Page 1

PRESSURE MEASUREMENT

DPI 610

PORTABLE PRESSURE

CALIBRATOR/INDICATOR

CALIBRATION INSTRUCTIONS

K235

Issue Date: 12th March, 1999

© Druck Limited 1999

This document is the property of Druck Limited and may not be copied or otherwise reproduced, communicated in any way to

third parties, nor stored in any Data Processing System without the express written authority of Druck Limited.

Druck Limited, Fir Tree Lane, Groby, Leicester LE6 0FH, England. Tel: (0116) 231 7100 Fax: (0116) 231 7103

K235 Issue 2

Page 2

Calibration Procedures

DPI 610

DPI 610

PORTABLE PRESSURE CALIBRATOR/INDICATOR

CALIBRATION INSTRUCTIONS

K235

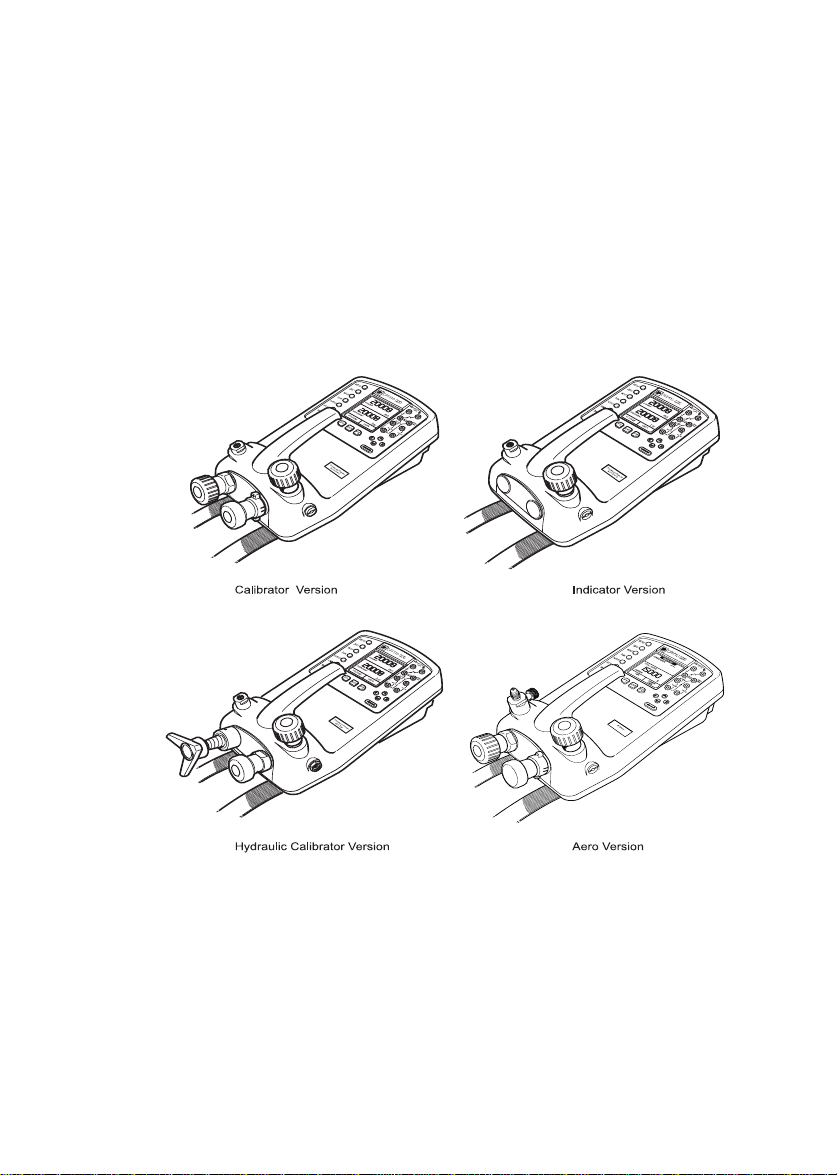

DPI 610 Instrument Versions

© Druck Ltd. 1998

This document is the property of Druck Limited and may not, either in part or whole, be

copied or otherwise reproduced, communicated in any way to third parties nor stored in any

Data Processing system, without the express written authority of Druck Limited.

