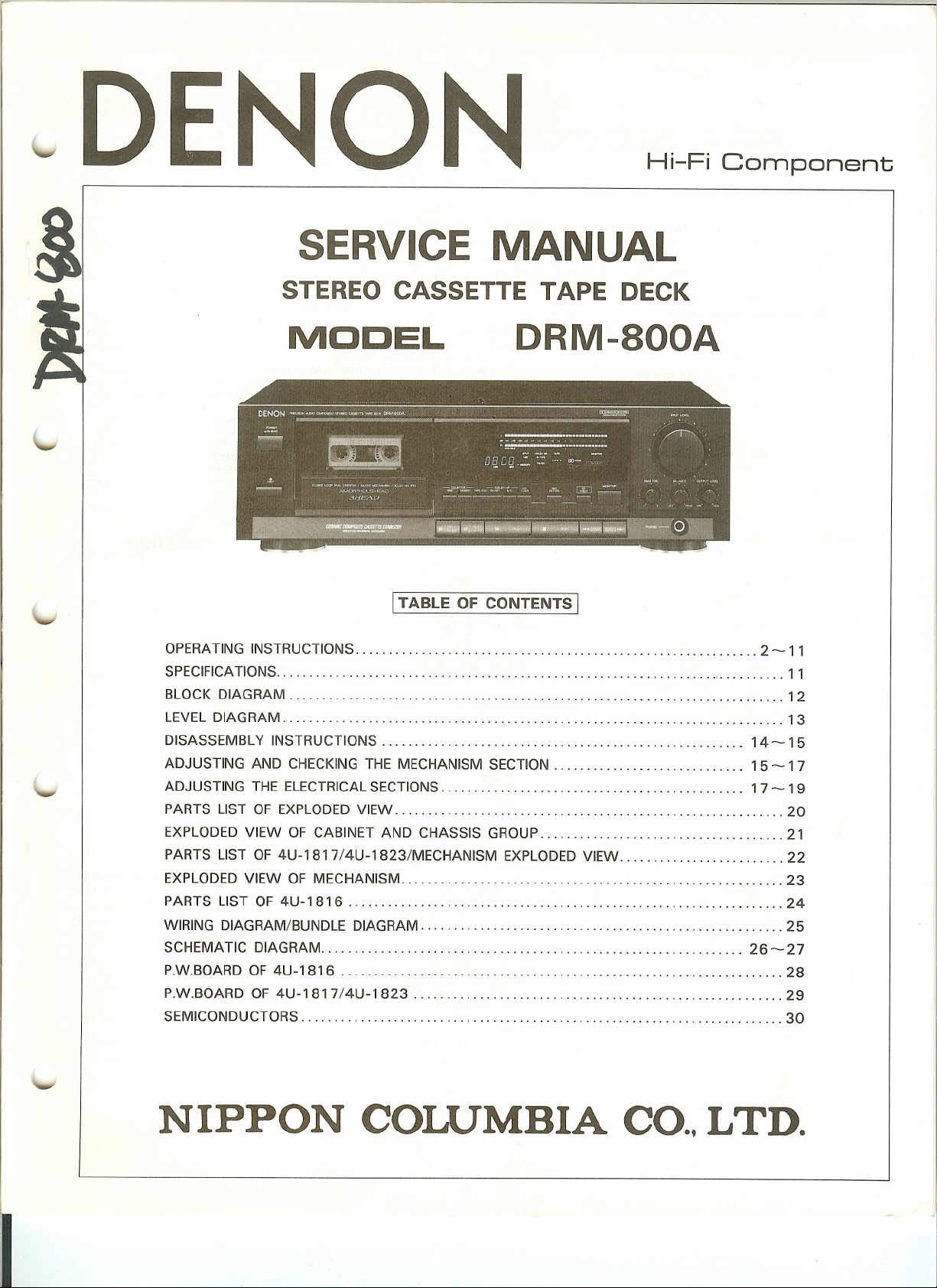

Page 1

Hi-Fi Component

SERVICE MANUAL

STEREO CASSETTE TAPE DECK

IVIODEL

I TABLE OF CONTENTS I

OPERATING INSTRUCTIONS 2 - 11

SPECIFICATIONS 11

BLOCK DIAGRAM 12

LEVEL DIAGRAM 13

DISASSEMBLY INSTRUCTIONS 14 - 15

ADJUSTING AND CHECKING THE MECHANISM SECTION 15 - 1 7

ADJUSTING THE ELECTRICAL SECTIONS 17- 19

PARTS LIST OF EXPLODED ViEW 20

EXPLODED VIEW OF CABINET AND CHASSIS GROUP _ 21

PARTS LIST OF 4U-1817/4U-1823/MECHANISM EXPLODED ViEW 22

EXPLODED VIEW OF MECHANiSM _ 23

PARTS LIST OF 4U-181 6 24

WIRING DIAGRAM/BUNDLE DIAGRAM _ 25

SCHEMATIC DIAGRAM 26-27

PW.BOARD OF 4U-1816 28

P.W.BOARD OF 4U-1817/4U-1823 29

SEMICONDUCTORS 30

DRM-800A

I

NIPPON COLUMBIA CO., LTD.

Page 2

IMPORTANT TO SAFETY

WARNING:

TO PREVENT FIRE OR SHOCK HAZARD, DO.

NOT EXPOSE THIS APPLIANCE TO RAIN OR

MOISTURE.

CAUTION:

1. Handle the power supply cord carefully

Do not damage or deform the power supply cord. If it

is damaged or deformed, it may cause electric shock

or malfunction when used. When removing from wall

outlet, be sure to remove by holding the plug attach·

ment and not by pull ing the cord.

2. Do not open back plate

In order to prevent electric shock, do not open the

back plate. If problems occur, contact your DENON

dealer.

3. Do not place anything inside

Do not place metal objects or spill liquid inside the

cassette deck. Electric shock or malfunction may result.

Please, record and retain the Model name and serial number

of your set shown on the rating label.

Model No. DRM-80QA Serial No. _

IMPORTANT

The wires in this mains lead are co loured in accordance

with the following code:

The colours of the wires in the mains lead of this ap·

paratus may not correspond with the co loured markings

identifying the terminals in your plug proceed as follows.

The wire which is coloured blue must be connected to

the terminal which is marked with the letter N or

coloured black.

The wire which is coloured brown must be connected

to the terminal which is marked with the letter L or

coloured red.

To ensure safe operacion, the three·pin plug supplied

must be connected only with a standard three·pin powe'r

point which is effectively earthed through the normal

household wiring.

Extension cords used with the equipment must be three·

core and be correctly wired to provide connection to

earth. Wrongly wired extension cords are a major cause

of fatalities.

The fact that the equipment operates satisfactorily does

not imply that the power point is earthed and that the

installation is completely safe. For your safety,. if in

any doubt about the effective earthing of the power

point, contact a qualified electrician.

(BRITISH MODEL ONLY)

Blue: Neutral

Brown: Live

FOR YOUR SAFETY

(AUSTRALIAN MODEL ONLY)

NOTE ON USE!HINWEISE ZUM GEBRAUCH!OBSERVATIONS RELATIVES A L'UTILISATION

""-

r /"I,... ""

I ?fon

X

.

Avoid high temperatures

Allow for sufficient heat dispersion when installed on a

rack.

Vermeiden Sic hohe Temperaturen

Sehen Sie zu, daB eine zureichende Luftzirkulation

gewahrleistet wird, wenn das Gerat auf ein Regal

gestellt wird.

Eviter des temperatures elevees

Tenir compte d'une dispersion de chaleur suffisante lors

de I'installation sur une etagere.

Keep the set free from moisture, water, and dust.

.

Halten Sic das Gerat fern von Feuchtigkeit. Wasser und

Staub,

Proteger I'appareil contre I'humidite, f'cau et la pous-

siere.

~

Unplug the power cord when not using the set for long

periods of time.

Wenn das Gerat eine langere Zeit nicht verwcndet

werden soil. trennen Sie das Netzkabel vom Netzstecker.

Debrancher Ie cordon d'alimentation 10rsque I'appareil

n'est pas utilise pendant de longues periodes

~

Do twt let foreign objects in the set.

Keine fremden GegcnsU~nde in das Gerat kommen

lassen.

Ne pas laisser des objets etrangers dans I'appareil.

00 not let insecticides, benzene, and thinner come in

contact with the set.

lassen Sie das Gerat nicht mit Insektiziden, Benzin oder

Verdunnungsmitleln in Beruhrung kommen.

Ne pas meUre en contact des insecticides, du benzene et

un diluant avec I'appareil.

I

NIPI

No.1~

MINA-

TEL: (

TLX: .

CASU

Handle the power cord carefully.

Hold the plug when unplugging the cord.

Gehen Sie vorsichtig mit dem Netzkabe! urn.

Halten Sie das Kabel am Stecker, wenn Sie den Stecker

herausziehen.

Manipuler Ie cordon d'alimentation avec precaution.

Tenir la prise Jars du debranchement du cordon.

00 not obstruct the ventilation holes.

Die Beluftungsoffnungen durfen nicht verdeckt werden.

Ne pas obstruer les trous d'aeration.

r:>:;

"(For sets with ventilation holes)

Never disassemble or modify the set in any way.

Versuchen Sie niemals das Gerat auseinander zu neh-

men oder auf jegliche Art zu verandern.

Ne jamais demonter ou modifier I'appareil d'une man-

iere ou d'une autre.

2

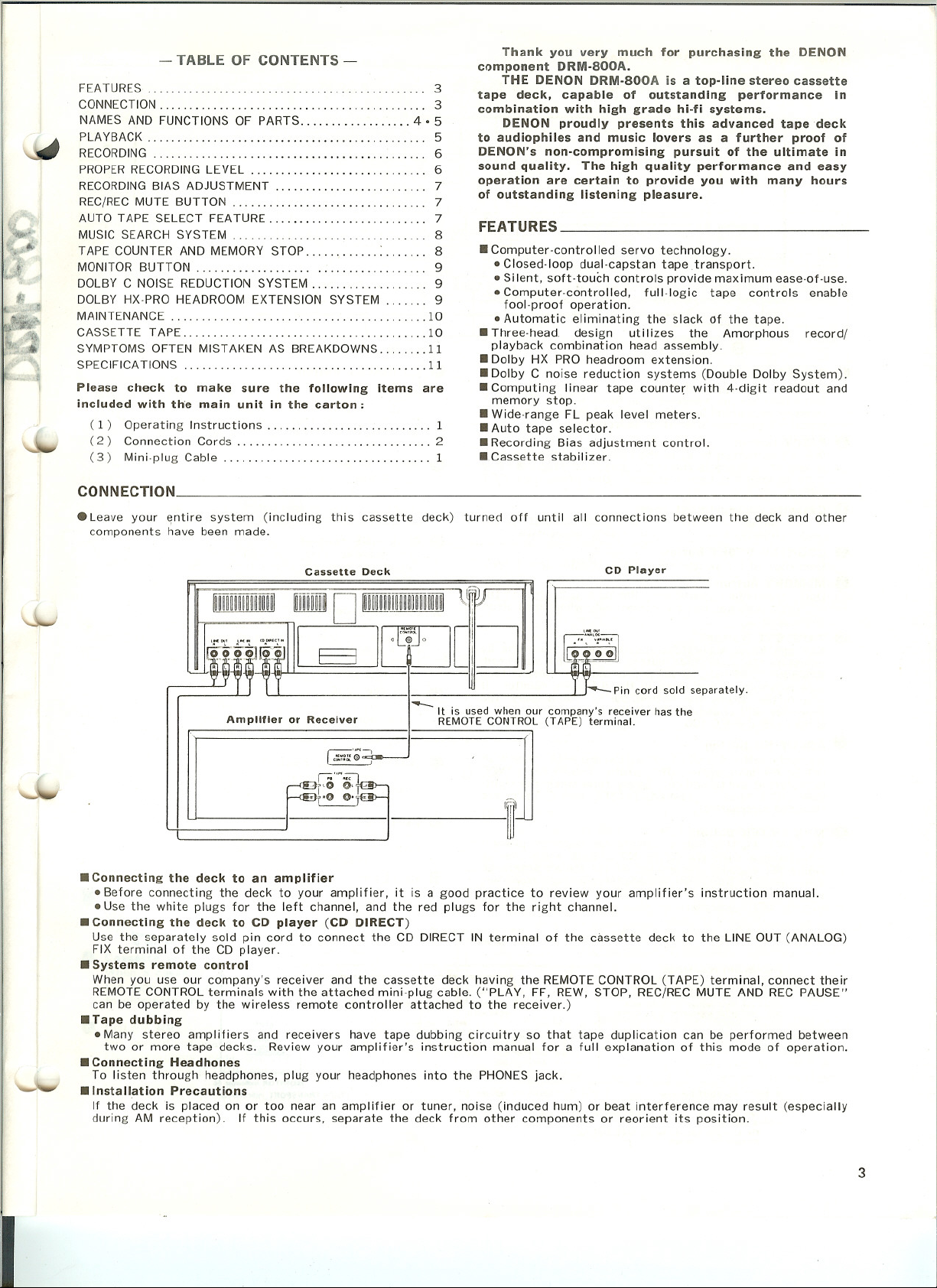

Page 3

- TABLE OF CONTENTS-

FEATURES 3

CONNECTION 3

NAMES AND FUNCTIONS OF PARTS 4·5

PLA YBACK 5

RECORDING 6

PROPER RECORDING LEVEL 6

RECORDING BIAS ADJUSTMENT 7

REC/REC MUTE BUTTON 7

AUTO TAPE SELECT FEATURE 7

MUSIC SEARCH SySTEM 8

TAPE COUNTER AND MEMORY STOP : 8

MONITOR BUTTON 9

DOLBY C NOISE REDUCTION SySTEM 9

DOLBY HX·PRO HEADROOM EXTENSION SySTEM 9

MAINTENANCE 10

CASSETTE TAPE 10

SYMPTOMS OFTEN MISTAKEN AS BREAKDOWNS 11

SPECIFICATIONS 11

Please check to make sure the following items are

included with the main unit in the carton:

( 1) Operating Instructions .

( 2) Connection Cords 2

(3) Mini·plug Cable 1

CONNECTION

Thank you very much for purchasing the DENON

component DRM·800A.

THE DENON DRM·800A is a top·line stereo cassette

tape deck, capable of outstanding performance in

combination with high grade hi-fi systems.

DENON proudly presents this advanced

to audiophiles and music lovers as a further proof of

DENON's non-compromising pursuit of the ultimate in

sound quality. The high quality performance and easy

operation are certain to provide you with many hours

of outstanding listening pleasure.

FEATURES

• Computer·controlled servo technology.

• Closed· loop dual·capstan tape transport.

• Si lent, soft·touch controls provide maximum ease·of·use.

• Computer·controlled, full·logic tape controls enable

fool·proof operation.

• Automatic eliminating the slack of the tape.

• Three·head design utilizes the Amorphous record/

playback combination head assembly.

• Dolby HX PRO headroom extension.

• Dolby C noise reduction systems (Double Dolby System).

