Page 1

Instruction Manual

D100304X012

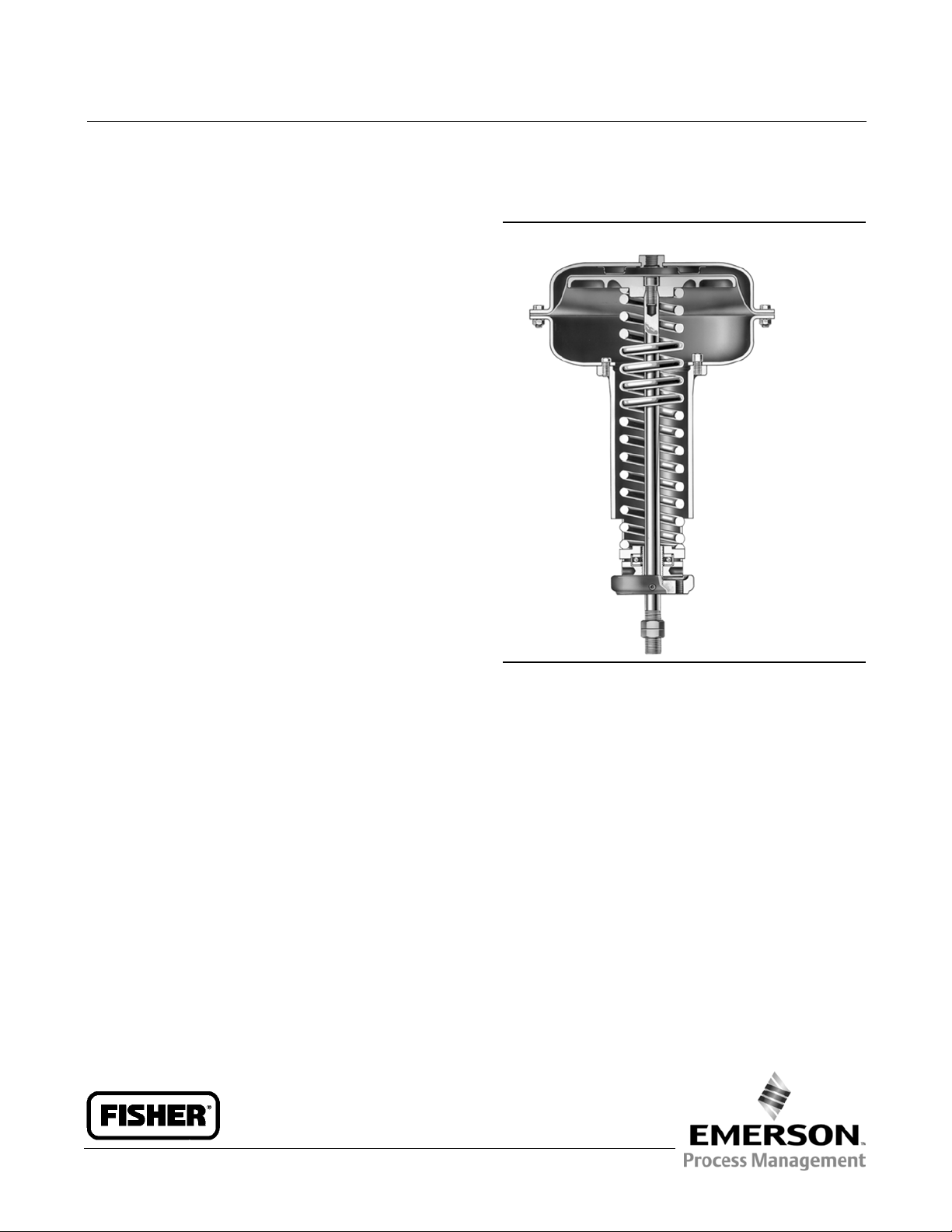

Fisherr 656 Diaphragm Actuator

656 Actuator

August 2012

Contents

Introduction 1.................................

Scope of Manual 1.............................

Description 1.................................

Principle of Operation 2.........................

Specifications 2...............................

Maximum Pressure Limitations 3................

