Page 1

Describes how to control the printer and necessary information

when you develop applications.

Describes setup and installation of the product and peripherals.

Describes how to handle the product.

Describes general specifications and character code tables.

Describes features for the product.

Technical Reference Guide

Product Overview

Setup

Application Development Information

Handling

Appendix

M00081203

Rev. D

Page 2

Cautions

• No part of this document may be reproduced, stored in a retrieval system, or transmitted in any form or

by any means, electronic, mechanical, photocopying, recording, or otherwise, without the prior written

permission of Seiko Epson Corporation.

• The contents of this document are subject to change without notice. Please contact us for the latest

information.

• While every precaution has been taken in the preparation of this document, Seiko Epson Corporation

assumes no responsibility for errors or omissions.

• Neither is any liability assumed for damages resulting from the use of the information contained herein.

• Neither Seiko Epson Corporation nor its affiliates shall be liable to the purchaser of this product or third

parties for damages, losses, costs, or expenses incurred by the purchaser or third parties as a result of:

accident, misuse, or abuse of this product or unauthorized modifications, repairs, or alterations to this

product, or (excluding the U.S.) failure to strictly comply with Seiko Epson Corporation’s operating and

maintenance instructions.

• Seiko Epson Corporation shall not be liable against any damages or problems arising from the use of any

options or any consumable products other than those designated as Original Epson Products or Epson

Approved Products by Seiko Epson Corporation.

Trademarks

EPSON is a registered trademark of Seiko Epson Corporation.

Exceed Your Vision and ESC/POS are registered trademarks or trademarks of Seiko Epson Corporation.

®

Windows

countries.

microSD is registered trademarks of SD Card Association.

Wi-Fi

QR Code® is a registered trademark of DENSO Wave Incorporated.

AndroidTM is a trademark of Google Inc.

IOS

license.

All other trademarks are the property of their respective owners and used for identification purpose only.

is registered trademarks or trademarks of Microsoft Corporation in the United States and other

®

, WPATM, and WPA2TM are either registered trademarks or trademarks of Wi-Fi Alliance®.

®

is a trademark or registered trademark of Cisco in the U.S. and other countries and is used under

ESC/POS® Command System

Epson ESC/POS is a proprietary POS printer command system that includes patented or patent-pending

commands.

ESC/POS is compatible with most Epson POS printers and displays.

ESC/POS is designed to reduce the processing load on the host computer in POS environments. It comprises

a set of highly functional and efficient commands and also offers the flexibility to easily make future

upgrades.

© Seiko Epson Corporation 2014-2016. All rights reserved.

2

Page 3

For Safety

Key to Symbols

The symbols in this manual are identified by their level of importance, as defined below. Read the

following carefully before handling the product.

You must follow warnings carefully to avoid serious bodily injury.

WARNING

Provides information that must be observed to prevent damage to the equipment or loss of data.

Possibility of sustaining physical injuries.

CAUTION

Possibility of causing physical damage.

Possibility of causing information loss.

Provides information that must be observed to avoid damage to your equipment or a

malfunction.

Provides important information and useful tips.

3

Page 4

Warnings

WARNING

To avoid risk of electric shock, do not set up this product or handle cables during a

thunderstorm

Never insert or disconnect the power plug with wet hands.

Doing so may result in electric shock.

Handle the power cable with care.

Improper handling may lead to fire or electric shock.

Do not modify or attempt to repair the cable.

Do not place any heavy object on top of the cable.

Avoid excessive bending, twisting, and pulling.

Do not place the cable near heating equipment.

Check that the plug is clean before plugging it in.

Be sure to push the plug all the way in.

Be sure to use the specified power source.

Connection to an improper power source may cause fire or electric shock.

Do not place multiple loads on the power outlet.

Overloading the outlet may lead to fire.

Shut down your equipment immediately if it produces smoke, a strange odor, or

unusual noise.

Continued use may lead to fire. Immediately unplug the equipment and contact your dealer

or a Seiko Epson service center for advice.

Never attempt to repair this product yourself.

Improper repair work can be dangerous.

Never disassemble or modify this product.

Tampering with this product may result in injury or fire.

Do not allow foreign matter to fall into the equipment.

Penetration by foreign objects may lead to fire.

If water or other liquid spills into this equipment, do not continue to use it.

Continued use may lead to fire. Unplug the power cord immediately and contact your dealer

or a Seiko Epson service center for advice.

Do not use aerosol sprayers containing flammable gas inside or around this product.

Doing so may cause fire.

4

Page 5

Cautions

CAUTION

Do not connect cables in ways other than those mentioned in this manual.

Different connections may cause equipment damage or fire.

Be sure to set this equipment on a firm, stable, horizontal surface.

The product may break or cause injury if it falls.

Do not use this product in locations subject to high humidity or dust levels.

Excessive humidity and dust may cause equipment damage or fire.

Do not place heavy objects on top of this product. Never stand or lean on this product.

Equipment may fall or collapse, causing breakage and possible injury.

Take care not to injure your fingers on the manual cutter

When you remove printed paper

When you perform other operations such as loading/replacing roll paper

Do not open the roll paper cover without taking the necessary precautions, as this can

result in injury from the autocutter fixed blade.

To ensure safety, unplug this product before leaving it unused for an extended period.

Do not knock or strike the printer. This may cause defective print.

Do not catch cables or place foreign matter under the printer.

5

Page 6

Restriction of Use

When this product is used for applications requiring high reliability/safety, such as transportation

devices related to aviation, rail, marine, automotive, etc.; disaster prevention devices; various safety

devices, etc.; or functional/precisio

consideration to including fail-safes and redundancies into your design to maintain safety and total

system reliability. B e ca use this product was not inten

high reliability/safety, such as aerospace equipment, main communication equipment, nuclear

power control equipment, or medical equipment related to direct medical care, etc., please make

your own judgment on this product's suitability aft

n devices, etc., you should use this product only after giving

ded for use in applications requiring extremely

er a full evaluation.

About this Manual

Aim of the Manual

This manual aims to provide all the information necessary for the development, design, and

installment of POS systems, order entry systems, and other receipt issuing systems that use TM-

T83II-i.

Manual Content

The manual is made up of the following sections:

Chapter 1

Chapter 2

Chapter 3

Chapter 4

Appendix

Product Overview

Setup

Application Development Information

Handling

Product Specifications

Setting Items for Software Setting Mode

Character Code Tables

6

Page 7

Contents

■ For Safety .............................................................................................................................. 3

Key to Symbols ....................................................................................................................................... 3

Warnings ................................................................................................................................................. 4

Cautions.................................................................................................................................................. 5

■ Restriction of Use.................................................................................................................. 6

■ About this Manual................................................................................................................ 6

Aim of the Manual ................................................................................................................................. 6

Manual Content .................................................................................................................................... 6

■ Contents................................................................................................................................ 7

Product Overview ........................................................................11

■ Features............................................................................................................................... 11

■ Product Configurations...................................................................................................... 13

Bundled items....................................................................................................................................... 13

Options.................................................................................................................................................. 13

■ Part Names and Functions ................................................................................................ 14

Power Switch ........................................................................................................................................ 14

Power Switch Cover............................................................................................................................. 14

Roll paper cover / Cover open lever................................................................................................. 15

Cutter cover ......................................................................................................................................... 15

Control Panel........................................................................................................................................ 15

Interfaces.............................................................................................................................................. 16

Status LED.............................................................................................................................................. 17

Push Button ........................................................................................................................................... 17

Wired LAN Status LED........................................................................................................................... 18

■ Online and Offline ..............................................................................................................19

Online .................................................................................................................................................... 19

Offline .................................................................................................................................................... 19

■ Error Status........................................................................................................................... 20

Automatically Recoverable Errors...................................................................................................... 20

Recoverable Errors............................................................................................................................... 20

Unrecoverable Errors ........................................................................................................................... 21

■ NV Memory ........................................................................................................................ 22

NV Graphics Memory .......................................................................................................................... 22

Memory Switches (Customized Value)..............................................................................................22

R/E (Receipt Enhancement) .............................................................................................................. 22

Maintenance Counter ........................................................................................................................ 22

Setup .............................................................................................23

■ Flow of Setup ...................................................................................................................... 23

■ Installing the Product ......................................................................................................... 28

Installing the Printer Vertically............................................................................................................. 29

Hanging the Printer on a Wall............................................................................................................. 30

7

Page 8

■ Changing the Paper Width................................................................................................ 32

■ Adjusting the Paper Roll Near-End Sensor ....................................................................... 33

■ Installing the microSD Card............................................................................................... 35

■ Connecting the Product to the Network .......................................................................... 36

For Wired LAN connection ..................................................................................................................36

■ Connecting the Peripherals .............................................................................................. 37

Connecting the Optional External Buzzer .........................................................................................37

Connecting the Serial Communication Device ...............................................................................40

Key Input Device via a USB Interface.................................................................................................40

Connecting the Cash Drawer............................................................................................................. 41

■ Connecting the AC Adapter............................................................................................. 42

■ Attaching the Power Switch Cover................................................................................... 43

■ Setting the Memory Switches/Receipt Enhancement.................................................... 44

Functions ...............................................................................................................................................46

■ Network Setting .................................................................................................................. 53

Confirming Network Setting ................................................................................................................54

Initializing the Network Setting ............................................................................................................55

■ Enabling PHP....................................................................................................................... 57

■ Enabling HTTPS Communication....................................................................................... 58

■ Settings for Server Direct Print ........................................................................................... 59

■ Settings for Connected Devices ....................................................................................... 60

■ Registering Web Contents................................................................................................. 62

Creating Web Contents ......................................................................................................................62

Specifications for when PHP is enabled.............................................................................................63

Verifying the integrity of Web contents with md5 files .....................................................................64

Certificate files ......................................................................................................................................64

Registering Web Contents...................................................................................................................65

■ Settings for Spooler............................................................................................................. 67

■ Settings for Print Forwarding .............................................................................................. 68

■ Settings for Device Data Notification ............................................................................... 69

Application Development Information...................................... 70

■ Controlling the Printer ........................................................................................................ 70

Epson ePOS SDK ...................................................................................................................................71

ePOS-Device XML.................................................................................................................................72

ePOS-Print XML......................................................................................................................................74

Server Direct Print .................................................................................................................................75

Device Data Notification..................................................................................................................... 76

Web Server............................................................................................................................................77

Spooler and Print Forwarding..............................................................................................................78

■ Software and Manuals....................................................................................................... 81

How to Get Manuals and the Utility ...................................................................................................82

■ EPSON TMNet WebConfig.................................................................................................. 83

Starting EPSON TMNet WebConfig .....................................................................................................83

Help Screen Display .............................................................................................................................83

8

Page 9

Version Screen Display ........................................................................................................................ 83

General Information ............................................................................................................................ 84

Information - Wired - TCP/IP................................................................................................................ 85

Information - Wireless - TCP/IP ............................................................................................................ 85

Information - Web Contents ............................................................................................................... 86

Information - Time ................................................................................................................................ 86

Web Service Settings - Device Admin - Printer ................................................................................. 87

Web Service Settings - Device Admin - Customer Display.............................................................. 88

Web Service Settings - Device Admin - Key Input Device .............................................................. 88

Web Service Settings - Device Admin - Serial Communication Device........................................ 89

Web Service Settings - Device Admin - Search Printer.................................................................... 89

Web Service Settings - Spooler - Settings .......................................................................................... 90

Web Service Settings - Spooler - Print forwarding ............................................................................ 90

Web Service Settings - Web Contents - Update Settings ................................................................ 91

Web Service Settings - Server Access - Direct Print.......................................................................... 92

Web Service Settings - Server Access - Status Notification ............................................................. 93

Web Service Settings - Server Access - Device Data Notification ................................................. 94

System Settings - Network - Wired ...................................................................................................... 95

System Settings - Network - Wired - TCP/IP........................................................................................ 95

System Settings - Network - Wireless................................................................................................... 96

System Settings - Network - Wireless - TCP/IP .................................................................................... 97

System Settings - Security - Authenticate Server .............................................................................. 97

System Settings - Security - SSL............................................................................................................ 98

System Settings - Proxy - Proxy ............................................................................................................ 99

System Settings - Time - Time .............................................................................................................. 99

Admin Settings - Maintenance - Reset............................................................................................ 100

Admin Settings - Administrator Information - Administrator .......................................................... 100

Admin Settings - Administrator Information - Password ................................................................. 100

PHP settings......................................................................................................................................... 101

■ Status sheet....................................................................................................................... 102

■ Setting/Checking Modes ................................................................................................ 108

Self-test Mode .................................................................................................................................... 108

NV Graphics Print Mode ................................................................................................................... 110

Receipt Enhancement Information Print Mode ............................................................................. 111

Software Setting Mode...................................................................................................................... 112

Hexadecimal Dumping Mode ......................................................................................................... 115

■ Easy Setup......................................................................................................................... 116

■ Checking/Updating TM-i Firmware ................................................................................ 117

Checking the TM-i Firmware Version................................................................................................ 117

Updating TM-i Firmware .................................................................................................................... 117

Handling .....................................................................................118

■ Installing and Replacing Roll Paper ............................................................................... 118

■ Removing Jammed Paper .............................................................................................. 120

■ Cleaning the Printer ......................................................................................................... 121

Cleaning the Printer Case................................................................................................................. 121

Cleaning the Thermal Head ............................................................................................................. 121

■ Preparing for Transport..................................................................................................... 122

9

Page 10

Appendix.................................................................................... 123

■ Product Specifications..................................................................................................... 123

Software Specifications .....................................................................................................................124

Controllable Peripherals ....................................................................................................................125

Printing Specifications ........................................................................................................................125

Character Specifications...................................................................................................................126

Printable Area .....................................................................................................................................128

Printing and Cutting Positions............................................................................................................129

Paper Specifications ..........................................................................................................................130

Electrical Characteristics ...................................................................................................................131

Environmental Conditions..................................................................................................................132

External Dimensions and Mass ..........................................................................................................133

AC Adapter (PS-180)..........................................................................................................................134

■ Setting Items for Software Setting Mode ........................................................................ 135

■ Character Code Tables ................................................................................................... 138

10

Page 11

Chapter 1 Product Overview

Product Overview

This chapter describes features of the product.

Features

TM-T83II-i is a receipt printer which can print directly from a smart device application or Web

application.

