Page 1

Dell PowerEdge C8000

Hardware Owner’s

Manual

Regulatory Model: B10S

Regulatory Type: B10S001

Page 2

Notes, Cautions, and Warnings

NOTE: A NOTE indicates important information that helps you make better use of

your computer.

CAUTION: A CAUTION indicates potential damage to hardware or loss of data if

instructions are not followed.

WARNING: A WARNING indicates a potential for property damage, personal

injury, or death.

____________________

Information in this publication is subject to change without notice.

© 2013 Dell Inc. All rights reserved.

Reproduction of these materials in any manner whatsoever without the written permission of Dell Inc.

is strictly forbidden.

Trademarks used in this text: Dell™, the DELL logo, PowerEdge™ are trademarks of Dell Inc.

Intel is a registered trademark of Intel Corporation in the United State or other countries.

Other trademarks and trade names may be used in this publication to refer to either the entities claiming

the marks and names or their products. Dell Inc. disclaims any proprietary interest in trademarks and

trade names other than its own.

Regulatory Model B10S

Regulatory Type: B10S001

2013 - 10 P/N XXXXX Rev. A05

Page 3

Contents

1 About the System . . . . . . . . . . . . . . . . . . 11

Accessing System Features During Startup. . . . . . . 12

Front-Panel Features and Indicators . . . . . . . . . . 13

Back-Panel Features and Indicators

Server Enclosure Indicator Codes

. . . . . . . . . . 15

. . . . . . . . . . . . 18

NIC Indicator Codes . . . . . . . . . . . . . . . . . . . 20

Sled Bay Numbering

Fan Bay Numbering

. . . . . . . . . . . . . . . . . . . 22

. . . . . . . . . . . . . . . . . . . 23

Sled Module Configuration . . . . . . . . . . . . . . . 24

Sled Features

Compute Sleds

Storage Sleds

Power Sleds

Service Tag

Server Enclosure

Sleds

. . . . . . . . . . . . . . . . . . . . . . 26

. . . . . . . . . . . . . . . . . . . 26

. . . . . . . . . . . . . . . . . . . . 34

. . . . . . . . . . . . . . . . . . . . 36

. . . . . . . . . . . . . . . . . . . . . . . . 38

. . . . . . . . . . . . . . . . . . 38

. . . . . . . . . . . . . . . . . . . . . . . . 39

POST Error Codes . . . . . . . . . . . . . . . . . . . . 42

Collecting System Event Log for Investigation

. . . 42

Contents 3

Page 4

System Event Log. . . . . . . . . . . . . . . . . . . . . 50

Processor Error

Memory Ecc

. . . . . . . . . . . . . . . . . . . 50

. . . . . . . . . . . . . . . . . . . . . 51

PCIe Error . . . . . . . . . . . . . . . . . . . . . . 53

IOH Core Error

SB Error

. . . . . . . . . . . . . . . . . . . 54

. . . . . . . . . . . . . . . . . . . . . . . 55

POST Start Event . . . . . . . . . . . . . . . . . . 56

POST End Event

POST Error Code Event

. . . . . . . . . . . . . . . . . . . 57

. . . . . . . . . . . . . . . 58

BIOS Recovery Event . . . . . . . . . . . . . . . . 59

ME Fail Event

SEL Generator ID

. . . . . . . . . . . . . . . . . . . . . . . . . . . 61

BMC

. . . . . . . . . . . . . . . . . . . . 59

. . . . . . . . . . . . . . . . . . 60

2 Using the System Setup Program . . . . . 67

4 Contents

Other Information You May Need

. . . . . . . . . . . . 66

System Setup Menu . . . . . . . . . . . . . . . . . . . 67

System Setup Options at Boot

Using the System Setup Program Navigation Keys

General Help

Console Redirection

. . . . . . . . . . . . . . . . . . . . . . . 69

. . . . . . . . . . . . . . . . . . . 69

Enabling and Configuring Console Redirection

Main Menu

. . . . . . . . . . . . . . . . . . . . . . . . 74

Main Screen

System Settings

. . . . . . . . . . . . . . . . . . . . 74

. . . . . . . . . . . . . . . . . . . 75

. . . . . . . . . . . . . . 68

. . . 68

. . . 69

Page 5

Advanced Menu . . . . . . . . . . . . . . . . . . . . . 77

Power Management

CPU Configuration

. . . . . . . . . . . . . . . . 78

. . . . . . . . . . . . . . . . . 88

Memory Configuration . . . . . . . . . . . . . . . 92

SATA Configuration

PCI Configuration

. . . . . . . . . . . . . . . . . 95

. . . . . . . . . . . . . . . . . . 98

USB Configuration . . . . . . . . . . . . . . . . . 105

Security Menu . . . . . . . . . . . . . . . . . . . . . . 107

Server Menu

View System Log

Boot Menu

. . . . . . . . . . . . . . . . . . . . . . . 109

. . . . . . . . . . . . . . . . . . 115

. . . . . . . . . . . . . . . . . . . . . . . . 116

Exit Menu . . . . . . . . . . . . . . . . . . . . . . . . 118

Command Line Interfaces for System Setup

. . . . . . . . . . . . . . . . . . . . . . . . . . 120

Options

IPMI Command List

Power Management Settings

. . . . . . . . . . . . . . . . . . . 145

. . . . . . . . . . . . . . 154

SNMP . . . . . . . . . . . . . . . . . . . . . . . . . . 156

About MIB and Traps

. . . . . . . . . . . . . . . . 156

SNMP Support for the Server Enclosure

Fan Controller Board

FCB Firmware Behavior

MIB Tree Diagram for FCB

FCB SNMP MIB

. . . . . . . . . . . . . . . . 156

. . . . . . . . . . . . . . 158

. . . . . . . . . . . . . 160

. . . . . . . . . . . . . . . . . . . 161

SNMP Support for the External PDU

Power Management Controller Board . . . . . . . 167

PMC Firmware Behavior

MIB Tree Diagram for PMC

. . . . . . . . . . . . . . 169

. . . . . . . . . . . . 170

PMC SNMP MIB . . . . . . . . . . . . . . . . . . 171

Contents 5

Page 6

3 Installing System Components . . . . . . . 187

Safety Instructions . . . . . . . . . . . . . . . . . . . 187

About the Illustrations . . . . . . . . . . . . . . . . . 188

Recommended Tools

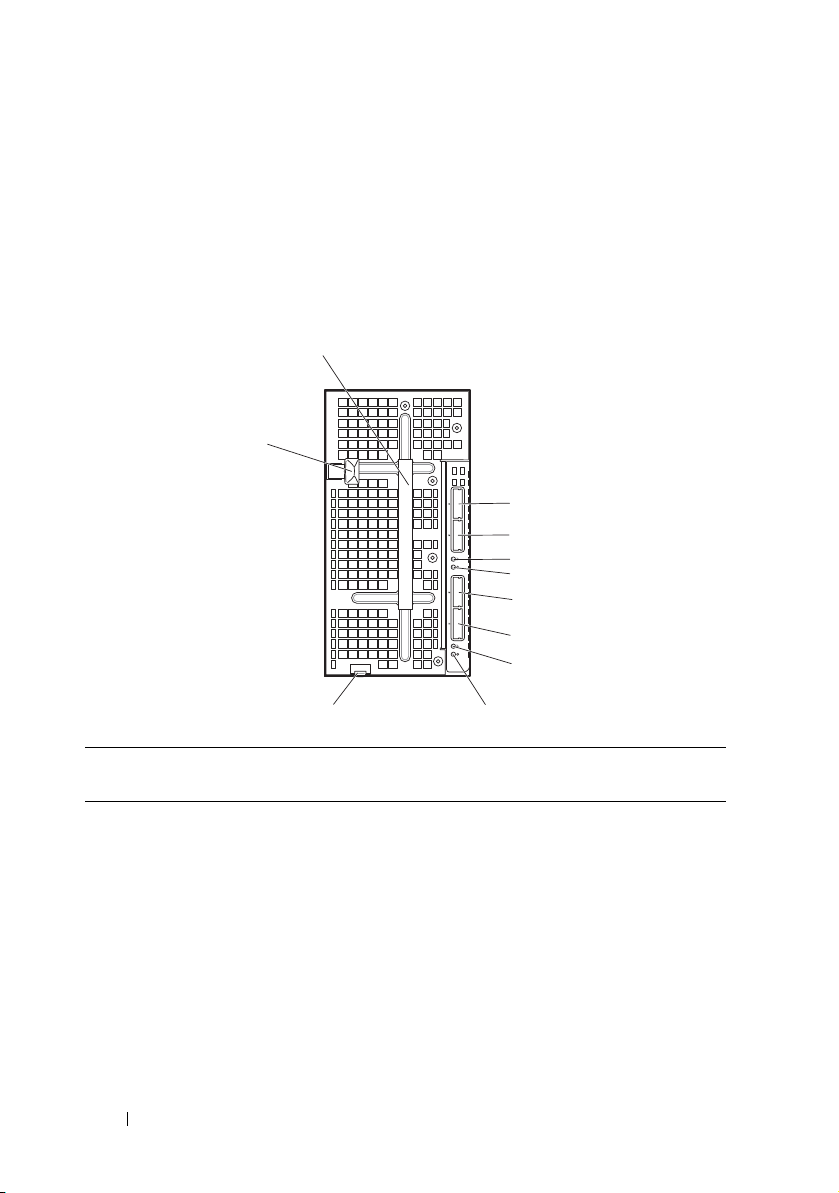

Inside the System

. . . . . . . . . . . . . . . . . . 188

. . . . . . . . . . . . . . . . . . . . 189

Sled Blank . . . . . . . . . . . . . . . . . . . . . . . 190

Removing a Double-Wide Sled Blank

. . . . . . 190

Installing a Double-Wide Sled Blank . . . . . . . 190

Removing a Single-Wide Sled Blank

Installing a Single-Wide Sled Blank

Compute Sleds

Removing a Compute Sled

Installing a Compute Sled

Storage Sled

Removing a Storage Sled

Installing a Storage Sled

Power Sled

Inside a Power Sled

Removing a Power Sled

Installing a Power Sled

. . . . . . . . . . . . . . . . . . . . . 192

. . . . . . . . . . . . 192

. . . . . . . . . . . . . 194

. . . . . . . . . . . . . . . . . . . . . . 194

. . . . . . . . . . . . . 194

. . . . . . . . . . . . . 195

. . . . . . . . . . . . . . . . . . . . . . . 196

. . . . . . . . . . . . . . . . 198

. . . . . . . . . . . . . . 198

. . . . . . . . . . . . . . 200

Removing the PSU1/3 Module Assembly

Installing the PSU1/3 Module Assembly

Removing the PSU2/4 Module Assembly

Installing the PSU2/4 Module Assembly

Removing the PSU Module

. . . . . . . . . . . . 205

. . . . . . . 191

. . . . . . . 191

. . . . . 201

. . . . . 203

. . . . . 203

. . . . . 204

Installing the PSU Module . . . . . . . . . . . . 206

6 Contents

Page 7

Fan Modules . . . . . . . . . . . . . . . . . . . . . . . 207

Removing a Fan Module

Installing a Fan Module

. . . . . . . . . . . . . . 207

. . . . . . . . . . . . . . . 208

Front Panel Board

Removing the Front Panel Board

Installing the Front Panel Board

Fan Controller Board

Removing the Fan Controller Board

Installing the Fan Controller Board

Backplane/Fan Bay Cage

Removing the Backplane/Fan Bay Cage

Installing the Backplane/Fan Bay Cage

PDU Power Supply

PDU Power Supply Indicator Code

Removing a PDU Power Supply

. . . . . . . . . . . . . . . . . . . . 209

. . . . . . . . . . 209

. . . . . . . . . . 210

. . . . . . . . . . . . . . . . . . . 211

. . . . . . . . 211

. . . . . . . . . 212