Installation 3..................................

Adjustment 3..................................

Maintenance 4.................................

Disassembly 4................................

Assembly 5...................................

Parts Ordering 7................................

Parts List 7....................................

Handwheel Assembly 7........................

Casing-Mounted Adjustable Down

Travel Stop 11..............................

Figure 1. Fisher 656 Actuator

W0454

Introduction

Scope of Manual

This instruction manual includes installation, maintenance, and parts information for Fisher 656 diaphragm actuators.

Refer to separate manuals for instructions covering the valve, positioner, and accessories.

Description

Fisher 656 actuators are long stroke, spring opposed, direct-acting diaphragm actuators. They operate Vee-Ballt

control valves, butterfly valves, built-in turbine valves, louvers, dampers and similar equipment. They are suitable for

either push-down-to-close (PDTC) or push-down-to-open (PDTO) applications and are available in sizes 30, 40 and 60

to provide 54 mm (2.125 inch), 64 mm (3.5 inch) and 105 mm (4.125 inch) travel, respectively.

Do not install, operate, or maintain a 656 actuator without being fully trained and qualified in valve, actuator, and

accessory installation, operation, and maintenance. To avoid personal injury or property damage, it is important to

carefully read, understand, and follow all the contents of this manual, including all safety cautions and warnings. If you

have any questions about these instructions, contact your Emerson Process Management sales office before

proceeding.