*1

This product supports ePOS-Device

peripherals or network compatible TM printers.

*1: ePOS-Device: Epson original technology to control TM printers or POS peripherals via a smart

device application or Web application. This technology is realized by ePOS-Device Service

running on the products.

and ePOS-Print *2 and are capable of controlling POS

1

*2: ePOS-Print: Epson original printing function t

systems supported by XML and Web services. This technology is realized by the ePOS-Print

Service running on the products.

hat has a high compatibility with a variety of

11

Page 12

Functions

•Enables connection to peripherals (barcode scanners, etc) via a USB or serial interface.

•The Epson ePOS SDK is provided for iOS, Android and Windows application, and Web

application development.

The Epson ePOS SDK is a software development kit that integrates the ePOS-Print SDK and the

ePOS-Device SDK. It is recommended that applica

SDK is migrated to the Epson ePOS SDK. For detail, refer to the Migration Guide included with

the Epson ePOS SDK.

*1

• Uses the communication box

function to enable communications between applications. This

function allows for communications, etc. between tablet terminals. (ePOS-Device SDK,

ePOS-Device XML)

•Supports Server Direct Print that sends a request for print data from the product to the Web server

at regular

intervals.

•Since print data can be saved in the spooler, applications can be released from processing print

jobs regardless of the printer status.

*2

•When a network printer is registered, print forwarding process can be realized. Also, if the printer

is not ready to print, you can print from another printer.

•Device data notification function is realized, allowing for notifications to be sent from devices

such as barcode scanners to Web servers to trigger applications.

•Equipped with Web server that supports the scripting language "PHP" and database "SQLite3".

tion software developed with the ePOS-Device

*2

*2

•Enables HTTPS *3 communication.

•Supports TLS 1.2. SSL3.0 is not supported.

*4

*1: For more information on the communication box, see the ePOS-Device SDK for iOS User's

Manual, the ePOS-Device SDK for Android User's Manual, the ePOS-Device SDK for JavaScript

User's Manual, and the ePOS-Device XML User's Manual.

*2: TM-i firmware Ver. 4.1 or later.

*3: TM-i firmware Ver. 4.3 or later.

*4: TM-i firmware Ver. 4.4 or later.

For information on how to use these functions, see "Controlling the Printer" on page 70.

12

Page 13

Product Configurations

Bundled items

•AC adapter (Model: PS-180)

• Roll paper (for operation check)

• Roll paper guide for 58 mm width paper

• User's Manual

•Power switch cover

•Waterproof power switch cover

• Wall-hanging bracket

•Screws for installing the wall-hanging bracket

•Rubber feet for vertical installation

•Switch panel for vertical installation

Chapter 1 Product Overview

1

Options

•Affixing tape for fixing the printer (Model: DF-10)

•Buzzer unit (Model: OT-BZ20)

13

Page 14

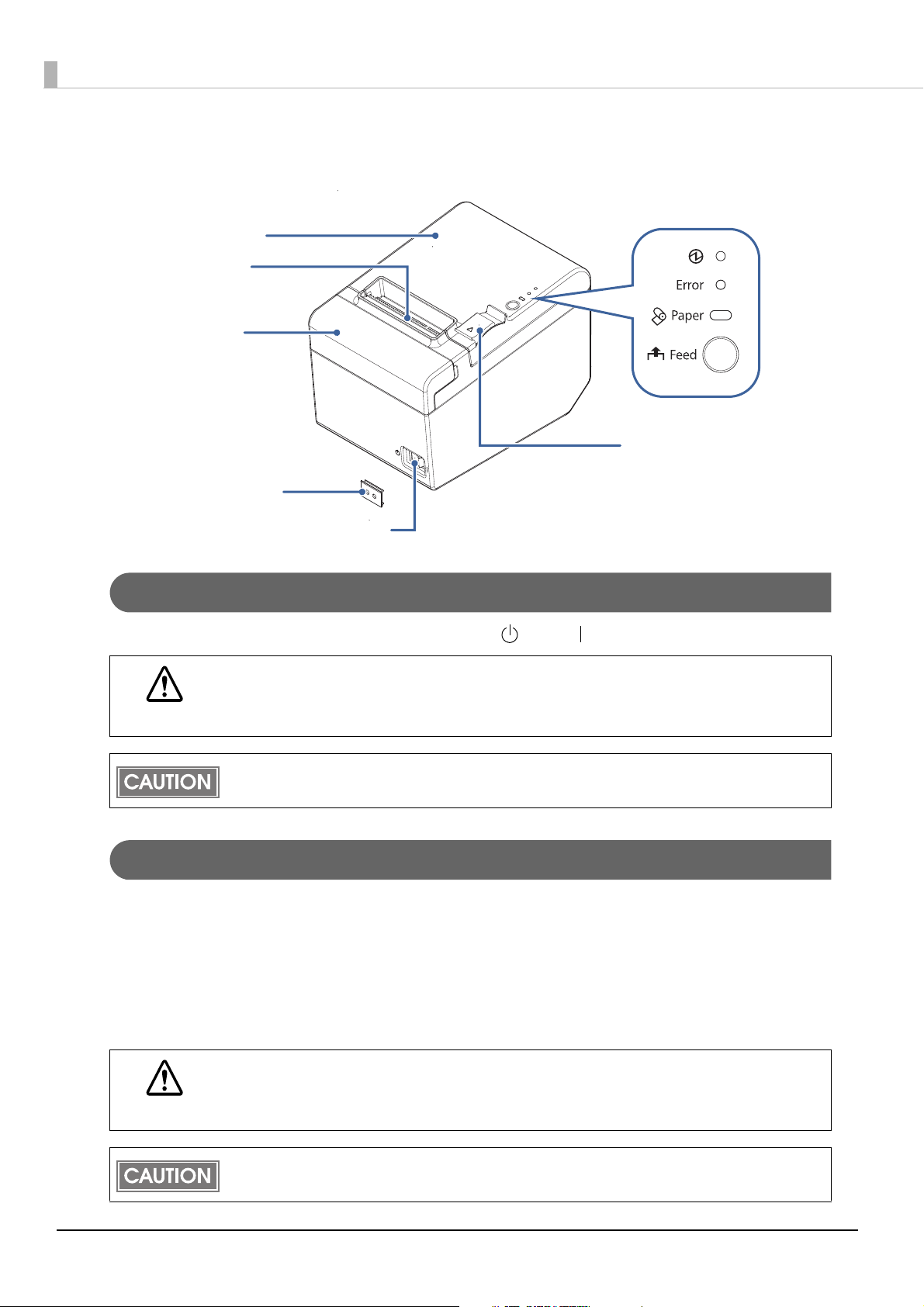

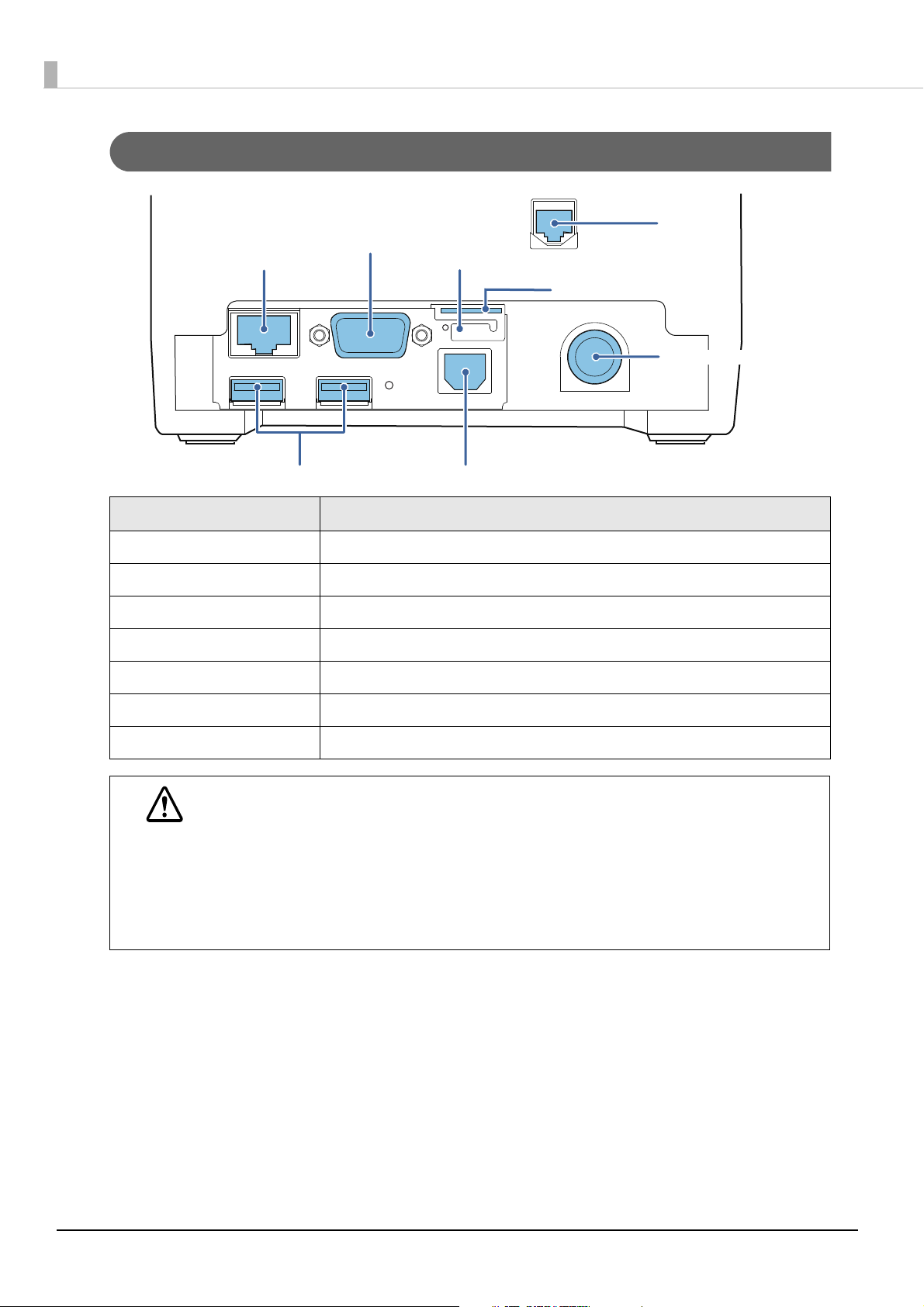

Part Names and Functions

Roll paper cover

Control panel

Cover open lever

Power swit ch

Cutter cover

Power switch cover

Manual cutter

Power Switch

Turns the printer on or off. The marks on the switch: ( : OFF/ : ON)

Before turning on the product, be sure to check that the AC adapter is connected to the

power supply.

CAUTION

After the product is turned on, it requires about 30 seconds until it is ready to print.

Power Switch Cover

Install the power switch cover that comes with the TM-T83II-i onto the printer to prevent

inadvertent changing of the power switch, to prevent tampering, and to improve the appearance of

the printer.

To operate the power switch, insert an object with a pointed tip such as a ballpoint pen into the hole

on the power switch cover.

A waterproof cover for the power switch is also included.

If an accident occurs with the power switch cover attached, unplug the power cord

immediately.

WARNING

Continued use of the printer may cause fire or electric shock.

14

Use the waterproof power switch cover if the printer is installed in a humid location or exposed

to water. If current leakage occurs, it could result in electric shock.

Page 15

Chapter 1 Product Overview

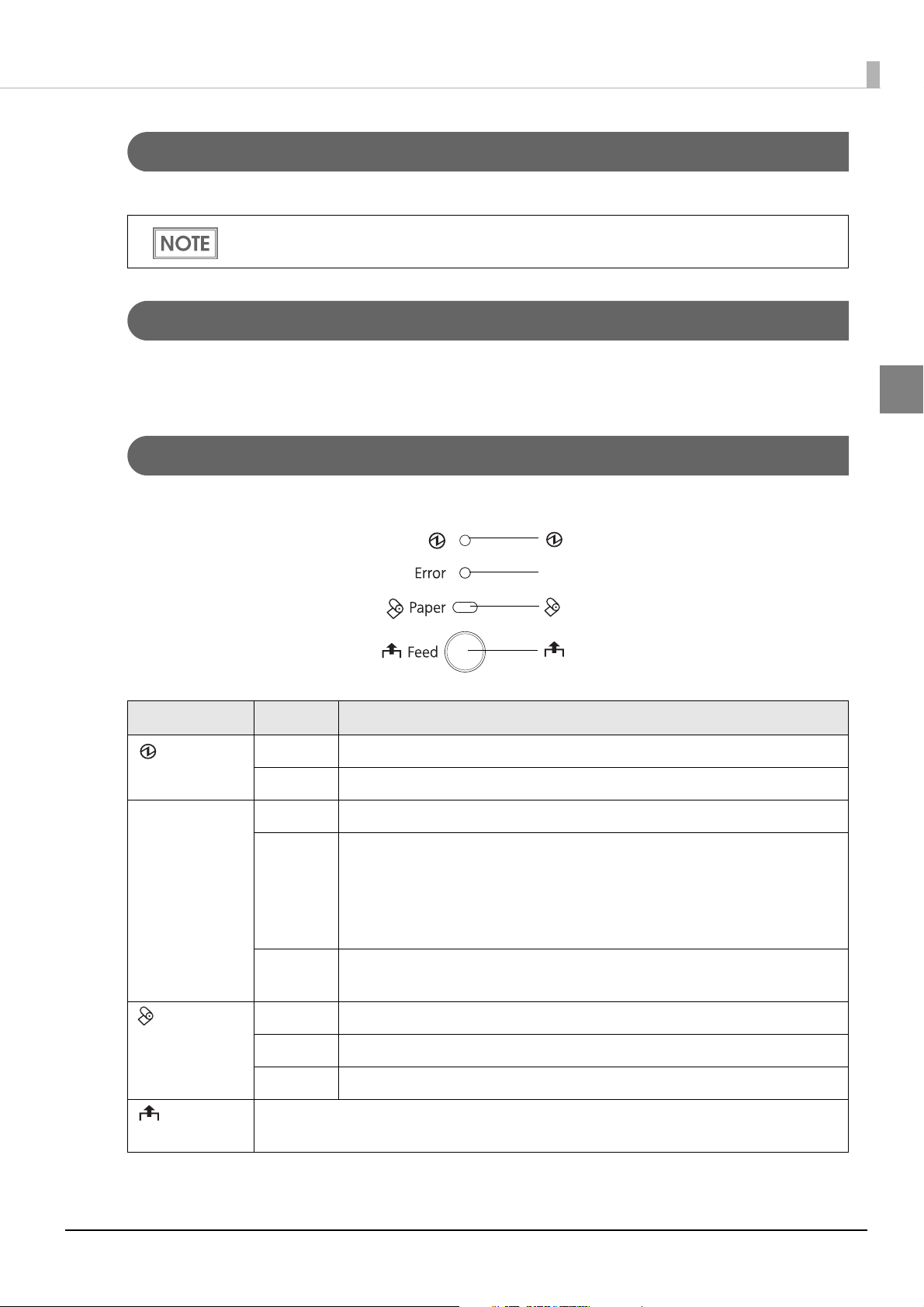

(Power) LED

Error LED

Paper LED

Feed button

Roll paper cover / Cover open lever

When setting or replacing the roll paper, use the cover open lever to open the roll paper cover.

