Emerson Fisher CV500, Fisher V500, Fisher 8510, Fisher 8560, Fisher Vee-Ball V150 Instruction Manual

...

Instruction Manual

D102137X012

KALREZ System - Rotary-Shaft Valves

May 2011

KALREZr Packing System

for Fisherr Rotary‐Shaft Valves

Contents

Introduction 1.................................

Scope of Manual 1.............................

Description 1.................................

Installation 1...................................

Introduction

Scope of Manual

This instruction manual includes installation, maintenance, and parts information for KALREZ valve stem packing

(KVSP) systems. These systems are available for Fisher rotary valves with 12.7 through 38.1 mm (1/2 through 1‐1/2

inch) shaft diameters. The system can be used with many rotary valves, as shown in table 1. Refer to appropriate valve

and actuator instruction manuals for necessary information relating to the disassembly and assembly of the valve and

actuator.

Removing the Actuator 2.......................

Installing a KALREZ Packing System 4.............

Tightening Procedures 5...................

Other Considerations 5..........................

Do not install, operate, or maintain a KALREZ packing system without being fully trained and qualified in valve,

actuator, and accessory installation, operation, and maintenance. To avoid personal injury or property damage, it is

important to carefully read, understand, and follow all the contents of this manual, including all safety cautions and

warnings. If you have any questions about these instructions, contact your Emerson Process Management sales office

before proceeding.

Description

See table 1 for valve designs and shaft diameters where KALREZ packing systems can be applied.

Emerson Process Management offers KALREZ packing systems that you can easily install into your existing valves or

that you can purchase with new valves. The KVSP 500 Series uses Vespelr CR‐6100 backup rings and KALREZ seal

rings.

The external live‐loading provides a constant load over the life of the packing material, which reduces the need for

packing box adjustment and maintenance.

Installation

Use these instructions to install KALREZ packing in valves that have standard packing, or when inspecting or replacing

KALREZ packing.

Table 2 lists part numbers for KALREZ packing sets only. When retrofitting valves to KALREZ packing, contact your

Emerson Process Management sales office for information on additional parts needed.

www.Fisher.com

KALREZ System - Rotary-Shaft Valves

May 2011

Table 1. Specifications

Instruction Manual

D102137X012

Applicable Valve Designs

A41, 8510, 8510B (single arrangements only), 8550,

(1/2, 5/8, 3/4, 7/8, 1, 1‐1/4 and 1‐1/2 inches). See

table 2

and 8560 valves; V100, V150, V200, V300 and V500

Vee‐Ballt valves; and CV500 Cam‐Vee‐Ball valves.

See table 2

Applicable Shaft Diameters

Vee‐Ball and Eccentric Disc Valves:

J 19.1, J 22.2, J 25.4, J 31.8, and J 38.1 mm

1. The pressure/temperature limits in this manual, in the valve literature, and any applicable code or standard limitation should not be exceeded.

J 12.7, J 15.9,

Pressures and Temperatures

Maximum Application Temperature

260_C (500_F)

Maximum Application Pressure

Pressure is limited to the maximum valve rating

(1)

Removing the Actuator

WARNING

Avoid personal injury from sudden release of process pressure or uncontrolled movement of parts. Before performing any

installation operations:

D Do not remove the actuator from the valve while the valve is still pressurized.

D Always wear protective gloves, clothing, and eyewear when performing any maintenance operations to avoid personal

injury.

D Disconnect any operating lines providing air pressure, electric power, or a control signal to the actuator. Be sure the

actuator cannot suddenly open or close the valve.

D Use bypass valves or completely shut off the process to isolate the valve from process pressure. Relieve process pressure

on both sides of the valve. Drain the process media from both sides of the valve.

D Vent the power actuator loading pressure and relieve any actuator spring precompression.

D Use lock‐out procedures to be sure that the above measures stay in effect while you work on the equipment.

