Page 1

New Brunswick Incubator Shakers

I-26/26R

Operating Manual

M1324-0050

Revision E

Page 2

2

COPYRIGHT:

Copyright © 2012 Eppendorf AG, Hamburg. No part of this publication may be

reproduced without the prior permission of the copyright owner.

The company reserves the right to change information in this document without notice. Updates to

information in this document reflect our commitment to continuing product development and

improvement.

TRADEMARKS:

Eppendorf

Logo™ are trademarks of Eppendorf AG, Hamburg, Germany.

Excella

Inc., USA.

Slo-Blo

Trademarks are not marked in all cases with ™ or ® in this manual.

Eppendorf has attempted to identify the ownership of all trademarks from public records. Any

omissions or errors are unintentional.

®

is a registered trademark, and New Brunswick™ and the New Brunswick

®

and Innova® are trademarks owned and registered by New Brunswick Scientific Co.,

®

is a trademark owned and registered by Littlefuse, Inc. Corporation Illinois, USA.

October 4, 2012

Revision E

M1324-0050

I-26/26R Incubator Shakers M1324-0050 Operating Manual

Page 3

3

ALERT! Possible risk to equipment!

This equipment must be operated as described in this manual.

If operational guidelines are not followed, equipment damage

and personal injury can occur.

Please read the entire Operating Manual before attempting to use this

equipment.

Do not use this equipment in a hazardous atmosphere or with

hazardous materials for which the equipment was not designed.

Eppendorf is not responsible for any

damage to this equipment that may result from the use of an

accessory not manufactured by Eppendorf.

New Brunswick Operating Manual

Page 4

4

TABLE OF CONTENTS

1 USER INSTRUCTIONS ......................................................................................................................................6

1.1 HAZARD ICONS...............................................................................................................................................6

1.2 DANGER LEVELS.............................................................................................................................................6

1.3 MANUAL CONVENTIONS.................................................................................................................................6

1.4 ABBREVIATIONS.............................................................................................................................................6

2 OVERVIEW..........................................................................................................................................................7

2.1 FRONT VIEW .................................................................................................................................................. 8

2.2 SPECIFICATIONS ............................................................................................................................................. 8

2.3 CERTIFICATIONS............................................................................................................................................. 9

3 INSPECTION, VERIFICATION & UNPACKING OF EQUIPMENT........................................................11

3.1 INSPECTION OF BOXES.................................................................................................................................. 11

3.2 PACKING LIST VERIFICATION....................................................................................................................... 11

3.3 UNPACKING OF EQUIPMENT ......................................................................................................................... 11

4 PREPARING THE LOCATION....................................................................................................................... 12

4.1 PHYSICAL LOCATION....................................................................................................................................12

4.2 ENVIRONMENT .............................................................................................................................................12

4.3 ELECTRICAL REQUIREMENTS ....................................................................................................................... 12

4.4 SPACE REQUIREMENTS.................................................................................................................................13

5 INSTALLING THE I-26/26R............................................................................................................................14

5.1 TOOLS REQUIRED FOR INSTALLATION..........................................................................................................14

5.2 LEVELING A SINGLE SHAKER ....................................................................................................................... 14

5.3 ADDING A BASE ........................................................................................................................................... 15

5.4 PREPARING THE OPTIONAL BASE ................................................................................................................. 15

5.5 MOUNTING THE I-26/26R ON THE OPTIONAL BASE...................................................................................... 17

5.6 INSTALLING THE I-26/26R STACKING KIT....................................................................................................19

5.7 STACKING THE I-26/26R .............................................................................................................................. 20

5.8 STACKING A THIRD I-26/26R.......................................................................................................................21

5.8.1 Load and Speed Graphs ......................................................................................................................... 21

6 FEATURES.........................................................................................................................................................23

6.1 KEYPAD .......................................................................................................................................................23

6.2 LED DISPLAY .............................................................................................................................................. 23

6.3 USER INTERFACE KEYS ................................................................................................................................24

6.4 STATUS INDICATORS .................................................................................................................................... 24

6.5 FUNCTION INDICATORS ................................................................................................................................25

7 GETTING STARTED........................................................................................................................................26

7.1 PLATFORM ASSEMBLIES...............................................................................................................................26

7.2 INSTALLATION OF CLAMPS...........................................................................................................................26

7.3 INSTALLING/SLIDING OUT PLATFORM ..........................................................................................................27

7.4 ELECTRICAL CONNECTIONS ......................................................................................................................... 28

8 OPERATION ...................................................................................................................................................... 30

8.1 STARTING THE SHAKER................................................................................................................................30

8.2 CONTINUOUS (UNLIMITED) RUN ..................................................................................................................31

I-26/26R Incubator Shakers M1324-0050 Operating Manual

Page 5

5

8.3 CHECKING ANY SETPOINT............................................................................................................................ 31

8.4 TIMED FUNCTIONS ....................................................................................................................................... 31

8.5 ALARM FUNCTIONS...................................................................................................................................... 32

8.6 TEMPERATURE SETPOINT .............................................................................................................................33

8.7 TEMPERATURE OFFSET CALIBRATION..........................................................................................................33

8.8 POWER FAILURE........................................................................................................................................... 34

8.9 SPEED CALIBRATION.................................................................................................................................... 34

8.10 TILT SWITCH................................................................................................................................................ 34

9 PREVENTIVE MAINTENANCE.....................................................................................................................36

9.1 CLEANING EXTERNAL SURFACES................................................................................................................. 36

9.2 FUSE REPLACEMENT .................................................................................................................................... 36

9.3 BELT REPLACEMENT ....................................................................................................................................39

10 SERVICE............................................................................................................................................................. 42

10.1 TROUBLESHOOTING......................................................................................................................................42

10.2 REPLACEMENT PARTS.................................................................................................................................. 43

10.3 ACCESSORIES............................................................................................................................................... 44

10.3.1 Available Platforms, 46 x 76 cm (18 x 30 in).....................................................................................44

10.3.2 Flask Clamps for Universal Platforms..............................................................................................44

10.3.3 Replacement Clamp Hardware Kits..................................................................................................44

10.3.4 Carriers and Test Tubes.....................................................................................................................45

10.3.5 Optional Bases for I-26/26R..............................................................................................................45

10.3.6 Stacking Kit for I-26/26R................................................................................................................... 46

10.3.7 Optional Handles............................................................................................................................... 46

11 DRAWINGS........................................................................................................................................................ 47

11.1 CONTROL SCHEMATICS................................................................................................................................47

11.2 LIST OF DRAWINGS ......................................................................................................................................51

12 INDEX..................................................................................................................................................................52

New Brunswick Operating Manual

Page 6

6

11

1.1 Hazard Icons

General hazard

Electrical shock hazard

1.2 Danger levels

The following danger levels are used in safety messages throughout this manual.

DANGER

WARNING

CAUTION

ALERT

Will lead to severe injuries or death.

May lead to severe injuries or death.

May lead to light or moderate injuries.

May lead to material damage.

U

SSEERR IINNSSTTRRUUCCTTIIOONNS

U

Risk of material damage

Crush warning

S

1.3 Manual conventions

Depiction Meaning

1.

2.

1.4 Abbreviations

RPM

VA

VAC

DC

RTD

LED

Perform these actions in the sequence described.

List

References useful information.

Revolutions per Minute

Volt Amp

Voltage in Alternating Current

Direct Current

Resistance Temperature Detector

Light Emmitting Diode

I-26/26R Incubator Shakers M1324-0050 Operating Manual

Page 7

7

22

The I-26/26R large stackable incubator shakers are large capacity orbital shakers that

utilize a triple eccentric counter-balanced drive mechanism. They provide horizontal

plane rotary motion in a 2.54 cm (1 in) diameter circular orbit. A Proportional / Integral

(PI) microprocessor controller with instantaneous digital feedback controls the speed

over a range of 25-400 rpm.

The I-26 provides temperature control from 5C above ambient to 60C. The refrigerated

I-26R assures temperature control down to 15C below ambient, with a minimum

setpoint of 4C. Ambient temperature is measured one meter from the front of the unit.

The shakers may be operated either continuously or in a timed mode via a programmable

timer for shaking periods of 0.1 to 99.9 hours.

For safe operation, the I-26/26R models are designed with a safety switch that

automatically stops the shaker mechanism when the door is opened.

The I-26/26R is equipped with visual and audible alarms that alert the user to the

following conditions:

The end of a timed run

Deviations from speed setpoint

Deviations from temperature setpoint

Power failure

Door open

Unstable operating conditions (tilt switch—visual alarm only)

A wide variety of slide-out platforms can be used with the I-26/26R. Dedicated

platforms and universal platforms are available for a variety of flask sizes. Test tube

racks, microtiter plate holders, and test tube rack holders are also available (a universal

platform is needed for all test tube racks and holders). For further information on these

accessories, see Section 10.3.

