Page 1

Instruction Manual

Page 2

IMPORTANT SAFETY INSTRUCTIONS

Your Elna 7200 sewing machine is designed and constructed for HOUSEHOLD use only. Read all

instructions before using this machine.

DANGER – To reduce the risk of electric shock:

1. Your sewing machine should never be left unattended when plugged in. Always unplug the machine

from the electrical outlet immediately after using and before cleaning.

2. Always unplug before replacing light bulb. Replace bulb with same type rated 12 Volts, 5 watts.

3. Do not reach for the machine if it has fallen into water. Unplug immediately.

4. Do not place or store machine where it can fall or be pulled into a tub or sink. Do not place it in or

drop it into water or other liquid.

WARNING – To reduce the risk of burns, fire, electrical shock or injury:

1. Do not allow machine to be used as a toy. Supervision is necessary when this machine is used by

or near children.

2. Use this sewing machine only for its intended use as described in this manual. Only use

attachments recommended by the manufacturer as described in this manual.

3. Never operate this machine if it has a damaged cord or plug, is not working properly, has been

dropped or damaged or dropped into water. Return the machine to the nearest authorized dealer or

service center for examination, repair, electrical or mechanical adjustment.

4. This machine is equipped with a special connection cord which, if damaged, must be replaced by

an identical cord. This can be obtained from your dealer.

5. Never operate the sewing machine with any air opening blocked. Keep ventilation openings of the

sewing machine and foot control free from the accumulation of lint, dust and fibers.

6. Never drop or insert any object into any opening.

7. Do not use outdoors.

8. Do not operate where aerosol (spray) products are being used or where oxygen is being

administered.

9. To disconnect, turn machine off and remove plug from outlet.

10. Do not unplug by pulling on cord. To unplug, grasp the plug, not the cord.

11. Keep fingers away from all moving parts, especially the needle.

12. Always use the proper needle plate. The wrong plate can cause the needle to break.

13. Do not use bent needles.

14. Do not pull or push fabric while stitching. This may deflect the needle causing it to break.

15. Switch the sewing machine off when making any adjustment in the needle area, such as threading

needle, changing needle, threading bobbin, changing presser foot, etc.

16. Always unplug the sewing machine from the electrical outlet when removing covers, lubricating or

making any other servicing adjustments mentioned in the instruction manual.

SAVE THESE INSTRUCTIONS

IMPORTANT

Be sure to keep machine away from static electricity, heat sources, humidity and direct sunlight.

USA only

Yo ur machine comes equipped with a polarized plug (one prong wider than the other). A polarized plug

reduces the risk of electrical shock. This plug is intended to fit into a polarized outlet. If the plug does

not fit fully into the outlet, reverse the plug. If it still does not fit, contact a qualified electrician to install

the proper outlet. Do not modify the plug in any way.

Use only foot control Model 21371 (UL, CSA).

1

Page 3

TABLE OF CONTENTS

SECTION I – Machine Parts and Functions

Part Names .............................................................................. 3

Standard Accessories ............................................................. 4

Presser Foot and Accessory Definitions .............................. 5-6

How to Attach Stitch Chart Brackets ....................................... 7

Stitch Chart ..............................................................................7

Write ‘n Clip Board ...................................................................7

Quilt Table ................................................................................ 8

Knee Lifter ............................................................................... 8

Connecting Machine to Power Supply ....................................9

Main Function of Keys ........................................................... 10

Keyboard Selection Keys ................................................ 11-13

Setting Quick Resumption, Sound and

Language Modes ........................................................ 14-15

Controlling Sewing Speed ..................................................... 15

Foot Pressure Dial ................................................................. 15

How to Drop the Feed Dog.................................................... 16

Presser Foot Lever ................................................................ 16

Additional Presser Foot Clearance ....................................... 16

Attaching and Removing Presser Feet ................................. 17

Attaching and Removing Shank ............................................ 17

Seam Allowance Lines ..........................................................17

Centimeter/Inch Quick Measurements.................................. 17

Adjusting Needle Thread Tension ......................................... 18

Using the Fine Adjustment Screw ......................................... 19

SECTION II – Getting Ready to Sew

Selecting the Correct Needle and Thread ............................ 20

Changing Needles .................................................................20

Needle Definitions ................................................................. 21

Winding a Bobbin ............................................................ 22-23

Inserting the Bobbin .............................................................. 24

Threading the Machine.................................................... 25-26

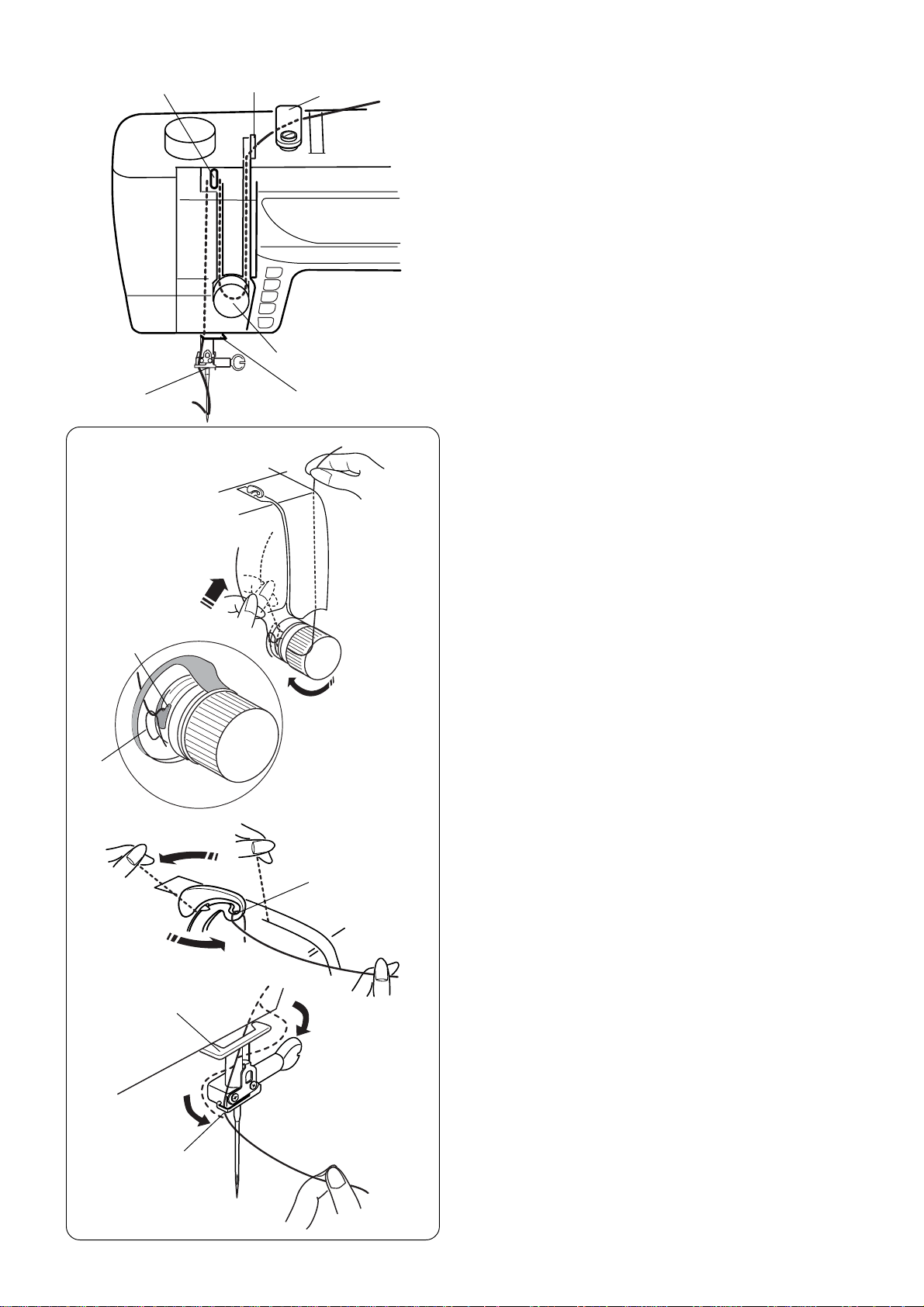

Built-in Needle Threader ....................................................... 27

Drawing Up the Bobbin Thread ............................................ 28

SECTION III – Basic Sewing

How to Select a Stitch ........................................................... 29

Straight Stitch ........................................................................ 29

Starting to Sew ...................................................................... 29

Finishing Off a Seam ............................................................. 29

Cutting the Threads ............................................................... 30

Changing Sewing Direction ................................................... 30

Adjusting Needle Position ..................................................... 30

Adjusting Stitch Length ........................................................ 31

Programming My Personal Settings................................ 31-32

Sewing on Heavy Fabrics ...................................................... 33

Gathering ...............................................................................33

Zipper Insertion ............................................................... 34-35

Rolled Hem ........................................................................... 36

Zigzag Stitch .......................................................................... 37

Overcasting............................................................................ 37

Satin Stitch Appliqué ............................................................. 38

3-Step Zigzag ........................................................................ 38

Mending a Tear ......................................................................39

Serpentine Stitch – Applying Elastic .....................................39

Blind Hem Stitches ................................................................ 40

Buttonhole Variations ............................................................ 41

Sensor Buttonholes ......................................................... 42-45

Corded Buttonhole ................................................................ 46

4 Step Memory Classic Buttonhole ................................. 47-48

4 Step Memory Bound Buttonhole .................................. 49-50

How to Sew on a Button ........................................................ 51

Tr iple Seam............................................................................ 52

Shell Tuck ...............................................................................52

Stretch Seam ......................................................................... 52

Super Overlock Stitch............................................................ 53

Super Stretch Stitch .............................................................. 53

Double Overlock Stitch .......................................................... 53

Overcast Stitch ...................................................................... 54

Arrowtack ............................................................................... 54

Bartacks .................................................................................55

Darning .................................................................................. 56

Eyelets ................................................................................... 57

SECTION IV - Quilting

Piecing Fabrics Together ....................................................... 58

Perfect Start Angle Lines....................................................... 58

Quilt Stitches ......................................................................... 58

Walking Foot .......................................................................... 59

Walking Foot with Quilt Guide ............................................... 59

Quilt Guide ............................................................................. 60

Straight Stitch Needle Plate .................................................. 60

Buttonhole Appliqué .............................................................. 61

Patchwork .............................................................................. 62

Free Motion Quilting or Stippling........................................... 62

Stippling Stitch ....................................................................... 63

Basting Stitch......................................................................... 63

SECTION V – Heirloom

Pintucks ................................................................................. 64

Bridging (Fagoting) ................................................................ 64

Hemstitches ...........................................................................65

Fringing .................................................................................. 66

Drawn Work ...........................................................................66

Smocking ............................................................................... 67

SECTION VI – Decorative Sewing

French Knots ......................................................................... 68

Scallop Edges ........................................................................ 68

Corded Trim ........................................................................... 69

Single Cord For Gathering Heavy Fabric.............................. 69

Twin Needle Sewing ........................................................ 70-71

Satin Stitches – Elongation ................................................... 72

Face to Face .......................................................................... 72

Mirror Image .......................................................................... 72

SECTION VII – Programming Combinations

Single Repeat with Memory Auto-Lock ................................. 73

Combining a Sequence .........................................................74

Inserting a Second Color ................................................ 74-75

Reset Combined Sequence to Beginning ............................. 75

Reset Combined Sequence to Beginning of

Incomplete Stitch .............................................................. 75

Combining Letters ................................................................. 76

How to Preview the Combined Sequence ............................ 77

Editing .................................................................................... 77

Uniformly Adjusting Stitch Width or Length .......................... 78

Individually Adjusting Stitch Width or Length........................ 79

Alignment of Stitches within a Sequence ............................. 79

Permanent Memory

Saving, Overwriting, Recalling and Deleting .............. 80-81

SECTION VIII – Taking Care of Your Machine

Cleaning the Hook Area and Feed Dog ................................ 82

Replacing the Bobbin Case................................................... 83

Changing the Light Bulb ........................................................83

STITCH CHART ................................................................... 84

OPTIONAL ACCESSORIES................................................. 85

WARNING MESSAGES .................................................. 86-87

TROUBLESHOOTING ..........................................................88

INDEX .............................................................................. 89-90

NOTE: Information found in this instruction manual

is current at the time of printing. Elna reserves the

right to change and update specifications and

information as needed.