1

K235 Issue No. 2

Page 3

DPI 610 Calibration Procedures

Calibrator Version

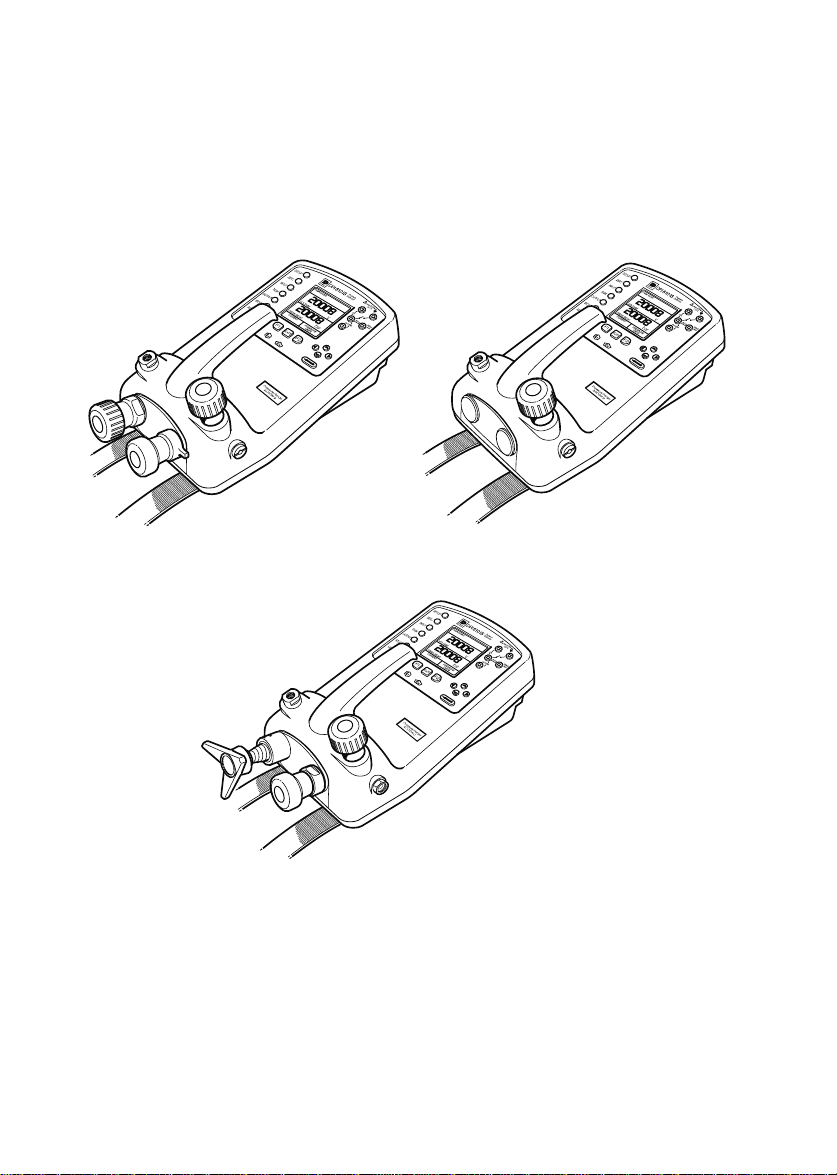

DPI 610 IS Intrinsically Safe Instrument Versions

K235 Issue No. 2

2

Page 4

Calibration Procedures

DPI 610

Contents

General...................................................................................................5

Introduction.............................................................................................6

General Procedures..........................................................................6

Calibration Protection .......................................................................6

Calibration Check .............................................................................7

Calibration Adjustment......................................................................7

Test Equipment.................................................................................7

Using The Calibration Men u.............................................................7

Change Calibration PIN Number ............................................................8

Calibrate Internal Ranges .......................................................................9

Pressure ...........................................................................................9

Voltage Input Range ( 5 Volts)........................................................10

Voltage Input Range (30 Volts).......................................................12

Voltage Input Range (50 Volts).......................................................14

Current Input Range (55 mA)..........................................................16

Current Output Range (24 mA).......................................................18

Ambient Temperature Channel .......................................................21

Calibrate External Ranges....................................................................22

Pressure .........................................................................................22

Service .................................................................................................24

Approved Service Agents ..............................................................24

Returned Goods Procedure...........................................................25

Safety Precautions (Returned Goods) ......................................25

Tables

Table 1 - Internal/External Pressure Transducer V erification .................26

Table 2 - Voltage Input Calibration Tolerances (Standard models) ........27

Table 3 - Current Input Calibration Tolerances ......................................28

Table 4 - Current output Calibration Tolerances ....................................29

Table 5 - Voltage Input Calibration Tolerances (IS models only) ............27

3

K235 Issue No. 2

Page 5

DPI 610 Calibration Procedures

INTRINSIC SAFETY CONDITIONS OF USE

This handbook covers the calibration instructions for both standard

instruments and intrinsically safe models. Intrinsically safe models are

designed to be intrinsically safe when operated in accordance with the

BASEEF A Certification document and schedule which is supplied.

BASEEFA Certificate of Conformity No. Ex 99E2002X

BASEEF A being an Approv ed Certification Body, in accordance with

Article 14 of the Council Directive of th European Communities of 18th

December, 1975 (76/117/EEC) certifies that the apparatus has been

found to comply with harmonised European Standards:

EN 50014: 1992

EN 50020: 1994

and has successfully met the examination and test requirements

recorded in confidential report Number

98(C)0818 (ERA Report Ref.3627/856), dated January, 1999

NOTE: For intrinsically safe models, attention is dra wn to P ages 4/5

of the Certificate of conformity.

INTRINSICALLY SAFE MODELS SHOULD BE CALIBRATED IN A SAFE AREA

K235 Issue No. 2

4

Page 6

Calibration Procedures

DPI 610

General

This publication covers the calibration procedures f or DPI 610 Portable Pressure Calibrator/

Indicators and should be read in conjunction with Druck Publications K213 and K239.