. . . . . . . . . . . . . . . . 212

. . . . . . 212

. . . . . . 216

. . . . . . . . . . . . . . . . . . . . 217

. . . . . . . . . 217

. . . . . . . . . . 217

Installing a PDU Power Supply . . . . . . . . . . . 219

4 Rack Mount Configuration . . . . . . . . . . 221

Installation Guidelines . . . . . . . . . . . . . . . . . 221

Recommended Tools

. . . . . . . . . . . . . . . . . . . 222

Installation Tasks

. . . . . . . . . . . . . . . . . . . . 222

Installing the Tool-Less Rail Solution

in the Rack

. . . . . . . . . . . . . . . . . . . . . . . . 223

Removing Sled Modules from the Server

Enclosure

. . . . . . . . . . . . . . . . . . . . . . . . 228

Installing the Server Enclosure into the Rack . . . . . 228

Contents 7

Page 8

Replacing Sled Modules in the Server

Enclosure. . . . . . . . . . . . . . . . . . . . . . . . 230

Installing the External PDU into the Rack

Connecting the Power Cables

. . . . . . . . . . . . . 237

. . . . . . . 231

Connecting the Power Cables to the

Server Enclosure with Internal

Power Source

. . . . . . . . . . . . . . . . . . . 237

Connecting the Power Cable to the

Server Enclosure with External

Power Source. . . . . . . . . . . . . . . . . . . 238

Connecting the Server Enclosure to

a Rack PDU

. . . . . . . . . . . . . . . . . . . . . . . 239

Connecting a Network Switch to

a Rack PDU

Connecting the PDU to the Network

Powering Up the Systems

. . . . . . . . . . . . . . . . . . . . . . . 242

. . . . . . . . . . 243

. . . . . . . . . . . . . . . 246

5 Troubleshooting. . . . . . . . . . . . . . . . . . . 251

Safety First—For You and Your System . . . . . . . . 251

Installation Problems

. . . . . . . . . . . . . . . . . 251

8 Contents

Troubleshooting System Startup Failure

Troubleshooting External Connections

Troubleshooting the Video Subsystem

Troubleshooting a USB Device

. . . . . . . . 252

. . . . . . . . 252

. . . . . . . . . 252

. . . . . . . . . . . . 252

Troubleshooting a Serial I/O Device. . . . . . . . . . 253

Troubleshooting a NIC

. . . . . . . . . . . . . . . . . 254

Page 9

Troubleshooting a Wet Enclosure . . . . . . . . . . . . 255

Troubleshooting a Damaged Enclosure

. . . . . . . . . 256

Troubleshooting Enclosure Fan Modules . . . . . . . . 257

Troubleshooting Cooling Problems

Troubleshooting Sled Components

Troubleshooting System Memory

Troubleshooting a Hard-Drive

Troubleshooting Expansion Cards

. . . . . . . . . . . 262

. . . . . . . . . . . 267

. . . . . . . . . 267

. . . . . . . . . . . 269

. . . . . . . . . 270

Troubleshooting Processors . . . . . . . . . . . . 270

Troubleshooting the System Board

Troubleshooting the System Battery

IRQ Assignment Conflicts

. . . . . . . . . . . . . . . . 273

. . . . . . . . 271

. . . . . . . . 272

6 Updating Firmware Images and

Monitoring the PDU Power

Status . . . . . . . . . . . . . . . . . . . . . . . . . . 275

Verifying and Updating the Fan Controller

Board Firmware Via the Compute Sled

Viewing the Fan Controller Board

Firmware Version Information

Updating the Fan Controller Board

Firmware . . . . . . . . . . . . . . . . . . . . . . 275

. . . . . . . . . 275

. . . . . . . . . . . 275

Verifying and Updating the Fan Controller

Board Firmware Via SNMP

Before You Begin

Checking FCB Indicators

Resetting the FCB Network Connection

. . . . . . . . . . . . . . . 276

. . . . . . . . . . . . . . . . . . 276

. . . . . . . . . . . . . . 277

. . . . . . 277

Viewing or Changing the FCB

Configuration Information . . . . . . . . . . . . . 278

Contents 9

Page 10

Configuring the SNMP Traps . . . . . . . . . . . 278

Updating the FCB Firmware

. . . . . . . . . . . . 279

Viewing the FCB Firmware Version

Information . . . . . . . . . . . . . . . . . . . . 280

Monitoring the External PDU Power Status

and Updating the PDU PMC Firmware

Before You Begin

. . . . . . . . . . . . . . . . . 280

Checking PDU Indicators

. . . . . . . . . 280

. . . . . . . . . . . . . 281

Resetting the PDU Network Connection . . . . . 281

Viewing or Changing the PMC

Configuration Information

. . . . . . . . . . . . . 282

Configuring the SNMP Traps . . . . . . . . . . . 282

Updating the PMC Firmware

. . . . . . . . . . . 283

Viewing the PMC Firmware Version

Information . . . . . . . . . . . . . . . . . . . . 284

7 Jumpers and Connectors. . . . . . . . . . . . 285

Server Enclosure Boards . . . . . . . . . . . . . . . 285

Front Panel Board Connectors

Fan Controller Board Connectors. . . . . . . . . 286

Power Management Board Connectors

. . . . . . . . . . 285

. . . . . 287

8 Getting Help . . . . . . . . . . . . . . . . . . . . . . 289

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 291

10 Contents

Contacting Dell . . . . . . . . . . . . . . . . . . 289

Page 11

1

About the System

The PowerEdge C8000 server enclosure features ten vertically aligned sled

bays which support a full sled or a mixed sled enclosure. A full sled enclosure

can include up to five C8220X double-wide compute sleds, ten C8220

single-wide compute sleds, or five C8000XD storage sleds. A mixed sled

enclosure can support a mixture of differing sled types. To function as a

system, a compute sled is inserted into the PowerEdge C8000 server enclosure

that supports fans and is connected to an external power source or an internal

power source (power sleds). The redundant system fans are shared resources

of the sleds in the PowerEdge C8000 server enclosure.

NOTE: To ensure proper operation and cooling, all bays in the enclosure must be

populated at all times with either a sled or with a sled blank.

NOTE: Throughout this manual, the PowerEdge C8000 server enclosure is referred

to as simply the "server enclosure" or the "chassis".

About the System 11

Page 12

Accessing System Features During Startup

The following keystrokes provide access to system features during startup.

The SAS/SATA card or PXE hotkey support are available only in the BIOS

boot mode. Hotkey function is not available in the Unified Extensible

Firmware Interface (UEFI) boot mode.

Keystroke Description

<F2> Enters the System Setup program. See "System Setup Menu" on

page 67.

<F11> Enters the BIOS Boot Manager or the Unified Extensible

Firmware Interface (UEFI) Boot Manager, depending on the

system's boot configuration.

<F12> Starts Preboot eXecution Environment (PXE) boot.

<Ctrl><C> Enters the LSI 2008 SAS Mezzanine Card Configuration Utility.

For more information, see the SAS adapter documentation.

<Ctrl><H> Enters the LSI 2008 SAS Mezzanine Card Configuration Utility.

For more information, see the documentation for your SAS RAID

card.

<Ctrl><S> Enters the utility to configure onboard NIC settings for PXE boot.

For more information, see the documentation for your integrated

NIC.

<Ctrl><I> Enters the onboard SAS and SATA controller’s configuration

utility.

12 About the System

Page 13

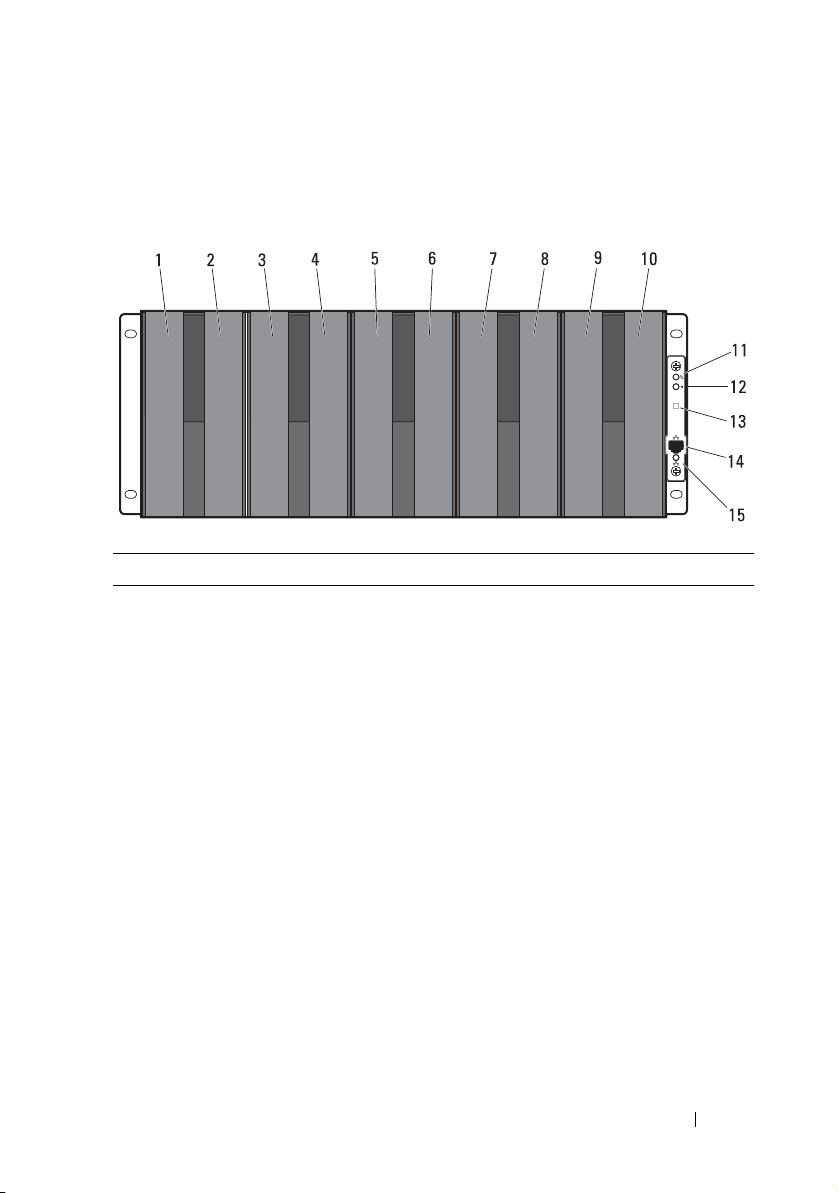

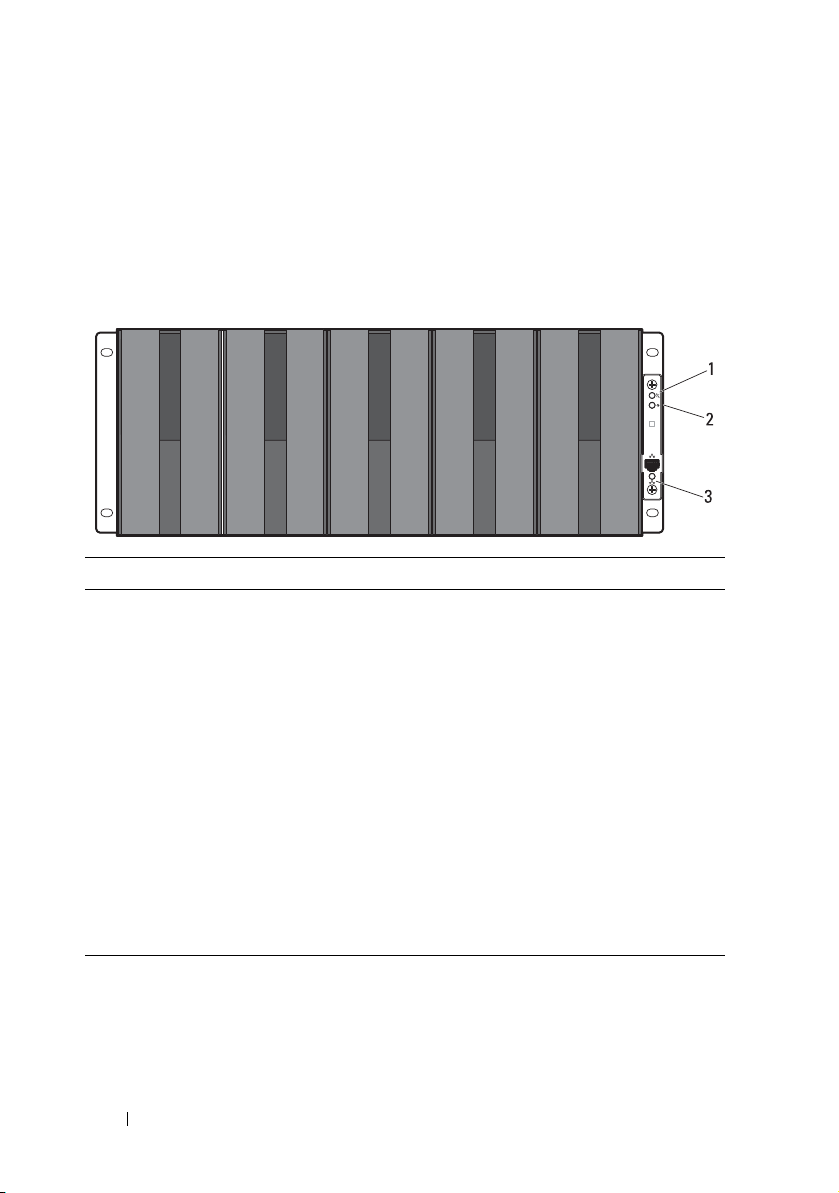

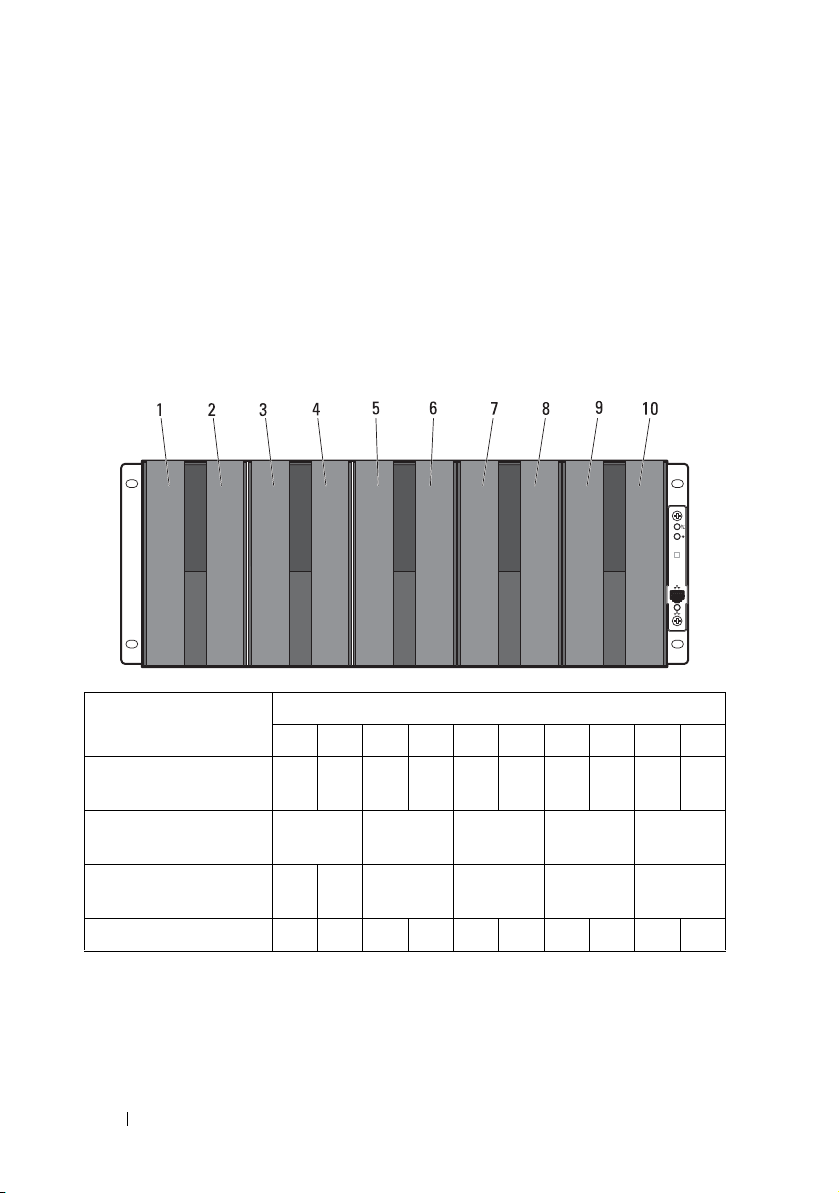

Front-Panel Features and Indicators

Figure 1-1. Front-Panel Features and Indicators

Item Feature Icon Description

1 - 10 Sled bays 1 to 10 Installs up to five C8220X compute sleds,

ten C8220 compute sleds, five C8000XD

storage sleds, or a mixture of differing sled

types.

NOTE: Sled bays 1 and 2 support installation

of two C8220 or one C8220X compute sleds.

For server enclosure with internal power

source, C8000XD storage sleds install in sled

bays 3 to 10 only.

Sled bays 5 and 6 Installs up to two power sleds or two C8220

compute sleds or a combination of the two

sled types.

