Page 1

Register your instrument!

www.eppendorf.com/myeppendorf

InjectMan

Operating manual

®

4

Page 2

Copyright© 2013 Eppendorf AG, Hamburg.

Eppendorf

®

and the Eppendorf logo are registered trademarks of Eppendorf AG,

Hamburg, Germany.

InjectMan

®

4, FemtoJet® and Eppendorf PiezoXpert® are registered trademarks of

Eppendorf AG, Hamburg, Germany.

Registered trademarks are not marked in all cases with ™ or ® in this manual.

No part of this publication may be reproduced without the prior permission of the

copyright owner.

5192 900.010-00/072013

Page 3

Table of contents

InjectMan

®

English (EN)

Operating manualInjectMan® 4seeon p.Fig.Tab.p.

English (EN)Operating manual

Table of contents

1 Operating instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.1 Using this manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.2 Danger symbols and danger levels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.2.1 Danger symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.2.2 Danger levels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.3 Symbols used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2 Product description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.1 Delivery package . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.1.1 Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.1.2 Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.2 Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.3 Main illustration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.3.1 Motor module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.3.2 Control board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.4 Control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.5 Joystick . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.5.1 Dynamic range. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.5.2 Direction of movement of the joystick. . . . . . . . . . . . . . . . . . . . . . 16

2.5.3 Joystick key functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.6 Speed ranges. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4

3

3 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3.1 Intended use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3.2 Warnings for intended use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3.3 Warning signs on the device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.4 Information on product liability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.1 Preparing installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.1.1 If there is any damage, make a claim . . . . . . . . . . . . . . . . . . . . . . 20

4.1.2 Delivery incomplete . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.1.3 Microscope adapter assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.2 Selecting the location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.3 Mounting overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.3.1 Module (X, Y, Z). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

4.3.2 Z-module holder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4.3.3 Slider . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4.3.4 Angle head. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4.3.5 Swivel joint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Page 4

Table o f co nte nts

InjectMan

4

®

4

English (EN)

4.4 Mounting the motor module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.4.1 Mounting the Z-module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4.4.2 Mounting the Y-module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4.4.3 Mounting the X-module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

4.4.4 Mounting the angle head . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

4.5 Inserting the capillary holder into the angle head . . . . . . . . . . . . . . . . . . . . 28

4.6 Inserting the capillary into the capillary holder . . . . . . . . . . . . . . . . . . . . . . 29

4.6.1 Inserting Femtotips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

4.7 Setting the injection angle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

4.8 Aligning the motor module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

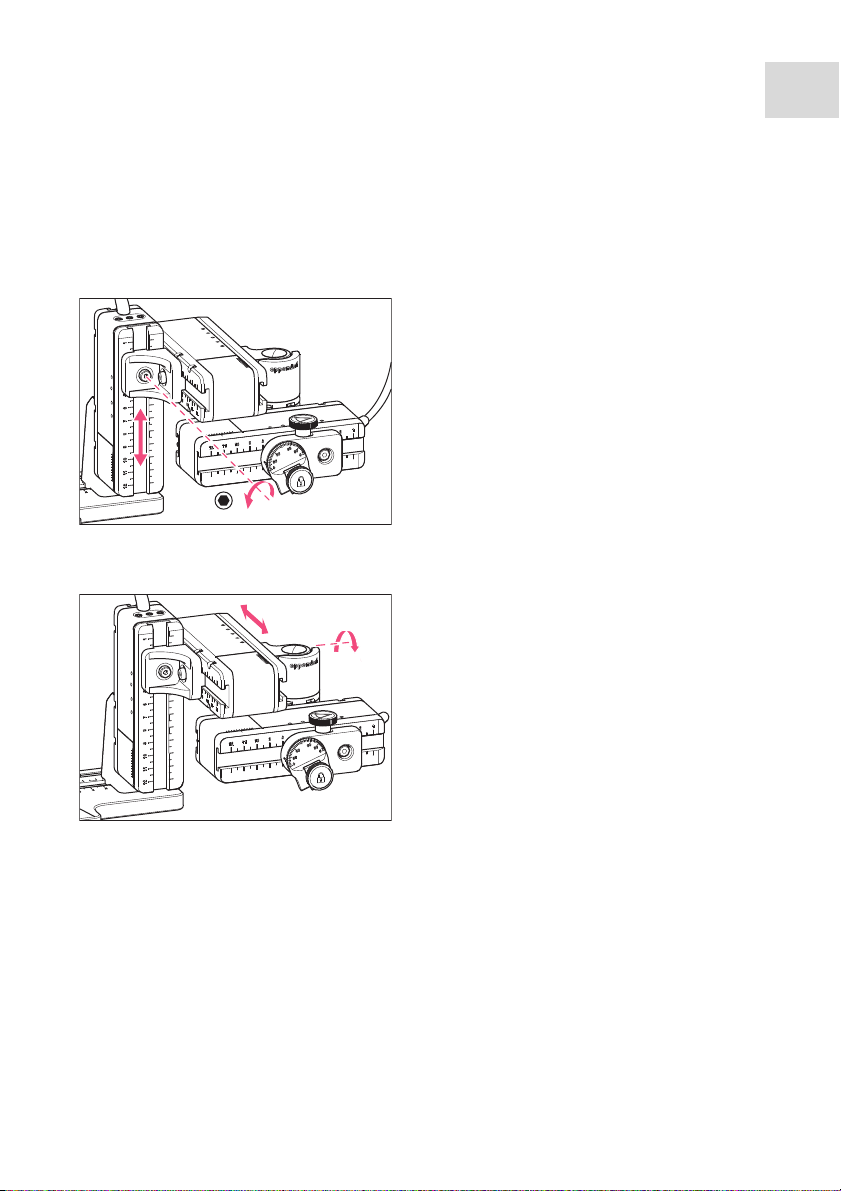

4.8.1 Aligning the height . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4.8.2 Aligning the depth . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4.8.3 Aligning the width . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

4.8.4 Aligning the angle head. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

4.9 Entering mounting parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

4.9.1 Microscope and adapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

4.9.2 Motor module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

4.9.3 Angle head. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

4.10 Converting the swivel joint for left side mounting . . . . . . . . . . . . . . . . . . . . 34

4.11 Converting the angle head for left side mounting . . . . . . . . . . . . . . . . . . . . 37

4.12 Connect the motor module to the control board. . . . . . . . . . . . . . . . . . . . . . 38

4.13 Setting installation parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

4.13.1 First set-up wizard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

4.14 Connecting an external device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

4.14.1 Connecting the FemtoJet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

4.14.2 Connecting the PiezoXpert . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

4.14.3 Connecting the Computer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

4.14.4 Connecting two devices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

5 Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

5.1 Display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

5.1.1 Application display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

5.1.2 Display of coordinates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

5.1.3 Menu display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

5.2 Applications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

5.2.1 Application parameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

5.2.2 Application – Adherent cell injection . . . . . . . . . . . . . . . . . . . . . . 48

5.2.3 Application – ICSI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

5.2.4 Application – Developmental biology . . . . . . . . . . . . . . . . . . . . . . 49

5.2.5 Application – Physiology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

5.2.6 Application – My application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

5.3 Main menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

5.4 Navigating the menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

5.4.1 Entering or changing parameters . . . . . . . . . . . . . . . . . . . . . . . . . 52

Page 5

Table of contents

InjectMan

®

English (EN)

6 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

6.1 Switching the device on or off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

6.1.1 Switching on the device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

6.1.2 Switching the device off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

6.2 Activating or deactivating the control board. . . . . . . . . . . . . . . . . . . . . . . . . 53

6.2.1 Activating the control board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

6.2.2 Deactivating the control board . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

6.3 Defining the start screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

6.3.1 Defining the application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

6.3.2 Defining the selected application . . . . . . . . . . . . . . . . . . . . . . . . . 54

6.4 Replacing the capillary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

6.4.1 Manually positioning the capillary . . . . . . . . . . . . . . . . . . . . . . . . 55

6.4.2 Automatically positioning the capillary . . . . . . . . . . . . . . . . . . . . . 55

6.5 Changing the sample . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

6.6 Changing the speed range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

6.6.1 Changing parameters using the selection dial . . . . . . . . . . . . . . . 56

6.6.2 Changing parameters in the menu . . . . . . . . . . . . . . . . . . . . . . . . 57

6.7 Capillary positions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

6.7.1 Saving a position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

6.7.2 Moving to the position using the softkey . . . . . . . . . . . . . . . . . . . 58

6.7.3 Moving to the position using the joystick key . . . . . . . . . . . . . . . . 58

6.7.4 Deleting a stored position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

6.7.5 Overwriting a stored position . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

6.8 Vertical limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

6.8.1 Defining the lower limit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

6.8.2 Deleting the lower limit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

6.8.3 Defining the upper limit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

6.8.4 Deleting the upper limit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

6.9 Horizontal limit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

6.9.1 Defining the horizontal limit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

6.9.2 Deleting the horizontal limit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

6.10 Speed function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

6.10.1 Speed menu and parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

6.10.2 Setting the parameters for Speed . . . . . . . . . . . . . . . . . . . . . . . . . 62

6.11 Inject function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

6.11.1 Inject menu and parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

6.11.2 Executing the Inject function . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

6.12 Step injection function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

6.12.1 Step injection menu and parameters. . . . . . . . . . . . . . . . . . . . . . . 65

6.12.2 Executing the Step injection function . . . . . . . . . . . . . . . . . . . . . . 66

4

5

Page 6

Table o f co nte nts

InjectMan

6

®

4

English (EN)