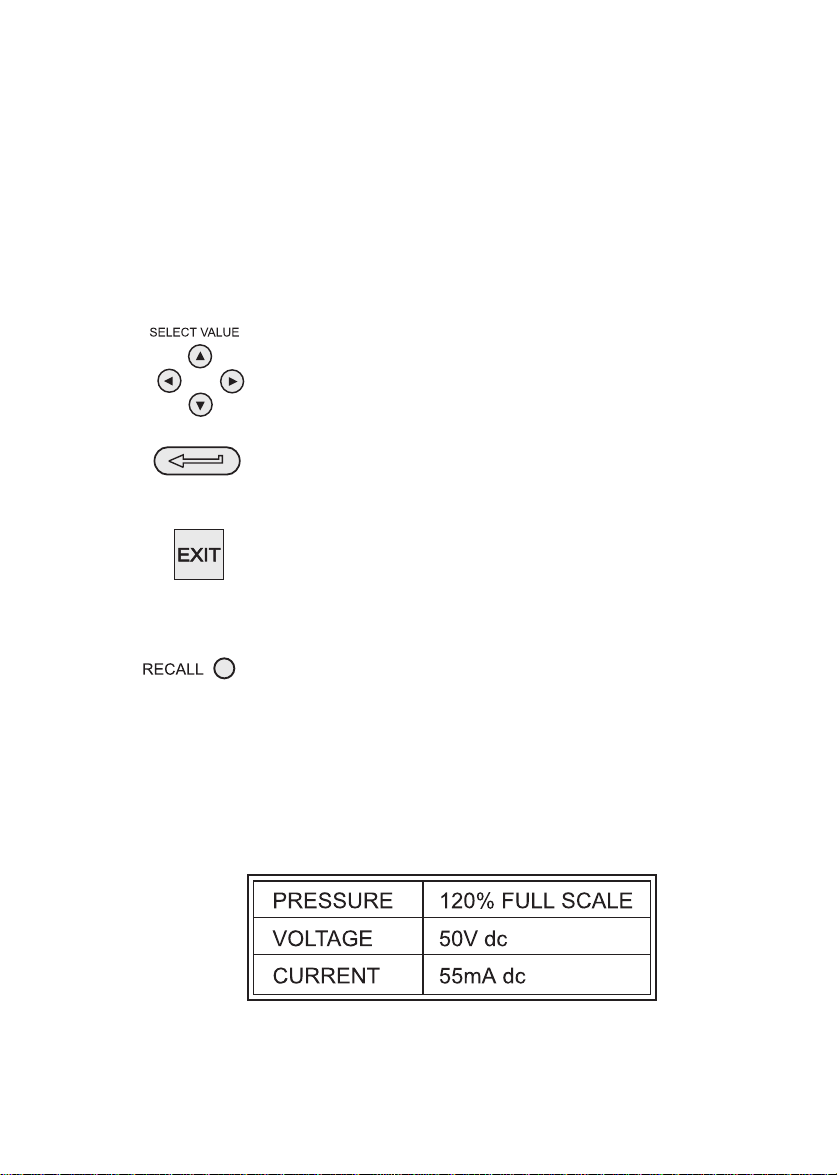

The following key symbols are used in the procedure diagrams which follow and are

repeated here (from K213), to allow this supplement to stand alone. P ages 1 to 7 of K213

and K239 detail the operator controls and general information which is relevant to all

options of the DPI 610 Instrument.

Shaded cursor keys indicate that a combination of these four ke ys,

Up, Down, Left and Right should be used to (e.g.) enter an alpha

numeric value or to select a function.

Indicates the ENTER key. Used to confirm an operation or a

selection. Shading indicates key operation.

Exit key, used to clear current menu selection and return to next

menu level abov e current lev el. Used as an escape k ey from current

operation. Shading indicates key operation.

Hardkey (total 7). Legend beside key symbol indicates function.

Shading indicates key operation.

Maximum Instrument Ratings

The following table shows the maximum measurement ratings of the standard instr ument

which should not be exceeded. Pressure overrange (120% of FS) is indicated by the

pressure display flashing. Voltage or current overrange, causes either the voltage or current

display to flash.

,[30V dc (IS)]

Note:

For the DPI 610 AERO version, when the AERO task is selected,the display

flashes if the voltage or current input overranges by 110% of the above maximum

values. The pressure display flashes at altitudes below -3000 ft and above

50,000 ft or at airspeeds greater than 600 kts,depending upon the mode selected.

5

K235 Issue No. 2

Page 7

DPI 610 Calibration Procedures

Introduction

The instrument is supplied by the manufacturer, complete with calibration certificate(s).

The re-calibration interval will depend on the total measurement uncertainty which is

acceptable for a particular application. In order that the instrument remains within the

quoted accuracy, it is suggested that it’s calibration be checked at 90 day inter vals.

The DPI 610 is a very precise measuring instrument and the test equipment and conditions

of test must be suitable for the type of work. The use of a Class A compensated deadweight

tester is essential. The tests should be carried out in a controlled environment by a

competent, trained person.

If, when the accuracy of the instrument is checked, it is f ound to fall outside the specification,

calibration adjustment can be undertaken to compensate errors.

The manufacturer offers a comprehensive and, if required, NAMAS accredited calibration

service.

General Procedures

The following general hints are provided as a guide to calibration procedures.

Do

Use high quality

time before calibration (minimum 1 hour).

Conduct the calibration in a temperature and preferably, humidity controlled environment.

Recommended temperature is 21°C, ±2°C.

Use deadweight testers carefully and away from draughts.

Review and become familiar with the whole calibration procedure before commencing the

calibration process.

Ensure that the instrument is NOT set to BASIC mode. The Instrument’ s calibration routines

are not accessible from this mode. If necessary, use the TASK key to select another mode

(e.g.) ADVANCED.

Repeatable and Linear

pressure sources and allow adequate stabilisation

Calibration Protection

In order to protect against accidental loss,the calibration of this instrument is

protected by a PIN number. Initially, this PIN number is set to 4321. To prevent

unauthorised access to the calibration routines, it is recommended that this PIN

number should be changed at the earliest opportunity(refer to Page 8).

K235 Issue No. 2

6

Page 8

Calibration Procedures

DPI 610

Calibration Check

At the chosen interval, the instrument readings should be compared with a known standard.

Any deviations between the instrument and the standard should be noted, taking due

account of the traceability (accuracy to a National Standard). If these deviations exceed

the published tolerance, or any other suitable chosen performance standard, then the

user may wish to carry out a calibration adjustment.

It is recommended that measurements be checked at 0, 20, 40, 60, 80 and 100% of full

scale on an ascending and descending run. Refer to Tables 1 to 4, pages 27 to 30, for

details of test inputs and tolerances.

Calibration Adjustment

If the instrument is operating correctly, only zero and full scale calibration will vary. Any

excessive non-linearity or temperature effects indicate a fault. In these circumstances,the

instrument should be returned to a qualified service agent (refer to pages 22 and 23).