NOTE: If the enclosure is configured with

only one power sled, a C8220 compute sled

or a power sled blank must be mounted into

the adjacent sled bay.

NOTE: The sled bays must always be

populated with either a sled or a sled blank

to ensure proper system cooling.

About the System 13

Page 14

Item Feature Icon Description

11 Chassis status

indicator

12 Chassis

identification

indicator

13 Thermal sensor Monitors the inlet ambient temperature.

14 Ethernet connector Embedded 10/100 Mbit NIC connector.

Indicates the power and health status of

the whole system.

Lights blue when the chassis ID signal is

generated.

15 NIC link/activity

indicator

Indicates state of the network link and

activity.

14 About the System

Page 15

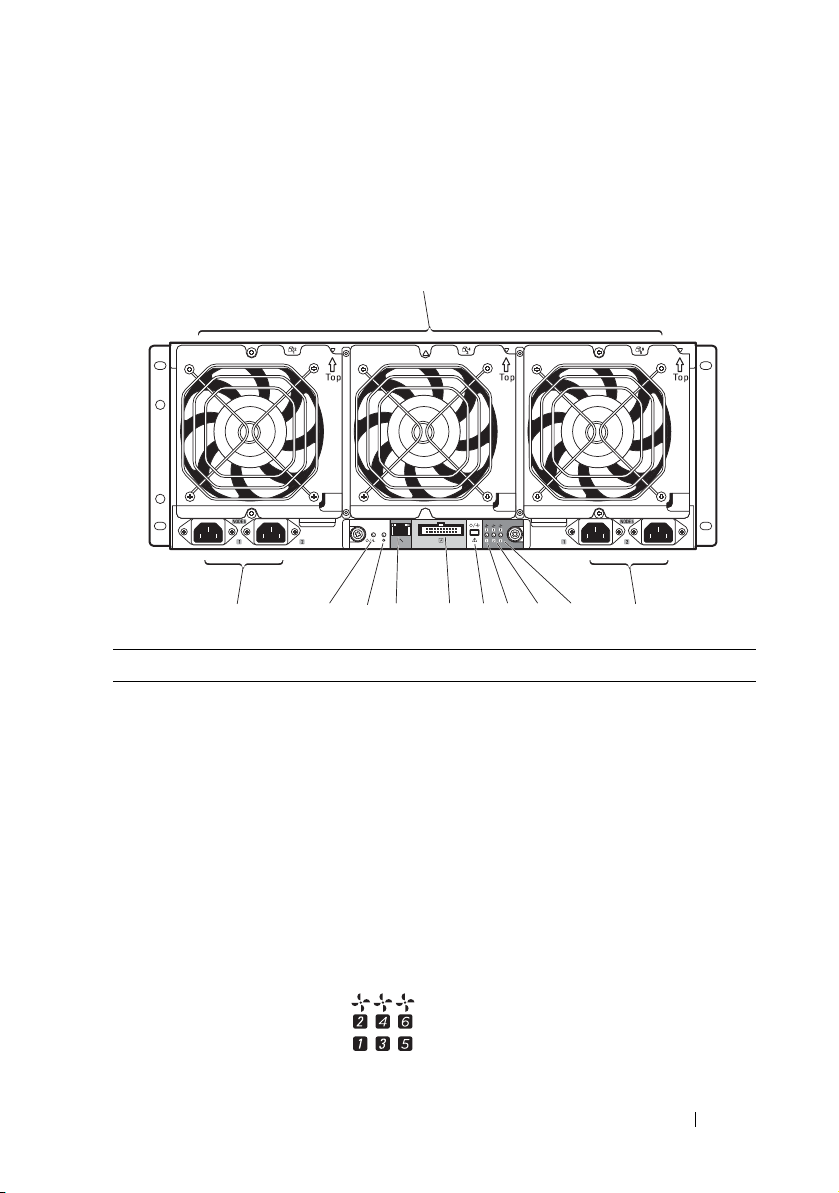

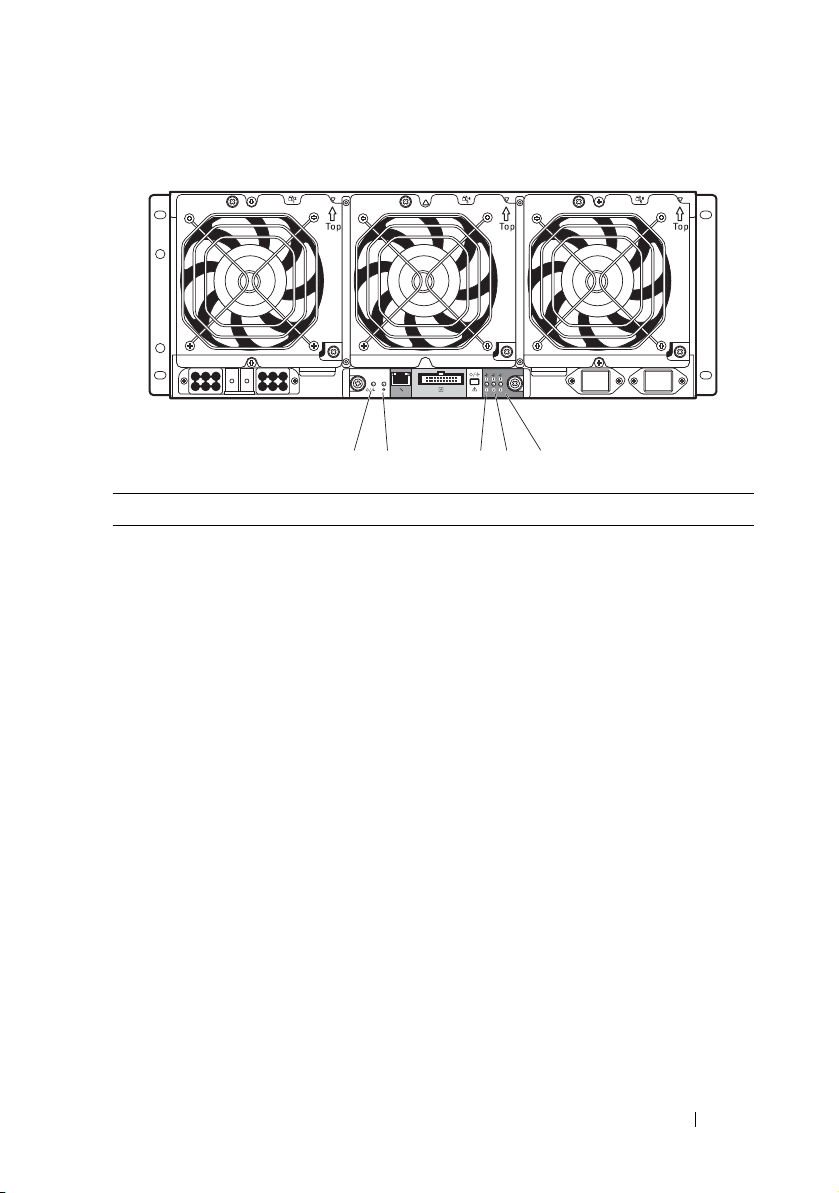

Back-Panel Features and Indicators

1

22

3

4

5

6

7

8910

Figure 1-2. Back-Panel Features and Indicators — Server Enclosure with Internal

Power Source

Item Feature Icon Description

1 Fan modules Provides cooling solution to the enclosure.

2 AC power sockets Connect the power cables to these power

sockets. When connected to a power

source, main power is automatically

distributed to the enclosure.

NOTE: Always connect the enclosure's AC

3, 4, 5 Fan fault indicators

1 to 6

power sockets to a single power source,

switch, or PDU.

NOTE: Before installing a compute or

storage sled to the front of the enclosure,

install the power sleds and connect power to

the enclosure.

Indicates the function status of the system

fans.

About the System 15

Page 16

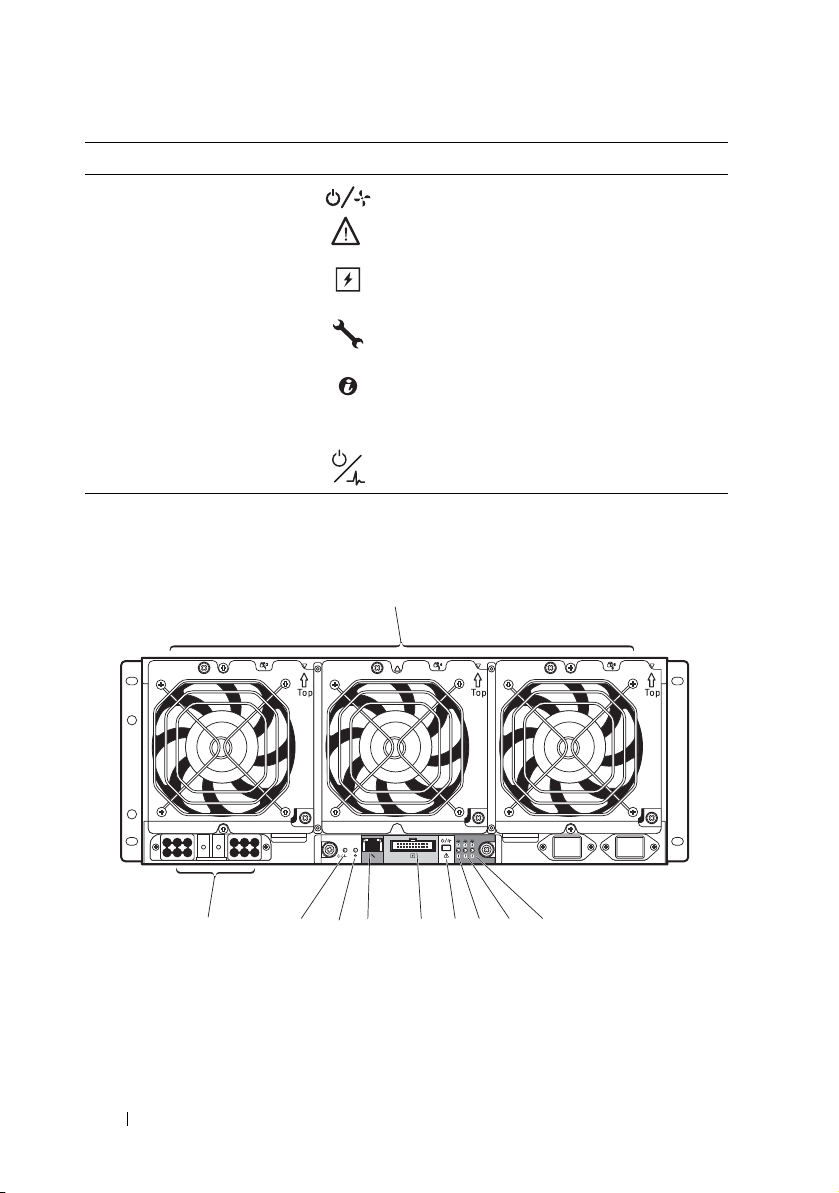

Item Feature Icon Description

1

2

3

4

5

6

789

10

6Service mode

button

Press this button within 4 seconds to enter

service mode.

7External PDU

connector

8 BMC management

port

9Chassis

identification

indicator

10 Power/event

indicator

Figure 1-3. Back-Panel Features and Indicators — Server Enclosure with External

Power Source

Connects to a PDU control connector.

Dedicated management port.

Lights blue when the chassis ID signal is

generated.

Indicates the power and health status of the

enclosure.

16 About the System

Page 17

Item Feature Icon Description

1 Fan modules Provides cooling solution to the enclosure.

2, 3, 4 Fan fault indicators

1 to 6

Indicates the function status of the system

fans.

5Service mode

button

6External PDU

connector

7 BMC management

port

8 Chassis

identification

indicator

9Power/event

indicator

10 DC power socket Connect the DC power cable to this power

Press this button within 4 seconds to enter

service mode.

Connects to a PDU control connector.

Dedicated management port.

Lights blue when the chassis ID signal is

generated.

Indicates the power and health status of the

enclosure.

socket. When connected to an external

PDU, main power is automatically

distributed to the enclosure.

NOTE: Always connect the enclosure's DC

power socket to a PDU.

NOTE: Before installing a compute or

storage sled to the front of the enclosure,

connect power to the enclosure.

About the System 17

Page 18

Server Enclosure Indicator Codes

The indicators on the front and back of the server enclosure displays

operational status of the enclosure, fan modules, and chassis controller

boards.

Figure 1-4. Server Enclosure Front-Panel Indicators

Item Indicator Color Status Indicator Code

1 Chassis status

indicator

2 Chassis

identification

indicator

3 NIC link/activity

indicator

Green Solid Indicates a valid power source is

connected to the server enclosure

and that the enclosure is

operational.

Off Off Power is not connected.

Amber Blinking Indicates a fault event occurred.

Blue Blinking Indicates a chassis ID signal is

generated.

Blue Off Chassis ID signal is not generated.

Green Solid Linking at 100 Mbps speed

(maximum).

Green Blinking Transmit or receive activity.

Off Off No activity.

18 About the System

Page 19

Figure 1-5. Server Enclosure Back-Panel Indicators

5

4

3

21

Item Indicator Color Status Indicator Code

1Power/event

indicator

2Chassis

identification

indicator

3 Fan 1 and 2

fault indicator

4 Fan 3 and 4

fault indicator

Green Solid Indicates a valid power source is

connected to the server enclosure

and that the enclosure is

operational and power is applied to

the fan controller board.

Green Blinking Power is connected to the

enclosure but the managed devices’

or sleds’ power is off.

Amber Blinking Indicates a fault event occurred.

Off Off Power is not connected.

Blue Blinking Indicates a chassis ID signal is

generated.

Blue Off Chassis ID signal is not generated.

Amber Blinking Indicates a fault event occurred in

fans 1 and 2.

Off Off Fans 1 and 2 are operational.

Amber Blinking Indicates a fault event occurred in

fans 3 and 4.

Off Off Fans 3 and 4 are operational.

About the System 19

Page 20

Item Indicator Color Status Indicator Code

5 Fan 5 and 6

fault indicator

Amber Blinking Indicates a fault event occurred in

fans 5 and 6.

Off Off Fans 5 and 6 are operational.