6.13 Home function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

6.13.1 Home menu and parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

6.13.2 Setting the parameter for Home . . . . . . . . . . . . . . . . . . . . . . . . . . 66

6.13.3 Move the capillary out with the home key . . . . . . . . . . . . . . . . . . 67

6.13.4 Move the capillary back with the home key . . . . . . . . . . . . . . . . . 67

6.13.5 Setting the offset. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

6.13.6 Terminate the home function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

6.14 Clean function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

6.14.1 Clean menu and parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

6.14.2 Setting the parameter for Clean . . . . . . . . . . . . . . . . . . . . . . . . . . 69

6.14.3 Execute the Clean function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

6.14.4 Terminate the Clean function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

6.15 PiezoXpert function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

6.15.1 PiezoXpert menu and parameters . . . . . . . . . . . . . . . . . . . . . . . . . 70

6.15.2 Execute the PiezoXpert function . . . . . . . . . . . . . . . . . . . . . . . . . . 71

6.16 Installation function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

6.16.1 Installation menu and parameters . . . . . . . . . . . . . . . . . . . . . . . . . 71

6.16.2 Installation parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

6.16.3 Control board parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

6.16.4 Module parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

6.17 Function function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

6.17.1 Function menu and parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . 72

6.17.2 Executing Zero coordin. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

6.17.3 Executing Center motors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

6.17.4 Executing User default . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

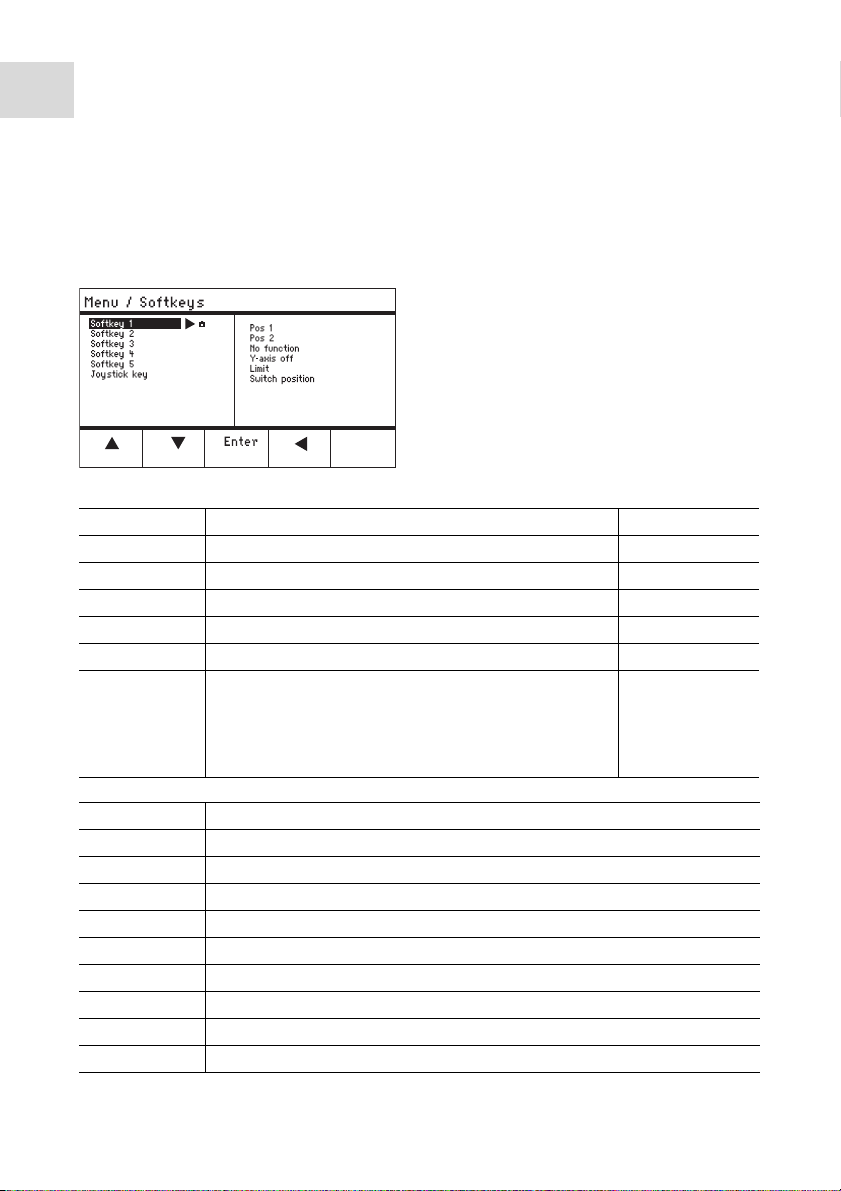

6.18 Softkeys function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

6.18.1 Softkeys menu and parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

6.18.2 Executing Softkeys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

6.18.3 Executing Joystick key. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

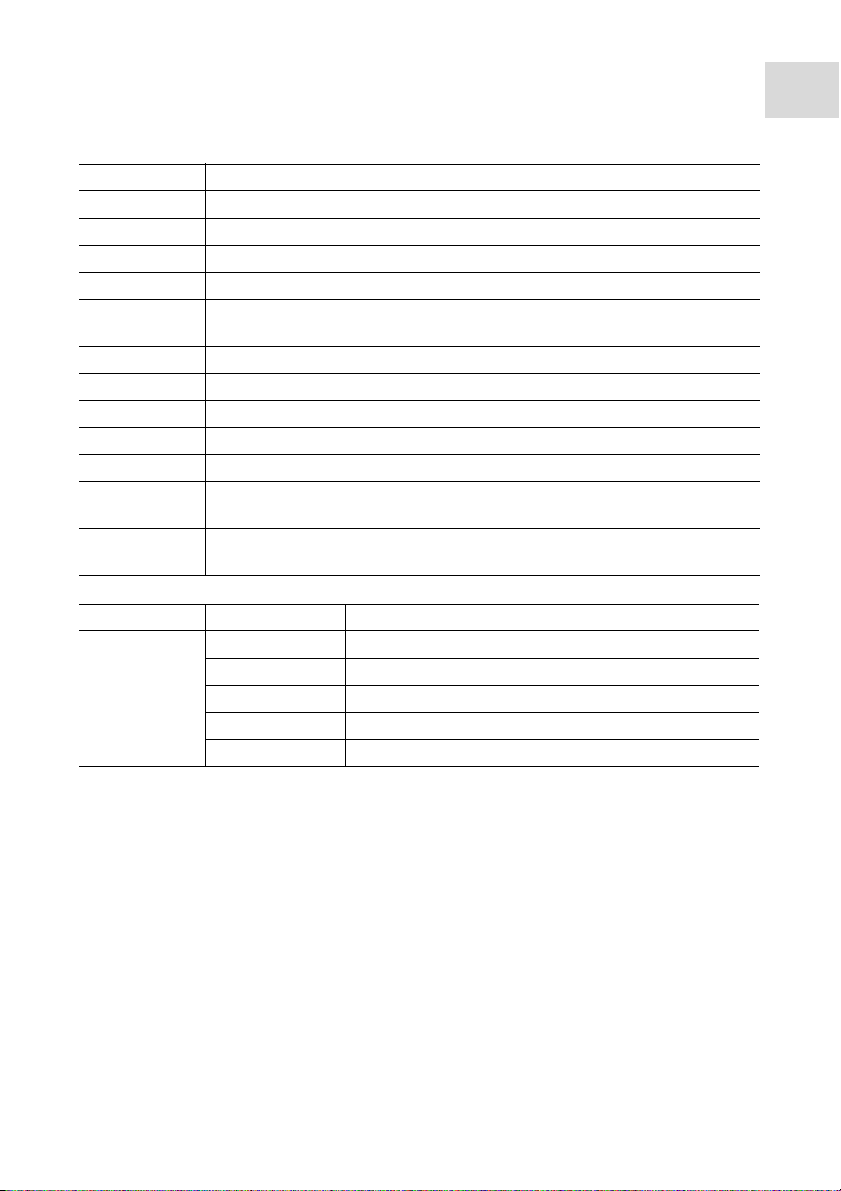

6.19 Change appl. function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

6.19.1 Change appl. menu and parameters . . . . . . . . . . . . . . . . . . . . . . . 76

6.19.2 Defining the selected application as the start screen . . . . . . . . . . 76

6.19.3 Defining the application as the start screen . . . . . . . . . . . . . . . . . 77

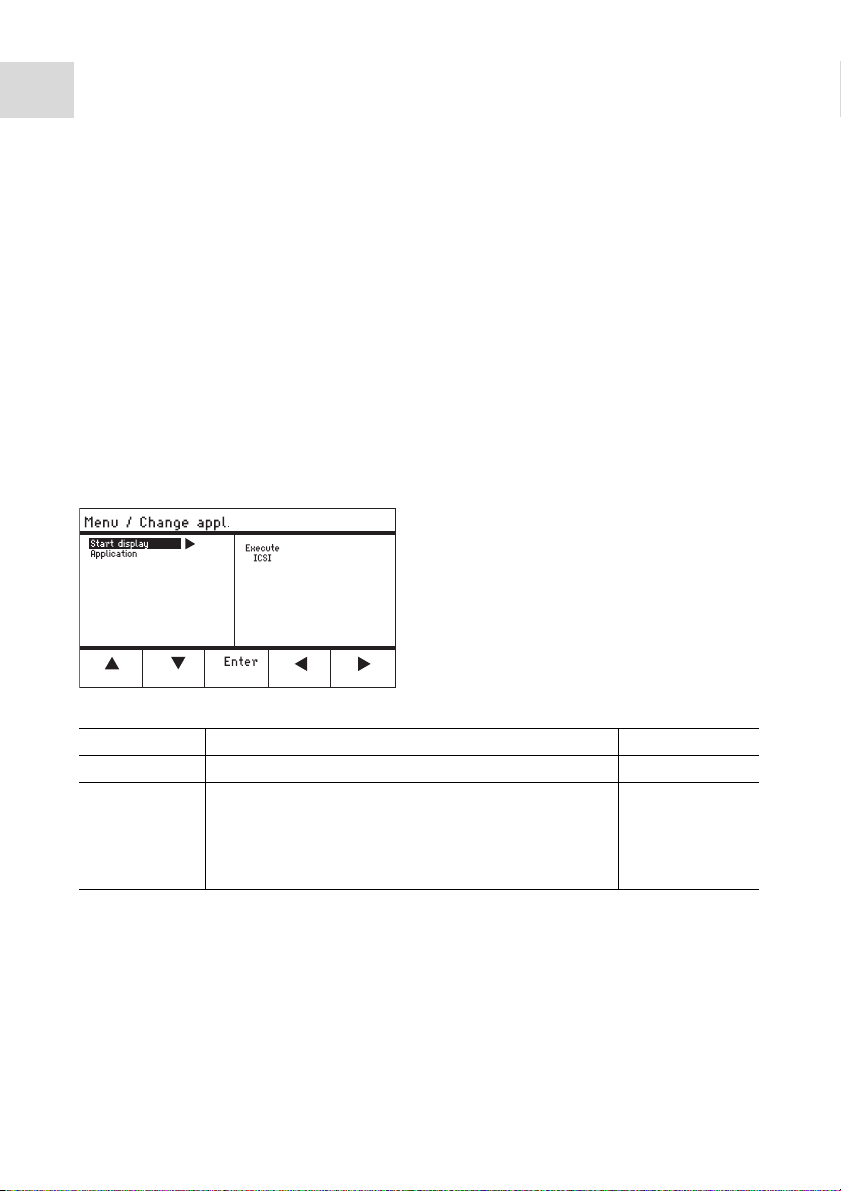

6.20 Service function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

6.20.1 Service menu and parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

6.20.2 Execute the Selftest function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

6.21 Resetting parameters to the factory settings . . . . . . . . . . . . . . . . . . . . . . . . 78

6.21.1 Perform reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

6.21.2 Carrying out a reset in the menu . . . . . . . . . . . . . . . . . . . . . . . . . . 78

6.22 Remote computer control of the InjectMan 4 . . . . . . . . . . . . . . . . . . . . . . . . 78

Page 7

Table of contents

InjectMan

®

English (EN)

7 Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

7.1 General errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

7.1.1 Motor module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

7.1.2 Capillary. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

7.1.3 Control board and display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

7.1.4 Joystick . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

7.1.5 Software and parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

7.2 Error messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

7.2.1 Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

7.2.2 Error. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

8 Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

8.1 Replacing fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

8.2 Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

8.3 Service and maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

8.4 Disinfection/decontamination . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

9 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

9.1 Power supply. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

9.2 Interfaces. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

9.3 Ambient conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

10 Transport, storage and disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

10.1 Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

10.2 Decontamination before shipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

10.3 Transport . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

10.4 Disposal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

4

7

11 Ordering Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

11.1 InjectMan 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

11.2 Accessories for InjectMan 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

11.3 Tools for InjectMan 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

11.4 Microscope adapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

11.5 Accessories for adapters for microscope . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

11.6 Capillaries for research applications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

11.7 Capillaries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

11.8 Universal capillary holder and accessories. . . . . . . . . . . . . . . . . . . . . . . . . . 91

11.9 CellTram and accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

11.10 FemtoJet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

11.11 FemtoJet express. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

11.12 Accessories for FemtoJet/FemtoJet express . . . . . . . . . . . . . . . . . . . . . . . . . 93

11.13 PiezoXpert. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Page 8

Operating instructions

InjectMan

8

English (EN)

®

4

1 Operating instructions

1.1 Using this manual

Read this operating manual completely before using the device for the first time.

Please also note the operating instructions for the accessories, if applicable.

This operating manual is part of the product. Thus, it must always be easily accessible.

Enclose this operating manual when transferring the device to third parties.

If this manual is lost, please request another one. You will find the current version on

our webpage www.eppendorf.com/worldwide

1.2 Danger symbols and danger levels

The safety instructions in this manual appear with the following danger symbols and

danger levels:

1.2.1 Danger symbols

Hazard point Cuts

Material damage Electric shock

Biohazard

.

1.2.2 Danger levels

DANGER Will lead to severe injuries or death.

WAR NIN G Can lead to severe injuries or death.

CAUTION Can lead to light to moderate injuries.

ATTENTION May lead to material damage./Paragraph

1.3 Symbols used

Depiction Meaning

1.

2.

Actions in the specified order

Actions without a specified order

• List:

Text Display or software texts

Additional information

Page 9

Product description

2 Product description

2.1 Delivery package

Quantity Description

1X-module

1Y-module

1Z-module

1 YZ-connector

1 Swivel joint

1 Angle head

1 Control board

1Mains/power cord

1Cable sheathing

1 Operating manual

2.1.1 Tools

Quantity Description

7 1.5 mm, 2 mm, 2.5 mm, 3 mm, 4 mm, 5 mm, 6 mm Allen key

1 3 mm Allen torque key

1 1.3 mm Allen key

1 Tool bag

InjectMan

English (EN)

®

4

9

2.1.2 Accessories

Quantity Description

1 Connecting cable for FemtoJet/FemtoJet express

2 Positioning aids for capillary holders

1 Spare parts kit

1Label

2.2 Features

The micromanipulator InjectMan 4 has been especially developed for work processes that

require intuitive movement of the capillary.

The InjectMan 4 combines the classical benefits of a mechanical system with the benefits

of an accurate electrically driven system.

Page 10

Product description

InjectMan

10

®

4

English (EN)

The capillary is controlled by a joystick. A greater forwards or backwards movement of

the joystick results in an acceleration of the capillary movement. The movement ranges

enable moving to any position in the working range of the micromanipulator.

The dynamic movement of the joystick is especially suitable for serial injections and

working techniques that require fast injection movement.

The software control provides predefined applications, freely programmable softkey

functions, a freely programmable application and the storage of different positions all

space coordinates.

2.3 Main illustration

The motor module is mounted on a special microscope adapter or on a free-standing

stand (magnetic). The control board is mechanically separated from the motor module.

Abb. 2-1:InjectMan 4 — right side mounting

1

Fig. 2-1: InjectMan 4 — right side mounting

1 Motor module 2 Control board

2

Page 11

Product description

InjectMan

®

English (EN)

2.3.1 Motor module

The motor module is made up of three modules. The capillary can be moved in all three

spatial axes due to the layout of the modules. The X-module with the capillary can be

swung out of the working range using the swivel joint. The injection angle of the capillary

can be set to any angle on the angle head.

Abb. 2-2:Motor module

1

4

4

11

2

3

Fig. 2-2: Motor module

1 Z-module

2 YZ-connector

3 Angle head

5

6

4 Y-module

5 Swivel joint

6 X-module

Page 12

Product description

InjectMan

12

®

4

English (EN)

2.3.2 Control board

The control board contains the key pad, the display and the joystick, and, to the side, the

selection dial. The direction of movement and the speed of the joystick are transferred to

the capillary. The responsitivity of the movement and the size of the working range are

predefined in the software setting. On the control panel, the working range can be

selected and modified via the selection dial.