Test Equipment

The following laboratory standard test equipment will be required for the calibration

procedures:-

tnemurtsnI

egnaR

noitarbilaC

tnempiuqE

noitarbilaC

ytniatrecnU

ycaruccA

tupnIV5

tupnIV05

tupnIAm55

tuptuOAm42

pmeTtneibmA

± mpp03 ± tigid1 ± mpp01 ± 5 mV

)sepyTSI(tupnIV03

± mpp54 ± tigid1 ± mpp11 ± 011 mV

± mpp54 ± tigid1 ± mpp11 ± 011 mV

± mpp051 ± stigid4 ± mpp001 ± An1

± mpp051 ± stigid4 ± mpp061 ± An1

± 2.0 °C ± 1.0 °C ± tigid1

txE/tnIerusserPthgiewdaeDAssalC%520.0<

Using the Calibration Menu

The calibration routines are selected from the Setup menu as detailed on page 8. The

calibration routines are not accessible whilst the instrumement is in BASIC mode. If

necessary therefore,use the TASK key to select another mode (e.g.) ADVANCED before

attempting to access the CALIBRATION mode.

7

K235 Issue No. 2

Page 9

DPI 610 Calibration Procedures

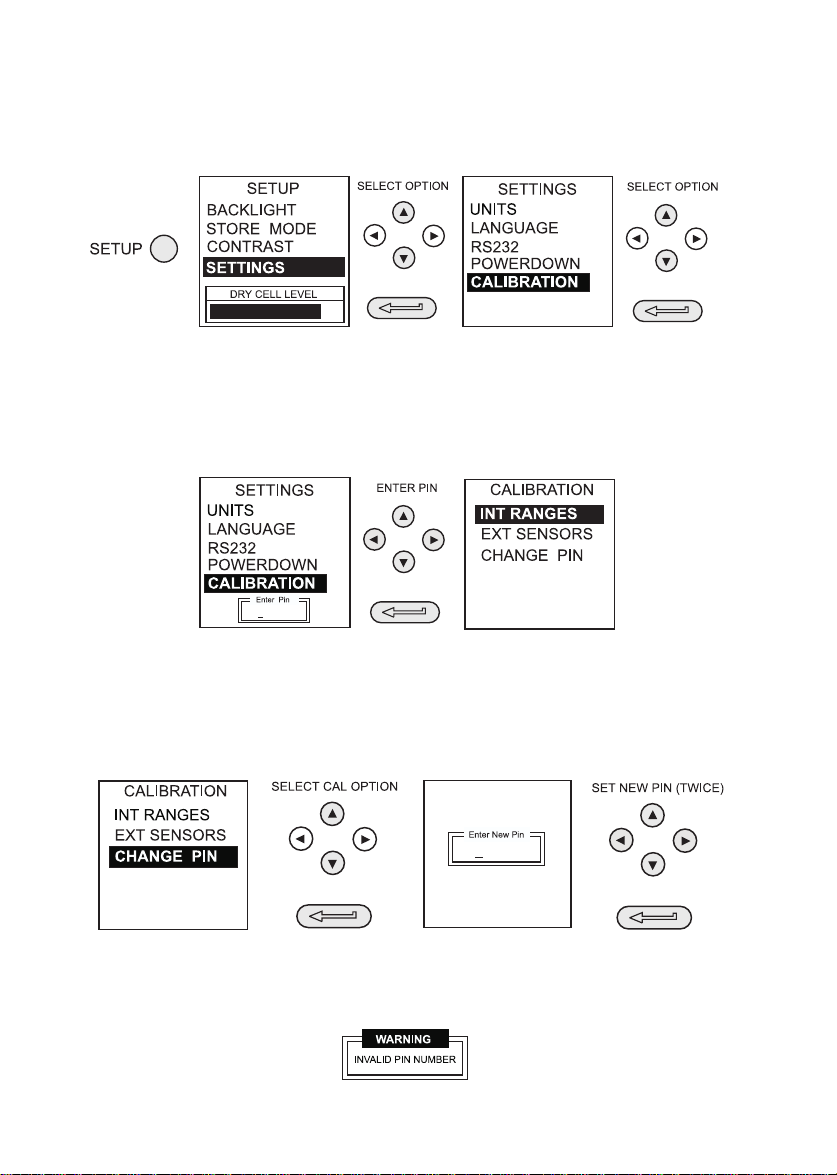

To enter the CALIBRATION mode, press SETUP and select CALIBRATE from the menu

as shown below.

Use a combination of the cursor keys to enter the PIN number (Initially set to 4321) as

shown below. The Up and Dow n keys enter numer als (0 to 9) or (9 to 0) respectively and the

right and left keys shift number position. If the Enter pin prompt disappears before the first

digit is entered, press ENTER to re-display.

Change Calibration PIN Number

The Calibration PIN number is changed from the Calibration Menu. Use the cursor keys to

select CHANGE PIN and proceed as follows.

Note that the new PIN number requires to be entered twice, the second entry being used to

verify the change. If the second PIN number entry differs from the first, the PIN number is

not changed and the following error message is displayed.