• Computing linear tape counter with 4-digit readout and

memory stop.

• Wide·range FL peak level meters.

• Auto tape selector.

• Recording Bias adjustment control.

.Cassette stabilizer.

tape deck

• Leave your entire system (including this cassette deck) turned off until all connections between the deck and other

components have been made.

Cassette Deck

CD Player

mmmmm ~~mm D mlm~mm~m !

G;JL!J[[J

Pin cord sold separately .

Amplifier or Receiver

• Connecting the deck to an amplifier

• Before connecting the deck to your amplifier, it is a good practice to review your amplifier's instruction manual.

• Use the white plugs for the left channel, and the red plugs for the right channel.

• Connecting the deck to CD player (CD DIRECT)

Use the separately sold pin cord to connect the CD DIRECT IN terminal of the cassette deck to the LINE OUT (ANALOG)

FIX terminal of the CD player.

• Systems remote control

When you use our company's receiver and the cassette deck having the REMOTE CONTROL (TAPE) terminal, connect their

REMOTE CONTROL terminals with the attached mini·plug cable. ("PLAY, FF, REW, STOP, REC/REC MUTE AND REC PAUSE"

can be operated by the wireless remote controller attached to the receiver.)

• Tape dubbing

• Many stereo amplifiers and receivers have tape dubbing circuitry so that tape duplication can be performed between

two or more tape decks. Review your amplifier's instruction manual for a full explanation of this mode of operation.

• Connecting Headhones

To listen through headphones, plug your headphones into the PHONES jack .

• Installation Precautions

If the deck is placed on or too near an amplifier or tuner, noise (induced hum) or beat interference may result (especially

during AM reception). If this occurs, separate the deck from other components or reorient its position.

..••........ It is used when our company's receiver has the

REMOTE CONTROL (TAPE) terminal.

I

3

Page 4

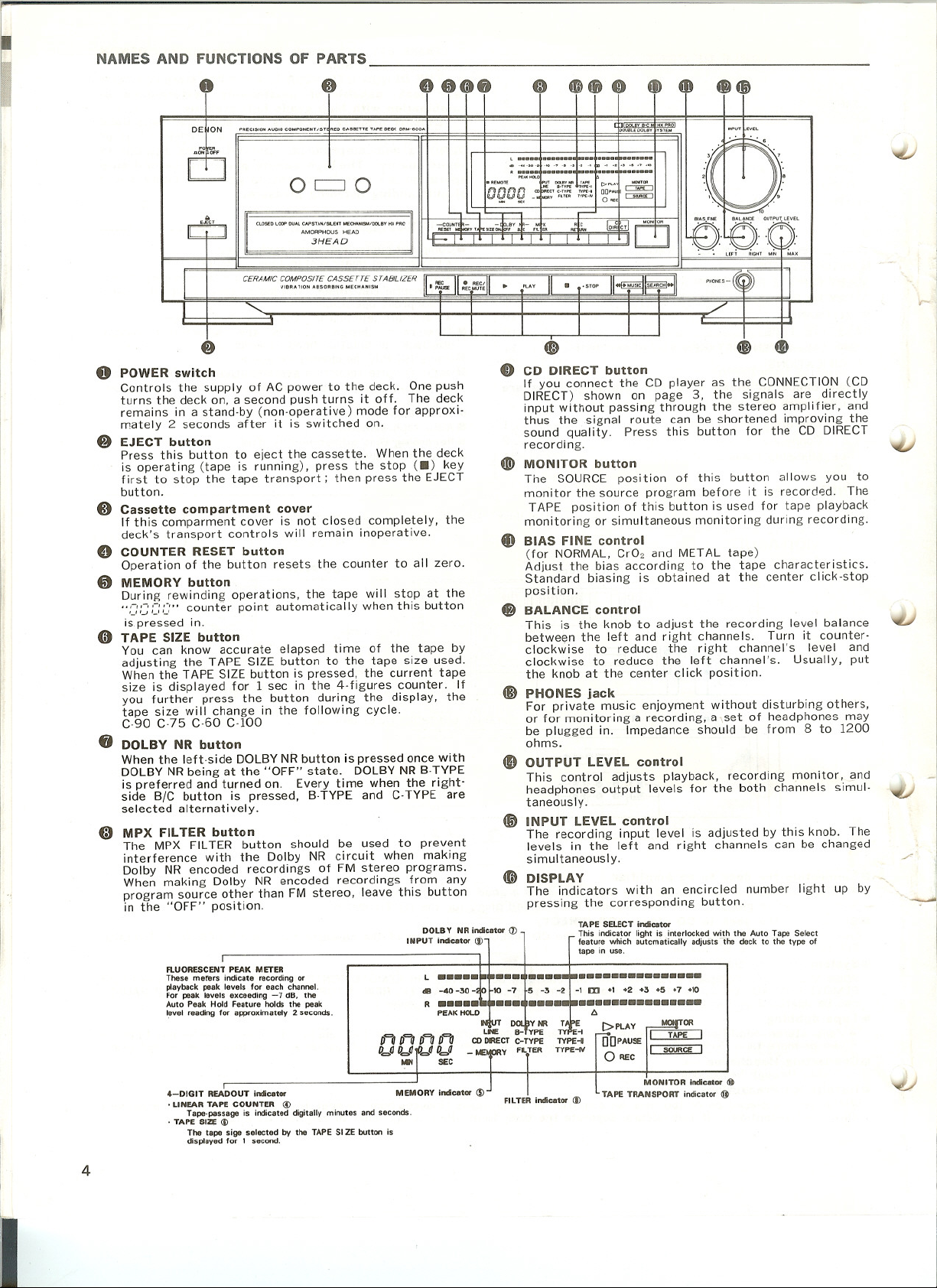

NAMES AND FUNCTIONS OF PARTS

o 0008

DEtJON PRECISION AUOIO COMPONENT/STdAEO CJ.SSETTE TAPE DECK DRM-600A rD~;"';;T~'M

J:1~~~F

OCJO

3HEAD

CERAMIC COMPOSITE CASSETTE STABILIZER

YIBRATION ABSORBING foIECH •••• NISM

CO_40.J,Q_t -10-7-5-3-2 _1 ., _2"_5·7'10

R ••••• a •••••••••••••••••••••

, · .. ··I·· .... ·I···F.· .. I .... ···

DQDQ _£~'c,.:;:; ;;;:;.

~T 0:::;;- 1'~~_1

POWER switch

Controls the supply of AC power to the deck. One push

turns the deck on, a second push turns it off. The deck

remains in a stand·by (non-operative) mode for approxi·

mately 2 seconds after it is switched on.

EJECT button

Press this button to eject the cassette. When the deck

is operating (tape is running), press the stop (.) key

first to stop the tape transport; then press the EJECT

button.

Cassette compartment cover

If this comparment cover is not closed completely, the

deck's transport controls will remain inoperative.

COUNTER RESET button

o

Operation of the button resets the counter to all zero.

MEMORY button

o

During rewinding operations, the tape will stop at the

":~:C:C::~,'" counter point automatically when this button

is pressed in.

TAPE SIZE button

You can know accurate elapsed time of the tape by

adjusting the TAPE SIZE button to the tape size used.

When the TAPE SIZE button is pressed, the current tape

size is displayed for 1 sec in the 4-figures counter _ If

you further press the button during the display, the

tape size will change in the following cycle.

C·90 C·75 C-60 C·100

DOLBY NR button

When the left·side DOLBY NR button is pressed once with

DOLBY NR being at the "OFF" state. DOLBY NR B·TYPE

is preferred and turned on. Every time when the right·

BIC button is pressed, B·TYPE and C-TYPE are

side

selected alternatively.

«;) MPX FILTER button

The MPX FILTER button should be used to prevent

interference with the Dolby NR circuit when making

Dolby NR encoded recordings of FM stereo programs.

When making Dolby NR encoded recordings from any

program source other than FM stereo, leave this button

in the "OFF" position.

flUORESCENT PEAK METER

These mefers indicate recording or

playback peak levels for each channel.

For peak levels exceeding

Auto Peak Hold Feature holds the peak

I!"vel reading for approximately 2 seconds.

4-DIGIT READOUT indicator

• LINEAR TAPE COUNTER @

Tape-passage is indicated digitally minutes and seconds .

• TAPE SIZE (I)

The tape sige selected by the TAPE 51 ZE button is

displayed for 1 second.

-7 dB, the

DOLBY NR indicator (1)

INPUT indicator ())

III

R

CD DIRECT button

If you connect the CD player as the CONNECTION (CD

DIRECT) shown on page 3, the signals are directly

input without passing through the stereo amplifier, and

thus the signal route can be shortened improving the

sound quality. Press this button for the CD DIRECT

recording.

MONITOR button

The SOURCE position of this button allows you to

monitor the source program before it is record8d. The

T APE position of this button is used for tape playback

monitoring or simultaneous monitoring during recording.

BIAS FINE control

(for NORMAL, Cr02 and METAL tape)

Adjust the bias according to the tape characteristics.

Standard biasing is obtained at the center click-stop

position.

BALANCE control

This is the knob to adjust the recording level balance

between the left and right channels. Turn it counter-

clockwise to reduce the right channel's level and

clockwise to reduce the left channel's. Usually, put

the knob at the center click position.

PHONES jack

For private music enjoyment without disturbing others,

or for monitoring a recording, a ,set of headphones may

be plugged in. Impedance should be from

ohms.

OUTPUT LEVEL control

This control adjusts playback, recording monitor, and

headphones output levels for the both channels simul·

taneous Iy.

f!i) INPUT LEVEL control

The recording input level is adjusted by this knob. The

levels in the left and right channels can be changed

simultaneously.

~ DISPLAY

The indicators with an encircled number light up by

pressing the corresponding button.

TAPE SELECT indicator

This indicator light is.interlocked with the Auto Tape Select

feature which autcmatically adjusts -the deck to the type of

tape in use.

•••••••••••••••

-1

m +1 +2 +3 +5 +7 +10

•••••••••••••••

FI L TER indicator (j)

t:.

[> PLAY

00 PAUSE

o 'lEC

TAPE TRANSPORT indicator @

_OR

TAPE

SOURCE

MONITOR indicator @

8 to 1200

---

I

4

Page 5

I

~ REC RETURN Button

When this button is pressed at the recording state, the

tape is rewound to the starting point. When the starting

q;) Tape transport controls

PLAY PLA Y button

STOP

REC PAUSE

button

button

~

about 5 sec of non· recorded part can automatically be created.

If only the RECORD button is pressed, the deck is placed in the REC

To begin recording, press the RECORD and PLAY buttons simultaneously.

Press this button

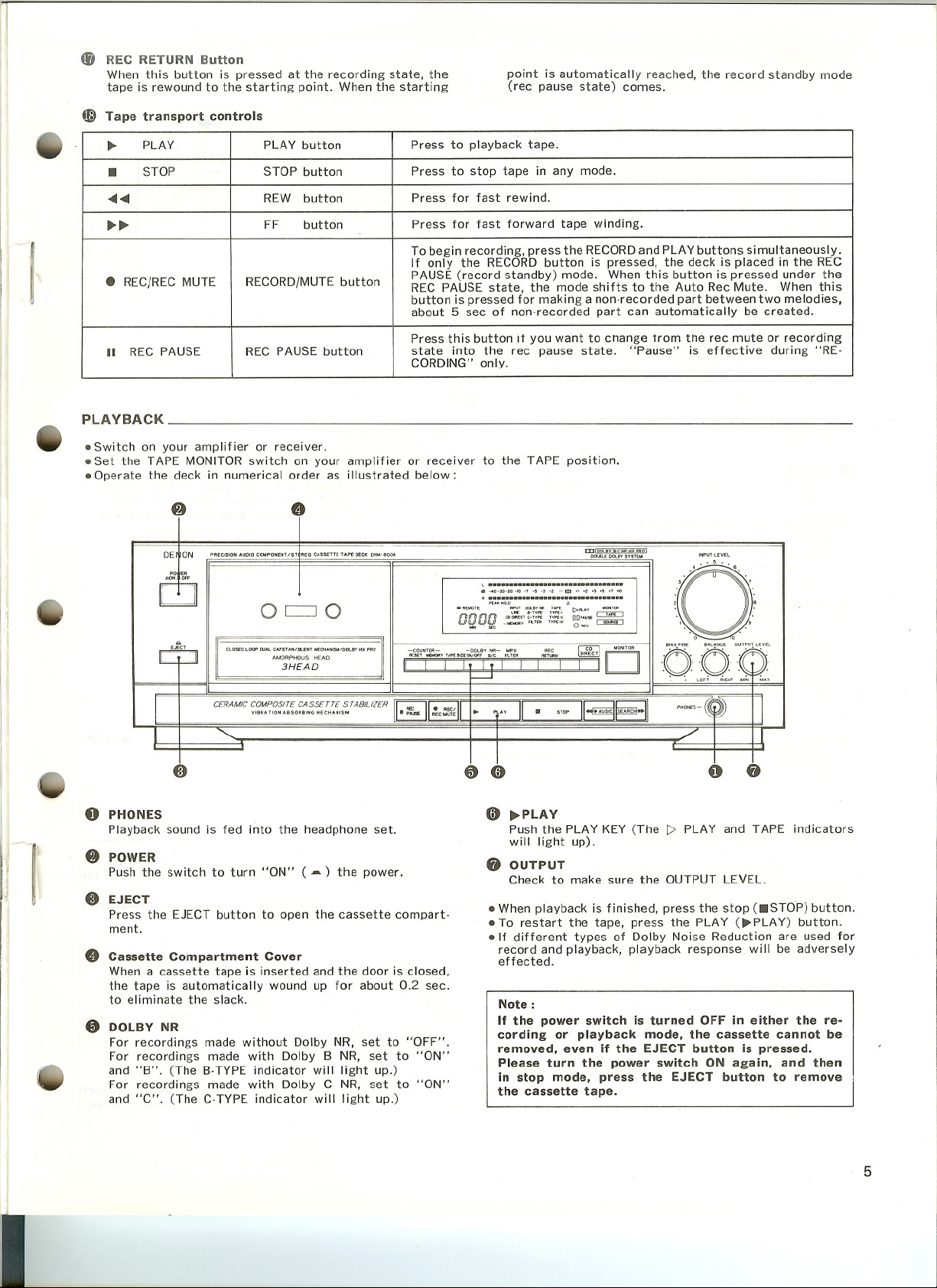

PLAyBACK _

• Switch on your amplifier or receiver.

• Set the TAPE MONITOR switch on your amplifier or receiver to the TAPE position.

• Operate the deck in numerical order as illustrated below:

Press for fast rewind.

REC PAUSE button

Press for fast forward tape winding.

It you want to cnange trom tne rec mute or recording

PAUSE (record standby) mode.

REW

FF

STOP button

Press to playback tape.

Press to stop tape in any mode.

state into the rec pause state. "Pause" is effective during "RE-

RECORD/MUTE button

When this button is pressed under the

When this

point is automatically reached, the record standby mode

(rec pause state) comes.