2

Page 4

@3

@2

@1

@9

#9

$0

#0

q

@0

w

#8

e

r

$1

!9

t

#2

y

#1

#3

u

$2

!8

!7

#4

i

@8

@7

!6

o

@6

@5

#7

!5

@4

!0

!1

#5

!4

#6

!2

!3

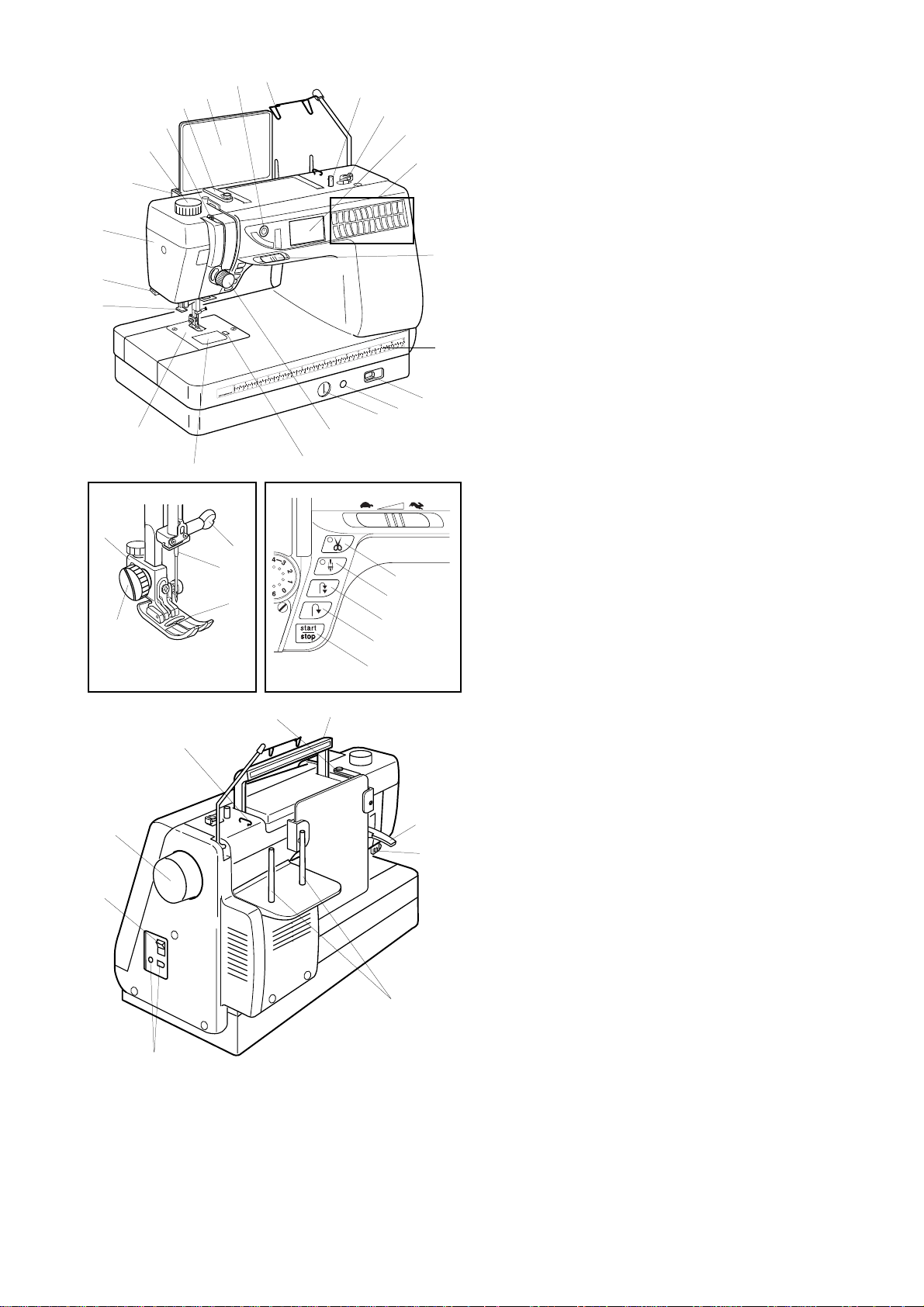

SECTION I

Machine Parts and Functions

Part Names

1. Stitch chart brackets (to attach, see page 7)

2. Foot pressure dial

3. Thread take-up lever

4. Thread guide plate

5. Stitch chart

6. LCD screen brightness control

7. Retractable thread guide (pull up)

8. Bobbin winder spindle

9. Bobbin winder stop

10. LCD screen

11. Selection keys (see pages 11–13)

12. Speed control lever

13. Centimeter/inch quick measurements

14. Feed dog lever

15. Knee lifter insert channel

16. Fine adjustment screw

17. Thread tension dial

18. Bobbin cover plate release button

19. Bobbin cover plate

20. Needle plate

21. Built-in needle threader

22. Thread cutter

23. Face plate

24. Auto-thread cut key

25. Up/down needle key

26. Auto-lock key

27. Reverse key

28. Start/stop key

29. Shank

30. Thumbscrew

31. Needle clamp screw

32. Needle

33. Presser foot

34. Carrying handle

35. Presser foot lever

36. Buttonhole lever

37. Spool pins

38. Machine sockets

39. Power switch

40. Flywheel (always turn toward you)

41. Upper thread guide

42. Bobbin winding tension disc

3

Page 5

123

456

789

10 11 12

13 14 15

16 17 18

19 20 21

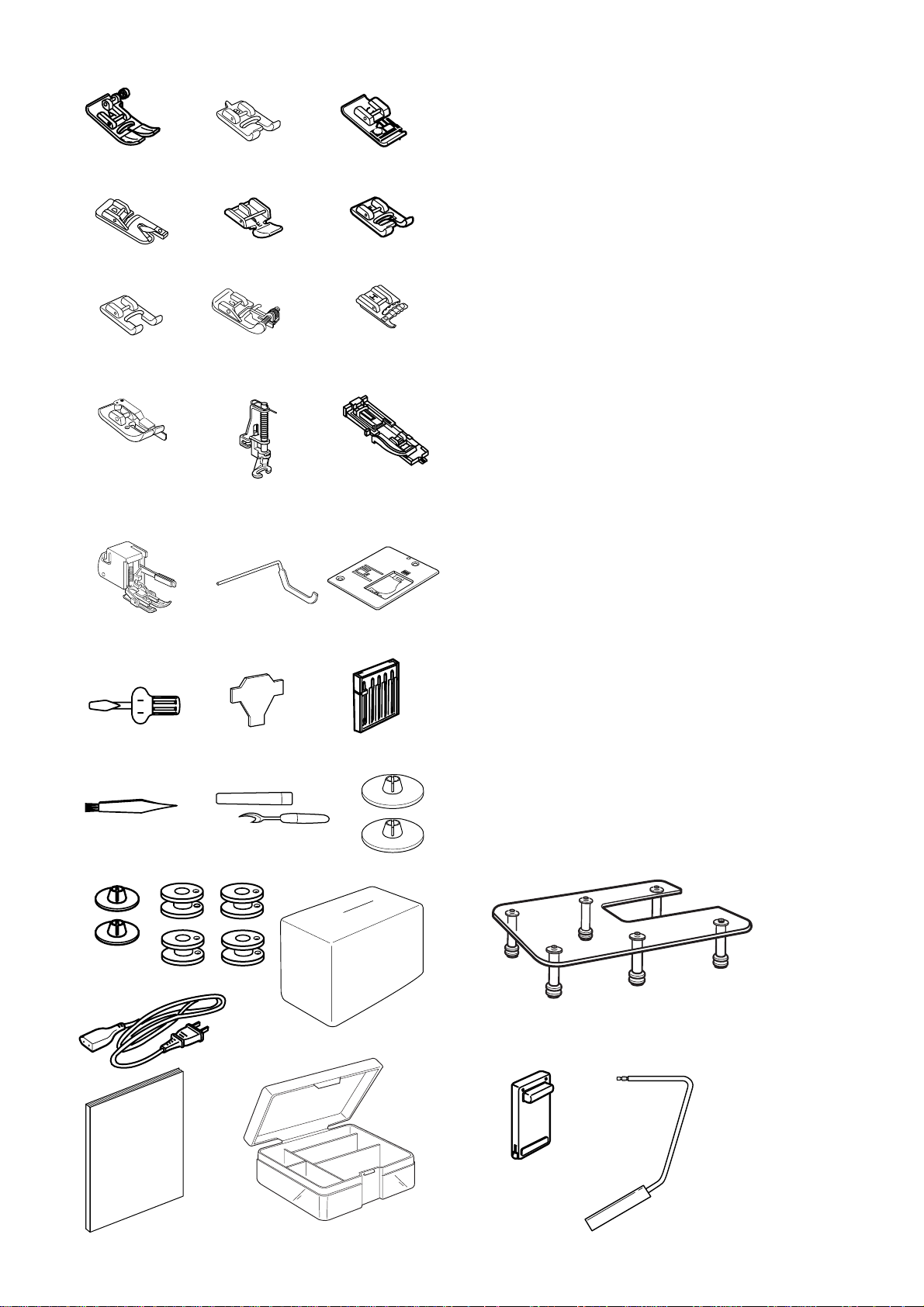

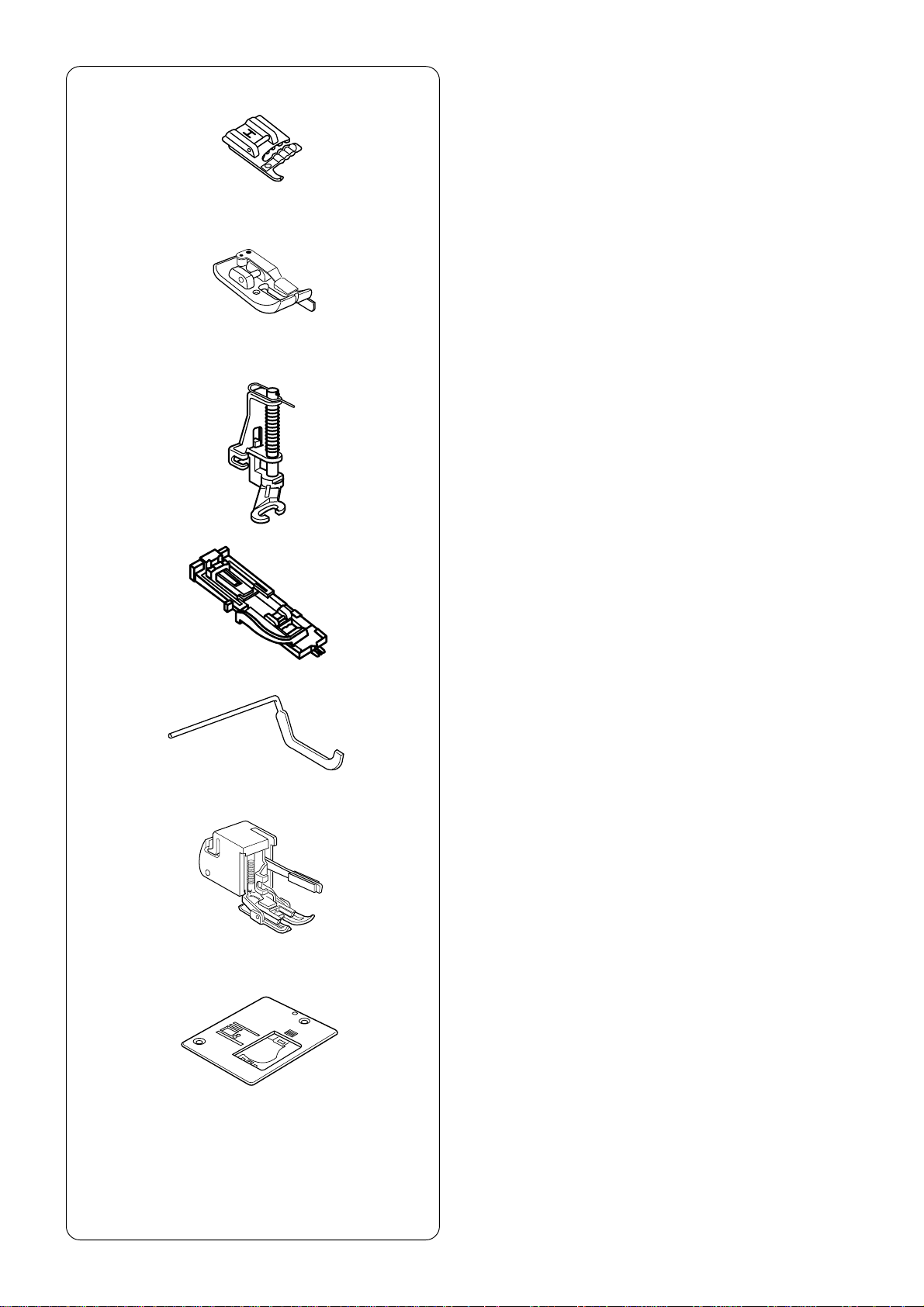

Standard Accessories

1. A: Standard metal foot (attached to machine)

2. B: Buttonhole foot (4-step)

3. C: Overlock foot

4. D: Hemmer foot

5. E: Zipper foot

6. F: Satin stitch foot

7. F-2:Open toe satin stitch foot

8. G:Blind hem foot

9. H: Multi-cord foot

10. Scant 1/4˝ foot

11. P-2:Open toe embroidery/darning foot

12. R: Automatic buttonhole foot

13. Open toe walking foot

14. Quilt guide

15. Straight stitch needle plate

16. Screwdriver

17. Screw key

18. Set of needles

19. Lint brush

20. Seam ripper

21. Large spool holders (2)

22. Small spool holders (2)

23. Bobbins (5 total, 1 in machine)

24. Dust cover

25. Quilt table

26. Power supply cord

27. Instruction book

28. Accessory box

29. Foot control

30. Knee lifter

22 23 24

26

28

27

25

29

4

30

Page 6

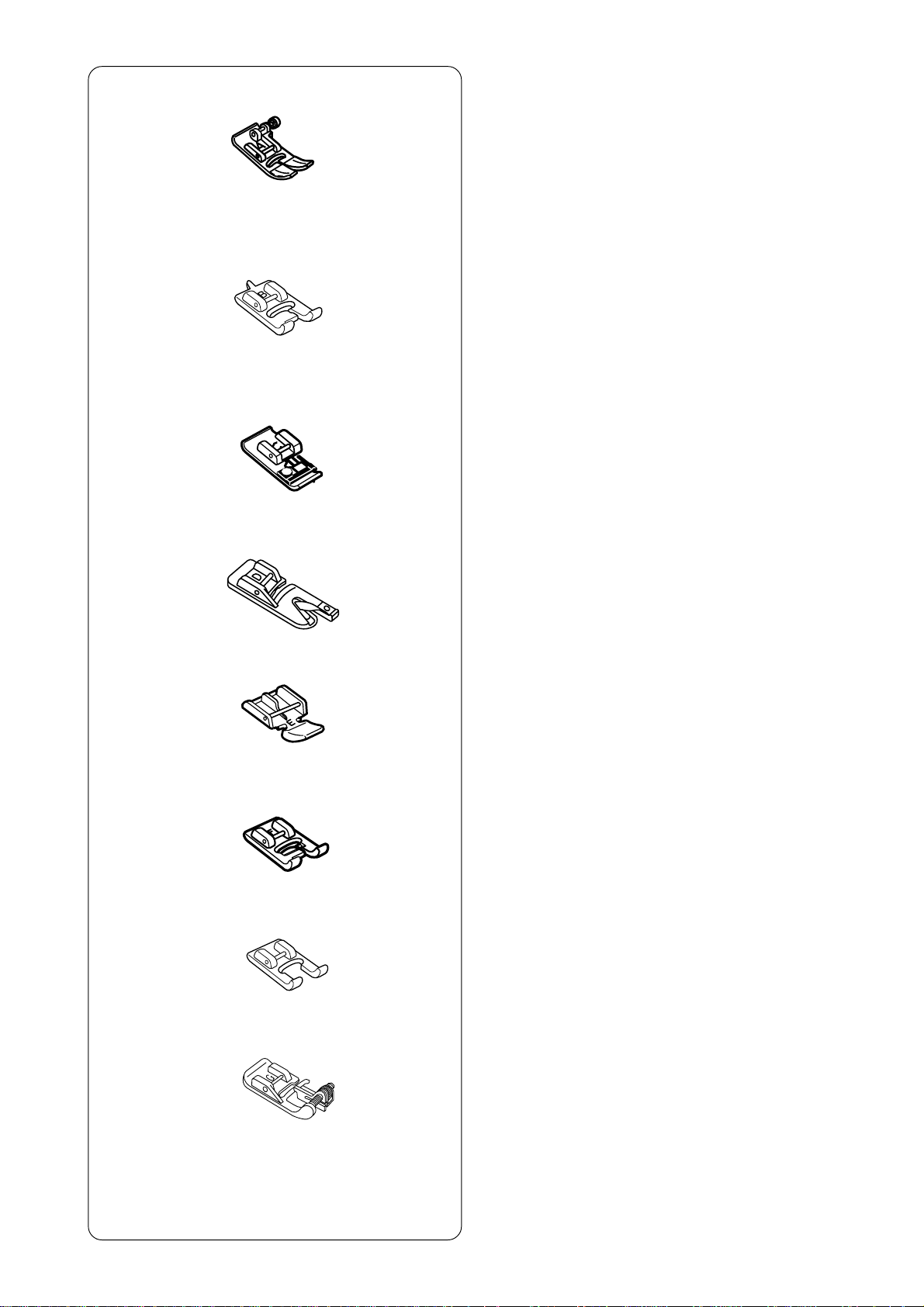

Presser Foot and Accessory Definitions

A: Standard Metal Foot

This foot comes attached to your machine. It is

mainly used for straight stitches and zigzag

stitches longer than 1.0. The button locks the foot

in a horizontal position helping to sew over

multiple layered seams.

B: Buttonhole Foot

Sew oversized buttonholes for novelty buttons or a

decorative accent. The two cutout grooves on the

underside of the foot ensure that the buttonhole

sides lie parallel to each other.

C: Overlock Foot

Prevent fabric edges from raveling by finishing the

edge with a zigzag stitch. The brush on the foot

helps the stitch lie flatter and reduces puckering.

Use with medium weight fabrics.

D: Hemmer Foot

Insert the fabric into the spiral on this foot. The

spiral rolls the fabric, creating a rolled hem. An

easy, professional way to sew hems.

E: Zipper Foot

Use when sewing zippers into place. The grooves

on the underside ensure the foot glides over the

zipper coil. Attach either to the left or right of the

needle to sew each side of the zipper.

F: Satin Stitch Foot

The cutout on the underside of the foot is

designed to accommodate dense stitch formation.

Ideal when sewing satin and decorative stitches.

F- 2: Open Toe Satin Stitch Foot

Ideal for precision embroidery, appliqué, cutwork

and monogramming. The cutout on the underside

of the foot accommodates satin stitching and the

open front ensures greater visibility while sewing.

G: Blind Hem Foot

The guide on the foot helps ensure that the needle

catches only one or two fibers of the hem,

resulting in an invisible hemline.

5

Page 7

H: Multi-Cord Foot

Design your own braids or trims. Place one to

three cords in the foot and sew over cord(s) for a

simple couching method. Or sew over one cord

with a zigzag to gather heavier weight fabrics.

Scant 1/4˝ Foot

Accuracy is the key to successful patchwork/quilt

sewing. Sewn from 3.5 needle position; the edge

of the foot provides a perfect 1/4˝ seam guide. Or

use 4.5 needle position and achieve the desirable

scant 1/4˝ often requested by quilters.

P-2: Open Toe Embroidery/Darning Foot

Skipped stitches are no longer a concern when

sewing free motion embroidery, stippling, darning

and monogramming. The spring-loaded foot

moves up and down at the same time as the

needle. Another benefit when using this foot is the

front cutout provides maximum visibility.

R: Automatic Buttonhole Foot

Place button in foot to determine the buttonhole

size. The machine will automatically sew the

corresponding buttonhole.

Quilt Guide

The quilt guide is helpful when sewing parallel,

evenly spaced rows of stitching. May be used with

a walking foot.

Open Toe Walking Foot

Great for keeping quilt layers from shifting when

sewing and keeping stripes and checks matched.

Fabrics lie between an upper feed dog (on walking

foot) and lower feed dog (on machine) to move

fabrics simultaneously, preventing them from

slipping.

Straight Stitch Needle Plate

Skipped stitches or puckered fabric? The small

needle entry hole in this plate prevents the needle

from pushing your fabric underneath the needle

plate. (Must use center needle position.)

6

Page 8

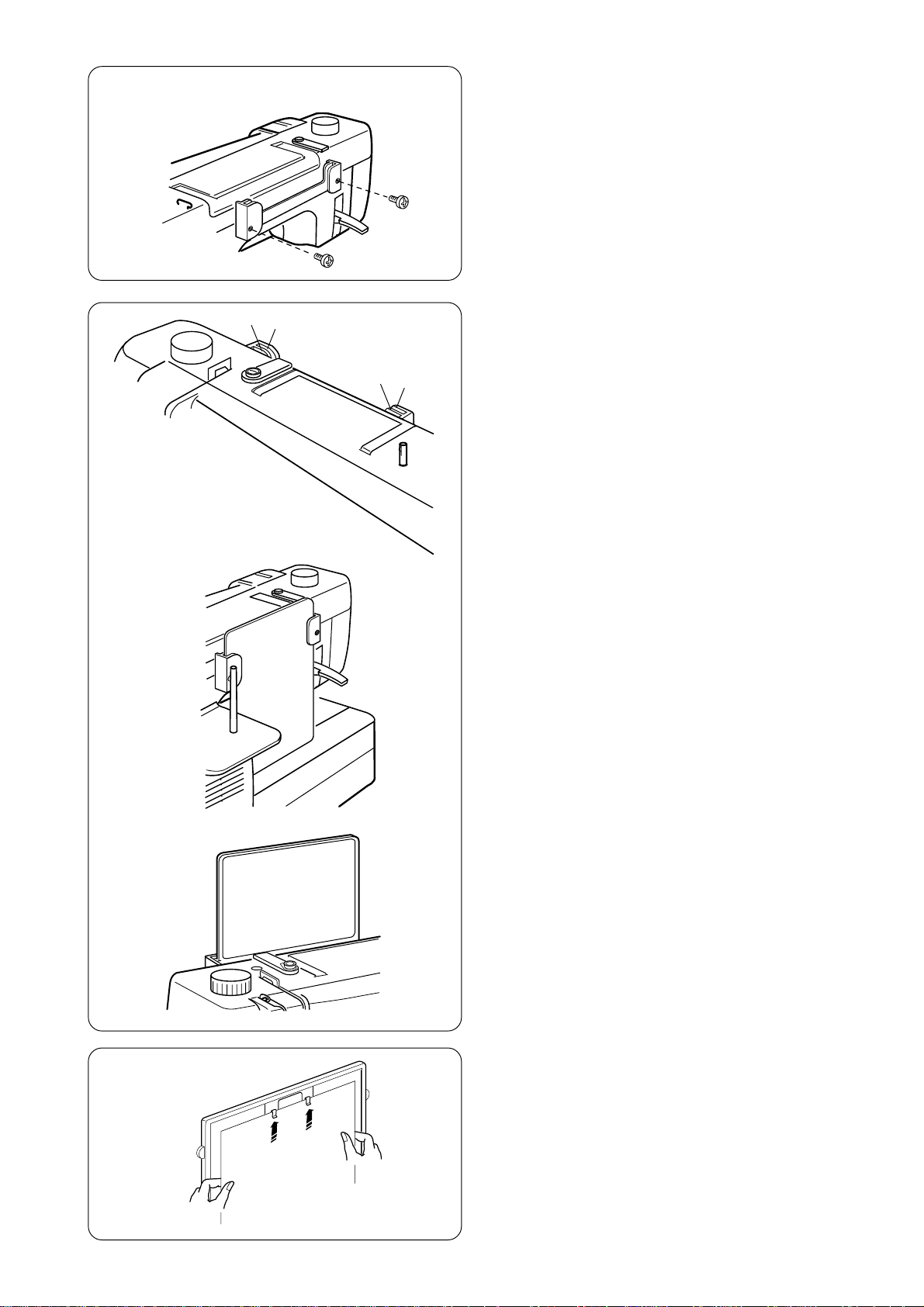

How to Attach Stitch Chart Brackets

Align the screws with the holes on the backside of

the machine. Firmly tighten screws with

screwdriver.

e

w

q

w

Stitch Chart

The stitch chart can be placed in two positions on

the chart bracket, store or view.

q

Store Position

The back slots q on the bracket are for store

position e. Slide stitch chart down between the

back slots until the stitch chart rests against

machine bed.

r

View Position

The front slots w on the brackets are for view

position r. Pull up and out the stitch chart from

back slots. Slide stitch chart down between the

front slots.

Write ‘n Clip Board

Need a handy place for posting information? Flip

over the stitch chart to write messages and then clip

paper or sewing instructions, notes, etc., to board.

NOTES:Do not clip multiple layers of paper or

cardboard. Slide paper under clips; do not

raise clips.

