Page 1

GE Healthcare

Girae® Incubator

Service Manual

To reorder this manual, order kit:

• 6600-0847-801 (USA)

• 6600-0847-802 (INTL)

Copyright 2001 by Datex-Ohmeda, Inc.

All rights reserved.

6600-0356-000 103

Page 2

© 2001 by Datex-Ohmeda, Inc.

All rights reserved. General Electric Company reserves the right to make changes in specications and features

shown herein, or discontinue the product described at any time without notice or obligation. Contact your

GE Representative for the most current information. Girae and Panda

®

are registered trademarks owned by

Datex-Ohmeda, Inc. GE and GE Monogram are trademarks of General Electric Company. All other company and

product names mentioned may be trademarks of the companies with which they are associated.

Page 3

Table of Contents

About this Manual ................................................................................................................xiii

Scope and Intended Users ...........................................................................................................................................xiii

Conventions ......................................................................................................................................................................... xiii

References ..........................................................................................................................................................................xiv

User Responsibility ...........................................................................................................................................................xiv

Important .............................................................................................................................................................................. xiv

Important Safety Information ..........................................................................................xvii

Warnings ..............................................................................................................................................................................xvii

Service Language Disclaimer .........................................................................................................................xviii

Cautions .............................................................................................................................................................................. xxv

Symbol Denitions ......................................................................................................................................................... xxvi

Chapter 1: Functional Description ...................................................................................... 1

1.1 Control Board .................................................................................................................................................................1

1.2 Relay Board ....................................................................................................................................................................3

1.3 Display Driver Board / EL Display .........................................................................................................................4

1.4 LED Board .........................................................................................................................................................................5

1.5 Power Supply .................................................................................................................................................................. 5

1.6 Peripheral Components .............................................................................................................................................5

1.7 DataLink Option ............................................................................................................................................................6

1.8 Servo Controlled Oxygen Option ...........................................................................................................................7

1.9 Humidier .........................................................................................................................................................................8

Chapter 2: Service Checkout ................................................................................................ 9

2.1 Mechanical Checks ...................................................................................................................................................... 9

2.2 Controller Checks....................................................................................................................................................... 10

2.3 Humidity Check .......................................................................................................................................................... 11

2.4 Servo Controlled Oxygen Check ......................................................................................................................... 12

2.4.1 Leak Check ..................................................................................................................................................... 12

© 2001 by Datex-Ohmeda, Inc.. All rights reserved. 6600-0356-000 103 iii

Page 4

Table of Contents

Chapter 3: Calibration and Maintenance ........................................................................ 19

2.4.2 Pre-use Checkout ........................................................................................................................................ 12

2.4.3 Supply Valve Leak Test ............................................................................................................................. 13

2.5 Scale Check .................................................................................................................................................................. 14

2.5.1 Mechanical Check ....................................................................................................................................... 14

2.5.2 Weight Checks .............................................................................................................................................. 14

2.5.2.1 Center Weight Check .................................................................................................................... 14

2.5.2.2 O Center Weight Check ............................................................................................................. 15

2.6 Other Accessory Checks......................................................................................................................................... 15

2.7 Cable Connections and Mechanical Controls .............................................................................................. 16

3.1 Service Maintenance Schedule ........................................................................................................................... 19

3.2 Special Tools ................................................................................................................................................................ 21

3.3 System Calibration .................................................................................................................................................... 21

3.4 Line Voltage Calibration ......................................................................................................................................... 22

3.5 Humidier Calibration ............................................................................................................................................. 22

3.6 Servo Controlled Oxygen Calibration ............................................................................................................... 23

3.7 Scale Calibration ........................................................................................................................................................ 24

3.8 Leakage Current ........................................................................................................................................................ 25

3.9 Ground Resistance Check...................................................................................................................................... 25

Chapter 4: Troubleshooting ............................................................................................... 27

4.1 Startup Sequence ...................................................................................................................................................... 27

4.2 Service Screen............................................................................................................................................................. 28

