Page 1

Doc. N. 595R36300 Edition 1.0.6 – 02/2020

SERVICE MANUAL

BLAST CHILLER FREEZER RANGE 30 50 70 2020

Page 2

SERVICE MANUAL Blast Chiller Freezer SKCH 30 50 70

Document made by Product Care – Technical Training & Service – Vallenoncello PN/Italy

All the images and information of this document are property of ©Electrolux Professional Spa. This document and

all of its contents cannot be copied or used, in part or entirely without the written authorization of Electrolux Professional Spa.

©Electrolux Professional Spa.

DOC NUMBER 595R36300 2

Page 3

SERVICE MANUAL Blast Chiller Freezer SKCH 30 50 70

EDITION

DESCRIPTION

DATE

1.0.0

First publication

FEBRUARY. 2019

1.0.1

Modification pag 3.12.13.14

JUNE 2019

1.0.2

Modification pag 12.26.35.40.63.65.71.101.121

JULY 2019

1.0.3

Modification pag 17.38.63.109.110.111.132.133.134

JULY 2019

1.0.4

Modification pag 4.19.22.23.68.81

SEPTEMBER 2019

1.0.5

Modification pag 1.54

OCTOBER 2019

1.0.6

Modification pag 1.67 to 74.160

FEBBRARY 2020

REVISIONS UPDATE:

Foreward

The service manual (here in after Manual) provides the engineer with information necessary for correct and

safe use of the machine (or “appliance“).

The following must not be considered a long and exacting list of warnings, but rather a set of instructions suitable for improving machine performance in every respect and, above all, preventing injury to persons and animals and damage to property due to improper operating procedures.

All persons involved in machine transport, installation, commissioning, use and maintenance, repair and disassembly must consult and carefully read this manual before carrying out the various operations, in order to

avoid wrong and improper actions that could compromise the machine's integrity or endanger people.

If, after reading this manual, there are still doubts regarding machine use, do not hesitate to contact the Manufacturer or the Customer Care to receive prompt and precise assistance for better operation and maximum

efficiency of the machine. During all stages of machine assessment, always respect the current regulations on

safety, work hygiene and environmental protection. It is the user's responsibility to make sure the machine is

started and operated only in optimum conditions of safety for people, animals and property.

IMPORTANT

• The manufacturer declines any liability for operations carried out on the appliance without respecting

the instructions given in this manual.

• The manufacturer reserves the right to modify the appliances presented in this publication without no-

tice.

• No part of this manual may be reproduced without the consent of the manufacturer.

• This manual is available in digital format by:

o contacting the dealer or reference customer care;

o downloading the latest and up to date manual/technical bulletin(s) on the web site;:

trolux.com/professional.

The manual must always be part of the documentation available when servicing the machine.

www.elec-

DOC NUMBER 595R36300 3

Page 4

SERVICE MANUAL Blast Chiller Freezer SKCH 30 50 70

6 GN 1/1

10 GN 1/1

10 GN 2/1

6 GN 1/1

10 GN 1/1

10 GN 2/1

Change

Change

6 GN 1/1

10 GN 1/1

10 GN 2/1

6 GN 1/1

10 GN 1/1

10 GN 2/1

208V 3~

208V 3~

208V 3~

208V 3~

208V 3~

MODELS COVERED BY THE SERVICE MANUAL

This manual is relative to the following list of appliances.

MODEL TYPE

30 KG

BUILT IN

50 KG

BUILT IN

70 KG

BUILT IN

30 KG

REMOTE

50 KG

REMOTE

70 KG

REMOTE

DESCRIPTION

VOLTAGE

GAS REF.

CLIMATC

CLASS

AMPERE

REFR.

QUANTITY g.

IP

PROTECTION

PASTRY

60X40

380/415V

3~ 50HZ

R452

R404a

PASTRY

60X40

380/415V

3~ 50HZ

R452

R404a

PASTRY

60X40

380/415V

3~ 50HZ

R452

R404a

PASTRY

60X40

380/415V

3~ 50HZ

Change

term.valve

PASTRY

60X40

380/415V

3~ 50HZ

term.valve

5 5 5 5 5 5

6.3 8.4 11.5 4.4 8.6 8.6

1150 2000 3000 / / /

X4 X4 X4 X4 X4 X4

PASTRY

60X40

380/415V

3~ 50HZ

term.valve

MODEL TYPE

USA

30 KG

BUILT IN

50 KG

BUILT IN

70 KG

BUILT IN

30 KG

REMOTE

50 KG

REMOTE

70 KG

REMOTE

DESCRIPTION

PASTRY

60X40

VOLTAGE

GAS REF.

CLIMATC

CLASS

AMPERE

KW

REFR.

QUANTITY g.

IP

PROTECTION

208V 3~

60HZ

R448A R448A R448A R448A R448A R448A

MCA 15

MOP 35

2.7 4.5 5.5

1150 2000 3000 / / /

X4 X4 X4 X4 X4 X4

PASTRY

60X40

60HZ

PASTRY

60X40

60HZ

PASTRY

60X40

60HZ

PASTRY

60X40

60HZ

PASTRY

60X40

60HZ

5 5 5 5 5 5

MCA 24

MOP 60

MCA 31

MOP 80

/ / /

DOC NUMBER 595R36300 4

Page 5

SERVICE MANUAL Blast Chiller Freezer SKCH 30 50 70

INDEX

1. GENERAL INFORMATION ...........................................................................................10

1.1 GENERAL INFORMATION .................................................................................................................... 10

1.2 SAFETY INFORMATION/PRECAUTIONS ............................................................................................ 11

1.3 PERSONAL PROTECTION EQUIPMENT ............................................................................................ 12

1.4 GENERAL SAFETY INFORMATION ..................................................................................................... 13

1.4.1 Residual Risks ................................................................................................................................. 13

1.5 SAFETY SIGNS TO BE PLACED NEAR THE M ACHINE AREA ........................................................ 15

1.6 DATA PLATE (IDENTIFICATION STICKER) / QR-Code sticker ........................................................... 16

1.6.1 Serial Number (Production Date) .................................................................................................... 17

1.7 TECHNICAL DATA AND DRAWINGS WITH MEASUREMENTS ......................................................... 18

1.8 GENERAL REFERENCE TO APPLICABLE PRODUCT CERTIFICATIONS ....................................... 19

1.9 EQUIPMENT MODULES AND INTERACTIONS .................................................................................. 19

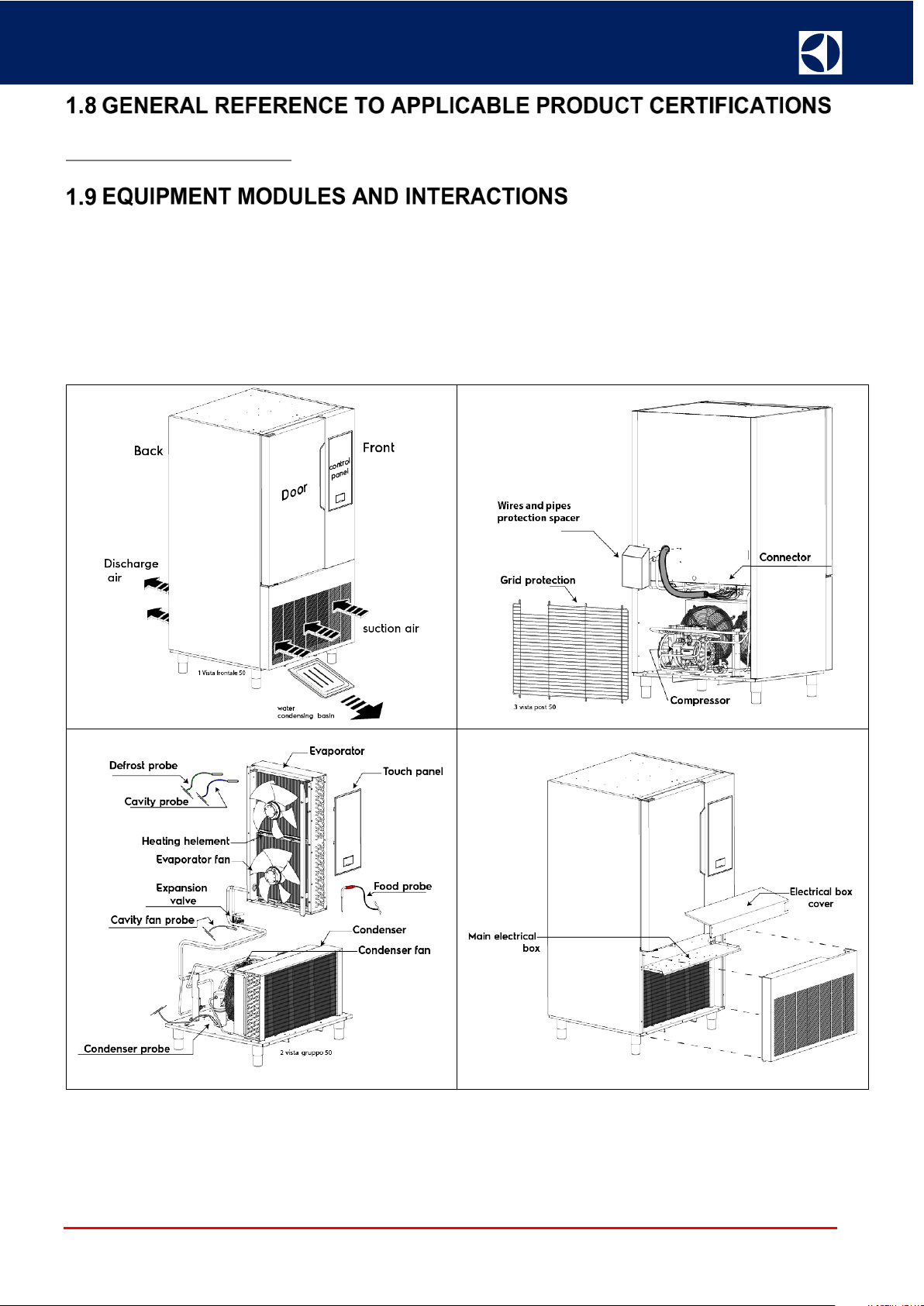

1.9.1 Blast chiller /freezer 50 kg 10 gn 1/1 and 70 kg 10 gn 2/1 ............................................................. 19

