Page 1

Operating manual

Operating manual

Eppendorf Research® plus

Research plus - Operating Manual - en

Operating manual

Page 2

Copyright

©

2010 Eppendorf AG, Hamburg. No part of this publication may be reproduced without

the prior permission of the copyright owner.

Trademarks

Combitips

trademarks of Eppendorf AG, Hamburg, Germany.

Registered trademarks are not marked in all cases with ™ or

®

, eppendorf®, epT.I.P.S.®, Multipette®, Repeater® and Research® are registered

®

in this manual.

U.S. Pat. No.

5,531,131

4,961,350

For user adjustment with adjustment display, spring to reduce force for tip fitting and for further

features patents are pending.

Research plus - Operating Manual - en-02/0210

Page 3

Eppendorf Research® plus — Operating manual

Table of contents

Table of contents

1 Product description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.1 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.2 Delivery package . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.3 Main illustration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.3.1 Research plus single-channel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.3.2 Research plus multi-channel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.4 Materials. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.1 Intended use. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.2 Warnings for intended use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.1 Setting the volume (only Research plus variable) . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.2 Using pipette tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.3 Aspirating liquid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.4 Dispensing liquid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.1 Error search . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5.1 Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5.2 Sterilizing or disinfecting the pipette. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.2.1 Autoclaving . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.2.2 Disinfection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5.3 Replacing O-rings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5.3.1 Removing the O-ring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5.3.2 Mounting a new O-ring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5.4 Research plus disassembly and assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.4.1 Single-channel up to 1 000 L . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.4.2 5 mL and 10 mL single-channel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.4.3 Multi-channel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

5.5 Adjusting pipettes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5.5.1 General notes on user and factory adjustment settings . . . . . . . . . . . . . . . . . 22

5.5.2 Changing the user adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5.5.3 Changing the factory adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

5.5.4 Research plus variable - changing the factory adjustment . . . . . . . . . . . . . . . 25

5.5.5 Error limits in accordance with ISO 8655-2. . . . . . . . . . . . . . . . . . . . . . . . . . . 31

5.6 Decontamination before shipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

6 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

6.1 Research plus single-channel variable. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

6.2 Research plus multi-channel variable. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

6.3 Research plus fix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

6.4 Ambient conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

7 Ordering information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Table of contents

3

Page 4

Eppendorf Research® plus — Operating manual

1 Product description

1 Product description

1.1 Features

The Research plus pipettes are piston-stroke pipettes that operate according to the air-cushion

principle.

When the control button is pressed, the piston in the pipette moves in the same direction. If the

1

control button and the piston are moved upwards, the liquid can be aspirated into the pipette tip.

With the downward movement of the piston, the liquid is dispensed (measuring stroke).

Blow-out occurs if the downward piston stroke exceeds the first stop.

Depending on the Research plus pipette it is possible to dispense volumes from 0.1 L to 10 mL.

The Research plus family consists of single-channel and multi-channel pipettes (8 and

12-channels) with variable volume settings, as well as single-channel fixed-volume pipettes. You

can find a list of all available models of the Research plus in the "Technical Data" section.

All Research plus pipettes are fully autoclavable.

You can adjust the Research plus pipettes. The side viewing window displays the change in the

adjustment.

When attaching a pipette tip, the spring-loading action of the tip cone is activated (exceptions

5 mL and 10 mL pipettes).

Product description

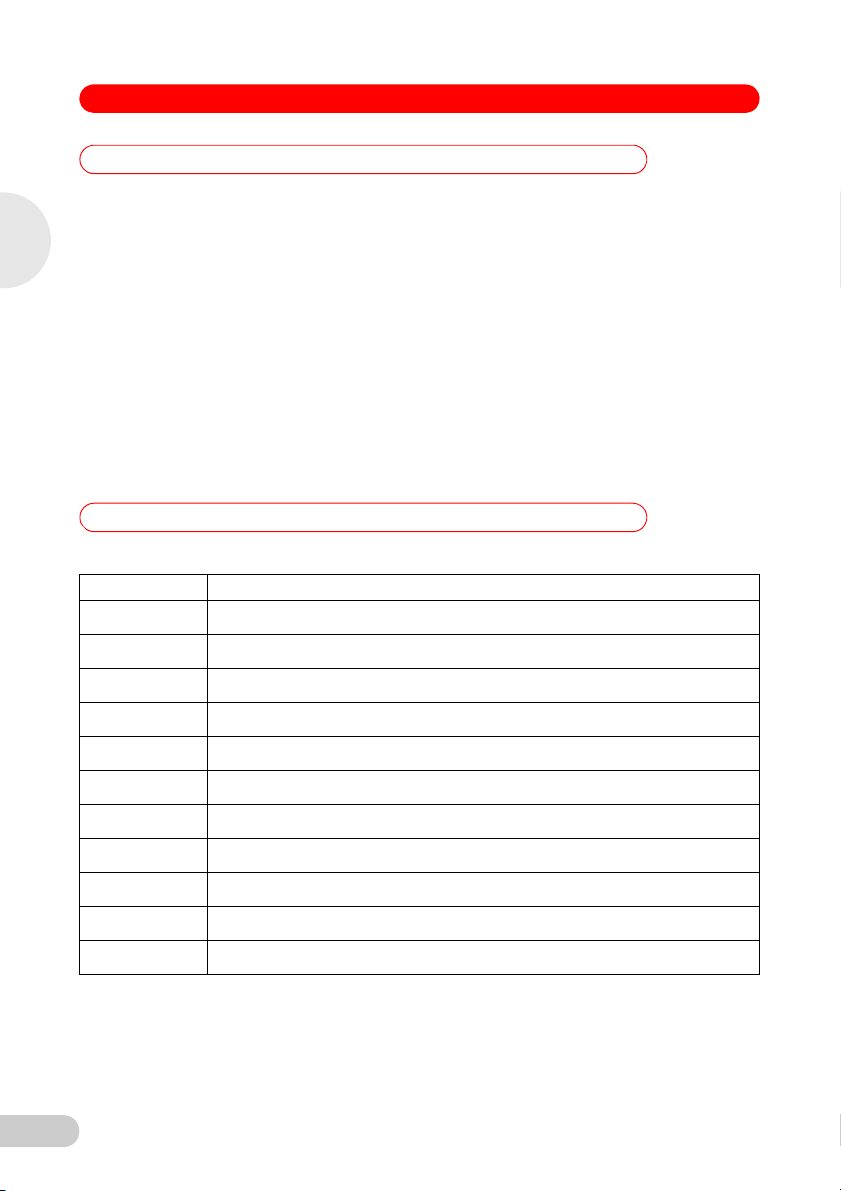

1.2 Delivery package

The Research plus delivery package contains:

Pcs. Description

1 Research plus operating manual

1 Certificate

1 Adjustment tool (Allen key with a blue handle)

1 Mini CD

1 Black locking ring for single-channel pipettes ≤ 1,000 L

5 Red adjustment seal

5 Protective filters for 5 mL and 10 mL pipettes

1 Pipette key for opening the lower part (5 mL and 10 mL)

1 O-ring tool for cutting the O-rings (only multi-channel 100 L and 300 L)

1 Safety plug tool

1 Pin for loosening the safety plug

4

Page 5

Eppendorf Research® plus — Operating manual

1

2

3

4

5

6

8

9

7

10

1 Product description

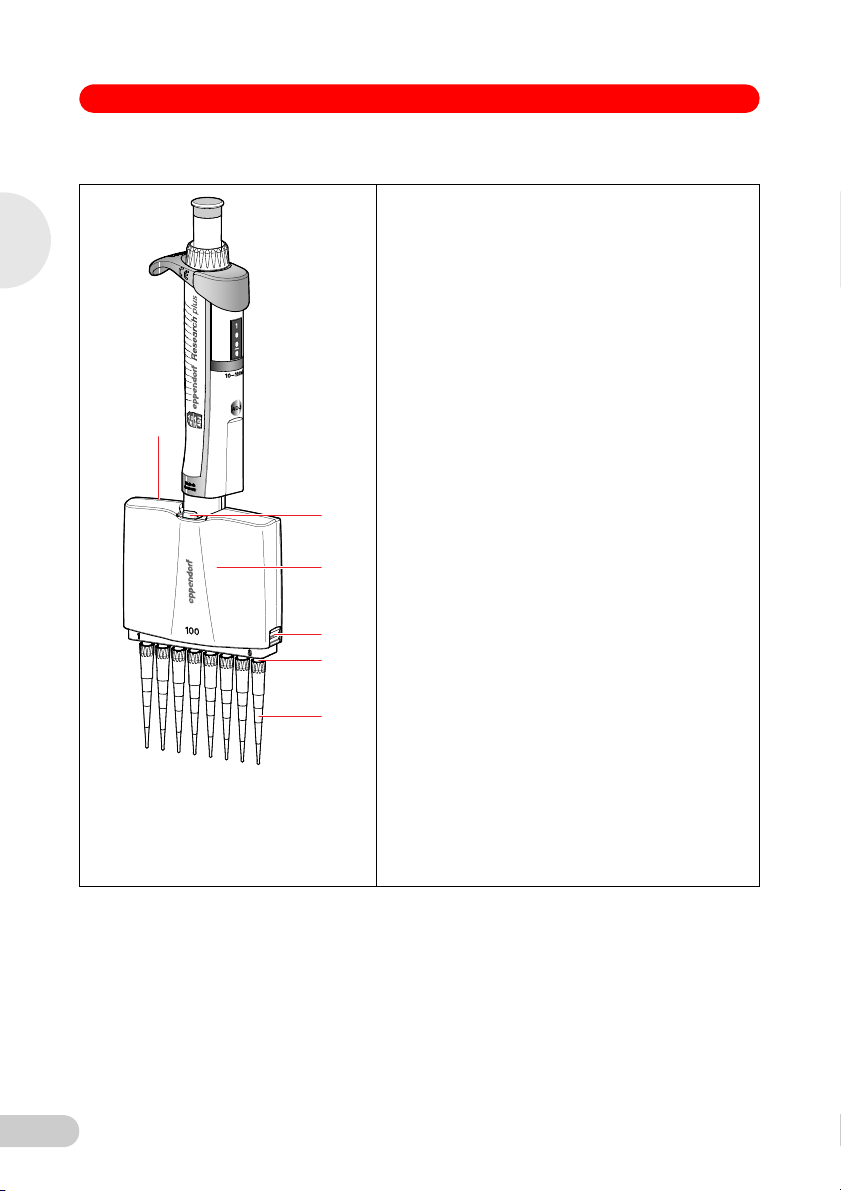

1.3 Main illustration

1.3.1 Research plus single-channel

1 Control button

The control button and the trays of the matching epT.I.P.S. pipette

tips have the same color.

