Page 1

For Europe model

SERVICE MANUAL

MODEL

STEREO CASSETTE DECK

DRR-M31

Some illustrations using in this service manual are slightly different from the actual set.

16-11, YUSHIMA 3-CHOME, BUNKYOU-KU, TOKYO 113-0034 JAPAN

Telephone: 03 (3837) 5321

X0166V.02 DE/CDM 0302

Page 2

SAFETY PRECAUTIONS

The following check should be performed for the continued protection of the customer and service technician.

LEAKAGE CURRENT CHECK

Before returning the unit to the customer, make sure you make either (1) a leakage current check or (2) a line to chassis

resistance check. If the leakage current exceeds 0.5 milliamps, or if the resistance from chassis to either side of the

power cord is less than 460 kohms, the unit is defective.

2DRR-M31

2

Page 3

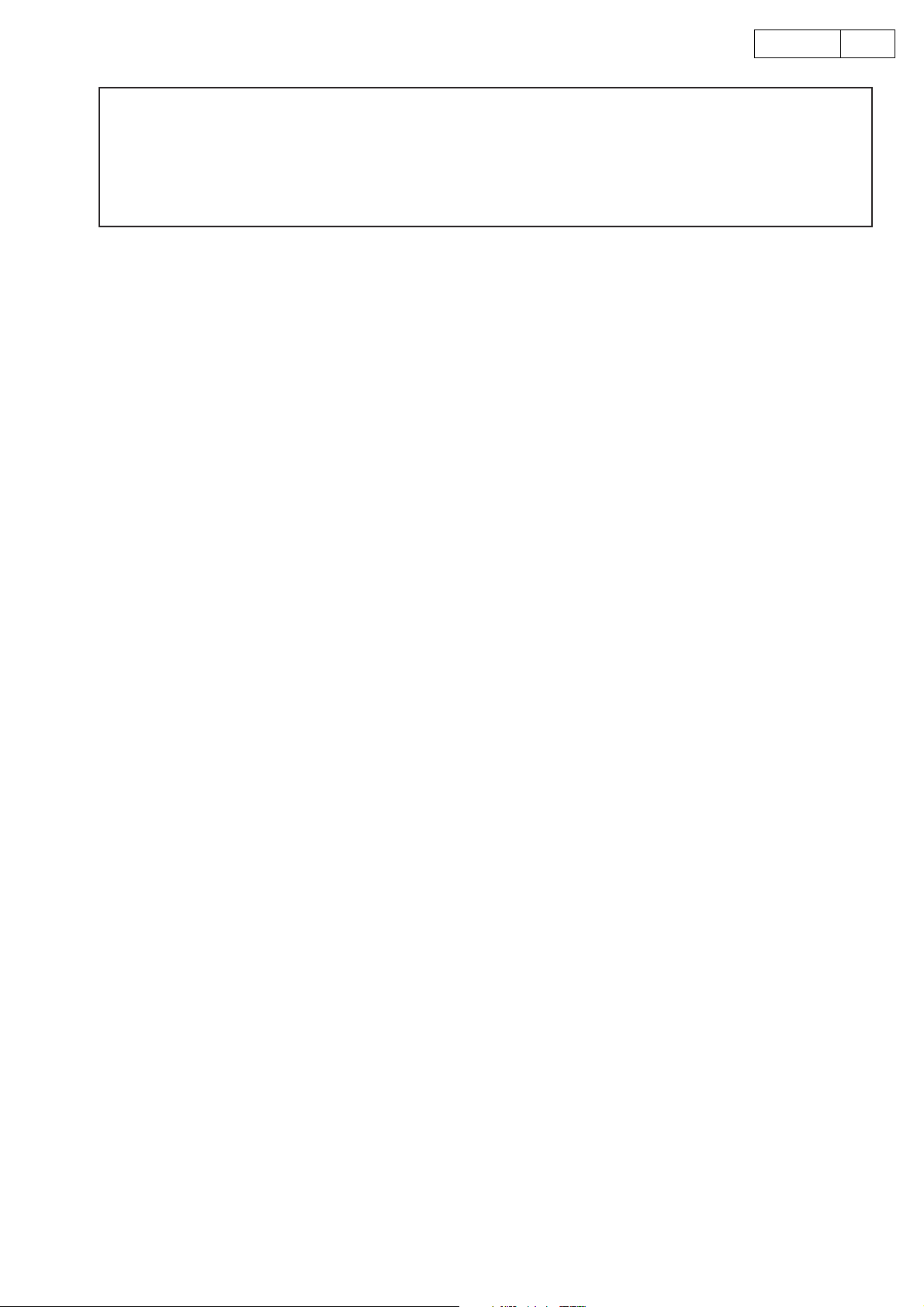

DISASSEMBLY

(Follow the procedure below in reverse order when reassembling)

1. TOP COVER

(1) Remove 2 screws ① fixing from the both

sides.

(2) Remove 5 screws ② fixing to the Rear Plate,

then detach the Top Cover in the arrow direction .

2. FRONT PANEL

(1) Disconnect 1 HCU joiner coming from the

front P.W.B.

(2) Remove 4 screws ③ fixing the Front Panel at

the bottom.

(3) Whil releasing 2 hooks, detach the Front

Panel.

3DRR-M31

3. CASSETTE MECHA. ASS’Y

(1) Remove 4 screws ④ fixing the Cassette

Mecha. Ass’y.

(2) Disconnect 3 connectors, then detach the

Cassette Mecha. Ass’y.

3

Page 4

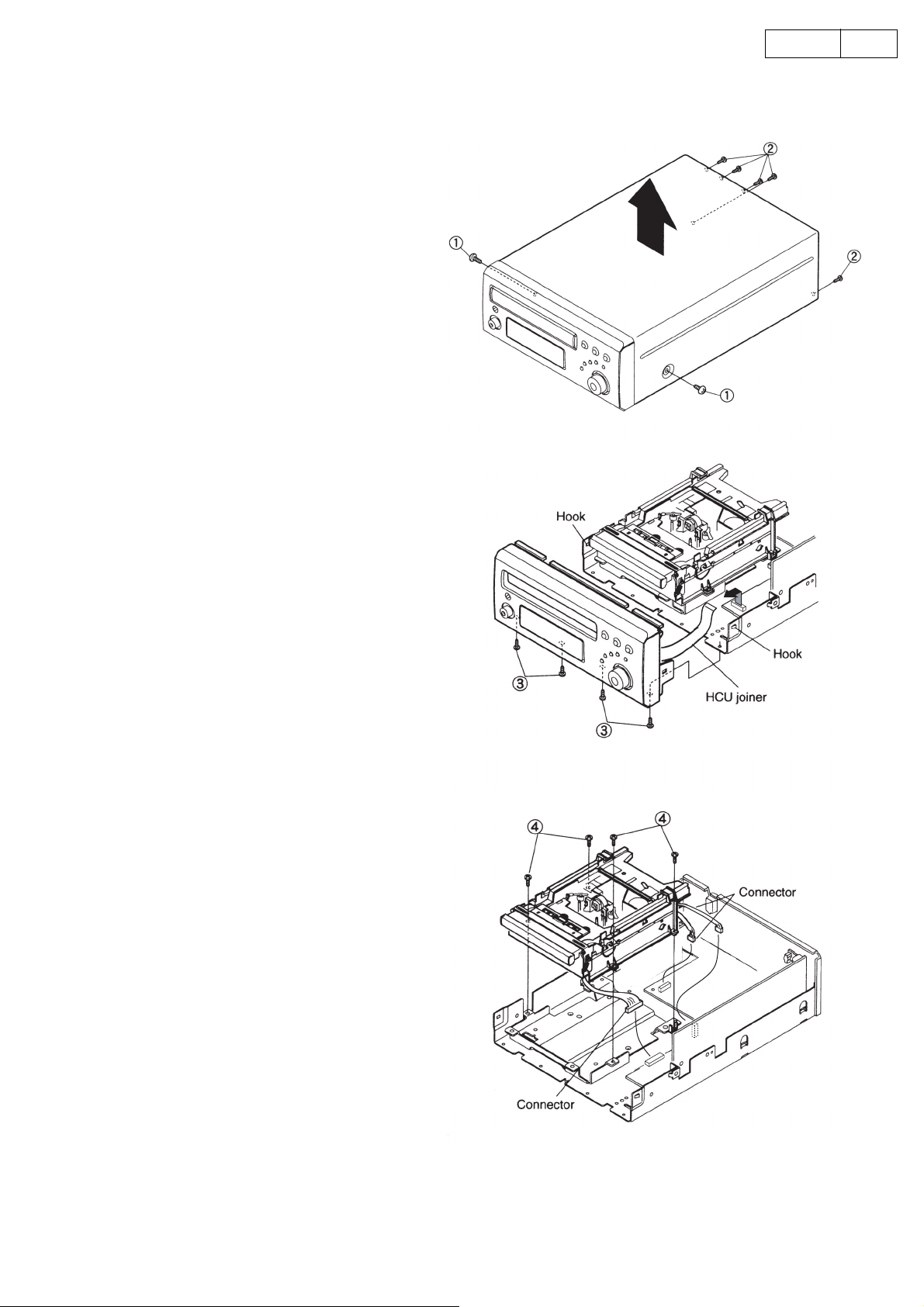

4. REAR PLATE

(1) Pull up the Power Cord together with the cord

bush to disengage from the Rear Plate.

(2) Remove 3 screws ⑤ fixing the 4P pin jack and

AC outlet respectively.

(3) Remove 1 screw ⑥ , and detach the Rear Plate.

5. MAIN P.W.B.

(1) Remove 1 screw ⑦ fixing the AMP P.W.B.

(2) Pull up the AMP P.W.B. as shown in the arrow

direction, and disconnect 2 connectors.

(3) Remove 4 screws ⑧ fixing the Main P.W.B.

(4) Release 3 pieces of P.W.B. spacers.

(5) Disconnect the connector from the Trans Unit.

(6) Take off the Main P.W.B.

4DRR-M31

Connector

6. DISPLAY P.W.B.

(1) Pull out the knob (E).

(2) Remove the nut and washer ⑨ for the rotary

switch.

(3) Remove 9 screws ⑩ .

(4) Take off the Display P.W.B.

