Page 1

For U.S.A., Canada

Hi-Fi Full Automatic

Turntable system

& Europe model

MODEL DP-29F

FULL AUTOMATIC TURNTABLE SYSTEM

(with MM Cartridge)

SPEED

45

33

30

SIZE

17

SAFETY PRECAUTIONS

The following check should be performed for the continued protection of the customer and service technician.

LEAKAGE CURRENT CHECK

Before returning the unit to the customer, make sure you make either (1) a leakage current check or (2) a line to chassis

resistance check. If the leakage current exceeds 0.5 milliamps, or if the resistance from chassis to either side of the

power cord is less than 460 kohms, the unit is defective.

Some illustrations using in this service manual are slightly different from the actual set.

X0135

NC

0203

Page 2

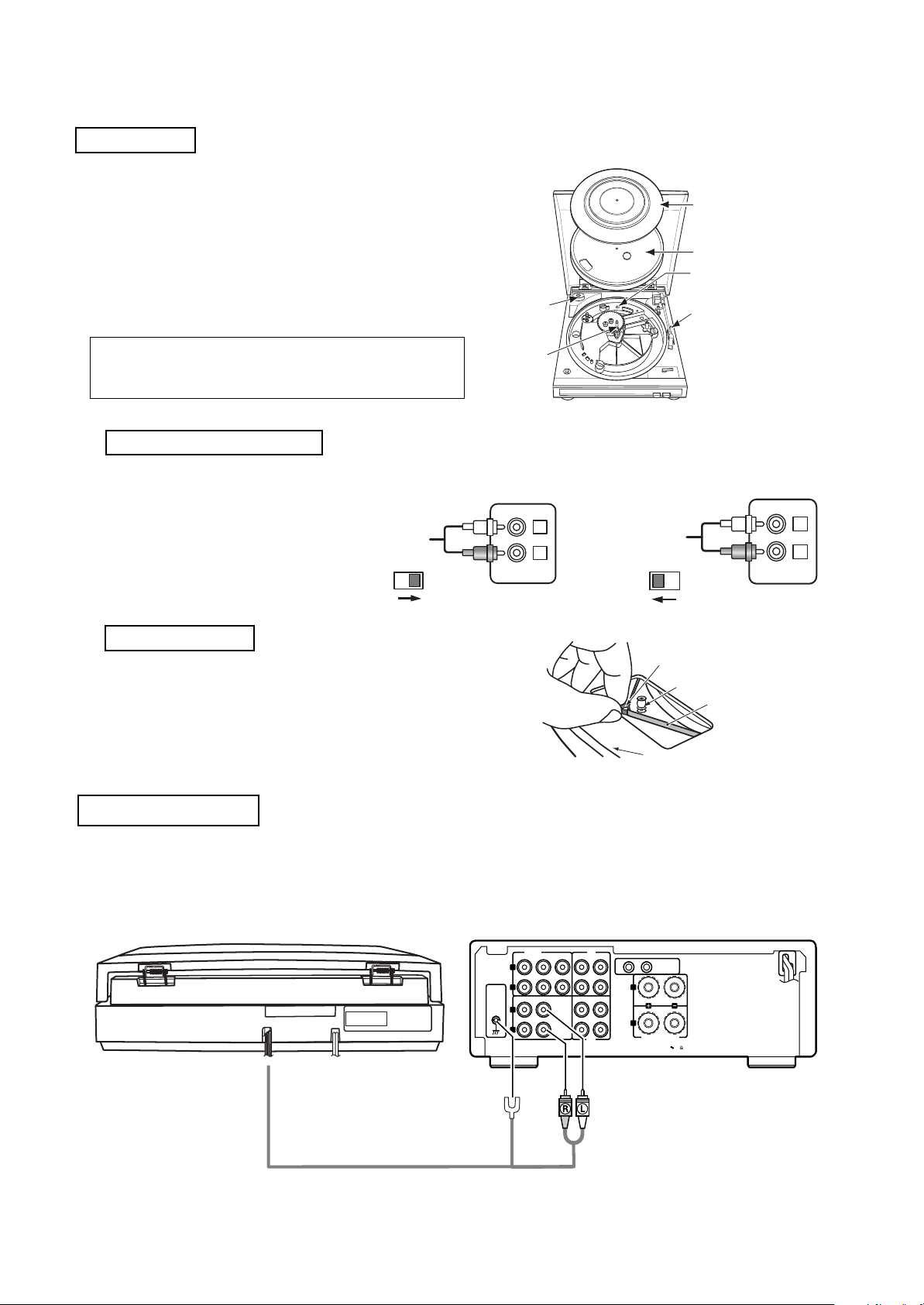

ASSEMBLY

1. Remove the main unit with the packing from

the box and take off the packing.

2. Set the 45-rpm adaptor on the main unit as

shown in the diagram.

3. Insert the turntable onto the center spindle.

4. Set the belt on the driving pulley. (The belt is

wound on the turntable.)

5. Set the turntable sheet on the turntable.

6. Remove the tie securing the tonearm.

45-rpm adaptor

Turntable sheet

Turntable

Equalizer Amplifier switch

Tonearm fixing tie

NOTE:

The turntable will not function if this tie is not

removed.

7.

8.

Equalizer Amplifier switch

9.

This unit has built-in RIAA

10.

equalizer amplifier,so it can

11.

be connected to an amplifier

12.

without PHONO(turntable)

13.

input jack. According to the

14.

amplifier, set the EQUALIZER

15.

AMPLIFIER SWITCH.

16.

When the unit is connected

to the PHONO(MM) jacks:

ON

OFF

Setting the belt

Grasp both sides of the tape and set the belt on the

motor pulley. Once the belt is set properly, remove

the tape.

Set the belt on the motor pulley properly as shown

in the diagram.

Center spindle

L

R

PHONO

When the unit is connected

to the AUX jacks, etc:

ON

OFF

AUX

Tape

Driving roller

Belt

Tur ntable

L

R

CONNECTIONS

1. Connect the left (white) and right (red) output cords respectively to your amplifier’s PHONO jacks

etc .

2. Connect the ground wire to the amplifier’s signal ground terminal.

3. Plug the power cord into a wall outlet. (Or if the amplifier has power outlets, plug it in there, but

before doing so, read the amplifier’s manual and check that the capacity is sufficient.)