2 Volume adjustment ring

To set the volume for the variable pipettes.

3 Ejector

The ejector moves the ejector sleeve and ejects the pipette tip.

4 Volume display (only variable pipettes)

The set volume is read from top to bottom.

5 Adjustment opening

The adjustment opening is fitted with the gray adjustment seal

before delivery.

6 Adjustment display

Set to "0" before delivery.

7 Labeling field

Space for labels containing internal lab information. The serial

number appears at the bottom.

8 Ejector sleeve

Eject the pipette tips after use.

9 Spring-loaded tip cone

The spring loading action optimizes the force required for

attaching and ejecting tips (no spring-loaded action with 5 mL

and 10 mL pipettes). The 5 mL and 10 mL pipettes have an

easily replaceable protection filter in the tip cone.

10 Pipette tip

The Research plus pipettes can only be used in combination with

matching pipette tips. It is recommended to use epT.I.P.S.

1

Product description

5

Page 6

Eppendorf Research® plus — Operating manual

1

2

3

4

5

6

1 Product description

1.3.2 Research plus multi-channel

1

Product description

For an explanation of the upper part of the pipette,

refer to the main illustration of the single-channel

pipette (see p. 5).

1 Lever

To loosen the multi-channel lower part.

2 Multi-channel lower part

The multi-channel lower part is freely rotatable. The

lower part does not detach when it is rotated. The

outer channels are labeled with the numbers 1 and 8

(or 12).

The multi-channel version has a piston for each

channel so that fewer than 8 or 12 tips can also be

fitted.

The lower part can be converted from an 8 to a

12-channel version with the same volume range.

The multi-channel lower part can be opened,

enabling you to replace or remove individual

channels.

3 Latches on the right and left

To release the cover plate with the interior ejector

rail.

4 Spring-loaded tip cones

The spring loading action optimizes the force

required for attaching and ejecting tips.

5 Pipette tips

It is recommended to use epT.I.P.S.

6 Cover plate

Detachable cover plate with an interior ejector rail.

The cover plate is opposite the side with the

6

lever (1). In the view shown here, the cover plate is

the rear side of the lower part.

Page 7

Eppendorf Research® plus — Operating manual

1 Product description

1.4 Materials

CAUTION! Aggressive substances can damage the device, dispensing unit and

accessories.

CAUTION!

Check for material compatibility before using organic solvents and aggressive

chemicals.

Follow the cleaning instructions (see Cleaning on p. 14).

The user-accessible components of the Research plus are made of the following materials:

Component Material

External surfaces of the upper part Purified polypropylene (PP),

Exterior and interior of lower parts Purified polypropylenen (PP),

polycarbonate (PC),

polyetherimide (PEI),

foil

polyvinylidene fluoride (PVDF),

polyetherimide (PEI),

polyphenylene sulfide (PPS),

polyetheretherketone (PEEK),

polytetrafluorethylene (PTFE),

ethylene-propylene-diene rubber (EPDM),

silicone,

steel (stainless steel and spring steel)

1

Product description

Pipette tip Material

epT.I.P.S. Polypropylene (PP)

epDualfilter T.I.P.S. filter Polyethylene (PE)

7

Page 8

Eppendorf Research® plus — Operating manual

2 Safety

2Safety

2.1 Intended use

The Research plus is a lab device intended for dispensing liquids in the volume range from

0.1 L to 10 mL, in combination with matching pipette tips. In vivo applications (applications in or

on the human body) are not permitted.

The Research plus may only be operated by trained specialist staff. All users must have read the

operating manual carefully and familiarized themselves with the device's mode of operation.

2.2 Warnings for intended use

2

WARNING! Damage to health due to handling infectious liquids and pathogenic

germs.

WARNING!

Observe the national regulations for handling these substances, the biological

security level of your laboratory, the material safety data sheets and the

Safety

WARNING!

manufacturer's application notes.

Wear personal protective equipment (PPE).

Follow the instructions regarding hygiene, cleaning and decontamination.

For complete instructions regarding the handling of germs or biological material of

risk group II or higher, please refer to the "Laboratory Biosafety Manual" (source:

World Health Organization, current edition of the Laboratory Biosafety Manual).

WARNING! Damage to health due to toxic, radioactive or aggressive chemicals.

Observe the national regulations for handling these substances as well as the

material safety data sheets and manufacturer's application notes.

Wear personal protective equipment (PPE).

CAUTION! Danger to persons from careless use.

Never point the opening of a Research plus fitted with pipette tip at yourself or

CAUTION!

anyone else.

Only initiate dispensing if it is safe to do so.

For all dispensing tasks, make sure that you are not endangering yourself or

anyone else.

CAUTION! Poor safety due to incorrect accessories and spare parts.

The use of accessories and spare parts other than those recommended by Eppendorf

CAUTION!

may impair the safety, functioning and precision of the device. Eppendorf cannot be

held liable or accept any liability for damage resulting from the use of incorrect or

non-recommended accessories and spare parts or from the improper use of such

equipment.

Only use accessories and original spare parts recommended by Eppendorf.

NOTICE! Damage to device from missing pipette tips.

Only use the Research plus with fitted pipette tips.

NOTICE!

When using standard tips (without a filter): use the 1 - 10 mL and 0.5 - 5 mL

pipettes only with the protection filter inserted.

8

Page 9

Eppendorf Research® plus — Operating manual

2 Safety

NOTICE! Carry-over, contamination and incorrect dispensing results due to the

incorrect use of pipette tips.

NOTICE!

The pipette tips are for single use only. Prolonged use can have a negative impact on

dispensing tasks.

Use the pipette tips only once.

Do not autoclave the epT.I.P.S. Dualfilter.

NOTICE! Incorrect dispensing volume for special liquids and from temperature

differences.

NOTICE!

Solutions which differ greatly from water in terms of their physical data, or temperature

differences between the pipette, pipette tip and liquid can result in incorrect dispensing

volumes.

Avoid temperature differences between pipette, pipette tip and liquid.

Make sure that the temperature is constant, between 20 and 25°C and at ±0.5°C.

Check the dispensing volume and readjust the pipette in case of deviations.

2

Safety

9

Page 10

Eppendorf Research® plus — Operating manual

3 Operation

3 Operation

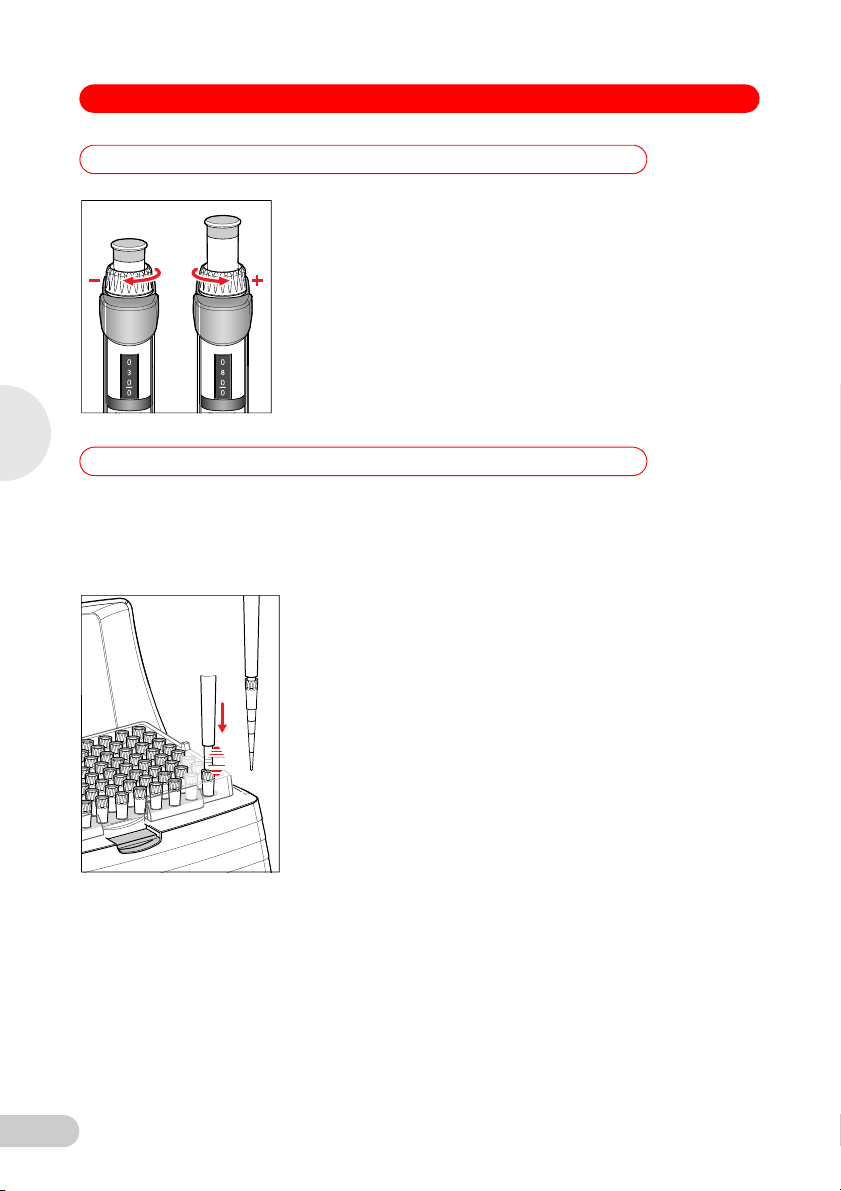

3.1 Setting the volume (only Research plus variable)

Turn the volume setting ring as depicted to adjust the

volume.

