Page 1

e

SERVICE MANUAL

MODEL JP E3 E2 EK EA E1 E1K E1C

Ver. 7

Please refer to the

MODIFICATION NOTICE.

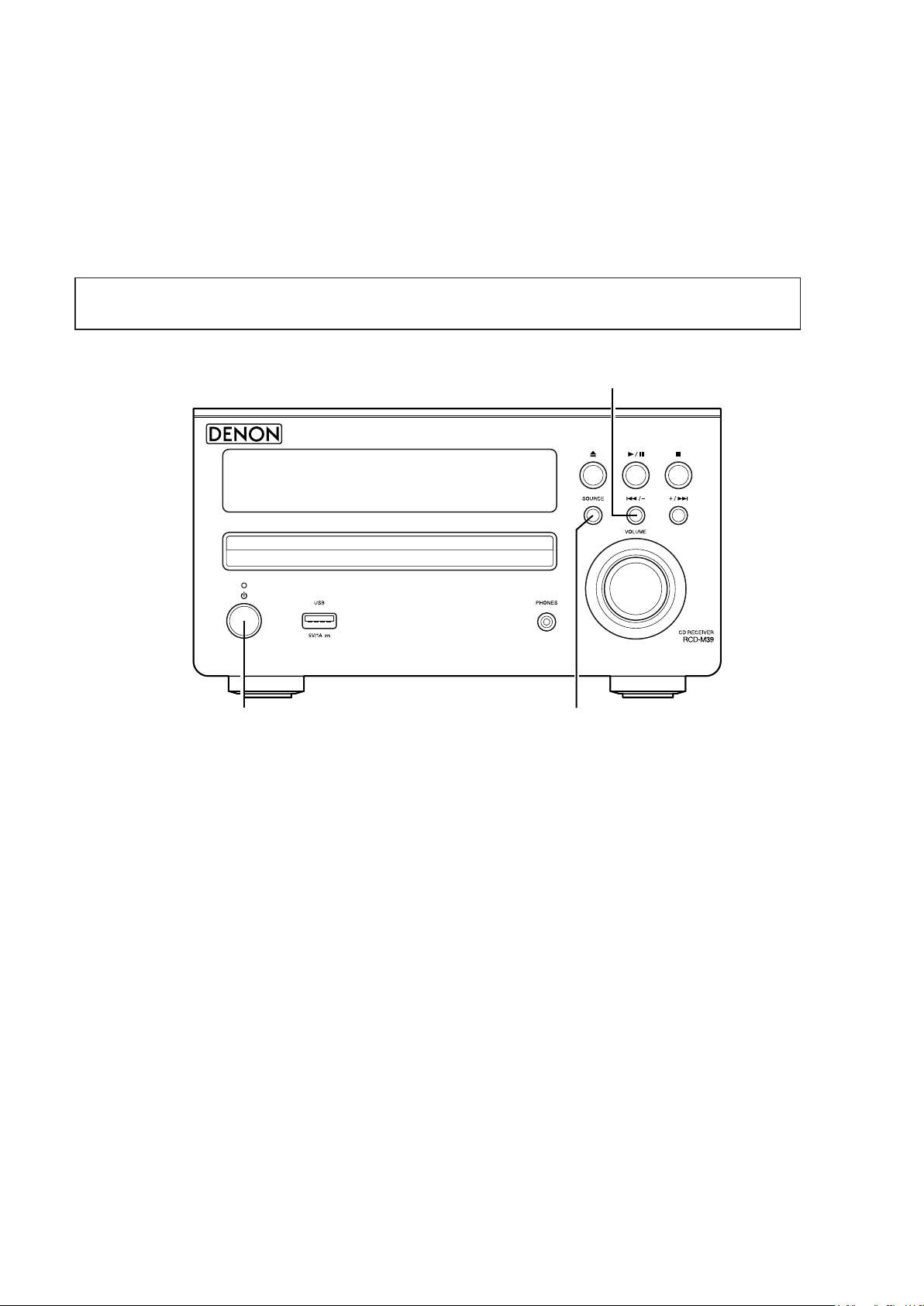

RCD-M39

RCD-M39DAB

P P P

P

CD RECEIVER

• The part list can be found in a separate le.See the part list in Excel format.

For purposes of improvement, specications and design are subject to change without notice.

•

Please use this service manual with referring to the operating instructions without fail.

•

Some illustrations using in this service manual are slightly different from the actual set.

•

e

D&M Holdings Inc.

S0603-0V07DM/DG1212

Copyright 2012 D&M Holdings Inc. All rights reserved.

WARNING: Violators will be prosecuted to the maximum extent possible.

Page 2

CONTENTS

ABOUT THIS MANUAL

What you can do with this manual ............................................3

Using Adobe Reader (Windows version) ..................................4

NOTE FOR SCHEMATIC DIAGRAM

Specications

CAUTION IN SERVICING

Initializing STEREO CD RECEIVER .......................................10

Support for Asia-Pacic tropical climate regions .....................10

DISASSEMBLY

About the photos used for "descriptions in the

DISASSEMBLY" section .........................................................12

1. LOADER PANEL ASSY .......................................................12

2. FRONT PANEL ASSY .........................................................13

3. CD MECHA .........................................................................14

4. HEAT SINK SUB ASSY .......................................................15

5. REAR PANEL ASSY ............................................................17

6. POWER UNIT ASSY ...........................................................19

7. MCU PCB UNIT ASSY ........................................................19

8. TRANS ................................................................................19

Note Handling and Replacement of the Laser pick-up

1. Protection of the LD .............................................................20

2. Precautions when handling the laser CD mechanism .........20

3. Cautions on assembling and adjustment ............................20

4. Determining whether the laser pick-up is defective .............20

Service Mode

How to input ...........................................................................21

1. Version display mode ..........................................................21

2. VFD checking mode ............................................................21

3. Cold start mode (initialization) .............................................22

4. CD test mode ......................................................................22

5. CD heat run mode ...............................................................26

6. Accumulated laser on time display mode ............................28

VERSION UPGRADE PROCEDURE OF FIRMWARE

1. ABOUT REPLACE THE MICROPROCESSOR

WITH A NEW ONE ..................................................................29

2. UPDATE MODE ..................................................................29

TROUBLE SHOOTING

1. VFD dosen't light .................................................................45

2. No Sound, Noise generated ................................................46

MEASURING METHOD AND WAVEFORMS

1. MCUCD PCB : TEST POINT ..............................................50

2. INPUT PCB : TEST POINT ................................................51

3. WAVEFORMS .....................................................................52

...........................................................................9

..........................................................................21

.............................................................3

.........................................7

........................................................10

........................................................................11

.......20

............29

............................................................45

..........................50

BLOCK DIAGRAM

CurrentBLOCK DIAGRAM

LEVEL DIAGRAM

WIRING DIAGRAM

PRINTED WIRING BOARDS

AMP ........................................................................................59

POWER ..................................................................................59

FRONT ...................................................................................60

SPEAKER ..............................................................................60

CONNECTOR ........................................................................61

CONNETER ...........................................................................61

CONNETER ...........................................................................61

MCU .......................................................................................62

DIGITAL INPUT ......................................................................63

DC-DC ....................................................................................63

REGULATOR .........................................................................63

DAB ........................................................................................63

SCHEMATIC DIAGRAMS (1/3)

MCU&CD ................................................................................64

DIGITAL INPUT .......................................................................65

POWER & AMP ......................................................................66

EXPLODED VIEW

EXPLODED VIEW OF CD MECHANISM UNIT

PARTS LIST OF EXPLODED VIEW

PARTS LIST OF CD MECHANISM UNIT

PACKING VIEW

PARTS LIST OF PACKING & ACCESSORIES

SEMICONDUCTORS

1. IC's ......................................................................................72

2. FL DISPLAY.........................................................................91

PARTS LIST OF PCB UNIT

...................................................................55

.....................................................56

....................................................................57

..................................................................58

...................................................59

...............................................64

...................................................................67

.......................68

.......................................69

...............................70

.......................................................................71

.......................71

...............................................................72

.....................................................94

2

Page 3

ABOUT THIS MANUAL

Read the following information before using the service manual.

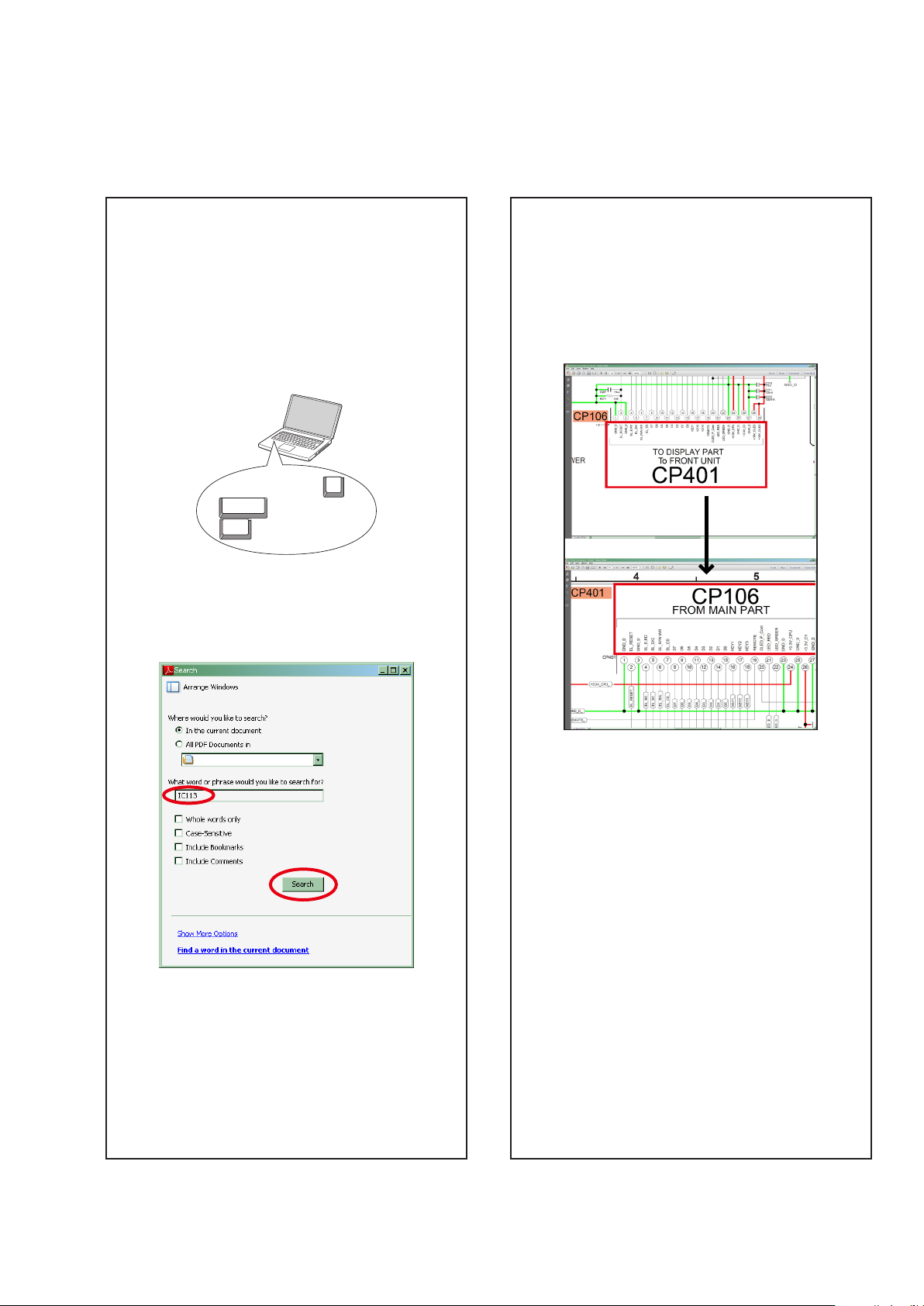

What you can do with this manual

Search for a Ref. No. (phrase)

(Ctrl+Shift+F)

You can use the search function in Acrobat Reader to

search for a Ref. No. in schematic diagrams, printed

wiring board diagrams, block diagrams, and parts lists.

1.Press

2.Enter the Ref. No. you want to search for in the

Ctrl+Shift+F

on the keyboard.

• The Search window appears.

F

Shift

Ctrl

Search window, and then click the

• A list of search results appears.

Search

button.

Jump to the target of a schematic diagram

connector

Click the Ref. No. of the target connector in the red box

around a schematic diagram connector.

• The screen jumps to the target connector.

3.Click an item on the list.

• The screen jumps to the page for that item, and

the search phrase is displayed.

• Page magnification stays the same as before the

jump.

3

Page 4

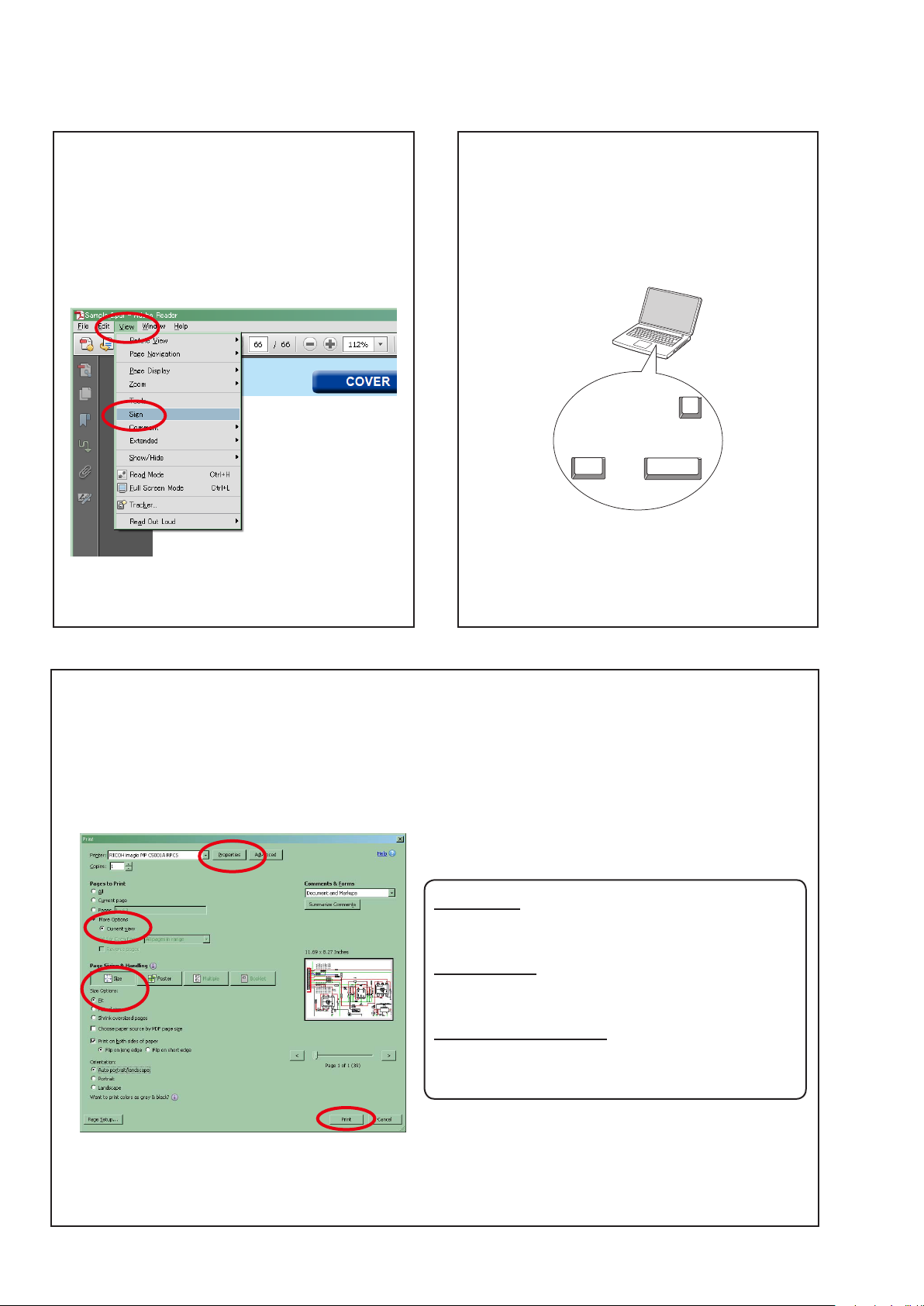

Using Adobe Reader (Windows version)

Add notes to this data (Sign)

The Sign function lets you add notes to the data in this

manual.