D The valve packing box may contain process fluids that are pressurized, even when the valve has been removed from the

pipeline. Process fluids may spray out under pressure when removing the packing hardware or packing rings, or when

loosening the packing box pipe plug.

D Check with your process or safety engineer for any other hazards that may be present from exposure to process media.

You must remove the actuator from the valve when you install KALREZ packing systems. To allow proper

readjustment of the Vee‐Ball, eccentric disc, or valve disc position, it is recommended that you remove the valve from

the pipeline. Refer to appropriate valve and actuator instruction manuals.

WARNING

Avoid personal injury or equipment damage from uncontrolled movement of parts. If a spring‐return actuator is used, be

sure the actuator spring is resting on its travel stop. If something is obstructing shaft rotation, it is possible that

disconnecting the shaft connector will allow the spring to force the actuator to the end of its rotation. Refer to the

appropriate valve and actuator instruction manuals to remove the actuator.

2

Instruction Manual

D102137X012

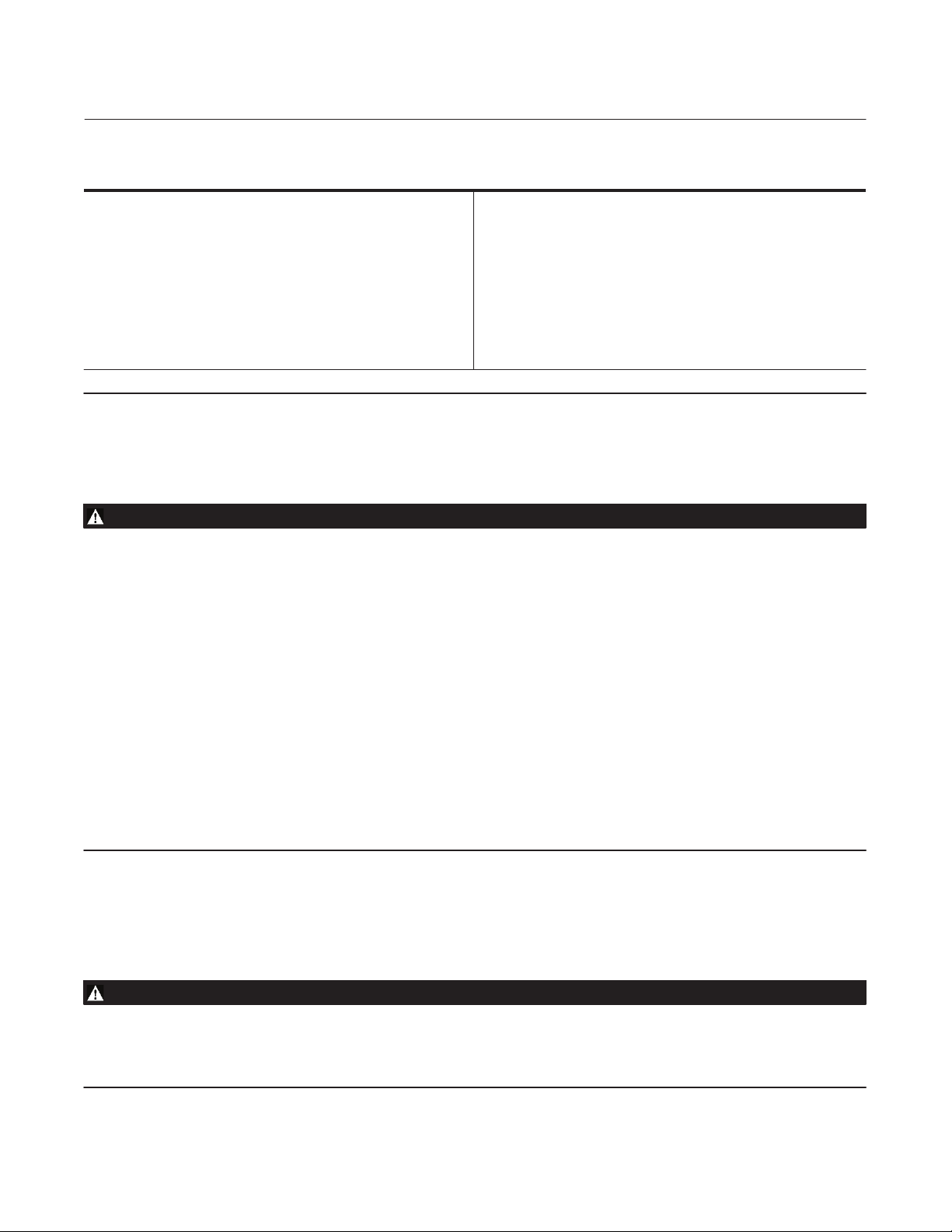

Figure 1. KALREZ Packing Arrangements

KALREZ System - Rotary-Shaft Valves

May 2011

OUTBOARD END

44B7499-A

8510

STANDARD

PACKING BOX

V100 - 12.7, 19.1, 25.4, 31.8

(1/2, 3/4, 7/8, 1, 1‐1/4 ) SHAFT

V150 - 12.7, 19.1, 25.4

(1/2, 3/4, 1 SHAFT

V200 & V300 - 12.7, 15.9, 19.1, 25.4

(1/2, 5/8, 3/4, 1) SHAFT

V500 - 12.7, 15.9, 25.4, 31.8

(1/2, 5/8, 1, 1‐1/4) SHAFT

8510, 8550, 8560, & A41 - 12.7, 15.9, 19.1,

25.4,31.8 (1/2, 5/8, 3/4, 1, 1‐1/4) SHAFT

STANDARD

PACKING BOX

V100, V500, 8510, 8550, 8560 &

A41 - 38.1 (1‐1/2) SHAFT

8510 - 38.1 (1‐1/2) SHAFT

OUTBOARD END

PACKING BOX

8510 - 12.7, 15.9, 19.1, 25.4,

31.8 (1/2, 5/8, 3/4, 1, 1‐1/4)

SHAFT

OUTBOARD END

PACKING BOX

OPTIONAL DEEP

PACKING BOX

V100 - 12.7, 19.1, 25.4 (1/2,3/4, 7/8, 1) SHAFT

STANDARD

V150 - 31.8, 38.1 (1‐1/4, 1‐1/2) SHAFT

V200 - 31.8 (1‐1/4) SHAFT

V150 - 31.8, 38.1 (1‐1/4, 1‐1/2) SHAFT

PACKING BOX

OPTIONAL DEEP

PACKING BOX

V100 - 38.1 (1‐1/2) SHAFT

OPTIONAL DEEP

PACKING BOX

V100 - 31.8 (1‐1/4) SHAFT

mm(INCHES)