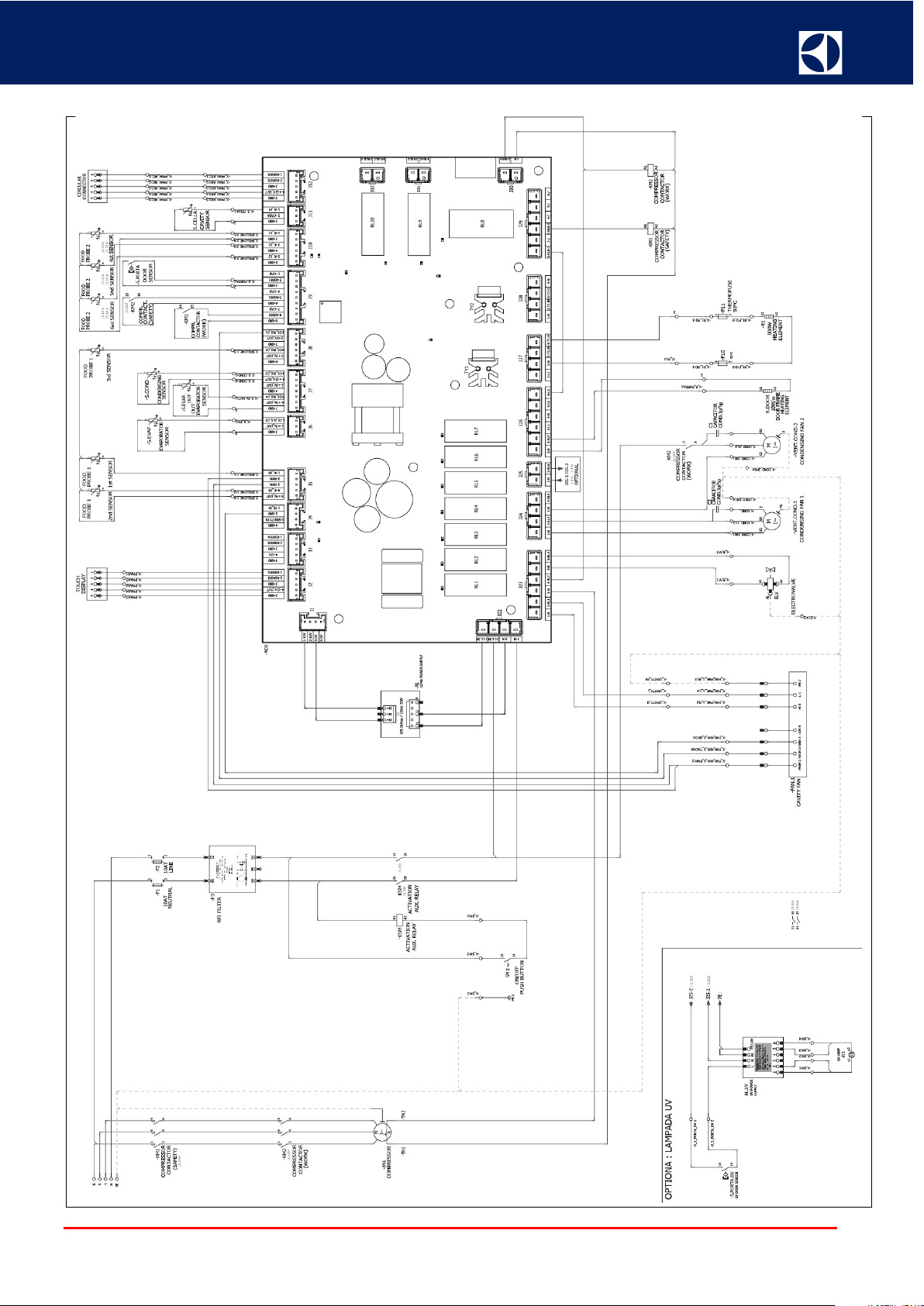

1.9.2 Electrical schema interactions 50_70 kg Europa ........................................................................... 20

1.9.3 Electrical schema interactions 50_70 kg USA ................................................................................. 21

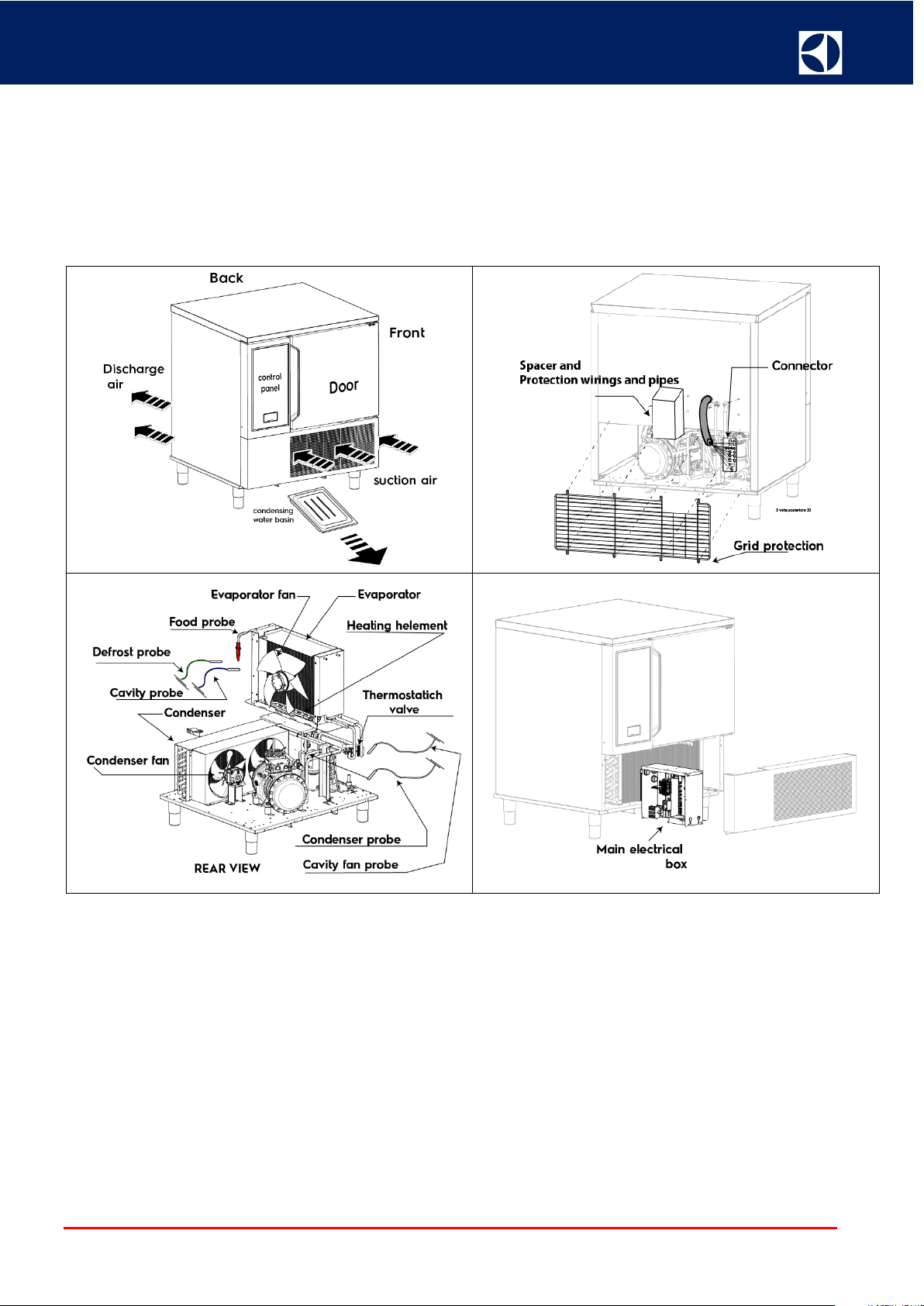

1.9.4 Blast chiller /freezer 30kg 6 gn 1/1 .................................................................................................. 22

1.9.5 Electrical schema interactions 30 kg Europa .................................................................................. 23

