Denon DN-HC1000S Service Manual

Copyright 2009 D&M Holdings Inc. All rights reserved.

WARNING: Violators will be prosecuted to the maximum extent possible.

●

For purposes of improvement, specifications and design are subject to change without notice.

●

Please use this service manual with referring to the operating instructions without fail.

●

Some illustrations using in this service manual are slightly different from the actual set.

Ver. 2

Please refer to the

MODIFICATION NOTICE.

SERVICE MANUAL

MODEL JP E3 E2 EK E2A E2C E1K EUT

DN-HC1000S

33

USB MIDI CONTROLLER

S0013-1V02DM/DG0911

Please heed the points listed below during servicing and inspection.

◎

Heed the cautions!

Spots requiring particular attention when servicing, such

as the cabinet, parts, chassis, etc., have cautions indicated

on labels or seals. Be sure to heed these cautions and the

cautions indicated in the handling instructions.

◎

Caution concerning electric shock!

(1) An AC voltage is impressed on this set, so touching in-

ternal metal parts when the set is energized could

cause electric shock. Take care to avoid electric shock,

by for example using an isolating transformer and

gloves when servicing while the set is energized, unplugging the power cord when replacing parts, etc.

(2)There are high voltage parts inside. Handle with extra

care when the set is energized.

◎

Caution concerning disassembly and

assembly!

Though great care is taken when manufacturing parts from

sheet metal, there may in some rare cases be burrs on the

edges of parts which could cause injury if fingers are

moved across them. Use gloves to protect your hands.

◎

Only use designated parts!

The set's parts have specific safety properties (fire resistance, voltage resistance, etc.). For replacement parts, be

sure to use parts which have the same properties. In particular, for the important safety parts that are marked z on

wiring diagrams and parts lists, be sure to use the designated parts.

◎

Be sure to mount parts and arrange

the wires as they were originally!

For safety reasons, some parts use tape, tubes or other insulating materials, and some parts are mounted away from

the surface of printed circuit boards. Care is also taken with

the positions of the wires inside and clamps are used to

keep wires away from heating and high voltage parts, so

be sure to set everything back as it was originally.

◎

Inspect for safety after servicing!

Check that all screws, parts and wires removed or disconnected for servicing have been put back in their original positions, inspect that no parts around the area that has been

serviced have been negatively affected, conduct an insulation check on the external metal connectors and between

the blades of the power plug, and otherwise check that

safety is ensured.

(Insulation check procedure)

Unplug the power cord from the power outlet, disconnect

the antenna, plugs, etc., and turn the power switch on. Using a 500V insulation resistance tester, check that the insulation resistance between the terminals of the power

plug and the externally exposed metal parts (antenna terminal, headphones terminal, microphone terminal, input

terminal, etc.) is 1MΩ or greater. If it is less, the set must

be inspected and repaired.

Concerning important safety

parts

Many of the electric and structural parts used in the set

have special safety properties. In most cases these properties are difficult to distinguish by sight, and using replacement parts with higher ratings (rated power and

withstand voltage) does not necessarily guarantee that

safety performance will be preserved. Parts with safety

properties are indicated as shown below on the wiring diagrams and parts lists is this service manual. Be sure to replace them with parts with the designated part number.

(1) Schematic diagrams ... Indicated by the z mark.

(2) Parts lists ... Indicated by the z mark.

Using parts other than the designated

parts could result in electric shock, fires or

other dangerous situations.

SAFETY PRECAUTIONS

The following check should be performed for the continued protection of the customer and service technician.

LEAKAGE CURRENT CHECK

Before returning the unit to the customer, make sure you make either (1) a leakage current check or (2) a line to chassis

resistance check. If the leakage current exceeds 0.5 milliamps, or if the resistance from chassis to either side of the

power cord is less than 460 kohms, the unit is defective.