The height of the control button changes as the volume is

adjusted.

The numbers on the volume display are to be read from

the top to the bottom. The decimal places are below the

hyphen.

The volume is displayed up to 1 000 L in L. For the 5 mL

and 10 mL sizes, the volume is displayed in mL.

We recommend to adjust the volume setting from a higher

value to a lower value. If required, turn beyond the

3

3.2 Using pipette tips

The liquid to be dosed is aspirated into pipette tips. It is recommended to use epT.I.P.S. The

epT.I.P.S. pipette tips are available in different purities, as tips with and without a filter and as

special tips. When using liquids whose surface tension is lower than that of water (e.g., due to the

presence of a wetting agent in the liquid), the use of the special tips epT.I.P.S. LoRetention is

recommended.

Operation

required value and then back again.

The pipette is only functional if a pipette tip has been

attached. You can either attach the pipette tip by hand or

directly insert the end of the pipette into a tip held in the tip

storage box. If attaching a pipette tip by hand, it must be

handled in such a way to avoid contamination and heating of

the pipette tip.

The color of the control button of the Research plus matches

the color of the epT.I.P.S. tray.

If you are using pipette tips without a filter, insert the

protection filter into the 5 mL and 10 mL pipettes.

If you are using the 5 mL or 10 mL epDualfilter T.I.P.S.,

remove the protection filter in the pipette. This also

applies to 5 mL / 10 mL filter tips of other manufacturers.

The filters can interfere with each other. The

backpressure of the two filters makes it difficult to exactly

identify the first stop (see p. 11).

Fit the suitable pipette tip(s) on the tip cone, applying light

pressure.

The pipette tip is securely attached to the tip cone when

it responds with spring-loaded action (exceptions: no

spring-loading action for 5 mL and 10 mL single-channel

pipettes)

You can deactivate the spring loading action of the tip cone in

the case of single-channel pipettes (see p. 17).

10

Page 11

Eppendorf Research® plus — Operating manual

3 Operation

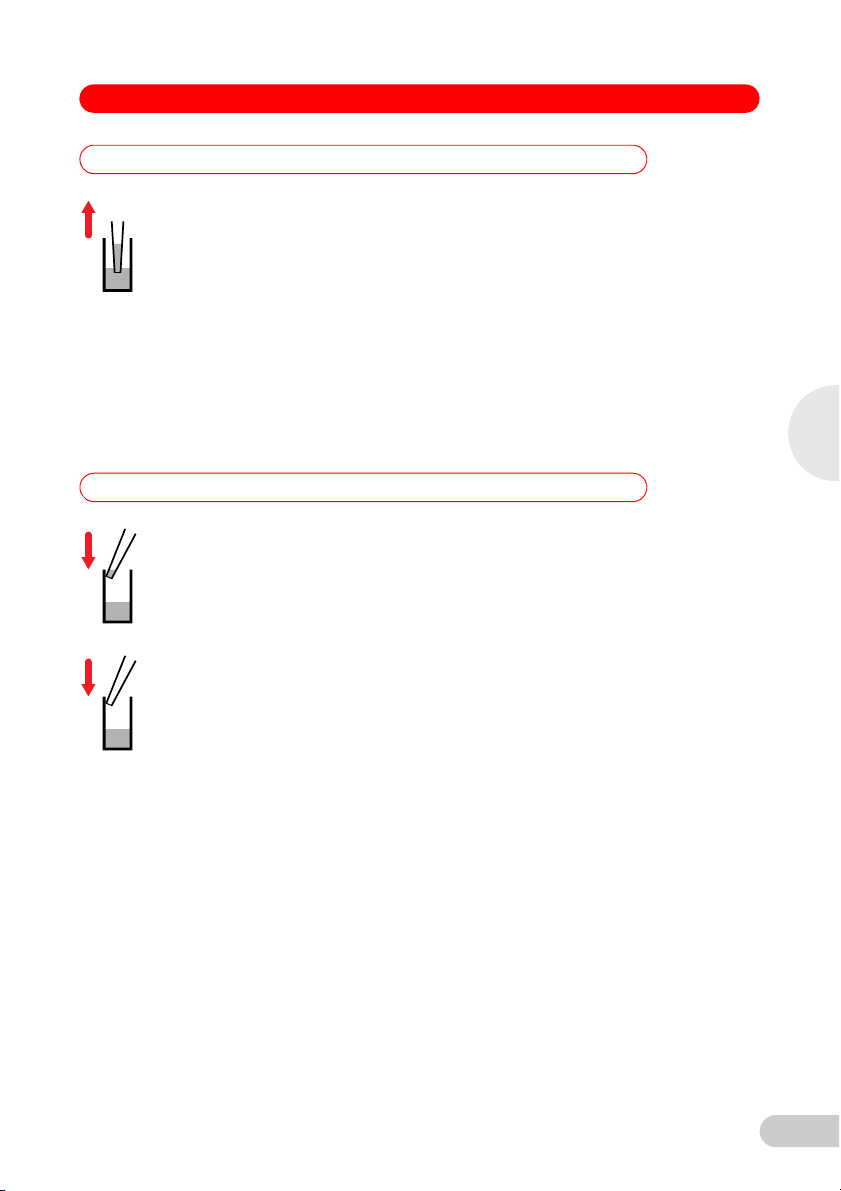

3.3 Aspirating liquid

1. The liquid to be aspirated must be taken from a suitable vessel. For

multi-channel pipettes, we recommend the reagent reservoir "Tip-Tub".

2. Press down the control button to the first stop (measuring stroke).

3. Immerse the pipette tip(s) vertically approx. 4 mm into the liquid.

4. To aspirate liquid, allow the control button to slide back slowly. Maintain the

immersion depth, so that no air is aspirated accidentally.

5. In the case of large volumes: before removing the pipette tip from the liquid,

wait for approx. 3 seconds. To ensure maximum precision and accuracy, we

recommend to wet each new tip initially by aspirating and dispensing the

liquid one to three times. Only then should pipetting commence.

6. Remove the tip(s) slowly from the liquid.

7. Wipe the tip(s) slowly against the tube wall to ensure that no outer wetting

remains on the tip.

3

3.4 Dispensing liquid

1. Place the tip(s) on the tube wall at an angle.

2. Press the control button slowly until the first stop (measuring stroke) and

wait until the flow of liquid stops.

3. To empty the tip(s) completely, press down the control button until the

second stop (blow-out).

4. Hold down the control button and wipe the tip(s) against the tube inner wall.

5. Let the control button slide back slowly outside of the tube.

6. To eject the tips, press the ejector.

Pipette tips are for single use only.