O

VVEERRVVIIEEW

O

W

New Brunswick Operating Manual

Page 8

8

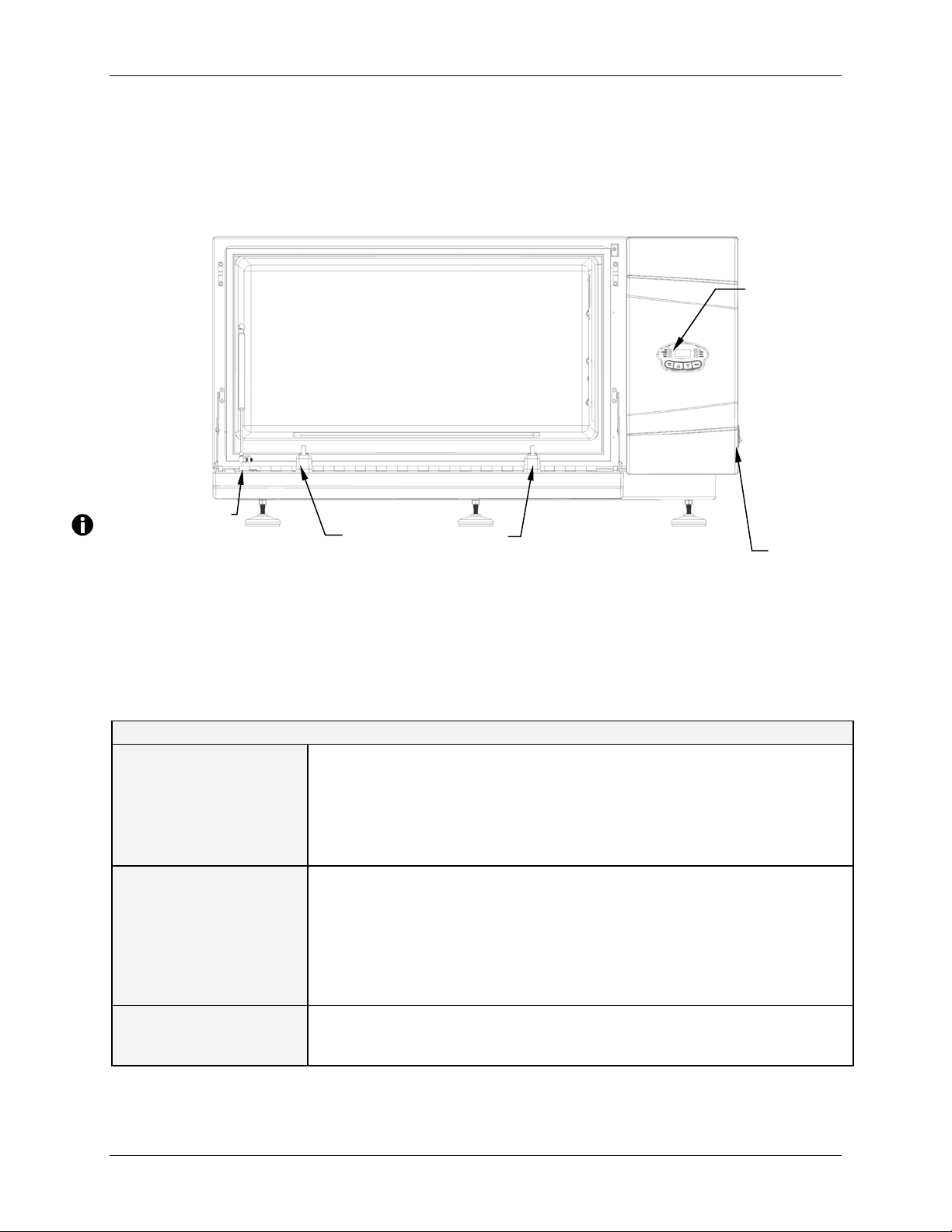

2.1 Front View

This drawing is for reference, to acquaint you with the user interface controls:

Figure 1: Front View

USER

INTERFACE

(display,

indicator lights

& keypad

)

Door is open

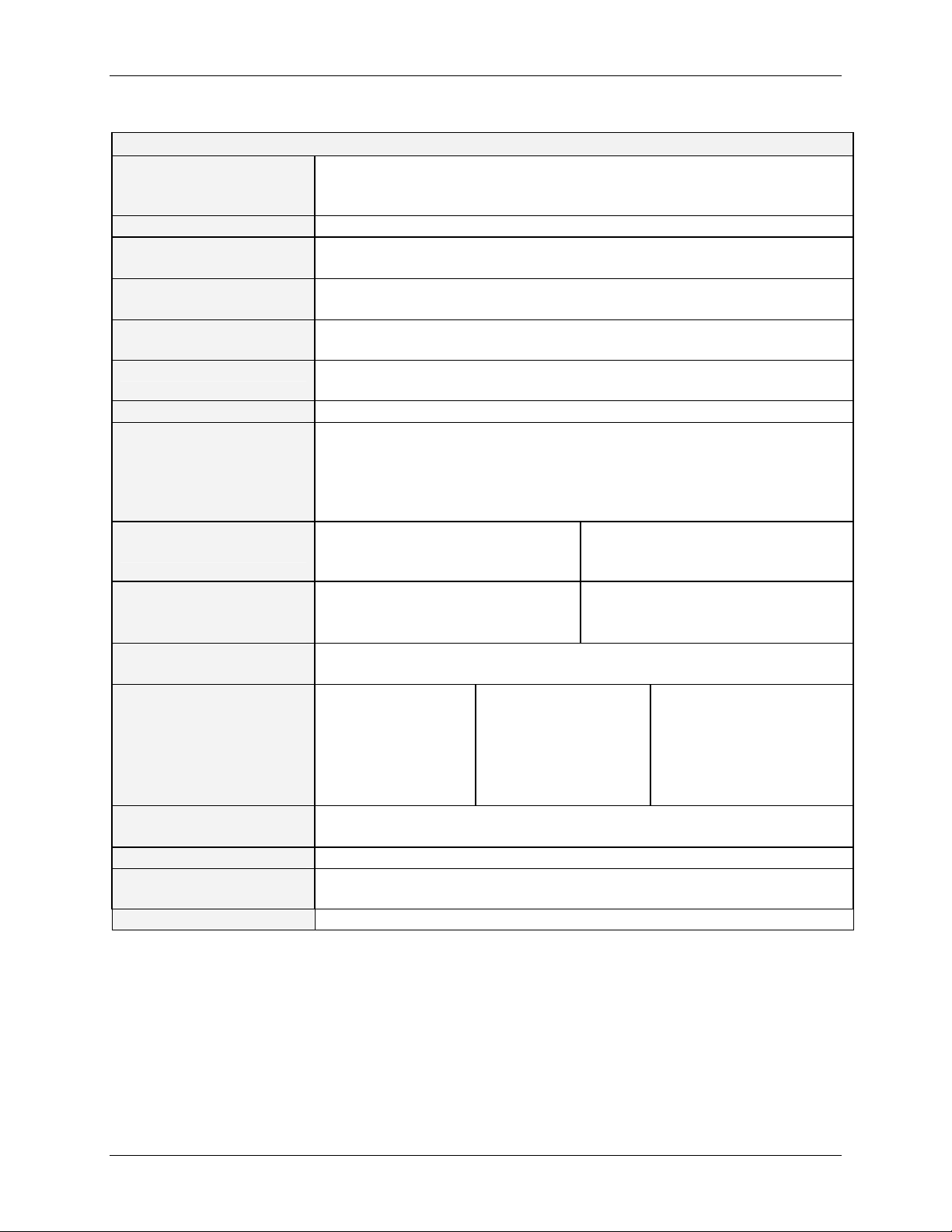

2.2 Specifications

These specifications assume a maximum load of 34 pounds (15.5 kg), including

platforms, clamps, glassware and contents.

SHAKING

Speed

Control Accuracy

Indication

Stroke/Orbit

TEMPERATURE

I-26 Range

I-26R Range

Control Accuracy

Indication

Heaters

ALARMS

Single unit: 25-400 rpm

2 or 3 units stacked: 25-250 rpm

1 rpm

3 Digit LED, in 1 rpm increments

2.5 cm (1 in)

5°C above ambient temperature to 60°C

15°C below ambient (minimum 4°C) to 60°C

0.1°C from 30-40 °C, 0.5°C over the remaining range.

3 Digit LED, in 0.1°C increments

Long-life, low-watt density resistance-type heaters with high

temperature thermostats

Visible and audible warning indication when speed deviates more

than 5 rpm or temperature more than 1°C from setpoints, and when

timer has expired. Audible alarm can be muted.

PLATFORM RESTS

on back of door

I-26/26R Incubator Shaker

...continued...

ON/OFF Switch

I-26/26R Incubator Shakers M1324-0050 Operating Manual

Page 9

9

I-26/26R Incubator Shaker

LED DISPLAY

RS 232

SETPOINT

RETENTION

AUTOMATIC

RESTART

STACKING

DRIVE

DRIVE MOTOR

SAFETY

ELECTRICAL

REQUIREMENTS

SAFETY

REGULATORY

STANDARDS

CE REGULATORY

STANDARDS

OVERALL

DIMENSIONS

Width

Depth (Front to Back)

Height (excluding

optional base)

CHAMBER

DIMENSIONS

PLATFORM

WEIGHT

FUSES

Indicates speed, temperature, running time alarm conditions, and

displays readout of internal clock (actual accumulated operating

time). Character height: 14.3 mm (9/16 in)

Provides access for remote data logging

All setpoints and operating status are retained in non-volatile

memory

Automatic restart after power is restored, indicated by flashing

display

Up to three units may be stacked; the second and third units require

stacking kit(s).

Triple-eccentric counterbalanced drive with nine permanently

lubricated ball bearings

Solid-state brushless DC motor.

An independent mechanical sensing “tilt switch” shuts off the motor

in an unbalanced condition. Drive Interrupt shuts off power to shaker

when door opens. Acceleration/deceleration circuit prevents sudden

starts and stops, minimizing both splashing and mechanical

damage.