1.9.6 Electrical schema interactions 30 kg USA ....................................................................................... 24

1.10 DEFINITIONS/GLOSSARY.................................................................................................................. 25

2. INSTALLATION AND COMMISSIONING .....................................................................26

2.1 INSTALLATION ...................................................................................................................................... 26

2.2 PRE-CONNECTION PREPARATIONS ................................................................................................. 26

2.3 LIST OF POSSIBLE INSTALLATION SOLUTIONS .............................................................................. 27

2.4 ROOM REQUIREMENTS ...................................................................................................................... 27

2.5 REFRIGERATION POWER OF REMOTE UNIT ................................................................................... 27

2.5.1 Refrigeration power table ................................................................................................................ 27

2.6 CONNECTION REMOTE UNIT ............................................................................................................. 28

2.6.1 Technical Instructions / Installation Precautions ............................................................................. 28

2.6.2 General Information ......................................................................................................................... 28

2.6.3 Basic Installation – Overview ........................................................................................................... 28

2.6.4 Installation Steps ............................................................................................................................. 29

2.6.5 System Evacuation .......................................................................................................................... 30

2.6.6 Procedures for Refrigerant Charge ................................................................................................. 30

2.6.7 Piping ............................................................................................................................................... 31

2.6.8 Basic Accessories of a Cooling System .......................................................................................... 32

DOC NUMBER 595R36300 5

Page 6

SERVICE MANUAL Blast Chiller Freezer SKCH 30 50 70

2.6.9 Expansion Valve .............................................................................................................................. 34

2.6.10 Setting the Expansion valve .......................................................................................................... 34

2.6.11 Correct position of the thermostatic sensor ................................................................................... 34

2.6.12 Identification of the thermostatic valve .......................................................................................... 35

2.6.13 Charge MOP .................................................................................................................................. 36

2.6.14 Quantity of refrigerant to charge .................................................................................................... 36

2.6.15 Electrical connection ...................................................................................................................... 37

2.6.15.1 Electrical box drawing on remote unit ................................................................................ 37

2.6.15.2 Electrical box in the BCF: IE. Of clamp connections ...................................................... 38

2.7 UNPACKING AND POSITIONING THE EQUIPMENT .......................................................................... 39

2.8 COMMISSIONING ................................................................................................................................. 40

2.8.1 Power connection on bcf 380/400V ................................................................................................. 40

2.8.2 Power connection on bcf 208V (USA) ............................................................................................. 40

2.8.3 Description Main Display ................................................................................................................. 41

2.8.3.1 Icon description, Message of Dialogues .............................................................................. 42

2.8.4 Softwar update ................................................................................................................................ 44

2.8.5 Programming file ............................................................................................................................. 45

2.8.5.1 How to update: ..................................................................................................................... 45

2.8.6 Programming parameters ................................................................................................................ 46

2.8.6.1 How to update: ..................................................................................................................... 46

2.8.7 Pnc & ser upload (pncserial.json) .................................................................................................... 47

2.8.7.1 How to update pnc & ser (pncserial.json): ........................................................................... 47

2.8.7.2 How to install update pnc & ser (pncserial.json): ................................................................. 50

2.8.8 Usb data transfer ............................................................................................................................. 52

2.8.8.1 Users management lite ........................................................................................................ 52

2.8.8.2 What follows is a diagram to show menu navigation ........................................................... 52

2.8.8.3 Select types .......................................................................................................................... 53

2.8.8.4 Select type ............................................................................................................................ 53

2.8.8.5 Select file .............................................................................................................................. 54

2.8.8.6 Select file or add new file ..................................................................................................... 54

2.8.8.7 Enter file name ..................................................................................................................... 55

2.8.8.8 Select Items .......................................................................................................................... 55

2.8.8.9 Confirm ................................................................................................................................. 56

2.8.8.10 Replace or add items ......................................................................................................... 56

2.8.8.11 Skip, Duplicate, Add ........................................................................................................... 57

2.8.8.12 Enter item name ................................................................................................................. 57

2.8.8.13 Types list for service:.......................................................................................................... 58

2.8.8.14 File names .......................................................................................................................... 58

2.8.8.15 Item names ......................................................................................................................... 58

2.8.8.16 Errors and Warnings: ......................................................................................................... 58

2.8.9 How to acess to service area .......................................................................................................... 60

2.8.9.1 How to show the “data monitor” ........................................................................................... 61

2.8.9.2 How to exit from “data monitor” and “bypass” ..................................................................... 61

2.8.9.3 How to enter in “bypass” ...................................................................................................... 61

2.8.9.4 How to upload the pnc and serial number............................................................................ 61

2.8.9.5 How to upload the parameter and interogation .................................................................... 61

DOC NUMBER 595R36300 6

Page 7

SERVICE MANUAL Blast Chiller Freezer SKCH 30 50 70

2.8.9.6 Service ambiente explanation .............................................................................................. 62

2.9 WIZARD ................................................................................................................................................. 69

2.9.1 Installation wizard check .................................................................................................................. 69

2.9.2 Manual Test Wizard ......................................................................................................................... 77

2.9.2.1 Start manual wizard .............................................................................................................. 77

3. USE OF APPLIANCE ....................................................................................................80

3.1 OPERATING INSTRUCTIONS .............................................................................................................. 80

3.2 PREVENTIVE MAINTENANCE PLAN (FOR SERVICE): OPERATION FREQUENCY ....................... 80

4. DETAILED APPLIANCE AND COMPONENTS DESCRIPTION/FUNCTIONING ......81

4.1 MAIN BOARD “PETRA” ......................................................................................................................... 81

4.1.1 Functionality..................................................................................................................................... 81

4.2 USER INTERFACE “TOUCH”................................................................................................................ 82

4.2.1 Functionality touch panel ............................................................................................................. 82

4.2.2 PMH power supply 100-240 Vac to 12V dc ..................................................................................... 83

4.3 SEMI-ERMETIC COMPRESSOR .......................................................................................................... 84

4.3.1 Over view ......................................................................................................................................... 84

4.3.2 Expected use of the unit .................................................................................................................. 84

4.3.3 What follows is forbidden: ................................................................................................................ 84

4.3.4 Compressor identification ................................................................................................................ 84

4.3.5 Airing of the installation room .......................................................................................................... 84

4.3.6 Pipes Connections ........................................................................................................................... 85

4.3.7 Table of pipe connection of Dorin compressor ................................................................................ 86

4.3.8 Electrical connections ...................................................................................................................... 86

4.3.9 Protection System ........................................................................................................................... 87

4.3.10 Commissioning: Preliminary Works ............................................................................................... 87

4.3.11 Compressors Replacement ........................................................................................................... 88

4.3.12 Compressor Disassembly .............................................................................................................. 88

4.3.13 Number of starts ............................................................................................................................ 88

4.3.14 Rotalock Valves ............................................................................................................................. 89

4.3.15 Crankcase heater installations ...................................................................................................... 90

4.3.16 Electrical Connection Of The Compressor On The Unit ............................................................... 91

4.3.17 Evaporator Fan .............................................................................................................................. 92

4.3.17.1 Functionality fan ................................................................................................................. 92

4.3.17.2 Electrical Connections Fan ................................................................................................ 93

4.3.18 Probe’s ........................................................................................................................................... 94

4.3.18.1 Probe’s feature ................................................................................................................... 94

4.3.18.2 Electrical Connections Probes ........................................................................................... 94

4.3.18.3 Probe functions .................................................................................................................. 95

4.3.19 Food Probe .................................................................................................................................... 95

4.3.19.1 Functionality ....................................................................................................................... 95

DOC NUMBER 595R36300 7

Page 8

SERVICE MANUAL Blast Chiller Freezer SKCH 30 50 70

4.3.19.2 Electrical Connections Food Probes .................................................................................. 98

4.3.20 Heater Evaporator ......................................................................................................................... 99

4.3.20.1 Functionality ....................................................................................................................... 99

4.3.20.2 Electrical Connections Evaporator Heater ......................................................................... 99

4.3.21 Test Digital I/O: Step By Step Digital Operable Components Testing ........................................ 100

4.3.22 Identify rapid“test cycles and components” ................................................................................. 100

5. TROUBLESHOOTING .................................................................................................102

5.1 TECHNICIAN TROUBLESHOOTING .................................................................................................. 102

6. SERVICING THE APPLIANCE ...................................................................................108

6.1 LIST OF NEEDED TOOLS .................................................................................................................. 108

6.1.1 Ordinary Tools ............................................................................................................................... 108

6.1.2 Special Tools: List, Description And Spare Part Code Per Each Special Tool ............................. 108

6.2 IMPORTANT PROCEDURES FOR INSTALLATION .......................................................................... 109

6.2.1 Storage of components ................................................................................................................. 109

6.2.2 Cleaning the pipes ......................................................................................................................... 109

6.2.3 Installation of refrigeration system components ............................................................................ 109

6.3 REPLACING EQUIPMENT COMPONENTS ....................................................................................... 110

6.3.1 Disassembly/Reassemble Of Components Range 50_70 Kg ....................................................... 110

6.3.1.1 Accessing the components on the back side of the appliance .......................................... 110

6.3.1.2 Rack supports .................................................................................................................... 110