4.3 Alarm Messages ......................................................................................................................................................... 32

4.3.1 “Air Probe Failure” Alarm .......................................................................................................................... 32

4.3.2 “Air Temp >38C” or “Air Temp >40C” Alarm ..................................................................................... 32

4.3.3 “Baby Hot” or “Baby Cold” Alarm ......................................................................................................... 33

4.3.4 “Baby Mode Disabled” Alarm ................................................................................................................. 33

4.3.5 “Baby Probe 1 (or 2) Failure” Alarm ..................................................................................................... 33

4.3.6 “Bad Membrane Switch” Alarm ............................................................................................................ 33

4.3.7 “Bed Heater Failure” Alarm ..................................................................................................................... 34

4.3.8 “Bed Up/Down Pedal Failure” Alarm .................................................................................................. 34

4.3.9 “Bed Up/Down Pedal Switches Disabled” Alarm .......................................................................... 35

4.3.10 “Down Pedal Pressed” Alarm .............................................................................................................. 35

4.3.11 “Fan Always in High Speed” Alarm ................................................................................................... 35

4.3.12 “Fan Failure” Alarm .................................................................................................................................. 35

4.3.13 “Humidier Failure” Alarm .................................................................................................................... 36

4.3.14 “Motor Drive Failure” Alarm ................................................................................................................. 37

iv 6600-0356-000 103 © 2001 by Datex-Ohmeda, Inc.. All rights reserved.

Page 5

Table of Contents

4.3.15 Power Failure (LED Indicator) .............................................................................................................. 37

4.3.16 “Temperature out of Calibration” Alarm ........................................................................................ 37

4.3.17 “Up Pedal Pressed” Alarm ..................................................................................................................... 38

4.4 Error Codes ................................................................................................................................................................... 38

4.4.1 System Failure 0 ..........................................................................................................................................38

4.4.2 System Failure 1 ..........................................................................................................................................39

4.4.3 System Failure 2 ..........................................................................................................................................39

4.4.4 System Failure 3 ..........................................................................................................................................39

4.4.5 System Failure 5 ..........................................................................................................................................40

4.4.6 System Failure 6 ..........................................................................................................................................40

4.4.7 System Failure 7 ..........................................................................................................................................40

4.4.8 System Failure 8 ..........................................................................................................................................40

4.4.9 System Failure 11 ........................................................................................................................................ 41

4.4.10 System Failure 12 ..................................................................................................................................... 41

4.4.11 System Failure 13 ..................................................................................................................................... 41

4.4.12 System Failure 14 ..................................................................................................................................... 41

4.4.13 System Failure 15 .................................................................................................................................... 42

4.4.14 System Failure 16 .................................................................................................................................... 43

4.4.15 System Failure 18 ..................................................................................................................................... 43

4.4.16 System Failure 19 ..................................................................................................................................... 44

4.4.17 System Failure 20 ..................................................................................................................................... 44

4.4.18 System Failure 22 .................................................................................................................................... 44

4.4.19 System Failure 23 .................................................................................................................................... 45

4.4.20 System Failure 25 ..................................................................................................................................... 45

4.4.21 System Failure 26 ..................................................................................................................................... 46

4.4.22 System Failure 27 ..................................................................................................................................... 46

4.4.23 System Failure 28 ..................................................................................................................................... 46

4.4.24 System Failure 29 ..................................................................................................................................... 46

4.4.25 System Failure 30 ..................................................................................................................................... 47

4.4.26 System Failure 33 ..................................................................................................................................... 47

4.4.27 System Failure 34 ..................................................................................................................................... 47

4.4.28 System Failure 35 ..................................................................................................................................... 48

4.4.29 System Failure 50 ..................................................................................................................................... 48

4.4.30 System Failure 51 ..................................................................................................................................... 48

4.4.31 System Failure 52 ..................................................................................................................................... 48

4.4.32 System Failure 53 ..................................................................................................................................... 48