Operation

11

Page 12

Eppendorf Research® plus — Operating manual

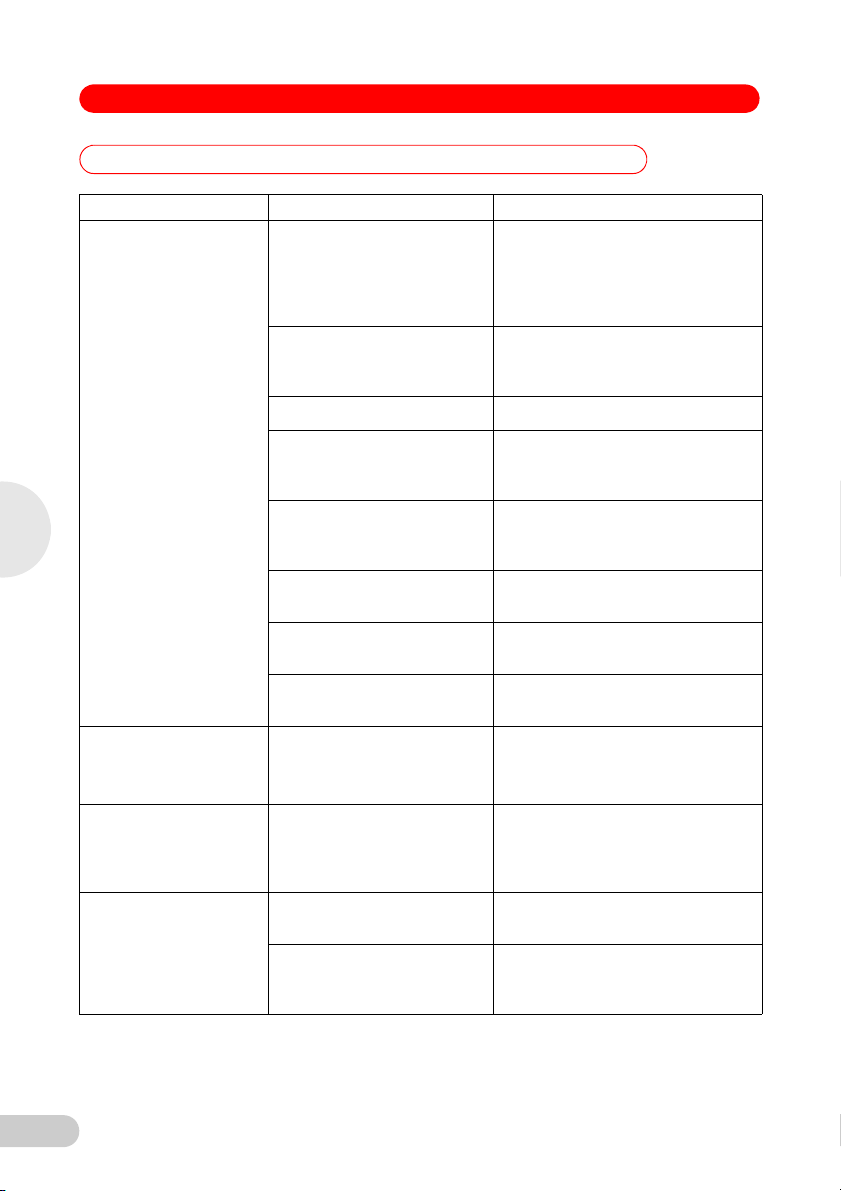

4 Troubleshooting

4 Troubleshooting

4.1 Error search

Symptom Possible cause Solution

Liquid is dripping from

the tip and/or the

dispensed volume is

incorrect.

• The tip is loose or the

pipette tip is poorly fitted.

Press the tip on firmly, use

epT.I.P.S. If using 5 mL and

10 mL epDualfilter T.I.P.S., do

not use protection filters in the

pipette.

• Liquid with high vapor

pressure and/or different

density.

Wet the tip several times and

adjust the pipette for the liquid

used.

• Pipetted too quickly. Move the control button slowly.

• The tip is withdrawn from

the liquid too quickly.

4

• Liquid aspirated with

blow-out and dispensed

with blow-out.

• The piston is soiled or

damaged.

Slowly remove the tip with a

time delay (approx. 3 seconds)

from the liquid.

Repeat dispensing correctly.

Clean the piston, relubricate

slightly and/or replace.

• The tip cone is damaged. Replace the lower part or

channel.

Troubleshooting

The control button jams

and does not move

smoothly.

The adjustment seal has

been removed; the

adjustment display has

been changed.

No spring-loading action

of the tip cone when

taking up pipette tips.

• The O-rings of the tip

cones are damaged.

• The piston is soiled.

• The seal is soiled.

• The pipette is blocked.

• The pipette has been

adjusted for another

liquid.

• Spring-loading action is

blocked by a locking ring.

• The use of a 5 mL or

10 mL pipette.

Replace the O-rings (only

100 L, 300 L multi-channel).

Clean the lower part.

5 mL and 10 mL sizes: replace

the protection filter.

Adjust the pipette for the liquid

used (see Adjusting pipettes on

p. 22).

Remove the locking ring again.

No remedy. The tip cone does not

respond with spring-loaded action in

combination with these sizes.

12

Page 13

Eppendorf Research® plus — Operating manual

4 Troubleshooting

To avoid dispensing errors, check the precision and accuracy of the Research plus at regular

intervals. The "PICASO" program (from Version 2.3) is available to determine the permitted

measured systematic and random errors. If the pipette is used at an extremely high location, it

must be adjusted to the ambient air pressure. A SOP (Standard Operation Procedure) for

checking pipettes can be found on the Research plus CD and on our website

www.eppendorf.com

.

4

Troubleshooting

13

Page 14

Eppendorf Research® plus — Operating manual

5 Maintenance

5 Maintenance

5

NOTICE! Aggressive substances can damage the pipette, pipette tips and the

accessories.

NOTICE!

Check for material compatibility before using organic solvents and aggressive

chemicals.

Follow the cleaning instructions.

• All single and multi-channel lower parts are wear parts. Clean them after contamination, use

of aggressive chemicals and/or heavy stress. If the lower parts are worn or damaged, replace

Maintenance

the respective parts.

• Faulty dispensing results are sometimes due to lack of maintenance.

5.1 Cleaning

NOTICE! Damage to device from unsuitable cleaning fluids or sharp or pointed

objects

NOTICE!

Unsuitable cleaning fluids can damage the surfaces and printing.

Never use corrosive cleaning fluids, strong solvents or abrasive polishes.

Note the information on chemical resistance (see the Research plus CD).

Do not use acetone to clean the Research plus.

Do not use sharp objects to clean the Research plus.

Remove any contamination on the outside of the Research plus as follows:

Wet a cloth with a mild cleaning fluid and water and remove the contamination.

To remove heavy contamination resulting from liquid penetration, disassemble the lower part

of the pipette (see Research plus disassembly and assembly on p. 17) and clean it with

demineralized water.

Relubricate the piston sealing rings after contamination, use of aggressive chemicals and/or

heavy stress. Remove the old grease before relubricating.

Only use the grease specified in the ordering information (see the enclosed CD).

14

Page 15

Eppendorf Research® plus — Operating manual

5 Maintenance

5.2 Sterilizing or disinfecting the pipette

NOTICE! Damage to device from incorrect handling.

Do not use any additional disinfectants, decontamination agents or sodium

NOTICE!

hypochlorite during autoclaving or UV exposure.

When autoclaving make sure that the temperature does not exceed 121°C.

Before using disinfecting agents or decontaminating agents, test for material

compatibility and check the manufacturer's instructions about chemical resistance.

Consider also the material of the pipette.

5.2.1 Autoclaving

All Research plus pipettes are completely steam autoclavable.

Before autoclaving

1. Remove any contamination from the exterior and in the lower part (see Research plus

disassembly and assembly on p. 17).

2. If you remove existing grease, slightly relubricate the piston seal using only the grease

specified in the ordering information (see the enclosed CD).

Procedure

Follow the operating manual of the autoclave manufacturer.

1. Autoclave at: 121°C; 20 minutes; 1 bar overpressure

2. When placing the Research plus into the autoclave, make sure that the temperature at the

pipette does not exceed 121°C.

3. You can put the Research plus into the autoclave as a whole unit or with the lower part

removed. Do not disassemble the lower part.

4. For 5 mL and 10 mL pipettes: remove the old protection filter. Add a new protection filter and

install it after autoclaving. Autoclave the protection filter only once.

5. If lower parts have been removed, make sure that no lower parts are confused during

reassembly. (Tip: Use one plastic beaker per pipette).

After autoclaving

Cool the pipette down to room temperature and leave to dry.

For 5 mL / 10 mL pipettes: the protection filter swells during autoclaving. Slightly compress

the protection filter when inserting it into the tip cone.

The piston does not need to be relubricated after autoclaving. If autoclaving is carried out as

described above, no gravimetric testing or adjustment is necessary.

5

Maintenance

15

Page 16

Eppendorf Research® plus — Operating manual

5 Maintenance

5

5.2.2 Disinfection

Carefully wipe off the outer surfaces with disinfectant, DNA/RNA decontamination agents or

70% isopropanol.

You can wipe the outside of the tip cone and the ejector sleeve with a sodium hypochlorite

solution of 4%.

After the exposure time of the sodium hypochlorite solution has elapsed, remove thoroughly

with demineralized water.

The Research plus pipettes may be temporarily subjected to the UV light of a sterile bench ( ≥254

Maintenance

nm).

5.3 Replacing O-rings

The 100 L and 300 L multi-channel lower parts are equipped with O-rings. These are wear

parts. Replace old, worn or damaged O-rings. Defective O-rings result in the incorrect positioning

of the tips and in dispensing errors.

5.3.1 Removing the O-ring

1. Push the opening of the O-ring tool (included in the delivery package) against the tip cone

from the side so that the sharp edge in the opening of the O-ring tool is positioned on top of

the o-ring. Do not slide the O-ring tool onto the cone!

2. Supporting the O-ring tool with your thumb, push it firmly against the tip cone.

This O-ring is cut in one place.

3. Remove the O-ring tool and the O-ring from the tip cone.

5.3.2 Mounting a new O-ring

1. Fit the mounting aid (shortened pipette tip, included in the delivery package of the O-rings)

on the tip cone.

2. Push the new O-ring over the tip onto the tip cone.

3. Check that the pipette tips are correctly positioned. Ensure that the tips are tightly sealed and

properly aligned.

16

Page 17

Eppendorf Research® plus — Operating manual

1

2

3 4

1

2

3

4

5 Maintenance

5.4 Research plus disassembly and assembly

5.4.1 Single-channel up to 1 000 μL

Removing the lower part

PUSH UP TO RELEASE

1. Keep the ejector pressed and remove the ejector sleeve .

2. and : on the lower part, slide the ring marked "PUSH UP TO RELEASE" up by about

5 mm until the lower part comes off.

3. : take the lower part out of the upper part.

Deactivating the spring-loading action: installing the locking ring

For the following dispensing tasks it can be helpful to deactivate the spring loading action of the

tip cone.

• A pipette tip is to be used for a long period.

• The pipette tip is slightly bended during dispensing.

Deactivating this action can also be helpful for pipette tips which are not designed for the

Eppendorf pipette tip cone.

The spring loading action of the tip cone can be deactivated by installing

the locking ring. The locking ring is included in the delivery package.

1. Push the black locking ring onto the lower part from the top. Slightly

squeeze the clamps on the lower part when doing so.

