Page 1

S/5

Datex-Ohmeda

TM

Light Monitor, F-LM1, F-LMP1

Technical Reference Manual

CAUTION: U.S. Federal law restricts this device to sale by or on the order of a licensed medical practitioner.

Datex-Ohmeda, Inc.

P.O. Box 7550

Madison, WI 53707-7550, USA

Tel. +1-608-221-1551

Fax +1-608-222-9147

All specifications are subject to change without notice.

Outside the USA, check local laws for any restriction that may apply.

Order Code M1037863

October 2005

Healthcare Finland Oy

Helsinki, Finland

P.O. Box 900

FIN-00031 GE, FINLAND

Tel: +358 10 39411

Fax : +358 9 146 3310

www.datex-ohmeda.com www.gehealthcare.com

© 2005 Copyright General Electric Company

Page 2

Intended purpose

Datex-Ohmeda S/5 Light Monitor, F-LM1, F-LMP1 is intended for stationary and mobile monitoring of

patient’s ECG, SpO2, body temperature, invasive and non-invasive blood pressures as well as respiration

and CO2 in hospitals and ambulances. When used outdoors, the monitor must be in the protective case. The

monitor is intended for use by qualified medical personnel only. The S/5 Light Monitor is intended for

patients with weight from 5 kg (11 lb.) up. Respiration monitoring is intended for patients three years old and

up.

Classification according to IEC 60601-1

• CLASS I EQUIPMENT and INTERNALLY POWERED EQUIPMENT according to the type of protection against

electrical shock.

• TYPE BF or CF equipment according to the degree of protection against electric shock is indicated with a

symbol beside each patient connector.

• Degree of protection against harmful ingress of water as detailed in the IEC 60529: Monitor: IPX1,

vertically falling water drops shall have no harmful effects (applicable when the monitor is in upright

position, or tilted backwards). In the protective case IPX4, splash proof, when the case is closed

properly, the monitor is intact and operates on battery power. Power adapter: IPX0, ordinary equipment.

• EQUIPMENT not suitable for use in the presence of a FLAMMABLE ANESTHETIC MIXTURE with air or with

oxygen or nitrous oxide.

• CONTINUOUS OPERATION according to the mode of operation.

• CSPR 11: Group 1, Class A

Classification according to EU Medical Device Directive

• The monitor is classified as IIb.

Responsibility of the manufacturer

GE Healthcare Finland Oy (GE) is responsible for the safety, reliability and performance of the equipment only

if:

• assembly, operations, extensions, readjustments, modifications, service and repairs are carried out by

authorized personnel.

• the electrical installation of the relevant room complies with appropriate requirements.

• the equipment is used in accordance with the User’s Reference Manual and serviced and maintained in

accordance with the Technical Reference Manual.

The CO2 measuring option (N-LCM) is manufactured for GE Healthcare Finland Oy by

Welch Allyn OEM Technologies, 8500 SW Creekside Place, Beaverton, OR 97008 USA.

Trademarks

Trademarks Datex, Ohmeda, S/5, MemCard, ComWheel and Oxytip+ are property of GE Healthcare Finland

Oy. All other product and company names are property of their respective owners.

Page 3

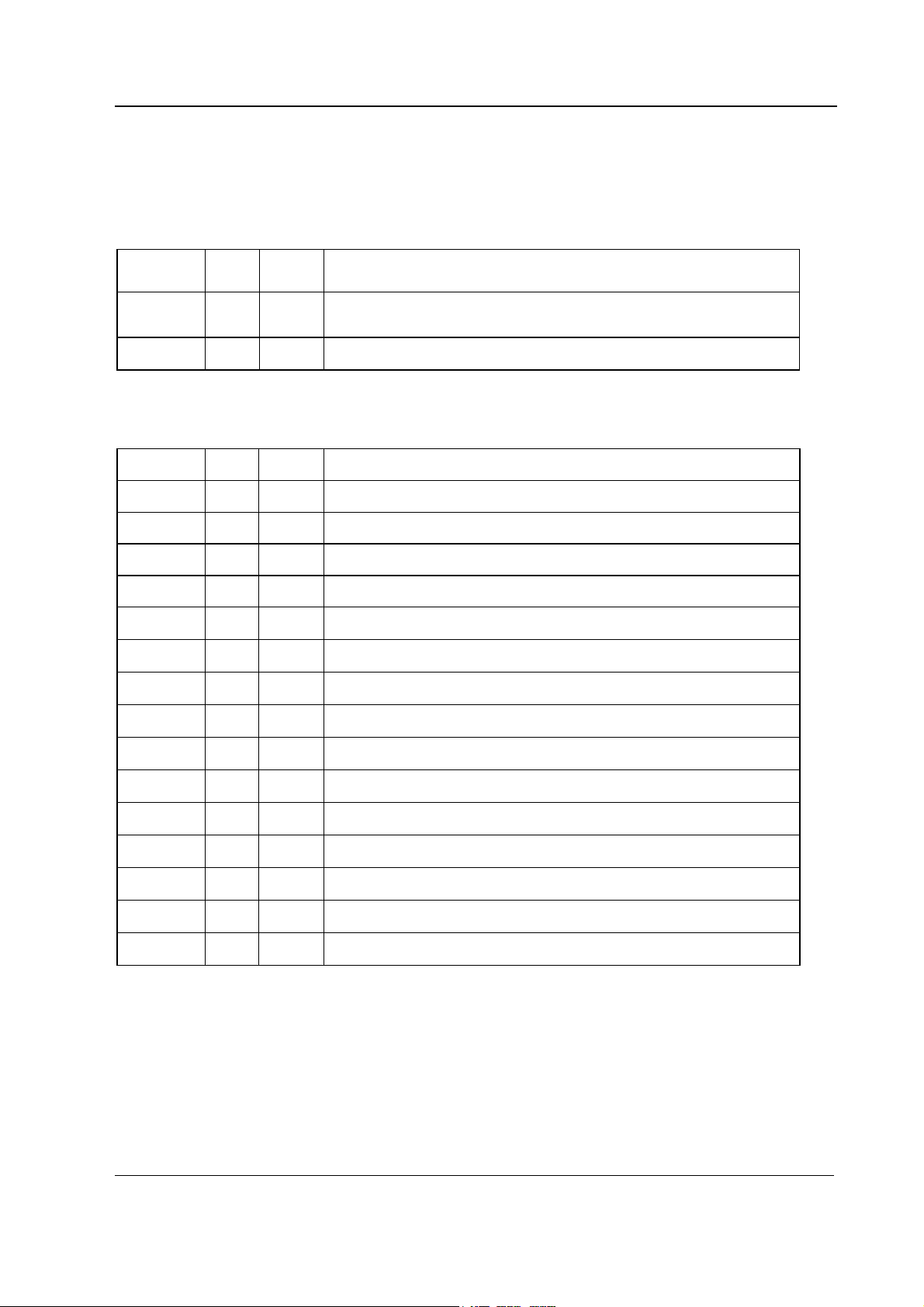

Master table of contents

Datex-Ohmeda S/5TM Light Monitor

Technical Reference Manual, M1037863

PART I, General Service Guide

Document

No.

M1051339

8001934-2

M1051339

8000060-1

8000060-1

8000060-1

8000060-1

890201-5

M1051340

890200-5

896192-1

8000060-1

M1051358

896551-2

896552-2

896553-2

896554-2

-

Updated Updated

Description

Introduction, Safety, Architecture, Functional check, Service check, General

troubleshooting, Service Menu, General specifications

Planned Maintenance Instructions

PART II, Product Service Guide

CPU

Power Supply Unit

Hemodynamic Unit

CO2 Unit

Isolation Power Supply Unit for CO2 Unit

Datex-Ohmeda Light Monitor Recorder, N-LREC

Datex-Ohmeda Light Monitor Power Adapter, N-LPOW

Datex-Ohmeda Light Monitor Battery Module, F-LBAT

Datex-Ohmeda Light External Battery Charger, N-LCHGR

DataCard and Network Options, N-LDATA, N-LNET, N-LDNET

Spare Parts, Upgrade Kits and Exploded Views

Optional N-LCM Upgrade for Light Monitor

Optional N-LDNET Upgrade for Light Monitor

Optional N-LDATA Upgrade for Light Monitor

Optional N-LNET Upgrade for Light Monitor

Method of Replacing the Lamp Unit (LCD Backlight)

1

2

1

2

3

4

5

6

7

8

9

10

11

12

Document No. M1037863

Page 4

Datex-Ohmeda S/5 Light Monitor

2

Document No. M1037863

Page 5

Table of contents

TABLE OF CONTENTS

PART 1 - GENERAL SERVICE GUIDE

TABLE OF CONTENTS i

Part 1 - General Service Guide i

TABLE OF FIGURES iii

1 INTRODUCTION 1

1.1 Notes to the reader............................................................................................................................... 2

1.2 About this manual................................................................................................................................ 2

1.3 Related documents .............................................................................................................................. 2

1.4 Installation .......................................................................................................................................... 3

1.4.1 Choosing the location .................................................................................................................. 3

1.4.2 Warnings.....................................................................................................................................3

1.5 Symbols .............................................................................................................................................. 4

1.5.1 Symbols on equipment ................................................................................................................ 4

1.5.2 Symbols on transport packaging................................................................................................... 6

2 SAFETY 8

2.1 Safety precautions ...............................................................................................................................8

2.1.1 Warnings.....................................................................................................................................8

2.1.2 Cautions....................................................................................................................................11

2.2 ESD precautionary procedures............................................................................................................ 12

2.3 Safety test ......................................................................................................................................... 13

3 ARCHITECTURE 14

3.1 Monitor structure................................................................................................................................ 14

3.2 Power supply unit...............................................................................................................................16

3.3 CPU...................................................................................................................................................16

3.4 NIBP unit ...........................................................................................................................................17

3.5 ECG unit ............................................................................................................................................ 17

3.6 STP unit .............................................................................................................................................17

3.7 CO2 unit............................................................................................................................................. 17

3.8 Display unit........................................................................................................................................ 18

3.8.1 Slave display.............................................................................................................................18

3.9 Power adapters..................................................................................................................................18

3.9.1 N-LPOW..................................................................................................................................... 18

3.10 Host serial communications ...........................................................................................................18

3.10.1 Module bus ........................................................................................................................... 18

3.10.2 Computer interface (RS-232) ................................................................................................. 18

3.10.3 CO2 module........................................................................................................................... 19

3.10.4 Power board .......................................................................................................................... 19

3.10.5 Recorder ...............................................................................................................................19

4 CLEANING 20

5 FUNCTIONAL CHECK 21

5.1 General functional inspection .............................................................................................................21

5.1.1 Recorder test.............................................................................................................................23

5.1.2 PCMCIA card test.......................................................................................................................23

5.1.3 Network test .............................................................................................................................. 24

Document No. M1051339

i

Page 6

Datex-Ohmeda S/5 Light Monitor

ECG board tests......................................................................................................................... 25

5.1.4

5.1.5 STP board tests ......................................................................................................................... 25

5.1.6 NIBP board test ......................................................................................................................... 26

5.1.7 Mainstream CO2 test.................................................................................................................. 26

5.2 Performance checks........................................................................................................................... 27

6 SERVICE CHECK 30

6.1 General service information................................................................................................................ 30

6.2 Service check procedure .................................................................................................................... 30

6.2.1 Visual inspection ....................................................................................................................... 31

6.2.2 Recorder test............................................................................................................................. 35

6.2.3 PCMCIA card test....................................................................................................................... 35

6.2.4 Network test.............................................................................................................................. 35

6.2.5 ECG measurement..................................................................................................................... 36

6.2.6 Respiration measurement.......................................................................................................... 37

6.2.7 Temperature measurement ........................................................................................................ 39

