkjet Printer

Epson WF-7525 / Epson WF-7521 / Epson WF-7520/

Epson WF-7515 / Epson WF-7511 / Epson WF-7510/

Epson WF-7018 / Epson WF-7015 / Epson WF-7012/

Epson WF-7011 / Epson WF-7010

SEMF10-012

Page 2

Notice:

All rights reserved. No part of this manual may be reproduced, stored in a retrieval system, or transmitted in any form or

by any means, electronic, mechanical, photocopying, recording, or otherwise, without the prior written permission of

SEIKO EPSON CORPORATION.

All effort have been made to ensure the accuracy of the contents of this manual. However, should any errors be

detected, SEIKO EPSON would greatly appreciate being informed of them.

The contents of this manual are subject to change without notice.

The above not withstanding SEIKO EPSON CORPORATION can assume no responsibility for any errors in this

manual or the consequences thereof.

EPSON is a registered trademark of SEIKO EPSON CORPORATION.

Note :Other product names used herein are for identification purpose only and may be trademarks or registered

trademarks of their respective owners. EPSON disclaims any and all rights in those marks.

Copyright 2011 SEIKO EPSON CORPORATION

I&I CS Quality Assurance Department

Page 3

Safety Precautions

All safety procedures described here shall be strictly adhered to by all parties servicing and maintaining this

product.

DANGER

Strictly observe the following cautions. Failure to comply could result in serious bodily injury or loss of life.

1. Always disconnect the product from the power source and peripheral devices when servicing the product or

performing maintenance.

2. When performing works described in this manual, do not connect to a power source until instructed to do so.

Connecting to a power source causes high voltage in the power supply unit and some electronic components

even if the product power switch is off. If you need to perform the work with the power cable connected to a

power source, use extreme caution to avoid electrical shock.

WARNING

Strictly observe the following cautions. Failure to comply may lead to personal injury or loss of life.

1. Always wear protective goggles for disassembly and reassembly to protect your eyes from ink in working. If

any ink gets in your eyes, wash your eyes with clean water and consult a doctor immediately.

2. When using compressed air products; such as air duster, for cleaning during repair and maintenance, the use

of such products containing flammable gas is prohibited.

PRECAUTIONS

Strictly observe the following cautions. Failure to comply may lead to personal injury or damage of the product.

1. Repairs on Epson product should be performed only by an Epson certified repair technician.

2. No work should be performed on this product by persons unfamiliar with basic safety knowledge required for

electrician.

3. The power rating of this product is indicated on the serial number/rating plate. Never connect this product to

the power source whose voltages is different from the rated voltage.

4. Replace malfunctioning components only with those components provided or approved by Epson;

introduction of second-source ICs or other non-approved components may damage the product and void any

applicable Epson warranty.

5. The capacitors on the Main Board may be electrically charged right after the power turns off or after driving

motors which generates counter electromotive force such as when rotating the PF Roller or when moving the

CR Unit. There is a risk to damage the Main Board if the Head FFC is short-circuited with the capacitors on

the Main Board electrically charged, therefore, after the power turns off or after motors are driven, leave the

printer untouched for approximately 30 seconds to discharge the capacitors before starting disassembly/

reassembly.

Page 4

6. To prevent the circuit boards from short-circuiting, be careful about the following when handling FFC or

cables.

When handling FFC, take care not to let the terminal section of FFC touch metal parts.

When connecting cables/FFC to the connectors on circuit boards, connect them straight to the connectors to avoid

slant insertion.

7. In order to protect sensitive microprocessors and circuitry, use static discharge equipment, such as anti-static

wrist straps, when accessing internal components.

8. Do not tilt this product immediately after initial ink charge, especially after performing the ink charge several

times. Doing so may cause ink to leak from the product because it may take some time for the waste ink pads

to completely absorb ink wasted due to the ink charge.

9. Never touch the ink or wasted ink with bare hands. If ink comes into contact with your skin, wash it off with

soap and water immediately. If you have a skin irritation, consult a doctor immediately.

10. When disassembling or assembling this product, make sure to wear gloves to avoid injuries from metal parts

with sharp edges.

11. Use only recommended tools for disassembling, assembling or adjusting the printer.

12. Observe the specified torque when tightening screws.

13. Be extremely careful not to scratch or contaminate the following parts.

Nozzle plate of the printhead

CR Scale

PF Scale

Coated surface of the PF Roller

Gears

Rollers

LCD

Scanner Sensor

Exterior parts

14. Never use oil or grease other than those specified in this manual. Use of different types of oil or grease may

damage the component or give bad influence on the printer function.

15. Apply the specified amount of grease described in this manual.

16. Make the specified adjustments when you disassemble the printer.

17. When cleaning this product, follow the procedure described in this manual.

18. When transporting this product after filling the ink in the printhead, pack the printer without removing the

ink cartridges in order to prevent the printhead from drying out.

19. Make sure to install antivirus software in the computers used for the service support activities.

20. Keep the virus pattern file of antivirus software up-to-date.

21. When disassembling/reassembling this product, if you find adhesive power of the double-sided tape which

secure the parts or FFC is not enough, replace the tape with new one and attach it correctly to the specified

points where the parts or FFC should be secured.

22. Unless otherwise specified in this manual, the labels attached on the returned product should be transferred to

the corresponding attachment positions on the new one referring to the labels on the returned product.

Page 5

About This Manual

This manual, consists of the following chapters, is intended for repair service personnel and includes information

necessary for properly performing maintenance and servicing the product.

CHAPTER 1. PRODUCT DESCRIPTIONS

Provides a general overview and specifications of the product.

CHAPTER 2. OPERATING PRINCIPLES

Describes the theory of mechanical operations of the product.

CHAPTER 3. TROUBLESHOOTING

Describes the step-by-step procedures for the troubleshooting.

CHAPTER 4. DISASSEMBLY / REASSEMBLY

Describes the disassembly/reassembly procedures for main parts/units of the product.

CHAPTER 5. ADJUSTMENT

Describes the required adjustments for servicing the product.

CHAPTER 6. MAINTENANCE

Describes maintenance items and procedures for servicing the product.

Symbols Used in this Manual

Various symbols are used throughout this manual either to provide additional information on a specific topic or

to warn of possible danger present during a procedure or an action. Pay attention to all symbols when they are

used, and always read explanation thoroughly and follow the instructions.

Indicates an operating or maintenance procedure, practice or condition that, if not strictly observed,

could result in serious injury or loss of life.

Indicates an operating or maintenance procedure, practice, or condition that, if not strictly observed,

could result in bodily injury, damage or malfunction of equipment.

May indicate an operating or maintenance procedure, practice or condition that is necessary to

accomplish a task efficiently. It may also provide additional information that is related to a specific

subject, or comment on the results achieved through a previous action.

For Chapter 4 “Disassembly/Reassembly”, symbols other than indicated above are used to show additional

information for disassembly/reassembly. For the details on those symbols, see "4.2 Disassembly/Reassembly

Procedures (p46)".

Page 6

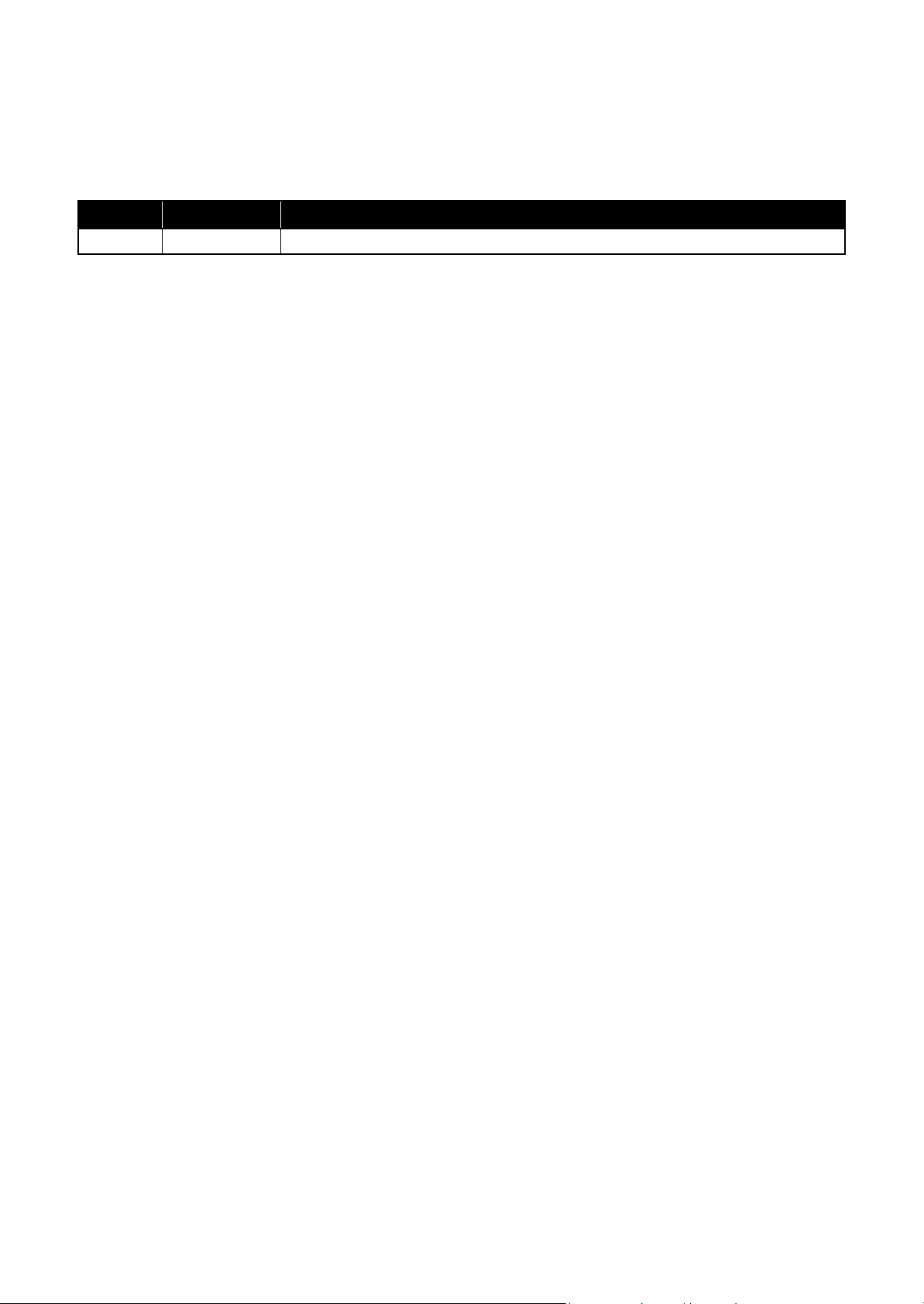

Revision Status

Revision Date of Issue Description

A Aug. 24, 2011 First Release

Page 7

Epson WF-7520/7510/7010 series Revision A

Contents

Chapter 1 Product description

1.1 Features . ................................................................................................................................................................... 10

1.2 Printing Specifications . ............................................................................................................................................ 12

1.2.1 Basic Specifications. ........................................................................................................................................ 12

1.3 Scanner Specifications (WF-7520/7510 series only) ............................................................................................... 13

1.3.1 Basic Specifications. ........................................................................................................................................ 13

1.4 Control Panel . ........................................................................................................................................................... 14

1.4.1 Operation Buttons. ........................................................................................................................................... 14

1.4.2 LEDs and LCD Indications ............................................................................................................................. 16

1.5 Various Settings . ...................................................................................................................................................... 19

1.5.1 Panel Operation . .............................................................................................................................................. 19

1.5.1.1 Setup Menu Configuration (WF-7520/7510 series only) ....................................................................... 19

1.5.1.2 Forced Power OFF (WF-7010 series only)............................................................................................. 20

1.5.1.3 Printer Status Sheet ................................................................................................................................. 20

Chapter 2 Operating Principles

2.1 Overview . ................................................................................................................................................................. 22

2.2 Motors and Sensors . ................................................................................................................................................ 22

2.3 Optical Sensor Control . ............................................................................................................................................ 25

2.4 Power-On Sequence . ................................................................................................................................................ 26

Chapter 3 Troubleshooting

3.1 Troubleshooting. ....................................................................................................................................................... 30

3.1.1 Error Message List. .......................................................................................................................................... 30

3.1.2 Troubleshooting Workflow ............................................................................................................................. 31

3.1.3 Fatal Error Code . ............................................................................................................................................. 33

3.1.4 FAX Troubleshooting (WF-7520/7510 series only) ....................................................................................... 37

3.1.4.1 FAX Log ................................................................................................................................................. 37

3.1.4.2 Error Code/Superficial Phenomenon-Based Troubleshooting ............................................................... 42

Chapter 4 Disassembly/Reassembly

4.1 Overview . ................................................................................................................................................................. 45

4.1.1 Tools . ............................................................................................................................................................... 45

4.1.2 Jigs . .................................................................................................................................................................. 45

4.2 Disassembly/Reassembly Procedures . ..................................................................................................................... 46

4.2.1 Parts/Units Need to be Removed in Advance ................................................................................................. 46

4.2.2 Disassembling Flowchart ................................................................................................................................ 48

4.2.2.1 Exterior Parts . ......................................................................................................................................... 48

4.2.2.2 Printer Mechanism .................................................................................................................................. 52

4.3 Detailed Disassembly/Reassembly Procedure for each Part/Unit............................................................................ 55

4.4 Routing FFCs/cables . ............................................................................................................................................... 63

4.5 Connector Summary . ................................................................................................................................................ 67

7

Page 8

Epson WF-7520/7510/7010 series Revision A

Chapter 5 Adjustment

5.1 Required Adjustments .............................................................................................................................................. 69

5.2 Details of Adjustments . ............................................................................................................................................ 75

5.2.1 PF Timing Belt Tension Check ....................................................................................................................... 75

5.2.2 Checking the Platen Gap . ................................................................................................................................ 76

5.2.3 Scanner Timing Belt Tension Check . .............................................................................................................. 77

5.2.4 MAC Address Setting. ..................................................................................................................................... 78

Chapter 6 Maintenance

6.1 Overview . ................................................................................................................................................................. 80

6.1.1 Cleaning . .......................................................................................................................................................... 80

6.1.2 Lubrication. ...................................................................................................................................................... 80

6.2 Lubrication Points and Instructions.......................................................................................................................... 81

8

Page 9

CHAPTER 1

PRODUCT DESCRIPTION

Page 10

Epson WF-7520/7510/7010 series Revision A

1.1 Features

In this chapter, the product names are called as follows:

WF-7520 series: Epson WF-7525/Epson WF-7521/Epson WF-7520

WF-7510 series: Epson WF-7515/Epson WF-7511/Epson WF-7510

WF-7010 series: Epson WF-7018/Epson WF-7015/Epson WF-7012/Epson WF-7011/

Epson WF-7010

WF-7520/7510/7010 series are an A3 color inkjet printer based on Epson WorkForce 840/Epson Stylus Office

BX925FWD. Major features are as follows.

