Page 1

Product Bulletin

657 and 667 Actuators

D100087X012

Fisherr 657 and 667 Diaphragm Actuators

Fisher 657 and 667 spring-opposed diaphragm

actuators position the valve plug in the valve in

response to varying controller or valve positioner

pneumatic output signals applied to the actuator

diaphragm. Zero setting of the actuator is determined

by the compression of the actuator spring. Span is set

by both the actuator spring rate and the number of

springs available. The 657 actuator is direct-acting; the

667 is reverse-acting. These actuators are designed to

provide dependable on-off or throttling operation of

automatic control valves.

Features

Application Versatility–Five actuator types in eleven

sizes are available for an extensive variety of

applications. Spring rates, travel stops, and manual

operators are available for nearly any control valve

application.

Excellent Linearity Between Loading Pressure and

Travel–A molded diaphragm travels in a deep

diaphragm casing, minimizing area change

throughout the travel.

W2174-2 W1916-3

657 ACTUATOR

Fisher 657 and 667 Actuators Mountedon

easy-et Valves

667 ACTUATOR

61.1:657

May 2012

High Degree of Dynamic Stability and Frequency

Response–A shallow casing on the pressure side

means reduced volume on that side, thereby

minimizing response time.

High Thrust Capability–The molded diaphragm

allows maximum thrust for given diaphragm size.

Long Service Life–Rugged thick-walled cast iron and

steel construction provides increased stability,

corrosion protection, and protection from

deformation should over-pressurization occur.

www.Fisher.com

Cold Service Applications–Enhanced product

specifications for all sizes of 657 and 667 diaphragm

actuators allow performance to -50_C(-58_F). Use

of a positioner is recommended to ensure

responsiveness in applications operating below

-40_C(-40_F).

Positive Connections–A split block stem connection

provides a solid transfer of motion while allowing

easy mounting. The absence of linkages helps to

avoid lost motion and inaccurate valve positioning.

Page 2

Product Bulletin

61.1:657

May 2012

Specifications

657 and 667 Actuators

D100087X012

Standard Operating Pressure Range

(1)

657 and 667: J 0.2to1.0bar(3to15psig)orJ 0.4

to 2.0 bar (6 to 30 psig)

657-4 and 667-4: 0.2to1.9bar(3to27psig)

667 Size 76:

J 0.4to2.0bar(6to30psig)orJ 0to

3.1 bar (0 to 45 psig)

Maximum Travel

See table 1

Output Indication

Stainless steel disk or pointer and graduated scale

Stroking Speed

Dependent on actuator size, travel, spring rate, initial

spring compression, and supply pressure. If stroking

speed is critical, consult your Emerson Process

Management sales office

Maximum Allowable Thrust

(2)

See table 1

Construction Materials (refer to figure 1)

Diaphragm Casing

Sizes 30

Size 80:

Size 100:

-

87: Steel

J Cast iron or J steel

J Cast aluminum

Diaphragm

Sizes 30

-

87: J Nitrile on nylon, J Silicone on

polyester

Size 100: Nitrile on polyester

Diaphragm Plate

657 Sizes 30

657 Sizes 70

667 Sizes 30

667 Sizes 70

-

60, 100: J Cast aluminum

-

87: J Cast iron or J steel

-

60, 100: J Cast aluminum or J steel

-

87: J Cast iron or J steel

Actuator Spring: Steel

Spring Adjustor: Steel

Spring Seat:

J Steel or J cast iron

Actuator Stem: Steel

Travel Indicator: Stainless steel

O-Rings: Nitrile

Seal Bushing: Brass

Stem Connector: Zinc-plated steel

Yoke

Sizes 30

-

80: J Cast iron or J steel

Size 100: Steel

Operating Temperature Range

Standard Construction (Nitrile Elastomers): -40 to

82_C(-40to180_F)

Optional Construction (Silicone Diaphragm):

C(-40to300F)

149

Maximum Valve Packing Box Temperature: 427_C

(800_F) with cast iron yoke

(1)

-40 to

Construction Materials for Cold Service

[to -50_C(-58_F)] 657 and 667--all sizes

Yoke: Steel (Grade LCC)

Diaphragm: Silicone

O-Rings:

Bolting: Stainless Steel B8M Cl 2

Stem Connector: Stainless Steel

Lubricant: Silicone

Volumetric Displacement

See table 2

Stem and Yoke Boss Diameters

See table 1

Signal Connections

Sizes 30 - 60 and 667 Size 76: 1/4 NPT internal

Approximate Weight

Sizes 70 and 87: 1/2 NPT internal

Size 80

See table 3

657: 3/4 NPT internal with 1/4 NPT internal bushing

667: 1/2 NPT internal with 1/4 NPT internal bushing

Size 100: 1 NPT internal with 1/4 NPT internal bushing

Effective Diaphragm Area

See table 1

1. The pressure and temperature limits in this bulletin and in any applicable standard o r code limitation shouldnot be exceeded.

