Page 1

656 Actuator

D100086X012

Fisherr 656 Diaphragm Actuator

The Fisher 656 actuator is a bracket-mounted,

direct-acting, diaphragm actuator for either throttling

or on-off service. Principal applications include

operation of butterfly valves and built-in turbine

valves, louvers, dampers, and other similar equipment.

Features

Mounting Versatility–Four tapped holes in the

actuator base permit either bracket or plate

mounting.

Product Bulletin

61.1:656

February 2013

Long Actuator Travel–Deep casings provide up to

105 mm (4.125 inches) of maximum travel with a

size 60 actuator.

Application Versatility–Wide spring selection is

available for nearly any control application. Spring

selection procedures are quick and accurate.

Severe Service Capability–Rugged yoke and casings

provide stability and corrosion resistant protection.

Installation

The actuator may be installed in any position.

Dimensions are shown in figure 1.

W1996-2

YOKE

W0454-1

TRAVEL STOP

ADJUSTING SCREW

SPRING SEAT

BEARING

BEARING SEAT

TYPICAL CONSTRUCTION

Fisher 656 Actuator

www.Fisher.com

Page 2

Product Bulletin

61.1:656

February 2013

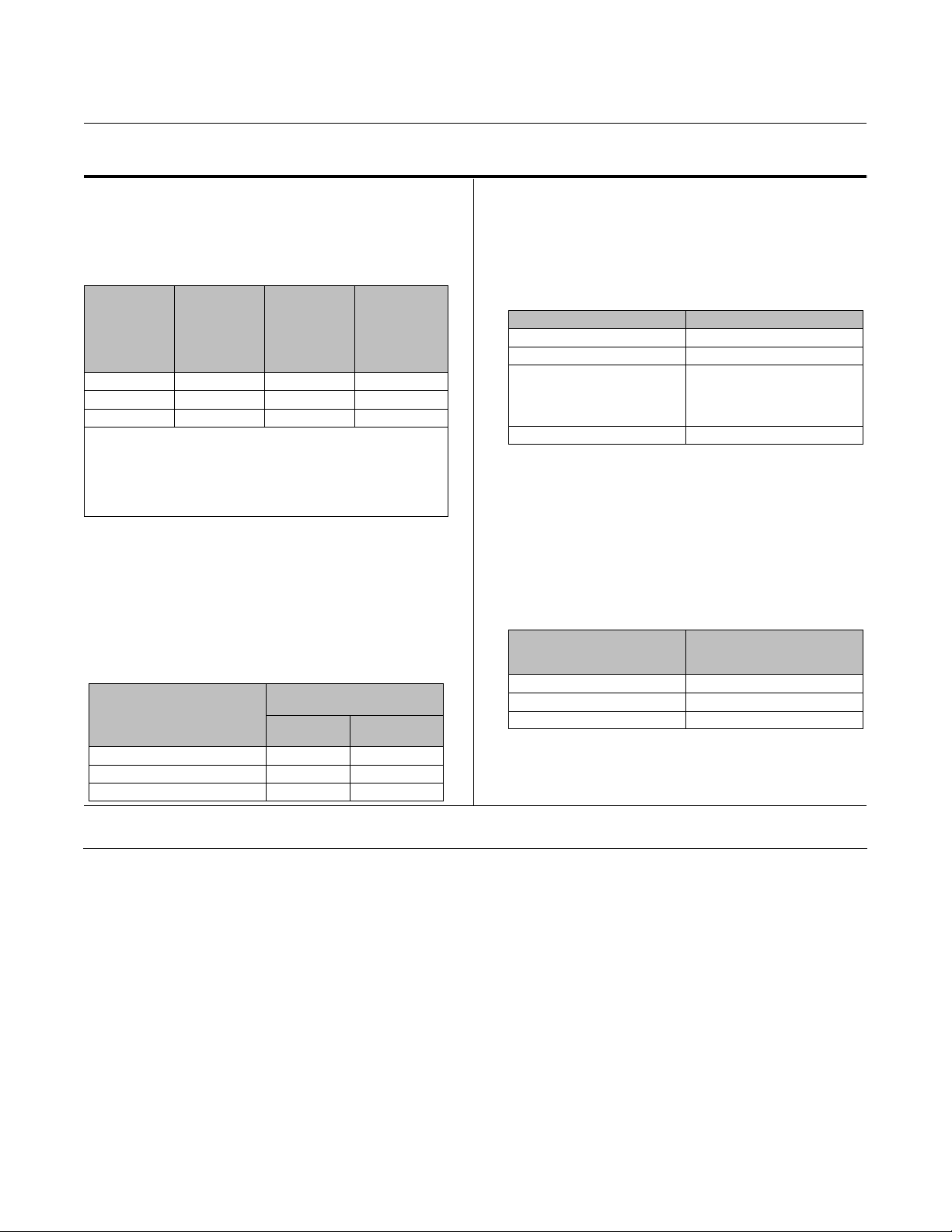

Specifications

656 Actuator

D100086X012

Maximum Recommended Casing Operating

Pressure

(1)