Abb. 2-3:Control board - front

4

Fig. 2-3: Control board - front

1 Joystick

Dynamic movement

2 Display

coarse

2

1

fine

fine

menu

3

home

3 Control panel

4 Selection dial

For increasing or reducing the speed

Page 13

Abb. 2-4:Control board - rear

Product description

InjectMan

®

English (EN)

4

13

8

Fig. 2-4: Control board - rear

1 Mains power switch On/Off

2 Connection for an external device

Foot control, FemtoJet, FemtoJet

express, PiezoXpert or PC

3 Connection for a Y-module

4 Connection for an X-module

ext. Device

Z-Axis

32

Y-Axis

X-Axis

45

1

SERVICE

7

6

5 Connection for a Z-module

6 Service interface

7 Mains/power connection

8 Fuse

Page 14

Product description

InjectMan

14

®

4

English (EN)

2.4 Control panel

With the keys on the control panel you can switch on the control board and select the size

of the working range. The softkeys are used to open applications, execute functions,

navigate the menu and set parameters.

Abb. 2-5:Control panel

7

6

5

Fig. 2-5: Control panel

1 home key

Moves the capillary out of the working

range into a defined position

2 Display

Displays the software

3 standby key

Switches the control board on or off or

cancels automatic movements

4 Softkeys 1 – 5

For selecting the application, triggering

the function, navigating or setting

parameter values

fine

x–fine

menu

homecoarse

4

5 menu key

Opens the menu

6 fine/x-fine key

For setting the medium or low speed

range

7 coarse key

For setting the high speed range

1

2

3

Page 15

Product description

InjectMan

®

English (EN)

2.5 Joystick

The joystick controls the capillary in all three spatial axes. The movement of the capillary

is accelerated the further the joystick is moved forwards or backwards.

Abb. 2-6:Joystick

1

2

Fig. 2-6: Joystick

1 Joystick key 2 Joystick

Controls movements in the X, Y and

Z-axis

2.5.1 Dynamic range

The size of the dynamic range is limited by the movement range of the modules (X, Y and

Z).

When the joystick is moved, the capillary starts moving into the direction of the joystick

movement. The movement of the capillary is accelerated the further the joystick is moved.

The movement stops when the joystick is released.

4

15

Page 16

Product description

InjectMan

16

®

4

English (EN)

2.5.2 Direction of movement of the joystick

The joystick can be moved along the horizontal plane. This controls the motors of the

X-module and the Y-module. The joystick can be moved in one axis at a time or in a

combination of axes. Rotating the joystick moves the motor module on the vertical axes.

Abb. 2-7:Movement in the X and Y-axis

Move the capillary in the horizontal

direction (X and Y-axis).

Fig. 2-7: Movement in the X and Y-axis

Abb. 2-8:Movement in the Z-axis

Fig. 2-8: Movement in the Z-axis

2.5.3 Joystick key functions

Abb. 2-9:Function

Fig. 2-9: Function

Move the capillary in the vertical

direction (Z-axis).

Trigger function (e.g., trigger injection).

Page 17

Product description

InjectMan

®

English (EN)

2.6 Speed ranges

There are three speed ranges in the movement range of the joystick. The speed can be set

using the selection dial on the control board and in the Speed menu.

Speed ranges:

• coarse – for a large working range

• fine – for a medium working range

• x-fine – for a small working range

4

17

Page 18

Safety

InjectMan

18

English (EN)

®

4

3Safety

3.1 Intended use

The InjectMan 4 has been designed and manufactured for use in biological, chemical and

physical research. It is used for the precise positioning of microcapillaries and similar

tools as well as for the transfer of very small sample volumes.

The InjectMan 4 has been designed and manufactured for research use only.

The InjectMan 4 is intended exclusively for indoor use and for operation by qualified staff.

3.2 Warnings for intended use

WARNING! Risk of injury due to flying capillaries and glass splinters.

If exposed to high pressures, capillaries may detach themselves from the grip

heads and become projectiles.

Capillaries can crack as a result of incorrect handling.

Wear protective goggles.

Never aim capillaries at people.

Use capillaries with an outer diameter that matches the grip head

specifications.

Always mount / dismount capillaries when they are depressurized.

Mount the capillary correctly in the grip head.

Do not touch the capillary with the Petri dish or other objects.

CAUTION! Risk of cuts from broken capillaries.

Capillaries are made of glass and are very fragile.

Wear your personal protective equipment (PPE).

Always mount capillaries depressurized.

Never aim capillaries at people.

Handle the capillaries very carefully.

NOTICE! Mechanical damage to the motor modules.

Excessive load leads to increment errors or destruction of the drive.

Do not drive the modules against mechanical obstructions.

Do not hold any objects near the modules.

Load the motor module with a maximum of 100 g.

Page 19

WARNING! Damages to health due to infectious liquids and pathogenic

germs.

When handling infectious liquids and pathogenic germs, observe the national

regulations, the biological security level of your laboratory, the material safety

data sheets, and the manufacturer's application notes.

Wear personal protective equipment.

Consult the "Laboratory Biosafety Manual" (Source: World Health

Organization, Laboratory Biosafety Manual, as amended) for comprehensive

regulations on the handling of risk group II germs or biological materials.

3.3 Warning signs on the device

Warning symbol Meaning

Warns of the risk of injury caused by capillary tips

Warns of the danger of crushing on the motor module

Safety

InjectMan

English (EN)

®

4

19

Read the operating manual

3.4 Information on product liability

In the following cases, the designated protection of the device may be compromised.

Liability for any resulting property damage or personal injury is then transferred to the

operator:

• The device is not used in accordance with the operating manual.

• The device is used outside of its intended use.

• The device is used with accessories or consumables which are not recommended by

Eppendorf.

• The device is maintained or repaired by people not authorized by Eppendorf.

• The user makes unauthorized changes to the device.

Page 20

Installation

InjectMan

20

English (EN)

®

4

4 Installation

4.1 Preparing installation

NOTICE! Damage to the control board as a result of incorrect handling.

Grasp the control board on the housing.

Do not lift the control board using the joystick.

Never place the control board on the joystick.

Keep the packaging and the transport securing devices for later transport or

storage.

Do not operate the device if there is visible damage to the device itself and/or to

its packaging.

1. Check the packaging for damage.

2. Carefully remove the motor module and the control board from the packaging.

3. Check that everything is included in the delivery.

4. Check the modules, the control board and the accessories for damage.

4.1.1 If there is any damage, make a claim

1. Contact customer service.

4.1.2 Delivery incomplete

1. Contact customer service.

4.1.3 Microscope adapter assembly

The microscope adapter is not included in the scope of delivery and must be ordered

separately.

1. Assemble the microscope adapter in accordance with the assembly instructions for the

microscope adapter.

4.2 Selecting the location

Select the location for the device according to the following criteria:

• Mains connection in accordance with the name plate.

• A bench with a horizontal and even work surface which is designed to support the

weight of the device.

• A mat or table that is cushioned against vibrations.

• The location is protected from direct sunlight and drafts.

The mains/power switch and cutting unit of the mains/power line must be easily

accessible during operation (e.g, residual current circuit breaker).

Page 21

4.3 Mounting overview

Abb. 4-1:Overview for right-hand side mounting

Installation

InjectMan

English (EN)

®

4

21

1

Fig. 4-1: Overview for right-hand side mounting

1 Z-module holder

For left side mounting

2 Microscope adapter

3 Z-module holder

For right side mounting

4 Z-module

5 Y-module

2

3

6 Swivel joint

7 X-module

8 Universal capillary holder

(not included in the delivery package)

9 Angle head

10 YZ-connector

4

5 6

7

8910

Page 22

Installation

InjectMan

22

®

4

English (EN)

4.3.1 Module (X, Y, Z)

Abb. 4-2:Y-module

Fig. 4-2: Y-module

1

2

Y

4

3

5

1 Cable

2 Module identification

3 Movable rail

4 Scale

Movement range of the rail

5 Fixed rail

Page 23

4.3.2 Z-module holder

Abb. 4-3:Z-module holder, front and back

Installation

InjectMan

English (EN)

®

4

23

1

4

Fig. 4-3: Z-module holder, front and back

1 Slider

2 Screw

Attach Z-module

4.3.3 Slider

Abb. 4-4:Slider

1

2

3 Screw

Attach Z-module holder to the adapter

4 Stop angle

4

3

2

3

Fig. 4-4: Slider

1 Slider

2 Lock washer

3 Flat washer

4 Screw

Page 24

Installation

InjectMan

24

®

English (EN)

4.3.4 Angle head

Abb. 4-5:Angle head

4

Fig. 4-5: Angle head

1 Identification

For setting the angle

2 Knurled screw

For setting the injection angle

3 Universal capillary holder

(not included in the delivery package)

1

5

4 Positioning aid

5 Knurled screw

2

3

4

For fixing the universal capillary holder

Page 25

4.3.5 Swivel joint

Abb. 4-6:Swivel joint for right side mounting

Installation

InjectMan

®

4

25

English (EN)

5

1

6

7

2

3

8

4

Fig. 4-6: Swivel joint for right side mounting

1 Slider

Y-module

2 Turntable

3 Allen screws

4 Slider

X-module

5 Stop plate

6 Upper joint

7 Mounting mark

| stands for left side mounting

|| stands for right side mounting

8 Lower joint

4.4 Mounting the motor module

The motor module can be mounted on the right-hand or left-hand side of the microscope

adapter. The following describes mounting on the right-hand side. For mounting on the

left-hand side, the swivel joint and the angle head must be modified.

The motor module is mounted as standard on an inverse microscope. It can also

be mounted on a universal stand. Mounting on a universal stand is described in

the corresponding manual.

Page 26

Installation

InjectMan

26

®

4

English (EN)

4.4.1 Mounting the Z-module

Prerequisites

• 3 mm Allen torque key

1. Push the Z-module holder onto the

microscope adapter and tighten.

2. Push the fixed rail onto the Z-module

holder until it reaches the stop angle and

tighten the screw.

The connecting cable faces to the rear.

4.4.2 Mounting the Y-module

Prerequisites

• 3 mm Allen torque key

Page 27

Installation

InjectMan

®

English (EN)

1. Push the YZ-connector onto the fixed rail

of the Y-module and tighten.

2. Push the Y-module with the

YZ-connector onto the Z-module and

tighten.

4

27

4.4.3 Mounting the X-module

Prerequisites

• 3 mm Allen torque key

1. Push the swivel joint onto the fixed rail

of the X-module and tighten.

Page 28

Installation

InjectMan

28

®

4

English (EN)

4.4.4 Mounting the angle head

Prerequisites

• 3 mm Allen torque key

2. Push the swivel joint with the X-module

onto the Y-module and tighten.

1. Push the angle head onto the X-module.

2. Slightly tighten the angle head.

4.5 Inserting the capillary holder into the angle head

Prerequisites

• A universal capillary holder from Eppendorf is available.

• A capillary holder (4 mm diameter) from a different manufacturer is available.

Page 29

1. Loosen the knurled screw on the angle

head.

2. Insert the capillary holder into the

clamp.

3. Align the capillary holder in such a way

that the capillary tip is located approx.

20 mm above and approx. 20 mm from

the outside of the operating point.

4. Place the positioning aid on the capillary

holder and tighten.

5. Tighten the knurled screw.

4.6 Inserting the capillary into the capillary holder

WARNING! Risk of injury due to flying capillaries and glass splinters.

If exposed to high pressures, capillaries may detach themselves from the grip

heads and become projectiles.

Capillaries can crack as a result of incorrect handling.

Wear protective goggles.

Never aim capillaries at people.

Use capillaries with an outer diameter that matches the grip head

specifications.

Always mount / dismount capillaries when they are depressurized.

Mount the capillary correctly in the grip head.

Do not touch the capillary with the Petri dish or other objects.

Installation

InjectMan

English (EN)

®

4

29

NOTICE! Mechanical damage to the motor modules.

Excessive load leads to increment errors or destruction of the drive.

Do not drive the modules against mechanical obstructions.

Do not hold any objects near the modules.

Load the motor module with a maximum of 100 g.

Standard capillary: Only use the 0 grip head with capillaries with an outer

diameter of 1.0 mm to 1.1 mm. If you would like to use other capillaries, order

the matching grip head.

Page 30

Installation

InjectMan

30

®

4

English (EN)

1. Push the capillary into the grip head

until it reaches the stop and tighten the

grip head.

4.6.1 Inserting Femtotips

1. Remove the grip head.

2. Screw the adapter for Femtotips into the universal capillary holder.

3. Screw the Femtotip into the adapter and tighten.

4.7 Setting the injection angle

+

1. Turn the knurled screw to set the

injection angle.

Page 31

Installation

InjectMan

English (EN)

4.8 Aligning the motor module

Centrally align the modules in order to be able to use the full movement range of the

modules.

4.8.1 Aligning the height

1. Undo the screw on the YZ-connector.

2. Align the Y-module on the scale of the

Z-module and tighten the screw.

4.8.2 Aligning the depth

1. Undo the screw on the swivel joint.

2. Align the X-module on the scale of the

Y-module and tighten the screw.