Common futures

Printer

Maximum print speed: 15 ppm (A4, monochrome, draft printing mode)

O6-Chip Turbo 2 Printhead (Black: 128 nozzles x 3, Color: 128 nozzles x 1 per color)

Maximum print resolution: 5760 x 1440 dpi

Auto duplex printing up to A3 paper with the Duplex Unit (WF-7520/7010 series only)

Four independent ink cartridges are installed (pigment inks)

Interface

In addition to USB connection, wired/wireless LAN connection are available

Scanner (WF-7520/7510 series only)

CIS type sensor (scanning resolution: 1200 x 2400 dpi)

ADF up to A3 paper scanning

Note"*": Auto duplex scanning is available only for WF-7520 series. (A4 or letter sized paper only)

*

Differences between the models

WF-7520/7510/7010 series are different as shown below.

Table 1-1. Differences between the Models

Item WF-7520 series WF-7510 series WF-7010 series

LCD display size 2.5 inch 2.5 inch No

Auto duplex printing Yes No Yes

Scanner / ADF Yes Yes No

USB host

(for PictBridge / Backup of an external storage device)

FAX Yes Yes No

Wi-Fi Yes Yes Yes

2nd cassette Yes No Yes

Note *: The availability of the WiFi varies depending on the destinations.

Available: EHC/Euro/CISMEA/ESP/ETT/EKL

Not available: EAL/Latin/EAL/ECC/EHK

Yes Yes No

*

Product description Features 10

Page 11

Epson WF-7520/7510/7010 series Revision A

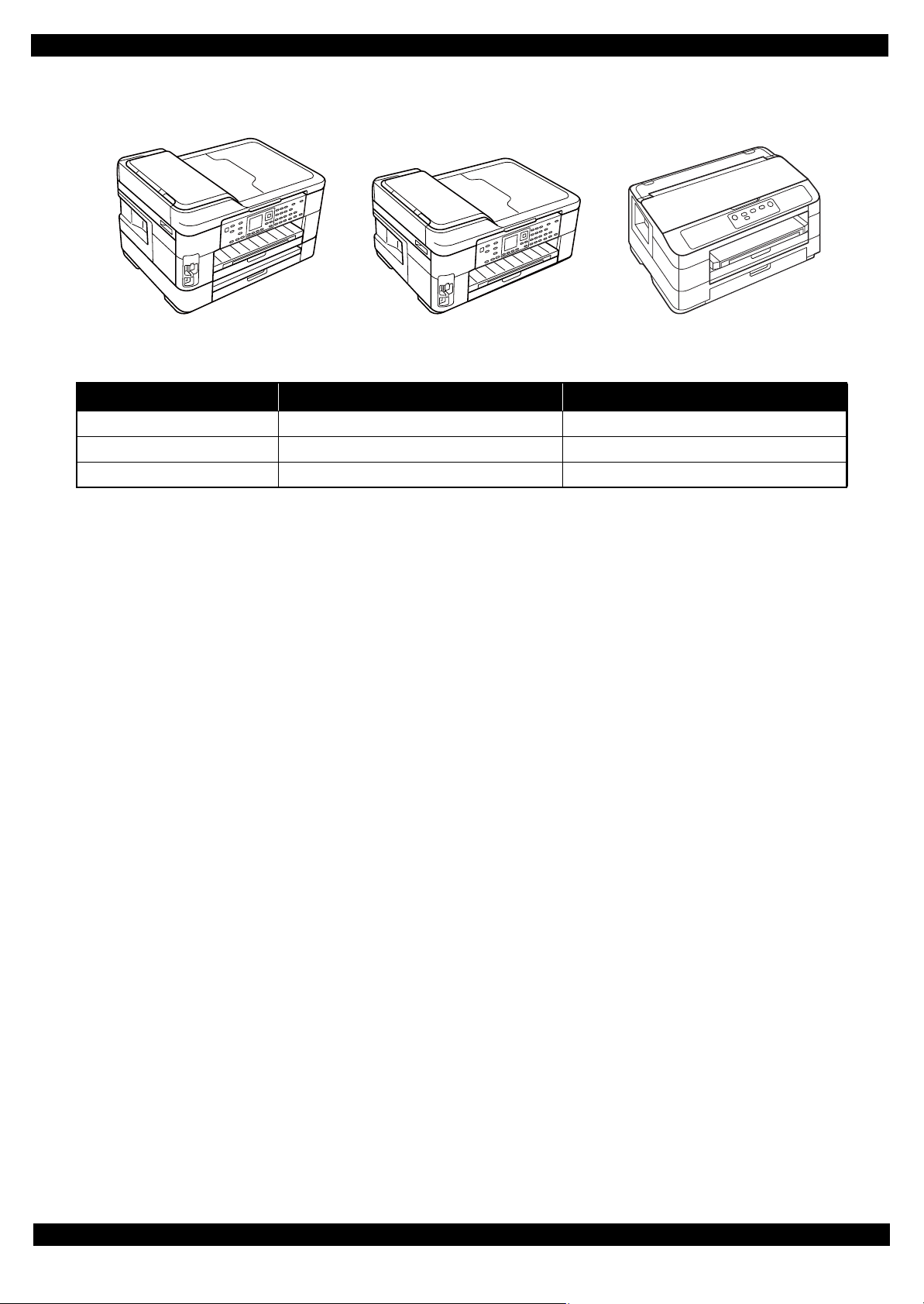

WF-7520 series WF-7510 series WF-7010 series

External view

Figure 1-1. External View

Table 1-2. Dimensions

Model Dimensions (W x D x H)

WF-7520 series 559 mm x 418 mm x 365 mm 18.9 kg

WF-7510 series 559 mm x 418 mm x 287 mm 15.6 kg

WF-7010 series 558 mm x 414 mm x 264 mm 12.3 kg

*1

Weight

*2

Note *1: Paper support for rear ASF and stacker are closed. Rubber feet are included.

*2: Excluding the weight of ink cartridges and power cable.

Product description Features 11

Page 12

Epson WF-7520/7510/7010 series Revision A

1.2 Printing Specifications

1.2.1 Basic Specifications

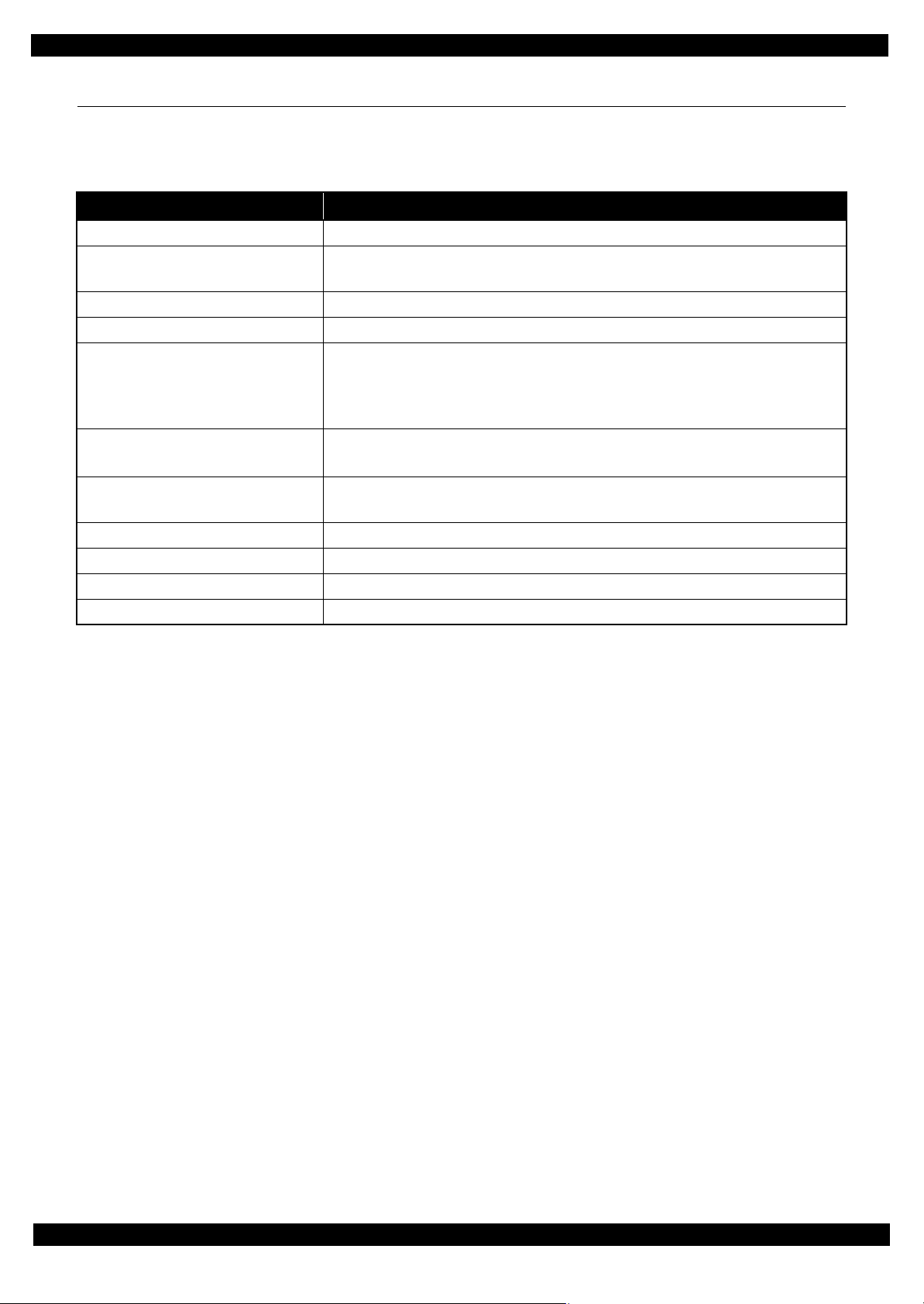

Table 1-3. Printer Specifications

Item Specification

Print method On-demand ink jet

Nozzle configuration Black: 384 nozzles (128 nozzles x 3)

Color: 384 nozzles (128 nozzles x 1 per color)

Color Black, Cyan, Magenta, Yellow

Print direction Bi-directional minimum distance printing, Unidirectional printing

Print resolution Horizontal x Vertical (dpi)

• 360 x 120

• 360 x 360

• 360 x 720

Control code • ESC/P Raster command

• ESC/P-R (RGB) command

Input buffer size Printing from PC: 64 KBytes

Stand-alone printing: 132 KBytes

Paper feed method Friction feed

Paper feed amount 250 pages (plain paper*), 20 pages (photo paper), 50 pages (postcard)

Paper path Front feed, front out

PF interval 0.01764 mm (1/1440 inch)

• 720 x 720

• 1440 x 720

• 5760 x 1440

Note *: For paper thickness: 0.11 mm, 80 g/m2.

Product description Printing Specifications 12

Page 13

Epson WF-7520/7510/7010 series Revision A

1.3 Scanner Specifications (WF-7520/7510 series only)

1.3.1 Basic Specifications

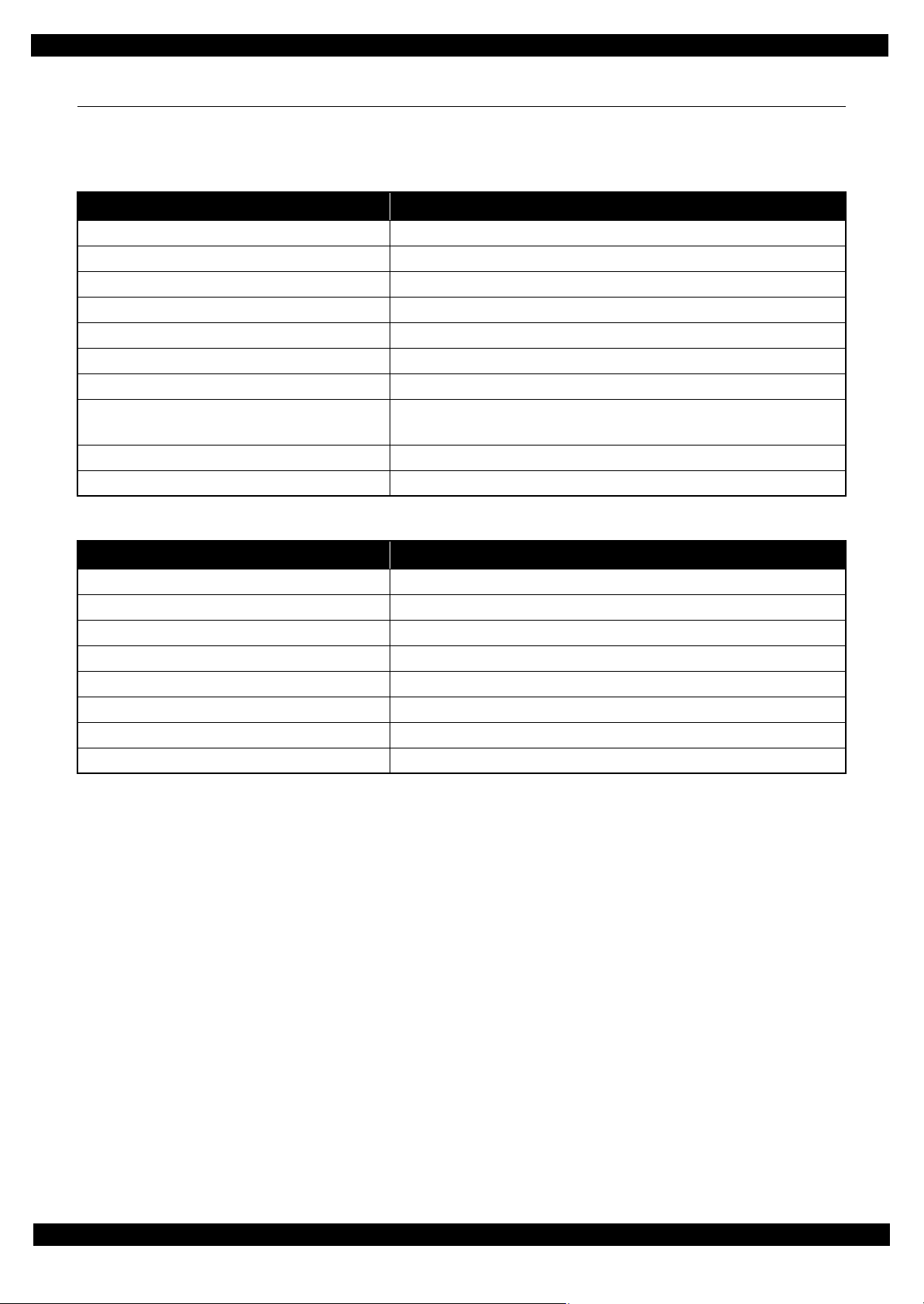

Table 1-4. Basic Specifications

Item Specification

Scanner type Flatbed, color

Scanning method Moving carriage, stationary document

Home position The rear left corner

Photoelectric device CIS

Light source LED

Maximum document sizes A3 or US B (tabloid)

Scanning range 11.7” x 17” (297 mm x 431.8 mm)

Maximum resolution Main scan: 1,200 dpi

Sub scan: 2,400 dpi

Maximum effective pixels 14,040 x 20,400 pixels

Pixel depth 16 bit per pixel (input) and 1 bit or 8 bit per pixel (output)