DE/ilON ""ECISIO" AUDIO COMPONENT/srtREo CJ,.S5ETTE T.o.?EOECI( DRM-I!OOA

<1~t~F

Oc:::JO

3HEAD

CERAMIC COMPOSITE CASSETTE STABILIZER

VI!3RAfiON AeSOFlBING MECHANI5N

o PHONES

Playback sound is fed into the headphone set.

@ POWER

Push the switch to turn "ON" (-) the power.

8 EJECT

Press the EJECT button to open the cassette compart-

ment .

9 Cassette Compartment Cover

When a cassette tape is inserted and the door is closed,

the tape is automatically wound up for about 0.2 sec.

to eliminate the slack.

8 DOLBY NR

For recordings made without Dolby NR, set to "OFF".

For recordings made with Dolby B NR, set to "ON"

and "B". (The B·TYPE indicator will light up.)

For recordings made with Dolby C NR, set to "ON"

and "C". (The C-TYPE indicator will light up.)

~ .

ell -00-30-20 -II) _7 _, .~ -2 ., m ., _2 '3 ., .7 '10

~ .

PE" ~"-o .

.;;~EDU DU ro~CT !f!f ;~~~: ~: ... :~ I w;,:.: I

IbO~lbq~_r.IIEWOfI.fLTE ••• T1I'£-<II OALC~

80

.....

·0- ·0· ~;'~~~'"

• : LEFT RIGHT j,!1~ t M .••• X

o

o

o ~PLAY

Push the PLAY KEY (The [> PLAY and TAPE indicators

will light up).

8 OUTPUT

Check to make sure the OUTPUT LEVEL.

• When playback is finished, press the stop (. STOP) button.

• To restart the tape, press the PLA Y (~PLA Y) button.

• If different types of Dolby Noise Reduction are used for

record and playback, playback response will be adversely

effected.

Note:

If the power switch is turned OFF in either the re-

cording or playback mode, the cassette cannot be

removed, even if the EJECT button is pressed.

Please turn the power switch ON again, and then

in stop mode, press the EJECT button to remove

the cassette tape.

I

I

5

Page 6

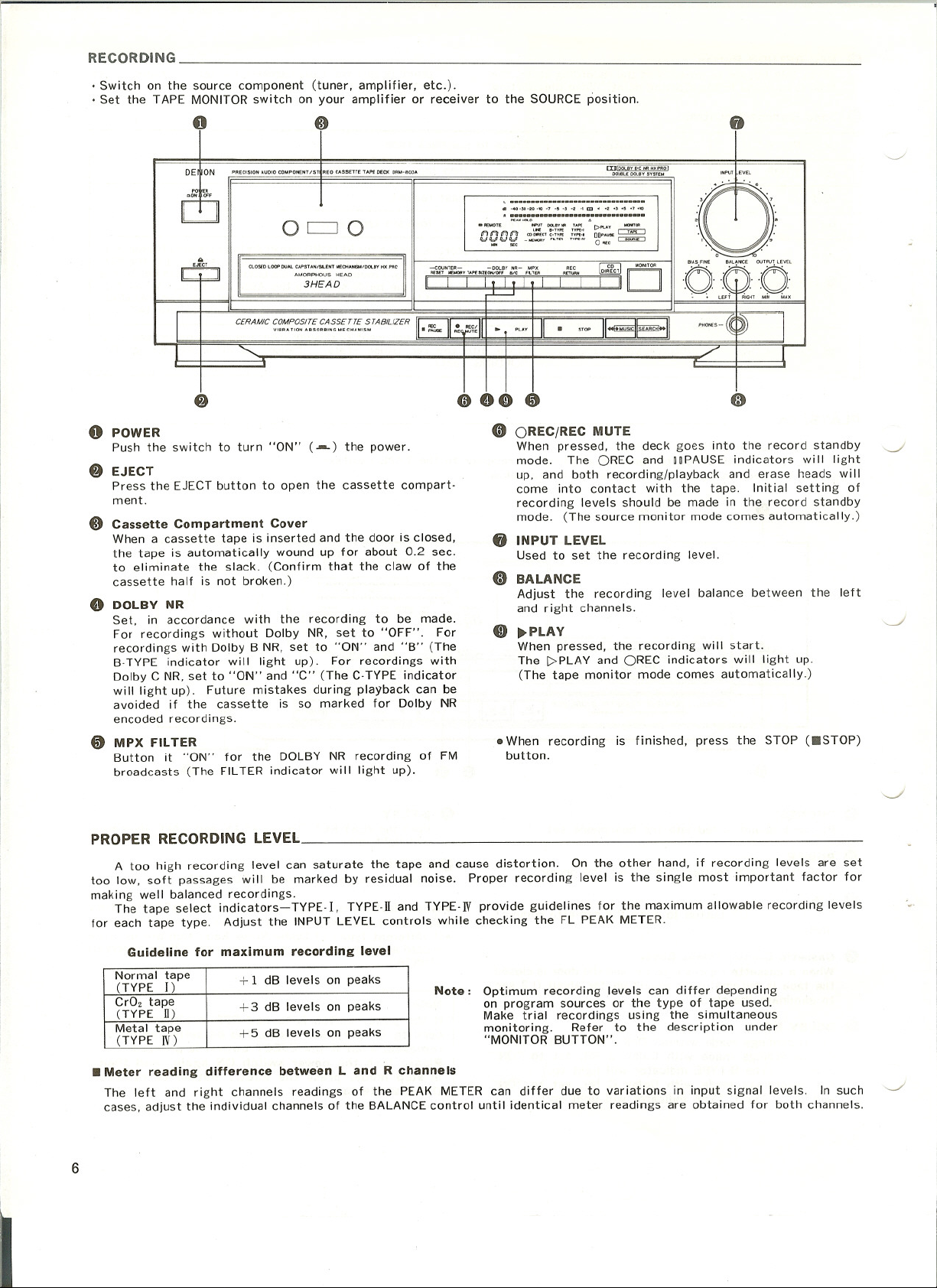

RECORDING

• Switch on the source component (tuner, amplifier, etc.).

• Set the TAPE MONITOR switch on your amplifier or receiver to the SOURCE position.

--------------------------------

o

DErilON "RECISIO~ AUDIO COMPONENT/ST'IIED CASSETTE TAPE DEe!<: 00101-600'"

Oc::JO

3HEAO

CERAMIC COMPOSITE CASSETTE STABILIZER

VIBRATION ABSORBING t.lECHANISM

o POWER

Push the switch to turn "ON" (.--) the power.

f} EJECT

Press the EJECT button to open the cassette compart·

ment.

e Cassette Compartment Cover

When a cassette tape is inserted and the door is closed,

the tape is automatically wound up for about 0.2 sec.

to eliminate the slack. (Confirm that the claw of the

cassette half is not broken.)

e DOLBY NR

Set, in accordance with the recording to be made.

For recordings without Dolby NR, set to "OFF". For

recordings with Dolby B NR, set to "ON" and "B" (The

B·TYPE indicator will light up). For recordings with

Dolby C NR, set to "ON" and "C" (The C·TYPE indicator

will light up). Future mistakes during playback can be

avoided if the cassette is so marked for Dolby NR

encoded recordings .

• MPX FILTER

Button it "ON" for the DOLBY NR recording of FM

broadcasts (The FILTER indicator will light up).

W~EB~~:S~:l~~OI

~_-~_4~-~-3~~m"4q'5'1'~

~ .

""A~ ••••• O l'!

n Pc Pc DI1 a:~:cT 1!~ ;~~: ~::u~ I 7'': 1

fbO~fbor::

~l'Eo.o:'J<!yFLTEKTyP£-IV Oou:c ~

~[I""""II

·O:~~;,~Q:

Co

o OREC/REC MUTE

When pressed, the deck goes into the record standby

mode. The OREC and ODPAUSE indicators will light

up, and both recording/playback and erase heads will

come into contact with the tape. Initial setting of

recording levels should be made in the record standby

mode. (The source monitor mode comes automatically.)

8 INPUT LEVEL

Used to set the recording level.

o BALANCE

Adjust the recording level balance between the left

and right channels.

o ~PLAY

When pressed, the recording will start.

The C>PLAY and OREC indicators will light up.

(The tape monitor mode comes automatically.)

• When recording is finished, press the STOP (IISTOP)

button.

PROPER RECORDING LEVEL _

A too high recording level can saturate the tape and cause distortion. On the other hand, if recording levels are set

too low, soft passages will be marked by residual noise. Proper recording level is the single most important factor for

making well balanced recordings.

The tape select indicators- TYPE- I, TYPE-II and TYPE· N provide guidelines for the maximum allowable recording levels

for each tape type. Adjust the INPUT LEVEL controls while checking the FL PEAK METER.

Guideline for maximum recording level

[ )

Cr02 tape

Normal tape

• Meter reading difference between Land R channels

The left and right channels readings of the PEAK METER can differ due to variations in input signal levels. In such ~

cases, adjust the individual channels of the BALANCE control until identical meter readings are obtained for both channels.

+ 3 dB levels on peaks

+5 dB levels on peaks

+ 1 dB levels on peaks

Note: Optimum recording levels can differ depending

I

on program sources or the type of tape used.

Make trial recordings using the simultaneous

monitoring. Refer to the description under

"MONITOR BUTTON".

6

Page 7

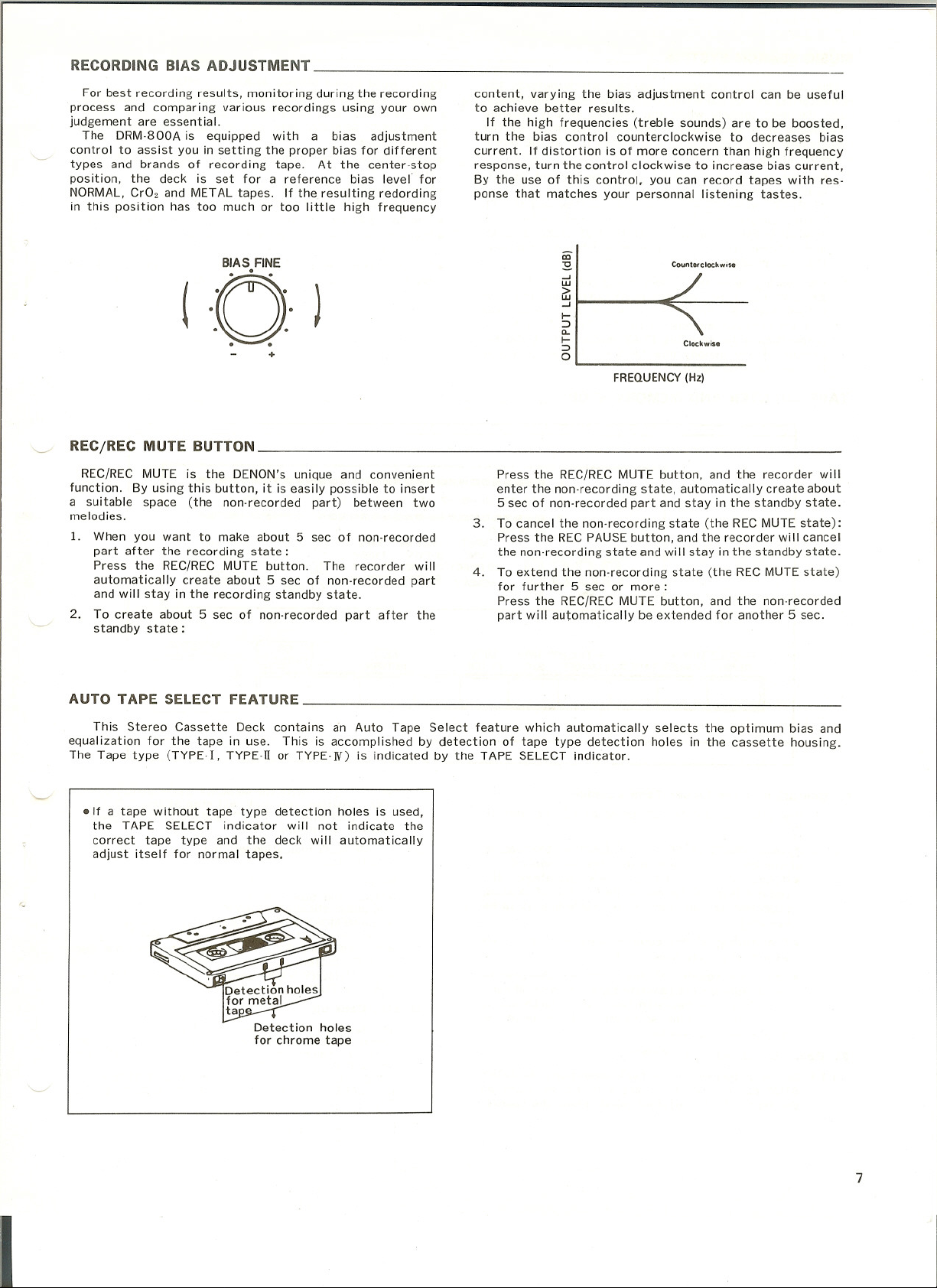

RECORDING BIAS ADJUSTMENT

For best recording results, monitoring during the recording

process and comparing various recordings using your own

judgement are essential.

The DRM-800A is equipped with a bias adjustment

control to assist you in setting the proper bias for different

types and brands of recording tape. At the center-stop

position, the deck is set for a reference bias level' for

NORMAL,

in this position has too much or too little high frequency

CrGz and METAL tapes. If the resulting redording

~

w

>

f-

::J a..

f-

~

:3

)

·0·

RECjREC MUTE BUTTON

REC/REC MUTE is the DENON's unique and convenient

function. By using this button, it is easily possible to insert

a suitable space (the non-recorded part) between two

melodies.

1. When you want to make about 5 sec of non-recorded

part after the recording state:

Press the REC/REC MUTE button. The recorder will

automatically create about 5 sec of non-recorded part

and will stay in the recording standby state.

2. To create about 5 sec of non-recorded part after the

standby state:

content, varying the bias adjustment control can be useful

to achieve better results.

If the high frequencies (treble sounds) are to be boosted,

turn the bias control counterclockwise to decreases bias

current. If distortion is of more concern than high frequency

response, turn the control clockwise to increase bias current,

By the use of this control, you can record tapes with res-

ponse that matches your personnal listening tastes.

w

0

3. To cancel the non-recording state (the REC MUTE state):

4. To extend the non-recording state (the REC MUTE state)

iD

::J

FREQUENCY (Hz)

Press the REC/REC MUTE button, and the recorder will

enter the non-recording state, automatically create about

5 sec of non-recorded part and stay in the standby state.

Press the REC PAUSE button, and the recorder will cancel

the non-recording state and will stay in the standby state_

for further 5 sec or more:

Press the REC/REC MUTE button, and the non-recorded

part will automatically be extended for another 5 sec.