®

4

31

Page 32

Installation

InjectMan

32

®

4

English (EN)

4.8.3 Aligning the width

4.8.4 Aligning the angle head

1. Undo the screw on the Z-module holder.

2. Align the Z-module on the scale of the

microscope adapter and tighten the

screw.

1. Undo the screw on the angle head.

2. Align the angle head on the scale of the

X-module.

4.9 Entering mounting parameters

To facilitate remounting the mounting parameters can be recorded.

1. Enter the mounting parameters in the tables.

4.9.1 Microscope and adapter

Name Type

Microscope

Adapter

Attachment side of the

motor module

Page 33

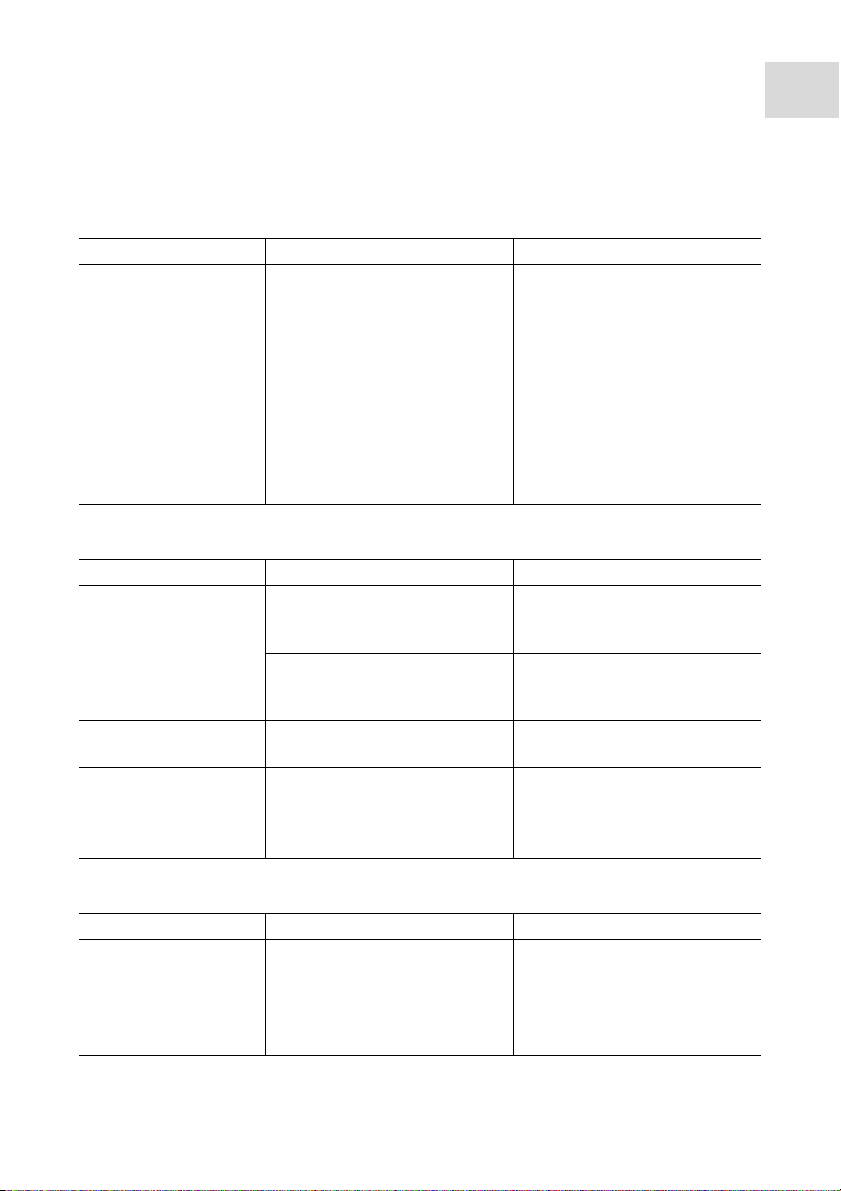

4.9.2 Motor module

1

Position Description Position [mm]

1 Z-module holder on the adapter

2 Z-module on the Z-module holder

3 YZ-connector on the Z-module

4 YZ-connector on the Y-module

5 Swivel joint on the Y-module

6 Swivel joint on the X-module

7 Angle head on the X-module

3 4

2

5

Installation

InjectMan

English (EN)

6

7

®

4

33

4.9.3 Angle head

Name Position [mm] Degrees

Capillary holder

Injection angle

Page 34

Installation

InjectMan

34

®

4

English (EN)

4.10 Converting the swivel joint for left side mounting

Prerequisites

• 2 mm Allen key

• Right side mounting marks (||) are aligned above each other

1. Rotate the lower joint until both Allen

screws are accessible.

2. Unscrew the Allen screws.

Page 35

InjectMan

English (EN)

3. Remove the stop plate.

4. Rotate the lower joint back.

5. Rotate the upper joint by 180°.

The sliders must be at a 90° angle to

each other.

Installation

®

4

35

Page 36

Installation

InjectMan

36

English (EN)

®

4

6. Align the left side mounting marks (I).

7. Fit the stop plate in such a way that the

pins sit in the holes of the turntable.

8. Rotate the swivel joint by 180°.

9. Screw down the stop plate.

• Left side mounting marks (|) are aligned

above each other.

Page 37

10.Check the position of the joints.

• The sliders must be at a 90° angle to

each other.

90°

4.11 Converting the angle head for left side mounting

Prerequisites

• 1.3 mm Allen key

1. Undo the set screw and pull the knurled

screw off the spindle.

Installation

InjectMan

English (EN)

®

4

37

Page 38

Installation

InjectMan

38

English (EN)

®

4

2. Rotate the angle head by 180°.

3. Push the knurled screw onto the spindle

end and fasten it with the set screw.

4. Turn the knurled screw until the desired

+

angle is set.

4.12 Connect the motor module to the control board

WARNING! Risk from incorrect supply voltage

Only connect the device to power supplies which correspond with the

electrical requirements on the name plate.

Only use sockets with a protective earth (PE) conductor and suitable power

cable.

NOTICE! Damage to the control board as a result of incorrect handling.

Grasp the control board on the housing.

Do not lift the control board using the joystick.

Never place the control board on the joystick.

Page 39

Installation

InjectMan

English (EN)

NOTICE! Material damage from incorrect connections.

Only electrical connections may be made to devices described in the

operating manual.

Other connections are permitted only following consultation and agreement

with Eppendorf AG.

Only connect devices that meet the safety requirements defined in

IEC 60950-1.

NOTICE! Short circuit caused by incorrect installation.

Failure to observe the order of steps may result in a short circuit.

Prerequisites

• InjectMan 4 is switched off.

• The power cable is disconnected.

1. Connect the module (X,Y,Z) plug with the ports on the control board.

2. Tighten the fixing screws on the plug manually.

3. Connect the power cable.

4. Switch on the mains switch.

5. Set the installation parameters. You can use the software wizard First set-up or the

Installation menu to set the Side and Angle parameters.

®

4

39

4.13 Setting installation parameters

Installation parameters must be set:

• for the first set-up

•after a reset

The following settings are defined:

• Installation side of the motor module

• Operating angle for the capillary

• Center motors

• Adjust motors

•Set date

Page 40

Installation

InjectMan

40

®

4

English (EN)

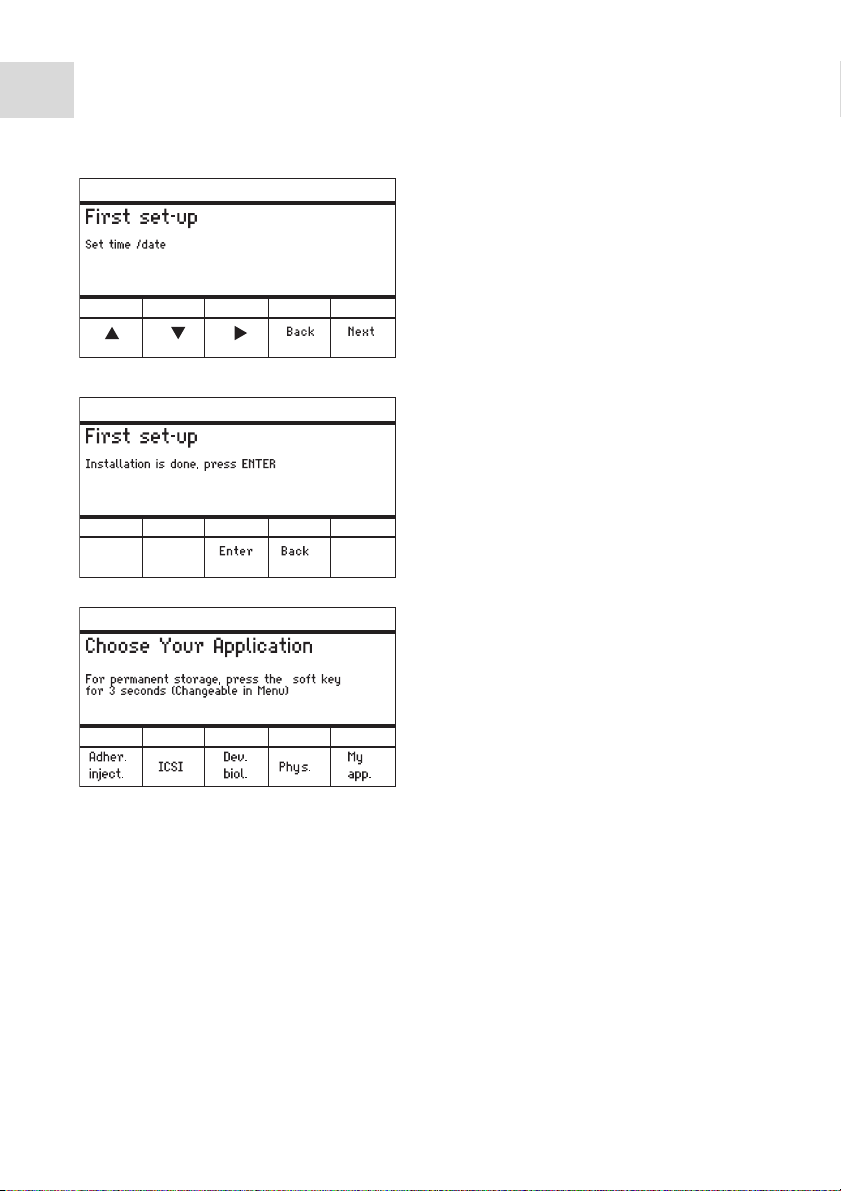

4.13.1 First set-up wizard

Prerequisites

• The micromanipulator is switched on.

1. Select the First set-up application.

2. Select the installation side.

3. Select Next.

4. Set the operating angle.

5. Select Next.

Page 41

Installation

InjectMan

®

English (EN)

6. Select the Execute function to move all

motors to the middle position.

7. Select Next.

8. Insert the capillary holder into the angle

head.

9. Select Next.

10.Manually align the modules.

11.Select Next.

4

41

12.Remove the capillary holder.

13.Insert the capillary into the capillary

holder.

14.Insert the capillary holder with the

capillary into the angle head.

15.Finely adjust the position of the capillary

holder and the modules.

16.Select Next.

Page 42

Installation

InjectMan

42

English (EN)

®

4

17.Set the time and the date.

18.Select Next.

19.Select Enter.

• The installation is complete and the modules are adjusted.

• The application screen displays My application

Page 43

Installation

InjectMan

®

English (EN)

4.14 Connecting an external device

The following devices can be connected to the control board:

• Eppendorf FemtoJet

• Eppendorf PiezoXpert

•Computer

4.14.1 Connecting the FemtoJet

Prerequisites

• Devices are switched off.

The operation is described in the manual for the FemtoJet.

1. Connect the FemtoJet to the port for external devices.

2. Switch on the FemtoJet.

The initialization phase starts.

3. Switch on the control board.

• After completion of the initialization phase, the status message Injector ready appears

on the application screen.

4.14.2 Connecting the PiezoXpert

Prerequisites

• Devices are switched off.

4

43

The operation is described in the manual for the PiezoXpert.

1. Connect the PiezoXpert to the port for external devices.

2. Switch on the PiezoXpert.

The initialization phase starts.

3. Switch on the control board.

• After completion of the initialization phase, the status message PiezoXpert ready

appears on the application screen.

Page 44

Installation

InjectMan

44

®

4

English (EN)

4.14.3 Connecting the Computer

Prerequisites

• A data cable is available.

• Devices are switched off.

Control with a computer is described in the Cell Technology · PC Control

manual.

1. Connect the data cable to the port for external devices.

2. Connect the computer to the data cable.

3. Switch on the control board.

4.14.4 Connecting two devices

Prerequisites

• Y-connector is available.

• Devices are switched off.

Two devices can be connected with a Y-connector.

The following combinations are possible:

• Computer and FemtoJet

• FemtoJet and PiezoXpert

1. Connect the Y-connector to the port for external devices.

2. Connect the device combination.

3. Connect the devices.

• After initialization, status messages appear on the application screen.

Page 45

Software

InjectMan

English (EN)

®

5 Software

5.1 Display

The display shows current settings, for example, the selected working range, the position

of the motors and defined limits.