Table 1-5. ADF Specifications

Item Specification

Document loading Face-up

Maximum document sizes A4 to A3/tabloid

Supported paper type Plain paper only

Paper thickness 64 to 95 g/m

Maximum number of documents which can be set 30 sheets or 3 mm at maximum

Document path Feeds from upper tray and ejects to lower tray

Document set position Center

Auto duplex scanning

Note *: WF-7520 series only

*

A4 or US Letter only

2

Product description Scanner Specifications (WF-7520/7510 series only) 13

Page 14

Epson WF-7520/7510/7010 series Revision A

WF-7520 series only

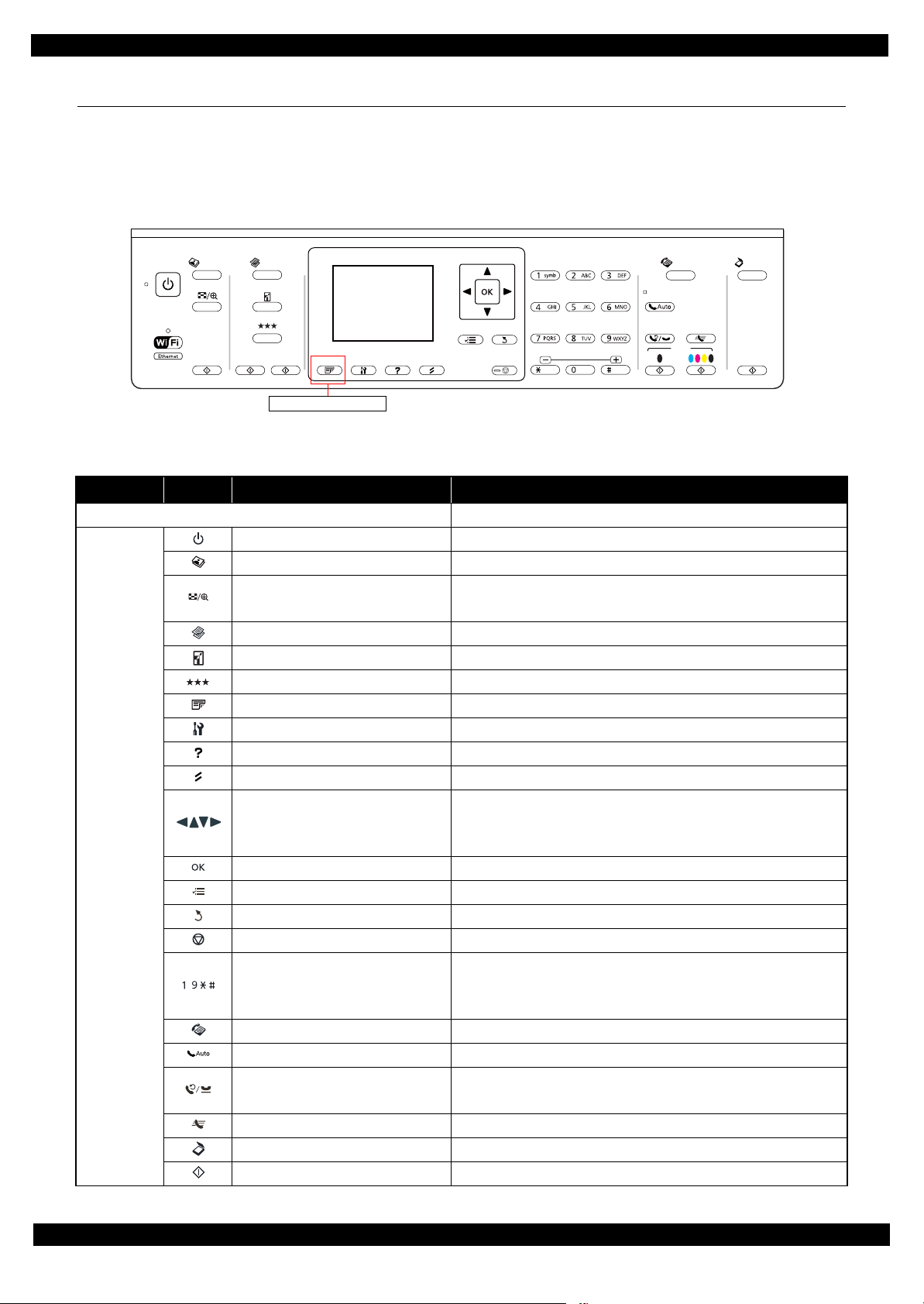

1.4 Control Panel

1.4.1 Operation Buttons

The operation buttons, LEDs, and LCD are shown below. See Table 1-6 and Table 1-7 for the functions.

WF-7520/7510 series

Photo Fax

Print

Copy

Menu

Back

Stop

Start

Figure 1-2. Control Panel (WF-7520/7510 series)

Table 1-6. Operation Buttons, LEDs and LCD (WF-7520/7510 series)

Item Icon Name Function

LCD Indicates the printer status, error, and menu screen.

Power Turns the power on/off.

Photo Enters photo mode.

• Enters zoom setting screen for selected image.

• Switches preview screens on LCD.

• Selects menus.

• Specifies the number of copies.

• Moves the cursor in fax mode.

• Specifies the date/time

• Specifies the number of copies

• Specifies fax numbers

Button/

touch panel

Display/Crop

Copy Enters copy mode.

Reduce/Enlarge Specifies copy magnification.

Quality Specifies print quality.

2-Sided Specifies auto duplex print setting. (WF-7520 series only)

Setup Enters setup mode.

Help Displays help for solutions to problems.

Reset Resets the current setting and displays the home screen.

Arrows

OK Activates the setting you have selected.

Menu Displays detailed settings for each mode.

Back Cancels/returns to the previous menu.

Stop Stops printing.

-

,

,

Ten key

Scan

Start

Fax Enters fax mode.

Auto Answer Turns on/off auto answer mode.

Redial/Pause

• Displays the last number dialed.

• Inserts a pause symbol (-) when entering numbers in fax mode.

Speed Dial Displays speed dial list in fax mode.

Scan Enters scan mode.

Start Starts copying in each mode.

Product description Control Panel 14

Page 15

Epson WF-7520/7510/7010 series Revision A

Note : The WiFi logo and button on the control panel vary

depending on the destinations. (See Table 1-1.)

Table 1-6. Operation Buttons, LEDs and LCD (WF-7520/7510 series)

Item Icon Name Function

Power

LED

Note : See "1.4.2 LEDs and LCD Indications (p16)" for more details about the LCD.

Network Indicates the network connection status.

Auto Answer On when the fax is in auto answer mode.

• Lights when the printer is on.

• Flashes when the printer is in process.

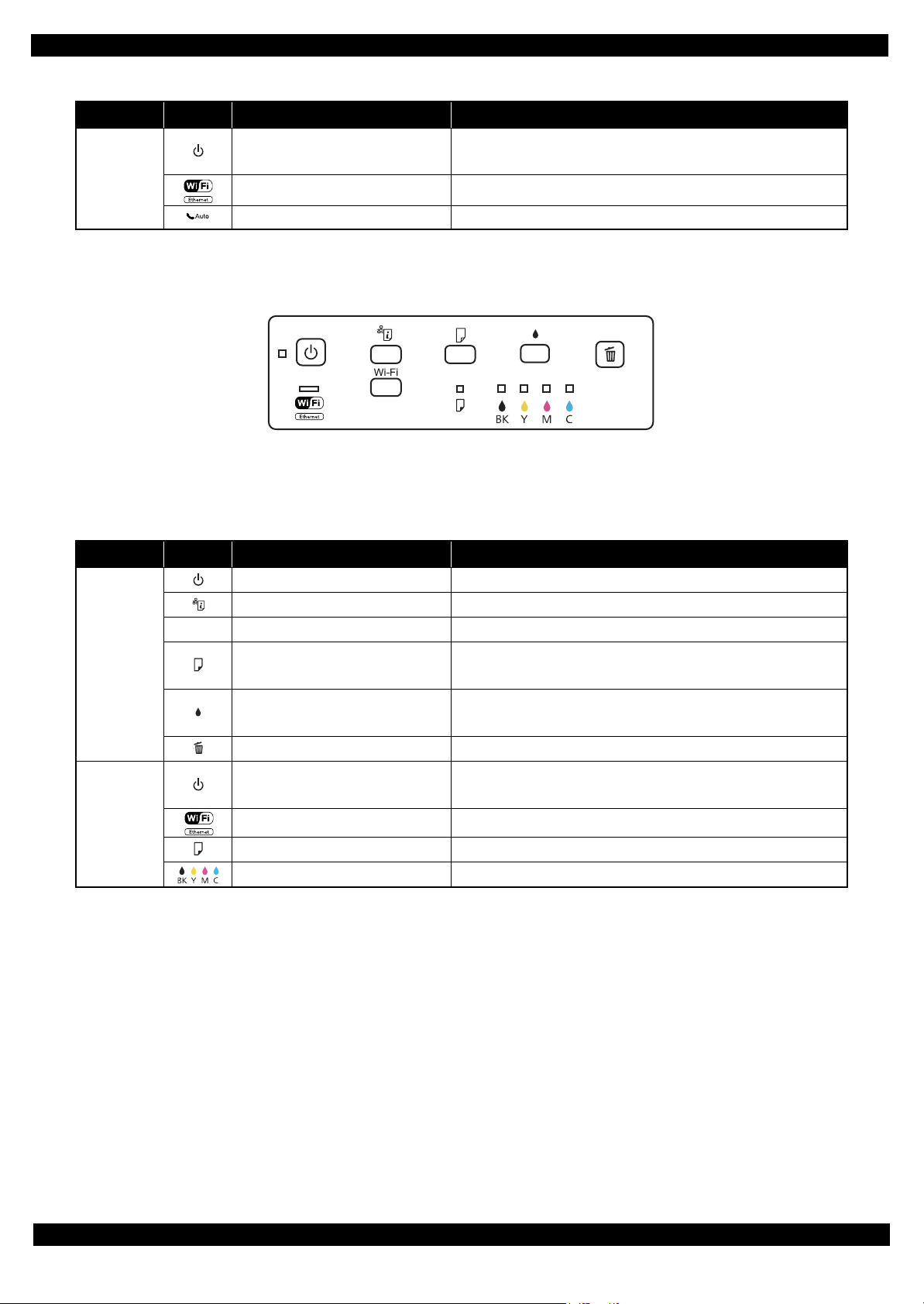

WF-7010 series

Figure 1-3. Control Panel (WF-7010 series)

Table 1-7. Operation Buttons and LEDs (WF-7010 series)

Item Icon Name Function

Power Turns the power on/off.

Network status sheet Prints a network status sheet.

---

Button

LED

Note : See "1.4.2 LEDs and LCD Indications (p16)" for more details about the LEDs.

Note *: The corresponding color LED is indicated.

Wi-Fi Configures the wireless network.

Paper feed/eject

Ink

Cancel Cancels printing during a print job.

Power

Network Indicates the network connection status.

Paper Indicates error status for paper.

*

Ink

• Loads or ejects paper.

• Resumes printing after a paper out error, multiple page feed error.

• Starts ink replacement.

• Starts head cleaning.

• Lights when the printer is on.

• Flashes when the printer is in process.

Indicates error status for ink.

Product description Control Panel 15

Page 16

Epson WF-7520/7510/7010 series Revision A

1.4.2 LEDs and LCD Indications

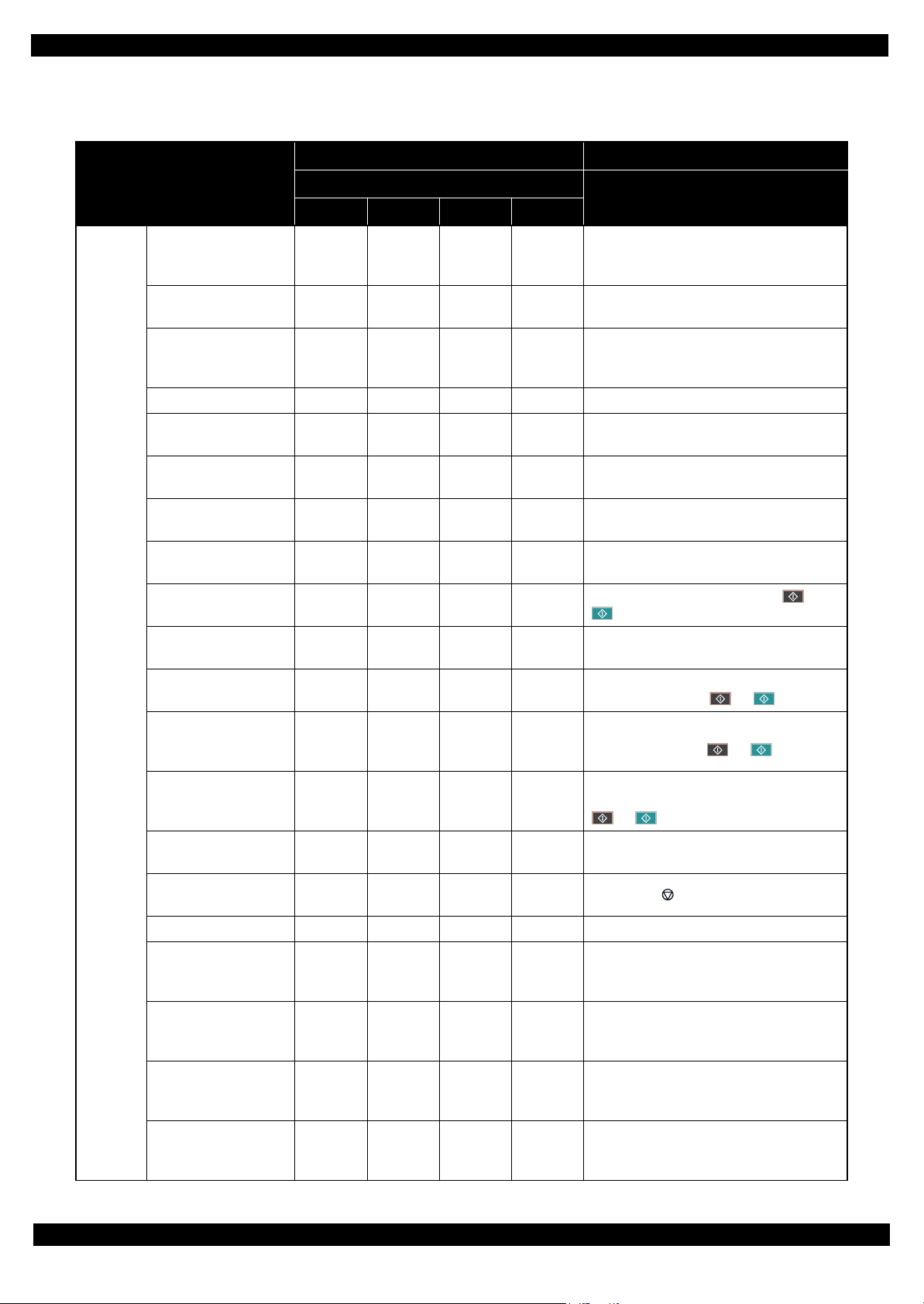

Table 1-8. LEDs and LCD Indications

WF-7010 series WF-7520/7510 series

Operating

Status

LED

LCD Message

Power Network Paper Ink

Printer error. Turn power off and then on

again. For details, see your documentation or

visit Epson.com.