2. Do not exceed thethrust limits in thisbulletin.

3. Includes diaphragmcasing seals, casing-mounted handwheel on 657, seal bushingon 667.

Options

J Oversize signal connections, J Plastic yoke covers,

J Watertight yoke (sealed construction for certain

applications where valve stem and packing must be

protected)

(3)

Ethylene Propylene

2

Page 3

657 and 667 Actuators

D100087X012

Product Bulletin

61.1:657

May 2012

Available Configurations

Direct Action

All 657 actuators are direct acting. Applying air

pressure to the upper diaphragm casing forces the

actuator stem downward. When this pressure is

reduced, the opposing spring force moves the

actuator stem upward. Should the loading pressure

fail, the spring forces the stem to the extreme upward

position. This provides fail-open action for

push-down-to-close valves and fail-closed action for

push-down-to-open valves.

657–Adirect- acting actuator used on sliding-stem

valves. Available in sizes 30 through 100. See figures 1,

2, 5, and 6.

657-4–A 657 actuator in sizes 70 and 87, designed

with 102 mm (4-inch) travel.

667–A reverse-acting actuator used on sliding-stem

valves. Available in sizes 30 through 100 and 76. See

figures1,2,and7.

667-4–A 667 actuator in sizes 70 and 87, designed

with 102 mm (4-inch) travel.

Accessories

Handwheels

Handwheels for diaphragm actuators are often used as

adjustable travel stops. They also provide a ready

means of positioning the control valve in an

emergency. The specifications in tables 5 and 6 apply

to handwheels on both 657 and 667 Series actuators.

For repeated or daily manual operation, the unit

should be equipped with a side-mounted handwheel

actuator.

Reverse Action

All 667 actuators are reverse acting. Applying air

pressure to the lower diaphragm casing forces the

actuator stem upward against the opposing spring

force. When this loading pressure is reduced, the

spring moves the actuator stem downward. Should

the loading pressure fail, the spring forces the stem to

the extreme downward position. These actuators

provide fail-closed action for push-down-to-close

valves and fail-open action for push-down-to-open

valves.

Contents

Features 1.....................................

Specifications 2................................

Available Configurations 3.......................

Direct Action 3.................................

Reverse Action 3...............................

Accessories 3..................................

Handwheels 3.................................

Adjustable Travel Stops 7........................

Other 7.......................................

Ordering Information 14.........................