6.3.1.3 Cell probe (blue) ................................................................................................................. 111

6.3.1.4 Evaporator probe (grey) ..................................................................................................... 112

6.3.1.5 Food probe ......................................................................................................................... 114

6.3.1.6 Condenser probe (black) .................................................................................................... 115

6.3.1.7 Outevaporator probe (green) ............................................................................................. 115

6.3.1.8 Thermostat ......................................................................................................................... 116

6.3.1.9 Evaporator fan .................................................................................................................... 116

6.3.1.10 Heating element ............................................................................................................... 118

6.3.1.11 Comand Panel .................................................................................................................. 118

6.3.1.12 Control Panel .................................................................................................................... 119

6.3.1.13 Frame heating element cable ........................................................................................... 119

6.3.1.14 Evaporator ........................................................................................................................ 120

6.3.1.15 Electrical box .................................................................................................................... 122

6.3.1.16 Compressor ...................................................................................................................... 123

6.3.1.17 Solenoid valve .................................................................................................................. 124

6.3.1.18 Finned Coil Condenser .................................................................................................... 125

6.3.1.19 Condenser fan .................................................................................................................. 127

6.3.1.20 Tanic receiver ................................................................................................................... 127

6.3.1.21 Dehidrator Filter ................................................................................................................ 127

6.3.1.22 Door .................................................................................................................................. 128

6.3.1.23 Door gasket ...................................................................................................................... 128

6.3.1.24 Door switch ....................................................................................................................... 128

6.3.1.25 Thermostatich valve ......................................................................................................... 129

Access display and replacement of mambrane sticker .................................................... 130

6.3.2 Disassembly/Reassemble Of Components Range 30 Kg ............................................................. 133

6.3.2.1 Accessing the components on the back side of the appliance .......................................... 133

DOC NUMBER 595R36300 8

Page 9

SERVICE MANUAL Blast Chiller Freezer SKCH 30 50 70

6.3.2.2 Rack supports .................................................................................................................... 134

6.3.2.3 Cell probe (blue) ................................................................................................................. 135

6.3.2.4 Evaporator probe (grey) ..................................................................................................... 136

6.3.2.5 Food probe ......................................................................................................................... 137

6.3.2.6 Condenser probe (black) .................................................................................................... 138

6.3.2.7 Out evaporator probe (green) ............................................................................................ 138

6.3.2.8 Thermostat ......................................................................................................................... 139

6.3.2.9 Evaporator fan .................................................................................................................... 139

6.3.2.10 Heating element ............................................................................................................... 141

6.3.2.11 Command Panel ............................................................................................................... 141

6.3.2.12 Control Panel .................................................................................................................... 142

6.3.2.13 Frame heating element cable ........................................................................................... 142

6.3.2.14 Evaporator ........................................................................................................................ 143

6.3.2.15 Electrical box .................................................................................................................... 145

6.3.2.16 Compressor ...................................................................................................................... 146

6.3.2.17 Solenoid valve .................................................................................................................. 147

6.3.2.18 Finned Coil Condenser .................................................................................................... 148

6.3.2.19 Condenser fan .................................................................................................................. 150

6.3.2.20 Tanic receiver ................................................................................................................... 150

6.3.2.21 Dehydrator Filter ............................................................................................................... 150

6.3.2.22 Door .................................................................................................................................. 151

6.3.2.23 Door gasket ...................................................................................................................... 151

6.3.2.24 Door switch ....................................................................................................................... 151

6.3.2.25 Thermostatich valve ......................................................................................................... 152

Access display and replacement of mambrane sticker .................................................... 153

6.3.3 Preventive Maintenance Plan ........................................................................................................ 156

6.3.3.1 Refert to document “Check list preventive maintenance ................................................... 156

7. RELATED DOCUMENTS ............................................................................................156

7.1 EXPLODED VIEW ............................................................................................................................... 156

7.1.1 List Of The Vital and Wear&Tear Parts ......................................................................................... 156

7.1.2 List Of Available Accessories ........................................................................................................ 156

7.1.3 List Of Consumables ..................................................................................................................... 156

7.1.4 List Of Spares Wear And Tear ...................................................................................................... 156

7.2 ELECTRICAL WIRING DIAGRAM ....................................................................................................... 156

7.3 PARAMETERS LIST: ........................................................................................................................... 157

DOC NUMBER 595R36300 9

Page 10

SERVICE MANUAL Blast Chiller Freezer SKCH 30 50 70

1. GENERAL INFORMATION

To ensure safe use of the machine and a proper understanding of the manual it is necessary to be familiar

with the terms and typographical conventions used in the documentation. The following symbols are used in

the manual to indicate and identify the various types of hazards:

WARNING

Danger for the health and safety of operators.

WARNING

Danger of electrocution - dangerous voltage.

CAUTION

Risk of damage to the machine or the product.

WARNING

Danger of magnetic fields.

IMPORTANT

Important instructions or information on the product

Read the instructions before using the appliance

Clarifications and explanations

• Only specialised personnel are authorised to operate on the machine.

• This appliance must not be used by minors and adults with limited physical, sensory or mental

abilities or without adequate experience and knowledge regarding its use.

– Do not let children play with the

– Keep all packaging and detergents away from children.

– Cleaning and user maintenance shall not be made by children without supervision.

• Do not store explosive substances, such as pressurized containers with flammable propellant, in

this appliance or close to the appliance

• Do not remove, tamper with or make the machine “CE“ marking illegible.

• Refer to the data given on the machine’s data plate “CE“ marking for relations with the Manufacturer

(e.g. when ordering spare parts, etc.).

• When scrapping the machine, the “CE“ marking must be destroyed.

appliance.

DOC NUMBER 595R36300 10

Page 11

SERVICE MANUAL Blast Chiller Freezer SKCH 30 50 70

• Risks mainly of a mechanical, thermal and electrical nature exist in the machine. Where possible the risks

have been neutralised:

– directly, by means of adequate design solutions.

– indirectly by using guards, protection and safety devices.

• During maintenance several risks remain, as these could not be eliminated, and must be

neutralised by adopting specific measures and precautions.

• Do not carry out any checking, cleaning, repair or maintenance operations on moving

parts. Workers must be informed of this prohibition by means of clearly visible signs.

• To guarantee machine efficiency and correct operation, periodical maintenance must be carried out

according to the instructions given in this manual.

• Make sure to periodically check correct operation of all the safety devices and the insulation of

electrical cables, which must be replaced if damaged.

• Extraordinary machine maintenance operations must only be carried out by specialized Technicians

provided with all the appropriate personal protection equipment (safety shoes, gloves, glasses, overalls, etc.), tools, utensils and ancillary means.

• Never operate the machine, removing, modifying or tampering with the guards, protection or safety devices.

• Before carrying out any operation on the machine, always consult the manual which gives the correct

procedures and contains important information on safety.

DOC NUMBER 595R36300 11

Page 12

SERVICE MANUAL Blast Chiller Freezer SKCH 30 50 70

—

●

○

—

○

—

●

○

— —

—

●

●

— —

Installation

●

●2

●

Normal use

●

●

●

1

○

—

—

○ ●

●

1 or 2

○

—

cleaning

○ ●

●

○

—

Maintenance

○ ●

○ ○

—

○ ●

○ ○

—

● ● ●

—

●

PPE REQUIRED

○

PPE AVAILABLE OR TO BE USED IF NECESSARY

—

PPE NOT REQUIRED

Summary table of the Personal Protection Equipment (PPE) to be used during the various stages of the machine's service life.X

Stage

Transport

Handling

Unpacking

Adjustments

Routine cleaning

Extraordinary

Dismantling

Scrapping

Protective

garments

—

○

●

Safety

footwear

●

Gloves Glasses

○

○

1 or 2

Safety

helmet

—

Key:

1.

2.

During these operations, the worn gloves must be heatproof to protect hands from contact with hot

food or hot parts of the appliance and/or when removing hot items from

protection equipment by operators, specialized personnel or users can involve exposure to chemical

risk and possible damage

During these operations, the worn gloves must be cut-resistant.

tion equipment by operators, specialized personnel or users can involve exposure to damage

health (depending on the

to

health (depending on the

model).

model).

Failure to use the personal

it.

Failure to use the personal protec-

to

DOC NUMBER 595R36300 12

Page 13

SERVICE MANUAL Blast Chiller Freezer SKCH 30 50 70

Contact with live parts during maintenance operations carried out with

the electrical panel powered

The machines are provided with electric and/or mechanical safety devices for protecting workers and the machine

itself. Therefore, the user must not remove or tamper with such devices. The Manufacturer declines any liability

for damage due to tampering or their non-use.

Never operate the machine, removing, modifying or tampering with the guards, protection or safety devices.

Do not make any modifications to the parts supplied with the appliance.

Several illustrations in the manual show the machine, or parts of it, without guards or with guards removed. This

is purely for explanatory purposes.

Do not use the machine without the guards or with the protection devices deactivated.

Do not remove, tamper with or make illegible the safety, danger and instruction signs and labels on the machine.

Air recirculation must take into account the air necessary for combustion, 2 m³/h/kW of gas power, and also the

"well-being" of persons working in the kitchen.