7

Page 9

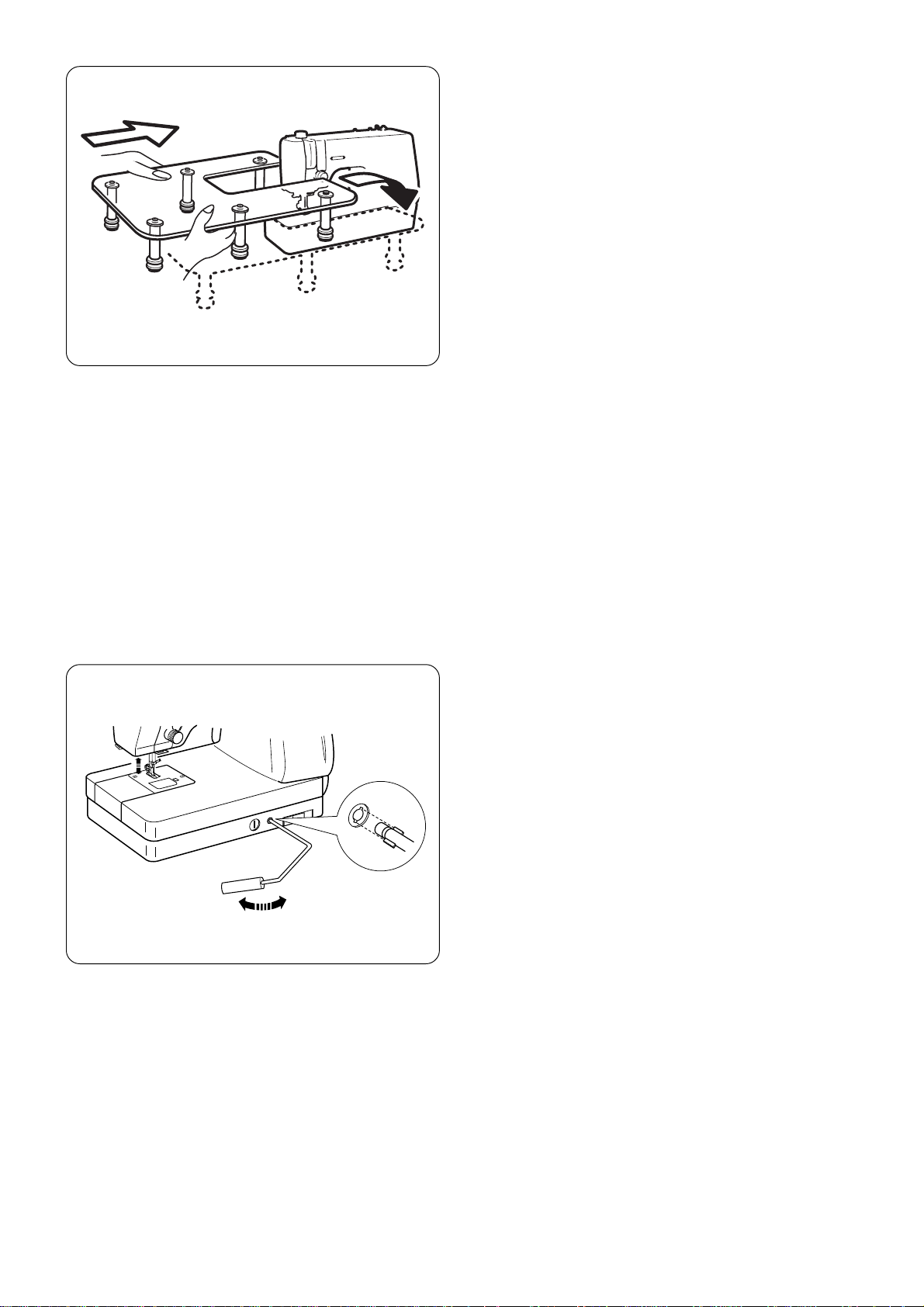

Quilt Table

The table provides more sewing surface to support

large fabric pieces to make sewing easier.

Assemble table by attaching six legs to underside

of quilt table with screws.

Attaching Table to Machine

Fit the table around the machine, as shown in the

illustration. If necessary, adjust height of legs to

level table with machine bed by tightening or

loosening leg screws.

Knee Lifter

The knee lifter allows you to raise or lower the

presser foot without using your hands. This is

especially beneficial when pivoting corners or

sewing patchwork pieces.

Insert knee lifter aligning the slots with the

notches.

The presser foot rises equal to the amount of

pressure applied to the knee lifter. Stop sewing

before moving the knee lifter to the right to raise

the presser foot. Release the knee lifter to lower

the presser foot.

CAUTION:

Do not touch the knee lifter while sewing because the

tension discs will open resulting in the upper thread

tension loosening. In addition, the fabric will not feed

properly.

8

Page 10

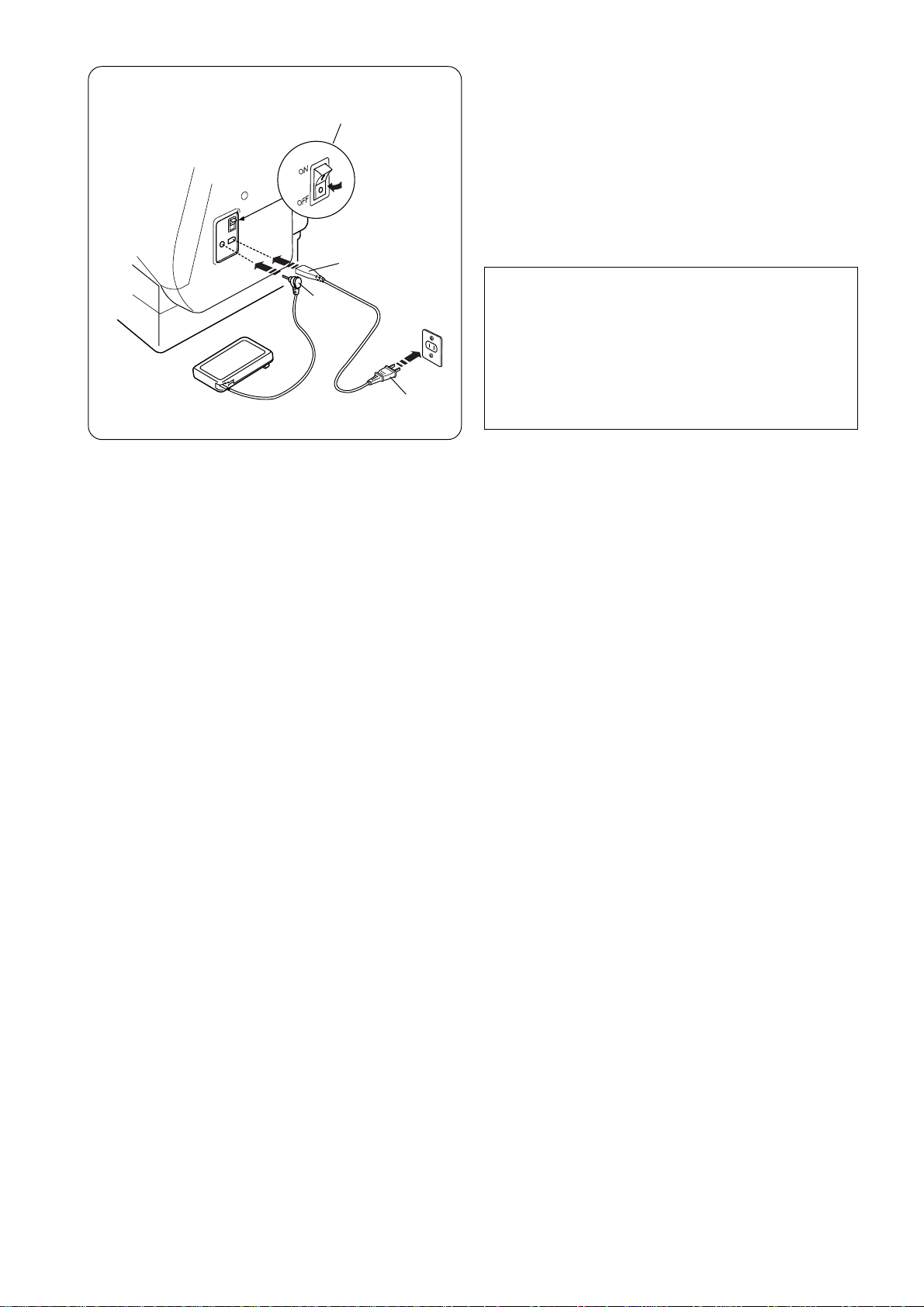

Connecting Machine To Power Supply

w

q

e

r

Before connecting the power cord, make sure the

voltage and frequency shown on the machine are

identical to your electrical power.

To connect machine to power supply, turn off the

power switch q. Insert the foot control plug w

and machine plug e into the machine and the

power supply plug r into the wall socket.

Your machine may come equipped with a

polarized plug (one prong wider than the other). A

polarized plug reduces the risk of electrical

shock. This plug is intended to fit into a polarized

outlet. If the plug does not fit fully into the outlet,

reverse the plug. If it still does not fit, contact a

qualified electrician to install the proper outlet. Do

not modify the plug in any way.

IMPORTANT: When using your sewing machine the

first few times, place waste fabric under the presser

foot and run the machine without thread for a few

minutes. Wipe away excess oil.

NOTE: After turning off the machine, wait 5 seconds

before turning it on again.

For Your Safety

Do not use extension cords or plug adapters.

Do not touch plug with wet hands.

Always turn off the power/light switch first and then

unplug from the electrical outlet. Examples:

•when leaving the machine unattended

• when cleaning the machine

Always turn off the power/light switch:

• when attaching or removing parts such as

needle, presser foot, needle plate

• when threading needle or bobbin

Do not place anything on the foot control.

Do not place heavy items on cords. Do not subject

cords to heat. Do not use damaged cords. Have

the cord repaired immediately.

While the machine is in operation, always keep

your eye on the sewing area and do not touch any

moving parts such as the thread take-up lever,

flywheel or needle.

9

Page 11

Main Function of Keys

qq

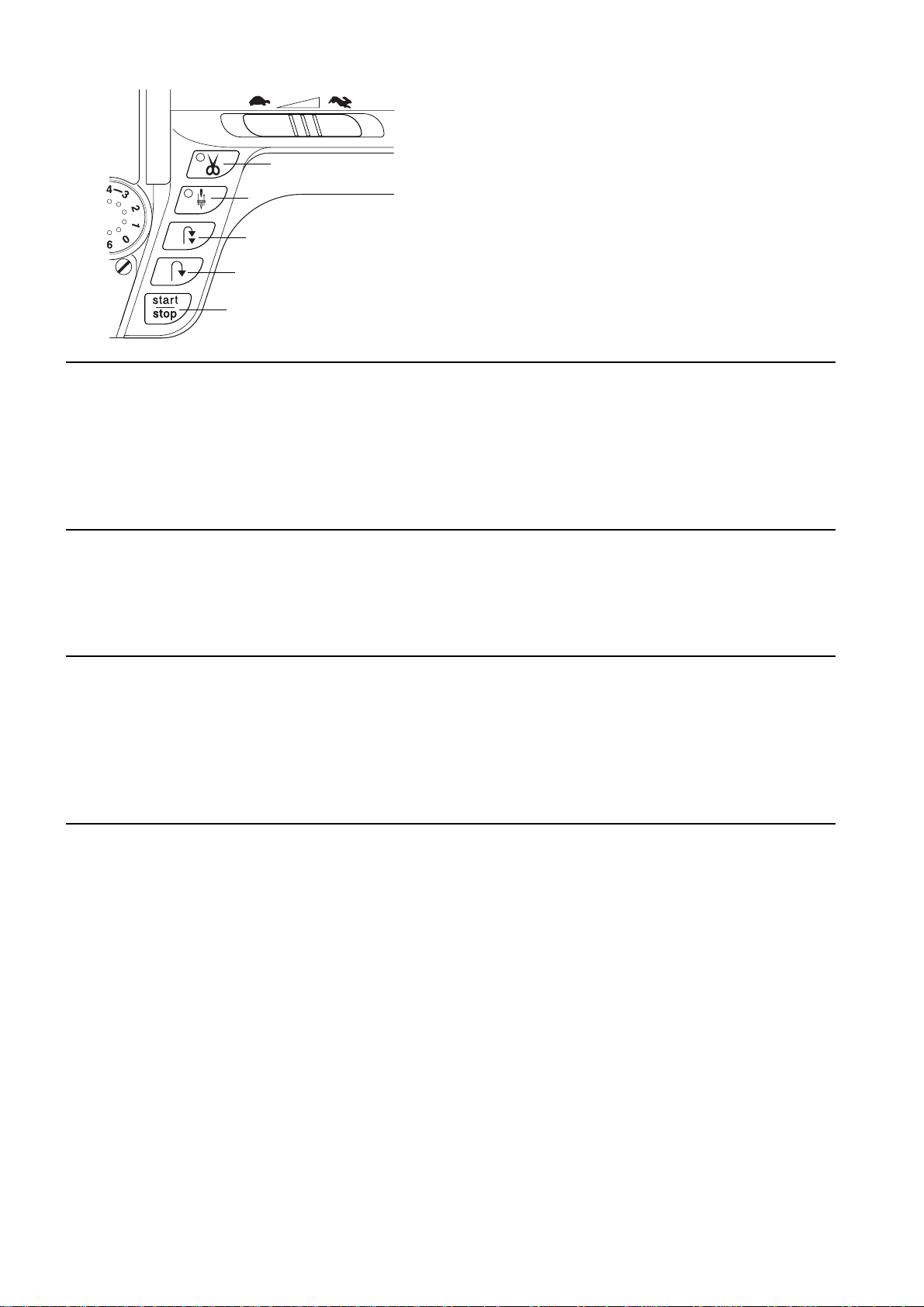

q Start/Stop Key (changes color to indicate

qq

function)

t

r

e

w

q

ww

w Reverse Key

ww

If you are sewing 1 (straight stitch), 2 (zigzag stitch) or 3 (3-step zigzag stitch), press and hold this

key. The machine will sew in reverse until you release the key while using the foot control or Start/Stop

key. If the foot control is disconnected, the machine will sew in reverse until you release the key with

or without using the Start/Stop key.

If you are sewing any other stitches, utility or decorative, the machine will immediately stop and sew a

lockstitch when you press this key.

ee

e Auto-Lock Key

ee

Press this key while sewing 1 (straight stitch), 2 (zigzag stitch) or 3 (3-step zigzag stitch) and the

machine will sew a few stitches in place and stop automatically.

Press this (green) key to start the machine.

The first few stitches will be sewn at a slow speed

and then machine sews at the speed set by the

speed control lever. Press (red) key again to stop

machine. Press and continue to hold key down to

sew at slow speed, release key to sew at set

speed. Press key again to stop.

NOTE: The foot control must be detached to use

this key.

Press this key while sewing utility or decorative stitches and the machine will complete the stitch,

lockstitch and stop.

rr

r Up/Down Needle Key

rr

If the needle is up when you press this key, the needle will go down to its lowest position and the LED

signal will turn on. The needle will continue to stop in the down position

If the needle is down when you press this key, the needle will go to its highest position and the LED

signal will turn off. The needle will continue to stop in the up position.

NOTE: The needle will always stop in the up position after auto thread cutting or buttonholes.

tt

t Auto Thread Cut Key

tt

When the machine has stopped sewing, press this key to cut the needle and bobbin threads. (The LED signal

blinks during auto thread cutting.)

CAUTION: Use the thread cutter on the face plate for threads heavier than 30 wt. or decorative

threads.

Clean the auto thread cut mechanism regularly. See page 82.

After auto thread cutting, pull the needle and bobbin threads up and back under the foot.

Auto thread cutting is not recommended when a thread spool is almost empty, as thread will not unwind

smoothly, causing the thread to bunch or slip.

10

Page 12

w

!9

e r t y u i o !0

q

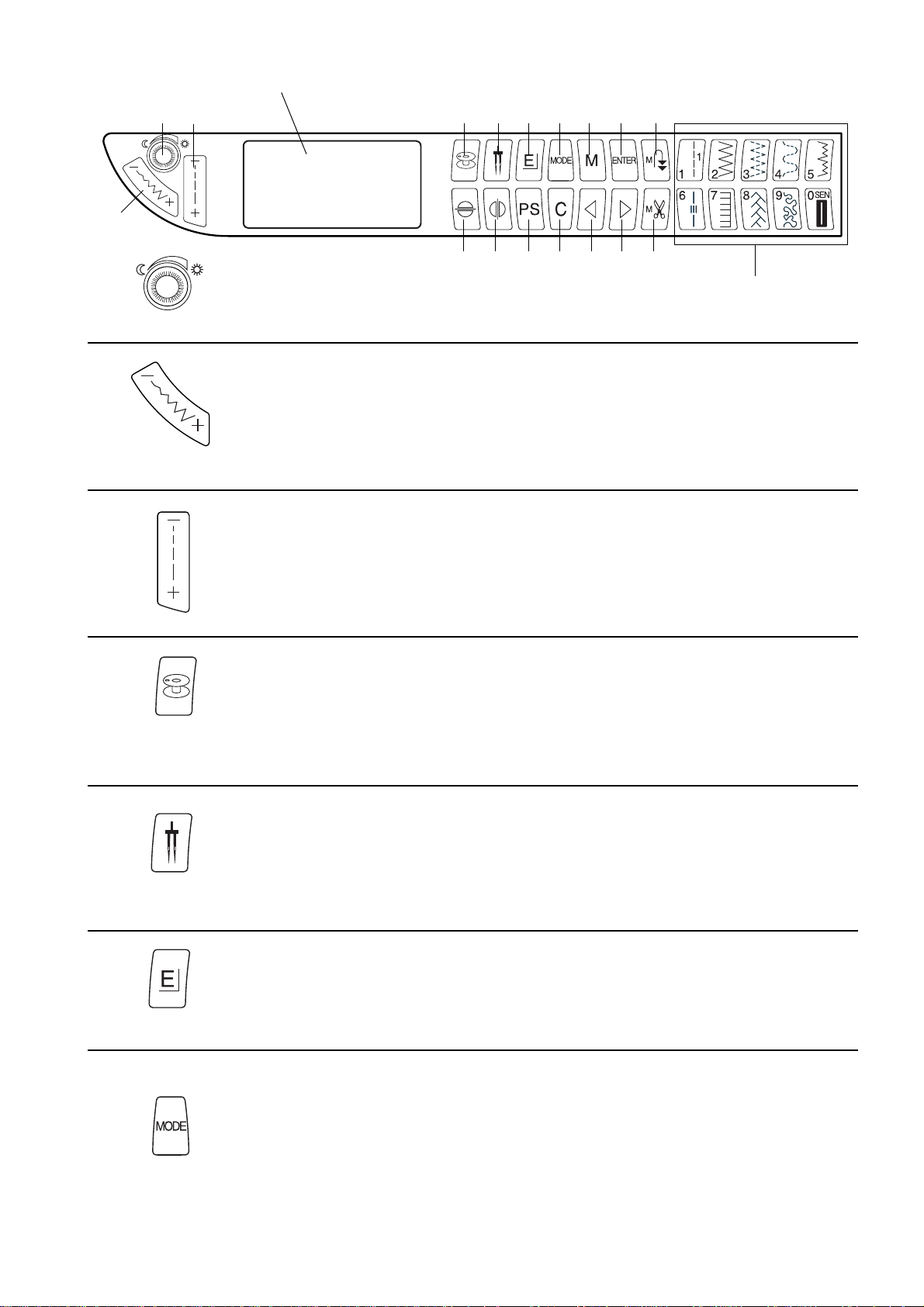

Keyboard Selection Keys

!1 !2 !3 !4 !5 !6 !7

1. LCD Screen Brightness Control

Lighten or darken the screen with this dial.

2. Stitch Width and Needle Position Key

Press “–” or “+” side of key to change setting.

Press “–” or “+” to move needle position left or right.

Straight stitches (1, 6, 011, 012, 061, 062 and 063) can be sewn from

many needle positions by pressing the “–” or “+” side of the key. Center

needle position is 3.5.

3. Stitch Length Key

Press “–” or “+” side of key to change setting. Depending on the stitch

selected, stitch length can be set between 0.0 and 5.0.

!8

NOTE: Fine fabrics should have a stitch length between 1.5 and 2.5,

medium fabrics between 2.0 and 3.0 and heavier fabrics between 3.0 and

4.0.

4. Bobbin Winding Key

Press this key to wind a bobbin. The machine features a separate motor for

bobbin winding making it possible to sew and wind a bobbin at the same

time.