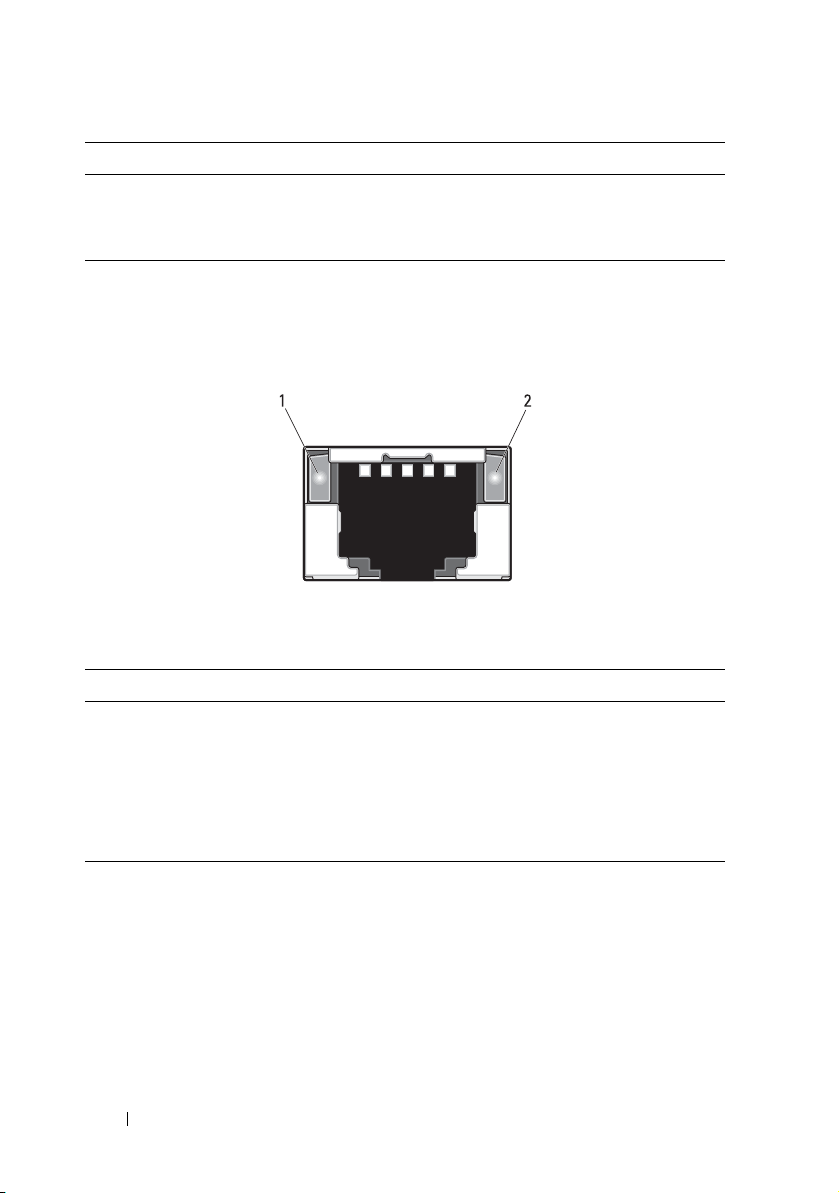

NIC Indicator Codes

Figure 1-6. NIC Indicators (Front-Panel Ethernet Connector)

1 link indicator 2 activity indicator

Indicator Status Indicator Code

Link indicator Solid amber Linking at 10 Mbps port speed

Solid green Linking at 100 Mbps port speed (maximum)

Activity

indicator

Solid green No activity

Blinking green Transmit or receive activity

Off Idle

20 About the System

Page 21

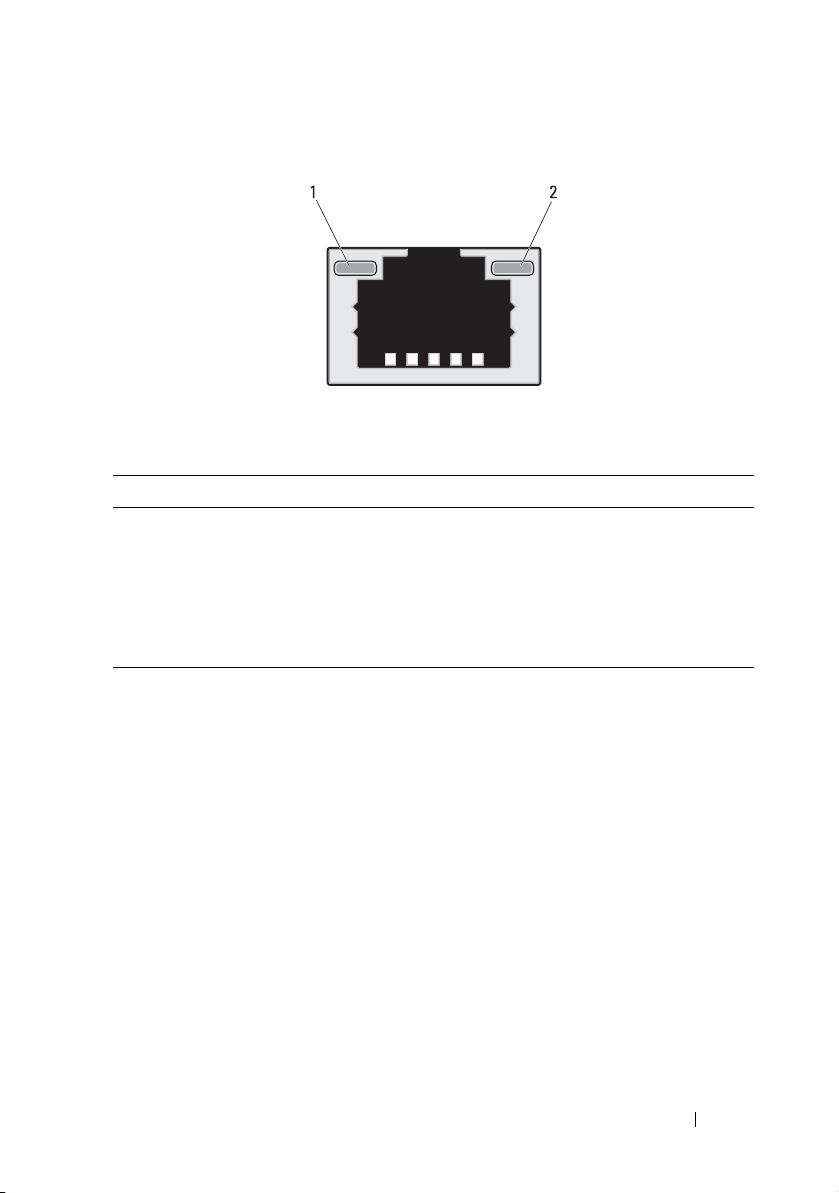

Figure 1-7. NIC Indicators (BMC management port)

1 link indicator 2 activity indicator

Indicator Status Indicator Code

Link indicator Blinking amber Linking at 10 Mbps port speed

Blinking green Linking at 100 Mbps port speed (maximum)

Activity

indicator

Solid green No activity

Blinking green Transmit or receive activity

Off Idle

About the System 21

Page 22

Sled Bay Numbering

The front of the server enclosure is divided into ten vertical bays. A C8220

single-wide compute sled occupies one sled bay in the server enclosure and a

C8220X double-wide compute sled or C8000XD storage sled occupies two

sled bays in the server enclosure. When installing a sled module into the

server enclosure, you should install the sled module in sled bay 1 first, then

work toward the right of the enclosure.

Figure 1-8. Sled Bay Numbering

Sled Bays

Sled module type

C8220 single-wide

12345

compute sled

C8220X double-wide

compute sled

C8000XD storageb

sled

Power sled

a. Sled bays 5 and 6 support installation of two power sleds or two C8220 compute sleds or a

combination of the two sled types.

b. For server enclosure with internal power source, install C8000XD storage sleds in sled bays 3 to 10

only.

c. Install power sleds in sled bays 5 and 6 only.

c

a6a

78910

22 About the System

Page 23

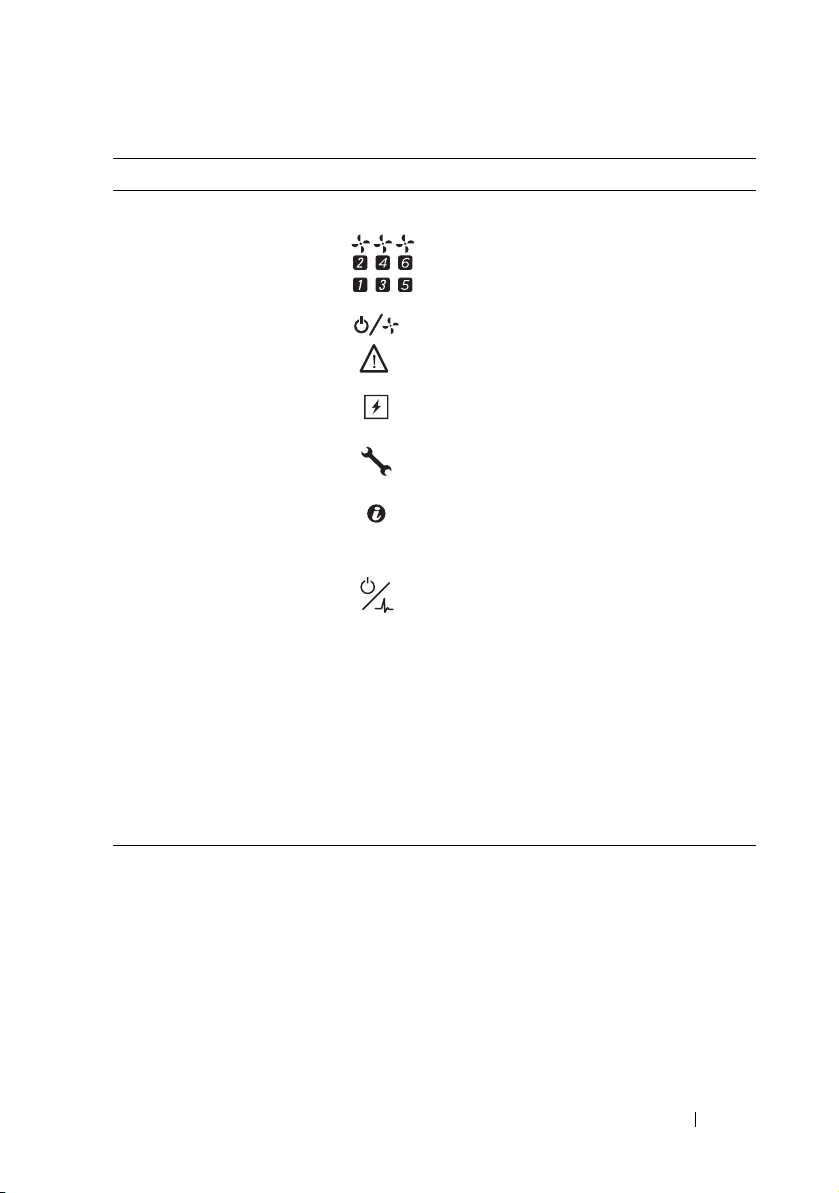

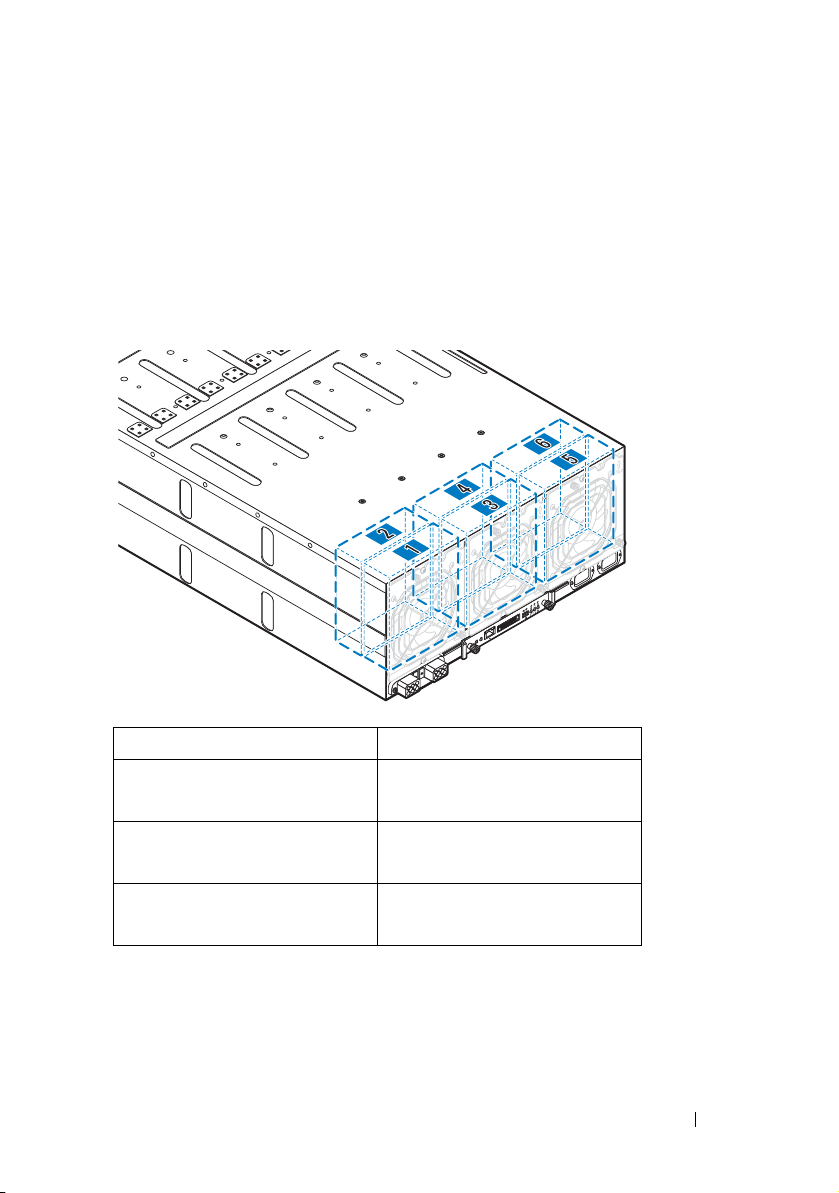

Fan Bay Numbering

The back of the PowerEdge C8000 server enclosure includes three hotswappable fan modules that provide the system with a redundant cooling

source. Each fan module contains two cooling fans. All three fan modules

must be installed at all times to ensure proper cooling.