Do not open the roll paper cover during printing or while the autocutter is operating.

Cutter cover

The autocutter is inside the cutter cover. Open the cover when roll paper is jammed in the printer or

to return the cutter blade manually.

Control Panel

1

Name Status Description

(Power) LED On Power is being supplied.

Off Power is not being supplied.

Error LED Off Normal operation (online)

On Immediately after the power is turned on or immediately after a reset

(offline).

Automatically goes off after a while to indicate that the printer is ready.

The end of the roll paper is detected, and when printing has stopped

(offline). If this happens, replace the roll paper.

Flashing An error has occurred

(For details about the flash codes, see

Paper LED Off There is a sufficient amount of roll paper remaining.

On There is little or no roll paper remaining.

Flashing A self-test printing standby state and macro execution standby state

Feed button Pressing this button once feeds the roll paper by one line. Holding this button down

feeds the roll paper continuously.

"Error Status" on page 20.)

15

Page 16

Interfaces

Drawer kick

connector

Serial port

micro SD card slot

Protective cover

Ethernet port

USB host ports

USB device port

DC-in connector

Name Description

Drawer kick connector Connects a cash drawer or the optional buzzer unit.

Ethernet port Connect the LAN cable here to connect to the network.

USB host port (Type A) Connects peripherals via a USB interface.

USB device port (Type B) Connects a computer when setting the product with TM-T83II Utility.

DC-In connector Connects the AC adapter.

microSD card slot Used when using the PHP function.

Serial port Connects a serial communication device.

CAUTION

When connecting devices other than USB ports, make sure to check the devices or

Make sure that the protective cover is securely fit into place while the product is oper-

For Ethernet ports, make sure that the outdoor aerial LAN cables are connected

manuals, etc. for current consumption. The total value should be 800 mA or less.

Never use devices that provide no information on current consumption.

ating.

through a surge protector. Failure to do so may lead to device error resulting from

indirect lightning.

16

Page 17

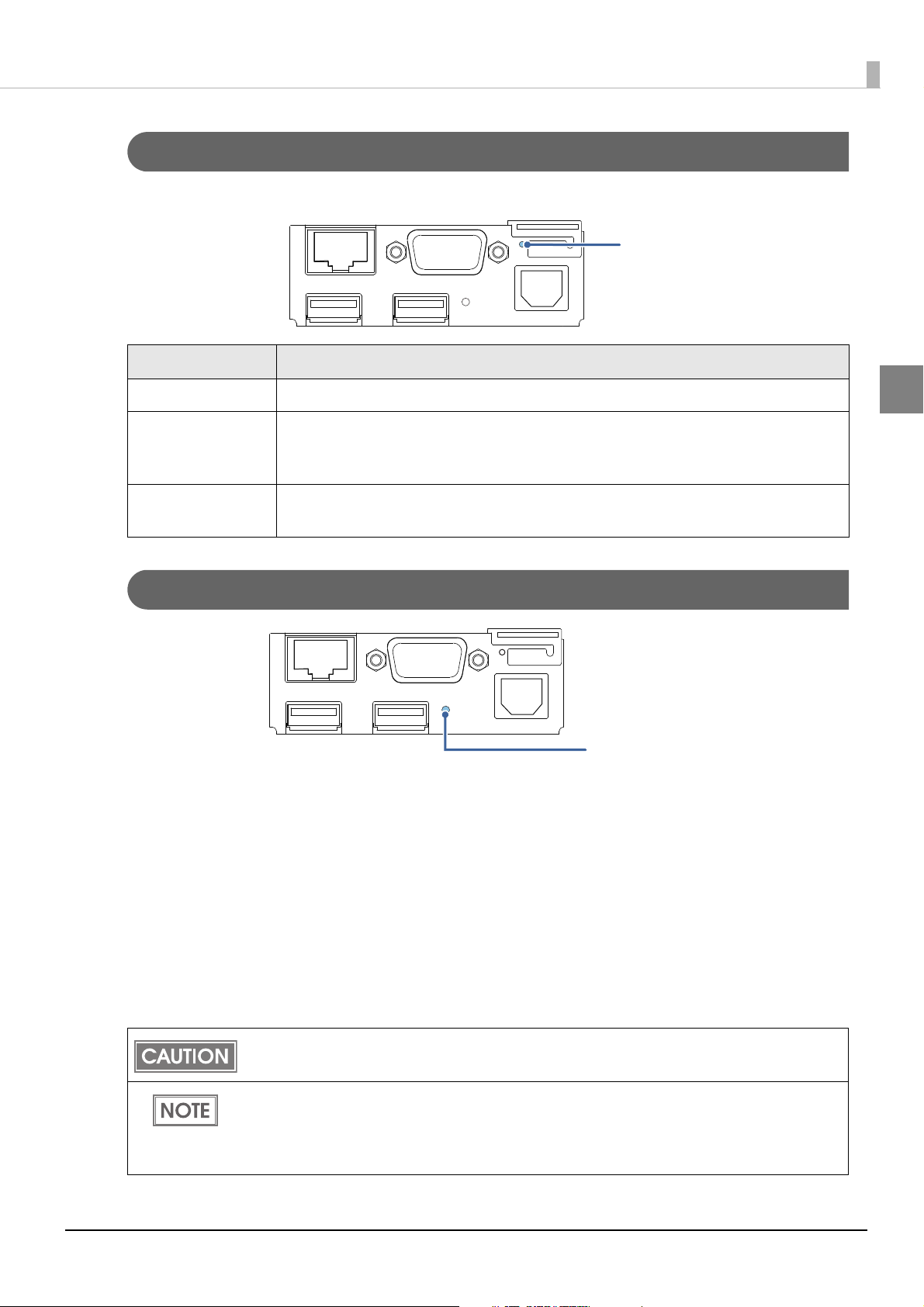

Chapter 1 Product Overview

Status LED

Push button

Status LED

With the status LED on the rear of the product, you can check the interface board status.

LED Description

On (Green) Operating normally.

On (Orange) Starting up.

If the status LED is on in orange even after 30 seconds have passed since the

printer is turned on, repair is required.

Off Power is not turned on.

If the status LED is off even if the printer is turned on, repair is required.

Push Button

Press the push button with a thin object such as a tweezers.

The push button has the following functions:

•Status sheet printing:

Make sure the product is turned on, press the push button for approximately 3 seconds. When you

release the button, a status sheet on which ne

"Confirming with a status sheet" on page 54.)

twork parameters are printed will be ejected. (See

1

•Initialization:

Make sure the product is turned on, press the push button for approximately 10 seconds. When

you release the button, network setting will be initialized. (See

on page 55

.)

To print a status sheet, release the push button within 10 seconds. If the button is kept down for

10 seconds or more, the network setting will be initialized.

Press the push button after the status LED color has changed from orange to green. After

the printer is turned on, it takes about 20 to 30 seconds until the status LED color changes to

green.

Even if the button is pressed while the status LED is on in orange, the button will not operate.

"Initializing the Network Setting"

17

Page 18

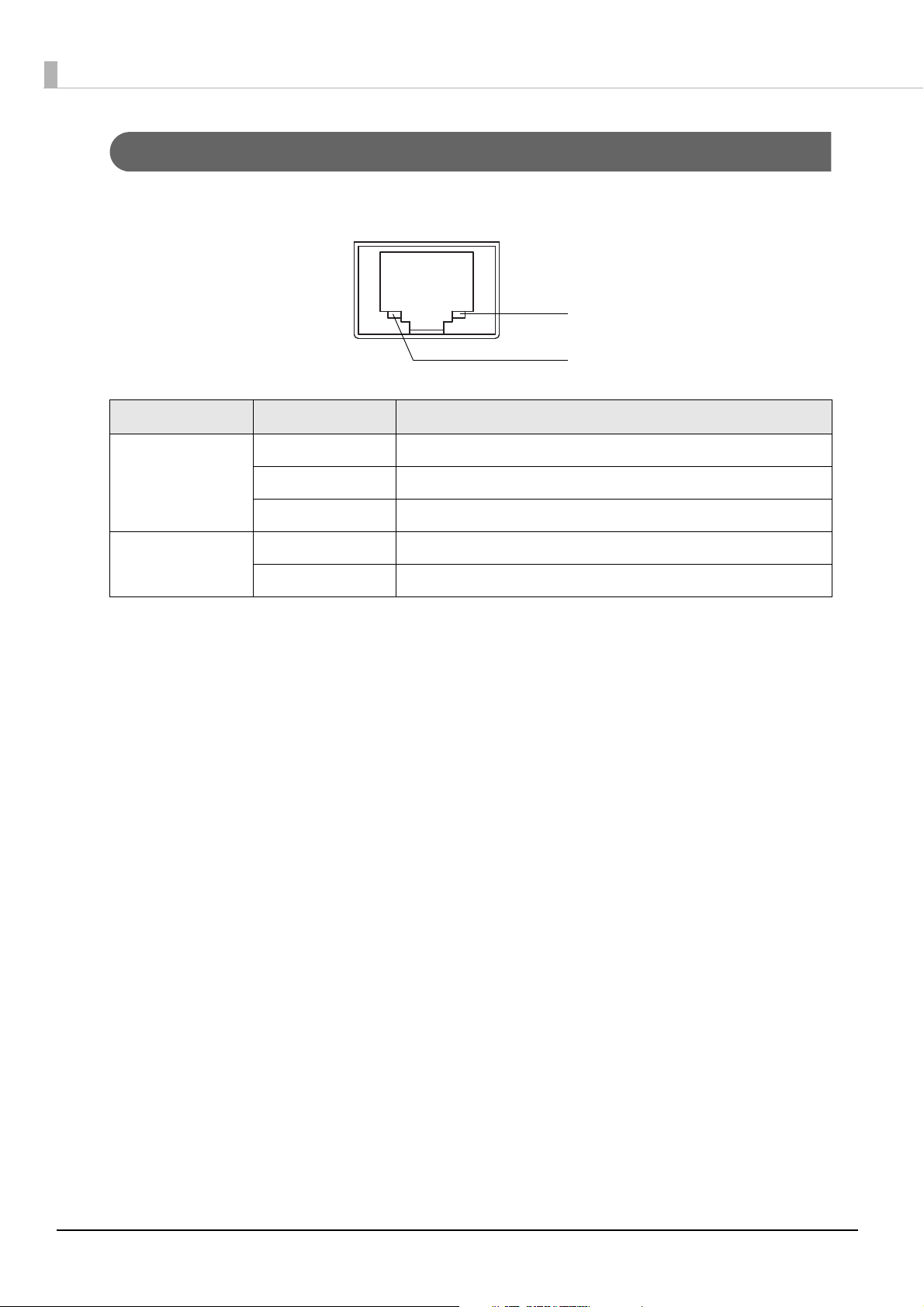

Wired LAN Status LED

LED (Green)

LED (Yellow)

With the Wired LAN Status LED on the rear of the product, you can check the communication status

of the product.

LED Status Description

Green On Link established

Flashing Transmitting/receiving data

Off Link not established

Yellow On 100BASE-TX

Off 10BASE-T

18

Page 19

Chapter 1 Product Overview

Online and Offline

Online

When no events to go offline have occurred, the printer is online and ready for normal printing.

Offline

The printer automatically goes offline under the following conditions:

•During power on (including resetting with the interface) until the printer is ready

•During the self-test

•When the roll paper cover is open.

•While roll paper is fed using the Feed button.

•When printing stops due to end of paper. (When

or the printer is set so that printing stops upon detection of roll paper near-end.)