Inadequate ventilation causes asphyxia.

Do not obstruct the ventilation system in the place where this appliance is installed.

Do not obstruct the vents or ducts of this or other appliances.

Place emergency telephone numbers in a visible position.

The measured sound level emitted “A“ does not exceed 70 dB (“A“).

Turn the appliance off in case of fault or poor operation.

Do not use products (even if diluted) containing chlorine (sodium hypochlorite, hydrochloric or muriatic acid, etc.)

to clean the appliance or the floor under it.

Do not use metal tools to clean steel parts (wire brushes or Scotch Brite type scouring pads).

Do not allow oil or grease to come into contact with plastic parts.

Do not allow dirt, fat, food or other residuals to form deposits on the appliance.

Do not spray water or use steam to clean the equipment.

Do not store or use gasoline or other flammable vapours, liquids or items near this or any other appliance.

Do not spray aerosols near this appliance while it is in operation.

Never check for leaks with an open flame.

1.4.1 Residual Risks

The machine has several risks that were not completely eliminated from a design standpoint or with the installation of adequate protection devices. Nevertheless, through this manual the Manufacturer has taken steps to

inform operators of such risks, carefully indicating the personal protection equipment to be used by them. Sufficient spaces are provided for during the machine installation stages in order to limit these risks.

To preserve these conditions, the areas around the machine must always be:

Kept free of obstacles (e.g. ladders, tools, containers, boxes, etc.);

Clean and dry;

Well lit.

For the Customer's complete information, the residual risks remaining on the machine are indicated below: such

actions are deemed improper and therefore strictly forbidden.

Residual risk Descripti on of hazardous situa tion

Slipping or falling The operator can slip due to water or dirt on the floor

Burns/abrasions (e.g. heating elements)

Electrocution

Tipping of loads

Mechanical safety characteristics, hazards

DOC NUMBER 595R36300 13

The operator deliberately or unintentionally touches some components

inside the machine without using protective gloves

When handling the machine or the packing containing it, using unsuitable lifting systems or accessories or with the unbalanced load

Page 14

SERVICE MANUAL Blast Chiller Freezer SKCH 30 50 70

Mechanical safety characteristics, hazards

The appliance does not have sharp edges or protruding parts. The guards for the moving and live parts are fixed

to the cabinet with screws, to prevent accidental access.

Protection devices installed on the machine

The guards on the machine are:

(e.

fixed guards

release connectors that can only be removed or opened with tools.

g. casings, covers, side panels, etc.), fixed to the machine and/or frame with screws or quick-

DOC NUMBER 595R36300 14

Page 15

SERVICE MANUAL Blast Chiller Freezer SKCH 30 50 70

Prohibition Meaning

Do not remove the safety devices

Do not use water to extinguish fires (placed on electrical parts)

Danger Meaning

Danger of burns

Keep the area around the appliance clear and free from combustible materials. Do not keep flammable materials in the vicinity of

the appliance

Install the appliance in a well-ventilated place to avoid the creation

of dangerous mixtures of unburnt gases in the same room

Danger of electrocution (shown on electrical parts with indication of

voltage)

Risk of electromagnetic fields

Access forbidden to wearers of electrical stimulator (pacemakers)

End of use: When the appliance is no longer to be used, make it unusable by removing the mains power

supply wiring.

DOC NUMBER 595R36300 15

Page 16

SERVICE MANUAL Blast Chiller Freezer SKCH 30 50 70

F.Mod.

Factory model description

Comm.Model

Commercial description

Type Ref.

Refer to model of family (used on spc)

PNC

Production number code

Ser.No

Serial number

V

Power supply voltage / phase

Hz

Power supply frequency

kW

Max. Power input

A

Current absorption

Cyclopentane

Expanding gas used in insulation

IP

Dust and water protection rating

CE

CE marking

L

Logo IMQ/GS

Refrigerant Type

Gas type used

Climatic class

Refer to climatic test

Defrost power

KW

GWP

Global Warning Potential

CO2 eq

Quantity of greenhouse gases

CAP.

Nominal capacity

Electrolux Professional

The main identification sticker is located bottom left side and under condenser panel. QR-Code sticker on control

panel upper side (visible when opening the door) The meaning of the various information is listed below:

The meaning of the various information is listed below.

Legend of data plate

SPAViale Treviso, 15

33170Pordenone (Italy)

DOC NUMBER 595R36300 16

Manufacturer:

Page 17

SERVICE MANUAL Blast Chiller Freezer SKCH 30 50 70

18 YEAR

1.6.1 Serial Number (Production Date)

The serial is necessary to find the correct spare part or to ask tech. support.

EXAMPLE: Serial Number

8 01 1 0001

01 WEEK

0001 APPLIANCE

MANUFACTURED

DOC NUMBER 595R36300 17

Page 18

SERVICE MANUAL Blast Chiller Freezer SKCH 30 50 70

Max High

30KG 6GN

50KG 10GN

70KG 10GN

Models

X Y Z

30KG 6GN

50KG 10GN

70KG 10GN

Please, for technical data and overall drawings refer to Installation Manual available on website www.electro-

lux.com/professional.

Table reference of dimensional units

Models

1/1

1/1

2/1

The minumum entrance dimension, if you dismantle the door,condenser panel,hinge,door microswicth support

top (if necessary) refer to letter Z:

Width

mm

897 937 1130 1050 1484 169_(rem.155)

895 939 1800 1720 1482 240_(rem.220)

1250 1092 1800 1720 1873.3 320_(rem.290)

Deep

mm

1/1

1/1

2/1

(adj.level)

mm

726 551 862

726 551 864

1051 662 1017

Min High

(adj.level)mm

Whit door open Weight KG

DOC NUMBER 595R36300 18

Page 19

SERVICE MANUAL Blast Chiller Freezer SKCH 30 50 70

Please, for overall certifications refer to Conformity Certificate and Conformity Declaration available on website

www.electrolux.com/professional

.