www.Fisher.com

Page 2

656 Actuator

August 2012

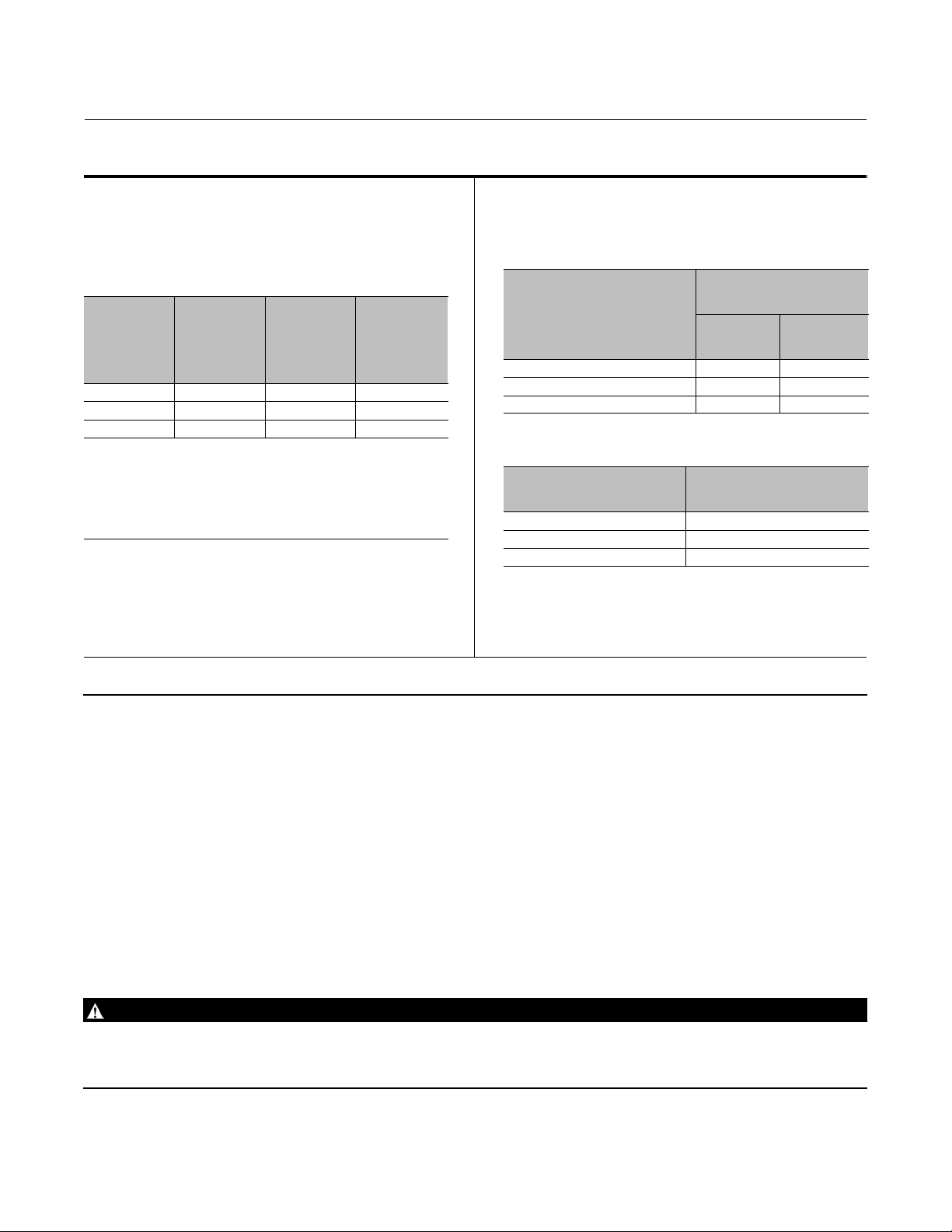

Table 1. Specifications

Instruction Manual

D100304X012

Maximum Recommended Casing Operating

Pressure

(1)

Casing Pressure Connection

1/4 NPT internal

2.4 bar (35 psig)

Maximum Travel

(3)

(2)

Maximum

Diaphragm

(1)

,

Casing

Pressure

Bar (Psig)

(2,3)

,

Actuator Weight

Options

J Top-mounted handwheel/adjustable travel stop

J Casing-mounted adjustable down travel stop

Maximum Allowable Casing Pressure

Maximum

Actuator

Size

30 8.6 (125) 1.0 (15) 9.7 (140)

40 4.5 (65) 0.69 (10) 5.2 (75)

60 2.8 (40) 0.69 (10) 3.4 (50)

1. Additional pressure may be added when the actuator is at full travel. If the Maxi

mum Excess Diaphragm Pressure is exceeded, damage to the diaphragm or dia

phragm casing mightresult. See theMaximum Pressure Limitationsection.

2. Maximum diaphragm casing pressure must not be exceeded and mustnot produce

a force on the actuator stem greater than the max imum allowable actuator output

thrustorthemaximumallowablestemload.SeetheMaximumPressureLimitation

section.

3. This maximum casing pressure is not to be used for normal operating pressure. Its

purpose is to allow for typicalregulator supply settingsand/or relief valve tolerances.

Casing

Pressure for

Actuator

(2)

Sizing

Bar (Psig)

,

Maximum

Excess

Diaphragm

Pressure

Bar (Psig)

Operating Temperature Range

J -40 to 82C(-40to180F) with Nitrile Elastomer

J

-40 to 149C(-40to300F) with Silicone

Diaphragm

1. Control and stability may be impaired if thispressure is exceeded.

2. Exceeding this pressure can cause damage to the diaphragm, diaphragm casing,or other parts.

3. The temperaturelimits in thismanual and any applicablestandard or code limitation for valve should not be exceeded.

MAXIMUM RATED

STEM TRAVEL,

ACTUATOR SIZE

30 54 (2.125) Not available

40 89 (3.5) 76 (3)

60 105 (4.125) 97 (3.8125)

Actuator Size

30 23 (50)

40 32 (70)

60 73 (160)

mm (INCHES)

Standard

Travel

Stop

Approximate

Shipping Weight,

kg (Pounds)

Optional

Travel

Stop

Principle of Operation

In a direct acting diaphragm actuator, increasing loading pressure moves the actuator stem downward, compressing

the spring. When the diaphragm pressure is decreased, the spring moves the actuator stem upward. In the event of

failure of the loading pressure, the actuator stem moves to the extreme upward position.

Specifications

Refer to table 1 for Specifications of the 656 actuator. See the actuator nameplate for specific information for your

actuator.

WARNING

To avoid personal injury or damage to equipment that may result in the malfunction of the control valve or loss of control

of the process caused by excessive pressure, do not exceed the Maximum Pressures listed in table 1. Refer to the following

Maximum Pressure Limitations section.