• Macro execution standby state

•When an error has occurred

the roll paper end sensor detects the end of paper

1

19

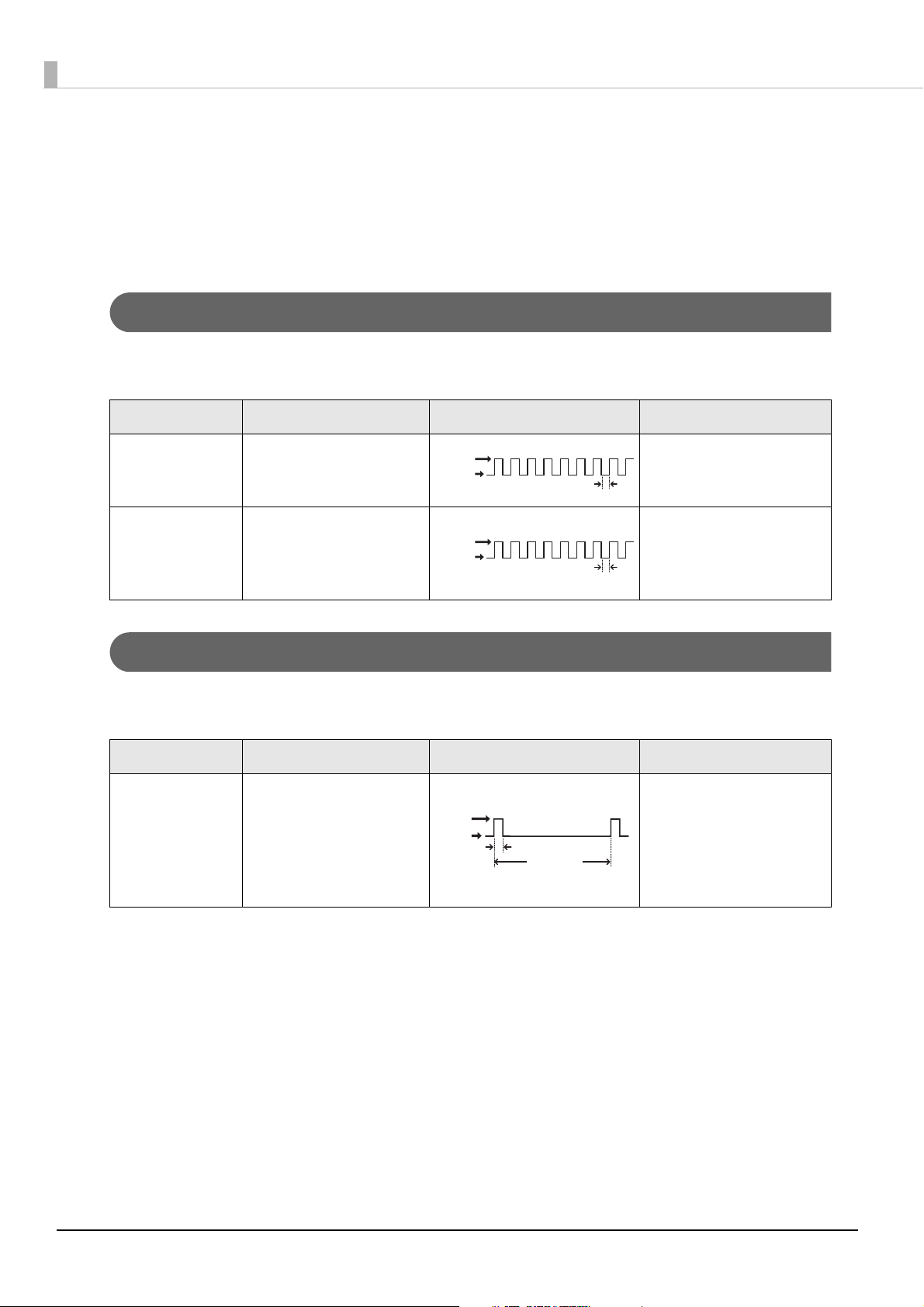

Page 20

Error Status

LED ON

LED OFF

Approx. 160 ms

Approx. 2560 ms

There are three possible error types: automatically recoverable errors, recoverable errors, and

unrecoverable errors. Check the error LED flash code.

When connection to peripherals fails, check the status LEDs at the lower rear of the product.

Automatically Recoverable Errors

Printing is no longer possible when automatically recoverable errors occur. The y can be recovered

easily, as described below.

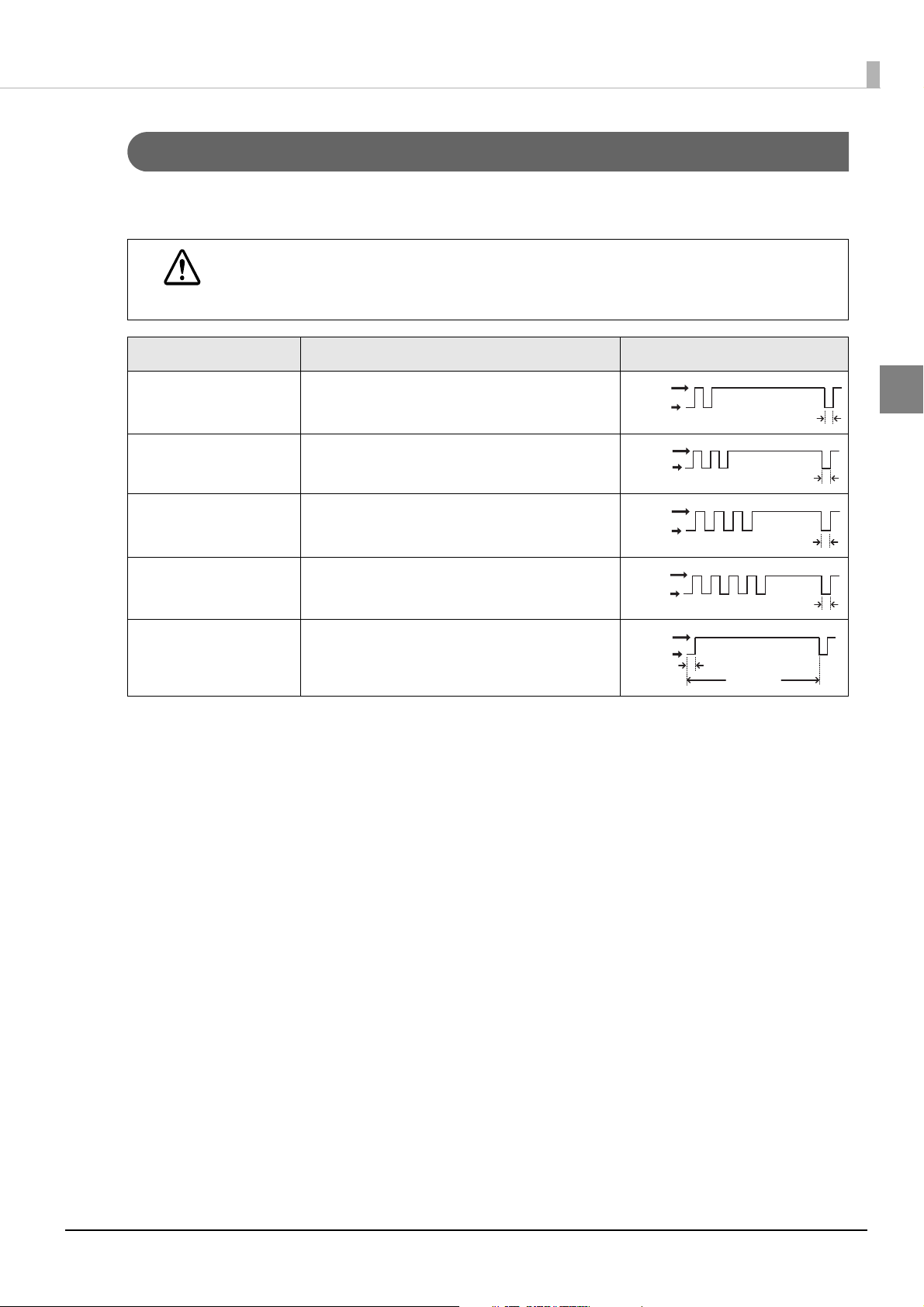

Error Error description Error LED flash code Recovery measure

Roll paper cover

open error

Print head

temperature

error

The roll paper cover was

opened during printing.

A high temperature

outside the head drive

operating range was

LED ON

LED OFF

LED ON

LED OFF

Approx. 160 ms

Approx. 160 ms

Recovers automatically

when the roll paper

cover is closed.

Recovers automatically

when the print head

cools.

detected.

Recoverable Errors

Printing is no longer possible when recoverable errors occur. T hey can be recovered easily by turning

the power on again after eliminating the cause of the error.

Error Error description Error LED flash code Recovery measure

Autocutter error Autocutter does not

work correctly.

Remove the jammed

paper or foreign matter in

the printer, close the roll

paper cover, and then

turn the power on to

recover.

20

Page 21

Chapter 1 Product Overview

LED ON

LED OFF

Approx. 160 ms

LED ON

LED OFF

Approx. 160 ms

LED ON

LED OFF

Approx. 160 ms

LED ON

LED OFF

Approx. 160 ms

LED ON

LED OFF

Approx. 160 ms

Approx. 2560 ms

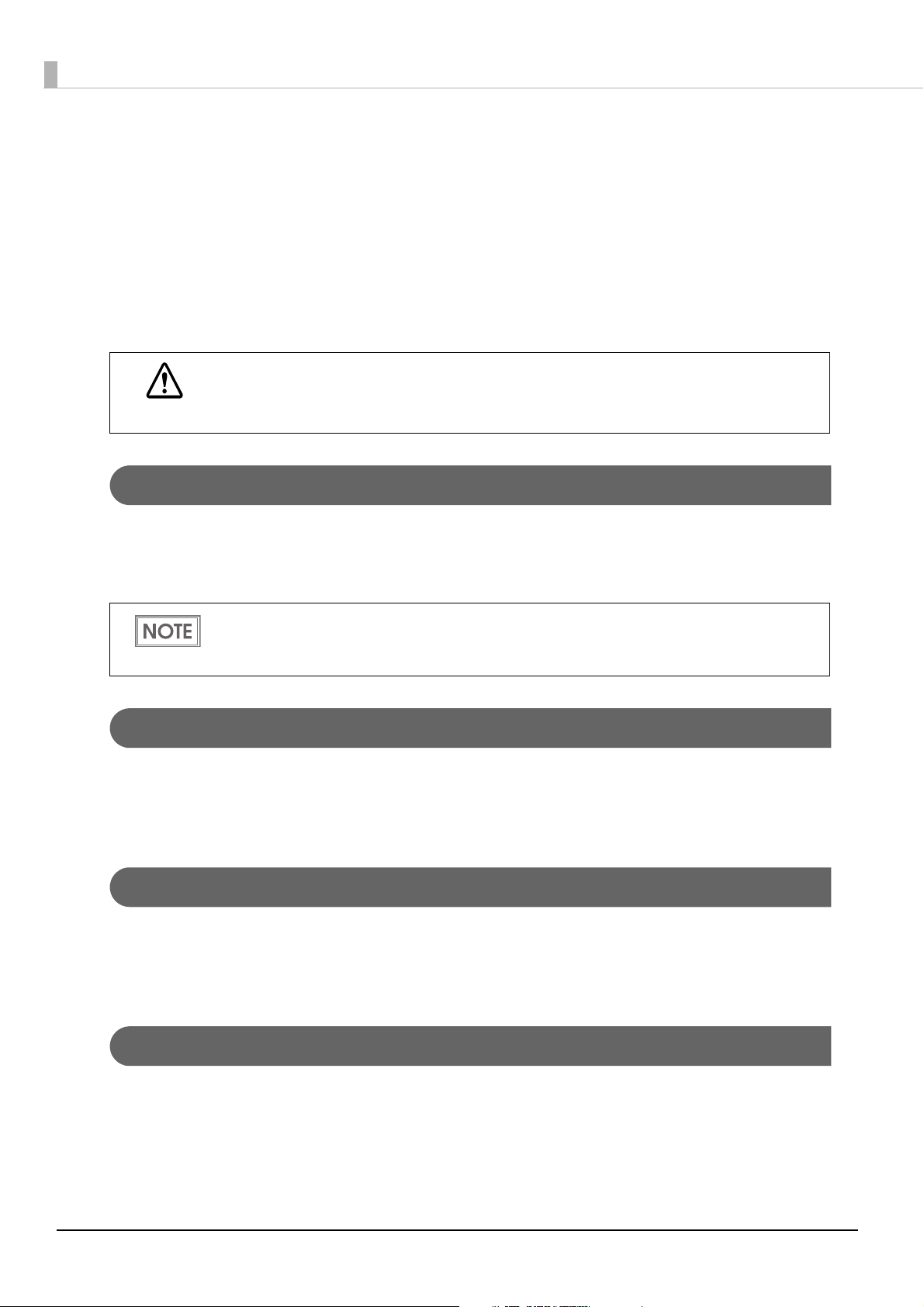

Unrecoverable Errors

If the same error occurs again even after turning the power back on, contact your dealer or a Epson

service center.

Turn off the power immediately when unrecoverable errors occur.

CAUTION

Error Error description Error LED flash code

Memory R/W error After R/W checking, the printer does not

work correctly.

High voltage error The power supply voltage is extremely high.

Low voltage error The power supply voltage is extremely low.

CPU execution error The CPU is executing an incorrect address.

Internal circuit

Internal circuits are not connected correctly.

connection error

1

21

Page 22

NV Memory

The product's NV memory (Non-Volatile Memory) stores data even after the product power is

turned off. NV memory contains the following memory areas for the user:

•NV graphics memory

•Memory switches (customized value)

•R/E (Receipt Enhancement)

•Maintenance counter

As a guide, NV memory rewriting should be 10 times or less a day when you program

applications.

CAUTION

NV Graphics Memory

Graphics, such as shop logos to be printed on receipts, can be stored.

Use the TM-T83II Utility to register graphics.

To check the registered graphics, select [Operation Check] - [Print Logo] in TM-T83II Utility.

For detailed information about the TM-T83II Utility, see the TM-T83II Utility User’s Manual.

For information about how to use the NV graphics memory print mode, see

Print Mode" on page 110

.

"NV Graphics

Memory Switches (Customized Value)

With the memory switches (customized value), which are software switches for the product, you can

set paper width, print density, f o nt, power supply unit capacity, a utomatic paper cut, and paper

reduction. See

"Setting the Memory Switches/Receipt Enhancement" on page 44.

R/E (Receipt Enhancement)

Graphics, such as shop logos can be printed on top or bottom of receipts by setting R/E (Receipt

Enhancement). For information about R/E, see "Setting the Memory Switches/Receipt

Enhancement" on page 44

.

Maintenance Counter

With this function, printer information, such as the number of line feeds, the number of autocuts,

and product operation time after the printer starts working, is automatically stored in NV memory.

You can read the information with the TM-T83II Utility or in a self-test to

or part replacement.

use it for periodical checks

22

Page 23

Chapter 2 Setup

Setup

This chapter describes the installation and setup procedure of the product and peripherals required

to use the product.

Yo u can utilize "Easy Setup", which enables settings to the TM-i to be made in a simple manner using

a USB memory that contains a file of EPSON TMNet WebConfig setting values.

For detail, refer the “TM-i series Easy Setup Guide”.