Paper jam inside, in back, or in ADF. Press

OK to see how to remove jammed paper.

Scanner error. Turn power off and then on

again. In the error is not fixed, visit

Printer fatal error

Printer fatal error

(paper jam)

Scanner fatal error

*1

Flash at

high speed

Flash at

high speed

Flash at

high speed

Flash at

high speed

Flash at

high speed

Flash at

high speed

--- --- --- ---

Flash at

high speed

Flash at

high speed

Epson.com for technical support.

ADF fatal error

ADF paper jam error

Waste ink pad end error Flash

Waste ink pad near end

error

Paper jam error Flash

No paper cassette error Flash

Paper out error Flash

Multi-feed error Flash

Paper length mismatch

error for duplex

printing

Paper size mismatch

error

Incorrect paper size

*1

error

Printer/printer driver

mismatch error

*1

*1

*3

--- --- --- --- Automatic Document Feeder (ADF) error.

--- --- --- ---

Alternate

flash 1

Alternate

flash 1

Flash

Flash

Flash

*2

*2

*2

*2

*2

*2

*2

*2

---

---

--- Flash ---

--- ON ---

--- ON ---

--- ON ---

--- ON ---

--- ON ---

Alternate

flash 2

Alternate

flash 2

Paper jam in the Automatic Document

Feeder (ADF).

A printer's ink pad is at the end of its service

life. Please contact Epson Support.

A printer's ink pad is nearing the end of its

service life. Please contact Epson Support.

Paper jam. Press OK to see how to remove

jammed paper.

Load Cassette correctly and press or

.

Paper out or paper jam. Check paper size and

load paper in paper cassette.

Multi-page feed error. Remove and reload

the paper, then press or .

Incorrect paper size detected. Load correct

paper size and press or .

No paper source matches paper size setting.

Load appropriate paper in Cassette 1. Press

or .

--- --- --- ---

Flash

*2

---

Flash at

high speed

Flash at

high speed

Paper size is incorrect. Load US B 11x17in

size plain paper in Cassette.

Error Press .

Cover open error Flash --- Flash 2 Flash 2 Close the scanner unit.

You need to replace the following ink

*4

cartridge(s).

Ink end error Flash

*2

--- --- ON

<Ink Cartridges>XXXXXXX

Ink cartridge detection

error

Flash

Ink cartridge detection

error (non-Epson

Flash

cartridge)

No ink cartridge error Flash

*2

*2

*2

--- --- ON

--- --- ON

--- --- ON

Cannot recognize the following cartridge(s).

*4

Try installing them again.

<Ink Cartridges>XXXXXXX

Ink cartridge is not recognized. Please

*4

replace the cartridge.

<Ink Cartridges>XXXXXXX

The cartridge is installed incorrectly. Press it

*4

down until it clicks.

<Ink Cartridges>XXXXXXX

*5

*5

*5

*5

Product description Control Panel 16

Page 17

Epson WF-7520/7510/7010 series Revision A

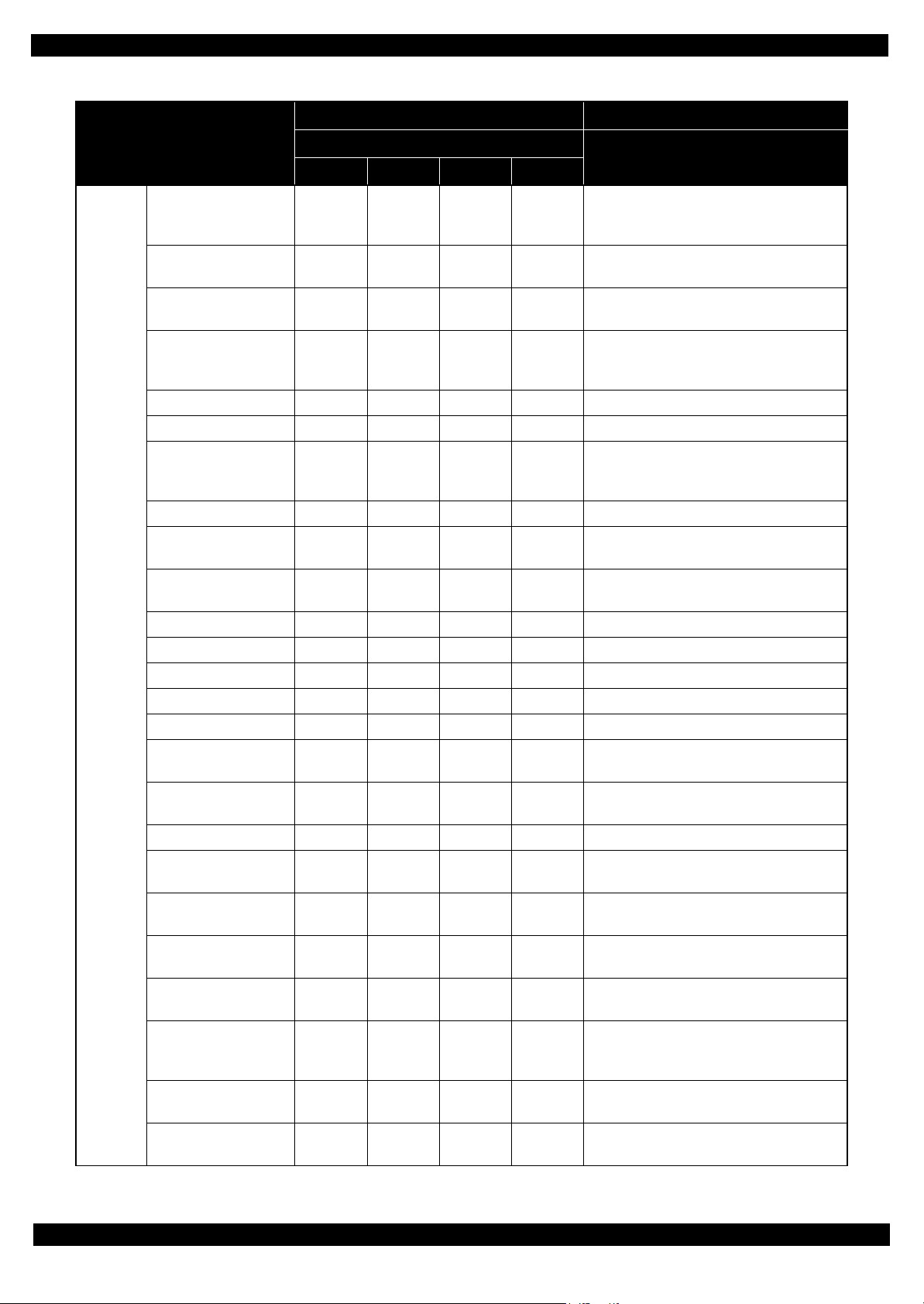

Table 1-8. LEDs and LCD Indications

WF-7010 series WF-7520/7510 series

Operating

Status

LED

LCD Message

Power Network Paper Ink

Starting filling of ink

(after carriage moves)

Ink cartridge cover open

error

Flash --- --- ---

*2

Flash

--- --- ---

Starting initialization Flash --- --- ---

Replace the cartridge(s) and close the

scanner unit.

<Ink Cartridges>XXXXXXX

*5

The ink cartridge cover is open. Close the ink

cartridge cover.

Install the ink cartridges. See the setup sheet

for details.

Initializing...Please wait.

Initializing Flash --- --- ---

Do not turn off until initialization is

complete. This takes about 7 minutes.

Filling of ink Flash --- --- --- Charging ink...Please wait.

Checking ink cartridges Flash --- --- --- Checking the ink cartridges...

Drying 1st side

(printing from PC)

Flash --- --- ---

Printing 2-sided document. Do not touch the

paper in the output tray until printing is

complete.

Printing (PC) Flash --- --- --- Printing...

Printing nozzle check

pattern

Printing printer status

sheet

Flash --- --- --- Printing...

Flash --- --- --- Printing...

Printing (UPNP) Flash Flash --- --- Printing...

Receiving data Flash Flash --- --- Receiving data...

Canceling (PC)

*6

Flash --- --- --- Canceling...

Cleaning (PC) Flash --- --- --- Cleaning print head...Please wait.

Print head cleaning Flash --- --- --- Cleaning print head...Please wait.

Canceling nozzle check

pattern print

Canceling printer status

sheet print

Initializing network Flash

Waiting for network

initialization

Network initialization

(LED ON)

Network initialization

(LED OFF)

Preparing to update

firmware (cancel OK)

Updating firmware Flash

Flash --- --- --- Canceling...

Flash --- --- --- Canceling...

Flash

OFF

OFF

ON

*2

*2

*2

*2

*2

*7

Flash --- --- ---

--- --- --- ---

ON --- --- ---

OFF --- --- ---

Flash at

high speed

--- --- Preparing to update...

Updating firmware...Do not turn power off.

OFF OFF OFF

It turns off and on automatically when

complete.

Preparing to update

firmware

Canceling firmware

update

ON

ON

*2

*2

Flash at

high speed

Flash at

high speed

--- --- Preparing to update...

--- --- Canceling...

Product description Control Panel 17

Page 18

Epson WF-7520/7510/7010 series Revision A

Table 1-8. LEDs and LCD Indications

WF-7010 series WF-7520/7510 series

Operating

Standby

Operating/

*8

Standby

Status

LED

LCD Message

Power Network Paper Ink

Powering OFF

Flash at

high speed

--- --- --- Turning off...

Powering ON Flash Flash --- --- Starting up...Please wait.

Feeding a paper

(load/eject)

Flash --- --- --- Printing...

No error ON --- --- --- ---

Ink level low ON

Waste ink pad near end

error

ON

Requiring ink cartridges

(carriage is at the

Flash --- --- ---

replacement position)

Ink end error

(during Bk mode)

Ink end error

(out of Bk mode)

ON

ON

No ink cartridge error ON

*2

*2

*2

*2

*2

--- --- Flash

---

Alternate

flash 1

--- --- ON

--- --- ON

--- --- ON

*4

Alternate

flash 2

*4

*4

*4

Ink low.

A printer's ink pad is nearing the end of its

service life. Please contact Epson Support.

Replace the cartridge(s) and close the

scanner unit.

<Ink Cartridges>XXXXXXX

You can temporarily copy, print and fax in

B&W on plain paper on the next job.

You need to replace the following ink

cartridge(s).

<Ink Cartridges>XXXXXXX

The cartridge is installed incorrectly. Press it

down until it clicks.

<Ink Cartridges>XXXXXXX

Ink cartridge detection

error

Ink cartridge detection

error (non-Epson

cartridge)

ON

ON

*2

*2

--- --- ON

--- --- ON

Cannot recognize the following cartridge(s).

*4

Try installing them again.

<Ink Cartridges>XXXXXXX

Ink cartridge is not recognized. Please

*4

replace the cartridge.

<Ink Cartridges>XXXXXXX

When starting up --- Flash --- --- ---

Not connected --- --- --- --- ---

Connected via wired

LAN (with IP)

--- ON --- --- ---

*5

*5

*5

*5

*5

Note : Flash Turns on and off at intervals of 1.25 seconds.

Flash 2 On for 0.5 sec., Off for 0.5 sec., On for 0.5 sec. and Off for 1.0 sec.

Flash at high speed Turns on and off at intervals of 0.5 seconds.

Alternate flash 1 Same as “Flash”

Alternate flash 2 Turns on and off at intervals of 1.25 seconds.

Note *1: WF-7520/7510 series only

*2: Flashes if the status arises when printing starts or when the printer starts up, but lights if the status arises when printing is

complete.

*3: WF-7520/7010 series only

*4: The corresponding ink LED flashes/lights.

*5: The corresponding ink cartridge product number is indicated.

*6: Occurs when cancelling printing from PC, UPNP printing.

*7: Lights and then flashes.

*8: This does not occur independently. Occurs together with operating or standby state.

Product description Control Panel 18

Page 19

Epson WF-7520/7510/7010 series Revision A

1.5 Various Settings

1.5.1 Panel Operation

1.5.1.1 Setup Menu Configuration (WF-7520/7510 series only)

The following explains the setup menu structure and the outline of the menu functions.

Table 1-9. Setup Menu Configuration (WF-7520/7510 series only)

Menu Description

Setup Ink Levels --- Displays the status of ink cartridges.

Maintenance Print Head Nozzle Check Prints a nozzle check pattern.

Print Head Cleaning Runs a print head cleaning.

Print Head Alignment Prints a gap adjustment pattern.

Ink Cartridge Replacement Starts ink cartridge replacement.

Printer Setup Paper Size Loaded

Sound Turns the sound on/off.

Screen Saver

Display Format Specifies display format for the images in the memory card.

Date/Time Selects display format for data/time.

Daylight Saving Time Selects daylight saving time.

Country/Region Selects country/region.

Language Selects the language displayed on the LCD.

Paper Size Notice

Wi-Fi/Network

Settings

File Sharing Setup USB

External Device

Setup

Print Status Sheet --- Prints a printer status sheet.

Restore Default

Settings

Wi-Fi Setup Selects a connection method for wireless LAN.

General Network Setup

Wi-Fi/Network Connection

Check

Confirm Network Settings • Displays the network information.

Wi-Fi/Network

Print Settings Configures the print and paper settings when printing an image in

Photo Adjustments Configures the color correction for photo.

Reset Fax Send/Receive

Settings

Reset Fax Data Settings Deletes the fax data settings.

Reset Wi-Fi/Network

Settings

Reset All except Wi-Fi/

Network & Fax Settings

Reset All Settings Initializes the all settings.

*1

*2

*1

Selects the paper size.

Configures the screen saver setting.

Checks the paper size and selects whether to alert users when an

error occurs (Off/On).

Configures the general setting for network.

• Checks the network connection status.

• Prints the connection check result.

• Prints a network status sheet.

Sets the access priority when accessing the storage device

connected to the USB host port to USB or Wi-Fi/Network.

external device.

Initializes the fax send/receive settings.

Initializes the Wi-Fi/network settings.

Initializes the settings except Wi-Fi/network/fax settings.

Note *1: WF-7520 series only

*2: Not available for some destinations.

Product description Various Settings 19

Page 20

Epson WF-7520/7510/7010 series Revision A

1.5.1.2 Forced Power OFF (WF-7010 series only)

For WF-7010 series, the power can be turned off forcibly by the following panel operation. If the power is turned

off forcibly, the same process of the normal power-off is executed.

Operation method

1. Press the power button and then stop button, and hold down the buttons for seven seconds or more.

2. When the Power LED starts flashing, release the buttons.

1.5.1.3 Printer Status Sheet

WF-7520/7510/7010 series print the printer status sheet by the following operation.

Table 1-10. Status Sheet

Model Procedure

WF-7520/7510 series 1. Press the setup button.

2. Select “Print Status Sheet” from the setup menu.

3. Press the OK button.

WF-7010 series Turn the power on while pressing the paper feed/eject button.

Note : When printing the network status sheet to check the network information, follow the procedure below.