5. Twin Needle Key

Press this key to reduce the width of an individual stitch. The twin needle

symbol is shown in the LCD screen when it is activated. Press the key

again to cancel twin needle function.

6. Elongation Key

Satin stitches 081 to 089 can be lengthened up to five times their regular

size without the stitch length varying. Press this key to change the

elongation. The LCD screen displays the elongated size: X1, X2, X3, X4

or X5.

7. Select Mode Key

When you switch on the machine, the Direct Select Mode is active. You can

select the first ten stitches (illustrated on the keyboard) with a single touch

of the key.

Touch the “MODE” key to activate the 3 Digit Mode. You can select all

stitches by entering the 3 digits for the desired stitch.

Touch “MODE” key again to reactivate the Direct Select Mode.

11

Page 13

8. Memory Save/Recall Key

The 3 Digit Mode has four separate memories for saving a sequence of

stitches. Press this key to activate memory 1 (M1). Press key again to

activate M2. Continue to press this key to access M3, M4 or to exit memory.

Once a memory is activated, press the “ENTER” key to save the sequence.

To recall a saved memory, press “M” key until desired memory appears.

To activate the saved sequence, press “Mirror Image” key.

9. Enter Key

Press this key after selecting a stitch in the 3 Digit Mode and that stitch will

be memorized. Up to 50 stitches can be combined together.

These stitches cannot be memorized into a sequence: 010, 011, 071 – 076,

078 and 079.

10. Memory Auto-Lock Key

After combining a sequence of stitches in the 3 Digit Mode with the ENTER

key, press this key. Begin sewing; at the end of the sequence the machine

will automatically lock the last stitch and stop.

• symbol will appear in LCD screen.

11. Face to Face Key

When this key is pressed after selecting a stitch, the stitch will be flipped

vertically (as it appears on the stitch chart) and a symbol will appear in the

LCD screen.

Stitches that are compatible with this key are identified on the stitch chart

with an “F” directly following the stitch number.

12. Mirror Image Key

When this key is pressed after selecting a stitch, the stitch will be flipped

horizontally (as it appears on the stitch chart) and a symbol will appear in

the LCD screen.

If you have activated the permanent memories (M1, M2, M3, M4), press

this key to recall the saved sequence.

13. My Personal Setting Key

Select a stitch in Direct Select Mode or 3 Digit Mode and override the

factory settings by changing width/needle position, length, face to face,

mirror image or elongation. Press this key after changing settings. Press

“ENTER” key. New settings will now be saved as the default settings with

PS symbol in LCD screen.

14. Clear Key

When this key is pressed, the last memorized stitch or the stitch that is

above the cursor will be cleared. Press and hold the “C” key; the entire

sequence is cleared. If this key is pressed after sewing a sequence, the

sequence will be deleted.

15. Review Memory Left Key

Use this key to review stitches in a memorized sequence when all stitches

do not appear on the screen.

OR

Press this key to move the cursor left until it is under the stitch that will be

edited.

12

Page 14

16. Review Memory Right Key

Use this key to review stitches in a memorized sequence when all stitches do

not appear on the screen.

OR

Press this key to move the cursor right until it is under the stitch that will be

edited.

17. Memory Auto Thread Cut Key

Press this key after selecting a stitch and when the Auto-Lock key is pressed

the machine will automatically cut threads after lockstitching is completed.

Press this key after the last stitch in a sequence and when the sequence

finishes sewing, the machine will automatically cut the threads.

NOTE:After this key is pressed, the Auto Thread Cut Key LED signal turns on.

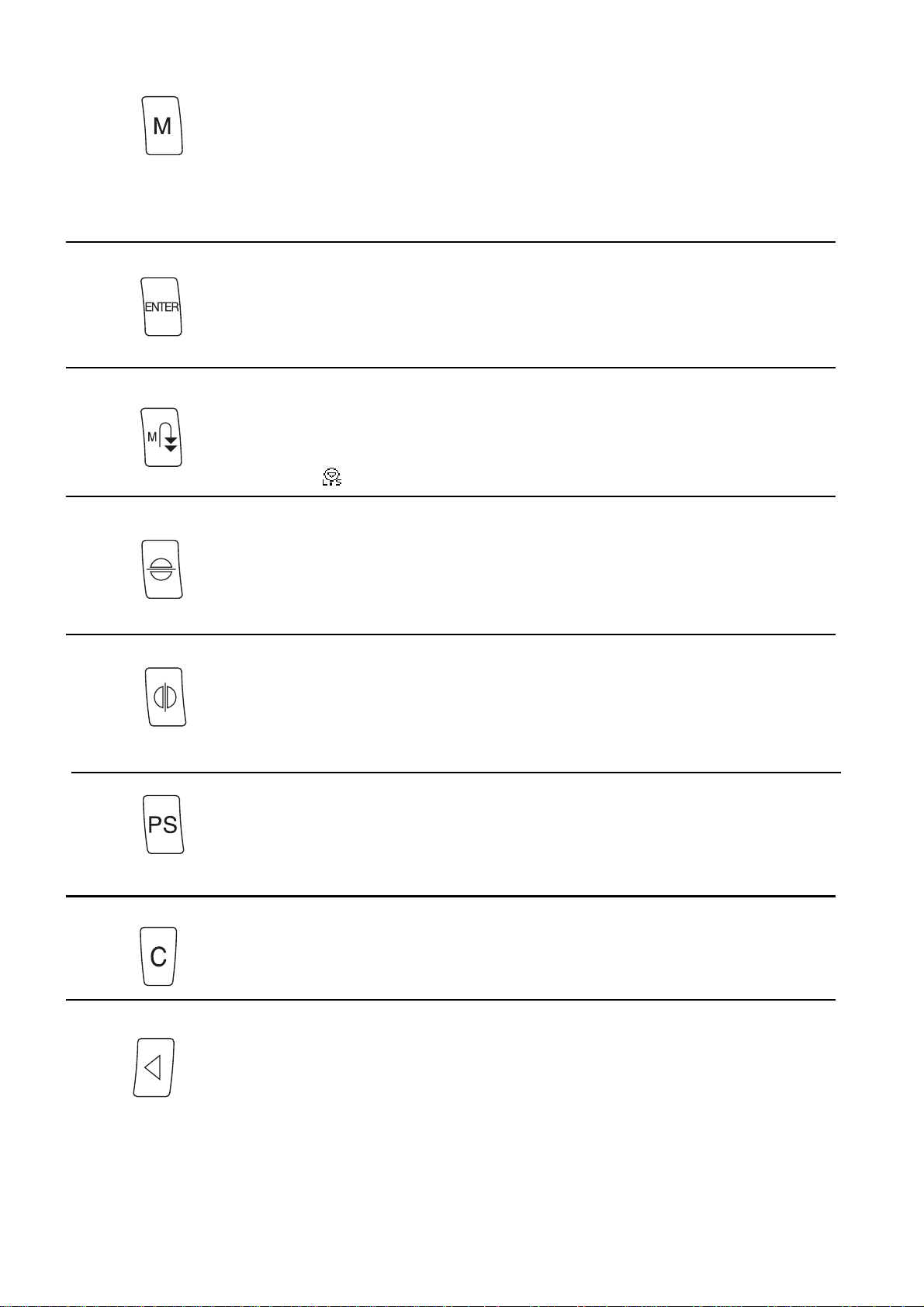

18. Stitch Selection Keys

You can select a stitch in the Direct Select Mode

by pressing the key that is illustrated with the

desired stitch.

To select stitches in the 3 Digit Mode, simply

press the three digits for the desired stitch. To

cancel the stitch you selected, press the “C” key or

select a different stitch.

q

w e r t

a.

b.

c.

d.

e.

y

u

i

19. Symbols in the LCD Screen

q Selected stitch. (The number 1 to the right of

the stitch illustration means only one stitch will

be sewn if used in a sequence.)

w Recommended range for setting needle thread

tension dial.

e Elna recommends using this presser foot for

best sewing results.

r Stitch width or needle position – computer

automatically sets width or needle position after

a stitch is selected.

t Stitch length – computer automatically sets

length after a stitch is selected.

y Quick Resumption Mode. Switch off the

machine. The last stitch(es) that were sewn will

appear when machine is switched on.

See page 14.

u Tw in or single needle. See page 11.

i Sound Mode. Machine beeps after touching

any key. See page 14.

Other symbols that can appear:

a. My Personal Settings are applied to this

stitch.

b. Face to Face is active for this stitch.

c. Mirror Image is active for this stitch.

d. Face to Face and Mirror Image are active

for this stitch.

e. Elongation is available for this stitch.

13

Page 15

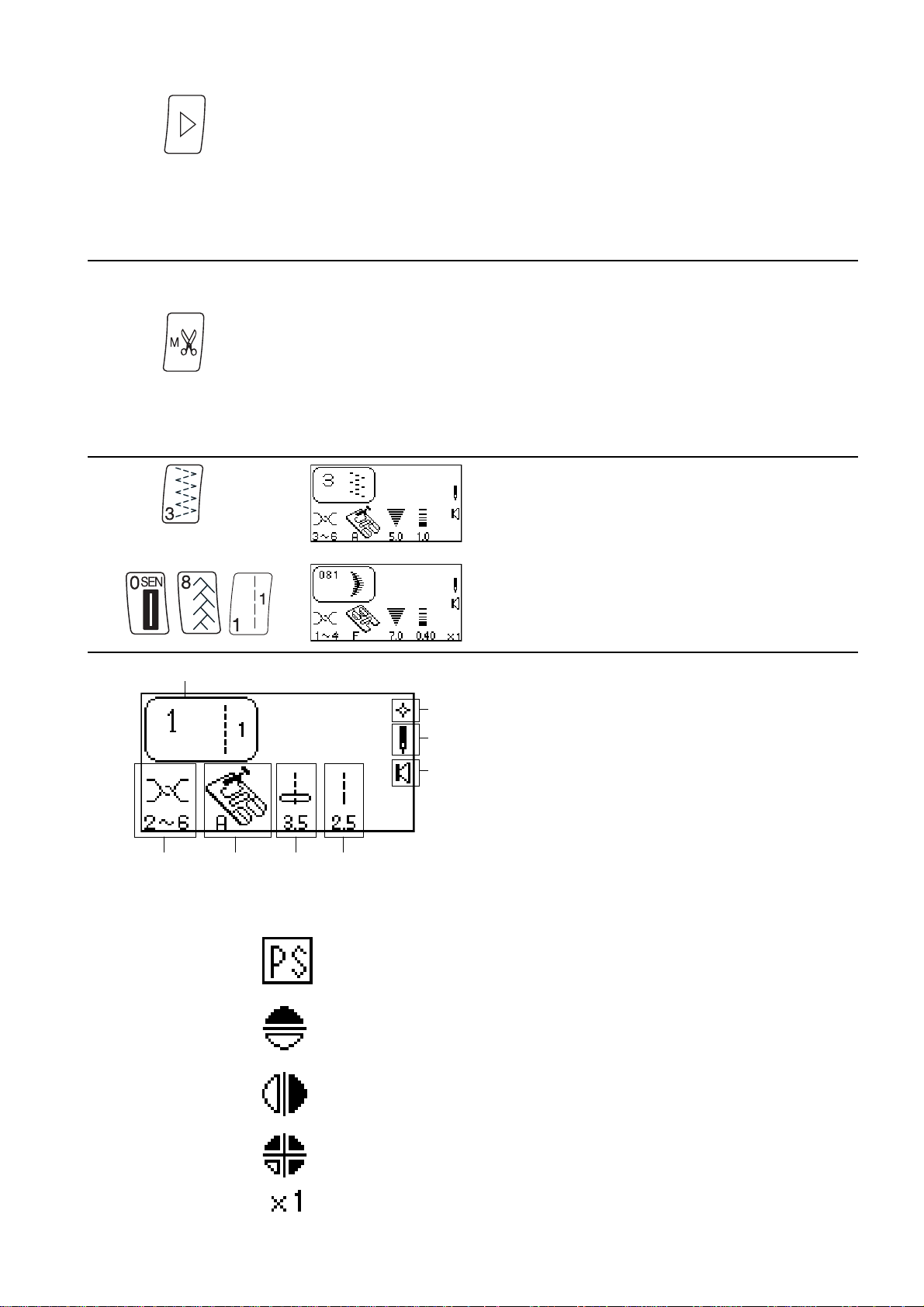

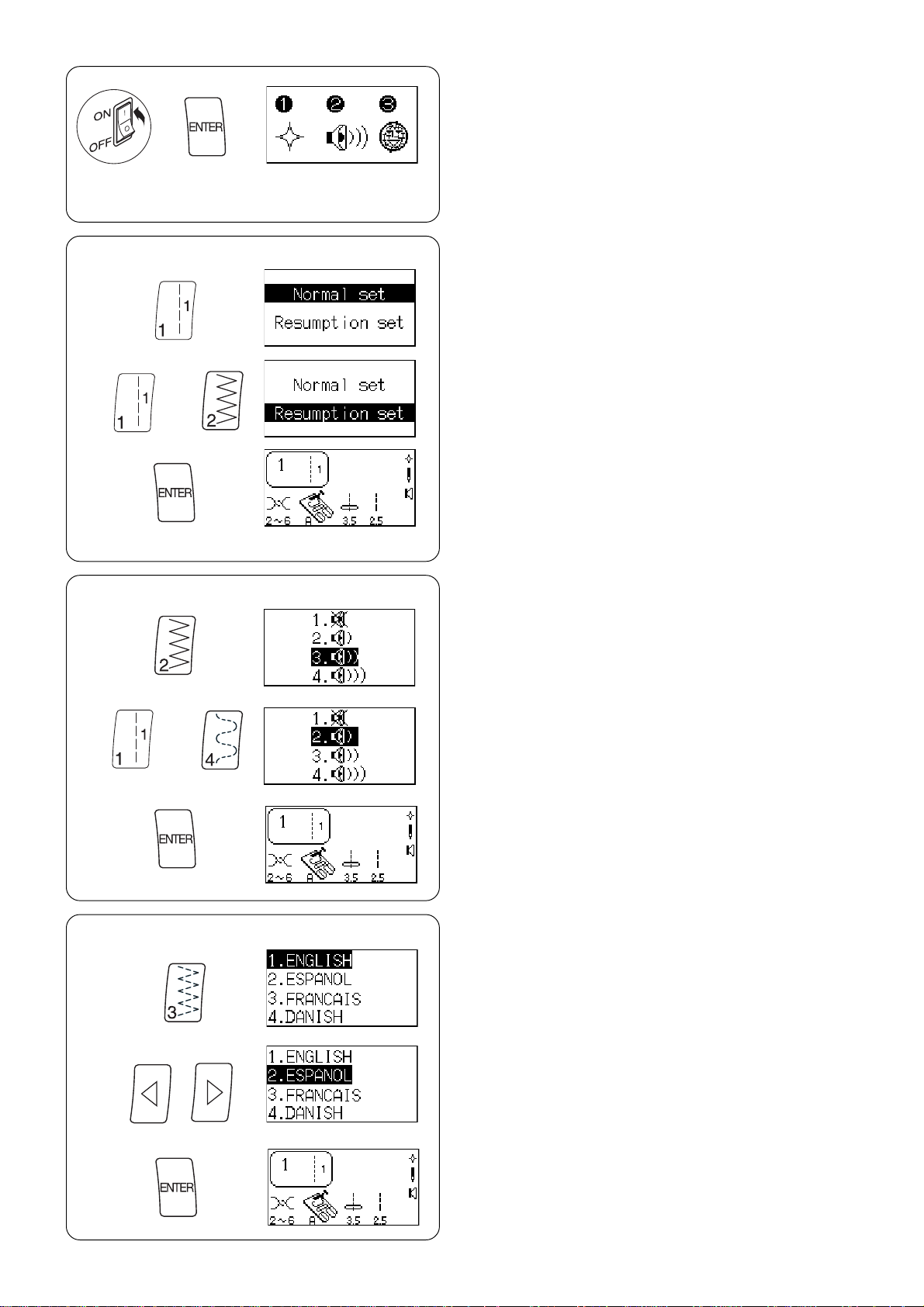

Setting Quick Resumption, Sound and

Language Modes

These three modes/functions can be set according

to your preferences. Each new setting requires

you to turn OFF the power switch. Turn ON the

power switch while pressing “ENTER” key.

Message screen appears. Press “1” key to change

quick resumption or “2” key to change sound or “3”

key to change language.

z

x

c

z

x

~

Quick Resumption – The last stitch or

memorized sequence of stitches that were sewn

will appear when machine is switched on.

z Press “1” key.

x Press “1” or “2” key to change setting between

Normal Set and Resumption Set.

c Press “ENTER” key.

Sound – Tu rn off the beep sound (warning beep

sounds will not be turned off) or change the beep

volume.

z Press “2” key.

x Press “1”, “2”, “3”, or “4” key to change between

settings.

c

z

x

c

~

c Press “ENTER” key.

Language – Choose one of the 10 languages:

English, Spanish, French, Danish, German, Italian,

Dutch, Russian, Slovenian, or Swedish.

z Press “3” key.

x Press “Review Memory Right” key or “Review

Memory Left” key to change between languages.

c Press “ENTER” key.

14

Page 16

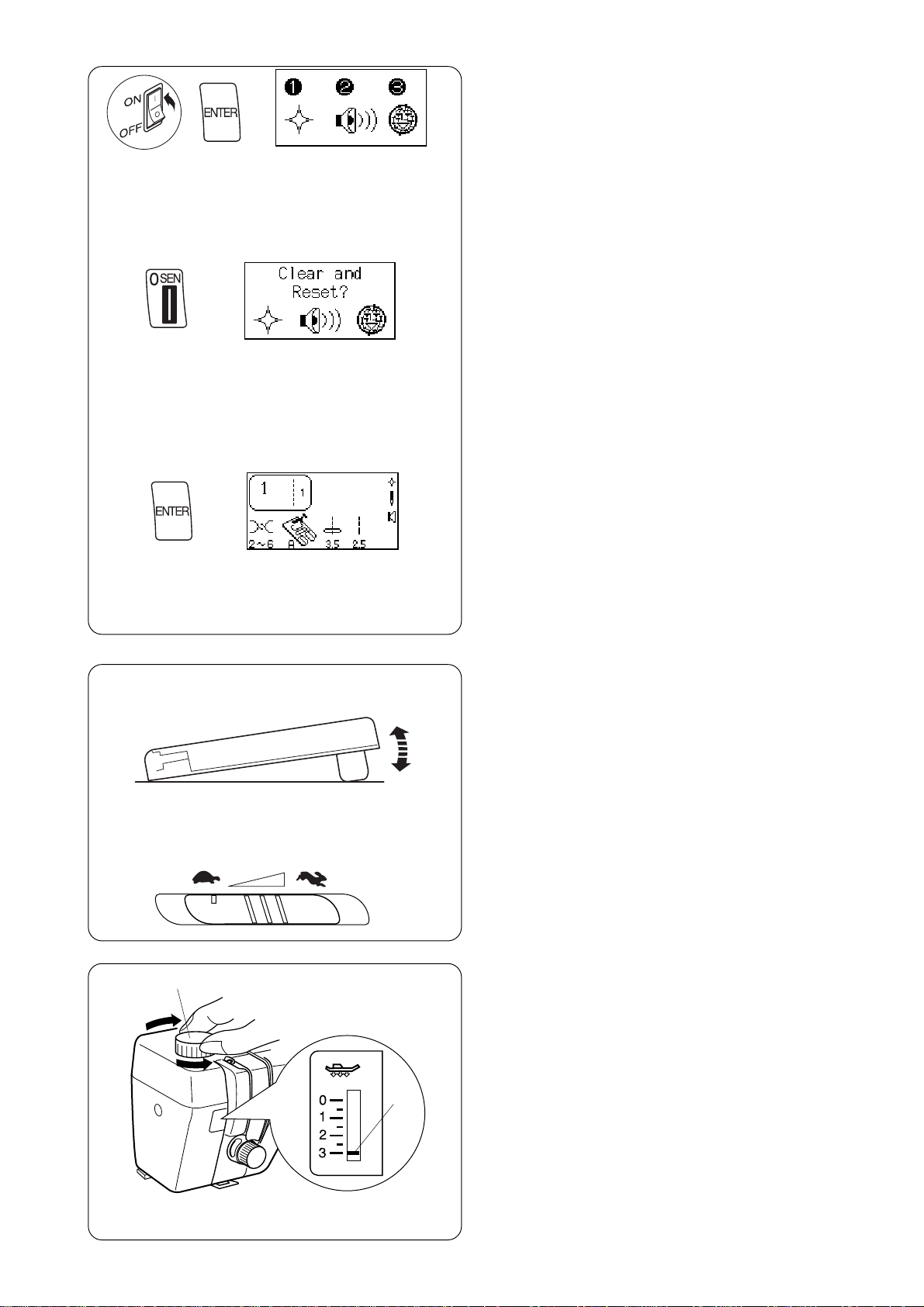

Reset to Factory Default

It is possible to reset the machine to the factory

defaults with English language as default.