100 Volts, 50/60 Hz

120 Volts, 60 Hz

230 Volts, 50 Hz

UL61010A-1

UL61010-2-010

See DECLARATION OF CONFORMITY

Single Unit

128.3 cm (50.5 in)

77 cm (30.32 in)

70 cm (27.56 in)

86.4 cm (34 in) Wide X 58.4 cm (23 in ) Deep X 39.4 cm (15.5 in)

High clearance above platform

Aluminum, 46 cm X 76 cm (18 in X 30 in)

I-26: 167.8 kg (370 lbs)

I-26R: 181.5 kg (400 lbs)

Two 8.0A 250V, Slo-Blo

Two Units

128.3 cm (50.5 in)

77 cm (30.32 in)

133.5 cm (52.56 in)

®

I-26: 800 VA per shaker

I-26R: 1500 VA per shaker

CAN/CSA-C22.2 No 1010.1

CAN/CSA-C22.2 No 1010.2.010

Three Units

128.3 cm (50.5 in)

77 cm (30.32 in)

197 cm (77.56 in)

2.3 Certifications

The I-26 and I-26R have been tested to comply with UL and CAN/CSA electrical safety

standards (see “Safety Regulatory Standards” in the specifications table). As attested in

the CE Declaration of Conformity reproduced on the following page, they also conform

to the appropriate EU standards.

New Brunswick Operating Manual

Page 10

10

I-26/26R Incubator Shakers M1324-0050 Operating Manual

Page 11

11

N

33

I

NNSSPPEECCTTIIOON

I

,

,

V

EERRIIFFIICCAATTIIOONN

V

&

&

U

NNPPAACCKKIINNGG OOFF

U

3.1 Inspection of Boxes

After you receive your order from Eppendorf/New Brunswick, inspect the boxes

carefully for any damage that may have occurred during shipping. Report any damage to

the carrier and to your local New Brunswick or Eppendorf Sales Order Department.

3.2 Packing List Verification

Verify against your packing list that you have received the correct materials.

3.3 Unpacking of Equipment

CRUSH WARNING!

Do not attempt to lift the I-26/26R by hand.

Always use a lifter or other suitable equipment when raising or handling

the shaker.

E

QQUUIIPPMMEENNT

E

T

To unpack your I-26/26R, you will need the following:

Hammer

Forklift or other lifting equipment to lift 168 kg (370 lb) or more

Shears to cut 12.7 mm (½ in)wide plastic strapping

Tool to remove 7.6 cm (3 in) metal staples

If any part of your order was damaged during shipping, is missing, or fails to operate, fill

out the "Customer Feedback" online at www.nbsc.com/CustomerFeedback.aspx or call

Eppendorf/New Brunswick or your distributor's service department.

New Brunswick Operating Manual

Page 12

12

44

4.1 Physical Location

It is essential that the instrument be situated in an area where there is sufficient space for

the shaker and platform to clear walls and obstructions during operation. The surface on

which the unit is placed must be smooth, level, and able to support the shaker under full

load operating conditions.

CRUSH WARNING!

Do not attempt to lift the I-26/26R by hand.

Always use a lifter or other suitable equipment when raising or handling

the unit.

4.2 Environment

The shaker is designed to operate optimally in the following ambient conditions:

5º to 35°C

20 to 80% Relative Humidity non-condensing

P

RREEPPAARRIINNGG TTHHEE

P

L

OOCCAATTIIOON

L

N

4.3 Electrical Requirements

100, 120 or 230 VAC (depending on your selection)

800 VA for each I-26, 1500 VA for each I-26R

I-26/26R Incubator Shakers M1324-0050 Operating Manual

Page 13

13

4.4 Space Requirements

Figure 1a: Dimensions

DEPTH:

77 cm

30.32 in

DOOR

EXTENSION:

48.4 cm

19.05 in

WIDTH: 128.3 cm

50.5 in

HEIGHT:

70 cm

27.56 in

DOOR WIDTH:

99.5 cm

39.16 in

Be sure to allow four inches (10 cm) around the shaker for proper ventilation, and 24

inches (61 cm) on the right side for service access to fan and refrigeration assemblies.

New Brunswick Operating Manual

Page 14

14

55

I

NNSSTTAALLLLIINNGG TTHHEE

I

CRUSH WARNING!

Do not attempt to lift the I-26/26R by hand.

Always use a lifter or other suitable equipment when raising or handling

the unit.

5.1 Tools Required for Installation

To install the I-26/26R on an optional base and/or to stack I-26/26R units, the following

tools will be needed:

Number 2 Phillips head screwdriver

Level, 25.4 cm (10 in)

Two adjustable wrenches

Forklift or other lifting equipment to lift more than 168 kg (370 lb)

Metal leveling shims

II--2266//2266RR

5.2 Leveling a Single Shaker

Do NOT use feet if you are stacking shakers or adding a base.

Make sure that the shaker is placed on a level surface and that all four feet are solidly on

the surface. If the shaker is not level, adjust the feet as needed to achieve leveling:

1. Immobilize the top lock nut against the unit with one wrench whenever you adjust

the foot, to keep the threaded stud from falling out.

Figure 2: Adjustable Foot

BOTTOM OF

UNIT

FOOT

LOCK NUT

FLATS FOR WRENCH

I-26/26R Incubator Shakers M1324-0050 Operating Manual

Page 15

15

2. With a second wrench against the flats of the threaded stud, just above the foot:

rotate clockwise to lower the foot or counter-clockwise to raise the foot.

3. Place a level on the top of the unit.

4. If necessary, make further adjustments by repeating all steps until the unit is level.

5. Fully load the shaker, and do a test run at normal speed. Make additional leveling

adjustments if necessary.

The maximum foot height adjustment is ~ 6.4 mm (¼ in). If a higher

adjustment is required, you will need to add metal shims.

5.3 Adding a Base

There are three bases available for your I-26/26R shaker(s). The height of the base

depends on whether you are installing one unit on the base, or stacking two or three units:

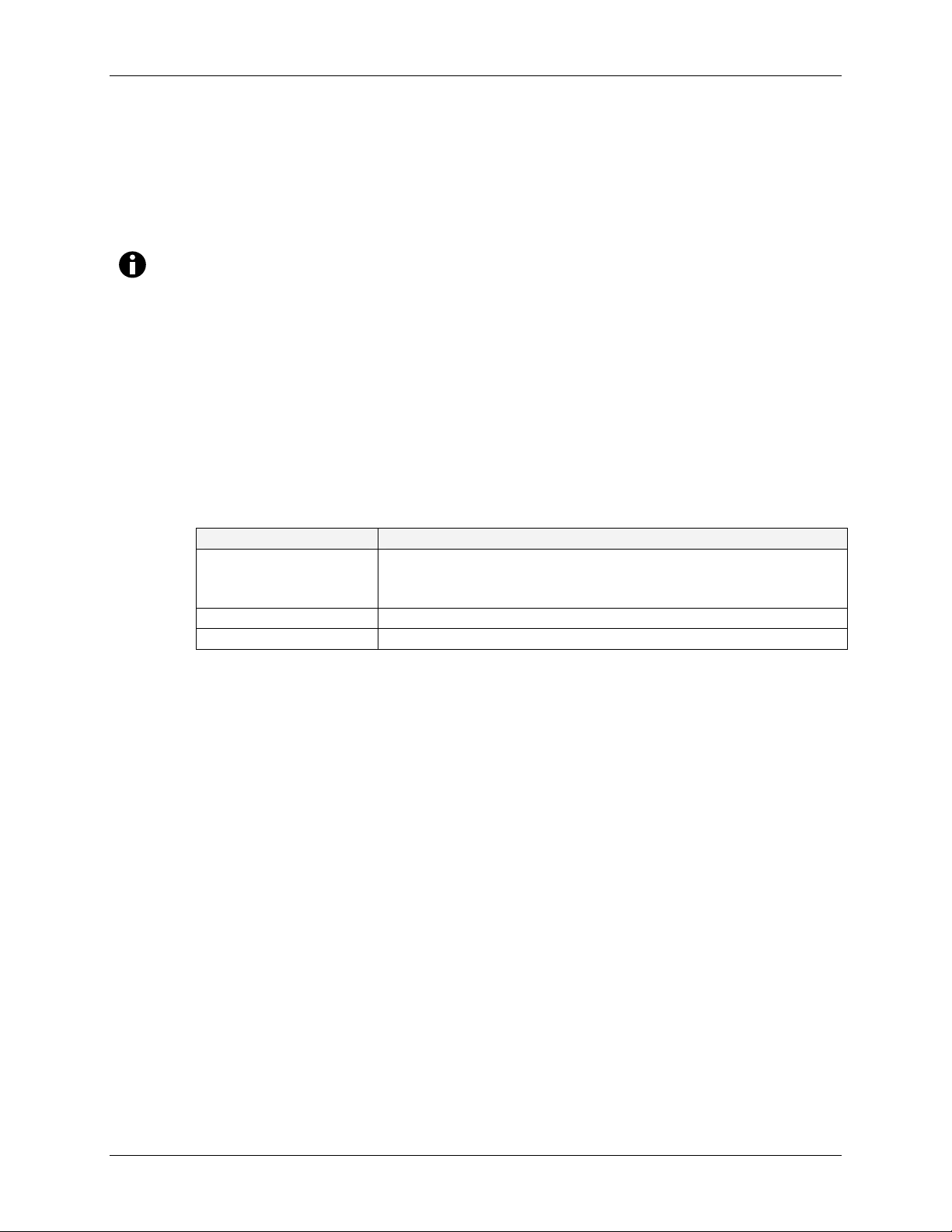

Table 1: Optional Bases

Number of Shakers Base Height

43.2 cm (17 in)

1

2 stacked 33.0 cm (13 in)

3 stacked 10.2 cm (4 in)

One 10.2 cm (4 in) base & one 33.0 cm (13 in) base,

bolted together at the factory

5.4 Preparing the Optional Base

1. Place the base on a sturdy (capable of bearing the weight of the combined base

shakers and shaker contents), level surface, making sure that all four corners are

solidly on the surface.