Save the le once you have nished adding notes.

[Example using Adobe Reader X]

On the "

View

" menu, click "

• The Sign pane appears.

[Example using Adobe Reader 9]

On the "

Document

" menu, click "

Sign

".

Sign

".

Magnify schematic / printed wiring board

diagrams - 1

(Ctrl+Space, mouse operation)

Ctrl+Space

Press

mouse to select the area you want to view.

• The selected area is magnied.

• When you want to move the area shown, hold down

Space

and drag the mouse.

• When you want to show a full page view, press

Ctrl+0

on the keyboard.

on the keyboard and drag the

0

Ctrl Space

Print a magnied part of the manual

The Properties dialog box and functions will vary depending on your printer.

1. Drag the mouse to magnify the part you want to print.

2. On the "

File

" menu, click "

3. Congure the following settings in the Print dialog box.

Print

".

• Properties

Click this button and check that the printer is set to a

suitable paper size.

• Page to print

Select the following checkbox.

More Options

"

• Page Sizing & Handling

Select the following checkbox.

"

Size

Size Options

" / "

Current View

" : "

" : "

Fit

"

"

4. Click the

Print

button to start printing.

4

Page 5

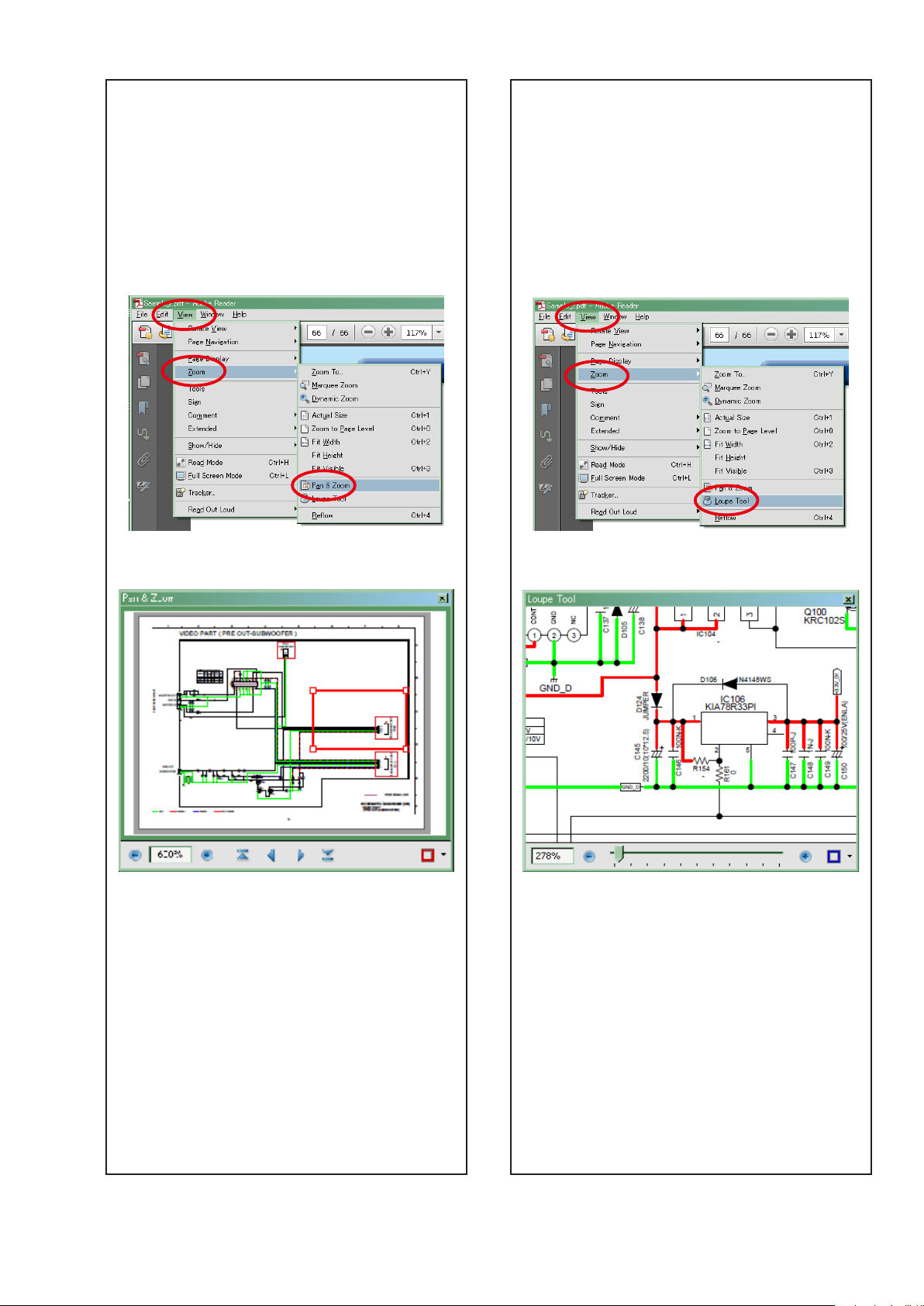

Magnify schematic / printed wiring board

diagrams - 2

(Pan & Zoom function)

The Pan & Zoom function lets you see which part of a

magnied diagram is being shown in a separate window.

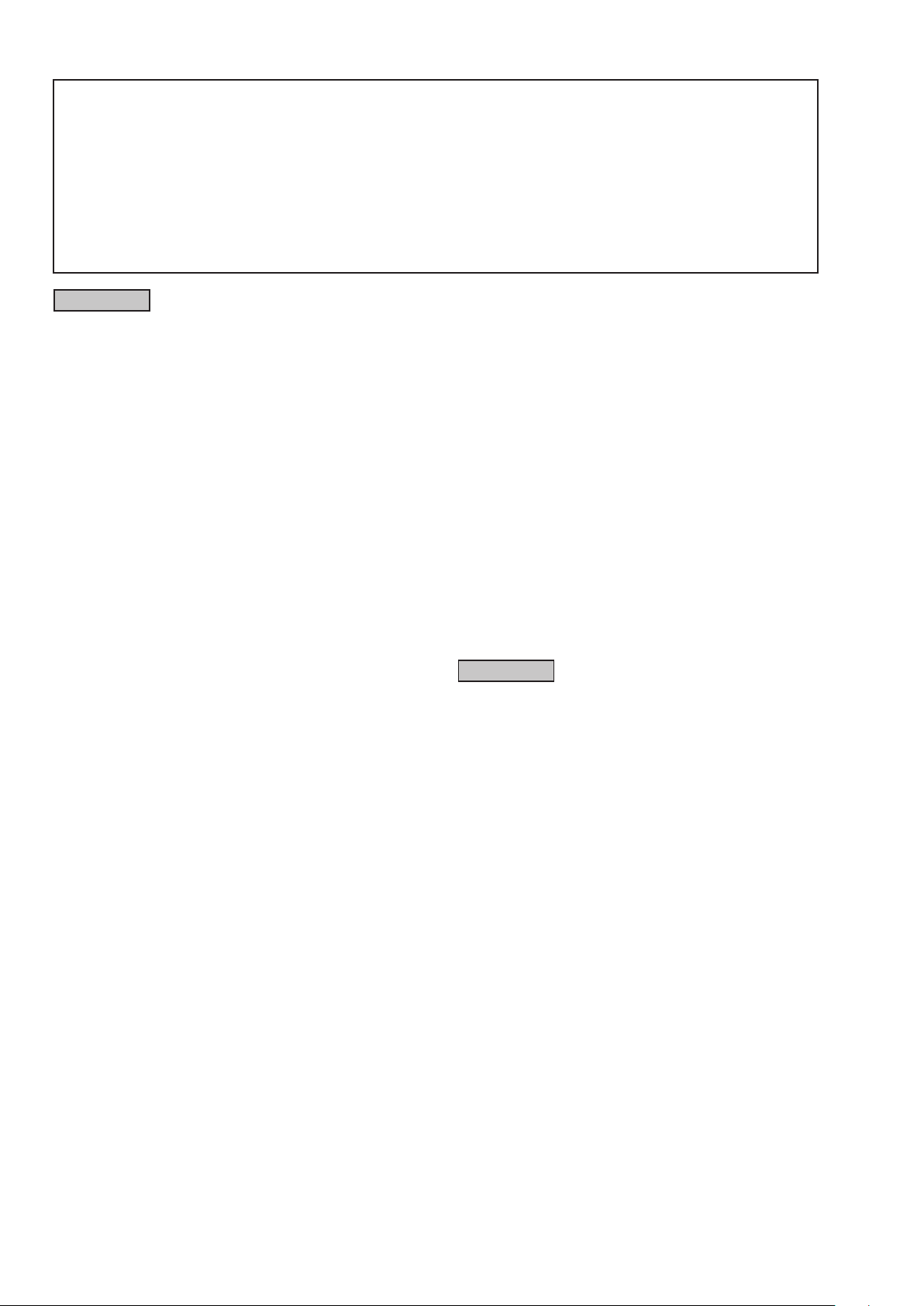

Magnify schematic / printed wiring board

diagrams - 3

(Loupe Tool function)

The Loupe Tool function lets you magnify a specific

part of a diagram in a separate window.

[Example using Adobe Reader X]

On the "

Pan & Zoom

"

• The Pan & Zoom window appears on the screen.

View

" menu, point to "

".

Zoom

", and then click

[Example using Adobe Reader X]

On the "

Loupe Tool

"

• The Loupe Tool window appears on the screen.

View

" menu, point to "

".

Zoom

", and then click

[Example using Adobe Reader 9]

On the "

then click "

Tools

" menu, point to "

Pan & Zoom Window

Select & Zoom

[Example using Adobe Reader 9]

", and

".

On the "

then click "

5

Tools

" menu, point to "

Loupe Tool Window

Select & Zoom

".

", and

Page 6

SAFETY PRECAUTIONS

The following check should be performed for the continued protection of the customer and service technician.

LEAKAGE CURRENT CHECK

Before returning the unit to the customer, make sure you make either (1) a leakage current check or (2) a line to chassis

resistance check. if the leakage current exceeds 0.5 milliamps, or if the resistance from chassis to either side of the

power cord is less than 460 kohms, the unit is defective.

Be sure to test for leakage current with the AC plug in both polarities, in addition, in each power ON, OFF and STANDBY

mode, if applicable.

CAUTION

Please heed the points listed below during servicing and inspection.

◎Heed the cautions!

Spots requiring particular attention when servicing, such

as the cabinet, parts, chassis,etc., have cautions indicated

on labels. be sure to heed these causions and the

cautions indicated in the handling instructions.

◎Caution concerning electric shock!

(1) An AC voltage is impressed on this set, so touching

internal metal parts when the set is energized could

cause electric shock. Take care to avoid electric

shock, by for example using an isolating transformer

and gloves when servicing while the set is energized,

unplugging the power cord when replacing parts, etc.

(2) Tere are high voltage parts inside. Handle with extra

care when the set is energized.

◎ Caution concerning disassembly and

assembly!

Through great care is taken when manufacturing parts

from sheet metal, there may in some rare cases be burrs

on the edges of parts which could cause injury if ngers

are moved across them. Use gloves to protect your hands.

◎Only use designated parts!

The set's parts have specific safety properties (fire

resistance, voltage resistance, etc.). For replacement

parts, be sure to use parts which have the same

poroperties. In particular, for the important safety parts

that are marked z on wiring diagrams and parts lists, be

sure to use the designated parts.

◎ Be sure to mount parts and arrange the wires

as they were originally!

For safety seasons, some parts use tape, tubes or other

insulating materials, and some parts are mounted away

from the surface of printed circuit boards. Care is also

taken with the positions of the wores omsode amd clamps

are used to keep wires away from heating and high

voltage parts, so be sure to set everything back as it was

originally.

◎Inspect for safety after servicing!

Check that all screws, parts and wires removed or

disconnected for servicing have been put back in their

original positions, inspect that no parts around the area

that has been serviced have been negatively affected,

conduct an inslation check on the external metal

connectors and between the blades of the power plug,

and otherwise check that safety is ensured.

(Insulation check procedure)

Unplug the power cord from the power outlet, disconnect

the antenna, plugs, etc., and turn the power switch on.

Using a 500V insulation resistance tester, check that the

inplug and the externally exposed metal parts (antenna

terminal, headphones terminal, input terminal, etc.) is

1MΩ or greater. If it is less, the set must be inspected and

repaired.

CAUTION

Concerning important safety

parts

Many of the electric and structural parts used in the set

have special safety properties. In most cases these

properties are difficult to distinguish by sight, and using

replacement parts with higher ratings (rated power and

withstand voltage) does not necessarily guarantee that

safety performance will be poreserved. Parts with safety

properties are indicated as shown below on the wiring

diagrams and parts lists is this service manual. Be sure to

replace them with parts with the designated part number.

(1) Schematic diagrams ......Indicated by the z mark.

(2) Parts lists ......Indicated by the z mark.

Using parts other than the designated

parts could result in electric shock, res

or other dangerous situations.

6

Page 7

NOTE FOR SCHEMATIC DIAGRAM

NOTE FOR PARTS LIST

WARNING:

Parts indicated by the z mark have critical characteristics. Use ONLY replacement parts recommended by the manufacturer.

CAUTION:

Before returning the set to the customer, be sure to carry out either (1) a leakage current check or (2) a line to chassis resistance check. If

the leakage current exceeds 0.5 milliamps, or if the resistance from chassis to either side of the power cord is less than 460 kohms, the set

is defective.

WARNING:

DO NOT return the set to the customer unless the problem is identied and remedied.

NOTICE:

ALL RESISTANCE VALUES IN OHM. k=1,000 OHM / M=1,000,000 OHM

ALL CAPACITANCE VALUES ARE EXPRESSED IN MICRO FARAD, UNLESS OTHERWISE INDICATED. P INDICATES MICRO-MICRO

FARAD. EACH VOLTAGE AND CURRENT ARE MEASURED AT NO SIGNAL INPUT CONDITION. CIRCUIT AND PARTS ARE SUBJECT

TO CHANGE WITHOUT PRIOR NOTICE.

NOTE FOR PARTS LIST

1.

Parts for which "nsp" is indicated on this table cannot be supplied.

2.

When ordering of part, clearly indicate "1" and "I" (i) to avoid mis-supplying.

3.

Ordering part without stating its part number can not be supplied.

4.

Part indicated with the mark "★" is not illustrated in the exploded view.

5.

Not including General-purpose Carbon Film Resistor in the P.W.Board parts list. (Refer to the Schematic Diagram for those parts.)

6.

Not including General-purpose Carbon Chip Resistor in the P.W.Board parts list. (Refer to the Schematic Diagram for those parts.)

WARNING:

Parts marked with this symbol z have critical characteristics. Use ONLY replacement parts recommended by the manufacturer.