6.2.8 Invasive blood pressure measurement........................................................................................ 39

6.2.9 SpO2 measurement ................................................................................................................... 40

6.2.10 Non Invasive Blood Pressure measurement ............................................................................ 41

6.2.11 Mainstream CO2 measurement .............................................................................................. 43

6.2.12 For Light Monitor.................................................................................................................... 44

7 ADJUSTMENTS AND CALIBRATIONS 45

7.1 Pressure safety level detection “OFFSET”............................................................................................. 45

7.2 NIBP calibrations ............................................................................................................................... 45

7.2.1 Calibration check....................................................................................................................... 45

7.2.2 Calibration ................................................................................................................................ 46

7.3 Temperature calibration ..................................................................................................................... 47

7.4 Invasive pressure calibration .............................................................................................................. 48

8 GENERAL TROUBLESHOOTING 49

8.1 Troubleshooting flowchart .................................................................................................................. 49

9 SERVICE MENU 50

9.1 SW version / unit ID ........................................................................................................................... 50

9.2 Language selection ............................................................................................................................ 51

9.3 Monitor configuration......................................................................................................................... 51

10 GENERAL SPECIFICATIONS 52

10.1 Parameter specifications................................................................................................................ 52

10.1.1 ECG ...................................................................................................................................... 52

10.1.2 Impedance respiration...........................................................................................................52

10.1.3 Pulse oximetry (SpO2)/Pleth.................................................................................................. 53

10.1.4 Temperature.......................................................................................................................... 53

10.1.5 Non-invasive blood pressure.................................................................................................. 54

10.1.6 Invasive blood pressure (LMP1 models only)........................................................................... 54

10.1.7 CO2 (option N-LCM) ............................................................................................................... 55

10.2 General ......................................................................................................................................... 55

10.2.1 Environmental conditions ...................................................................................................... 56

10.3 Option codes ................................................................................................................................. 56

10.4 Display .......................................................................................................................................... 56

10.4.1 Slave display......................................................................................................................... 56

10.4.2 Trends................................................................................................................................... 57

10.4.3 Alarms .................................................................................................................................. 57

10.5 Light Monitor battery module (optional) (w/2 battery slots) .............................................................. 57

10.6 Light Monitor backup battery (optional)........................................................................................... 57

ii

Document No. M1051339

Page 7

Table of contents

External power adapter...................................................................................................................57

10.7

10.8 Light External Battery Charger (optional) .......................................................................................... 58

10.9 Output specifications .....................................................................................................................58

10.9.1 Nurse Call and Defibrillator Synchronization Signals ................................................................ 58

APPENDICES 59

FUNCTIONAL CHECK form A-1

SERVICE CHECK form B-1

EMC Guidance C-1

TABLE OF FIGURES

Figure 1 S/5 Light Monitor with battery module and power adapter ..................................................................... 1

Figure 2 Main block diagram of Light Monitor, revision 03 .................................................................................14

Figure 3 General troubleshooting chart............................................................................................................. 49

Document No. M1051339

iii

Page 8

Datex-Ohmeda S/5 Light Monitor

v

i

Document No. M1051339

Page 9

1 INTRODUCTION

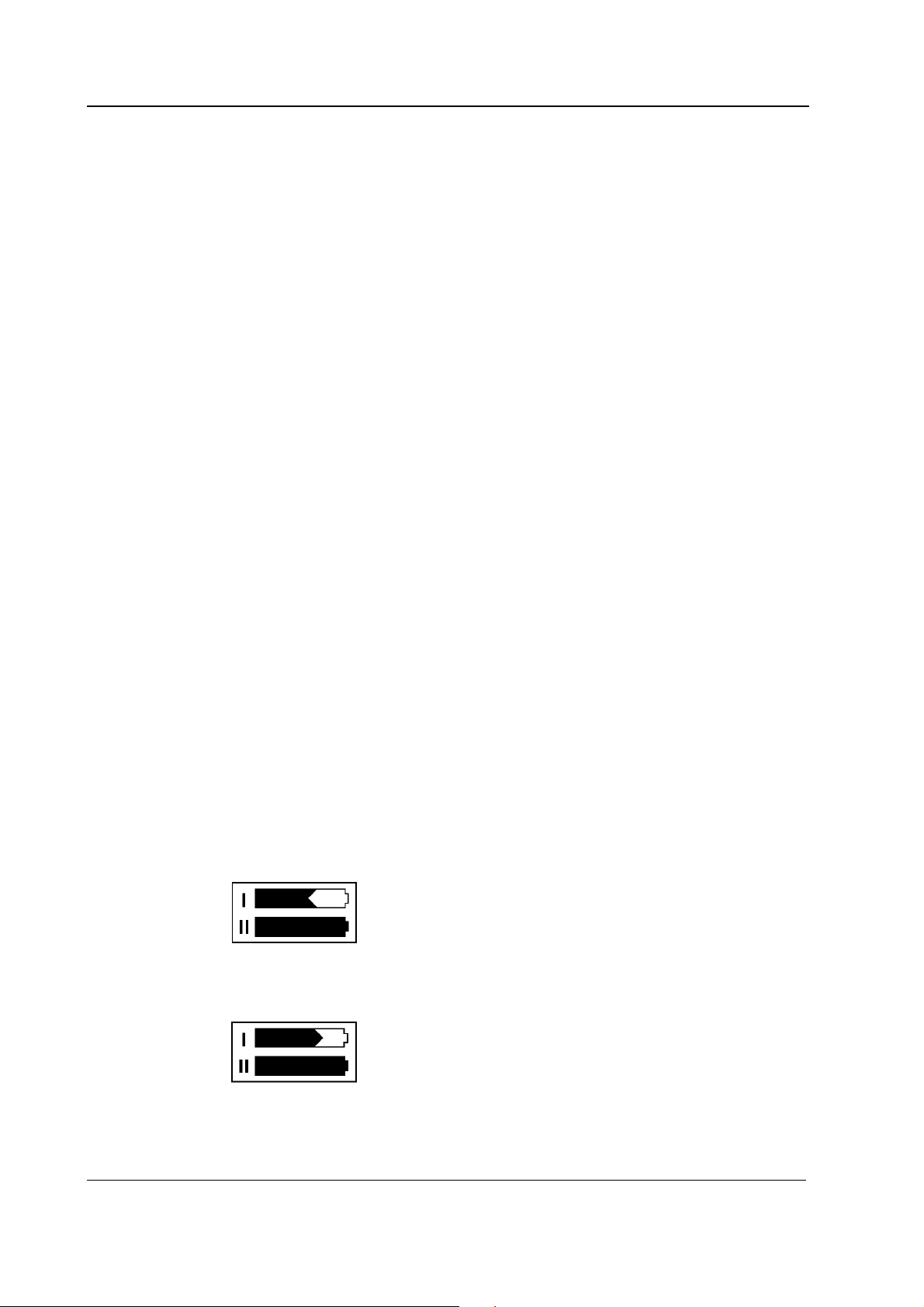

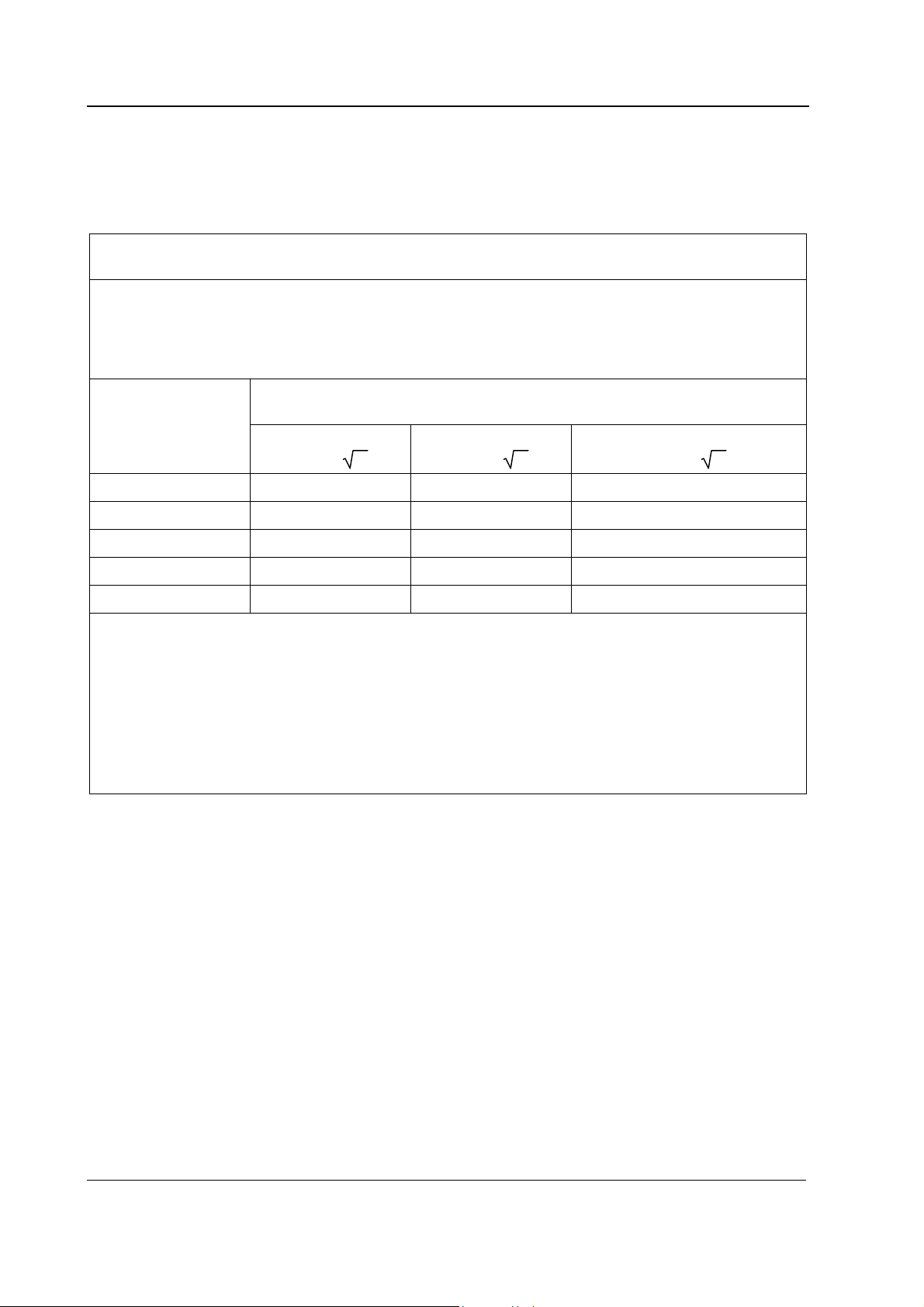

The S/5 Light Monitor is a portable factory configurated compact monitor designed for stationary

and mobile indoor monitoring of a patient’s vital signs. The monitor is available in two

configurations; F-LM1 and F-LMP1. The difference between the configurations is illustrated in

table 1. Additionally, the monitor can be equipped with an optional recorder and battery module.

An external power adapter is provided for power supply. The Light Monitor has also data card

option and Ethernet interface which enables connecting the monitor to the network for remote

monitoring the patient and data collection.