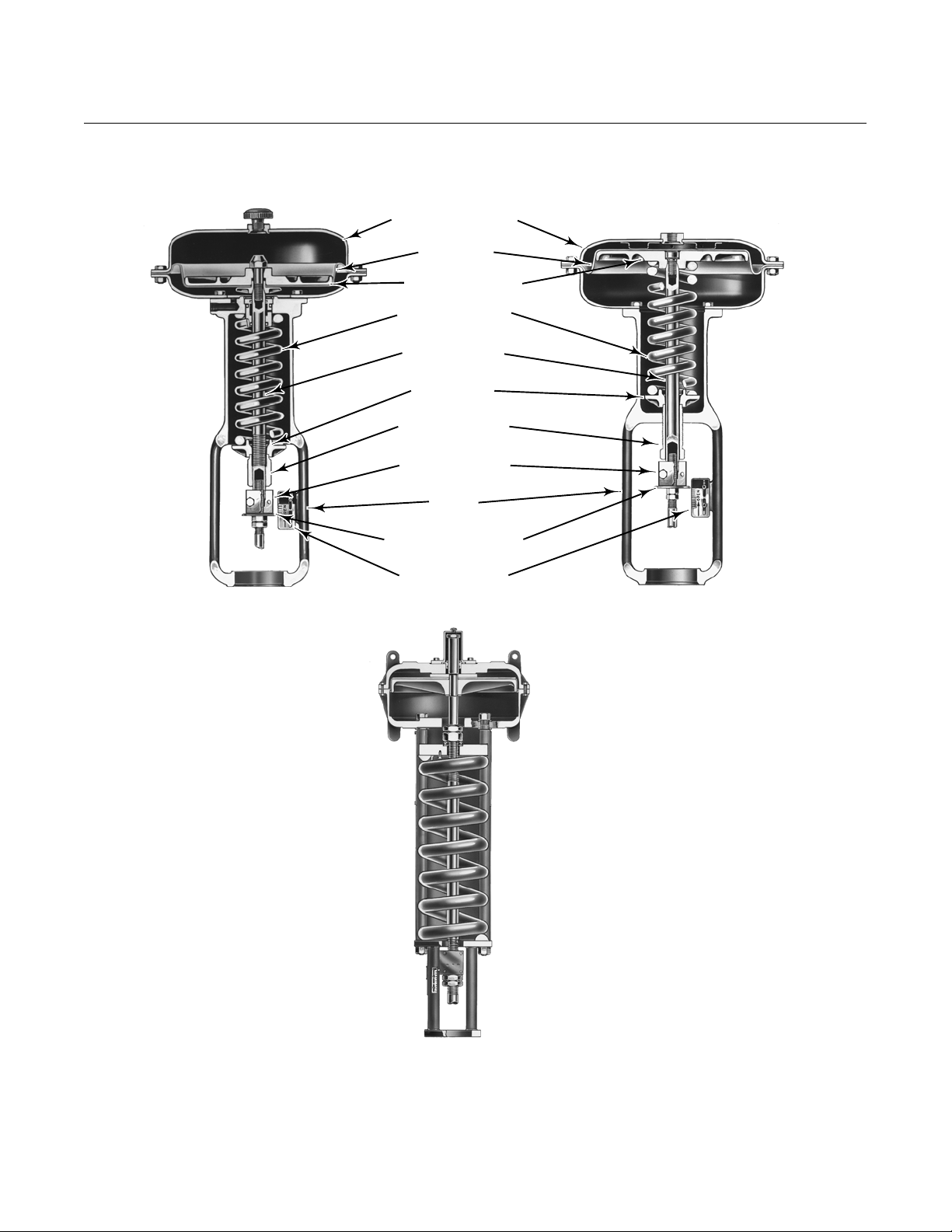

Top-Mounted Handwheels–Typical 657 and 667

actuators with handwheels mounted on the

diaphragm case are shown in figure 2 (not available on

a 667 actuator, size 80). On the 657 actuator, the

handwheel can be set to limit the travel in the upward

direction; on the 667 actuator, travel in the downward

direction can be restricted. A P-2 travel stop (figure 4)

is available for a 667 actuator, sizes 45-60 to limit

travel in either the upward ordownwarddirections.An

actuator with a P-2 travel stop is limited to a maximum

travel of 19 mm (0.75 inch). The handwheel on the size

100 is similar in function to those on the smaller sizes,

but it uses a gear drive similar to the drive employed

on the integral side-mounted handwheels (see figure

2).

Tables

Additional Specifications 5.......................

Volumetric Casing Displacement 6................

Approximate Actuator Weights

(without handwheel) 6........................

Thrust Capabilities 7............................

Handwheel Specifications 10.....................

Adjustable Travel Stop Styles 11..................

Dimensions 14.................................