2. Insert the lower part into the upper part until it engages audibly.

3. Keep the ejector pressed. The ejector rod protrudes from the upper

part.

4. Fit the ejector sleeve onto the ejector rod. It is fitted correctly if it

engages slightly.

Remove the locking ring to reactivate the spring-loading action.

5

Maintenance

17

Page 18

Eppendorf Research® plus — Operating manual

1

2

3

4

5 Maintenance

5

Opening and assembling the lower part (≤1 000 μL)

To avoid confusion of parts, only disassemble and assemble one pipette at a time.

Hint!

Opening the lower part:

1. On the piston mount (1) push the locking mechanisms

Maintenance

2. Remove the piston mount.

3. Remove the piston (2) and the piston spring (3). The

Assembling the lower part:

1. Carefully guide the piston and the piston spring into the

2. Keep the piston and the piston spring pressed.

3. Keep the locking mechanisms on the piston mount

4. Mount the piston mount in such a way that the two locking

5. Gently press a pipette tip against the inserted piston. The

Installing the lower part and ejector sleeve:

1. Insert the lower part into the upper part until it engages

2. Set the maximum volume and operate the control button

3. Keep the ejector pressed. The ejector rod protrudes from

4. Fit the ejector sleeve onto the ejector rod. It is fitted

5. Carry out a gravimetric test of the systematic and random

This test ensures that no parts were confused during

assembly and that the pipette has been assembled correctly.

together slightly.

piston is under spring tension. Pistons and piston springs

will look different for the individual volume versions.

cylinder. Make sure that the piston is guided correctly in

the piston spring and in the cylinder. There must not be

any perceptible resistance. Stop pushing as soon as

any resistance is felt This may indicate that the piston is

not positioned correctly in the cylinder. There is a risk of

bending the piston if too much force is applied. Carefully

pull out the piston and repeat the process correctly. In the

case of piston springs with double windings (4), these

windings must point downwards.

pressed with the other hand.

mechanisms engage in their retainers.

piston must move down in the cylinder without any

noticeable resistance.

audibly.

several times. It must run smoothly and resistance-free.

the upper part.

correctly if it engages slightly.

error (see Technical data on p. 35).

18

Page 19

Eppendorf Research® plus — Operating manual

1

2

3

4

1 2 3 4 5 6

5 Maintenance

5.4.2 5 mL and 10 mL single-channel

Replace the protection filter in the tip cone after each contact with liquid or if it is frayed.

4

1

30°

2

1

1. : unscrew the ejector sleeve.

2. : keep the ejector pressed and turn the lower part to the left or right by approximately 30°.

The lower part is automatically released from the upper part.

3. : open the lower part: fit the pipette key (included in the delivery package) onto the lower

part. Hold the cylinder and unscrew it from the lower part.

See the next figure.

4. Hold the piston (4) which is now partly visible in the lower part.

5. Push the piston mount (1) slightly downwards (3 mm) and turn it by 45°.

The piston spring pushes the piston mount upwards. The lower part opens.

The lower part consists of the following:

2

3

5

Maintenance

1 5 mL / 10 mL piston mount 2 Piston spring

3 Upper part of the lower part 4 Piston (with seal)

5 Cylinder and tip cone 6 Protection filter in the tip cone

19

Page 20

Eppendorf Research® plus — Operating manual

1

2

3

1

2

3

5 Maintenance

5

Before assembling the pipette, first install the piston mount, the piston spring and the piston in the

upper part of the lower part. Further assembly is as shown in the figures. Carry out the procedure

in reverse order. After the assembly:

The assembly is performed in reverse order. After the assembly:

Carry out a gravimetric test of the systematic and random error (see Technical data on

p. 35).

This test ensures that no parts were confused during assembly and that the pipette has been

assembled correctly.

Maintenance

5.4.3 Multi-channel

Loosen and open the 10 μL, 100 μL and 300 μL multi-channel lower part

1. and : slide the lever on the lower part to the left or right.

This separates the lower part from the upper part so that it can be removed.

2. Put down the lower part with the lever facing downwards.

3. : slide the two latches (right and left at the side) down. Use a coin to do this.

The lower part is still lying with the lever facing downwards.

4. Take off the cover plate with the integrated ejector rail.

Do not remove the ejector rail from the cover plate. The spring for the ejector rail could

accidentally come off and get lost.

20

Page 21

Eppendorf Research® plus — Operating manual

1

2

3

4

5

1

2

3

4

5

5

5 Maintenance

Removing and installing channels

Channels must only be removed and installed if the multi-channel lower part is separated from

the upper part! The channels in the lower parts consist of a piston, a cylinder and a spring. The

channels for 100 L and 300 L are equipped with an O-ring at the tip cone (see Replacing

O-rings on p. 16).

1. and : position a pipette tip under the piston and carefully take the piston off the upper

rail.

2. Carefully pull the piston out in an upward direction. Do not bend the piston.

3. Hold the tip cone at the lower end and push it slightly upwards .

This compresses the spring.

4. : lift the tip cone slightly and release it from the lower rail.

5. : relax the spring by letting the tip cone slide back again above the lower rail.

6. : take the tip cone with the cylinder and the spring out of the upper rail.

Before installation, slide the piston into the cylinder. Install the channels in reverse order.

Assembling the 10 - 300 μL multi-channel pipette

1. Fit the cover plate with the integrated ejector.

2. Push the latches upwards.

3. To mount, push the lower part into the upper part until it audibly engages.

4. Carry out a gravimetric test of the systematic and random error (see p. 35).

This test ensures that no parts were confused during assembly and that the pipette has been

assembled correctly.

5

Maintenance

21

Page 22

Eppendorf Research® plus — Operating manual

5 Maintenance

5

5.5 Adjusting pipettes

NOTICE! Incorrect dispensing volume for special liquids and from temperature

differences.

NOTICE!

Solutions which differ greatly from water in terms of their physical data, or temperature

differences between the pipette, pipette tip and liquid can result in incorrect dispensing

volumes.

Maintenance

Avoid temperature differences between pipette, pipette tip and liquid.

Make sure that the temperature is constant, between 20 and 25°C and at ±0.5°C.

Check the dispensing volume and readjust the pipette in case of deviations.

The systematic and random errors recorded on delivery can be found in the Certificate

Hint!

of Conformity. This certificate is included in the delivery. Changes to the factory

adjustment will render the certificate void.

5.5.1 General notes on user and factory adjustment settings

The Research plus was adjusted, tested and fitted with a gray adjustment seal with the

abbreviation "ADJ" before delivery. The adjustment display on the side reads "0".

Changing the adjustment of the Research plus is sometimes recommended for solutions which

are very different from water with regard to their density, viscosity, surface tension and/or vapor

pressure etc. If the density of an aqueous solution changes by approximately ±10%, for example

because of the salt concentration, the volume changes by approximately ±0.2%. This statement

does not apply if other relevant properties of the liquid also change.

If the pipette is used at extremely high altitudes, it must be calibrated to the ambient air pressure.

At 1 000 m above sea level, the volume error of a 100 L pipette is about –0.3%.

When using special tips, that is, tips that significantly differ from standard tips in their geometry,

changing the adjustment can improve the dispensing accuracy (systematic error). The CD

Research plus contains adjustment tips for epT.I.P.S. long.

Adjustment changes can be reset by simple steps.

In addition to changing the user adjustment, a Research plus with variable volume setting can be

permanently changed by altering the factory adjustment (see Changing the factory adjustment

on p. 25).

Changes made to the user or factory adjustment do not affect dispensing precision (random

error). Precision can be improved by exchanging worn parts. Precision is also considerably

affected by handling.

Before changing the adjustment or factory calibration, you must check the existing dispensing

volume.

The actual volume can be checked by weighing:

22

Page 23

Eppendorf Research® plus — Operating manual

5 Maintenance

The density of distilled water is approx. 0.9982 mg/L at 20°C and 0.9965 mg/L at 27°C.

If the set volume corresponds to the actual volume, no correction is necessary.

If there is a difference between the actual volume and the set volume of distilled water, please

check the following:

• Is there any liquid dripping from the tip?

• Is the pipette tip fitted leak-proof?

• Is the tip cone undamaged?

• Are the piston and the cylinder leak-proof?

Adequate leak tightness is ensured when no drop is formed at the pipette tip after aspiration

of the nominal volume with distilled water and a waiting time of approx. 15 s. Hold the pipette

vertically, making sure not to touch the pipette tip. Prewet the tip several times in the case of

nominal volumes ≤ 20 L.

• Does the temperature of the pipetted liquid correspond to:

– the temperature of the device?

– the ambient air temperature?

• Is the weighing location free from drafts?

• Does the work method and pipetting speed permit complete aspiration and dispensing of the

liquid?

• Has the correct numerical value for "Density liquids at weighing temperature" been used for

the calculation of the actual volume?

• Is the set volume correct?

• For very small volumes (<10 L): is the fine balance sufficiently sensitive (balance resolution:

0.001 mg)?

• Were original epT.I.P.S pipette tips used for testing?

Information as to which pipette tip must be used as a test tip for checking the technical data

can be found in the "Technical Data" chapter of the operating manual.

No adjustment changes are allowed unless you can answer all the questions with "yes". In all

other cases, the problems associated with the questions answered with "no" must be eliminated.

If the problem is remedied by exchanging a complete lower part or other parts that have an effect

on the volume, proper assembly must be verified by carrying out a gravimetric test. Information

on the systematic and random errors to be met can be found in the "Technical Data" chapter.