Introduction

l

ll

Figure 1 S/5 Light Monitor with battery module and power adapter

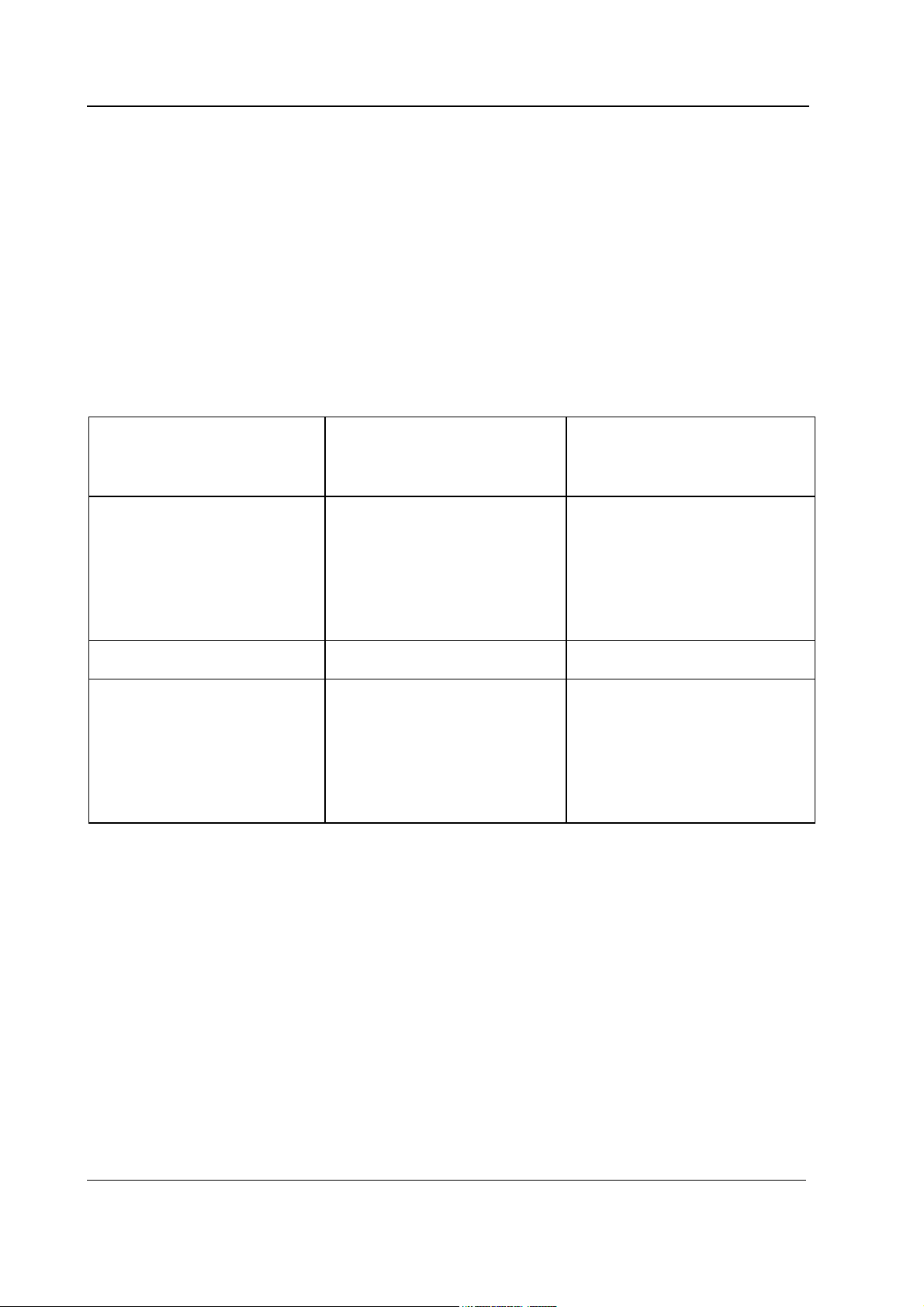

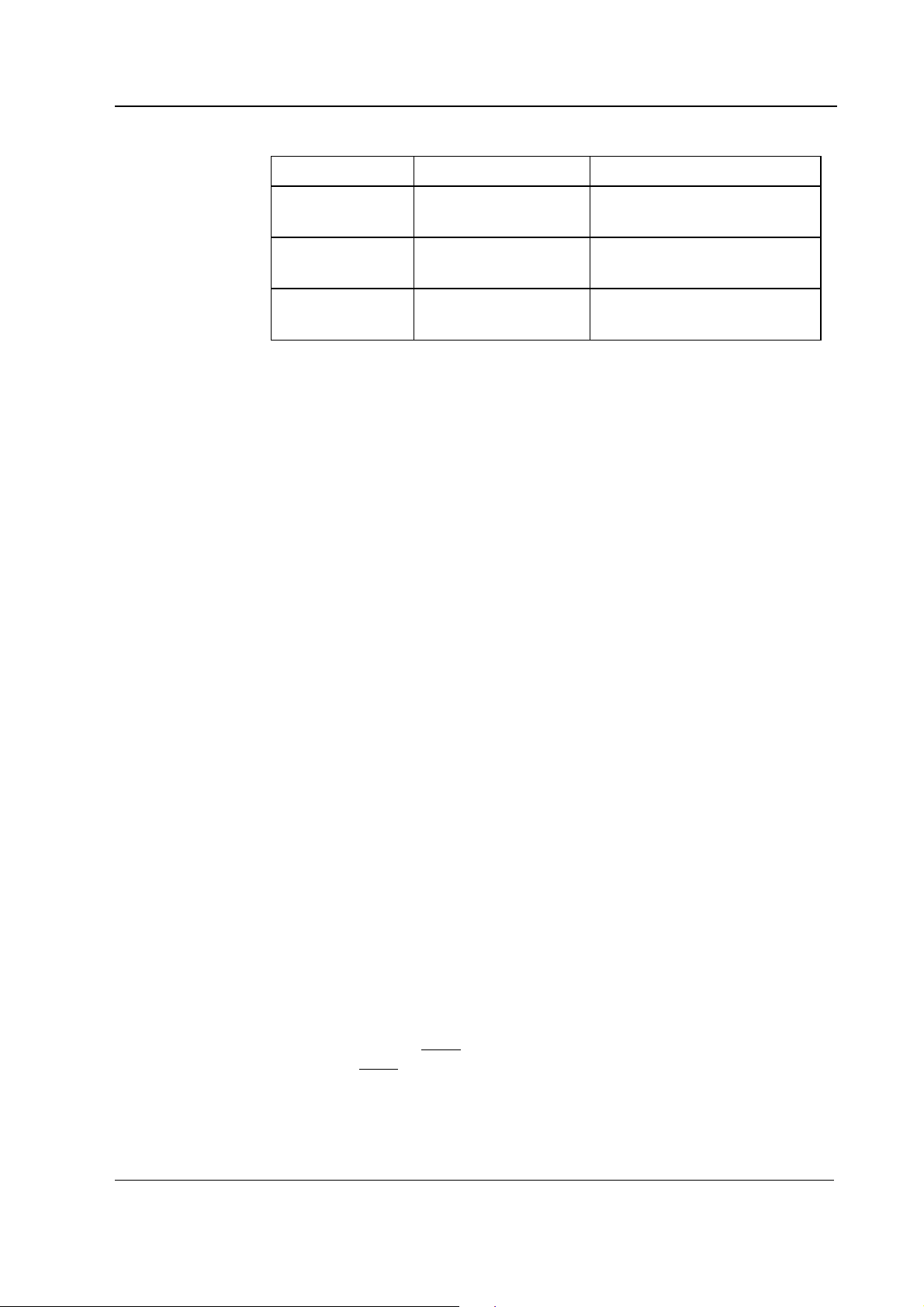

Table 1 Basic parameter configurations

ECGR NIBP SpO2 TEMP InvBP

F-LM1

F-LMP1

1)

number of channels

• • •

• • •

Parameters

1)

1

1)

1

-

1)

2

Parameter explanations:

ECGR ECG and respiration

NIBP Non-invasive blood pressure

Pulse oximetry

SpO

2

TEMP Temperature

InvBP Invasive blood pressure

Document No. M1051339

1

Page 10

Datex-Ohmeda S/5 Light Monitor

The following factory configurable parameters and functions are available:

• N-LNET; Network option

• N-LDATA; DataCard option

• N- LDNET; Network and DataCard options

• N-LCM; Mainstream CO

To all monitors following options are available:

• N-LREC; Thermal printer

• N-LPOW; External power supply, input: 110/230 VAC

• F-LBAT; Battery Module w/ two batteries

• N-LCHGR; External battery charger w/ two batteries

• N-LBB; Rechargeable built-in backup battery

1.1 Notes to the reader

GE Healthcare reserves the right to make changes in product specifications without prior notice.

The information in this manual is believed to be accurate and reliable; however, the manufacturer

assumes no responsibility for its use.

GE Healthcare assumes no responsibility for the use or reliability of its software on equipment that

is not furnished by GE Healthcare.

1.2 About this manual

This technical reference manual is intended for service personnel who will perform service and

maintenance procedures on the Light Monitor.

option

2

This technical reference manual is divided into two parts:

• Part I contains a general description of the monitor and service procedures.

• Part II contains detailed descriptions of the component parts of the monitor.

1.3 Related documents

S/5 Light Monitor User's Reference Manual

The User’s Reference Manual provides detailed instructions and references for the operation and

configuration of the monitor. Everyday service, maintenance procedures and troubleshooting hints

are also included.

Patient Monitor Supplies and Accessories

The Patient Monitor Supplies and Accessories Catalogue provides information on all supplies and

accessories available for the monitor.

2

Document No. M1051339

Page 11

Introduction

1.4 Installation

1.4.1 Choosing the location

The monitor can be placed on a flat surface or hung with the handle from the bed or wall rails. Make

sure that the surface or rail holds up to at least 10 kg/22 lb.

1.4.2 Warnings

WARNING The monitor or its components should not be used adjacent to or stacked with

other equipment. If adjacent or stacked use is necessary, the monitor and its

components should be observed to verify normal operation in the configuration

in which it will be used.

When choosing the location, refer to the appendix C later in this document.