3

Page 4

Product Bulletin

61.1:657

May 2012

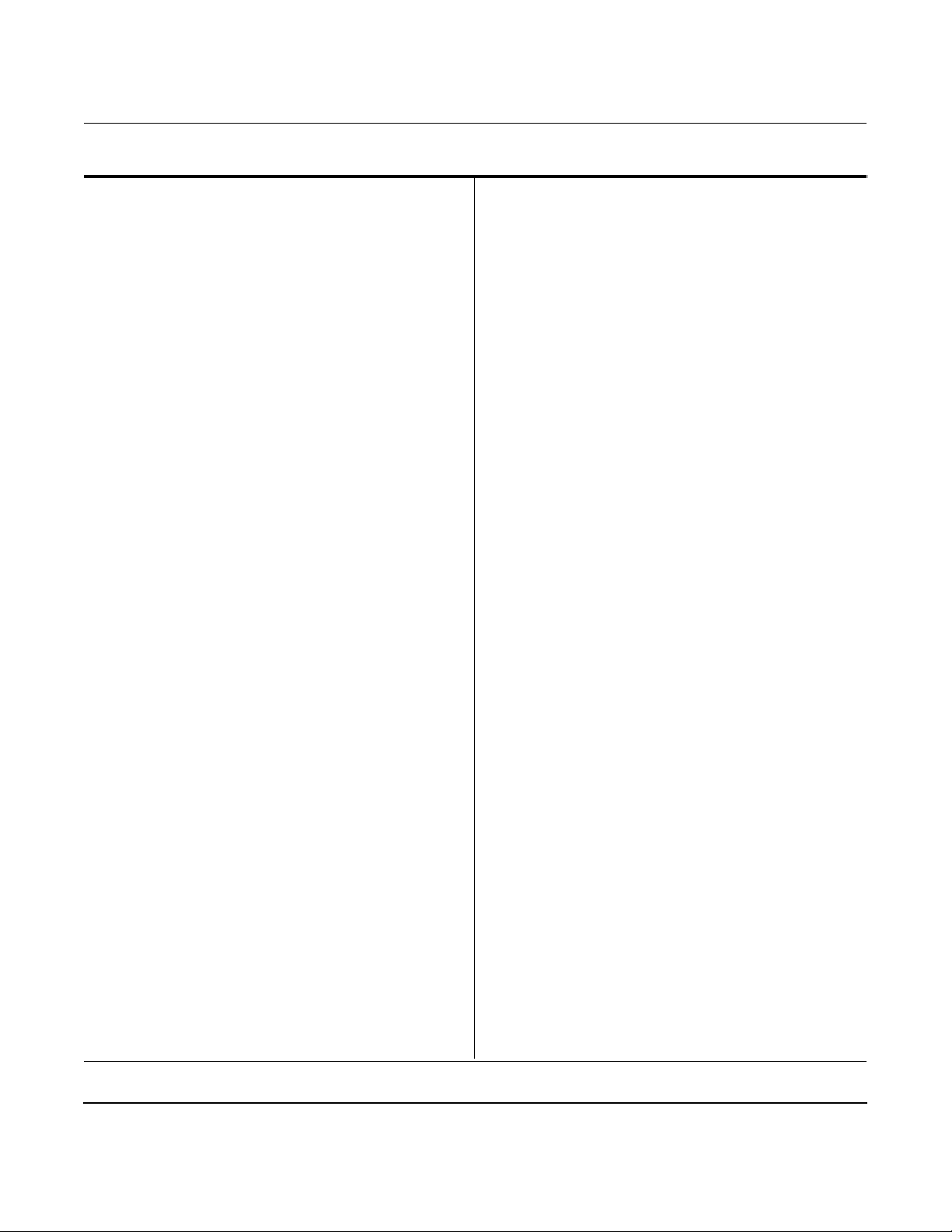

Figure 1. Typical Actuators

657 and 667 Actuators

D100087X012

DIAPHRAGM CASINGS

DIAPHRAGM

DIAPHRAGM PLATE

ACTUATOR SPRING

ACTUATOR STEM

SPRING SEAT

SPRING ADJUSTOR

STEM CONNECTOR

YOKE

W0364-2

667 SIZES 30-87

TRAVEL INDICATOR DISK

INDICATOR SCALE

W0363-2

657 SIZES 30-87

W0366-1

657 SIZE 100

4

Page 5

Product Bulletin

657 and 667 Actuators

D100087X012

Table 1. Additional Specifications for Fisher 657 and 667 Series Actuators

EFFECTIVE

ACTUATOR

SIZE

DIAPHRAGM

AREA

2

cm

30 297 54 9.5 19 10,231

34 445 54 9.5 29 10,231

40 445 71 12.7 38 12,010

45 677 71 12.7 51 25,132

46 1006 71 12.7 51 33,584

50 677 90 19.1 51 25,131

60 1006 90 19.1 51 30,246

(2)

70

1419 90 19.1

76(667) 1006 90 19.1 51 30,246

80 1761 127

(2)

87

1419 127 25.4

100 2902

2

Inch

30 46 2-1/8 3/8 0.75 2300

34 69 2-1/8 3/8 1.125 2300

40 69 2-13/16 1/2 1.5 2700

45 105 2-13/16 1/2 2 5650

46 156 2-13/16 1/2 2 7550

50 105 3-9/16 3/4 2 5650

60 156 3-9/16 3/4 2 6800

(2)

70

220 3-9/16 3/4

76(667) 156 3-9/16 3/4 2 6800

80 273 5

(2)

87

220 5 1

100 450

1. These values are based on material limitations such as yoke, stem connection, diaphragm plate, and travel stop strengths.

2. Values also apply to657-4 and 667-4 actuators.

3. For 657-4 and 667-4actuator constructions.

4. Steel construction.

5. H=Heavy actuator-to-valve bolting.

YOKE

BOSS

DIAMETER

(5)

127H

178 50.8

(5)

5H

7 2

STEM

DIA

MAXIMUM

TRAVEL

mm N

76

(3)

102

25.4

31.8 88,075

76

76

(3)

102

31.8

102 200,160

Inch Lb

3

(3)

4

1

1-1/4 19,800

3

3

(3)

4

1-1/4

4 45,000

61.1:657

May 2012

MAXIMUM

ALLOWABLE

THRUST

39,142

63,392

39,142

8800

14,150

8800

(1)

(4)

(4)

5

Page 6

Product Bulletin

61.1:657

May 2012

Table 2. Volumetric Casing Displacement for Fisher 657 and 667 Series Actuators

ACTUATOR

SIZE

30 540 918 1080 1180 --- --- --- --- ---

34 and 40 934 1470 1700 1850 2330 2790 --- --- ---

45 and 50 1560 --- 2790 3000 3720 4420 5410 --- ---

46, 60, and 76 2180 --- 3880 4210 5280 6340 7740 --- ---

70 and 87 3490 5240 5950 6420 7830 9240 11,110 14,880 18,570

80 4820 --- -- - --- 10,490 12,450 14,860 19,340 ---

100

46, 60, and 76

100

1. Clearance volume indicates casing volume at zerotravel.

2. Includes clearance volume.

657 10,880 --- --- 16,400 19,170 21,940 25,630 33,000 40,380

667 12,780 --- --- 18,320 21,070 23,840 27,530 34,900 42,280

30

34 and 40

45 and 50

70 and 87

80

657 664 --- --- 1002 1170 1339 1564 2014 2464

667 780 --- --- 1118 1286 1455 1680 2130 2580

CLEARANCE

VOLUME

cm

Inch

33

57

95

133

213

294

(1)

3

3

11 16 19 29 38 51 76 102

0.4375 0.625 0.75 1.125 1.5 2 3 4

56

90

---

---

320

---

66

104

170

237

363

---

72

113

183

257

392

---

TRAVEL, mm

Casing Volume

TRAVEL, INCH

Casing Volume

---

142

227

322

478

640

(2)