2

Page 3

Instruction Manual

D100304X012

656 Actuator

August 2012

Maximum Pressure Limitations

The casing and diaphragm of 656 actuators are pressure operated. This air pressure provides energy to compress the

spring, to stroke the actuator, and to seat the valve. The following explanations describe the maximum pressure limits

for an actuator. Refer to the nameplate or table 1 for maximum values for your actuator.

D Maximum Casing Pressure for Actuator Sizing: This is the maximum pressure that can be applied at less than full

travel of the actuator. If this stroking pressure is exceeded before the upper diaphragm plate contacts the travel

stop, damage to the stem or other parts might result.

D Maximum Excess Diaphragm Pressure: Additional pressure may be added when the actuator isatfulltravel.Ifthe

Maximum Excess Diaphragm Pressure is exceeded, damage to the diaphragm or diaphragm casing might result.

Because the actuator has traveled its specified travel, andthediaphragmheadisphysicallystoppedfrommovement,

the energy from any additional air pressure is transmitted to the diaphragm and diaphragm casings. The amount of air

pressure that can be added once the actuator has traveled to the stops is limited by the resultant adverse effects that

may occur. Exceeding this limiting factor could result in leakage or casing fatigue due to the deformation of the upper

diaphragm casing.

D Maximum Diaphragm Casing Pressure: If the Maximum Diaphragm Casing Pressure is exceeded, damage to the

diaphragm, diaphragm casing, or actuator might result.

Installation

When an actuator and valve are shipped together, the actuator is normally mounted on the valve. Follow the valve

instructions when installing the valve and actuator in a pipeline. If the actuator is shipped separately, or if it is

necessarytomounttheactuatoronthevalve,fourholeshavebeentappedintotheyokebosstoanchorittoa

mounting bracket.

WARNING

Always wear protective gloves, clothing, and eyewear when performing any maintenance operations to avoid personal

injury.

To avoid personal injury or property damage caused by bursting of pressure retaining parts, be certain the diaphragm

casing pressure does not exceed the limits listed in the Specifications table. Use pressure relieving or pressure limiting

devices to prevent the diaphragm casing pressure from exceeding these limits.

If installing into an existing application, also refer to the WARNING at the beginning of the Maintenance section in this

instruction manual.

To make the stem connection, follow the appropriate assembly step 10 in the Maintenance section. Standard actuator

sizes 30 and 40 have mounting holes tapped 3/8 inch UNC, and the size 60 mounting holes are tapped 1/2 inch UNC.

A 1/4 NPT loading pressure connection is located in the top of the upper diaphragm case. Using either pipe or tubing,

connect either the loading pressure connection or valve positioner input connection (if a valve positioner is furnished,

the loading pressure connection to the actuator will be made at the factory) to the output pressure connection on the

controller. Keep the length of the pipe or tubing as short as possible to avoid transmission lag in the control signal.

Adjustment

When the actuator is completely installed and connected to the controller, it should be checked for correct travel,

freedom from friction and correct PDTC or PDTO action.

3

Page 4

656 Actuator

August 2012

Instruction Manual

D100304X012

The actuator spring and diaphragm have been selected to meet the requirements of the application. It should be

noted that the actuator spring has a constant rate of compression and that adjustment of the spring compression

merely shifts the initial spring setpoint up or down to make the actuator travel within the initial spring setpoint and the

maximum diaphragm pressure indicated on the nameplate.

In some instances, however, such as high friction butterfly and ball valves, the actuator will fully stroke with less

diaphragm pressure than indicated on the nameplate. To increase the pressure required to initiate actuator stem

movement, turn the lower bearing seat (key 14) up toward the spring case. To decrease the pressure at which

movement begins, turn the lower bearing seat down, away from the spring case.

Maintenance

WARNING

Avoid personal injury or property damage from sudden release of process pressure or uncontrolled movement of parts.

Before performing any maintenance operations:

D Do not remove the actuator from the valve while the valve is still pressurized.

D Always wear protective gloves, clothing, and eyewear when performing any maintenance operations to avoid personal

injury.