2.4 bar (35 psig)

(1a)

(2)(4)

,

Maximum

Diaphragm

Casing

Pressure

Bar (Psig)

Maximum Allowable Casing Pressure

Maximum

Actuator

Size

30 8.6 (125) 1.0 (15) 9.7 (140)

40 4.5 (65) 0.69 (10) 5.2 (75)

60 2.8 (40) 0.69 (10) 3.4 (50)

1a. Additional pressure may be added when the actuator is at full t ravel.If the

Maximum Excess DiaphragmPressure is exceeded,damage to the diaphragm or

diaphragm casing mightresult. Seethe Maximum Pressure Limitation section.

2a. Maximum diaphragmcasing pressuremust not beexceeded and must not

produce a force on the actuator stem greater than the maximumallowable actuator

output thrust or the maximumallowable stem load. See theMaximum Pressure

Limitation section.

3a. This maximumcasing pressure is not to be used fornormal operating pressure.Its

purpose is toallow for typical regulator supplysettings and/or relief valve tolerances.

Casing

Pressure for

Actuator

(2a)

Sizing

Bar (Psig)

,

Maximum

Excess

Diaphragm

Pressure

Bar (Psig)

Net Stem Force Output

See table 1

Springs Commonly Used with Rotary Valves

(2a,3a)

,

Operating Temperature Range

J -40 to 82C(-40to180F) with Nitrile Elastomer

J

-40 to 149C(-40to300F) with Silicone

Diaphragm

Construction Materials

Part Description Construction Material

Diaphragm Nitrile

Diaphragm plate and yoke Cast iron

Diaphragm casings, spring,

spring seats, travel stop, stem,

bearings, bearing seat, and

bearing race

Adjustment screw Brass

Casing Pressure Connection

1/4 NPT internal

Mounting and Stem Thread Information

Seefigure1

Actuator Weight

See table 2

Maximum Travel

Actuator Size

MAXIMUM RATED STEM

ACTUATOR SIZE

30 54 (2.125) Not available

40 89 (3.5) 76 (3)

60 105 (4.125) 97 (3.8125)

1. Control andstability may be impaired ifthis pressure isexceeded.

2. Exceeding thispressure can cause damage to the diaphragm, diaphragmcasing, or other parts.

3. For fluidand temperature capabilities of optionalmaterials, consultyour Emerson Process Management sales office

4. The pressure/temperaturelimits in this bulletinand any applicable standard or code limitation forvalve should not be exceeded

TRAVEL mm (INCHES)

Standard

Travel Stop

Optional

Travel Stop

Options

Top-mounted handwheel/adjustable travel stop

(4)

(3)

(standard)

Steel

Approximate

Shipping Weight,

kg (Pounds)

30 23 (50)

40 32 (70)

60 73 (160)

Ordering Information

When ordering, specify:

1. Actuator type and size

2. Spring range (see table 2)

3. Handwheel or optional travel stop

4. Loading pressure range and volume requirement

2

Page 3

656 Actuator

D100086X012

Product Bulletin

61.1:656

February 2013

Table 1. Stem Force Output and Other Actuator Data

(1)

Stem Fully

Retracted

NET STEMFORCE

Stem Fully Extended

(3)

Loading as Shown

ACTUATOR

SIZE

Maximum

Range

TYPICAL SPRINGS

Part Number Color Code

Metric Units

Bar --- --- Newtons Newtons Bar cm

30

40

60

0.17 to0.66

0.21 to0.86

0.29 to1.2

0.26 to1.3

0.27 to1.6

0.21 to1.8

0.21 to0.88

0.41 to1.9

0.30 to2.2

0.26 to0.90

0.24 to1.1

0.49 to1.9

0.48 to2.3

1F361627032

1K509827032

1N751527032

1F177027092

1F177127092

1F177227092

1L217427042

1L217327042

1N844027082

1K162727082

1N937327082

1K162827082

1P270227042

Aluminum and orange

Aluminum and dark green

Aluminum and red

Tan

Brown

Pink

White

Dark green

(5)

None

(5)

None

(5)

None

(5)

None

(5)

None

734

939

1321

1143

1232

939

1468

2802

2002

3541

3350

6503

6410

2322

1735

698

525

1699

1108

2424

1201

1632

5360

3336

3034

2224

US Units

Psig --- --- Pounds Pounds Psig SquareInches

2.5 to9.6

3.0 to12.5

30

4.3 to17.6

3.7 to18.4

3.9 to23.9

3.1 to26.1

3.1 to12.7

40

6.0 to27.4

4.3 to31.2

3.7 to13.1

60

3.5 to16.1

7.1 to27.0

6.9 to33.5

1. Others available;consult with your Emerson Process Management sales office for spring characteristics.

2. For maximum rated stemtravel with standard travel stop and zero handwheel limitation.

3. Stem forceequals initial spring compression withzero loading pressure.

4. Stem forceequals: (loading pressure X diaphragmarea with stemfully extended) minus force ofsprings at maximumcompression. Higherpressures canbeused,

but they must not exceed maximumallowable casing pressure or create stem force greater than safeload limit of any control device component.