Counterclockwise

Clockwise

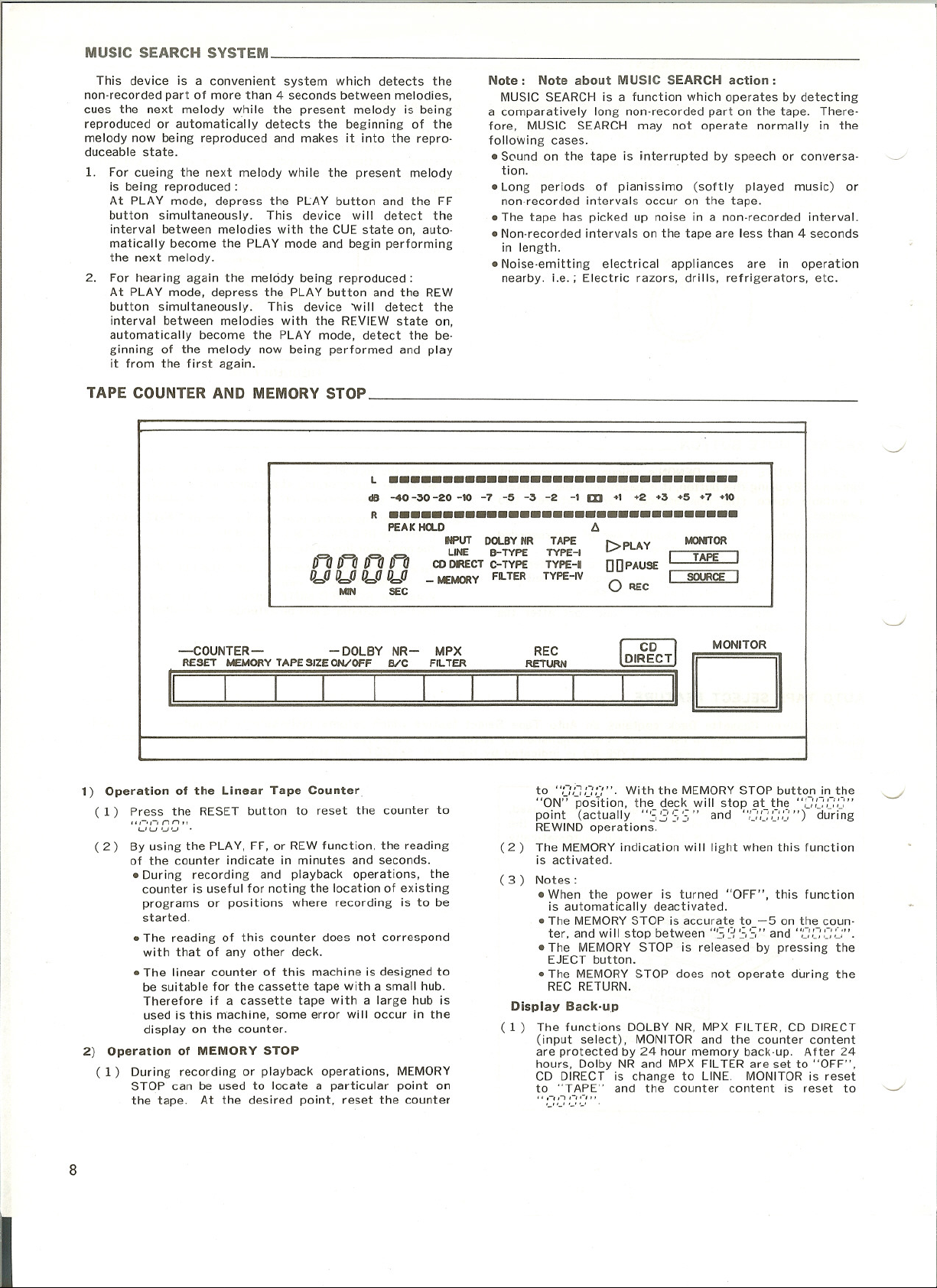

AUTO TAPE SELECT FEATURE

This Stereo Cassette Deck contains an Auto Tape Select feature which automatically selects the optimum bias and

equalization for the tape in use. This is accomplished by detection of tape type detection holes in the cassette housing.

The Tape type (TYPE-

• If a tape without tape type detection holes is used,

the TAPE SELECT indicator will not indicate the

correct tape type and the deck will automatically

adjust itself for normal tapes.

I, TYPE- II or TYPE- N) is indicated by the TAPE SELECT indicator.

Detection holes

for chrome tape

I

7

Page 8

MUSIC SEARCH SYSTEM _

This device is a convenient system which detects the

non-recorded part of more than 4 seconds between melodies,

cues the next melody while the present melody is being

reproduced or automatically detects the beginning of the

melody now being reproduced and makes it into the repro-

duceable state.

1. For cueing the next melody while the present melody

is being reproduced:

At PLAY mode, depress the PLAY button and the FF

button simultaneously. This device will detect the

interval between melodies with the CUE state on, auto-

matically become the PLAY mode and begin performing

the next melody.

2. For hearing again the melody being reproduced:

At PLAY mode, depress the PLAY button and the REW

button simultaneously. This device 'Will detect the

interval between melodies with the REVIEW state on,

automatically become the PLAY mode, detect the be-

ginning of the melody now being performed and play

it from the first again.

TAPE COUNTER AND MEMORY STOP _

LINE

DIRECT

MONITOR

FLTER

+2 +3 +5 +7 +10

FIL TER

DOLBY NR

B- TYPE

I

TAPE

TAPE

TYPE-I

SEC

TYPE-IV

DO PAUSE

I

[>PLA Y

I~ I I

D I I

II

I

TYPE-I

MPX

RETURN

REC

MONITOR

- MEMORY

~

- DOLBY NR-

I

I

••••••••••••••••••••••••••••••••

••••••••••••••••••••••••••••••••

SOURCE

PEAK HOLD

dB -40 -30 -20 -10 -7 -5 -3 -2

o REC

-1 m +1

t:"

B/C

L

Note: Note about MUSIC SEARCH action:

MUSIC SEARCH is a function which operates by detecting

a comparatively long non-recorded part on the tape. There-

fore, MUSIC SEARCH may not operate normally in the

following cases.

• Sound on the tape is interrupted by speech or conversa-

tion ..

• Long periods of pianissimo (softly played music) or

non-recorded intervals occur on the tape.

• The tape has picked up noise in a non-recorded interval.

• Non-recorded intervals on the tape are less than 4 seconds

in length.

• Noise-emitting electrical appliances are in operation

nearby _ i.e.; Electric razors, dri lis, refrigerators, etc.

D

1) Operation of the Linear Tape Counter

( 1) Press the RESET button to reset the counter to

Il'-',-rnl'l"

L'LI 1..1 I...} •

(2) By using the PLAY, FF, or REW function. the reading

of the counter indicate in minutes and seconds.

• During recording and playback operations, the

counter is useful for noting the location of existing

programs or positions where recording is to be

started .

• The reading of this counter does not correspond

with that of any other deck.

• The linear counter of this machine is designed to

be suitable for the cassette tape with a small hub.

Therefore if a cassette tape with a large hub is

used is this machine, some error will occur in the

display on the counter.

2) Operation of MEMORY STOP

( 1) During recording or playback operations, MEMORY

STOP can be used to locate a particular point on

the tape. At the desired point, reset the counter

8

to

":::i::::". With the MEMORY STOP button in the

"ON" pOSition, the deck will stop at the "L:C:C,':~'"

point (actually

REWIND operations.

(2) The MEMORY indication will light when this function

is activated.

( 3) Notes:

o When the power is turned "OFF", this function

is automatically deactivated.

• The MEMORY STOP is accurate to - 5 on the coun-

ter, and will stop between "5~~~,S" and IjC,rC:::II,~:".

• The MEMORY STOP is released by pressing the

EJECT button.

o The MEMORY STOP does not operate during the

REC RETURN.

Display Back-up

( 1) The functions DOLBY NR, MPX FILTER, CD DIRECT

(input select), MONITOR and the counter content

are protected by 24 hour memory back-up. After 24

hours, Dolby NR and MPX FILTER are set to "OFF",

CD DIRECT is change to LINE. MONITOR is reset

to "TAPE" and the counter content is reset to

I' '-1" ,-/1-'"

,_,1_' 1_"_' .

"5355" and ",'~'C:Ci/)") during

I

Page 9

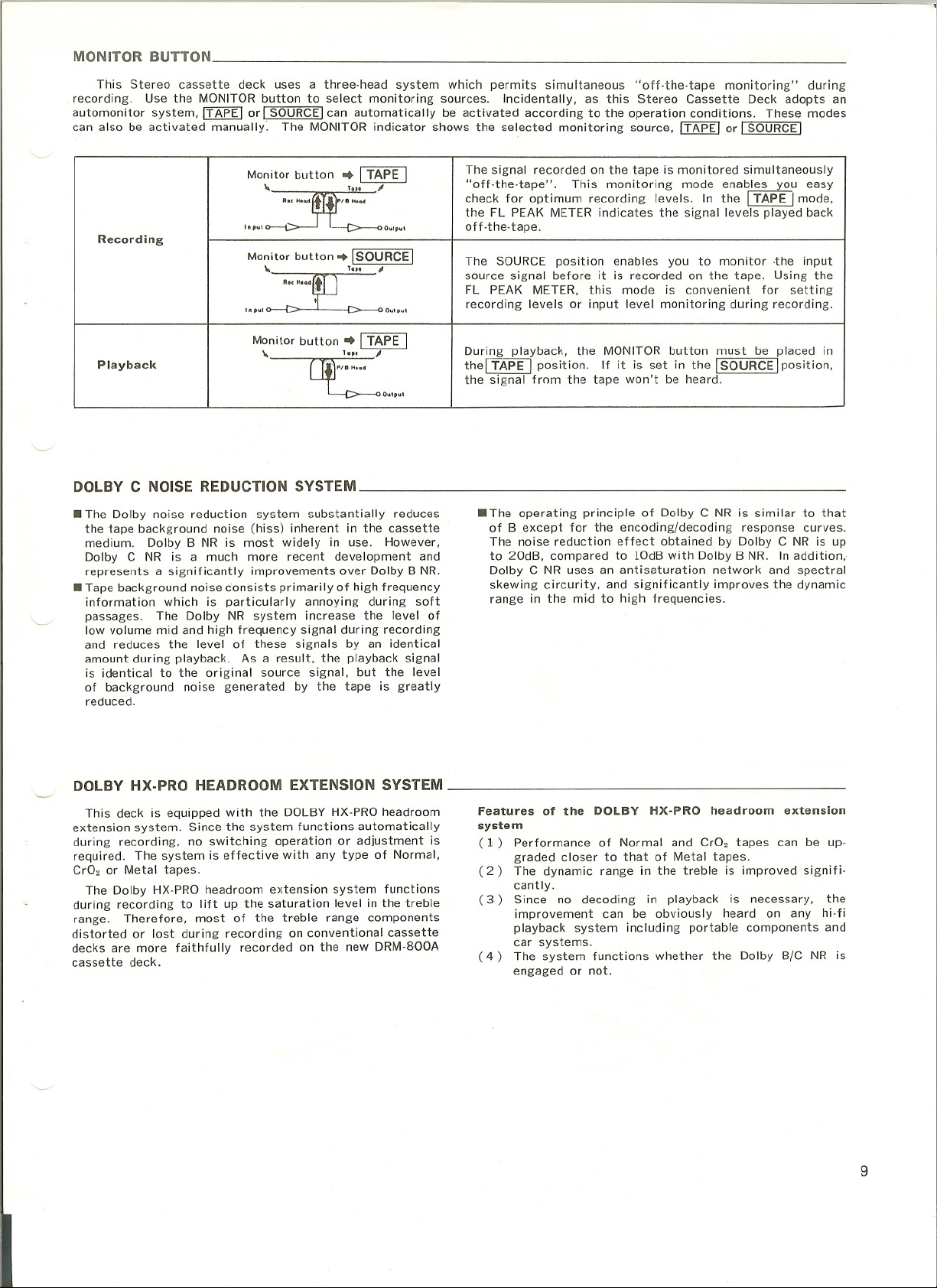

MONITOR BUTTON _

This Stereo cassette deck uses a three-head system which permits simultaneous "off-the-tape monitoring" during

recording. Use the MONITOR button to select monitoring sources. Incidentally, as this Stereo Cassette Deck adopts an

automonitor system, IT APE! or! SOURCE! can automatically be activated according to the operation conditions. These modes

can also be activated manually~ The MONITOR indicator shows the selected monitoring source, ITAPE! or! SOURCE!

Monitor button •• I TAPE I

\_ Ta,. ,

11I'1l1

PIe H.,w

---{:>----oO\&tp .• t

The signal recorded on the tape is monitored simultaneously

"off-the-tape". This monitoring mode enables you easy

check for optimum recording levels. In the

the FL PEAK METER indicates the signal levels played back

I TAPE I mode,

off-the-tape.

Recording

Monitor button "I SOURCE I

The SOURCE position enables you to monitor -the input

source signal before it is recorded on the tape. Using the

FL PEAK METER, this mode is convenient for setting

recording levels or input level monitoring during recording.

During playback, the MONITOR button must be placed in

thelTAPE

the signal from the tape won't be heard.

I position. If it is set in the ISOURCE Iposition,

Playback

:=: ... ~ .... ,

Inpu.t t [::>-----0o""" •• ,

Monitor button ••

~ ~~

~OUIP"I

I TAPE I

DOLBY C NOISE REDUCTION SYSTEM _

• The Dolby noise reduction system substantially reduces

the tape background noise (hiss) inherent in the cassette

medium. Dolby B NR is most widely in use. However,

Dolby C NR is a much more recent development and

represents a significantly improvements over Dolby B NR.

• Tape background noise consists primarily of high frequency

information which is particularly annoying during soft

passages. The Dolby NR system increase the level of

low volume mid and high frequency signal during recording

and reduces the level of these signals by an identical

amount during playback. As a result, the playback signal

is identical to the original source signal, but the level

of background noise generated by the tape is greatly

reduced.

• The operating principle of Dolby C NR is simi lar to that

of B except for the encoding/decoding response curves.

The noise reduction effect obtained by Dolby C NR is up

to 20dB, compared to lOdB with Dolby B NR. In addition,

Dolby C NR uses an antisaturation network and spectral

skewing circurity, and significantly improves the dynamic

range in the mi.d to high frequencies.

DOLBY HX-PRO HEADROOM EXTENSION SYSTEM _

This deck is equipped with the DOLBY HX-PRO headroom

extension system. Since the system functions automatically

during recording, no switching operation or adjustment is

required. The system is effective with any type of Normal,

CrO, or Metal tapes.

The Dolby HX·PRO headroom extension system functions

during recording to lift up the saturation level in the treble

range. Therefore, most of the treble range components

distorted or lost during recording on conventional cassette

decks are more faithfully recorded on the new DRM-800A

cassette deck.

Features of the DOLBY HX-PRO headroom extension

system

( 1) Performance of Normal and CrO, tapes can be up-

graded closer to that of Metal tapes.

(2) The dynamic range in the treble is improved signifi-

cantly.