WF-7520/7510 series: Select “Wi-Fi/Network Settings” - “Confirm Wi-Fi/Network Settings”, and press th

(See "1.5.1.1 Setup Menu Configuration (WF-7520/7510 series only) (p19) ".)

WF-7010 series: Press the “network status sheet” button. (See

"1.4.1 Operation Buttons (p14)"

.)

e OK butt

on.

Product description Various Settings 20

Page 21

CHAPTER 2

OPERATING PRINCIPLES

Page 22

Epson WF-7520/7510/7010 series Revision A

A

Printhead

1

2

5

3

4

B

7

6

2.1 Overview

In this chapter, the product names are called as follows:

WF-7520 series: Epson WF-7525/Epson WF-7521/Epson WF-7520

WF-7510 series: Epson WF-7515/Epson WF-7511/Epson WF-7510

WF-7010 series: Epson WF-7018/Epson WF-7015/Epson WF-7012/Epson WF-7011/

Epson WF-7010

This chapter describes the operating principles of WF-7520/7510/7010 series printer mechanism.

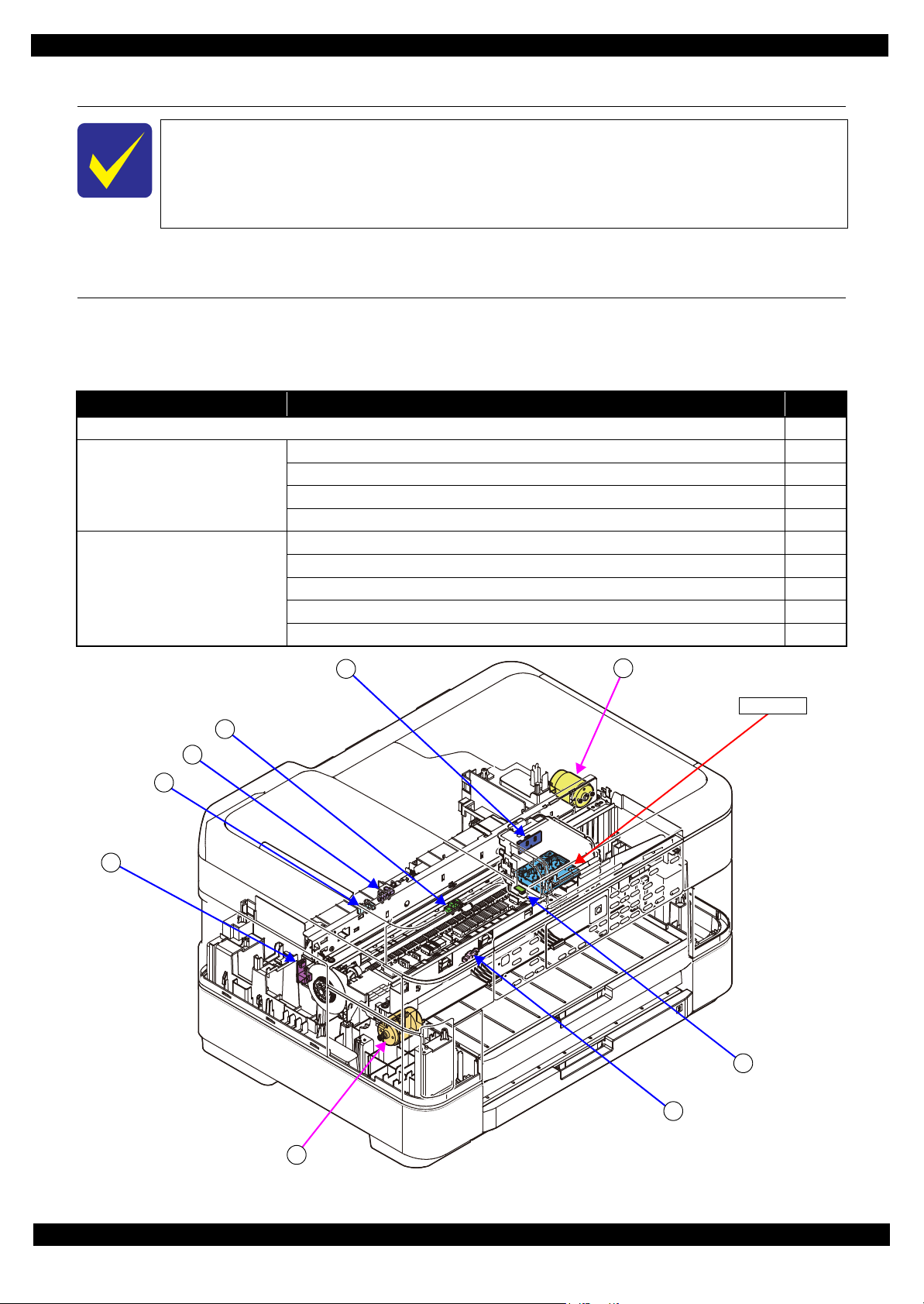

2.2 Motors and Sensors

The following table lists the motors and sensors of WF-7520/7510/7010 series.

Printer Mechanism

Table 2-1. List of Motors & Sensors (Printer Mechanism)

Mechanism Motor or Sensor No.

Printhead ---

Carriage mechanism CR Motor A

CR Encoder 1

PW Sensor 2

Cover Open Sensor 3

Paper loading/feed mechanism PF Motor B

PF Encoder 4

PE Sensor 5

Pre-PE Sensor 6

Paper Stopper Lever Sensor 1st 7

Figure 2-1. Motors & Sensors (Printer Mechanism)

Operating Principles Overview 22

Page 23

Epson WF-7520/7510/7010 series Revision A

2

1

A

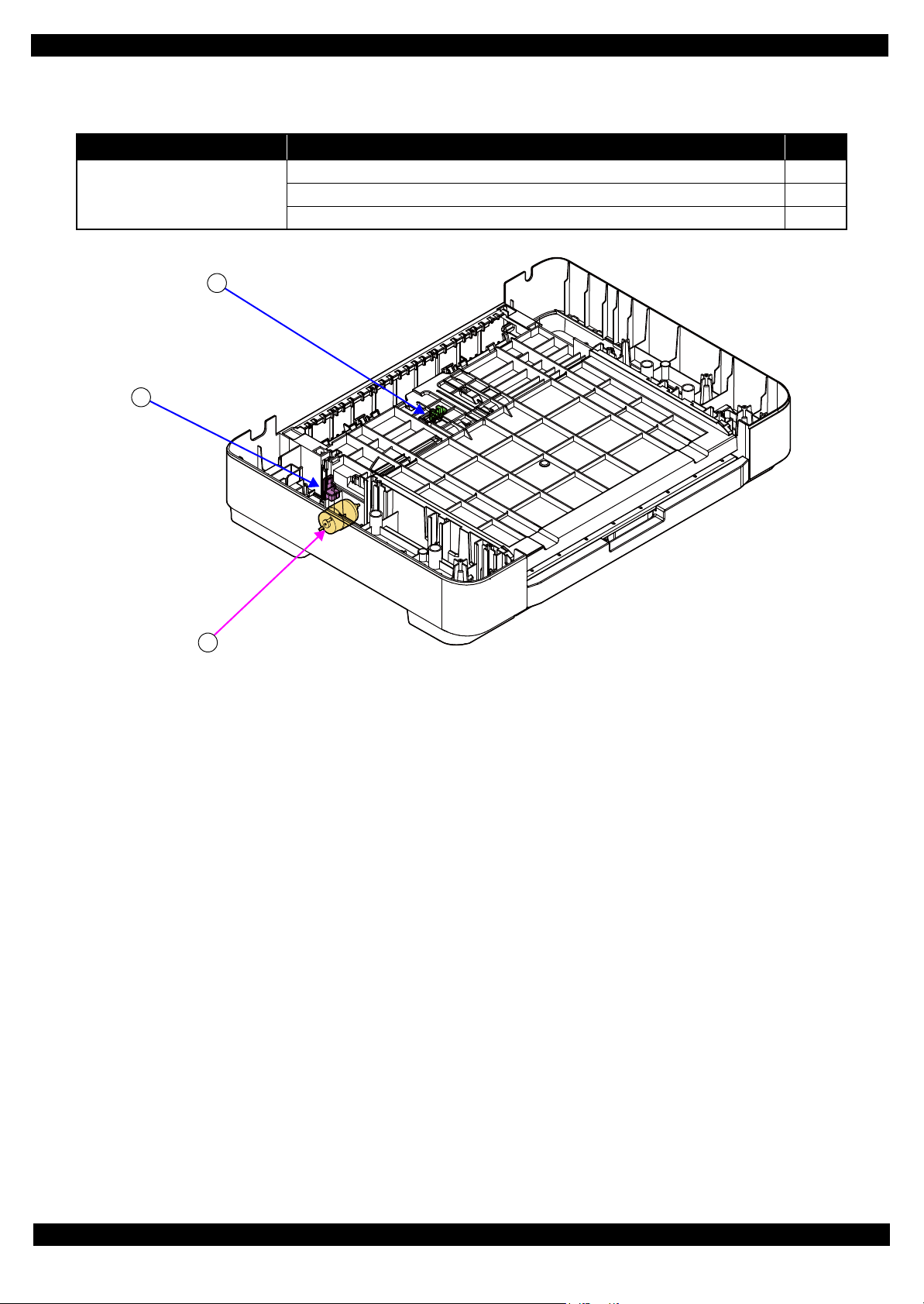

2nd cassette (WF-7520/7010 series only)

Table 2-2. List of Motors & Sensors (2nd Cassette)

Mechanism Motor or Sensor No.

Paper loading/feed mechanism Pickup Motor A

Pickup Encoder 1

Paper Stopper Lever Sensor 2nd 2

Figure 2-2. Motors & Sensors (2nd Cassette)

Operating Principles Motors and Sensors 23

Page 24

Epson WF-7520/7510/7010 series Revision A

1

A

A

1

2

3

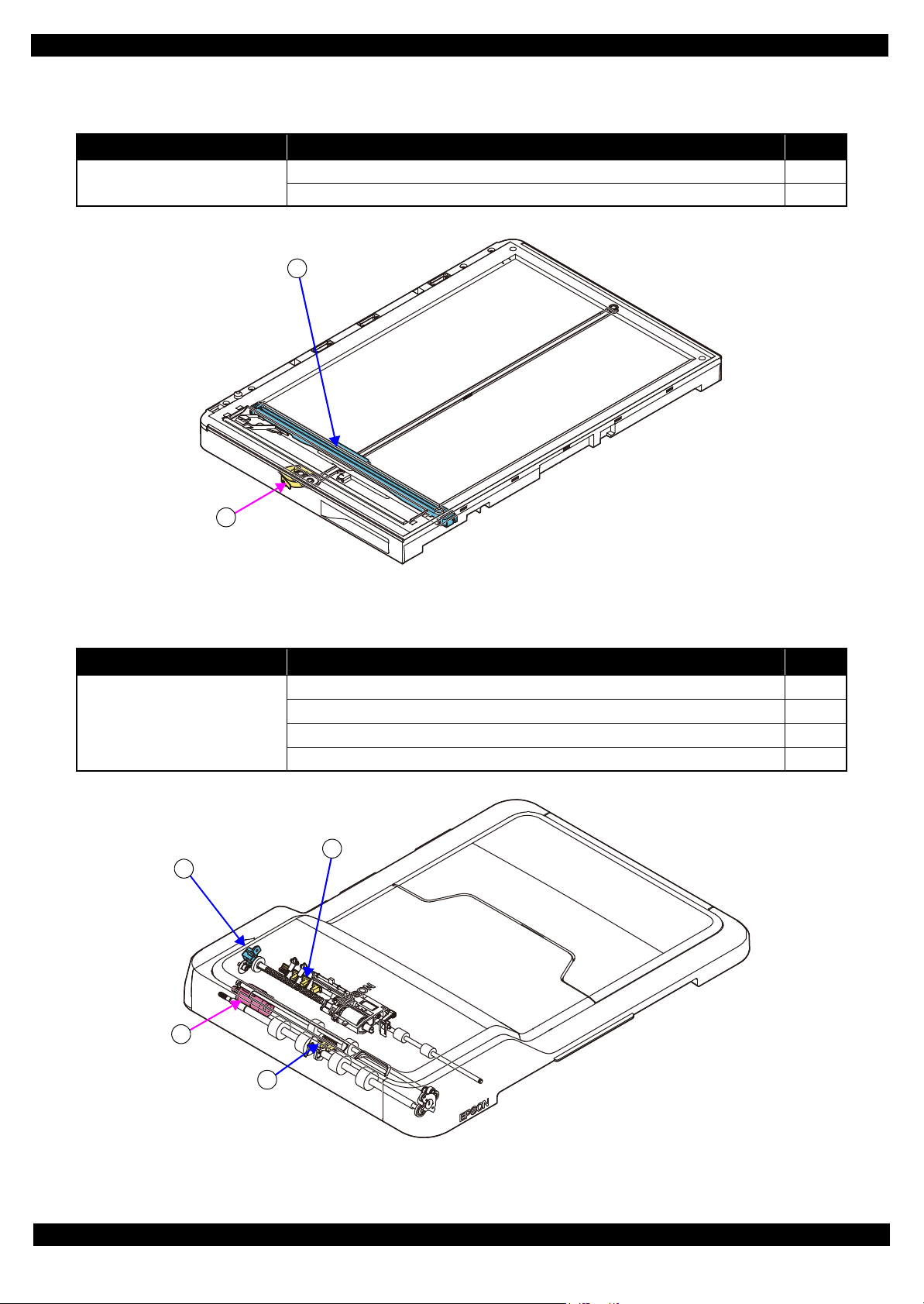

Scanner (WF-7520/7510 series only)

Table 2-3. List of Motors & Sensors (Scanner)

Mechanism Motor or Sensor No.

Scanner mechanism Scanner Motor Assy A

CIS Unit 1

Figure 2-3. Motors & Sensors (Scanner)

Table 2-4. List of Motors & Sensors (ADF)

Mechanism Motor or Sensor No.