5. Part numberstamped on spring.

1F361627032

1K509827032

1N751527032

1F177027092

1F177127092

1F177227092

1L217427042

1L217327042

1N844027082

1K162727082

1N937327082

1K162827082

1P270227042

Aluminum and orange

Aluminum and dark green

Aluminum and red

Tan

Brown

Pink

White

Dark green

(5)

None

(5)

None

(5)

None

(5)

None

(5)

None

165

211

297

257

277

211

330

630

450

796

753

1462

1441

522

390

157

118

382

249

545

270

367

1205

750

682

500

(2)

with Diaphragm

1.4

2.1

1.4

2.1

2.4

1.4

2.1

2.4

20 psig

30 psig

20 psig

30 psig

35 psig

20 psig

30 psig

35 psig

EFFECTIVE DIAPHRAGM AREA

(4)

,

Stem Fully

Retracted

Stem Fully

(3)

Extended

2

425 310

645 445

1387 1032

66 48

100 69

215 160

(4)

Table 2. Springs Commonly Used with Rotary Valves

INPUT SIGNAL

MAXIMUM RATED TRAVEL

SPRING PARTNUMBER

1. With standard travel stop and zero handwheel limitation.

2. For torqueoutputs using commonsprings, contactyour Emerson Process Management sales office.

WITH POSITIONER 1.4BAR(20PSIG) 2.4BAR(35PSIG)

WITHOUT POSITIONER 0.2to1.0BAR(3to15PSIG) 0.4to2.1BAR(6to30PSIG)

ACTUATOR SIZE 30 40 60 30 40 60

(1)

,mm(INCHES) 54 (2.125) 89 (3.5) 105 (4.125) 54(2.125) 89 (3.5) 105 (4.125)

(2)

1K509827032 1K217427042 1K162727082 1F177220792 1L217327042 1K162827082

3

Page 4

Product Bulletin

61.1:656

February 2013

Table 3. Dimensions

DIMENSION

ACTUATOR

SIZE

30 67 289 314 490 54 171 1/2-20 19 73 3/8-16 U NC

40 79 333 454 723 57 222 3/4-16 19 73 3/8-16 UNC

60 79 473 692 1014 64 222 3/4-16 32 99 1/2-13 UNC

30 2.62 11.38 12.38 19.32 2.12 6.75

30 3.12 13.12 17.88 28.38 2.25 8.75 0.75 2.88

40 3.12 18.62 27.25 39.94 2.50 8.75 1.25 3.88

A C

Without

Handwheel

E

With

Handwheel

H J

mm

Inches

S(Stem

Thread)

See above

X

Bolt Circle

Diameter

0.75 2.88

Figure 1. Dimensions (also see table 3)

J

1/4-18 NPT

656 Actuator

Y(4Holes)

D100086X012

Thread

See above

E

C

57

1

H

1U6162-C

A1506-1

Note:

1

Duplicated on opposite side: each hole 5/16-18 UNC-2B tapped 13 (0.50) deep.

S

A

(2.25)

X

Y

mm

(INCH)

Neither Emerson,Emerson Process Management, nor any of their affiliated entities assumes responsibility for the selection, use or maintenance

of any product. Responsibility for proper selection, use,and maintenance of anyproduct remains solely with thepurchaser and enduser.

Fisher is a markowned by one of the companiesin the Emerson ProcessManagement business unit of Emerson Electric Co. Emerson ProcessManagement,

Emerson, and the Emerson logo are trademar ks and service marks of Emerson Electric Co. All other marks are the property of their respective owners.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they arenot

to be construed as warranties or guarantees, express or implied, regarding the products or services described herein or their use orapplicability. All sales are

governed by our terms and conditions, which are available upon request. Wereserve the right to modify or improve the designs or specifications of such

products at any time without notice.

Emerson ProcessManagement

Marshalltown, Iowa 50158 USA

Sorocaba, 18087 Brazil

Chatham, Kent ME44QZ UK

Dubai, United Arab Emirates

Singapore 128461 Singapore

www.Fisher.com

E 1993, 2013 Fisher Controls InternationalLLC. All rights reserved.

4

Loading...

Loading...