5

Maintenance

23

Page 24

Eppendorf Research® plus — Operating manual

5 Maintenance

5

5.5.2 Changing the user adjustment

If the adjustment is changed, the volume changes by a certain value. Strictly speaking, the

change only applies to the testing volume.

Auxiliary equipment

• Supplied adjustment tool (order no. 3120 633.006)

• Supplied red adjustment seal (ADJ)

Example

You readjust a 10 -100 L pipette with a volume setting of 100 L by 1 L (1 L 1%). If the

Maintenance

volume setting is 10 L, the pipette is also adjusted by 1 L ( 10%).

1. Remove the gray adjustment seal.

2. Keep the ejector pressed.

3. Insert the adjustment tool (from the delivery package).

4. Turn the adjustment tool until the adjustment display shows the desired value.

5. Place the Research plus on a horizontal surface

(table). When completing the adjustment, look

absolutely vertically at the window and read the set

value via the backsight in the viewing window.

6. Carry out weighings to verify accuracy and precision.

7. After the tests, close the opening with the red adjustment seal (from the delivery package).

If the adjustment is meant for a specific liquid, mark the pipette accordingly. Use the labeling area

on the pipette for this purpose and write down the liquid and the volume. Carry out a gravimetric

test for each adjustment change. Follow the test procedures of EN ISO 8655-2 and 8655-6. A

SOP (Standard Operation Procedure) and further information on user and factory adjustment

settings can be found on the Research plus CD and on our website www.eppendorf.com

24

.

Page 25

Eppendorf Research® plus — Operating manual

5 Maintenance

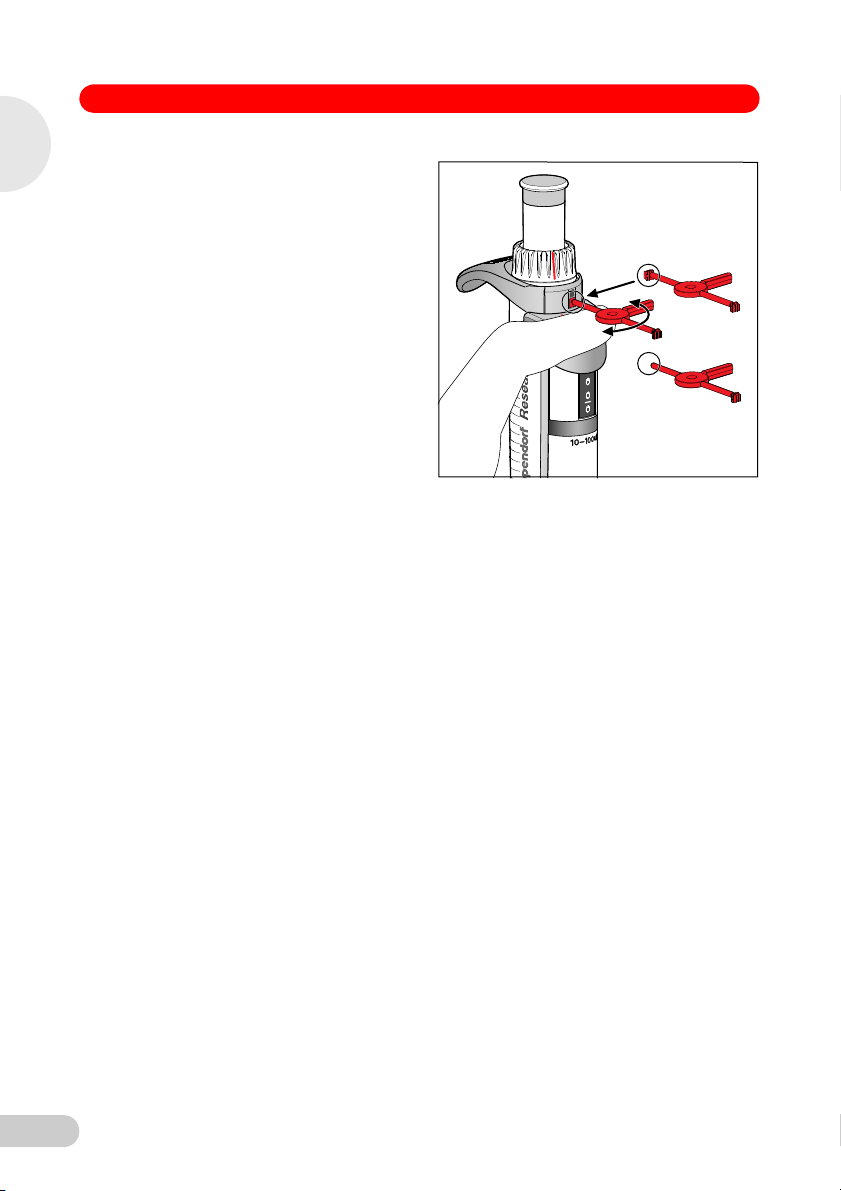

5.5.3 Changing the factory adjustment

Auxiliary equipment

• Supplied safety plug tool

• Supplied pin to loosen the safety plug

It is possible to change the factory adjustment with the

corresponding accessories for a Research plus with variable

volume setting. If the factory adjustment of the Research plus has

been changed by a user, this can be recognized by a red safety

plug behind the ejector. If the Research plus has been adjusted and

calibrated by Eppendorf AG, this is indicated by a gray safety plug.

The systematic and random errors recorded on delivery can be found in a "Certificate of

Conformity". This certificate is included in the delivery. Changes to the factory adjustment will

render the certificate void.

If the dispensing accuracy is only be to changed temporarily, the correct method is to change the

user adjustment. Before changing the user or factory adjustment, observe the general notes

(see General notes on user and factory adjustment settings on p. 22) and the associated

gravimetric tests.

In the case of Research plus fixed-volume pipettes, modifications are only possible by

Hint!

changing the user adjustment (see Changing the user adjustment on p. 24).

5.5.4 Research plus variable - changing the factory adjustment

If a gravimetric test indicates that an error needs to be corrected and you are required to carry out

a change to the factory adjustment, proceed as follows:

1. Check whether the adjustment display on

the side is set to "0".

If the adjustment display is not set to "0",

you will first need to set it to "0" with the

adjustment tool. In this case, instead of

continuing with the factory adjustment

changes, carry out a gravimetric test of the

Research plus with the adjustment display

set to "0".

5

Maintenance

25

Page 26

Eppendorf Research® plus — Operating manual

5 Maintenance

5

2. Mark the volume setting ring and the ejector

with a common mark with a pen. This mark

serves as an orientation for factory

adjustment changes. When changing the

factory adjustment, you can turn the volume

setting ring, without the volume display

changing. The mark on the volume setting

ring and the ejector informs you how far you

Maintenance

have moved from the factory setting.

3. Keep the ejector pressed and remove the

safety plug with the pin.

26

Page 27

Eppendorf Research® plus — Operating manual

5 Maintenance

4. Continue to keep the ejector pressed. Insert

the safety plug tool such that the counter

locking mechanism is pushed down.

5. Turn the volume setting ring slightly to change the volume. Proceed as shown in the figure.

5

Maintenance

27

Page 28

Eppendorf Research® plus — Operating manual

5 Maintenance

5

Maintenance

This results in the following approximate volume changes:

Single-channel

Nominal volume

Color code

2.5 L

dark gray

10 L

medium gray

20 L

light gray

20 L

yellow

100 L

yellow

200 L

yellow

300 L

orange

1 000 L

blue

5 mL

purple

10 mL

turquoise

+½ revolution +¼ revolution –¼ revolution –½ revolution

0.106 l 0.053 l –0.053 L –0.106 L

0.53 l 0.27 l –0.27 L –0.53 L

1.06 l 0.53 l –0.53 L –1.06 L

1.07 l 0.54 l –0.54 L –1.07 L

5.4 l2.7 l –2.7 L –5.4 L

10.8 l5.4 l –5.4 L –10.8 L

10.7 l5.4 l –5.4 L –10.7 L

L 27 L –27 L –54 L

54

271 L 135 L –135 L –271 L

542 L 271 L –271 L –542 L

28

Page 29

5 Maintenance

Multi-channel

Nominal volume

Color code

10 L

medium gray

Eppendorf Research® plus — Operating manual

5

+½ revolution +¼ revolution –¼ revolution –½ revolution

Maintenance

0.53 l 0.27 l –0.27 L –0.53 L

100 L

yellow

300 L

orange

The values mentioned are theoretical values and are for orientation purposes only. The

volume changes mentioned apply to each volume setting. For the volume change, you

should first set the optimal value for 10% of the nominal volume and then carry out a

gravimetric test. Afterwards carry out gravimetric tests to check 50% and 100% of the

nominal volume with this setting. Change the selected setting again if necessary to achieve

the best possible correction for all volumes. Use the error limits in accordance with ISO

8655-2 (see p. 31) and the technical data provided by Eppendorf AG (see p. 35) to decide

whether the data obtained meets your requirements.

6. Slide the locking mechanism up and carry

out a gravimetric test of the changes which

have been made.

5.4 l2.7 l –2.7 L –5.4 L

10.7 l5.4 l –5.4 L –10.7 L

7. If the measured gravimetric values meet your requirements: Slide the locking mechanism up.

29

Page 30

Eppendorf Research® plus — Operating manual

5 Maintenance

5

8. Insert the red safety plug on the tool into the

opening of the Research plus and break it

off from the tool.

The red safety plug on the pipette indicates

that the Research plus has been adjusted

by the user. If the adjustment display had

also been set to "0" before, you must close

the opening with a new, red adjustment seal

Maintenance

at the position for the adjustment seal.