K235 Issue No. 2

8

Page 10

Calibration Procedures

DPI 610

Calibrate Internal Ranges

Pressure

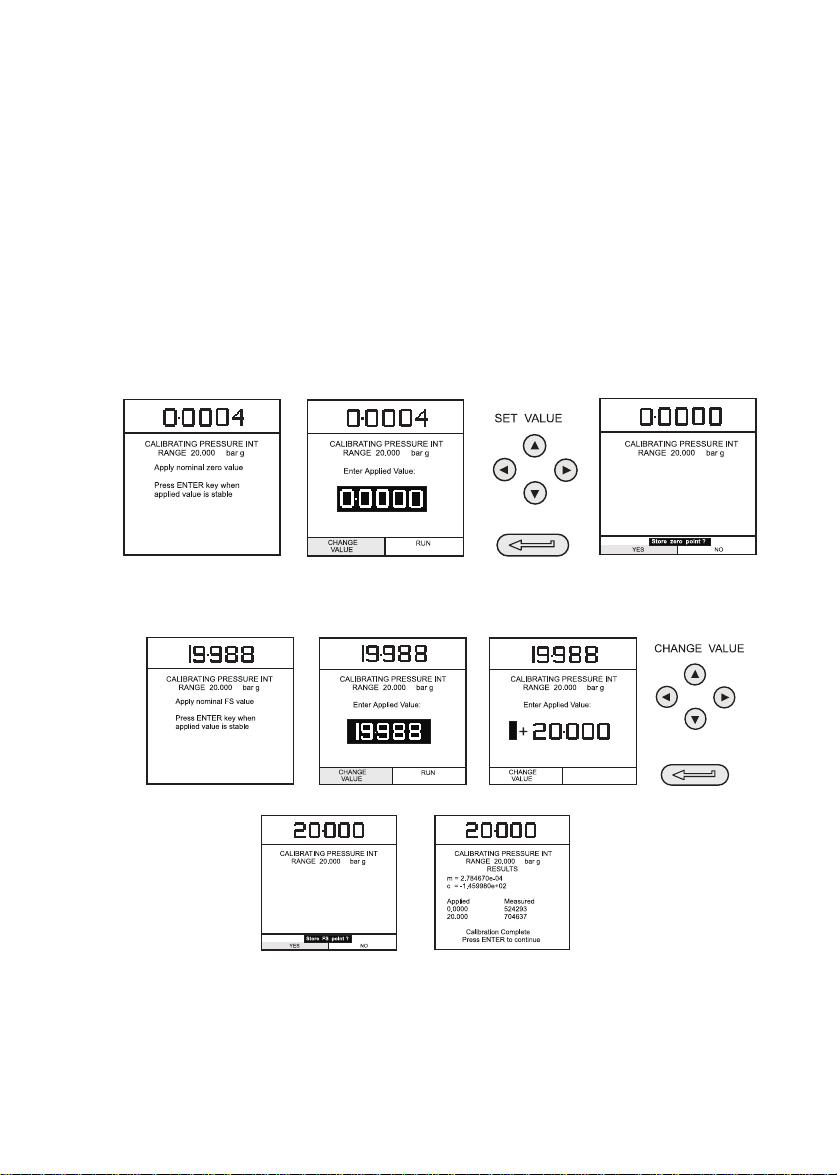

The following procedure should be adopted for calibrating the inter nal pressure range.

Note: If calibrating the hydraulic calibrator version, the calibrator must first be primed

as detailed on pages 39 to 42 of K213, pages 37 to 41 of K239.

(1) Connect the outlet port of the instrument to a pressure standard.

(2) Allow the instrument’s temperature to stabilise for a minimum of 1 hour.

(3) Switch the instrument on, enter CALIBRATION mode and select INT RANGES

from the CALIBRATION menu as shown on Page 8 and then PRESSURE INT.

(4) Apply zero pressure and store the zero point as shown below (e.g.),

(5) Close the vent valve, apply full scale pressure and store the full scale (FS)

point as shown below (e.g.),

(6) Press the ENTER key to accept the calibration. Press the EXIT key four times

to quit the CALIBRATION and SETUP modes.

(7) Check calibration by applying test pressures detailed in Table 1, Page 27.

9

K235 Issue No. 2

Page 11

DPI 610 Calibration Procedures

Voltage Input Range (5 Volts)

The following procedure should be adopted for calibrating the internal 5 Volt range.

(1) Switch the instrument on, enter CALIBRATION mode and select INT RANGES

from the CALIBRATION MENU as shown on Page 8.

(2) Select 5V range for calibration as shown below.

(3) Link the voltage input terminals with a short lead and enter the zero point as

shown below (e.g.),

(4) Remove the shorting link from the voltmeter terminals, connect the Vin terminals

of the instrument to a variable voltage source and connect a digital voltmeter

across the source as shown below.

max 30V

+

Cal V

-

DVM

Vin

mA Sink

mA in

55mA

max

Standard Version IS Version

K235 Issue No. 2

10

Page 12

Calibration Procedures

(5) Set the variable supply voltage to 5V ± 0.1V and enter the measured Full Scale

voltage applied as shown below (e.g.),

(6) Press the ENTER key to accept the calibration. Press the EXIT key once to

return to the calibration menu or four times to quit the CALIBRATION and SETUP

modes.

DPI 610

(7) Verify the instrument calibration by applying the test voltages given inTable 2

to the voltmeter (after both voltage ranges have been calibrated).

(8) Disconnect the calibration/test setup.

11

K235 Issue No. 2

Page 13

DPI 610 Calibration Procedures

Voltage Input Range (30 Volts)

The following procedure, which applies only to IS models, should be adopted for

calibrating the internal 30 Volt range.

(1) Switch the instrument on, enter CALIBRATION mode and select INT RANGES

from the CALIBRATION MENU as shown on Page 8.

(2) Select 30V range for calibration as shown below.

CALIBRATION

PRESSURE INT

VOLTAGE IN

SELECT CAL OPTION

SELECT RANGE

5 VOLTS

30 VOLTS

SELECT CAL OPTION

CURRENT IN

CURRENT OUT

TEMPERATURE

(3) Link the voltage input terminals with a short lead and enter the zero point as shown

below (e.g.),

SET VALUE

CALIBRATING VOLTAGE

RANGE +/- 30V

Apply nominal zero value

Press ENTER key when

applied value is stable

CALIBRATING VOLTAGE

RANGE +/- 30V

Enter Applied Value:

CHANGE

VALUE

RUN

CALIBRATING VOLTAGE

RANGE +/- 30V

Store zero point ?