2. If the base is not level, place metal shims as needed under the base until it is level.

3. If you are mounting a single shaker, use the 43.2 cm (17 in) base as shown in Figure

3b. Bolt the shaker to the base using the hardware provided.

New Brunswick Operating Manual

Page 16

16

Figure 3a: Optional Short Base, 10.2 cm (4 in)

REAR CORNER

BRACE

10.2 cm (4 in)

BASE

FRONT SIDE BRACE

Figure 3b: Optional Tall Base, 43.2 cm (17in)

BASE MATING SUPPORTS

33 cm (13 in) BASE

4. As shown in Figures 3a-b, depending on the height of your base, install the front side

braces and rear corner braces on the base with the hardware provided, matched to the

holes in the base.

I-26/26R Incubator Shakers M1324-0050 Operating Manual

Page 17

17

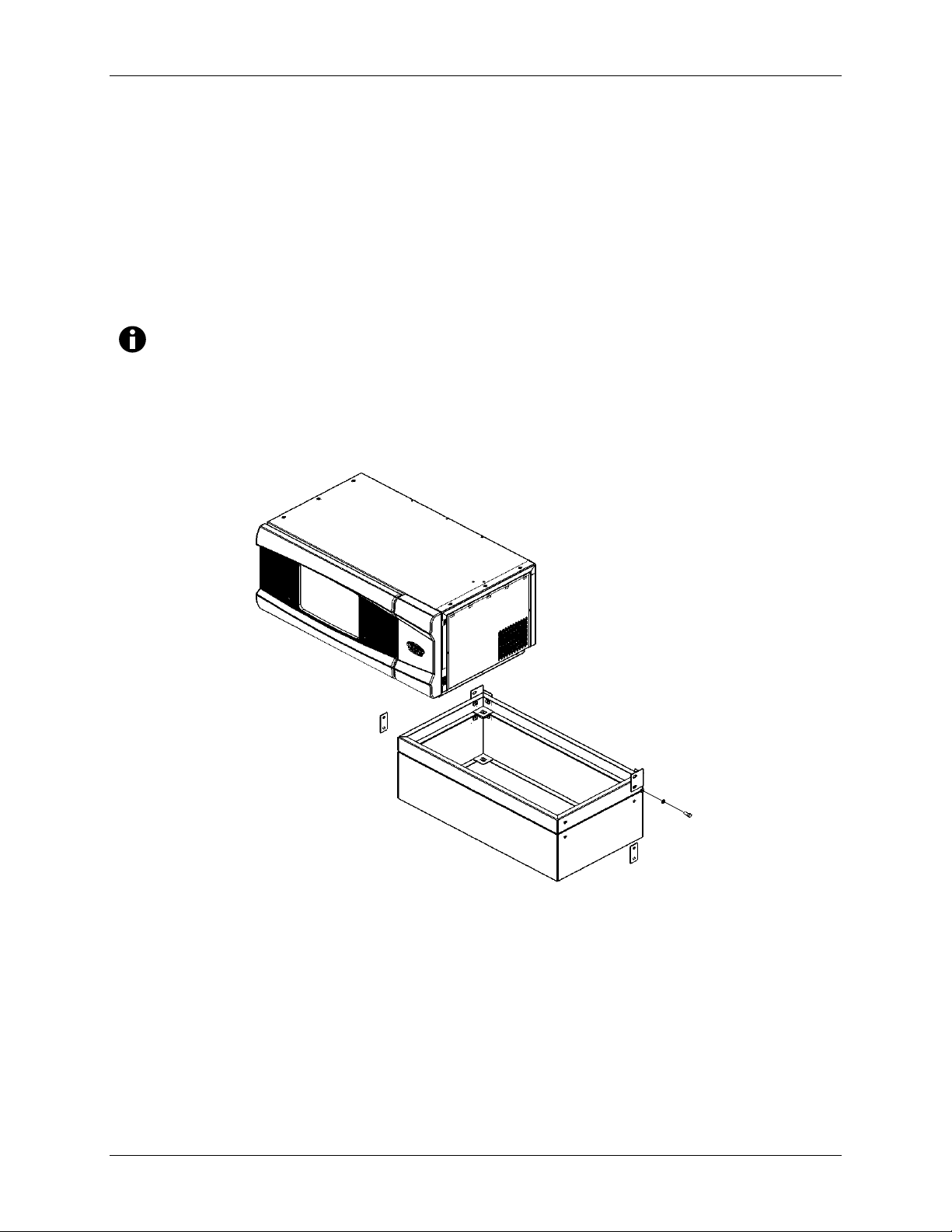

5.5 Mounting the I-26/26R on the Optional Base

1. Using a forklift or lifter, raise the I-26/26R so that its back end is tilted toward the

rear of the base.

2. Remove all six feet from the bottom of the shaker. They will not be needed for

stacking, but you may want to keep them for future use.

3. With two assistants, each holding the shaker on one side, lower the unit onto the base,

rear panel first. Slowly and gently remove the forklift or lifter and lower the front of

the unit onto the base by hand.

Optional handles are available to facilitate maneuvering the shaker onto the

base. See Section 10.3.7 for details.

Figure 4: Mounting Shaker on Base

4. Using the ½-13 x 1¼-inch Allen head screws, ½-inch lock washers, and washers

provided, secure the rear of the I-26/26R to the corner braces in the base. With the

remaining ½-13 x 1¼-inch Allen head screws, ½-inch lock washers, and washers,

attach the front corner braces to the unit.

5. Attach the front corner braces to the base using the two sets of ½-13 x 1¼-inch Allen

head screws, lock washers, and washers provided, and secure as shown in Figure 5.

New Brunswick Operating Manual

Page 18

18

Figure 5: Mounting Corner Braces

With the corner braces securely in place, the shaker mounted on its base will look like

this:

Figure 6: Shaker Installed on Base

6. Make sure the shaker is level; add metal shims under the base as needed to level the

unit.

7. Fully load the shaker and do a test run at normal speed. Make additional leveling

adjustments if necessary.

I-26/26R Incubator Shakers M1324-0050 Operating Manual

Page 19

19

5.6 Installing the I-26/26R Stacking Kit

CAUTION!

If the shaker you will place on the bottom is already mounted on a 43.2 cm

(17 in) base, follow these instructions first:

To stack two shakers: (1) remove the 10.2 cm (4 in) high section of the base,

(2) remove the base mating supports, (3) move the corner braces from the

10.2 cm base to the 33.0 cm (13 in) base, (4) reinstall the shaker on the

33.0 cm base.

To stack three shakers: (1) remove the 33.0 cm (13 in) high section from the

bottom of the base, (2) remove the base mating supports.

1. Remove the six ½-inch plastic slotted set screws and the three ¼-inch plastic socket set

screws from the top of the shaker installed on the base.

Figure 7: Preparing to Stack Shakers

2. Using the six ½-13 x 1-inch hex head screws, lock washers, and washers provided,

attach the stacking kit stacking rails to the top sides of the unit installed on the base.

Secure the rails in place as shown in Figure 8.

3. Install the stacking stop bracket to the top back of the unit installed on the base, using

the three ¼-20 x 5/8-inch hex head screws, lock washers, and washers provided, as

shown in Figure 8 on the following page.

New Brunswick Operating Manual

Page 20

20

STOP BRACKET

Figure 8: Installing Stacking Kit Brackets

STACKING RAILS

5.7 Stacking the I-26/26R

1. Using a forklift or lifter, raise the I-26/26R to be stacked so that its back end is tilted

toward the rear of the mounting brackets.

2. Remove the feet from the unit. They will not be needed for stacking, but you may

want to keep them for future use.

3. With two assistants, each holding the unit on one side, lower the shaker onto the

mounting brackets, rear panel first. Slowly and gently remove the forklift or lifter

and lower the front of the unit onto the mounting brackets by hand.

Figure 9: Stacked Shakers

Fasten upper shaker

to stacking rails on

both sides and to the

rear stop bracket.

I-26/26R Incubator Shakers M1324-0050 Operating Manual

Page 21

21

4. As indicated in the above drawing, secure the bottom of the upper I-26/26R to the

side stacking rails using the six ½-13 x 1-inch screws, lock washers, and washers

provided. Also secure the upper unit to the stop rail using three ¼-20 x 5/8-inch hex

head screws, lock washers and washers.

5. As before, make sure the shakers are level; add metal shims under the base if needed.

6. Fully load the shaker and do a test run at normal speed. Make additional leveling

adjustments if necessary.

5.8 Stacking a Third I-26/26R

CAUTION!

Be sure to use the 10.2 cm (4 in) base only when you stack 3 shakers.

ALERT!

When stacking 3 shakers, it is imperative that all shaker loads be balanced.

These shakers operate best at maximum speed with a load of 15.5 kg 1.4

kg (34 lbs, 3 lbs), which includes all platforms, clamps, and filled

glassware. (See Load & Speed graphs in Section 5.8.1 for more information)

To stack a third shaker, repeat the procedures in sections 5.6 and 5.7 to install the

stacking kit, stack the shaker, and level the entire assembly.

5.8.1 Load and Speed Graphs

Figures 9a and 9b, show the maximum recommended speed for unstacked and

stacked shakers, according to load.