PB

AUX-2 TAPE MD

REC

12

White

SYSTEM

CONNECTOR

L

R

SPEAKER SYSTEM

SPEAKER IMPEDANCE

4 16

Output cord

SIGNAL

Ground wire

2

INPUTS

CD

DVD/AUX

L

R

GND

TUNER PHONO TAPE MD

L

R

Red

Page 3

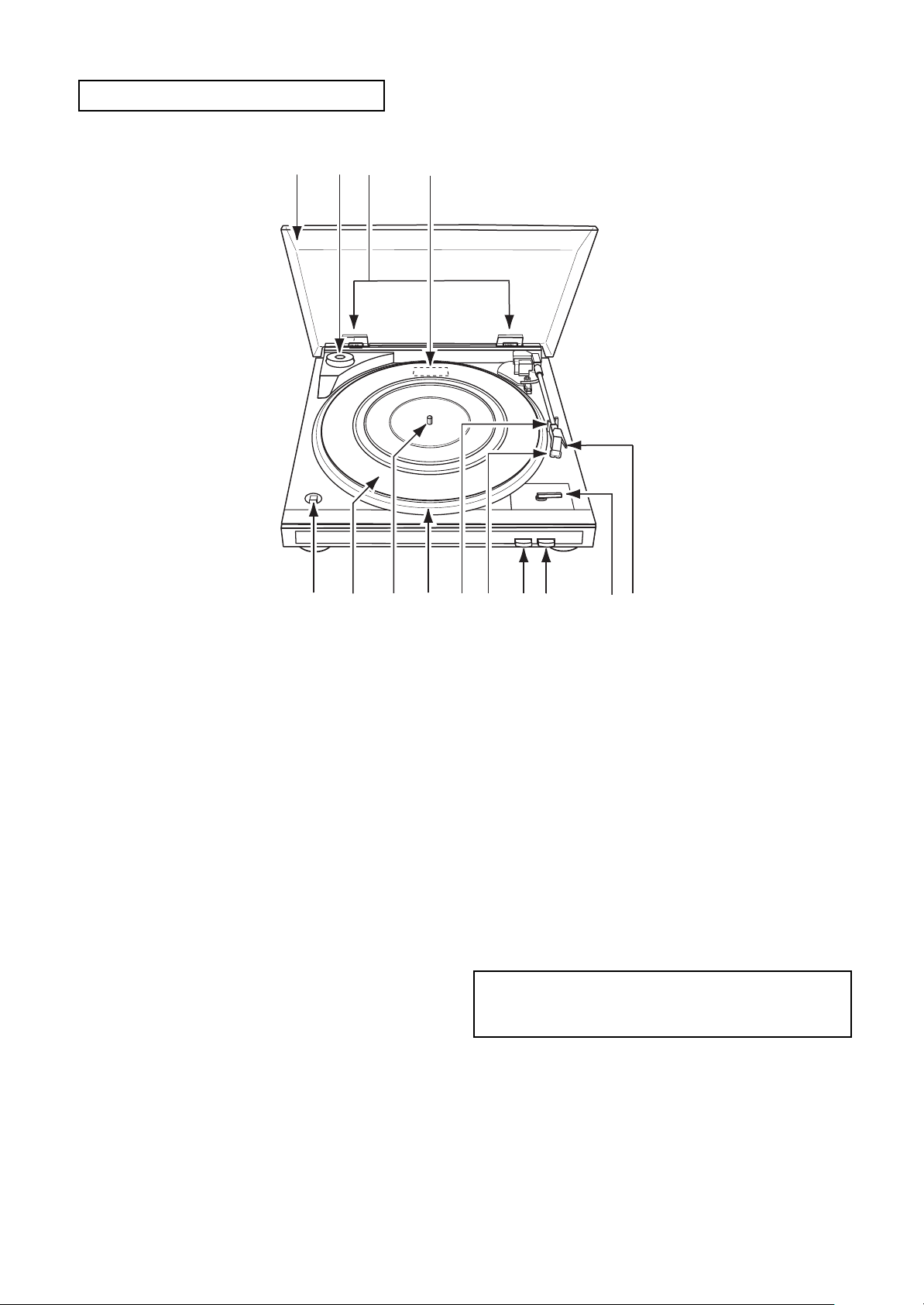

PART NAMES AND FUNCTIONS

23 4

1

14

1 Dust cover

2 45 rpm adaptor and holder

3 Dust cover hinge

4 Equalizer amplifier switch

5 Finger lever

6 Size Select Lever

Set according to the size of the record.

7 STOP Button

Press to stop playback.

8START Button

Press to start playback.

9 Cartridge

13

12

11

8

9

10

10 Tone arm rest

Holds the tone arm.

11 Platter

12 Spindle

13 Rubber mat

Place on the turntable.

14 SPEED Select Button

Set according to the record speed.

For 33 1/3 rpm: £

For 45 rpms: ¢

NOTE:

As this set is light, it may move when buttons or

knobs are operated, so do not press too

strongly.

