Page 1

e

SERVICE MANUAL

MODEL JP E3 E2 EK K2A E1C E1K EUT

Ver. 1

DP-200USB

FULL AUTOMATIC TURNTABLE SYSTEM

P P

For purposes of improvement, specications and design are subject to change without notice.

●

Please use this service manual with referring to the operating instructions without fail.

●

Some illustrations using in this service manual are slightly different from the actual set.

●

e

Denon Brand Company, D&M Holdings Inc.

X0392 V.01 DE/CDM 0811

Page 2

SAFETY PRECAUTIONS

The following check should be performed for the continued protection of the customer and service technician.

LEAKAGE CURRENT CHECK

Before returning the unit to the customer, make sure you make either (1) a leakage current check or (2) a line to chassis

resistance check. if the leakage current exceeds 0.5 milliamps, or if the resistance from chassis to either side of the power

cord is less than 460 kohms, the unit is defective.

CAUTION

Heed the cautions!

◎

Spots requiring particular attention when servicing, such

as the cabinet, parts, chassis,etc., have cautions indicated

on labels. be sure to heed these causions and the cautions

indicated in the handling instructions.

Caution concerning electric shock!

◎

(1) An AC voltage is impressed on this set, so touching

internal metal parts when the set is energized could

ca use e lectric shock. Take car e to avoid elect ric

shock, by for example using an isolating transformer

and gloves when servicing while the set is energized,

unplugging the power cord when replacing parts, etc.

(2) Tere are high voltage parts inside. Handle with extra

care when the set is energized.

Caution concerning disassembly and

◎

Please heed he points listed below during servicing and inspection.

assembly!

Through great care is taken when manufacturing parts

from sheet metal, there may in some rare cases be burrs

on the edges of parts which could cause injury if ngers

are moved across them. Use gloves to protect your hands.

Only use designated parts!

◎

Th e s et's parts hav e s pec ifi c safety properties (fi re

resistance, voltage resistance, etc.). For replacement parts,

be sure to use parts which have the same poroperties. In

particular, for the important safety parts that are marked

on wiring diagrams and parts lists, be sure to use the

z

designated parts.

Be sure to mount parts and arrange the wires

◎

as they were originally!

For safety seasons, some parts use tape, tubes or other

insulating materials, and some parts are mounted away

from the surface of printed circuit boards. Care is also

taken with the positions of the wores omsode amd clamps

are used to keep wires away from heating and high voltage

parts, so be sure to set everything back as it was originally.

Inspect for safety after servicing!

◎

Ch eck that all scr ews , pa rts and wir es r emo ved or

disconnected for servicing have been put back in their

original positions, inspect that no parts around the area that

has been serviced have been negatively affected, conduct

an inslation check on the external metal connectors and

between the blades of the power plug, and otherwise

check that safety is ensured.

(Insulation check procedure)

Unplug the power cord from the power outlet, disconnect

the antenna, plugs, etc., and turn the power switch on.

Using a 500V insulation resistance tester, check that the

inplug and the externally exposed metal parts (antenna

terminal, headphones terminal, input terminal, etc.) is

1MΩ or greater. If it is less, the set must be inspected and

repaired.

CAUTION

Concerning important safety

parts

Many of the electric and structural parts used in the set

have sp ecial safe ty properties. In most cases thes e

properties are difficult to distinguish by sight, and using

replacement parts with higher ratings (rated power and

withstand voltage) does not necessarily guarantee that

safety performance will be poreserved. Parts with safety

properties are indicated as shown below on the wiring

diagrams and parts lists is this service manual. Be sure to

replace them with parts with the designated part number.

(1) Schematic diagrams ...... Indicated by the z mark.

(2) Parts lists ...... Indicated by the z mark.

Using parts other than the designated

parts could result in electric shock, res

or other dangerous situations.