9. Document the changes made and the measurements conducted. Remove the mark on the

volume setting ring and the ejector. The red safety plug on the pipette indicates that the

Research plus has been adjusted and calibrated by the user.

30

Page 31

Eppendorf Research® plus — Operating manual

5 Maintenance

5.5.5 Error limits in accordance with ISO 8655-2

Error limits in accordance with ISO 8655-2 - Research plus variable single-channel

Model Test tip

epT.I.P.S. Color

code

Volume range

Length

0.1 - 2.5 L

Increment:

0.002 L

0.5 - 10 L

Increment:

0.01 L

2 - 20 L

Increment:

0.02 L

2 - 20 L

Increment:

0.02 L

10 - 100 L

Increment:

0.01 L

20 - 200 L

Increment:

0.02 L

dark gray

0.1 - 10 L

34 mm

medium gray

0.1 - 20 L

40 mm

light gray

0.5 - 20 L L

46 mm

yellow

2 - 200 L

53 mm

yellow

2 - 200 L

53 mm

yellow

2 - 200 L

53 mm

Testing

volume

Systematic Random

± % ± μL± % ± μL

0.1 L ± 100.0 ± 0.1 ± 75.0 ± 0.075

0.25 L ± 50.0 ± 0.125 ± 30.0 ± 0.075

1.25 L ± 10.0 ± 0.125 ± 6.0 ± 0.075

2.5 L ± 5.0 ± 0.125 ± 3.0 ± 0.075

0.5 L ± 24.0 ± 0.12 ± 16.0 ± 0.08

1 L ± 12.0 ± 0.12 ± 8.0 ± 0.08

5 L ± 2.4 ± 0.12 ± 1.6 ± 0.08

10 L ± 1.2 ± 0.12 ± 0.8 ± 0.08

2 L ± 10.0 ± 0.2 ± 5.0 ± 0.1

10 L ± 2.0 ± 0.2 ± 1.0 ± 0.1

20 L ± 1.0 ± 0.2 ± 0.5 ± 0.1

2 L ± 10.0 ± 0.2 ± 5.0 ± 0.1

10 L ± 2.0 ± 0.2 ± 1.0 ± 0.1

20 L ± 1.0 ± 0.2 ± 0.5 ± 0.1

10 L ± 8.0 ± 0.8 ± 3.0 ± 0.3

50 L ± 2.0 ± 0.8 ± 0.6 ± 0.3

100 L ± 0.8 ± 0.8 ± 0.3 ± 0.3

20 L ± 8.0 ± 1.6 ± 3.0 ± 0.6

100 L ± 2.0 ± 1.6 ± 0.6 ± 0.6

200 L ± 0.8 ± 1.6 ± 0.3 ± 0.6

Error limits

Error

5

Maintenance

31

Page 32

Eppendorf Research® plus — Operating manual

5 Maintenance

5

Maintenance

Error limits in accordance with ISO 8655-2 - Research plus variable single-channel

Model Test tip

epT.I.P.S. Color

code

Volume range

Length

30 - 300 L

Increment:

0.02 L

100 - 1 000 L

Increment:

1 L

0.5 - 5 mL

Increment:

5 L

1 - 10 mL

Increment:

10 L

orange

20 - 300 L

55 mm

blue

50 - 1 000 L

71 mm

purple

0.1 - 5 mL

120 mm

turquoise

1 – 10 ml

165 mm

Testing

volume

Systematic Random

± % ± μL± % ± μL

30 L ± 13.0 ± 3.9 ± 5.0 ± 1.5

150 L ± 3.0 ± 3.9 ± 1.0 ± 1.5

300 L ± 1.3 ± 3.9 ± 0.5 ± 1.5

100 L ± 8.0 ± 8.0 ± 3.0 ± 3.0

500 L ± 2.0 ± 8.0 ± 0.6 ± 3.0

1 000 L ± 0.8 ± 8.0 ± 0.3 ± 3.0

0.5 mL ± 8.0 ± 40.0 ± 3.0 ± 15.0

2.5 mL ± 1.6 ± 40.0 ± 0.6 ± 15.0

5.0 mL ± 0.8 ± 40.0 ± 0.3 ± 15.0

1.0 mL ± 6.0 ± 60.0 ± 3.0 ± 30.0

5.0 mL ± 1.2 ± 60.0 ± 0.6 ± 30.0

10.0 mL ± 0.6 ± 60.0 ± 0.3 ± 30.0

Error limits

Error

32

Page 33

Eppendorf Research® plus — Operating manual

5 Maintenance

Error limits in accordance with ISO 8655-2 - Research plus variable multi-channel

Model Test tip

epT.I.P.S. Color

code

Volume range

Length

0.5 - 10 L

Increment:

0.01 L

medium gray

0.1 - 20 L

40 mm

Testing

volume

Systematic Random

± % ± μL± % ± μL

0.5 L ± 48.0 ± 0.24 ± 32.0 ± 0.16

1 L ± 24.0 ± 0.24 ± 16.0 ± 0.16

5 L ± 4.8 ± 0.24 ± 3.2 ± 0.16

10 L ± 2.4 ± 0.24 ± 1.6 ± 0.16

Error limits

Error

5

Maintenance

10 - 100 L

Increment:

0.01 L

30 - 300 L

Increment:

0.02 L

yellow

2 - 200 L

53 mm

orange

20 - 300 L

55 mm

10 L ± 16.0 ± 1.6 ± 6.0 ± 0.6

50 L ± 3.2 ± 1.6 ± 1.2 ± 0.6

100 L ± 1.6 ± 1.6 ± 0.6 ± 0.6

30 L ± 26.0 ± 7.8 ± 10.0 ± 3.0

150 L ± 5.2 ± 7.8 ± 2.0 ± 3.0

300 L ± 2.6 ± 7.8 ± 1.0 ± 3.0

33

Page 34

Eppendorf Research® plus — Operating manual

5 Maintenance

5

5.6 Decontamination before shipment

If you wish to return the pipette to Eppendorf AG or an Eppendorf AG service partner to be

checked or repaired, please note the following:

CAUTION! Use of a contaminated device may result in personal injuries and

damage to the device.

CAUTION!

Clean and decontaminate the Research plus before shipping or storage according

Maintenance

to the cleaning instructions.

Read the instructions regarding the decontamination certificate included on the

Research plus CD or visit (www.eppendorf.com/decontamination

Enter the serial number of the Research plus in the decontamination certificate.

This can be found at the lower end of the entry field.

Enclose the fully-completed decontamination certificate for returned goods with the

Research plus.

Hazardous substances are:

• solutions presenting a hazard to health

• potentially infectious agents

• organic solvents and reagents

• radioactive substances

• proteins presenting a hazard to health

• DNA

1. Please note the information in the document "Decontamination certificate for product

returns". You can find it as a PDF file on our homepage www.eppendorf.com

2. Enter the serial number of the Research plus in the decontamination certificate.

This can be found at the lower end of the entry field.

3. With the shipment please include the completed and signed "Decontamination certificate for

product returns" for each pipette.

).

.

34

Page 35

Eppendorf Research® plus — Operating manual

6 Technical data

6 Technical data

6.1 Research plus single-channel variable

Research plus variable single-channel

Model Test tip

epT.I.P.S. Color

code

Volume range

Length

0.1 - 2.5 L

Increment:

0.002 L

0.5 - 10 L

Increment:

0.01 L

dark gray

0.1 - 10 L

34 mm

medium gray

0.1 - 20 L

40 mm

Testing

volume

0.1 L ± 48 ± 0.048 ± 12 ± 0.012

0.25 L ± 12 ± 0.03 ± 6 ± 0.015

1.25 L ± 2.5 ± 0.031 ± 1.5 ± 0.019

2.5 L ± 1.4 ± 0.035 ± 0.7 ± 0.018

0.5 L ± 8 ± 0.04 ± 5 ± 0.025

1 L ± 2.5 ± 0.025 ± 1.8 ± 0.018

5 L ± 1.5 ± 0.075 ± 0.8 ± 0.04

10 L ± 1.0 ± 0.1 ± 0.4 ± 0.04

Error limits

Error

Systematic Random

± % ± μL± % ± μL

6

Technical data

2 - 20 L

Increment:

0.02 L

2 - 20 L

Increment:

0.02 L

10 - 100 L

Increment:

0.1 L

20 - 200 L

Increment:

0.2 L

light gray

0.5 - 20 L L

46 mm

yellow

2 - 200 L

53 mm

yellow

2 - 200 L

53 mm

yellow

2 - 200 L

53 mm

2 L ± 5 ± 0.1 ± 1.5 ± 0.03

10 L ± 1.2 ± 0.12 ± 0.6 ± 0.06

20 L ± 1.0 ± 0.2 ± 0.3 ± 0.06

2 L ± 5 ± 0.1 ± 1.5 ± 0.03

10 L ± 1.2 ± 0.12 ± 0.6 ± 0.06

20 L ± 1.0 ± 0.2 ± 0.3 ± 0.06

10 L ± 3 ± 0.3 ± 1 ± 0.1

50 L ± 1 ± 0.5 ± 0.3 ± 0.15

100 L ± 0.8 ± 0.8 ± 0.2 ± 0.2

20 L ± 2.5 ± 0.5 ± 0.7 ± 0.14

100 L ± 1 ± 1 ± 0.3 ± 0.3

200 L ± 0.6 ± 1.2 ± 0.2 ± 0.4

35

Page 36

6 Technical data

Research plus variable single-channel

Model Test tip

6

30 - 300 L

Increment:

0.2 L

100 - 1 000 L

Technical data

Increment:

1 L

0.5 - 5 mL

Increment:

0.005 mL

1 - 10 mL

Increment:

