Endress+Hauser CYM290 Specifications

TI01198C/07/EN/03.16

71326008

Products

Solutions Services

Technical Information

Liquiline To Go CYM290 and

Liquiline To Go Ex CYM291

Portable multiparameter device for Memosens

pH, conductivity and oxygen sensors.

Measuring device for hazardous and non-hazardous areas

Application

Liquiline To Go is a portable multiparameter handheld for pH,

ORP, conductivity and oxygen measurement. The outstanding

features of the device include:

• Operation in hazardous areas to Zone 0 (CYM291)

• Use of digital Memosens sensors

• The robust, high-performance polymer housing stands for

excellent shock resistance and dimensional stability even

with intensive impact from moisture.

Your benefits

Reliability and flexibility

• Easy commissioning

• Memosens: plug & play lab-calibrated sensors

• Waterproof and robust housing with IP66/67 protection

Safety

• Active indication of cable disconnect

• CYM291 Ex Approvals: IECEx, ATEX

Liquiline To Go CYM290 and Liquiline To Go Ex CYM291

1

2

3

4

Function and system design

Liquiline To Go CYM290 and Liquiline To Go Ex CYM291 are portable multiparameter measuring

devices for the use of analog (CYM290 only) and digital sensors.

The device automatically detects when a Memosens sensor is connected and switches to the

appropriate measured variable. By simply plugging in a new Memosens sensor, the device can

measure conductivity, the pH value and oxygen.

Operation is simple and intuitive, and supported by info text and help.