(3) Since no decoding in playback is necessary, the

improvement can be obviously heard on any hi·fi

playback system including portable components and

car systems.

(4) The system functions whether the Dolby B/C NR is

engaged or not.

9

Page 10

MAINTENANCE _

• Removing the cassette compartment cover

It will be more convenient if the cassette compartment

cover is removed during the cleaning of the pinchroller

and heads, or during demagnetizing of heads.

Follow these procedures:

1. Press the EJECT button to open the cassette com-

partment_

2. Hold only the cover of the cassette compartment and

pull it up. The compartment cover is removed from

the front.

When attaching the cassette compartment cover, reverse

the above procedure.

• Head Cleaning

After long usage, tape coating or dust may adhere to

the heads causing deterioration of sound. Clean them

regularly. Use a cotton swab moistened with cleaning

solution (such as alcohol).

Note:

1. Some cleaning cassettes on the market have a strong

abrasive effect and scratch the heads. Use cotton

swabs instead of cleaning cassettes.

2 .. Since the use of metal tapes is apt to collect more

dust on the heads, clean the heads more often to

enjoy optimum sound.

• Clean ing the pinchroller and the capstan

If the pinchroller or the capstan accumulate dust, tape

transport may become unstable resulting from sl ippage

during recording or playback. The tape can also be da-

maged by being rolled up around the capstan.

Clean them with a cotton swab or a soft cloth moistened

with cleaning solution (such as alcohol).

• Demagnetizing the heads

The heads may become magnetized after long usage or

by having a strongly magnetized object brought near them.

The result is a generation of noise, loss of the high

frequency range, or erasing the treble components of

pre-recorded tapes and adding noise.

Demagnetize the heads on a regular basis.

• Procedure

1. Be sure to turn "off" the power supply.

2. Turn the' demagnetizer "on" while it is more than

30cm away from the heads. Bring the demagnetizer

near the heads and slowly move it in a small circle

four or five times.

3. Slowly move the demagnetizer away from the heads

and turn "off" the power of the demagnetizer when

it is about 30cm away from the heads.

CASSETTE TAPE _

• Handling Precautions

• C120 cassettes

C120 cassettes are not recommended as they use a very

thin tape base which may become tangled around the

capstan or pinchroller.

• Tape slack

This cassette deck incorporates an automatic tape slack-

ness preventive mechanism, but it can not prevent such

a slackness as shown below. Remove it with a pencil or

the like prior to use.

• Storage Precautions

• Do not store cassette tapes in a place where they will

be subject to:

• Extremely high temperature or excessive moisture

• Excessive dust • Direct sunlight

• Magnetic fields (near TV set or speakers)

• To eliminate tape slack, store your cassettes in cassette

cases with hub stops.

• Accidental Erasure Prevention

• Every cassette has erasure prevention tabs for each side.

To protect your valuable recorded tapes from accidental

or inadvertent erasure, remove the tab for the appropriate

side with a screwdriver or other tools .

• To record on a tape with the erasure prevention tabs

removed, cover the tab holes with plastic tape.

Erasure prevention

Erasure prevention

tab for side B

tab for side A

10

I

Page 11

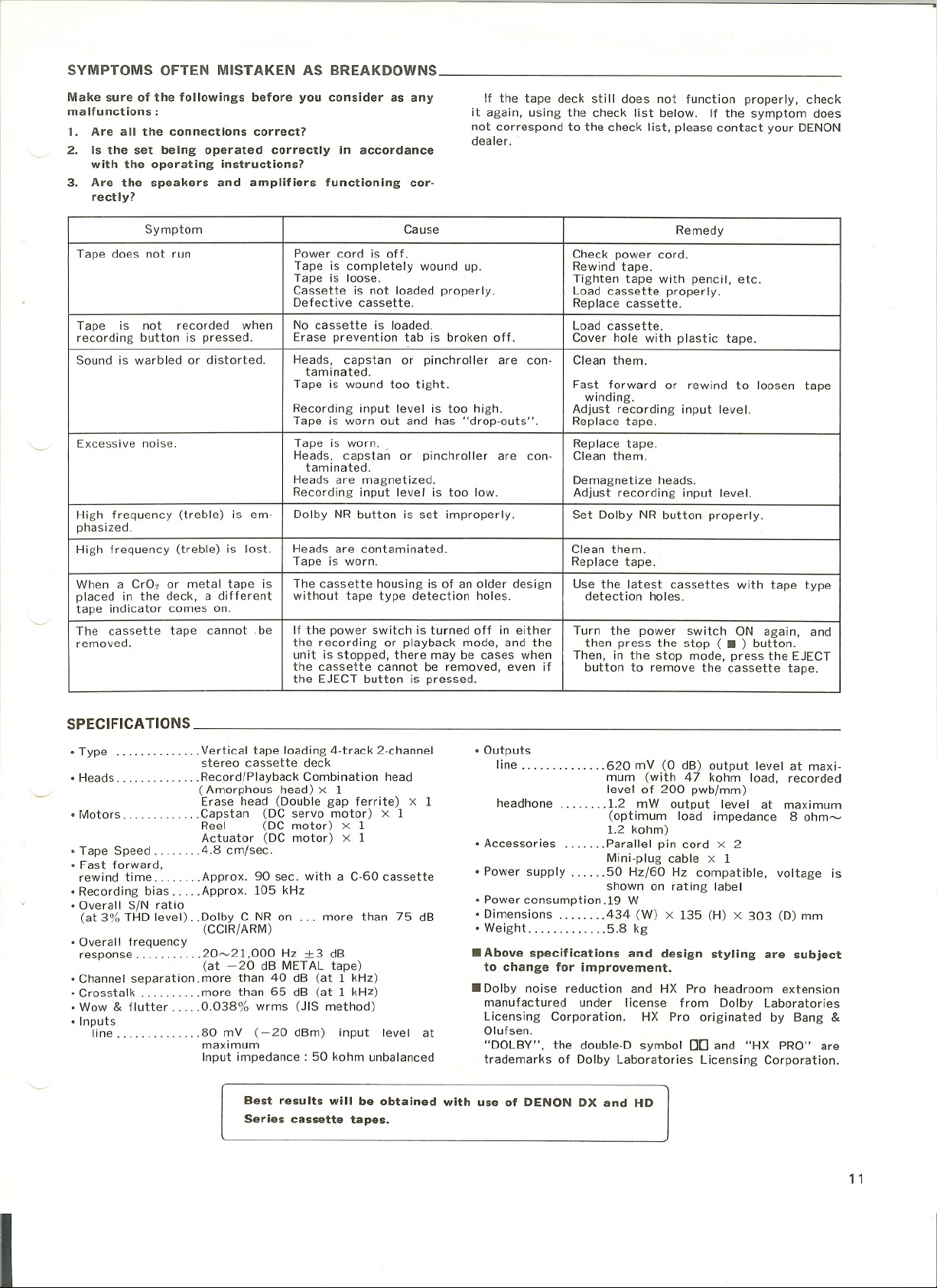

SYMPTOMS OFTEN MISTAKEN AS BREAKDOWNS _

Make sure of the followings before you consider as any

malfunctions:

1. Are all the connections correct?

2. Is the set being operated correctly in accordance

If the tape deck sti II does not function properly, check

it again, using the check list below. If the symptom does

not correspond to the check list, please contact your DENON

dealer ..

with the operating instructions?

3. Are the speakers and amplifiers functioning cor-

rectly?

con-

Clean them.

rewind to loosen

con· Clean them.

switch

forward

pinchroller

or

are

is not recorded when

ON

cassette

cannot. be

or

pinchroller

No cassette is loaded. Load cassette.

and

tape

capstan

power

again,

Tape is wound too tight.

Heads are magnetized.

The

High frequency (treble) is lost.

or

are

If the power switch is turned off in either

tape

.

Symptom

Power cord is off.

Cause

Heads are contaminated.

Heads, capstan

Dolby NR button is set improperly.

Erase prevention tab is broken off.

The cassette housing is of an older design

without tape type detection holes.

the recording or playback mode, and the

Tape is worn .. Replace tape.

Fast

Turn the

Clean them.

detection holes.

Check power cord.

Rewind tape.

Tighten tape with pencil, etc.

Adjust recording input level.

Replace tape.

Demagnetize heads.

Adjust recording input level.

Replace cassette.

Cover hole with plastic tape.

Replace tape.

Remedy

Set Dolby NR button properly.

Load cassette properly.

Use the latest cassettes with tape type

then press the stop ( • ) button.

Then, in the stop mode, press the EJECT

button to remove the cassette tape.

SPECIFICATIONS _

• Type _ Vertical tape loading 4-track 2-channel

• Heads Record/Playback Combination head

• fv1otors .

• Tape Speed ..

• Fast forward,

rewind time Approx. 90 sec. with a C·60 cassette

• Recording bias Approx. 105 kHz

• Overall SIN ratio

(at 3% THD level) .. Dolby C NR on ... more than 75 dB

• Overall frequency

response 20~21,000 Hz ±3 dB

• Channel separation. more than 40 dB (at 1 kHz)

• Crosstalk. _ more than 65 dB (at 1 kHz)

• Wow & flutter 0.038% wrms (JIS method)

• Inputs

line 80 mV (-20 dBm) input level at

stereo cassette deck

(Amorphous head)

Erase head (Double gap ferrite)

.... Capstan (DC servo motor)

Reel (DC motor)

Actuator (DC motor)

... 4.8 cm/sec.

(CCIR/ARM)

(at -20 dB METAL tape)

maximum

Input impedance: 50 kohm unbalanced

x 1

x 1

x 1

x 1

x 1

• Outputs

line _ _ 620 mV (0 dB) output level at maxi-

headhone 1.2 mW output level at maximum

• Accessories Parallel pin cord x 2

• Power supply 50 Hz/60 Hz compatible, voltage is

• Power consumption .19 W

• Dimensions 434 (W)

• Weight _ 5.8 kg

mum (with 47 kohm load, recorded

level of 200 pwb/mm)

(optimum load impedance 8 ohm~

1.2 kohm)

Mini-plug cable

shown on rating label

x 1

x 135 (H) x 303 (D) mm

• Above specifications and design styling are subject

to change for improvement.

• Dolby noise reduction and HX Pro headroom extension

manufactured under license from Dolby Laboratories

Licensing Corporation. HX Pro originated by Bang

Olufsen.

"DOLBY", the double·D symbol DD and "HX PRO" are

trademarks of Dolby Laboratories Licensing Corporation.

Best results will be obtained with use of DENON DX and HD

Series cassette tapes.

&

I

11

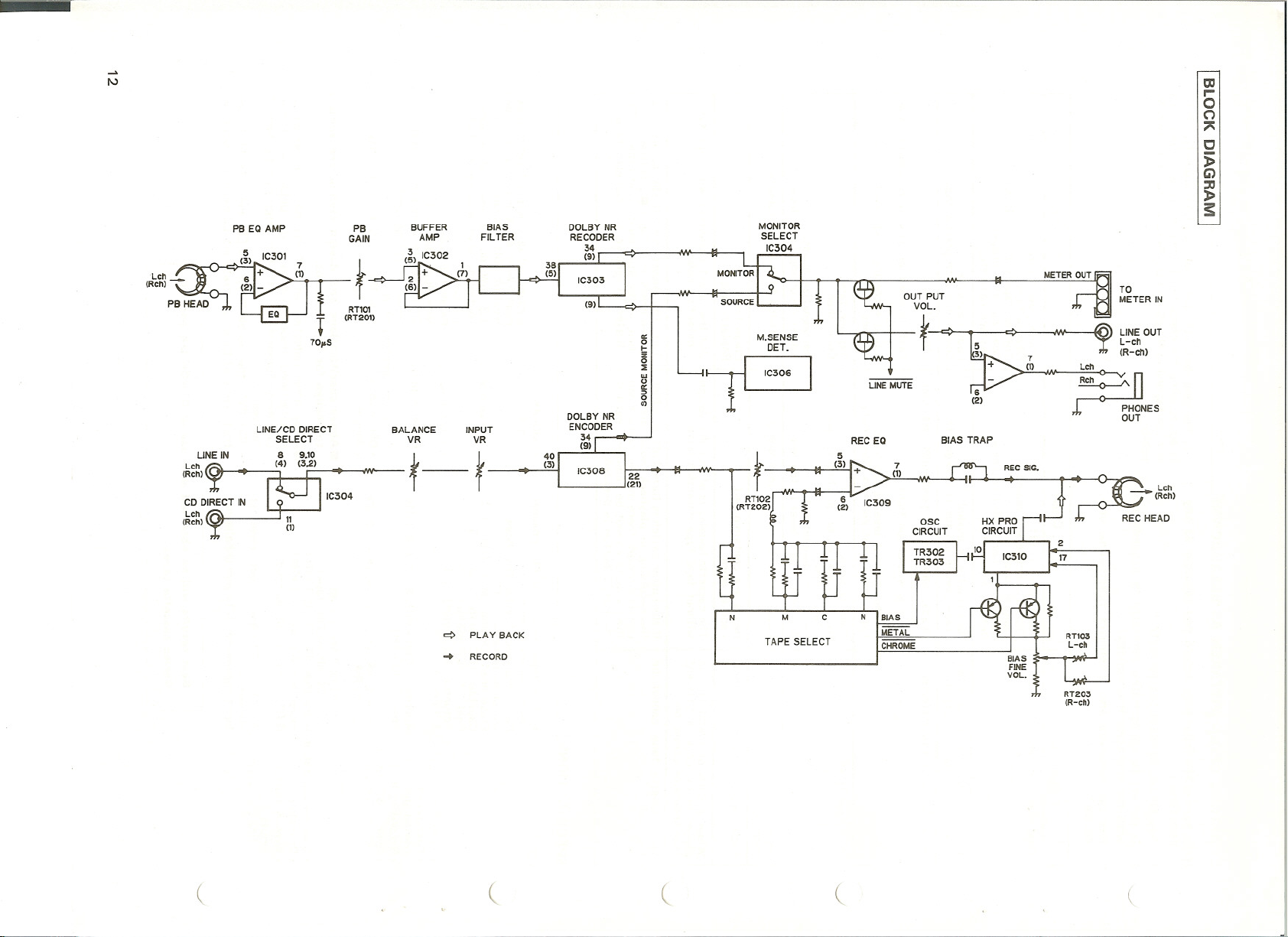

Page 12

N

en

r-

o

(")

~

c

»

G)

:xl

»

s:

PB EO AMP

PB

GAIN

BIAS

FIL TER

DOLBY NR

RECODER

34

(9)

MONITOR

SELECT

IC304

TO

METER IN

Leh

(Reh)

LINE IN

70l'S

LINE/CD DIRECT

SELECT

IC304

BALANCE

VR

f-r

INPUT

VR

~ PLA Y BACK

••• RECORD

a::

o

f-

Z

o

::E

Ul

<J

a::

;;;)

o

<I)

40

(3)

(21)

22

~

M.SENSE

DET.

t

RT102

(RT202)

N M

LINE MUTE

REC EO

BIAS TRAP

BIAS

FINE

VOL.