7

5

6

3

Page 4

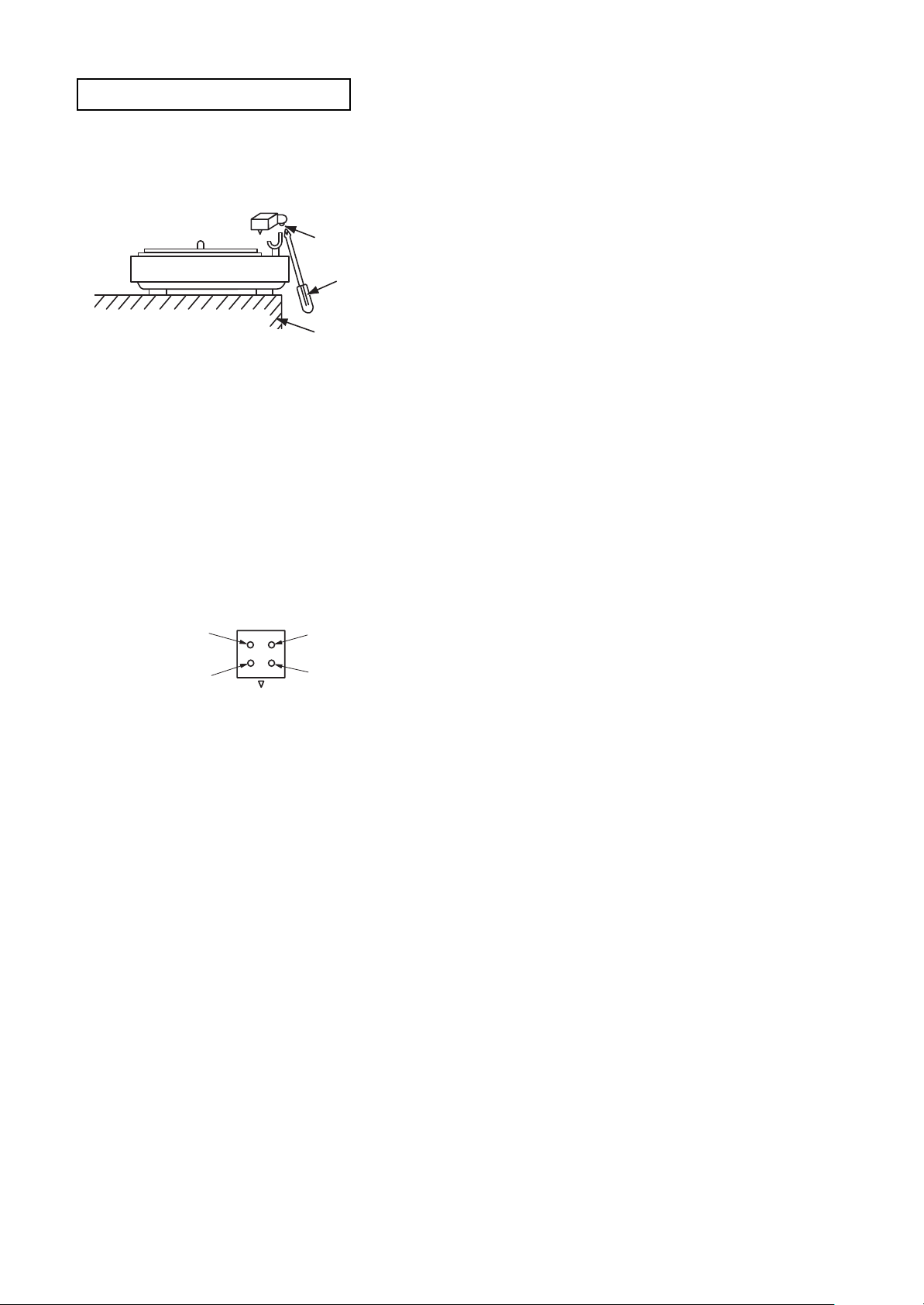

CARTRIDGE REPLACEMENT

(The cartridge forms a single body with the head shell. Use the following procedure to replace it.)

1. Remove the screw on the bottom of the head

shell sa shown in the diagram.

Screw (philips) small

Screwdriver

(philips) small

Desk, table, etc

2. Rotate the entire head shell gently in both directions.

The neck of the head shell is attached to the pipe

arm.

Turn it gently until the shell comes loose.

3. Carefully remove the head shell.

(Be careful not to break the lead wire.)

4. Remove the tip of the lead wire from the carridge terminal.

5. Install the new cartridge (with head shell).

The polarities are as shown on the diagram.