1.9.1 Blast chiller /freezer 50 kg 10 gn 1/1 and 70 kg 10 gn 2/1

DOC NUMBER 595R36300 19

Page 20

SERVICE MANUAL Blast Chiller Freezer SKCH 30 50 70

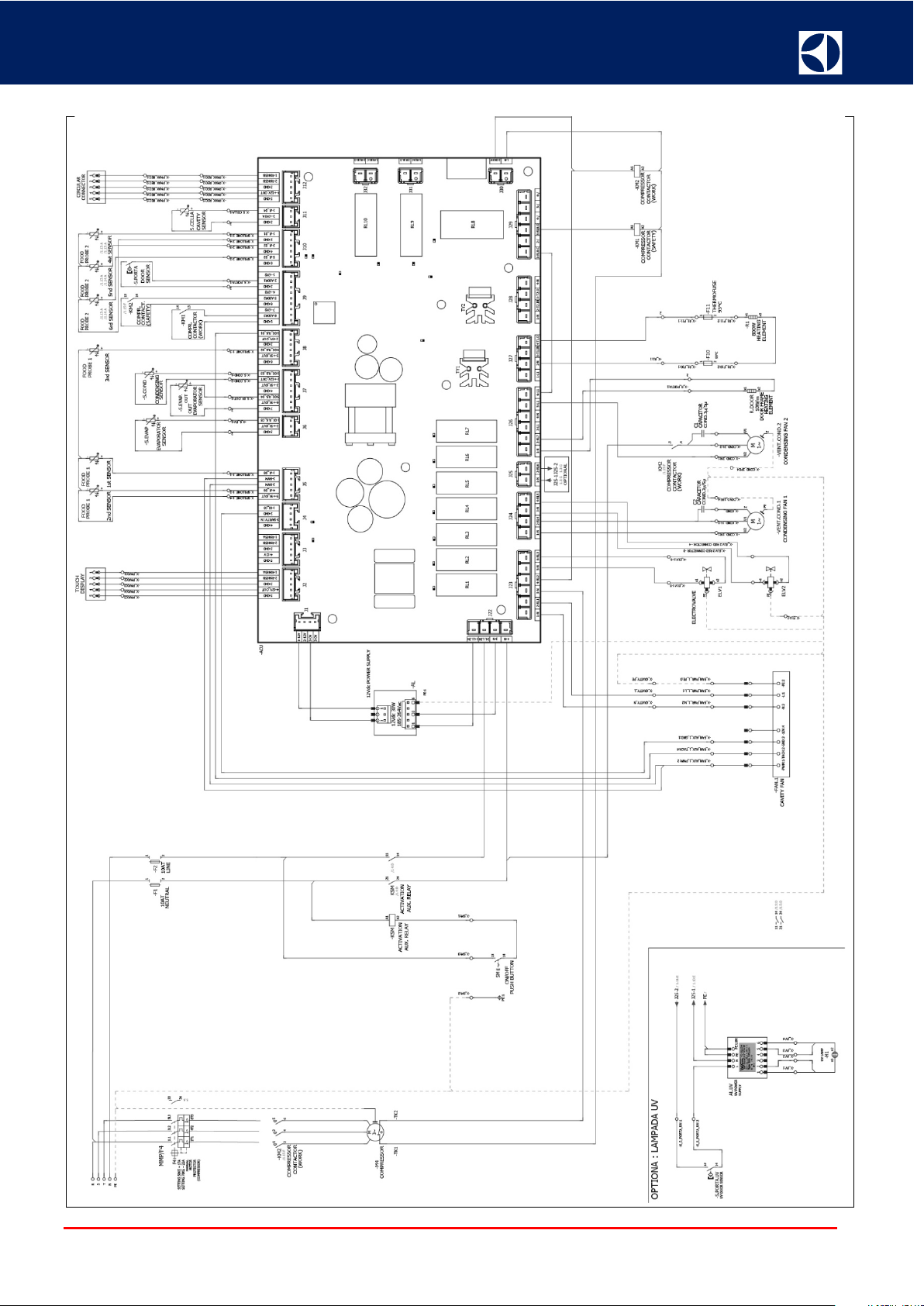

1.9.2 Electrical schema interactions 50_70 kg Europa

DOC NUMBER 595R36300 20

Page 21

SERVICE MANUAL Blast Chiller Freezer SKCH 30 50 70

1.9.3 Electrical schema interactions 50_70 kg USA

DOC NUMBER 595R36300 21

Page 22

SERVICE MANUAL Blast Chiller Freezer SKCH 30 50 70

1.9.4 Blast chiller /freezer 30kg 6 gn 1/1

DOC NUMBER 595R36300 22

Page 23

SERVICE MANUAL Blast Chiller Freezer SKCH 30 50 70

1.9.5 Electrical schema interactions 30 kg Europa

DOC NUMBER 595R36300 23

Page 24

SERVICE MANUAL Blast Chiller Freezer SKCH 30 50 70

1.9.6 Electrical schema interactions 30 kg USA

DOC NUMBER 595R36300 24

Page 25

SERVICE MANUAL Blast Chiller Freezer SKCH 30 50 70

COMPONENTS

DEFINITION

EXPLANATION

Cavity fan probe

Probe

Set the On Off cavity Fans

Cavity probe

Probe

Set the temperature of cavity

Compressor

Pump

Suction and discharge the refrigerant gas

Condenser

Heat exchanger

Reduce the temperature. of refrigerant from high to low)

Condenser fan

Fans

Fan taking the hot temperature off

Condenser probe

Probe

Temperature sensor of the condenser

Connect. term. board

Plate connections

Main SS plate where is connected all device present on cavity

Electrical box

Main electronic com.

Box with all electronic components (boards fuse, etc.)

Evaporator

Heat exchanger

Remove the hot air in the cavity

Evaporator fan

Fans

Fan to uniformity the cavity temperature.

Evaporator probe

Probe

Temperature sensor of the evaporator

Food probe

Probe (multi sensor)

Temperature sensor of food product

HP

Pressure

HP= High pressure side discharge compressor

LP

Pressure

Lp=Lower pressure side suction compressor

Thermostatic valve

Expansion valve

Increase or degrees the injection of refrigerant on evaporator

DOC NUMBER 595R36300 25

Page 26

SERVICE MANUAL Blast Chiller Freezer SKCH 30 50 70

2. INSTALLATION AND COMMISSIONING

Refer to IN (Installation manual) code 595R361””

Refer to the installation drawing for information about supply power connection and general clearances of the

unit sides from walls and ceiling.

IMPORTANT: servicing the unit requires access to the rear side; it is therefore needed to either provide

enough space to move the unit from its working position or installing the unit with space enough all around it.

IMPORTANT for remote connections piping configuration:

servicing the unit requires access to the rear side; it is therefore needed to either provide enough space to

move the unit from its working position or installing the unit with space enough all around it.

Furthermore, it is highly recommended connecting the unit by using hoses in at least three turns, like shown in

the picture below, to allow acceptable movement of the unit without causing damages or fractures (picture reports the scheme of 30kg model).

DOC NUMBER 595R36300 26

Page 27

SERVICE MANUAL Blast Chiller Freezer SKCH 30 50 70

RELATIV HUMID-

CONDENSATION

MASS OF STEAM

3

25°C

60%

16,7°C

12,0 g/kg

4

30°C

55%

20,0°C

14,8 g/kg

5

40°C

40%

23,9°C

18,8 g/kg

7

35°C

75%

30,0°C

27,3 g/kg

-10 -20 -36 -40

881156 H290CS R404A 6570 4520 2050 1590 A IR 40°C 30 meters

881157 H390CS R404A \ 5870 3430 \ AIR 40°C 30 meters

881158 H505CS R404A 11740 8130 3690 2850 A IR 40°C 30 meters

881159 H751CS R404A 15990 11110 6010 \ A IR 40°C 30 meters

881160 H1001CS R404A 22190 14490 7190 5570 A IR 40°C 30 meters

881168 H290CS R404A 6570 4520 2050 1590 WA TER 10° to 30° 30 meters

881170 H390CS R404A \ 5870 3430 \ W A TER 10° to 30° 30 meters

881171 H505CS R404A 11740 8130 3690 2850 WA TER 10° to 30° 30 meters

881172 H751CS R404A 15990 11110 6010 \ WA TER 10° to 30° 30 meters

881173 H505CS R404A 11740 8130 3690 2850 A IR and WATER 40°C 30 meters

881221 H290CS R452A 6310 4350 2030 1590 A IR 40°C 30 meters

881222 H390CS R452A \ 5770 3380 \ A IR 40°C 30 meters

881223 H505CS R452A 11650 8040 3600 2770 A IR 40°C 30 meters

881224 H751CS R452A 15620 10870 5910 \ A IR 40°C 30 meters

881225 H1001CS R452A 21760 15140 7100 5560 A IR 40°C 30 meters

881226 H290CS R452A 6310 4350 2030 1590 WA TER 10° to 30° 30 meters

881227 H390CS R452A \ 5770 3380 \ W A TER 10° to 30° 30 meters

881228 H505CS R452A 11650 8040 3600 2770 WA TER 10° to 30° 30 meters

881229 H751CS R452A 15620 10870 5910 \ WA TER 10° to 30° 30 meters

881230 H505CS R452A 11650 8040 3600 2770 A IR and WATER 40°C 30 meters

EVAP TEM in WATT

PNC REM OT E UNI T

COM PRESSOR

AM B.

TEMP./

Wate r

tem p.

MAX pipe s USED

Type Gas

CONDENSA T IO N

1. Casters: models with built-in cooling unit (no remote configuration).

2. Plinth: guarantee free access to the unit rear side.

3. Marine feet: guarantee free access to the unit rear side.

4. Remote configuration: see IMPORTANT note at 2.7.1.

5. Stack with oven: 30kg model (see the information below).

INFORMATION:

with the stacking kit, optional accessory of the 30kg 6gn1/1BCF (595R441--).

BCF 30kg model can be stacked under Oven. Reference installation instructions available

According to IEC/EN 60335-2-89 and IEC/EN ISO 23953, room requirements depend on the unit climatic class:

see the table below.

For the specific unit climatic class refer to the installation manual and to the unit data plate.

CLIMATIC CLASS

TEMPERATURE

ITY

POINT

PRESENT IN THE AIR

2.5.1 Refrigeration power table

DOC NUMBER 595R36300 27

Page 28

SERVICE MANUAL Blast Chiller Freezer SKCH 30 50 70

2.6.1 Technical Instructions / Installation Precautions

The instructions below are general guidelines, but they do contain the major points that shall be taken into account for proper and safe product installation for assuring best performances and preventing warranty voidance.

Caution: Refrigeration systems are pressurized circuits! It is therefore of the utmost importance that

the condensing units are removed and / or installed only by technically qualified personnel, with

knowledge of the equipment and of the processes to be adopted.

2.6.2 General Information

Inspect the unit for detecting possible damages occurred during the transport: report to the carrier immediately if any damage.

The warranty does not cover damage due to storage, transport or installation of the condensing unit

carried out in the wrong position.

Warning: Make sure you have read and understand all procedures and caution messages before

you execute any maintenance or installation tasks! It is imperative – for your own safety - that the testing

devices used are functioning well and properly sized.

2.6.3 Basic Installation – Overview

The installation site shall be well ventilated, ensuring that there will be sufficient air flow behind the condenser

(refer to Figure 1)

Figure 1 – Natural airflow through the roof

If the flow of air to the condenser is limited (or even partially blocked), system performance and reliability can be

drastically reduced. Condensing units are designed to operate at ambient temperatures up to 43°C (110°F).

Therefore, make sure that the temperature at the installation site does not exceed the recommended limit.

Warning: it is necessary to periodically clean the condenser, so that no particles damage or block

the air circulation.

Warning: pay the utmost attention when working with flammable refrigerants.

DOC NUMBER 595R36300 28

Page 29

SERVICE MANUAL Blast Chiller Freezer SKCH 30 50 70

2.6.4 Installation Steps

INFORMATION:

Select and size the equipment needed to assemble the refrigeration system according to the project specifications

(pipes, valves, accessories, condensing unit). Carefully observe the scope for each model.

IMPORTANT: Size pipe/hose based on the condensing unit dimensions (do not size based on the evapo-

rator).

Phases

1. Weld the pipes to the condensing unit and evaporator connections. Check the seal (leak test) in

all soldered or threaded connections.