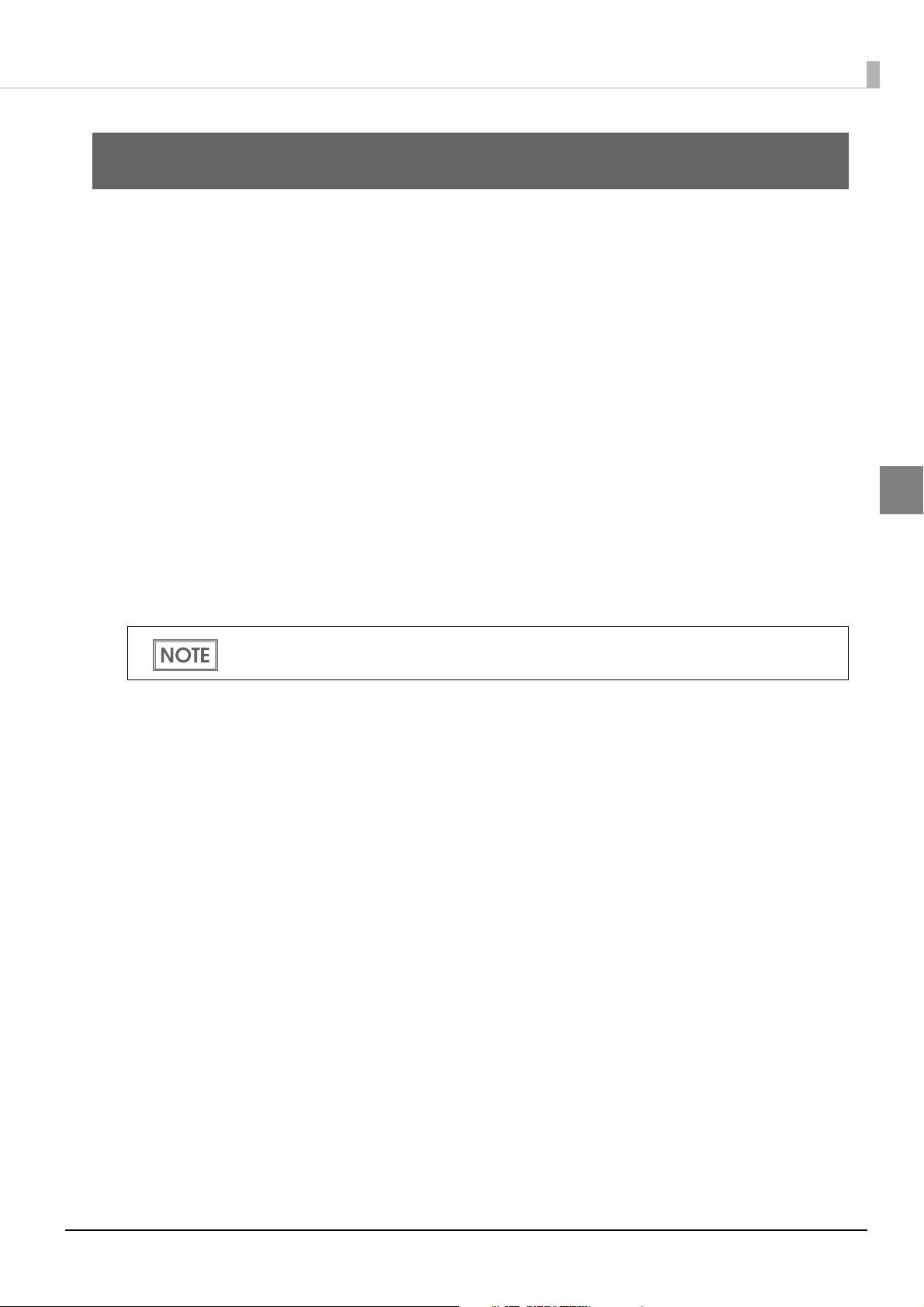

Flow of Setup

The setting items are different depending on the system to be used. Check the items by referring to

"Controlling the Printer" on page 70.

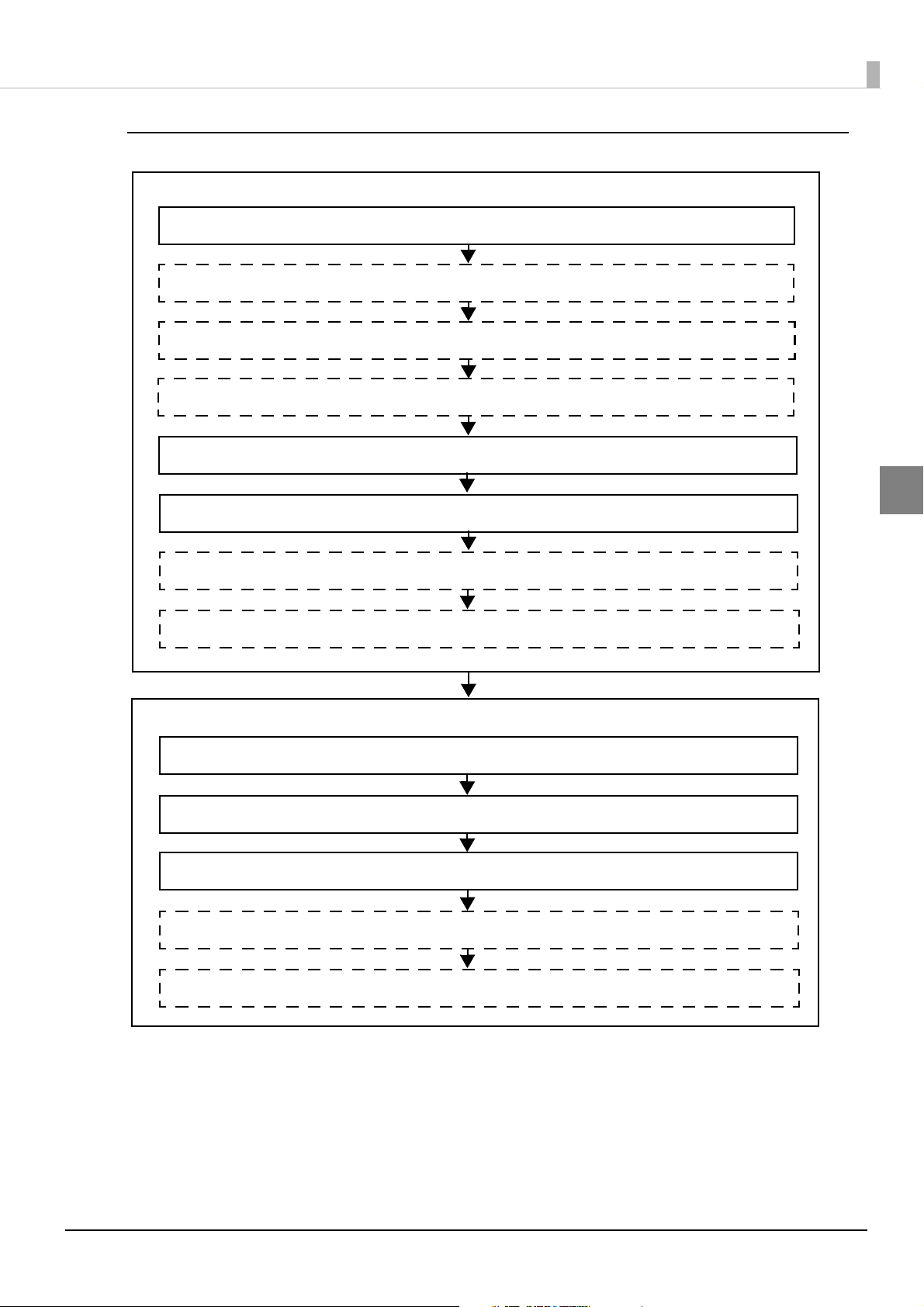

•Epson ePOS SDK, ePOS-Device XML, ePOS-Print XML (

•Server Direct Print (page 25)

•Device Data Notification (page 26)

•Using This Product as a Web Server (

This chapter consists of the following sections along with the setup flow of the product and

peripherals.

In this setup flow, necessary items are in a frame with a solid line. Optional items are explained

in an frame with a dotted line.

page 27)

page 24)