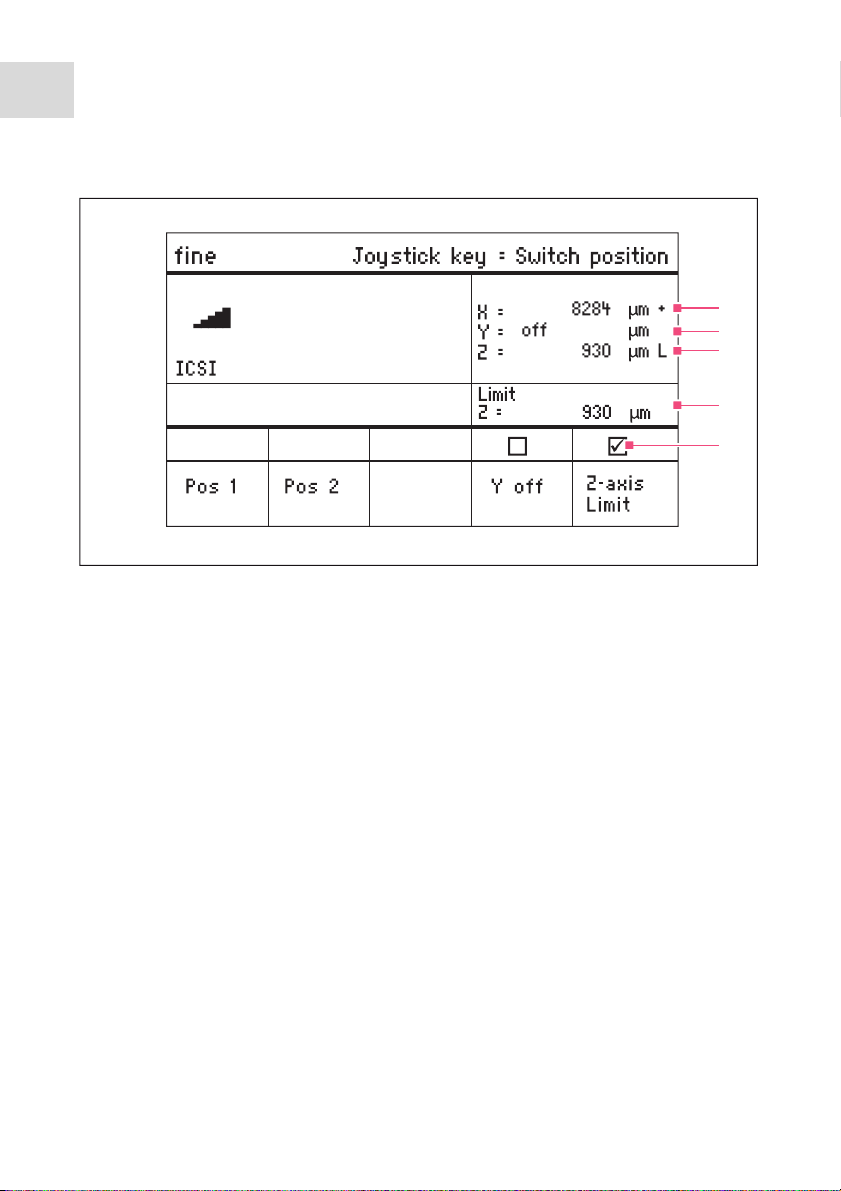

5.1.1 Application display

Abb. 5-1:Display layout - ICSI application as an example

4

45

1

2

3

4

5

Fig. 5-1: Display layout - ICSI application as an example

1 Status line with working range

2 Active application with speed bars

3 Connected device

4 Status fields of the softkeys

5 Softkeys

6 Function of the joystick key

7 Display of coordinates

8 Display of the defined limits

6

7

8

Page 46

46

Software

InjectMan

®

4

English (EN)

5.1.2 Display of coordinates

Abb. 5-2:Display of coordinates

Fig. 5-2: Display of coordinates

1

2

3

4

5

1 Motor limit stop

+ = positive, - = negative

2 Axis is deactivated

3 Lower limit (Z-axis Limit) reached

4 Display of the lower limit

5 Lower limit activated

Page 47

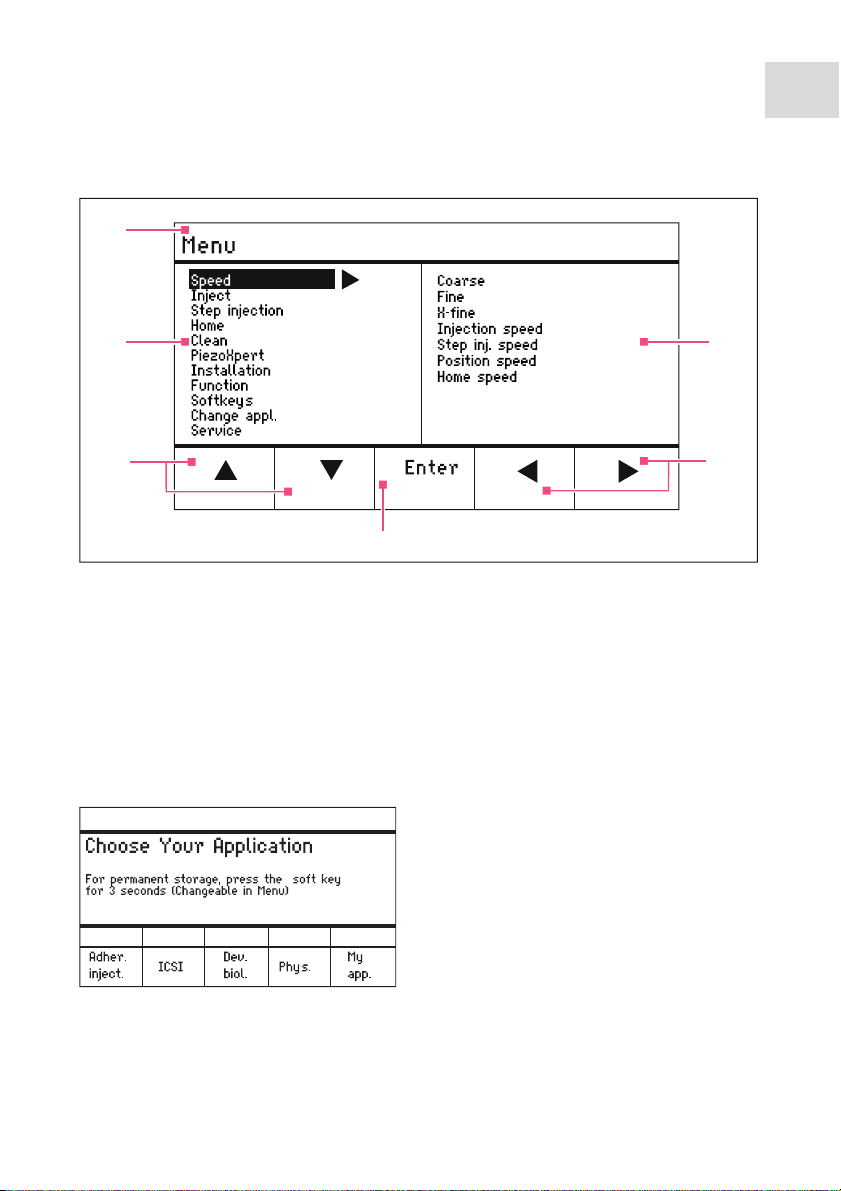

5.1.3 Menu display

Abb. 5-3:Menu and parameter display

1

Software

InjectMan

English (EN)

®

4

47

2

3

Fig. 5-3: Menu and parameter display

1 Navigation path

2 Menu

3 Arrow up/down softkey

For navigation and changing

parameters.

5.2 Applications

Abb. 5-4:Application screen

6

5

4

4 Enter softkey

For confirming input, executing the

function, saving parameters

5 Arrow left/right softkey

Navigation

6 Parameter

Fig. 5-4: Application screen

Page 48

48

Software

InjectMan

®

4

English (EN)

Application selection

• Select the application

• Store the main application

5.2.1 Application parameter

Predefined functions of the different applications.

• Pos 1 – Save the X, Y and Z values of the capillary position. Switch the position using

the joystick key.

• Pos 2 – Save the X, Y and Z values of the capillary position. Switch the position using

the joystick key.

• Activate or deactivate the Step inject function.

• Y off – Switch off the movement of the capillary in the Y-axis. Prevents moving

sideways during injection.

• Z-axis Limit – Save the downward limit for the vertical capillary movement.

• Axial – Switch on the capillary movement along the assembly bracket. Suitable for

straight capillaries.

• Reduce or increase the Limit value for the limit.

•Execute the Clean function.

5.2.2 Application – Adherent cell injection

This application is suitable for injection into adherent cells.

Abb. 5-5:Application 1 Adherent cell injection

Fig. 5-5: Application 1 Adherent cell injection

Parameter selection

• Joystick key – Inject

• Freely program the softkey

• Reduce the value for Z-axis Limit

• Set the lower limit (Z-axis Limit)

• Increase the value for Z-axis Limit

• Execute the function

Page 49

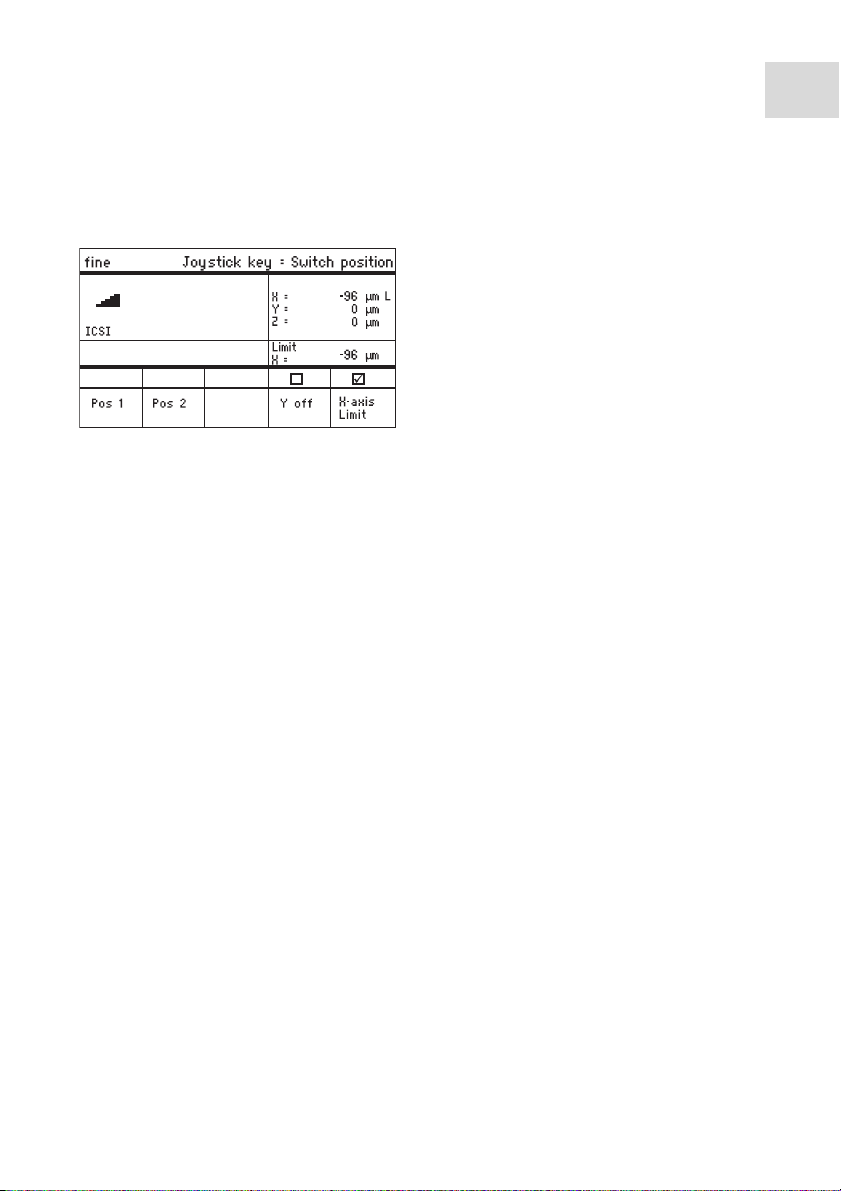

5.2.3 Application – ICSI

This application is suitable for intracytoplasmic sperm injection.

Abb. 5-6:Application 2 ICSI

Fig. 5-6: Application 2 ICSI

Parameter selection

• Joystick key – Switch position

• Save positions 1 and 2

• Freely program the softkey

• Deactivate the control of the axis of movement (Y-axis)

• Set the lower limit (Z-axis Limit)

5.2.4 Application – Developmental biology

This application is suitable for developmental biology.

Abb. 5-7:Application 3 Developmental biology

Software

InjectMan

English (EN)

®

4

49

Fig. 5-7: Application 3 Developmental biology

Parameter selection

• Joystick key – Inject

• Save position 1

• Activate the Step inject function

• Switch on the axial movement of the Z-axis

• Freely program the softkey

• Set the lower limit (Z-axis Limit)

Page 50

50

Software

InjectMan

®

4

English (EN)

5.2.5 Application – Physiology

This application is suitable for physiology.