Tu rn OFF the power switch. Press “ENTER” key

while turning power switch ON. Message screen

appears.

Press “0” key. Message screen appears.

Press “ENTER” key to confirm and reset to factory

default.

q

OR

Tu rn off power switch to cancel the reset.

Controlling Sewing Speed

Sewing speed can be varied with the foot control.

The harder you press on the foot control, the

faster the machine runs.

The maximum sewing speed can be varied by

sliding the speed control lever. For a faster speed,

slide it to the right; for a slower speed, slide it to

the left.

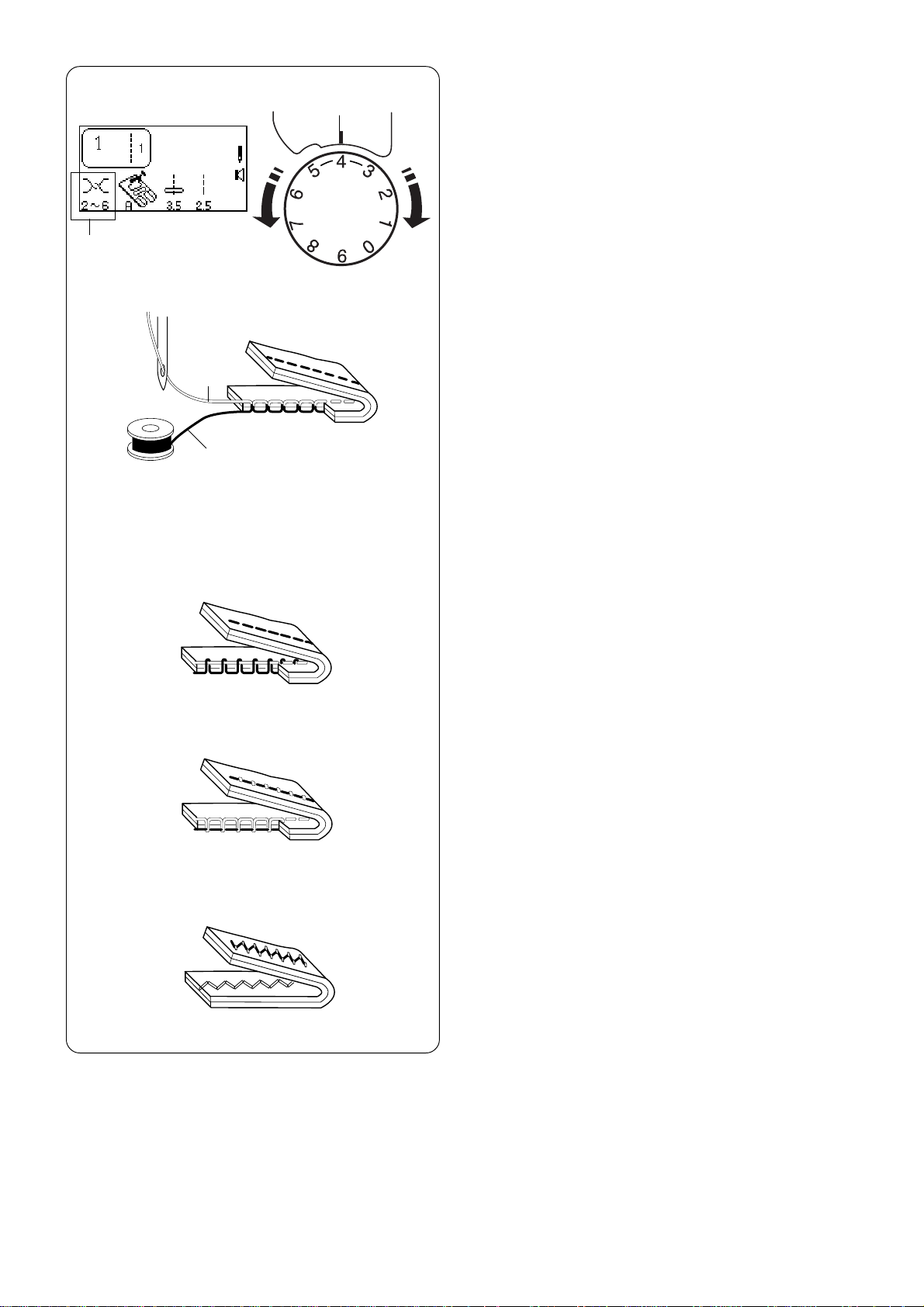

Foot Pressure Dial

w

Change the pressure on the presser foot by rotating

the foot pressure dial q to move the indicator w.

Set the pressure at “3” for regular sewing.

Reduce the pressure to “2” for appliqué, cutwork,

drawn work, basting and embroidery.

Velours and knits with a lot of stretch may require a

“1” setting.

NOTE: Never reduce the pressure below “0”.

15

Page 17

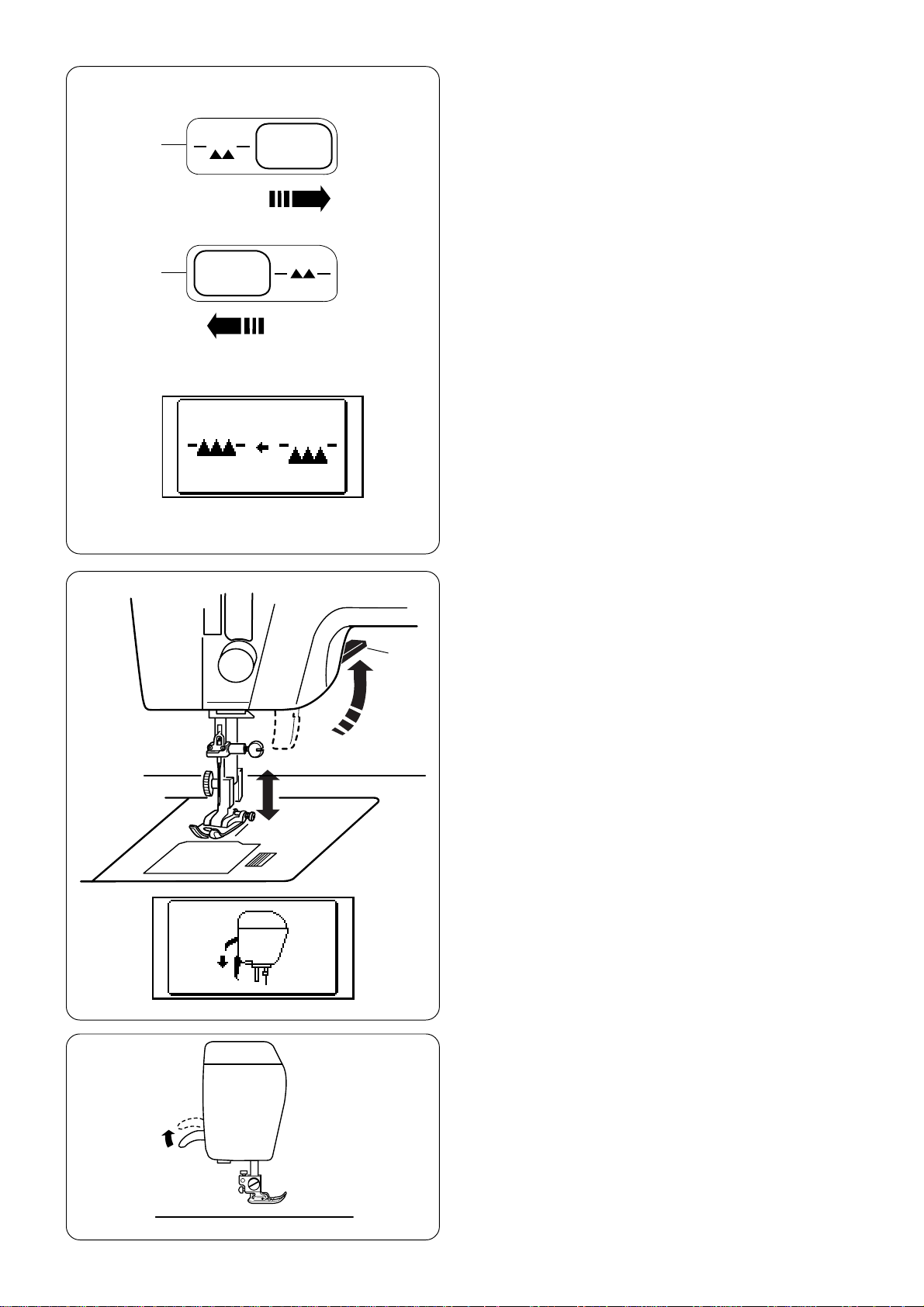

q

w

How To Drop the Feed Dog

The feed dog can be dropped out of position for

special sewing techniques: free motion embroidery,

stippling, button sewing, etc.

The feed dog must always be up for regular sewing.

The machine will run with the feed dog down if the

following stitches are selected: 1, 2, 3, 4, 011, 014,

015, 016, 017, 042, 061 and 062. The machine will not

sew with the feed dog down if any other stitches are

selected.

NOTE: The foot displayed in the LCD screen

changes to the open toe embroidery/darning foot

when the feed dog is down, except after selecting

stitch 2.

Locate the feed dog lever on the front right side of

the machine. Slide the lever either to the right

(down) q or to the left (up) w. To bring up the feed

dog, hand turn the flywheel after sliding lever to the

left.

If the feed dog is down, a message illustration will

appear in the LCD screen when sewing begins.

q

Presser Foot Lever

Raise and lower the foot with this lever q.

Before sewing can occur the presser foot must be

lowered to close the tension discs. If you attempt to

sew with the foot in the up position, the LCD screen

will show this message illustration to remind you to

lower the foot.

q

Additional Presser Foot Clearance

You can raise the presser foot about 6.5 mm (1/4˝)

higher than the normal up position for easy removal

of the presser foot or to place heavy fabrics under

the presser foot. Pull the presser foot lever q up

beyond the normal up position.

16

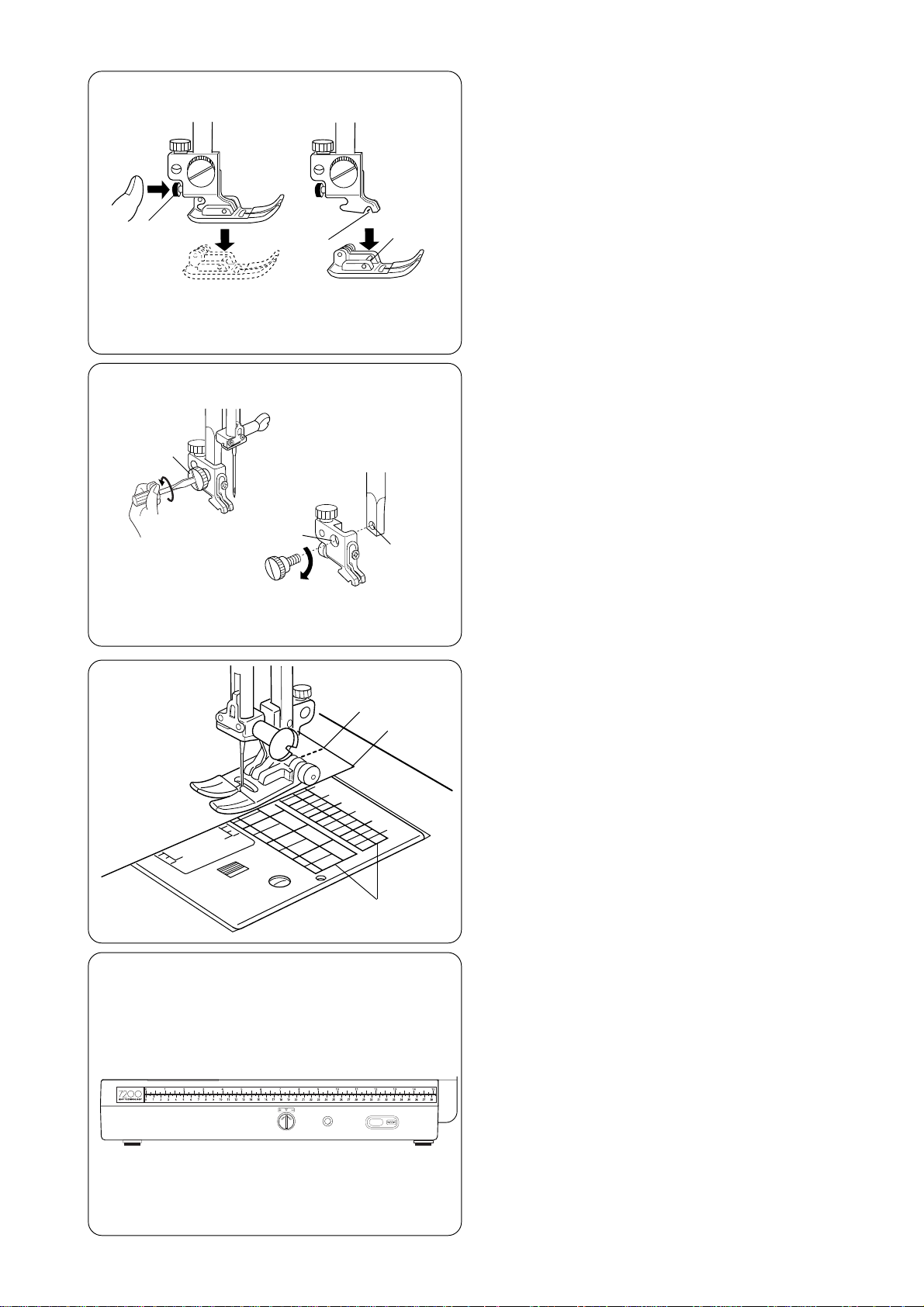

Page 18

q

q

w

e

Attaching and Removing Presser Feet

Press the “Up/Down Needle” key until the needle

is in the raised position.

Tu rn OFF the power switch. Raise the presser foot

and press the red button q on back of the shank.

The presser foot will drop off.

Place the selected presser foot so the pin e on

the foot lies just under the groove w of the shank.

Lower the presser bar and attach the foot.

Attaching and Removing Shank

Tu rn OFF the power switch. Raise the presser

bar.

Tu rn the thumbscrew q counterclockwise with the

screwdriver to remove the shank.

w

q

w

e

e

To attach, match the hole in the shank w with the

hole in the presser bar e. Put thumbscrew in hole

and turn clockwise to tighten.

Seam Allowance Lines

The lines on the needle plate and bobbin cover plate

help you measure seam width.

The numbers indicate the distance (in millimeters

and inches) between the center needle position 3.5

q and the seam allowance line w. Use the seam

allowance line as a guide for the fabric edge e.

Centimeter/Inch Quick Measurements

Use this handy tool located on the machine base

for quick measurements.

17

Page 19

Adjusting the Needle Thread Tension

q

e

r

w

Choosing the Correct Tension - Straight Stitch

The ideal straight stitch will have threads locked

between the two layers of fabric.

According to the LCD screen, needle thread tension

can range from 2 – 6 q and is normally set on 4.

Align the number 4 on the tension dial with the

setting mark w.

If you look at the needle thread e (top thread) and

bobbin thread r (bottom thread), you will notice

that there are no gaps. Each stitch is smooth and

even.

Occasionally the needle thread tension needs to be

adjusted. Examples:

— stiff or heavy fabric

— sewing more than two layers of fabric

—type of stitch

— thread

When adjusting needle thread tension, the higher

numbers tighten, the lower numbers loosen.

• Tension is too tight

The bobbin thread shows through on the topside of

the fabric and it will feel bumpy.

Tu rn the dial to a lower number to loosen the needle

thread tension.

•Tension is too loose

The needle thread shows through on the underside

of the fabric and it will feel bumpy.

Tu rn the dial to a higher number to tighten the

needle thread tension.

• Adjusting Tension for Zigzag and Satin Stitches

The upper thread tension should be slightly looser

when sewing a zigzag or a satin stitch. The upper

thread should appear slightly on the underside of

the fabric.