D Disconnect any operating lines providingair pressure, electric power, or a control signal to the actuator. Be sure the

actuator cannot suddenly open or close the valve.

D Use bypass valves or completely shut off the process to isolate the valve from process pressure. Relieve process pressure

from both sides of the valve. Drain the process media from both sides of the valve.

D Vent the power actuator loading pressure and relieve any actuator spring precompression.

D Use lock-out procedures to be sure that the above measures stay in effect while you are working on the equipment.

D The valve packing box may contain process fluids that are pressurized, even when the valve has been removed from the

pipeline. Process fluids may spray out under pressure when removing the packing hardware or packing rings, or when

loosening the packing box pipe plug.

D Check with your process or safety engineer for any additional measures that must be taken to protect against process

media.

Disassembly

1. If the actuator is installed on a control valve, isolate or bypass the control valve.

2. Shut off the diaphragm loading pressure and remove the pipe or tubing from the loading pressure connection in

thetopofthediaphragmcase.

3. Turn the lower bearing seat (key 14) down, away from the spring case to relieve all spring compression.

4. If the entire actuator is to be removed from its mounting, disconnect the actuator stem (key 10) from the stem

connector, clevis, etc., and remove the jam nuts (key 23). Loosen the cap screws that hold the yoke (key 9) to its

mounting plate or bracket, and lift the entire actuator from its mounting.

5. Remove the diaphragm case cap screws and nuts (keys 19 and 20) and lift the upper diaphragm case (key 1 ) off t he

actuator. Remove the diaphragm (key 2).