Figure 1-9. Fan Bay Numbering

Fan Bay Cooling Fans

Fan module 1 Fan 2

Fan 1

Fan module 2 Fan 4

Fan 3

Fan module 3 Fan 6

Fan 5

About the System 23

Page 24

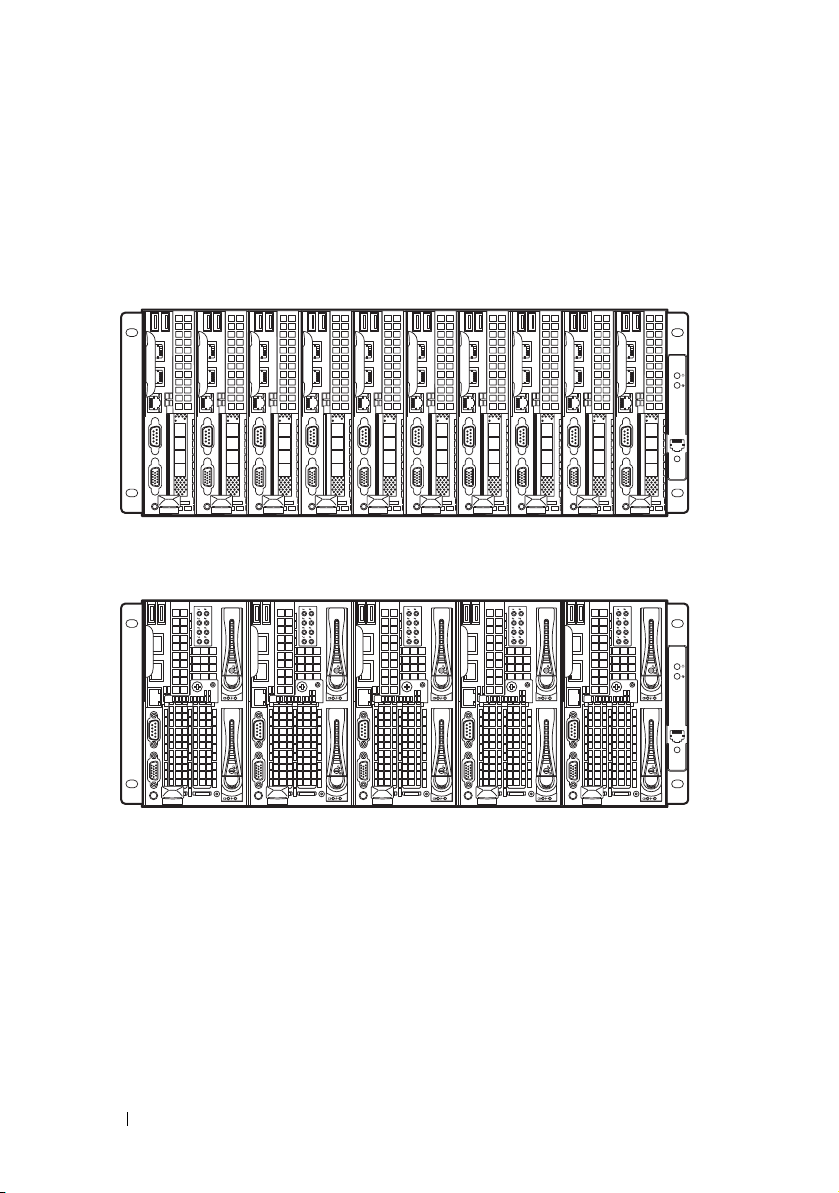

Sled Module Configuration

The following illustrations are sample sled module configurations available on

the PowerEdge C8000 server enclosure.

Figure 1-10. C8220 Single-Wide Compute Sleds

Figure 1-11. C8220X Double-Wide Compute Sleds

24 About the System

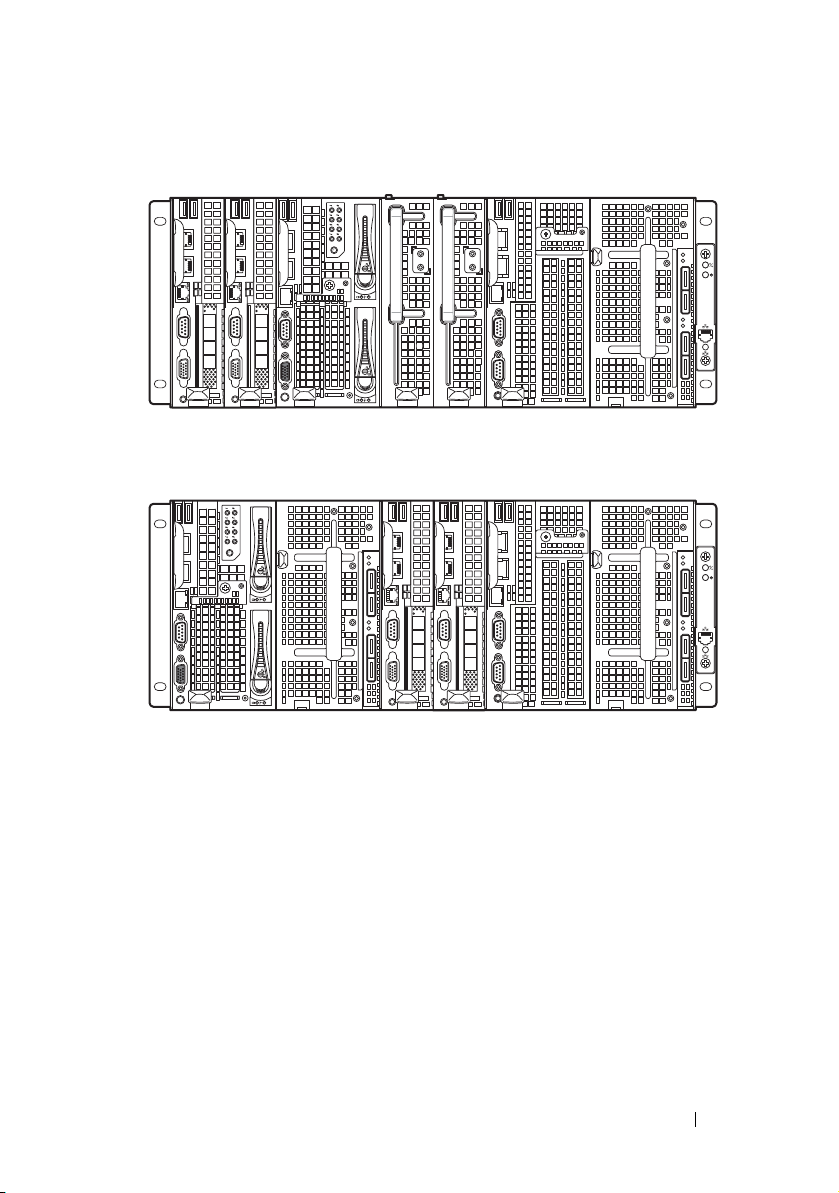

Page 25

Figure 1-12. Mixed Sleds — Server Enclosure with Internal Power Source

Figure 1-13. Mixed Sleds — Server Enclosure with External Power Source

About the System 25

Page 26

Sled Features

Compute Sleds

The PowerEdge C8000 server enclosure holds up to ten single-wide compute

sleds or five double-wide compute sleds. Each compute sled is equivalent to a

standard server built with a processor(s), memory, network interface,

baseboard management controller, and local hard-drive storage.

Single-Wide Compute Sled

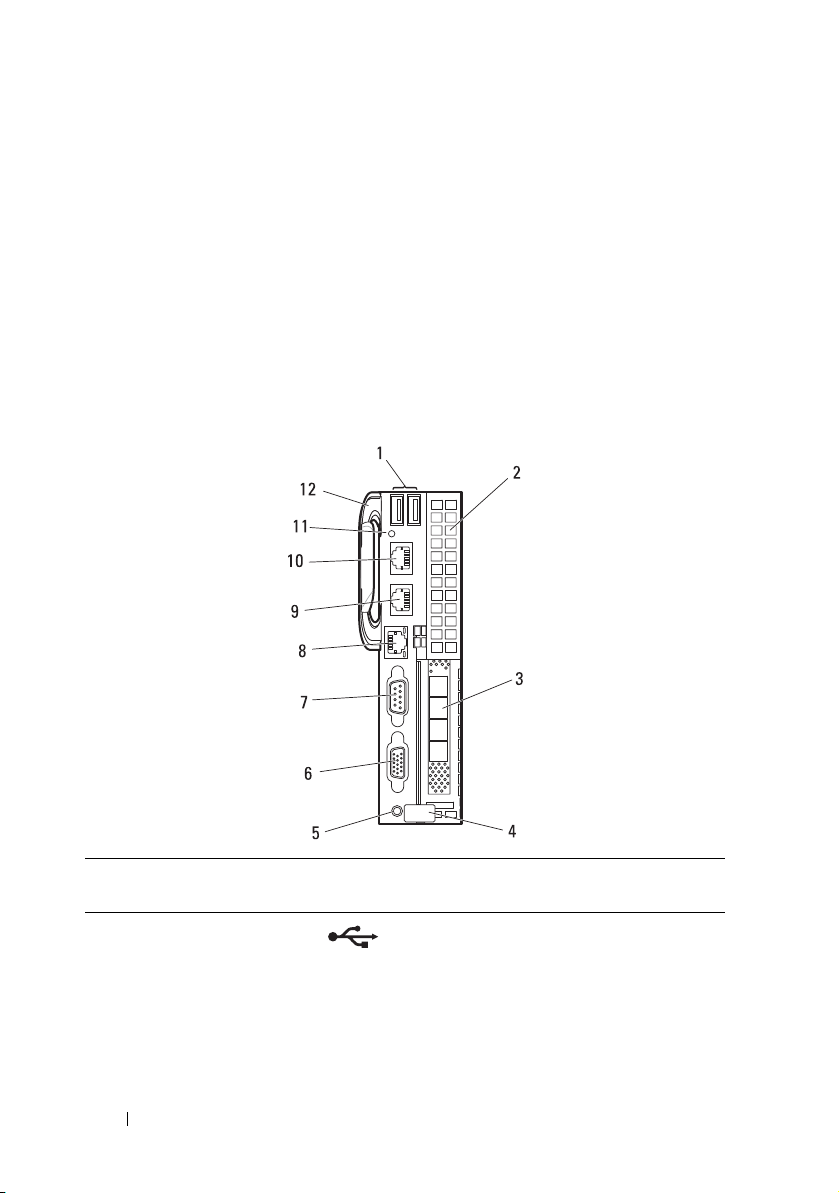

Figure 1-14. Sled Features — C8220 Single-Wide Compute Sled

Item Indicator, Button, or

Connector

1 USB connectors Connects USB devices to the sled. The

2 Mezzanine card

expansion slot

3 Low profile PCIe

expansion slot

Icon Description

ports are USB 2.0 compliant.

Installs an I/O module mezzanine card.

Installs a low profile PCI Express x16 card.

26 About the System

Page 27

Item Indicator, Button, or

Connector

4 Release latch Press to release the sled from the enclosure.

5Power-on indicator/

power button

Icon Description

The power-on indicator lights when the

sled power is on. The power-on indicator

lights amber when the system critical event

occurs.

NOTE: The power-on indicator lights amber

according to critical system error log (SEL)

assertion. If the SEL is full or a deassertion

event occurred while sensor monitoring is

paused (e.g. fan monitoring is paused during

system power off), the power-on indicator

turns amber. To turn off an amber LED and

reset the power-on indicator to normal

condition (solid green), either perform a

BMC cold reset or reseat the sled in the

server enclosure.

The power button turns the compute

sled on.

NOTES:

• When powering on the sled, the video

monitor can take from several seconds

to over 2 minutes to display an image,

depending on the amount of memory

installed in the system.

• On ACPI-compliant operating systems,

turning off the sled using the power

button causes the sled to perform a

graceful shutdown before power to the

sled is turned off.

• To force an ungraceful shutdown, press

and hold the power button for five

seconds.

About the System 27

Page 28

Item Indicator, Button, or

2

1

Connector

6 VGA connector Connects a VGA display to the system.

7 Serial connector Connects a serial device to the system.

Icon Description

8 BMC management

port

9 Ethernet connector 2 Embedded 10/100/1000 Mbit NIC

10 Ethernet connector 1 Embedded 10/100/1000 Mbit NIC

11 Sled identification

indicator

12 Handle Hold to pull the sled from the enclosure.

Dedicated management port.

connector.

connector.

Lights blue to identify a particular sled and

system board.

28 About the System

Page 29

Double-Wide Compute Sled

The C8220X double-wide compute sled includes two types of configuration,

a double-wide compute sled with front-access 2.5-inch hot-plug hard-drives

and a double-wide compute sled with general-purpose graphics processing

unit (GPGPU).

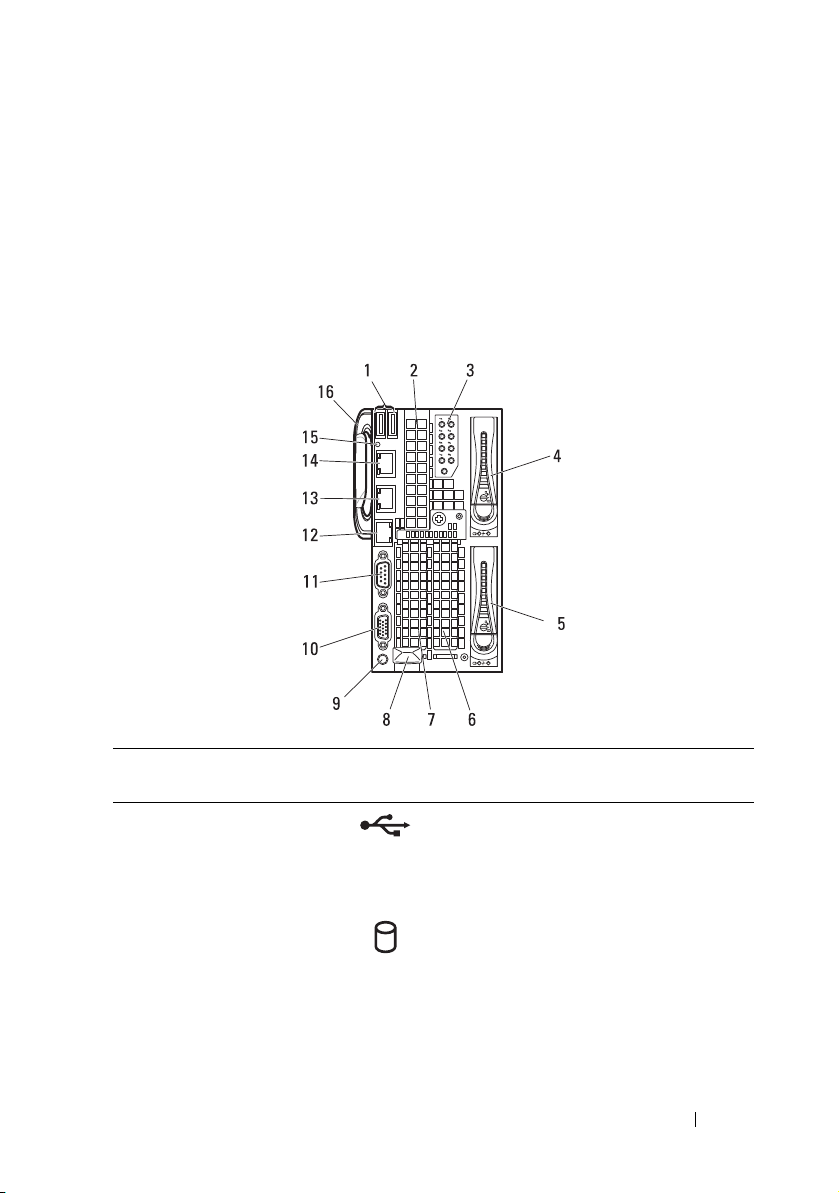

Figure 1-15. Sled Features — C8220X Double-Wide Compute Sled with Front-Access

Hot-Plug Hard-Drives

Item Indicator, Button, or

Connector

1 USB connectors Connects USB devices to the sled. The

2 Mezzanine card

expansion slot

3 Hard-drive indicators

0 to 7

4, 5 Hard-drive bay Installs two 2.5-inch hot-plug hard-drives.