H

L

L

E

ground wire (white side)

(white)

Top

Tip side (as seen from the rear of the cartridge)

H

(Red)

R

E

ground wire (red side)

R

6. Assemble by following the removal procedure

in reverse order.

Use one drop of Cemedyne #3000 to atttach the

neck of the head shell and the pipe arm.

4

Page 5

METHOD OF ADJUSTMENT

1. Relationship between belt and pulley.

Check that the belt is not touching the collars

(A) of the motor pulley. If it is, remove the turntable and reattach the belt at the center of the

turntable skirt.

Motor pulley

Should not touch

here (A)

Belt

2. Speed adjustment

If the speed is off, adjust it with the variable

resistor on the motor control board.

Adjust for 33 r.p.m first, then set at 45 r.p.m

and check.

After adjusting, check the two speeds (33 and

45 r.p.m) once again.

This diagram shows the bottom panel.

Adj. Hole for 45 r.p.m

Adj. Hole for 33 r.p.m

Motor

Lead in

• Count increases when turned clockwise

• Count decreases when turned counterclockwise

Lead out

• Count increases when turned clockwise

• Count decreases when turned counterclockwise

This diagram shows the bottom panel.

Foot

Lead in adjust hole

Lead out adjust hole

L.IN

RET

SW

4. Stylus tip height adjustment

(1) Adjust the stylus tip height under standard

conditions.

(Standard conditions: with the turntable,

turntable sheet, and record set)

(2) The styus tip height should be adjusted to

about 6mm when returned (5-7mm at the

outermost position for 17cm records).

Foot

3. Lead in and lead out adjustment

(1) Lead in

(Test record: Hitachi HT-5 (30cm))

Check that the stylus lowers at 5 to 25

counts for both 17 cm and 30 cm records.

(2) Lead out

(Test record: Nippon Columbia EM-1001

(17cm))

Check that the pickup returns at 3 to 15

counts (3mm pitch).

If the counts are off , adjust as follows:

(a) Fasten the pickup to the arm rest.

(b) Insert a screwdriver into the lead in or lead

out adjustment holes and adjust.

Cartridge

Record

Turntable sheet

Stylus tip

Stylus tip height

Turntable

(3) If the stylus tip is too high, sound may be

distorted and the stylus may not advance.

If it is too low, it may scratch the record

when returning.

(4) Adjust using the lifter screw.

Turn clockwise to lower the stylus tip.

Turn counterclockwise to lift the stylus tip.

Adjust screw

Tip lifted when

turned this way

Tone arm

5

Page 6

NOTE FOR PARTS LIST

l Part indicated with the mark " " are not always in stock and possibly to take a long period of time for supplying, or in

some case supplying of part may be refused.

l When ordering of part, clearly indicate "1" and "I" (i) to avoid mis-supplying.

l Ordering part without stating its part number can not be supplied.

l Part indicated with the mark "H" is not illustrated in the exploded view.

l Not including Carbon Film ±5%, 1/4W Type in the P.W.Board parts list. (Refer to the Schematic Diagram for those parts.)

WARNING:WARNING:

WARNING:

WARNING:WARNING:

Parts marked with this symbol

Use ONLY replacement parts recommended by the manufacturer.

have critical characteristics.

ll

Resistors

l

ll

Ex.:RN 14K 2E 182 G FR

Type Shape Power Resist- Allowable Others

and per- ance error

formance

t

RD : Carbon 2B : 1/8W F :±1% P : Pulse-resistant type

RC : Composition 2E : 1/4W G : ±2% NL : Low noise type

RS : Metal oxide film 2H : 1/2W J :±5% NB : Non-burning type

RW : Winding 3A : 1W K : ±10% FR : Fuse-resistor

RN : Metal film 3D : 2W M :±20% F : Lead wire forming

RK : Metal mixture 3F : 3W

t

3H : 5W

t

t

] Resistance

1 8 2 ⇒ 1800 ohm = 1.8 kohm

s

s

• Units: ohm

1 R 2 ⇒ 1.2 ohm

s

s

• Units: ohm

Indicates number of zeros after effective number.