Document No. M1051339

3

Page 12

Datex-Ohmeda S/5 Light Monitor

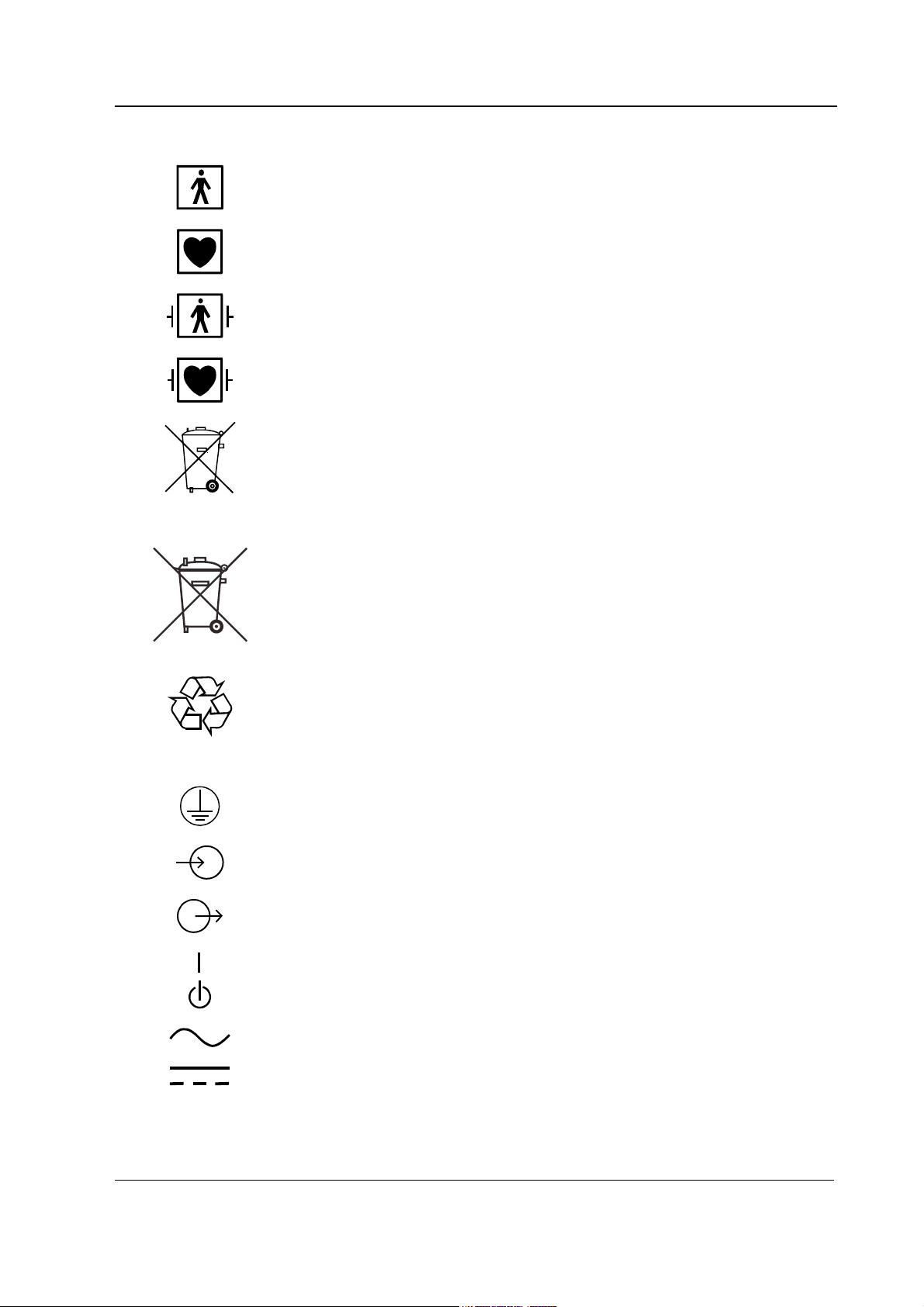

1.5 Symbols

1.5.1 Symbols on equipment

on the rear panel

indicates the

warning:

Attention, consult accompanying documents.

Electric shock hazard. Do not open monitor frame. Refer servicing to qualified personnel.

Do not touch any part of monitor or patient connections during defibrillation procedure.

Disconnect power supply before servicing. Use only external power adapter N-LPOW.

on the rear panel dust

filter indicates the

reminder:

on the patient

connector panel

indicates the

cautions:

on the external power

adapter indicates the

cautions:

on the battery unit

indicates the

warnings and

cautions:

on the CPU board

indicates the caution:

Check rear panel dust filter regularly, and clean at least once a month.

Use only the specified cables and accessories.

Ensure proper contact of the return electrode of the electrosurgery unit to your patient to

avoid possible burns at ECG electrode or other probe sites.

For continued protection against fire hazard, replace only with same type and rating of fuse.

Make sure voltage selector is set according to local voltage.

For indoor use only. For patient transport outdoors use the monitor in protective case and

battery powered.

Do not immerse in liquid or allow any liquid to enter the interior.

Do not put in fire.

Do not short-circuit any terminals.

Do not disassemble or mutilate.

Use only with Battery Module or External Battery Charger.

Discharge and charge batteries fully every 3 months or more often, if required, to restore full

capacity.

Sealed NiCd battery must be recycled or disposed of properly. Discharge before disposing.

There is a lithium battery on the CPU board. Discard useless battery according to local

regulations.

on the CO

4

Document No. M1051339

sensor Do not immerse the sensor in liquids or autoclave it.

2

Page 13

Introduction

d

SpO

: Type BF (IEC-60601-1) protection against electrical shock, not defibrillation proof.

2

: Type CF (IEC-60601-1) protection against electrical shock, not defibrillation proof.

T

1

NIBP: Type BF (IEC-60601-1) defibrillator-proof protection against electrical shock.

ECG, P

, P2: Type CF (IEC-60601-1) defibrillator-proof protection against electrical shock.

1

Battery packs contain heavy metal cadmium (chemical symbol Cd) and, in case of

disposal, must be separated from other waste according to local regulations.

Ni-Cd

Ni-C

This symbol indicates that the waste of electrical and electronic equipment must not be

disposed as unsorted municipal waste and must be collected separately. Please contact

an authorized representative of the manufacturer for information concerning the

decommissioning of your equipment.

Battery packs contain Ni-Cd and they can be recycled.

Protective earth terminal

Input voltage

Output voltage

Power ON/STANDBY

IPX-class:

IPX0

Alternating current

Direct current

Degree of protection against harmful ingress of water as detailed in the IEC 60529:

– ordinary equipment

Document No. M1051339

5

Page 14

Datex-Ohmeda S/5 Light Monitor

IPX1

IPX4

– vertically falling water drops shall have no harmful effects.

– splash proof

SN, S/N Serial number

Battery charging LEDs: LEDs will blink while batteries are being charged, and will stay

illuminated when batteries are fully charged and the monitor is connected to mains.

The monitor is connected to the network (optional).

The DataCard (option) is inserted. If symbol is blinking the card is faulty, or it is not

inserted properly.

A blinking heart next to the heart rate or pulse rate value indicates the beats detected

A lung next to the respiration rate value indicates that respiration rate is calculated from

the impedance respiration measurement.

Silence alarm indicator. When displayed on the upper left corner of the screen, indicates

that all the alarms are silenced. When in the menu or digit fields, indicates that the

alarm source has been turned off.

Ethernet connectors

Printer connector

Sample gas outlet

Do not immerse the sensor in liquids.

ESD warning symbol for electrostatic sensitive devices. Pins of connectors identified

with the ESD warning symbol should not be touched. Connections should not be made

to these connectors unless ESD precautionary procedures are used. See section ”

ESD precautionary procedures“ in this Technical Reference Manual for details.

Symbol for non-ionizing electromagnetic radiation. Interference may occur in the vicinity

of equipment marked with this symbol.

1.5.2 Symbols on transport packaging

The contents of the transport package are fragile and have to be handled with care.

This symbol indicates the correct upright position of the transport package.

2.2

6

Document No. M1051339

The transport package must be kept in a dry environment.

Page 15

Introduction

This symbol is to indicate the temperature limitations within which the transport package

should be kept and handled.

Document No. M1051339

7

Page 16

Datex-Ohmeda S/5 Light Monitor

2 SAFETY

2.1 Safety precautions

2.1.1 Warnings

WARNING Indicates situations in which the user or the patient may be in danger of injury

or death.

Explosion hazard

• Do not use the monitor in presence of flammable anesthetics.

Electrical shock hazard

• Use only hospital grade grounded electrical outlets and power cord. Grounding reliability

can only be achieved when the equipment is connected to a receptacle marked ‘hospital

grade’.

• Do not remove cover. Refer servicing to qualified service personnel.

• Avoid any conductive contact to the probes and sensors.

• Disconnect the monitor from the electrical outlet before cleaning. Let it dry completely

before reconnecting it to the electrical outlet.

• Do not autoclave any part of the monitor with steam or ethylene oxide. Do not immerse in

liquid or allow liquid to enter the interior of any part.

• Make sure that external equipment is hospital grade grounded before connecting it to the

monitor. Do not connect any external equipment to the monitor, except that specified by GE

Healthcare.

• When connecting external equipment to the monitor, make sure that the whole combination

complies with safety standard IEC 60601-1-1 for the medical electrical systems and with

the requirements of local authorities. Non-medical electrical equipment connected to the

monitor shall be supplied from an extra isolating transformer which has a protectively

earthed outlet.

• Do not leave loose any sensor cables connected to patient. Either connect them to the

monitor or detach them from the patient.

• Do not use the monitor, any parts thereof or any accessories, if they have become wet or

exposed to liquid.

• Where the integrity of the external protective conductor installation or arrangement is in

doubt, equipment shall be operated from its internal power source.

8

Document No. M1051339

Page 17

Patient safety

Safety

• Always make sure that necessary alarm limits are set and operative when you start

monitoring.

• When the alarms are suppressed, observe the patient frequently.

• Connect only one patient to one monitor at a time.

• Constant attention by a qualified professional is needed whenever a patient is under

anesthesia or connected to a ventilator. Some equipment malfunctions may pass

unnoticed in spite of the monitor alarm.

• Do not use antistatic or electrically conductive breathing tubes. They may increase the risk

of burns when electrosurgery unit is utilized.

• Do not use the monitor during magnetic resonance imaging (MRI).

• ECG, Impedance Respiration, InvBP: Ensure proper contact of the return electrode of the

electrosurgery unit to your patient to avoid possible burns at sensor sites.

• ECG, Impedance Respiration, InvBP: Make sure that no part of the patient connections

touches any electrically conductive material including earth.

• Impedance Respiration: In obstructive apnea, thoracic movements and impedance

variations may continue.

• NIBP: The monitor sets the inflation pressure automatically according to the first

measurement. Reset the case to reset the inflation limit before measuring a new patient.

• PATIENTS WITH PACEMAKERS OR ARRHYTHMIAS: Monitor may count the pacemaker pulses

as heart beats during cardiac arrest, some arrhythmias, and with certain types of

pacemakers particularly in ON R mode. Do not rely entirely upon rate meter alarms. Keep

patients with pacemakers and arrhythmias under close surveillance.

• PACEMAKER PATIENTS: The impedance respiration measurement may cause rate changes

in Minute Ventilation Rate Responsive Pacemakers. Set the pacemaker rate responsive

mode off or turn off the impedance respiration measurement on the monitor.

• SpO

: A damaged sensor, or a sensor soaked in liquid, may cause burns during

2

electrosurgery.

• SpO

: Change measuring site frequently. Change sensor site and check skin and circulatory

2

status every 2-4 hours with adults, and every hour with small children.

• The output signals are not floating and they must not be connected directly to a patient.

• Do not use delayed analog signals for defibrillator or intra-aortic balloon bump

synchronization.

• The monitor is intended for use by qualified medical personnel only.

• InvBP: All invasive procedures involve risks to the patient. Use aseptic technique. Follow

catheter manufacturer’s instructions.

• InvBP: Use only defibrillator proof cables and transducers.

• Operation of the monitor outside the specified values may cause inaccurate results.

• The monitor or its components should not be used adjacent to or stacked with other

equipment. If adjacent or stacked use is necessary, the monitor and its components should

be observed to verify normal operation in the configuration in which it will be used.

Document No. M1051339

9

Page 18

Datex-Ohmeda S/5 Light Monitor

WARNING Use only approved accessories, mounts and defibrillator-proof cables and

invasive pressure transducers. For a list of approved supplies and accessories,

see the Supplies and Accessories catalog. Other cables, transducers and

accessories may cause a safety hazard, damage the equipment or system,

result in increased emissions or decreased immunity of the equipment or

system or interfere with the measurement. Protection against cardiac

defibrillator discharge is due in part to the accessories for pulse oximetry

), temperature (T) and invasive pressure (P) measurement.

(SpO

2

Single-use accessories are not designed to be re-used. Re-use may cause a risk

of contamination and affect the measurement accuracy.

Service

• Only trained personnel with proper tools and test equipment should perform the tests and

repairs described in this manual. Unauthorized service may void the monitor warranty.

• Switch the power off, unplug the power cord, and remove the batteries before service.

• The monitor is always energized with 12 V when the batteries are connected, even though

the power cord is removed and ON/STBY switch is in STBY position.

• Do not touch any exposed wire or conductive surface while covers are off and the monitor is

energized. The voltages present can cause injury or death.

• Electrostatic discharge through the PC boards may damage the components. Before

replacing PC boards, wear a static control wrist strap. Handle all PC boards by their nonconductive edges and use anti static containers when transporting them.