(2)

,cm

,Inch

---

170

270

387

564

760

657 and 667 Actuators

D100087X012

3

3

---

---

330

472

678

907

---

---

---

---

980

1180

---

---

---

---

1133

---

Table 3. Approximate Actuator Weights (without handwheel)

ACTUATOR

SIZE

30 16 15 36 34

34 22 22 48 48

40 23 23 51 50

45 37 41 82 90

46 49 55 107 121

50 42 43 92 94

60 53 55 116 122

70 107 115 235 254

76 --- 86 --- 190

80 234 284 515 626

87 116 118 255 260

100 346 544 762 1200

657 667 657 667

Kg Lb

ACTUATOR

6

Page 7

657 and 667 Actuators

D100087X012

Product Bulletin

61.1:657

May 2012

Table 4. Thrust Capabilities

TRAVEL

mm Bar N

19

29

38

51

76

102

Inch Psig Lb

0.75

1.125

1.5

1. For Size 76 667 actuators, contact yourEmerson Process Management sales office.

2. Consult Fisher 657 and 667 instruction manuals(D100306X012, D100307X012,

D100310X012, and D100311X012)for additional information onmaximum pressure

limitations.

2

3

4

ACTUATOR

SIZE

30

34

40

45

46

50

60

70

80

87

100

30

34

40

45

46

50

60

70

80

87

100

(1)

by Input Signal Range

PRESSURE RANGE

TO ACTUATOR

DIAPHRAGM

(2)

0.2-1 2250 1840

0.4-2 3890 3270

0.2-1 3380 3380

0.4-2 5830 5530

0.2-1 3380 2760

0.4-2 5530 3680

0.2-1 4670 4670

0.4-2 8410 8870

0.2-1 6940 6250

0.4-2 13,190 11,800

0.2-1 5140 3740

0.4-2 8410 7010

0.2-1 6940 4860

0.4-2 13,190 8330

0.2-1 7830 7830

0.4-2 18,590 13,700

0.2-1 10,110 11,250

0.4-2 18,950 19,680

0.2-1 6850 7830

0.4-2 18,590 13,700

0.2-1 16,010 8010

0.4-2 32,030 36,030

0.2-1 12,010 ---

0.4-2 22,019 28,024

3-15 506 414

6-30 874 736

3-15 759 759

6-30 1311 1242

3-15 759 621

6-30 1242 828

3-15 1050 1050

6-30 1890 1995

3-15 1560 1404

6-30 2964 2652

3-15 1155 840

6-30 1890 1575

3-15 1560 1092

6-30 2964 1872

3-15 1760 1760

6-30 4180 3080

3-15 2272 2528

6-30 4260 4424

3-15 1540 1760

6-30 4180 3080

3-15 3600 1800

6-30 7200 8100

3-15 2700 --6-30 4950 6300

THRUST

CAPABILITIES

657 667

Clockwise rotation of the handwheel on the 657

actuator moves the actuator stem downward,

compressing the spring. Spring action returns the

stem as the handwheel is turned countercloc kwise.

With the 667 actuator, counterclockwise rotation

moves the stem upward, and spring action returns the

stem on clockwise rotation.

Side-Mounted Handwheels–Figure 3 shows the

side-mounted handwheels (designated by the letters

MO) applicable to sizes 34 through 87, 657 and 667

actuators. Size 30 actuators do not have a

side-mounted handwheel available.

All side-mounted handwheels can be used to stroke

the valve in either direction at any point in the actuator

stem travel. Unlike the top-mounted handwheel, the

side-mounted handwheel can be positioned to limit

travel in either direction, but not both at the same

time. With the handwheel in the neutral position,

automatic operation is possible throughout full valve

travel. In any other position, valve travel will be

restricted. The handwheel is furnished with a

spring-loaded ball detent which prevents vibration

from changing the setting.

Adjustable Travel Stops

Top-mounted adjustable travel stops are available for

657 and 667 Series actuators. They are used to limit

travel in the up, down, or up and down directions.

Figure 4 illustrates the different constructions. Table 7

locates the different style constructions with actuator

type and use.

Other

Accessories such as transducers, positioners, position

transmitters, air relays, volume boosters, switching

valves, lockup valves, limit switches, and solenoid

valves are also available for actuator mounting. They

are described in separate publications. Contact your

Emerson Process Management sales office for details.