ADF mechanism ADF Motor A

ADF PE Sensor 1

ADF DOC Sensor 2

ADF Encoder 3

Figure 2-4. Motors & Sensors (ADF)

Operating Principles Motors and Sensors 24

Page 25

Epson WF-7520/7510/7010 series Revision A

PF Encoder

With cover

Without cover (light-emitting

and receiving devices)

Left side of Printer Mechanism

PF Encoder

Light passes

Light does not pass

PF Scale

PF Timing Belt PF Motor

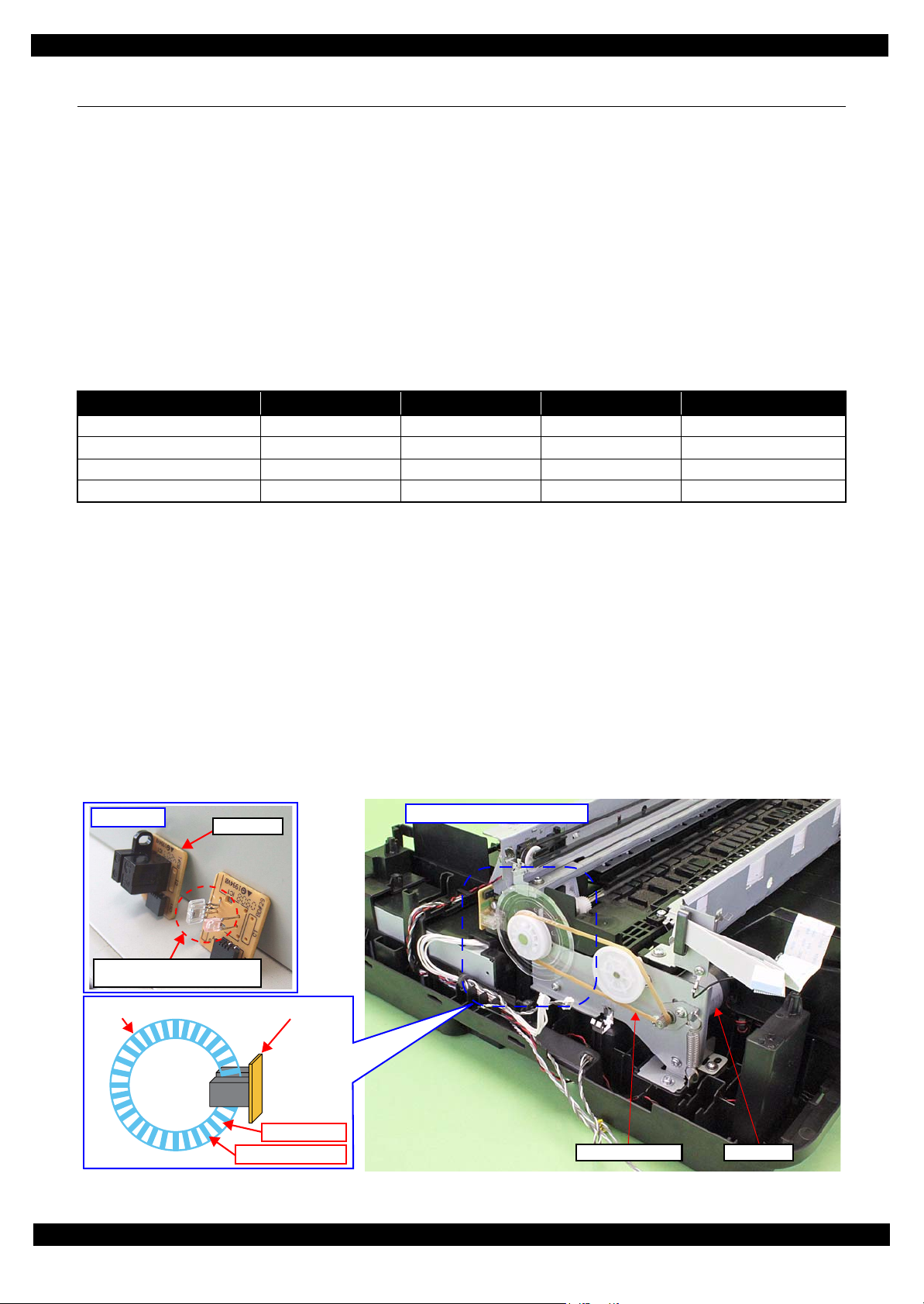

2.3 Optical Sensor Control

WF-7520/7510/7010 series uses the optical sensor to control itself. The following describes the operating

principles of optical sensor control.

Control method

To ensure accurate printing, each part must be controlled to make an adequate amount (time) of movement. The

optical sensors read the amount (time) of movements as follows to printer to control it for achieving accurate printing.

1. Rotates the motors for control of the printer, and transmits drive force to the each part via the gear or the

timing belt.

2. The encoder reads the drive amount of each part from the scale one by one to printer to monitor that the part

drives for an adequate amount (time).

Controlled parts

The following table lists where the optical sensor control is used.

Table 2-5. Controlled Parts

Item Motor Scale Encoder Transmission method

PF/ASF (1st cassette) PF Motor PF Scale PF Encoder PF Timing Belt

CR CR Motor CR Scale CR Encoder CR Timing Belt

ASF (2nd cassette*2) Pickup Motor Pickup Scale Pickup Encoder Gear

*3

ADF

Note *1: See Fig. 2-1 (p22) and Fig. 2-2 (p23) for the positions of the parts.

*2: WF-7520/7010 series only

*3: WF-7520/7510 series only

ADF Motor ADF Scale ADF Encoder Gear

Operating principles

The following describes the PF drive control as an example of the actual operation for the optical sensor.

The PF scale consists of light-passing and light-blocking portions on its surface, and runs through the slit between

the encoder’s light-emitting and light-receiving devices. While the printer is operating, the encoder always emits

light from light-emitting device toward the light-receiving device, and the light-receiving device detects light when

the light is transmitted through the light-passing portion of the scale, and does not detect light when the light is

blocked by the light-blocking portion of the scale. According to the counts of light-detected and non detected times,

the printer controls paper feed drive direction and amount.

When the encoder cannot read light-emitting/blocking counts correctly due to the misalignment, broken or

contaminated scale, paper jam, foreign object and increasing a load, the fatal error occurs and the printer stops.

*1

Figure 2-5. PF Drive Control Section

Operating Principles Optical Sensor Control 25

Page 26

Epson WF-7520/7510/7010 series Revision A

%4NQEM %4

130

130

130

130

%4NQEM

KUTGNGCUGF

130

130

130

130

130

130

130

130

130

2.4 Power-On Sequence

This section describes the power-on sequences for this product. The preconditions are as follows.

Condition 1: Normal power-on sequence (See Table 2-6.)

Turning on the printer after turning it off without an error.

Initial ink charge has finished and every cartridge has sufficient ink.

No paper on the paper path.

The Printhead is capped with the Cap of the Ink System Assy.

The Carriage is normally fixed by the CR Lock.

Condition 2: Power-on sequence after recovering from a paper jam error (See Table 2-7.)

Turning on the printer after turning it off with a paper jam error.

There still remains paper on the paper path out of the detecting area of the PE sensor.

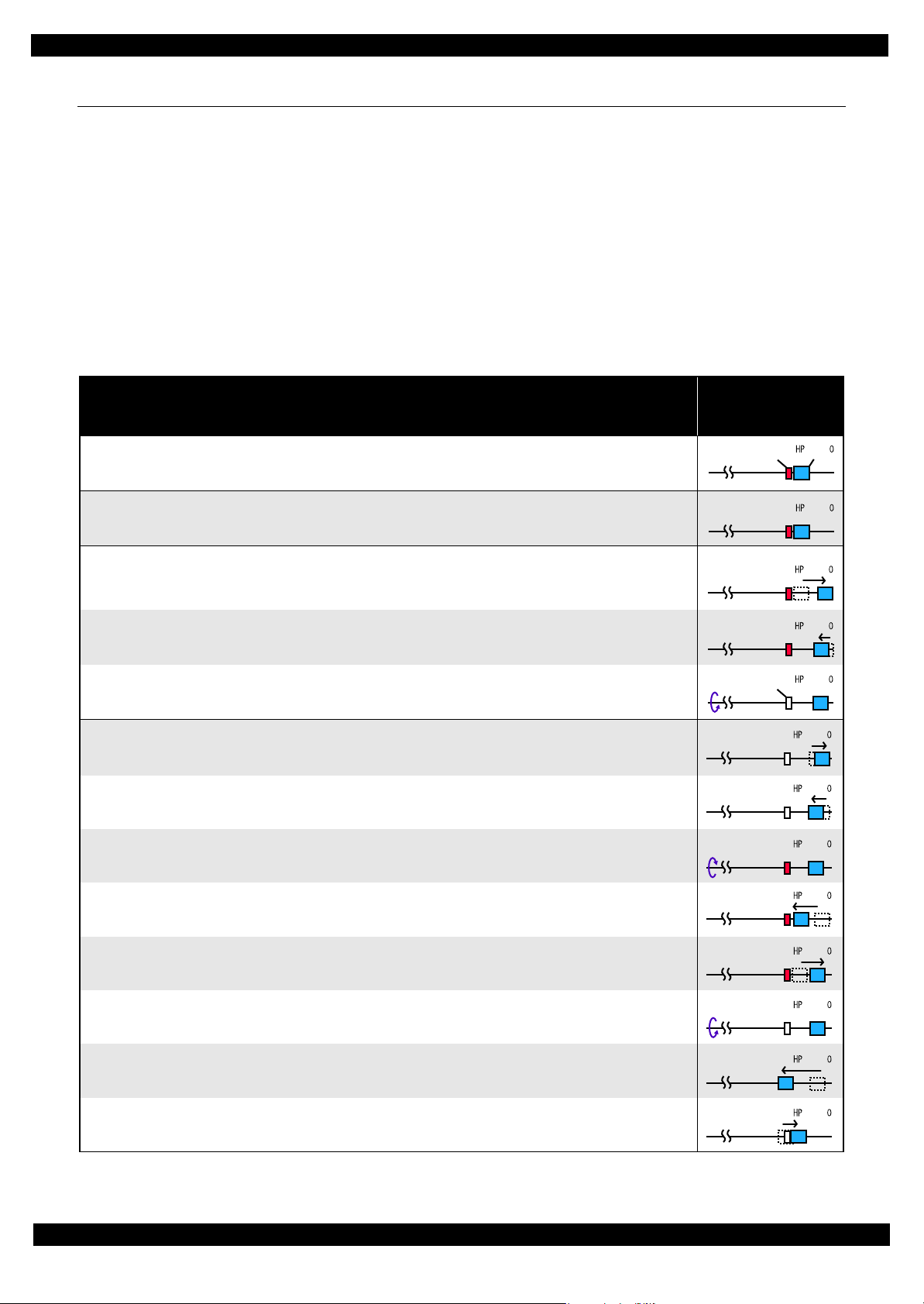

Table 2-6. Condition 1: Normal Power-on Sequence

Operation

1. Printhead initialization

1-1.Initializes the Printhead, and checks for the fuse on the board in the Printhead.

*2

*4

*1

Carriage/PF Roller

movement and

position

*3

2. Checking for waste ink overflow

2-1.Checks the waste ink counter if the waste ink overflow is occurring.

3. Avoiding deadlock sequence

3-1.The carriage moves to the 0-digit side slowly and confirms it touches the Right Frame.

3-2.The carriage slightly moves to the 130-digit side slowly.

3-3.The PF Motor rotates clockwise, and releases the CR lock.

*5

4. Seeking the home position

4-1.The carriage moves to the 0-digit side slowly and confirms it touches the Right Frame. The position when it

touches the Right Frame is set as the origin position temporarily.

4-2.The carriage slowly moves to the CR lock set position.

4-3.The PF Motor rotates counterclockwise, and sets the CR lock.

4-4.The carriage moves to the 130-digit side slowly and confirms it touches the CR lock.

4-5.The carriage slowly moves toward the 0-digit side and reaches the CR lock set position.

4-6.The PF Motor rotates clockwise, and releases the CR lock.

4-7.The carriage moves to the 130-digit side slowly and confirms it does not touch the CR lock.

4-8.The carriage slowly moves to its home position, and the origin position is fixed.

Afterward, the carriage position is monitored according to the signals from the CR Encoder.

Operating Principles Power-On Sequence 26

Page 27

Epson WF-7520/7510/7010 series Revision A

130

130

130

130

130

130

130

130

130

130

130

130

Table 2-6. Condition 1: Normal Power-on Sequence

Operation

5. PF initialization

5-1.The PF Motor rotates clockwise for approximately one second.

5-2.The PE sensor detects if paper exists

6. Low temperature operation sequence

6-1.The carriage moves back and forth between the CR lock and the 130-digit side for two times.

*6

and the PF Motor rotates clockwise for approximately 0.5 second.

*7

7. PF measurement and PW sensor initialization

7-1.The carriage slowly moves to the 130-digit side.

7-2.The carriage moves to the VHCheck position quickly and stops; meanwhile the voltage values detected by the PW

sensor at the specified three points are recorded. At the same time, the PF Motor rotates clockwise and its load is

measured.

7-3.The carriage detects the voltage of the PW sensor at the carriage stop position (the black area at the Paper Guide

Front).

7-4.The carriage returns near its home position. At the same time, the PF Motor rotates clockwise and its load is

measured.

*2

*1

Carriage/PF Roller

movement and

position

*3

8. Detecting ink cartridge and initializing ink system

8-1.After the carriage slightly moves to the 130-digit side and checks the ink end sensor, detects the ink remaining.

8-2.The carriage slowly returns to its home position.

8-3.The carriage slowly moves to the 0-digit side to the CR lock set position.

8-4.The PF Motor rotates counterclockwise and sets the CR lock.

8-5.The carriage slowly returns to its home position.

*8

Note *1: The PF motor drive is not transmitted to the Pickup Roller during this power-on sequence.

*2: The rotation directions of the PF Motor are as follows.

Clockwise: Paper is fed normally

Counterclockwise: Paper is fed backward

*3: The conditions of the CR lock are as follows.

Red CR lock is set

White CR lock is released

*4: The fatal error occurs if there is a problem such as the fuse blew.

*5: Confirm that the CR lock is not get stuck in the gap of the carriage or any other parts preventing the carriage from moving.

*6: Eject paper if any.

*7: Executed when the detected temperature is under 5 oC (41oF) by the thermistor on the Printhead.

*8: The empty suction operation may occur depending on situations.

Operating Principles Power-On Sequence 27

Page 28

Epson WF-7520/7510/7010 series Revision A

130

130

Table 2-7. Condition 2: Power-on Sequence after Recovering from a Paper Jam Error

Carriage/PF Roller

Operation

Executes No.1 to No.5 on the normal power-on sequence (Table 2-6).

6. Detecting remaining paper

6-1.The carriage moves to the 130-digit side and confirms there is no paper.

6-2.The carriage quickly returns to its home position, and the paper jam error occurs again.

When the user removes the paper and releases the paper jam error by panel operation, the normal power-on sequence from No.1 (Table 2-6) is executed

*2

again.

*1

Note *1: “Paper exists” is detected when the carriage touches the paper. When “paper does not exist” is detected, the power-on sequence

of condition 1 (Table 2-6) is executed from No.6.

*2: If the paper jam error cannot be solved after repeating the power-on sequence on condition 2 (Table 2-7) twice, the printer turns

into the paper jam fatal error for the third time.

movement and

position

Operating Principles Power-On Sequence 28

Page 29

CHAPTER 3

TROUBLESHOOTING

Page 30

Epson WF-7520/7510/7010 series Revision A

3.1 Troubleshooting

In this chapter, the product names are called as follows:

WF-7520 series: Epson WF-7525/Epson WF-7521/Epson WF-7520

WF-7510 series: Epson WF-7515/Epson WF-7511/Epson WF-7510

WF-7010 series: Epson WF-7018/Epson WF-7015/Epson WF-7012/Epson WF-7011/

Epson WF-7010

This section describes the error message list, troubleshooting workflow, fatal error code and FAX

Troubleshooting.