YES NO

(4) Remove the shorting linkfrom the voltmeter terminals, connect the Vin terminals

of the instrument to a variable voltage source and connect a digital voltmeter

across the source as shown below.

max 30V

+

K235 Issue No. 2

Cal V

DVM

Vin

-

mA Sink

mA in

55mA

max

12

Page 14

Calibration Procedures

DPI 610

(5) Set the variable supply voltage to 30V ± 0.1V and enter the measured Full Scale

voltage applied as shown below (e.g.),

SET VALUE

CALIBRATING VOLTAGE

RANGE +/- 30V

Apply nominal FS value

Press ENTER key when

applied value is stable

CALIBRATING VOLTAGE

RANGE +/- 30V

Enter Applied Value:

CALIBRATING VOLTAGE

RANGE +/- 30V

Enter Applied Value:

CHANGE

VALUE

CALIBRATING VOLTAGE

RANGE +/- 30V

Store FS point ?

YES NO

RUN

CALIBRATING VOLTAGE

RANGE +/- 30V

RESULTS

m = 1.395879e-05

c = -7.128004e+00

Applied Measured

0.0000 526380

29.984 873988

Calibration Complete

Press ENTER to continue

CHANGE

VALUE

RUN

(6) Press the ENTER key to accept the calibration. Press the EXIT key four times

to quit the CALIBRATION and SETUP modes.

(7) Verify the instrument calibration by applying the test voltages given inTable 5

to the voltmeter (after both voltage ranges have been calibrated).

Note: Max input 30V dc - APPLY ONLY THE TEST VOLTAGES SHOWN IN

THE SHADED AREA of Table 2.

(8) Disconnect the calibration/test setup.

13

K235 Issue No. 2

Page 15

DPI 610 Calibration Procedures

Voltage Input Range (50 Volts)

The following procedure should be adopted for calibrating the inter nal 50 Volt range,

(NOT ON IS MODELS).

(1) Switch the instrument on, enter CALIBRATION mode and select INT RANGES

from the CALIBRATION MENU as shown on Page 8.

(2) Select 50V range for calibration as shown below.

(3) Link the voltage input terminals with a short lead and enter the zero point as shown

below (e.g.),

(4) Remove the shorting linkfrom the voltmeter terminals, connect the Vin terminals

of the instrument to a variable voltage source and connect a digital voltmeter

across the source as shown below.

K235 Issue No. 2

14

Page 16

Calibration Procedures

(5) Set the variable supply voltage to 50V ± 0.1V and enter the measured Full Scale

voltage applied as shown below (e.g.),

(6) Press the ENTER key to accept the calibration. Press the EXIT key four times

to quit the CALIBRATION and SETUP modes.

DPI 610

(7) Verify the instrument calibration by applying the test voltages given inTable 2

to the voltmeter (after both voltage ranges have been calibrated).

(8) Disconnect the calibration/test setup.

15

K235 Issue No. 2

Page 17

DPI 610 Calibration Procedures

Current Input Range (55 mA)

The following procedure should be adopted for calibrating the current input range.

(1) Switch the instrument on, enter CALIBRATION mode and select INT RANGES

from the CALIBRATION MENU as shown on Page 8.

(2) Select CURRENT IN range for calibration as shown below.

(3) Open circuit the mA in terminals and enter the zero point as shown below.

(4) Connect the mA in terminals of the instrument to a variable current source and

connect a digital milliammeter in series wth the supply as shown below.

max 30V

Vin

IS Version

MILLIAMMETER

A

55mA

max

mA in

-

+

Vin

24V out

Standard Version

K235 Issue No. 2

MILLIAMMETER

max 50V

CAT II

55mA

mA in

mA Sink

Xmtr

mA out 10V out

A

-

max

+

16

Page 18

Calibration Procedures

(5) Set the input current to 55 ± 0.1mA and enter the measured Full Scale

input current as shown below (e.g.),

(6) Press the ENTER key to accept the calibration. Press the EXIT key four times

to quit the CALIBRATION and SETUP modes.

DPI 610

(7) Verify the instrument calibration by applying the test currents given inTable 3

to the milliammeter.

(8) Disconnect the calibration/test setup.

17

K235 Issue No. 2

Page 19

DPI 610 Calibration Procedures

Current Output Range (24 mA)

The following procedure should be adopted for calibrating the current output range.

(1) Switch the instrument on, enter CALIBRATION mode and select INT RANGES

from the CALIBRATION MENU as shown on Page 8.

(2) Select CURRENT OUT range for calibration as shown below.

(3) Connect a digital milliammeter to the instrument as shown below.

Note: On standard instruments, during a current out calibration routine, the

24V dc output is automatically turned on. On IS instruments an external

supply is required

max 50V

CAT II

max 30V

Vin

mA in

mA Sink

mA

mA out 10V out

24V out

Standard Version

K235 Issue No. 2

Xmtr

55mA

max

VOLTAGE

SOURCE

18

Vin

-

mA

mA Sink

mA in

55mA

max

+

IS Version

Page 20

Calibration Procedures

(4) Measure the 10% Full Scale output current and enter the value measured on the

external milliammeter as shown below (e.g.),

(5) Measure the 90% Full Scale output current and enter the value measured on the

external milliameter as shown below (e.g.),

DPI 610

(6) Press the ENTER key to accept the calibration. Press the EXIT key four times

to quit the CALIBRATION and SETUP modes.

(7) Verify the instrument’s output current calibration by setting up the loop test

currents as shown in Ta ble 4 and checking the set values against the

milliammeter standard. The procedure is as follows.

Note: Select the appropriate steps 8 to 10, depending upon model type.

19

K235 Issue No. 2

Page 21

DPI 610 Calibration Procedures

Standard Calibrator Versions Only

(8) Press the OUTPUT key, select mA VALUE and turn on the 24V supply as shown

below (e.g.),

(9) Set the loop output current to 5 mA as shown below and check that the output

current, measured on the milliammeter standard is within the limits given in Table 4.