7

(1)

~~

RT203

(R-eh)

LINE OUT

L-ch

(R-Ch)

PHONES

OUT

(

(

( (

(

Page 13

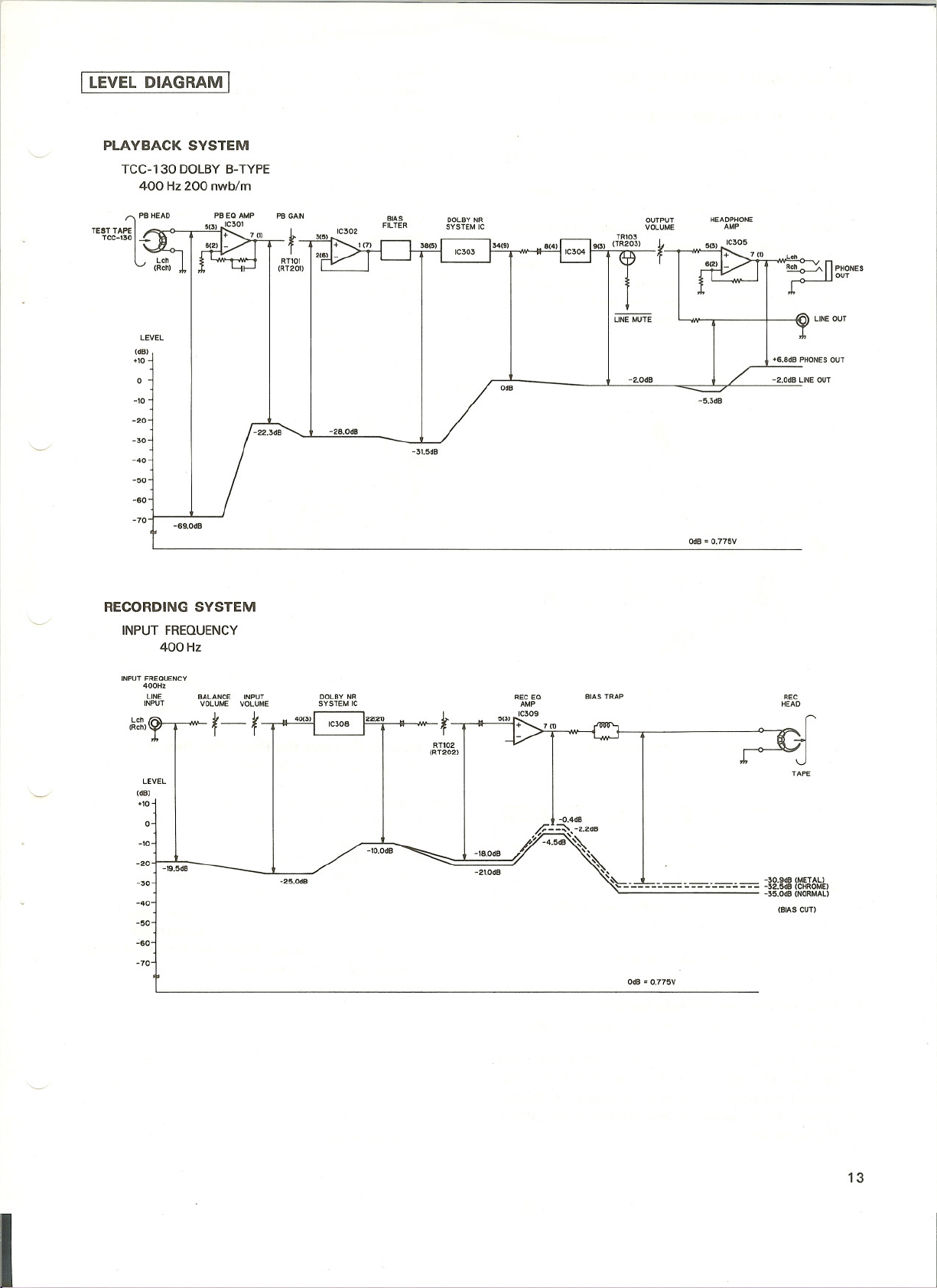

I LEVEL DIAGRAM [

PLAYBACK SYSTEM

TCC-l 30 DOLBY B- TYPE

400 Hz 200 nwb/m

LEVEL

(dB)

-10

-10

-20

-30

-40

-50

-60

-70

-59.0dS

RECORDING SYSTEM

INPUT FREQUENCY

400 Hz

-28.0dB

OdB

LINE MUTE

-2.0dB

OUTPUT

VOLUME

t

HEADPHONE

-5.3dB

OdS = O.775V

AMP

~OUT

~ n PHONES

LINE OUT

+6.BdB PHONES OUT

-2.0dB LINE OUT

INPUT FREQUENCY

400Hz

LINE

INPUT

Loh

(Rch)

LEVEL

(dB)

-10

o

-10

-20

-19.5dB

-30

-40

-50

-60

-70

BALANCE INPUT

VOLUME VOLUME

t-t

DOLBY NR

SYSTEM Ie

40(;5) I 122(21)

-25.0dB

-10.0dB

RT102

(RT202)

REC Ea

AMP

IC309

BIAS TRAP

-O.4dB

ft.':'~, -2.2dB

-21.0dB

.~t-. 'W

/7 ,.,- "'" ,'"': 1o!i<_

~~-~~~~---- - .

~\ --.-==-.:==-:

'~---- (BIAS CUT)

OdS = O.775V

REC

HEAD

TAPE

-~~·gdB (NORMAL)

I

13

Page 14

I DISASSEMBLY INSTRUCTIONS I

1. How to Remove the Front Panel

(1) Remove the four screws (4 x 10 CTTS-P) (36) in the top

side of the top cover (27). Move the top cover to the rear

and rise it to remove it.

(2) Press the eject knob (14), open the cassette window (23)

and remove the mechanism as shown in the figure.

Note: Handle the cassette window with care because it

can be scratched easily.

(3) Remove the four screws (3 x 1 0 CBTS-P) (30) and the two

screws (3 x6 CBTS-S) (35) on top of the front panel (16),

the five hooks on the top, the three hooks on the bottom

and pull the unit forward to detach it.

,.

(4) Remove the connectors attached to the leads from the

mechanism that are attached to the audio board and the

power supply board. Remove the style pins that secure the

wires.

Mechanism

W891 --(8P) --CN891 (WHITE)

W892 -- (7P) -- CN892 (WHITE)

W171 --(6P) --CN171

W172 -- (4P) -- CN 172

Note: Be sure to check that the connectors are reconnect-

ed correctly when the unit is reassembled.

(5) Lift the unit up to remove it.

Note: When the reassembly is performed make sure that

the stays at the bottom of the unit enter the slots in

the chassis and that no wires are pinched between

the unit and the chassis.

Power supply

circuit board

Audio circuit board

5 hooks on the top of the front panel

I.Ej~

I I

3 hooks on the bottom of the front panel

2. How to Remove the Mechanism

(1) Remove the top cover (27) and front panel (16). (Refer to

Step 1 .)

(2) Remove the screw (3 x 1 0 CBTS-P) (30) on the shield

bracket (18) and the screws (3 x 6 CBTS-S) (35) and

detach the shield bracket. (Refer to the disassembly figure.)

(3) Remove the two securing screws (3 x 1 0 CBTS-P) (30) for

the mechanism.

14

3. How to Remove the Front Ese. Assembly

(1) Remove the top cover (27) and the front panel (16). (Refer

to Step 1 .)

(2) Remove the wires from the front esc. assembly (9) that are

connected to the audio board and power supply board.

Front Ese. Assembly

W141 --(13P) __ CN141

W151 --( 3P) __ CN151

W121 __ ( 3P) __ CN121 (Blue)

W291 --(25P) __ CN291

(3) Remove the two front esc. hooks from the bottom of the

chassis and the front esc. assembly can be removed to-

wards the front.

Front ese. hooks (2)

Audio circuit board

Power supply

circuit board

I

Page 15

4. How to Remove the Meter Circuit Board

(1) Remove the top cover (27) and front panel (16). (Refer to

Step 1 .)

(2) Remove the front esc. assembly (9). (Refer to Step 3,)

(3) Remove the three screws (3

the unit board, the seven hooks and remove the meter

board.

Note: When replacing the (tactile-takuto) switch (X) insert

it so it is not raised after assembly.

x 1 0 CBTS-P) (30) that secure

o X

7m/~;na ""Eu",.

5. How to Remove the Audio Circuit Board

(1) Remove the top cover (27) and the front panel. (Refer to

Step 1 .)

(2) Remove the two cushions (26) attached to the chassis and

the shield bracket (18).

(3) Remove the front esc. assembly. (Refer to Step 3,)

(4) Remove the shield bracket (18).

(5) Remove the wires from the power supply board that are

connected to the unit.

(6) Remove the two screws (3

4-pin jack and 2-pin jack, the three screws (3 x 1 0 CBTS-P)

that secure the circuit board and the two hooks that secure

the board to the chassis and the board can pulled out of the

assembly.

x 1 0 CBTS-P) that press the

6. How to Remove the Power Supply Board

(1) Remove the top cover and front panel. (Refer to Step 1).

(2) Pull out the power switch lever (1 3) from the power switch.

(3) Remove the wires from the unit that are attached to the

audio board or power supply board.

(4) Remove the three screws (3

the power supply circuit board and raise the board to

remove it.

ADJUSTING AND CHECKING THE

MECHANISM SECTION

1. Exchanging pinch roller

Before exchanging the pinch roller, clean the tape contact sur-

faces of the pinch roller and of the capstan shaft.

Defects on tape playing are primarily caused by a dirty pinch

roller or capstan shaft.

The right pinch roller arm

the spring

arm @ can be taken out by removing @, the nylon nut

® and the slit washer ® . The left pinch roller

x 1 0 CBTS-P) (30) that secure

® can be detached by removing

@ and washers @ and @.

After exchanging the pinch roller, run a tape without a C-90 butt

and verify that no tape curling occurs at the tape guide

and the tape guide part on the record/playback head.

@

Note: Most service operations for the audio board can be

performed by removing the bottom plate from the

rear of the chassis. Refer to the previously described

disassembly procedures if it is necessary to remove

the enrire unit.

Assembly is the reverse of disassembly. Each part

must be mounted in the correct position or the unit

may not be able to be installed. Make sure that each

part is mounted correctly during assembly.