AMP

4

Page 5

ADJUSTMENTS

6

ADJUSTMENTS

Adjusting and Checking the Mechanism Section

5DRR-M31

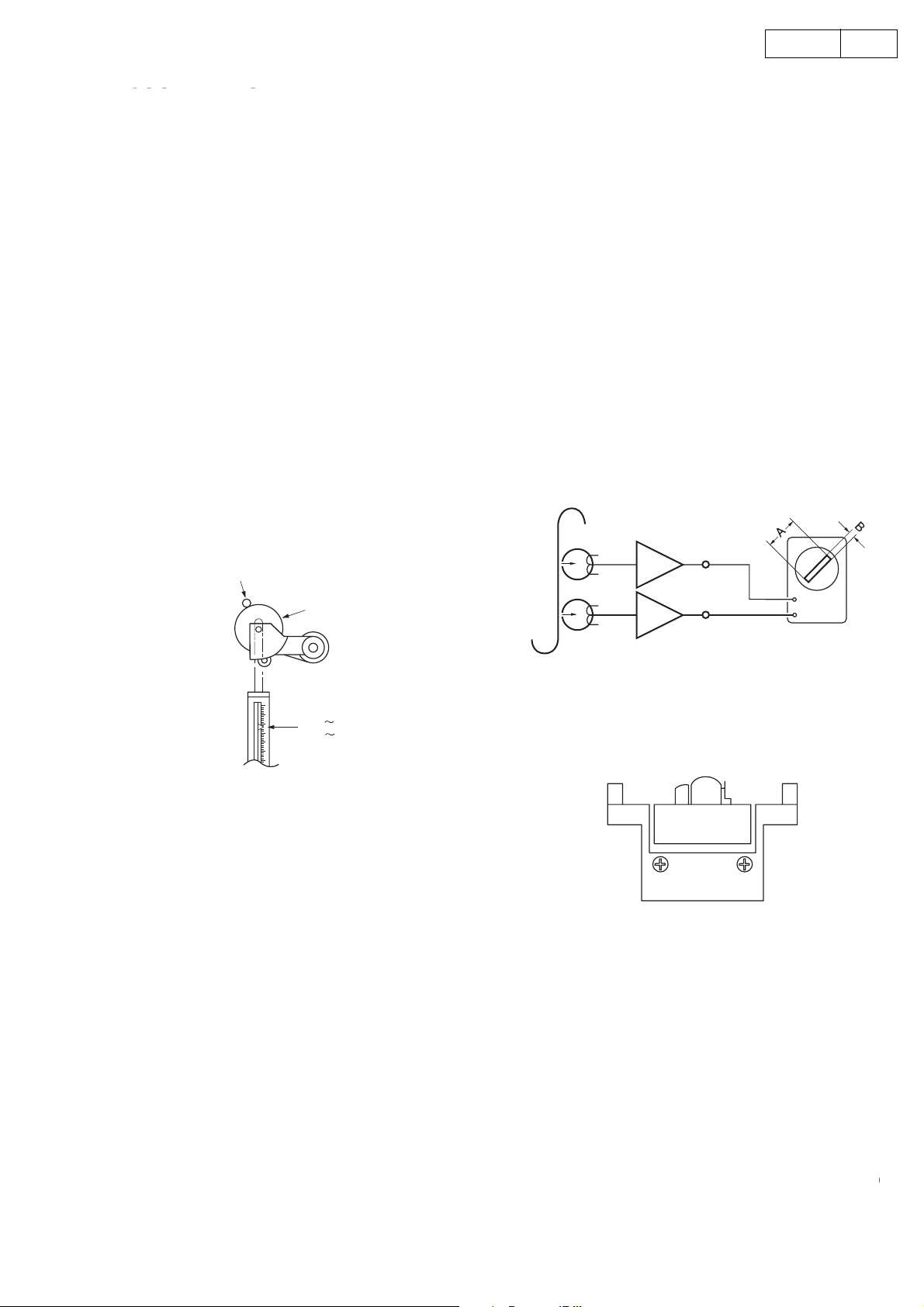

1. Replacement of the pinch roller

Before replacing the pinch roller, clean the tape contact

surface of the pinch roller and the tape contact surface of

the capstan shaft. After replacement, run a C-90 tape

without a pad and check for the presence of tape curl at

the tape guide portion of the head.

2. Checking the pinch roller pressure

Set to the playback condition and hook a bar-type spring

scale to the bracket above the center line of the pinch

roller. Pull the pinch roller away from the capstan shaft,

then allow the pinch roller to come into contact with the

capstan shaft and check that the reading of the bar-type

spring scale is between 2.45 N~3.92 N (250~400 g) when

the pinch roller starts to rotate or pull force indicates more

than 7.85 mN (80 g).

Replace the pinch roller when the value falls outside of

the specified range.

Capstan shaft

Pinch roller

4. Adjustment of the recording/playback head

Azimuth adjustment

Load side A of the A-BEX TCC-153 test tape facing

forward, and adjust.

(1) Play in the FWD direction and turn the azimuth

adjustment nut for the FWD side so that the

Lissajous’s figure becomes maximum at (A) and

minimum at (B).

(2) Play in the REV direction and turn the azimuth

adjustment nut for the REV side as adjusting the

FWD side method.

(3) Adjust (1) and (2) again.

(4) Apply screw lock to the adjustment locations.

PB Amp

LINE OUT

L

V

R

H

2.45 3.92N

(250

400g)

3. Replacement of the recording/playback

assembly

3-1 Removal of the head assembly

(1) Remove the 2 BRACKET-HEAD fastening screws.

(2) Remove one screw fixing P.W.B.

3-2 Mounting the recording/playback head assembly

Perform by following the steps of Section 3-1

Removal of the head assembly in reverse.

head

A-BEX TCC-153

REC/PB HEAD

A

FWD SIDE

B

REV SIDE

5. Checking the winding torque

Load a cassette type torque meter (Sony TW2111A at

the FWD side) and check that the reading of the torque

meter during playback is

294 to 686 mN-cm (30 to 70 g-cm) at the center value.

5

Page 6

6. Checking the back tension torque at the time

r

of recording and playback

Load a cassette type torque meter (Sony TW2111A at

the FWD side, Sony TW2121A at the REV side) and check

that the reading of the torque meter during playback is

9.8~58.5 mN-cm (1~6 g-cm) and that there is no

unevenness.

7. Checking the FF and REW torque

Load a cassette type torque meter (Sony TW2231) and

check that the value indicated by the torque meter for

winding and rewinding is between 686 mN-cm~

(70~150 g-cm).

1.47 N-cm

Adjusting and Checking the Electrical Section

6DRR-M31

8. Checking the FF and REW time

Load a Type 1 tape (UD-1), and check that the time for

FF and REW is less than 120 seconds. When outside of

the specified range, check Steps 5 and 6.

9. Checking the erroneous erasure prevention,

and the metal and chrome switch operations

Check that detection lever is operating the switch properly

depending upon the presence or absence of a hole.

Measuring instruments needed for the adjustments

(1) Low frequency oscillator

(2) Variable resistance attenuator

(3) Electronic voltmeter

(4) Oscilloscope

(5) Frequency counter

(6) Adjustment screwdriver

(7) Test tapes

MTT-111, MTT-114N, MTT-150, Type1 tape (UD-1)

(8) Mirror cassette for the transport (A-BEX TCC-902)

Adjustment precaution

(1) Before adjustments, use gauze or a swab moistened

with alcohol to wipe the surface of the heads, the

capstan shaft, and the pinch roller.

(2) Demagnetize the record/playback head and the

erase head with a head eraser.

(3) Completely demagnetize the driver to be used for

the adjustments.

(4) Unless otherwise specified, set the various operation

controls as indicated below.

Dolby NR switch: Off

1. Tape transport check

Load the mirror cassette for the transport, and illuminate

the area around the fixed guide of the record/playback

head with a lamp and observe.

Check that the tape edge is not hitting the tape guide

portion.

Note that the tape transport is the greatest factor affecting

the performance of the cassette deck. Never move the

inspection locations without good reason.

For information about replacement and adjustment of the

record/playback head, see the section “Adjustment and

checking of the mechanism”.

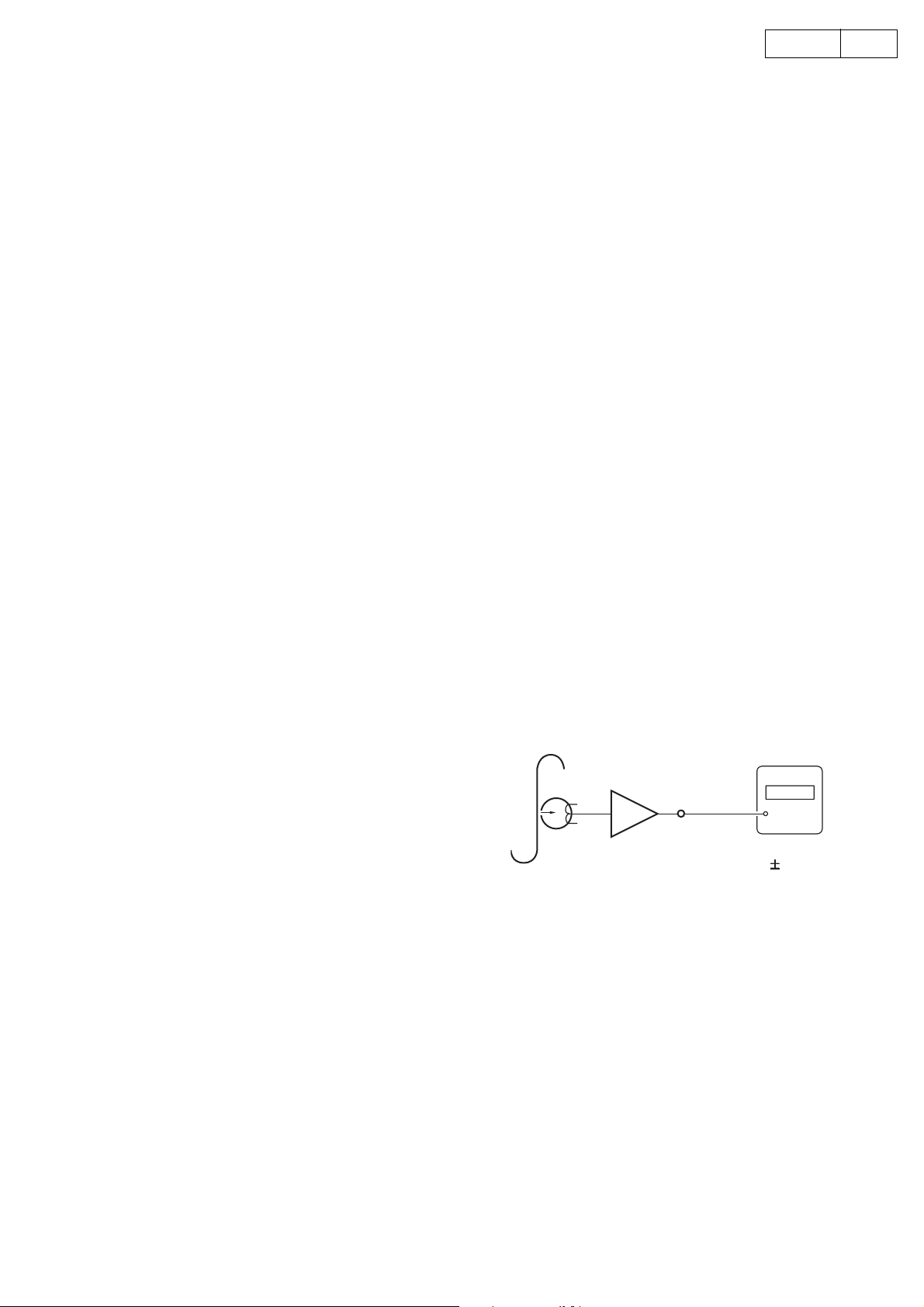

2. Tape speed check and adjustment

(1) Connect the frequency counter to the LINE OUT pin

and load the test tape (MTT-111).

(2) Playback FWD side of the test tape. At about halfway

through the tape, where the tape transport is stable,

confirm that the frequency counter will have a

reading within the range of 3,000 Hz ±10 Hz.

(3) Check REV side also that the counter reading

indicates within 2955~3045Hz.

Note: Adjust within 30 seconds, after pre-heating

(Play) of 20min, or more.