7

Page 8

Product Bulletin

61.1:657

May 2012

Figure 2. Typical Top-Mounted Handwheels

657 and 667 Actuators

D100087X012

W0368-2

657 ACTUATOR

(EXCEPT SIZE 100)

W0370-1

TOP VIEW

W0369-2

667 ACTUATOR

(EXCEPT SIZES 80 AND 100)

W0370-1

657 ACTUATOR SIZE 100

(GEAR DRIVEN)

8

Page 9

657 and 667 Actuators

D100087X012

Figure 3. Typical Side-Mounted Handwheels for Fisher 657 and 667 Series Actuators

W0371-1 W0372-1

SIZES 34 THROUGH 60

SIZES 70, 76, 80, AND 87

Product Bulletin

61.1:657

May 2012

SECTION A-A

Figure 4. Adjustable Travel Stops

STYLE 1

657 AND 657-4

UP STOP

STYLE 2

657 AND 657-4

DOWN STOP

STYLE 10

667 DOWN STOP

STYLE 11

667 UP

AND DOWN STOP

40A8764-E

STYLE 12

667 UP STOP

STYLE 13

667 UP STOP

STYLE 14

667 UP STOP

40A38A1211-E

STYLE P2

667 UP AND

DOWN STOP

9

Page 10

Product Bulletin

61.1:657

May 2012

Table 5. Fisher 657 Handwheel Specifications

TOP-MOUNTED HANDWHEEL SIDE-MOUNTED HANDWHEEL

657

ACTUATOR

SIZE

30 171 0.3 190 6670 --- --- --- ---

34 and40 222 0.3 210 10,010 304 0.2 230 10,010

45 and50 222 0.3 420 15,080 355 0.3 360 15,080

46 and60 222 0.3 490 22,690 355 0.3 540 22,690

70 and87 355 0.3 590 29,360 432 0.8 160 29,360

80 355 0.3 770 37,770 432 0.4 240 37,770

(2)

100

30 6.75 8 42 1500 --- --- --- ---

34 and40 8.75 8 48 2250 12 5.14 52 2250

45 and50 8.75 8 95 3390 14 6.65 81 3390

46 and60 8.75 8 110 5100 14 6.65 122 5100

70 and87 14 8 132 6600 17 20 36 6600

80 14 8 173 8490 17 10 53 8490

(2)

100

1. Tangential handwheel force required to produce thehandwheel output force shown. (Proportional tohandwheel outputforce).

2. Top-mounted with gear drive.

3. Maximum force available to compress the actuatorspring and close thevalve.

Handwheel

Diameter

mm N N mm N N

406 6 270 160,000 --- --- --- ---

Inch

16 144 60 36,000 --- --- --- ---

Turns Per

mm Travel

Turns Per

Inch Travel

Rim Force

Lb Lb Inch

(1)

Maximum

Handwheel

Output

(3)

Force

Handwheel

Diameter

Turns Per

mm Travel

Turns Per

Inch Travel

657 and 667 Actuators

D100087X012

Maximum

Handwheel

Rim Force

(1)

Lb Lb

Output

Force

(3)

10

Page 11

Product Bulletin

657 and 667 Actuators

D100087X012

Table 6. Fisher 667 Handwheel Specifications

TOP-MOUNTED HANDWHEEL SIDE-MOUNTED HANDWHEEL

(1)

Maximum

Handwheel

Output

(3)

Force

667

ACTUATOR

SIZE

Handwheel

Diameter

Turns Per

mm Travel

Rim Force

45 and50 355 0.3 360 15,080

46 and60 355 0.3 540 22,690

70, 76, and 87 432 0.8 160 29,360

667

ACTUATOR

SIZE

Inch

Turns Per

Inch Travel

Lb Lb

45 and50 14 6.65 81 3390

46 and60 14 6.65 122 5100

70, 76, and 87 17 20 36 6600

667

ACTUATOR

SIZE

Handwheel

Diameter

mm N N mm N N

Turns

Per

mm

Travel

Rim

Force

30 171 0.3 200 6670 30 --- --- --- ---

34 and40 222 0.3 230 10,010 34 and40 304 0.2 230 10,010

45 and50

46, 60, and 76

70 and87

(2)

100

667

ACTUATOR

SIZE

222 0.2 460 17,790

355 0.2 430 26,690

222 0.2 460 17,790

355 0.2 430 26,690

355 0.2 520 26,690

762 mm Bar 0.2 410 44,480

406 6 270 160,000 80 432 0.4 240 37,770

Turns

Inch

Per

Inch

Lb Lb

Travel

30 6.75 8 45 1500 30 --- --- --- ---

34 and40 8.75 8 51 2250 34 and40 12 5.14 52 2250

45 and50

46, 60, and 76

70 and87

(2)

100

1. Tangential handwheel force required to produce thehandwheel output force shown. (Proportional tohandwheel outputforce).

2. Top-mounted with gear drive.

3. Maximum force available to compress actuator spring.

8.75 6 103 4000

14 6 97 6000

8.75 6 103 4000

14 6 97 6000

14 6 118 6000

30 InchBar 6 92 10000

16 144 60 36,000 80 17 10 53 8490

(1)

61.1:657

May 2012

Maximum

Handwheel

Force

Output

(3)

Table 7. Adjustable Travel Stop Styles

Actuator Size 30 34 40 45 46 50

(1)

60 and

667 Size 76

70 87 80 100

657 Up Stop 1 1 1 1 1 1 1 1 1 NOTE 2 NOTE 2

657 DownStop 2 2 2 2 2 2 2 2 2 --- ---

667 Up Stop

12, 13

(3)

,1412, 13

(3)

,1412, 13

(3)

,1412, 13

(3)

,1412, 13

(3)

,1412, 13

14

(3)

,

12, 13

14

(3)

,

12 12 13

(3)

667 DownStop 10 10 10 10 10 10 10 10 10 --- NOTE 2

667 Up and

Down Stop

1.Seefigure4.