2

DP-200USB

Page 3

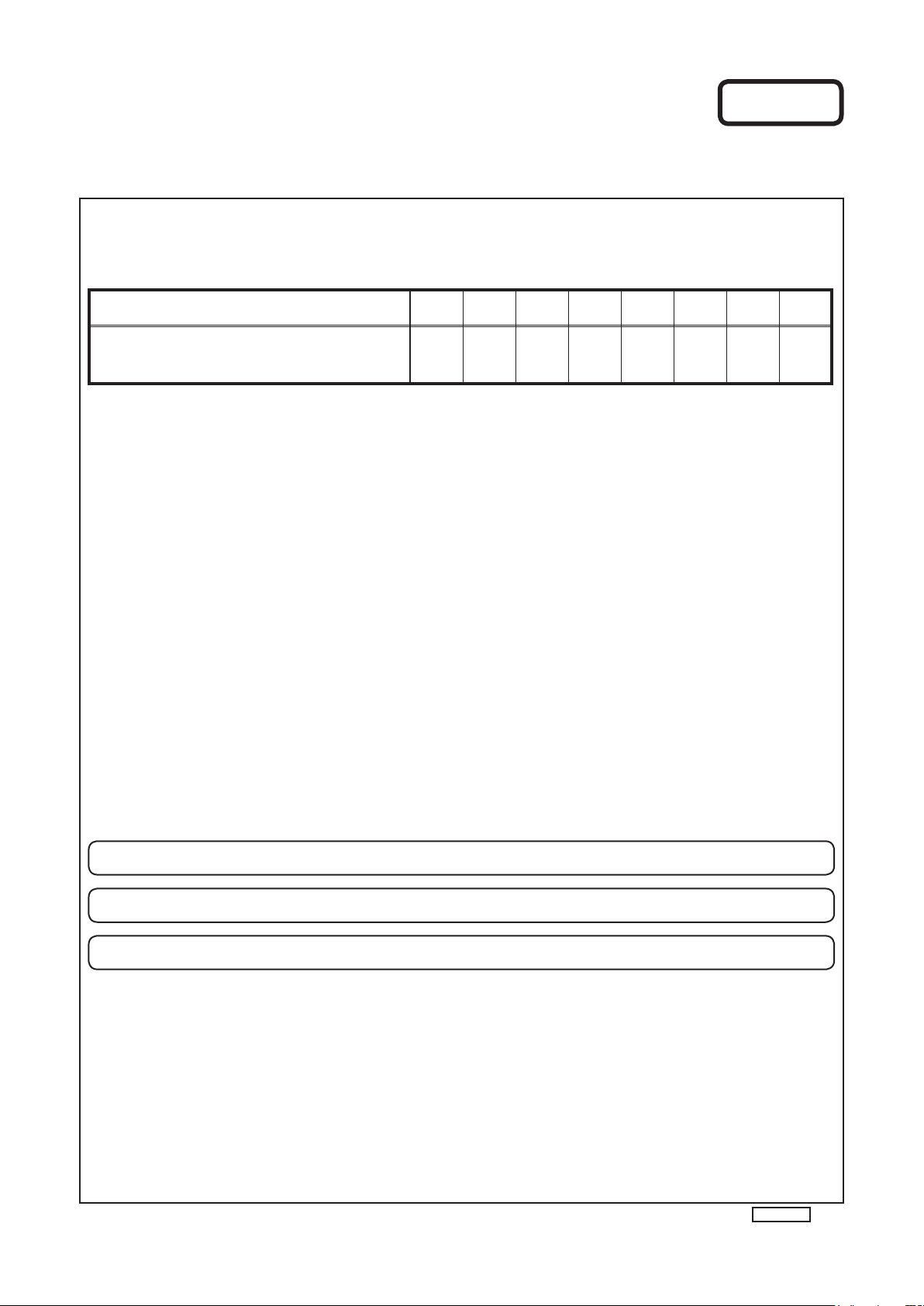

DIMENSION

3

DP-200USB

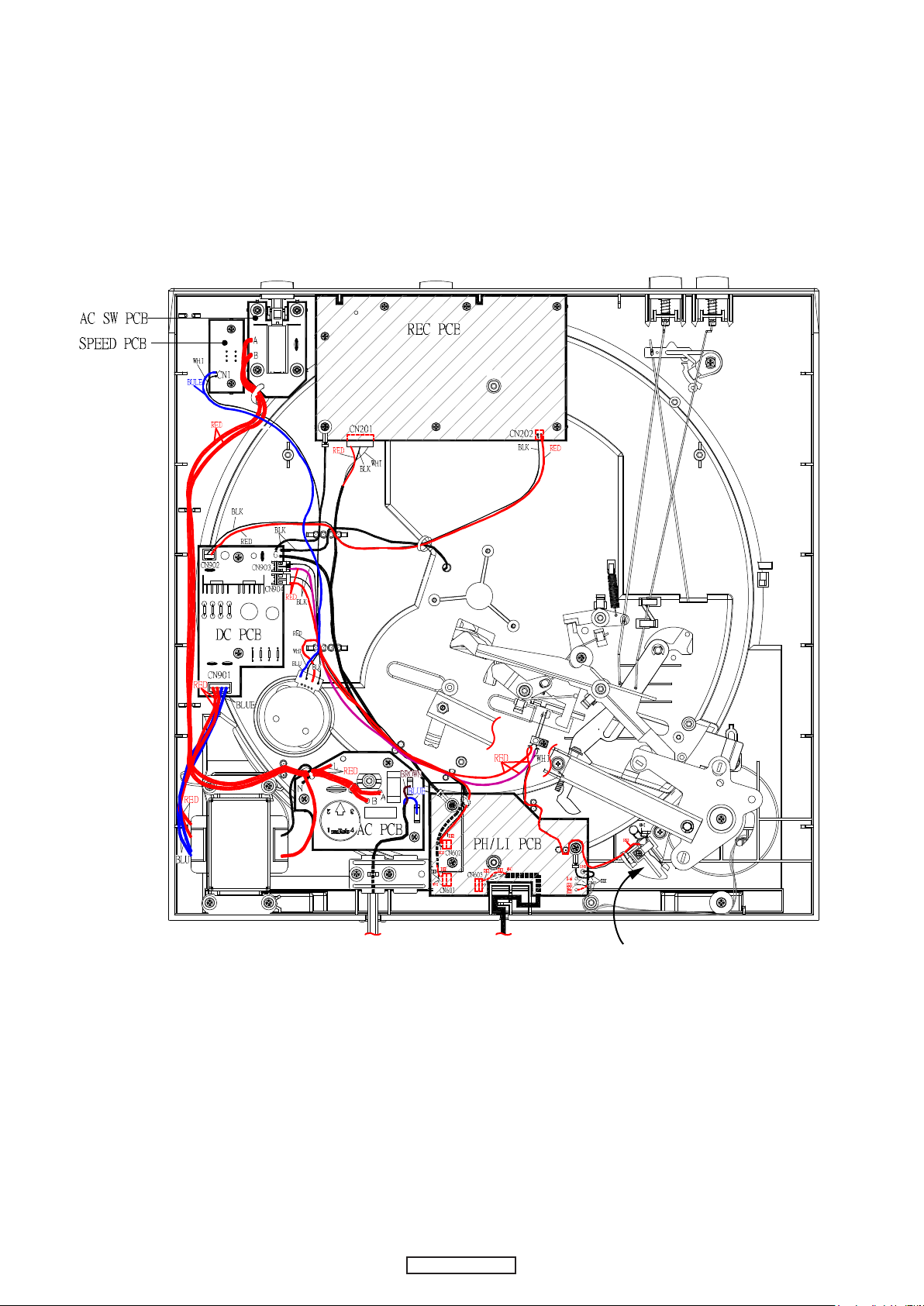

Page 4

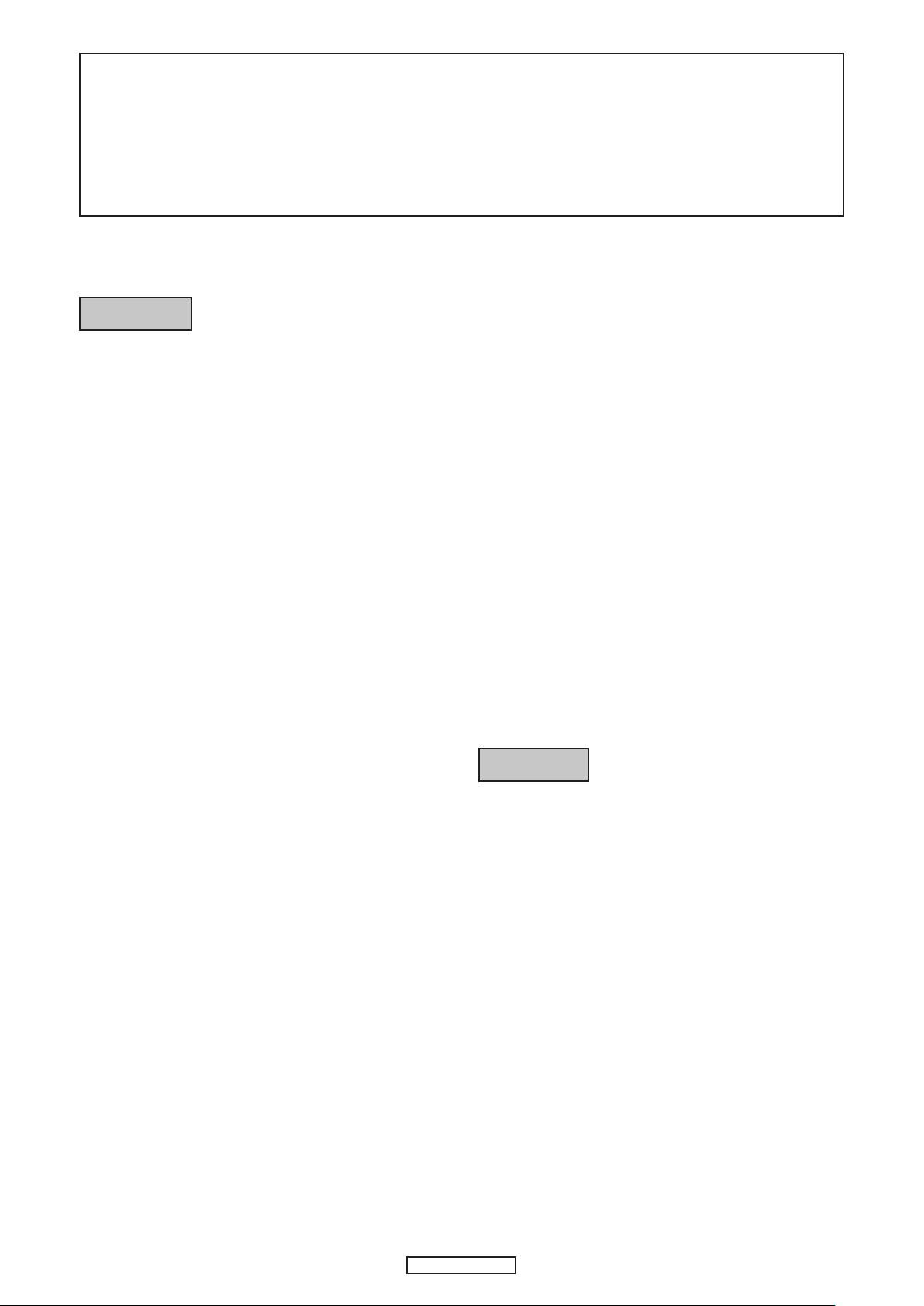

WIRE ARRANGEMENT

SW1

Leaf

SW

Leaf SWSgnal wireAC cord

4

DP-200USB

Page 5

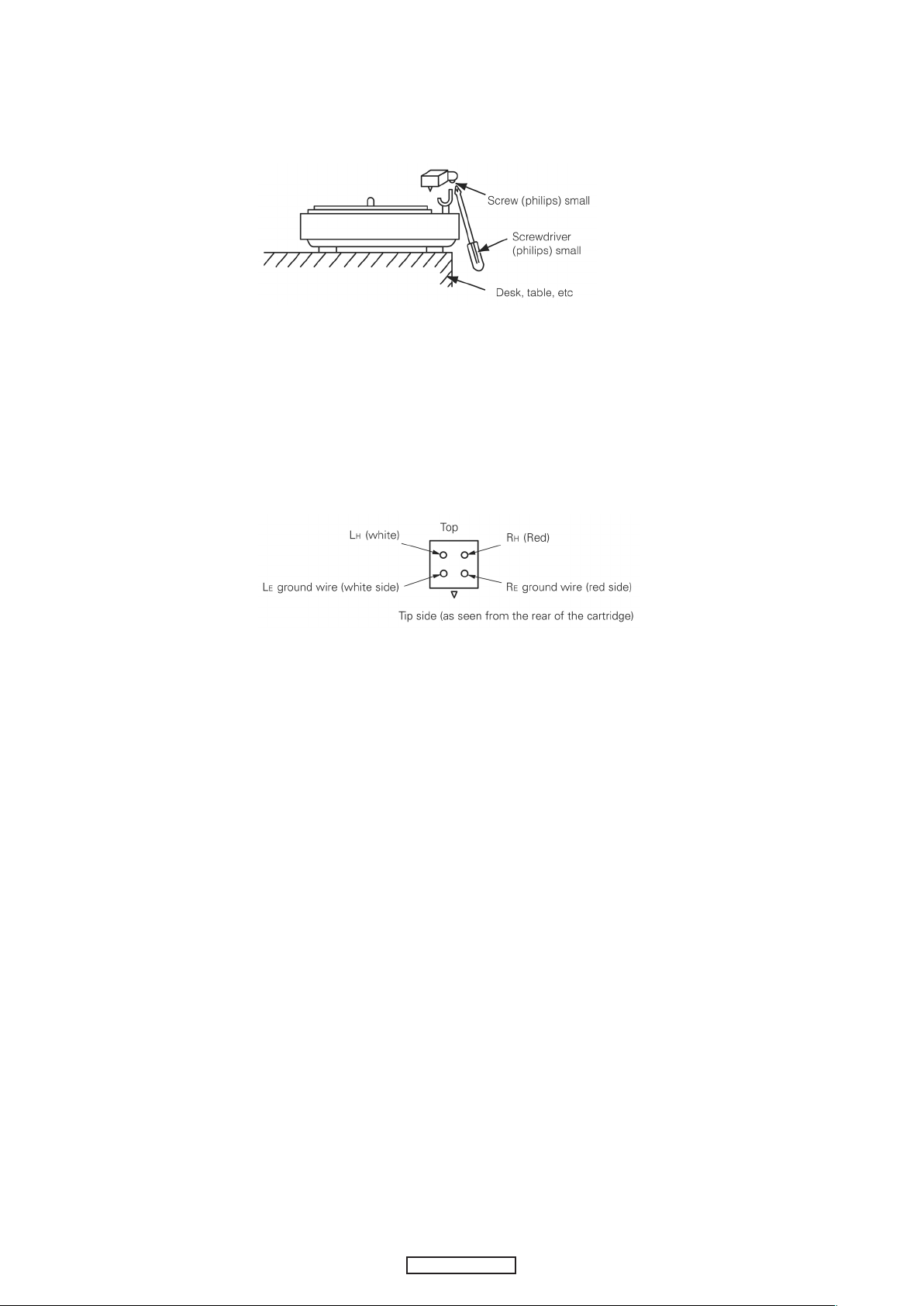

CARTRIDGE REPLACEMENT

(The cartrige forms a single body with the head shell. Use the following procedure to replace it.)

1.Remove the screw on the bottom of the head shell as shown in the diagram.

2. Rotate the entire head shell gently in both directions.

The neck of the head shell is attached to the pipe arm.

Turn it gently until the shell comes loose.

3. Carefully remove the head shell.

(Be careful not to break the lead wire.)

4. Remove the tip of the lead wire from the carridge terminal.

5. Install the new cartridge (with head shell).

The polarities are as shown on the diagram.

6. Assemble by following the removal procedure in reverse order.

Use one drop of Cemedyne #3000 to attach the neck of the head shell and the pipe arm.