(10) Repeat (9) for all output values given in Table 4.

IS Calibrator Versions Only

(8) Connect an external supply as shown on page 18, press the OUTPUT key and

select mA VALUE as shown below (e.g.),

(9) Set the loop output current to 5 mA as shown below and check that the output

current, measured on the milliammeter standard is within the limits given in Table 4.

(10) Repeat (9) for all output values given in Table 4.

K235 Issue No. 2

20

Page 22

Calibration Procedures

DPI 610

Ambient Temperature Channel

The following procedure should be adopted for calibrating the ambient temperature

measurement channel.

(1) Switch the instrument on, enter the CALIBRATION mode and select

TEMPERATURE as shown below.

(2) Allow the instrument’s temperature to stabilise in the calibration environment for

at least one hour.

(3) Read the environmental temperature on a calibrated digital thermometer and

enter the recorded value as shown below. Example shown for a measured

ambient temperature of 21.5 degrees Celsius.

Note: Only one temperature point is required.

(4) Press the ENTER key to accept the calibration. Press the EXIT key once to

return to the calibration menu or four times to quit the CALIBRATION and SETUP

modes.

21

K235 Issue No. 2

Page 23

DPI 610 Calibration Procedures

Calibrate External Ranges

Pressure

The following procedure should be adopted for calibrating exter nal pressure ranges.

(1) Connect the required external transducer to the EXT TRANSDUCER socket

located on the rear of the instrument.

(2) Allow the instrument’s temperature and the temperature of the external

transducer to stabilise in the calibration environment for a minimum of 1 hour.

(3) Switch the instrument on, enter CALIBRA TION mode and select EXT SENSORS

from the CALIBRATION menu as shown below.

(4) Select the transducer to be calibrated from the transducer menu by means of the

cursor keys and press ENTER as shown below.

If the sensor to be calibrated is not in the directory, or no sensors are listed in the

directory, press the F1 key (ADD NEW SENSOR). This will place the sensor in

the directory, allowing it to then be selected.

(5) Connect the pressure standard to the inlet of the external transducer, apply the

zero point pressure and store the zero point as shown below (e.g.),

K235 Issue No. 2

22

Page 24

Calibration Procedures

(6) Apply the full scale pressure to the external transducer and store the Full Scale

(FS) point as shown below (e.g.),

(7) Release the applied pressure and disconnect the pressure reference. Press

the ENTER key to accept the calibration. Press the EXIT key once to return to

the calibration menu or four times to quit the CALIBRATION and SETUP modes.

DPI 610

(8) Check the calibration of the external transducer by applying the test pressures

as detailed in Table 1, page 27.

23

K235 Issue No. 2

Page 25

DPI 610 Calibration Procedures

Service

Approved Service Agents

The following are approved Service Agents for Druck Instruments.

FRANCE

Druck SA, 19 Rue Maurice Pellerin,

92600 Asnières, France.

Tel: (1) 41 32 34 64

Fax: (1) 47 93 00 48

GERMANY

Druck Messtechnik GmbH,

Lessingstrasse 12, 61231 Bad Nauheim,

Germany.

Tel: 6032 35028

Fax: 6032 71123

HOLLAND

Druck Nederland B.V., Postbus 232,

Zuideinde 37, 2991 LJ Barendrecht,

The Netherlands.

Tel: 1806 11555

Fax: 1806 18131

JAPAN

Druck Japan KK, Medie Corp Building 8,

2-4-14 Kichijyoji-Honcho, Musashino,

Tokyo 180, Japan.

Tel: 422 20 7123

Fax: 422 20 7155

UK

Druck Ltd., Fir Tree Lane, Groby,

Leicester, LE6 OFH.

Tel: 0116 231 7100

Fax: 0116 231 7103

USA

Druck Incorporated, 4 Dunham Drive,

New Fairfield, Connecticut 06812, USA.

Tel: 203 746 0400

Fax: 203 746 2494

ITALY

Druck Italia Srl., Via Capecelatro 11,

20148 Milano, Italy.

Tel: 2 48707166

Fax: 2 48705568

K235 Issue No. 2

24

Page 26

Calibration Procedures

DPI 610

Returned Goods Procedure

Should the instrument become unserviceable, it can be returned to the Druck

Service Department

Please contact our Service Department, either by 'phone or fax, to obtain a Returned

Goods Authorisation (RGA) number. Please be prepared to provide the following

information:-

Product (i.e. DPI 610)

Pressure range :

Serial number :

Details of defect/work to be undertaken

Calibration traceability requirements

Operating conditions

Safety Precautions (Returned Goods)

You must also tell us if the product has been in contact with anything hazardous or

toxic and inform us of the relevant COSH references and precautions to be taken when

handling.

Important notice

Service or recalibration by unauthorised sources will affect the warranty and may not

guarantee future performance.