6, 7 Low profile PCIe

expansion slots

Icon Description

ports are USB 2.0 compliant.

Installs an I/O module mezzanine card.

Indicates drive activity and status.

Installs up to two low profile PCI Express

x8 card when plugged into horizontal

expansion card connectors.

About the System 29

Page 30

Item Indicator, Button, or

Connector

8 Sled release latch Press to release the sled from the

9Power-on indicator/

power button

Icon Description

enclosure.

The power-on indicator lights when the

sled power is on.The power-on indicator

lights amber when the system critical

event occurs.

NOTE: The power-on indicator lights amber

according to critical system error log (SEL)

assertion. If the SEL is full or a deassertion

event occurred while sensor monitoring is

paused (e.g. fan monitoring is paused during

system power off), the power-on indicator

turns amber. To turn off an amber LED and

reset the power-on indicator to normal

condition (solid green), either perform a

BMC cold reset or reseat the sled in the

server enclosure.

The power button turns the compute sled

on.

NOTES:

• When powering on the sled, the video

monitor can take from several seconds

to over 2 minutes to display an image,

depending on the amount of memory

installed in the system.

• On ACPI-compliant operating

systems, turning off the sled using the

power button causes the sled to

perform a graceful shutdown before

power to the sled is turned off.

• To force an ungraceful shutdown, press

and hold the power button for five

seconds.

10 VGA connector Connects a VGA display to the system.

11 Serial connector Connects a serial device to the system.

30 About the System

Page 31

Item Indicator, Button, or

2

1

1

3

4

5

6

7

8

9

10

11

2

12

Connector

12 BMC management

port

13 Ethernet connector 2 Embedded 10/100/1000 Mbit NIC

14 Ethernet connector 1 Embedded 10/100/1000 Mbit NIC

15 Sled identification

indicator

16 Handle Hold to pull the sled from the enclosure.

Figure 1-16. Sled Features — C8220X Double-Wide Compute Sled with GPGPU

Icon Description

Dedicated management port.

connector.

connector.

Lights blue to identify a particular sled

and system board.

Item Indicator, Button, or

1 USB connectors Connects USB devices to the sled. The ports

2 Mezzanine card

Connector

expansion slot

Icon Description

are USB 2.0 compliant.

Installs an I/O module mezzanine card.

About the System 31

Page 32

Item Indicator, Button, or

Connector

3 Sled cover/ GPGPU

card assembly

4 Sled release latch Press to release the sled from the enclosure.

5Power-on indicator/

power button

Icon Description

Installs up to two GPGPU cards when

plugged into horizontal GPGPU card risers.

The power-on indicator lights when the sled

power is on.The power-on indicator lights

amber when the system critical event occurs.

NOTE: The power-on indicator lights amber

according to critical system error log (SEL)

assertion. If the SEL is full or a deassertion

event occurred while sensor monitoring is

paused (e.g. fan monitoring is paused during

system power off), the power-on indicator turns

amber. To turn off an amber LED and reset the

power-on indicator to normal condition (solid

green), either perform a BMC cold reset or

reseat the sled in the server enclosure.

The power button turns the compute sled on.

NOTES:

• When powering on the sled, the video

monitor can take from several seconds to

over 2 minutes to display an image,

depending on the amount of memory

installed in the system.

• On ACPI-compliant operating systems,

turning off the sled using the power

button causes the sled to perform a

graceful shutdown before power to the

sled is turned off.

• To force an ungraceful shutdown, press

and hold the power button for five

seconds.

6 VGA connector Connects a VGA display to the system.

7 Serial connector Connects a serial device to the system.

32 About the System

Page 33

Item Indicator, Button, or

2

1

Connector

8 BMC management

port

9 Ethernet connector

2

10 Ethernet connector

1

11 Sled identification

indicator

12 Handle Hold to pull the sled from the enclosure.

Icon Description

Dedicated management port.

Embedded 10/100/1000 Mbit NIC connector.

Embedded 10/100/1000 Mbit NIC connector.

Lights blue to identify a particular sled and

system board.

About the System 33

Page 34

Storage Sleds

1

2

3

4

5

6

7

8

910

11

The C8000XD storage sled is a direct attached storage for the server

enclosure. The storage sled provides dedicated data storage to a C8220X sled

or C8220 sled. Each storage sled supports up to a maximum of 12 x 3.5-inch/

2.5-inch hard-drives or 24 x 2.5-inch SSD hard-drives.

Figure 1-17. Sled Features — C8000XD Storage Sled

Item Indicator, Button, or

Connector

1 Handle Hold to pull the hard-drive cage from the

2 Mini-SAS connector A2 Connects to a compute sled’s host bus

3 Mini-SAS connector A1 Connects to a compute sled’s HBA or

34 About the System

Icon Description

sled.

adapter (HBA) or RAID controller card.

RAID controller card.

Page 35

Item Indicator, Button, or

Connector

4, 8 Sled power/status

indicator

5, 9 Sled identification

indicator

6 Mini-SAS connector B2 Connects to a compute sled’s HBA or

7 Mini-SAS connector B1 Connects to a compute sled’s HBA or

10 Sled release tab Press to release the sled from the

11 Hard-drive cage release

latch

Icon Description

The power-on indicator lights green

when the sled power is on and power is

applied to the SAS expander board.

The power-on indicator alternately lights

green and blinks amber when a critical

event occurs.

Lights blue to identify a particular miniSAS connector and sled.

RAID controller card.

RAID controller card.

enclosure.

Press to release the hard-drive cage from

the sled.

About the System 35

Page 36

Power Sleds

You can install up to two hot-swappable power sleds in the server enclosure

that supports internal power source. Each power sled installs up to two

1400 W power supply modules that are capable of delivering 2800 W power

to the server enclosure at an input range of 200-240 V.

Figure 1-18. Sled Features — Power Sled

36 About the System

Page 37

Item Indicator, Button, or

Connector

1 PSU1/3 status

indicator

2 PSU2/4 status

indicator

3 Handle Hold to pull the sled from the enclosure.

4 Release latch Press to release the sled from the enclosure.

Icon Description

The PSU1/3 status indicator lights green

indicating that a valid power source is

connected to the power supply and that

power supply is operational.

The PSU1/3 status indicator lights amber

indicating a problem with the PSU module.

• PSU module fan locked (15 s)

• PSU module over temperature protection

(OTP)

• PSU module over current protection

(OCP)

• PSU module over voltage protection

(OVP)

• PSU module under voltage protection

(UVP)

The PSU2/4 status indicator lights green

indicating that a valid power source is

connected to the power supply and that

power supply is operational.

The PSU2/4 status indicator lights amber

indicating a problem with the PSU module.

• PSU module fan locked (15 s)

• PSU module over temperature protection

(OTP)

• PSU module over current protection

(OCP)

• PSU module over voltage protection

(OVP)

• PSU module under voltage protection

(UVP)

About the System 37

Page 38

Service Tag

The following illustrations provide location of the Service Tag number on the

server enclosure, compute sleds, and storage sleds.

Server Enclosure

Figure 1-19. Service Tag Location for Server Enclosure

38 About the System

Page 39

Sleds

Figure 1-20. Service Tag Location for C8220 Single-Wide Compute Sled

Figure 1-21. Service Tag Location for C8220X Double-Wide Compute Sled with 3.5-inch

(4-Drive Bay) Hard-Drives

About the System 39

Page 40

Figure 1-22. Service Tag Location for C8220X Double-Wide Compute Sled with 2.5-inch

(8-Drive Bay) Hard-Drives

Figure 1-23. Service Tag Location for C8220X Double-Wide Compute Sled with GPGPU

40 About the System

Page 41

Figure 1-24. Service Tag Location for C8000XD Storage Sled

About the System 41

Page 42

POST Error Codes

Collecting System Event Log for Investigation

Whenever possible, the system BIOS will output the current boot progress

codes on the video screen. Progress codes are 32-bit quantities plus optional

data. The 32-bit numbers include class, subclass, and operation information.

The class and subclass fields point to the type of hardware that is being

initialized. The operation field represents the specific initialization activity.

Based on the data bit availability to display progress codes, a progress code

can be customized to fit the data width. The higher the data bit, the higher

the granularity of information that can be sent on the progress port. The

progress codes may be reported by the system BIOS or option ROMs.

The Response section in the following table may be divided into 3 types:

• Warning or Not an error – The message is displayed on the screen. An error

record is logged to the SEL. The system will continue booting with a

degraded state. The user may want to replace the erroneous unit.

• Pause – The message is displayed on the screen, an error is logged to the

SEL, and user input is required to continue. The user can take immediate

corrective action or choose to continue booting.

• Halt – The message is displayed on the screen, an error is logged to the

SEL, and the system cannot boot unless the error is resolved. The user

needs to replace the faulty part and restart the system.

Error

Code

0010h Local Console

0011h Local Console

Error Message Response Error Cause Corrective Actions

Resource

Conflict

Controller Error

42 About the System

Pau s e Video d evice

initialization

failed

Pau s e Video d evice

initialization

failed

See "Troubleshooting the

Video Subsystem" on

page 252.

If the problem persists, see

"Getting Help" on page 289.

See "Troubleshooting the

Video Subsystem" on

page 252.

If the problem persists, see

"Getting Help" on page 289.

Page 43

Error

Code

0012h Local Console

0013h ISA IO

0014h ISA IO Resource

0015h ISA IO

0016h ISA Floppy

0017h ISA Floppy

0018h ISA Floppy

Error Message Response Error Cause Corrective Actions

Output Error

Controller Error

Conflict

Controller Error

Controller Error

Input Error

Output Error

Pau s e Video d evice

initialization

failed

Pau s e ISA devi c e

initialization

failed

Pau s e ISA devi c e

initialization

failed

Pau s e ISA devi c e

initialization

failed

Pause Floppy device

initialization

failed

Pause Floppy device

initialization

failed

Pause Floppy device

initialization

failed

See "Troubleshooting the

Video Subsystem" on

page 252.

If the problem persists, see

"Getting Help" on page 289.

See "Troubleshooting

Expansion Cards" on

page 270.

If the problem persists, see

"Getting Help" on page 289.

See "Troubleshooting

Expansion Cards" on

page 270.

If the problem persists, see

"Getting Help" on page 289.

See "Troubleshooting

Expansion Cards" on

page 270.

If the problem persists, see

"Getting Help" on page 289.

See "Troubleshooting a USB

Device" on page 252.

If the problem persists, see

"Getting Help" on page 289.

See "Troubleshooting a USB

Device" on page 252.

If the problem persists, see

"Getting Help" on page 289.

See "Troubleshooting a USB

Device" on page 252.

If the problem persists, see

"Getting Help" on page 289.

About the System 43

Page 44

Error

Code

0019h USB Read Error Pause USB port

001Ah USB Write Error Pause USB port

001Bh USB Interface

001Ch Mouse Interface

001Eh Keyboard Not

001Fh Keyboard

Error Message Response Error Cause Corrective Actions

initialization

failed

initialization

failed

Pau s e USB port

Error

Pau s e Mouse de vice

Error

Pause No keyboard

Detected

Pau se Key board

Controller Error

initialization

failed

initialization

failed

detected

controller

initialization

failed

See "Troubleshooting a USB

Device" on page 252.

If the problem persists, see

"Getting Help" on page 289.

See "Troubleshooting a USB

Device" on page 252.

If the problem persists, see

"Getting Help" on page 289.

See "Troubleshooting a USB

Device" on page 252.

If the problem persists, see

"Getting Help" on page 289.

To enable USB device, see

"USB Configuration" on

page 105.

See "Troubleshooting a USB

Device" on page 252.

If the problem persists, see

"Getting Help" on page 289.

To enable USB device, see

"USB Configuration" on

page 105.

See "Troubleshooting a USB

Device" on page 252.

If the problem persists, see

"Getting Help" on page 289.

See "Troubleshooting a USB

Device" on page 252.

If the problem persists, see

"Getting Help" on page 289.

44 About the System

Page 45

Error

Code

0020h Keyboard Stuck

0021h Keyboard

0023h Memory

0024h Memory

0025h Memory Non-

0026h MP Service Self

0027h PCI IO

Error Message Response Error Cause Corrective Actions

Key Error

Locked Error

Correctable

Error

Uncorrectable

Error

Specific Error

Tes t Er r or

Controller Error

Pau s e Keybo ard ke y

stuck

Pau se Key board

locked

Pau se Memor y

correctable

error detected

Pau se Memor y

uncorrectable

error detected

Pause Memory non-

specific error

detected

Pause MP service self

test error

detected

Pau s e PCI devi c e

initialization

failed

Disconnect and reconnect the

keyboard to the compute sled.

If the problem persists, see

"Getting Help" on page 289.

Disconnect and reconnect the

keyboard to the compute sled.

If the problem persists, see

"Getting Help" on page 289.

Remove AC power to the

system for 10 seconds and

restart the system.

See "Troubleshooting System

Memory" on page 267.

If the problem persists, see

"Getting Help" on page 289.

See "Troubleshooting System

Memory" on page 267.

If the problem persists, see

"Getting Help" on page 289.

See "Troubleshooting System

Memory" on page 267.

If the problem persists, see

"Getting Help" on page 289.

See "Troubleshooting

Processors" on page 270.

If the problem persists, see

"Getting Help" on page 289.

See "Troubleshooting

Expansion Cards" on

page 270.