18

Page 20

e

w

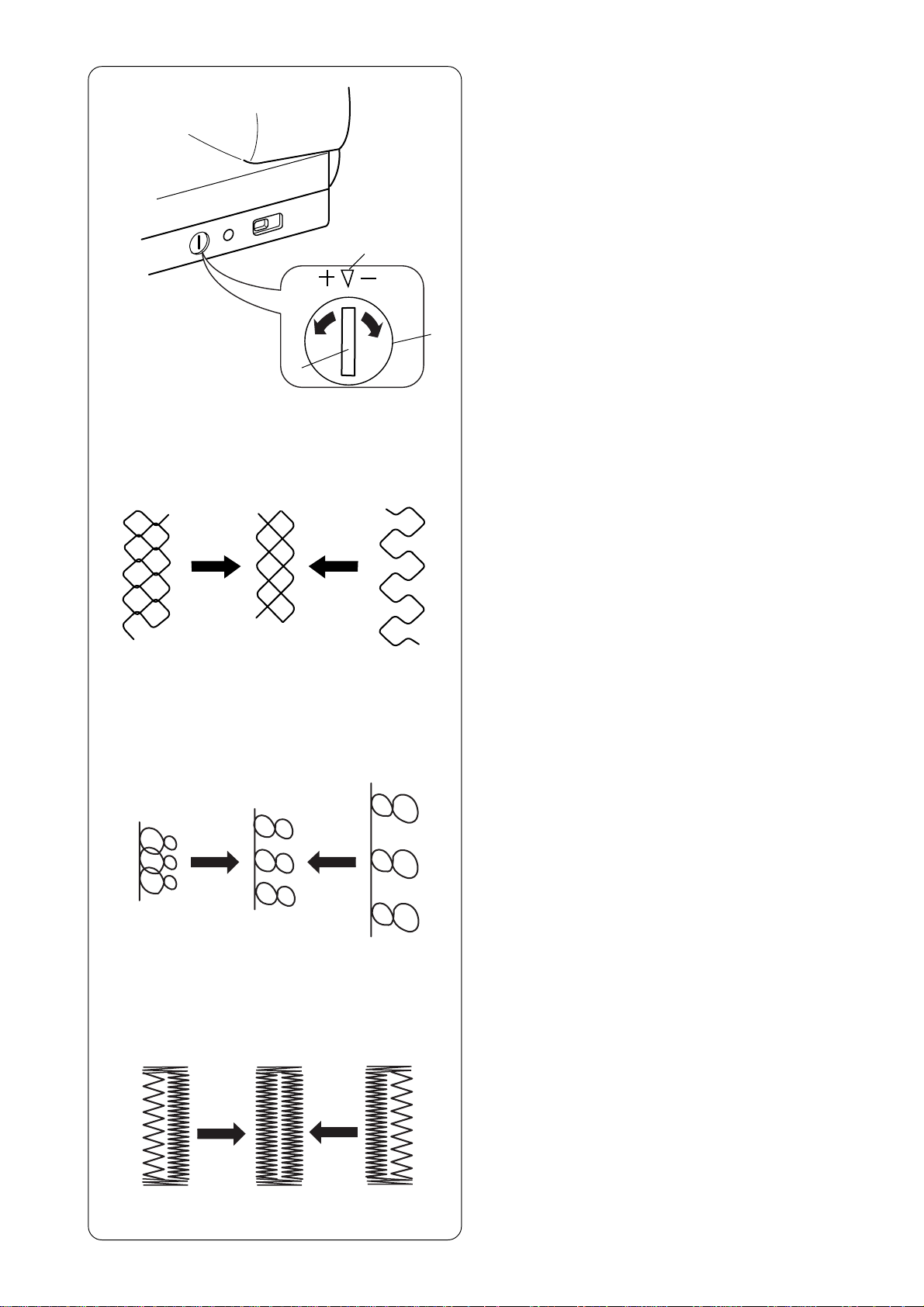

Using the Fine Adjustment Screw

Choice of fabrics and threads may affect the stitch

formation when sewing decorative stitches, letters

and numbers or classic 4 step memory buttonhole

(071). The fine adjustment screw can be used to

either lengthen or shorten the stitch.

q Fine adjustment screw

w Standard mark

e Setting mark

To fine tune, use a screwdriver to move the setting

mark.

q

rt

• If stitches are too short r, correct by turning the

screw in the direction of “+”.

• If stitches are too long t, correct by turning the

screw in the direction of “–”.

(+) (–)

u

y

(+) (–)

• If letters are overlapped y, correct by turning the

screw in the direction of “+”.

• If letters are too spread out u, correct by turning the

screw in the direction of “–”.

071 Classic 4 Step Memory Buttonhole

(Applies only to this style.)

Always make the adjustment according to the left side.

When adjustment screw is turned, it changes both

sides of the buttonhole.

io

(+) (–)

• If left side of buttonhole is less dense (too open) i

compared to right side, corrected by turning screw in

direction of “+”.

• If left side of buttonhole is more dense (too closed)

o compared to right side, corrected by turning

screw in direction of “–”.

NOTE: After making any fine turning adjustment press

“Enter” key or reselect buttonhole to reset machine.

19

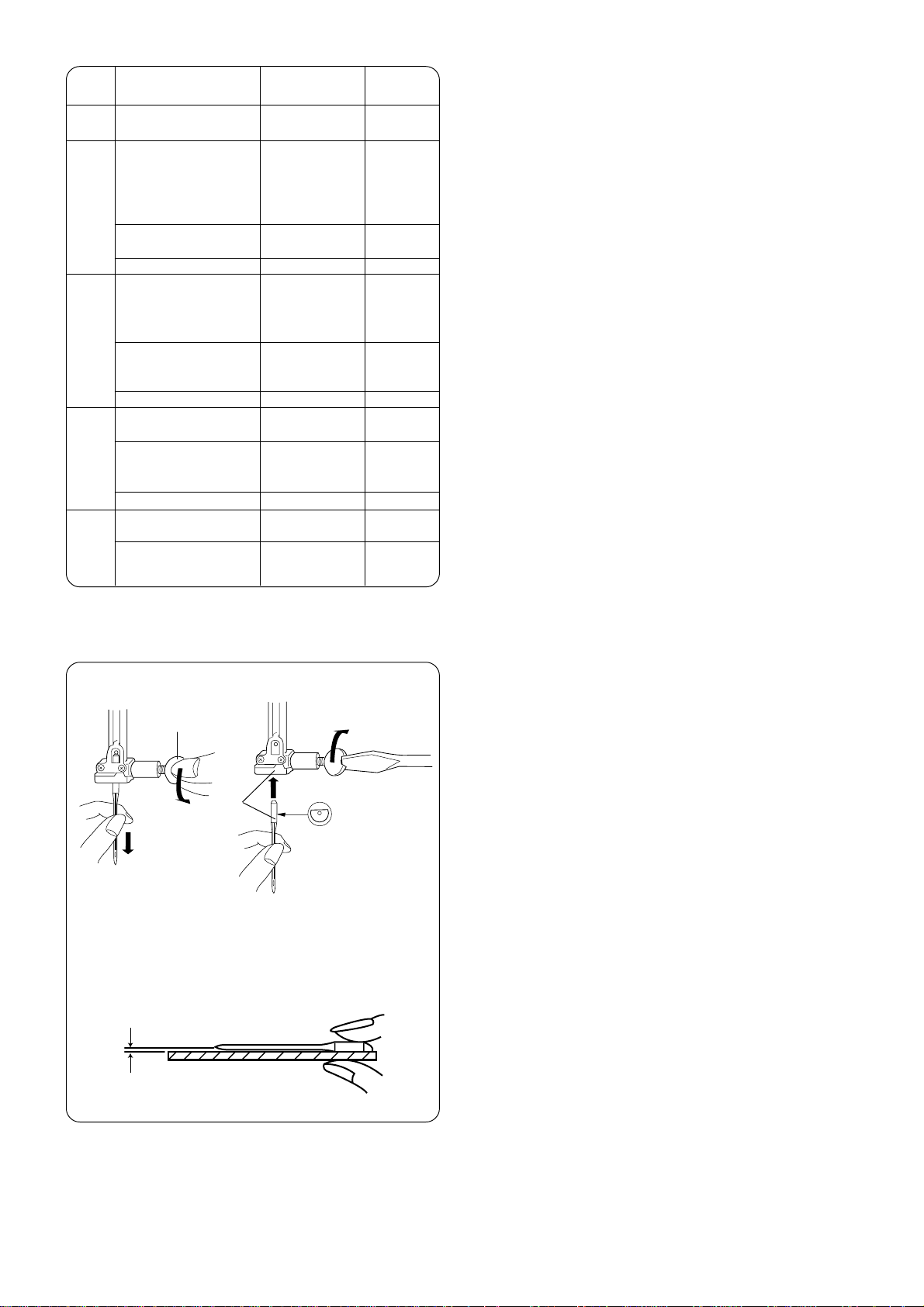

Page 21

Weight

Fabric Needle Type

Very Chiffon, Fine Lace, Universal 9 (65)

Light Organdy Ball Point 9 (65)

Light

Batiste, Lawn, Crepe

de Chine, Challis,

Handkerchief Linen,

Crepe, Taffeta, Satin

Single Knits, Jersey, Stretch 11 (75)

Swimwear, Tricot Ball Point 11 (75)

Leather, Suede Leather 11(75)

Medium Flannel, Velour, Velvet,

Velveteen, Corduroy,

Linen, Gabardine,

Wool, Terry, Burlap

Double Knits, Stretch

Velour, Stretch Terry,

Sweater Knits

Leather, Vinyl, Suede

Heavy

Denim, Sailcloth,

Ticking

Coating, Polar Fleece,

Drapery, and

Upholstery Fabrics

Leather, Suede

Ver y

Canvas, Duck,

Heavy

Upholstery Fabrics

Topstitching for

Special Finish

Stretch 11 (75)

Universal 11 (75)

Universal 14 (90)

Ball Point 14 (90)

Leather 14 (90)

Denim 16 (100)

Universal 16 (100)

Leather 16 (100)

Universal 18 (110)

Topstitching 11 (75)

Needle

Size

12 (80)

14 (90)

SECTION II

Getting Ready to Sew

Selecting the Correct Needle and Thread

There are many kinds of fabrics, threads and

needles. It is important to use the correct ones

together.

Always purchase good quality thread. It should be

strong, smooth and even in thickness. Use the

same thread for needle and bobbin. Always test

thread and needle size on a scrap piece of fabric.

In general, fine threads (the larger the number, the

finer the thread) and needles (the smaller the

number, the finer the needle) are used for sewing

lightweight fabrics and heavier threads and larger

needles are used for sewing heavyweight fabrics.

There are many specialty needles available from

your sewing machine dealer.

Check your needles frequently for rough or blunt

tips. Snags and runs in knits, fine silks and silklike

fabrics are permanent and are often caused

by damaged needles.

zx

q

w

c

NOTE: A universal needle size 14/90 comes

inserted in your machine

Changing Needles

z Tu rn ON the power switch. Press the “Up/

Down Needle” key to raise the needle. Lower

the presser foot. Turn OFF the power switch.

Tu rn the needle clamp screw q

counterclockwise to loosen. Remove the

needle from the clamp.

x Insert the new needle into needle clamp with

the flat side to the back, pushing it up as far

as it will go w. Tighten the clamp screw firmly.

c To determine if the needle is defective, place

the flat side of the needle on something flat (a

needle plate, piece of glass, etc.). The gap

between the needle and the flat surface

should be consistent.

Never use a bent or blunt needle, as it may cause

skipped stitches or thread breakage. Defective

needles can ruin the fabric. Always purchase good

quality needles. Change needles often.

20

Page 22

q

w

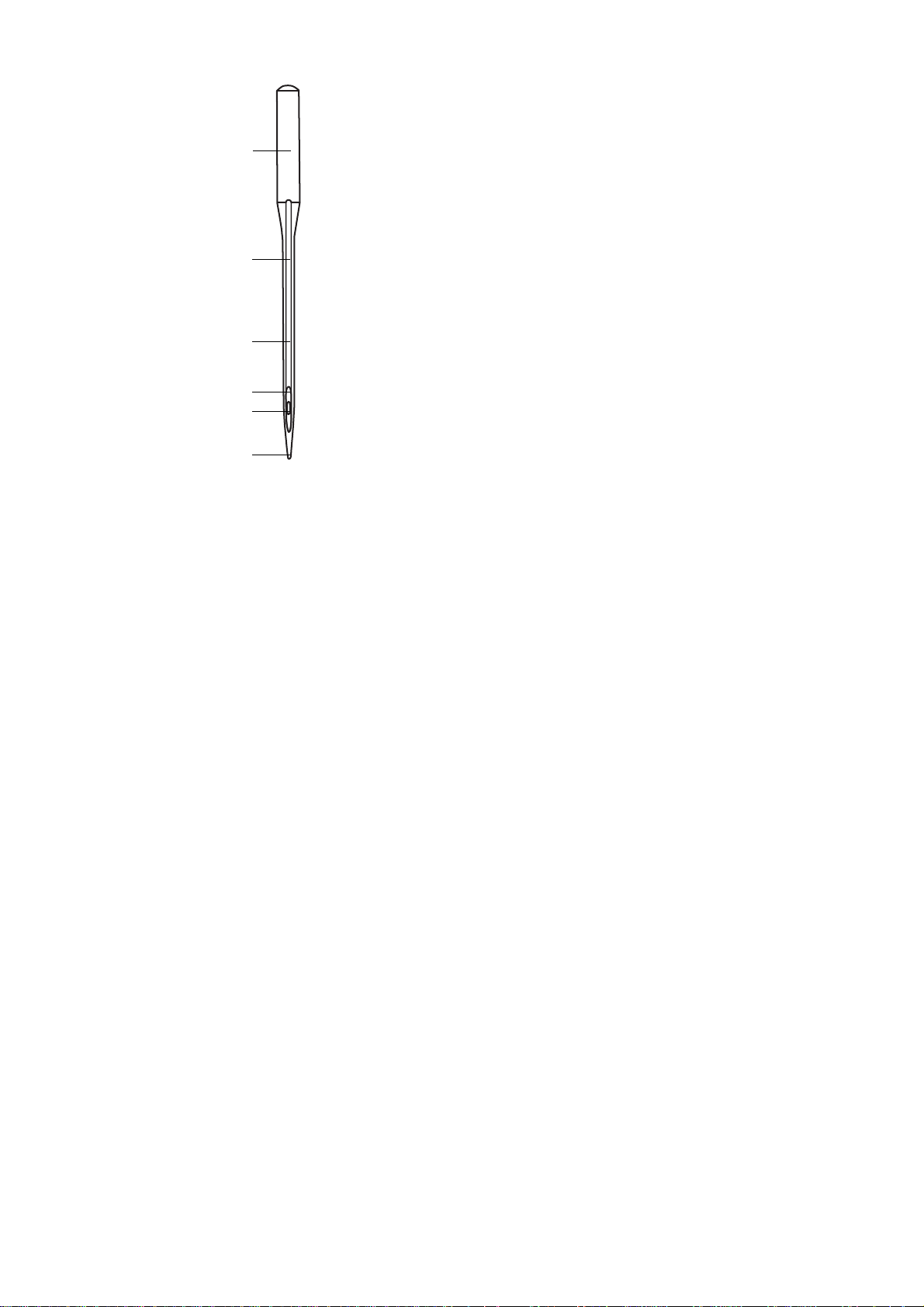

Needle Definitions

The illustration identifies the main parts of a

sewing machine needle.

q Body

w Shaft

e Long groove (round side of needle)

r Short groove (flat side of needle)

t Eye

y Point

Universal – an all-purpose needle that handles

most woven and knit fabrics.

e

r

t

y

Ball point – the point spreads the fibers,

preventing tears and is especially suited for loose

knits and interlock knits. Not recommended for

embroidery.

Stretch – specially designed to prevent skipped

stitches in synthetic suedes and elasticized knits

(swimwear).

Denim – the sharp point effectively pierces

densely woven fabrics such as denim and canvas.

Topstitching – the extra sharp point penetrates

layers of fabrics; extra large eye and large groove

accommodate heavyweight topstitching thread.

Metallic – the large grooved shaft helps prevent

delicate metallic threads from shredding. Another

plus, a larger than average eye makes for easier

threading.

Embroidery – a slightly rounded tip minimizes

breakage and skipped stitching when using

specialty threads like rayon, acrylic or other highsheen

threads during machine embroidery.

Self-Threading – the needle eye has a slit

opening on the side to allow the thread to be

easily inserted.

Leather – the cutting point creates small holes in

leather and suede. Holes remain after stitching is

removed.

Quilt – the tapered point easily penetrates

through multiple layers and crossed seams.

Wing/Hemstitch – wide flat edges (wings) extend

outwards near the eye; they separate fibers and

create holes for beautiful heirloom stitches.

Twin/Double – 2 needles are joined on a crossbar

and share a single shaft. Sews two parallel rows

of stitching. Available in universal and ballpoint.