7

Page 8

m

WARNING AND LASER SAFETY INSTRUCTIONS

GB

WARNING

All ICs and many other semi-conductors are

susceptible to electrostatic discharges (ESD).

Careless handling during repair can reduce

life drastically.

When repairing, make sure that you are

connected with the same potential as the

mass of the set via a wrist wrap with

resistance.

Keep components and tools also at this

potential.

F

ATTENTION

D

WARNUNG

I

WAARSCHUWING

AVVERTIMENTO

NL

Alle IC’s en vele andere halfgeleiders zijn

gevoelig voor elektrostatische ontladingen

(ESD).

Onzorgvuldig behandelen tijdens reparatie

kan de levensduur drastisch doen

verminderen.

Zorg ervoor dat u tijdens reparatie via een

polsband met weerstand verbonden bent met

hetzelfde potentiaal als de massa van het

apparaat.

Houd componenten en hulpmiddelen ook op

ditzelfde potentiaal.

Tous les IC et beaucoup d’autres semiconducteurs sont sensibles aux décharges

statiques (ESD).

Leur longévité pourrait être considérablement

écourtée par le fait qu’aucune précaution

n’est prise a leur manipulation.

Lors de réparations, s’assurer de bien être

relié au même potentiel que la masse de

l’appareil et enfiler le bracelet serti d’une

résistance de sécurité.

Veiller a ce que les composa

outils que l’on utilise soient également a ce

potentiel.

nts ainsi que les

GB

Safety regulations require that the set be restored to its original condition

and that parts which are identical with those specified be used.

NL

Veiligheidsbepalingen vereisen, dat het apparaat in zijn oorspronkelijke

toestand wordt terug gebracht en dat onderdelen, identiek aan de

gespecifieerde worden toegepast.

Alle IC und viele andere Halbleiter sind

empfindlich gegen elektrostatische

Entladungen (ESD).

Unsorgfältige Behandlung bei der Reparatur

kann die Lebensdauer drastisch vermindern.

Sorgen sie dafür, das Sie im Reparaturfall

über ein Pulsarmband mit Widerstand mit

dem Massepotential des Gerätes verbunden

sind.

Halten Sie Bauteile und Hilfsmittel ebenfalls

auf diesem Potential.

D

Bei jeder Reparatur sind die geltenden Sicherheitsvorschriften zu beachten.

Der Originalzustand des Gerats darf nicht verandert werden

Fur Reparaturen sind Original-Ersatzteile zu verwenden.

I

Le norme di sicurezza esigono che l’apparecchio venga rimesso nelle

condizioni originali e che siano utilizzati pezzi di ricambiago idetici a quelli

specificati.

Tutti IC e parecchi semi-conduttori sono

sensibili alle scariche statiche (ESD).

La loro longevita potrebbe essere fortemente

ridatta in caso di non osservazione della piu

grande cauzione alla loro manipolazione.

Durante le riparazioni occorre quindi essere

collegato allo stesso potenziale che quello

della massa dell’apparecchio tramite un

braccialetto a resistenza.

Assicurarsi che i componenti e anche gli

utensili con quali si lavora s

questo potenziale.

iano anche a

.

F

“Pour votre sécurité, ces documents

doivent être utilisés par des

spécialistes agrées, seu ls habilités à

réparer votre appareil en panne.”

Les normes de sécurité exigent que l’appareil soit remis a l’état d’origine et

que soient utilisées les pièces de rechange identiques à celles spécifiées.

LASER SAFETY

This unit employs a laser. Only a qualified service person should remove the cover or attempt to service t

device, due to possible eye injury.

his

USE OF CONTROLS OR ADJUSTMENTS OR PERFORMANCE OF PROCEDURE OTHER THAN THOSE

SPECIFIED H

EREIN MAY RESULT IN HAZARDOUS RADIATION EXPOSURE.

AVOID DIRECT EXPOSURE TO BEAM

WARNING

The use of optical instruments with this product will increase eye hazard.

Repair handling should take place as much as possible with a disc loaded inside the player

WARNING LOCATION: INSIDE ON LASER COVERSHIELD

CAUTION VISIBLE AND INVISIBLE LASER RADIATION WHEN OPEN AVOID EXPOSURE TO BEAM

ADVARSEL SYNLIG OG USYNLIG LASERSTRÅLING VED ÅBNING UNDGÅ UDS

ADVARSEL SYNLIG OG USYNLIG LASERSTRÅLING NÅR DEKSEL Å PNES UNNGÅ EKSPONERING FOR STRÅLEN

VARNING SYNLIG OCH OSYNLIG LASERSTRÅLNING NÄR DENNA DEL ÄR ÖPPNAD BETRAKTA EJ STRÅLEN

VARO! AVATT AESSA OLET ALTTIINA NÄKYVÄLLE JA NÄKYMÄTTÖMÄLLE LASER SÄ

VORSICHT SICHTBARE UND UNSICHTBARE LASERSTRAHLUNG WENN ABDECKUNG GEÖFFNET NICHT DEM STRAHL AUSSETSEN

DANGER VISIBLE AND INVISIBLE LASER RADIATION WHEN OPEN AVOID DIRECT EXPOSURE TO BEAM

ATTENTION RAYONNEMENT LASER VISIBLE ET INVISIBLE EN CAS D'OUVERTURE EXPOSITION DANGEREUSE AU FAISCEAU

Æ

TTELSE FOR STRÅLING

TEILYLLE. ÄLÄ KATSO SÄTEESEEN

030804ec

8

Page 9

SPECIFICATIONS

n Audio section

Power amplifer

Rated output:

30 W + 30 W (6 Ω, 1 kHz T.H.D 10 %)

n Tuner section

Receiving range (E2,EK model):

FM: 87.50 MHz – 108.00 MHz

DAB (EK model): BAND3 170 MHz – 240 MHz

Receiving range (E3 model):

FM: 87.50 MHz – 107.90 MHz

Usable sensitivity:

FM: 1.2 μV/75 Ω

DAB (EK model): –93 dBm/50 Ω

FM stereo separation: 35dB(1kHz)

n CD section

Playback frequency response: 2Hz ~ 20kHz

Wow & flutter: Below measurable limits (± 0.001%)

Sampling frequency: 44.1kHz

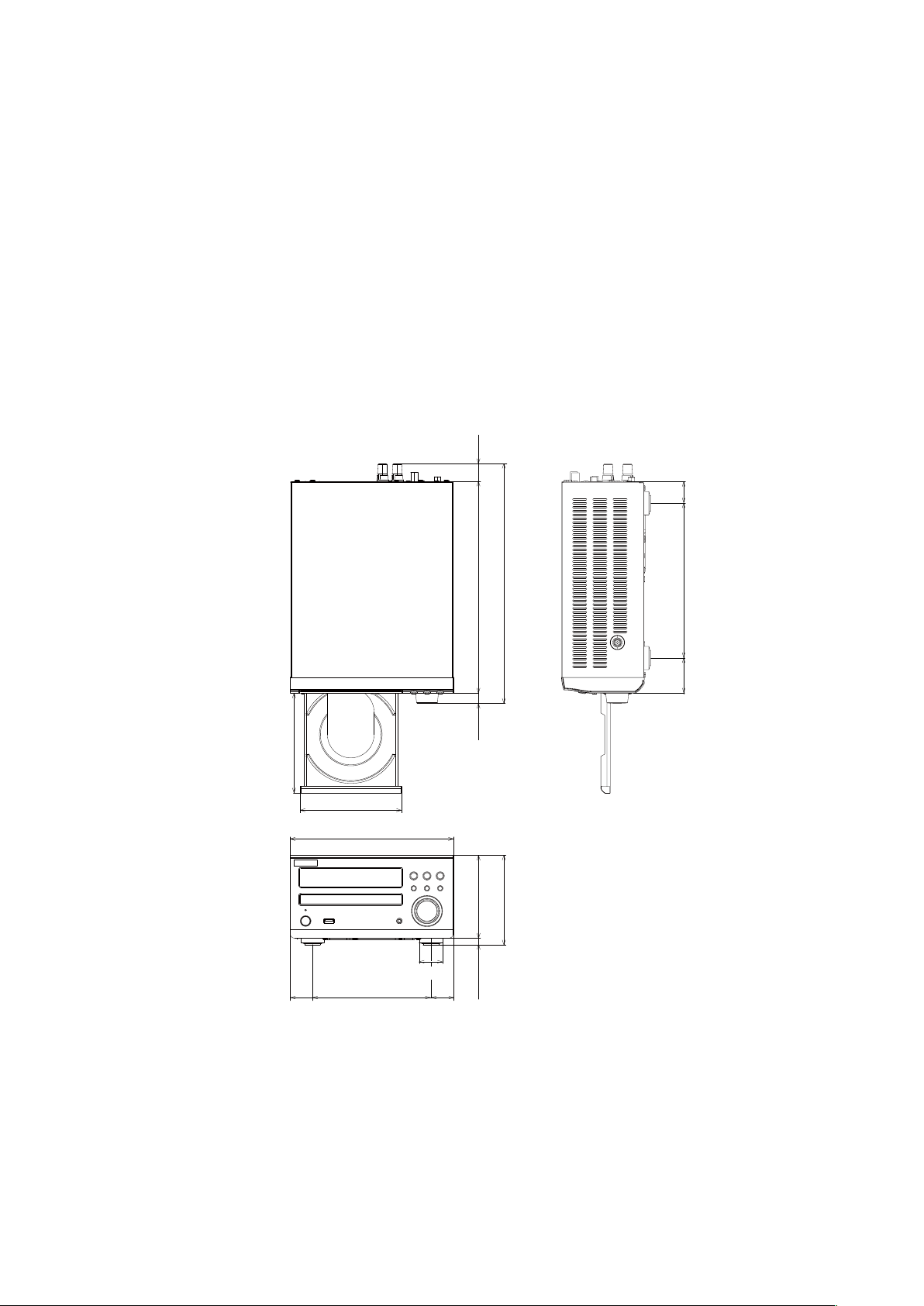

DIMENSION

n Clock/Timer section

Clock method: Crystal oscillator (Within 1 – 2 minutes per month)

Timer: Everyday/Once timer: One each

Sleep timer: 90 minutes, maximum

n General

Power supply (E2,EK model): AC 230 V, 50/60 Hz

Power supply (E3 model): AC 120 V, 60 Hz

Power consumption: 70 W

Approx. 0.3 W (standby)

25.0

129.1

130.0

210.0

152.0 29.029.0

30.0

272.0

8.5 106.5

11.0

308.0

115.0

199.045.0 28.0

9

Page 10

CAUTION IN SERVICING

Initializing STEREO CD RECEIVER

STEREO CD RECEIVER initialization should be performed when the μcom, peripheral parts of μcom, and Digital PCB.

are replaced.

1. Turn off the power using "Power operation (X)" button, unplug the power cord.

2. Plug the power cord into a power outlet while pressing "8 / –" and "SOURCE" button simultaneously.

Initialize.

*

NOTE: All user settings will be lost and this factory setting will be recovered when this initialization mode.

So make sure to memorize your setting for restoring after the initialization.

8 / -

Power operation (X) SOURCE

Support for Asia-Pacic tropical climate regions

Before selling this product, purchase and attach the tropical standard supporting part.

For this part, see the part list on page 67.

For where to attach the part, see the exploded view.