New Brunswick Operating Manual

Page 22

22

Figure 9a: Load & Speed for One Unstacked Shaker

400

350

300

250

200

150

Maximum Recommended Speed (RPM)

100

50

0

<30 30 to 36 36 to 40 40 to 60 >60

50,

125 ,

250 mL

20 % Ful l

Pl atfo rm and L oad (lb)

1L ,

2L ,

2.8L

20% Full

In both Figures 9a and 9b, “20% Full” refers to the amount of liquid in the

flasks. The platforms are fully loaded with flasks.

Figure 9b: Load & Speed for Stacked Shakers

250

200

150

50,

125,

100

Maximum Rec omm ended Sp ee d (RP M)

50

0

<30 30 to 36 36 to 40 40 to 60 >60

250 mL

20% Full

Platf orm a nd Load ( lb)

1L ,

2L ,

2.8L

20% Full

I-26/26R Incubator Shakers M1324-0050 Operating Manual

Page 23

23

6.1 Keypad

STATUS

INDICATORS

Figure 10: Keypad

66

F

EEAATTUURREES

F

DISPLAY

USER

INTERFACE

KEYS

S

6.2 LED Display

The digital display on the control panel is a three-digit LED DISPLAY. During normal

shaker operation, the display will indicate:

Shaker status (On/Off)

Shaking speed

Chamber temperature

Setpoints

Hours remaining (in a timed run)

Door (“

In addition, if the shaker should enter into an unstable operating condition (unbalanced

load causing excess vibration, unlevel floor, etc.), the warning message “tLt” will appear

in the LED display and the tilt switch will shut the shaker off.

LId”) open

New Brunswick Operating Manual

Page 24

24

6.3 User Interface Keys

START/STOP

SELECT

▲ (UP), ▼(DOWN)

6.4 Status Indicators

Four status indicator lights are located to the left of the LED DISPLAY. They are:

SET

POWER

HEAT

TIME

This key is used to start or stop the shaker. It will

also activate or stop the timer when a timed run is

desired.

This key is used to change the displayed parameter.

These keys are used to adjust the setpoint of a

displayed parameter up or down. They also allow

the user to enter the SET MODE for setpoint

changes.

Indicates that the shaker is in the SET MODE,

when setpoints are being displayed and can be

altered. This is activated by the SELECT key

or by pressing the ▲(UP), ▼(DOWN) arrow.

Illuminates and blinks during power up or if

power is interrupted during a run. Press the

SELECT key and change to another function to

turn off this indicator.

Illuminates to indicate that the heater is on.

Indicates that the timer is in operation. The

shaker can be programmed to run for a preset

time from 0.1 to 99.9 hours. The timer can be

disengaged without stopping an ongoing run.

I-26/26R Incubator Shakers M1324-0050 Operating Manual

Page 25

25

6.5 Function Indicators

Four function indicator lights are located to the right of the LED DISPLAY. They indicate

the current parameter(s) being displayed:

C

Interior chamber temperature. Can be set from

4°C to 60°C, when in SET MODE, using the

▲(UP), ▼(DOWN) arrow key. It indexes at

0.1°C increments unless the key is pressed for

4 seconds, after which it indexes in 1°C

increments.

RPM

Revolutions per minute. When in

SET MODE,

use the ▲(UP), ▼(DOWN) arrow key to change

the speed. It indexes at 1 RPM increments

unless the key is pressed for 4 seconds, after

which it indexes by increments of 10 RPM.

HRS

Time remaining in a timed run. Can be set

from 0.1 to 99.9 hours, in 0.1 increments or, if

the ▲(UP), ▼(DOWN) arrow key is pressed for

4 seconds, in increments of 5 hours.

The countdown begins when the START/STOP

key is pressed. If the START/STOP key is

pressed again, the shaking stops (but

temperature is maintained) and the timer

pauses until the START/STOP key is pressed

again.

When a timed run ends, the HRS indicator will

blink. Press the

SELECT key and change to

another function to turn off this indicator.

MUTE

This feature is controlled by the SELECT key.

When activated, the audible alarm is muted,

remaining so until it is reactivated. If

MUTE is

activated when the shaker is turned off using

the

ON/OFF switch, MUTE will be engaged

when it is powered up again. To activate (or

deactivate) the

SELECT key until the MUTE indicator

MUTE function, press the

illuminates; press the ▲ or ▼ KEY to display

ON or OFF, as desired; then press SELECT.

New Brunswick Operating Manual

Page 26

26

77

7.1 Platform Assemblies

The I-26/26R can be used with a New Brunswick universal, dedicated, or Sticky Pad

platform. Universal platforms accept a variety of clamps for flasks, test tubes, etc.

Dedicated platforms are supplied with clamps already installed. Sticky Pad platforms do

not have holes because they do not require clamps; the adhesive quality of the Sticky Pad

or Sticky Tape applied to the platform holds flasks in place.

Sticky Pad and Sticky Tape are options that are sold separately.

A platform is a separate item, not included with the shaker assembly, but which is

required for operation. (See Section 7.3 for details about installing and removing

the platform, and Section 10.3 for details about available accessories.)

7.2 Installation of Clamps

If you are not using a New Brunswick Universal Platform, skip this section. Flask

clamps purchased for use with universal platforms require installation. All New

Brunswick clamps are shipped complete with hardware. Clamps are installed by securing

the base of the clamp to the platform with the smaller Phillips head (+) screws supplied

with the New Brunswick clamps.

Clamps for 2- and 2.8-liter flasks are shipped with an additional girdle to keep the flasks

in place. We strongly recommend the use of this additional girdle because it keeps the

flask from spinning inside the clamp. The girdle is an assembly of springs and sections

of rubber tubing. One girdle is already in place on the clamp, the other is packed

separately. To install these double girdle clamps:

1. Place the clamp on the platform, aligning its mounting holes with holes on the

platform. Secure the clamp in place using the flat Phillips head screws provided

(#S2116-3051, 10-24 x 5/16-inch); see Figure 11b to help you identify them.

2. With the first girdle in place, as delivered, on the upper part of the clamp body (see

Figure 11a), insert an empty flask into the clamp.

3. After making sure the sections of tubing are located between the clamp legs, roll the

first girdle down the legs of the clamp as far as it can go. The tubing sections will

rest against the platform, and the springs will be under the clamp base.

4. Place the second girdle around the upper portion of clamp body (just as the first

girdle was initially). Make sure that its spring sections rest against the clamp legs,

while its rubber tubing sections sit against the flask, in between the clamp legs.

G

EETTTTIINNGG

G

S

TTAARRTTEED

S

D

I-26/26R Incubator Shakers M1324-0050 Operating Manual

Page 27

27

Figure 11a: 2- & 2.8-Liter Clamp Installation

CLAMP

MOUNTING

HOLES (5)

UPPER GIRDLE

WITH GIRDLE

TUBES

LOWER

GIRDLE WITH

GIRDLE TUBES

CLAMP BODY

(LEGS AND BASE)

Figure 11b: Clamp Fastener

The upper girdle secures the flask within the clamp, and the bottom girdle

keeps the flask from spinning.

7.3 Installing/Sliding out Platform

The I-26/I-26R is delivered with the subplatform bolted in place on the bearing housing.

The addition of a platform is required for shaker operation.

Installing a platform of any variety is very easy:

1. Remove the two knobs and washers on the front of the subplatform.

2. Using the side handles of the platform (see Figure 12), place the platform on the

guide strips on the flat of the open door.

3. Push it toward the rear of the unit, aligning the bottom of the platform with the top of

the subplatform, and making sure the sides are squared up with the subplatform sides.

4. When it is fully inserted and mated to the subplatform, replace the washers and knobs

on the subplatform.

New Brunswick Operating Manual

Page 28

28

5. Verify that the platform is now secured to the subplatform and the drive.

Figure 12: Installing Platform

PLATFORM

KNOB

SUBPLATFORM

All platforms, once installed, will easily slide in and out of the shaker:

1. Unscrew both knobs and remove the knobs and the washers on the front of the

platform to release the platform from the subplatform.

2. Pull the platform forward to rest on the door guide strips. The two stop pins in the

door will keep the platform from falling off the subplatform.

3. Slide it back in and be sure to replace the washers and knobs before operating the

shaker again.

7.4 Electrical Connections

Before making electrical connections, verify that the power source voltage matches the

voltage on the ELECTRICAL SPECIFICATION PLATE and that the ON/OFF SWITCH is on

OFF position. The ELECTRICAL SPECIFICATION PLATE is located on the rear panel

the

of the unit near the POWER CONNECTOR.

I-26/26R Incubator Shakers M1324-0050 Operating Manual

Page 29

29

Connect the POWER CORD to the POWER CONNECTOR (Universal Voltage Input

Module), then connect the other end to a suitable, grounded receptacle.

Figure 13: Rear Panel

POWER

CONNECTOR

ELECTRICAL

SPECIFICATION

PLATE

ON/OFF

SWITCH

New Brunswick Operating Manual

Page 30

30

8.1 Starting the Shaker

To initially start the shaker, close the door and turn the ON/OFF SWITCH on the right side

panel of shaker to the ON position. When the shaker begins to operate, the LED DISPLAY

will track the speed as it accelerates to the last entered setpoint. The shaking action may

be started or stopped by pressing the

Figure 14: ON/OFF Switch Location

88

START/STOP KEY on the KEYPAD.

O

PPEERRAATTIIOON

O

KEYPAD

N

DOOR HANDLE (cut-

out under rim)

ON/OFF SWITCH

The shaker will not operate if the door is open. This is indicated by the word

LId appearing in the LED DISPLAY.