2

23

Page 24

Epson ePOS SDK, ePOS-Device XML, ePOS-Print XML

8. Setting the Memory Switches/Receipt Enhancement (page 44)

Settings for EPSON TMNet WebConfig

1. Installing the Product (page 28)

Settings for Printer

2. Changing the Paper Width (page 32)

3. Adjusting the Paper Roll Near-End Sensor (page 33)

4. Connecting the Peripherals (page 37)

5. Connecting the Product to the Network (page 36)

6. Connecting the AC Adapter (page 42)

7. Attaching the Power Switch Cover (page 43)

9. Network Setting (page 53)

11. Settings for Connected Devices (page 60)

12. Settings for Spooler (page 67)

13. Settings for Print Forwarding (page 68)

10. Enabling HTTPS Communication (page 58)

24

Page 25

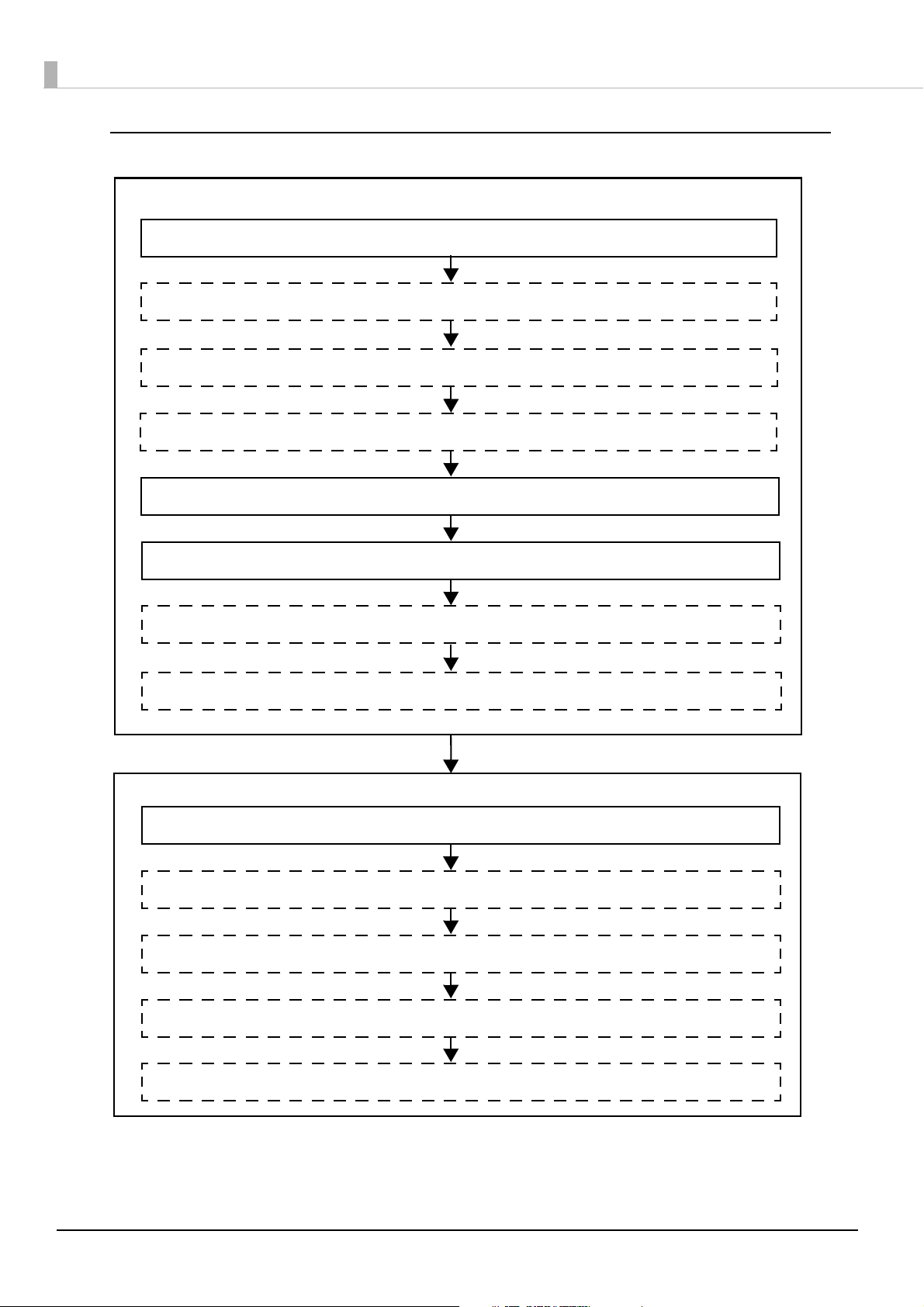

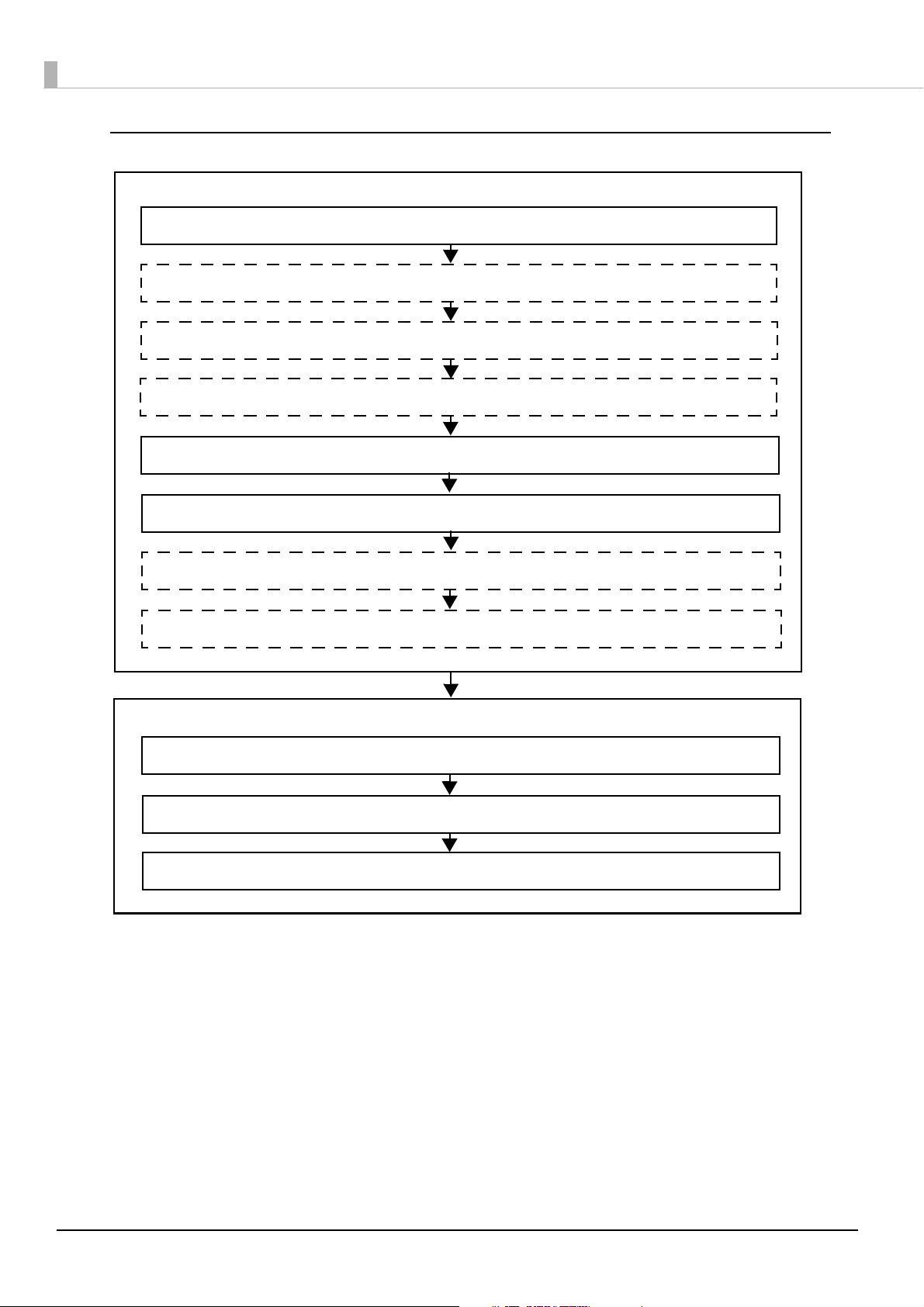

Server Direct Print

Settings for EPSON TMNet WebConfig

1. Installing the Product (page 28)

Settings for Printer

2. Changing the Paper Width (page 32)

3. Adjusting the Paper Roll Near-End Sensor (page 33)

4. Connecting the Peripherals (page 37)

5. Connecting the Product to the Network (page 36)

6. Connecting the AC Adapter (page 42)

7. Attaching the Power Switch Cover (page 43)

8. Setting the Memory Switches/Receipt Enhancement (page 44)

9. Network Setting (page 53)

12. Settings for Spooler (page 67)

11. Settings for Connected Devices (page 60)

13. Settings for Print Forwarding (page 68)

10. Settings for Server Direct Print (page 59)

Chapter 2 Setup

2

25

Page 26

Device Data Notification

Settings for EPSON TMNet WebConfig

1. Installing the Product (page 28)

Settings for Printer

2. Changing the Paper Width (page 32)

3. Adjusting the Paper Roll Near-End Sensor (page 33)

4. Connecting the Peripherals (page 37)

5. Connecting the Product to the Network (page 36)

6. Connecting the AC Adapter (page 42)

7. Attaching the Power Switch Cover (page 43)

8. Setting the Memory Switches/Receipt Enhancement (page 44)

9. Network Setting (page 53)

11. Settings for Device Data Notification (page 69)

10. Settings for Connected Devices (page 60)

26

Page 27

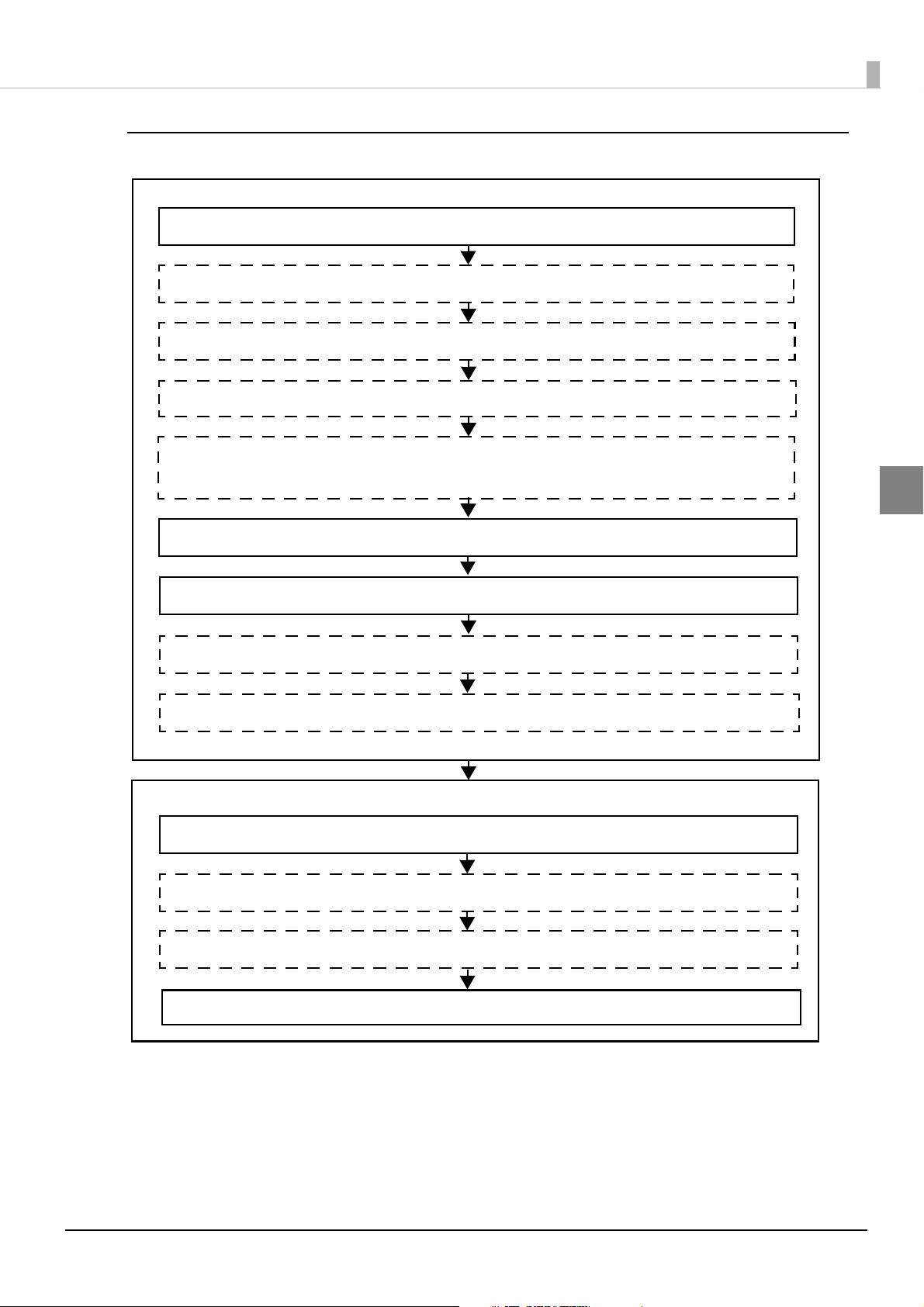

Using This Product as a Web Server

Settings for Printer

Settings for EPSON TMNet WebConfig

1. Installing the Product (page 28)

2. Changing the Paper Width (page 32)

3. Adjusting the Paper Roll Near-End Sensor (page 33)

4. Connecting the Peripherals (page 37)

6. Connecting the Product to the Network (page 36)

7. Connecting the AC Adapter (page 42)

8. Attaching the Power Switch Cover (page 43)

9. Setting the Memory Switches/Receipt Enhancement (page 44)

10. Network Setting (page 53)

13. Registering Web Contents (page 62)

12. Enabling PHP (page 57)

5. Installing the microSD Card (page 35)

Ava ilable when PHP is enabled.

11. Enabling HTTPS Communication (page 58)

Chapter 2 Setup

2

27

Page 28

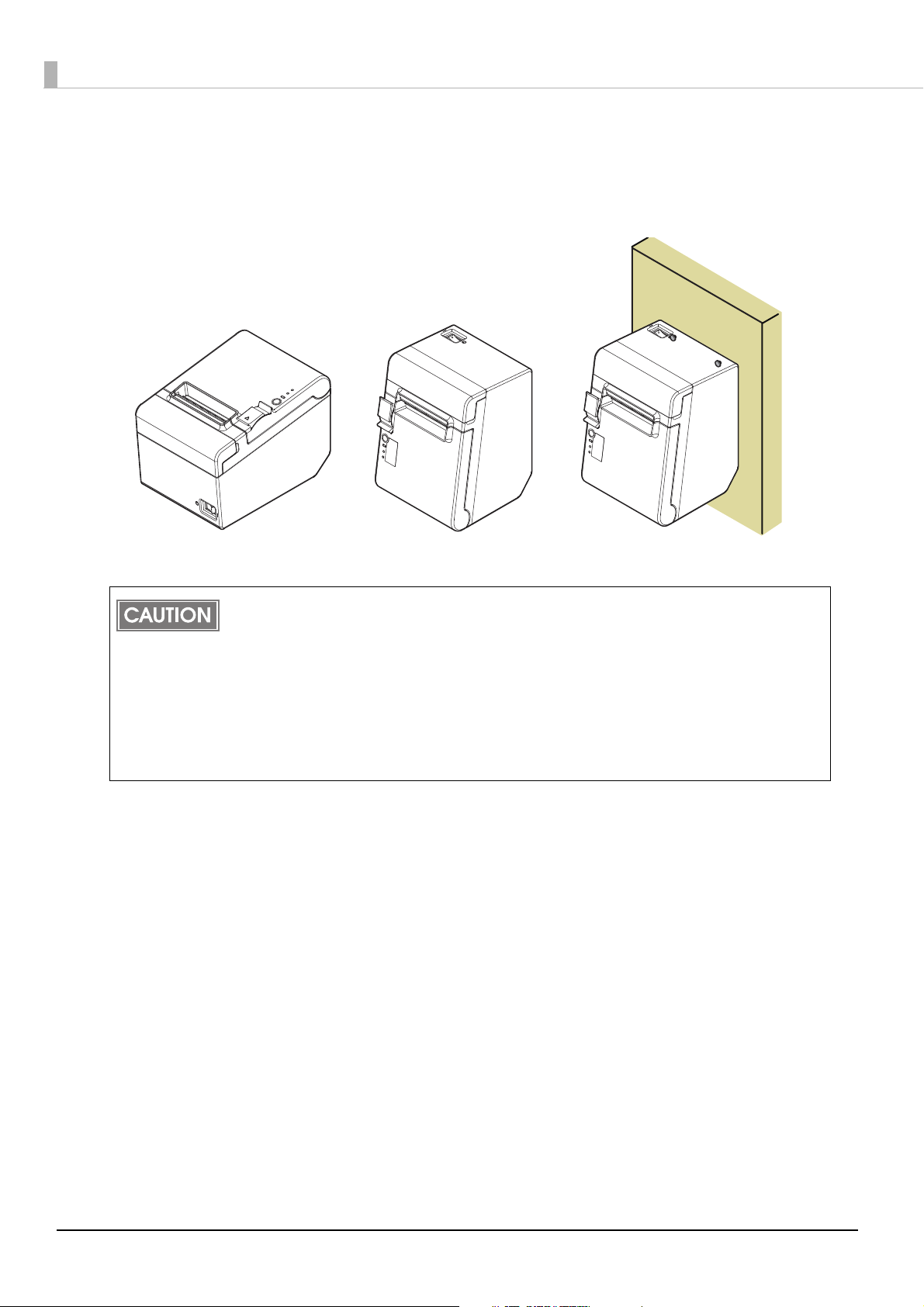

Installing the Product

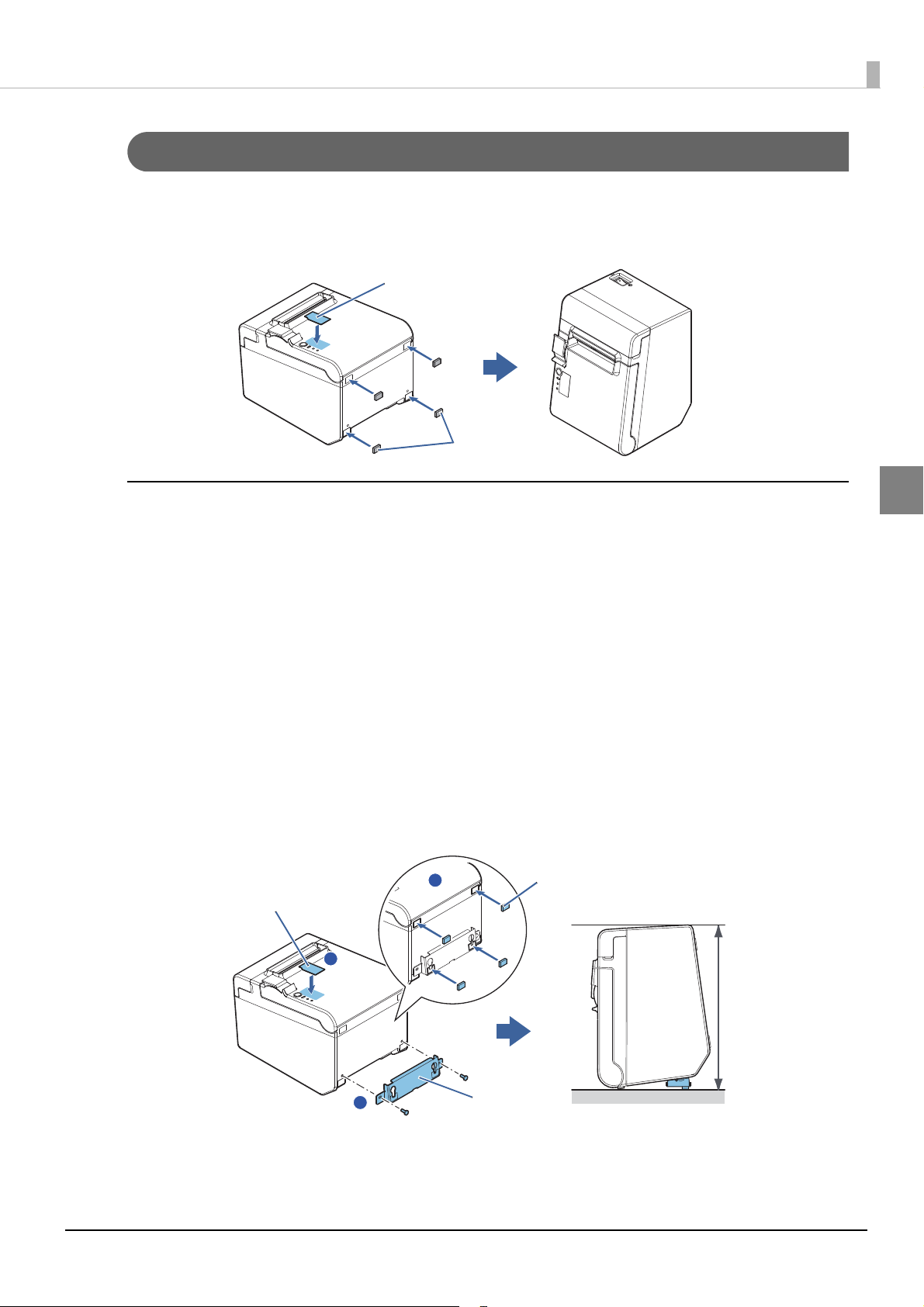

Horizontal Installation Vertical Installation Hanging Installation

You can install the printer horizontally on a flat surface (with the paper exit on top) or vertically

(with the paper exit at the front). Also, you can hang it on a wall using the included accessories.