5

DP-200USB

Page 6

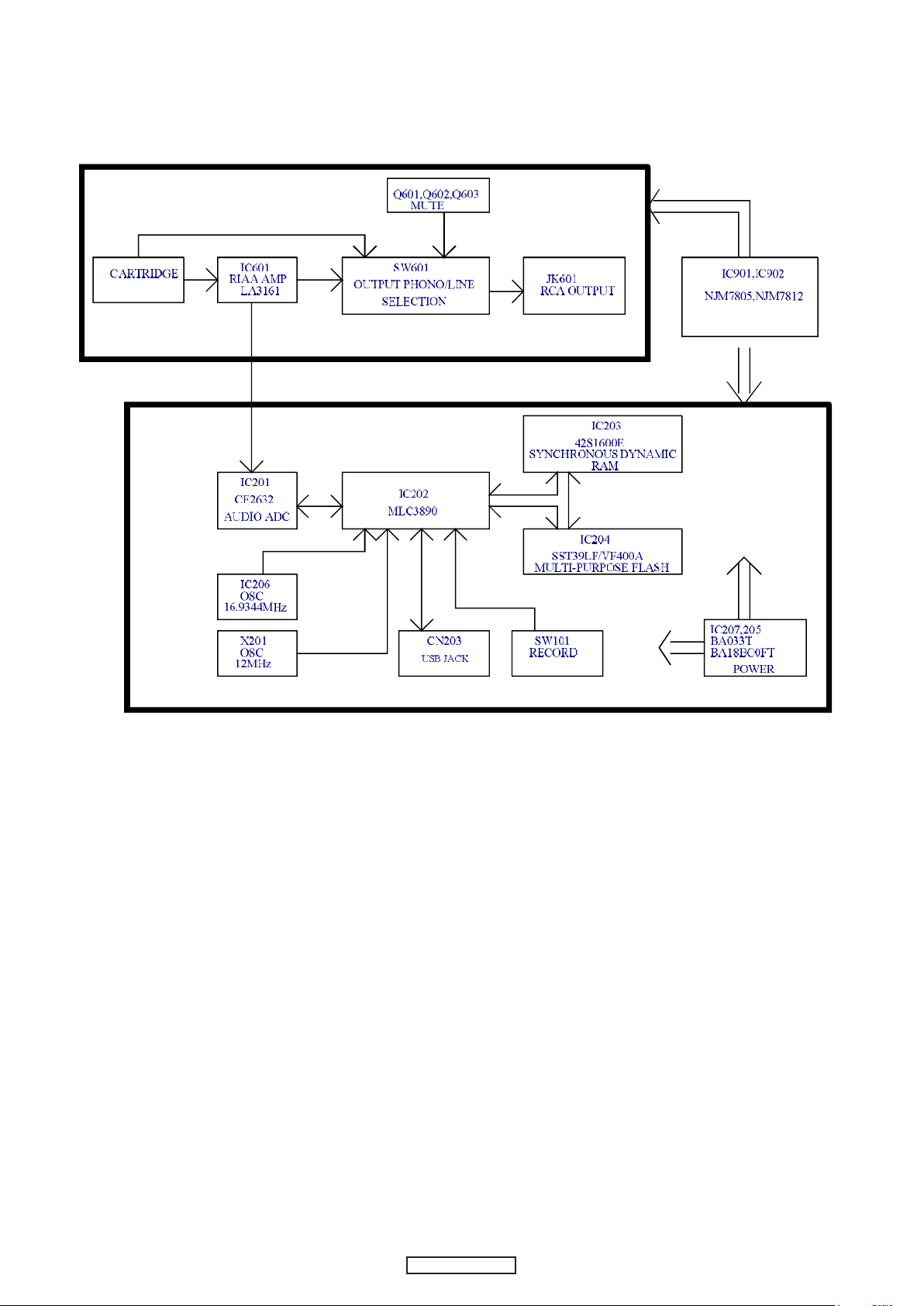

BLOCK DIAGRAMS

6

DP-200USB

Page 7

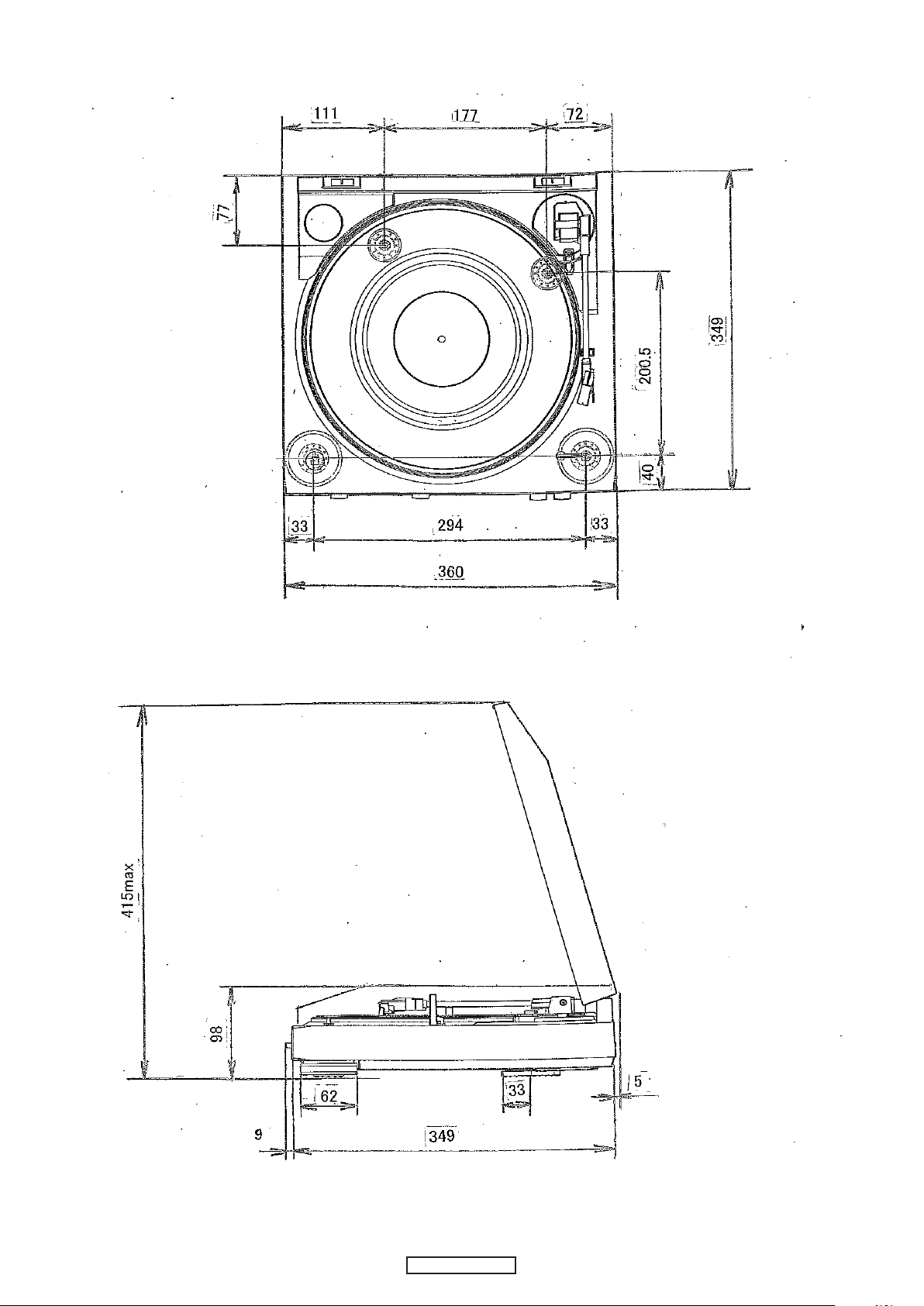

METHOD OF ADJUSTMENT

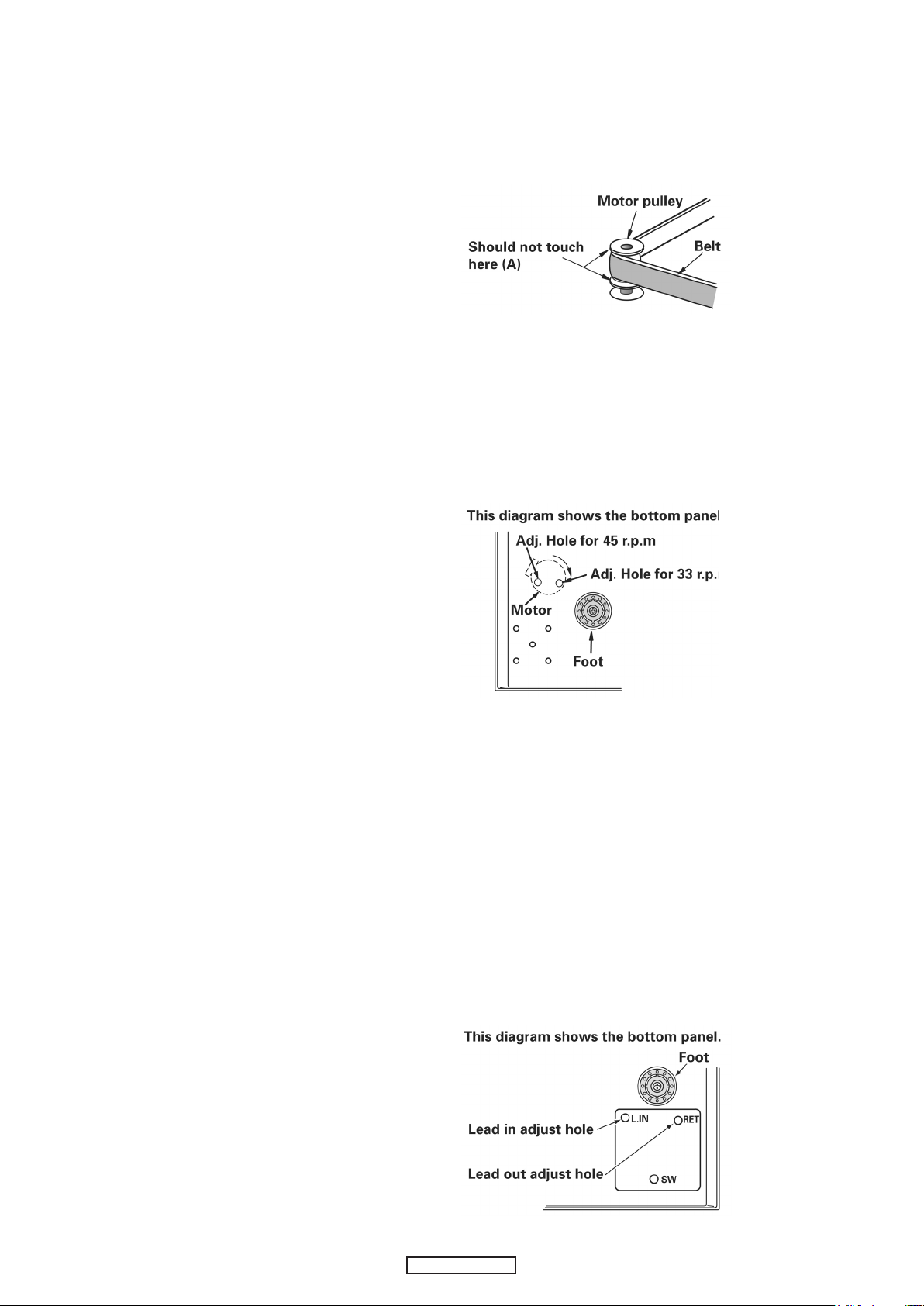

1.Relationship between belt and pulley.

Check that the belt is not touching the collars (A) of the motor

pulley. If it is, remove the turntable and reattach the belt at the

center of the turntable skirt.

2.Speed adjustment

If the speed is off, adjust it with the variable resistor on the

motor control board.

Adjust for 33 r.p.m rst, then set at 45 r.p.m and check.

After adjusting, check the two speeds (33 and 45 r.p.m) once

again.

3.Lead in and lead out adjustment

(1) Lead in

(test record: Hitachi HT-5 (30cm))

Check that the stylus lowers at 5 to 25 counts for both 17cm and 30 cm

records.

(2) Lead out

(Test record: Nippon Columbia EM-1001 (17cm))

Check that the pickup returns at 3 to 15 counts (3mm pitch).

If the counts are off, adjust as follows:

(a) Fasten the pickup to the arm rest.

(b) Insert a scrwedriver into the lead in or lead out adjustment holes and

adjust.

Lead in

Count increases when turned clockwise

・

Count decreases when turned counterclockwise

・

Lead out

Count increases when turned clockwise

・

Count decreases when turned counterclockwise

・

7

DP-200USB

Page 8

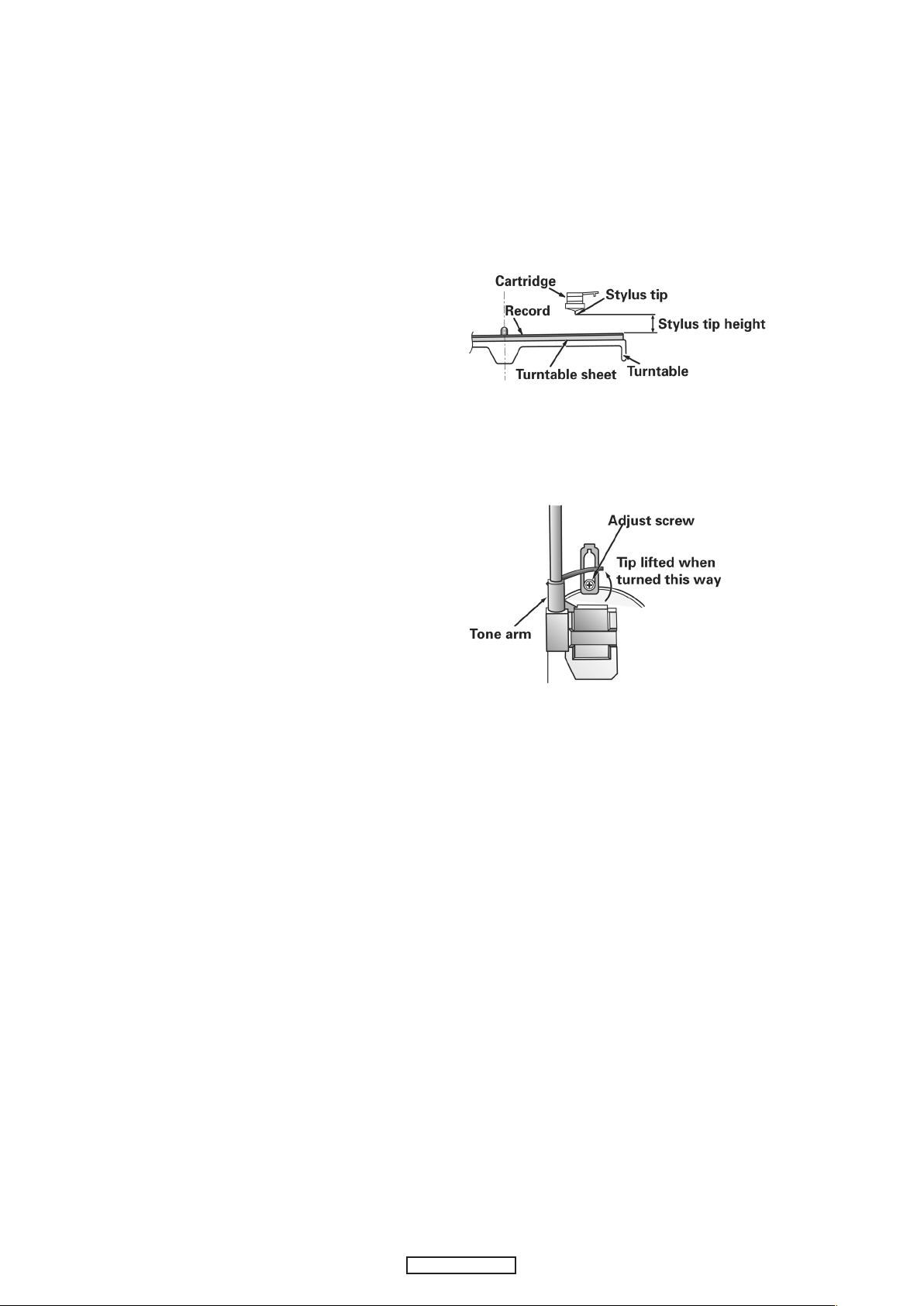

4.Stylus tip height adjustment

(1) Adjust the stylus tip height under standard conditions.

(Standard conditions: with the turntable, turntable sheet,

and record set)

(2) The stylus tip theight should be adjusted to about 6mm

when returned (5-7mm at the outermost position for 17cm

records).

(3) If the stylus tip is too high, sound may be distorted and the

stylus may not advance.

If it is too low, it may scratch the record when returning.

(4) Adjust using the lifter screw.

Turn clockwise to lower the stylus tip.

・

Turn counterclockwise to lift the stylus tip.

・

8

DP-200USB

Page 9

SEMICONDUCTORS

AD5/EAD533AD6/EAD634AD7/EAD735AD8/EAD836AD9/EAD9

37

AD10/EAD1038AD11/EAD1139AD12/EAD12

40

BA0/EAD1341BA1/EAD14

42

LDQM/EAD15

43

UDQM/EAD1 6

44

SDSCN

45

VDD

46

VSS

47

CKE

48

RASN

49

IOVDD

50

IOVSS

51

SDCLK

52

CASN

53

WEN

54

EAD17/GP34

55

EAD18/GP35

56

EAD19/GP36

57

EAD20/GP37

58

EWEN

59

EOEN/GP38

60

ECSN

61

XI16EN/SPIDI

62

GP0163GP02

64

GP2797SCOR/GP2898BCLK/GP2999DATA/GP30

100

LRCK/GP31

101

SBDT/GP32

102

SBCK/GP33

103

GP23

104

VDD

105

VSS

106

NTRST

107

RESETN

108

IOVSS

109

XTI

110

XTO

111

TEST

112XI113XO114

IOVDD

115

USBD+

116

USBD-

117

IOVSS

118

PLL2VSS

119

FILTER2

120

PLL2VDD

121

PLL1VSS

122

FILTER1

123

PLL1VDD

124

ADIN5

125

ADIN4

126

ADIN3

127

ADIN2

128

Only major semiconductors are shown, general semiconductors etc. are omitted to list.

The semiconductor which described a detailed drawing in a schematic diagram are omitted to list.