I-26/26R Incubator Shakers M1324-0050 Operating Manual

Page 31

31

8.2 Continuous (Unlimited) Run

1. Press SELECT until the RPM INDICATOR is illuminated.

2. If the display indicates that the shaker is OFF, press the START/STOP KEY.

3. Press either

▲(UP), ▼(DOWN) KEY to enter SET MODE (the SET INDICATOR will

illuminate).

4. Set the speed by using the

▲ or ▼ KEY until the desired setpoint is displayed.

Continued pressure on the ▲ or ▼ KEY will cause the setting to change more rapidly.

The setpoint may be changed during a run without stopping the shaker by

following steps 1-4 above.

8.3 Checking Any Setpoint

1. Press SELECT until the desired indicator is illuminated.

2. Briefly press either the ▲ or ▼ KEY to enter the SET MODE and display the current

setpoint.

Holding the ▲ or ▼ for more than 0.5 seconds causes the speed

setpoint to change. Should this occur, resetting will be necessary.

8.4 Timed Functions

The shaker may be programmed to automatically stop after a preset time period of 0.1 to

99.9 hours. There must be power to the shaker in order to set the timer, although a timed

run can be initiated while the unit is either stopped or operating.

To set the timer:

1. Press the

2. Press either

SELECT KEY until the HRS INDICATOR is illuminated.

▲ or ▼ KEY to enter the SET MODE and set the desired run time, between

0.1 and 99.9 hours.

If the shaker is stopped, skip to Step 5 below. If the shaker is already running:

3. Press the

START/STOP KEY. The shaker will stop and the display will read OFF.

4. Press the START/STOP KEY again; the TIME INDICATOR will light and the shaker will

start the timed run.

If the shaker is stopped:

5. Press the START/STOP KEY. The shaker will start in untimed mode.

New Brunswick Operating Manual

Page 32

32

6. Press the START/STOP KEY again. The shaker will stop and the display will read

OFF.

7. Press the START/STOP KEY a third time; the TIME INDICATOR will light and the

shaker will start the timed run.

To disable the visual alarm (flashing TIME INDICATOR), press the SELECT KEY and

change to any other function.

To cancel the timer while the shaker is running:

1. Press the SELECT KEY until the HRS indicator lights.

2. Press the

will read

▼ KEY until 0.0 is displayed, then press the START/STOP KEY. The display

OFF, the shaker will stop, and the TIME INDICATOR light will turn off.

3. Press the START/STOP KEY to continue in untimed mode.

To cancel the timer while the shaker is stopped:

1. Press the ▼ KEY until 0.0 is displayed, then press the START/STOP KEY. The TIME

INDICATOR

will light and the shaker will run.

2. Press the START/STOP KEY. The shaker will stop and the TIME INDICATOR will turn

off.

3. Press the START/STOP KEY a third time, and the shaker will run in untimed mode.

8.5 Alarm Functions

The I-26/26R shakers have an audible alarm which is activated at predetermined times.

It can be deactivated by using the MUTE function:

1. Press the SELECT key until the MUTE indicator illuminates.

2. Press the

▲ or ▼ KEY to display ON, then press the SELECT KEY.

To reactivate the audible alarm:

1. Press the SELECT key until the MUTE indicator illuminates.

2. Press the ▲ or ▼ KEY to display OFF, then press the SELECT KEY.

There is also a visual “tilt” alarm; see Section 8.10 for details.

I-26/26R Incubator Shakers M1324-0050 Operating Manual

Page 33

33

8.6 Temperature Setpoint

Press the SELECT KEY until the function C INDICATOR illuminates. The temperature can

be set from 5C above ambient temperature to 60C (non-refrigerated units) or from 4C

to 60C (refrigerated units). Increasing or decreasing the setpoint is accomplished with

the ▲ or ▼ KEY. Ambient temperature is measured one meter from the front of the unit.

During operation, if the temperature of the chamber is more than 1.0C higher or lower

than the temperature setpoint, an alarm is triggered. This alarm consists of a flashing C

INDICATOR

achieves the set temperature.

8.7 Temperature Offset Calibration

The temperature probe and the temperature controller are calibrated together at the

factory. The temperature probe measures the temperature of the air at the probe’s

location, near the heat exchanger return vent. The controller uses the probe input to

adjust air temperature, up or down, to match the temperature setpoint.

Depending on various conditions within the chamber, such as flask placement and size,

the heat produced by growing organisms, heat losses due to liquid evaporation from

flasks, etc., the display temperature may differ from temperatures within the flasks

themselves.

If you wish to have the temperature display (“Indicated Temperature”) match the

temperature at a given point, or match the average of a series of points within the

chamber (“Actual Temperature”), proceed as follows:

1. Let the unit equilibrate at or near the desired temperature. Record the Indicated

Temperature.

2. Record the Actual Temperature.

3. Calculate the temperature correction value: Actual Temperature – Indicated

Temperature = Temperature Correction Value.

4. Press the

5. Simultaneously press the ▲ or ▼ KEY. The display will indicate CAL.

6. Using the

above.

7. Simultaneously press the

memory.

and audible beep. The alarm will automatically deactivate as the unit

SELECT KEY until the function C INDICATOR illuminates.

▲ or ▼ KEY, enter the Temperature Correction Value calculated in Step 3

▲ or ▼ KEY to save the Temperature Correction Value to

New Brunswick Operating Manual

Page 34

34

The °C light will pulse rapidly to indicate it is not operating in the factory

default mode. It will pulse for a longer duration and less rapidly (with a

frequency of approximately one second) to indicate temperature is more

than one degree above or below setpoint.

To return to the factory calibration:

1. Press the SELECT KEY until the function C INDICATOR illuminates.

2. Simultaneously press the ▲ or ▼ KEY. The display will indicate CAL.

3. Using the ▲ or ▼ KEY, set the Temperature Correction Value to zero.

4. Simultaneously press the

▲ or ▼ KEY. The rapid pulsing of the C INDICATOR will

stop.

8.8 Power Failure

In the event of a power failure, the I-26/26R shakers are equipped with an automatic

restart function.

If the shaker was in operation prior to the power interruption, the shaker will begin to

operate at its last entered setpoint. The

LED DISPLAY will flash, indicating that a power

failure has occurred. Press any key to stop the flashing of the LED display.

8.9 Speed Calibration

To calibrate the shaking speed:

1. Set the shaker to a speed that can easily be measured. If you are using a strobe,

minimum speed should be 250 RPM.

2. Compare the reading on the display to the measured reading.

If an adjustment is needed:

1. Press the

2. Press the

SELECT KEY until the RPM indicator light illuminates.

▲ or ▼ KEYS simultaneously. The display will indicate CAL.

3. Press either the ▲ or ▼ KEY to change the displayed value to match the measured

speed.

4. Press the▲ or ▼ KEYS simultaneously to save the adjustment.

5. Turn unit

OFF using the power switch, then turn it back ON.

8.10 Tilt Switch

I-26/26R Incubator Shakers M1324-0050 Operating Manual

Page 35

35

The shaker is equipped with an independent mechanical sensing tilt switch that shuts off

the motor when it senses that the shaker is in an unbalanced condition, indicating tLt

(“tilt”) on the LED display.

When this happens, troubleshoot the situation to restore balance, then turn the power

switch OFF, then ON again to reset the system.

New Brunswick Operating Manual

Page 36

36

99

ELECTRICAL SHOCK WARNING!

When performing maintenance on the unit, always turn off the shaker

and disconnect the power cord from the power supply.

9.1 Cleaning External Surfaces

The unit may be cleaned using a damp cloth or any standard household or laboratory

cleaner to wipe down its outer surfaces. Do not use abrasive or corrosive compounds to

clean this instrument, as they may damage the unit and void the warranty.

9.2 Fuse Replacement

I-26 models require one 8-amp electrical fuse, which is housed in the fuse holder located

on the M1324-7004 PCB (see Figure 15d). I-26R models have two 8-amp electrical

fuses, housed in the two fuse holders located on the M1324-7003 PCB (see Figure 15e).

To check or replace a fuse:

1. Set the ON/OFF SWITCH to Off and disconnect the POWER CORD from the power

source.

2. Remove the front right bezel from the shaker: with one hand, grasp the top edge, and

with the other, using the cut-out provided on the bottom, grasp the bottom edge. Pull

the bezel up from the bottom, then out and away. Set it aside.

3. With reference to Figure 15a, remove the two screws that fasten the electrical panel

in place. Set the screws aside for reuse.

Figure 15a: Front Bezel Removed

P

P

RREEVVEENNTTIIVVEE

M

M

AAIINNTTEENNAANNCCE

Remove

screws

E

ELECTRICAL

PANEL

I-26/26R Incubator Shakers M1324-0050 Operating Manual

Page 37

37

4. Swing the ELECTRICAL PANEL to the right to access the PCB board that houses the

fuse(s); see Figures 15b (I-26) and 15c (I-26R).

Figure 15b: Rear of Electrical Panel (I-26)

FUSE HOLDER

(see Figure 15d for details)

Figure 15c: Rear of Electrical Panel (I-26R)

FUSE HOLDERS

(see Figure 15e for details)

New Brunswick Operating Manual

Page 38

38

Figure 15d: Fuse Holder Detail (I-26)

FUSE

Figure 15e: Fuse Holder Detail (I-26R)

FUSES

5. Remove the fuse and check it. If it has failed, replace the fuse.

6. Swing the

ELECTRICAL PANEL to the left, flush against the unit.

7. Using the screws set aside, fasten the ELECTRICAL PANEL in place.

8. With two hands, reinstall the front bezel, snapping the top in place first, then the

bottom. Verify that it fits snugly and securely.