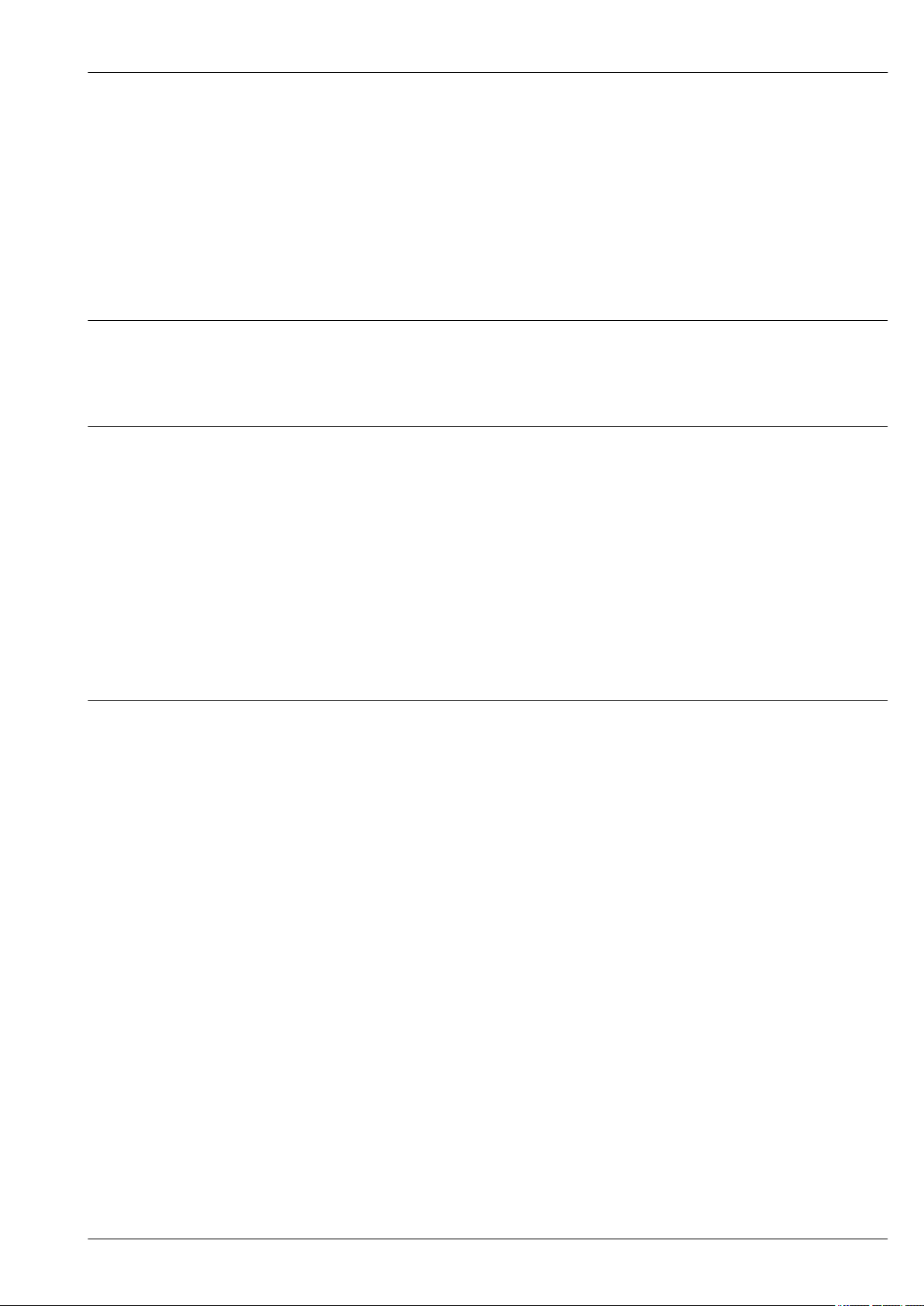

Liquiline To Go CYM290

QVGA TFT illuminated display

Liquiline To Go Ex CYM291

LCD STN 7-segment display with 3 lines and icons

A0024765

1 Liquiline To Go functions

1 Connections

2 Display

3 Keypad

4 Holder for pH sensors

2 Endress+Hauser

Liquiline To Go CYM290 and Liquiline To Go Ex CYM291

Communication and data processing

Liquiline To Go CYM290 and CYM291 automatically detects when a Memosens sensor is connected

and switches to the appropriate measured variable. Memosens is indicated on the display. Only one

sensor can be connected to the measuring device at the time. Liquiline To Go CYM290 has a pHsocket according to DIN 19262 for analog pH sensors.

Dependability

Reliability

Maintainability

Integrity

Memosens technology digitizes the measured values in the sensor and transmits the data to the

transmitter using a non-contact connection that is free from potential interference. The result:

• Automatic error message if sensor fails or connection between sensor and transmitter is

interrupted

• Immediate error detection increases measuring point availability

Easy handling

Sensors with Memosens technology have an integrated electronics unit that stores calibration data

and other information (e.g. total operating hours and operating hours under extreme measuring

conditions). Once the sensor has been connected, the sensor data are transferred automatically to

the transmitter and used to calculate the current measured value. As the calibration data are stored

in the sensor, the sensor can be calibrated and adjusted independently of the measuring point. The

result:

• Easy calibration in the measuring lab under optimum external conditions increases the quality of

the calibration.

• Pre-calibrated sensors can be replaced quickly and easily, resulting in a dramatic increase in the

availability of the measuring point .

• Maintenance intervals can be defined based on all stored sensor load and calibration data and

predictive maintenance is possible.

• The sensor history can be documented on external data carriers and in evaluation programs. Thus,

the current application of the sensors can be made to depend on their previous history.

With inductive transmission of the measured value using a non-contact connection, Memosens

guarantees maximum process safety and offers the following benefits:

• All problems caused by moisture are eliminated.

– Plug-in connection remains free from corrosion

– Measured value distortion from moisture is not possible.

– The plug-in system can even be connected under water.

• The transmitter is galvanically decoupled from the medium.

• EMC safety is guaranteed by screening measures for the digital transmission of measured values.