Frequency counte

PB Amp

LINE OUT

MTT-111

3000

3000Hz

10Hz

6

Page 7

3. Azimuth Adjustment

)

(1) Connect an electronic voltmeter to the Line Out

terminal, and set Test tape MTT-114N into the Unit.

(2) Playback FWD side,and adjust the azimuth screw A

so as to get maximum indication on the voltmeter,

then make the same adjustment with the screw B for

REV side.

(3) Readjust if the output level difference exceeds 2dB

after adjustment, and also confirm that the phase

difference in the both channels is within ±45

Note: In order to prevent the backlash of the azimuth

screw, end in the clockwise rotation.

7DRR-M31

PB Amp

LINE OUT

.

MTT-114N

V. V

4. PB Output Level Adjustment

(1) Connect an electronic voltmeter to the Line Out

terminal, and set Test tape MTT-150 into the Unit.

(2) Playback FWD side, and adjust the VR301 (Lch) and

VR302 (Rch) so that the voltmeter indicates 400mV

±0.5dB.

5. REC Level Adjustment

(1) Set Test Tape (Type1 tape: UD-1) into the Unit,and

record 400mV −10dB 400Hz signal at JK301 input

level on the tape.

(2) Playback the recorded signal, and adjust VR304 (Lch)

and VR303 (Rch) so that the voltmeter indicates

−10dB ±0.5dB at JK301 output level.

MTT-150

400Hz

A

FWD SIDE

ATT

V. V

B

REV SIDE

PB Amp

LINE OUT

V. V

REC Amp

LINE IN

LINE OUT

PB Amp

Type 1 tape(UD-1

7

Page 8

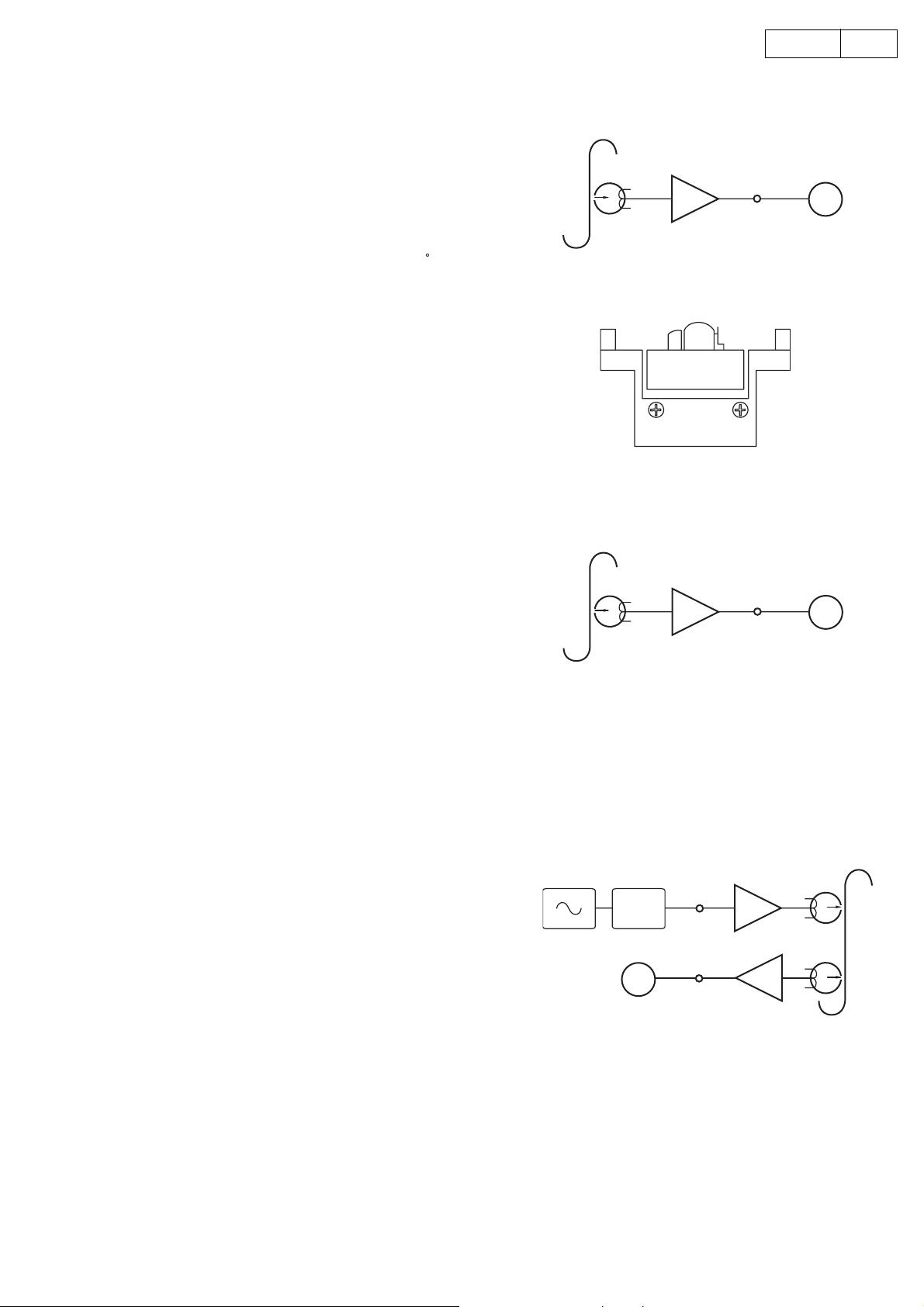

6. Bias Current Adjustment

)

(1) Set Test Tape (Type1 tape: UD-1) into the Unit, and

record 400mV -23dB 1.25kHz/12.5kHz signal at JK301

level on the tape.

(2) Playback the recorded signal, and adjust VR306 (Lch)

and VR305 (Rch) so that the level difference between

both frequencies becomes within the range of

+2dB ~ -0.5dB on the voltmeter.

ADJUSTMENT POINTS

ATT

1.25kHz

12.5kHz

V. V

LINE IN LINE OUT

JK301

8DRR-M31

REC Amp

LINE IN

LINE OUT

PB Amp

Type 1 tape(UD-1

(Deck Mecha.)

MAIN P.W.B

Azimuth Adjust

R/P Level Adjust

PB GAIN Adjust

Tape Speed Adjust

Rch

VR304

Lch

VR303

Lch

VR301

Rch

VR302

Lch

VR306

Rch

VR305

AMP P.W.B

8

Page 9

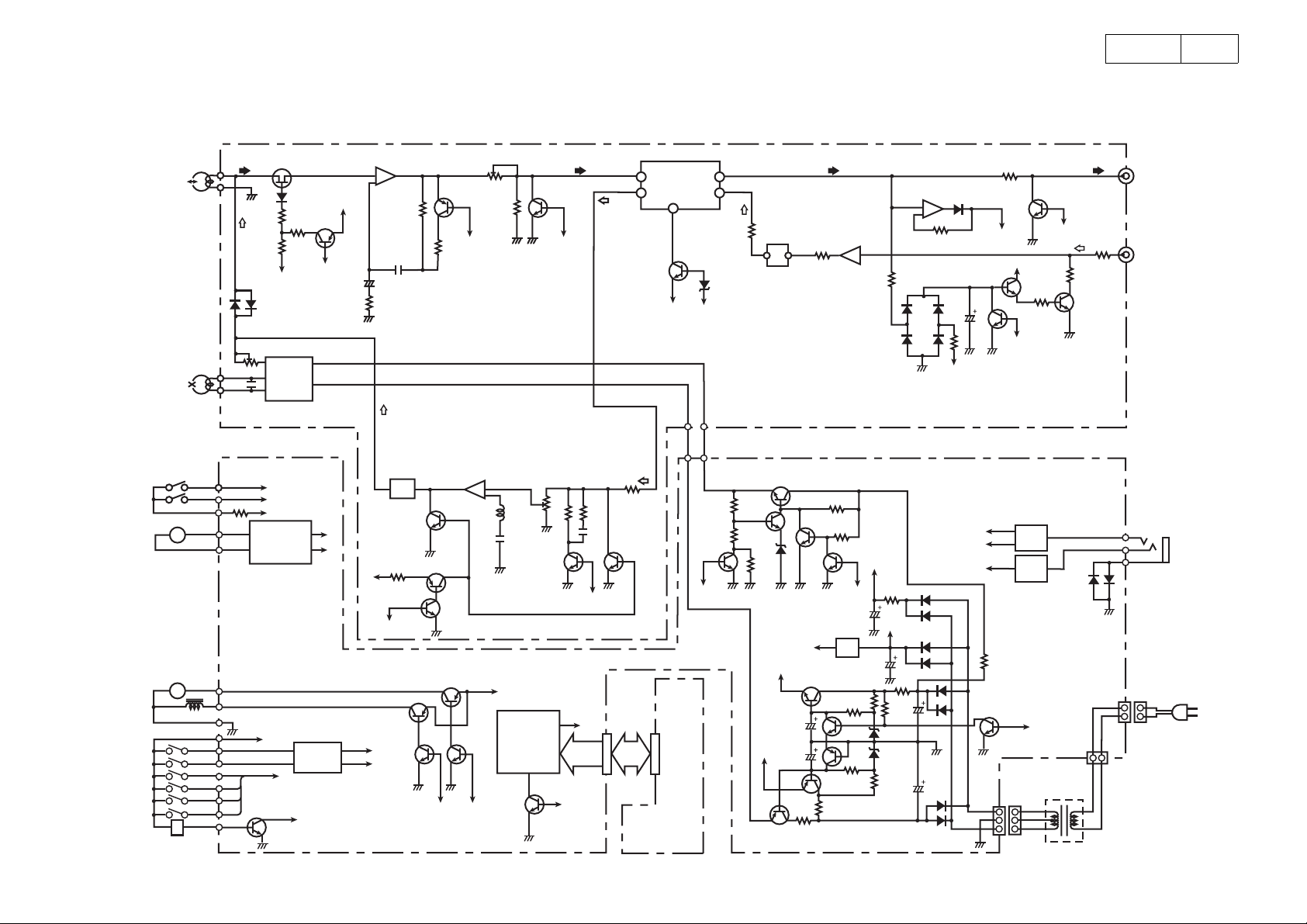

BLOCK DIAGRAM

DRR-M31

9

CLOSE

OPEN

LOADING

MOTOR

CAPSTAN

MOTOR

SOL

R/P HEAD

E. HEAD

HALL IC

M

M

CrO2 SW

NOR SW

F. REC

R. REC

HALF

MODE

TU201,202

BIAS ADJ.

VR201,202

μCOM. CLOSE

μCOM. OPEN

+5V

IC302

MOTOR

DRIVE

+5V

μCOM

R/P

SWITCHING

-7V

L203

TR204

TR205

BIAS OSC

μCOM

TR506

TR507

μCOM. REEL PULSE

μCOM

R/P

+B

-7V

+7V

TR203

PLAYBACK

AMP

IC201

BIAS TRAP

+5V

μCOM

R. MUTE

TR501

NOR

CrO

2

TR307

TR308

SOLENOID

μCOM

PLAY BACK LEVEL ADJ.

VR203,204

TR206,207

NOR

REC AMP REC LEVEL ADJ.