4.4.33 System Failure 55 ..................................................................................................................................... 49

4.4.34 System Failure 98 ..................................................................................................................................... 49

4.4.35 System Failure 99 ..................................................................................................................................... 49

4.5 Troubleshooting Symptoms ................................................................................................................................. 49

4.6 Additional Troubleshooting Tips ......................................................................................................................... 53

© 2001 by Datex-Ohmeda, Inc.. All rights reserved. 6600-0356-000 103 v

Page 6

Table of Contents

4.6.1 Raising and Lowering the Elevating Base ........................................................................................ 53

4.6.2 Incubator Heaters and Bed Safety Thermostat ............................................................................ 53

4.6.3 Power Supplies ............................................................................................................................................. 54

4.6.4 Switches/Thermostat ................................................................................................................................ 54

4.6.5 Humidier Heater/Safety Thermostat ............................................................................................... 55

4.6.6 Compartment Air Probe and Patient Probes .................................................................................. 55

4.6.7 Incubator Heat Sink Sensor Thermistor ............................................................................................ 56

4.6.8 Elevating Base Motor ................................................................................................................................. 56

4.6.9 Troubleshooting the 50 Pin Ribbon Cable........................................................................................ 56

4.6.10 Troubleshooting the Toroidal Transformer ...................................................................................57

4.6.11 Interpreting Serial Numbers ................................................................................................................ 57

4.7 Servo Controlled Oxygen ....................................................................................................................................... 58

4.7.1 Servo Controlled Oxygen Service Screen ......................................................................................... 58

4.7.2 Servo Controlled Oxygen Alarm Messages ..................................................................................... 59

4.7.3 Servo Controlled Oxygen Troubleshooting Tips ............................................................................ 63

4.7.3.1 Check Supply Valves ..................................................................................................................... 63

4.7.3.2 Check Calibration Valve/Calibration Fan ............................................................................. 63

4.7.3.3 Check Cooling Fan ......................................................................................................................... 63

4.7.3.4 Sensor Housing Temperature Sensor Temperature to Resistance Curve ...........64

Chapter 5: Repair Procedures ............................................................................................ 65

5.1 Hood Removal for Replacement ....................................................................................................................... 66

5.2 Porthole Door Replacement ................................................................................................................................. 67

5.3 Uprights and End Caps .......................................................................................................................................... 68

5.3.1 Re-installing the Upright .......................................................................................................................... 69

5.4 Compartment Probe Repairs .............................................................................................................................. 70

5.5 Lower Unit Repairs .................................................................................................................................................... 71

5.5.1 Removing the Chassis Cover with the Storage Drawer in Place ..........................................71

5.5.2 Incubator Fan/Motor/Optical Sensor ................................................................................................. 72

5.5.3 Incubator Heater Replacement ........................................................................................................... 73

5.5.3.1 To Remove the Heater Closest to the Foot of the Bed .................................................. 73

5.5.3.2 To Remove the Heater Closest to the Head of the Bed ................................................ 74

5.5.4 Elevating Base .............................................................................................................................................. 75

5.5.5 Chassis Replacement ................................................................................................................................ 79

5.5.6 Bed Up/Down Pedal Switch .................................................................................................................... 79

5.5.7 Humidier Assembly Repairs ................................................................................................................. 81

5.5.7.1 Tips for Repairing the Humidier Assembly on an Old Style Unit ............................81

5.5.7.2 Humidier Disassembly ............................................................................................................... 82

5.5.7.3 Humidier Reassembly ................................................................................................................ 83

5.6 Bed Tilt Brake Pad Replacement ....................................................................................................................... 85

vi 6600-0356-000 103 © 2001 by Datex-Ohmeda, Inc.. All rights reserved.