CAUTION

CAUTION

2

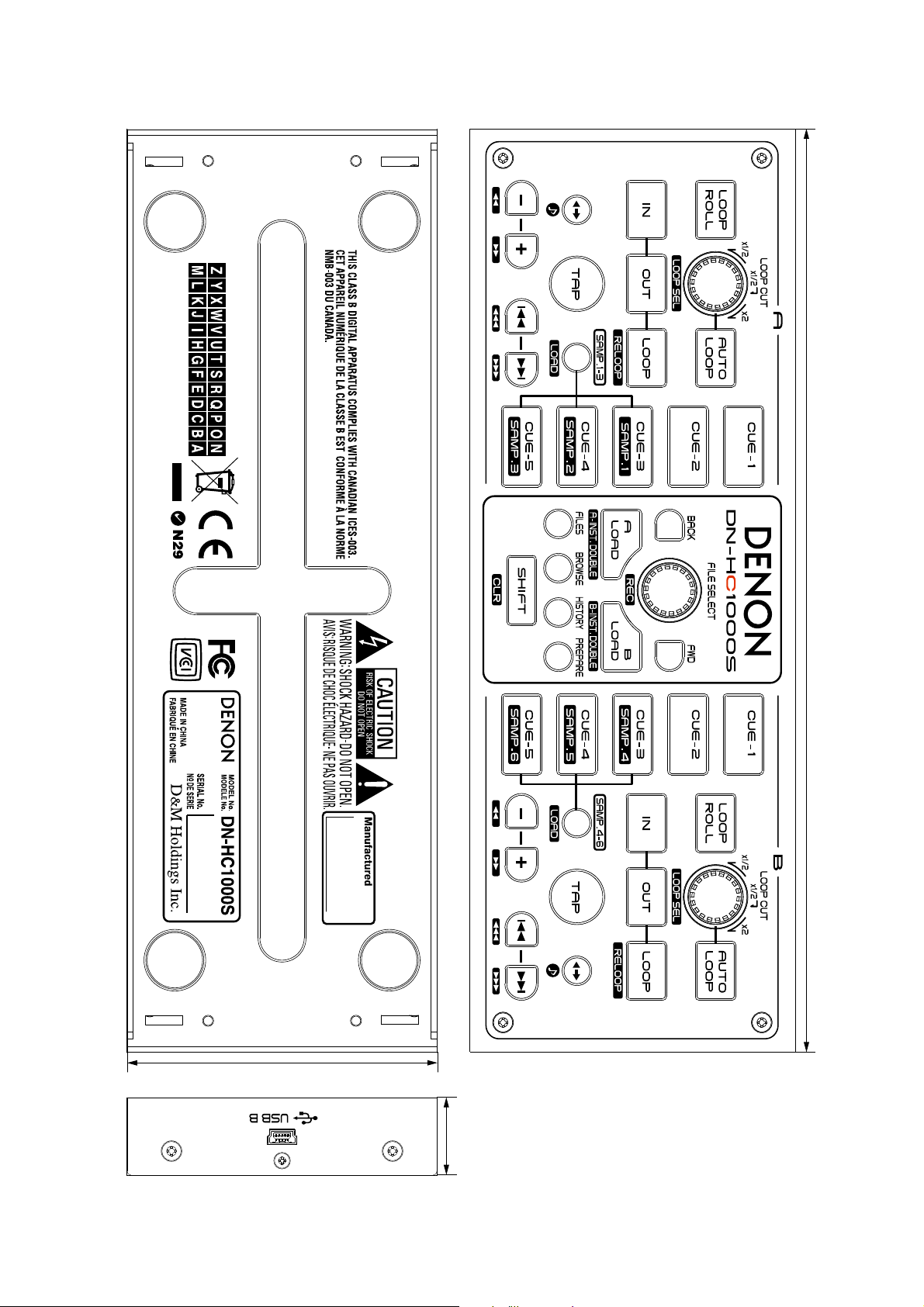

DIMENSION

25 mm

250 mm

88 mm

3

HOW TO CHECK FIRMWARE VERSION?

X: 1(Auto Loop), 2(IN), 3(OUT), 4(TAP)

Y: 1(CUE1), 2(CUE2),3(CUE3),4(CUE4),5(CUE5)

Z: 1(CUE1),2(CUE2),3(CUE3),4(CUE4),5(CUE5),

6(Auto Loop),7(IN),8(OUT),9(TAP)

(1) Press the Shift and FWD button at the same time, then connect HC1000S to PC with USB cord to check the light

buttons that represent Firmware version.

Firmware Version Leds (Ver X .YZ)

※ The first release is "Ver 1.17".

(2) Press the Shift button to retrurn to Normal Mode.

FIRMWARE UPDATE

Use the procedure described below to update the firmware to a newer version.