• Do not break or bypass the patient isolation barrier when testing LM-STP and LM-ECG

boards.

• Do not perform any testing or maintenance on the monitor while they are being used on a

patient.

• There are special components used in this monitor, which are vital to assure reliability and

safety. GE Healthcare assumes no responsibility for damage if replacement components

not approved by GE Healthcare are used.

• Replace the fuse with a fuse of the same type and the same rating.

• Perform electrical safety checks and current leakage tests to the monitor after service.

10

Document No. M1051339

Page 19

2.1.2 Cautions

CAUTION Indicates situations in which the unit or devices connected to it may be

damaged.

• Use licensed patient cables and accessories only, see Datex-Ohmeda Catalogue Patient

Monitor Supplies and Accessories. Other cables and accessories may damage the system

or interfere with measurement.

• Before connecting power cord, ensure that the input voltage selector is set correctly in the

external power adapter.

• Use the monitor outdoors with the battery power only.

• Do not store the monitor beyond the specified temperature range.

• Do not use hypochlorite, ammonia-, phenol- or acetone-based cleaners. They may damage

the monitor.

• Clean rear panel fan dust filter once a month or whenever needed.

• Leave space around the monitor for ventilation to prevent the monitor from overheating.

• Do not apply pressurized air to any outlet, or tubing connected to the monitor. Pressure may

destroy sensitive elements.

Safety

Battery cautions

• When used in moving vehicle mount the monitor properly.

• Dispose of the device and parts thereof in accordance with local regulations.

• Vibrations during transport may disturb SpO

, ECG, impedance respiration and NIBP

2

measurements.

• CO

• CO

• DataCards: Do not subject cards to excessive heat, bending, or magnetic fields.

• InvBP: Mechanical shock to invasive blood pressure transducer may cause severe shifts in

, SpO2: Do not apply force to sensors or sensor cables.

2

: Do not force the water-trap into place.

2

zero balance and calibration, and produce erroneous readings.

• Electromagnetic interference from radio-frequency transmitting devices in ambulances may

affect the performance of this medical device.

• Do not put in fire.

• Do not short-circuit any terminals.

• Do not use damaged or leaking batteries.

• Do not disassemble or break the batteries.

• Use only with Battery Module.

• Charge and discharge batteries fully every 3 months or more often, if required, to restore full

capacity.

• Sealed NiCd battery must be recycled or disposed properly. Discharge before disposing.

11

Document No. M1051339

Page 20

Datex-Ohmeda S/5 Light Monitor

Storage and transport

• For allowed storage and transport conditions refer to the documentation delivered with the monitor.

Points to note

• Medical electrical equipment needs special precautions regarding electromagnetic compatibility and

needs to be installed and put into service by qualified personnel according to the electromagnetic

compatibility information provided in the Appendix C.

• Portable and mobile RF communications equipment can affect the medical electrical equipment.

• The allowed cables, transducers and accessories for the system are listed in the Supplies and

Accessories catalog delivered with the monitor.

• The equipment is suitable for use in the presence of electrosurgery. Please notice the possible

limitations in the parameter sections and in the "Safety precautions" section.

• Service and reparations are allowed for authorized service personnel only.

• CISPR 11 classifications:

− Group 1 contains all ISM (Industrial, scientific and medical) equipment in which there is

intentionally generated and/or used conductively coupled radio-frequency energy which is

necessary for the internal functioning of the equipment itself.

− Class A equipment is suitable for use in all establishments other than domestic and those directly

connected to the public low-voltage power supply network that supplies buildings used for domestic

purposes.

2.2 ESD precautionary procedures

• To avoid electrostatic charges to build up, it is recommended to store, maintain and use the

equipment at a relative humidity of 30% or greater. Floors should be covered by ESD

dissipative carpets or similar. Non-synthetic clothing should be used when working with the

component.

• To prevent applying a possible electrostatic discharge to the ESD sensitive parts of the

equipment, one should touch the metallic frame of the component or a large metal object

located close to the equipment. When working with the equipment and specifically when the

ESD sensitive parts of the equipment may be touched, a grounded wrist strap intended for use

with ESD sensitive equipment should be worn. Refer to the documentation provided with the

wrist straps for details of proper use.

ESD precautionary procedure training

It is recommended that all potential users receive an explanation of the ESD warning symbol and

training in ESD precautionary procedures.

The minimum contents of ESD precautionary procedure training should include an introduction to

the physics of electrostatic charge, the voltage levels that can occur in normal practice and the

damage that can be done to electronic components if they are touched by an operator who is

electrostatically charged. Further, an explanation should be given of methods to prevent build-up of

electrostatic charge and how and why to discharge one’s body to earth or to the frame of the

equipment or bond oneself by means of a wrist strap to the equipment or the earth prior to making

a connection.

12

Document No. M1051339

Page 21

2.3 Safety test

Measure leakage current according to following procedures:

• Connect the GND electrode of the test device to the body of the 9-pin D-connector of the Light

Monitor. The nuts that are for locking the male cable connector can be used as well.

Safety

Document No. M1051339

13

Page 22

Datex-Ohmeda S/5 Light Monitor

3 ARCHITECTURE

The Light Monitor is a compact patient monitor with fixed configuration. The monitor is designed for

stationary and mobile indoor monitoring of a patient’s vital signs. The monitor can be equipped

with an optional recorder and battery module. An external power adapter is provided for power

supply.