Page 7

Table of Contents

5.7 Caster Replacement ................................................................................................................................................ 86

5.8 Controller and Display Module Procedures ................................................................................................... 87

5.8.1 Display Module ............................................................................................................................................. 87

5.8.2 Probe Panel ................................................................................................................................................... 88

5.8.2.1 Battery ................................................................................................................................................. 89

5.8.3 Controller Components ........................................................................................................................... 90

5.8.3.1 Control Board ................................................................................................................................... 91

5.8.3.2 Relay Board ....................................................................................................................................... 91

5.8.3.3 Solid State Relay .............................................................................................................................. 91

5.8.3.4 Power Supply .................................................................................................................................... 91

5.8.3.5 Toroidal Transformer .................................................................................................................... 92

5.8.3.6 Circuit Breakers, Power Switches, and Power Outlets ...................................................92

5.9 Servo Controlled Oxygen Service Procedures .............................................................................................. 93

5.9.1 Installing Oxygen Sensors ...................................................................................................................... 93

5.9.2 Replacing the Vent Screen ...................................................................................................................... 94

5.9.3 Sensor Housing Repairs ........................................................................................................................... 94

5.9.3.1 Sensor Housing Boards, Calibration Fan Assembly, and Sensor Plug Assembly 94

5.9.3.2 Calibration Valve ............................................................................................................................. 95

5.9.4 Valve Housing Repairs .............................................................................................................................. 96

5.9.4.1 Regulator Assembly ..................................................................................................................... 96

5.9.4.2 Supply Valves .................................................................................................................................. 97

5.9.5 Servo Oxygen Board Repairs ................................................................................................................. 97

Chapter 6: Illustrated Parts ................................................................................................ 99

6.1 Exploded Views ........................................................................................................................................................... 99

6.1.1 Probe Housing, Display Module, and Electrical Enclosure .....................................................100

6.1.2 Bed and Side Doors ..................................................................................................................................108

6.1.3 Hood and Compartment Air Probe ..................................................................................................114

6.1.4 Chassis ...........................................................................................................................................................116

6.1.5 Humidier .....................................................................................................................................................120

6.1.6 Elevating Base, Old Designs .................................................................................................................122

6.1.7 Elevating Base, Current Design...........................................................................................................124

6.1.8 Hood Latch, Wire Covers, and Uprights..........................................................................................126

6.1.9 Servo Control Oxygen .............................................................................................................................130

6.1.10 Accessory Hangers ................................................................................................................................137

6.1.11 Storage Drawer .......................................................................................................................................138

6.2 Accessories .................................................................................................................................................................147

6.3 Labels ............................................................................................................................................................................148

6.4 PCB Layouts ...............................................................................................................................................................152

6.5 Wiring Diagrams ......................................................................................................................................................156

© 2001 by Datex-Ohmeda, Inc.. All rights reserved. 6600-0356-000 103 vii

Page 8

Table of Contents

Appendix A: Compartment and Skin Probe Characteristics ...................................... 167

Appendix B: Specications ............................................................................................... 169

B.1 Power Requirements..............................................................................................................................................169

B.2 Accessory Outlets ....................................................................................................................................................169

B.3 Standards ....................................................................................................................................................................169

B.4 Operating Environment ........................................................................................................................................170

B.5 Storage Conditions .................................................................................................................................................170

B.6 User Control Settings .............................................................................................................................................170

B.7 Alarms ...........................................................................................................................................................................170

B.8 Performance ..............................................................................................................................................................171

B.8.1 System ............................................................................................................................................................171

B.8.2 Humidity ........................................................................................................................................................171

B.8.3 Servo Control Oxygen .............................................................................................................................171

B.9 Weight Scale ..............................................................................................................................................................172

B.10 Mechanical Specications ................................................................................................................................172

B.10.1 Accessories................................................................................................................................................172

Appendix C: RS-232 Serial Data ....................................................................................... 173

C.1 RS-232 Connector ...................................................................................................................................................173

C.2 Data Stream .............................................................................................................................................................173

C.3 Nurse Call ....................................................................................................................................................................174

Appendix D: Additional Safety Information...................................................................177

viii 6600-0356-000 103 © 2001 by Datex-Ohmeda, Inc.. All rights reserved.