I-26/26R Incubator Shakers M1324-0050 Operating Manual

Page 39

39

9.3 Belt Replacement

To gain access to the drive belt, your service technician will follow these steps with

reference to Figures 16, 16a & 17:

1. Make sure that the power is switched off and the shaker is unplugged.

2. For safety and to facilitate removal of the drive assembly, using a Phillips head

screwdriver, follow these steps with reference to Figure 16 to remove the door (save

all hardware for reuse):

a. Remove the brackets that hold the door to its check latches.

b. Remove the gas shock bracket.

c. Carefully close the door so the latches are holding the door closed.

d. Unscrew the hinge from the base of the shaker.

e. Remove the door.

Figure 16: Removing the Door

DOOR LATCH

GAS SHOCK

BRACKET

DOOR CHECK

LATCH BRACKET

3. Remove the platform.

4. With reference to Figure 16a on the following page, remove the drive assembly

following these steps:

a. Using a 7/32-inch Allen key (hex wrench), remove the four bolts that hold the

subplatform in place, and remove the subplatform.

b. Disconnect the motor by unplugging its connector.

New Brunswick Operating Manual

Page 40

40

c. With a wrench, remove the nuts that hold the bearing housing to the bottom

weldment.

d. Position the counterweight so it is closest to you, and tie it in place with tie wraps

or strong cord, in order to prevent it from dropping against your fingers or

causing you to lose your grip.

e. Remove the bearing housing with care: it weighs 21.3 kg (47 lbs).

Figure 16a: Removing the Drive Assembly

SUBPLATFORM

BOTTOM

WELDMENT

BEARING

HOUSING

5. Turn the bearing housing over to access the belt, motor and pulley.

To replace the drive belt, follow these steps with reference to Figure 17 on the

following page:

1. Loosen the four hex nuts that hold the motor assembly in place and remove the old belt.

2. Guide the belt onto the two pulley grooves.

3. Tighten the motor nuts.

4. Check the belt adjustment by applying finger pressure to the belt midway between the

two pulleys. The belt should deflect approximately 9-10 mm (3/8 in).

5. If the deflection is not right, loosen the nuts, readjust the belt, and retighten the motor

nuts.

I-26/26R Incubator Shakers M1324-0050 Operating Manual

Page 41

41

Figure 17: Belt Replacement & Adjustment

DRIVE BELT

PULLEY

BEARING

HOUSING

FOUR MOTOR FIXING BOLTS

(loosen for belt tensioning)

MOTOR

If an adjustment is required:

1. Loosen the four hex nuts on the motor assembly.

2. Move the motor assembly until the belt is tight.

3. Tighten the hex nuts and recheck the belt tension by exerting pressure on the belt.

The belt should deflect approximately 9-10 mm (3/8 in).

Reassembly:

1. In reverse order, reinstall the bearing housing. Once it is securely in place, remove

the tie wraps/cord.

2. Secure the wiring to ensure no interference during rotation.

3. Reinstall the subplatform and platform.

4. Recalibrate speed (see Section 8.9).

New Brunswick Operating Manual

Page 42

42

10.1 Troubleshooting

If any problems occur with your shaker, do not attempt to perform any service on the unit

other than specified in this manual. Unauthorized servicing may void the warranty.

Please contact your local Sales Order Department

In any correspondence with New Brunswick or Eppendorf, please refer to the Model

Number and Serial Number of your unit. This information is on the

SPECIFICATION PLATE

CONNECTOR

panel, below the chamber door seal.

There are some problems, however, that you can investigate and correct yourself. Refer

to the following Troubleshooting Guide:

Symptom(s) Probable Cause(s) & Solution(s)

Shaker does not run.

Shaker runs slowly

and/or no speed

indication.

. The Serial Number is also labeled in the lower right corner of the front

, located on the rear panel of the unit, above the POWER

S

1100

ELECTRICAL

No power; display is not on; power cord is not plugged in and/or

power switch is off: plug in power cord (to working electric

outlet), and turn on power switch.

Door is open: close door firmly, making sure latch is engaged.

Door is closed but not completely: door magnet is not adjusted

correctly; call for service.

On/Off switch is not working: call for service.

Tilt switch has been triggered. Check to ensure the load is

evenly distributed and that the shaker is level on a solid surface.

Restart by pressing the START/STOP button.

Fuse(s) burned out: check and replace as needed.

If you recently replaced a fuse, it may not have been seated

properly: remove and reinstall the fuse carefully.

Shaking speed has been set to Zero by program running or by

computer interface: reset shaking speed.

Defective main board: call for service

Defective display controller board: call for service.

Jammed shaking mechanism: check for debris; if necessary,

call for service

Defective motor: call for service

Drive belt out of alignment or worn: call for service.

If you recently replaced a fuse, it may not have been seated

properly: remove and reinstall the fuse carefully.

Incorrect speed calibration: recalibrate shaking speed.

Defective main board: call for service.

Defective tach board: call for service

Defective motor: call for service.

Drive belt is out of alignment or worn: call for service.

...continued...

EERRVVIICCE

S

E

I-26/26R Incubator Shakers M1324-0050 Operating Manual

Page 43

43

Symptom(s) Probable Cause(s) & Solution(s)

Shaker does not run at

set speed.

Incubator does not

reach set temperature.

indication.

Shaker is overloaded and/or you are using baffled flasks:

remove some contents & balance load.

Defective motor: call for service.

Drive belt out of alignment or worn: call for service.

Load out of balance: unload all contents, then reload. Operating noise

Loose component(s) in platform, subplatform and/or drive

assembly: call for service.

Heater fuse blown: replace.

Compressor fuse blown: replace.

Compressor over-pressure switch activated: call for service.

Ambient temperature too high or too low: cool or heat the room

as needed.

Defective heater: call for service.

Defective refrigeration system: call for service.

Incorrect temperature indication (see below).

Defective RTD assembly: call for service. Incorrect temperature

Defective main board: call for service.

10.2 Replacement Parts

When ordering replacement parts, or requesting service information, please provide the

Model Number and Serial Number of your shaker. This information is on the

ELECTRICAL SPECIFICATION PLATE, located on the rear panel of the unit. The Serial

Number is also labeled in the lower right corner of the front panel, below the chamber

door seal.

Part Description Qty Req’d Part Number

8.0A Fuse (Motor) 1 (I-26)

2 (I-26R)

15A Circuit Breaker 1 P0400-4305

120V 15A Power Cord 1 P0720-2024

220V Power Cord 1 P0720-2021

Poly-V Belt 1 P0700-7070

Gasket, Door 1 M1324-9508

Damper, Slam-Preventing (gas shock bracket) 2 P0640-0385

AC Connector, Power Entry 1 P0460-2205

Drive Assembly 1 M1324-5010

P0380-3790

Belt Replacement Hardware:

Part Description Qty Req’d Part Number

3/8-16 NC x 1¼-inch long flat head Allen

screw

3 S1127-3206

New Brunswick Operating Manual

Page 44

44

10.3 Accessories

When ordering accessories, please provide the Model Number and Serial Number of your

shaker. This information is on the ELECTRICAL SPECIFICATION PLATE, located on the

rear panel of the unit. The Serial Number is also labeled in the lower right corner of the

front panel, below the chamber door seal.

10.3.1 Available Platforms, 46 x 76 cm (18 x 30 in)

Dedicated Platforms include flask clamps, pre-installed:

Application Capacity Part Number

125 ml Erlenmeyer Flasks 60 M1324-9905

250 ml Erlenmeyer Flasks 40 M1324-9906

500 ml Erlenmeyer Flasks 24 M1324-9907

1 L Erlenmeyer Flasks 15 M1324-9908

2 L Erlenmeyer Flasks 12 M1324-9909

2.8 L Erlenmeyer Flasks 6 M1324-9910

A Sticky Pad Platform (P/N M1324-9911), eliminates the need for flask clamps.

Sticky Pad (P/N M1250-9700) sold separately.

A Universal Platform (P/N M1324-9904) provides maximum flexibility for

mixing various sized glassware on a single platform. Flask clamps, test tube racks

and accessories sold separately.

10.3.2 Flask Clamps for Universal Platforms

Clamp Size Part Number

10 ml Erlenmeyer Flask ACE-10S

25 ml Erlenmeyer Flask M1190-9004

50 ml Erlenmeyer Flask M1190-9000

125 ml Erlenmeyer Flask M1190-9001

250 ml Erlenmeyer Flask M1190-9002

500 ml Erlenmeyer Flask M1190-9003

1 L Erlenmeyer Flask ACE-1000S

2 L Erlenmeyer Flask ACE-2000S

2.8 L Fernbach Flask ACFE-2800S

10.3.3 Replacement Clamp Hardware Kits

New Brunswick Flask Clamps come complete with the proper hardware kits.

However, from time to time you may want to obtain some additional Hardware

Kits. The following table identifies the proper screws for your shaker application

by reference to the head style and size.

I-26/26R Incubator Shakers M1324-0050 Operating Manual

Page 45

45

Description Part Number Qty. Application

10-24 x 5/16 (7.9 mm) flat

Phillips head screw

S2116-3051 1 7.9 mm (5/16 in) thick

aluminum

10.3.4 Carriers and Test Tubes

Accessory Description Part

Adjustable angle Test Tube

Rack for tubes 8 – 11 mm

diameter

Adjustable angle Test Tube

Rack for tubes 12 - 15 mm

diameter

Adjustable angle Test Tube

Rack for tubes 15 –18 mm

diameter

Adjustable angle Test Tube

Rack for tubes 18 – 21 mm

diameter

Adjustable angle Test Tube

Rack for tubes 22 – 26 mm

diameter

Adjustable angle Test Tube

Rack for tubes 26 - 30 mm

diameter

Microplate holder rack

(stacked)

Microplate holder rack

(single layer)

Angled Test Tube Rack Holder* for user-supplied test tube

racks that are 4-5 in. (10-13 mm) wide and up to 15 in.