21

Page 23

q

w

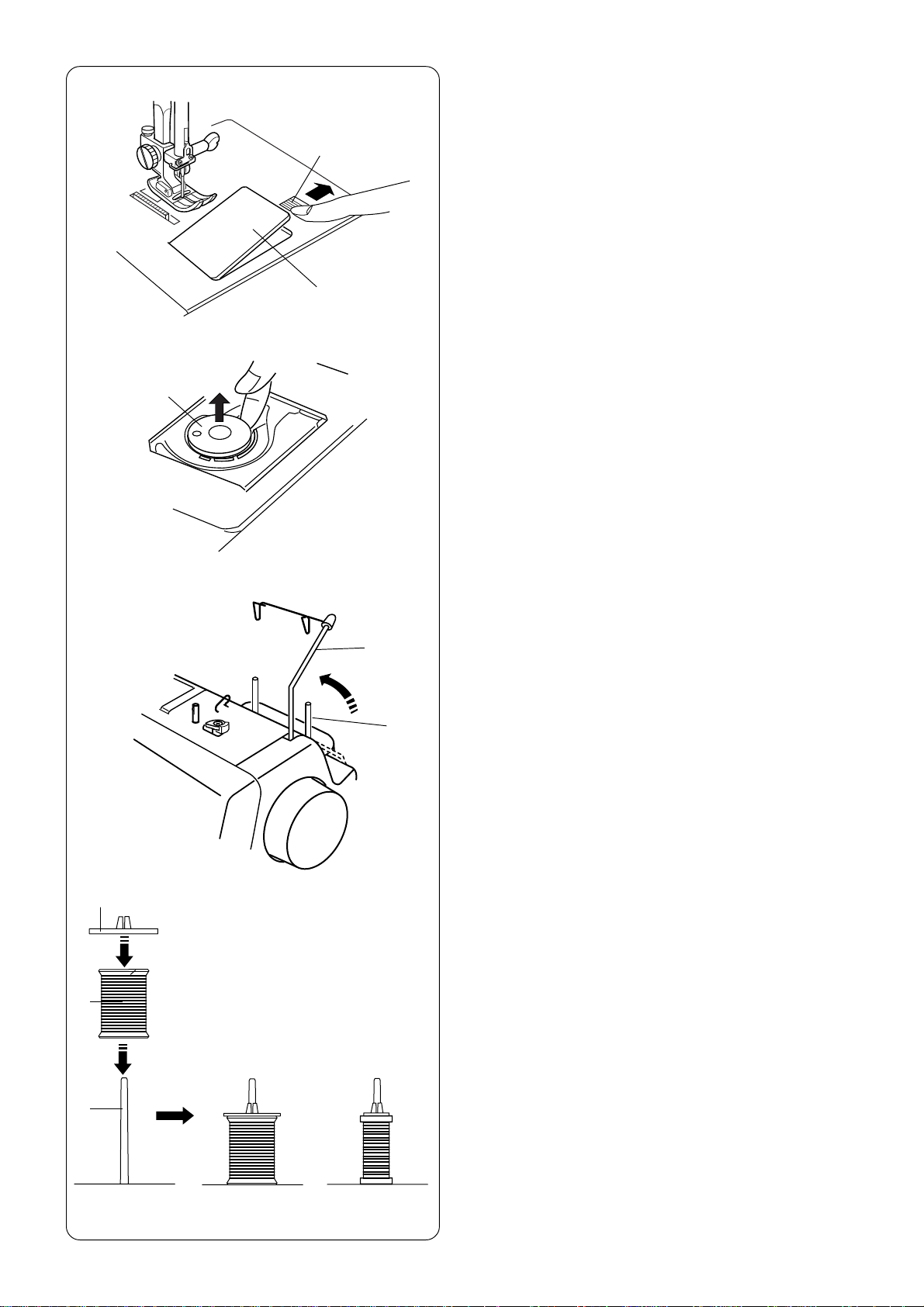

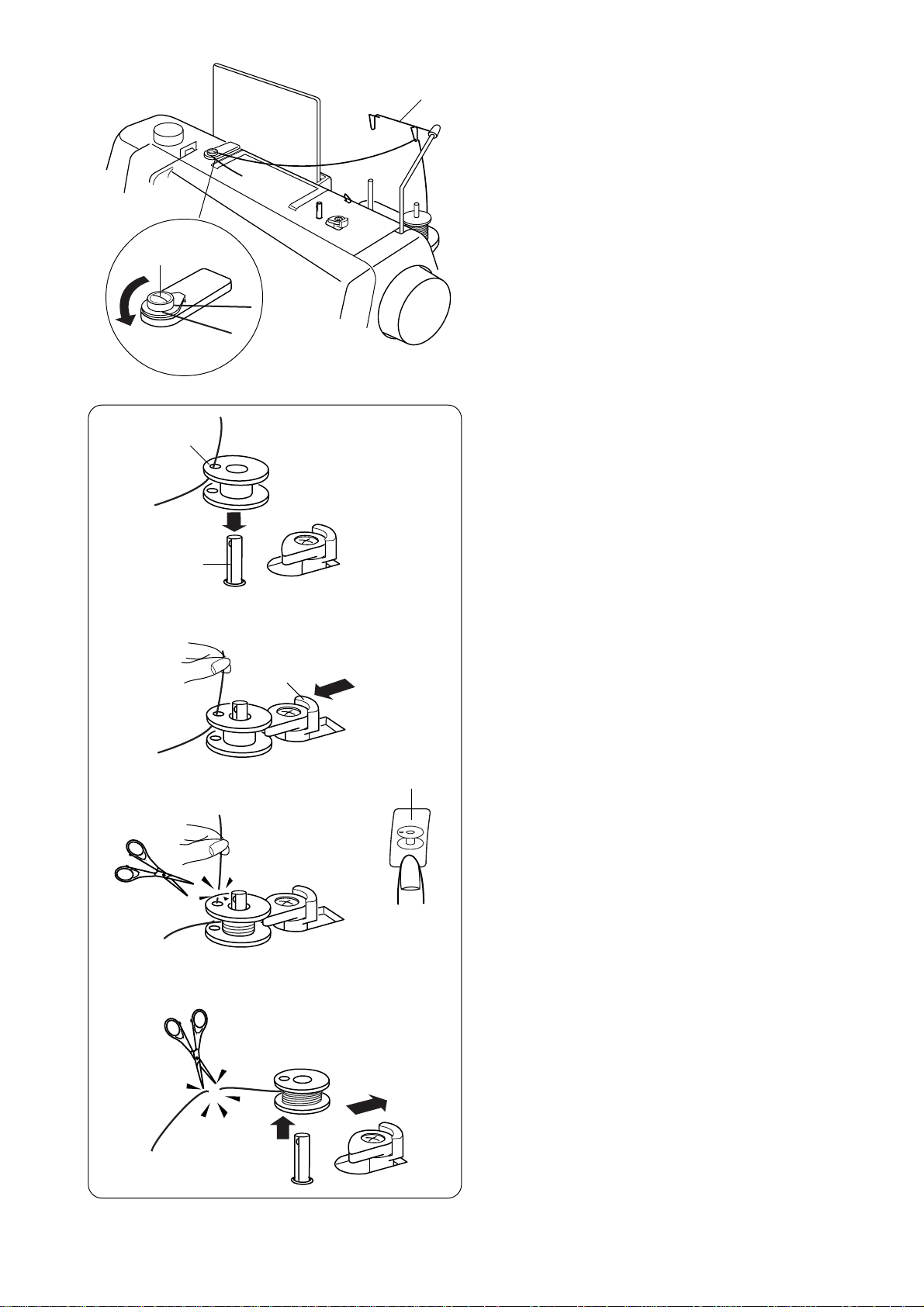

Winding a Bobbin

To remove bobbin, slide bobbin cover plate release

button q to the right and lift away the bobbin cover

plate w.

Lift out the bobbin e.

e

Tu rn ON the power switch.

CAUTION: Avoid using a bobbin if it is almost

empty, as thread may tangle.

Always use bobbin type supplied with machine.

Pull up the retractable thread guide r.

r

y

t

y

u

Place the spool of thread t on the right side spool

pin y with the thread coming off the spool as

shown. Attach the spool holder u and press it

firmly against the spool of thread.

NOTE: Spool holder needs to be changed according

to the type of thread spool

i Large spool

io

o Small spool

22

Page 24

w

e

q

Pull the thread up and through the right retractable

thread guide q from behind.

Pull the thread under and around the bobbin winding

tension disc w.

Pass the thread through the hole in the bobbin e

from inside to the outside. Place the bobbin on the

bobbin winder spindle r.

r

t

Push bobbin winder stop t to the left.

y

Holding the free end of the thread, press the

“Bobbin Winding” key y. (A separate motor winds

the bobbin, allowing you to sew at the same time

bobbin winding occurs.)

Press the “Bobbin Winding” key to STOP bobbin

winding after the bobbin has made a few turns. Cut

the thread tail close to the hole in the bobbin.

Press the “Bobbin Winding” key again. When the

bobbin is fully wound, bobbin winding is stopped

and bobbin winder stop will automatically move

right. If you do not wind a full bobbin, stop bobbin

winding and return bobbin winder stop to the right.

Cut thread.

23

Page 25

q

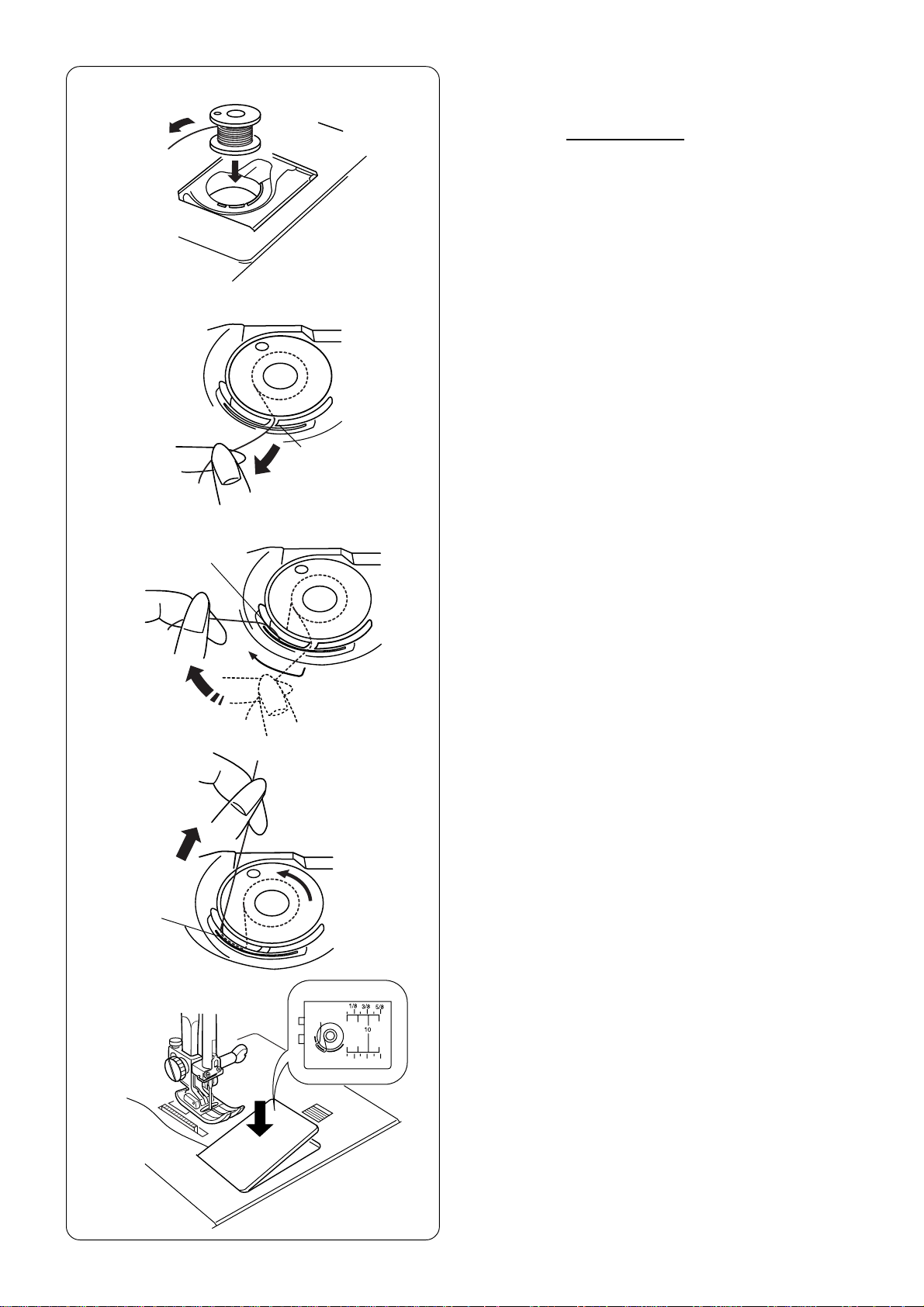

Inserting the Bobbin

Place the bobbin in the bobbin case with the

thread running counterclockwise.

Guide the thread into notch q on the front side of

the bobbin case.

e

w

Hold the bobbin with your right hand and pull the

thread to the left, through the tension spring

blades w.

Continue pulling the thread lightly until the thread

slips into notch e.

Pull out about 15 cm (6˝) of thread.

Replace the bobbin cover plate.

Refer to the chart shown on the bobbin cover

plate to check the threading.

24

Page 26

r

e

q

w

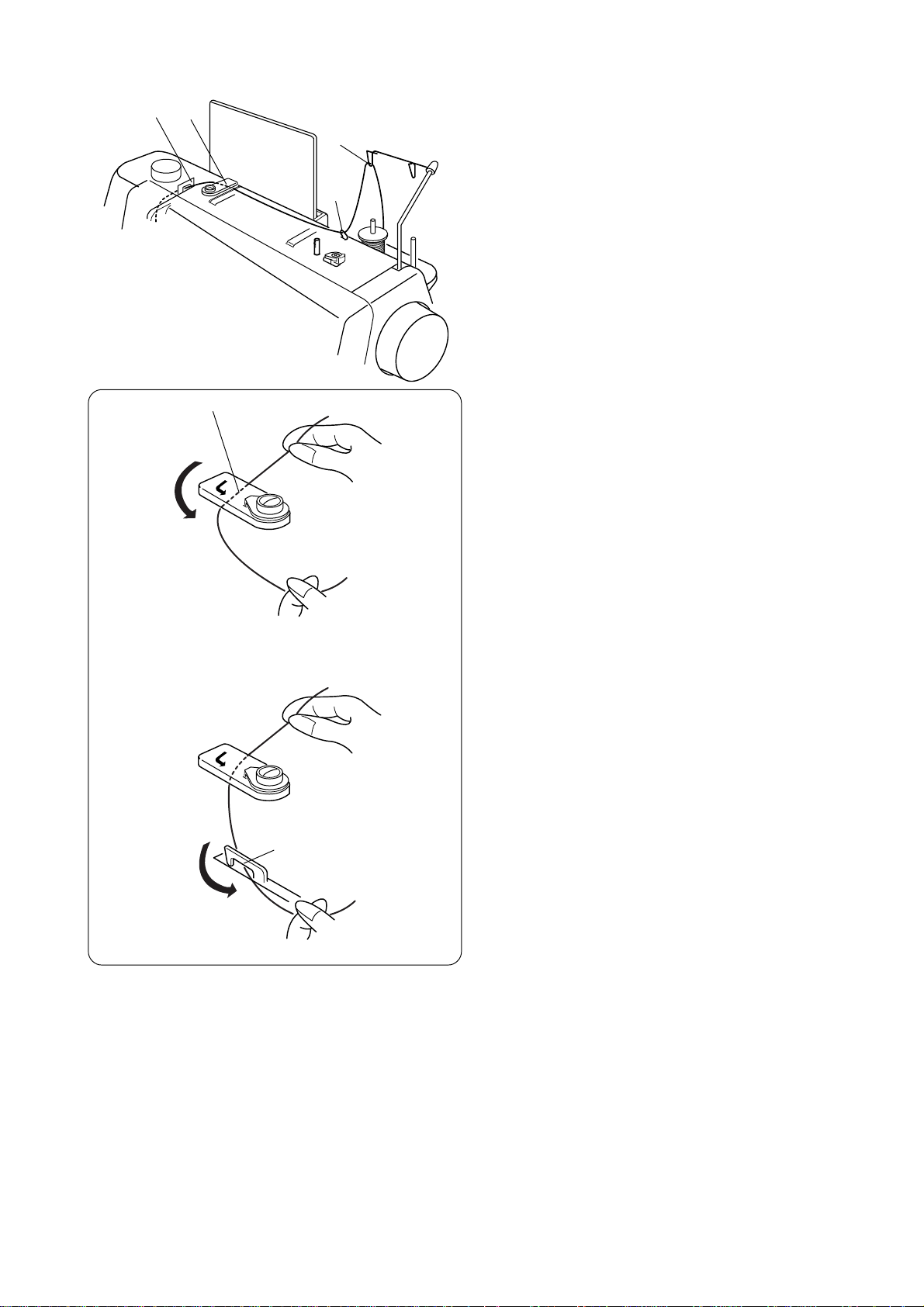

Threading the Machine

Raise the presser foot. Press the “Up/down Needle”

key until the needle is in an up position.

Place the spool of thread on the left spool pin with

the thread coming off the spool as shown and

attach the spool holder.

Pull the thread up and through the left retractable

thread guide q from behind.

Pull the thread under the upper thread guide w.

e

Using both hands, firmly insert the thread under the

thread guide plate e.

Pull thread forward under the left thread guide r.

r

25

Page 27

u

r

e

t y

t

y

o

i

u

Continue to pull the thread down into the right

channel and around the tension dial from right to

left.

Pull up on the thread until it is inserted between the

tension discs and under the loop of the check

spring t. Check that the thread is coming out

over the notch y of the disc.

Pull thread up the left channel to the take-up lever.

Pass thread from right to left side down into eye of

take-up lever u.

i

Proceed down to the lower thread guide i and pull

thread left. Slide the thread right behind the needle

bar thread guide o.

Thread the needle from front to back manually or

use the built-in needle threader.

o

26

Page 28

q

Built-in Needle Threader

Press the “Up/Down Needle” key q until the

needle is in an up position. Turn OFF the power

switch. Lower the presser foot.

Lower the needle threader lever w as far as it will

go. Hook e is automatically inserted into the

needle eye.

w

r

e

t

Bring the thread around guide r and under hook

e.

e

Slowly release the lever while holding the thread

end and let the needle threader return to its

original position. A loop of thread t is pulled

through the needle eye.

Pull the thread loop off the guide to the back and

manually bring the thread through the needle eye.

• The needle threader can be used with #11 to #16

size needles. Thread weight may vary from 30 to

100.

NOTE: Needle threader cannot be used with a

twin needle or wing needle.

If the needle threader does not catch a thread

loop, check the needle and positioning.

27

Page 29

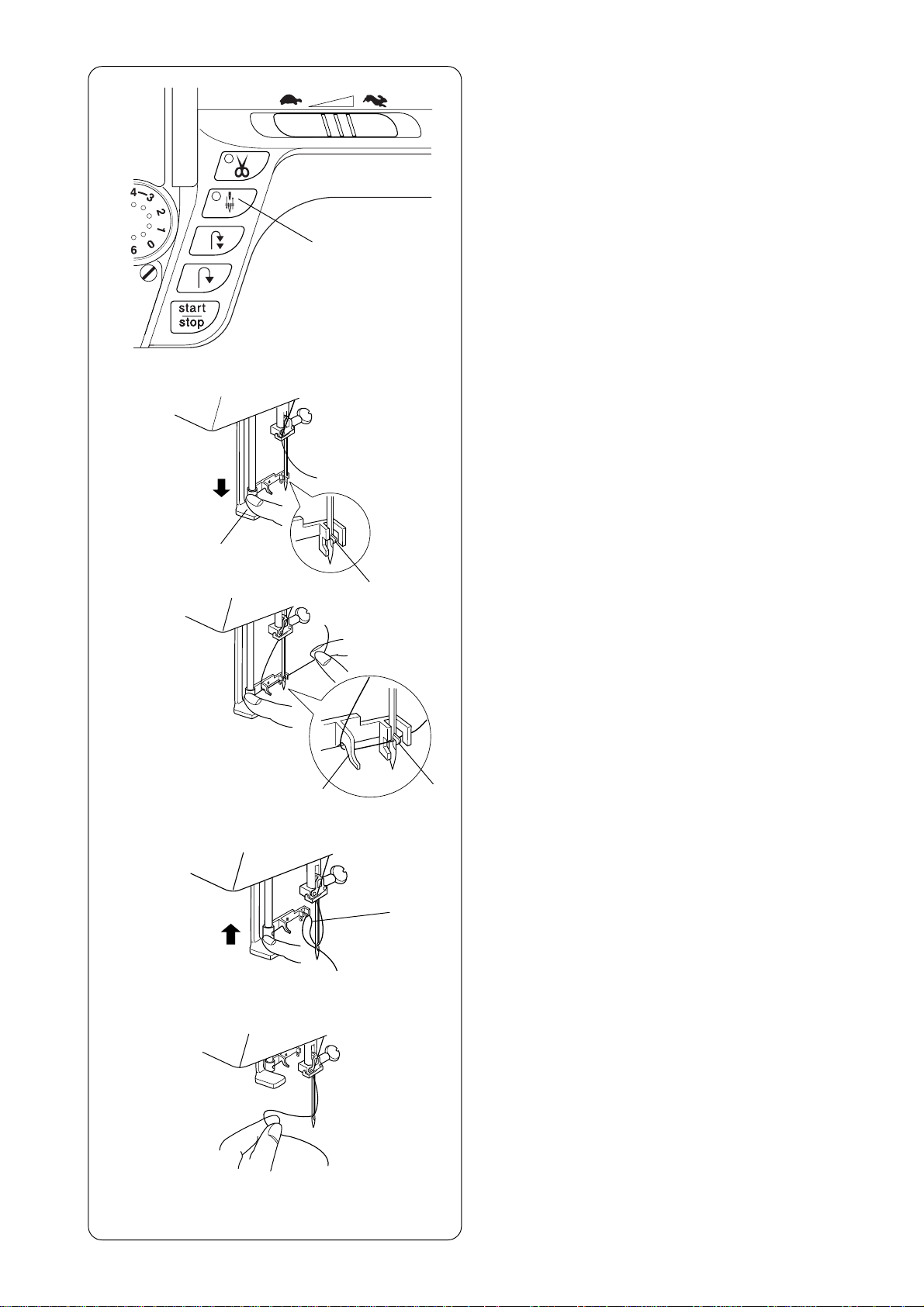

Drawing Up the Bobbin Thread

Tu rn ON the power switch. Raise the presser foot

and hold the needle thread lightly with your left

hand.

Press the “Up/Down Needle” key q twice to pick

up the bobbin thread.

q

Draw up the needle thread together with a loop of

bobbin thread.

Slide 10 cm (4˝) of both threads to the back under

the presser foot.

28

Page 30

z

SECTION III

Basic Sewing

How to Select a Stitch

x

z Select stitches 1 – 0 in Direct Select Mode by

touching the corresponding key.

x Select stitches in the 3 Digit Mode by pressing

“MODE” key and then the 3 corresponding

keys.

Set-up your machine according to the LCD screen.

See page 13.

Straight Stitch

When the machine is turned on, it is automatically

set to sew a straight stitch in the center needle

position (Exception: Quick Resumption Mode. See

page 14).

The straight stitch is used to sew a seam in woven

fabrics. The straight stitch can also be used for

gathering, basting, sewing in a zipper, pintucks,

rolled hems and twin needle hems.