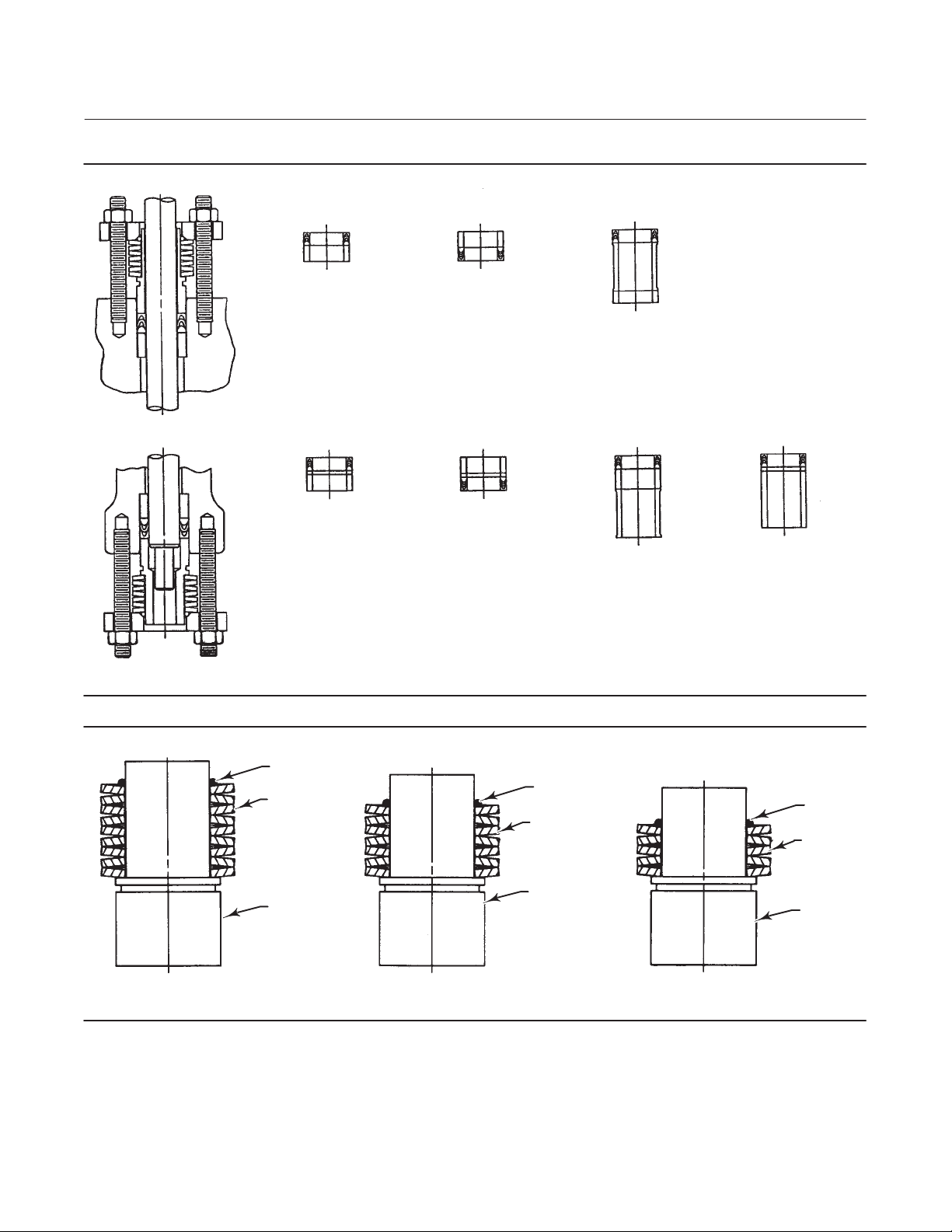

Figure 2. Belleville Spring Stacking Order

O-RING

BELLEVILLE

SPRINGS (9)

PACKING

FOLLOWER

12B8319-A

SIZE 12.7 & 15.9 mm

(1/2 & 5/8‐inch) SHAFT

B2409-1

12B8320-A

SIZE 19.1, 22.2 & 25.4 mm

(3/4, 7/8, & 1‐inch) SHAFT

O-RING

BELLEVILLE

SPRINGS (7)

PACKING

FOLLOWER

O-RING

BELLEVILLE

SPRINGS (5)

PACKING

FOLLOWER

12B8321-A

SIZE 31.8 & 38.1 mm

(1‐1/4 & 1‐1/2 inch) SHAFT

3

KALREZ System - Rotary-Shaft Valves

May 2011

Instruction Manual

D102137X012

Installing a KALREZ Packing System

Refer to figure 1.

Note

When installing a KALREZ packing system into an insulated valve, do not cover the Belleville packing springs with insulation.

CAUTION

Use caution when removing existing internal packing parts. Do not scratch, nick, or dent the valve shaft.

Note

The valve shaft surface condition is critical in obtaining a good seal. If the valve shaft surface is scratched, nicked, or worn, replace

the valve shaft before installing the KALREZ Packing System.