2. Obtain the vacuum in the circuit (check with the pressure gauge if the vacuum is stable).

3. Fill the required refrigerant mass (kg): the gas should preferably be charged in the liquid phase.

4. To ascertain the correct behavior of the system, switch ON and monitor:

a. Low/high pressures

b. Liquid/gas lines suction temperatures

5. If detecting low performance or excessive pressures, fine tune the set up by either filling more

refrigerant or discharging it until reaching the correct pressures/temperatures (see below additional general notes for more details).

Refrigerant mass set up:

• Taking into account both the temperature set on the BCF chamber and the temperature where the remote

condenser is installed, when the liquid/gas lines suction temperature gets closer to the design values, proceed

with the final adjustments (phase 5 mentioned above).

• The superheating at the evaporator (given by the difference between temperatures at the piping surface at

the point where the expansion valve's sensor is fixed, and the evaporation temperature

5°C and 10°C (9°F and 18°F). Superheating at the compressor’s inlet must be between 10°C and 15°C

(18°F and 27°F), where in such case it is the difference between the temperature at the surface of the return

pipe, at a distance 150 mm (6") from the compressor, and the evaporation temperature. The sub-cooling in

the condenser shall be between 3°C and 10°C (5°F and 18°F), i.e., the condensing temperature less than

the temperature at the pipe's surface at the condenser's outlet.

(*) Evaporation temperature obtained by converting the suction pressure into temperature.

Cleaning the System (in case condensing unit replacement):

• Cleaning the system before installing a new condensing unit is mandatory to completely remove residues and

other contaminants.

• The manufacturer recommends the installation of a filter-dryer at the suction line during the cleaning operation

to retain and filter any undesired particles

• It is recommended to make the joints by braze-welding

Welding operations:

• While welding keep nitrogen (N2) circulating into the pipes with a pressure between 1 and 2 psig (equivalent

to 1.08 - 1.15 bar): this will prevent oxidations and scale forming, hence ensuring that the piping is free from

any contaminants (oil, grease, oxides).

• Use a damp cloth when welding valves or fittings or pipes to prevent the components overheatingbecause of

the heat propagation.

• The compressor and the filter- dryer are extremely susceptible to humidity. As such, they shall only be opened

during installation or replacement phases. In case of opening, do not leave them exposed to air for more than

10 min.

Leakage test

• During the system leakage tests, never pressurize the pipes using air, oxygen or acetylene. There is a poten-

tial risk of fire and/or explosion.

(*)) shall be between

DOC NUMBER 595R36300 29

Page 30

SERVICE MANUAL Blast Chiller Freezer SKCH 30 50 70

• After the installation is finished, pressurize the system using nitrogen and/or a small refrigerant charge up to

100 psig (equivalent to 7,8 bar); never use pressures higher than 150 psig (equivalent to 11.35 bar) for preventing the low-pressure switch damage.

.

(Figure 2) Leakage tests with soapy water bubbles

• Check for leaks using an electronic detector or a halide detector (torch). An alternative method is to check

leakage with soapy water bubbles (see Figure 2). When all fittings are properly checked, depressurize the

system and go to the next step.

2.6.5 System Evacuation

Warning: Never use the compressor itself to evacuate the system, nor energize the system when it

is under vacuum, as it may cause the compressor be damaged because of short-circuit caused by overload.

To evacuate the system, use a high vacuum pump and a vacuum gage. The system shall be evacuated up to

0,5mmHg (equivalent to 0,0066bar) or less. In any case, at least 20 minutes of vacuum must be applied (see

Figure 3)

Figure 3 – Vaccum operation scheme

Warning: Never use anti-freeze elements (methyl alcohol and derivates), as they cause irreversible

damages to the cooling system.

2.6.6 Procedures for Refrigerant Charge

The refrigerant shall only be charged after the proper vacuum has been achieved. Please check on the compressor or condensing unit tag what is the type of refrigerant that should be used to charge the system. Break the

vacuum only when the compressor is switched off.

It is recommended that the refrigerant charge be provided in the liquid state (with the compressor switched off),

through the high side (tank liquid valve) and by the refrigerant mass measurement (kg), according to the system

specification.

DOC NUMBER 595R36300 30

Page 31

SERVICE MANUAL Blast Chiller Freezer SKCH 30 50 70

Wait for 15 minutes before switching on the system again, to allow the gas to be evenly distributed and balance

the pressure levels.

The fine-tuning of the refrigerant charge must be done while the system is running (compressor switched on), by

observing the sight glass. The charge will be complete when there are no more bubbles forming.

When performing a condensing unit replacement always check the specified refrigerant charge.

2.6.7 Piping

Piping shall be sized so that:

It is flexible, to avoid rupture due to expansion and due to the transmission of vibration usually caused by compressors.

Ensure that the refrigerant is well distributed through the evaporator(s), and prevent the liquid from flowing back

to the compressor. To do that, use an expansion valve with proper dimensions, and an inverted siphon at the

outlet of each evaporator.

Figure 4 – Evaporator under the condensing unit

Prevent the liquid from flowing back to the compressor when the system stops and the evaporator(s) is/are located

above the Condensing Unit, using an inverted siphon and suction accumulator (see Figure 4).

Aid the return of lubricating oil coming from the evaporator(s) to the system where the Condensing Unit is located

over 3000 mm above the evaporator(s), using an inverted siphon every 3000 mm in the piping.

Allow secondary operations, such as attaching measurement instruments, isolating stretches for maintenance

purposes and pump down.

Warning: The diameter of the fittings for the condensing units and evaporators shall not be used as

a parameter to select the diameters of the other system components.

Warning: After replacement the condensing unit and its accessories must be handled and recycled

according to the material group (ferrous, non-ferrous, polymers, oils,) directives. These recommendations are intended to minimize the adverse impacts on the environment.

DOC NUMBER 595R36300 31

Page 32

SERVICE MANUAL Blast Chiller Freezer SKCH 30 50 70

Suction Accumulator

2.6.8 Basic Accessories of a Cooling System

Filter-Dryer

Installed at the liquid line, its function is to retain particles and mainly remove

residual humidity from the system.

Sight Glass

It is installed at the liquid line, just after the filter -dryer and used to monitor

the system refrigerant charge. Some models also allow humidity detection.

Pressure Control

Some Condensing Units are fitted with High / Low Pressure Switches. Their

function is to prevent the compressor from operating under pressure levels

that are outside of their application range.

Solenoid Valve

It is installed at the liquid line, prior to the expansion valve and used for the

pump down procedure.

Oil Separator

It is installed at the discharge line, when the evaporator is below the compressor's height (long distances)

It is installed at the suction line, just before the compressor. It prevents liquid

refrigerant from flowing back towards the compressor.

Conditions that favor the flow-back of liquid to the compressor and where the

use of a suction accumulator is recommended:

• Systems with more than one evaporator

• High refrigerant charges

• Operations with defrosting by hot gas

• Where the distance from the compressor to the evaporator is over 15 me-

ters (50 feet)

• Evaporator(s) above the condensing unit

Fan Speed Control

DOC NUMBER 595R36300 32

The Fan Speed Control controls the head pressure in air-cooled condensers

by reducing the fan speed to maintain head pressure as the outside temperatures/condenser pressure drops. As the motor speed drops under lower ambient/load condition fan noise is also reduced.

Page 33

SERVICE MANUAL Blast Chiller Freezer SKCH 30 50 70

Fuse plug

to let pressure escape. In case of release the melt part replace with new one

Schrader Valve

Used for service operation (Refrigerant Charge).

Suction Filter

It is recommended to clean the systems if the compressor has burned out. Installed at the suction line, its main task is to retain the contaminants (result of

the burning of the compressor), and to retain system particles.

A/C systems can include a pressure release valve that is usually mounted at

the compressor or fuse plug mounted on the receiver dryer.The relief valve can

open at a preset pressure and then reclose.The center of the fuse plug melts

same capacity.

DOC NUMBER 595R36300 33

Page 34

SERVICE MANUAL Blast Chiller Freezer SKCH 30 50 70

2.6.9 Expansion Valve

It is installed at the liquid line, before the evaporator.

Its function is to keep the pressure different between the condenser and the evaporator; it also adjusts the refrigerant flow within the evaporator. For systems operating under low evaporating temperatures (lower than -17.7°C

(0°F), it is recommended using an expansion valve fit with MOP (Maximum Operation Pressure), to protect the

compressor against high pressures during the suction phase at the start of the procedure.

2.6.10 Setting the Expansion valve

The valve is already set from factory in the standard condition and it is suitable for most installations.

If adjustment is needed, it is possible proceeding by means of the expansion valve rod adjustment.

By rotating the rod clockwise, the expansion valve overheat increases, while turning the rod counterclockwise

then it will decrea the overheating

IMPORTANT: Turn the rod maximum 45° each time; wider rotations will provoke flash-gas!

To eliminate evaporator swing, increase overheating by turning the rod clockwise until it stops.

Rotate the rod anticlockwise step by step until the swing will reappear.

From this position, turn the rod 45° clockwise.

When the calibration is done (swing approximately at the average), the refrigerator will no longer swing and the

evaporator can be considered as working at full capacity (see Figure 5).