2. Top-mounted handwheel, see figure2.

3. Adjustable handwheel up stop.

4. 38 mm (1.5 inch)maximum travel.

5. Adjustable handwheelup and down stop, 19 mm (0.75 inch) maximumtravel.

--- 11 11 11

(4)

,P2

(5)11(4)

,P2

(5)11(4)

,P2

(5)

11

(4)

(5)

,P2

--- --- --- ---

---

11

Page 12

Product Bulletin

61.1:657

May 2012

657 and 667 Actuators

D100087X012

Figure 5. Fisher 646 Electro-Pneumatic Transducer

on 657 Actuator

W4917-1

Figure 6. Fisher 3582i Valve Positioner on

657 Actuator

Figure 7. Fisher 4200 Position Transmitter on

667 Actuator

W4273-1

12

W4930

Page 13

Product Bulletin

657 and 667 Actuators

D100087X012

Table 8. Dimensions

DIMENSION

REFERENCE

657, -4

B

667, -4

C 289 333 333 406 473 536 406 473 536 473 635 536 729

D 54 54 71 71 71 71 90 90 90 90 127 127 127

657

657-4

657MO

657-4 MO

E

667

667-4

667MO

657-4 MO

657

H

c

667

H

s

J

c

J

s

657, -4

K

667, -4

657, -4

M

667, -4

657

657MO

657-4MO

N

667

667MO

667-4MO

657, -4

B

667, -4

C 11.38 13.12 13.12 16.00 18.62 21.12 16.00 18.62 21.12 18.62 25.00 21.12 28.69

D 2.125 2.125 2.8125 2.8125 2.8125 2.8125 3.5625 3.5625 3.5625 3.5625 5 5 5

657

657-4

657MO

657-4 MO

E

667

667-4

667MO

657-4 MO

657

H

c

667

H

s

J

c

J

s

657, -4

K

667, -4

657, -4

M

667, -4

657

657MO

657-4MO

N

667

667MO

667-4MO

1. MO = Manual operator.

2. Also available with 7 inch boss.

3. With group 1 springs, E=1959 mm (77.12inch). With group 2springs, E=1497 mm(58.94 inch).

4. With group 1 springs, E=2345 mm (92.31inch). With group 2springs, E=1883 mm(74.12 inch).

5. With group 1 springs, M=2103 mm (82.81inch). With group 2 springs, M=1654 mm (65.12inch).

30 34 40 45 46 47 50 60 70 76 80 87 100

0

38

440

---

(1)