6. Lift out the diaphragm plate (key 4) and stem (key 10). They may be separated by removing the cap screw (key 3).

4

Page 5

Instruction Manual

D100304X012

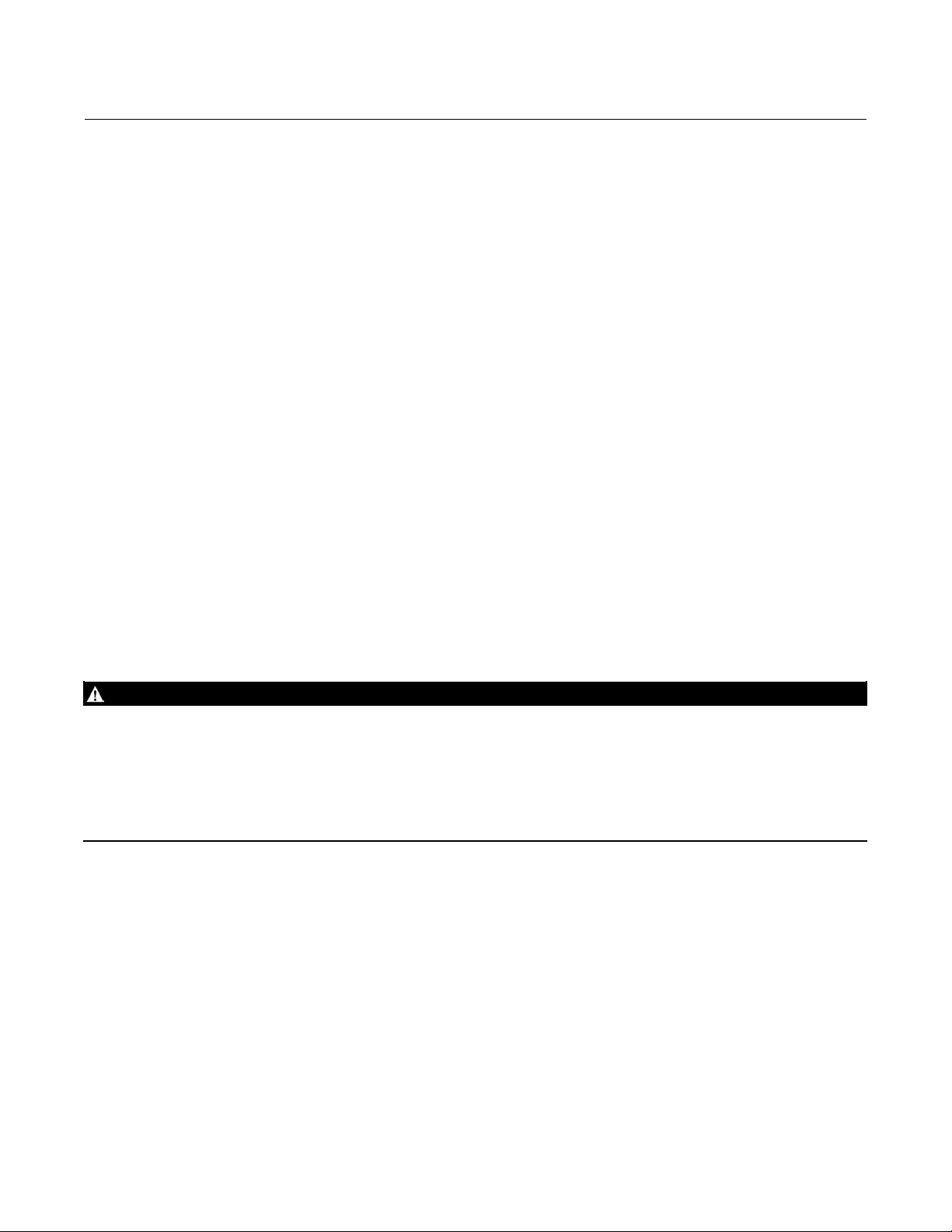

Figure 2. Travel Stop Orientation for Size 60

MOUNTING BOSS

A

ON ACTUATOR YOKE

A

656 Actuator

August 2012

A

11A0001-A

LOCATE FOUR TRAVEL

STOPS MARKED A

MOUNTING BOX

ON ACTUATOR YOKE

7. Take out the actuator spring (key 6).

8. The lower diaphragm case (key 5) can be removed from the yoke, if required, by loosening the travel stops and cap

screws (keys 7 and 8).

9. Remove the lower spring seat (key 11) and thrust bearing (key 13). Unscrew the lower bearing seat (key 14) from

the adjusting screw (key 12).

10. Remove the set screw (key 22) and remove theadjustingscrewtocompletedisassembly.

Assembly

1. Apply lithium grease lubricant, or equivalent, to the adjusting screw threads (key 12) and screw this into the yoke

(key 9). Replace set screw (key 22). The set screw should engage the machined thread relief in the adjusting screw.

2. With the eared portion up, screw the lower bearing seat (key 14) all the way onto the adjusting screw.

3. Apply lithium grease lubricant, or equivalent, to the thrust bearing (key 13) and position it on the lower bearing seat

(key14).Laythelowerspringseat(key11)ontopofthethrustbearingassembly.

4. Mountthelowerdiaphragmcase(key5)tothetopoftheyoke(key9)usingthetravelstopsandcapscrews(keys7

and 8). Alternate screws and travel stops on the sizes 30 and 40. See figure 2 for the correct orientation of the size

60.

5. Position the actuator spring (key 6) on the lower spring seat.

6. Attach the diaphragm plate (key 4) to the actuator stem (key 10) with the cap screw (key 3). Apply lithium grease

lubricant, or equivalent, to the stem. Place this assembly, actuator stem first, into the yoke with the actuator stem

through the spring adjustor (key 12).

7. Position the diaphragm (key 2) on the diaphragm plate (key 4) and align the holes with the lower diaphragm casing

(key 5). Attach the upper diaphragm case (key 1) to the lower diaphragm casing (key 5) using the cap screws and

nuts

(keys 19 and 20).

Note

When you replace actuator diaphragms in the field, take care to ensure the diaphragm casing bolts are tightened to the proper

load to prevent leakage, but not crush the material.

5

Page 6

656 Actuator

August 2012

Note

Do not use lubricant on these bolts and nuts. Fasteners must be clean and dry.