10

Page 11

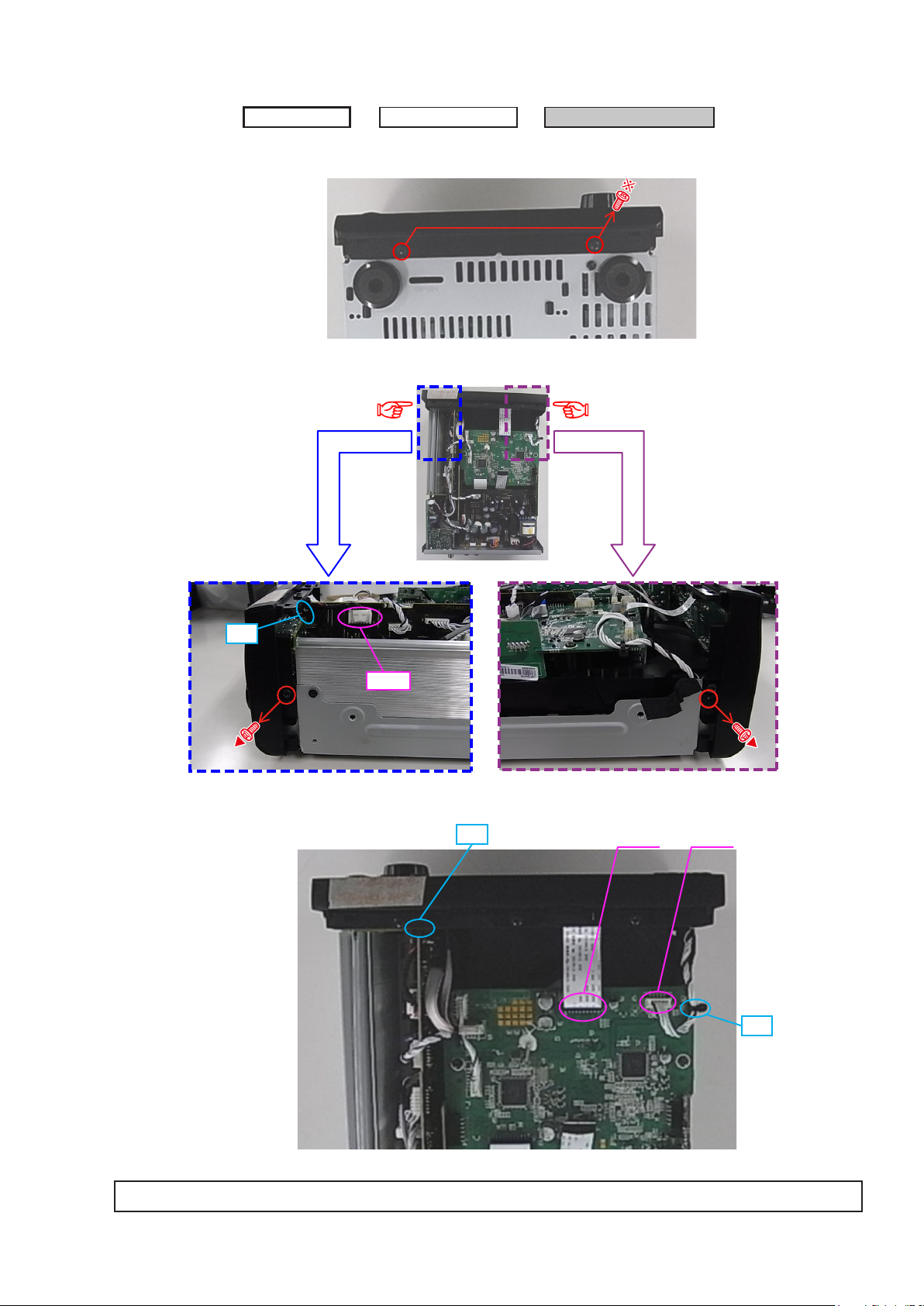

DISASSEMBLY

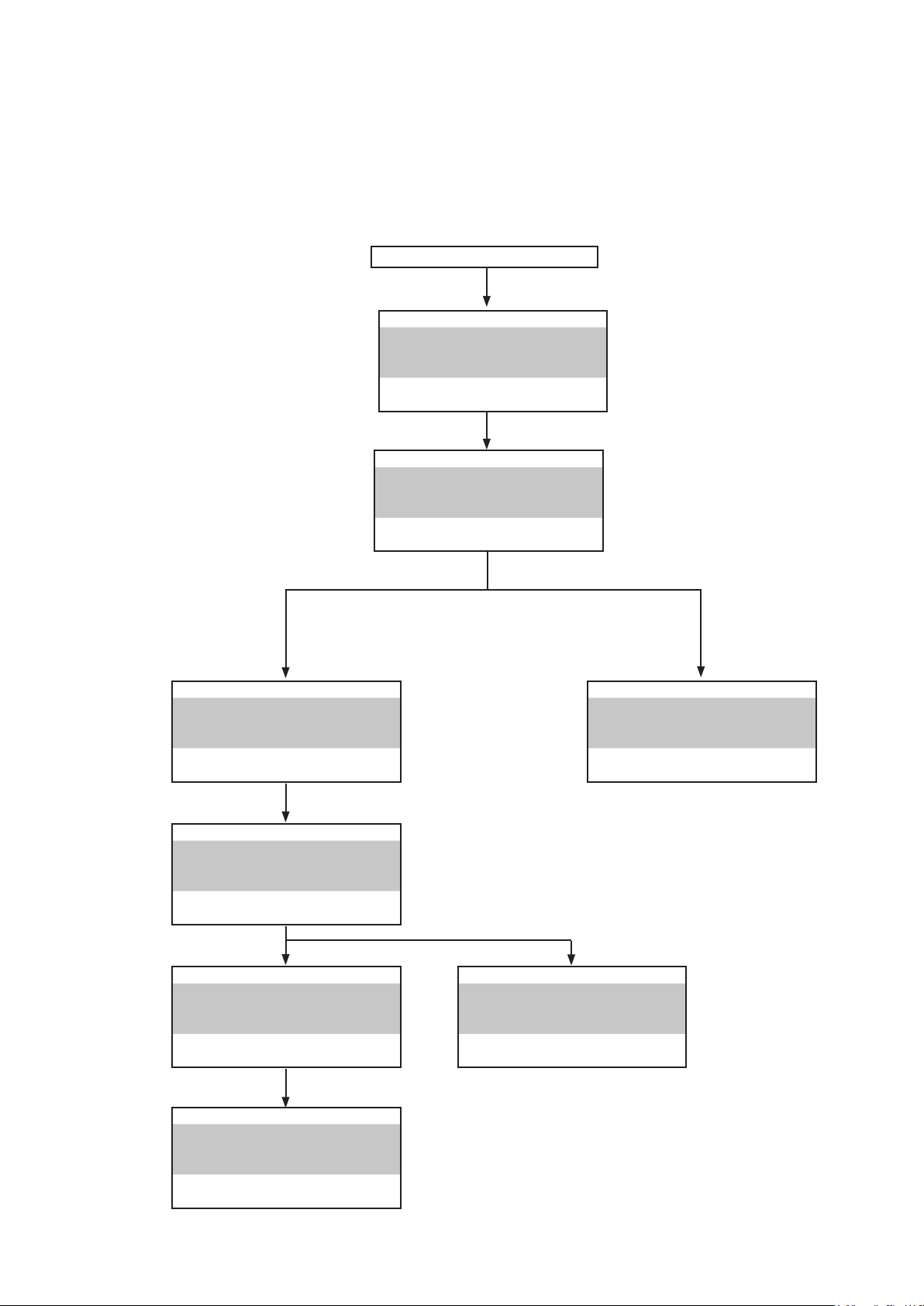

• Disassemble in order of the arrow of the gure of following ow.

• In the case of the re-assembling, assemble it in order of the reverse of the following ow.

• In the case of the re-assembling, observe "attention of assembling" it.

• If wire bundles are untied or moved to perform adjustment or parts replacement etc., be sure to rearrange them neatly

as they were originally bundled or placed afterward.

Otherwise, incorrect arrangement can be a cause of noise generation.

TOP COVER

LOADER PANEL ASSY

"DISASSEMBLY

Refer to

1. LOADER PANEL ASSY"

"EXPLODED VIEW"

and

LOADER PANEL

(Ref. No. of EXPLODED VIEW : 3)

FRONT PANEL ASSY

"DISASSEMBLY

Refer to

2. FRONT PANEL SUB ASSY"

"EXPLODED VIEW"

and

FRONT PANEL

(Ref. No. of EXPLODED VIEW : 6)

HEAT SINK SUB ASSY

"DISASSEMBLY

Refer to

4. HEAT SINK SUB ASSY"

"EXPLODED VIEW"

and

HEAT SINK

(Ref. No. of EXPLODED VIEW : 18)

REAR PANEL ASSY

"DISASSEMBLY

Refer to

5. REAR PANEL ASS'Y"

"EXPLODED VIEW"

and

REAR PANEL

(Ref. No. of EXPLODED VIEW : 21)

POWER UNIT ASSY

"EXPLODED VIEW"

Refer to

6. POWER UNIT ASS'Y"

"EXPLODED VIEW"

and

POWER UNIT

(Ref. No. of EXPLODED VIEW : P1)

TRANS

"EXPLODED VIEW"

Refer to

8. TRANS"

"EXPLODED VIEW"

and

TRANS

(Ref. No. of EXPLODED VIEW : P6)

Refer to

and

CD MECHA

(Ref. No. of EXPLODED VIEW : P8)

MCU PCB UNIT ASSY

"EXPLODED VIEW"

Refer to

7. MCU PCB UNIT ASSY"

"EXPLODED VIEW"

and

MCU PCB UNIT

(Ref. No. of EXPLODED VIEW : P3)

CD MECHA ASS'Y

"DISASSEMBLY

3. CD MECHA ASS'Y"

"EXPLODED VIEW"

11

Page 12

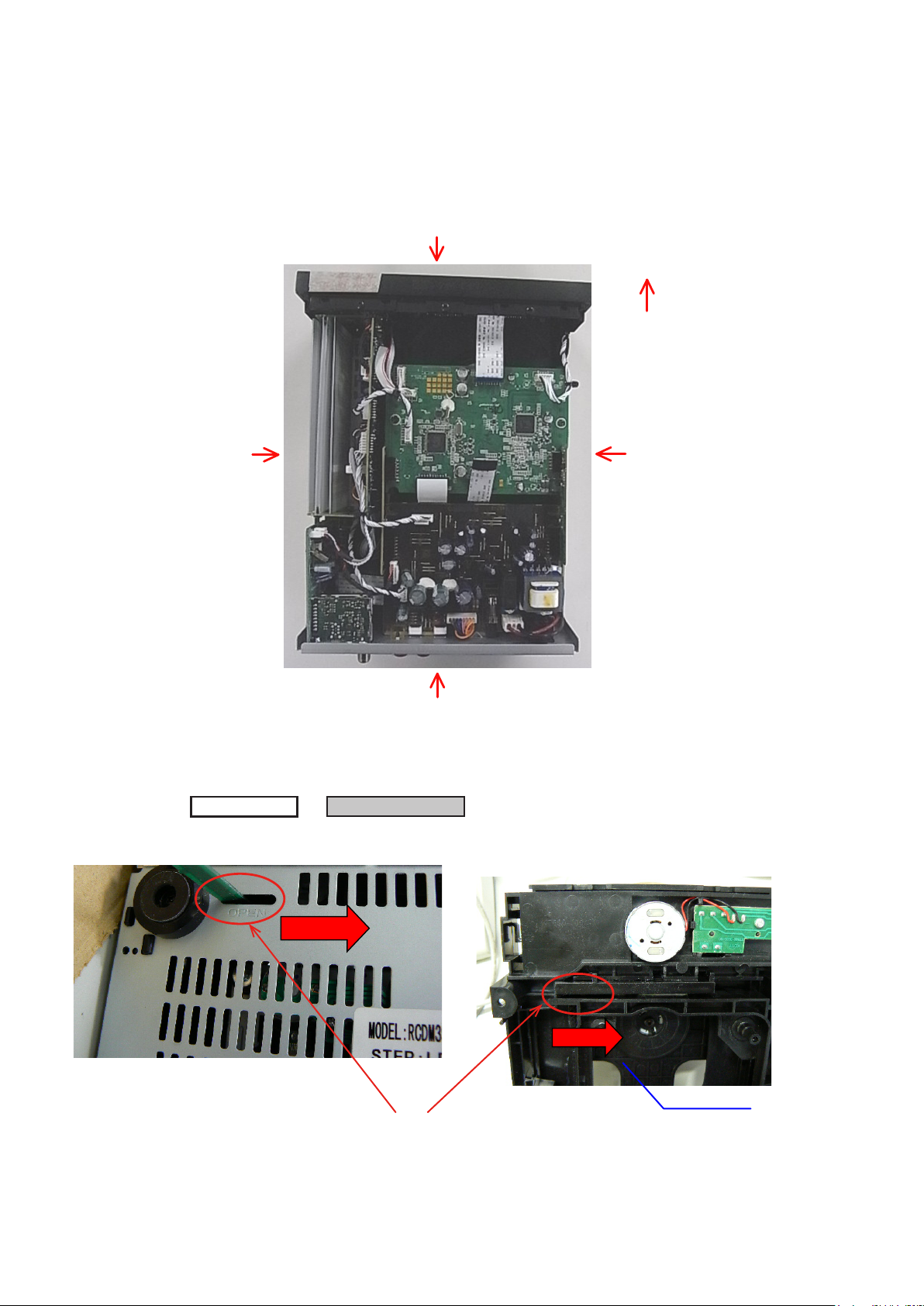

About the photos used for "descriptions in the DISASSEMBLY" section

• The direction from which the photographs used herein were photographed is indicated at "Direction of photograph: ***"

at the left of the respective photographs.

• Refer to the table below for a description of the direction in which the photos were taken.

• Photographs for which no direction is indicated were taken from above the product.

• The photograph is RCD-M39 model.

The viewpoint of each photograph

(Photografy direction)

[View from above]

Direction of photograph: C

Direction of photograph: B

Front side

Direction of photograph: D

1. LOADER PANEL ASSY

Proceeding : TOP COVER

(1) Detach the LOADER PANEL.

You can slide in the arrow direction to pull out the TRAY.

Direction of photograph: A

LOADER PANEL

→

CD MECHA

12

Page 13

2. FRONT PANEL ASSY

Proceeding : TOP COVER

(1) Remove the screws.

View from bottom

(2) Disconnect the connector wire, then remove the screws.

Direction of

photograph: C

LOADER PANEL

→

FRONT PANEL ASSY

→

Direction of

photograph: D

cut

CWAJ

(3) Cut the wire clamp band, then disconnect the connector wires.

cut

Direction of photograph: B

CWMF FCMA

cut

Please refer to "EXPLODED VIEW" for the disassembly method of each PCB included in FRONT PANEL ASSY.

13

Page 14

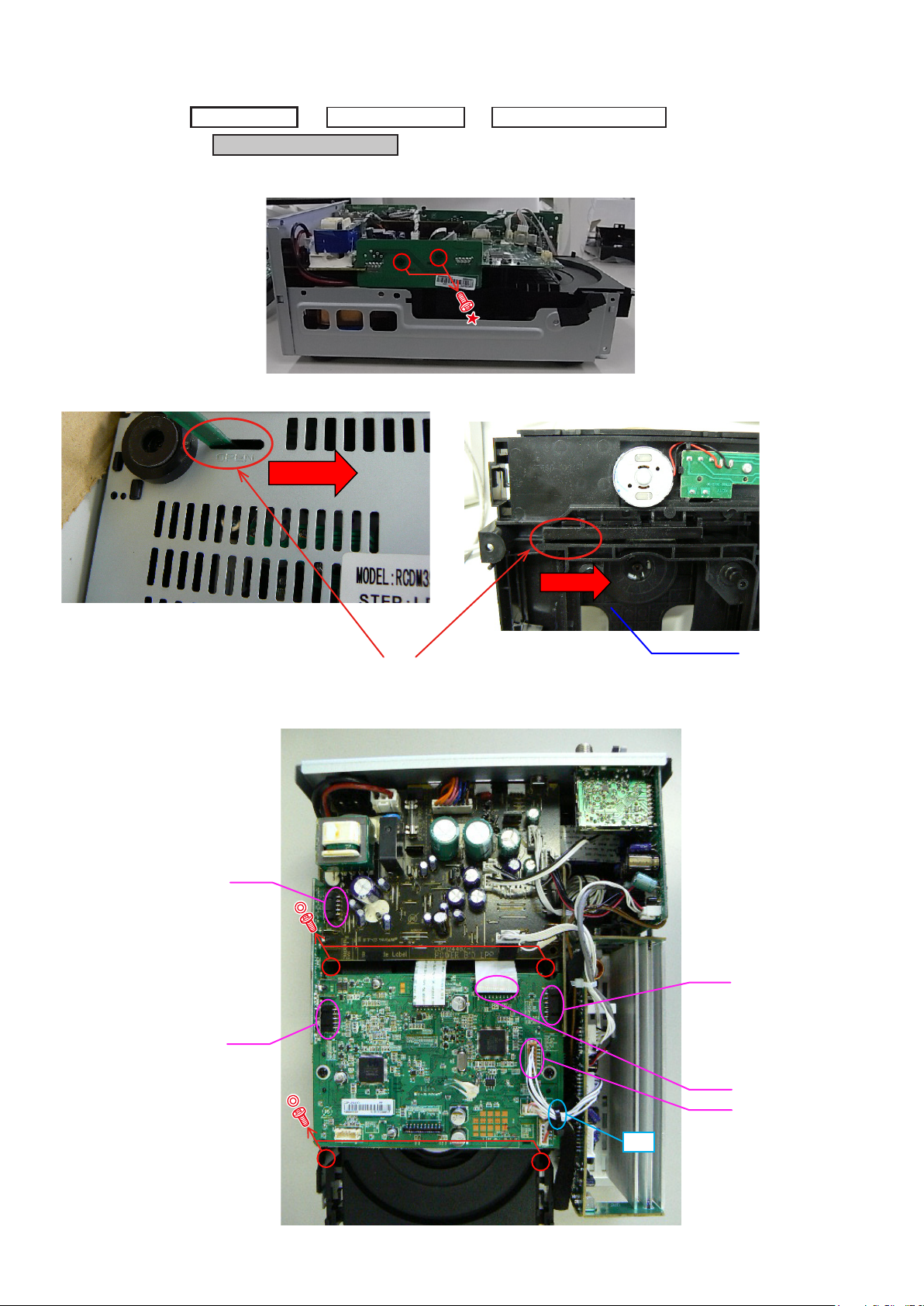

3. CD MECHA

Proceeding : TOP COVER

CD MECHANISM ASS'Y

→

(1) Remove the screws.

Direction of photograph: D

(2) Pull out the TRAY.

LOADER PANEL

→

FRONT PANEL ASS'Y

→

You can slide in the arrow direction to pull out the TRAY.

(3) Cut the wire clamp band, then disconnect the connector wires. Remove the screws.

PMSN

Direction of photograph: B

PMMO

CD MECHA

PMUP

FCMC

CMMD

14

cut

Page 15

4. HEAT SINK SUB ASSY

Proceeding : TOP COVER

HEAT SINK SUB ASSY

→

(1) Cut the wire clamp band, then disconnect the connector wires.

Direction of photograph: B

LOADER PANEL

→

→

FRONT PANEL ASS'Y

CWSQ

CWIL

CBSK

cut

(2) Remove the screws.

Direction of photograph: C

CMMD

cut

15

Page 16

(3) Remove the screws.

View from bottom

(4) Disconnect the connector wires.

CBAM

Direction of photograph: C

HEAT SINK SUB ASSY

Please refer to "EXPLODED VIEW" for the disassembly method of each PCB included in HEAT SINK SUB ASSY.

16

Page 17

5. REAR PANEL ASSY

Proceeding : TOP COVER

HEAT SINK SUB ASSY

→

(1) Remove the screws.