IC301

TR303

TR304

TR502

TR504 TR505

MOTOR

μCOM

+12V

RESET

VR301

VR302

IC501

μCOM

TR208,209

μCOM

R/P

TR510

TR305,306

NOR

+5V

P. OFF

PB IN

REC OUT

TR301,302

IC203

DOLBY IC

TR201

-7V

KEY

& LED

DISTLAY PWB

PB OUT ( Lch )

REC IN

D.RP

TR509 ( μCOM )

TR312

2

CrO

R/P PWB

TR313

-7V

TR328

MPX

FILTER

L201,202

TR314

+7V

TR327

TR315

+5V

TR326

TR324

IC205

TR316

μCOM

BIAS

IC304

TR325

IC204

LEVEL DETECT AMP ( A/D )

AUTO LEVEL CONTROL

P. OFF

+12V

DOLBY IC

PB OUT ( Rch )

MAIN PWB

μCOM. SO

μCOM. SI

μCOM. SCK

μCOM

A/D INPUT

TR211

μCOM

R. MUTE

TR323

TP215,216

TR317

( LINE MUTE OUT )

+7V

TR212

P. ON

LD405

(

Green

T101

POWER TRANS

LINE OUT

LINE MUTE

LINE IN

TR213,214

CD SYNCHRO

JK301

AC PLUG

(

9

Page 10

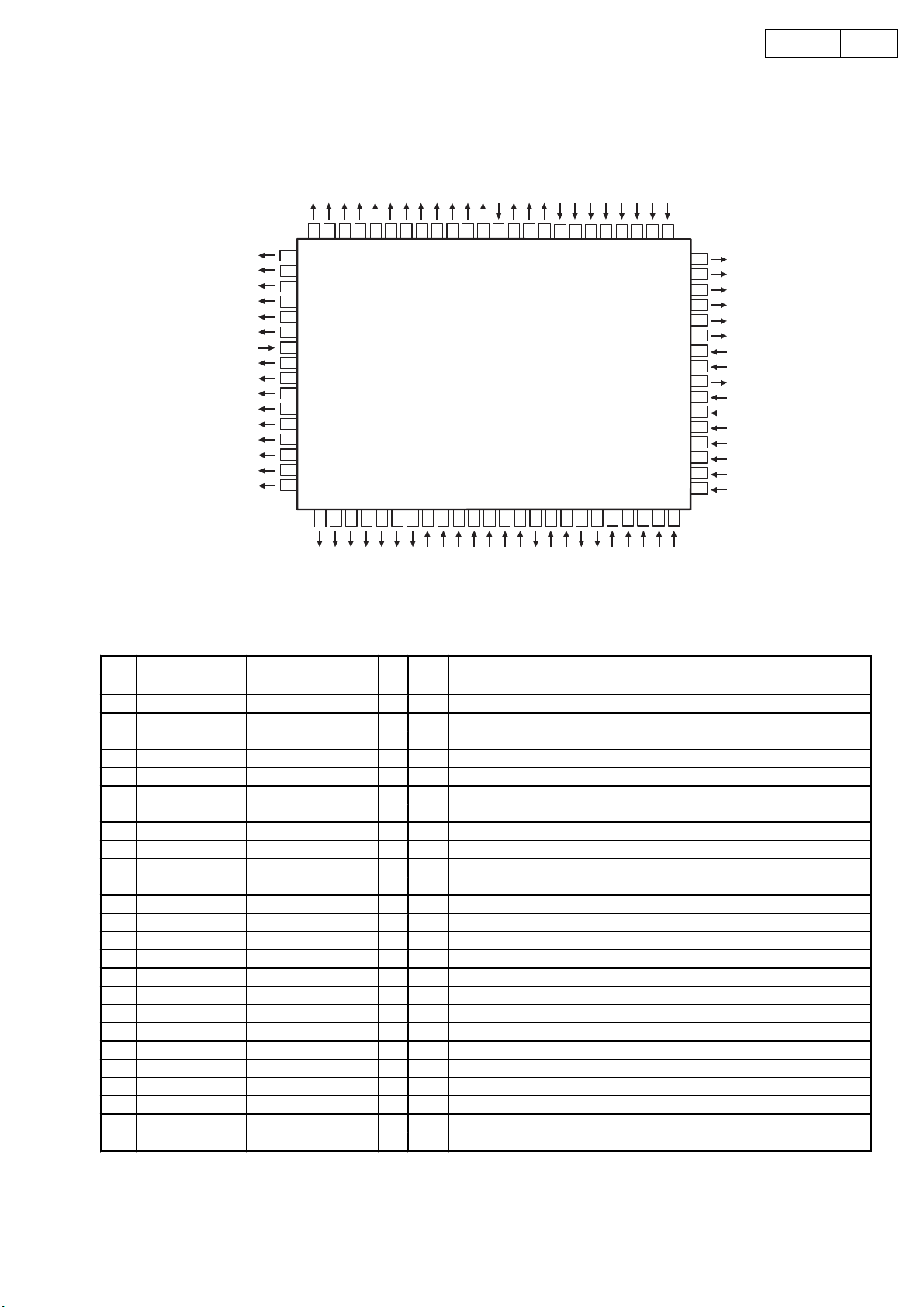

SEMICONDUCTORS

IC's

µ µ

µPD78044FGF (IC203)

µ µ

P113 / FIP21

P112 / FIP20

P111 / FIP19

P110 / FIP18

P107 / FIP17

P106 / FIP16

VLOAD

P105 / FIP15

P104 / FIP14

P103 / FIP13

P102 / FIP12

P101 / FIP11

P100 / FIP10

P97 / FIP9

P96 / FIP8

P95 / FIP7

10DRR-M31

P114 / FIP22

P115 / FIP23

P116 / FIP24

P117 / FIP25

P120 / FIP26

P121 / FIP27

P122 / FIP28

P123 / FIP29

P124 / FIP30

P125 / FIP31

P126 / FIP32

P127 / FIP33

VDD

P70

P71

P72

IC (VPP)

P00 / INTP0

P01 / INTP1

P02 / INTP2

P03 / INTP3

P30 / TO0

P31 / TO1

P32 / TO2

6061

62

64

63

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

57

59

58

55

56

54

53

5152

TOP VIEW

46

4748

49

50

41

42

P33 / TI1

40

39

P34 / TI2

P35 / PCL

38

P36 / BUZ

37

36

P37

X2

35

X1

34

VSS

33

32

XT2

31

P04 / XT1

30

AVREF

29

AVDD

28

P10 / ANI0

27

P11 / ANI1

26

P12 / ANI2

25

P13 / ANI3

43

45

44

3

2

P94 / FIP6

P93 / FIP5

P92 / FIP4

4567

P91 / FIP3

P90 / FIP2

P81 / FIP1

P80 / FIP0

1

11

9

8

10

VDD

P26 / SO0

P27 / SCK0

P25 / SI0

12 13

P24 / BUSY

14

P23 / STB

P22 / SCK1

15 16

P21 / SO1

17 18 19 20

P74

RESET

P20 / SI1

P73

21

AVSS

22

23 24

P17 / ANI7

P16 / ANI6

P15 / ANI5

P14 / ANI4

PPPPPD78044FGF Terminal Function

Pin

No.

10 P26/SO0

11 P26/SI0 REC REV I Hi-z Deck mecha REC REV SW input

12 P24/BUSY PACK I Hi-z Deck mecha PACK SW input

13 P23/STB

14 P22/SCK1 SERCLK I Hi-z DENON BUS communication clock signal (Edge intervention)

15 P21/SO1 SEROUT O Hi-z DENON BUS communication output data signal

16 P20/SI1 SER IN I Hi-z DENON BUS communication input data signal

17 RESET RESET I Hi-z Reset input

18 P74 R MUTE

19 P73 HEADSW O Hi-z Head switching control signal (L: PB only)

20 AVSS AVSS O

21 P17/AN17 RVSMOD I Hi-z Reverse mode input signal

22 P16/AN16 KEYIN 2 I Hi-z Tact operating button input No.2

23 P15/AN15 KEYIN 1 I Hi-z Tact operating button input No.1

24 P14/AN14 KEYIN 1 I Hi-z Tact operating button input No.0

25 AN13 MSREF I Hi-z Music serch detection reference voltage

Port Name Symbol I/O Ini Function

1 P94/FIP6 MTCONT2 O Hi-z Reel, Loader motor control

2 P93/FIP5 MTCONT1 O Hi-z Reel, Loader motor control

3 P92/FIP4 LED FP O Hi-z LED output FWD, PLAY ind. (H: light )

4 P91/FIP3 LED RP O Hi-z LED output REV, PLAY ind. (H: light )

5 P90/FIP2 LED REC O Hi-z LED output REC ind. (H: light )

6 P81/FIP1 LED SRS O Hi-z LED output CD SRS ind. (H: light )

7 P80/FIP0 LED PWR O Hi-z LED output POWER. (H: light )

8VDD VDD

+5V Power

9 P27/SCK0 REC FWD I Hi-z Deck mecha REC FWD SW input

I Hi-z Not used (connect to GND)

I Hi-z Not used (connect to GND)

Hi-z REC mute control signal (H: mute)

Analog GND

10

Page 11

11DRR-M31

Pin

No.

26 P12/ANI2 TEST I Hi-z Board check mode input terminal

27 P11/ANI1 AD-L I Hi-z Audio signal L-ch

28 P10/ANI0 AD-R I Hi-z Audio signal R-ch

29 AVDD AVDD

30 AVREF AVREF

31 P04/XT1

32 XT2 XT2 O

33 VSS VSS

34 X1 X1 I

35 X2 X2 O

36 P37

37 P36/BUZ

38 P35/PCL

39 P34/TI2 SOL O Hi-z Solenoid control signal

40 P33/TI1 MOT O Hi-z Motor control signal

41 P32/TO2 MODESW I Hi-z Deck mecka mode SW input signal (H: stop)

42 P31/TO1 LOADOUT I Hi-z Loader open input signal

43 P30/TO0 LOADIN I Hi-z Loader close input signal

44 P03/INTP3 STANBY I Hi-z Power shut off detection signal (H: normal,L: shut off)

45 P02/INTP2 REEL I Hi-z Supply reel pulse input signal

46 P01/INTP1

47 P00/INTP0 SERINT I Hi-z DENON BUS communicate intervention signal

48 IC IC

49 P72

50 P71

51 P70

52 VDD VDD

53 P127/FIP33 L MUTE O Hi-z Line mute control signal (L: mute)

54 P126/FIP32 DOLBY O Hi-z Not used: DOLBY switching signal (H: off)

55 P125/FIP31 DOLB/C O Hi-z Not used: DOLBY B/C switching signal (H: B)

56 P124/FIP30 DOLR/P O Hi-z DOLBY REC /PB switching signal (L: PB)

57 P123/FIP29 MPXFIL O Hi-z Not used : MPX filter control signal

58 P122/FIP28

59 P121/FIP27 BIAS O Hi-z Bias control signal (H: OSC)

60 P120/FIP26

61 P117/FIP25

62 P116/FIP24

63 P115/FIP23

64 P114/FIP22

65 P113/FIP21

66 P112/FIP20

67 P111/FIP19

68 P110/FIP18

69 P107/FIP17

70 P106/FIP16

71 VLOAD VLOAD

72 P105/FIP15

73 P104/FIP14

74 P103/FIP13

75 P102/FIP12

76 P101/FIP11

77 P100/FIP10

78 P97/FIP9

79 P96/FIP8

80 P95/FIP7

Port Name Symbol I/O Ini Function

Analog power (+5v)