(38 mm) long.

Angled Test Tube Rack Spacer Bar* for use with TTR-210

to accommodate test tubes racks that are less than 5 in.

(13 mm) wide.

* Universal Platform Required

80 tube capacity M1289-0100 7

60 tube capacity M1289-0010 9

48 tube capacity M1289-0001 9

60 tube capacity M1289-0200 7

44 tube capacity M1289-0020 9

34 tube capacity M1289-0002 9

42 tube capacity M1289-0300 7

31 tube capacity M1289-0030 9

24 tube capacity M1289-0003 9

30 tube capacity M1289-0400 7

23 tube capacity M1289-0040 9

18 tube capacity M1289-0004 9

22 tube capacity M1289-0500 7

16 tube capacity M1289-0050 9

13 tube capacity M1289-0005 9

20 tube capacity M1289-0600 7

16 tube capacity M1289-0060 9

12 tube capacity M1289-0006 9

3 deep well or 9 standard M1289-0700 16

5 deep well or standard TTR-221 4

Number

TTR-210

TTR-215

Platform

Capacity

4

NA

10.3.5 Optional Bases for I-26/26R

Description Part Number

10.2 cm (4 in) Base (“Short Base”) M1324-0600

33.0 cm (13 in) Base (“Medium Base”) M1324-0800

43.2 cm (17 in) Base (“Tall Base”) M1324-0700

New Brunswick Operating Manual

Page 46

46

The 43.2 cm (17 in) Tall Base is made of the 10.2 cm (4 in) and 33.0 cm (13 in)

bases, bolted together at the factory.

10.3.6 Stacking Kit for I-26/26R

Description Part Number

Stacking hardware (to stack two units) M1324-0500

10.3.7 Optional Handles

Description Part Number

Screw-in handles (4 pieces in kit) M1282-5042

Each shaker has two threaded holes at the bottom of both side panels. You can

screw the optional handles into these holes. They are useful for lifting the shaker

onto an optional base, for example.

CRUSH WARNING!

Make sure that any persons who will use these handles (for minor

moves or lifts only) take proper precautions to protect their hands, feet

and backs from injury.

Do not use the screw-in handles to lift the shaker if it is fastened to a base.

I-26/26R Incubator Shakers M1324-0050 Operating Manual

Page 47

47

11.1 Control Schematics

Figure 18: Control Schematics, Overview

1111

D

D

WIINNGGSS

RRAAW

For a larger version of this drawing, contact your sales or service

representative.

New Brunswick Operating Manual

Page 48

48

230Vac/50Hz OPERATION

COND. FAN

ORANGE

M1324-8017

OVER PRESSURE

SWITCH

M1324-8016

COMPRESSOR

UNIT

Figure 19a: 230V Schematic

POWER

TRANSFORMER

M1324-8015

N

230V

100V

120V

TB001

RED

ORANGE

BLACK

WHITE

YELLOW

VIOLET

M1324-8001

BLUE

RED

WHITE

ORANGE

BLACK

BLACK

BLACK

1

BLACK

VIOLET

2

M1324-8017

FROM

M1324-7003

J4-1

J4-3

J4-5

J4-2

J4-4

J4-6

Figure 19b: 100V/60 Hz Schematic

100Vac/60Hz OPERATION

POWER

TRANSFORMER

M1324-8015

230V

100VN120V

TB001

COND. FAN

ORANGE

M1324-8017

OVER PRESSURE

SWITCH

M1324-8016

COMPRESSOR

UNIT

BLUE

RED

ORANGE

WHITE

BLACK

BLACK

BLACK

BLACK

1

VIOLET

2

M1324-8017

FROM

M1324-7003

ORANGE

BLACK

RED

WHITE

YELLOW

VIOLET

M1324-8001

J4-3

J4-5

J4-1

J4-2

J4-4

J4-6

I-26/26R Incubator Shakers M1324-0050 Operating Manual

Page 49

49

Figure 19c: 100V/50 Hz Schematic

100Vac/50Hz OPERATION

POWER

TRANSFORMER

M1324-8015

230V

100VN120V

FROM

M1324-7003

ORANGE

RED

BLACK

WHITE

YELLOW

VIOLET

M1324-8001

J4-3

J4-1

J4-5

J4-2

J4-4

J4-6

COND. FAN

ORANGE

M1324-8017

OVER PRESSURE

SWITCH

M1324-8016

COMPRESSOR

UNIT

BLUE

RED

ORANGE

WHITE

BLACK

BLACK

BLACK

M1324-8017

BLACK

1

VIOLET

2

TB001

Figure 19d: 120V Schematic

COND. FAN

ORANGE

M1324-8017

OVER PRES SURE

SWITCH

M1324-8016

COMPRESSOR

UNIT

120Vac/60Hz OPERATION

TB001

BLUE

BLACK

BLACK

1

BLACK

2

M1324-8017

VIOLET

FROM

M1324-7003

RED

ORANGE

BLACK

WHITE

YELLOW

VIOLET

M1324-8001

J4-1

J4-3

J4-5

J4-2

J4-4

J4-6

New Brunswick Operating Manual

Page 50

50

Figure 20: Refrigeration Diagram

I-26/26R Incubator Shakers M1324-0050 Operating Manual

Page 51

51

11.2 List of Drawings

Figure Description Page

1 Front View 8

1a Dimensions 13

2 Adjustable Foot 15

3a Optional 4-Inch Base 16

3b Optional 17-Inch Base 16

4 Mounting Shaker on Base 17

5 Mounting Corner Braces 18

6 Shaker Installed on Base 18

7 Preparing to Stack Shakers 19

8 Installing Stacking Kit Brackets 20

9 Stacked Shakers 20

9a Load & Speed for One Unstacked Shaker 22

9b Load & Speed for Stacked Shakers 22

10 Keypad 23

11a 2- & 2.8-Liter Clamp Installation 27

11b Clamp Fastener 27

12 Installing Platform 28

13 Rear Panel 29

14 ON/OFF Switch Location 30

15a Front Bezel Removed 36

15b Rear of Electrical Panel (I-26) 37

15c Rear of Electrical Panel (I-26R) 37

15d Fuse Holder Detail (I-26) 38

15e Fuse Holder Detail (I-26R) 38

16 Removing the Door 39

16a Removing the Drive Assembly 40

17 Belt Replacement & Adjustment 41

18 Control Schematics, Overview 47

19a 230V Schematic 48

19b 100V/60 Hz Schematic 48

19c 100V/50 Hz Schematic 49

19d 120V/60 Hz Schematic 49

20 Refrigeration Diagram 50

New Brunswick Operating Manual

Page 52

52

A

Abbreviations

Glossary of · 6

Accessories · 44

Actual Temperature · 33

Alarm Functions · 32

ALERT

Explanation of · 6

Audible Alarm

Disabling · 32

B

Base Part Numbers · 45

Base Sizes · 15, 45

Belt Replacement · 39

Belt Replacement Hardware · 43

C

Calibrating Speed · 34

Carriers · 45

CAUTION

Explanation of · 6

Symbol for · 3

Certifications · 9

Checking Setpoints · 31

Clamps

Installation of · 26

Continuous Run · 31

Control Schematics · 47, 48, 49

D

DANGER

Explanation of · 6

Declaration of Conformity · 9

Dimensions · 13

Drawing Index · 51

Drawings

List of · 51

1122

Flask Clamps · 44

Function Indicators · 25

Fuse

Replacement · 36

H

Handles · 17, 46

Hazard symbols · 6

I

Indicated Temperature · 33

Inspection

of Boxes · 11

Installing Clamps · 26

L

LED Display · 23

Leveling

Base (optional) · 15

One shaker, no base · 14

Shaker on base · 18

LId in Display · 23, 30

Load & Speed Graphs · 21, 22

M

Manual Conventions · 3, 6

N

NOTE

Symbol for · 3

NOTICE

Explanation of · 6

O

Operation · 30

Overview · 7

I

NNDDEEX

I

X

E

Electrical Connections · 28

Electrical Requirements · 12

Environment · 12

F

Features

Status Indicators · 24

I-26/26R Incubator Shakers M1324-0050 Operating Manual

P

Platform

Installing the · 27

Sliding the · 27

Platform Assemblies · 26

Platforms · 44

Power Failure · 34

Problems · 42

Page 53

53

R

Refrigeration Diagram · 50

Regulatory Standards · 9

Replacement Parts

Clamp Hardware Kits · 44

Replacement Parts · 43

S

Space Requirements · 13

Specifications · 8

Speed Calibration · 34

Stacking

Installing Hardware Kit · 19

Stacking Kit · 46

Starting the Unit · 30

Status Indicators · 24

T

Temperature Correction Value · 33

Temperature Offset Calibration · 33

Temperature Setpoint · 33

Test Tubes · 45

Tilt Switch · 7, 35

Timed Functions · 31

Timer

Cancelling the · 32

tLt in Display · 23, 35

Troubleshooting · 42

U

Unlimited Run · 31

User Interface Keys · 24

V

Visual Alarm

Disabling · 32

W

WARNING

Explanation of · 6

Symbol for · 3

New Brunswick Operating Manual

Page 54

54

I-26/26R Incubator Shakers M1324-0050 Operating Manual

Loading...

Loading...