Direction of photograph: A

(2) Remove the screws.

LOADER PANEL

→

FRONT PANEL ASS'Y

→

REAR PANEL ASSY

→

View from bottom

(3) Remove the screws.

Direction of photograph: C

17

Page 18

(4) Disconnect the connector wire, then remove the screws.

CN91

PMSE

Direction of photograph: B

FCMC

(5) Remove the screws.

Direction of photograph: D

Please refer to "EXPLODED VIEW" for the disassembly method of each PCB included in REAR PANEL SUB ASSY.

18

Page 19

6. POWER UNIT ASSY

→

Proceeding : TOP COVER

HEAT SINK SUB ASSY

→

Please refer to "EXPLODED VIEW" for the disassembly method of POWER UNIT.

LOADER PANEL

→

REAR PANEL ASSY

→

FRONT PANEL ASS'Y

→

7. MCU PCB UNIT ASSY

Proceeding : TOP COVER

HEAT SINK SUB ASSY

→

Please refer to "EXPLODED VIEW" for the disassembly method of MCU PCB UNIT.

LOADER PANEL

→

REAR PANEL ASSY

→

FRONT PANEL ASS'Y

→

8. TRANS

Proceeding : TOP COVER

HEAT SINK SUB ASSY

→

TRANS

LOADER PANEL

→

REAR PANEL ASSY

→

FRONT PANEL ASS'Y

→

POWER UNIT ASSY

→

MCU PCB UNIT ASSY

→

POWER UNIT ASSY

→

Please refer to "EXPLODED VIEW" for the disassembly method of TRANS.

19

Page 20

NOTE HANDLING AND REPLACEMENT OF THE LASER PICK-UP

1. Protection of the LD

Short a part of the LD circuit by soldering. After connection to a circuit, remove the short solder.

2. Precautions when handling the laser CD mechanism

• Handle the laser pick-up so that it is not exposed to dust.

• Do not leave the laser pick-up bare. Be sure to cover it.

• If dust adheres on lens of the pick-up, blow it off with a blower brush.

• Do not shock the laser pick-up.

• Do not watch the light of the laser pick-up.

3. Cautions on assembling and adjustment

• Be sure that to the bench, jig, head of soldering iron (with ceramic) and measuring instruments are well grounded.

• Workers who handle the laser pick-up must be grounded.

• The nished mechanism (prior to anchoring in the set) should be protected against static electricity and dust. The

mechanism must be stored that damaging outside forces are not received.

• When carrying the nished mechanism, hold it by the chassis body

• For proper operation, storage and operating environment should not contain corrosive gases. For example H2S, SO2,

NO2, CI2 etc. In addition storage environment should not have materials that emit corrosive gases especially from

silicic, cyanic, formalin and phenol group. I the mechanism or the set, existence of corrosive gases may cause no

rotation in motor.

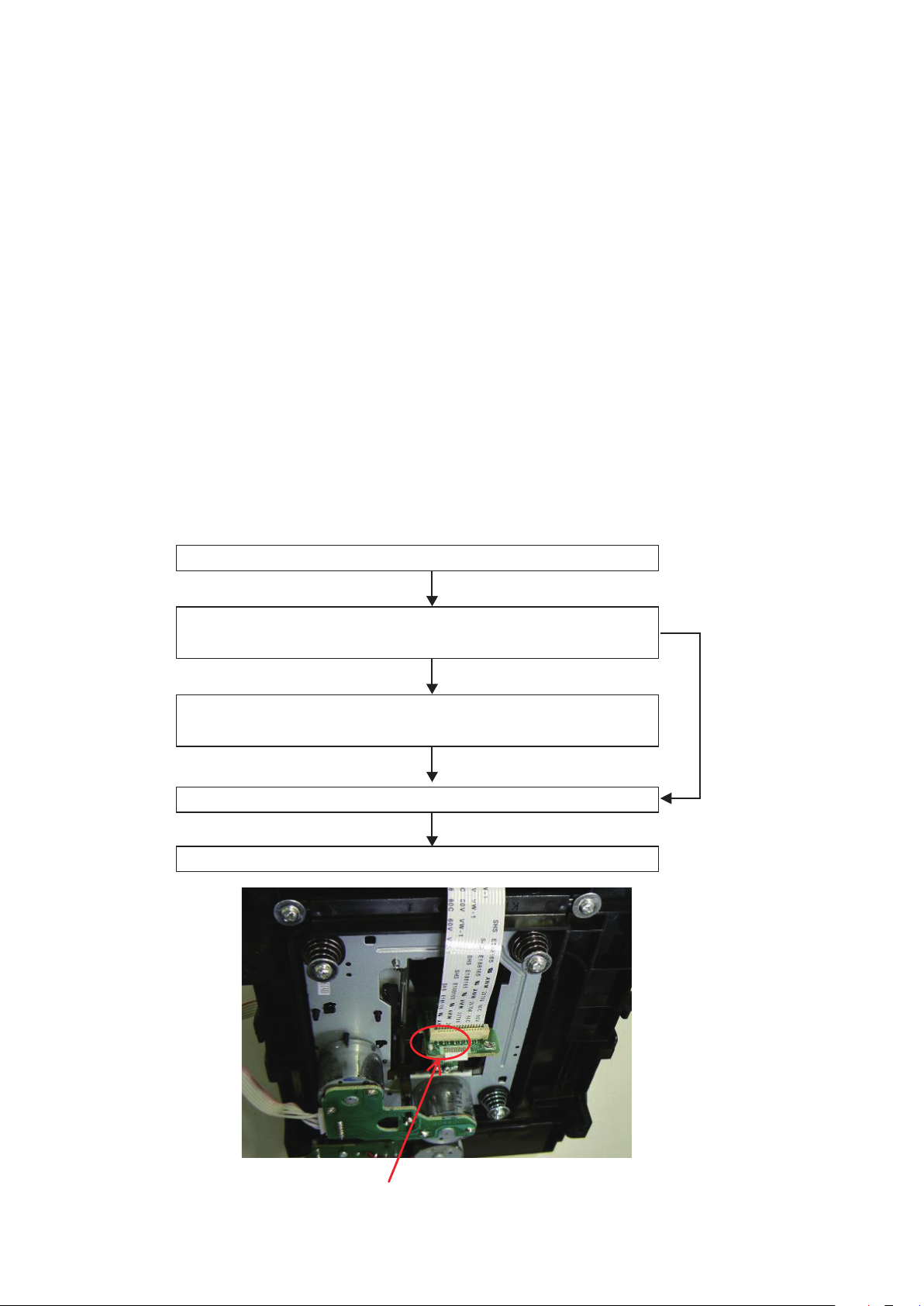

4. Determining whether the laser pick-up is defective

Disc no read, unsteady playback, etc.

Measure the waveform at RFO on "MCU CD PCB wRFO".

(For measuring points and waveforms, Rrfer to 50 page.)

Range between 0.4 and 1.1(Vp-p)

Laser drive current (Iop) check

(For how to check, see 4. CD test mode, 4.7.Laser current is display.)

Laser current (IOP) memorizing after replacement

Present value exceeds the initial value

by 1.5 times

Traverse Unit replacing

NO

Protective soldering place for laser diode.

20

Page 21

SERVICE MODE

How to input

Plug AC cord into power outlet while pressing both the button A and the button B at the same time.

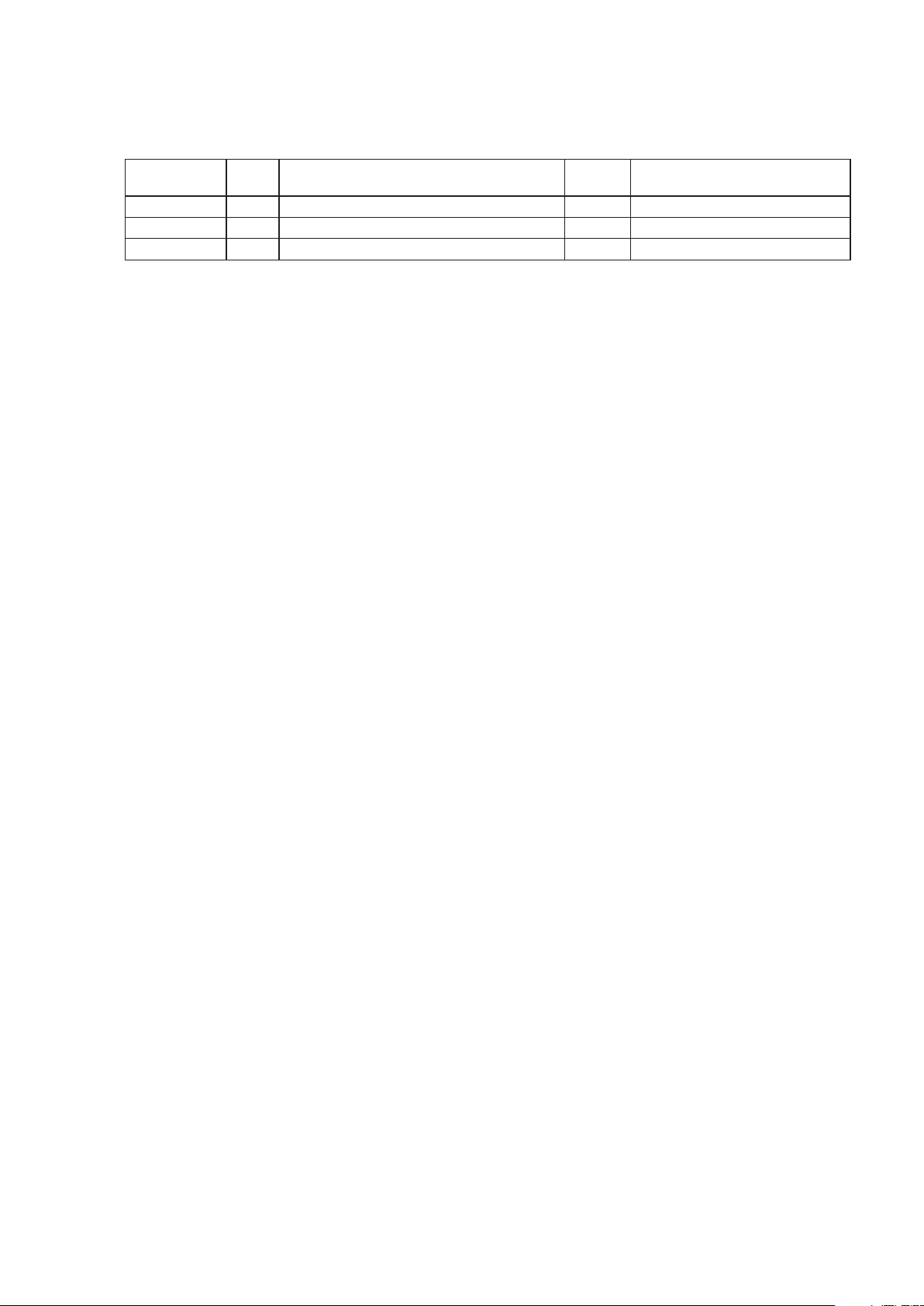

No. Mode Button A Button B

1 Version display mode

2 VFD checking mode

3 Cold start mode (initialization) SOURCE

4 CD test mode SOURCE

5 CD heat run mode

6 Accumulated laser on time display mode

7 Displaying the protection history mode SOURCE

2 8

5

2

2

Power operation (X)

Power operation (X)

Power operation (X)

1. Version display mode

(1) Plug AC cord into power outlet while pressing "2" and "8 / –" button same time on Main Unit.

(2) Press the "SDB/TONE" button to the display the 2nd item information on the Display.

Main µ-com Ver.】→【USB µ-com Ver.】→【Main µ-com Ver.】→

【

Main µ-com Ver.

【

】

V e r 1 2 0 6 0 8 0 2 v E 2

8

+ /

+ /

/ –

/ –

9

9

・・・

USB µ-com Ver.

【

】

U S B V E R

2 0 1 2 0 5 2 4 0 1

(3) Unplug AC cord to clear this mode.

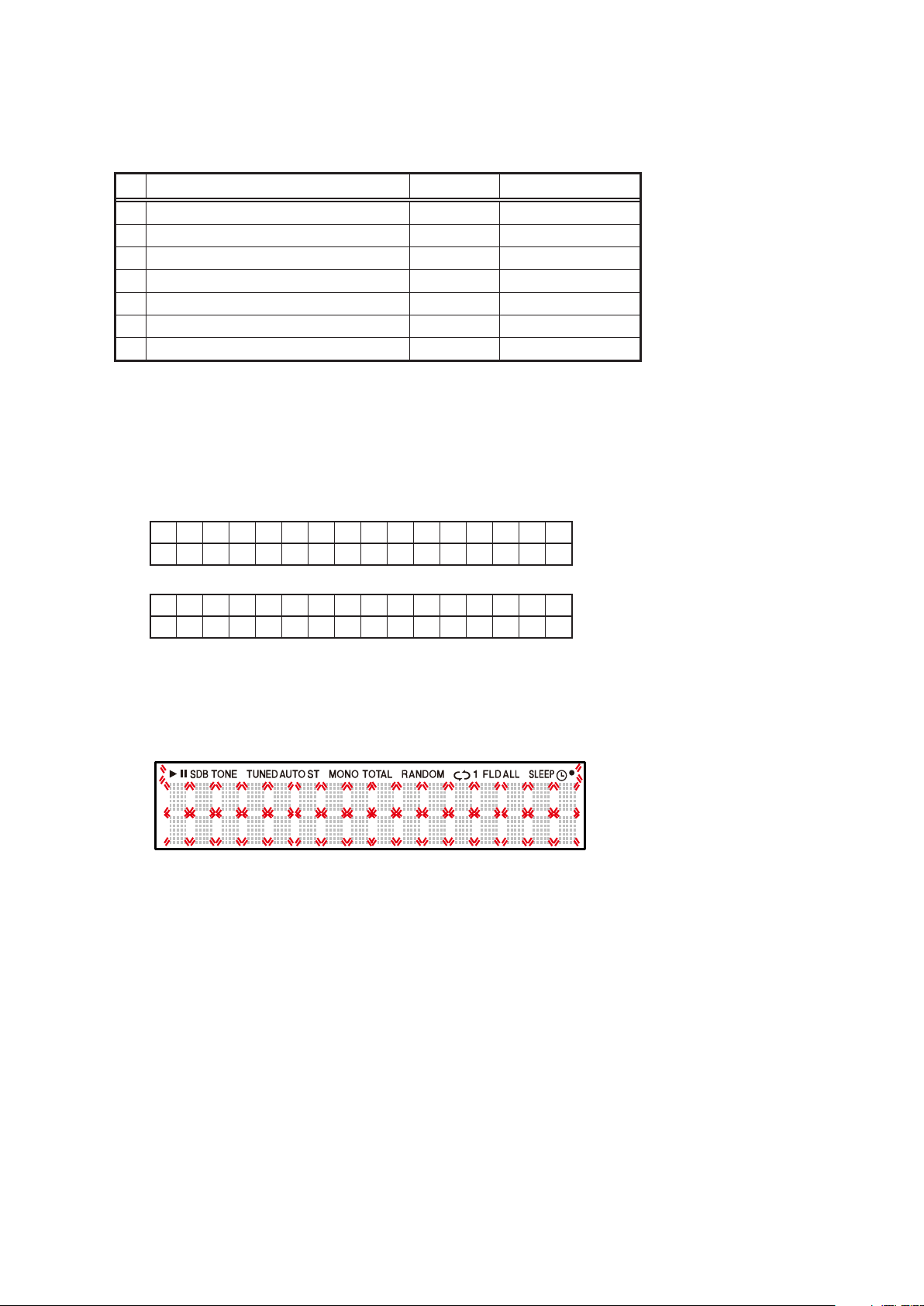

2. VFD checking mode

(1) Plug AC cord into power outlet while pressing "Power operation (X)" and "5" button same time on Main Unit.