Normal condition

Pinch roller arm L

~~~~

Tape gUide p' h II R

/ . /1 I! Tape

Nylon nut Erasure head Recording/Playback head

Defective running condition

~I'J~~

~ C",

Special nut

Curl

mc ro er arm

15

I

Page 16

2. Verifying pinch roller crimping

In the playback condition, hook a stick type spring balance to the

bracket on the central axis of the pinch roller. After pulling the

pinch roller away from the capstan shaft, let the pinch roller con-

tact the capstan shaft as it is and verify that the readings on the

stick type spring balance are 350 to 450 g on the right side and

1 50 to 250 9 on the left when the pinch roller starts turning. If

the readings exceed the standard values, replace spring

® or

@.

Pinch roller spring

Pinch roller

.. : Left side 150-250 g

,.

ill: 'q -,~ Right side 350-450 g

3. Exchanging recording/playback head ®

Detach the front panel first.

3-1 Dismounting recording/playback head

(1) Detach the recording/playback head locking screw

and the azimuth adjusting nut @.

(2) Remove soldering on the head wire and separate the me-

chanical unit to dismount the recording/playback head.

3-2 Recording/playback head installation

Assembly is the reverse of the installation procedure de-

scribed in section 3-1. The soldering for the head wire is

performed as shown in Figure 3-1 .

®

4-2 Adjustment of tilt angle

(1) Set THG-80 1 (jig board) in the mechanical unit and place

THG-80 1 (jig shaft) on the recording head to inspect the

gap between the jig board. If the jig shaft is tilted forward,

the tilt screw ® is too tight. Loosen it slightly and

adjust the tilt screw ® until the jig stick is parallel to the

jig board and the gap is completely eliminated.

(2) Readjusting the tilt may cause the height adjustment to slip.

After adjusting the tilt, be sure to verify the height.

If the height is misaligned, turn the special height adjustment

nut ® and the tilt screw @ to the same angle to

shift the recording/playback head so it is parallel to the jig

board for height readjustment. After the adjustment is

completed, tighten the lock nuts.

4-3 Azimuth Adjustment

Playback test tape A-BEX TCC-1 53 and perform the adjust-

ment by turning the azimuth adjustment nut

and B in the Lissajous wave figure are at the maximum and

the minimum positions respectively. After azimuth adjust-

ment is completed, check again to make sure there is no dis-

location on the head height with the readjusting jig

THG-801. After the adjustment is completed, secure the

lock nuts on the adjusted parts.

Figure 4-2.1 Forward tilt case Figure 4-2.2 Backward tilt case

Tilt angle

Jig board

Jig shaft

Tilt angle

® until A

Jig board

BLACK ~ BLACK

~ L-J-o o-!.---J ~ , . I WHITE --t:? O-!-- WHITE ['

_-..----~~B-LA-C-K-~-~ ~ BLACK ~

~ ~[ ~_======~== IWHITF I \

4. Recording/playback head Adjustment

4-1 Height adjustment (adjust with head adjustment jig

THG-801 )

(1) Set THG-801 (jig board) on the mechanical unit and perform

the adjustment by turning the special height adjustment nut

WHITE '- WHITE

® so the 3.8 mm part on THG-801 (jig shaft) can move

without touching the tape guide on the recording/playback

0.

head

(2) Turn the azimuth adjusting nut ® so that the record-

ing/playback head does not tilt while adjusting the height,

and make a rough visual adjustment.

16

A-BEX TCC-153

Note: Be sure to mount the head adjust spacer.

5. Erasure Head 8 Exchange

5-1 Remove the locking screw @ for the erasure head.

5-2 Remove the solder on the head wire, and separate the me-

chanical unit to dismount the erasure head.

I

Page 17

6. Tape guide height verification

Set the jig board THG-801 on the mechanical unit. Adjust it by

turning the verification adjustment nut

mm part on the jig stick THG-801 jig shaft move without con-

tacting the tape guide part of the tape guide

7. Verifying fast-forwarding torque

Load a cassette-type torque meter and verify that the reading on

the torque meter at the median value is 30-80 g-cm during

playback.

If the reading is outside the standard, verify the voltage of the

reel motor (3.3 V ±0.3 V). If the voltage is low the torque is weak

and when the voltage is high the torque is strong .

Also verify the reel thrusting gutter in Item 8.

8. Verification Reel Driver Thrust Movement

Verify that the thrust movement is 3.0 to 4.0 mm.

9. FF and REW Torque Verification

@ so that the 3.8

@ .

o When using cassette-type torque meter:

Verify that the readings at the end of the fast-forward and

rewind is 80-160 g-cm.

o Load the cassette half-modified jig and hook the tip of a dial

tension meter (fu!1 scale 100-300 g) on the triangle part.

Switch to the FF (REW) position and feed a tape at a some-

what slower pace than the speed of the tape that is rolled in.

Verify that the value on the dial tension meter at that time is

more than 80 g-cm.

10. Back tension torque verification for

recording/playback

Load a cassette-type torque meter to verify that the reading on

the torque meter for recording/playback is 6 to 16 g-cm and

there is no unevenness.

If the reading is outside the standard values, verify the reel thrust

gutter or replace the spring(D

11. FF and REW Time Verification

Load a DENON HD-7E/60 cassette tape and verify that the FF

and REW time is 80 to 110 seconds. If the reading is outside the

standard values, verify Items 8 and 10.

12. Accidental erasure prevention, metal and

chrome switch function verification

Verify that switch @ is functioning normally depending on

whether the hole is present or not.

I ADJUSTING THE ELECTRICAL SECTIONS I

ELECTRICAL SYSTEM ADJUSTMENT

a Gauges necessary for adjustment

(1) Low frequency oscillator (2) Variable resistance attenuator

(3) Electronic voltmeter (4) Oscilloscope (5) Frequency

counter (6) Adjustment driver (7) Trap coil adjustment

square regulation shaft

(8) Test tape (SONY TY224)

(A-BEX TCC-153, TCC-130, TCC-262B/162B)

(DENON'HD-7E/60)

(9) Mirror cassette for playing (A-BEX TCC-902)

• Adjustment Notes

(1) Clean the head surface, capstan axis. pinch roller, etc. with

gauze or cotton swabs soaked with alcohol before adjusting.

(2) Demagnetize the recording head and erasure head with the

head eraser.

(3) Completely demagnetize the adjusting driver.

(4) Set function switches as follows unless specifically indicat-

ed.

o MONITOR switch: TAPE

o INPUT volume: Maximum (right side)

o DOLBY NR switch: OFF

o BIAS volume: Center (clicking detent in center)

o OUT PUT volume: Maximum (right side)

o BALANCE volume: Center (clicking detent in center)

1. Tape playing check

Load a mirror cassette for playing and examine the area around

the fixed guide of the recording/playback head at playing condi-

tion with lighting and verify that the tape edge is not contacting

the tape guide part. The tape playing is the most important ele-

ment that determines the capacity of the entire cassette deck.

Make every effort to avoid moving the adjusting part. Also, refer

to "Adjustment and verification of mechanical system" for ex-

changing and adjusting the recording/playback head.

2. Azimuth adjustment

2-1 After verifying the tape playback, load the test tape (A-BEX

TCC-153).

2-2 Playback the test tape and make any necessary adjustment

by turning the azimuth adjustment nut so that A and B in the

Lissajous wave figure are at the maximum and minimum

levels respectively.

I

13. Pulse detection LED and reel table clearance

verification

Verify that the gap between the surface of the shutter part of the

reel table and LED is approximately 1 mm.

LED

I

A-BEX TCC-153

~ .,,,,.om,"'Y 1 mm

17

Page 18

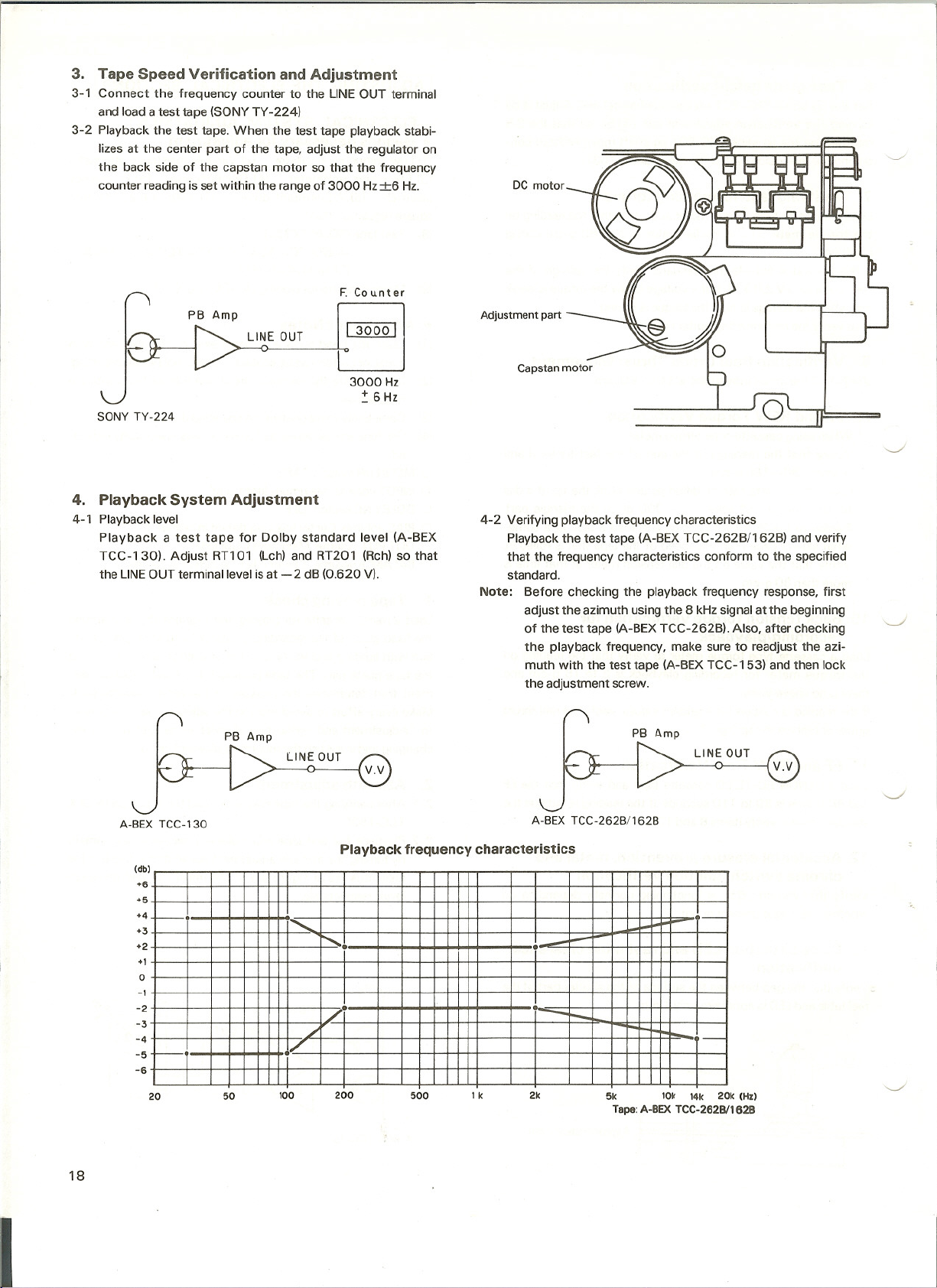

3. Tape Speed Verification and Adjustment

3-1 Connect the frequency counter to the LINE OUT terminal

and load a test tape (SONY TY -224)

3-2 Playback the test tape. When the test tape playback stabi-

lizes at the center part of the tape, adjust the regulator on

the back side of the capstan motor so that the frequency

counter reading is set within the range of 3000 Hz ±6 Hz.

F.Counter

PB Amp

LINE OUT

DC motor

Adjustment part

3000 Hz

:!: 6 Hz

SONY TY -224

4. Playback System Adjustment

4-1 Playback level

Playback a test tape for Dolby standard level (A-BEX

TCC-130), Adjust RT1 01 (Lch) and RT201 (Rch) so that

the LINE OUT terminal level is at -2 dB (0.620 V).

LINE OUT

V.V

Capstan motor

4-2 Verifying playback frequency characteristics

Playback the test tape (A-BEX TCC-262B/162B) and verify

that the frequency characteristics conform to the specified

standard.

Note: Before checking the playback frequency response, first

adjust the azimuth using the 8 kHz signal at the beginning

of the test tape (A-BEX TCC-262B). Also, after checking

the playback frequency, make sure to readjust the azi-

muth with the test tape (A-BEX TCC-1 53) and then lock

the adjustment screw.

LINE OUT

V.V

18

A-BEX TCC-130

(db)

-

-

+6

+5

+4

+3

+2

+,

o

-1

-2

-3

-4

-5

-6

-

......•..•

20 50

100

A-BEX TCC-262B/162B

Playback frequency characteristics

..

1 k 2k

200

"-

•

500

I

1

5k 10k 14k 20k (Hz)

Tape: A-BEX TCC-262B/162B

I

Page 19

5. Recording System Adjustment

5-1 Adjusting recording/playback comprehensive frequency

characteristics

(1) Load a test tape DENON HD-7E/60. Record with a -38 dB

1 kHz input level signal into the LINE IN terminal and play-

back.

(2) Make a sample recording using a 10-kHz input signal and

playback this recording. Adjust RT1 03 (left channel) and

RT203 (right channel) so that they conform to the following

specified characteristics.

Record/Playback Overall Frequency Response

(db)

·

I

+6

•

./

-'

+5

+4

+3

+2

+1

o

-1

-2

-3

-4

-5

-6

20

1 · ...•...•...

'.

50

I

/

..........•.

100 200 500

1k

.-

_.-

2k

V.V

Tape: HD-7E Dolby: off

Level: -20 dB from Dolby

LI NE OUT

PB Amp

5k 10k 14k 20k (Hz)

5-2 Recording/Playback Level Adjustment

(1) Load the test tape DENON HD-7E/60. Make a sample

recording with the 1 kHz (-38 dB) signal and play this sec-

tion back.

(2) Adjust RT -102 (Lch) and RT -202 (Rch) so that the output

from LINE OUT terminal is the same as the output at record-

ing monitoring time.

Dolby C Record/Playback Overall Frequency Response

(db)

.-'

I

"

•...

+6

I

+5

+4

+3

+2

+1

o

-1

-2

-3

-4

-5

-6

20

I

,

--..... •... ,,~

1

50

100

200 500

5-3 Dolby C recording and playback comprehensive frequency

characteristics verification

(1) Set the Dolby NR switch at "C" position.

(2) Use a test tape DENON HD-7E/60 and record and playback

as in Item 5 -1 to verify that they satisfy the characteristics

standards.

•

1""-_

•

~

•

./0-

2k

5k 10k 14k 20k (Hz)

Tape: HD-7E Dolby: on. C

Level: - 20 dB from Dolby

19

Page 20

PARTS LIST OF EXPLODED VIEW

11 3 11 88 1 04 P.S. LEVER ASS'Y

11 3 11 90 134

11 3 1187 202 EJECT KNOB

11 1430615200 WINDOW

4630617005 SPRING

1442048001 FRONT PANEL

103 1223237 ESC BAR

4140527106 SHIELD BRACKET

4450048016 CORD HOLDER

1120670 102 KNOB ASS'Y

11 2 0555 007

1031401033 C. WINDOW

445 0056008 CORD BUSH

4122008012 BUSHING PLATE

461 0502 004 CUSHION

102 0386 004 TOP COVER

1031225235 FRONT ESC

4737508017

2 4140525001 EARTH BRACKET

3 1050830106 BOTTOM COVER

1040183119 FOOT ASS'Y

4737002018

411 0857356 CHASSIS

4122782008 SHIELD PLATE

4610178001 RUBBER SHEET

VM864 CASSETTE MECHA

1031224249 FRONT ESC ASS'Y

4737502013

477 0262 006 SPECIAL SCREW

Ref. No.

Australia 4110857372

P.S. LEVER ASS'Y

P.S. LEVER ASS'Y

EJECT KNOB

WINDOW

EJECT KNOB

FRONT PANEL

ESC BAR

ESC BAR

FRONT ESC

KNOB ASS'Y

KNOB ASS'Y

C. WINDOW

C. WINDOW

CUSHION

TOP COVER

FRONT ESC ASS'Y

FRONT ESC

CHASSIS

CHASSIS Asia

FOOT ASS'Y

Part No. Part Name Remarks