If the problem persists, see

"Getting Help" on page 289.

About the System 45

Page 46

Error

Code

0028h PCI IO Read

0029h PCI IO Write

002Ah Serial Port Not

002Bh Serial Port

002Ch Serial Port Input

002Dh Serial Port

002Eh Microcode

Error Message Response Error Cause Corrective Actions

Error

Error

Detected

Controller Error

Error

Output Error

Update Error

Pau s e PCI devi c e

initialization

failed

Pau s e PCI devi c e

initialization

failed

Pau s e Serial de v ice

initialization

failed

Pau s e Serial de v ice

initialization

failed

Pau s e Serial de v ice

initialization

failed

Pau s e Serial de v ice

initialization

failed

Pause Processor

microcode

update error

See "Troubleshooting

Expansion Cards" on

page 270.

If the problem persists, see

"Getting Help" on page 289.

See "Troubleshooting

Expansion Cards" on

page 270.

If the problem persists, see

"Getting Help" on page 289.

See "Troubleshooting a Serial

I/O Device" on page 253.

If the problem persists, see

"Getting Help" on page 289.

See "Troubleshooting a Serial

I/O Device" on page 253.

If the problem persists, see

"Getting Help" on page 289.

See "Troubleshooting a Serial

I/O Device" on page 253.

If the problem persists, see

"Getting Help" on page 289.

See "Troubleshooting a Serial

I/O Device" on page 253.

If the problem persists, see

"Getting Help" on page 289.

Check microcode. A BIOS

update is required.

If the problem persists, see

"Getting Help" on page 289.

46 About the System

Page 47

Error

Code

002Fh No Microcode

8012h SATA 0 Device

8013h SATA 1 Device

8014h SATA 2 Device

8015h SATA 3 Device

Error Message Response Error Cause Corrective Actions

Be Updated

Not Found

Not Found

Not Found

Not Found

Pause Processor

microcode load

failed

Pause SATA 0 device

not found

Pause SATA 1 device

not found

Pause SATA 2 device

not found

Pause SATA 3 device

not found

Ensure that your processors

match and conform to the

type described in the

processor technical

specifications outlined in

your system’s Getting Started

Guide.

Check if the SATA port 0 is

enabled. See "SATA

Configuration" on page 95.

Install a SATA device to SATA

port 0.

If the problem persists, see

"Getting Help" on page 289.

Check if the SATA port1 is

enabled. See "SATA

Configuration" on page 95.

Install a SATA device to SATA

port 1.

If the problem persists, see

"Getting Help" on page 289.

Check if the SATA port 2 is

enabled. See "SATA

Configuration" on page 95.

Install a SATA device to SATA

port 2.

If the problem persists, see

"Getting Help" on page 289.

Check if the SATA port 3 is

enabled. See "SATA

Configuration" on page 95.

Install a SATA device to SATA

port 3.

If the problem persists, see

"Getting Help" on page 289.

About the System 47

Page 48

Error

Code

8016h SATA 4 Device

8017h SATA 5 Device

8018h Sparing Mode is

8019h Mirror Mode is

8020h Supervisor and

Error Message Response Error Cause Corrective Actions

Not Found

Not Found

not be

Configured!!,

Please check

Memory

Configuration!!

not be

Configured!!,

Please check

Memory

Configuration!!

User Passwords

have been

cleared

Pause SATA 4 device

not found

Pause SATA 5 device

not found

Pau se Memo ry

Sparing Mode

Failed

Pause Memory Mirror

Mode Failed

Pau s e Supervi s or and

User Passwords

have been

cleared

Check if the SATA port 4 is

enabled. See "SATA

Configuration" on page 95.

Install a SATA device to SATA

port 4.

If the problem persists, see

"Getting Help" on page 289.

Check if the SATA port 5 is

enabled. See "SATA

Configuration" on page 95.

Install a SATA device to SATA

port 5.

If the problem persists, see

"Getting Help" on page 289.

Check if the memory

configuration is set to Sparing

mode. See "Memory

Configuration" on page 92.

If the problem persists, see

"Getting Help" on page 289.

Check if the memory

configuration is set to Sparing

mode. See "Memory

Configuration" on page 92.

If the problem persists, see

"Getting Help" on page 289.

Reset password. See the

compute sled’s

documentation for more

information.

If the problem persists, see

"Getting Help" on page 289.

48 About the System

Page 49

Error

Code

8021h CMOS Battery

8100h Memory device

Error Message Response Error Cause Corrective Actions

Error

disabled by

BIOS

Pause No CMOS

battery

Pau se Memor y

Device Error

See the compute sled’s

documentation for more

information.

See "Troubleshooting System

Memory" on page 267.

If the problem persists, see

"Getting Help" on page 289.

About the System 49

Page 50

System Event Log

Processor Error

Message: “Processor Sensor, IERR error, Processor 1”

Table 1-1. Processor Error

Byte Field Value Description

1 NetFunLun 10h

2 Platform Event Command 02h

3 Generator ID 01h Generated by BIOS

4 Event Message Format

Ve rs io n

5 Sensor Type 07h Processor

6 Sensor Number 04h Processor Sensor Number

7 Event Direction Event Type 6Fh Bit 7: 0 = Assert Event Bit 6: 0 =

8 Event Data1 AXh 00h: IERR 01h: Thermal Trip

9 Event Data2 XXh 00h: Processor1

10 Event Data3 FFh FFh: Not Present

04h Event Message Format Revision.

04h for this specification

(depends on platform)

Event Type Code

02h: FRB1/BIST Failure

03h: FRB2/Hang in POST Failure

04h: FBR3/Processor

Startup/Initialization Failure

0Ah: Processor Automatically

Throttled

01h: Processor2

02h: Processor3

04h: Processor4

50 About the System

Page 51

Memory Ecc

Message: “Memory Sensor, Correctable ECC error, SBE warning threshold,

CPU1 DIMM_A1”

Table 1-2. Memory ECC

Byte Field Value Description

1 NetFunLun 10h

2 Platform Event Command 02h

3 Generator ID 01h Generated by BIOS

4 Event Message Format

Ve rs io n

5 Sensor Type 0Ch Memory

6 Sensor Number 60h Memory Sensor Number (depend

7 Event Direction Event Type 6Fh Bit 7: 0 = Assert Event

8 Event Data1 AXh 00h: Correctable ECC Error

04h Event Message Format Revision.

04h for this specification

on platform)

Bit 6: 0 = Event Type Code

01h: Uncorrectable ECC Error

03h: Memory Scrub Failed

04h: Memory Device Disabled

08h: Spare

About the System 51

Page 52

Table 1-2. Memory ECC

Byte Field Value Description

9 Event Data2 XXh Bit 7:4

0x00: SBE warning threshold

0x01: SBE critical threshold

0x0F: Unspecified

Bit 3:0

0x00: CPU1 DIMM A1-8 slots

(1~8)

0x01: CPU2 DIMM B1-8 slots

(9~16)

0x02: CPU3 DIMM C1-8 slots

(17~24)

0x03: CPU4 DIMM D1-8 slots

(25~32) And so on…

10 Event Data3 XXh DIMM bit-map location of bits

Bit 0=1: DIMM1 error event

Bit 1=1: DIMM2 error event …

Bit7=1: DIMM8 error event

52 About the System

Page 53

PCIe Error

Message: “Critical Interrupt Sensor, PCI PERR, Device#, Function#,

Bus#”

Table 1-3. PCIe Error

Byte Field Value Description

1 NetFunLun 10h

2 Platform Event Command 02h

3 Generator ID 01h Generated by BIOS

4 Event Message Format

Ve rs io n

5 Sensor Type 13h Critical Interrupt

6 Sensor Number 73h PCI Sensor ID (depend on

7 Event Direction Event Type 6Fh Bit 7: 0 = Assert Event

8 Event Data1 AXh 04h: PCI PERR

9 Event Data2 XXh Bit 7:3Device Number

10 Event Data3 XXh Bit 7:0 Bus Number

04h Event Message Format Revision.

04h for this specification

platform)

Bit 6: 0 = Event Type Code

05h: PCI SERR

07h: Bus Correctable Error

08h: Bus Uncorrectable Error

0Ah: Bus Fatal Error

Bit 2:0Function Number

About the System 53

Page 54

IOH Core Error

Message: “Critical Interrupt Sensor, Fatal Error, xxxx bit, QPI[0] Error”

Table 1-4. IOH Core Error

Byte Field Value Description

1 NetFunLun 10h

2 Platform Event Command 02h

3 Generator ID 01h Generated by BIOS

4 Event Message Format

Ve rs io n

5 Sensor Type C0h OEM Defined Interrupt

6 Sensor Number XXh 71h: QPI Sensor ID (depend on

7 Event Direction Event Type 6Fh Bit 7: 0 = Assert Event Bit 6: 0 =

8 Event Data1 AXh 07h: Core

9 Event Data2 XXh Local Error Bit

10 Event Data3 XXh 00h: QPI[0] Error

04h Event Message Format Revision.

04h for this specification

platform)

72h: INT Sensor ID (depend on

platform)

Event Type Code

08h: Non-Fatal

0Ah: Fatal

01h: QPI[1] Error

02h: QPI[2] Error

03h: QPI[3] Error

04h: QPI[0] Protocol Error

05h: QPI[1] Protocol Error

06h: QPI[2] Protocol Error

07h: QPI[3] Protocol Error

23h: Miscellaneous Error

24h: IOH Core Error

54 About the System

Page 55

SB Error

Message: “Critical Interrupt Sensor, Correctable, MCU Parity Error”

Table 1-5. SB Error

Byte Field Value Description

1 NetFunLun 10h

2 Platform Event Command 02h

3 Generator ID 01h Generated by BIOS

4 Event Message Format

Ve rs io n

5 Sensor Type 13h Critical Interrupt

6 Sensor Number 77h SB Sensor ID (depend on

7 Event Direction Event Type 6Fh Bit 7: 0 = Assert Event

8 Event Data1 AXh 07h: Correctable

9 Event Data2 XXh Bit 7:5Reserved Local error bit

10 Event Data3 FFh FFh: Not Present

04h Event Message Format Revision.

04h for this specification

platform)

Bit 6: 0 = Event Type Code

08h: Uncorrectable

number (4 ~ 0)

00000b: HT Periodic CRC Error

00001b: HT Protocol Error

00010b: HT Flow-Control Buffer

Overflow

00011b: HT Response Error

00100b: HT Per-Packet CRC Error

00101b: HT Retry Counter Error

00111b: MCU Parity Error

About the System 55

Page 56

POST Start Event

Message: “System Event, POST starts with BIOS xx.xx.xx”

Table 1-6. POST Start Event

Byte Field Value Description

1 NetFunLun 10h

2 Platform Event Command 02h

3 Generator ID 01h Generated by BIOS

4 Event Message Format

Ve rs io n

5 Sensor Type 12h System Event

6 Sensor Number 81h POST Start (depend on platform)

7 Event Direction Event Type 6Fh Bit 7: 0 = Assert Event

8 Event Data1 AXh 01h: OEM System Boot Event

9 Event Data2 XXh 7~4: BIOS 1st Field Version

10 Event Data3 XXh 7~6: BIOS 2nd Field Version lower

04h Event Message Format Revision.

04h for this specification

Bit 6: 0 = Event Type Code

(0~15)

3~0: BIOS 2nd Field Version

higher 4bits (0~63)

2bits (0~63)

5~0: BIOS 3rd Field Version

(0~63)

56 About the System

Page 57

POST End Event

Table 1-7. POST End Event

Byte Field Value Description

1 NetFunLun 10h

2 Platform Event Command 02h

3 Generator ID 01h Generated by BIOS

4 Event Message Format

Ve rs io n

5 Sensor Type 12h System Event

6 Sensor Number 85h POST End (depend on platform)

7 Event Direction Event Type 6Fh Bit 7: 0 = Assert Event

8 Event Data1 AXh 01h: OEM System Boot Event

9 Event Data2 XXh Bit 7 = Boot Type

10 Event Data3 FFh FFh: Not Present

04h Event Message Format Revision.

04h for this specification

Bit 6: 0 = Event Type Code

0b: PC Compatible Boot

(Legacy) 1b: uEFI Boot

Bit 3:0 = Boot Device

0001b: Force PXE Boot

0010b: NIC PXE Boot

0011b: Hard Disk Boot

0100b: RAID HDD Boot

0101b: USB Storage Boot

0111b: CD/DVD ROM Boot

1000b: iSCSI Boot

1001b: uEFI Shell

1010b: ePSA Diagnostic Boot

About the System 57

Page 58

POST Error Code Event

Message: “System Firmware Progress, POST error code: UBLBh.”

Table 1-8. POST Error Code Event

Byte Field Value Description

1 NetFunLun 10h

2 Platform Event Command 02h

3 Generator ID 01h Generated by BIOS

4 Event Message Format

Ve rs io n

5 Sensor Type 0Fh System Firmware Progress

6 Sensor Number 86h POST Error (depend on platform)

7 Event Direction Event Type 6Fh Bit 7: 0 = Assert Event

8 Event Data1 AXh 00: System Firmware Error (POST

9 Event Data2 XXh Upper Byte

10 Event Data3 XXh Lower Byte

04h Event Message Format Revision.

04h for this specification

Bit 6: 0 = Event Type Code

Error)

58 About the System

Page 59

BIOS Recovery Event

Table 1-9. BIOS Recovery Event

Byte Field Value Description

1 NetFunLun 10h

2 Platform Event Command 02h

3 Generator ID 01h Generated by BIOS

4 Event Message Format

Ve rs io n

5 Sensor Type 12h System Event

6 Sensor Number 89h BIOS Recovery fail (depend on

7 Event Direction Event Type 6Fh Bit 7: 0 = Assert Event Bit 6: 0 =

8 Event Data1 AXh 01h: OEM BIOS recovery Event

9 Event Data2 XXh 01h:Start Recovery

10 Event Data3 FFh FFh: Not Present

04h Event Message Format Revision.

04h for this specification

platform)

Event Type Code

02h:Recovery Success

03h:Load Image Fail

04h:Signed Fail

ME Fail Event

Table 1-10. BIOS Recovery Event

Byte Field Value Description

1 NetFunLun 10h

2 Platform Event Command 02h

3 Generator ID 01h Generated by BIOS

4 Event Message Format

Ve rs io n

5 Sensor Type 12h System Event

6 Sensor Number 8Ah ME fail (depend on platform)

04h Event Message Format Revision.