(2) All segment of VFD is turning on and off every one second. MUTING ON

(3) Unplug AC cord to clear this mode.

.

21

Page 22

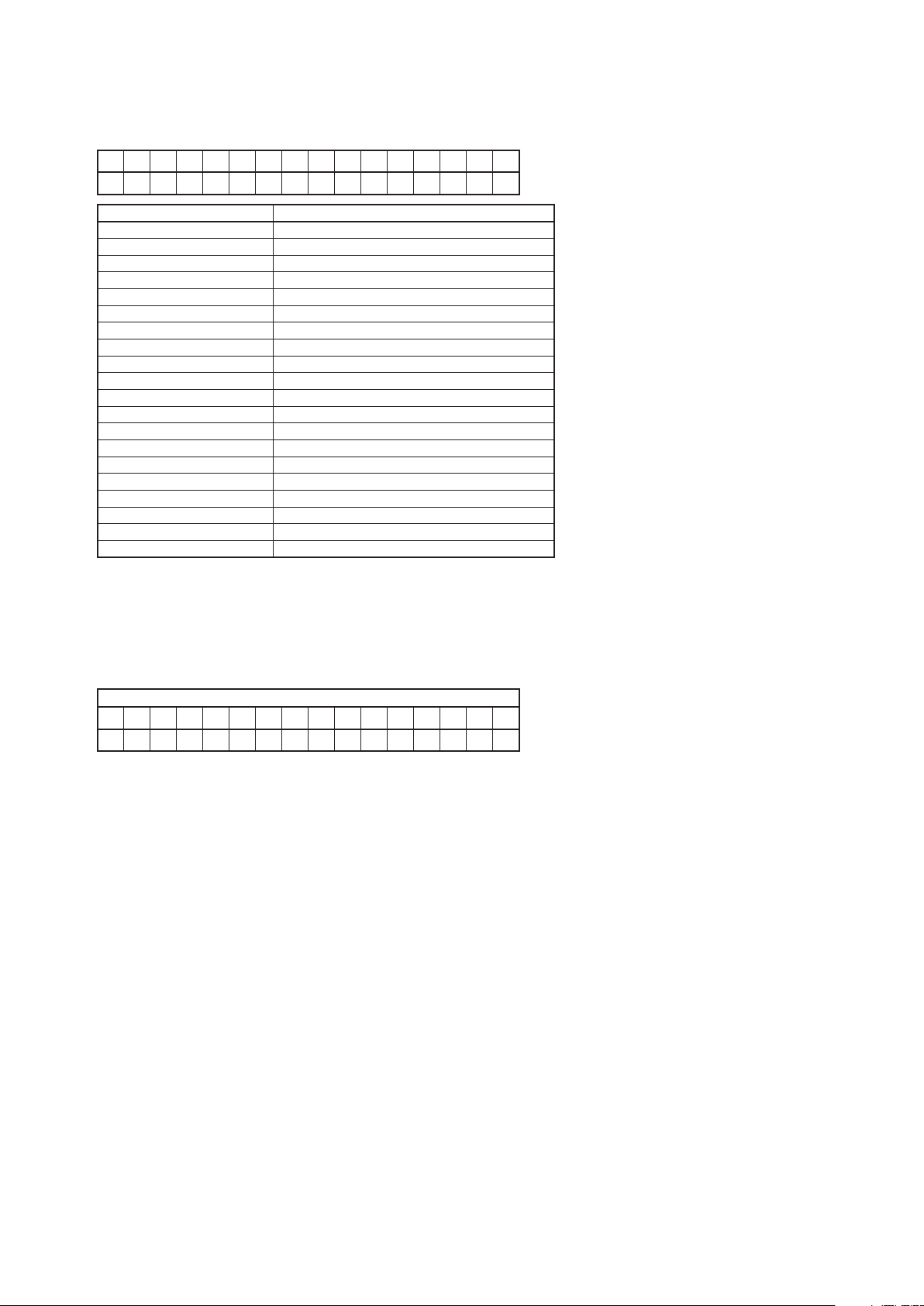

3. Cold start mode (initialization)

(1) Plug AC cord into power outlet while pressing "SOURCE" and "8 / -" button same time on Main Unit.

Initialize.

I N I T I A L I Z E

Default

SOURCE DISC

TUNER BAND EK:DAB, otherFM

TUNER frequency Minimum reception frequency

TUNER PRESET 0

Set -/+ PRESET

SDB OFF

BASS 0

TREBLE 0

BLANCE CENTER

DIMMER 100%

VOLUME 8

Clock E3:AM12:00, Other:0:00

ALARM SOURCE DISC

ALARM ON E3:AM12:00, Other:0:00

ALARM OFF E3:AM12:00, Other:0:00

SPK OPTIMISE ON

iPod MODE REMOTE

AUTO STANDBY E2/EK:ON, E3:OFF

DAB Module (EK) Initialzed Module

Protection memory NO PROTECT

The following settings are not initialized.

※

• Laser ON TIME and Laser Current

• Power supply abnormal ag

(2) After initialization, the unit will start in normal mode (Power On).

4. CD test mode

(1) Plug AC cord into power outlet while pressing "Power operation (X)" and "SOURCE" button same time on Main Unit.

" 1 3 "

0 0 C D T E S T M O D E

(2) Move the slide to the initially set position (10 mm towards the outside from the innermost position).

(3) Check by performing key input. Refer to 4.2

q

~

4.2y.

(4) Cancel the mode by turning the power back on.

Do not push the button without the explanation.

※

4.1 Disc loading

(1) Press the "5" button to open the tray.

(2) Set a disc on the tray, then press the "5" button again to close the tray.

(3) Move the slide to the initially set position (10 mm towards the outside from the innermost position) and stop in this

status.

(

1, 3

ashing

)

22

Page 23

4.2 Servo check

• Press the "5" button. Execute the following steps.

Press "1/3" button continuously for over 1second to switch directly to SUB CODE readout in step t.

※

LD ON (with servo still stopped)

q

" 1 3 "

0 1 L D O N

FOCUS ON (disc rotation, tracking off)

w

If no disc loaded, retry then stop.

z

" 1 3 "

0 2 F o c u s O N

CLV ON

e

" 1 3 "

0 3 C L V O N

TRACKING ON

r

" 1 3 "

(

1, 3

(

1, 3

(

1, 3

ashing

ashing

ashing

)

)

)

0 4 T r a c k i n g O N

SUB CODE readout (playback sound output)

t

" 1 3 "

0 5 @ @

When display is as in t and the "1/3" button is pressed, conduct BER (Block Error Rate) display for 2 seconds.

y

" 1 3 "

Tr

ashing / @@:T.No / XX:XX:Time

(

1, 3

X X : X X

(

1, 3

ashing

)

)

E R R # # # # # #

ashing / ######:B.E.R

(

1, 3

)

23

Page 24

4.3 Pickup movement

(1) In the stop mode, pickup moves in REV (inwards) or FWD (outwards) direction when "8 / -" or "+ / 9" button

pressed.

(2) When "8 / -" button pressed, move to stop operation after detection that inner switch has turned on.

(3) Pickup movement stops when button released.

4.4 Stop

(1) When "2" button is pressed, play operation and servo stop.

(2) After stopping, conduct reading of auto adjust values.

4.5 All servo on

• Press and hold the "SOURCE" button for 5 seconds and longer to turn on all servos. The system is automatically

adjusted and the playback operation starts. (Playback sound output)

" 1 3 "

@ @

Tr

ashing / @@:T.No / XX:XX:Time

(

1, 3

X X : X X

)

4.6 Adjustment value display

(1) When "DIRECT" button is pressed, the adjustment values are displayed in the following order.

FOCUS BALANCE

q

" 1 3 "

X X X X

F O C U S B A L A N C E

FOCUS GAIN

w

" 1 3 "

ashing / XXXX:Adjustment value

(

1, 3

)

X X X X

F O C U S G A I N

TRACKING BALANCE

e

" 1 3 "

ashing / XXXX:Adjustment value

(

1, 3

)

X X X X

T R A C K I N G B A R A N C E

TRACKING GAIN

r

" 1 3 "

ashing / XXXX:Adjustment value

(

1, 3

)

X X X X

T R A C K I N G G A I N

FOCUS OFFSET

t

" 1 3 "

ashing / XXXX:Adjustment value

(

1, 3

)

X X X X

F O C U S O F F S E T

TRACKING OFFSET

y

" 1 3 "

ashing / XXXX:Adjustment value

(

1, 3

)

X X X X

T R A C K I N G O F F S E T

ashing / XXXX:Adjustment value

(

1, 3

)

24

Page 25

RFRP

u

" 1 3 "

X X X X

R F R P

2) Press the "2" button, "4. CD test mode (1)" display reappears.

(

If auto adjustment is not completed, proper values are not displayed.

※

4.7 Laser current is display

(1) When the "2" button is pressed for over 1 second while the RCD-M39 is in the stop mode(Display of "4. CD test

mode (1)"), the laser turns on and the laser current is measured.

" 1 3 "

ashing / XXXX:Adjustment value

(

1, 3

)

S / C : X X m A / Y Y m A

L A S E R C U R R E N T

• The rst current value is measured 3 seconds after the laser turns on.

• The current value is updated every 3 seconds.

• The laser drive current undergoes A/D conversion for calculation. Decimal values are discarded.

2) Press the "2" button, "4. CD test mode (1)" display reappears.

(

ashing / XX:Stored data(stored in the EEPROM) / YY:Current value

(

1, 3

Stored data is not cleared, initialazation of "3. Cold start mode".

※

)

4.7.1 Overwriting the stored data

(1) When the "1/3" button is pressed for over 5 seconds while the laser current is displayed, the current value is

stored in the EEPROM (overwriting the stored data).

" 1 3 "

S T O R E D

L A S E R C U R R E N T

(2) Press the "

(3) Once rewriting is completed, the display in No.4.7(1) reappears.

Rewriting is performed upon shipment from the factory and when the mechanism is replaced.

※

" button, the initial value is stored in the EEPROM.

1/3

(

1, 3

ashing

)

25

Page 26

5. CD heat run mode

(1) Plug AC cord into power outlet while pressing "2" and "+ / 9" button same time on Main Unit. (Be sure to insert

the CD before this operation)

1

3

C D 1 1

(

1, 3

Tr

lit / Normal display except when 1, 3 lit

4 2 : 5 2

.)

(2) Switches to mode according to button input. See No.5.1 and No.5.2.

(3) If an error occurs, display the error and stop operation at that point. Number of operations held. See No.5.3 to

No.5.5.

(4) Heat run no. cleared when "2" button pressed.

(5) Mode canceled and tray opened after "5" button pressed.

(6) Press the "Power operation (X)" button to clear this mode too.

5.1 Normal heat run mode

• After CD heat run mode has started, re-read TOC and press the "1/3" button. (Be sure to nish reading the TOC

before push "1/3" button) Count this as the 0th heat run repetition.

Play from the rst to last track on disc.

q

If disc being used has less than 20 tracks, play all tracks. If disc has 21 or more tracks, skip to nal track after

w

playback of rst track has nished.

After disc playback has nished, move pickup to innermost position and open tray.The heat run repetition no. is

e

incremented (increased by 1) when the tray is opened.

When loader open status detected, close tray again, re-read TOC and start playback from the rst track on the

r

disc.

Conduct q to r repeatedly.

t

During playback is display

【

1

3

】

C D 0 1

Number of heat run is display (No.5.1 e)

【

1

3

(

1, 3

Tr

lit / Normal display except when 1, 3 lit

0 1 : 4 7

】

.)

C D X X X X

5.2 Automatic mounting mode

(1) After CD heat run mode has started, re-read TOC and press the "2" buton once in the stop mode.

(2) TOC reading ⇒ Search for rst track on disc ⇒ tray open ⇒ tray close ⇒ TOC reading ⇒ repeat. No. heat run

repetitions displayed on time display section.

(3) Increment the heat run repetition no. at the point when the loader has nished opening.

When the tray is open

【

1

3

】

lit / XXXX:No. of heat run repetitions

(

1, 3

)

C D X X X X

When the tray is closed

【

1

3

】

lit / XXXX:No. of heat run repetitions

(

1, 3

)

C L O S E

26

(

1, 3

lit

)

Page 27

When TOC is read

【

1

3

】

R E A D I N G

(

5.3 Error display

1

3

1, 3

lit)

C D E X - X X

Error code

E1-00 Disc cannot be detected

E1-01 Tracking offset adjustment not possible

E1-02 Focus offset adjustment not possible

E2-00 Focus servo dropped during playback.

E2-01 Focus servo dropped during searching.

E2-03 Focus servo dropped during TOC reading.

E2-06 Focus servo dropped during manual search.

E2-10 Subcode can no longer be read during playback

E2-11 Subcode can no longer be read during searching

E2-12 Subcode can no longer be read during TOC reading

E2-14 Subcode cannot be read during pause

E2-15 Subcode cannot be read during manual search

lit / X-XX:Error cord

(

1, 3

)

E3-00 TOC could not be read within specied time

E3-01 PVD/SVD analysis could not be completed within specied time

E4-04 Search time out

E4-05 Error in communications with CD decoder

E5-00 Inner switch not on

E6-00 Inner switch not off

E9-00 Tray is not opened by the specied time.

E9-01 Other error

Number of heat runs performed when error occurred

【

】

(1) Press the "+/9" button while the error is displayed.

(2) No. heat runs is displayed for 5 seconds, the error display reappears.

1

3

C D X X X X

【

lit / XXXX:Number of heat runs repeated when error occurred

(

1, 3

Track no. and elapsed time when error occurred

】

)

(1) Press the "8/ -" button while the error is displayed.

(2) The track no. and time when the error occurred is displayed for 5 seconds, then error display reappears.

1

3

C D 0 1

lit / mm:ss:Number of heat runs repeated when error occurred

(

1, 3

Tr

m m : s s

)

27

Page 28

6. Accumulated laser on time display mode

(1) Plug AC cord into power outlet while pressing "Power operation (X)" and "2" button same time on Main Unit.

X X X X X h o u r

L A S E R O N T I M E

• The laser drive times are added and the result is displayed.

• One count corresponds to 10 minutes. (Valuesunder 10 minutes are discarded.)

• Count values are stored in the EEPROM every 10 minutes.

• The accumulated laser on time is displayed in hours.

• The count values are not cleared, even when the set is initialazation(3. Cold start mode).

• Minimum display specication.

• No. digits stored in EPROM: 4, 0xFFFF

• No. digits displayed: 5

• When the time exceeds 10922 hours, the stored data is not updated and the value is xed to 0xFFFF.

(The display is xed to 10922 hours.)

(2) Unplug AC cord to clear this mode.

6.1 Count value is reset

(1) When the "1/3" button is pressed for over 5 seconds while the acumulated laser on time is displayed, the count

value is reset.

C L E A R

L A S E R O N T I M E

(2) After resetting is completed, the display in "6. Accumulated laser on time display mode(1)" (00000 hours on the top

line) reappears.

Count value is reset upon shipment from the factory and when the mechanism is replaced.

※

7. Displaying the protection history mode

(1) Plug AC cord into power outlet while pressing "SOURCE" and "+/

(2) The last protection incident.

(3) Unplug AC cord to clear this mode too.

No protection incident

【

】

" button same time on Main Unit.