Analog refernce voltage

Not used: open

GND

Main systemclock input

Main systemclock output

Internal connection terminal,connect to Vss

Hi-z5V power

connect to GND

LED-PR

LED-PG

I Hi-z Not used: either pull up/down

O Hi-z Not used open

O Hi-z Not used open

O Hi-z Not used open

I Hi-z Not used

O Hi-z Not used: open

O Hi-z Not used: open

O Hi-z Not used: open

O Hi-z Not used: open

O Hi-z Not used: open

O Hi-z Not used: open

O Hi-z Not used: open

O Hi-z Not used: open

O Hi-z Not used: open

O Hi-z Not used: open

O Hi-z Not used: open

O Hi-z Not used: open

O Hi-z Not used: open

O Hi-z Not used: open

O Hi-z Not used: open

O Hi-z connect to GND

O Hi-z connect to GND

O Hi-z connect to GND

O Hi-z connect to GND

O Hi-z connect to GND

O Hi-z connect to GND

O Hi-z connect to GND

OHi-zPOWER OFF:H

OHi-zPOWER ON:H

11

Page 12

HA12136AF (IC302)

12DRR-M31

REC IN

16 15

BIAS

REC IN

PB IN

GND

14 13 12 11 10 9

SW

SW

321

CC

V

PB IN

BIAS

REF

V

BUF

AMP

BUF

AMP

REC/PB

NR ON/OFF

PB OUT

PB OUT

SIDE

CHAIN

SIDE

CHAIN

DET

DET

REC OUT

87654

REC OUT

TRANSISTOR

DTA114TK

DTA124EK

DTC114TK

DTC124EK

DTC143EK

DTC323TK

FRONT VIEW

B

E

DTA Series DTC Series

R1

IN

(B)

R2

C

DTA114TK 10kohm

DTA124EK

R1 R2

22kohm 22kohm

OUT (C)

GND (E)

IN

(B)

DTC114TK

DTC124EK

DTC143TK

DTC323TK

R1

R2

R1

10kohm

22kohm

4.7kohm

2.2kohm

OUT (C)

GND (E)

R2

22kohm

4.7kohm

12

Page 13

PRINTED WIRING BOARDS

1U-3501-1 MAIN UNIT / 1U-3501-2 AMP UNIT / 1U-3501-3 DISP UNIT

DRR-M31

13

13

COMPONENT SIDE

Page 14

DRR-M31

14

14

FOIL SIDE

Page 15

NOTE FOR PARTS LIST

l Part indicated with the mark "" are not always in stock and possibly to take a long period of time for supplying, or in

some case supplying of part may be refused.

l When ordering of part, clearly indicate "1" and "I" (i) to avoid mis-supplying.

l Ordering part without stating its part number can not be supplied.

l Part indicated with the mark " " is not illustrated in the exploded view.

l Not including Carbon Film ±5%, 1/4W Type in the P.W.Board parts list. (Refer to the Schematic Diagram for those parts.)

WARNING:

Parts marked with this symbol

Use ONLY replacement parts recommended by the manufacturer.

have critical characteristics.

15DRR-M31

ll

Resistors

l

ll

Ex.: RN 14K 2E 182 G FR

Type Shape Power Resist- Allowable Others

and per- ance error

formance

t

RD : Carbon 2B : 1/8W F : ±1% P : Pulse-resistant type

RC : Composition 2E : 1/4W G : ±2% NL : Low noise type

RS : Metal oxide film 2H : 1/2W J : ±5% NB : Non-burning type

RW : Winding 3A : 1W K : ±10% FR : Fuse-resistor

RN : Metal film 3D : 2W M : ±20% F : Lead wire forming

RK : Metal mixture 3F : 3W

Resistance

1 8 2 ⇒ 1800 ohm = 1.8 kohm

s

s

• Units: ohm

1 R 2 ⇒ 1.2 ohm

s

s

• Units: ohm

t

3H : 5W

Indicates number of zeros after effective number.

2-digit effective number.

1-digit effective number.

2-digit effective number, decimal point indicated by R.

t

t

ll

Capacitors

l

ll

Ex.: CE 04W 1H 2R2 M BP

Type Shape Dielectric Capacity Allowable Others

and per- strength error

formance

t

CE : Aluminum foil 0J : 6.3V F : ±1% HS : High stability type

electrolytic

CA : Aluminum solid 1A : 10V G : ±2% BP : Non-polar type

electrolytic

CS : Tantalum electrolytic 1C : 16V J : ±5% HR: Ripple-resistant type

CQ : Film 1E : 25V K : ±10% DL : For change and discharge

CK : Ceramic 1V : 35V M : ±20% HF : For assuring high

CC : Ceramic 1H : 50V Z : +80% U : UL par t

CP : Oil 2A : 100V –20% C : CSA part

CM : Mica 2B : 125V P : +100% W : UL-CSA type

CF : Metallized 2C : 160V –0% F : Lead wire forming

CH : Metallized 2D : 200V C : ±0.25pF

Capacity (electrolyte only)

2 2 2 ⇒ 2200µF

s

s

• Units: µF.

2 R 2 ⇒ 2.2µF

s

s

• Units: µF.

Capacity (except electrolyte)

2 2 2 ⇒ 2200pF=0.0022µF

s

s

(More than 2) Indicates number of zeros after effective number.

• Units: pF.

2 2 1 ⇒ 220pF

s

s

(0 or 1) Indicates number of zeros after effective number.

• Units: pF.

• When the dielectric strength is indicated in AC, "AC" is included after the dieelectric

strength value.

t

2E : 250V D : ±0.5pF

2H : 500V = : Others

2J : 630V

Indicates number of zeros after effective number.

2-digit effective number.

1-digit effective number.

2-digit effective number, decimal point indicated by R.

2-digit effective number.

2-digit effective number.

t

t

requency

15

Page 16

PARTS LIST OF P.W.B. UNIT ASS'Y

1U-3501 DECK UNIT ASS'Y

Ref. No. Part No. Part Name Remarks New

SEMICONDUCTORS GROUP

IC201 263 0402 005 BA6209

IC202 268 0073 905 ICP-N15T

IC203 262 3178 003 UPD78044FGF-212-3B9 *

IC204 263 0792 003 NJM78M06FA(S)

IC301 263 0896 909 NJM2068MD-TE1

IC302 263 1171 908 HA12136AF

IC303-305 263 0615 902 BA15218F-DXE2

TR103 269 0088 906 DTC114TKT96

TR201-204 269 0102 905 DTC124EKT146

TR205 269 0119 901 DTA124EKT96(TAPE)

TR206 269 0102 905 DTC124EKT146

TR207,208 272 0163 005 HIT5610

TR209-213 269 0102 905 DTC124EKT146

TR214 273 0384 900 2SC2412KT96(S)

TR215 273 0426 907 2SC2412KLNT146

TR216 269 0102 905 DTC124EKT146

TR217 272 0164 004 KTD2058Y

TR218,219 273 0384 900 2SC2412KT96(S)

TR220 269 0102 905 DTC124EKT146

TR221 269 0119 901 DTA124EKT96(TAPE)

TR222 269 0102 905 DTC124EKT146

TR223 274 0201 002 HIT5609

TR224 269 0102 905 DTC124EKT146

TR225 273 0384 900 2SC2412KT96(S)

TR226 271 0309 905 2SA1037AKT146S

TR227,228 274 0202 001 KTB1366Y

TR229 271 0309 905 2SA1037AKT146S

TR230 273 0384 900 2SC2412KT96(S)

TR231 271 0309 905 2SA1037AKT146S

TR232 273 0384 900 2SC2412KT96(S)

TR301,302 275 0042 905 2SK373(Y)TPE2

TR303,304 269 0086 908 DTA114TKT96

TR305,306 269 0048 904 DTC143EK-T96

TR307,308 269 0102 905 DTC124EKT146

TR309,310 273 0426 907 2SC2412KLNT146

TR311-314 269 0066 902 DTC323TKT96

TR315,316 273 0466 909 2SC2120

TR317,318 269 0066 902 DTC323TKT96

TR319,320 269 0088 906 DTC114TKT96

TR321,322 269 0066 902 DTC323TKT96

TR323 269 0102 905 DTC124EKT146

TR324,325 269 0119 901 DTA124EKT96(TAPE)

TR326 273 0426 907 2SC2412KLNT146

16DRR-M31

D201-213 276 0375 905 1N4148T77 (TAPE)

D214,215 276 0772 003 1N4004

D216,217 276 0375 905 1N4148T77 (TAPE)

D218-223 276 0772 003 1N4004

D224,225 276 0375 905 1N4148T77 (TAPE)

D226 276 0772 003 1N4004

D227 276 0375 905 1N4148T77 (TAPE)

D301-314 276 0375 905 1N4148T77 (TAPE)

ZD201 276 0760 989 MTZJ7.5B T77

ZD202 276 0636 903 MTZJ8.2BT77

16

Page 17

Ref. No. Part No. Part Name Remarks New

ZD203 276 0760 905 MTZJ3.6B T77

ZD204 276 0636 903 MTZJ8.2BT77

ZD206 276 0760 905 MTZJ3.6B T77

ZD207 276 0760 918 MTZJ3.9B T77

ZD208,209 276 0760 963 MTZJ6.2B T77

ZD210,211 276 0636 903 MTZJ8.2BT77

ZD212 276 0760 950 MTZJ5.6B T77

ZD301 276 0760 963 MTZJ6.2B T77

ZD302 276 0636 903 MTZJ8.2BT77

LD101,102 393 9616 009 SLR-136B-81

LD103,104 393 9617 008 SLR-236B-81

LD105 393 9618 007 SLR-9336DS-91

RESISTORS GROUP

R101 247 2005 961 RM73B--181JT

R106-108 247 2006 986 RM73B--561JT

R109,110 247 2006 915 RM73B--271JT

R111,112 247 2008 926 RM73B--222JT

R113-116 247 2007 943 RM73B--102JT

R117 247 2005 961 RM73B--181JT

R118 247 2005 945 RM73B--151JT

R119 247 2005 961 RM73B--181JT

R120 247 2006 928 RM73B--301JT

R121 247 2005 945 RM73B--151JT

R122 247 2005 961 RM73B--181JT

R123 247 2006 928 RM73B--301JT

R127 247 2005 987 RM73B--221JT

R201 247 2009 983 RM73B--103JT

R202 247 2009 909 RM73B--472JT (1608)

R203,204 247 2009 983 RM73B--103JT

R205 247 2007 943 RM73B--102JT

R206,207 244 2051 945 RS14B3A010JNBST(S)

R208 247 2007 943 RM73B--102JT

R209,210 247 2011 942 RM73B--473JT

R211-213 247 2007 943 RM73B--102JT

R214-216 247 2011 942 RM73B--473JT

R218 247 2007 943 RM73B--102JT

R219 247 2012 925 RM73B--104JT

R220 247 2006 902 RM73B--331JT (1608)

R221-223 247 2007 943 RM73B--102JT

R224,225 247 2011 942 RM73B--473JT

R226 247 2009 909 RM73B--472JT (1608)