Abb. 5-8:Application 4 Physiology

Fig. 5-8: Application 4 Physiology

Parameter selection

• Joystick key – Joystick off

• Save position 1

• Freely program the softkey

• Switch on the axial movement of the Z-axis

• Deactivate the control of the axes of movement (X and Y-axis)

• Set the lower limit (Z-axis Limit)

5.2.6 Application – My application

No softkeys are preprogrammed for this application. This application can be individually

programmed.

Abb. 5-9:Application 5 My application

Fig. 5-9: Application 5 My application

Parameter selection

• Freely program the joystick key

• Freely program all softkeys

Page 51

Software

InjectMan

English (EN)

5.3 Main menu

Abb. 5-10:Main menu

Fig. 5-10: Main menu

Menu Parameter

Speed Set the speed parameters

Inject Set the injection parameters

Step injection Set the injection parameters

Home Set the parameters for the Home movement

Clean Set the parameters for the Clean movement

PiezoXpert Set the parameters for an optional device

Installation Set the device parameters

Function Execute the device function

Softkeys Program softkeys

Change appl. Change the selected application or activate the application screen

Service Execute the service function on a user basis

®

4

51

Page 52

52

Software

InjectMan

®

4

English (EN)

5.4 Navigating the menu

Abb. 5-11:Software navigation

Fig. 5-11: Software navigation

Navigate the menu using the arrow keys. Pressing Enter will confirm the selection. You

can switch between menus and submenus with the arrow keys to the left and to the right.

5.4.1 Entering or changing parameters

Parameters can be changed in the menu using the arrow keys, the selection dial or the

rotating wheel on the joystick.

Abb. 5-12:Changing the parameters

Change values with the upwards or

downwards arrow keys.

Change values using the selection dial.

Change values using the upper part of

the joystick.

Save with Enter.

Fig. 5-12: Changing the parameters

Page 53

6Operation

WARNING! Electric shock due to damage to device or mains cable.

Only switch on the device if the device and mains cable are undamaged.

Only use devices that have been properly installed or repaired.

In case of danger, disconnect the device from the mains supply by pulling the

power plug from the device or the mains socket or, by using the isolating

device intended for this purpose (e.g., emergency stop switch in the

laboratory).

Do not move the joystick immediately after power-on. Wait until the initialization

is completed. The completion of initialization is indicated by the display

switching to the operating state.

6.1 Switching the device on or off

6.1.1 Switching on the device

1. Switch on the device at the mains power switch.

• The motor module and the control board are switched on.

• The device runs through an initialization phase.

• The application screen will appear.

6.1.2 Switching the device off

1. Switch off the device at the mains power switch.

The motor module and the control board are deenergized.

Operation

InjectMan

English (EN)

®

4

53

6.2 Activating or deactivating the control board

6.2.1 Activating the control board

Prerequisites

• The display shows STANDBY.

1. Press the standby key.

• The keys, joystick, selection dial and softkeys are activated.

• The display shows the application screen.

6.2.2 Deactivating the control board

The step m otors slowly move to the ne xt parking position. This prevents the motors falling

back to the parking position and the capillary jumping.

1. Press the standby key.

• The keys, joystick and selection dial are deactivated

• The display shows STANDBY.

Page 54

Operation

InjectMan

54

English (EN)

• Current movements are stopped.

• The motor module remains switched on so that the step motors keep their current

position.

®

4

6.3 Defining the start screen

An application can be selected as the default application. The micromanipulator then

starts with the defined application. The application screen with all the applications can be

redefined in the Start display menu.

6.3.1 Defining the application

1. Press and hold the softkey of the desired application for 3 seconds.

• The micromanipulator starts with the defined application.

6.3.2 Defining the selected application

1. In the Change appl. menu, select the Start display submenu.

2. Confirm with Execute.

3. Close the menu.

• The micromanipulator starts with the selected application.

6.4 Replacing the capillary

Prerequisites

• The capillary is depressurized.

WARNING! Risk of injury due to flying capillaries and glass splinters.

If exposed to high pressures, capillaries may detach themselves from the grip

heads and become projectiles.

Capillaries can crack as a result of incorrect handling.

Wear protective goggles.

Never aim capillaries at people.

Use capillaries with an outer diameter that matches the grip head

specifications.

Always mount / dismount capillaries when they are depressurized.

Mount the capillary correctly in the grip head.

Do not touch the capillary with the Petri dish or other objects.

CAUTION! Risk of injury from capillaries

Capillaries can easily penetrate your skin.

After changing a capillary, swivel it immediately back to the working range.

Page 55

Operation

InjectMan

®

English (EN)

CAUTION! Risk of crushing between the modules

The modules automatically move in all spatial axes.

Do not reach into the movement range of the modules.

1. Move the capillary out of the working range using the home key.

2. Swing the X-module forwards.

3. Undo the grip head on the capillary holder.

4. Carefully pull the capillary out of the grip head.

5. Push the new capillary into the grip head until it reaches the stop and tighten the grip

head.

6. Swing the X-module back.

4

55

6.4.1 Manually positioning the capillary

Suitable when using capillaries of different lengths (e.g., self-pulled capillary).

1. Press Back manual.

2. Manually position the capillary in the working range.

6.4.2 Automatically positioning the capillary

Suitable when using industrial capillaries (e.g., Femtotips).

1. Press home.

• The capillary automatically moves back into the working range.

Page 56

56

Operation

InjectMan

®

4

English (EN)

6.5 Changing the sample

CAUTION! Risk of crushing between the modules

The modules automatically move in all spatial axes.

Do not reach into the movement range of the modules.

1. Press the home key to move the capillary

2. Swing the X-module backwards.

3. Change the sample.

4. Swing the X-module back.

5. Press the home key to move the capillary

6.6 Changing the speed range

6.6.1 Changing parameters using the selection dial

out of the working range.

back into the working range.

coarse

1. Press the key for the desired speed range

on the control panel.

2. Turn the selection dial to change the

fine

fine

menu

speed.

Page 57

Operation

InjectMan

®

English (EN)

6.6.2 Changing parameters in the menu

Prerequisites

• An application has been selected.

1. Press the menu key.

2. Select theSpeed menu.

3. Select the desired parameter.

4. Change the value.

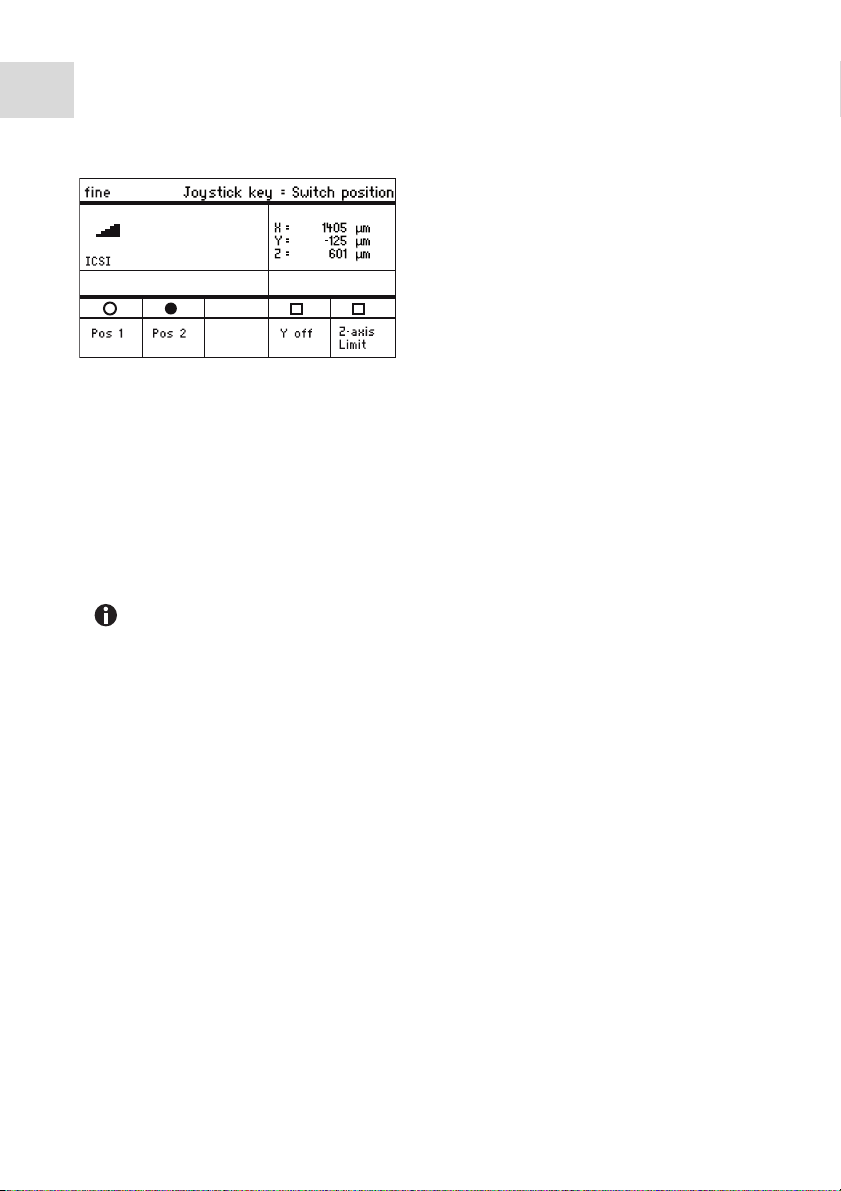

6.7 Capillary positions

To secure the capillary when moving a slide and to move it back to the same work position

you can store the positions. Depending on the application, a maximum of five positions

can be stored.

As soon as the capillary leaves a stored position, the filled circle is displayed as an empty

circle, to show that this position is now stored. If no positions are stored, the status field

will be empty.

4

57

6.7.1 Saving a position

Prerequisites

• An application has been selected.

1. Move the capillary to the desired

position.

2. Hold the Pos 1 softkey for approx. one

second to store the working position of

the capillary.

• An acoustic signal will sound.

• Pos 1 is marked.

• The stored position is displayed in the

status field.

Page 58

Operation

InjectMan

58

English (EN)

®

4

3. Move the capillary to the desired

position (e.g., parking position).

4. Press and hold the Pos 2 softkey for

approx. one second to store the parking

position of the capillary.

• An acoustic signal will sound.

• Pos 2 is marked.

• The stored position is displayed in the

status field.

6.7.2 Moving to the position using the softkey

Prerequisites

• At least one position is stored.

1. Press a softkey with a stored position.

• You will move to the selected position.

• The joystick is deactivated until the position has been reached.

• The LEDs of the softkeys flash.

• In the softkey status field a filled circle is displayed.

If a stored position is lower than the lower limit (Z-axis Limit), the position on the

Z-axis will only be approached up to the defined limit.

6.7.3 Moving to the position using the joystick key

Prerequisites

• At least one position is stored.

•The Joystick key parameter must be set to the Switch position value.

Press the joystick key.

You will move to the first position

Press the joystick key.

• You will move to the next position.

6.7.4 Deleting a stored position

Prerequisites

• A position is stored.

1. When the position has been reached, hold the softkey.

• An acoustic signal will sound.

• The position has been deleted.

• The status field is empty

Page 59

Operation

InjectMan

®

English (EN)

6.7.5 Overwriting a stored position

Prerequisites

• A position is stored.

1. Press the softkey for a different position.

• You will move to the position.

2. When the position has been reached, press and hold the softkey for the position to be

overwritten.

• The old position is overwritten with the current coordinates.

3. Press the softkey.

• An acoustic signal will sound.

• In the softkey status field a filled circle is displayed.

• The stored position is displayed in the coordinate field.