(1) Press the BACK and FWD button at the same time, then connect DN-HC1000S to PC.

(2) DN-HC1000S will enter updating mode. CUE-1(A, B) will light to indicate "Update Ready."

(3) PC Operation System will pop-up a new hard disc, named DN-HC1000S.

(4) Copy updated file (EX: DN-HC1000S_v1.13.bin), and paste on "DN-HC1000S" hard disc.

(5) It will start updating. After updating successfully, DN-HC1000S will switch to Midi Controller automatically.

(6) Firmware updating State:

CUE-1(A, B): Update Ready

CUE-2(A, B): Update Data(0%)

CUE-3(A, B): Update Data(50%)

CUE-4(A, B): Update Data(100%)

CUE-5(A, B): Update Success (* If it doesn't light, it means "Updating Error")

ALL LED LIGHT UP

(1) Press the BACK and SHFT button at the same time, then connect DN-HC1000S to PC.

4

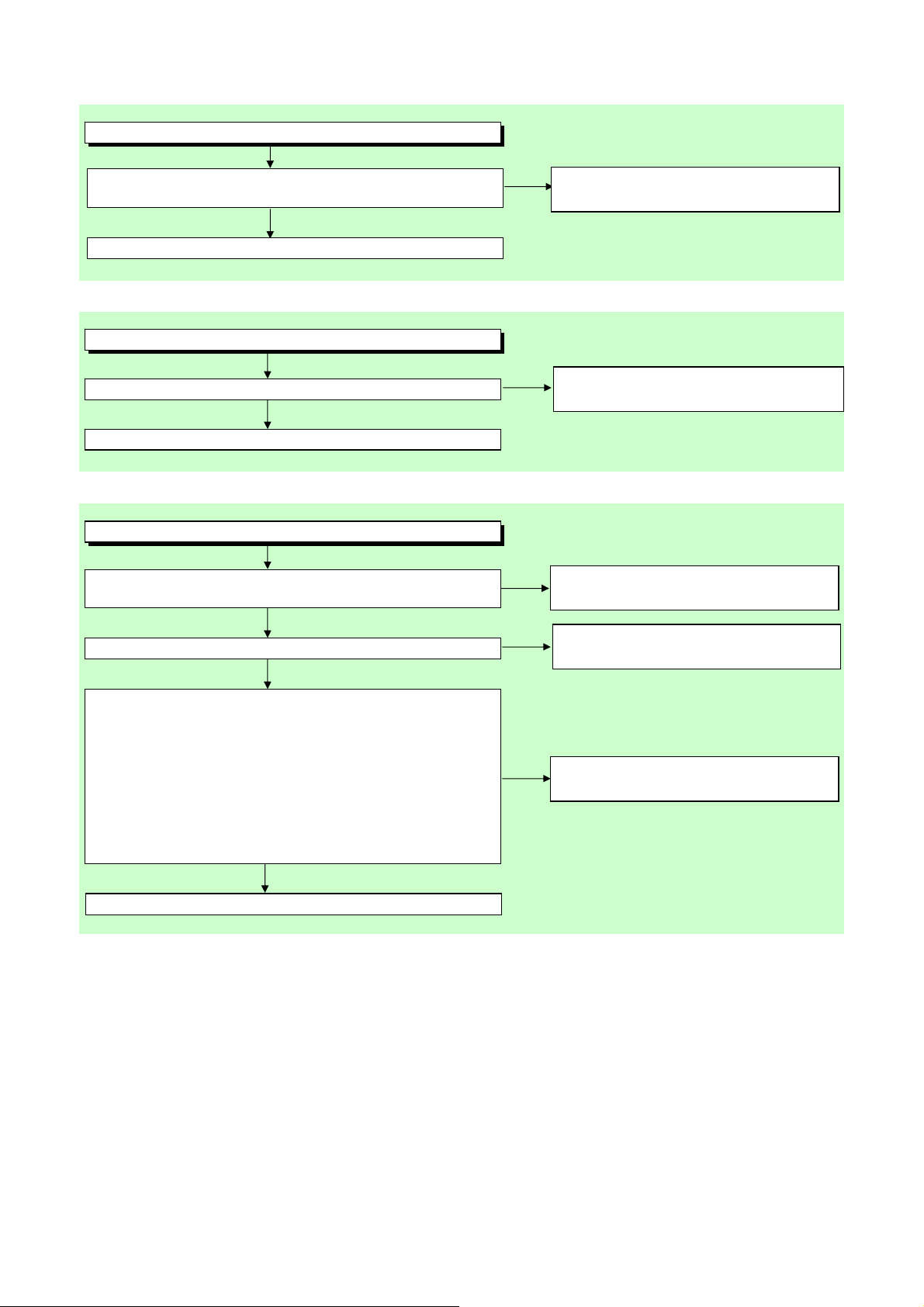

TROUBLE SHOOTING

FLOW CHART NO.1䇭(MAIN UNIT

)

FLOW CHART No.2䇭

(

MAIN UNIT

)

FLOW CHART No.3䇭(MAIN䇭UNIT

)

The power cannot be turned on.

No

Yes

Is the USB cable or the USB terminal of the PC

side normal?

Is normal state restored when once unplugged USB cord is plugged

again?

Check JK101 and the periphery circuit, and replace it if defective.