R227 247 2009 983 RM73B--103JT

R228 247 2012 925 RM73B--104JT

R229 247 2009 983 RM73B--103JT

R230 247 2012 925 RM73B--104JT

R231 247 2008 926 RM73B--222JT

R232 247 2009 925 RM73B--562JT

R235 247 2011 942 RM73B--473JT

R237 247 2011 942 RM73B--473JT

R238,239 247 2010 969 RM73B--223JT

R241 247 2009 983 RM73B--103JT

R242,243 247 2009 909 RM73B--472JT (1608)

R244 247 2009 925 RM73B--562JT

R245 247 2010 969 RM73B--223JT

R246 247 2005 987 RM73B--221JT

R247 244 2051 974 RS14B3A102JNBST(S)

17DRR-M31

17

Page 18

Ref. No. Part No. Part Name Remarks New

R248 241 2313 985 RD14B2E4R7JFRST

R249 244 2051 974 RS14B3A102JNBST(S)

R250 247 2005 987 RM73B--221JT

R251,252 241 2313 985 RD14B2E4R7JFRST

R253 247 2007 943 RM73B--102JT

R254 241 2379 987 RD14B2E102JNBST

R255,256 247 2007 943 RM73B--102JT

R257 247 2005 903 RM73B--101JT

R258,259 247 2010 969 RM73B--223JT

R260,261 247 2009 983 RM73B--103JT

R262 247 2011 942 RM73B--473JT

R263-265 247 2009 983 RM73B--103JT

R266 247 2005 987 RM73B--221JT

R267 247 2018 903 RM73B--0R0KT

R268 247 2009 983 RM73B--103JT

R269 247 2012 925 RM73B--104JT

R270 247 2011 942 RM73B--473JT

R271 247 2018 903 RM73B--0R0KT

R272 247 2010 969 RM73B--223JT

R273 247 2008 926 RM73B--222JT

R274 241 2313 985 RD14B2E4R7JFRST

R275 247 2009 983 RM73B--103JT

R276 241 2381 946 RD14B2E472JNBST

R277 241 2379 987 RD14B2E102JNBST

R278 247 2009 938 RM73B--622JT

R279 247 2010 901 RM73B--123JT

R281 247 2009 909 RM73B--472JT (1608)

R282 247 2009 925 RM73B--562JT

R283,284 247 2008 968 RM73B--332JT

R301,302 247 2015 948 RM73B--225KT

R303 247 2009 983 RM73B--103JT

R304 247 2011 942 RM73B--473JT

R305 247 2005 903 RM73B--101JT

R306 247 2006 944 RM73B--391JT

R307 247 2013 979 RM73B--434JT

R308 247 2010 998 RM73B--303JT

R309 247 2010 972 RM73B--243JT

R310,311 247 2015 948 RM73B--225KT

R312 247 2012 925 RM73B--104JT

R313 247 2011 942 RM73B--473JT

R314 247 2006 944 RM73B--391JT

R315 247 2005 903 RM73B--101JT

R316 247 2009 983 RM73B--103JT

R317 247 2010 972 RM73B--243JT

R318 247 2010 998 RM73B--303JT

R319 247 2009 909 RM73B--472JT (1608)

R320 247 2013 979 RM73B--434JT

R321 247 2006 902 RM73B--331JT (1608)

R322,323 247 2010 969 RM73B--223JT

R324 247 2008 926 RM73B--222JT

R325 247 2006 902 RM73B--331JT (1608)

R326,327 247 2009 983 RM73B--103JT

R328 247 2010 943 RM73B--183JT

R329-331 247 2010 956 RM73B--203JT

R332,333 247 2011 984 RM73B--683JT

R334-336 247 2010 985 RM73B--273JT

R337 247 2005 903 RM73B--101JT

R338 247 2010 985 RM73B--273JT

R339 247 2005 903 RM73B--101JT

R340,341 247 2014 965 RM73B--105JT

R342 247 2018 903 RM73B--0R0KT

18DRR-M31

18

Page 19

Ref. No. Part No. Part Name Remarks New

R343 247 2008 984 RM73B--392JT

R345 247 2008 984 RM73B--392JT

R346,347 247 2008 942 RM73B--272JT

R348,349 247 2007 943 RM73B--102JT

R350 247 2010 914 RM73B--133JT

R351 247 2007 969 RM73B--122JT

R352 247 2010 914 RM73B--133JT

R353 247 2007 969 RM73B--122JT

R354 247 2009 983 RM73B--103JT

R355,356 247 2009 909 RM73B--472JT (1608)

R357,358 247 2006 944 RM73B--391JT

R359-362 247 2011 926 RM73B--393JT

R363,364 247 2010 985 RM73B--273JT

R365 247 2006 960 RM73B--471JT

R366 247 2007 972 RM73B--132JT

R367 247 2008 913 RM73B--202JT

R368,369 247 2009 970 RM73B--912JT

R370 247 2006 960 RM73B--471JT

R371 247 2007 972 RM73B--132JT

R372 247 2008 913 RM73B--202JT

R373,374 247 2011 942 RM73B--473JT

R375 247 2018 903 RM73B--0R0KT

R376,377 247 2009 954 RM73B--752JT

R378 247 2007 943 RM73B--102JT

R379,380 247 2008 926 RM73B--222JT

R381 247 2007 943 RM73B--102JT

R382 247 2012 983 RM73B--184JT

R383 247 2005 987 RM73B--221JT

R384,385 247 2008 942 RM73B--272JT

R386 247 2010 998 RM73B--303JT

R387 247 2012 983 RM73B--184JT

R388 247 2006 902 RM73B--331JT (1608)

R389,390 247 2010 901 RM73B--123JT

R391 247 2010 998 RM73B--303JT

R393 247 2010 998 RM73B--303JT

R394 247 2010 901 RM73B--123JT

R395 247 2010 998 RM73B--303JT

R396 247 2010 901 RM73B--123JT

R397 247 2010 998 RM73B--303JT

R398,399 247 2010 969 RM73B--223JT

R400 247 2006 960 RM73B--471JT

R401,402 247 2008 984 RM73B--392JT

R403 247 2006 902 RM73B--331JT (1608)

R404,405 247 2012 925 RM73B--104JT

R406,407 247 2001 981 RM73B--4R7KT

R409 247 2010 998 RM73B--303JT

R410 247 2010 969 RM73B--223JT

R411,412 247 2009 983 RM73B--103JT

R413 247 2010 969 RM73B--223JT

R422 247 2005 903 RM73B--101JT

R423,424 247 2009 967 RM73B--822JT

19DRR-M31

VR301-306 211 6095 923 V06QB473 (TAPE)

CAPACITORS GROUP

C102 257 0512 903 CK73F1E104ZT

C201 254 4524 998 CE04W1H220MT SMG/RE3

C202 254 4524 943 CE04W1H010MT SMG/RE3

19

Page 20

Ref. No. Part No. Part Name Remarks New

C203 257 0516 909 CK73B1E223KT

C204 257 0512 903 CK73F1E104ZT

C205 254 4541 942 CE04W1E101MT SMG/RE3

C206 254 4524 985 CE04W1H100MT SMG/RE3

C207 257 0511 904 CK73F1H103ZT

C208 254 4537 707 CE04W1A102MC SMG/RE3

C209 257 0511 904 CK73F1H103ZT

C210 254 4524 943 CE04W1H010MT SMG/RE3

C211 254 4524 956 CE04W1H2R2MT SMG/RE3

C212 254 4541 939 CE04W1E470MT SMG/RE3

C213 257 0512 903 CK73F1E104ZT

C214 254 4538 913 CE04W1C220MT SMG/RE3

C215 257 0509 929 CK73B1H102KT

C216 254 4524 969 CE04W1H3R3MT SMG/RE3

C217,218 257 0509 929 CK73B1H102KT

C220,221 254 4541 942 CE04W1E101MT SMG/RE3

C222 254 4403 721 CE04W1E222MC (SMG)

C223 257 0511 904 CK73F1H103ZT

C224 254 4524 985 CE04W1H100MT SMG/RE3

C232 254 4403 718 CE04W1E102MC (SMG)

C234 254 4403 718 CE04W1E102MC (SMG)

C235-237 254 4541 939 CE04W1E470MT SMG/RE3

C238,239 254 4524 985 CE04W1H100MT SMG/RE3

C301,302 257 0509 929 CK73B1H102KT

C303,304 257 0508 959 CC73CH1E681JT

C305,306 254 4536 915 CE04W1A470MT SMG/RE3

C307,308 255 1264 995 CQ93M1H562JT(B)

C309,310 257 0506 951 CC73CH1H101JT

C311,312 254 4524 943 CE04W1H010MT SMG/RE3

C313 254 4541 939 CE04W1E470MT SMG/RE3

C314 257 0512 903 CK73F1E104ZT

C315 254 4541 939 CE04W1E470MT SMG/RE3

C316,317 257 0512 903 CK73F1E104ZT

C318,319 257 0507 934 CC73CH1H221JT

C320 255 1265 923 CQ93M1H822JT(B)

C321 255 1265 936 CQ93M1H103JT(B)

C322,323 255 1264 982 CQ93M1H472JT(B)

C324 257 0516 909 CK73B1E223KT

C325 254 4536 957 CE04W1A471MT SMG/RE3

C326 254 4524 943 CE04W1H010MT SMG/RE3

C327,328 254 4541 900 CE04W1E100MT SMG/RE3

C329 254 4524 943 CE04W1H010MT SMG/RE3

C331 256 1059 912 CF93A1H224JT (JL)

C332,333 254 4524 956 CE04W1H2R2MT SMG/RE3

C334 256 1059 912 CF93A1H224JT (JL)

C336,337 254 4524 956 CE04W1H2R2MT SMG/RE3

C338,339 254 4524 930 CE04W1HR47MT SMG/RE3

C340,341 257 0512 903 CK73F1E104ZT

C342,343 254 4524 943 CE04W1H010MT SMG/RE3

C344,345 257 0512 903 CK73F1E104ZT

C346,347 254 4524 956 CE04W1H2R2MT SMG/RE3

C348,349 254 4524 972 CE04W1H4R7MT SMG/RE3

C350 254 4524 956 CE04W1H2R2MT SMG/RE3

C351,352 257 0506 951 CC73CH1H101JT

C353 257 0512 903 CK73F1E104ZT

C354 254 4524 956 CE04W1H2R2MT SMG/RE3

C355 254 4524 972 CE04W1H4R7MT SMG/RE3

C356,357 254 4524 901 CE04W1H0R1MT SMG/RE3

C358,359 255 1265 936 CQ93M1H103JT(B)

C362,363 254 4524 972 CE04W1H4R7MT SMG/RE3

C364 254 4541 939 CE04W1E470MT SMG/RE3

20DRR-M31

20

Page 21

Ref. No. Part No. Part Name Remarks New

C365 256 1058 968 CF93A1H823JT (JL)

C366 257 0509 903 CK73B1H821KT

C367 255 1265 936 CQ93M1H103JT(B)

C368 257 0509 903 CK73B1H821KT

C369 255 1265 936 CQ93M1H103JT(B)

C370 254 4541 939 CE04W1E470MT SMG/RE3

C371 256 1058 968 CF93A1H823JT (JL)