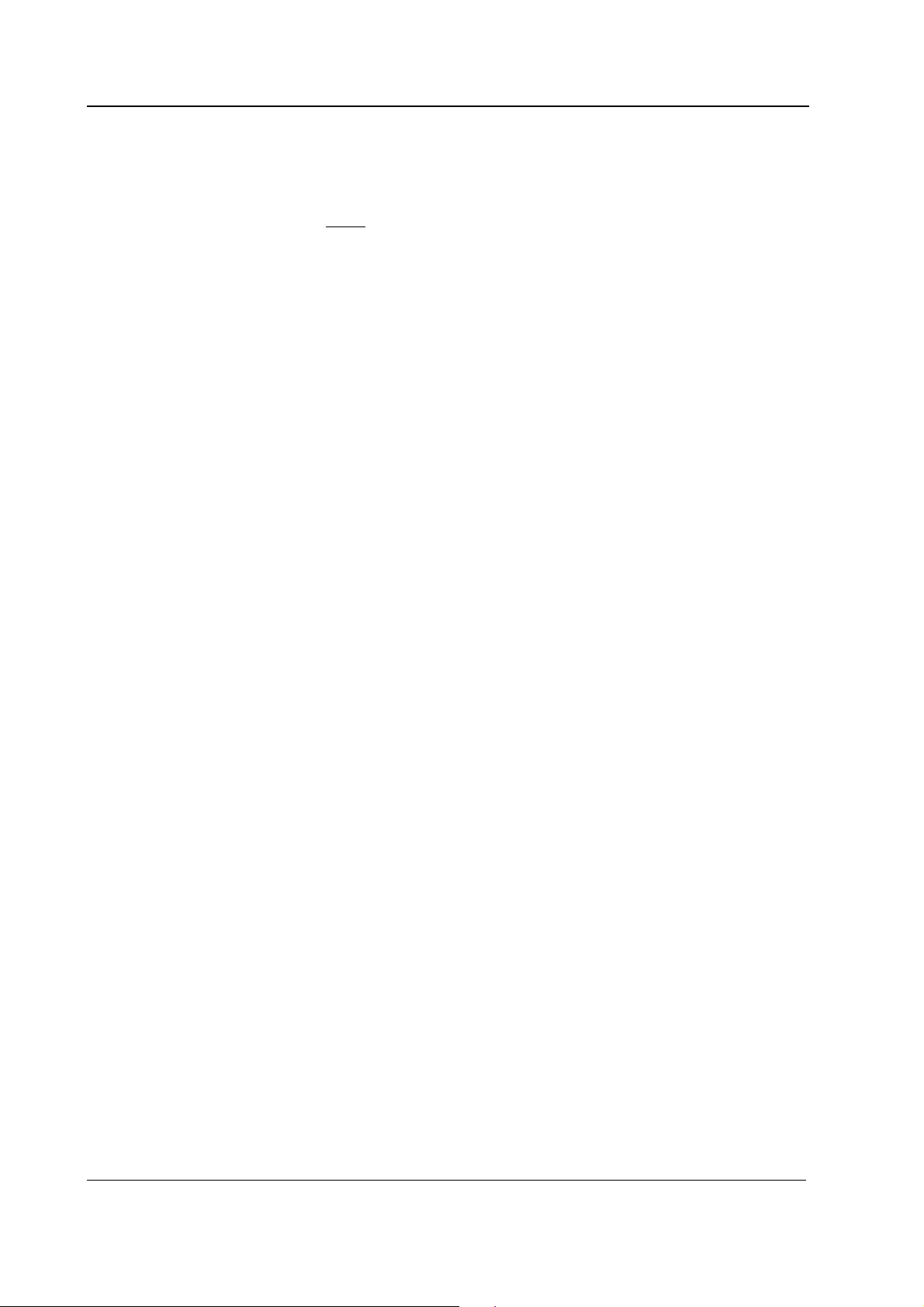

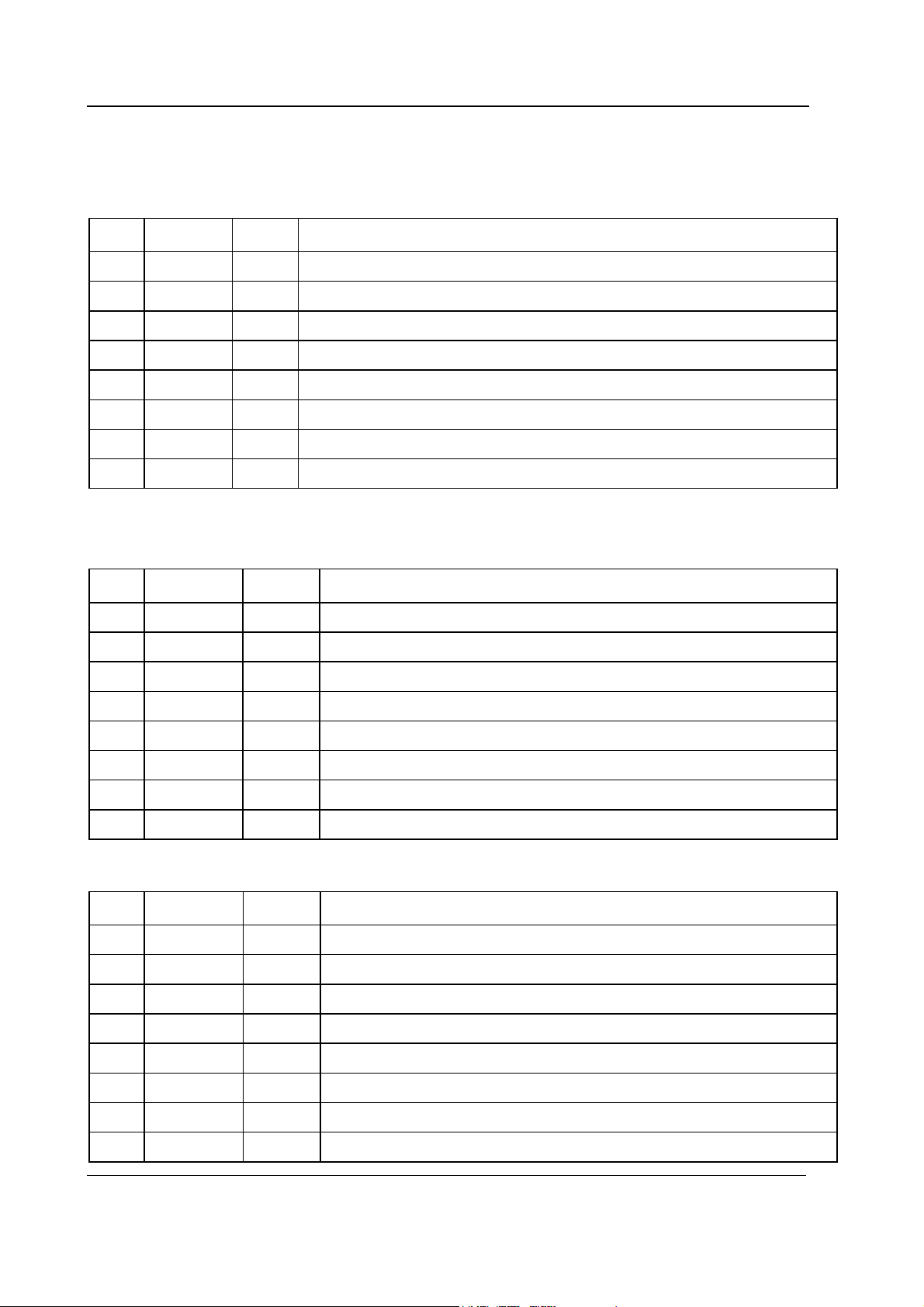

3.1 Monitor structure

Keyboard

Patient

connector

panel

NIBP

ECG &

Respiration

InvBP(S),

TEMP(S) &

SpO2

MS-CO2

NESTPR

NIBP UNIT

Pwr data

ECG UNIT

STP UNIT

CO2 UNIT

Buttons &

ComWheel

POWER SUPPLY

Alarm leds

BOARD

Data buffers

Module bus

ECG

direct output

CO2 data

DSYNC,

NCALL

RS-232

Backlight

Inverter

CPU

BOARD

Display

Slave

Display

Speaker

Recorder

PCMCIA

ISA bus

Ethernet

Patient

isolated

14

Document No. M1051339

Battery data (12C)

Battery module

ECG Direct,

DSYNC, NCALL

Computer

Interface

Ext. power

supply: mains

or DC/DC

Battery #1

Battery #2

Figure 2 Main block diagram of Light Monitor, revision 03

The monitor can be divided into the following parts:

1. CPU board

The CPU board controls display and slave display, loudspeaker and recorder according the

data collected from the other units.

LM_blck_rev03_dgrm.vsd

Page 23

2. STP unit

The STP unit is a parameter board that measures invasive blood pressure(s), body

temperature and oxygen saturation of the blood (SpO2).

3. ECG unit

The ECG unit is a parameter board that measures 3-lead ECG.

4. NIBP unit

The NIBP unit is a parameter board that measures non-invasive blood pressure.

Architecture

5. CO

unit

2

The CO

unit measures carbon dioxide consentration of the respiration gases. Measurement

2

is performed by an OEM product manufactured by Welch Allyn.

6. Network unit

The unit enables connecting the Light Monitor to the network for remote monitoring the

patient and data collection.

7. Memory unit

The memory unit is an optional data storage module. It is used for storing patient related

physiological data by removable PC-card.

8. Power supply board

Board delivers power from one of the power sources, external power supply or one of the

two batteries. The other operations are:

• battery management: secondary battery charge/discharge control and capacity

gauge

• keyboard and ComWheel reading

• alarm and charge led control/drive

• buffering serial communication

9. Display

The display is 8.4” Active Matrix Color TFT LCD. The resolution is 640 x 480 pixels.

10. Printer

The built-in thermal printer provides a real time waveform printing, numerical data and trend

data printout up to 24 hours.

11. Battery module

Two rechargeable and removable secondary batteries are located in the separate battery

module.

12. Keyboard and Comwheel

Keyboard and ComWheel actions are read by the power supply board.

13. Backup Battery

Built-in NiCd battery is located inside the monitor. It provides typically up to 30 min

operation time to the monitor.

Document No. M1051339

15

Page 24

Datex-Ohmeda S/5 Light Monitor

3.2 Power supply unit

The power supply board functions can be summarized as follows:

• Charge the batteries.

• Choose between battery and mains operation.

3.3 CPU

• Distribute power to the CPU, CO

• Control the alarm LEDs.

• Read the input from the keyboard and ComWheel.

The CPU, CO

, STP, ECG, and NIBP boards are connected to the power supply board for centrally

2

, STP, ECG, and NIBP boards.

2

distributed power. Thus all signals transmitted between these boards are transmitted via the power

supply board. The power supply board controls the reset of the CPU board via the startup key.

The CPU board functions can be summarized as follows:

• Process the data transmitted from the CO

• Control the CO

• Control the display, loudspeaker and recorder.

• Generate alarm signals.

• Generate nurse call signal.

, STP, ECG, and NIBP boards.

2

, STP, ECG, NIBP and power supply boards.

2

The display, the loudspeaker and the recorder, are all connected directly to the CPU board. The

CPU board includes the circuitry required to control these units. The CPU board communicates with

the power supply board over a 9600 baud serial communication channel. The ECG, STP and NIBP

boards are connected to the CPU board via the power supply board. The CPU board communicates

with these boards over a 500 kbaud serial communications channel. The reset of the ECG, STP and

NIBP boards is controlled separately.

16

Document No. M1051339

The CPU board generates a nurse call signal in the event of an alarm situation. The signal is

transmitted via the power supply board to the serial I/O connector on the monitor rear panel.

Page 25

3.4 NIBP unit

The NIBP unit consists of the NIBP board, an air pump, and pneumatic valves. The NIBP board

functions can be summarized as follows:

• Control the function of the air pump and the pneumatic valves.

• Measure the pressure variation of the NIBP cuff.

The pressure variation of the NIBP cuff is analyzed on the NIBP board and transmitted to the CPU

board over a serial communication channel.

3.5 ECG unit

The ESTP board functions can be summarized as follows:

• Measure ECG

• Generate defibrillation synchronization signal

The ECG signal is monitored and analyzed on the ECG board and transmitted to the CPU board over

a serial communication channel.

The ECG board is electrically patient isolated. The operating voltage 10...16 V is generated from the

+ 12 V received from the power supply board. The ECG board is reset by the CPU board.

Architecture

The ECG board generates a defibrillation synchronization signal. The signal is transmitted via the

CPU and power supply board to the serial I/O connector on the monitor rear panel. The

defibrillation synchronization signal is available also on the patient connector on the patient

connector panel.

3.6 STP unit

The STP board functions can be summarized as follows:

• Measure SpO

The signals from the parameters being monitored are analyzed on the STP board and transmitted to

the CPU board over a serial communication channel.

The STP board is patient isolated. The operating voltage is generated from the +12 V voltage

received from the power supply board. The STP board is reset by the CPU board.

3.7 CO2 unit

The CO2 unit consists of the CO2 board, an isolated power supply, and a pump. The CO2 board

functions can be summarized as follows:

• Process the CO

• Generate end tidal and inspiratory CO

• Control the Mainstream CO

The waveform data is processed on the CO

communication channel.

, temperature and invasive blood pressure.

2

waveform generated by the mainstream CO2 sensor.

2

values, and breaths per minute data.

2

sensor motor and heater.

2

board and transmitted to the CPU board over a serial

2

Document No. M1051339

17

Page 26

Datex-Ohmeda S/5 Light Monitor

3.8 Display unit

The main CPU directly controls the monitor display, an 8.4 inch color LCD. Supply voltages for the

display are connected via the CPU board. The inverter board provides high voltage for the display

backlights. The CPU controls the display brightness by adjusting the backlight voltage.

NOTE: The LCD display backlight circuit runs on a high voltage. Do not touch the inverter

board or the backlight tube leads when powered.

3.8.1 Slave display

Internal VGA compatible display controller with 640 × 480 resolution. The slave display can be

connected to external VGA connector, X7.

3.9 Power adapters

3.9.1 N-LPOW

The external power adapter N-LPOW is connected to the power connector on the monitor rear panel. The adapter includes a switch for the voltage range and a LED indicating energization. The power adapter supplies 12.5 V to operate the monitor and 18.5 V to charge the batteries. Fuses are located on the primary side of the adapter for overvoltage protection. See the part II/7 for more information.

3.10 Host serial communications

3.10.1 Module bus

The module bus is an asynchronous, CMOS-level serial communication between host processor

and Datex-Ohmeda based parameter modules and CO

and RXDM signals are used. The TXDM signal is module bus transmit line from host to modules and

the RXDM signal is a receive line from modules to host. Modules are wired-OR connected to RXDM

line.

The module communication link is also provided in the D15 male connector on the rear panel.

3.10.2 Computer interface (RS-232)

The computer interface is an asynchronous, RS-232-level serial communication between the Light

Monitor and external device e.g. PC. External device is connected to the D15 male connector on

rear panel.

measurement by Welch Allyn. Only TXDM

2

18

Document No. M1051339

Page 27

3.10.3 CO2 module

The CO2 module, manufactured by Welch Allyn is used in the Light Monitor for CO2 mainstream

measurement. Communication with the host is provided by an asynchronous serial link. Signals

used in the communication are TXDC, RXDC. The TXDC signal is transmit line from host to CO

module and the RXDC signal is a receive line from CO

3.10.4 Power board

Host communicates with the power board on an asynchronous serial link. TXDP and RXDP signals

are used. The TXDP signal is transmit line from host to power board and the RXDP signal is a receive

line from power board to host.

3.10.5 Recorder

The host sends data to the printer via an asynchronous serial link. TXDR, RXDR, CTSR and RTSR

signals are used. The TXDR signal is transmit line from host to recorder and the RXDR signal is a

receive line from recorder to host CTSR and RTSR lines are used for handshaking.

module to host.

2

Architecture

2

Document No. M1051339

19

Page 28

Datex-Ohmeda S/5 Light Monitor

4 CLEANING

Before cleaning:

• Turn the power to Standby

• Disconnect the power cord from the mains power supply

After cleaning:

• Let dry completely

• Reconnect the power cord and turn the power ON

CLEANING CASING /

SURFACE

when needed

Wipe gently with a cloth, moistured

with a mild detergent.

Let dry completely before

reconnecting the power cord.

CLEANING DUST

FILTER

at least once a month

Pull out the filter frame on the rear

panel. Do not remove any screws!

Shake the filter and blow out the

dust.

If the filter is damaged, replace it

with a new one (p/n 888260).

PERMITTED CLEANERS PERMITTED DISINFECTANTS

Datex-Ohmeda cleaning fluid

Other mild detergents

For more detailed information see User’s Reference Manual.

Ethanol

Isopropyl alcohol

Chlorite compounds

Glutaraldehyde

CLEANING PATIENT

ACCESSORIES

See the instructions delivered with

the accessory.

NOT ALLOWED

Do not use Hypochlorite, acetone-,

phenol- or ammonia based cleaners.

Do not autoclave the device.

Do not immerse the device in liquids

or allow liquids to enter the interior of

any part.