9

P R O T E C T I O N :

N O P R O T E C T

The last protection incident was AMP protection

【

】

P R O T E C T I O N :

A M P

The last protection incident was Power protection

【

】

P R O T E C T I O N :

P O W E R

7.1 Clearing the protection history

(1) Start up the error (protection history display) mode, display the error, then press and hold in the "1/3" button over 5

seconds.

Display of Clearing

【

】

P R O T E C T I O N :

C L E A R

Protection history reset by initialazation (3. Cold start mode), too.

※

28

Page 29

VERSION UPGRADE PROCEDURE OF FIRMWARE

1. ABOUT REPLACE THE MICROPROCESSOR WITH A NEW ONE

When replaced of the U-PRO (Microprocessor) or the Flash ROM, conrm contents of the following.

PWB Name Ref. No. Description

MCU IC11 TMPM330FYFG

MCU IC11 CVIT5CN5

MCU IC41 TMP92FD28FG

After replaced

A

: Mask ROM (With software). No need write-in of software to the microprocessor.

B

: Flash ROM (With software). Usually, no need write-in of software. But, when the software was updated, you

should be write-in of the new software to the microprocessor or ash ROM. Please check the software version.

C

: Empty Flash ROM (Without software). You should be write-in of the software to the microprocessor or ash ROM.

Refer to “Update procedure” or “writing procedure”, when you should be write-in the software.

2. UPDATE MODE

Software for MAIN CPU and USB CPU can be updated.

There are two mode of update, regarding to the target of software as below.

2.1. Update MAIN CPU's software to internal Flash-ROM

The target devise is internal ash ROM of CPU (IC11) on CUP12448 (MCU PCB).

The updating of software takes about 30 seconds.

After

replaced

B

B

B

Remark

for E3,E2P model

for EK model

Procedure of the MAIN CPU's Update and download

NECESSARY EQUIPMENT

The following items are required for updating/downloading.

• Windows PC (OS: Windows2000 or WindowsXP) with Serial port

• RS-232C Dsub-9 pin cable (female to female/straight type)

• 8U-210100S Writing Kit

• 606050028012P / 7P FFC(1.0)L=240

• Update tool (BootTool_M330.exe)

• Update data for MAIN CPU (RCDM39_yymmdd-0z.s32)

NOTE :

The yy is two digits of year. The mm is month. The dd is date. The vv is release number.

29

Page 30

Procedure of the MAIN CPU's Update

(1) Double click the "BootTool_M330.zip" folder. Unzip the rmware to your PC.

(2) Disconnect the mains cord from the unit.

Caution :

(3) Connect the RS-232C on the DATA UPDATE KIT and the Serial Port of windows PC with RS-232C cable.

(4) Connect the 7P FFC to the rear panel of the unit from DATA UPDATE KIT.

Caution :

When you 7P FFC please disconnect the mains cord from the unit.

A FFC pin has the connection direction.

Refer to the photograph.

This side is contacts of 7P FFC.

7P FFC

For updating the MAIN microcomputer

(5) Connect the mains cord into the unit.

S706-709 LOW S702 5V

PC

30

Page 31

(6) Unzip the "BootTool_M330.zip" and double click the icon of "BootTool_M330.exe".

(7) Please conrm "Connected" on state space.

If "Connected" is not indicated, please check connection with unit or setting of ComPort or Boudlate.

Press "Connect" button.

"Connected" will be indicated.

(8) Select the Ram File and Flash File.

Press "…" button on "Ram File" and choose "OnBoard_M330.s32" le.

Press "…" button on "Flash File" and choose "RCDM39_yymmdd-0z.s32" le.

31

Page 32

(9) Press the "Start" button. The unit will start to update rmware.

Necessary time will be 30 seconds.

Check Sum

Message of updating will be finished.

Press the "Start" button.

The unit will start to update firmware.

(10) Disconnect the mains cord from the unit, and then disconnect the 7P FFC of DATA UPDATE KIT from the unit.

(11) UPDATE completion.

(12) Please check the version in "SERVICE MODE : 1. Version Display Mode" (Refer to 21 page).

32

Page 33

2.2 Update USB CPU's software to internal Flash-ROM

The target devise is internal ash ROM of CPU (IC41) on COP12284 (MCU PCB).

The updating of software takes about 30 seconds.

Procedure of the USB CPU's Update and download

NECESSARY EQUIPMENT

The following items are required for updating/downloading.

• Windows PC (OS: Windows2000 or WindowsXP) with Serial port.

• RS-232C Dsub-9 pin cable (female to female/straight type)

• 8U-210100S Writing Kit

• 606050028012P / 7P FFC(1.0)L=240

• Update tool (FlashProg.exe, other les and folders in Flash Programmer folder)

• Update data for USB CPU (Bolero_USB-20120524-01.s32)

NOTE

: The yy is two digits of year. The mm is month. The dd is date. The vv is release number.

Procedure of the UDSB CPU's Update

(1) Create the MODEL NAME folder into anywhere on your PC's hard disk.

(Ex. : RCD-M39)

(2) Put the "USB" folder into the MODEL NAME folder.

(3) Double click the "USB" folder.

RCD-M39

33

Page 34

(4) Double click the "Flash Programmer" folder.

RCD-M39

(5) Double click FlashProg_b35.exe, and launch the Flash Programmer.

RCD-M39

NOTE

: When a Flash Programmer does not launch even if double-clicked FlashProg_b35.exe, please refer to "2.3.

When a Flash Programmer did not launch".

34

Page 35

(6) The following dialog box appears several seconds later after the Flash Programmer launch.

Click OK.

NOTE

: Since Flash Programmer communicates with the unit automatically, the above dialog box appears when it fails in

communication.

(7) Click the Setup in the menu bar and select the Device.

35

Page 36

(8) Choose the TMP92FD28 in the Device, and choose the 900/H1 in the Series.

And click Object File tab.

(9) Click Browse.

36

Page 37

(10) Choose the Motorola S Format(*.s16,*.s24, *.s32) in Files of type.

Bolero_USB-2012052401.s32, and click Open.

Bolero_USB-2012052401.s32

Bolero_USB-20120524-01

(11) Click Communication tab.

RCD-M39 Bolero_USB-20120524-01

37

Page 38

(12) Choose the Serial port number in the COM Port.

Check the Data Rate Auto.

Input the 9.00 in the Clock.

And Click OK.

(13) Click the File in the menu bar and select the Exit.

(14) Disconnect the mains cord from the unit.

38

Page 39

(15) Connect the RS-232C on the DATA UPDATE KIT and the Serial Port of windows PC with RS-232C cable.

(16) Connect the 7P FFC to the rear panel of the unit from DATA UPDATE KIT.

Caution

: A FFC pin has the connection direction.

Refer to the photograph

7P FFC

For updating the USB microcomputer

.

This side is contacts of 7P FFC.

S706-709 LOW S702 5V

PC

(17) Connect the mains cord into the unit.

(18) Press the "Power operation (X)" button to turn on the unit.

(19) Double click FlashProg_b35.exe, and launch the Flash Programmer again.

(20) The Flash Programmer communicates automatically.

When communication succeeds between a unit and a program, a dialog box saying "Erase All data in this device?

(Y/N)" appears.

Click Yes.

39

Page 40

(21) Click OK.

(22) Click P (Program) to start update.

(23) Software is written into the microprocessor.

The writing of software takes about 30 seconds.

40

Page 41

(24) If the software is updated successfully, a dialog box saying "R006: Programming completed successfully." appears.

Click OK.

(25) Click the File in the menu bar and select the Exit.

(26) Press the "Power operation (X)" button to turn off the unit.

(27) Disconnect the mains cord from the unit, and then disconnect the 7P FFC of DATA UPDATE KIT from the unit.

(28) UPDATE completion

(29) Please check the version in "SERVICE MODE : 1. Version Display Mode". (Refer to 21 page)

41

Page 42

2.3. When a Flash Programmer did not launch

(1) Open the FlashProg.ini in the Flash Programmer folder by text editor. (EX.: Notepad, etc)

(2) Delete the text "OpenFile=C:\...(your PC setting)...\???.s32".

42

Page 43

(3) Save the FlashProg.ini.

43

Page 44

(4) Close the text editor.

(5) Probably you can launch the Flash Programmer. Go to the "Procedure of the UDSB CPU's Update "step 5.

44

Page 45

TROUBLE SHOOTING

1. VFD dosen't light

Check Power Supply Voltages for System µ-com.

MCU_CD B'D

• ST+3.9V, [PMSN] : 1pin

• [D109] cathode

OK

Check Reset signal for System µ-com.

MCU_CD B'D

• [IC11] : 82pin RESET

"H" level O.K.?

OK

Check Oscillation waveform.

MCU_CD_B'D

• [IC11] : 72pin

10MHz OK?

OK

Check Power On Signal.

MCU_CD B'D

• [IC11]:86pin P_DWN

"H" level OK?

OK

Check Power Supply Voltages for VFD.

FRONT B'D

• [FL81] : 38pin HV

• [FL81] : 37pin VDD

• [FL81] : 1pin F1-43pin F2

NG

NG

NG

NG

NG

Check Soldering.

• [PMSN] : 1pin

• SUB TRANS B'D

Check Soldering.

• [IC11] on MCU_CD B'D

Check Soldering.

• [X101] on MCU_CD B'D

Check Soldering.

• [PMMO] : 2pin on MCU_CD B'D

• SUB TRANS B'D

Check Soldering.

• FRONT B'D [CBFJ] : 3pin +VKK

• FRONT B'D [CBFJ] : 2pin FL1 / 1pin FL2

• FRONT B'D [FCFA] : 1pin VFD+3.3V

• POWER B'D [CBSK] : 2pin FL1 / 1pin FL2

• POWER B'D [CBSK] : 3pin VFD3.3V

• MCU_CD B'D [FCMA] : 1pin VFD+3.3V

Check Parts

• POWER B'D

Q909,D910,D909,D911,D912 OK?

Check Reset Signal for VFD.

FRONT B'D

• [FL81] : 35pin/RST

"H" level O.K.?

Check VFD dirive Signal.

FRONT B'D

• [FL81] : 32,33,34pin DA,CP,CS

END

OK

OK

NG

NG

Check Soldering.

• FRONT B'D [FCFA] : 3pin VFD_RST

• MCU_CD B'D [FCMA] : 3pin VFD_RST

• [IC11] on MCU_CD B'D

Check Soldering.

• FRONT B'D [FCFA] : 4,5,6pin

VFD_CE,VFD_CLK,VFD_DI

• MCU_CD B'D [FCMA] : 4,5,6pin

VFD_CE,VFD_CLK,VFD_DI

• [IC11] on MCU_CD B'D

45

Page 46

2. No Sound, Noise generated

2.1. CD PLAY

Check Power Supply Voltages for CD.

MCU_CD B'D

• [PMUP] : 1,2pin +8VM

• [PMMO] : 6,7pin USB_5V

POWWER B'D

• [PMSN] : 6pin DC_9V

OK

NG

Check Soldering.

• MCU_CD B'D [PMUP] : 1,2pin +8VM

[PMMO] : 7pin USB_5V

• POWER B'D

Check Parts

• [IC71]

Check Power Supply Voltages for CD.

MCU_CD B'D

• D+3.3V [IC22]: 2pi 3.3V OK?

• +1.5V [IC23] : 2pi 1.5V OK?

OK

Check Power Supply Voltages for DAC.

INPUT B'D

• [IC57] :1,8,20pin 3.3V OK?

• [IC54] :2pin 3.3V OK?

OK

Check Reset signal for CD.

MCU_CD B'D

• [IC21] : 69pin /RST "H" level O.K.?

• [IC41] : 61pin DSP_RST "H" level O.K.?

• [IC11] : 58pin CD_DSP_RST "H" level O.K.?

OK

Check Oscillation waveform.

MCU_CD B'D

• [IC21] : 49pin XO

16.9344MHz OK?

OK

NG

NG

NG

NG

Check Soldering.

• [IC22] on MCU_CD B'D

• [IC23] on MCU_CD B'D

Check Parts

• [IC22],[IC23]

Check Soldering.

• [CBIB] : 1pin SW+5V

• POWER B'D

Check Soldering.

• [IC11] : 58pin CD_DSP_RST on MCU_CD B'D

• [IC41] : 61pin DSP_RST on MCU_CD B'D

Check Soldering.

• [X201] on MCU_CD B'D

Check Oscillation waveform.

MCU_CD B'D

• [IC41]:73pin X2

9.0MHz OK?

OK

Check Clock Signal for DAC.

INPUT B'D

• [IC57]:12pin SCK

12.288MHz OK?

OK

Check controll signal for DAC.

INPUT B'D

• [IC57] : 17pin XSMT (Mute) "H" OK?

OK

NG

NG

NG

Check Soldering.

• [X401] on MCU_CD B'D

Check Soldering.

• [IC21] on MCU_CD B'D

• [FCMC] on MCU_CD B'D

• [FCIC] on INPUT B'D

Check Soldering.

• [IC11] on MCU_CD B'D

• [FCMC] : 8pin DAC_XSMT

• [FCIC] 8pin DAC_XSMT

46

Page 47

Check Digital Audio Data and Clock for DAC.

INPUT B'D

• [IC57] : 13,14,15,pin

BCK,DIN,LRCK

OK

NG

Check Soldering.

• [IC21] on MCU_CD B'D

• [IC51] : (DIR) on INPUT B'D

Check Analog Audio Data output from DAC.

INPUT B'D

• [IC57] : 6,7pin on INPUT B'D

OK

Check Analog Audio Data input for FUNCTION IC.

INPUT B'D

• [IC53] input 2,31pin

DAC_L , DA_R

OK

z

Check control signal for FUNCTION IC.

INPUT B'D

• [IC53] : 10,11,12pin

V_DATA,V_CLK,V_CE

OK

Check Analog Audio Data output from FUNCTION & PRE AMP.

• [IC53] : 8,25pin L_OUT,R_OUT

• [IC62] : 1,7 pin

OK

Check audio function mute signal.

INPUT B'D

• [Q608] : "H" level O.K.?

OK

NG

NG

NG

NG

NG

Check Soldering.

• [IC57] : 6,7pin on INPUT B'D

Check Soldering.

• [IC53] on INPUT B'D

Check Soldering.

• [IC11] on MCU_CD B'D

• [FCMC] : 12,13,14pin on MCU B'D

F_V_DATA,F_V_CLK,F_V_CE

• [FCIC] : 12,13,14pin on MCU B'D

F_V_DATA,F_V_CLK,F_V_CE

Check Soldering.

• [IC53] on INPUT B'D

• [IC62] on INPUT B'D

Check Soldering.

• [Q106],[112] on INPUT B'D

• [WF11] : 10pin F_MU on INPUT B'D

• [IC11],[Q103] on MCU_CD B'D

• [WN11] on MCU_CD B'D

Check Analog Audio Data input for POWER AMP.

AMP B'D

• [IC71] : 15(Lch),11(Rch)

OK

Check Analog Audio Data output for POWER AMP to SPEAKER.

AMP B'D

• [IC71] : (6,7:Lch) (4,5:Rch)

OK

Check SPEAKER RELAY control signal.

SPEAKER B'D

• [D706] : ANODE -12V O.K.?

OK

SPEAKER B'D

• [JK71]

END

NG

NG

NG

NG

Check Soldering.

• [CWIL] : 3,1pin on INPUT B'D

VOL_L,VOL_R

• [CBAL] on AMP B'D

Check Soldering.

• [IC71] : 6,7,4,5pin

• [CBAM] : (3,4:Lch)(1,2:Rch)

Check Soldering.

• [CBOM] : 11pin on SPEAKER B'D

• [CBAM] on AMP B'D

• [Q712],[Q713] OK? on AMP B'D

• [CBAD] : 5pin SP_ON on AMPB'D

• [CWMD],[IC11] on MCU_CD B'D

• [CBOM] on SPEAKER B'D

47

Page 48

2.2. DAB TUNER-in (EK model)

Check Power Supply Voltages for DAB TUNER UNIT.