C372,373 254 4541 939 CE04W1E470MT SMG/RE3

C374 257 0509 990 CK73B1H222KT

C375 254 4524 972 CE04W1H4R7MT SMG/RE3

C376 257 0509 990 CK73B1H222KT

C377 254 4524 972 CE04W1H4R7MT SMG/RE3

C379 257 0506 993 CC73CH1H151JT

C381 257 0506 993 CC73CH1H151JT

C382 257 0509 929 CK73B1H102KT

C391,392 257 0503 967 CC73CH1H150JT

C420 257 0512 903 CK73F1E104ZT

C423 254 4536 957 CE04W1A471MT SMG/RE3

C424 257 0512 903 CK73F1E104ZT

21DRR-M31

OTHER PARTS GROUP

CW81,82 205 0536 001 8P CONN.SOCKET

CX31 205 0233 032 3P EH CONNECTOR BASE

CX81,82 205 0535 002 8P CONN.BASE

CX151 205 1100 054 15P FFC BASE (P=1)

CX201,202 205 0581 001 2P VH CONNECTOR BASE

CY61,62 205 0343 061 6P CONN.BASE(KR-PH)

CY131 205 0375 039 13P CONN.BASE(KR-PH)

CY151 205 1006 051 15P FFC BASE(P=1)

! F301 206 1075 014 FUSE (1.25A)

! FF301 202 0040 909 FUSE CLIP (TAPE)

! FH301 202 0040 909 FUSE CLIP (TAPE)

JK301 204 8661 001 4P PIN JACK(GND)(CC)

JK302 204 8637 006 MINI JACK (STEREO)

! JK303 203 3961 004 1P AC OUTLET(E2)

L301 231 8077 008 BIAS OSC COIL

L302,303 232 0109 003 MPX FILTER

L304,305 235 0020 916 INDUCTOR 822JT

L307,308 235 0020 945 INDUCTOR 153JT

S101-109 212 0467 000 TACT SW(H=5)

S110 212 0497 009 SRBV231500 *

S111 212 1203 001 PUSH SW(2P-2TPS-2203

ST101,102 205 0452 017 STYLE PIN

TM101 412 9483 009 EARTH PLATE

W101 203 0406 009 1P CONTACT ASS

X201 399 0825 907 CSTLS4M19G56-A0

21

Page 22

EXPLODED VIEW

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

36

35

34

37

38

39

40

41

42

43

45

46

DRR-M31

22

45

WARNING:

Parts marked with this symbol have critical

characteristics.

43

Use ONLY replacement parts recommended by the

manufacturer.