Instruction Manual

D100304X012

a. The first four bolts tightened should be diametrically opposed and 90 degrees apart. Tighten these four bolts to

13 NSm(10lbfSft).

b. Tighten the remaining bolts in a clockwise, criss-cross pattern to 13 NSm(10lbfSft).

c. Repeat this procedure by tightening four bolts, diametrically opposed and 90 degrees apart, to a torque of 27

NSm(20lbfSft).

d. Tighten the remaining bolts in a clockwise, criss-cross pattern to 27 NSm(20lbfSft).

e. After the last bolt is tightened to 27 NSm(20lbfSft), all of the bolts should be tightened again to 27 NSm(20

lbfSft)inacircularpatternaroundtheboltcircle.Once completed, no more tightening is recommended.

8. If the actuator has been removed from its mounting, position it on its mounting plate or bracket, and secure with

cap screws.

9. Attach the pressure pipe or tubing to the loading pressure connection on top of the upper diaphragm case.

10. Attach the actuator stem to the stem connector or clevis and adjust the travel by using the appropriate procedure

below.

D For Push-Down-to-Open applications:

1. Set the controlled element (valve plug, louver, damper, etc.) in the closed position.

2. Turn the lower bearing seat (key 14) up toward the spring case far enough to ensure that the actuator stem is at the

top of its stroke.

3. Make the actuator stem connection, making sure that there is full engagement of the actuator stem threads.

Tighten slightly.

4. Apply loading pressure to the diaphragm case to move the controlled element toward its wide open position. Screw

the controlled element linkage into the actuator stem connection far enough to move the controlled element

toward its closed position 3.2 mm (1/8 inch), and tighten the stem connection securely. This adjustment ensures

that the controlled element will close before the actuator stem travels to the top of its stroke. The travel stops (key

7) in the lower diaphragm case ensure correct travel of the controlled element in the open direction.

5. If travel starts at a lower or higher pressure than is required for proper operation, turn the lower bearing seat (key

14) up or down respectively, as described in the Adjustment section.

D For Push-Down-to-Close applications:

1. Set the controlled element (valve plug, louver, damper, etc.) in the open position.

2. Turn the lower bearing seat (key 14) up toward the spring case far enough to ensure that the actuator stem is at the

top of its stroke.

3. Tighten the actuator stem connection slightly, making sure that there is full engagement of the actuator stem

threads.

4. Apply loading pressure to the diaphragm case and observe the travel of the controlled element to make sure that it

closes completely. If the travel is not correct, it can be changed by screwing the controlled element linkage in or out

of the stem connection. When the travel is set correctly, tighten the stem connection securely, and lock the jam

nuts (key 23).

5. If travel starts at a lower or higher pressure than is required for proper operation, turn the lower bearing seat in or

out respectively, as described in the Adjustment section.

6

Page 7

Instruction Manual

D100304X012

656 Actuator

August 2012

Parts Ordering

When corresponding with your Emerson Process Management sales office about this equipment, refer to the serial

number found on the actuator nameplate.

WARNING

Use only genuine Fisher replacement parts. Components that are not supplied by Emerson Process Management should

not, under any circumstances, be used in any Fisher valve, because they may void your warranty, might adversely affect the

performance of the valve, and could cause personal injury and property damage.

Parts List

Note

Part numbers are shown for recommended spares only. For Part

numbers not shown, contact your Emerson Process Management sales

office.

Key Description Part Number

1 Diaphragm Case, steel

Standard

2* Diaphragm, Nitrile

Size 30 2E791902202

Size 40 2E670002202

Size 60 2E859702202

3 Cap Screw, steel

4 Diaphragm Plate, cast iron

5 Lower Diaphragm Case, steel

6 Actuator Spring,steel

7 DownTravelStop,steel Sizes30&40(3req'd),

Size 60 (4 req'd)

8 CapScrew,steel Sizes30&40(3req'd),Size60(4req'd)

9 Yoke, cast iron

10 Actuator Stem, steel

11 Lower Spring Seat, steel

12 Adjusting Screw, brass

13 Thrust Bearing, steel ball bearing

14 Lower Bearing Seat, steel

Key Description Part Number

17 Nameplate, SST

18 Drive Screw, SST (6 req'd)

19 Cap Screw, steel Size 30 (12 req'd), Size 40 (16 req'd),

Size 60 (24 req'd)