FRONT ESC ASS'Y

CHASSIS

PUSH KNOB (A)

PUSH KNOB (A)

U.S.A., Canada

U.S.A., Canada

VOL KNOB (B)

VOL KNOB (B)

3 xl 0 CBTS(P)-B

U.S.A., Canada

3 x8 CBTS(S)-Z

4 xl 0 CBTS(P)-Z

PUSH KNOB (A)

U.S.A. only

Europe (Gold)

U.S.A. only

U.S.A., Canada

Europe (Gold)

U.S.A. only

U.S.A. only

U.S.A. only

Europe (Gold)

U.S.A., Canada

Europe (Gold)

Europe (Gold)

Europe (Gold)

Europe (Gold)

Europe (Gold)

Europe (Gold)

Europe (Gold)

U.S.A. only

Europe, U.K.

Europe (Gold)

Europe (Gold)

U.S.A. only

Lt

*

®

64

®

®

®

77

40

67

L£

~a

72

35

ILt

:~

LIS

2335737004

~0&Q31 026

Lt

®

~

41

42

50

74

69

36

63

66

61

51

2062061 001

UNIT 4U- 1823 M8

UNIT

PLUG

UNIT 4U- 1823 U8

UNIT 4U- 1823 K8

2048310035

LABEL

2048311 034

4737503041

BASE(S)

UNIT 4U- 1823 C8

BASE(S) 52

BASE(S) ®

~sia

2048264000 HIP JACK

70 4U- 1 823 Z8 PWR TRANS PWB

4737503038

0090027022

009 0028 005

001 0038075 . VINYL WIRE

205 0499 025 25P FFC CON. CN291

3934075001 FIP9BEM8

2124388907 TACT SWITCH

65 4U-1817Z84 VOLUME PWB ASS'Y

2110597003 V1620P30FA104 VR302

2110595005 Vl103P25C VR301

4U- 1 81 7 Z85 H. PHONE PWB

4U- 1 816 Z8 AUDIO PWB UNIT

2048310022

Part No. Part Name Remarks

4737002005

2050491 036 25P FFC CON. CN291

205 0491 023 17P FFC CON. CN191

2048260004

62 4U-1817Z82 MTR CONTROL PWB

2048311018 2P PIN JACK

2124698008 VOLTAGE SELECTOR

4U-1817 Z81 PWR LOGIC PWB

68

73

233 5736 005 POWER TRANS

206 2063 009 AC CORD WITH

60

2120286003

Ref. No.

ASS'Y

ASS'Y

ASS'Y

71

76

206 2025 005

2335738003

2335739002

2062024006

Europe, U.K.

PWR TRANS PWB U.S.A.

PWR TRANS PWB

PWR TRANS PWB

JK002

2P PIN JACK

U.K.

JOOl

PWR TRANS PWB Asia

4 xl 0 CTTS(P) NI

25P FFC CABLE

17P FFC CABLE

FL901

Canada

POWER SWITCH

4P PIN JACK

4P PIN JACK

MINI JACK

AC CORD Australia

Asia

AC CORD

POWER TRANS Canada

AC CORD WITH

SW901

4 xl 0 CTTS(P) BK

U.K., Australia

AC CORD

Australia

POWER TRANS

U.S.A., Canada

3 x6 CBTS(S)-Z

Europe

Asia only

U.S.A. only

U.S.A. only

Europe

Europe (Gold)

II'

[:

I: POWER TRANS

U.S.A.

I

(Gold) in the Remarks column refers to models with Gold front panels.

20

Page 21

-----------------~===----~~~===~==~---=~~"'="'="'="'=====--------

I 1 I 2 I

I EXPLODED VIEW OF CABINET AND CHASSIS GROUP I

4

Page 22

5

6 7 8

A

~

~) ~

~5

~ ~

~ J~

~ -" ~ ~

c

D

21

Page 23

•

PARTS LIST OF 4U-1817,4U-1823

(POWER/LOGIC SELECTION)

••

Ref. No.

0901-908

C933, 934

25 V

(4.7K-10K)T

929

25 V

(4.7K-4.7K)T

925,928

IC801

r

253 9030044 CK45 = 1 E472K

253 9030 963 CK45=lEl03KT

2539031917 CK45 = 1 E683KT

Part Name Remarks

2730178925

2690015908 OTC124XS

2690019904 OTA143XS

2760432903 1 SS270A TE

253 9030 947 CK45 = 1 E472KT

2740036905

272 0025 907

2690090907 OTC 143XS- T

2710183901

2760519907 1 SR35-200A T82

2760469918 HZS9C-2TD

2760483910 HZS30-2TO

2760466911 HZS7C-2TO

2760463927 HZS6C-3TO

2760459928 HZS5B-3TO

2760465925 HZS7B-3TD

2760218910

253 1180 921 CK45B1H102KT

2630618006 BA6800A

262 1393000

269 0022 904 OTA143ES

2790020000

2620447009

279 0021 009

2440077 028 RS14B30180JNBF 18H2W

2110595005 V1103P25C

2110597003 V1620P30FA104

Part No.

CK45=2GAC103P

HZ9A-2TE (TAPE)

BA6109U1

2SC1740 (RIS) T-70

2S0468 (C)TF

2SB562(C)T,F

2SA933 (GIRlS) T-93

2SB794(L)

2S0985 (L)

2538010007

fLP075206CW-155

~~

~OO V AC

0.0047 fLFI

0.01 fLF/25 V

0.068 fLF/25 V

0.01 fLFI

0.0047 fLFI

0.001 fLF/50 V

*

C909

908

C910

C913

C914

C921

C925

C928

C901,904

C902, 905

C911,912

OTHER PARTS GROUP

Ceramic

(00-3)

(22K-47K)T

or

*

CN891

SW901

SW801,815

Electrolytic C602, 702

2590007 702

Ref. No.

C903, 906

(KR-PH) CN892

(KR-PH) CN901

(SME) C929,932

(KR-PH) (RED)

XT901

2544252930

2544258769

2544252901

2544256 790

2544252927

2544261 730

2544258 947

2544256 907

CE04Wl V4R7MT

CE04WOJ222MC

SP CAP= =822MC

CE04W1C472MC

2544256790

2544260 951 CE04W1 H2R2MT

202 0022 008 FUSE HOLDER

2061031045

3990079009

POWER SWITCH

205 0343 087 8P CONN. BASE

2050343074 7P CONN. BASE

205 0321 070 7P CONN. BASE

CE04W1Al01MT

CE04Wl V221 MT

CE04W1A220MT

CE04W1 E222MC

CE04W1A470MT

CE04Wl H221 MC

CE04W1V470MT

CE04W1 El00MT

2544258 905

2544250 770

Part No. Part Name Remarks

2544255717

CE04W1 E222MC

2124388907

2120286003

FUSE (0.25 )A

TACT SWITCH (1M)

CST4,19MG

220 fLF/35 V

Asia only

2200 fLF/25 V

100fLF/l0V

22 fLF/l 0 V

2200 fLF/25 V

47fLF/l0V

220 fLF/50 V

47 fLF/35 V

10 fLF/25 V

4.7 fLF/35 V

2200 fLF/6.3 V

8200 fLF/5.5 V

4700 fLF/16 V

2.2 fLF/50 V

Asia only

22

PARTS LIST OF MECHANISM

Part No.

411 0858203

4110679301 MECHA BASE ASS'Y

4310242101 HEAD SLIDER ASS'Y

431 0282 006 HEAD PLATE ASS'Y

4258011009 STEEL BALL 03

431 0240006 BALL GUIDE PLATE

463 8230 002 SPRING

3918826001 ERASE HEAD

2

7

3

4

5

6

1

8

Ref. No.

ASS'Y

Part Name Remarks

MECHA BASE (G)

Page 24

Ref. No.

PLATE 40

ASS'Y

ASS'Y

ASS'Y

ASS'Y

ASS'Y

HOLDER 53

ASS'Y

441 0850008

445 8028009

4438671104

431 0241 005 BRAKE

2124665002

441 1069607

4140414206

4240142009

2170168003

Part No. Part Name Remarks

3910267008 REC/P.B HEAD

DC MOTOR FIX

CORD HOLDER

4330540003 HOOK STOPPER

4610154083 CUSHION

4338194105 PINCH ROLLER ARM

4638271 003 SPRING

2170161000 REEL MOTOR

421 8403 000 PULLEY

SPECIAL NUT

4638231 108 SPRING

4210446104 REEL DRIVER

463 0522 103 SPRING

4218401 109 REEL DRIVE WHEEL

4330449201

4410692101 LAMP HOLDER

433 8236 306

GEN0410 CASSETTE BOX SUB

445 8028 009 CORD HOLDER

4U-1831-42 HOLE SENSOR PWB

SLIDE SWITCH

4U- 1 831- 43 REEL PULSE PWB

4618127106 BRAKE SHOE

463 8234 105 SPRING

433 8232 300 BRAKE ARM ASS'Y

443 8648 302 METAL HOUSING

433 0495 103

1031209400 CASSETTE BOX

433 0459 411 C. BOX HOLDER

431 8097002 COLLAR

4630524101 BOX SPRING

4698013133 AIR DUMPER

1441859107 ESC. PLATE

3939179012

2123331 308 ROTARY ENCODER

3939178000 LN25RCP

3939026013 PN150C

1 03 1 221 514 STABILIZER

4630609 107 STABILIZER SPRING

4610491 209

4210389106 FLYWHEEL ASS'Y

MECHA STAY ASS'Y

477 0090074 WASHER

411 8966402 CAM MOTOR

OIL FENCE

4428018308 ENCODER BRACKET

433 0493 105

433 0494 104

CAM

CAM MOTOR

4248025 607 WORM GEAR

463 0538 003 SPRING

IDLER ARM (B) GEAR

IDLER ARM (A) ASS'Y

HOLE SENSOR (C)

LNO 1 05YP4(YW)

STABILIZER PAD (A)

HOLE SENSOR (A)

HOLE SENSOR (B)

93

154

183

111

317

320

323

315

318

311

313

308

155

158

159

160

201

202

203

204

205

206

208

301

171

153

180

181

182

200

100

103

104

105

106

107

108

112

113

150

152

316

319

321

322

329

314

310

312

307

209

210

Ref. No.

ASS'Y

SUB ASS'Y 161

ASS'Y

2 x8

ASS'Y

(L)

(R)

(L) ASS'Y

SLIT WASHER

2 x3 CBS-Z

SLIT WASHER

477 0294003

2.1 WASHER

2NUT

421 8383 007

4630618004

443 0948 000

4620086015 MOTOR CUSHION

4751121 108

4761114008 1.5 E. RING

4713801039

4751120109

SPECIAL SCREW

4761003009 3 E. RING

4751139103

4770265016 WASHER

477 0269 009

4737500002

471 3802025 2.6 x 14 CBS

4756020000

4713802012 2.6 x3 CBS-Z

4737001006

4713202010 2.6 x5 CBS

4737021002

425 8058004 WASHER

4U- 1 831 -4 MECHA. PWB UNIT

DRO 4A04

DCO 7 A02 CAPSTAN MOTOR

DCO 6A03 CAM MOTOR SUB

4428154107 CP SUPPORT

4410897003 SPRING GUIDE

433 0543 204 HOOK

463 0561 009 SPRING

412 8829 305 ANGLE

4638257001 SPRING

1038243401 CASSETTE SUPPORT

103 8243 414 CASSETTE SUPPORT

4338271 507 DUMPER GUIDE

473 7002 005

MOTOR PULLEY

471 1822010 CAMERA SCREW

463 0628 104 DUMPER SPRING

4751003006 3W

461 0473201 THRUST STOPPER

SHIELD COVER

463 8829 303

Part No. Part Name Remarks

443 0903 207 HEAD BLOCK

433 0407 308 TAPE GUIDE

433 0408 006 PINCH ROLLER ARM

4630414101 SPRING

463 0480 009 SPRING

4430539008 WASHER

477 0240002 WASHER

4210538106 CAPSTAN WHEEL

423 8026 108 BELT

4238030110 BELT

4630616006 SPRING

2170162009

NYLON NUT (M2)

3 x6 CBTS(P)-Z

2.6 x5 CBTS(S)-Z

2.6 x6 CFT(S)

REEL MOTOR SUB

3 x6 CBTS(S)-Z

FLYWHEEL SPRING

CASSETTE SPRING

461 0488 005

CAPSTAN MOTOR

STABILIZER PAD (B)

j /

I

Page 25

I 2

r OF MECHANISM UNIT I

3

4

E

I

Page 26

1

§

5

6

7

8

A

B

!./

/

/

/0

/

c

1

I

I

I

I

I

J

/

/

/

D

),

/

/

E

I

23

Page 27

..

I

PARTS LIST OF 4U-1816 (AUDIO SECTION)

272 0025 907

2690062 906 OTC124ES

Part No. Part Name Remarks

2630317006 M-5220P

2630711000 M-5218AP

2690014909 OTA124XS

2760459915 HZS5B-2TD

2760218949 HZ9B-1 TE

2760468906 HZS9B1T0

2760236918 HZ5B-3TE

2442036012 RO 14B2H3R9JFRF

2116077 938

2630455007 CX20187

2620276005 HD14066BP

2630354001

2730245900 2SC2603E/FT

2750048909

2690015908 OTC124XS

211 6077 983

211 6077 954

253 1179 916 CK45B1H121KT 120 PF/50 V

2539031 917 CK45 = 1 E683KT

2539030918 CK45= 1 E152KT

253 9030 947 CK45 = 1 E472KT

253 1034966 CF93A1H823JT

253 1179929 CK45B1H151KT 150 PF/50 V

Ref. No.

321

(22K-22K)T

205,207

TR304, 305

TR104,108

25 V

25 V

50 V

(22K-47K)T

IC303, 308

302, 303 TR103,106

314,316 317,318 319,320

C134,234

253 9030 921 CK45= 1 E222KT

3.901/2 W

REC CAL

BIAS

25 V

2SB562 (C)TF

V06PB 104 (1M) PB, GAIN

2SK381 (O)/(E)- T

V06PB473 (1M)

V06PB223 (1M)

,uPC1297CA

C160, 260

(22K-47K)T

0.068 ,uF/25 V

0.0015 ,uF/

0.0047 ,uF/

0.082 ,uF/

0.0022 ,uF/

C321

C307

C360

C131,231

C142,242

317,318 C144,244

C145,245

208,235 C110,137

210,237 C115,215

203, 255

C165,265

C170,270

C163,263

C164,264

214,241

213,240

21 2, 239

209,236 C112,139

206,232

C601,701

204, 247

C104,147

C325,326

C130,230

C116,216

207,233

C162,262

Ceramic

C103,155

(00-3) C305

(00-3) C319

Film C102,202

Electrolytic

Ref. No.

C308

100V

C114,141

C113,140

C109,136

C106,132

C108,135

25 V C161,261

C107,133

2554079925 CQ93P2A822JT

255 1212 905 CQ93M 1 H 1 03JT

2551210907 CQ93M 1 H682JT

255 1220900 CQ93M 1 H473JT

255 1214 903 CQ93M1 H153JT

255 1208906 CQ93M 1 H472JT

2544260951 CE04W1 H2R2MT

CE04W1 A 101 MT

2551211906 CQ93M1 H822JT

255 1209905 CQ93M1 H562JT

CE0401 H01 OMBPT

2543055905

2544254909

2544258 905 CE04W1 V4R7MT

2544252927 CE04W1A470MT

2544256910 CE04W1 E220MT

CE04W1 H01 OMT

2544260919 CE04W1 HR22MT

2544254 909 CE04W1 C 1 OOMT

2544228919

CE04W1C100MT

253 9030 963

2544260935 CE04W1 HR47MT

253 1179 903

2531131909 CK45B2H391KT

253 9030976

253 4464903 CC45SL2H0400T 4 PF/500 V

253 9036 909

2539030921

253 9030 989

2544252 930

2543056917

2544260948

2544254 909

253 9030 992 CK45 = 1 E333KT

253 1179945

2531180918

100 PF/50 V

CK45B1H221KT 220 PF/50 V

Remarks

CK45B1H821KT

CE0401 V4R7MBPT

CE04W1 C1 OOMT

CK45= 1 E1 03KT

CK45B1H101KT

390 PF/500 V

CK45=1E153KT

CK45= 1 E104ZT

Part No. Part Name

CK45 = 1 E222KT

CK45 = 1 E223KT

820 PF/50 V

CE04W1 HR 15MT (LL)

0.0083 ,uF/

0.01 ,uF/50 V

0.0068 ,uF/50 V

0.047 ,uF/50 V

0.015 ,uF/50 V

0.0047 ,uF/50 V

2.2 ,uF/50 V

100,uF/10V

0.0082 ,uF/50 V

0.0056 ,uF/50 V

1 ,uF/50 V

4.7 ,uF/35 V

10 ,uF/16 V

4.7 ,uF/35 V

47,uF/10V

22 ,uF/25 V

1 ,uF/50 V

0.22 ,uF/50 V

10,uF/16V

10 ,uF/16 V

0.01 ,uF/25 V

0.47 ,uF/50 V

0.033 ,uF/25 V

0.015 ,uF/25 V

0.1 ,uF/25 V

0.0022 ,uF/

0.022 ,uF/25 V

0.15 ,uF/50 V

24

~

Page 28

Ref. No.

BASE(S) JK301

(KR-PH) CN171

(KR-PH)

(KR-PH) CN151

L101,201

Part No.

231 0825 009

SKEWING COIL

2320109003

2048310022

235 0020 903

205 0233 061

205 0233 045

205 0491 023

204 8311 01 8

2P PIN JACK

235 0020 945

205 0343 032

2390010009

239 8022 002

205 0406 034

2050375039

Part Name Remarks

BIAS FILTER

232 9007 009

MPX FILTER

4P PIN JACK

4P PIN JACK

INDUCTOR 682JT

6P EH CONN. BASE

4P EH CONN. BASE

17P FFC CONN.

2P PIN JACK

INDUCTOR 153JT

3P CONN. BASE

HX STEP UP COIL

OSC COIL

3P CONN. BASE

13P CONN. BASE

U.S.A. only

U.S.A. only

5050131050

511 2046009

505 0038 030

501 1338067

2033667007

511 2047008

MANUAL 5150455005

203 2223 002

5040012060