46

26

29

27

35

34

23

24

22

37

14

4

9

40

41

42

39

38

30

25

28

21

16

19

18

17

32

31

20

36

5

2

1

33

15

13

11

10

12

7

8

6

3

22

Page 23

PARTS LIST OF EXPLODED VIEW

Ref. No. Part No. Part Name Remarks Q'ty New

1U-3501 DECK UNIT 1

13 - DISP UNIT

25 - MAIN UNIT

30 - AMP UNIT

1 131 0156 106 DENON BADGE 1

2 144 2820 119 FRONT PANEL 1 *

4 113 1890 007 DOLBY KNOB 1

5 114 0153 007 DOLBY KNOB GUIDE 1

6 143 1160 000 WINDOW(DRR) 1 *

7 146 2300 208 INNER PANEL 1 *

8 112 0900 005 VOLUME KNOB ASS 1 *

9 113 1955 007 POWER KNOB ASS'Y 1 *

10 113 1947 109 KNOB (L) 3P 1 *

11 113 1948 001 KNOB(S)3P 1 *

12 113 1949 000 KNOB(S)2P 1 *

14 449 0200 005 LED HOLDER 1

16 411 1940 408 MAIN CHASSIS 1 *

17 104 0317 008 FOOT 4

18 461 1066 002 FELT 4

20 443 9015 002 P.W. SPACER 2 *

21 412 2741 036 P.W.B.HOLDER (H=10) 3

22 233 6419 004 POWER TRANS(E2/EK) 1

! 23 412 5011 006 SAFETY BRACKET 1 *

! 26 415 0907 208 SAFETY COVER 1 *

27 477 0096 007 PUSH RIVET 1

31 412 4623 000 PCB SUPPORT(B) 1

33 412 4621 002 MECHA HOLDER 1

35 338 0190 006 CASSETTE MECHA 1

37 146 2299 005 LOADERLPANELL(DRR) 1 *

38 105 1420 104 REAR PLATE (DRR) 1 *

! 41 206 2089 106 AC CORD W/CON.E2 1

42 445 0056 008 CORD BUSH 1

43 102 0633 142 TOP COVER 1 *

★

★

★

★

★

★

★

415 0585 015 UL TUBE(16) BK L=30 1

445 8004 007 WIRE CLAMPER 5

204 0562 001 6P PH-PH CON CORD(S) 1

204 0563 000 6P PH-PH CON CORD 1

204 6737 018 13P PH-PH CON CORD 1 *

009 0159 084 15P FFC CABLE 1

513 1642 002 NO. SHEET 1

23DRR-M31

SCREWS

★

3 473 7015 005 3X6 CBTS(S)-B 4

15 473 7500 044 3X8 CBTS (P)-B 7

19 473 7002 005 3X6 CBTS(S)-Z 4

24 473 7004 016 4X6 CBTS (S)-Z 2

28 473 7002 005 3X6 CBTS(S)-Z 2

29 473 7501 014 3X14 CBTS (P)-Z 2

32 473 7002 005 3X6 CBTS(S)-Z 2

34 473 7015 005 3X6 CBTS(S)-B 4

36 473 7015 005 3X6 CBTS(S)-B 4

39 473 7015 005 3X6 CBTS(S)-B 2

40 473 7500 044 3X8 CBTS (P)-B 2

45 473 7015 005 3X6 CBTS(S)-B 5

46 477 0263 018 3P.SWELLING SCREW 2

473 7002 018 3X8 CBTS (S)-Z 4

23

Page 24

24DRR-M31

Ref. No. Part No. Part Name Remarks Q'ty New

★

473 7004 016 4X6 CBTS (S)-Z 2

24

Page 25

EXPLODED VIEW OF CASSETTE MECHANISM UNIT

DRR-M31

25

25

Page 26

PARTS LIST OF CASSETTE MECHANISM UNIT

Ref. No. Part No. Part Name Remarks

1

MAIN CHASSIS MT70-00486B 1

2

HEAD BASE MT70-00376A 1

3

4

6 958 7006 104 REEL BUSH MT72-00331C 2

7 958 7006 201 REEL BASE MT72-00039A 2

8

9

10

11 958 7011 005 CAM GEAR MT72-00407AA 1

12 958 7006 405 IDLER GEAR MT72-00306A 1

13

14

15

16

17

18

19

20

21 958 7006 502 BRAKE LEVER MT72-00021A 1

22

23

24

25 958 7006 609 CAM LOCK ARM MT72-00024A 1

26 958 7006 706 RF ARM MT72-00025A 1

27 958 7006 803 RF GEAR MT72-00305A 2

28

29 958 7009 703 SIDE BRACKET MT70-00388A 2

30 958 7007 006 AC LEVER MT72-00070A 1

31 958 7007 103 MAGNET CAP MT72-00264A 1

32

33

34

35

36

37

38

39

40 958 7007 200 B/T SPRING R 6107-001037 1

41 958 7007 307 AC LEVER SPRING 6107-000396 1

42

43 958 7007 404 BASE HEAD SPRING 6107-000331 1

44

45

46

47 958 7007 501 CAM LOCK SPRING 6107-000350 1

48

49 958 7007 608 RF ARM SPRING 6107-000351 1

50 958 7007 705

51 958 7007 802

52

53 958 7008 005 TAPPING SCREW 1.6X7.8 6002-000582 2

54 958 7008 102 SCREW 2X4 6003-000293 9

55 958 7008 209 SCREW 2X3.7 6003-000322 1

SUB.HEAD BASE MT70-00468A 1

SPRING PLATE MT70-00236A 1

BUSH P MT72-00249A 1

HEAD BRACKET MT72-00356A 1

HEAD GEAR MT72-00303A 1

BUSH C MT72-00250A 1

PULLEY C MT72-00100A 1

FLYWHEEL PULLY F MT72-00101A 1

FLYWHEEL PULLY R MT72-00102A 1

MOTOR PULLY MT72-00329A 1

ARM P MT72-00020A 1

GEAR P MT72-00302A 1

CAP P MT72-00262A 1

DIR GEAR MT72-00304A 1

PINCH ARM F MT72-00022A 1

PINCH ARM R MT72-00023A 1

CAP C MT72-00263A 1

RF SHAFT MT71-00138A 1

IDLER SHAFT MT71-00139A 1

CAPSTAN SHAFT F MT71-00140A 1

CAPSTAN SHAFT R MT71-00400A 1

PINCH SHAFT MT71-00020A 1

AZIMUTH PIN 6043-000169 1

BASE SHAFT S MT71-00161A 1

ROLLER P MT71-00019A 1

SPRING P 6107-001032 1

DIR SPRING 6107-000308 1

PINCH SPRING F 6107-000353 1

PINCH SPRING R 6107-000355 1

SPRING C 6107-000231 1

PINCH RETURN SPRING F

PINCH RETURN SPRING R

SUB.SPRING 6107-000335 1

6107-000177 1

6107-000395 1

Q'ty

Ref. No. Part No. Part Name Remarks

56

57

58 958 7008 306 WASHER 6031-000462 1

59 958 7008 403 WASHER 6031-000448 1

60 958 7008 500 WASHER 6031-000623 1

61

62

63 958 7008 607 SUB.BELT 6602-000131 1

64 958 7008 704 MAIN BELT 6602-000129 1

65 958 7008 801 CONTROL P.W.BOARD MT41-00141A 1

66 958 7008 908 CONNECTOR 3711-002727 1

67 958 7009 004 REEL CAP MT72-00331B 2

68

69 958 7011 102 MOTOR WIRE 3809-000241 1

70

71

72

73 958 7009 208 HALL IC 1009-000107 1

74 958 7009 305 DETECT SWITCH 3409-000185 4

75 958 7009 402 MODE SWITCH 3404-000306 1

76 958 7009 509 SOLENOID MT75-00026C 1

77

78 958 7009 606 MAGNET PLATE MT72-00078A 1

79

80

81

82

83

84

85

86

87 958 7011 209 SHIELD PLATE (MOTOR) MT71-00203B 1

88 958 7009 800 SCREW 2X17 6001-000092 1

89 958 7009 907 PLAIN WASHER 6031-001005 2

90 958 7010 006 MOTOR BRACKET MT70-00389A 1

91 958 7010 103 CUSHION MT73-00060A 3

92 958 7010 200 SCREW 2.6X4 6001-000067 3

93 958 7010 307 B/T WASHER 6031-000624 2

94 958 7010 404 B/T SPRING F 6107-000337 1

95 958 7010 501 RESISTOR 20KOHM 2001-000502 1

96 958 7010 608 DIODE 0402-000132 1

97 958 7010 705 UPPER PLATE MT70-00438A 1

98

99

200 958 7005 008 CHASSIS (OS) ASS'Y ADR04-008 1

201 958 7005 105 CHASSIS (HEAD) ASS'Y ADR02-049 1

202 958 7011 306

203 958 7011 403

204 958 7005 406 ARM (PLAY) ASS'Y ADR10-007 1

205 958 7011 500 FLYWHEEL (F) ASS'Y MT91-01012F 1

206 958 7005 600 FLYWHEEL (R) ASS'Y ADR15-033 1

207 958 7011 607 DC MOTOR ASS'Y MT91-K1501R 1

208 958 7011 704 HEAD ASS'Y MT91-K1101A 1

209 958 7005 901 CLUTCH ASS'Y ADR36-001 1

26DRR-M31

Q'ty

AZIMUTH SCREW 2X5 6009-000335 2

WASHER 6031-000622 2

FELT P MT74-00067A 1

FELT C MT74-00068A 1

HEAD CONNECTOR 3711-000485 1

PINCH ROLLER MT73-00010A 1

METAL BEARING A 6601-000120 1

METAL BEARING B 6601-000114 1

REC/PLAYBACK HEAD MT59-00037A 1

MOTOR 3101-000178 1

HEAD WIRE (BROWN) MT39-00026A 1

HEAD WIRE (BLUE) MT39-00027A 1

HEAD WIRE (GREEN) MT39-00028A 1

HEAD WIRE (ORANGE) MT39-00029A 1

HEAD WIRE (RED) MT39-00030A 1

HEAD WIRE (WHITE) MT39-00051A 1

HEAD WIRE (YELLOW) MT39-00031A 1

PAPER TAPE 0203-001063 1

EARTH SPRING 6107-000192 2

PINCH ROLLER (F) ASS'Y

PINCH ROLLER (R) ASS'Y

ADR10-0018 1

ADR10-0019 1

26

Page 27

27DRR-M31

Ref. No. Part No. Part Name Remarks

210 958 7006 007 GEAR P ASS'Y ADR17-005 1

LOADER SECTION (ACLM-574D)

101 958 7001 109 FLAME ASS'Y A1A001 1

104 958 7001 206 TRAY A1G031 1

105 958 7001 303 CHASSIS A1P001 1

107 958 7001 400 HOLDER ASS'Y A1A009 1

112 958 7001 507 ARM A A1G004 1

113 958 7001 604 ARM C A1G029 1

114 958 7001 701 ARM A1P020 1

115 958 7001 808 RETAINER A1P004 1

116 958 7001 905 PLATE A1G006 1

117 958 7002 001 ARM A1G007 1

118 958 7012 004 PULLEY C A1G037 1

119 958 7012 101 GEAR B A1G009 1

120 958 7002 302 GEAR LUCK A1G010 1

123 958 7002 409 EARTH PLATE A1P005 1

124 958 7002 506 SPRING A A1S001 1

125 958 7002 603 SPRING B A1S002 1

126 958 7002 700 BELT A1G035 1

127 958 7002 807 SWITCH MSS-8B S01W181 2

128 958 7012 208

131 958 7003 000 WASHER 2.1X4X0.5 P21W405 2

132 958 7003 107 WASHER 1.6X4X0.5 P16C405 2

133 958 7003 204

134 958 7003 301

135 958 7003 408 SCREW 2X4 BLACK M20N004 2

137 958 7003 505 SCREW 1.4X2 BLACK S14N002 1

142 958 7003 602 BALL 5 A1H006 1

144 958 7003 709 BUFFER A1G015 2

145 958 7003 806 NUT A1P007 1

146 958 7003 903 SCREW 1.7X8.2 A1H008 1

147 958 7004 009

148 958 7012 305 P TITE SCREW 3X8 M30P008 1

149 958 7012 509 CNW 6P-8P PH WIRE A1G051 1

150 958 7012 606 CNW 13P-13P PH WIRE A1G053 1

151 958 7012 703 CNW 6P-6P PH WIRE A1G036 1

152 958 7012 800

155 958 7012 402 LOADER ASS'Y ACLM-574D 1

MOTOR P.W.BOARD ASS'Y

B TITE SCREW 2X8 BLACK

B TITE SCREW 2.6X5 BLACK

P TITE SCREW 3X6 BLACK

CASSETTE DECK ADR-2174TB

A1A574D 1

N20B008 2

N26B005 4

M30P006 4

A1A013 1

Q'ty

27

Page 28

PACKING VIEW

28DRR-M31

201 205~

207

206

208

209

PARTS LIST OF PACKING & ACCESSORIES

Ref. No. Part No. Part Name Remarks Q'tyRef. No. Part No. Part Name Remarks Q'ty

201 505 0038 030 POLY COVER 1

202 511 3983 006 INST.MANUAL(E2) 1

203 515 0921 102 S.S.LIST(EX) 1

204 203 0704 002

205 203 0705 001 2P PIN CORD ASS'Y 2

206 505 0335 005 CABINET COVER 1

STEREO MINIPLUG CORD

1

28

207 503 1458 105 CUSHION(L) 1

208 503 1459 104 CUSHION(R) 1

209 501 2232 104 CARTON CASE 1

211 - E2 POS LABEL 2

212 - CONT.CARD(L) 1

Page 29

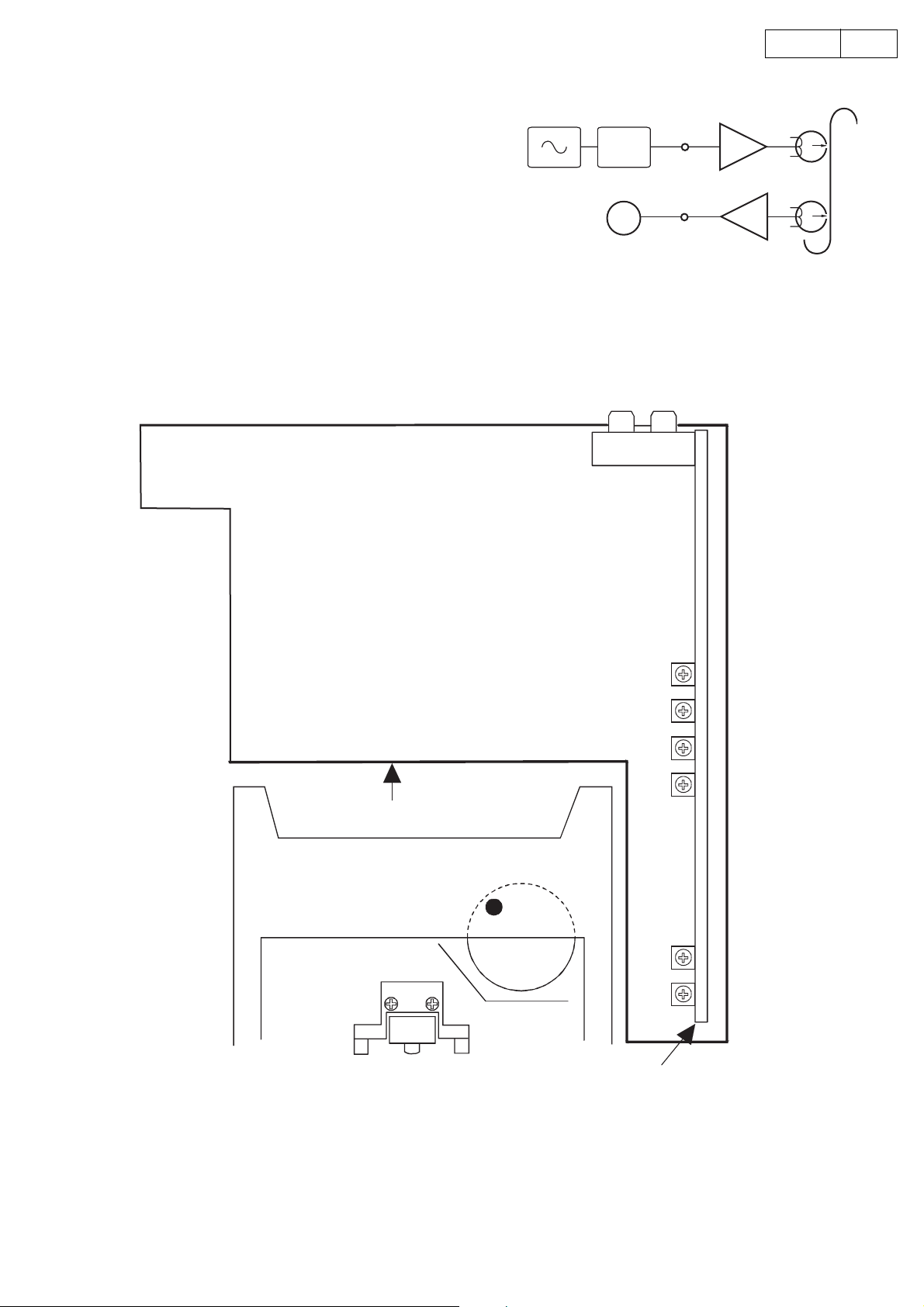

WIRING DIAGRAM

29DRR-M31

HEAD

CASSETTE MECHA.

AC CORD

4P-PINJACK

CX021

H203

CX022

CW082

CX031

CW081

CX082

CX081

MAIN P.W.B.

CY062

H301

CN303

AMP P.W.B.

CN401

CX151

CY131

DISP P.W.B.

AC OUTLET

POWER TRANS

29

Page 30

NOTE FOR SCHEMATIC DIAGRAM

WARNING:

Parts marked with this symbol

characteristics.

Use ONLY replacement parts recommended by the

manufacturer.

CAUTION:

Before returning the unit to the customer, make sure you

make either (1) a leakage current check or (2) a line to

chassis resistance check. If the leakage current exceeds

0.5 milliamps, or if the resistance from chassis to either

side of the power cord is less than 460 kohms, the unit is

defective.

WARNING:

DO NOT return the unit to the customer until the problem

is located and corrected.

NOTICE

ALL RESISTANCE VALUES IN OHM. k=1,000 OHM

M=1,000,000 OHM

ALL CAPACITANCE VALUES IN MICRO FARAD.

P=MICRO-MICRO FARAD

EACH VOLTAGE AND CURRENT ARE MEASURED AT

NO SIGNAL INPUT CONDITION.

CIRCUIT AND PARTS ARE SUBJECT TO CHANGE

WITHOUT PRIOR NOTICE.

have critical

30DRR-M31

1. Ω k kΩ M MΩ

2. µF p pF

3.

4.

30

Page 31

DRR-M31

31

1

2

3

45

6

7

8

SCHEMATIC DIAGRAMS (1/2)

A

B

OPEN : +7.2 V

CLOSE : +7.4 V

DRR-M31

E3

T5A

POWER TRANS (E3)

223 6453 002

AC CORD (E3)

206 2160 009

AC OUTLET (E3/J)

203 3990 004

C

D

SCHEMATIC DIAGRAMS (1/2)

1U-3501-1

1U-3501-2

E

31

Page 32

DRR-M31

32

1

2

3

45

6

7

8

SCHEMATIC DIAGRAMS (2/2)

A

+6V

PLAY:

REC PLAY:

STOP,

-7.4V

B

NORMAL : +9V

HIGH : +14V

STOP,PLAY : +4.6V

REC PLAY : +0.09V

STOP : +5V

C

REC PAUSE , PLAY : -2.8V

D

REC SIGNAL LINE

PB SIGNAL LINE

E

SCHEMATIC DIAGRAMS (2/2)

1U-3501-3

32

Loading...

Loading...