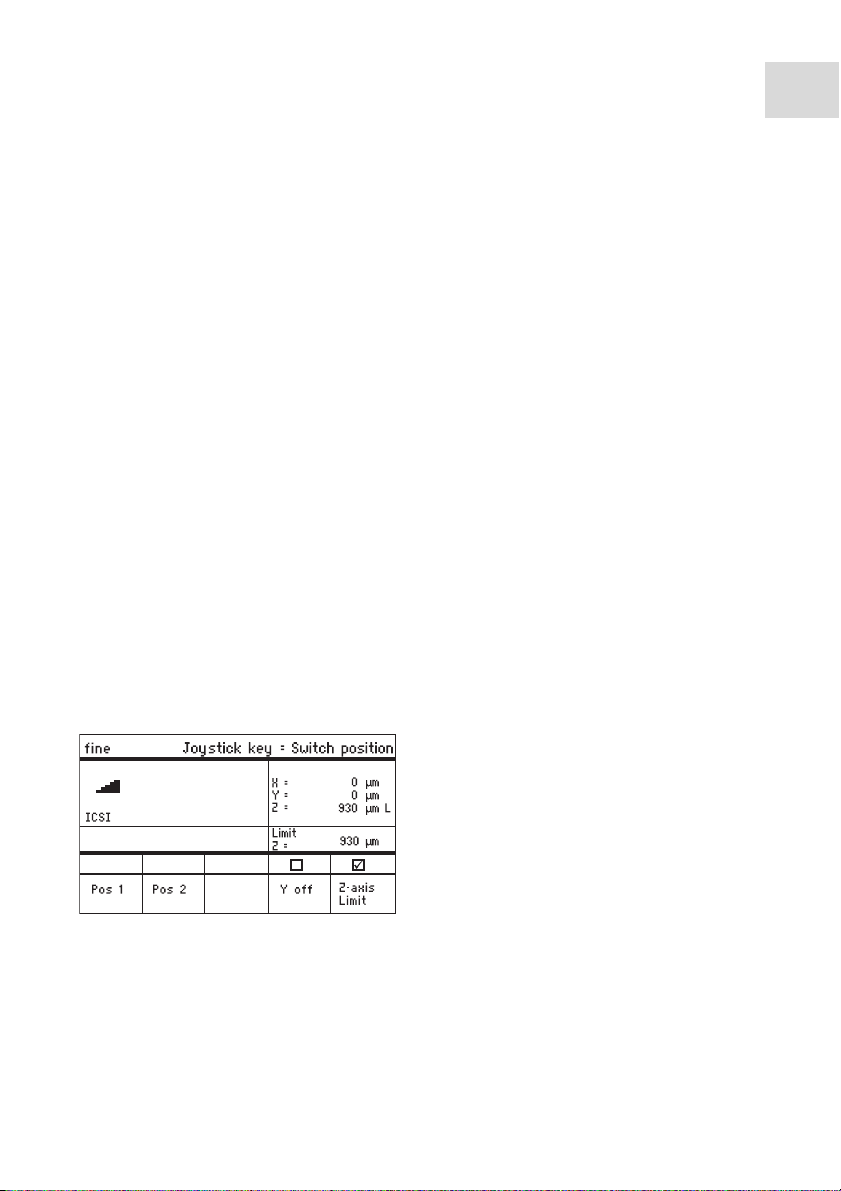

6.8 Vertical limits

For the Z-axis, a lower and upper limit can be defined. This prevents the capillary coming

into contact with the bottom of the Petri dish or moving against the condenser of the

microscope adapter.

•Lower limit – Z-axis Limit

• Upper limit – Upper limit

4

59

6.8.1 Defining the lower limit

Prerequisites

• An application has been selected.

1. Position the capillary a little way above the slide.

2. Press Z-axis Limit.

• The Z-coordinate is marked with L.

• The value for the limit (Limit Z) is displayed.

• Z-axis Limit is selected.

• The capillary cannot be moved any lower.

Page 60

60

Upper Limit

Menu / Installation / Upper Limit

Back

Set

Clear

X

Y

Z

Lim

=

=

=

0

0

2671

2671

µm

µm

µm U

µm

Operation

InjectMan

®

4

English (EN)

6.8.2 Deleting the lower limit

1. Press Z-axis Limit.

• The limit is deleted.

6.8.3 Defining the upper limit

1. In the Installation menu, select the Upper limit submenu.

The Upper Limit window appears.

2. Move the capillary to the top position.

3. Save the position with Set.

• The Z-coordinate is marked with U.

• The value for the limit (Lim) is displayed.

• The capillary cannot be moved any higher.

6.8.4 Deleting the upper limit

1. In the Installation menu, select the Upper limit submenu.

The Upper Limit window appears.

2. Save the position with Clear.

• The limit is deleted.

Page 61

Operation

InjectMan

®

English (EN)

6.9 Horizontal limit

For the X-axis, a limit can be defined for a horizontal injection. This prevents the capillary

from moving through the sample.

6.9.1 Defining the horizontal limit

1. In the Installation menu, select the Angle submenu.

2. Set the injection angle to 0° and save with Enter.

3. Close the menu.

The application screen now displays X-axis Limit.

4. Move the capillary to the desired final position for the X-axis.

5. Save the lateral limit with X-axis Limit.

• The X-coordinate is marked with L.

• The value for the limit (Limit X) is displayed.

• X-axis Limit is selected.

• The capillary cannot be moved any further to the side.

4

61

6.9.2 Deleting the horizontal limit

1. Press X-axis Limit.

The limit is deactivated.

2. In the Installation menu, select the Angle submenu.

3. Reset the injection angle to the operating angle and save with Enter.

• The lateral limit is deleted.

• The application screen displays Back again.

Page 62

62

Operation

InjectMan

®

4

English (EN)

6.10 Speed function

In the Speed menu you can set the speed of the working range and the speed at which

certain positions are approached or movements executed.

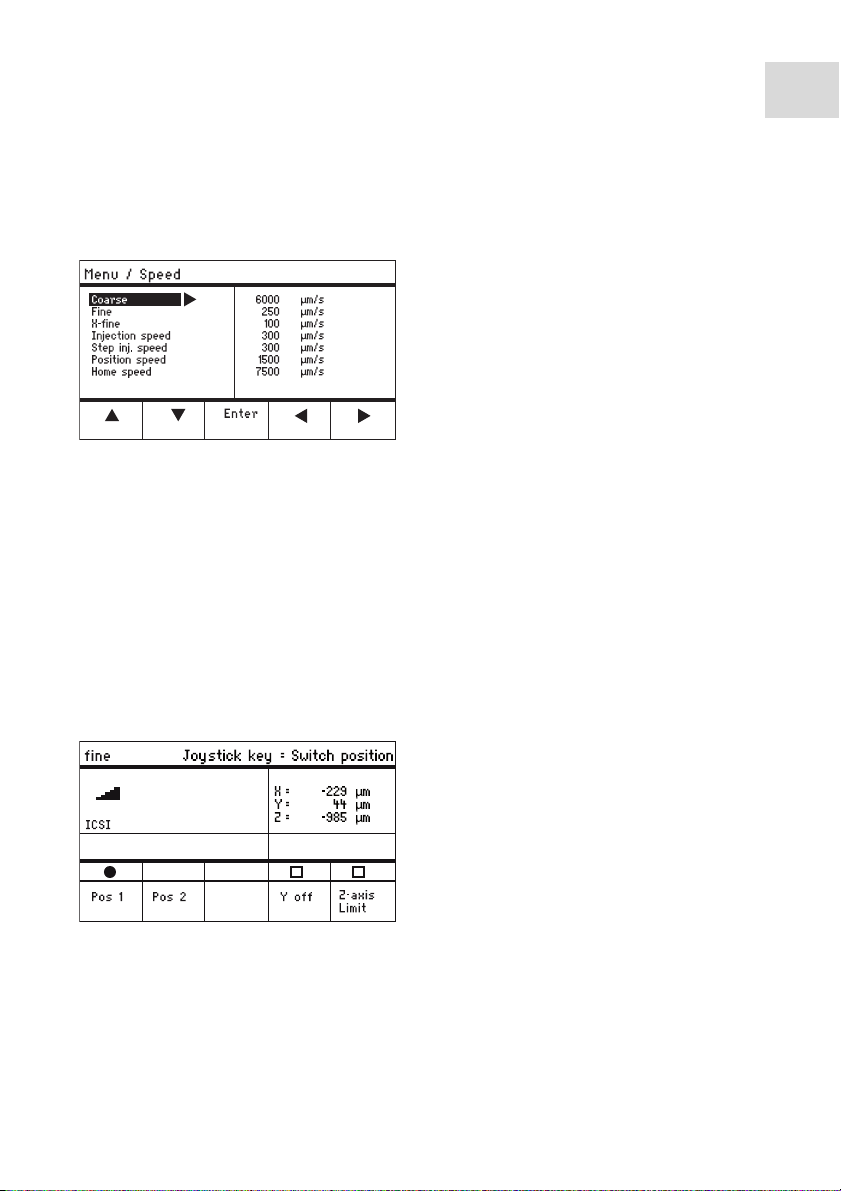

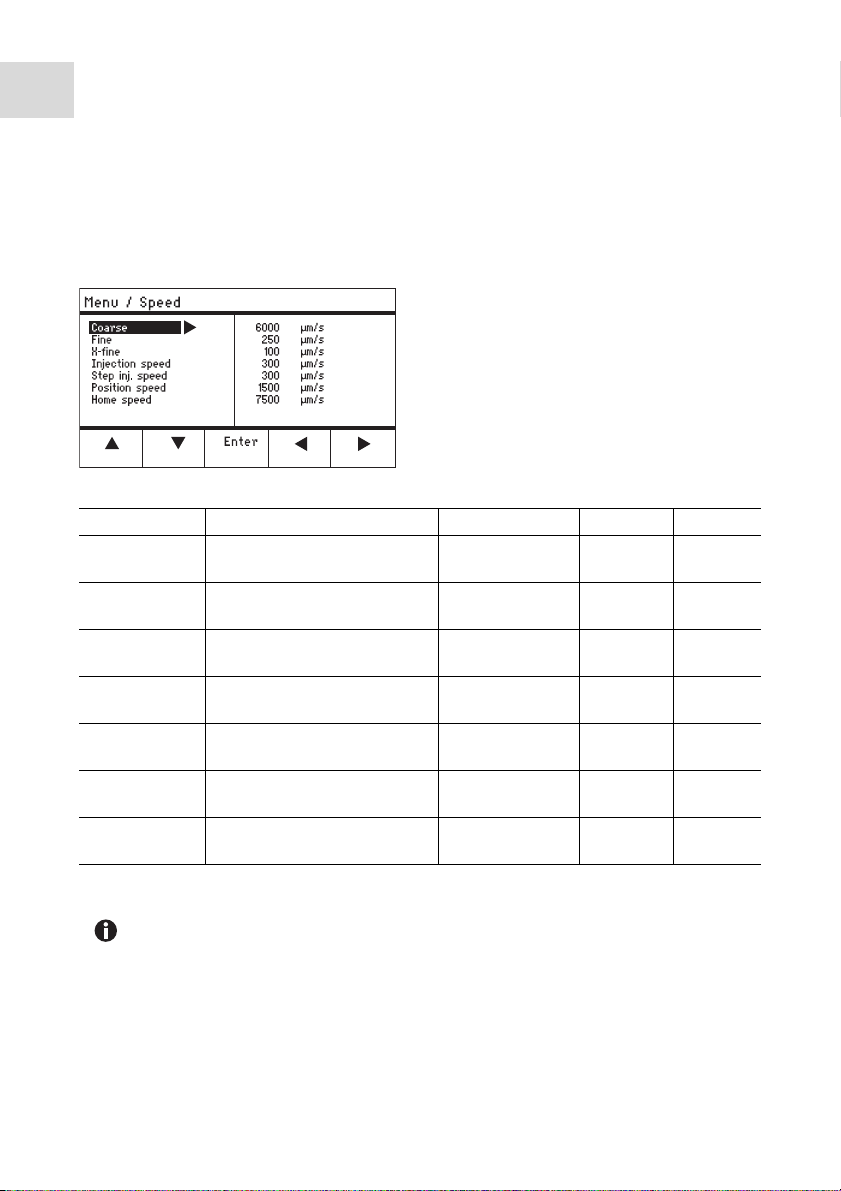

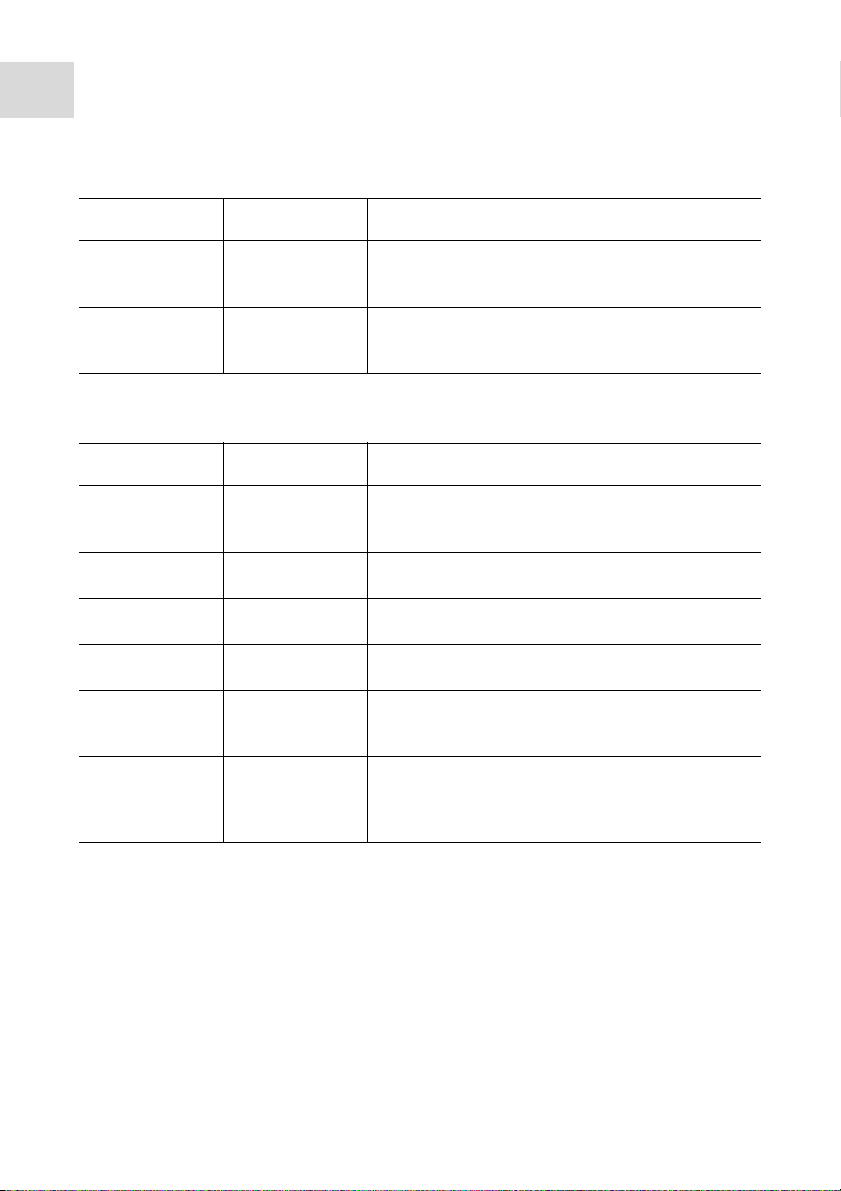

6.10.1 Speed menu and parameters

Abb. 6-1:Menu – Speed

Fig. 6-1: Menu – Speed

Parameter Value Range of values Increment Standard

Coarse Set the speed in μm per

5 – 10000 5 7500

second

Fine Set the speed in μm per

5 – 1000 5 1000

second

X-fine Set the speed in μm per

0 – 100 1 100

second

Injection speed Set the speed in μm per

5 – 10000 5 300

second

Step inj. speed Set the speed in μm per

5 – 10000 5 300

second

Position speed Set the speed in μm per

5 – 10000 5 1500

second

Home speed Set the speed in μm per

5 – 10000 5 7500

second

6.10.2 Setting the parameters for Speed

If a value of 0 is set for the X-fine parameter, then the change between the Fine

and X-fine working ranges is deactivated.