NOTE: Test sew a swatch of fabric and check

thread tension. Adjust tension dial if necessary.

See page 18.

w

q

e

w

Starting To Sew

Raise the presser foot and position the fabric next

to a seam allowance line on the needle plate. Pull

the threads under the foot towards the back and

lower the presser foot. Press the “Up/Down Needle”

key q (LED signal turns on) to lower the needle.

Press the foot control or “START/STOP” key.

Gently guide the fabric along the seam allowance

line letting the fabric feed naturally.

Press the “START/STOP” key or remove foot from

foot control to stop sewing.

.

Finishing Off a Seam

To fasten the threads at the beginning or end of a

seam, press and hold the “Reverse” key w.

OR

To lockstitch threads at the beginning or end of a

seam, press the “Auto-Lock” key e before sewing

begins or when reaching end of sewing.

29

Page 31

q

w

q

Cutting the Threads

After sewing is stopped, press the “Auto Thread

Cut” key q (LED signal turns on). (Needle should

be in down position before using auto thread cutting

mechanism to avoid extra needle penetrations.)

Raise the presser foot and remove the fabric.

Pull both threads to the back under the presser foot

so they are ready for sewing again.

OR

Specialty or heavy decorative threads: Press the

“Up/Down Needle” key to raise the needle. Raise

the presser foot. Remove the fabric; pull the threads

to the back and cut threads using the thread cutter

w. (The threads are cut the proper length to start

the next seam.)

Changing Sewing Direction

Stop the machine and press the “Up/Down Needle”

key q to bring the needle down into the fabric.

Raise the presser foot using either the presser foot

lever or knee lifter.

Pivot the fabric around the needle to change sewing

direction. Lower the presser foot. Sew in new

direction.

Adjusting Needle Position

When you press the “Stitch Width/Needle Position”

key, the needle position can be set between 0.0

and 7.0.

Press the top/left “–” side of the key to move needle

left.

Press the bottom/right “+” side of the key to move

needle right.

q Left position

w Center position

e Right position

The following stitches also have variable needle

position: 6, 011, 012, 060, 061, 062 and 063.

30

Page 32

1.0 2.5 5.0

Adjusting Stitch Length

When you press the “Stitch Length” key, the stitch

length can be set at 0.00 or between 1.0 and 5.0.

Press the top “–” side of the key to shorten the

stitch length.

Press the bottom “+” side of the key to lengthen

the stitch length.

Programming My Personal Settings

Stitches 1-126 can be programmed to override the

factory default settings.

z

x

c

z Change stitch length to 2.6.

x Press “My Personal Setting” key. Message

screen appears.

c Press “ENTER” key to save personal setting.

PS symbol appears in LCD screen to indicate

stitch has been altered from factory default

settings.

31

Page 33

Reset Stitch To Factory Default Settings

z

x

c

It is possible to reset the machine so personal

settings for an individual stitch revert to the factory

default settings.

z Display the stitch you want to reset in the LCD

screen.

x Press “My Personal Setting” key. Message

screen appears.

c Press “C” key. PS symbol disappears and

factory default settings are displayed.

z

x

c

Reset All Stitches To Factory Default Settings

It is possible to reset the machine so all personal

settings for all stitches revert to the factory default

settings.

z Tu rn OFF the power switch. Press “ENTER”

key while turning power switch ON. Message

screen appears.

x Press “ 9” key. Message screen appears.

c Press “ENTER” key to confirm and reset to factory

default.

OR

Tu rn off power switch to cancel the reset and

retain personal settings.

32

Page 34

Sewing On Heavy Fabrics

The black button on presser foot “A” locks the foot

in a horizontal position when pushed in before

lowering the presser foot. This ensures even

feeding at the beginning of seams and helps when

sewing many layers of fabric such as welt seams

used to hem jeans.

When the point of an increased thickness is

reached, lower the needle and raise the presser

foot. Press in the black button. Lower the foot and

continue sewing.

This button releases automatically after a few

stitches have been sewn.

NOTE: Increase stitch length between 3.0 and 4.0

for heavier fabrics.

Gathering

Gathering/shirring evenly distributes fullness in an

area with very tiny pleats. Gathering is one row or

two parallel rows. Shirring is three or more parallel

rows. Light to medium weight fabrics provide the

best results.

Decrease thread tension dial to between 1 and 3.

Increase stitch length to 5.0.

Sew two rows of parallel stitches. Sew first row

next to raw edge using foot edge as guide. Sew

second row next to first row using foot edge as

guide. Leave long thread tails at beginning and

end of each row.

Pull the bobbin threads simultaneously from each

end of the fabric until the desired amount is

gathered. Knot the threads at each end and

distribute the gathers evenly.

Reset thread tension dial to 4 and decrease stitch

length to 2.5.

Sew between two rows of stitching to secure

gathering.

OR

Lay gather fabric over flat fabric and sew the

two fabrics together directly on the second row

of gathering stitches.

33

Page 35

Zipper Insertion

Lapped Application

Lapped zippers are usually inserted into a side

seam of skirts or pants, for example.

Use zipper foot E instead of standard metal foot A.

Attach the pin on zipper foot E to the groove on

the shank.

•To sew the left side of the zipper, attach the zipper

foot on the right-hand side.

•To sew the right side of the zipper, attach the zipper

foot on the left-hand side.

Fabric Preparation

Add 1 cm (3/8˝) to the zipper size. Use this

measurement and mark the opening for the zipper.

Place right sides of fabric together and sew the

seam located below zipper placement. (Make sure

to reverse sew the stitches directly below the

zipper placement.)

Increase stitch length to 5.0 and baste the zipper

opening closed. Press the seam and basting seam

open.

Open zipper and place it face down on the seam

allowance. Teeth are on the seam line and zipper

top is 1 cm (3/8˝) from fabric top edge. Attach foot

with left side pin. Baste zipper in place, sewing

from bottom to top.

34

Page 36

Close zipper. Turn zipper face up (right seam

allowance forms a small fold at basting line) and

smooth zipper teeth away from seam. Attach foot

with right side pin. Reset straight stitch length to

2.5. Starting at the bottom, sew through the folded

seam allowance and zipper tape.

Stop just before the zipper foot reaches the slider

on the zipper tape. Lower the needle slightly into

the fabric. Raise the zipper foot and open the

zipper. Lower the foot and stitch the remainder of

the seam.

Close the zipper and spread the fabric flat with the

right side facing up. Baste through the opened

seam allowance and zipper tape.

Move the zipper foot to the left side pin. Guide the

edge of foot along the zipper teeth and stitch

through the garment and zipper tape. Stop about 5

cm (2˝) from the top of the zipper. Slightly lower

the needle into the fabric. Raise the foot, remove

the basting stitches from seam line and open the

zipper.

Lower the foot and stitch the remainder of the

seam, making sure the fold is even.

Remove remaining basting stitches.

35

Page 37

q

Rolled Hem

An easy, professional way to sew hems. The spiral

on the hemmer foot guides the fabric edge to

create a rolled hem. Recommended for fine, sheer

fabrics used in bridal wear.

Attach hemmer foot D.

Tr im about 6.5 mm (1/4˝) from corners to reduce

bulk.

Make a double 3 mm (1/8˝) fold approximately 8

cm (3˝) in length.

Align fabric hem edge with the inside of right

extension of foot q. Use this placement on foot as

guide. Lower presser foot. Sew 3 or 4 stitches while

holding needle and bobbin threads. Stop sewing.

w

Lower needle into fabric and raise presser foot.

Insert folded portion of fabric into spiral of foot w.

Lower presser foot and sew; lift up edge of fabric

to keep it feeding smoothly.

NOTE: Use zigzag with stitch width 1.0 – 2.0 for

variation.

36

Page 38

Zigzag Stitch

The zigzag stitch is a very versatile stitch. Simply

change its width and length. Use the zigzag to

finish raw seam edges, sew narrow hems, sew

satin stitch appliques and create beautiful

monograms.

Select 2.

qw er

Adjusting Stitch Width and Length

Press the “–” or “+” side of the keys to change the

stitch width and length.

q Narrower width (lower number)

w Wider width (higher number)

e Shorter stitch (lower number)

r Longer stitch (higher number)

NOTE: Settings can be altered during sewing.

Overcasting

Simple zigzag stitching is used for finishing raw

seam edges (overcasting) on most woven fabrics

to prevent fabric from unraveling. This is the

fastest way to finish an edge.

Select 2.

Attach overlock foot C.

• Do not set the stitch width lower than 5.0 when

using overlock foot C because the needle

could hit wires on the foot.

Place the fabric edge against the black guide on

the foot. Sew.

37

Page 39

Satin Stitch Appliqué

The zigzag stitch is commonly used for appliqué,

monogramming, stems of flowers and petals. (A

short zigzag stitch length creates the satin stitch.)

Threads of 100% cotton, rayon or silk provide the

best results.

• Apply stabilizer to the fabric for the stitch to form

correctly.

Select 2.

Attach satin stitch foot F.

Decrease stitch width to 3.5 and stitch length to

0.40.

Appliqué Preparation

1. Press fusible webbing to the wrong side of a

lightweight fabric.

2. Cut out design shape. Fuse design to main fabric.

3. Sew design to fabric with the needle swinging off

the appliqué.

4. When you reach a place where you need to turn,

lower the needle into the fabric at the outer edge of

the turn. Raise the presser foot, turn fabric, lower

the presser foot and continue sewing. (You may

need to set the foot pressure dial to 2.)

3-Step Zigzag

The 3-step zigzag (sometimes called a multiple

zigzag) is used to finish raw seam edges on

synthetics and other fabrics that tend to pucker.

This stitch gives a flatter edge finish than the

regular zigzag and is excellent for darning and

mending tears in fabric.

Select 3.

Place the fabric under the presser foot so the

needle swings off the fabric to the right or trim

away any excess fabric.

38

Page 40

Mending a Tear

Pull torn edges together and fuse a piece of

interfacing slightly larger than the tear to the wrong

side of the garment.

Select 3.

Decrease stitch length to 0.20 – 0.50.

Begin sewing above the tear. Stitch down the

middle, pulling edges together. Stop sewing just

beyond end of tear. Depending on the tear, you

might need to stitch area 2 or 3 times.

Serpentine Stitch

A delicate curve that is great for topstitching or for

applying elastic directly to fabric without making an

elastic casing.

Applying elastic

Select 4.

Attach satin stitch foot F.

1. Mark elastic and fabric into equal parts.

2. Match marks on elastic to fabric.

3. Place middle of elastic under center of presser

foot and stitch into place, making sure elastic is

evenly stretched.

HINT: Use stitches 3, 013 or 014 to apply elastic for

a different look. (Stitch length should be 2.5 or

higher.)

39

Page 41

Blind Hem Stitches

The stretch blind hem (5) is a great method for

finishing a hemline or sleeve.

Use the woven blind hem (064) on non-stretch

fabrics. Finish the raw hem edge with a zigzag or 3

step zigzag q before sewing the blind hem.

Select 5 or press “MODE” key and select 064.

w

e

y

r

q

t

Fold up the hem allowance and press. Fold under the

hem toward right side of garment. Leave a 6.5 – 10

mm (1/4˝ to 3/8˝) extension e at the right.

w Wrong side of the fabric

Position the fabric (wrong side up) so the folded edge

r is to the left side of the guide t. Lower the presser

foot. Hand turn the flywheel and check if wide zigzag

catches only one or two fibers of the fold. The straight

stitch (or narrow zigzag) will be sewn on the single

fabric layer.

If the guide needs adjustment: raise needle out of

fabric, lift presser foot, turn the adjustment nut y and

move the guide to the right or left. Reposition fabric

against guide, check needle swing by turning flywheel,

lower presser foot and sew hemline.

Unfold and open fabric right side facing up. Stitches

should be almost invisible.

NOTE: If the needle catches too much of the fold,

the stitches will show on the right side.

r

40

Page 42

Buttonhole Variations

All buttonholes should use interfacing that is the same weight as the fabric.

Interfacing is especially important when sewing on stretch fabrics.

0 or 071

072

073

074

Classic Buttonhole (Sensor or 4 Step Memory)

The most common buttonhole, found on blouses, shirts, pants, etc. It consists of

a bartack at each end and a compact zigzag stitch along each side.

Classic Keyhole Buttonhole

Accommodates the shank found on large buttons used on heavy coats and

jackets.

Rounded Buttonhole

Use this buttonhole for large buttons on lightweight fabric.

Stretch Buttonhole

Designed for non-woven fabrics such as knit and jersey. It provides a decorative

touch.

075

076

Knit Buttonhole

A simplified version of the stretch buttonhole.

Bound Buttonhole (4 Step Memory)

Made through the garment and interfacing before the facing is applied, resulting

in finished fabric edges, a custom tailored touch. Often found on garments made

from natural fibers.

Test sew the buttonhole on a sample swatch of the same fabric. Include the

interfacing and any seam allowances that will be in the actual garment. This is

very important to ensure the buttonhole style and fabric are compatible.

41

Page 43

Sensor Buttonholes (Totally Automated

Buttonholes)

Select a buttonhole - 0, 072 thru 075.

The LCD screen will briefly show a message

advising that the buttonhole lever must be lowered.

Alter the buttonhole width to match the fabric and

thread. See page 45.

When attaching buttonhole foot (R), make sure the

button opening is at the back of the foot.

q

Extend the buttonholder q to the back and place

the button in it. Push the holder together tightly

around the button.

Placing the button in the automatic buttonhole foot

(R) automatically sets the size of the buttonhole.

The buttonholder adjusts for buttons with a diameter

between 0.5 cm (3/16˝) to 2.5 cm (1˝). If your button

is larger than 2.5 cm (1˝), see page 47.

Pull the buttonhole lever down as far as it will go.

42

Page 44

Mark the buttonhole area on the fabric. Place both

threads to the left under the foot. Insert the

garment under the foot and hand turn the flywheel to

lower the needle at the starting point. Lower the

buttonhole foot.

q

qwe

w

Memory Auto Thread Cut Key

It is possible to program the machine to

automatically cut the threads when a buttonhole is

completed. To program - press the “Memory Auto

Thread Cut” key q after selecting the buttonhole

and before sewing begins; the LED light w will turn

on.

Begin sewing. If the buttonhole lever is not lowered,

the machine will stop and show a warning in the

LCD screen. Pull down the buttonhole lever and

sew.

While sewing a buttonhole, the LCD screen shows

which portion is currently being sewn.

0 Classic Buttonhole (Sensor)

The buttonhole will automatically sew:

q the front bartack, zigzag backwards on left side

and straight stitch forward on right side to front

bartack

w zigzag backwards on right side

e back bartack and stop

Variation – Reinforced Buttonhole

Suitable for heavyweight fabric. When Classic

Buttonhole sewing is complete, do not lift up

presser foot. Simply begin sewing again and sew

over first buttonhole.

43

Page 45

qwe

qwe

Press “MODE” key to access 3 Digit Mode for

Buttonholes 072 – 076.

072 Classic Keyhole Buttonhole

The buttonhole will automatically sew:

q the front left half of keyhole, zigzag backwards

on left side and straight stitch on right side to

front

w front right half of keyhole and zigzag backwards

on right side

e back bartack and stop

073 Rounded Buttonhole

The buttonhole will automatically sew:

q the front left half, zigzag backwards on left side

and straight stitch on right side to front

w front right half and zigzag backward on right

side

e back rounded end and stop

qw e

qw e

074 Stretch Buttonhole

The buttonhole will automatically sew:

q straight stitch on left side backwards and cross

stitch forward on left side

w front bartack

e straight stitch on right side backwards, back

bartack, cross stitch forward on right side and

stop

075 Knit Buttonhole

The buttonhole will automatically sew:

q front bartack and triple zigzag backwards on left

side

w back bartack

e triple zigzag forward on right side and stop.

After the buttonhole is completed and the machine

stops sewing, raise the presser foot.

Sewing Additional Buttonholes

To sew another buttonhole - raise foot, move fabric,

lower foot and sew.

When buttonhole sewing is finished, push the

buttonhole lever upward as far as it will go.

44

Page 46

q

w

e

t

Cutting Open Buttonhole

Place a pin just inside the bartack at each end to

prevent accidentally cutting bartacks. Cut

buttonhole open with the seam ripper.

Troubleshooting Tips

If the button is extremely thick and difficult to fit

through the test buttonhole, you can lengthen

the buttonhole by pulling the buttonholder on the

foot back a little extra. The length of the hole will

increase by that same amount.

Make sure there is not a gap between the slider

and the spring holder. If there is a gap, the sides

of the buttonhole will be different lengths t.

q Buttonholder

w Slider

e There should be no gap

r Spring holder

t Incorrect buttonhole

r

qw er

• How to Alter Buttonhole Stitch Width and

Length

Press the “–” or “+” side of the keys to alter the

buttonhole for different weights of fabric and thread.

q Narrower width

w Wider width

e Shorter stitch

r Longer stitch

• Alter Keyhole Buttonhole Stitch Length

According to Fabric and Thread

qw e

q 0.3 - Lightweight fabric

(for lawn and batiste)

w 0.4 - Mediumweight fabric

(for gabardine, linen and wool)

e 0.8 - Heavyweight fabric

(for coating and polar fleece)

45

Page 47

w

q

q

e

Corded Buttonhole

Corded buttonholes are found on coats and other

garments that require extra strong buttonholes. The

cording reinforces and accentuates the buttonhole.

Sew a corded buttonhole using the same

procedure as described for a classic buttonhole.

• Set the stitch width to match the thickness of the

cording.

q

With the buttonhole foot raised, hook the filler

cord q on the spur w at the back of the

buttonhole foot. Bring the ends forward under the

buttonhole foot.

Position the cord into the forks e on the front of

the foot to hold the ends tight.

q

q

Hand turn the flywheel to lower the needle into the

garment where the buttonhole will start and lower

the presser foot.

Press the foot control and slowly sew the

buttonhole. Each side of the buttonhole and the

bartacks will be sewn over the cord q. Remove the

fabric from the machine and cut only the sewing

threads.

Pull the left end of the cord q to tighten it. Thread

the end through a darning needle, draw to the wrong

side of the fabric and cut.

Cut open buttonhole.

46

Page 48

071 Classic Buttonhole (4 Step Memory)

The classic buttonhole is especially suited for

oversized novelty buttons or larger decorative

openings for weaving curtain rods and scarves, for

example. All buttonholes should use interfacing

suitable for the fabric weight.

Test sew the buttonhole on sample swatch.

Select 071. The LCD will briefly show two

messages.

Use either the R or B buttonhole foot. If you use the

R foot, fully extend open the buttonholder q

(maximum buttonhole size with this foot is 3.2 cm

or 1 1/4˝).

q

DO NOT pull down the buttonhole lever.

Alter the buttonhole width to match the fabric and

thread. See page 45.

Mark the buttonhole area on the fabric. Place both

threads to the left under the foot. Insert the

garment under the foot and hand turn the flywheel to

lower the needle at the starting point. Lower the

buttonhole foot.

Start sewing - zigzag backwards on left side. Stop

sewing when you reach the desired buttonhole

length.

Press “Reverse” key.

Start sewing - back bartack and zigzag forward on

right side. Stop sewing when you are opposite the

starting point.

Press “Reverse” key.

47

Page 49

Start sewing – front bartack, lockstitch. Machine

will automatically stop when buttonhole is

completed.

Sewing Additional Buttonholes