+3.3V is not outputted.

Is the +5V line voltage normal?

Yes

Refer to FLOW CHART NO.1 [The power

cannot be turned on.]

Check IC105 and the periphery circuit, and replace it if defective.

The key operation is not functioning.

A

re the contact point and the installation state of the key switches

䋨SW101~SW146 䋩 normal?

Yes

Re-install the switches (SW101~SW146)

correctly or replace the poor switch.

Does LED 䋨D101A䌾D118A䇮D101B䌾D118B䋩 light correctly ?

Check Q101䌾Q118 and the periphery circuit,

and replace it if defective.

When pressing each key switches, do the voltage of each pin of

IC101(shown below) decrease?

䇭

SW143,SW144,SW145,SW146 : IC101 34pin

SW136,SW137,SW138,SW139,SW140,SW141,SW142 : IC101 35pin

SW129,SW130,SW131,SW132,SW133,SW134,SW135 : IC101 36pin

SW122,SW123,SW124,SW125,SW126,SW127,SW128 : IC101 37pin

SW115,SW116,SW117,SW118,SW119,SW120,SW121 : IC101 38pin

SW108,SW109,SW110,SW111,SW112,SW113,SW114 : IC101 39pin

SW101,SW102,SW103,SW104,SW105,SW106,SW107 : IC101 40pin

Yes

Replace IC101.

Yes

Check the key switches 䋨SW101䌾SW146䋩

and their periphery, and service it if detective.