2-digit effective number.

1-digit effective number.

2-digit effective number, decimal point indicated by R.

ll

Capacitors

l

ll

Ex.:CE 04W 1H 2R2 M BP

Type Shape Dielectric Capacity Allowable Others

and per- strength error

formance

t

CE : Aluminum foil 0J : 6.3V F :±1% HS :High stability type

electrolytic

CA : Aluminum solid 1A : 10V G :±2% BP : Non-polar type

electrolytic

CS : Tantalum electrolytic 1C : 16V J :±5% HR : Ripple-resistant type

CQ : Film 1E : 25V K :±10% DL : For change and discharge

CK : Ceramic 1V : 35V M : ±20% HF : For assuring high

CC : Ceramic 1H : 50V Z : +80% U : UL part

CP : Oil 2A : 100V –20% C : CSA part

CM : Mica 2B : 125V P : +100% W : UL-CSA type

CF :Metallized 2C : 160V –0% F : Lead wire forming

CH :Metallized 2D : 200V C : ±0.25pF

t

2E : 250V D : ±0.5pF

2H : 500V = :Others

2J : 630V

t

t

frequency

] Capacity (electrolyte only)

2 2 2 ⇒ 2200µF

s

s

• Units: µF.

2 R 2 ⇒ 2.2µF

s

s

• Units: µF.

Indicates number of zeros after effective number.

2-digit effective number.

1-digit effective number.

2-digit effective number, decimal point indicated by R.

] Capacity (except electrolyte)

2 2 2 ⇒ 2200pF=0.0022µF

s

s

(More than 2) Indicates number of zeros after effective number.

• Units: µF.

2 2 1 ⇒ 220pF

s

s

(0 or 1) Indicates number of zeros after effective number.

• Units: pF.

• When the dielectric strength is indicated in AC, "AC" is included after the dieelectric

strength value.

2-digit effective number.

2-digit effective number.

6

Page 7

PARTS LIST OF EXPLODED

Ref. No.. Part No. Part Name Remarks Q'ty

1 941 0001 001 45 r.p.m. Adapter 1

2 941 0001 108 Strain Relief 1

3 941 0001 205 Dust Cover 1

5 941 0001 328 Bottom Cover for E3 1

5 941 0001 315 Bottom Cover for E2 1

6 941 0001 409 Knob for E3 2

6 941 0001 412 Knob for E2 2

7 941 0001 519 Rating Label for E3 1

7 941 0001 522 Rating Label for E2 1

8 941 0001 603 Pendulum (L) 1

9 941 0001 700 Pendulum (M) 1

10 941 0001 807 Select Record Knob for E3 1

10 941 0001 810 Select Record Knob for E2 1

11 941 0001 904 Serial No. Label 1

12 941 0002 000 Lifter 1

13 941 0002 107 Fixing Switch Set 1

14 941 0002 204 Pendulum (S) 1

15 941 0002 301 Shaft Holder 1

16 941 0002 408 Speed Bracket Ass'y 1

17 941 0002 505 Speed Support 1

19 941 0002 602 Selector 1

20 941 0002 709 Hinge Ass'y 1

21 941 0002 806 Select Plate 1

23 941 0002 903 Turntable 1

25 941 0003 009 Tonearm Shaft Set 1

27 941 0003 106 Locus Shaft 1

28 941 0003 203 Shaft 1

29 941 0003 300 Shaft 1

30 941 0003 407 Shaft 1

31 941 0003 504 Copper Washer 2

32 941 0003 601 Control Plate 1

36 941 0003 708 Cartridge 1

36-1 941 0003 805 Stylus Cover 1

36-2 DSN 82 Stylus 1

37 941 0003 902 Caution Label 1

38 941 0004 008 Washer 1

39 941 0004 105 Switch and Set Ass'y 1

40 941 0004 202 IC. P.W.B. Ass'y 1

41 941 0004 309 Micro Switch and Wire Ass'y 1

42 941 0004 406 Screw 1

43 941 0004 503 Screw 1

44 941 0004 707 AC Power Cord for E3 1

!