20 Hex Nut, steel Size30 (12 req'd), Size 40 (16 req'd),

Size 60 (24 req'd)

21 Valve Stem, 316 SST (Size 30 only)

22 Set Screw, steel

23 Hex Nut, steel (2 req'd)

25 Warning Nameplate

Handwheel Assembly

51 Handwheel, cast iron

54 Jam Nut, steel 1A353724122

133 Stem, brass

135 Pusher Plate Assembly, steel

137 Jam Nut, steel

138* O-ring, nitrile

Size 30 & 40 1D237506992

Size 60 1B885506992

139* O-ring, nitrile

Size 30 & 40 1D267306992

Size 60 1D547106992

140 Groove Pin, steel

141 CapScrew,steel Sizes30&40(6req'd),Size60(8req'd)

142 Handwheel body, cast iron

164 Body Extension, steel

171 Spacer, 416 SST (size 60 only)

*Recommended spare parts

7

Page 8

656 Actuator

August 2012

Figure 3. Fisher 656 Size 30 Actuator

A

APPLY THREAD LOCKING ADHESIVE (HIGH STRENGTH) TO SURFACE A

CK1580

A0345-1

Figure 4. Fisher 656 Size 40 & 60 Actuators

Instruction Manual

D100304X012

A

B

APPLY LITHIUM GREASE LUBRICANT ON SURFACES A & B

40A7798A

8

Page 9

Instruction Manual

D100304X012

Figure 5. Typical Top-Mounted Handwheel Assembly for Diaphragm Actuator, Size 30 & 40

656 Actuator

August 2012

LUBRICATE END OFSTEM AND PLATE WITH LITHIUM GREASE

LUBRICATE STEM THREADSWITH ANTI-SEIZE LUBRICANT

38A1209-D

9

Page 10

656 Actuator

August 2012

Figure 6. Typical Top-Mounted Handwheel Assembly for Diaphragm Actuator, Size 60

Instruction Manual

D100304X012

LUBRICATE END OF STEM AND PLATE WITH LITHIUM GREASE

LUBRICATE STEM THREADS WITH ANTI-SEIZE LUBRICANT

32B0262-B

10

Page 11

Instruction Manual

D100304X012

Figure 7. Casing-Mounted Adjustable Down Travel Stop for Size 30 and 40 Actuators (Style 2)

656 Actuator

August 2012

APPLY LUB

BV8054-D

Casing-Mounted Adjustable

Down Travel Stop (figure 7)

Key Description Part Number

54 Stop Nut

133 Travel Stop Stem

134 Washer

Key Description Part Number

139* O-Ring, nitrile

Sizes 30, 34, & 40 1D267306992

Sizes 45, 46, 50, & 60 1D547106992

Sizes 70 & 87 1D269106992

141 Cap Screw

142 Body

187 Travel Stop Cap

189 Jam Nut

241 Lubricant, Lithium Grease or equivalent

(not furnished with travel stop)

*Recommended spare parts

11

Page 12

656 Actuator

August 2012

Instruction Manual

D100304X012

Neither Emerson, Emerson Process Management, nor any of their affiliated entities assumes responsibility for the selection, use or maintenance

of any product. Responsibility for properselection, use, and maintenanceof any product remains solely with the purchaser and end user.

Fisher and Vee-Ball are marks owned by one of the companies in the Emerson Process Management business unit of Emerson Electric Co. Emerson Process

Management, Emerson, and the Emerson logo are trademarks and service marks of Emerson Electric Co. All other marks are the property of their respective

owners.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they arenot

to be construed as warranties or guarantees, express or implied, regarding the products or services described herein or their use or applicability. All sales are

governed by our terms and conditions, which are available upon request. We reservethe right to modify or improve the designs or specifications of such

products at any time without notice.

Emerson Process Management

Marshalltown, Iowa 50158 USA

Sorocaba, 18087 Brazil

Chatham, Kent ME4 4QZ UK

Dubai, United Arab Emirates

Singapore 128461 Singapore

www.Fisher.com

12

E 1974, 2012 Fisher Controls International LLC. All rights reserved.

Loading...

Loading...