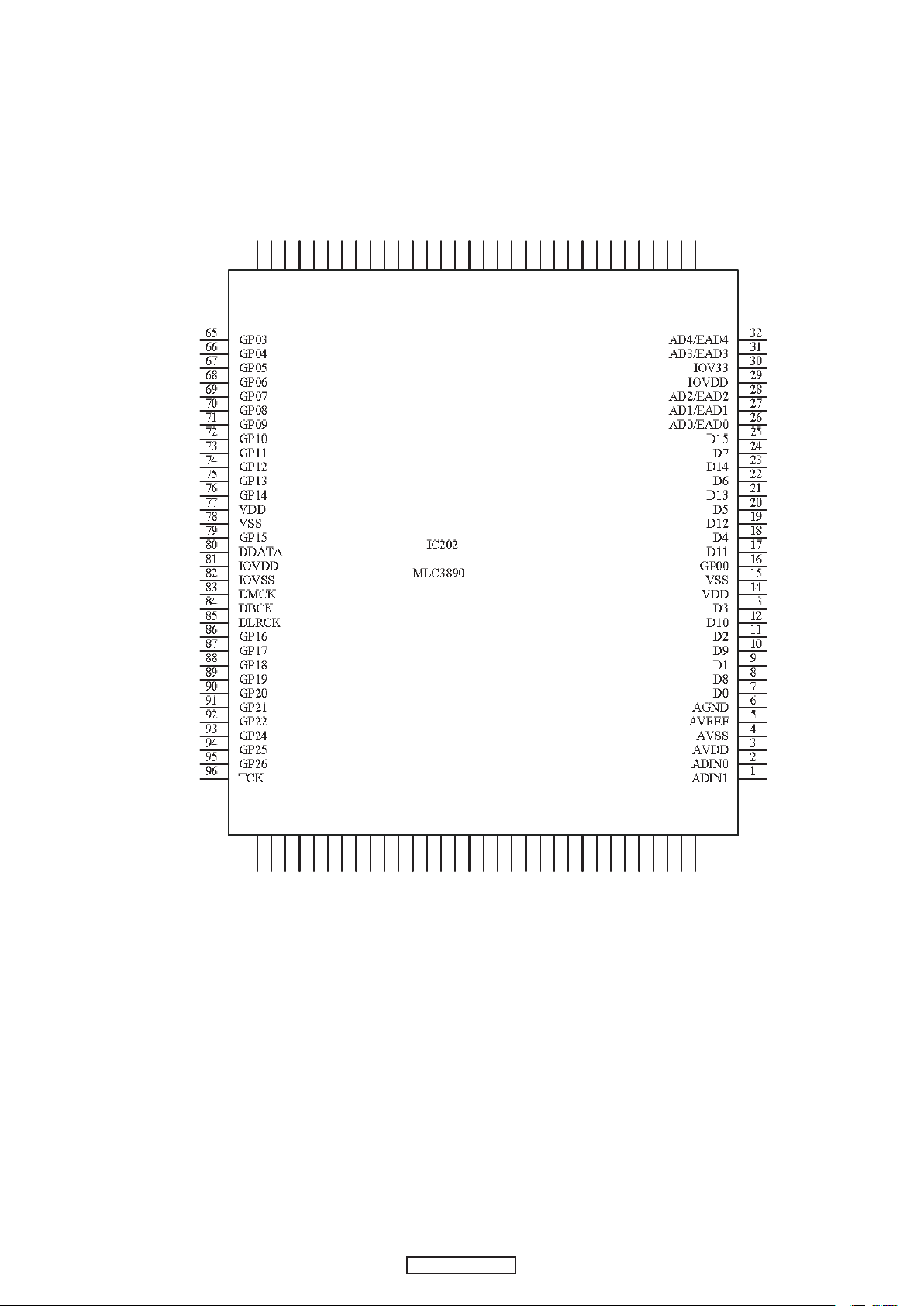

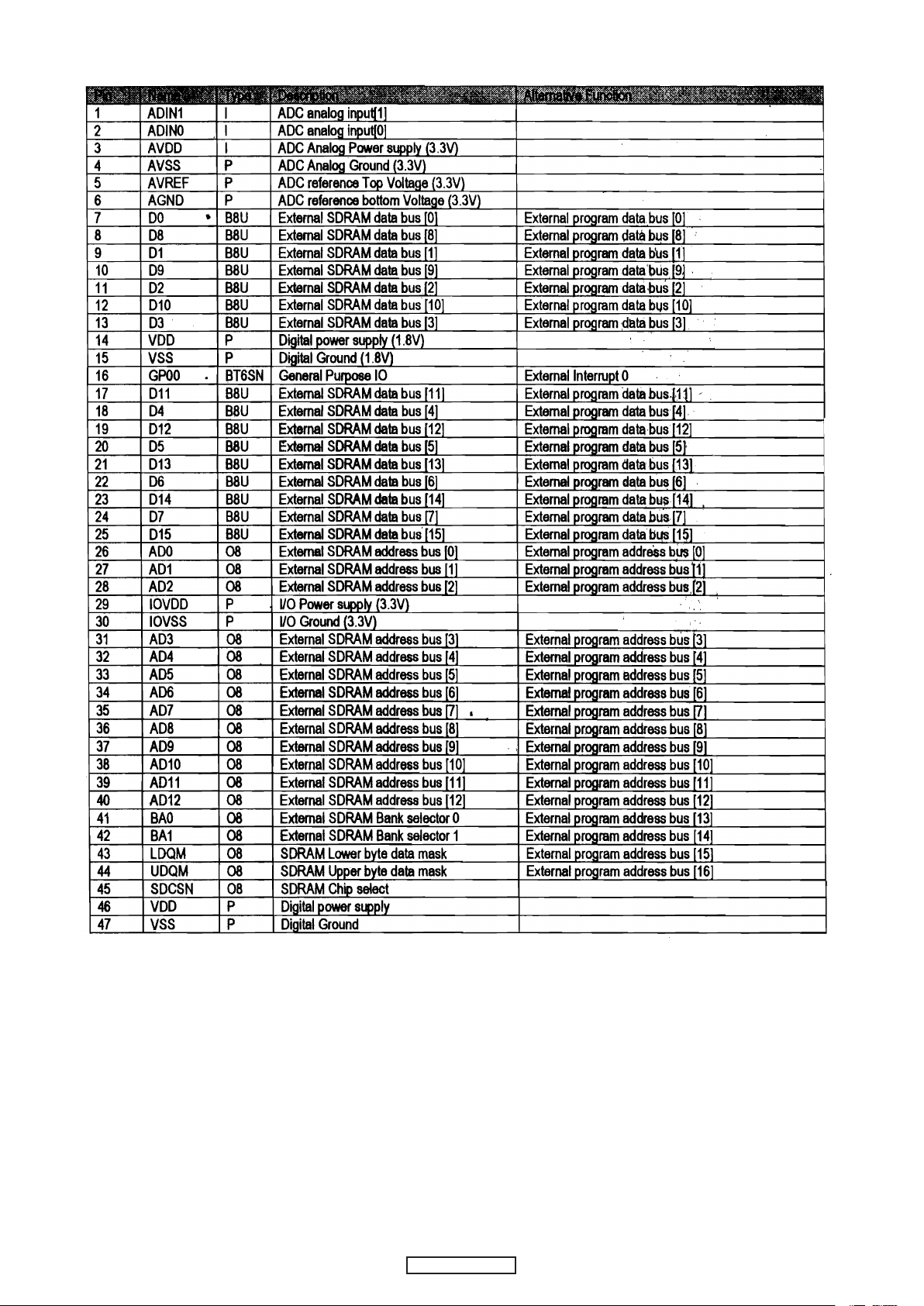

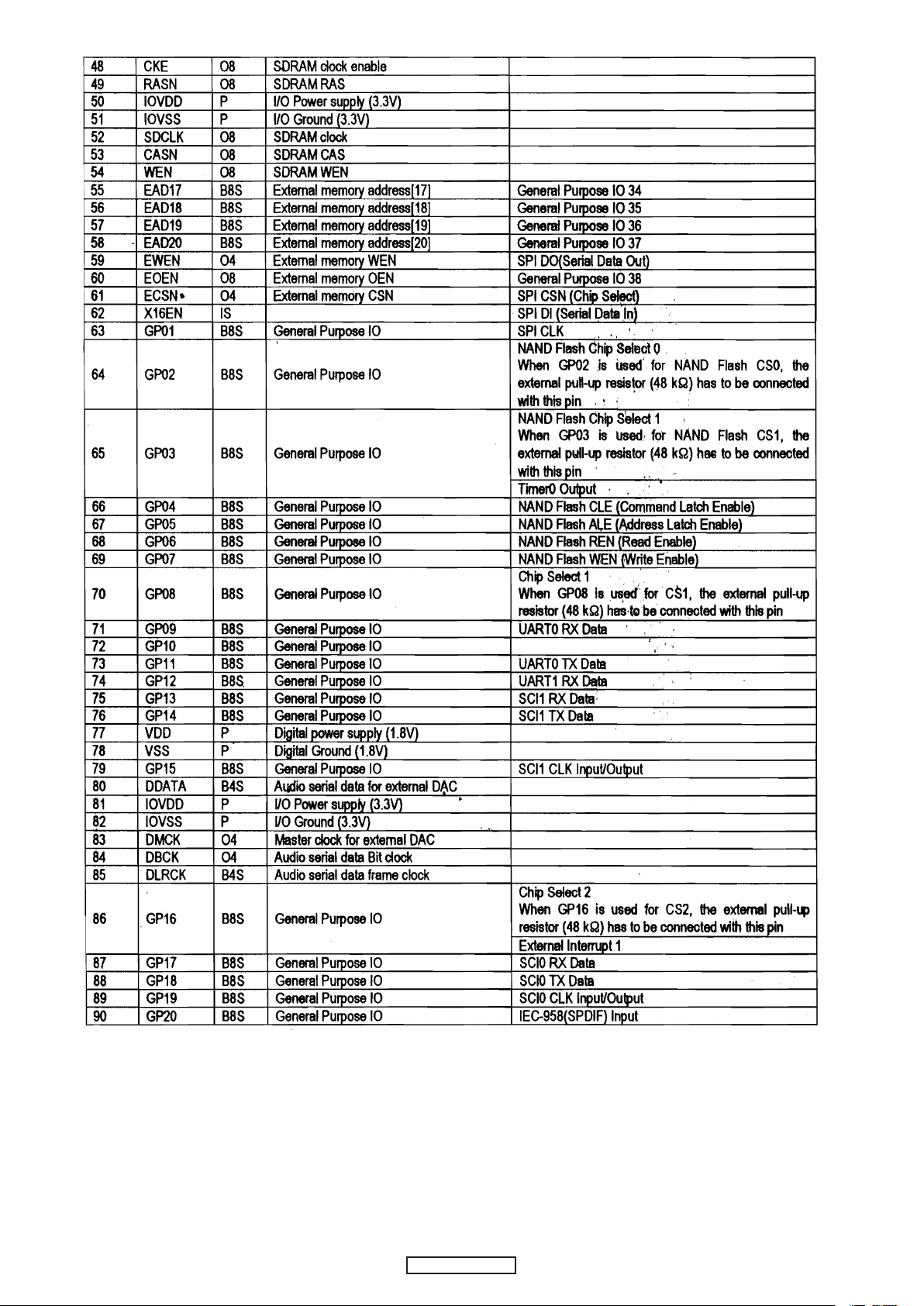

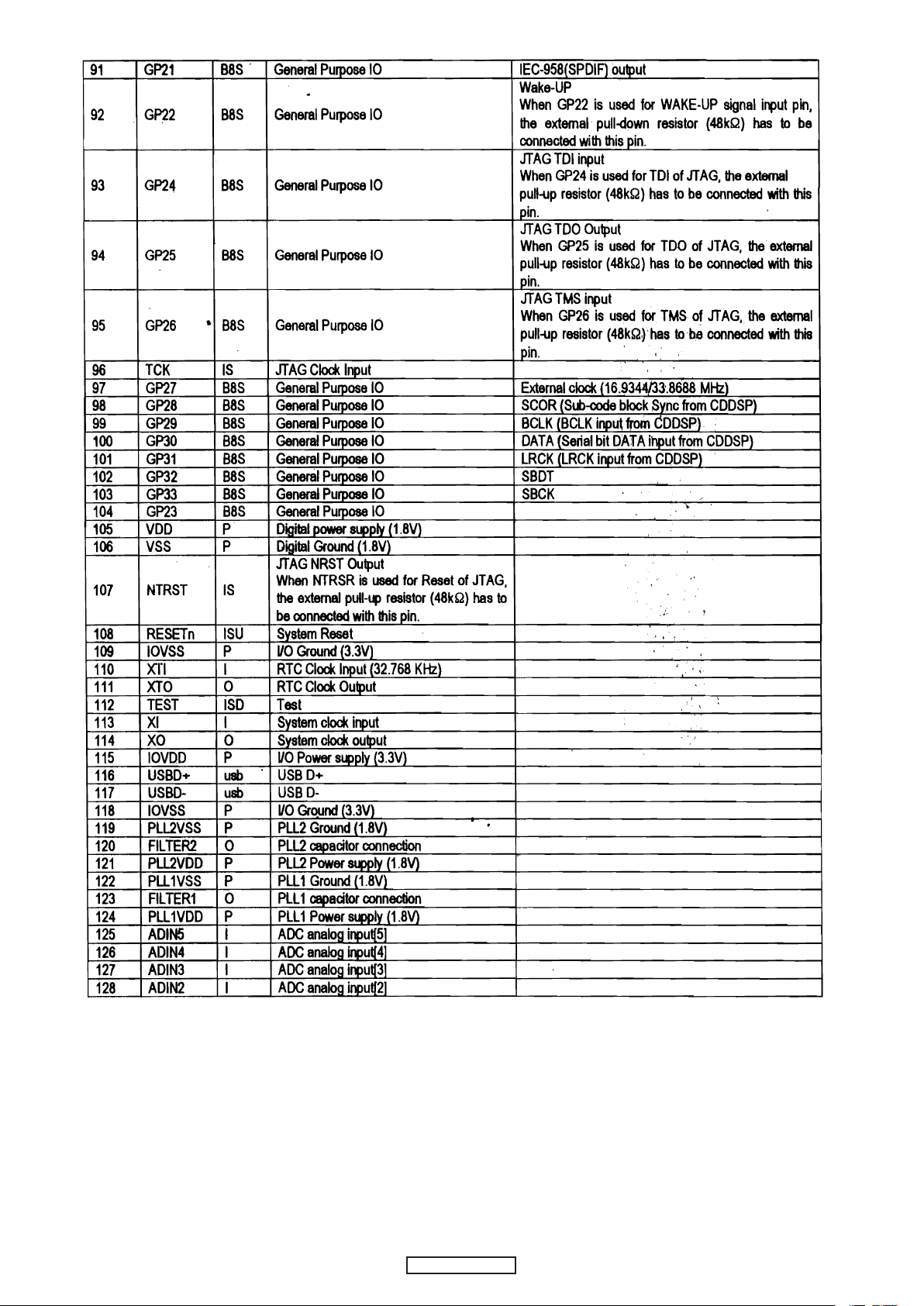

1. IC's

MLC3890 (IC202)

9

9

DP-200USB

DP-200USB

Page 10

Terminal Function

10

10

DP-200USB

DP-200USB

Page 11

11

11

DP-200USB

DP-200USB

Page 12

12

12

DP-200USB

DP-200USB

Page 13

IS42S16100E-7TL (IC203

)

13

13

DP-200USB

DP-200USB

Page 14

14

14

DP-200USB

DP-200USB

Page 15

SST39LF/VF400A (IC204

)

BLOCK DIAGRAM

PIN FUNCTION

15

15

DP-200USB

DP-200USB

Page 16

PRINTED WIRING BOARDS

REC P.W.B. UNIT (1/2)

16

DP-200USB

COMPONENT SIDE

Page 17

REC P.W.B. UNIT (2/2)

17

DP-200USB

FOIL SIDE

Page 18

PH/LI/SPEED/AC SW/AC/DC P.W.B. UNIT (1/2)

18

DP-200USB

COMPONENT SIDE

Page 19

PH/LI/SPEED/AC SW/AC/DC P.W.B. UNIT (2/2)

19

DP-200USB

FOIL SIDE

Page 20

NOTE FOR PARTS LIST

Parts for which "nsp" is indicated on this table cannot be supplied.