04h for this specification

About the System 59

Page 60

Table 1-10. BIOS Recovery Event

Byte Field Value Description

7 Event Direction Event Type 6Fh Bit 7: 0 = Assert Event

Bit 6: 0 = Event Type Code

8 Event Data1 AXh 01h: OEM ME fail Event

9 Event Data2 XXh 01h:ME fail

10 Event Data3 FFh FFh: Not Present

SEL Generator ID

Table 1-11. SEL Generator ID

Generator ID

BIOS 0x0001

BMC 0x0020

ME 0x002C

Windows 2008 0x0137

60 About the System

Page 61

BMC

The following table includes an overview of the system sensors.

In the Offset column:

• SI = Sensor Initialization

•SC = Sensor Capabilities

• AM = Assertion Mask

• DM = Deassertion Mask

• RM = Reading Mask

• TM = Settable/Readable Threshold Mask

Table 1-12. Sensor Summary

Sensor

Number

01h SEL Fullness Event Logging

02h P1 Thermal Trip Processor (07h) Sensor-specific

03h P2 Thermal Trip Processor (07h) Sensor-specific

Sensor Name Sensor Type Event/Reading Type Offset

Sensor-specific

Disabled (10h)

(6Fh)

(6Fh)

(6Fh)

SI: 67h

SC: 40h

AM: 0035h

DM: 0000h

RM: 0035h

SI: 01h

SC: 40h

AM: 0002h

DM: 0000h

RM: 0002h

SI: 01h

SC: 40h

AM: 0002h

DM: 0000h

RM: 0002h

About the System 61

Page 62

Table 1-13. Sensor Summary (continued)

Sensor

Number

04h CPU ERR2 Processor (07h) Sensor-specific

05h 12V Standby Voltage (02h) Threshold (01h) SI: 7Fh

06h 5V Voltage (02h) Threshold (01h) SI: 7Fh

07h 5V Standby Voltage (02h) Threshold (01h) SI: 7Fh

08h 3.3V Voltage (02h) Threshold (01h) SI: 7Fh

Sensor Name Sensor Type Event/Reading Type Offset

SI: 01h

(6Fh)

SC: 40h

AM: 0001h

DM: 0000h

RM: 0001h

SC: 59h

AM: 7A95h

DM: 7A95h

TM: 3F3Fh

SC: 59h

AM: 7A95h

DM: 7A95h

TM: 3F3Fh

SC: 59h

AM: 7A95h

DM: 7A95h

TM: 3F3Fh

SC: 59h

AM: 7A95h

DM: 7A95h

TM: 3F3Fh

62 About the System

Page 63

Table 1-14. Sensor Summary (continued)

Sensor

Number

09h 3.3V Standby Voltage (02h) Threshold (01h) SI: 7Fh

0Ah Battery low Battery (29h) Sensor-specific

41h MEZZ1 TEMP Temperature (01h) Threshold (01h) SI: 7Fh

41h CPU1 Temp Temperature (01h) Threshold (01h) SI: 7Fh

42h CPU2 Temp Temperature (01h) Threshold (01h) SI: 7Fh

Sensor Name Sensor Type Event/Reading Type Offset

SC: 59h

AM: 7A95h

DM: 7A95h

TM: 3F3Fh

SI: 67h

(6Fh)

SC: 40h

AM: 0001h

DM: 0000h

RM: 0001h

SC: 68h

AM: 0A80h

DM: 0A80h

TM: 3838h

SC: 68h

AM: 0A80h

DM: 0A80h

TM: 3838h

SC: 68h

AM: 0A80h

DM: 0A80h

TM: 3838h

About the System 63

Page 64

Table 1-15. Sensor Summary (continued)

Sensor

Number

43h DIMM ZONE 1

44h DIMM ZONE 1

45h PCH Temp Temperature (01h) Threshold (01h) SI: 7Fh

60h Memory Memory (0Ch) Sensor-specific

A0h Watchdog Watchdog 2 (23h) Sensor-specific

Sensor Name Sensor Type Event/Reading Type Offset

Temperature (01h) Threshold (01h) SI: 7Fh

Te mp

Temperature (01h) Threshold (01h) SI: 7Fh

Te mp

(6Fh)

(6Fh)

SC: 68h

AM: 0A80h

DM: 0A80h

TM: 3838h

SC: 68h

AM: 0A80h

DM: 0A80h

TM: 3838h

SC: 68h

AM: 0A80h

DM: 0A80h

TM: 3838h

SI: 01h

SC: 40h

AM: 0023h

DM: 0000h

RM: 0023h

SI: 67h

SC: 40h

AM: 000Fh

DM: 0000h

RM: 000Fh

64 About the System

Page 65

Table 1-16. Sensor Summary (continued)

Sensor

Number

A1h Soft Reset System Boot/

A2h AC lost Power Unit (09h) Sensor-specific

A3h Power off Power Unit (09h) Sensor-specific

Sensor Name Sensor Type Event/Reading Type Offset

Sensor-specific

Restart Initiated

(1Dh)

(6Fh)

(6Fh)

(6Fh)

SI: 01h

SC: 40h

AM: 0004h

DM: 0000h

RM: 0004h

SI: 01h

SC: 40h

AM: 0010h

DM: 0000h

RM: 0010h

SI: 01h

SC: 40h

AM: 0002h

DM: 0000h

RM: 0002h

About the System 65

Page 66

Other Information You May Need

WARNING: See the safety and regulatory information that shipped with your

system. Warranty information may be included within this document or as a

separate document.

• The Getting Started Guide provides an overview of rack installation,

system features, setting up your system, and technical specifications.

• The compute or storage sleds’ documentation provides information about

the sled features, configuring and managing the sled. This document is

available online at

• The Baseboard Management Controller Guide provides information about

installing and using the systems management utility. This document is

available online at

NOTE: Always check for updates on dell.com/support/manuals and read the

updates first because they often supersede information in other documents.

dell.com/support/manuals

dell.com/support/manuals

.

.

66 About the System

Page 67

2

Using the System Setup Program

The System Setup program is the BIOS program that enables you to manage

your system hardware and specify BIOS-level options. From the System Setup

program, you can:

• Change the NVRAM settings after you add or remove hardware

• View the system hardware configuration

• Enable or disable integrated devices

• Set performance and power management thresholds

• Manage system security

System Setup Menu

The system employs the latest Insyde® BIOS, which is stored in Flash

memory. The Flash memory supports the Plug and Play specification, and

contains a System Setup program, the Power On Self Test (POST) routine,

and the PCI auto-configuration utility.

This system supports system BIOS shadowing which enables the BIOS to

execute from 64-bit onboard write-protected DRAM.

You can configure items such as:

• Hard-drives and peripherals

• Password protection

• Power management features

The Setup utility should be executed under the following conditions:

• When changing the system configuration

• When a configuration error is detected by the system and you are

prompted to make changes to the Setup utility

• When redefining the communication ports to prevent any conflicts

Using the System Setup Program 67

Page 68

• When changing the password or making other changes to the security

setup

NOTE: Only items in brackets [ ] can be modified, Items that are not in brackets are

display only.

NOTE: PowerEdge C8000 server enclosure is referred to as simply the "server

enclosure" or the "chassis" in this manual.

System Setup Options at Boot

You can initiate Setup by pressing the following keys during POST:

Keystroke Description

<F2> Enter the System Setup

<F8> Load customized defaults

<F9> Load optimal defaults in Setup menu

<F10> Save and exit Setup

Using the System Setup Program Navigation Keys

The following table lists the keys found in the legend bar with their

corresponding alternates and functions:

Keys Function

F1 General Help

or Select Screen

or Select Item

Change Option/Field

Tab Select Field

Esc Exit

Enter Go to Sub Screen

Home Go to Top of Screen

End Go to Bottom of Screen

F10 Save and Exit

68 Using the System Setup Program

Page 69

General Help

In addition to the Item Specific Help window, the Setup Utility also provides

a General Help screen. This screen can be called up from any menu by

pressing <F1>. The General Help screen lists the legend keys with their

corresponding alternates and functions. To exit the help window, press

<Enter> or <Esc>.

Console Redirection

The console redirection allows a remote user to diagnose and fix problems on

a server, which has not successfully booted the operating system (OS). The

centerpiece of the console redirection is the BIOS Console. The BIOS

Console is a Flash ROM-resident utility that redirects input and output over

a serial or modem connection.

The BIOS supports console redirection to a serial port. If serial port based

headless server support is provided by the system, the system must provide

support for redirection of all BIOS driven console I/O to the serial port. The

driver for the serial console must be capable of supporting the functionality

documented in the ANSI Terminal Definition.

The console redirection behavior shows a change of string displays that

reduce the data transfer rate in the serial port and cause the absence or an

incomplete POST screen. If you see an abnormal POST screen after you

connect to the console, it is recommended to press <Ctrl><R> to reflash

the screen.

Enabling and Configuring Console Redirection

Console redirection is configured through the System Setup program. There

are three options available to establish console redirection on the system.

• External serial port

• Internal serial connector as Serial Over LAN (SOL)

•BMC SOL

Using the System Setup Program 69

Page 70

Enabling and Configuring Console Redirection Via COM1

To activate console redirection via COM1, you must configure the following

settings:

1

Connect the serial cable to the serial port and host system. See

"Compute

Sleds" on page 26 for the location of the serial port on the sled.

2

Press <F2> immediately after a power-on or reboot to enter System

Setup.

3

In the System Setup screen, select the

4

In the Server screen, select

Remote Access Configuration

Server

menu and press <Enter>.

and press

<Enter>.

5

In the Remote Access Configuration screen, verify the following settings:

• Remote Access: Enabled

• Serial port number: COM1

• Serial Port Mode: 115200 8,n,1

• Flow Control: None

• Redirection After BIOS POST: Always

• Terminal Type: ANSI

See "Remote Access Configuration" on page 113 for details. Make sure the

last four options syncs with the host and client.

6

Press <Esc> to return to the System Setup screen. Press <Esc> again,

and a message prompts you to save the changes.

Enabling and Configuring Console Redirection Via COM2 SOL

To activate console redirection via COM2 SOL, you must configure the

following settings:

1

Connect the serial cable to the serial port and host system. See

"Compute

Sleds" on page 26 for the location of the serial port on the sled.

2

Press <F2> immediately after a power-on or reboot to enter System

Setup.

3

In the System Setup screen, select the

4

In the Server screen, select

Remote Access Configuration

Server

menu and press <Enter>.

and press

<Enter>.

70 Using the System Setup Program

Page 71

5

In the Remote Access Configuration screen, verify the following settings:

• Remote Access: Enabled

• Serial port number: COM2 as SOL

• Serial Port Mode: 115200 8, n,1

• Flow Control: None

• Redirection After BIOS POST: Always

•Terminal Type: ANSI

See "Remote Access Configuration" on page 113 for details. Make sure the

host and client are on the same network.

6

Press <Esc> to return to the System Setup screen. Press <Esc> again,

and a message prompts you to save the changes.

Enabling and Configuring Console Redirection Via BMC SOL

When using the BMC management port, you have two options for

connecting and managing servers: Dedicated-NIC mode and Shared-NIC

mode. The following procedures show the setup option of the BMC

management port through a Dedicated-NIC or Shared-NIC.

To activate console redirection via a dedicated BMC management port, you

must configure the following settings:

1

Connect the sled system board and node power distribution board with a

BMC cable.

2

Connect the network cable to the BMC management port. See

"Compute

Sleds" on page 26 for the location of the BMC management port on the

sled.

3

Press <F2> immediately after a power-on or reboot to enter System

Setup.

4

In the System Setup screen, select the

5

In the Server screen, select

Remote Access Configuration

Server

menu and press <Enter>.

and press

<Enter>.

6

In the Remote Access Configuration screen, verify the following settings:

• Remote Access: Enabled

• Serial port number: COM2 as SOL

Using the System Setup Program 71

Page 72

• Serial Port Mode: 115200 8, n, 1

• Flow Control: None

• Redirection After BIOS POST: Always

• Terminal Type: ANSI

See "Remote Access Configuration" on page 113 for details. Make sure the

last four options syncs with the host and client.

7

In the Server screen, select

8

In the BMC LAN Configuration screen, verify the following settings:

• BMC LAN Port Configuration: Dedicated-NIC

• BMC NIC IP Source: DHCP or Static (Use DHCP if your network

servers are using automatic assignment of IP addresses)

• IP Address: 192.168.001.003

• Subnet Mask: 255.255.255.000

• Gateway Address: 000.000.000.000

See "Set BMC LAN Configuration" on page 111 for details. Make sure the

host and client are on the same network

9

Press <Esc> to return to the System Setup screen. Press <Esc> again,

and a message prompts you to save the changes.

To activate console redirection via a shared BMC management port, you must

configure the following settings:

1

Connect the sled system board and node power distribution board with a

BMC cable.

2

Connect the network cable to the Ethernet connector 1. See

Sleds" on page 26 for the location of the Ethernet connector 1 on the

sled.

3

Press <F2> immediately after a power-on or reboot to enter System

Setup.

4

In the System Setup screen, select the

5

In the Server screen, select

<Enter>.

BMC LAN Configuration

Server

menu and press <Enter>.

Remote Access Configuration

and press <Enter>.

"Compute

and press

72 Using the System Setup Program

Page 73

6

In the Remote Access Configuration screen, verify the following settings:

• Remote Access: Enabled

• Serial port number: COM2

• Serial Port Mode: 115200 8, n, 1

• Flow Control: None

• Redirection After BIOS POST: Always

•Terminal Type: ANSI

See "Remote Access Configuration" on page 113 for details. Make sure the

last four options syncs with the host and client.

7

In the Server screen, select

8

In the BMC LAN Configuration screen, verify the following settings:

BMC LAN Configuration

and press <Enter>.

• BMC LAN Port Configuration: Shared-NIC

• BMC NIC IP Source: DHCP or Static (Use DHCP if your network

servers are using automatic assignment of IP addresses)

• IP Address: 192.168.001.003

• Subnet Mask: 255.255.255.000

• Gateway Address: 000.000.000.000

See "Set BMC LAN Configuration" on page 111 for details. Make sure the

host and client are on the same network

9

Press <Esc> to return to the System Setup screen. Press <Esc> again,

and a message prompts you to save the changes.

Serial Port Connection List

Signal Type Setup Option OS

Setting

Serial Console

Redirection

BMC Serial

Over LAN

Remote

Access

Enabled COM1 3F8h/2F8h ttyS0 Serial Port

Enabled COM1 2F8h/3F8h ttyS1

Enabled COM2 as SOL 3F8h/2F8h ttyS1 Management

Enabled COM2 as SOL 2F8h/3F8h ttyS0

Serial Port

Number

Serial Port

Address

Using the System Setup Program 73

Output

Port

Page 74

Main Menu