1. Select the desired parameter.

2. Set the value for the parameter.

3. Close the menu.

Page 63

Operation

InjectMan

®

English (EN)

6.11 Inject function

This function performs an automatic injection movement. You can set the injection speed,

the injection time, the injection movement and fix the distance between the capillary and

the lower limit.

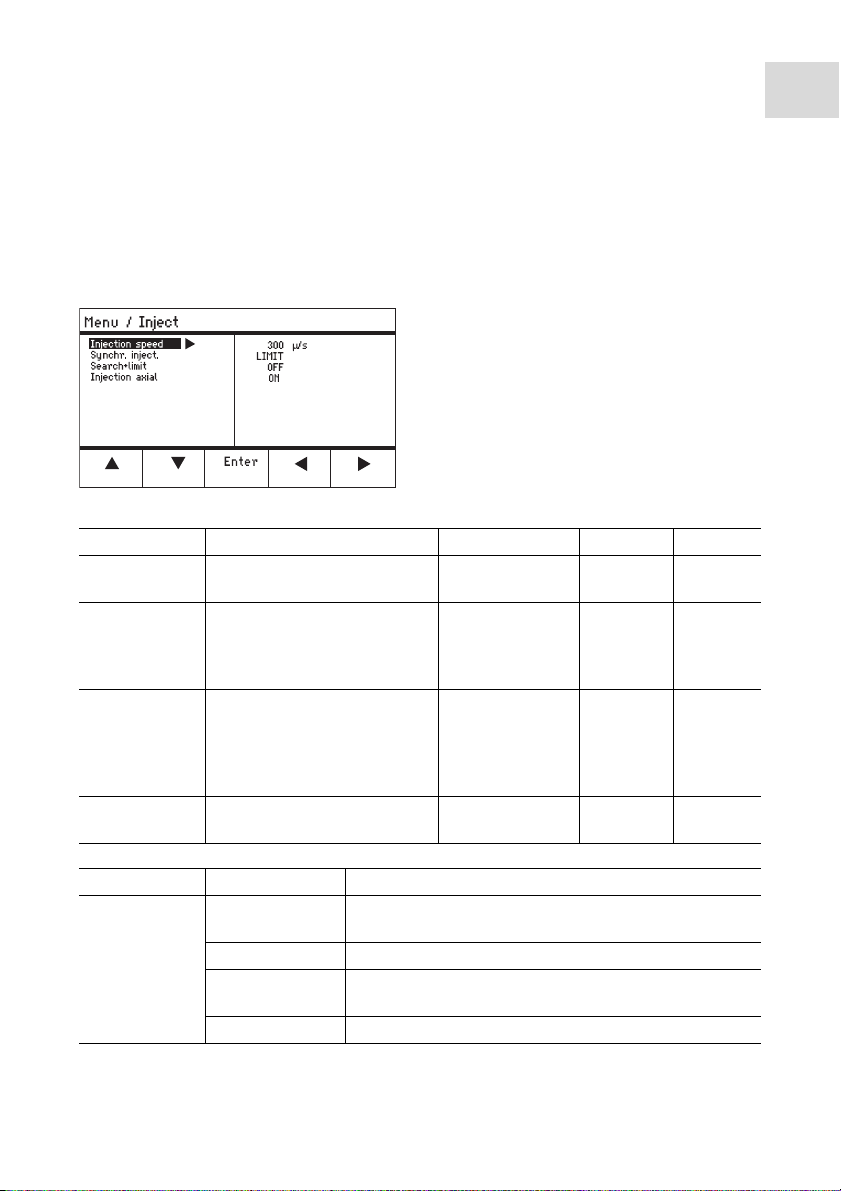

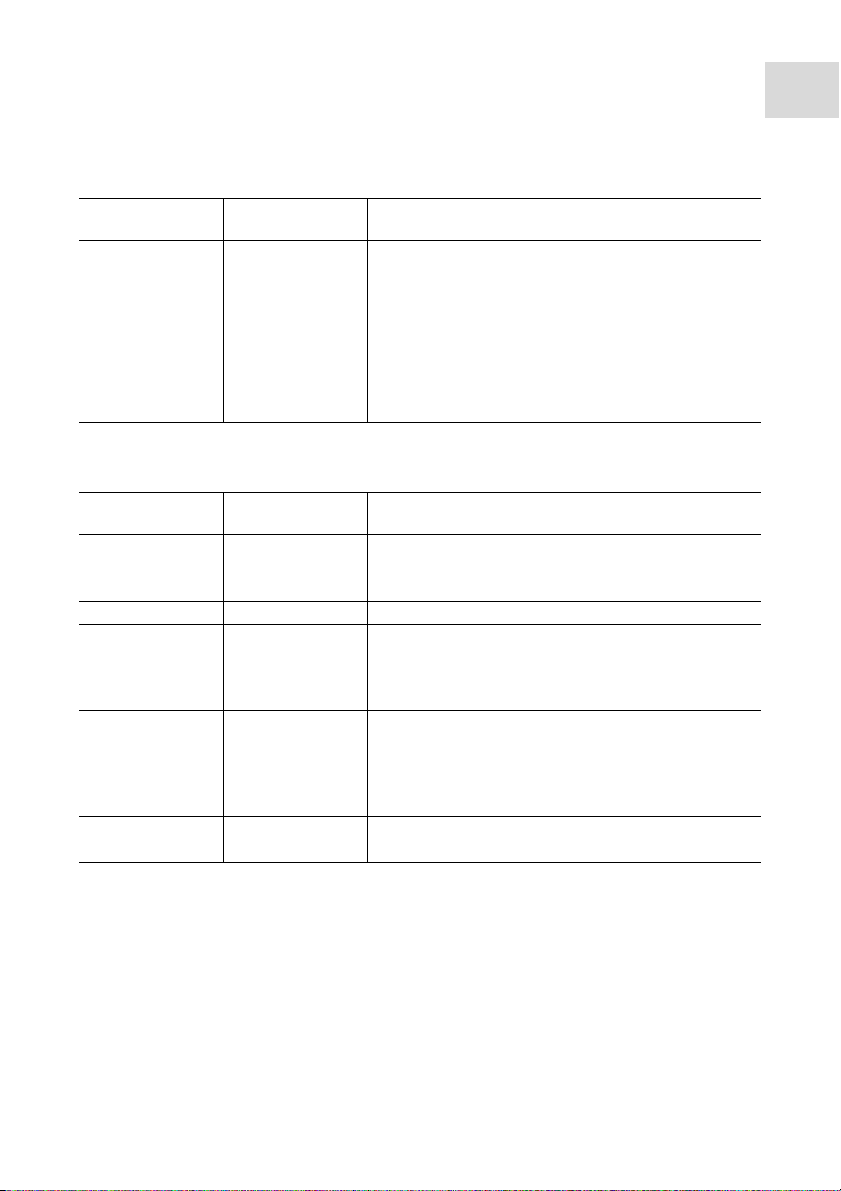

6.11.1 Inject menu and parameters

Abb. 6-2:Menu – Inject

Fig. 6-2: Menu – Inject

Parameter Value Range of values Increment Standard

Injection speed Set the injection speed in μm

5 – 10000 5 300

per second

Synchr. inject. Set the synchronized time of

injection

MOVE

IMMEDIATE

– LIMIT

LIMIT

PRESSURE

Search+limit Change the lower limit and

OFF/ON – OFF

the position of the capillary.

The distance between the

capillary and the limit

remains constant

Injection axial Switch the axial movement of

OFF/ON – On

the function on or off

4

63

Parameter Range of values Function

Synchr. inject. MOVE Injection movement without injection pressure (when

using non-connected injectors)

IMMEDIATE Injection pressure starts with the injection movement

LIMIT Injection pressure at the end of the injection distance

(Z-axis Limit)

PRESSURE Injection pressure without injection movement

Page 64

Operation

InjectMan

64

English (EN)

®

4

6.11.2 Executing the Inject function

Prerequisites

• A FemtoJet is connected.

• A lower limit (Z-axis Limit) has been defined.

1

5

6

7

8

3

1 Position the capillary

2 Trigger an automatic injection

3 Injection

4 Automatic movement to the starting

position

If the Search+limit parameter is activated you can inject cells with different

heights using the same injection parameters.

1. Press the joystick key.

• The capillary is moved to the side and to the lower limit at the injection angle.

• The injection is carried out automatically.

• The capillary is moved back to the starting position.

5 Capillary

6 Search level

7 Z-axis Limit

8 Cell

2

4

Page 65

Operation

InjectMan

English (EN)

6.12 Step injection function

With this function you can execute a straight injection over a defined distance. Step

injection can only be executed when a FemtoJet is connected.

6.12.1 Step injection menu and parameters

Abb. 6-3:Menu – Step injection

Fig. 6-3: Menu – Step injection

Parameter Value Range of values Increment Standard

Step injection Switch the function on or off OFF/ON – OFF

Step inj. speed Set the injection speed in μm

5 – 10000 5 300

per second

Step inj. dist. Set the injection path in μm 1 – 2000 1 20

Step inj. axial Switch the axial movement of

OFF/ON – On

the capillary on or off

Step inj. back Switch the backward

OFF/ON – On

movement of the capillary on

or off

Synchr. inject. Set the time of injection MOVE

– LIMIT

IMMEDIATE

LIMIT

PRESSURE

®

4

65

Parameter Range of values Function

Synchr. inject. MOVE Injection movement without injection pressure

IMMEDIATE Injection pressure starts with the injection movement

LIMIT Injection pressure at the end of the injection distance

(Step inj. dist.)

PRESSURE Injection pressure without injection movement

Page 66

66

Operation

InjectMan

®

4

English (EN)

6.12.2 Executing the Step injection function

Prerequisites

• A FemtoJet is connected.

• Step injection is assigned to a free softkey.

1. Activate Step injection.

2. Set all parameters.

3. Set the injection time on the FemtoJet.

4. Close the menu.

• The application screen displays Step injection.

5. Trigger the injection with the joystick key.

• The function is executed.

6.13 Home function

The Home function quickly moves the capillary out of the work area and is suitable for a

quick change of capillary.

6.13.1 Home menu and parameters

Abb. 6-4:Menu – Home

Fig. 6-4: Menu – Home

Parameter Value Range of values Increment Standard

Home speed Set the speed of the Home

5 – 10000 5 7500

function

Home offset Set vertical offset in μm 5 – 20000 5 0

6.13.2 Setting the parameter for Home

1. Set the speed.

2. Set the offset.

3. Close the menu.

Page 67

6.13.3 Move the capillary out with the home key

Prerequisites

• The parameters in the Home menu have been defined.

CAUTION! Risk of crushing between the modules

The modules automatically move in all spatial axes.

Do not reach into the movement range of the modules.

1. Press the home key.

The home key flashes.

• The capillary is moved out of the work

area.

•The home key lights up.

6.13.4 Move the capillary back with the home key

CAUTION! Risk of crushing between the modules

The modules automatically move in all spatial axes.

Do not reach into the movement range of the modules.

Operation

InjectMan

English (EN)

®

4

67

1. Press the home key.

• The capillary is moved back into the work area.

•The home function is terminated.

6.13.5 Setting the offset.

For capillaries of different lengths, an offset can be set. This defines a limit for the home

function.

Page 68

68

Operation

InjectMan

®

4

English (EN)

1. Change the offset using the arrow keys.

• The value for the offset is displayed in the status field.

6.13.6 Terminate the home function.

1. Press Back manual.

2. Move the capillary manually using the

The home function is terminated.

joystick.

6.14 Clean function