When ordering of part, clearly indicate "1" and "I" (i) to avoid mis-supplying.

Ordering part without stating its part number can not be supplied.

Not including General-purpose Carbon Chip Resistor in the P.W.Board parts list. (Refer to the Schematic Diagram for those parts.)

Parts marked with this symbol z have critical characteristics.

Use ONLY replacement parts recommended by the manufacturer.

Not including General-purpose Carbon Film Resistor in the P.W.Board parts list. (Refer to the Schematic Diagram for those parts.)

Part indicated with the mark "★" is not illustrated in the exploded view.

WARNING:

1.

2.

3.

4.

5.

6.

● Resistors

RD : Carbon

RC : Composition

RS : Metal oxide film

RW: winding

RN : Metal film

RK : Metal mixture

P : Pulse-resistant type

NL : Low noise type

NB : Non-burning type

FR : Fuse-resistor

F : Lead wire forming

2B : 1/8 W

2E : 1/4 W

2H : 1/2 W

3A : 1 W

3D : 2 W

3F : 3 W

3H : 5 W

F : ±1%

G : ±2%

J : ±5%

K : ±10%

M : ±20%

Ex.: RN

Type

14K

Shape

and performance

2E

Power

182

Resistance

G

Allowable

error

FR

Others

* Resistance

1800ohm=1.8kohm1 8 2

Indicates number of zeros after effective number.

2-digit effective number.

1.2ohm1 R 2

2-digit effective number, decimal point indicated by R.

1-digit effective number.

: Units: ohm

● Capacitors

CE : Aluminum foil

electrolytic

CA : Aluminium solid

electrolytic

CS : Tantalum electrolytic

CQ : Film

CK : Ceramic

CC : Ceramic

CP : Oil

CM: Mica

CF : Metallized

CH : Metallized

HS : High stability type

BP : Non-polar type

HR : Ripple-resistant type

DL : For change and discharge

HF : For assuring high requency

U : UL part

C : CSA part

W : UL-CSA part

F : Lead wire forming

0J : 6.3 V

1A : 10 V

1C : 16 V

1E : 25 V

1V : 35 V

1H : 50 V

2A : 100 V

2B : 125 V

2C : 160 V

2D : 200 V

2E : 250 V

2H : 500 V

2J : 630 V

F : ±1%

G : ±2%

J : ±5%

K : ±10%

M : ±20%

Z : ±80%

: - 20%

P : +100%

C : ±0.25pF

D : ±0.5pF

= : Others

Ex.: CE

Type

04W

Shape

and performance

1H

Dielectric

strength

3R2

CapacityMAllowable

error

BP

Others

・ Units:μF.

2200μF2 2 2

Indicates number of zeros after effective number.

2-digit effective number.

・ Units:μF.

2.2μF2 R 2

2-digit effective number, decimal point indicated by R

1-digit effective number.

* Capacity (electrolyte only)

・ When the dielectric strength is indicated in AC,"AC" is included after the dieelectric strength value.

* Capacity (except electrolyte)

・ Units:pF

2200pF=0.0022μF2 2 2

Indicates number of zeros after efective number.

(More than 2)

2-digit effective number.

・ Units:pF

220pF2 2 1

2-digit effective number.

Indicates number of zeros after effective numver.

(0 or 1)

20

DP-200USB

Page 21

PARTS LIST OF P.W.B. UNIT

* Parts for which "nsp" is indicated on this table cannot be supplied.

* P.W.B. ASS'Y for which "nsp" is indicated on this table cannot be supplied. When repairing the P.W.B. ASS'Y, check the board parts table and order

replacement parts.

* The parts listed below are for maintenance only, might differ from the parts used in the unit in appearances or dimensions.

Note:The symbols in the column "Remarks" indicate the following destinations.

E3 : U.S.A. & Canada model E2 : Europe model

REC PCB ASS'Y

Ref No. Part No. Part Name Remarks Q'ty New

SEMICONDUCTORS GROUP

IC201 941239000410S

IC202 941239000450S

IC203 941239000460S

IC204 941243000350D

IC205 00D9410049209

IC206 00D9580048800

IC207 00D9587058204

IC208 00D2623082924

IC(CE2632,SOP-14)

IC(MLC3890,TQFP-128)

IC(1S42S16100E-7TL,TSOP-50,ISSI)

IC ASS'Y (SST39LF/VF400A,TSOP-48)

IC(BA18BC0FP-E2,3PIN,TO-252-3,SMD)

IC(TC74HCU04AFN/TC74HCU04FAN(ELP.M)SOP-14)

IC(BA033FP-E2,TO-252-3)

IC(BD4730G-TR,SSOP-5)

417-BJR100-830

417-BJR100-831

417-BJR100-832

704-BJR100-7493

417-MCDS4-737

417-DJ150-419

417-CTB200-500

417-200USB-931

1 *

1 *

1 *

1 *

1 *

1 *

1 *

1 *

*

Q202,Q203 00D9587057409

D201 941209000470S

D202 00D9410046901

D203 00D9587056701

D204 00D9587051706

D204 nsp

D205 00D9580041807

D205 nsp

D206-D208 941209000470S

RESISTOR GROUP

R201 nsp

R202 nsp

R203 nsp

R204 nsp

R205-R208 nsp

R209 nsp

R210 nsp

R211,R212 nsp

R214 nsp

R216 nsp

R217 nsp

R218 nsp

R219-R221 nsp

R222 nsp

R223 nsp

R224 nsp

R225 nsp

R226 nsp

R227-R230 nsp

R231 nsp

R232 nsp

R233 nsp

R234 nsp

R235-R237 nsp

R238 nsp

R239,R240 nsp

R241,R242 nsp

R243 nsp

R244-R246 nsp

R247 nsp

R248,R249 nsp

R250,R251 nsp

R252,R253 nsp

R255,R254 nsp

R256 nsp

CHIP TRANSISTOR(2SC2412KT146R)

ESD DIODE(RSB6.8S 150mW.6.8V EMD2 ROHM)

SWITCHING DIODE(1SS355,UMD2,SMD,TAPING)

DIODE(RB160M-30,SOD-123)

LED (6224-10ID-A,RED )

LED HOLDER(LED-3Y,BLACK,H=4.0mm)

LED ( GREEN )

LED HOLDER(LED-3Y,BLACK,H=4.0mm)

ESD DIODE(RSB6.8S 150mW.6.8V EMD2 ROHM)

NOTE :

When update Firmware, please conrm a last version in SDI.

Use the service board after updating it.

CHIP RESISTOR(10K OHM,1/10W,0603,J,TP ,50V)

CHIP RESISTOR(15K OHM,1/10W,0603,J,TP ,50V)

CHIP RESISTOR(10K OHM,1/10W,0603,J,TP ,50V)

CHIP RESISTOR(15K OHM,1/10W,0603,J,TP ,50V)

CHIP RESISTOR(470 OHM,1/10W, 0603,J,TP,50V)

CHIP RESISTOR(4.7K OHM,1/10W, 0603,J,TP,50V)

CHIP RESISTOR(0 OHM,1/10W, 0603,J,TP,50V)

CHIP RESISTOR(470 OHM,1/10W, 0603,J,TP,50V)

CHIP RESISTOR(1M OHM,1/8W, 0805,J,TP 150V)

CHIP RESISTOR(10K OHM,1/10W,0603,J,TP ,50V)

CHIP RESISTOR(100 OHM,1/10W, 0603,J,TP,50V)

CHIP RESISTOR(1K OHM,1/10W, 0603,J,TP,50V)

CHIP RESISTOR(100 OHM,1/10W, 0603,J,TP,50V)

CHIP RESISTOR(4.7K OHM,1/10W, 0603,J,TP,50V)

CHIP RESISTOR(1K OHM,1/10W, 0603,J,TP,50V)

CHIP RESISTOR(0 OHM,1/10W, 0603,J,TP,50V)

CHIP RESISTOR(0 OHM,1/8W,1206,J,TP ,150V)

CHIP RESISTOR(100 OHM,1/8W,J,0805,150V)

CHIP RESISTOR(100 OHM,1/10W, 0603,J,TP,50V)

CHIP RESISTOR(47K OHM,1/10W,0603,J,TP ,50V)

CHIP RESISTOR(100K OHM,1/10W,0603 ,J,TP ,50V)

CHIP RESISTOR( 220 OHM,1/8W,0805,J,TP 150V )

CHIP RESISTOR(1M OHM,1/8W, 0805,J,TP 150V)

CHIP RESISTOR(0 OHM,1/10W, 0603,J,TP,50V)

CHIP RESISTOR(47K OHM,1/10W,0603,J,TP ,50V)

CHIP RESISTOR(39 OHM,1/10W,0603,J,TP ,50V)

CHIP RESISTOR(15K OHM,1/10W,0603,J,TP ,50V)

CHIP RESISTOR(10K OHM,1/8W,0805,J,TP 150V)

CHIP RESISTOR(220 OHM,1/10W,0603 ,J,TP 50V)

CHIP RESISTOR( 220 OHM,1/8W,0805,J,TP 150V )

CHIP RESISTOR(220 OHM,1/10W,0603 ,J,TP 50V)

CHIP RESISTOR(1K OHM,1/10W, 0603,J,TP,50V)

CHIP RESISTOR(10K OHM,1/8W,0805,J,TP 150V)

CHIP RESISTOR(1K OHM,1/8W, 0805,J,TP 150V)

CHIP RESISTOR(220 OHM,1/10W,0603 ,J,TP 50V)

416-CDN88-051

414-DJ1100G-207

414-CD1000-075

414-900-208

410-CD6000-122

504-BJR100-224

410-CD6000-124

504-BJR100-224

414-DJ1100G-207

412-CDVD2001-534

412-007USB-687

412-CDVD2001-534

412-007USB-687

412-CDVD2001-545

412-CDVD2001-523

412-CDVD2001-552

412-CDVD2001-545

412-DV330-308

412-CDVD2001-534

412-CDVD2001-530

412-CDVD2001-540

412-CDVD2001-530

412-CDVD2001-523

412-CDVD2001-540

412-CDVD2001-552

412-DJ3000-414

412-DV330-304

412-CDVD2001-530

412-CDVD2001-532

412-CDVD2001-537

412-DV330-333

412-DV330-308

412-CDVD2001-552

412-CDVD2001-532

412-DCM280-755

412-007USB-687

412-DV330-306

412-CDVD2001-521

412-DV330-333

412-CDVD2001-521

412-CDVD2001-540

412-DV330-306

412-DV330-305

412-CDVD2001-521

2

4

1

1

1 *

2 *

1 *

2 *

4

3

4

3

4

6

2

5

6

2

3

8

4

8

2

4

5

2

1

8

2

1

2

2

5

2

2

4

3

6

2

6

4

3

2

6

21

DP-200USB

Page 22

Ref No. Part No. Part Name Remarks Q'ty New

CAPACITORS GROUP

C201 nsp

C202 00D9587056206

C203 nsp

C204 00D9587056206

C205 nsp

C206 00D9587056400

C207 nsp

C208 00D9587056400

C209 00D9587054907

C210 nsp

C211 00D9587054907

C212 nsp

C213 00D9587056206

C214 nsp

C215,C216 nsp

C217,C218 nsp

C219 nsp

C220,C221 nsp

C222-C230 nsp

C231 nsp

C232,C233 nsp

C234 00D9587054907

C235,C236 nsp

C237 00D9587054907

C238 nsp

C239 nsp

C240 00D9587054907

C241 941134000530S

C242 nsp

C243,C244 nsp

C246-C248 nsp

C250-C252 nsp

C253 nsp

C254,C255 nsp

C256-C258 nsp

C259 nsp

C260,C261 nsp

C262 00D9587032709

C263 nsp

C264-C268 00D9587054907

C269 nsp

CHIP CAPACITOR(100pF/50V,J,0603 TYPE,NPO)

ELEC. CAPACITOR(1uF/50V,M,105 ,TAPING 4*7,MINI)

CHIP CAPACITOR(100pF/50V,J,0603 TYPE,NPO)

ELEC. CAPACITOR(1uF/50V,M,105 ,TAPING 4*7,MINI)

CHIP CAPACITOR(0.1uF/50V,Z,0603 TYPE,Y5V)

ELEC. CAPACITOR(22uF/16V,M,105 ,TAPING 4*7,MINI)

CHIP CAPACITOR(0.1uF/50V,Z,0603 TYPE,Y5V)

ELEC. CAPACITOR(22uF/16V,M,105 ,TAPING 4*7,MINI)

ELEC. CAPACITOR(100uF/10V,M,105 ,TAPING 5*7,MINI)

CHIP CAPACITOR(0.1uF/50V,Z,0603 TYPE,Y5V)

ELEC. CAPACITOR(100uF/10V,M,105 ,TAPING 5*7,MINI)

CHIP CAPACITOR(0.1uF/50V,Z,0603 TYPE,Y5V)

ELEC. CAPACITOR(1uF/50V,M,105 ,TAPING 4*7,MINI)

CHIP CAPACITOR(0.1uF/50V,Z,0603 TYPE,Y5V)

CHIP CAPACITOR(22pF/50V,J,0805 TYPE,NPO)

CHIP CAPACITOR(0.1uF/50V,Z,0603 TYPE,Y5V)

CHIP CAPACITOR(0.01uF/50V,K,0603 TYPE,X7R)

CHIP CAPACITOR(1200pF/50V,K,0603 TAPING,X7R)

CHIP CAPACITOR(0.1uF/50V,Z,0603 TYPE,Y5V)