INPUT B'D

• SW+5V

• DAB+3.3V (PFD1:2pin)

• DAB+1.5V (PFD1:1pin)

OK

Check controll signal for DAB TUNER.

INPUT B'D

• [PFD1] : 15,16pin

DAB_DATA , DAB_CLK

OK

Check Analogl Audio Data output from DAB TUNER.

INPUT B'D

• [DAB TUNER] output

[PFD1] : 24pin SPDIF

OK

Check Audio Data intput from FUNCTION IC.

INPUT B'D

• [IC51] : (DIR) 28pin

OK

NG

NG

NG

NG

Check Soldering.

• [CBIB] : 1pin SW+5V on INPUT B'D

• POWER B'D

• [IC55],[IC56] on INPUT B'D

Check Part

• [IC55],[IC56] on INPUT B'D

Check Soldering.

• [FCIC] : 16,17pin on INPUT B'D

• [FCMC] on MCU_CD B'D

• [IC11] on MCU_CD B'D

Check Soldering.

• [PFD1] on INPUT B'D

Check Soldering.

• [IC51] on INPUT B'D

to CD PLAY TOP

2.3. FM TUNER-in (E2, E3 model)

Check Power Supply Voltages for PREAMP & POWER AMP.

• INPUT B'D : +12V,-12V

• AMP B'D : +34V,-34V

OK

Check Power Supply Voltages for AM/FM TUNER.

INPUT_CD B'D

• [CBIB] : 1pin SW+5V

OK

Check Analog Audio Data output from TUNER PACK.

INPUT B'D

• TU_Pack (TM51) : 1pin TU_L , 2pin TU_R

OK

NG

NG

NG

Check Soldering.

• [CBIB] : 4,7pin +12V,-12V on INPUT B'D

• [CBAM] : 5,6,9,10pin +34V, -34V on AMP B'D

• POWER B'D

• SPEAKER B'D

Check Soldering.

• [CBIB] on INPUT B'D

• POWER B'D

Check Soldering.

• TU_Pack (TM51)

Check Analog Audio Data input for FUNCTION IC.

INPUT B'D

• [IC53] : 3,30pin TU_L , TU_R

OK

to CD PLAY z Mark

NG

48

Check Soldering.

• [IC63] on INPUT B'D

Page 49

2.4. iPod/USB PLAY

Check Power Supply Voltages for USB UNIT.

FRONT B'D

• [JK83 ] :1pin USB+5V

MCU_CD B'D

• [IC43] : 1pin +5VD_USB

• [PMMO] : 6,7pin USB_5V

USB_DC_TO_DC B'D

• [PMUO] : 6,7pin USB_5V

OK

Check Data input from USB UNIT

FRONT B'D

• [JK83] : 2,3pin +D,-D

OK

Refer to 2.1. CD PLAY

NG

NG

Check Soldering.

• [CBFF] : 1pin USB+5V on FRONT B'D

• [CWMF] on MCU_CD B'D

• [PFUN] : 6pin DC_9V on USB_DC_TO_DC B'D

• POWER B'D

Check Part

• [IC43] on MCU_CD B'D

• [IC32] on USB_DC_TO_DC B'D

Check Soldering.

• [CBFF] : 2,3pin +D,-D on FRONT B'D

• [CWMF],[IC41] on MCU_CD B'D

49

Page 50

MEASURING METHOD AND WAVEFORMS

R236

R416

R415

R237

R418

C222

C234

C202

LMSW6MGND

SLED-

SLED+

SPINDLE-

CWM2

SPINDLE+

Bar code Label

R404

R152

D101

C124

To check the waveforms, the GND (-) probe of the oscilloscope to specied reference voltage.

(Except for lnner SW, TRVSW)

NOTES

Measuring Disc: CD/TCD-784

CD-R/TCD-R082W

CD-RW/TCD-W082W

(It is better to use wires for extending between the probe and test points.)

• When watching the HF waveform, use the extending wire as short as possible.

• When HF waveform is noisy or cannot discriminate the eye-pattern, replace the Traverse Unit after measuring the lop.

• Point

q~Q7

1. MCUCD PCB : TEST POINT

is measured with the point shown below.

C246

L106

D110

D109

Q102

BK11

PMMO

D105

PMMO

98GND

GND

USB+5V

7

USB+5V

6

MCU_GND

5

PROT_V

4

PWR_ON

3

PWR_DN

2

ST+3.9V

1

C905

C420

C433

CWMF

C903

R902

Q101

R122

C113

C225

DGND

IC13

C121

R130

C233

C224

Q404

C221

R254

R210

R209

R204

C220

C217

R202

R205

C216

R208

C214

C213

C251

C237

TEI

FEI

C910

RFO

Q406

Q402

Q403

R411

A

R414

IC41

Q405

R412

C407

L401

R407

R408

C408

C231

R152

R404

R403

R402

Bar code Label

C431 C432

54321

R429

R428

GND

GNDD+D-

R431R430

C

C244

C255

C256

C257

D203

R217

C229

C230

C232

C234

R206

R221

R225

R216

C219

C242

R226

C239

VC

R236

R231

R237

RFEQO

C222

C201

C215

C212

C207

R201

C206

AGND

C208

C209

C210

C205

R415

C401

C402

C415

C417

R413

R417

R418

R419

R438

R437

R435

R133

R132

R131

D101

USB +5V

CWMF

C123

FCMA

C124

R901

DIR_OUT

FCMC

R243

FCM1

L201

L204

Q201

D202

C240

R241

R238

R239

R240

13121110987654123

C202

FCS+

LD_PD

LD_VR

LD_LD

PDIC_GND

PDIC_F

PDIC_C

PDIC_B

PDIC_A

PDIC_D

PDIC_E

TRK-14TRK+15FCS-16

R416

R458

R459

R425

R426

C421

R421

R433

IC42

R444

R434

C422

C418

R463

C132

C130

18171615141312

11

678910

N.C19

LED_RED

LED_GREEN

KEY1

KEY0

REMOTE

EX_INTERRUPT

VOL+

VOL-

HP_IN

GND

VFD_DI

ST+3.3V

GND

VFD_CLK

C901

C904

DIR_IN

D201

R242

PDIC_VCC

VFD_CE

DIR_CE

3

C248

PDIC_VC

VFD_RST

DIR_CLK

DIR_RST

FCM1

GND

DAC_FLT

12345

VFD +3.3V

DAC_FMT

FCMA

C122

DAC_DEMP

DAC_XSMT

C254

Q106

Q103

Q105

C907

C909

C304

GND

DIR_RERR

C218

R207

C305

F_V_DATA

F_V_CLK

R903

F_V_CE

R151

Q104

X101

TU_RST

DAB_DAO_TU_SDA

DAB_CLK_TU_CLK

DAB_ON_TU_CE

18171615141312111098765412

C249

C204

C250

R233

R234

P8

P4

P3

P5

C106

10Mhz

C107

C309

C308

R157

FCMC

R108

R109

R110

R111

R112

R115

R118

R116

R117

R119

C112

X102

32.768Khz

IC12

R309

R319

CUP12448Z

B'D : MCU_CD B'D

ICT

R156

R143

R146

C116

R160

R139

R140

C117

R308

C307

ADJ-1 ADJ-2IC RP

C913

R145

R144

C912

R106

R107

R103

R104

R105

R158

R159

R102

R101

R314

R313

R312

IC11

C118

R129

R127

R121

R120

C110

C120

CLM

OPM

C301

CWM2

D104

PMUP

+8VM

1

+8VM

2

GND_DRV

3

GND_DRV

4

MCU_BOOT

5

TX

6

7 RX

8 BOL_RESET

9 MCU_RESET

MCU+3.3V10

BOL_BOOT11

CWMD

CWM2

MGND

SLED-

SLED+

SPINDLE-

SPINDLE+1

234

5

CWM3

1 LOADING+

B

2

LOADING-

3

OPSW

4

MGND

CLSW5

PMUP

D108

CWMD

GND27

HP_MUTE

6

SP_ON

5

PROTECTOR

4

F_MUTE

3

SP_OPT

N.C1

C906

LMSW6

C325

CWM3

Component side

C908

GND

CD_SPDIF1819TU_INT19

R905

R232

R235

P6

P1

RN11

C103

P2

R114

C109

C111

P7

R320

Detail A Detail B

C233

C213

Q403

IC41

R254

R210

R204

R202

C214

R208

FEI

R411

C224

C221

R209

C220

TEI

RFO

C219

C215

R413

R206

C210

R221

VC

C205

R216

R226

C239

R231

RFEQO

C201

C208

C209

R225

C212

AGND

C242

C415

R417

C207

C417

C206

C402

R201

C401

RP

VC

DMO(R241)

TRO(R204)

FOO(R202)

FMO(R208)

FEI

TEI

RFO

RFEQO

i

y

r

u

e

t

w

q

A

PMMO

D105

PMMO

98GND

GND

USB+5V

7

USB+5V

6

MCU_GND

5

PROT_V

4

PWR_ON

3

PWR_DN

2

ST+3.9V

1

L401

Q406

R412

C217

R205

C216

C251

C237

Q404

Q402

Q405

R414

R407

C910

C407

Detail C

50

C301

CWM2

CWM3

1 LOADING+

2

LOADING-

3

OPSW

4

MGND

CLSW5

C905

R902

12345

C420

C433

C903

CWMF

CWM3

C

C325

C431 C432

R428

Q3Q3Q4

Q4

C DGND

R403

R402

R429

D+

D-

R431R430

Q1

Q2

o

Q0

54321

GND

GNDD+D-

LOAD+

LOAD-

OPSW

B MGND

CLSW

R435

USB +5V

CWMF

R901

Page 51

2. INPUT PCB : TEST POINT

ON/SEN

R545

C545

INPUT JACK

OPT IN

MP

JK51

L504

JK52

R532

IC51

R511

PMTQ

SPDIF

GND

L506

PCM9211

TM51

DAB_ON

DAB_DO

DAB_DI

D+5V

GND

C552

C564 C568

R533

C577

TM51

AUX

INT

C551

GND

RST

CBS8

CD_SPDIF

SEN

TU+5V

SCLK

SDA

C538

C536

R564

R565

INT

RST

DI/CLK

DO/SDA

R542

R543

R544

R546

C515

C576

C517

C507

R506

TU_L

ON/SEN

R541

R545

TU_R

R532

IC51

R511

PMTQ

R533

PCM9211

C577

X501

C502

C567C566

C502

D

C508

R506

C505

F_CE

F_CLK

C508

C531

F_CE

F_DATA

F_CLK

R501

CUP12447Z-1_MP

NJW1194

IC53

R516

R515

R514

RST

FMT

GND

CLK

RERR

DEMP

XSMT

DAC_FLT

RN51

R505

R504

R503

R502

RN53

RN52

RN54

C548

C514

C153

C509

C513

GND

RERR

DEMP

F_DATA

RN51

C514

C519

FCIC

DIR_IN

DIR_CE

R525

R509

C549

IC57

C544

XSMT

R505

RN52

C521

C532

C518

DIR_OUT

R508

R526

C572

FMT

DAC_FLT

R504

RN54

D/A INPUT _" I "

C525

C524

C540C541

C546

C547

C545

R527

C151

D506

R561

RST

CLK

R503

R502

RN53

C549

C548

C605

R611

R615

R528

C154

R535

C571

DIR_IN

DIR_CE

R525

IC57

SW+5V

C144

C528C529

CBIB

C145

R607

C610

R612

R616

IC62

R619

C621

R620

C623

DIR_OUT

R508

R509

GND

+12V

R610

C619

C618

C626

R526

GND

-12V

IC15

IC14

C609

C613

R617

C622

C540

RL61

C625

R621

C547

R629

C616

R628

C615

C620

BK61

CWIL

D507

D508

R573

GND

GND

VOL_R

GND

VOL_L

GND

F_MUTE

SP_OP_ON

CWIL

Q602

R618

C624

⑮BCK

⑯DIN

⑰ LRCK

D DGND

Component side

No. Symbol No. Symbol Reference voltage

q

w

e

r

t

y

u

i

o

Q0

Q1

Q2

Q3

Q4

Q5

Q6

Q7

TP RFEQO

TP RFO

TP FEI

R202(0Ω) FOO

TP TEI

R204(0Ω) TRO

R208(0Ω) FMO

R210(0Ω) DMO

CWM3(3) OPSW

CWM3(5) CLSW

CWM3(1) LOAD+

CWM3(2) LOAD-

CWMF(3) D+

CWMF(2) D-

IC57(13) BCK

IC57(14) DIN

IC57(15) LRCK

Ⓐ

Ⓑ

Ⓒ

Ⓓ

TP VC : q ~

CWM3(4) MGND : o ~

CWMF(5) DGND : Q3,

RN53 DGND :

i

Q2

Q4

Q5 ~ Q7

51

Page 52

3. WAVEFORMS

1.1 CD(TCD784) PLAY

1.3 CD-RW (TCDW082W) PLAY

1. DISC PLAY RF WAVEFORM (EYE-PATTERN) 2. DISC DETECTION

2.1 CD(TCD784) DETECTION

RFEQO

q

1.2 CD-R (TCDR082W) PLAY

RFEQO

q

RFO

w

FEI

e

FOO

r

TEI

t

TRO

y

FMO

u

DMO

i

2.2 CD-R (TCDR082W) DETECTION

RFO

w

FEI

e

FOO

r

TEI

t

TRO

y

FMO

u

DMO

i

1V/div

500mV/div

1V/div

1V/div

1V/div

500mV/div

1V/div

1V/div

500mV/div

1V/div

1V/div

1V/div

500mV/div

1V/div

RFEQO

q

2.3 CD-RW (TCDW082W) DETECTION

RFO

w

FEI

e

FOO

r

TEI

t

TRO

y

FMO

u

DMO

i

52

1V/div

500mV/div

1V/div

1V/div

1V/div

500mV/div

1V/div

Page 53

3. TOC READ 4. FOCUS ADJUSTMENT

3.1 CD(TCD784) READ

RFO

w

FEI

e

FOO

r

TEI

t

TRO

y

FMO

u

DMO

i

3.2 CD-R (TCDR082W) READ

RFO

w

FEI

e

FOO

r

4.1 CD(TCD784) FOCUS ADJUSTMENT

1V/div

500mV/div

1V/div

1V/div

1V/div

500mV/div

1V/div

4.2 CD-R (TCDR082W) FOCUS ADJUSTMENT

1V/div

500mV/div

1V/div

TEI

t

TRO

y

FMO

u

DMO

i

3.3 CD-RW (TCDW082W) READ

RFO

w

FEI

e

FOO

r

TEI

t

TRO

y

FMO

u

DMO

i

1V/div

1V/div

500mV/div

1V/div

4.3 CD-RW (TCDW082W) FOCUS ADJUSTMENT

1V/div

500mV/div

1V/div

1V/div

1V/div

500mV/div

1V/div

53

Page 54

5. CD Playback

LRCK

Q5

BICK

Q6

SDTI

Q7

STANDARD GND

WF12 (9)

6. USB playback

D+

Q3

D-

Q4

STANDARD GND

CN83 (5)

7. LOADER OPEN-CLOSE

OPSW

o

FCLSW

Q0

LOAD-

Q2

LOAD+

Q1

STANDARD GND

OPEN CLOSE

54

Page 55

BLOCK DIAGRAM

FL DISPLAY

FUTABA

USB

iPOD

CD

MECHA

(KT690)

16.934MHz

PICK-UP

RF_DATA