Page 9

List of Figures

Figure 1-1 Block Diagram ................................................................................................................................................2

Figure 1-2 Humidier .........................................................................................................................................................8

Figure 2-1 Connections and Controls ...................................................................................................................... 16

Figure 3-1 Control Board Test Points ....................................................................................................................... 20

Figure 4-1 First Service Screen ................................................................................................................................... 28

Figure 4-2 Second Service Screen ............................................................................................................................ 29

Figure 4-3 Status Menu .................................................................................................................................................. 29

Figure 4-4 Switch Diagnostic Diagram ................................................................................................................... 30

Figure 4-5 First Service Screen: Diagnostics ........................................................................................................ 31

Figure 4-6 Servo Controlled Oxygen Service Screen ........................................................................................ 58

Figure 5-1 Hood ................................................................................................................................................................. 66

Figure 5-2 Uprights and End Caps ............................................................................................................................ 68

Figure 5-3 Compartment Probe ................................................................................................................................. 70

Figure 5-4 Chassis Bottom Cover .............................................................................................................................. 71

Figure 5-5 Fan Motor ....................................................................................................................................................... 72

Figure 5-6 Heat Sink and Fan ...................................................................................................................................... 73

Figure 5-7 Bed Disassembly ........................................................................................................................................ 75

Figure 5-8 Elevating Base with Two-piece Shroud Assembly ...................................................................... 76

Figure 5-9 Elevating Base with Three-piece Shroud Assembly ................................................................... 77

Figure 5-10 Humidier Parts ........................................................................................................................................ 82

Figure 5-11 Replacing the Tilt Brake ........................................................................................................................ 85

Figure 5-12 Display Module ......................................................................................................................................... 87

Figure 5-13 Probe Panel ................................................................................................................................................ 88

Figure 5-14 Electronics Enclosure ............................................................................................................................. 90

Figure 5-15 Installing Sensors ..................................................................................................................................... 93

Figure 5-16 Sensor Housing......................................................................................................................................... 94

Figure 5-17 Valve Housing............................................................................................................................................96

Figure 6-1 Probe Panel Assembly ............................................................................................................................101

Figure 6-2 Display Module .........................................................................................................................................103

© 2001 by Datex-Ohmeda, Inc.. All rights reserved. 6600-0356-000 103 ix

Page 10

List of Figures

Figure 6-3 Electrical Enclosure .................................................................................................................................105

Figure 6-4 Humidier Transformer and RS232 Option ..................................................................................107

Figure 6-5 Bed ..................................................................................................................................................................109

Figure 6-6 Side Door (East/West) ............................................................................................................................111

Figure 6-7 Flip Door, Corner Brackets, and Grommets ..................................................................................113

Figure 6-8 Compartment Air Probe ........................................................................................................................115

Figure 6-9 Upper Chassis and Heat Sink .............................................................................................................117

Figure 6-10 Lower Chassis .........................................................................................................................................119

Figure 6-11 Humidier Assembly ............................................................................................................................121

Figure 6-12 Base and Elevating Column with Two-piece Shroud Assembly .......................................123

Figure 6-13 Base and Elevating Column with Three-piece Shroud Assembly ...................................125

Figure 6-14 Hood Latch and Wire Covers ...........................................................................................................127

Figure 6-15 Uprights and End Caps .......................................................................................................................129

Figure 6-16 Servo Control Oxygen Sensor Housing Assembly .................................................................131

Figure 6-17 Servo Control Oxygen Valve Housing .........................................................................................133

Figure 6-18 Expansion Chamber/Heatsink Vent ..............................................................................................134

Figure 6-19 Servo Control Oxygen Cooling Fan ................................................................................................135

Figure 6-20 Servo Control Oxygen PC Board .....................................................................................................136

Figure 6-21 Drainage Hangers and DIN Rail ......................................................................................................137

Figure 6-22 Storage Drawer (on Units with Two-piece Shroud Assembly) ..........................................138