CHIP CAPACITOR(0.1uF/ 50V,Z,0805 TYPE,Y5V)

CHIP CAPACITOR(22pF/50V,J,0805 TYPE,NPO)

ELEC. CAPACITOR(100uF/10V,M,105 ,TAPING 5*7,MINI)

CHIP CAPACITOR(100pF/50V,J,0603 TYPE,NPO)

ELEC. CAPACITOR(100uF/10V,M,105 ,TAPING 5*7,MINI)

CHIP CAPACITOR(0.1uF/50V,Z,0603 TYPE,Y5V)

CHIP CAPACITOR(0.1uF/ 50V,Z,0805 TYPE,Y5V)

ELEC. CAPACITOR(100uF/10V,M,105 ,TAPING 5*7,MINI)

ELEC. CAPACITOR(470uF/10V,M, 105 ,TAPING 8*12)

CHIP CAPACITOR(0.1uF/ 50V,Z,0805 TYPE,Y5V)

CHIP CAPACITOR(0.1uF/50V,Z,0603 TYPE,Y5V)

CHIP CAPACITOR(0.1uF/50V,Z,0603 TYPE,Y5V)

CHIP CAPACITOR(0.1uF/50V,Z,0603 TYPE,Y5V)

CHIP CAPACITOR(0.01uF/50V,K,0603 TYPE,X7R)

CHIP CAPACITOR(0.01uF/50V,K,0805 TYPE,X7R)

CHIP CAPACITOR(0.01uF/50V,K,0603 TYPE,X7R)

CHIP CAPACITOR(0.01uF/50V,K,0805 TYPE,X7R)

CHIP CAPACITOR(0.1uF/ 50V,Z,0805 TYPE,Y5V)

ELEC. CAPACITOR(220uF/10V,M,105 ,TAPING 6*7,MINI)

CHIP CAPACITOR(0.1uF/ 50V,Z,0805 TYPE,Y5V)

ELEC. CAPACITOR(100uF/10V,M,105 ,TAPING 5*7,MINI)

CHIP CAPACITOR(0.1uF/50V,Z,0603 TYPE,Y5V)

413-DCM280-767

413-SPPW3-234

413-DCM280-767

413-SPPW3-234

413-DCM280-773

413-SPPW3-236

413-DCM280-773

413-SPPW3-236

413-HMA2200-5017

413-DCM280-773

413-HMA2200-5017

413-DCM280-773

413-SPPW3-234

413-DCM280-773

413-CDN88-080

413-DCM280-773

413-DCM280-771

413-ME2-1049

413-DCM280-773

413-DV330-313

413-CDN88-080

413-HMA2200-5017

413-DCM280-767

413-HMA2200-5017

413-DCM280-773

413-DV330-313

413-HMA2200-5017

413-HT8015-169

413-DV330-313

413-DCM280-773

413-DCM280-773

413-DCM280-773

413-DCM280-771

413-DV330-312

413-DCM280-771

413-DV330-312

413-DV330-313

413-HT801K-192

413-DV330-313

413-HMA2200-5017

413-DCM280-773

4

3

4

3

26

2

26

2

10

26

10

26

3

26

4

26

5

2

26

6

4

10

4

10

26

6

10

1

6

26

26

26

5

3

5

3

6

1

6

10

26

OTHER PARTS GROUP

CN201 nsp

CN202 nsp

CN203 941643000340S

JR1 nsp

L201-L205 00D9587057108

L206-L208 90M-FC900430R

L209 00D9587057108

L210 941115000480S

L211 941119000490S

L212-L214 00D9587057108

L215 90M-FC900430R

SW101 941662000330S

X201 00D9580015707

X202 00D9580015600

3P SOCKET(CKM2501WR-3P 90°WHITE)

2P 2.0 CONNECTOR WIRE(AMW1007#26,L=250mm,+/+)

USB-A JACK(USB-A(F) DIP)

CHIP RESISTOR(0 OHM,1/8W,1206,J,TP ,150V)

BEAD CORE(TB36-863445NP T-26mm)

CHIP BEAD(SBK201209T-601Y-S)

BEAD CORE(TB36-863445NP T-26mm)

INDUCTOR(MPZ2012S101AT)

CHIP BEAD(ACM2012-900-2P-T)

BEAD CORE(TB36-863445NP T-26mm)

CHIP BEAD(SBK201209T-601Y-S)

TACT SW

CRYSTAL(12MHz)

CRYSTAL( 16.9344MHz )

22

DP-200USB

404-KMD3500-609A

404-HPR200-3055

420-D1PRO-262

412-DJ3000-414

415-HV3500K-090

415-1300-240

415-HV3500K-090

415-FU801-316

415-FU800-305

415-HV3500K-090

415-1300-240

403-200USB-337

427-KMD3500-047

427-KC710-019

1

1

1

2

9

4

9

1

1

9

4

1 *

1 *

1 *

Page 23

PH/LI PCB ASS'Y

Ref No. Part No. Part Name Remarks Q'ty New

SEMICONDUCTORS GROUP

IC601 941239000500S

IC(LA3161)

417-F606-720

1 *

Q601 90M-BA001610R

Q602,Q603 00D9410046406

Q604 00D9580040400

Q605 00D9587057603

D601,D602 00D9410046901

D603 941209000730S

D604 00D2760761904

RESISTOR GROUP

R602 nsp

R603 nsp

R604 nsp

R606 nsp

R607 nsp

R608 nsp

R609,R610 nsp

R611 nsp

R612 nsp

R613 nsp

R614 nsp

R615 nsp

R616 nsp

R617 nsp

R618 nsp

R619 nsp

R620,R621 nsp

R622 nsp

R623,R624 nsp

R625 nsp

R627,R628 nsp

R629 nsp

R630 nsp

CHIP TRANSISTOR(DTA124TKAT146)

TRANSISTOR(2SC4695)

DIGITAL TRANSISTOR(DTC124TS TAPING OR 2SC4120)

TRANSISTORS(2SC3330U-AC)

SWITCHING DIODE(1SS355,UMD2,SMD,TAPING)

DIODE(1N4001,1A/50V,TAPING 52mm)

ZENER DIODE(MTZJ9.1-B,1/2W,T-77)

CHIP RESISTOR(100 OHM,1/8W,J,0805,150V)

CHIP RESISTOR(470 OHM,1/10W, 0603,J,TP,50V)

CHIP RESISTOR(47K OHM,1/10W,0603,J,TP ,50V)

CHIP RESISTOR(150K OHM,1/10W,0603,J,TP ,50V)

CHIP RESISTOR(9.1K OHM,1/10W,0603,J,TP ,50V)

CHIP RESISTOR(200 OHM,1/10W,J,TP 0603,50V)

CHIP RESISTOR(680 OHM,1/10W,J,TP ,50V)

CHIP RESISTOR(470 OHM,1/10W, 0603,J,TP,50V)

CHIP RESISTOR(47K OHM,1/10W,0603,J,TP ,50V)

CHIP RESISTOR(150K OHM,1/10W,0603,J,TP ,50V)

CHIP RESISTOR(9.1K OHM,1/10W,0603,J,TP ,50V)

CHIP RESISTOR(200 OHM,1/10W,J,TP 0603,50V)

CHIP RESISTOR(100K OHM,1/10W,0603 ,J,TP ,50V)

CHIP RESISTOR(1K OHM,1/10W, 0603,J,TP,50V)

CHIP RESISTOR(100K OHM,1/10W,0603 ,J,TP ,50V)

CHIP RESISTOR(1K OHM,1/10W, 0603,J,TP,50V)

CHIP RESISTOR(6.2KOHM,1/10W,F,TP 0603,50V)

CHIP RESISTOR(10K OHM,1/10W,0603,J,TP ,50V)

CHIP RESISTOR(1K OHM,1/10W, 0603,J,TP,50V)

CHIP RESISTOR(390 OHM,1/4W,J,TP 1206,150V)

CHIP RESISTOR(100K OHM,1/10W,0603 ,J,TP ,50V)

CHIP RESISTOR(220K OHM,1/10W, 0603,J,TP,50V)

CHIP RESISTOR(470 OHM,1/10W, 0603,J,TP,50V)

416-HDJ9700-210

416-DAIA-273

416-1330-020

416-DJ1900-023

414-CD1000-075

414-DJ2500-110

414-3113-007

412-DV330-304

412-CDVD2001-545

412-CDVD2001-532

412-007USB-688

412-CDVD2001-543

412-MH2-1138

412-900-1060

412-CDVD2001-545

412-CDVD2001-532

412-007USB-688

412-CDVD2001-543

412-MH2-1138

412-CDVD2001-537

412-CDVD2001-540

412-CDVD2001-537

412-CDVD2001-540

412-900-985

412-CDVD2001-534

412-CDVD2001-540

412-200USB-1341

412-CDVD2001-537

412-007USB-678

412-CDVD2001-545

1

2

1

1

2

1

1

1

3

2

2

2

2

2

3

2

2

2

2

4

4

4

4

2

1

4

1

4

1

3

CAPACITORS GROUP

C601 nsp

C601 nsp

C602 00D9587032806

C603 00D9587055304

C604 nsp

C605 nsp

C606 00D9587032301

C607 00D9587032204

C608 941134000520S

C609 nsp

C610 nsp

C611 00D9587055304

C612 nsp

C613 nsp

C614 00D9587032301

C615 00D9587032204

C616 941134000520S

C617-C618 nsp

C619 00D9587032806

C621 00D9587032806

CHIP CAPACITOR(0.1uF/50V,Z,0603 TYPE,Y5V)

CHIP CAPACITOR(0.1uF/50V,Z,0603 TYPE,Y5V)

ELEC. CAPACITOR(100uF/16V,M,105 ,TAPING 6.3*7,MINI)

ELEC. CAPACITOR(4.7uF/50V,M,105 ,TAPING 4*7,MINI)

CHIP CAPACITOR(100pF/50V,J,0603 TYPE,NPO)

CHIP CAPACITOR(470pF/50V,J,0603 TYPE,NPO)

POLYESTER CAPACITOR(0.027uF/50V,J,TAPING)

POLYESTER CAPACITOR(0.0082uF/50V,J,TAPING)

E.C.(4.7uF/25V,MINI)

ELEC. CAPACITOR(33uF/16V,M,105 ,TAPING 5*7,MINI)

CHIP CAPACITOR(100pF/50V,J,0603 TYPE,NPO)

ELEC. CAPACITOR(4.7uF/50V,M,105 ,TAPING 4*7,MINI)

CHIP CAPACITOR(470pF/50V,J,0603 TYPE,NPO)

ELEC. CAPACITOR(33uF/16V,M,105 ,TAPING 5*7,MINI)

POLYESTER CAPACITOR(0.027uF/50V,J,TAPING)

POLYESTER CAPACITOR(0.0082uF/50V,J,TAPING)

E.C.(4.7uF/25V,MINI)

CHIP CAPACITOR(4700pF/50V,K,0603 TAPING,X7R)

ELEC. CAPACITOR(100uF/16V,M,105 ,TAPING 6.3*7,MINI)

ELEC. CAPACITOR(100uF/16V,M,105 ,TAPING 6.3*7,MINI)

23

DP-200USB

413-DCM280-773

413-DCM280-773

413-HT801K-193

413-HT801K-191

413-DCM280-767

413-007USB-786

413-HT8015-161

413-HT8015-160

413-SMX701-712

413-HDJ201-350

413-DCM280-767

413-HT801K-191

413-007USB-786

413-HDJ201-350

413-HT8015-161

413-HT8015-160

413-SMX701-712

413-007USB-789

413-HT801K-193

413-HT801K-193

2

2

4

2

4

2

2

2

4

2

4

2

2

2

2

2

4

4

4

4

Page 24

Ref No. Part No. Part Name Remarks Q'ty New

C622 941134000430S

C623 941134000510S

C624 941134000520S

C625 nsp

C626 941134000520S

C627 nsp

C628 00D9587032806

C629,C630 nsp

OTHER PARTS GROUP

CN601 nsp

CN602 nsp

CN603 00D9587066403

ELEC.CAPACITOR(22uF/25V,M,TAPING 5*11)

ELEC. CAPACITOR(220uF/16V,M,105( ,TAPING 6*7,MINI)

E.C.(4.7uF/25V,MINI)

CHIP CAPACITOR(4700pF/50V,K,0603 TAPING,X7R)

E.C.(4.7uF/25V,MINI)

CHIP CAPACITOR(4700pF/50V,K,0603 TAPING,X7R)

ELEC. CAPACITOR(100uF/16V,M,105 ,TAPING 6.3*7,MINI)

CHIP CAPACITOR(100pF/50V,J,0603 TYPE,NPO)

3P 2.5CONNECTOR WIRE

(UL2547#28*2C TS GRAY L=340mm)

2P 2.0 CONNECTOR WIRE

(L=270mm,UL1007#26 TS BLACK RED)

3P SOCKET(CKM2501WV-3P.180°WHTIE)

413-200USB-1119

413-RMX30-883

413-SMX701-712

413-007USB-789

413-SMX701-712

413-007USB-789

413-HT801K-193

413-DCM280-767

404-QFX-2425

404-200USB-3076

404-HV3500K-623A

1

1

4

4

4

4

4

4

1

1

1

JR1-JR4 nsp

L203,L204 90M-FC900430R

L601,L602 90M-FC900430R

L605 90M-FC900430R

RELY1 941682000440S

SW601 00D9410014001

nsp

nsp

CHIP RESISTOR(0 OHM,1/8W,1206,J,TP ,150V)

CHIP BEAD(SBK201209T-601Y-S)

CHIP BEAD(SBK201209T-601Y-S)

CHIP BEAD(SBK201209T-601Y-S)

RELAY(V23079-A2003-B301)