25

K235 Issue No. 2

Page 27

DPI 610 Calibration Procedures

saeulaVdeilppAlanimoN

elacSlluF%a

0

)rabm(052)rabm(005)rabm(057)rabm(059)rabm(057)rabm(005)rabm(052-

%02

%04

%06

%08

%001

%08

± egnardnuopmocSF%520.0

± egnardnuopmocSF%520.0

± egnardnuopmocSF%520.0

± egnardnuopmocSF%520.0

± egnardnuopmocSF%520.0

± egnardnuopmocSF%520.0

± egnardnuopmocSF%520.0

± egnardnuopmocSF%520.0

)segnarSBArof%01(%0

± SF%520.0 ± SF%520.0

± SF%520.0 ± SF%520.0

± SF%520.0 ± SF%520.0

± SF%520.0 ± SF%520.0

± SF%520.0 ± SF%520.0

± SF%520.0 ± SF%520.0

± SF%520.0 ± SF%520.0

noitaiveDelbissimreP

snoisreV016rotacidnIdna*CP snoisreV*CH

elbacilppAtoN

elbacilppAtoN

elbacilppAtoN

elbacilppAtoN

elbacilppAtoN

elbacilppAtoN

elbacilppAtoN

elbacilppAtoN

%06 ± SF%520.0

%04

%02

)segnarSBArof%01(%0

*PC = Pressure Calibrator, HC = Hydraulic calibrator

± SF%520.0 ± SF%520.0

± SF%520.0 ± SF%520.0

± SF%520.0 ± SF%520.0

± SF%520.0

Table 1 - Internal/External Pressure Transducer Verification

K235 Issue No. 2

26

Page 28

secnareloTnoitacifireVegnaRV05noitarbilaCegatloV secnareloTnoitacifireVegnaRV5noitarbilaCegatloV

egatloVdeilppA noitaiveDelbissimreP egatloVdeilppA noitaiveDelbissimreP

Calibration Procedures

27

K235 Issue No. 2

0504030201-

0

01

02

03

04

05

± ,gdr%50.0 ± SF%400.0

± ,gdr%50.0 ± SF%400.0

± ,gdr%50.0 ± SF%400.0

± ,gdr%50.0 ± SF%400.0

± ,gdr%50.0 ± SF%400.0

± ,gdr%50.0 ± SF%400.0

± ,gdr%50.0 ± SF%400.0

± ,gdr%50.0 ± SF%400.0

± ,gdr%50.0 ± SF%400.0

± ,gdr%50.0 ± SF%400.0

± ,gdr%50.0 ± SF%400.0

5432-

1-

0

1

2

3

4

5

± ,gdr%50.0 ± SF%400.0

± ,gdr%50.0 ± SF%400.0

± ,gdr%50.0 ± SF%400.0

± ,gdr%50.0 ± SF%400.0

± ,gdr%50.0 ± SF%400.0

± ,gdr%50.0 ± SF%400.0

± ,gdr%50.0 ± SF%400.0

± ,gdr%50.0 ± SF%400.0

± ,gdr%50.0 ± SF%400.0

± ,gdr%50.0 ± SF%400.0

± ,gdr%50.0 ± SF%400.0

DPI 610

Table 2 - Electrical Voltage Input Calibration Tolerances

(Applicable to Standard Models Only NOT IS Models)

Page 29

DPI 610 Calibration Procedures

secnareloTnoitacifireVegnaRAm55,noitarbilaCtnerruC

tnerruCdeilppA noitaiveDelbissimreP

5554535251-

50

5

51

52

53

54

55

± gdr%50.0 ± SF%400.0

± gdr%50.0 ± SF%400.0

± gdr%50.0 ± SF%400.0

± gdr%50.0 ± SF%400.0

± gdr%50.0 ± SF%400.0

± gdr%50.0 ± SF%400.0

± gdr%50.0 ± SF%400.0

± gdr%50.0 ± SF%400.0

± gdr%50.0 ± SF%400.0

± gdr%50.0 ± SF%400.0

± gdr%50.0 ± SF%400.0

± gdr%50.0 ± SF%400.0

± gdr%50.0 ± SF%400.0

Table 3 - Electrical Current Input Calibration Tolerances

K235 Issue No. 2

28

Page 30

Calibration Procedures

tnerruCdeilppA noitaiveDelbissimreP

DPI 610

secnareloTnoitacifireVegnaRAm42noitarbilaCtuptuOtnerruC

0

5

01

51

02

42

02

51

01

5

0

± gdr%50.0 ± SF%10.0

± gdr%50.0 ± SF%10.0

± gdr%50.0 ± SF%10.0

± gdr%50.0 ± SF%10.0

± gdr%50.0 ± SF%10.0

± gdr%50.0 ± SF%10.0

± gdr%50.0 ± SF%10.0

± gdr%50.0 ± SF%10.0

± gdr%50.0 ± SF%10.0

± gdr%50.0 ± SF%10.0

± gdr%50.0 ± SF%10.0

Table 4 - Current Output Calibration Tolerances

29

K235 Issue No. 2

Page 31

K235 Issue No. 2

DPI 610 Calibration Procedures

secnareloTnoitacifireVegnaRV05noitarbilaCegatloV secnareloTnoitacifireVegnaRV5noitarbilaCegatloV

egatloVdeilppA noitaiveDelbissimreP egatloVdeilppA noitaiveDelbissimreP

30

03428121-

60

6

21

81

42

03

± ,gdr%50.0 ± SF%400.0

± ,gdr%50.0 ± SF%400.0

± ,gdr%50.0 ± SF%400.0

± ,gdr%50.0 ± SF%400.0

± ,gdr%50.0 ± SF%400.0

± ,gdr%50.0 ± SF%400.0

± ,gdr%50.0 ± SF%400.0

± ,gdr%50.0 ± SF%400.0

± ,gdr%50.0 ± SF%400.0

± ,gdr%50.0 ± SF%400.0

± ,gdr%50.0 ± SF%400.0

5432-

1-

0

1

2

3

4

5

± ,gdr%50.0 ± SF%400.0

± ,gdr%50.0 ± SF%400.0

± ,gdr%50.0 ± SF%400.0

± ,gdr%50.0 ± SF%400.0

± ,gdr%50.0 ± SF%400.0

± ,gdr%50.0 ± SF%400.0

± ,gdr%50.0 ± SF%400.0

± ,gdr%50.0 ± SF%400.0

± ,gdr%50.0 ± SF%400.0

± ,gdr%50.0 ± SF%400.0

± ,gdr%50.0 ± SF%400.0

Table 5- Electrical Voltage Input Calibration Tolerances

(IS Models Only)

Loading...

Loading...