20

Document No. M1051339

Page 29

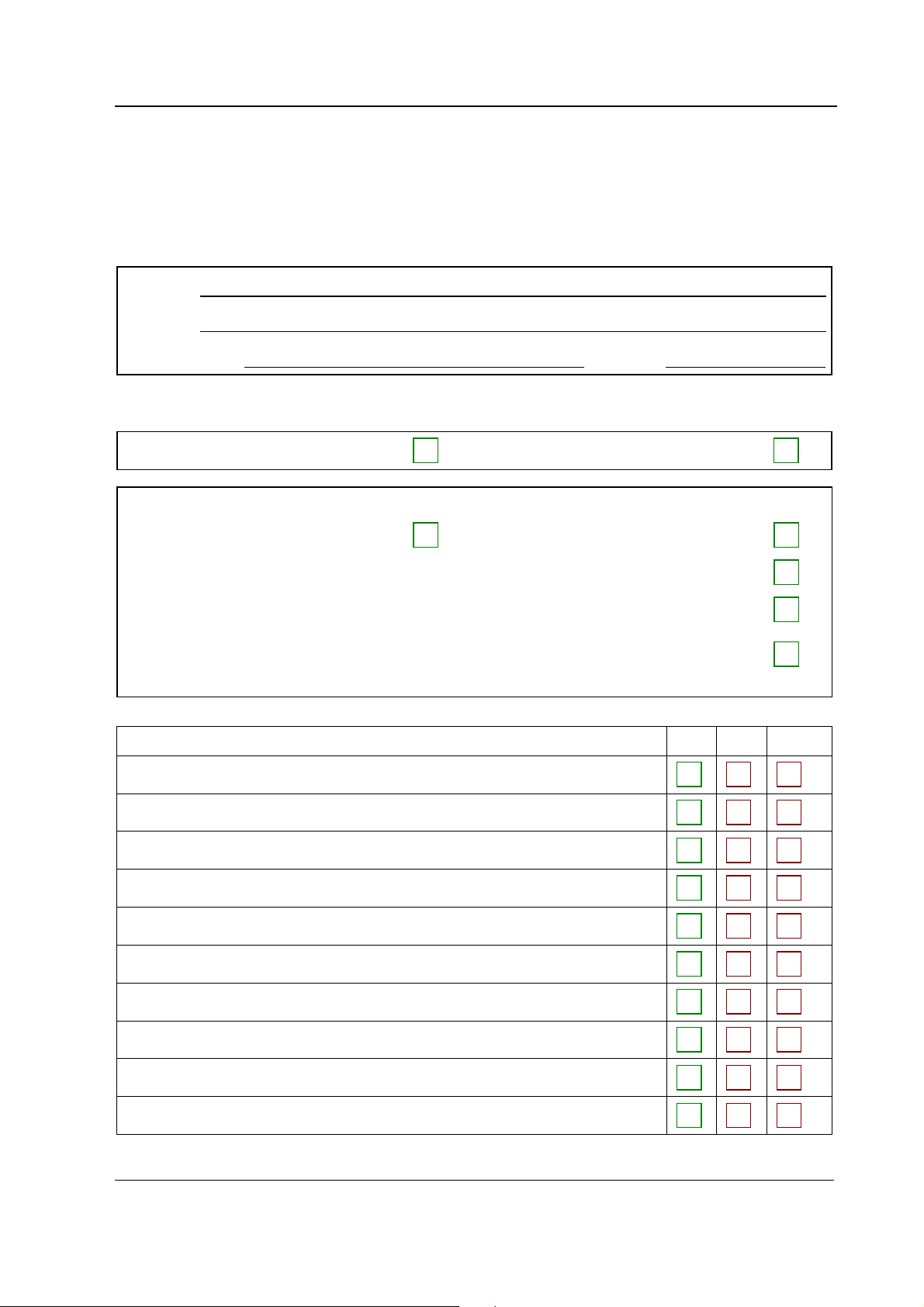

5 FUNCTIONAL CHECK

These instructions include complete procedures for functional check (FC) for Datex-Ohmeda Light

Monitors. The functional check is recommended to be performed after monitor installation and

after long storage.

The first part of the instructions contains check procedures that are done through the service menu.

These checks are especially recommended if the monitor has been stored for a long time without

using it.

When installing a new monitor, the performance checks with a simulator and accessories are

typically enough to ensure the correct function of the monitor. We recommend however always

performing the complete check to confirm that no hardware failures occurred during transportation.

The instructions are planned for the maximum functional configuration. Perform the procedures in

the ascending order and skip the items that do not correspond to your monitor configuration.

The instructions include a check form (Appendix A) to be filled in when performing the

corresponding procedures.

Functional check

The symbol

checklist.

All menu selections related to

Monitor Setup - Install/Service (password 16-4-34) -

Service (password 26-23-8) – Modules - ESTP - ECG

Menu selections related to other products e.g. simulators are written in following typeface:

" in the instructions means that the performed procedure should be signed in the

Datex-Ohmeda products are written in following typeface:

RESP - WAVE - NORM

- RATE - 20

Recommended tools:

Tool Order No.

Simulator capable of simulating ECG, RESP and invBP -

SpO2 finger probe SAS-F4

Adult NIBP cuff 572435

Adult NIBP hose 877235

MemCard- Data (only for monitors with data card option)

Temperature test plug set 884515

Mainstream CO2 sensor (only for monitors with CO2 option) 902300

Mainstream CO2 airway adapter (only for monitors with CO2 option) 902301/902302/902303

5.1 General functional inspection

1. Connect the power cord to the power adapter and the power adapter cable to the Light

Monitor.

Check that the green LED turns on in the power adapter and the LED in the lower right-hand

corner of the monitor turns on or starts flashing.

If the monitor contains a battery module, check that both battery charge status LEDs turn on

or start flashing.

Document No. M1051339

21

Page 30

Datex-Ohmeda S/5 Light Monitor

2. Switch the monitor on. Check that the monitor starts up properly, i.e.

− both alarm LED’s turn on and off

− the fan starts running

− the start-up sound is heard from the loudspeaker

− the normal monitoring screen appears

− no error messages appear on the screen *)

− If the monitor contains a recorder, two lines of start-up information should be

− check that the time and date are correct, adjust if necessary

− if the monitor contains an F-LBAT or N-LBB, check that the battery symbol is

3. Check the loudspeaker by adjusting the alarm volume in the Alarms Setup menu:

Press the

Select Alarms Setup - Alarm Volume

Test the whole volume scale from 1 to 10 by turning the ComWheel and check that the

alarm volume changes correspondingly. The alarm sound should be clear and audible at all

settings.

Select Main Menu

recorded

displayed

*) NOTE: “Check network connectors” will appear if the N-LNET or N-LDNET option is

installed.

Menu button.

4. Select Service View – Keyboard - Dummy Press.

Press the function keys one by one. Check that each key generates a sound from the

loudspeaker and the corresponding text.

5. Check that the time and date are correct, adjust if necessary.

Select Monitor Setup – Set Time and Date

NOTE: You cannot change the monitor’s time settings after a case has started. This prevents

losing the trend data.

NOTE: If the clock shows time 0:00 continuously after start-ups, the SRAM/Timekeeper’s

battery on the CPU board needs to be replaced.

Return to Main Menu by selecting Previous Menu - Main Menu

6. Check the battery (If F-LBAT or N-LBB option included):

Disconnect the power cord (without switching the monitor to standby).

Check that the monitor continues to run normally with battery. The battery indicator should

appear in the upper right hand corner of the screen:

22

Document No. M1051339

Page 31

"

5.1.1 Recorder test

7. Open the paper compartment cover. Check that the message “Recorder: Cover open”

8. Select Main Menu - Record/Print- Record Wave

Functional check

Reconnect the power cord and check that during charging, the charging symbol is displayed

and the Battery charge status LED starts flashing:

appears on the screen, then close the cover.

and check that the recorder starts recording. Select Stop Wave to stop recording.

Check that the quality of the recordings is acceptable.

"

5.1.2 PCMCIA card test

9. Insert the Memory card labeled “Data” in the DataCard slot. Check that the message “Data

Card inserted” appears in the message field and the white data card symbol in the upper

right hand corner of the screen appears within one minute.

"

Document No. M1051339

23

Page 32

Datex-Ohmeda S/5 Light Monitor

5.1.3 Network test

10. Connect the Mon-Net cable and the Identification plug to the monitor.

11. Check that the monitor connects to the Datex-Ohmeda Network, i.e. the network symbol

A message regarding the connection to Datex-Ohmeda Information Center should appear in

the message field on the screen.

12. Press the Menu button to enter the Network service menu:

Monitor Setup - Install/Service (Password 16-4-34) -

Service View (Password 26-23-8) - Monitor - Communication

Check that:

− the “location ID number” matches with the ID plug connected to X3

− the packets and bytes IN is increasing slowly

− the packets and bytes OUT is increasing quickly.

− the “connections” shows the names of the connected networks

− the counters for data errors (“CRC”, “Frame”, “Transm.”) are stable

NOTE: The counters may show values greater than 0. However, any values increasing

continuously indicate a problem.

is displayed on the upper right-hand corner of the screen.

13. Check that the counters for hardware errors (“Intern.”, “Missed”, “FIFO”, “Overrun”) all

show 0. If any of the counters show a value greater than 0, it indicates a problem on the

CPU board.

Return to the Monitor Setup menu by selecting Previous Menu repeatedly.

"

24

Document No. M1051339

Page 33

5.1.4 ECG board tests

14. Enter the ESTP : ECG service menu:

Press the

Monitor Setup - Install/Service (Password 16-4-34) -

Service View (Password 26-23-8) - Modules - ESTP : ECG

Check from the Service Data that:

− the “Timeouts”, “Bad checksums” and “Bad c-s by mod” values are not increasing

− the ECG/RESP board memories have passed the internal memory test, i.e. “RAM”,

15. Check that the module mains power frequency “Power Freq” value has been set according

to the supply frequency. If necessary, change the setting by selecting Power Freq.

16. Check that the “Resp Available” and “Resp measurement” both show ON.

NOTE: The Resp measurement shows OFF, if Resp is not selected to the screen setup. To

setup the screen, press the

Digit Fields.

Functional check

Menu button and select:

faster than by 50 per second.

“ROM” and “EEPROM” all state OK.

Menu key and select: Monitor Setup - Waveform Fields or

"

5.1.5 STP board tests

17. Enter the ESTP : STP service menu:

− Check that the “Timeouts”, “Bad checksums” and “Bad c-s by mod” values are not

increasing faster than by 50 per second.

− Check that the STP board memories have passed the internal memory test, i.e. “RAM”,

“ROM” and “EEPROM” all show OK.

18. Check that the protection for temperature calibration is on:

“Protect key” text in the menu should state OFF.

“Protect mode” text should state ON.

If necessary, change the protection mode in the Calibrations menu.

"

Document No. M1051339

25

Page 34

Datex-Ohmeda S/5 Light Monitor

5.1.6 NIBP board test

19. Enter the NIBP service menu:

Check that the “Timeouts”, “Bad checksums” and “Bad c-s by mod” values are not

increasing faster than by 50 per second.

Check that the NIBP board memories have passed the internal memory test, i.e. “RAM”,

“ROM” and “EEPROM” all show OK.

"

5.1.7 Mainstream CO2 test

20. Enter the CO2 service menu:

Press the

Monitor Setup - Install/Service (Password 16-4-34) -

Service View (Password 26-23-8) - Modules – CO2

Check from the Service Data that: “Timeouts”, “Bad checksums” and “send queue full”

values are not increasing faster than by 50 per second.

A value increasing faster than this indicates a failure in Module Bus communication.

"

Menu button and select:

26

Document No. M1051339

Page 35

5.2 Performance checks

1. Connect a 5-lead cable to the monitor. Configure the monitor screen so that all parameter

information is displayed, for example for the maximum configuration:

Press the

Monitor Setup - Waveform Fields/Digit Fields

Waveform Fields Digit Fields

Field 1 - ECG1 Field 1 -Temp

Field 2 - P1 Field 2 – NIBP

Field 3 – P2 Field 3 – Pleth

Menu button to enter the Main Menu and select:

Functional check

Field 4 - Resp Field 4 - CO

Return to

Connect the patient simulator and check that all parameter information is displayed as

configured on the screen.

NOTE: InvBP waveforms are not shown without a patient simulator.

Preset measurement settings for parameters, for example as follows:

Normal Screen.