SLIDE SW(SBB-22-14)

GROUND WIRE FOR MECHA

(L=50mm,AWM1007 AWG22,BLACK)

CABLE TIE

412-DJ3000-414

415-1300-240

415-1300-240

415-1300-240

415-DJU5000-297

403-PXE90-028

406-CDMIX1-518

504-S100-004

4

5

5

5

1 *

1

1

1

24

DP-200USB

Page 25

SPEED/AC SW/AC/DC PCB ASS'Y

Ref No. Part No. Part Name Remarks Q'ty New

SEMICONDUCTORS GROUP

IC901 00D9587058107

IC902 00D9410022103

IC(BA05T,3PIN)

IC(NJM7812FA 3PIN)

417-CDN34A-314

417-BJ1900L-231

1 *

1 *

D901-D908 00D9410046804

D909 00D9587056701

CAPACITORS GROUP

C01 00D9580045308

C02 90M-DK100940R

z

C03 90M-DK100940R

z

C901 00D9410055604

C902 941134000530S

C903 00D9587053209

C904 00D9580044105

C905 00D9587055906

C906 00D9587053209

C907 00D9410055604

C908 00D9587053500

OTHER PARTS GROUP

AC-L nsp

AC-N nsp

ATOA nsp

BTOB nsp

DIODE(1N4002/1N4002TA,1A/100V,TAPING)

DIODE(RB160M-30,SOD-123)

MEX CAPACITOR(0.1uF/250V,K,BULK)

AC SAFETY CAPACITOR(4700pF/250V,M,BULK,Y5V)

AC SAFETY CAPACITOR(4700pF/250V,M,BULK,Y5V)

METAL POLYESTER CAPACITOR(0.1uF/AC125V,K)

ELEC. CAPACITOR(470uF/10V,M, 105 ,TAPING 8*12)

CERAMIC CAPACITOR(0.1uF/50V,Z,TAPING,Y5V)

ELEC. CAPACITOR(1000uF/25V,M, 105 ,BULK 10*20)

ELEC.CAPACITOR(100uF/16V,M,105 ,TAPING 5*11)

CERAMIC CAPACITOR(0.1uF/50V,Z,TAPING,Y5V)

METAL POLYESTER CAPACITOR(0.1uF/AC125V,K)

ELEC. CAPACITOR(2200uF/16V,M, 105 ,BULK 13*21)

PIN(NS-1105)

PIN(NS-1105)

LEAD WIRE(L=370mm,AWM1617 AWG22,RED)

LEAD WIRE(L=370mm,AWM1617 AWG22,RED)

414-DV300-5014

414-900-208

413-PROTT1-432

413-1431-104

413-1431-104

413-DJ3500-884

413-HT8015-169

413-3113-035

413-DJ1900-111

413-PXE90-109

413-3113-035

413-DJ3500-884

413-3113-053

300-B604-114

300-B604-114

406-DJ5500-680

406-DJ5500-680

8

1

1

1

1

2

1

2

1

1

2

2

1

2

2

2

2

CN1 nsp

CN901 941644000540S

CN902 941644000550S

CN903,CN904

F01 941652000300S

z

F01 941652000420S

z

FL1 00D9410022608

z

JR1,JR2 nsp

SW1 941661000320S

SW2 00D9410058708

941644000560S

nsp

nsp

nsp

nsp

nsp

nsp

nsp

nsp

nsp

nsp

nsp

2P 2.0 CONNECTOR WIRE

(L=210mm,UL1007#26 TS BLUE/WHITE)

4P SOCKET(CKM2501WV-4P 180°WHITE)

2P SOCKET(CKM2001WV-2P,180°WHITE)

2P SOCKET(CKM2001WR-2P 90°WHITE)

FUSE(250mA/250V,UL/CSA,5*20mmSLOW)

FUSE(T125mA/250V,VDE/UL)

FILTER(FKOB160MH02)

CHIP RESISTOR(0 OHM,1/8W,1206,J,TP ,150V)

POWER SW(SDDLB1177U-HF3)

PUSH SW(SPEC12HC12-HF,L=12.5)

1P GROUND WIRE(L=190mm,AWM1617,AWG22,BLACK)

CERAMIC TUBE ( 4*2*11.5mm )

FUSE CLIPS(FS-001)

FUSE COVER

FUSE LABEL(20*4mm,t=0.08mm)

FUSE LABEL(20*4mm,t=0.08mm)

GROUNG WIRE(L=80mm,AWM1007 AWG22.BLACK)

HEAT SINK((AL,HW-7004))

HEAT-SHRINKABLE TUBE

SCREW(3*8mm TTB)

SCREW(3*L8)

E3

E2

F01

E2

E3

404-200USB-3074

404-HV3500K-629A

404-HP1010K-257A

404-DJ3000-847A

422-BJ2300A-021

422-Q2231-084A

415-1300-239

412-DJ3000-414

403-C304-218

403-300F-255

406-BJR100-999

605-KMD510P-034

420-KT350A-004

504-DJ2500J-046

501-200UBKE2-1176

501-200UBKE3-1176

406-DJ100-550

425-ST150-064

605-HDJ201F-050

602-2002-077

602-HP1010K-175

1

1

2

2

1 *

1 *

1

2

1

1

1

8

2

1

1 *

1 *

1

1 *

0 *

2

3

25

DP-200USB

Page 26

-MEMO-

26

DP-200USB

Page 27

EXPLODED VIEWS

Parts marked with this symbol have critical

characteristics.

Use ONLY replacement parts recommended by

the manufacturer.

WARNING:

印の部分は安全を維持するために重要

な部品です。従って交換時は必ず指定の

部品を使用してください。

27

DP-200USB

Page 28

POINTS OF GREASING

Maker NoteGrease

CR-S

PG671

KF-96H

G-488M

G-31SB

Daizo Corporation (Nichimoly)

Shin-Etsu Chemical Co., Ltd.

Kanto Kasei Co., Ltd.

Kanto Kasei Co., Ltd.

Dow Corning Toray Co., Ltd.

Synthetic oil based resin-use lithium grease

Non-silicone grease, COMPOSITION :

Poly-α-olefin, Lithium soap, PTFE etc.

Dimethyl silicone fluid 100.000mm2/s

Molybdenum disulfide grease

Synthetic oil based grease

<φ1.5>

<φ1.5>

<φ1.5>

<φ1.2>

<φ1.5>

<φ2>

<φ1.2>

<φ3.5>

<φ1.5>

<φ1.5>

<φ1.5>

<φ1.5>

<φ2>

<φ1.2>

<φ1.2>

<φ3.5>

(8.0mg<φ2.5>)

<φ1.5>

<φ2>

(8.0mg<φ2.5>)

28

DP-200USB

Page 29

PARTS LIST OF EXPLODED VIEW

* Parts for which "nsp" is indicated on this table cannot be supplied.

* P.W.B. ASS'Y for which "nsp" is indicated on this table cannot be supplied. When repairing the P.W.B. ASS'Y, check the board parts table and order

replacement parts.

* The parts listed below are for maintenance only, might differ from the parts used in the unit in appearances or dimensions.

Note:The symbols in the column "Remarks" indicate the following destinations.

BKE3 : U.S.A. & Canada model (Black model)

BKE2 : Europe model (Black model) SPE2 : Europe model (Premium Silver model)

Ref.No. Part No. Part Name

9 nsp

REC PCB ASS'Y

Remarks

704-200USB-8134

Q'ty New

1 *

10A nsp

10 -

11 -

12 -

1 00D9410012401

1-1 -

1-2 -

1-3 -

1-4 -

1-5 -

1-6 -

1-7 -

1-8 -

1-9 -

2 nsp

2-1 00D9410002204

2-2 00D9410007306

3 nsp

3-1 00D9410002709

3-2 00D9410010704

3-3 00D9410001205

3-4 00D9410008509

4 nsp

4-1 00D9410003407

4-2 00D9410009207

5 941469000380D

6 nsp

6-1 00D9410010607

6-2 00D9410002301

6-3 00D9410003106

6-4 00D9410003300

6-5 00D9587038606

6-6 00D9410007005

6-7 00D9410007704

6-8 941472000400S

6-9 00D9410009003

6-10 00D9410009207

6-11 00D9410009702

6-12 00D9410010102

7 00D9410012304

7-1 -

7-2 -

7-3 -

7-4 -

7-5 -

7-6 -

8 941684000390S

8 -

8-1 -

8-2 -

8-2 -

PH/LI/SPEED/AC SW/AC/DC PCB ASS'Y

PH/LI PCB ASS'Y

DC PCB ASS'Y

SPEED PCB ASS'Y

CAM GEAR ASS'Y

CAM GEAR CONTROL ASS'Y

CAM GEAR

FRICTION LINK

ACTUATING LINK

SPRING

WASHER

CS WASHER (3mm)

E-RING WASHER (2mm)

WASHER

PENDULUM ASS'Y

PENDULUM(S)

SPRING

DUST COVER ASS'Y

HINGES ASS'Y (BLUE)

HINGES ASS'Y (YELLOW)

DUST COVER

RUBBER(S.B.R)

SHAFT ASS'Y

SHAFT

E-RING WASHER (3mm)

RETURM LINK ASS'Y

SHAFT ASS'Y

CUEING LEVER ASS'Y

SHAFT HOLDER

LOCUS SHAFT

SHAFT

NUT(M3*P0.5)

SCREW

SPRING

SPRING

RUBBER CAP

E-RING WASHER (3mm)

WASHER( 5.5*3*0.7t)

WASHER

CENTER&PINION ASS'Y

SHAFT & HOLDER ASS'Y

SMALL GEAR

CENTER SHAFT

SPINDLE RING

SCREW(1.7*2.8mm)

STEEL BALL

MOTOR ASS'Y (M09S12U13-3,DC9~12V)

or MOTOR ASS’Y (CCM09-120R2-9)

PULLEY

MOTOR(M09S12U13-3,DC9~12V)

or MOTOR(CCM09-120R2-9)

704-200USB-8135

704-200USB-8136

704-200USB-8139

701-SL24F-192

703-SL24F-050

100-SL24F-248

300-SL24F-130

300-SL24F-131

603-SL24F-077

606-F200-006

606-F200-013

606-B300-029

606-SL24F-057

701-SL24F-822

100-SL24F-240

603-SL24F-066

701-DP29FK-2436

703-B600-026B

703-B600-030

100-DP29FK-325

604-B600-026A

702-SL24F-011

200-SL24F-116

606-F200-011

703-200-1239

703-L100-063

703-SL24F-052

100-SL24F-241

200-SL24F-112

200-SL24F-114

601-A100-004

602-SL24F-100

603-SL24F-072

603-SL24F-078

604-SL24F-039

606-F200-011

606-B300-039

606-SL24F-056

703-F703-253

703-SL24F-051C

100-SL24F-244

200-SL24F-105A

200-SL24F-123

602-SL24F-093

607-B600-002

704-F706-7303

704-F706-7303

200-SL24F-109

401-H703-038B

401-H703-038A

1 *

1

1

1

1

1

1

1

2

1

2

1

1

1

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

29

DP-200USB

Page 30

Ref.No. Part No. Part Name

13 941319000600S

13 941319000610S

13-1 -

13-1 -

13-2 -

13-3 -

13-4 00D9410003711

13-4-1 00DDSN84

13-5 -

13-6 -

14 941319000640S

14-1 -

14-2 -

14-3 -

14-4 -

15 nso

15 nsp

z

z

z

z

15-1 nsp

15-1 nsp

15-2 nsp

15-3 941611000060S

15-3 00D9410039109

15-4 941101000080S

15-4 941101000090S

15-5 nsp

15-5 nsp

16 00D9410001001

17 941411000630D

18 nsp

18 nsp

18 nsp

19 00D9410001603

20 00D9410001700

21 941412000110D

21 941412000120D

22 00D9410002000

23 00D9410002408

24 00D9410002505

25 941412000650S

26 00D9410002806

27 00D9410010403

28 941412000100D

28 941412000130D

29 941401000140D

29 941401000150D

29 941401000180D

30 941412000160D

30 941412000170D

31 941412000190D

31 941412000200D

32 941412000210D

32 941412000220D

33 00D9410003009

34 00D9410003504

35 00D9410002903

36 00D9410003601

37 nsp

38 nsp

39 941612000720S

40 941541000370D

TONE ARM ASS' Y

TONE ARM ASS' Y

TONEARM SETTING & HEADSHELL ASS'Y

TONEARM SETTING & HEADSHELL ASS'Y

ROTARY SHAFT & SPRING ASS'Y

BALANCE WEIGHT HOLDER PIN

CARTRIDGE(CN-6516[M-6516])

STYLUS

TONE ARM SHILED WIRE

(UL1571,32AWG,WHITE,370mm)

TONE ARM SHILED WIRE(UL1571,32AWG,RED,370mm)

SWITCH& SET ASS'Y

SWITCHING SETING ASS'Y

LEAF SW ASS’Y

LEAF SW(LSA-1123-4,2PIN)

SCREW(2*8 ,PTP)

TRANSFORMER & AC CORD ASS'Y

TRANSFORMER & AC CORD ASS'Y

AC PCB ASS'Y

AC PCB ASS'Y

AC SW PCB ASS'Y

AC POWER CORD(L=1980+/-50mm,VDE TYPE)

AC POWER CORD(L=2130mm,UL TYPE)

TRANSFORMER(AC230V,50Hz)

TRANSFORMER(AC120V,60Hz)

FUSE LABEL(20*4mm,t=0.08mm)

FUSE LABEL(20*4mm,t=0.08mm)

45 RPM ADAPTOR

STRAIN RELIEF

BOTTOM PLATE

BOTTOM PLATE

BOTTOM PLATE

PENDULUM(L)