44 941 0004 804 AC Power Cord for E2 1

!

45 941 0004 901 Insulator 1

46 941 0005 104 Transformer for E3 1

!

46 941 0005 201 Transformer for E2 1

!

47 941 0005 308 Rectifyer P.W.B. Ass'y 1

49 941 0005 405 Screw 2

50 941 0005 502 Square Knob for E3 1

50 941 0005 515 Square Knob for E2 1

51 941 0005 609 Nut 1

52 941 0005 706 Nut 1

53 941 0005 803 Nut 1

54 941 0005 900 Screw 5

55 941 0006 006 Screw 5

57 941 0006 103 Screw 6

58 941 0006 200 Screw 1

59 941 0006 307 Screw 1

60 941 0006 404 Screw 4

62 941 0006 501 Screw 2

63 941 0006 608 Screw 1

64 941 0006 705 Screw 1

7

Page 8

Ref. No.. Part No. Part Name Remarks Q'ty

65 941 0006 802 Screw 4

66 941 0006 909 Screw 2

67 941 0007 005 Screw 1

68 941 0007 102 Screw 1

69 941 0007 209 Spring 1

70 941 0007 306 Spring 1

71 941 0007 403 Spring (SUS,304, WP8) 1

72 941 0007 500 Spring (SUS,304, WP8) 1

73 941 0007 607 Spring (SUS,304, WP8) 1

74 941 0007 704 Spring 1

75 941 0007 801 Play Spring 1

76 941 0007 908 Stop Spring 1

77 941 0008 004 Spring 1

78 941 0008 101 Spring(Play,Stop Knob) 2

79 941 0008 208 Spring 1

80 941 0008 305 Spring 1

81 941 0008 402 Spring 1

82 941 0008 509 Rubber (S.B.R) 2

83 941 0008 606 Slipmat Packing Ass'y 1

84 941 0008 703 Rubber 4

85 941 0008 800 Belt 1

86 941 0008 907 Rubber Foot for Motor 3

87 941 0009 003 Rubber Cap 1

88 941 0009 100 Washer 1

89 941 0009 207 E-Ring(3mm) 4

90 941 0009 304 E-Ring(5mm) 2

91 941 0009 401 CS Washer (3mm) 3

92 941 0009 508 Washer 1

93 941 0009 605 E-Ring(2mm) 1

94 941 0009 702 Washer 1

95 941 0009 809 Washer 1

96 941 0010 005 Washer 1

97 941 0010 102 Washer 1

98 941 0010 209 Washer 2

99 941 0010 306 Washer 1

103 941 0010 403 Foot (ABS) 2

108 941 0010 500 Return Link Ass'y 1

111 941 0010 607 Cueing Lever Ass'y 1

113 941 0010 704 Hinge Ass'y 1

118 941 0014 302 Signal Wire 1

151 941 0012 113 Chassis for E2 1

151 941 0012 126 Chassis for E3 1

152 941 0012 207 Tone Arm Ass'y for E3 1

152 941 0012 210 Tone Arm Ass'y for E2 1

153 941 0012 304 Center & Pinion Ass'y 1

154 941 0012 401 Cam Gear Ass'y 1

155 941 0012 508 Motor Ass'y 1

8

Page 9

PARTS LIST OF P.W.B. UNIT

I.C. P.W.B. ASS'Y

Ref. No. Part No. Part Name Remarks Q'ty

40 941 0004 202 I.C. P.W.B. ASS'Y 1

SW101 941 0014 001 Slide Sw(SBB-22-14) 1

- Elec. Capacitor(4.7uF/50V,M,Bulk 5*11) 1

IC101 958 0049 702 IC(UPC1228HA,8pin) 1

C108,208 - Ceramic Capacitor(1000pF/50V K Y5P Taping) 2

C102,107 - Elec. Capacitor(4.7uF/50V,M,Taping 5*11) 2

C202,207 - Elec. Capacitor(4.7uF/50V,M,Taping 5*11) 2