If overheating in the evaporator is too high, this may be either due to an insufficient refrigerant fluid mass or to a

insufficiend dimension of the thermostatic valve (thermostatic valve not sized correctly).

Note: Variations of the overheating of ± 0.5 ° C are not considered swing.

Figure 5

2.6.11 Correct position of the thermostatic sensor

It is recommended to mount the sensor on a horizontal section of the suction line as close to the evaporator as

possible and in a position corresponding to the watch hands between 1 and 4.

Figure 6

DOC NUMBER 595R36300 34

Page 35

SERVICE MANUAL Blast Chiller Freezer SKCH 30 50 70

The position depends on the external diameter of the tube.

When the suction pipe has an outside diameter of 16 mm or less, it can be secured both in the positions (see

Figure7):

a. above the suction line

b. by the side of its own path, in horizontal position

Figure 7

When the tube has a diameter greater than 16 mm, the sensor must be secured beneath the horizontal axis of

the tubing itself to form a 45 ° angle with the same horizontal axis (see Figure 8)

Figure 8

Warning

The sensor must never be mounted at the bottom of the suction line, as it will

:

receive false control pulses due to the oil present at the bottom of the tube itself.

2.6.12 Identification of the thermostatic valve

The thermostatic element is equipped with a laser engraving on the top of the membrane (see Figure 9).

This engraving indicates the type of valve (with the numerical code), the field of evaporation temperature, MOP

point, the refrigerant and the maximum operating pressure and the type of nozzle installed

Figure 9

DOC NUMBER 595R36300 35

Page 36

SERVICE MANUAL Blast Chiller Freezer SKCH 30 50 70

2.6.13 Charge MOP

All MOP valves have a very small charge in the sensor.

This means that the valve or the element should be placed in the hottest position of the sensor otherwise a charge

migration may occur from the sensor to the element and the expansion valve will stop working.

The MOP charge has a limited charge in the sensor.

MOP means Maximum Operating Pressure (sometimes called “Motor Overload Protection”) and is the maximum

suction / evaporation pressure allowed in the suction / evaporation line.

The refrigerant liquid will evaporate when the temperature reaches the MOP point. As the suction pressure increases, the expansion valve starts reducing the pressure to 0.3 / 0.4 bar, below the MOP point, until fully closing

when the suction pressure will be equal to the MOP point.

2.6.14 Quantity of refrigerant to charge

The exact quantity of refrigerant to charge (see Figure 10) in the system depends on:

Figure 10

Data plate identification (in case of remote unit the reference are points 2 and 3)

Liquid container receiver (max quantity in kg of refrigerant)

Liquid spy (see Figure 11) on the system.(where present)

Figure 11

COMPLETE OPERATIONS IN SUMMARY - After correct cleaning and vacuum of the system:

a) Start to charge the refrigerant on suction/service pipe on the compressor.

b) Keep the appliance door opened

c) Switched ON the appliance

d) Charge a small amount of refrigerant step by step without freezing the pipe until air bubbles show on liquid spy.

e) Close the door and verify the evaporation pressure.

f) Check the overheating on external pipe of evaporator following the evaporation pressure/temperature

g) Check for presence of swing of pressure due to thermostatic valve (refer to chapter 2.5.10)

h) In case of swings, set the valve or add refrigerant.

Warnings: Do not provoke flash gas!!!!! The pipe must be slightly cooled not frozen!!

DOC NUMBER 595R36300 36

Page 37

SERVICE MANUAL Blast Chiller Freezer SKCH 30 50 70

2.6.15 Electrical connection

Use the separate power supply from remote unit and bcf.

For the power supply dimensioning, check the electric wiring diagram of the appliance: after retrieving current

absorption and power data relevant to the live lines, determine the cables sections able to support the ab-sorbed

current.

In order to detect the remote unit alarms, the connection between it and the BCF must be done with a six-wire

cable whose section is sufficient for signals.

The BCF electric wiring diagram shows the correspondence between the clamps of the remote unit and of the

BCF: labels are then present on both the remote unit and the BCF terminal clamps.

The main labels are:

T1-T2 = connection of power compressor

AP_AP = Alarm pressostat

AT_AT = Alarm Thermic compressor

More detail is in the chapter 2.6.15 (Electrical drawing present on electrical box of remote unit)

2.6.15.1 Electrical box drawing on remote unit

DOC NUMBER 595R36300 37

Page 38

SERVICE MANUAL Blast Chiller Freezer SKCH 30 50 70

2.6.15.2 Electrical box in the BCF: IE. Of clamp connections

Warning:

DOC NUMBER 595R36300 38

Remember use DIFFERENT power supplies for energizing the BCF and the remote unit.

Page 39

SERVICE MANUAL Blast Chiller Freezer SKCH 30 50 70

See reference instructions provided with the INSTALLATION MANUAL.

Warning: assemble the guides for the condensing tray only after positioning the unit in its final

location – Risk of damaging the guides if moving the unit with fork-lift when the guides are in place.

In case the unit are too large for movement in the room, it is possible reduce to remove the following parts and

gain some increased handling:

• Door

• Control panel

• Condenser panel

• Door hinge

• Rear side protection box (after removing the box pay attention not to damage pipes and cables)

• Bracket of door micro switch

• Foamed panel

Warning: before testing the unit, reassemble all the removed parts (also reseal the components

showing silicone traces) and check the door alignment.

DOC NUMBER 595R36300 39

Page 40

SERVICE MANUAL Blast Chiller Freezer SKCH 30 50 70

L1 / L2 / L3

N*

(Phase and Neutral)

~ 230 Volts

L1 and/or L2

L3

(Phase and Phase)

~ 400 Volts

L1 and/or L2

L3

(Phase and Phase)

~ 208 Volts

NOT USE THE

2.8.1 Power connection on bcf 380/400V

The units built-in are already predisposed with power cable, usually without plug.

The reference to the adsorbed current and the voltage are on the unit data plate.

The color of the main conductors present in the power cable are standard as:

Blue = N neutral

Dark= L1 Phase

Grey= L2 Phase

Brown= L3 Phase

Yellow and Green= Heart

The readings should be:

PLUG!

IT IS MANDATORY

USE A PERMA-

NENTLY CONNEC-

L1 / L2 / L3

N

+

(Phase and Earth) ~ 230 Volts

(Neutral and Earth) ~ 0 Volts (or approx. zero V)

Warning:

The combination and results obtained will permit you to find all wires: PHASE, NEUTRAL and

EARTH.

2.8.2 Power connection on bcf 208V (USA)

The units built-in are not predisposed with power cable.

The reference to the adsorbed current and the voltage are on the unit data plate.

The color of the main conductors present in the power cable are standard as:

White = L1 Phase

Grey = L2 Phase

Brown = L3 Phase

Yellow and Green= Heart

The readings should be:

(± 6% based on European

standards

L1 / L2 / L3

+

(Phase and Earth) ~ 120 Volts

Warning:

Warning: The power cable must be installed from technician, following the normative present in the

The combination and results obtained will permit you to find all wires: PHASE, and EARTH.

local place. The connection will be done on clamp present under the condenser panel and in the electrical

box predisposed for this connection. Other information are present in the Installation manual (USA)

DOC NUMBER 595R36300 40

Page 41

SERVICE MANUAL Blast Chiller Freezer SKCH 30 50 70

Main display Touch

1

B

Button ON OFF button

2

Utility drawers

C

USB key in/out

3

Multiphase drawer

D

Other connection aux

4

Main menu drawer

E

Open able flap

5

Cycle selection buttons

6

Temperature area

Time area

Chill

1

01:30

:00

USER

MAN U AL

1

2 3 4

7 5 6

Soft / Hard

0

°C

01:30

h:m

0

°C

A

B

C

D

E

2.8.3 Description Main Display

A

Warning

After pressing the ON/OFF button, the display illuminates and shows the screen below, in Manual mode, with the

default cycle:

:

screen

Start button

DOC NUMBER 595R36300 41

Page 42

SERVICE MANUAL Blast Chiller Freezer SKCH 30 50 70

Soft/

2.8.3.1 Icon description, Message of Dialogues

0℃

Hard

Temperature set

Soft chill cycle

Hard chill cycle

Skip phase

Time icon

Multitimer icon

Delayed start

Time (daily)

Delayed start

Restore Multi Time program

Move between the pages

Move between the pages or in-

crease/decrease a value

Sky hub

Settings

Chilling cycle

Freezing cycle

Lite Hot cycle

Stop cycle

Start cycle

History (cycle, temp.)

Probe icon

Precooling cycle

Preheating cycle

Automatic cycles

Programs ( personal)

Hygiene

Data Monitor

Cruise chilling

Turbo cooling

Defrost cycle

Conserve cycle

Help

Drawer ( up or down)

Manual cycles

Door open.

Alarms.

Compressor

Warnings pop-up

Information

DOC NUMBER 595R36300 42

User

Agenda

Page 43

SERVICE MANUAL Blast Chiller Freezer SKCH 30 50 70

Confirm and save the selection

Discard the selection or close a pop-

up

Come back to the previous menu

Clear all phases

Delete the pre-set

Clear all pre-sets

Read messages

Read message with attachment

Training

Media

Guidelines

Multicycles

Save program

Save all pre-sets