Endress+Hauser 3

Input

Liquiline To Go CYM290 and Liquiline To Go Ex CYM291

Measured variables

Measuring range

Types of input

→ Documentation of the connected sensor

→ Documentation of the connected sensor

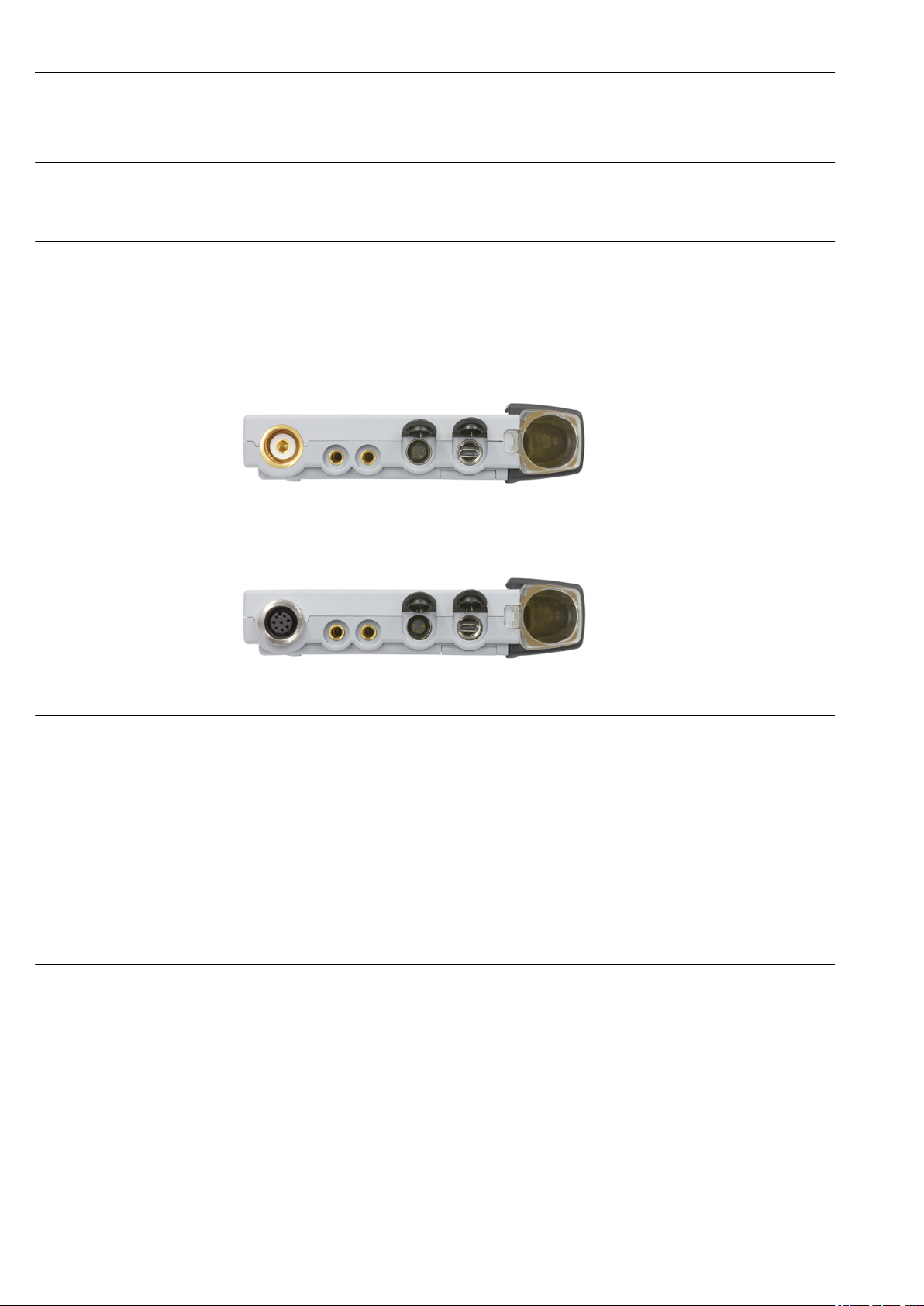

Connections

From right to left

• 1x micro USB-B for battery-free operation

• 1x M8 socket, 4-pin, for Memosens laboratory cable

• 2x socket, Ø 4 mm, for separate temperature sensor

• 1x socket:

– CYM290: DIN 19 262 for analog PH sensors

– CYM291: M12 8-pin Memosens cable

A0024762

2 CYM290 connections

Temperature inputs

Sensor inputs

3 CYM291 connections

2 x Ø 4 mm for integrated or separate temperature sensor

Measuring ranges

• Temperature sensor NTC30: -20 to +120 °C (-4 to 248 ° F)

• Temperature sensor Pt1000: -40 to +250 ° C(-40 to 482 ° F)

Measuring cycle

Approx. 1s

Measured error

123

< 0.2 K (Tamb = 23 °C); TK < 25 ppm/K

1) according to DIN EN 60746-1, at rated operating conditions

2) ± 1 digit

3) plus sensor error

Cable specification

M8 socket, 4-pin, for Memosens laboratory cable CYK20

A0024763

4 Endress+Hauser

Liquiline To Go CYM290 and Liquiline To Go Ex CYM291

Power supply

Supply voltage

Repeatability

Options

• Batteries: 4x AA (Mignon) alkaline or 4x NiMH rechargeable batteries

• Service time of up to 500 h

Performance characteristics

→ Documentation of the connected sensor

Setting up the device

Protective cover

The front of the device is protected by a cover. To operate the device, the

protective cover can be folded back completely and locked in place.