2

ECG & Resp - ECG Setup - HR Source – AUTO

- Resp Setup - Size - 1.0

- Resp Rate Source - AUTO

- Detection Limit - AUTO

NOTE: The RESP waveform or Digit Field has to be selected on the screen before the

respiration measurement can be turned on.

NIBP & Inv. Press - P1 Setup&Alarm - Label - ART

- P2 Setup&Alarm - Label - CVP

Press the

- Pleth Scale - AUTO

Menu button to enter the SpO2 & Temp and select

"

Document No. M1051339

27

Page 36

Datex-Ohmeda S/5 Light Monitor

2. Connect the patient simulator to the ECG and InvBP connectors, SpO

connector and temperature test plug to the Temp connector. Attach the SpO

finger and check that:

− the simulated waveforms are good

− the SpO

− the Pleth waveform is normal.

"

3. Set the InvBP simulator to +100 mmHg static pressure. Push the Zero All button and

check that:

− the InvBP waveforms set on the baseline

− the digital values go to zero

Set the simulator to 0 mmHg and press

the zeroing, turn the simulator to dynamic mode and check that the waveform is normal.

"

4. Check that the message “No probe” is displayed when there is no SpO

Connect a SpO

displayed when the probe is not connected to finger.

value is in expected range

2

Zero All button. After the monitor has completed

finger probe to the monitor and check that the message “Probe off” is

2

probe to the SpO2

2

probe on your

2

sensor connected.

2

"

5. Attach the SpO

pleth waveform is displayed and the SpO

Check that the HR value is calculated from SpO

connected.

sensor to your finger and check that after the message “Pulse search” the

2

value is in the expected range (95-99 %).

2

when ECG and InvBP (P1) cables are not

2

"

6. Remove the SpO2 sensor from your finger and check that the message “Probe off” is

displayed. Disconnect the sensor from the monitor and check that “No probe” message is

displayed.

"

7. Attach an adult NIBP cuff onto your arm and perform one NIBP measurement. Check that

the module identifies the cuff, i.e. the text “Adult” appears in the NIBP digit field for a short

time.

Check that the module gives a reasonable measurement result.

"

28

Document No. M1051339

Page 37

Functional check

8. Check that the message “No CO2 sensor” is displayed when there is no CO

connected. Connect a CO

displayed.

"

9. Wait until the “warming” message disappears and the CO

Breathe at least 5 times to the CO

are reasonable and the Respiratory value is calculated.

"

• Fill in all necessary documents.

sensor to the monitor and check that the message “warming” is

2

value appears on the screen.

2

sensor adapter and make sure that the measured values

2

sensor

2

Document No. M1051339

29

Page 38

Datex-Ohmeda S/5 Light Monitor

6 SERVICE CHECK

6.1 General service information

Field service of the Light Monitor is limited to replacing faulty printed circuit boards or mechanical

parts. Faulty printed circuit boards should be returned to GE Healthcare for repair.

GE Healthcare is always available for service advice. Please provide the unit serial number, full type

designation, and a detailed description of the fault.

The instructions are planned for the maximum functional configuration. Perform the procedures in

the ascending order and skip the items that do not correspond to your monitor configuration.

CAUTION Only trained personnel with appropriate equipment should perform the tests and

repairs outlined in this section. Unauthorized service may void warranty of the unit.

6.2 Service check procedure

These instructions include complete procedures for service check. The service check is

recommended to be performed after any service repair, however, the service check procedures

can be used also for determining possible failures.

The procedures should be performed in ascending order.

The instructions include a check form (Appendix B) which should be filled in when performing the

procedures.

Names of the keys are written in bold Helvetica typeface, for example

Selectable menu items are written in bold and italic typeface, for example Previous Menu.

Informative messages displayed on the screen are written in normal typeface, but separated with

quotation mark, for example ‘Please wait’.

The mark

check form.

The procedures are designed for monitors with monitor software of level 894727-4.1. However, for

the most part they apply to monitors with older monitor software as well.

Recommended tools

Tool Order No.

Patient simulator for ECG, Impedance Resp and BP -

Pressure manometer -

Temperature test set 884515

3- and 5-lead ECG cable -

SpO2 finger probe OXY-F4-N

InvBP transducer 78000

Adult NIBP cuff 572435

Adult NIBP hose 877235

Infant NIBP hose 877514

Infant NIBP cuff 877407

Mainstream CO2 sensor (only for monitors with 902300

Normal Screen.

" in the instructions means that the performed procedure should be signed in the

30

Document No. M1051339

Page 39

Tool Order No.

CO2 option)

Mainstream CO2 airway adapter (only for monitors

with CO2 option)

Screwdriver -Pozidrive- type

MemCard- Data (only for monitors with data card

option)

Recommended parts

Service check

902301/902302/

902303

Part Order No.

Fan filter 886841

Recorder paper 74205 if N-LREC option

6.2.1 Visual inspection

• Switch the monitor to standby

• Disconnect all the connection cables from the monitor’s rear panel.

1. Check internal parts:

− Make visual inspection for all external parts of the monitor. Check e.g. that the power

− Connect the power cord to the power adapter and check the supply voltage from the

Pin Signal

2

4

3

1

Notes

installed

cord receptacle is intact in the power adapter.

power adapter’s connector. PIN 1 voltage must be 12.7 V without load (Figure 1). If

necessary, adjust the 12.7 V with trimmer R23 (Figure 2).

1

2

3

4

12.7 V

GND

18.5 V

GND

Figure 1 Power adapter’s voltages

Document No. M1051339

31

Page 40

Datex-Ohmeda S/5 Light Monitor

Figure 2 Adjustment trimmer R23 in N-LPOW

− Clean or replace the fan filter.

− Clean the recorder unit, if necessary.

− Check that all shielding flaps (6 pcs) are properly closed. (Figure 3)

R23

Shielding Flaps

(6 pcs)

Figure 3 LM1-STP board EMC covers

"

2. Check external parts:

32

Document No. M1051339

− the patient panel sticker is intact

− all connectors are intact and attached properly

Page 41

− both screws on the patient panel are tightened properly

"

3. General functional inspection

− Connect the power cord to the Power Adapter and the Power Adapter cable to the Light

Monitor.

Check that the green LED turns on in the power adapter and the LED on the lower right-hand

corner of the monitor turns on or starts flashing.

Check that both Battery charge status LEDs turn on or start flashing.

− Switch the monitor on. Check that the monitor starts up properly, i.e.

− both alarm LEDs turn on and off

− the fan starts running

− the start-up sound is heard from the loudspeaker

− the normal monitoring screen appears

− no error messages appear on the screen *)

− if the monitor contains a recorder, two lines of start-up information should be recorded

Service check

− check that the time and date are correct, adjust if necessary

− if the monitor contains an F-LBAT or N-LBB, check that the battery symbol is displayed:

*) NOTE: ”Check network connectors" will appear if the N-LNET or N-LDNET option is installed.

− Enter the service menu and select Dummy Press.

Press the function keys one by one. Check that each key generates a sound from the

loudspeaker and the corresponding text.

"

4. Screen setup

− Configure the monitor screen according to the monitor configuration so that all necessary

parameter information is displayed, for example as follows:

Menu - Monitor Setup- Waveform Fields - Field 1 - ECG1

- Field 2 – P1

- Field 3 – P2

- Field 4 - Resp

- Digit Fields - Lower Field 1 - NIBP

- Lower Field 2 – CO2

- Lower Field 3 – Pleth

- Lower Field 4 – Temp

− Connect the patient simulator to the monitor and check that all needed parameter

information is shown on the screen.

NOTE: The RESP waveform or Digit Field has to be selected on the screen before the respiration

measurement can be turned on.

Document No. M1051339

33

Page 42

Datex-Ohmeda S/5 Light Monitor

5. Preset ECG, Respiration, InvBP and SpO

measurement settings:

2

ECG & Resp - ECG Setup - Hr Source - Auto

- Pacemaker - Show

- Resp Setup - Size - 1.0

- Resp Rate Source - Auto

- Measurement - On

- Detection Limit - Auto

NIBP & Inv. Press - P1 Setup&Alarm - Label - Art

P2 Setup&Alarm - Label - Cvp

SpO2 & Temp - Pleth Scale – Auto

6. Press the Menu button and check the loudspeaker by adjusting the alarm volume in the

Alarms Setup menu:

− Test the whole volume scale from 1 to 10 by turning the ComWheel and check that the

alarm volume changes correspondingly. The alarm sound should be clear and audible at

all settings.

7. Select Service View – Keyboard – Dummy Press.

Press the function keys one by one. Check that each key generates a sound from the

loudspeaker and the corresponding text.

"

8. Check that the time and date are correct, adjust if necessary:

Menu – Monitor Setup – Set Time and Date

− NOTE: You cannot change the monitor’s time settings after a case has started. This

prevents losing the trend data.

− NOTE: If the clock shows time 0:00 continuously after start-ups, the SRAM/Timekeeper’s

battery on the CPU board needs to be replaced.

9. Check the battery (If F-LBAT or N-LBB option included):

Disconnect the power cord (without switching the monitor to standby).

Check that the monitor continues to run normally with battery. The battery indicator should

appear in the upper right hand corner of the screen:

Reconnect the power cord and check that during charging, the charging symbol is displayed

and the Battery charge status LED starts flashing:

34

Document No. M1051339

Page 43

6.2.2 Recorder test

10. Open the paper compartment cover. Check that the message “Recorder: Cover open”

appears on the screen, then close the cover.

11. Select Main Menu - Record/Print- Record Wave

and check that the recorder starts recording. Select Stop Wave to stop recording.

Check that the quality of the recordings is acceptable.

"

6.2.3 PCMCIA card test

12. Insert the Memory card labeled “Data” in the DataCard slot. Check that the message “Data

Card inserted” appears in the message field and the white data card symbol in the upper

right hand corner of the screen appears within one minute.

"

6.2.4 Network test

Service check

13. Connect the Mon-Net cable and the Identification plug to the monitor.

14. Check that the monitor connects to the Datex-Ohmeda Network, i.e. the network symbol

is displayed on the upper right-hand corner of the screen.

A message regarding the connection to Datex-Ohmeda Information Center should appear in

the message field on the screen.

15. Press the Menu button to enter the Network service menu:

Monitor Setup - Install/Service (Password 16-4-34) -

Service View (Password 26-23-8) - Monitor - Communication

Check that:

− the “location ID number” matches with the ID plug connected to X3

− the packets and bytes IN is increasing slowly

− the packets and bytes OUT is increasing quickly.

− the “connections” shows the names of the connected networks

− the counters for data errors (“CRC”, “Frame”, “Transm.”) are stable

NOTE: The counters may show values greater than 0. However, any values increasing

continuously indicate a problem.

16. Check that the counters for hardware errors (“Intern.”, “Missed”, “FIFO”, “Overrun”) all show

0. If any of the counters show a value greater than 0, it indicates a problem on the CPU

board.

Return to the Monitor Setup menu by selecting Previous Menu repeatedly.

"

Document No. M1051339

35

Page 44

Datex-Ohmeda S/5 Light Monitor

6.2.5 ECG measurement

17. Enter the service menu:

Menu - Monitor Setup - Install/Service (Password 16-4-34) -

Service View (Password 26-23-8)

Take down the information regarding monitor software and unit id by selecting Scroll Vers

and turning the ComWheel or choose Record Vers if the recorder is installed.

"

18. Enter the ESTP : ECG service menu:

Menu - Monitor Setup - Install/Service (Password 16-4-34) -

Service View (Password 26-23-8) - Modules - ESTP : ECG

Check that the “Timeouts”, “Bad checksums” and “Bad c-s by mod” values are not

increasing faster than by 50 per second. Check also that the ECG/RESP board memories

have passed the internal memory test, i.e. the “RAM”, “ROM” and “EEPROM” state all OK.