C104,204 - Elec. Capacitor(10uF/25V,M,Taping 5*11) 2

C105,205 - Mylar Capacitor(0.01uF J 50V Taping) 2

C101,103 958 0021 306 Ceramic Capacitor(100pF/50V K SL Taping) 2

C201,203 958 0021 306 Ceramic Capacitor(100pF/50V K SL Taping) 2

C106,206 - Mylar Capacitor(0.0027uF Taping) 2

C301,302 - Elec. Capacitor(100uF/16V,M,Taping 6.3*11) 2

R107,207 - Carbon Film Resistor(100K Ohm J 1/6W Taping 26mm) 2

R105,205 - Carbon Film Resistor(27K Ohm J 1/6W Taping 26mm) 2

R101,103 - Carbon Film Resistor(470 Ohm J 1/6W Taping 26mm) 2

R201,203 - Carbon Film Resistor(470 Ohm J 1/6W Taping 26mm) 2

R102,202 - Carbon Film Resistor(47K Ohm J 1/6W Taping 26mm) 2

R106,108 - Carbon Film Resistor(1K Ohm J 1/6W Taping 26mm) 2

R206,208 - Carbon Film Resistor(1K Ohm J 1/6W Taping 26mm) 2

R104,204 - Carbon Film Resistor(390K Ohm J 1/6W Taping 26mm) 2

R301 - Carbon Film Resistor(120 Ohm J 1/4W Taping 26mm) 1

RECTIFYER P.W.B. ASS'Y

Ref. No. Part No. Part Name Remarks Q'ty

47 941 0005 308 Rectifyer P.W.B. Ass'y 1

C1 254 4254 080 Elec. Capacitor(1000uF/16V,M,Bulk 13*21) 1

D1~D4 941 0013 002 Diode(1N4002,1A/100V,Bulk) 4

MICRO SWITCH AND WIRE ASS'Y

Ref. No. Part No. Part Name Remarks Q'ty

41 941 0004 309 Micro Switch and Wire Ass'y 1

SW101 941 0014 205 Push Sw(SPEA12MC06-HF) 1

9

Page 10

WARNING:

Parts marked with this symbol have critical

characteristics.

Use ONLY replacement parts recommended by the

manufacturer.

10

The symbols above indicate the

following destinations.

E3 : U.S.A.&Canada model

E2 : Europe model

Page 11

PA CKING & ACCESSORIES

201

202

208

209

205

203

206

207

PARTS LIST OF PACKING & ACCESSORIES (not included EXPLODED VIEW)

Ref. No. Part No. Part Name Remarks Q'ty

201 941 0008 606 Slipmat Packing Ass'y 1

202 941 0011 114 Envelope sub Ass'y for E3 1

202 941 0011 127 Envelope sub Ass'y for E2 1

511 3872 007 Inst. Manual for E3 1

511 3872 007 Inst. Manual for E2 1

511 3865 001 Inst. Manual for E2 1

203 941 0011 224 Carton Case 1

205 941 0011 305 Cushion(L) 1

206 941 0011 402 Cushion(R) 1

207 941 0002 903 Turntable 1

208 941 0001 205 Dust Cover Ass'y 3+82 1

209 941 0011 509 Poly Cover for Main 1

11

Page 12

SCHEMATIC DIAGRAM

I.C. P.W.B. ASS'Y

WIRING DIAGRAM

GND

Tone Arm

BLK

WHT

WHT

RED

(L)

GND

PHONO

RED

(R)

GND

BRN

BRN

YEL

YEL

RECTIFYER P.W.B. ASS'Y

AC 120V

AC 230V

AC Cord

60Hz (U.S.A. & Canada)

50Hz (Europe)

POWER TRANS

BLK

Leaf Switch

RED

WHT

Leaf Switch

RED

RED

Fix to turn table

Shaft Earth

BLK

Phono Motor

12

BLK

WHT

RED

YEL

Speed Changable Switch

£33 ¢45

Loading...

Loading...