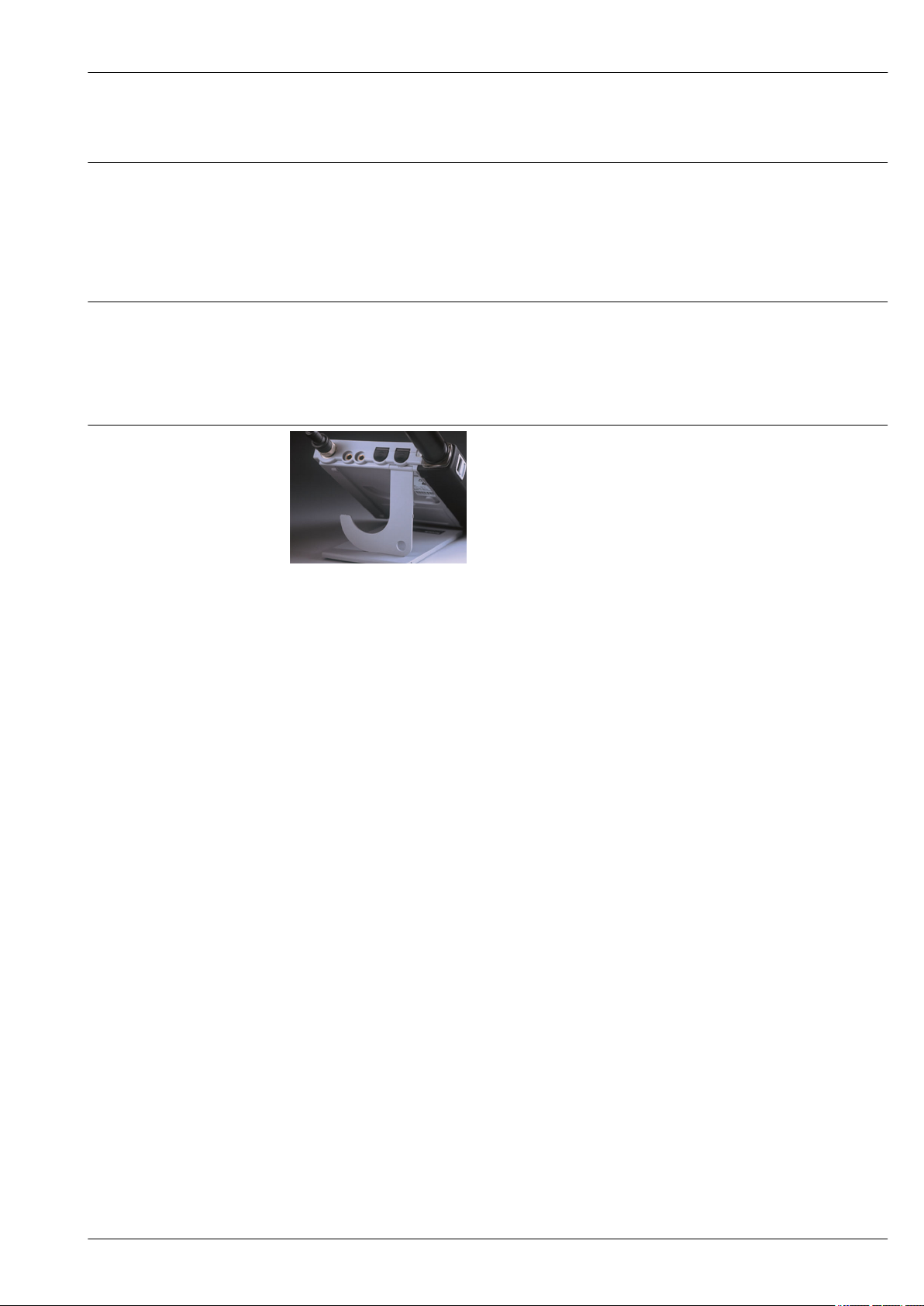

Hook

A fold-out hook is located on the back of the device, allowing you to

suspend it. This means your hands are free for the actual measurement.

The nameplate is located under the hook.

Stand

A0024707

The protective cover and hook can be joined to form a stand, allowing the

convenient and ergonomic operation of the device in the lab or on a

desktop.

Endress+Hauser 5

Loading...

Loading...