You can use the paper near-end sensor only when you install the printer horizontally.

When you install the printer vertically or hang it on a wall, be sure to disable the setting.

Otherwise false detection occur. For information about the paper near-end sensor, see

"Adjusting the Paper Roll Near-End Sensor" on page 33

Take measures to prevent the printer from moving by vibration during paper cutting and

when using a drawer. Affixing tape (Model: DF-10) is provided as an option.

Do not place the printer in dusty locations.

Do not knock or strike the printer. This may cause defective print.

Do not catch cables or foreign matter under the printer.

.

28

Page 29

Chapter 2 Setup

1

2

3

Wall hanging

bracket

Rubber feet

Control panel label

for vertical installation

207 mm

{8.15"}

Installing the Printer Vertically

When installing the printer vertically, be sure to attach the included control panel label for vertical

installation on the roll paper cover, and attach 4 rubber feet in the rectangular indents in the printer

case, as shown in the illustration below.

Control panel label for

vertical installation

Rubber feet

Vertical installation

Yo u can install the printer so that the roll paper cover is upright to the mounting surface using the

included wall hanging bracket.

Attach the control panel label for vertical installation on the roll paper

1

cover.

Install the wall hanging bracket on the printer, and fix it using 2 included

2

screws.

Attach 2 rubber feet in the rectangular indents in the printer case, and

3

attach 2 rubber feet within the scribed line on the hanging bracket.

Place the printer with the wall-hanging-bracket-side down.

4

2

29

Page 30

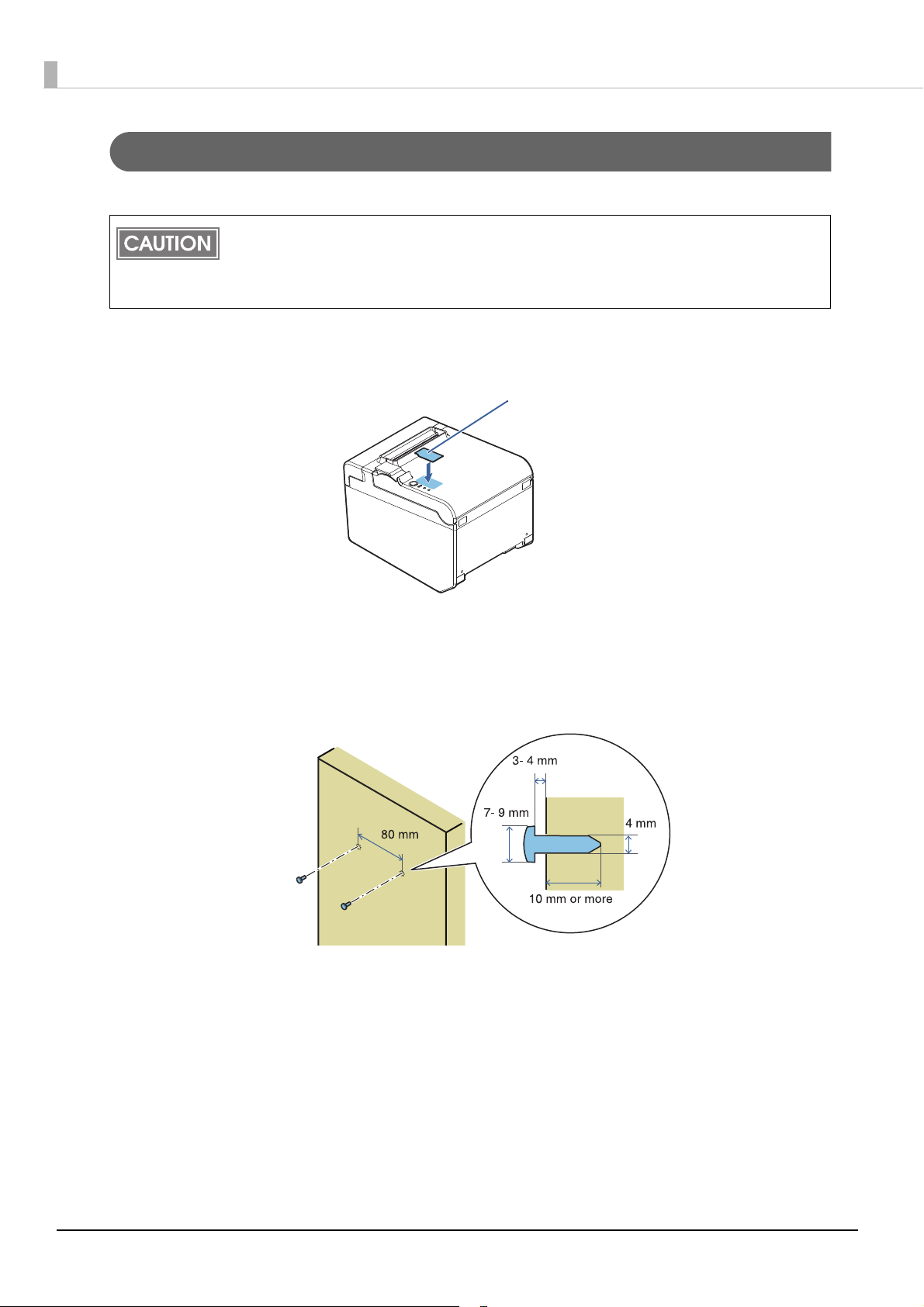

Hanging the Printer on a Wall

To hang the printer on the wall, follow the steps below.

To fix the printer securely, install the wall hanging bracket on a wall made of wood, concrete,

or metal. The thickness of the wall should be 10 mm {0.4"} or more.

Be sure to use metallic screws.

The screws on the wall side must have a pull-out strength of 150 N (15.3 kgf) or more.

Attach the included control panel label for vertical installation on the roll

1

paper cover.

Control panel label

for vertical installation

Install 2 screws (screw diameter: 4 mm {0.16"}, head diameter: 7 to 9 mm

2

{0.28 to 0.35"}) in the wall at an interval of 80 mm {3.15"}.

Make sure the length of the screw's body in the wall is 10 mm {0.39"} or more, and the length

outside the wall is 3 to 4 mm {0.12 to 0.16"}.

30

Page 31

Chapter 2 Setup

Screws

Wall hanging bracket

Remove the installed 2 screws from the printer, install the wall hanging

3

bracket on the printer, and fix it using the screws.

Align the holes in the wall hanging bracket with the screws on the wall, and

4

hook it securely.

2

31

Page 32

Changing the Paper Width

You can change the paper width from 80 to 58 mm by installing the included 58-mm width roll paper

guide. Follow the steps below to change the paper width.

Because some parts of the print head and the autocutter contact the platen and they may

become worn out, once you change the paper width from 80 to 58 mm and use the printer,

you cannot change it back to 80 mm.

When changing the paper width, be sure to make the setting for the paper width with the

memory switch. For information about the memory, see "Setting the Memory Switches/

Receipt Enhancement" on page 44

Open the roll paper cover.

1

Align 3 projections on the 58-mm width roll paper guide with the

2

rectangular holes in the printer, and push it downwards.

Roll paper guide

.

Rectangular holes

32

Page 33

Chapter 2 Setup

Adjusting the Paper Roll Near-End Sensor

When you install the printer horizontally, you can use the paper near-end sensor. Below are two

situations where a paper near-end sensor adjustment is required.

•To adjust the detection position to suit the diameter of the roll paper core used.

•To adjust the detection position of the remaining amount of roll paper.

To use the paper near-end sensor, it needs to be enabled with the memory switch. To set the

memory switch, see

When you install the printer vertically or hang it on a wall, be sure to disable the paper near-

end sensor. Otherwise false detection occur.

Since roll paper cores vary slightly in shape, depending on paper roll design and

manufacturing tolerances, it is impossible to detect the remaining paper exactly.

Use roll paper with a core inner diameter of 12 mm {0.47"} and outer diameter of 18 mm

{0.71"} so that the paper near-end sensor can detect the remaining paper as accurately as

possible.

"Setting the Memory Switches/Receipt Enhancement" on page 44.

Whether to let the Paper LED light when the roll paper is nearly out can be selected with the

memory switch. To set the memory switch, see

Enhancement" on page 44

Follow the steps below to adjust the roll paper near-end detector.

Open the roll paper cover, and remove the roll paper.

1

Loosen the adjustment screw fastening the sensor, and align the upper

2

.

"Setting the Memory Switches/Receipt

edge of the positioning plate with the adjustment position.

Adjustment position Remaining amount of paper (outer diameter)

Upper Approx. 27 mm {1.06"}

Lower (Initial setting) Approx. 23 mm {0.91"}

2

33

Page 34

Tighten the adjustment screw.

3

Make sure that the detection lever operates smoothly.

4

Positioning

Adjustment screw

Detection lever

plate

34

Page 35

Installing the microSD Card

Install the microSD card into the microSD card slot on the rear of the product.

Use a microSD card that has wear leveling functions

The microSD card can only be used if the PHP function is enabled.

The spooler cannot be used if PHP is enabled.

Installing the microSD Card

Open the protective cover on this product. Check the insertion direction of

1

the microSD card and insert it into the microSD card slot.

Insert the microSD card with its metal side facing down.

Push the microSD card to the bottom until it clicks.

Chapter 2 Setup

2

Close the protective cover.

2

Removing the microSD Card

Open the protective cover on this product and gently push the microSD

1

card into the slot.

Push the microSD card to the bottom until it clicks.

When the microSD card is slightly ejected, pull it out carefully.

2

Close the protective cover.

3

35

Page 36

Connecting the Product to the Network

For Wired LAN connection

Connect the product to a network by a LAN cable via a hub.

Insert a 10BASE-T/100BASE-TX LAN cable into the LAN connector until it clicks.

When LAN cables are installed outdoors, make sure devices without proper surge

protection are cushioned by being connected through devices that do have surge

CAUTION

protection.

Otherwise, the devices can be damaged by lightning.

Never attempt to connect the drawer kick cable, or a standard telephone line cable to

the LAN connector.

36

Page 37

Chapter 2 Setup

Optional external buzzer

Affixing tape

(1 pair, 2 pieces)

User’s Manual

Connecting the Peripherals

Connect each cable of a peripheral to a port or connector at the rear of the product.

When connecting USB interface devices, make sure to check the devices or manuals,

etc. for current consumption. The total value should be 800 mA or less. Never use

CAUTION

Connecting the Optional External Buzzer

Yo u can use the optional external buzzer (OT-BZ20) by connecting it to the drawer kick connector.

devices that provide no information on current consumption.

Make sure that the protective cover is securely fit into place while the product is oper-

ating.

The optional external buzzer and the drawer cannot be used together at the same time.

If you configure the memory switch (customized value) setting to enable the optional external

buzzer, the drawer cannot be opened because the pulse is not sent to the drawer kick

connector pin.

Make sure to use the accessory affixing tape (hook and loop fastener) to attach the optional

external buzzer to the product.

Be careful not to spill water, oil, solvent, or any other liquid over the product. Doing so may

result in malfunction of the product.

2

Check whether the following items are included.

Installation Position

This product is recommended to be installed on either side of the product.

Do not install the optional external buzzer at the roll paper exit.

To prevent liquid from entering inside, it is recommended to install the optional external

buzzer so that the volume adjustment knob is positioned sideways or downward. (For details

of the volume adjustment knob, see

"Adjusting the Buzzer Volume" on page 39.)

37

Page 38

Installation Procedures

Affixing tape

Drawer kick connector

Turn off the product.

1

Connect and disconnect the optional external buzzer while the product is turned off. If

you connect it while the product is turned on, the buzzer does not function correctly.

Clean and dry the printer case where the optional external buzzer will be

2

installed.

With 2 pieces of the affixing tape combined, peel off the sticker on one

3

side, and paste it around the center of the attaching surface of the

optional external buzzer.

Connect the cable of the optional external buzzer to the drawer kick

4

connector on the product.

Do not connect both the optional external buzzer and the drawer by using a splitter or

similar device.

38

Page 39

Chapter 2 Setup

Printer case

Volume adjustment knob

High

Low

Peel off the sticker on the other side of the affixing tape, and attach and fix

5

the optional external buzzer to the printer case.

Turn on the product.

6

When and how to beep can be set by TM-T83II Utility or the product's

7

customized value. (See "Setting the Memory Switches/Receipt

Enhancement" on page 44)

2

To use this product, be sure to enable the optional external buzzer with the product

setting. For the details on the setting, see "Setting the Memory Switches/Receipt

Enhancement" on page 44

When the optional external buzzer is enabled with the product setting, the drawer

cannot be driven.

.

Adjusting the Buzzer Volume

Turn the volume adjustment knob to adjust the buzzer volume.

39

Page 40

Connecting the Serial Communication Device

Use a serial cable to connect a device to the serial port of this product.

To communicate with a serial communication device, communication conditions of the device

should match those of this product.

Refer to the manual for the serial communication device to check the following con

•Communication Speed

•Data bit

•Parity

•Stop bit

•Flow control

The communication conditions of this product are configured using EPSON TMNet WebConfig.