1. Remove old packing parts from the packing box by using the valve instruction manual procedures. Refer to the

appropriate valve instruction manual to replace the valve shaft and valve parts.

2. If the piping and valve are insulated, do not allow the insulation to cover the KALREZ Belleville springs.

3. If you are converting an existing valve to this packing, remove existing packing box studs from the valve body, and

replace them with longer studs (as required).

Note

KVSP packing systems should be installed as a complete set, NOT AS INDIVIDUAL PIECES OR COMPONENTS.

Note

Ensure that the Belleville springs are stacked properly (see figure 2) and packing box parts are assembled in the correct order (see

figure 1). Packing parts cannot function properly if the Belleville springs or other packing parts are not stacked correctly.

4. All kits include a single use packet of KRYTOXr GPL 206 high performance fluorinated grease to maximize service

life and ease of assembly. KRYTOX lubricants are chemically inert to the chemicals regulated under the U.S. Clean

Air Act, non‐reactive to gaseous and liquid oxygen and chlorine services, with chemical compatibility consistent

with KALREZ and the KVSP Systems.

5. Apply the KRYTOX lubricant liberally to both the I.D. (inner diameter) and O.D. (outer diameter) surfaces of each

KVSP component before installing. All exposed surfaces of the packing assembly should be fully covered.

6. With the shaft in place in the valve, install the packing parts into the valve packing box. Carefully slide the packing

down the shaft while being careful not to force the packing and damage it on the shaft spline. Use figures 1 and 2 to

ensure that the packing parts and spring pack are assembled in the correct order.

7. Be careful NOT to position the KVSP packing system adjacent to any lubrication holes in the packing box which

could compromise its sealing performance.

4

Instruction Manual

D102137X012

KALREZ System - Rotary-Shaft Valves

May 2011

Tightening Procedures

A modified tightening procedure is recommended for live‐loading the KVSP System to help ensure the correct loading

force is used during the life of the packing and to help avoid any overcompression of the packing. This procedure also

creates open space within the spring set that allows dynamic movement of the packing system to compensate for any

volumetric changes that occur during thermal cycling.

Note

The following tightening procedure will change the final loading force to about 1/2 of a fully compressed disc spring.

1. Hand tighten the gland nuts on the Belleville disc springs and measure the uncompressed or free height.

2. Fully compress the Belleville disc springs alternately and evenly to the flat condition. The flat condition will be

evident by a sharp increase in the applied nut torque. Note that there may appear to be space left between the

springs; this is due to friction between the springs. Measure the compressed height.

3. Back off the disc spring deflection by 1/3 or 33% of the difference between (1) the free, uncompressed spring

height and (2) the fully compressed spring height.

4. The KVSP Systems are designed so the components move together during service to eliminate free space within

the packing system. This is part of the system's design and will occur automatically during service without further

adjustment from normal mechanical and thermal cycling. The resulting working height is then established half way

between (1) the free, uncompressed height and (2) the fully compressed position; this also provides approximately

50% of the load force available from the fully compressed disc spring. This new set position helps give the system an

ideal and balanced load, allowing for expansion and contraction due to temperature variations in the process and

maximizing the service life.

Other Considerations

When retrofitting an existing packing system or repacking a valve with KALREZ packing that has been in service, check

the condition of the packing bore after you have removed the packing. An easy method for cleaning debris and minor

imperfections from the bore is to use a brake cylinder hone attached to an electric drill. This method will do a good job

of cleaning the packing bore without changing the dimension of the bore.

When you have completed this exercise, a good guideline to use in checking the condition of the packing bore is the

20/20 rule. If less than 20% of the surface area of the bore is pitted and if there are no pits deeper than 0.020 inch,

then your packing should work fine. This does not need to be an exact measurement; visual inspection is adequate. If

the packing bore does not meet this criteria, however, you should replace the valve.