No

No

No

No

5

SEMICONDUCTORS

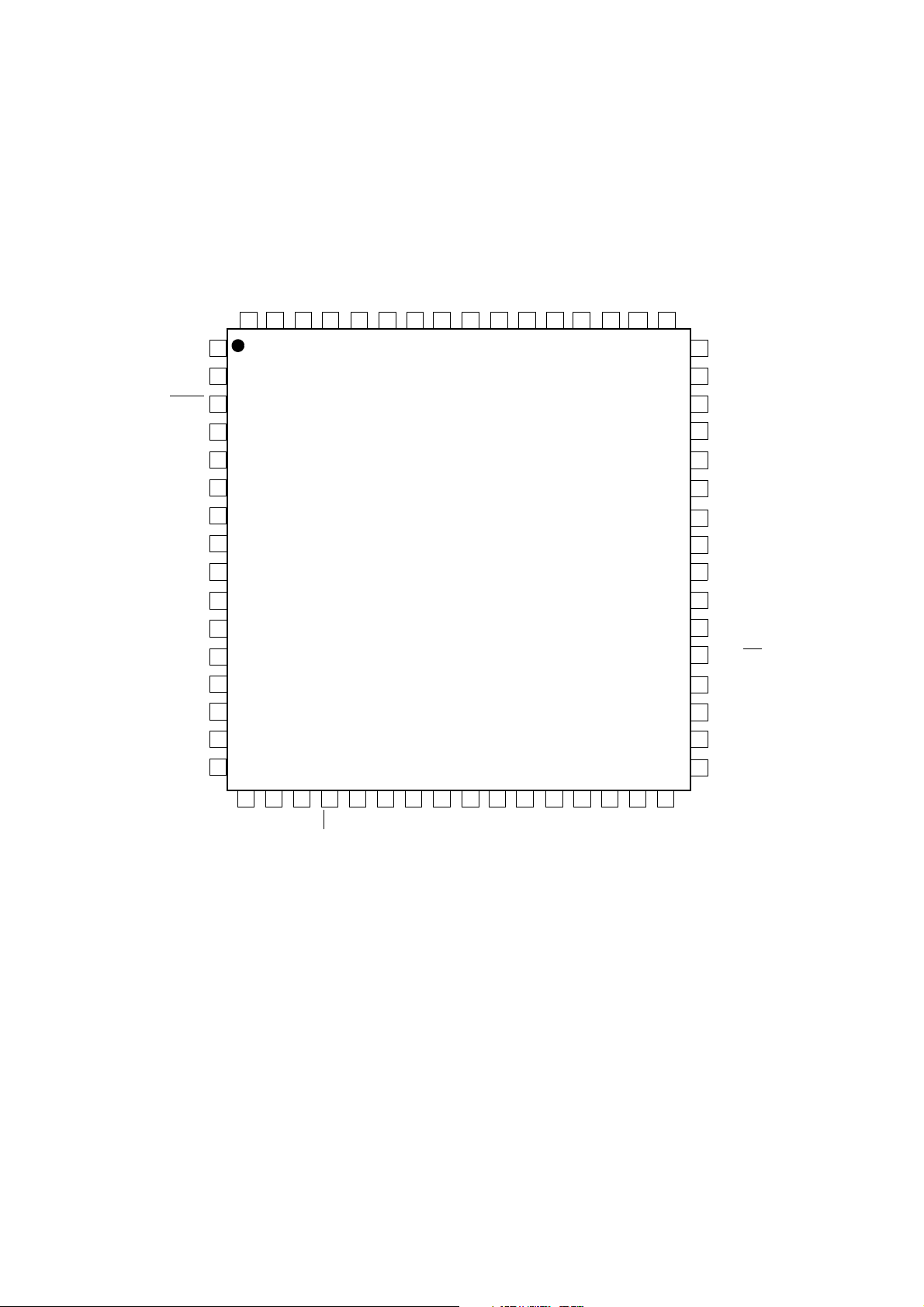

PTF2/TPM1CH4

1

2

3

4

5

6

7

8

RESET

PTF0/TPM1CH2

PTF3/TPM1CH5

PTF4/TPM2CH0

PTC6

PTF7

V

USB33

USBDP

USBDN

V

SS

V

DD

PTE7/SS1

PTE6/SPSCK1

PTB7/ADP7

PTD0/ADP8/ACMP+

PTD1/ADP9/ACMP–

V

DDAD

V

REFH

PTB1/MOSI2/ADP1

PTB6/ADP6

PTD5

PTG2/KBIP6

PTC5/RxD2

PTG4/XTAL

BKGD/MS

PTG3/KBIP7

PTD2/KBIP2/ACMPO

PTD6

PTD7

43

42

41

40

39

38

18 19 20 21 22

23

505152535455

17

32

33

49

48

64

9

PTF5/TPM2CH1

10

PTF6

11

PTE0/TxD1

16

PTE3/TPM1CH1

PTG0/KBIP024PTG1/KBIP1

25

PTA0

26

PTA1

27

PTB5/KBIP5/ADP5

37

PTB4/KBIP4/ADP4

36

PTB3/SS2/ADP3

35

PTB2/SPSCK2/ADP2

34

PTG5/EXTAL

56

V

SSOSC

57

PTC0/SCL

58

PTC1/SDA

59

PTF1/TPM1CH3

12

PTE1/RxD1

13

14

15

PTE2/TPM1CH0

PTA2

28 29 30 31

V

REFL

44

45

46

V

SSAD

47

PTC3/TxD2

63 62 61

PTC2

60

PTC4

IRQ/TPMCLK

PTE4/MISO1

PTE5/MOSI1

PTA3

PTA4

PTB0/MISO2/ADP0

PTA5

PTD4/ADP11

PTD3/KBIP3/ADP10

64-Pin QFP/LQFP

Only major semiconductors are shown, general semiconductors etc. are omitted to list.

The semiconductor which described a detailed drawing in a schematic diagram are omitted to list.

1. IC’s

MC9S08JM32 (IC101)

6

Loading...

Loading...