PENDULUM(M)

SELECT RECORD KNOB (ABS BLACK)

SELECT RECORD KNOB (ABS SILVER)

LIFTER(ABS BLACK)

SPEED BRACKER ASS'Y

SPEED SUPPORT

SELECTOR

SELECT PLATE

FOOT(ABS)

SOUARE KNOB

SOUARE KNOB

CHASSIS

CHASSIS

CHASSIS

KNOB

KNOB

POWER BUTTON

POWER BUTTON

RECORD BUTTON

RECORD BUTTON

TONEARM SHAFT SET

COPPER WASHER

TURNTABLE(AL)

CONTROL PLATE

PLATE

1P GROUNG WIRE(L=150mm,AWM1015 AWG22,BLACK)

SIGNAL WIRE(L=1200mm)

SOFTWARE DISC

Remarks

BKE2, BKE3

SPE2

BKE2, BKE3

SPE2

BKE2,SPE2

BKE3

BKE2,SPE2

BKE3

BKE2,SPE2

BKE3

BKE2,SPE2

BKE3

BKE2,SPE2

BKE3

BKE2

BKE3

SPE2

BKE3

SPE2

BKE2, BKE3

SPE2

BKE2

BKE3

SPE2

BKE2, BKE3

SPE2

BKE2, BKE3

SPE2

BKE2, BKE3

SPE2

704-200K-8140

704-200SP-8141

701-200K-4465

701-200SP-4469

703-SL34F-058

200-SL24F-118

402-F804-065

407-PXE90-090

407-PXE90-091

704-200USB-8142

701-SL24F-191

704-F601-1361

403-SL24F-011

602-K680-088

704-200USBE2-8157

704-200USBE3-8158

704-200USBE2-8156

704-200USB-8232

704-200USB-8138

409-3004-016E

409-HMD5000-053A

411-200USB-736

411-200USB-735

501-200UBKE2-1176

501-200UBKE3-1176

100-H200-016

100-29FBKEU-144

100-200-326BS

100-200KE3-326BS

100-200SP-326B

100-SL24F-234

100-SL24F-235

100-200K-236

100-200SP-236

100-SL24F-238

100-SL24F-242

100-SL24F-243

100-SL24F-245

100-SL24F-247

100-PXE90-332

100-200K-1662

100-200SP-1662

100-200K-2606

100-200KE3-2606

100-200SP-2606

100-200K-2607

100-200SP-2607

100-200K-2608

100-200SP-2608

100-200K-2609

100-200SP-2609

200-SL24F-107

200-SL24F-117A

200-F703-203

300-SL24F-126

300-HPR200-1622

406-120-763

408-200USB-094

429-200USB-051

Q'ty New

1 *

1 *

1 *

1 *

1

1

1

1

1

1

1

1

1

1

1

1 *

1 *

1 *

1 *

1 *

1

1

1 *

1 *

1 *

1 *

1

1

1

1

1

1

1

1 *

1 *

1

1

1

1

1

2

1 *

1 *

1 *

1 *

1 *

2 *

2 *

1 *

1 *

1 *

1 *

1

2

1

1

2 *

1

1

1 *

30

DP-200USB

Page 31

Ref.No. Part No. Part Name

41 00D9410003902

42 00D9410025401

44 nsp

44 nsp

45 nsp

46 nsp

47 nsp

48 00D9410005803

49 00D9410007209

50 00D9410007403

51 00D9410007500

52 00D9410007607

53 00D9410008101

54 941472000660S

55 00D9410008004

56 941472000670S

57 941472000680S

58 00D9410008703

59 00D9410008907

60 00D9580035402

61 00D9410008800

62 941409000690S

63 00D9410009100

64 00D9410009207

65 00D9410035307

66 00D9410009401

67 00D9410009508

68 00D9410010005

69 00D9580034908

70 00D9580035606

71 00D9410006006

72 00D9410005405

73 00D9410006103

74 00D9410006200

75 00D9410006404

76 00D9410006501

77 00D9410006608

78 00D9410006802

79 00D9410006909

80 00D9580034801

81 941519000700S

82 941519000710S

83 nsp

84 00D9410010102

85 nsp

CAUTION LABEL(70*10mm,t=0.1mm)

LABEL(BARE,36*8mm,t=1.2mm)

RATING LABEL(97*25mm,t=0.08mm)

RATING LABEL(97*25mm,t=0.08mm)

SEGREGATE SHEET(87.3*62.5*0.6t)

SEGREGATE SHEET(141.5*82*0.6t)

WIRE MOUNT(FW-2-3M,WHITE)

NUT

SPRING

SPRING(SUS,304,WPB)

SPRING(SUS,304,WPB)

SPRING(SUS,304,WPB)

SPRING(PLAY,STOP KNOB)

SPRING

SPRING

PLAY SPRING

STOP SPRING

RUBBER

MOTOR PLASTIC CUSHION

CUSHION RUBBER FOR TRANSFORMER

BELT

SLIPMAT

WASHER

E-RING WASHER (3mm)

E-RING WASHER (5mm)

CS WASHER (3mm)

WASHER

WASHER

SCREW(SAE1018,PTP, 3*L10)

SCREW(SAE1018,WPTP,M3*8)

SCREW(SAE1018,PTP, 3*L8)

SCREW(3*16mm)

SCREW

SCREW(2*10mm JMB BLACK)

SCREW(PTP)

SCREW(PTP)

SCREW

SCREW(M3*9 PTP)

SCREW

SCREW(SAE1018,PTP,M2.6*L8)

SCREW(WPTP,2.6*6,W=7.5)

SCREW(WPTP, 2.6*L7,CAP 10)

INSULATION SHEET(58*26.4*0.5t)

WASHER

LOCKING CABLE CLIP

(WC-1AM-M9B, 5.6,L=35.6mm,BLACK)

Remarks

BKE2,SPE2

BKE3

501-DP29FK-823

501-DV300-1067

501-200UE2-2176

501-200UE3-2176

501-200-2178

501-200-2179

504-ST100-118

601-SL24F-011

603-MD26-059

603-SL24F-067

603-SL24F-068

603-SL24F-069

603-SL24F-076

603-SL24F-079

603-L100-103

603-200-372

603-200-373

604-SL24F-036A

604-SL24F-038

604-DJ1900-064

604-PXE90-076

604-DP29FK-205A

606-F200-006

606-F200-011

606-F200-012

606-F200-013

606-H200-019

606-SL24F-055

602-M400-055

602-B600-056

602-B600-057

602-B600-059

602-B600-072

602-MD26-081

602-SL24F-092

602-SL24F-094

602-SL24F-095

602-SL24F-097

602-SL24F-098

602-SL24F-099

602-WPTP2606-660Z

602-DV300-5023

501-200-2200

606-SL24F-056

504-HV3500K-033

Q'ty New

1

1 *

1 *

1 *

1 *

1 *

1

1

1

1

1

1

3

1

1

1

1

4

3

2 *

1

1

1

2

1

1

1

1

4

3

9

2

4

1

4

2

1

4

2

10

4

2

1 *

1

1

31

DP-200USB

Page 32

PACKING VIEW

q

e

u

i

y

t

w

r

o

Q1

Q2

Q0

Q3

Q3

Q1

PARTS LIST OF PACKING & ACCESSORIES

* Parts for which "nsp" is indicated on this table cannot be supplied.

* The parts listed below are for maintenance only, might differ from the parts used in the unit in appearances or dimensions.

BKE3 : U.S.A. & Canada model (Black model)

BKE2 : Europe model (Black model) SPE2 : Europe model (Premium Silver model)

Ref.No. Parts No Part Name Remarks Q'ty New

Note: The symbols in the column "Remarks" indicate the following destinations.

1 00D9410011509

2 00D9410002903

3 nsp

4 00D9410011305

5 00D9410011402

6 00D9410008619

7 nsp

7 nsp

7-1 00D9410001001

7-2 941541000370D

7-3 941541000240D

7-3 941541000250D

7-4 nsp

7-5 nsp

8 941531000280D

8 941531000290D

9 nsp

10 nsp

10 nsp

10 nsp

11 nsp

11 nsp

11 nsp

12 941543000590S

13 nsp

POLYBAG

ALUMINIUM PLATTER

DUST COVER ASS'Y

POLYFOAM L

POLYFOAM R

SLIPMAT PACKING ASS' Y

I/B ASS'Y

I/B ASS'Y

45 RPM ADAPTOR

SOFTWARE DISC

I/B

I/B

SERVICE SHEET (543110032005D)

PE BAG

GIFT BOX

GIFT BOX

WARRANTY ASS'Y

BAR CODE

BAR CODE

BAR CODE

LABEL (CONT.CARD SUB ASS'Y)

LABEL (CONT.CARD SUB ASS'Y)

LABEL (CONT.CARD SUB ASS'Y)

NOTICE SHEET(543110068004D)

COLOR LABEL

SPE2,BKE2

BKE3

SPE2,BKE2

SPE2

BKE2,BKE3

BKE3

SPE2

BKE2

BKE3

SPE2

BKE2

BKE3

SPE2

505-HM500A-048

200-F703-203

701-DP29FK-2436

506-DP29FK-293L

506-DP29FK-293R

705-DP29FK-721A

701-200UBKE2-4476

701-200UBKE3-4477

100-H200-016

429-200USB-051

502-200UBKE2-2666

502-200UBKE3-2667

502-DCM280-1347H

505-DJ2500H-014

507-200SPE2-2236

507-200KE2-2236

701-DCM370E3-1810

501-200USPE2-1248

501-200UBKE2-1248

501-200UBKE3-1248

701-200USPE2-3513

701-200UBKE2-3513

701-200UBKE3-3513

502-DP200U-2678

501-300FSPE2-1906

1

1

1

1

1

1

1 *

1 *

1

1 *

1 *

1 *

1

1

1 *

1 *

1

1 *

1 *

1 *

2 *

2 *

2 *

1 *

2

32

DP-200USB

Page 33

-MEMO-

33

DP-200USB

Page 34

NOTE FOR SCHEMATIC DIAGRAM

WARNING:

Parts marked with this symbol z have critical characteristics.

Use ONLY replacement parts recommended by the manufacturer.

CAUTION:

Before returning the unit to the customer, make sure you

make either (1) a leakage current check or (2) a line to chassis

resistance check. If the leakage current exceeds 0.5 milliamps,

or if the resistance from chassis to either side of the

power cord is less than 460 kohms, the unit is defective.

WARNING:

DO NOT return the unit to the customer until the problem is

located and corrected.

NOTICE:

ALL RESISTANCE VALUES IN OHM. k=1,000 OHM

M=1,000,000 OHM

ALL CAPACITANCE VALUES IN MICRO FARAD.

P=MICRO-MICRO FARAD

EACH VOLTAGE AND CURRENT ARE MEASURED AT

NO SIGNAL INPUT CONDITION.

CIRCUIT AND PARTS ARE SUBJECT TO CHANGE

WITHOUT PRIOR NOTICE.

34

DP-200USB

Page 35

87654321

A

M 25

M 26

M 27

M 28

M 29

M 30

M 31

M 32

M 33

M 34

M 35

M 36

M 37

M 38

M 39

M 40

M 41

M 42

M 43

M 45

M 46

M 47

61

62

64

G P0163G P02

X I16EN /S PID I

M 49

R 247 220

R 248 220

R 249 220

C 224

0.1u

R 246 220

49

50

51

52

53

54

58

59

60

E C SN

EW EN

EO E N /G P38

W E N

C A SN

IO V S S

IO V D D

SD C L K

E A D 17/G P3455E A D 18/G P3556E A D 19/G P3657E A D 20/G P37

R 244 220

R 245 220

C 244

0.1u

37

40

42

43

44

45

46

47

48

V SS

C K E

V D D

R A SN

SD S C N

B A 0/E A D 1341B A 1/E A D 14

LD Q M /E A D 15

U D Q M /E A D 1 6

A D 10/EA D 1038A D 11/EA D 1139A D 12/EA D 12

A D 5/E A D 533A D 6/E A D 634A D 7/E A D 735A D 8/E A D 836A D 9/E A D 9

B

C

R 223

R 224

R 225R 210

G P2797SC O R /GP 2898B C L K /G P2999D A T A /G P30

LR C K /G P31

SB D T /G P32

SB C K /G P 33

G P23

V D D

V SS

N T R ST

R E SE TN

IO V S S

X T I

X T O

TE ST

X I

X O

IO V D D

U SB D +

U SB D ‑

IO V S S

PL L2 V SS

FIL T E R 2

PL L2V D D

PL L1 V SS

FIL T E R 1

PL L1V D D

A D IN 5

A D IN 4

A D IN 3

A D IN 2

R 211

470

R 212

470

0.1u

C 205

C 207

C 208

22u/16

0.1u

C 206

470

22u/16

R 206

13

14

V D D

1A11Y22A32Y43A53Y6G N D

4Y84A95Y105A116Y126A

L215

7

FB

100

101

102

103

104

105

106

107

108

109

110

111

112

113

114

115

116

117

118

119

120

121

122

123

124

125

126

127

128

R 2370R 2360R 2350

R 238

C 220

0.0012u

C 221

R 23147K

R 232

R 227100

100K

39

39

R 239

R 240

C 235

0.0012u

R 242

15K

C 236

100P

100P

47K

D

G

C 242

0.1u

C 241

470u/10

G

E

SCHEMATIC DIAGRAMS (1/3)

DP-200USB

F

Page 36

12V

87654321

A

12V

B

12V

C

D

E

SCHEMATIC DIAGRAMS (2/3)

DP-200USB

F

Page 37

87654321

A

B

C

D

E

SCHEMATIC DIAGRAMS (3/3)

DP-200USB

F

Loading...

Loading...