3.1.1 Error Message List

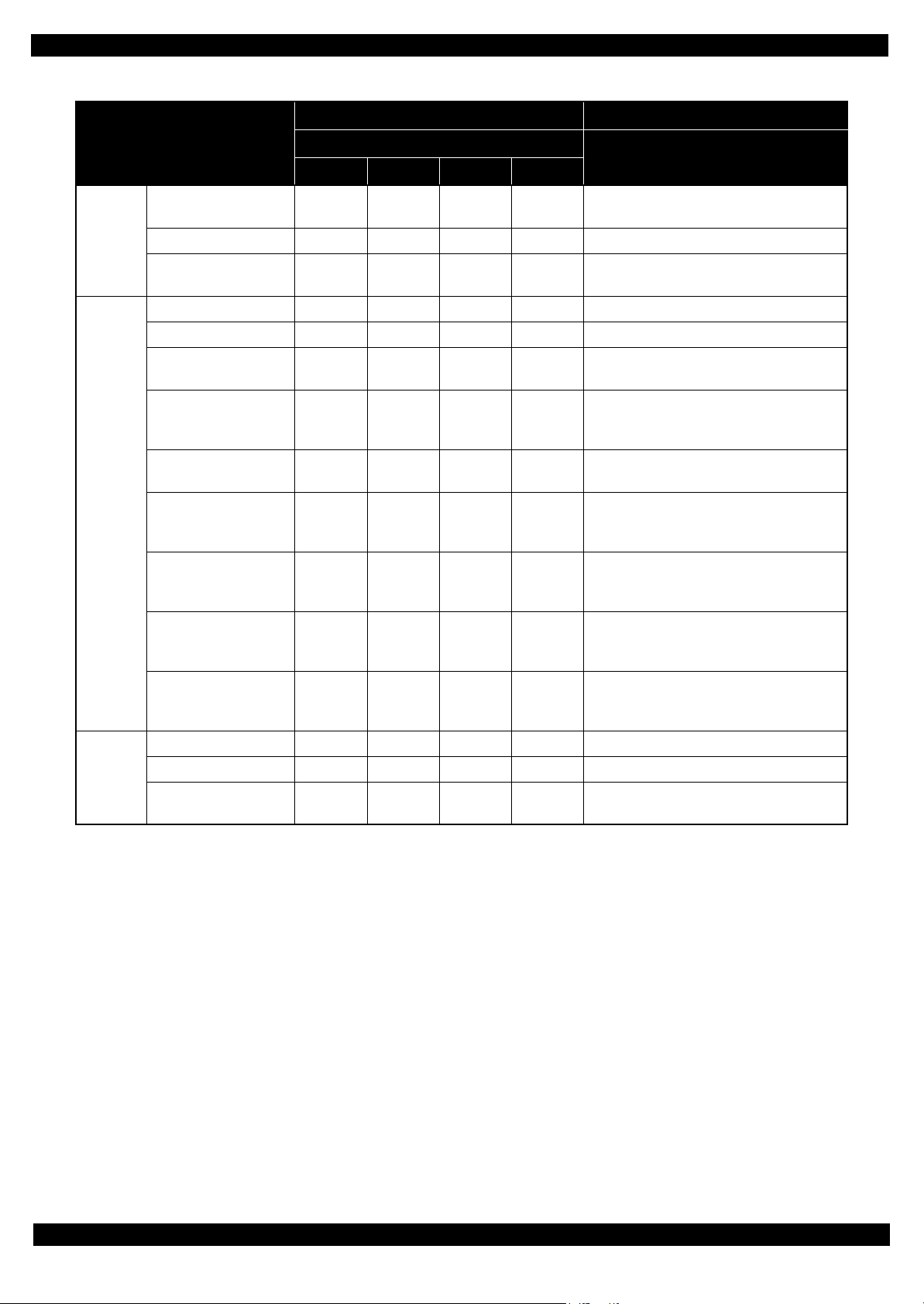

Table 3-1. Error Message List

WF-7010 series WF-7520/7510 series

Status

LED

LCD Message

Power Network Paper Ink

Printer fatal error

Printer fatal error

(paper jam)

Scanner fatal error

Flash at

high speed

Flash at

high speed

*1

--- --- --- ---

Flash at

high speed

Flash at

high speed

Flash at

high speed

Flash at

high speed

Flash at

high speed

Flash at

high speed

Printer error. Turn power off and then on again. For

details, see your documentation or visit Epson.com.

Paper jam inside, in back, or in ADF. Press OK to see

how to remove jammed paper.

Scanner error. Turn power off and then on again. In

the error is not fixed, visit Epson.com for technical

support.

ADF fatal error

ADF paper jam error

Waste ink pad end error Flash

Waste ink pad near end error Flash

Paper jam error Flash

No paper cassette error Flash

Paper out error Flash

Multi-feed error Flash

Paper length mismatch error

for duplex printing

Paper size mismatch error Flash

Incorrect paper size error

Printer/printer driver

mismatch error

*1

*1

*3

*1

--- --- --- --- Automatic Document Feeder (ADF) error.

--- --- --- ---

Alternate

flash 1

Alternate

flash 1

Flash

*2

*2

*2

*2

*2

*2

*2

*2

---

---

--- Flash ---

--- ON --- Load Cassette correctly and press or .

--- ON ---

--- ON ---

--- ON ---

--- ON ---

--- --- --- ---

Flash

*2

---

Flash at

high speed

Alternate

flash 2

Alternate

flash 2

Flash at

high speed

Paper jam in the Automatic Document Feeder

(ADF).

A printer's ink pad is at the end of its service life.

Please contact Epson Support.

A printer's ink pad is nearing the end of its service

life. Please contact Epson Support.

Paper jam. Press OK to see how to remove jammed

paper.

Paper out or paper jam. Check paper size and load

paper in paper cassette.

Multi-page feed error. Remove and reload the paper,

then press or .

Incorrect paper size detected. Load correct paper size

and press or .

No paper source matches paper size setting. Load

appropriate paper in Cassette 1. Press or .

Paper size is incorrect. Load US B 11x17in size plain

paper in Cassette.

Error Press .

Cover open error Flash --- Flash 2 Flash 2 Close the scanner unit.

Ink end error Flash

Ink cartridge detection error Flash

*2

*2

--- --- ON

--- --- ON

You need to replace the following ink cartridge(s).

*4

<Ink Cartridges>XXXXXXX

Cannot recognize the following cartridge(s). Try

*4

installing them again.

<Ink Cartridges>XXXXXXX

*5

*5

Troubleshooting Troubleshooting 30

Page 31

Epson WF-7520/7510/7010 series Revision A

Table 3-1. Error Message List

WF-7010 series WF-7520/7510 series

Status

Power Network Paper Ink

Ink cartridge detection error

(non-Epson cartridge)

No ink cartridge error Flash

Ink cartridge cover open

error

Note : Flash Turns on and off at intervals of 1.25 seconds.

Flash 2 On for 0.5 sec., Off for 0.5 sec., On for 0.5 sec. and Off for 1.0 sec.

Flash at high speed Turns on and off at intervals of 0.5 seconds.

Alternate flash 1 Same as “Flash”

Alternate flash 2 Turns on and off at intervals of 1.25 seconds.

Note *1: WF-7520/7510 series only

*2: Flashes if the status arises when printing starts or when the printer starts up, but lights if the status arises when printing is

complete.

*3: WF-7520/7010 series only

*4: The corresponding ink LED flashes/lights.

*5: The corresponding ink cartridge product number is indicated.

Flash

Flash

*2

*2

*2

LED

--- --- ON

--- --- ON

--- --- ---

LCD Message

Ink cartridge is not recognized. Please replace the

*4

cartridge.

<Ink Cartridges>XXXXXXX

The cartridge is installed incorrectly. Press it down

*4

until it clicks.

<Ink Cartridges>XXXXXXX

The ink cartridge cover is open. Close the ink

cartridge cover.

*5

*5

3.1.2 Troubleshooting Workflow

The following page describes the troubleshooting workflow. Follow the flow when troubleshooting problems.

Troubleshooting Troubleshooting 31

Page 32

Epson WF-7520/7510/7010 series Revision A

Start

Turn on the printer

Does power-on

sequence start?

Yes

Is Power-on sequence

finished without error?

Yes

Standby condition

Perform “Flow A”

What is returned reason?

ADF/Scanner

unit failure

Copy an image

Is scanning operation

finished without

trouble?

Yes

ADF failure?

Yes

Copy an image by ADF

Is ADF operation finished

without trouble?

Yes

*5

Finish

No

No

1

Printer failure only

No

No

No

Major problem without

error message

No Power

[Presumable Cause]

• Power Supply Unit damage

• Main Board damage

[Major Troubleshooting]

• Power Supply Unit

replacement

• Main Board replacement

Scanner failure

[Presumable Cause]

• Contamination of Scanner Glass

• Contamination of Document Pad

• CIS Unit bonding failure

• CIS Unit damage

• Scanner Motor Assy damage

[Major Troubleshooting]

• Scanner Glass cleaning

• Document Pad cleaning

• Document Pad replacement

• CIS Unit replacement

• Scanner Motor Assy replacement

ADF failure

[Phenomenon]

• No paper feed

• Double feed

• Paper jam

• Paper skew

[Presumable Cause]

• Wear of Pickup Roller

• Wear of ADF Pad Assy

• Gear damage

• ADF Motor damage

• Contamination of Scanner Glass

• Paper Sheet damage

• Foreign material

• ADF Paper Guide Upper Assy damage

• Wear of paper eject roller

• ADF Sensor damage

[Major Troubleshooting]

• ADF LD Assy replacement

• ADF Pad Assy replacement

• Scanner Glass cleaning

• Paper Sheet replacement

• Foreign material removal

• ADF Unit replacement

*1

1

Fatal error

Please refer to “ 3.1.3 Fatal Error

Code (p33)” for troubleshooting.

Flow A

Print check pattern

Is printing operation

finished without error?

Is printing operation

finished without trouble?

Return previous flow

Major problem without error message

Poor Printing

[Phenomenon]

• Poor printing quality

• Ink stain on paper

• Dot missing

• Paper eject without printing

[Presumable Cause]

• Driver / Panel mis-setting

• Contamination of CR Scale

• Contamination of Printhead

Cover

• Printhead damage

• Ink clogging of Printhead

• Contamination on Cap / Wiper

of Ink System Assy

• Ink System Assy damage

• Float of Paper Guide Front

Porous Pad

• Narrow PG

• PE Sensor Lever damage

• PE Sensor damage

[Major Troubleshooting]

• Driver / Panel re-setting

• CR Scale replacement

• Printhead Cover cleaning

• Printhead cleaning

• Ink Cartridge replacement

• Printhead replacement

• Rubber cleaning of Cap

• Ink System Assy replacement

• Paper Guide Front Porous Pad

re-installation

• Printer Mechanism (Frame

Base Assy) replacement

• PE Sensor Lever replacement

• PE Sensor replacement

[Occurrence Condition]

[Major Occurrence Timing]

[Troubleshooting]

Start

Yes

Yes

[Presumable Cause]

• Use of 3rd party media

• Edge guide mis-setting

• Foreign material

• Part come-off

• Contamination of paper feed

• Cassette Assy damage

[Major Troubleshooting]

• Recommendation of EPSON

• Edge guide re-setting

• Foreign material removal

• Part re-installation

• Roller replacement

• Cassette Assy replacement

[Presumable Cause]

• Foreign material

• Insufficient grease

• Gear damage

[Major Troubleshooting]

• Foreign material removal

• Lubrication of grease

• Gear replacement

Waste ink pad end error

This error occurs when

maintenance counter in EEPROM

exceeds the specified value.

• Power-on timing

• Print start timing

• Cleaning timing

• Ink Cartridge replacement timing

• Waste Ink Pad (Waste Ink Tray

Assy or Paper Guide Lower

Porous Pad) replacement

• Maintenance counter reset

No

No

Poor Paper Loading

roller in Duplex Unit

media

Abnormal Noise

Ink end error

[Occurrence Condition]

This error occurs when ink in Ink

Cartridge is empty.

[Major Occurrence Timing]

• Power-on timing

• Print start timing

• Cleaning timing

• Ink Cartridge replacement

timing

• During printing

[Troubleshooting]

• Ink Cartridge replacement

[NOTE]

If this error occurs during auto

duplex print operation, printer

stops and eject the paper

automatically even if the printing

is not completed.

Paper jam error

[Occurrence Condition]

This error occurs when the top/

bottom of paper cannot be

detected by PE Sensor within the

specified steps even if the paper

has been fed correctly.

[Major Occurrence Timing]

• Power-on timing

• Paper loading timing

• Paper eject timing

• Auto duplex print timing

[Major Troubleshooting]

1 Press the “OK” button to eject

the paper.

• If succeeded

Starts paper feeding operation

again if printer has print data.

• If failed

Occurs paper jam error again.

2 If fail in the above 1, remove

the paper by opening Scanner

Unit or Printer Cover and

taking off Duplex Unit.

3 Press the “OK” button again.

• If succeeded

Starts paper feeding operation

again if printer has print data.

• If failed

Occurs paper jam error again.

4 Check the following if failed in

Step 3.

• Foreign material

• Part come-off

• PE Sensor Lever

• PE Sensor

• Paper Guide Front Porous

Pad

• Main board

• Paper Stopper Assy

[NOTE]

If this error occurs during auto

duplex print operation, printer

stops and eject the paper

automatically even if the printing

is not completed. (print data of

adverse side & reverse side is

eliminated.)

Major problem with error message

Ink cartridge detection error

[Occurrence Condition]

This error occurs when Ink

Cartridge data is incorrect or Ink

Cartridge is not recognized

correctly.

[Major Occurrence Timing]

• Power-on timing

• Print start timing

• Cleaning timing

• Ink Cartridge replacement

timing

[Major Troubleshooting]

• Remove and reinstall Ink

Cartridge

• Ink Cartridge replacement

• CSIC Terminal replacement

• CR Contact Module

replacement

• Head FFC replacement

• Main Board replacement

Paper out error

[Occurrence Condition]

This error occurs when the top of

paper cannot be detected by PE

Sensor within the specified steps

even if the paper has been fed

correctly. (No paper / paper

loading failed / paper is fed at

slant)

[Major Occurrence Timing]

*4

• Paper loading timing

[Major Troubleshooting]

1 Put papers in Cassette Assy

and press the “OK” button.

2 If a paper stops before reaching

PE Sensor, remove it and

check the paper condition.

3 A) If no damage in the above 2,

set edge guide correctly after

putting papers in

Assy

and retry.

B) If damage in the above 2,

check foreign materials /

parts come-off / parts

transformation in paper path.

4 If the problem is not solved by

3-A & 3-B, check the following.

• Foreign material

• Part come-off

• Surface condition of Pickup

Roller or paper feed roller in

Duplex Unit

• PE Sensor Lever

• PE Sensor

• Pre-PE Sensor Lever

• Pre-PE Sensor

• Main Board

• PF Motor or Pickup Motor

• Cassette Assy

• Paper Stopper Assy

Cassette

No ink cartridge error

[Occurrence Condition]

This error occurs when Ink

Cartridge is not installed.

[Major Occurrence Timing]

• Power-on timing

[Troubleshooting]

• Ink Cartridge installation

Multi-feed error

[Occurrence Condition]

This error occurs on the following

case.

• The top of paper is detected

before the specified steps are

reached.

• Actual paper length is longer

than theoretical one.