For detail, refer to

"Settings for Connected Devices" on page 60.

ditions.

Key Input Device via a USB Interface

For key input devices such as barcode scanners and keyboards, connect a USB cable of a device to

the USB port at the rear of this product.

Use EPSON TMNet WebConfig to select a device control script and perform communication tests.

For detail, refer to

"Settings for Connected Devices" on page 60.

40

Page 41

Connecting the Cash Drawer

Drawer kick connector

With shielded

Drawer kick connector

Printer side

User side [Drawer kick side]

Drawer open/close switch

Drawer kick solenoid

Control device

1

2

3

4

5

6

Using the optional product for TM printer is recommended.

If the optional external buzzer is used, you cannot use a cash drawer.

Specifications of drawers differ depending on makers or models. When you use a

drawer other than specified, make sure its specification meets the following

WARNING

conditions.

Otherwise, devices may be damaged.

The load, such as a drawer kick solenoid, must be connected between pins 4 and 2 or pins

4 and 5 of the drawer kick connector.

When the drawer open/close signal is used, a switch must be provided between drawer

kick connector pins 3 and 6.

The resistance of the load, such as a drawer kick solenoid, must be 24

input current must be 1A or less.

Be sure to use the 24V power output on drawer kick connector pin 4 for driving the equip-

ment.

Use a shielded cable for the drawer connector cable.

Two driver transistors cannot be energized simultaneously.

Leave intervals longer than 4 times the drawer driving pulse when sending it

continuously.

Be sure to use the product power supply (connector pin 4) for the drawer power

source.

Do not insert a telephone line into the drawer kick connector.

Doing so may damage the telephone line or product.

Chapter 2 Setup

or more or the

2

Connect the connector of the drawer kick cable to the product.

Drawer Connection Circuitry

F. G

+24V

41

Page 42

Connecting the AC Adapter

Use PS-180 as the power supply unit for this product.

Be sure to use the included AC adapter as the power supply unit.

Using a nonstandard power supply can result in electric shock and fire.

WARNING

Make sure that the power is turned off, and connect the AC adapter in the following steps.

Push the DC connectors of the AC adapter all the way into the DC-In

1

connectors of the product.

Should a fault ever occur in the included AC adapter, immediately turn off the power to

the product and unplug the power supply cable from the wall socket.

Be sure to unplug the power supply unit’s cable from the wall socket whenever

connecting or disconnecting the power supply unit to the product.

Failure to do so may result in damage to the power supply unit or the product.

Make sure the wall socket power supply satisfies the rated voltage requirements of the

power supply unit. Never insert the power supply cable plug into a socket that does

not meet the rated voltage requirements of the power supply unit.

Doing so may result in damage to both the power supply and the product.

DC-in connector

42

Push the connector of the power code all the way into the AC inlet of the

2

AC adapter.

Push the power plug all the way into the grounded outlet.

3

Place the AC adapter with the label facing down.

4

Page 43

Chapter 2 Setup

Power switch cover

Power switch cover

(Waterproof)

Attaching the Power Switch Cover

Install the power switch cover that comes with the TM-T83II-i onto the product to prevent

inadvertent changing of the power switch, to prevent tampering, and to improve the appearance of

the product.

To operate the power switch, insert an object with a pointed tip such as a ballpoint pen into the hole

on

the power switch cover.

To detach the cover, also use a sharp-pointed object.

2

WARNING

If an accident occurs with the power switch cover attached, unplug the power cord

immediately.

Continued use of the product may cause fire or electric shock.

43

Page 44

Setting the Memory Switches/Receipt Enhancement

With the memory switch and R/E (receipt enhancement) function, which are software settings for

this printer, you can set the various functions. For an outline of the functions, see the following

section. Use the methods shown in the table below; TM-T83II Utility or Software Setting Mode to set

the memory switches and R/E functions.

Function TM-T83II Utility

Receive buffer capacity

Processing when data receive error

BUSY condition

Auto line feed

*2

*1

*1

USB power-saving function

Release condition of receive buffer BUSY

Paper sensor to output paper-end signals default

Error signal output

*1

Memory Switches

Paper near-end sensor

Sounds buzzer on signal output from DK connector pin 2

Sounds buzzer on signal output from DK connector pin 5

*1

Software Setting

Mode

- ✔

- ✔

- ✔

- ✔

- ✔

- ✔

- ✔

- ✔

✔✔

- ✔

- ✔

Paper width

Print density

Print speed

Character code table default

International character default

Interface selection

*2

*1

*1

Power supply unit capacity

Autocutting after closing cover

Customized Values

Paper reduction

Font A auto replacement

Font B auto replacement

Buzzer

Communication condition of serial interface

Communication condition of USB interface

*2

*1

✔✔

✔✔

✔✔

✔✔

✔✔

✔✔

✔✔

✔✔

✔✔

- ✔

- ✔

✔✔

✔✔

✔✔

44

Page 45

Chapter 2 Setup

Function TM-T83II Utility

Auto top logo

Auto bottom logo

Auto top/bottom logo extended functions

Receipt Enhancement

dpi: dots per inch

*1: No settings are required

*2: Do not change the settings

*3: Excluding some function

For information about the TM-T83II Utility, see the TM-T83II Utility User’s Manual.

To directly configure the product in the Software Setting Mode, see

on page 112.

Software Setting

*3

✔

✔ -

*3

✔

"Software Setting Mode"

Mode

-

-

2

45

Page 46

Functions

Receive buffer capacity

•4 KB (initial setting)

•45 bytes

Processing when data receive error

•Prints “?” (initial setting)

•Ignored

No settings are required.

BUSY condition

•Receive buffer full/Offline

•Receive buffer full (initial setting)

Do not change the settings.

Auto line feed

•Always enabled

•Always disabled (initial setting)

No settings are required.

USB power-saving function

•Disabled

•Enabled (initial setting)

Release condition of receive buffer BUSY

• Releases when the remaining receive buffer capacity becomes 256 bytes (initial setting)

• Releases when the remaining receive buffer capacity becomes 138 bytes

46

This function is enabled only when Receive buffer capacity is set to 4 KB.

Page 47

Paper sensor to output paper-end signals default

•Paper end sensor enabled, paper near-end sensor enabled (initial setting)

•Disabled

No settings are required.

Error signal output

•Disabled

•Enabled (initial setting)

No settings are required.

Chapter 2 Setup

Paper near-end sensor

•Disabled (initial setting)

•Enabled

Sounds buzzer on signal output from DK connector pin 2

•Disabled (initial setting)

•Enabled

Sounds buzzer on signal output from DK connector pin 5

•Disabled (initial setting)

•Enabled

Paper width

•80 mm (initial setting)

•58 mm

2

To change the paper width, you need to install the 58-mm width paper guide plate. For

information about how to change the paper width, see

"Changing the Paper Width" on page 32.

47

Page 48

Print density

Selectable from levels 1 to 13 (70% ~ 130%).

Initial setting: level 7 (100%)

Depending on the paper type, it is recommended to set the print density as shown in the table

below for the best print quality.

Original Paper type Density Level

TF50KS-EY, TF60KS-E, PD160R, PD190R, P220AGB-1, P35024,

AF50KS-E, KT55FA, KT48FA

F5041 8 (105%)

When the print density level is increased, printing speed may be reduced.

7 (100%)

Print speed

Selectable from levels 1 to 13 (Slow ~ Fast)

Initial setting: level 13

Depending on print conditions, such as print duty, print head temperature, and data

transmission speed, print speed is automatically adjusted, which may cause white lines due to

intermittent print (the motor sometimes stops). To avoid this, keep the print speed constant by

setting it lower, or set the transmission speed higher for the serial interface.

Character code table default

Selectable from 43 pages

Initial setting: Page 0 (PC437: USA, Standard Europe)

No settings are required.

International character default

Selectable from 18 sets

Initial setting: USA

No settings are required.

48

Page 49

Interface selection

Interface is fixed.

Do not change the settings.

Power supply unit capacity

Selectable from levels 1 to 3 (Low ~ High)

Initial setting: level 3

Autocutting after closing cover

•Cuts

•Does not cut (initial setting)

Chapter 2 Setup

2

Paper reduction

Extra upper space reduction

•Disabled (initial setting)

•Enabled

Extra lower space reduction

•Disabled (initial setting)

•Enabled

Line space reduction rate

•Not reduced (initial setting)

•25%

•50%

•75%

Line feed reduction rate

•Not reduced (initial setting)

•25%

•50%

•75%

Barcode height reduction rate

•Not reduced (initial setting)

•25%

•50%

•75%

49

Page 50

Font A auto replacement

•Does not replace (initial setting)

•Font B

This function is enabled only when Number of columns is set to Standard mode.

Font B auto replacement

•Does not replace (initial setting)

•Font A

This function is enabled only when Number of columns is set to Standard mode.

Buzzer

For information about how to connect the optional external buzzer, see "Connecting the

Optional External Buzzer" on page 37

When the optional external buzzer or Built-in buzzer is enabled, a cash drawer cannot be

used. Be sure to disable it when you use a cash drawer.

".

Sound duration (autocut)

•Does not sound (initial setting)

• 1000 ms

• 2000 ms

• 3000 ms

Sound duration (Cover open/Paper end)

•Does not sound (initial setting)

•Sounds continuously

• 10000 ms

Communication condition of serial interface

No settings are required.

50

Page 51

Communication condition of USB interface

•USB printer class

•USB vendor-defined class (initial setting)

Do not change the settings.

Auto top logo

TM-T83II Utility does not support the function for Number of lines to be deleted below top logo.

Key-code

Selectable from key-codes of registered logos

Chapter 2 Setup

Alignment

•Left

•Center

•Right

Number of lines to be deleted below top logo

Auto bottom logo

Key-code

Selectable from key-codes of registered logos

Alignment

•Left

•Center

•Right

2

51

Page 52

Auto top/bottom logo extended functions

TM-T83II Utility does not support the following functions.

Top logo print while paper feeding to the cutting position

Top logo print while clearing the buffer to recover from a recoverable error

Top logo print after paper feeding with the Feed button has finished

Top logo print while paper feeding to the cutting position

•Disabled

•Enabled (initial setting)

Top logo print when printer is powered on

•Disabled (initial setting)

•Enabled

Top logo print when roll paper cover is closed

•Disabled

•Enabled (initial setting)

Top logo print while clearing the buffer to recover from a recoverable error

•Disabled

•Enabled (initial setting)

Top logo print after paper feeding with the Feed button has finished

•Disabled (initial setting)

•Enabled

52

Page 53

Chapter 2 Setup

Network Setting

There are following methods for network settings.

•EPSON TMNet WebConfig: Set from the computer's web browser

•Easy Setup: Set from the USB memory where the configuration file is stored.

This section briefly explains how to set from EPSON TMNet WebConfig.

Though Easy Setup requires no network connection during setup, you must specify values

for all the setting items available for EPSON TMNet WebConfig.

For about Easy Setup, refer to “TM-i Series Easy Setup Guide”.

1. Connect via a wired LAN

Connect this product and a PC for setting via a wired LAN.

2. Check the IP address of this product

When this product is turned on and becomes ready for printing, it prints out the automatically

acquired IP address.

If no IP address is printed, print a status sheet and check the IP address.

3. Start EPSON TMNet WebConfig

Access the address bar of the Web browser on the PC for setting to start EPSON TMNet WebConfig.

When SSL is disabled: http://[This product's IP address]/webconfig

When SSL is enabled: https://[This product's IP address]/webconfig

For detail, see

"Starting EPSON TMNet WebConfig" on page 83.

4. Set up TCP/IP

Select the [System Settings] menu and then [Wired] - [TCP/IP], and set TCP/IP.

After setting, click [Apply] at the bottom of the screen. Then the settings are written to the product. If

[Apply] is not clicked, the settings are not applied.

For detail, see

"System Settings - Network - Wired - TCP/IP" on page 95.

2

53

Page 54

Confirming Network Setting

You can confirm the network setting with a status sheet or EPSON TMNet WebConfig.

Confirming with a status sheet

Print a status sheet and check the following items.

•Wired TCP/IP

Get IP Address

Set using Automatic Private IP Addressing (APIPA)

IP Address

Subnet Mask

Default Gateway

•Wireless

Communication Standard

Network Mode

SSID

Wireless LAN Frequency Region

Ad-Hoc Channel

Authenti

Security Mode

•Wireless TCP/IP

Get IP Address

Set using Automatic Private IP Addressing (APIPA)

IP Address

Subnet Mask

Default Gateway

About how to print the status sheet, see

cation Method

"Status sheet" on page 102.

Confirming with EPSON TMNet WebConfig

Refer to the followings.

• "General Information" on page 84

• "Information - Wired - TCP/IP" on page 85

54

Page 55

Chapter 2 Setup

Initializing the Network Setting

When network connection fails, follow the steps below to initialize the network setting to the

default.

Details of initialization

When initialization is performed, the following EPSON TMNet WebConfig setting items are

initialized. For details on EPSON TMNet WebConfig, refer to "Starting EPSON TMNet WebConfig"

on page 83

•System Settings - Network - Wired - TCP/IP

The IP address is set to DHCP.

•System Settings - Network - Wireless

The wireless LAN connection mode is set to Infrastructure mode, and the SSID is initialized to the

default value.

•System Settings - Network - Wireless - TCP/IP

The IP address for the wireless LAN is set to "192.168.192.168".

.

2

•System Settings - Time - Time

me server is disabled and the time difference is initialized to the default value.

The ti

•Admin Settings - Administrator Information - Password

The password required when starting up EPSON TMNet We b C o nfig is initialized to the default

value.

EPSON TMNet WebConfig settings other than those listed above are not initialized.

Files registered to EPSON TMNet WebConfig are saved.

(Certificate files, Web contents, PHP, etc.)

55

Page 56

Initialization procedure

Push button

Load the paper on the product and turn on the product.

1

Push and hold the push button for 10 seconds or longer.

2

The following initialization start message is printed.

Press the push button with a thin object such as a tweezers.

Do not turn off the power until the initialization is completed.

20 to 25 seconds later, the following message is printed, and a status sheet is

3

printed out.

56

Page 57

Chapter 2 Setup

Enabling PHP

To use PHP on this product, enable PHP using EPSON TMNet WebConfig.