440

---

478

---

478

---

121

119

--- 284 286 375 375 --- 378 378 292 222 303 292 401

171 222 222 222 222 356 222 222 356 356 356 356 ---

--- 305 305 356 356 --- 356 356 432 432 432 432 406

213

194

---

---

---

---

---

---

---

---

0.00

1.50

17.31

---

17.31

---

18.81

---

18.81

---

4.75

4.69

--- 11.19 11.25 14.75 14.75 --- 14.88 14.88 11.50 11.50 11.94 11.50 15.78

6.75 8.75 8.75 8.75 8.75 14.00 8.75 8.75 14.00 8.75 14.00 14.00 ---

--- 12.00 12.00 14.00 14.00 --- 14.00 14.00 17.00 17.00 17.00 17.00 16.00

8.38

7.62

---

---

---

---

---

---

---

---

25

38

498

---

498

---

573

---

573

---

164

121

222

224

226

214

---

---

---

---

---

---

1.00

1.50

19.62

---

19.62

---

22.56

---

22.56

---

6.44

4.75

8.75

8.83

8.88

8.44

---

---

---

---

---

---

25

38

548

---

548

---

594

---

594

---

164

137

272

244

248

248

---

---

---

---

---

---

1.00

1.50

21.56

---

21.56

---

23.38

---

23.38

---

6.44

5.38

10.69

9.62

9.75

9.75

---

---

---

---

---

---

38

38

659

---

659

---

768

---

768

---

202

159

291

310

306

362

---

---

---

---

---

---

1.50

1.50

25.94

---

25.94

---

30.25

---

30.25

---

7.94

6.25

11.44

12.19

12.06

14.25

---

---

---

---

---

---

38

38

656

---

656

---

748

---

748

---

202

159

291

310

306

362

---

---

---

---

---

---

1.50

1.50

25.81

---

25.81

---

29.44

---

29.44

---

7.94

6.25

11.44

12.19

12.06

14.25

---

---

---

---

---

---

ACTUATOR SIZE

38

38

---

---

---

---

---

---

---

---

---

---

395

---

---

---

---

---

---

---

---

---

Inches

1.50

1.50

---

---

---

---

---

---

---

---

---

---

15.56

---

---

---

---

---

---

---

---

---

mm

38

38

722

---

722

---

784

---

784

---

202

159

354

325

370

378

---

---

---

---

---

---

1.50

1.50

28.44

---

28.44

---

30.88

---

30.88

---

7.94

6.25

13.94

12.81

14.56

14.88

---

---

---

---

---

---

38

38

722

---

722

---

784

---

784

---

202

159

354

325

370

378

---

---

---

---

---

---

1.50

1.50

28.44

---

28.44

---

30.88

---

30.88

---

7.94

6.25

13.94

12.81

14.56

14.88

---

---

---

---

---

---

38

38

840

994

976

1124

933

1070

1164

1314

313

286

406

375

446

446

---

219

219

---

219

219

1.50

1.50

33.06

39.12

38.44

44.25

36.75

42.12

45.81

51.75

12.31

11.25

16.00

14.75

17.56

17.56

---

8.62

8.62

---

8.62

8.62

---

38

---

---

---

---

881

---

1112

---

---

159

---

375

---

446

---

---

---

---

219

---

---

1.50

---

---

---

---

34.70

---

43.76

---

---

6.25

---

14.75

---

17.56

---

---

---

---

8.62

---

---

---

1075

---

1183

---

1257

---

1392

---

227

---

435

432

503

503

254

384

---

254

384

---

---

---

42.31

---

46.56

---

49.50

---

54.81

---

8.94

---

17.12

17.00

19.81

19.81

10.00

15.12

---

10.00

15.12

---

61.1:657

May 2012

38

38

938

1089

1057

1204

1003

1143

1245

1394

313

286

780

419

527

527

---

219

219

---

219

219

1.50

1.50

36.94

42.88

41.62

47.38

39.50

45.00

49.00

54.88

12.31

11.25

18.88

16.50

20.75

20.75

---

8.62

8.62

---

8.62

8.62

---

---

(2)

NOTE 3

---

NOTE 4

---

1857

---

2346

---

---

---

451

451

NOTE 5

2105

---

---

---

---

---

---

---

---

(2)

NOTE 3

---

NOTE 4

---

73.12

---

92.38

---

---

---

17.75

17.75

NOTE 5

82.88

---

---

---

---

---

---

13

Page 14

Product Bulletin

61.1:657

May 2012

Figure 8. Dimensions (also see table 8)

657 and 667 Actuators

D100087X012

AU6713-D

657, 667,

657-4, AND 667-4

SIZES 30 THROUGH 87

AU6713-D

657, 667,

657-4, AND 667-4

SIZES 30 THROUGH 87

Ordering Information

When ordering, specify:

Application

1. On-off or throttling service

2. Input signal range

3. Maximum s upply pressure

4. Valvebodytypeandsizewithwhichtheactuator

will be used

5. Valve plug travel

A0171-2

ALL TYPES

SIZES 70, 80, 87, AND

667 SIZE 76

40A8196

657 AND 667

SIZE 100

8. Seismic requirements, if critical

9. Ambient temperature range

Actuator and Positioner

Be sure to specify: actuator type number; whether a

positioner is required; whether a top-mounted

handwheel is required; and whether an adjustable up

or down travel stop is required. Refer to the

Specifications section. Review the information under

each specification and in the referenced tables and

figures. Specify the desired choice wherever there is a

selection to be made.

6. Actuator thrust required with actuator stem both

fully retracted and fully extended

7. Stroking time requirements, if critical

14

Valve Body and Accessories

Refer to the separate valve body bulletin and bulletins

covering accessories for ordering information.

Page 15

657 and 667 Actuators

D100087X012

Product Bulletin

61.1:657

May 2012

15

Page 16

Product Bulletin

61.1:657

May 2012

657 and 667 Actuators

D100087X012

Neither Emerson, Emerson Process Management, nor any of their affiliated entities assumes responsibility for the selection, use or maintenance

of any product. Responsibility for proper selection, use, and maintenance of any product remains solely with the purchaser and end user.

Fisher andeasy-e are marks owned by one ofthe companies in the Emerson Process Management business unit of Emerson Electric Co. Emerson Process

Management, Emerson, and the Emerson logo are trademarks and service marks of Emerson Electric Co. All other marks are the property of their respective

owners.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they arenot

to be construed as warranties or guarantees, express or implied, regarding the products or services described herein or their use or applicability. All sales are

governed by our termsand conditions,which are available uponrequest. Wereserve the right to modify or improve the designs or specifications of such

products at any time without notice.

Emerson Process Management

Marshalltown, Iowa 50158 USA

Sorocaba, 18087 Brazil

Chatham, Kent ME4 4QZ UK

Dubai, United Arab Emirates

Singapore 128461 Singapore

www.Fisher.com

E 1990, 2012 Fisher Controls International LLC. All rightsreserved.

16

Loading...

Loading...