[Major Occurrence Timing]

• Paper loading timing

• Paper feed timing

• Paper eject timing

[Troubleshooting]

• PE Sensor Lever replacement

• PE Sensor replacement

• PW Sensor replacement

• Main Board replacement

Cover open error

[Occurrence Condition]

This error occurs when Scanner

Unit or Printer Cover is in open

condition.

[Major Occurrence Timing]

• Power-on timing

[Major Troubleshooting]

• Scanner Unit or Printer Cover

close

• Scanner Unit or Printer Cover

replacement

• Cover Open Sensor

replacement

• Main Board replacement

Paper length mismatch error

for duplex printing

[Occurrence Condition]

This error occurs when actual

paper size is not matched to

theoretical one (both shorter and

longer).

[Major Occurrence Timing]

• Auto duplex print timing

[Troubleshooting]

• PE Sensor Lever replacement

• PE Sensor replacement

• PW Sensor replacement

• Main Board replacement

No paper cassette error

[Occurrence Condition]

This error occurs when Cassette

Assy cannot be detected.

[Major Occurrence Timing]

• Paper loading timing

[Troubleshooting]

• Check connection for Paper

Stopper Lever Sensor cable

• Replace Paper Stopper Lever

Sensor

*2

Paper jam error

Please refer to “ Paper jam error”

of “Error occurs in printing

operation”.

Paper size mismatch error

[Occurrence Condition]

This error occurs when actual

paper size is not matched to

theoretical one. (shorter only)

[Major Occurrence Timing]

• Paper loading timing

*4

• Paper feed timing

• Paper eject timing

[Troubleshooting]

• PE Sensor Lever replacement

• PE Sensor replacement

• PW Sensor replacement

• Main Board replacement

*1: If the printer can turn on but turns off right away, the protection circuit may cut off the power

due to an error such as a circuit failure.

*2: For WF-7010 series, this error occurs only when the Printer Cover is opened.

*3: Only for fax printing for WF-7520/7510 series.

*4: Auto duplex printing is available only for WF-7520/7010 series.

*5: In case of “Not Trouble Found”, check fatal error code.

This flowchart is compiled based on the following contents.

• Our experience regarding the quality problem

• ESK’s repair data

• Printer Mechanism specification for WF-7520/7510/7010 series

WF-7010 series are not equipped with the Scanner / ADF unit,

therefore, the troubleshooting related to the Scanner / ADF unit is

not applied.

*3

Appendix Troubleshooting Workflow 32

Page 33

Epson WF-7520/7510/7010 series Revision A

3.1.3 Fatal Error Code

This section describes the fatal error code and the possible cause for this product.

Printer fatal error list

Table 3-2. Fatal Error List (Printer)

Error type

DC motor

error

Error

code

01H CR PID excess load error

02H CR PID excess speed error

03H CR PID reverse error

04H CR PID lock error

05H CR PID speed degradation error

08H CR load position reverse error

09H CR load position excess speed error

0AH CR load position excess load error

F1H PF PID excess load error

F2H PF PID excess speed error

F3H PF PID reverse error

F4H PF PID lock error

F6H PF PID excess torque limitation error • PF drive mechanism overload (paper jam/foreign object)

Error name Possible cause

• CR Encoder failure (contaminated/detached scale, Encoder Board failure)

• CR Motor failure

• Carriage overload error (paper jam/foreign object)

• Cable disconnection

• CR Encoder failure (contaminated/detached scale, Encoder Board failure)

• Motor driver failure (Main Board failure)

• Tooth skip of the CR Timing Belt

• Improper tension of the CR Timing Belt

• CR Encoder failure (contaminated/detached scale, Encoder Board failure)

• Tooth skip of the CR Timing Belt

• Improper tension of the CR Timing Belt

• Paper jam

• CR Encoder failure (contaminated/detached scale, Encoder Board failure)

• CR Motor failure

• Carriage overload error (paper jam/foreign object)

• Cable disconnection

• CR Encoder failure (contaminated/detached scale, Encoder Board failure)

• Motor driver failure (Main Board failure)

• Tooth skip of the CR Timing Belt

• Improper tension of the CR Timing Belt

• Paper jam

• CR Encoder failure (contaminated/detached scale, Encoder Board failure)

• Tooth skip of the CR Timing Belt

• Improper tension of the CR Timing Belt

• Paper jam

• CR Encoder failure (contaminated/detached scale, Encoder Board failure)

• Motor driver failure (Main Board failure)

• Tooth skip of the CR Timing Belt

• Improper tension of the CR Timing Belt

• CR Encoder failure (contaminated/detached scale, Encoder Board failure)

• CR Motor failure

• Carriage overload error (paper jam/foreign object)

• Cable disconnection

• PF Encoder failure (contaminated/detached scale, Encoder Board failure)

• PF Motor failure

• PF drive mechanism overload (paper jam/foreign object)

• Cable disconnection

• PF Encoder failure (contaminated/detached scale, Encoder Board failure)

• Motor driver failure (Main Board failure)

• Tooth skip of the PF Timing Belt

• Improper tension of the PF Timing Belt

• PF Encoder failure (contaminated/detached scale, Encoder Board failure)

• Tooth skip of the PF Timing Belt

• Improper tension of the PF Timing Belt

• Paper jam

• PF Encoder failure (contaminated/detached scale, Encoder Board failure)

• PF Motor failure

• PF drive mechanism overload (paper jam/foreign object)

• Cable disconnection

Troubleshooting 33

Page 34

Epson WF-7520/7510/7010 series Revision A

Table 3-2. Fatal Error List (Printer)

Error type

DC motor

error

Motor drive

time error

Printhead

system error

Error

code

Error name Possible cause

• PF Encoder failure (contaminated/detached scale, Encoder Board failure)

F8H PF load position reverse error

• Tooth skip of the PF Timing Belt

• Improper tension of the PF Timing Belt

• PF Encoder failure (contaminated/detached scale, Encoder Board failure)

F9H PF load position excess speed error

• Motor driver failure (Main Board failure)

• Tooth skip of the PF Timing Belt

• Improper tension of the PF Timing Belt

FAH PF load position excess load error • PF Encoder failure (contaminated/detached scale, Encoder Board failure)

• PF Motor failure

FCH PF load position error

• PF drive mechanism overload (paper jam/foreign object)

• Cable disconnection

• Pickup Encoder failure (contaminated/detached scale, Encoder Board

failure)

11H ASF PID excess load error

*

• Pickup Motor failure

• Pickup drive mechanism (2nd cassette) overload (paper jam/foreign object)

• Cable disconnection

• Pickup Encoder failure (contaminated/detached scale, Encoder Board

failure)

12H ASF PID excess speed error

*

• Pickup Motor driver failure (Main Board failure)

• Pickup Encoder failure (contaminated/detached scale, Encoder Board

failure)

13H ASF PID reverse error

*

• Paper jam

• Pickup Encoder failure (contaminated/detached scale, Encoder Board

failure)

14H ASF PID lock error

*

• Pickup Motor failure

• Pickup drive mechanism (2nd cassette) overload (paper jam/foreign object)

• Cable disconnection

16H ASF PID excess torque limitation error

18H ASF load position reverse error

*

• Pickup Roller (2nd cassette) overload (paper jam/foreign object)

*

• Pickup Encoder failure (contaminated/detached scale, Encoder Board

failure)

• Paper jam

• Pickup Encoder failure (contaminated/detached scale, Encoder Board

failure)

19H ASF load position excess speed error

*

• Motor driver failure (Main Board failure)

• Pickup Encoder failure (contaminated/detached scale, Encoder Board

failure)

1AH ASF load position excess load error

*

• Pickup Motor failure

• Pickup drive mechanism (2nd cassette) overload (paper jam/foreign

object)

• Cable disconnection

D1H CR (PID) driving time error

D2H CR (load position) driving time error

D3H PF (PID) driving time error

D4H PF (BS) driving time error

D5H ASF (PID) driving time error

D6H ASF (BS) driving time error

*

*

• Main Board failure

40H Transistor temperature error • Main Board failure

41H X-Hot detect error (pre printing)

42H X-Hot detect error (after flushing)

• Printhead failure

• Main Board failure

43H Head temperature error

Troubleshooting 34

Page 35

Epson WF-7520/7510/7010 series Revision A

Table 3-2. Fatal Error List (Printer)

Error type

Sequence

error

Sensor error

Ink device

error

Circuit error 80H Circuit error (include blowout of a fuse) • Main Board failure

Error

code

50H Home position error

51H Deadlock avoidance error

52H Impossible contact detection error

56H

5BH Insoluble paper jam error

60H PW detector error

61H PW detector confusion error

63H PE detector error

B0H -

CFH

Contact error at ink replacement timing

(Power-off)

Ink device error

Error name Possible cause

• Paper jam

• Foreign object

• Deformation of the Main Frame

• Paper jam

• Foreign object

• PW Sensor failure

• Main Board failure

• PW Sensor failure

• Main Board failure

• A piece of paper remaining

• Ink contamination on the Paper Guide Front Assy

• PE Sensor failure

• Main Board failure

• Ink Cartridge failure

• CSIC Terminal failure

• CR Contact Module failure

• Main Board failure

Note *: WF-7520/7010 series only

Troubleshooting 35

Page 36

Epson WF-7520/7510/7010 series Revision A

Scanner/ADF fatal error list (WF-7520/7510 series only)

Table 3-3. Fatal Error List (Scanner/ADF)

Error code Error name Possible cause

01H ADF PID excess speed error

02H ADF PID reverse error

03H ADF PID lock error • ADF Encoder failure (contaminated/detached scale, Encoder Board failure)

04H ADF PID acceleration lock detection error

05H ADF PID excess load error

06H ADF PID driving time error • Main Board failure

09H ADF BS+ excess speed error

0AH ADF BS+ reverse error

0BH ADF BS+ lock error • ADF Encoder failure (contaminated/detached scale, Encoder Board failure)

0DH ADF BS+ excess load error

0EH ADF BS+ driving time error • Main Board failure

10H Scanner HP detection error

20H Scanner LED light error

30H ADF option error • Main Board failure

36H ADF paper jam error • Paper jam

• ADF Encoder failure (contaminated/detached scale, Encoder Board failure)

• Motor driver failure (Main Board failure)

• ADF Encoder failure (contaminated/detached scale, Encoder Board failure)

• Paper jam

• ADF Motor failure

• ADF drive overload (paper jam/foreign object)

• Cable disconnection

• ADF Encoder failure (contaminated/detached scale, Encoder Board failure)

• Motor driver failure (Main Board failure)

• ADF Encoder failure (contaminated/detached scale, Encoder Board failure)

• Paper jam

• ADF Motor failure

• ADF drive overload (paper jam/foreign object)

• Cable disconnection

• CIS Unit failure

• Scanner Housing failure

• Main Board failure

• CIS Unit failure

• Main Board failure

Troubleshooting 36

Page 37

Epson WF-7520/7510/7010 series Revision A

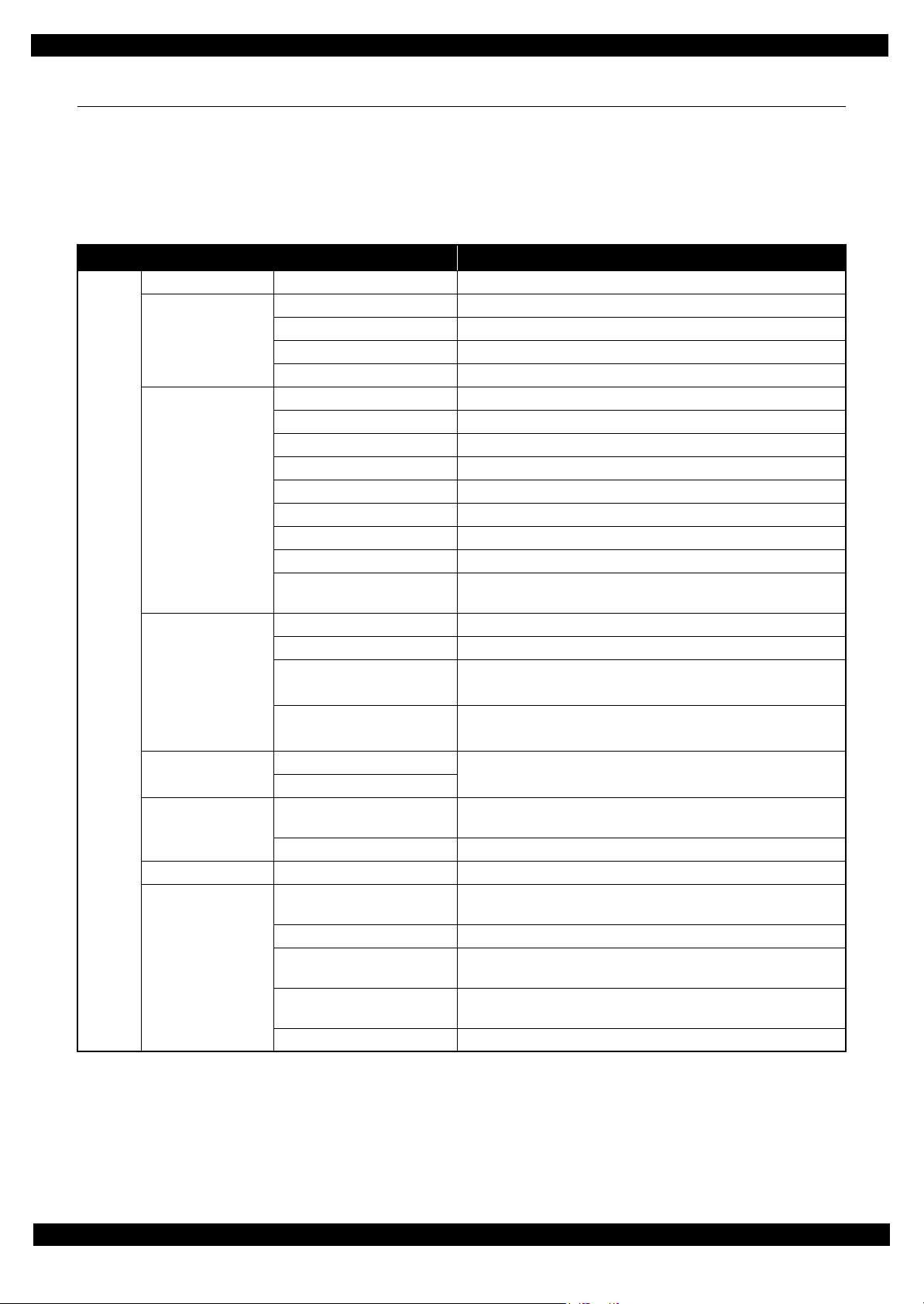

Item Information

Communication start

date / time

Year/month/day/hour/minute

Communication type Sending/receiving/polling reception

Communication ID

Sending/polling reception:

• Destination name of speed dial (first 20 characters)

• Telephone number (last 20 characters)

• Destination fax ID (20 characters)

Receiving:

• Destination fax ID (20 characters)

Airtime Hour/minute/second

Communication pages 0 to 100

Communication result

Common:

Normal/cancel/error code

*

Sending/polling reception:

No dial tone detected/No fax signal detected/Busy tone detected