0.01 mL

Eppendorf Research® plus — Operating manual

epT.I.P.S. Color

code

Volume range

Length

orange

20 - 300 L

55 mm

blue

50 - 1 000 L

71 mm

purple

0.1 - 5 mL

120 mm

turquoise

1 – 10 ml

165 mm

Testing

volume

Systematic Random

± % ± μL± % ± μL

30 L ± 2.5 ± 0.75 ± 0.7 ± 0.21

150 L ± 1 ± 1.5 ± 0.3 ± 0.45

300 L ± 0.6 ± 1.8 ± 0.2 ± 0.6

100 L ± 3 ± 3 ± 0.6 ± 0.6

500 L ± 1 ± 5 ± 0.2 ± 1

1 000 L ± 0.6 ± 6 ± 0.2 ± 2

0.5 mL ± 2.4 ± 12 ± 0.6 ± 3

2.5 mL ± 1.2 ± 30 ± 0.25 ± 6

5.0 mL ± 0.6 ± 30 ± 0.15 ± 8

1.0 mL ± 3 ± 30 ± 0.6 ± 6

5.0 mL ± 0.8 ± 40 ± 0.2 ± 10

10.0 mL ± 0.6 ± 60 ± 0.15 ± 15

Error limits

Error

36

Page 37

Eppendorf Research® plus — Operating manual

6 Technical data

6.2 Research plus multi-channel variable

Research plus variable multi-channel

Model Test tip

epT.I.P.S. Color

code

Volume range

Length

0.5 – 10 L

Increment:

0.01 L

10 – 100 L

Increment:

0.1 L

30 – 300 L

Increment:

0.2 L

medium gray

0.1 - 20 L

40 mm

yellow

2 - 200 L

53 mm

orange

20 - 300 L

55 mm

Testing

volume

0.5 L ± 12 ± 0.06 ± 8.0 ± 0.04

1 L ± 8.0 ± 0.08 ± 5.0 ± 0.05

5 L ± 4.0 ± 0.2 ± 2.0 ± 0.1

10 L ± 2.0 ± 0.2 ± 1.0 ± 0.1

10 L ± 3.0 ± 0.3 ± 2.0 ± 0.2

50 L ± 1.0 ± 0.5 ± 0.8 ± 0.4

100 L ± 0.8 ± 0.8 ± 0.3 ± 0.3

30 L ± 3.0 ± 0.9 ± 1.0 ± 0.3

150 L ± 1.0 ± 1.5 ± 0.5 ± 0.75

300 L ± 0.6 ± 1.8 ± 0.3 ± 0.9

Error limits

Error

Systematic Random

± % ± μL± % ± μL

6

Technical data

37

Page 38

6 Technical data

6.3 Research plus fix

Research plus fixed volume

6

Model Test tip

10 L medium gray

Technical data

20 L light gray

10 Lyellow

20 L ± 1.0 ± 0.2 ± 0.3 ± 0.06

25 L ± 1.0 ± 0.25 ± 0.3 ± 0.08

50 L ± 0.7 ± 0.35 ± 0.3 ± 0.15

100 L ± 0.6 ± 0.6 ± 0.2 ± 0.2

Eppendorf Research® plus — Operating manual

Error limits

epT.I.P.S. Color

code

Volume range

Length

0.1 - 20 L

40 mm

0.5 - 20 L L

46 mm

2 - 200 L

53 mm

Systematic Random

± % ± μL± % ± μL

± 1.2 ± 0.12 ± 0.6 ± 0.06

± 0.8 ± 0.16 ± 0.3 ± 0.06

± 1.2 ± 0.12 ± 0.6 ± 0.06

Error

200 L ± 0.6 ± 1.2 ± 0.2 ± 0.4

200 Lblue

250 L ± 0.6 ± 1.5 ± 0.2 ± 0.5

500 L ± 0.6 ± 3 ± 0.2 ± 1

1 000 L ± 0.6 ± 6 ± 0.2 ± 2

Test conditions according to ISO 8655-1, 8655-2 and 8655-6 for piston-stroke pipettes with air

cushion by means of a fine balance with evaporation protection, tested by the German gauging

office.

Number of determinations: 10; water according to ISO 3696; 20°C to 25°C ±0.5°C constant;

with pre-wetted pipette tip; dispensing against the tube wall.

38

50 - 1 000 L

71 mm

± 0.6 ± 1.2 ± 0.2 ± 0.4

Page 39

Eppendorf Research® plus — Operating manual

6 Technical data

6.4 Ambient conditions

Temperature range Relative humidity

Storage without transport packaging –5 to 45°C 10 to 95%

Operating conditions 5 to 40°C 10 to 95%

6

Technical specifications subject to change.

Technical data

39

Page 40

7 Ordering information

7 Ordering information

Hint!

7

Ordering information

Eppendorf Research® plus — Operating manual

The ordering information can be found on the Research plus CD.

40

Page 41

Eppendorf offices

Eppendorf offices

AUSTRALIA & NEW ZEALAND

Eppendorf South Pacific Pty. Ltd.

Phone: +61 2 9889 5000

Fax: +61 2 9889 5111

E-mail: Info@eppendorf.com.au

Internet: www.eppendorf.com.au

CANADA

Eppendorf Canada Ltd.

Phone: +1 905 826 5525

Fax: +1 905 826 5424

E-mail: canada@eppendorf.com

Internet: www.eppendorfna.com

FRANCE

Eppendorf France S.A.R.L.

Phone: +33 1 30 15 67 40

Fax: +33 1 30 15 67 45

E-mail: eppendorf@eppendorf.fr

Internet: www.eppendorf.fr

ITALY

Eppendorf s.r.l.

Phone: +390 2 55 404 1

Fax: +390 2 58 013 438

E-mail: eppendorf@eppendorf.it

Internet: www.eppendorf.it

AUSTRIA

Eppendorf Austria GmbH

Phone: +43 (0) 1 890 13 64 - 0

Fax: +43 (0) 1 890 13 64 - 20

E-mail: office@eppendorf.at

Internet: www.eppendorf.at

CHINA

Eppendorf China Ltd.

Phone: +86 21 38560500

Fax: +86 21 38560555

E-mail: market.info@eppendorf.cn

Internet: www.eppendorf.cn

GERMANY

Eppendorf Vertrieb

Deutschland GmbH

Phone: +49 2232 418-0

Fax: +49 2232 418-155

E-mail: vertrieb@eppendorf.de

Internet: www.eppendorf.de

JAPAN

Eppendorf Co. Ltd.

Phone: +81 3 5825 2363

Fax: +81 3 5825 2365

E-mail: info@eppendorf.jp

Internet: www.eppendorf.jp

BRAZIL

Eppendorf do Brasil Ltda.

Phone: +55 11 30 95 93 44

Fax: +55 11 30 95 93 40

E-mail:

eppendorf@eppendorf.com.br

Internet: www.eppendorf.com.br

CZECH REP. & SLOVAKIA

Eppendorf Czech & Slovakia s.r.o.

Phone: +420 323 605 454

Fax: +420 323 605 454

E-mail: eppendorf@eppendorf.cz

Internet: www.eppendorf.cz /

www.eppendorf.sk

INDIA

Eppendorf India Limited

Phone: +91 44 42 11 13 14

Fax: +91 44 42 18 74 05

E-mail: info@eppendorf.co.in

Internet: www.eppendorf.co.in

NORDIC

Eppendorf Nordic Aps

Phone: +45 70 22 2970

Fax: +45 45 76 7370

E-mail: nordic@eppendorf.dk

Internet: www.eppendorf.dk

SOUTH & SOUTHEAST ASIA

Eppendorf Asia Pacific Sdn. Bhd.

Phone: +60 3 8023 2769

Fax: +60 3 8023 3720

E-mail:

eppendorf@eppendorf.com.my

Internet: www.eppendorf.com.my

UNITED KINGDOM

Eppendorf UK Limited

Phone: +44 1223 200 440

Fax: +44 1223 200 441

E-mail: sales@eppendorf.co.uk

Internet: www.eppendorf.co.uk

SPAIN

Eppendorf Ibérica S.L.U.

Phone: +34 91 651 76 94

Fax: +34 91 651 81 44

E-mail: iberica@eppendorf.es

Internet: www.eppendorf.es

USA

Eppendorf North America, Inc.

Phone: +1 516 334 7500

Fax: +1 516 334 7506

E-mail: info@eppendorf.com

Internet: www.eppendorfna.com

SWITZERLAND

Vaudaux-Eppendorf AG

Phone: +41 61 482 1414

Fax: +41 61 482 1419

E-mail: vaudaux@vaudaux.ch

Internet: www.eppendorf.ch

OTHER COUNTRIES

Internet: www.eppendorf.com/

worldwide

Page 42

Your local distributor: www.eppendorf.com/worldwide

Eppendorf AG · 22331 Hamburg · Germany · Tel: +49 40 538 01-0 · Fax: +49 40 538 01-556

Eppendorf North America, Inc. · 102 Motor Parkway, Suite 410 · Hauppauge, NY 11788-5178 · USA

Tel: +1 516 334 7500 · Toll free phone: +1 800 645 3050 · Fax: +1 516 334 7506 · E-Mail: info@eppendorf.com

Europe, International: Tel: +49 1803 666 789 · E-Mail: support@eppendorf.com

North America: Tel: +1 800 645 3050 ext. 2258 · E-Mail: techserv@eppendorf.com

Asia Pacific: Tel: +60 3 8023 6869 · E-Mail: support_asiapacific@eppendorf.com

E-Mail: eppendorf@eppendorf.com

Application Support

Loading...

Loading...