5

KALREZ System - Rotary-Shaft Valves

May 2011

Table 2. Rotary KALREZ Applications and Packing Set Part Numbers

Valve Valve Size, NPs

V100 (std or deep packing box)

V150

V200

V500

8510

8510 (outboard end)

8550

8560 (CL150)

A41 (CL150)

V200

V300

V500

8510

8510 (outboard end)

8550

8560 (CL150)

8560 (CL300)

A41 (CL150)

A41 (CL300)

V100 (std or deep packing box)

V150, V200, V300

8510

8510 (outboard end)

8550

8560 (CL150)

8560 (CL300)

A41 (CL150)

A41 (CL300)

V100

V100 (deep packing box)

V100 (std or deep packing box)

V150, V200, V300

V500

CV500

8510

8510 (outboard end)

8550

8560 (CL150)

8560 (CL300)

A41 (CL150)

A41 (CL300)

V100 (std or deep packing box)

V150, V200, V300

V500

CV500

8510

8510 (outboard end)

8550

8560 (CL150)

8560 (CL300)

A41 (CL150)

A41 (CL300)

V100 (std or deep packing box)

V150, V300

V500

CV500

8510

8510 (outboard end)

8550

8560 (CL150)

8560 (CL300)

A41 (CL150)

A41 (CL300)

1, 1-1/2, 2

2

1

1

2

2

2

3

3

1-1/2, 2

2

1-1/2, 2

3

3

3

4

3

4

3

3

3, 4

4

4

4

6

4

6

4

4

4

6

6

3

3

6

6

6

8

4

8

4

8, 10, 12

8, 10

4

4

8, 10

8, 10

8, 10

10

8

10

8

12

12

6, 8

6, 8

12

12

12

12

10

12

10

Instruction Manual

D102137X012

Shaft Diameter KVSP‐500 PACKING SET

mm Inches Part Number

12.7 1/2 24B6255X012

15.9 5/8 24B6255X022

19.1 3/4 24B6255X032

22.2 7/8 24B6255X042

25.4 1 24B6255X052

31.8 1‐1/4 24B6255X062

38.1 1‐1/2 24B6255X072

6

Instruction Manual

D102137X012

KALREZ System - Rotary-Shaft Valves

May 2011

WARNING

Use only genuine Fisher replacement parts. Components that are not supplied by Emerson Process Management should not,

under any circumstances, be used in any Fisher valve, because they may void your warranty, might adversely affect the

performance of the valve, and could cause personal injury and property damage.

Note

Neither Emerson, Emerson Process Management, nor any of their affiliated entities assumes responsibility for the selection, use, or

maintenance of any product. Responsibility for the selection, use, and maintenance of any product remains with the purchaser and

end user.

7

KALREZ System - Rotary-Shaft Valves

May 2011

Instruction Manual

D102137X012

Fisher and Vee-Ball are marks owned by one of the companies in the Emerson Process Management business division of Emerson Electric Co. Emerson

Process Management, Emerson, and the Emerson logo are trademarks and service marks of Emerson Electric Co. KALREZ, Vespel, and KRYTOX are marks

owned by E.I. du Pont De Nemours Co. All other marks are the property of their respective owners.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they are not

to be construed as warranties or guarantees, express or implied, regarding the products or services described herein or their use or applicability. All sales

are governed by our terms and conditions, which are available upon request. We reserve the right to modify or improve the designs or specifications of

such products at any time without notice. Neither Emerson, Emerson Process Management, nor any of their affiliated entities assumes responsibility for the

selection, use or maintenance of any product. Responsibility for proper selection, use, and maintenance of any product remains solely with the purchaser

and end user.

Emerson Process Management

Marshalltown, Iowa 50158 USA

Sorocaba, 18087 Brazil

Chatham, Kent ME4 4QZ UK

Dubai, United Arab Emirates

Singapore 128461 Singapore

www.Fisher.com

8

EFisher Controls International LLC 1996, 2011; All Rights Reserved

Loading...

Loading...