Figure 6-23 Storage Drawer (on Units with Three-piece Shroud Assembly) .......................................139

Figure 6-24 Instrument Shelf (6600-0865-700) ................................................................................................139

Figure 6-25 Monitor Shelf (6600-0824-800) .......................................................................................................140

Figure 6-26 E-Cylinder Holder (6600-0836-800)...............................................................................................141

Figure 6-27 Tubing Management Arm (6600-0837-800) .............................................................................142

Figure 6-28 Dovetail Mount DIN Rail (6600-0659-803) ................................................................................143

Figure 6-29 Silo Support Assembly (6600-0853-800) ....................................................................................144

Figure 6-30 Rotating I.V. Pole Assembly (6600-0851-800) ...........................................................................145

Figure 6-31 Dovetail Extension (6600-0852-800) ...........................................................................................146

Figure 6-32 Control Board (6600-0212-850) ......................................................................................................152

Figure 6-33 Display Driver Board (6600-0215-850) ........................................................................................153

Figure 6-34 Relay Board (6600-0214-850) Revision Level 10 or Higher ................................................154

Figure 6-35 Relay Board (6600-0214-850) Revision Level 9 or Lower....................................................155

Figure 6-36 Wiring Diagram: Control Board ......................................................................................................156

Figure 6-37 Wiring Diagram: Elevating Base .....................................................................................................157

x 6600-0356-000 103 © 2001 by Datex-Ohmeda, Inc.. All rights reserved.

Page 11

List of Figures

Figure 6-38 Wiring Diagram: Electrical Enclosure ..........................................................................................158

Figure 6-39 Wiring Diagram: Graphics Display .................................................................................................159

Figure 6-40 Wiring Diagram: Incubator Heater, Relay Board Rev. Level 10 or Higher ...................160

Figure 6-41 Wiring Diagram: Incubator Heater, Relay Board Rev. Level 9 or Lower .......................161

Figure 6-42 Wiring Diagram: Incubator Fan and Sensor .............................................................................162

Figure 6-43 Wiring Diagram: Servo Humidier, Relay Board Rev. Level 10 or Higher .....................163

Figure 6-44 Wiring Diagram: Servo Humidier, Relay Board Rev. Level 9 or Lower ........................164

Figure 6-45 Wiring Diagram: Servo Control Oxygen ......................................................................................165

© 2001 by Datex-Ohmeda, Inc.. All rights reserved. 6600-0356-000 103 xi

Page 12

List of Figures

xii 6600-0356-000 103 © 2001 by Datex-Ohmeda, Inc.. All rights reserved.

Page 13

About this Manual

Scope and Intended Users

This service manual describes the service and maintenance of the Girae Incubator. The intended users for this

service manual are authorized service personnel.

Conventions

Various types of warnings, cautions, static control precautions, and information notes are used in this Service

Manual to alert you to possible safety hazards and to provide you with additional information:

WARNING:

A WARNING statement is used when the possibility of injury to the patient or the operator exists.

CAUTION:

A CAUTION statement is used when the possibility of damage to the equipment exists.

SENSITIVE TO ELECTROSTATIC DISCHARGE CAUTION

An Electrostatic Discharge (ESD) Susceptibility symbol is displayed to alert service personnel that the

part(s) are sensitive to electrostatic discharge and that static control procedures must be used to

prevent damage to the equipment.

NOTE: A note provides additional information to clarify a point in the text.

IMPORTANT: An Important statement is similar to a note, but is used for greater emphasis.

© 2001 by Datex-Ohmeda, Inc.. All rights reserved. 6600-0356-000 103 xiii

Page 14

About this Manual

References

The following table lists the part numbers for the manual kit in each language containing the Girae Incubator

Operation and Maintenance Manual and other documents pertaining to Girae Incubator:

Language Manual Kit

Czech M1141765

Danish 6600-0848-817

Dutch 6600-0848-810

English UK 6600-0848-812

English US 6600-0848-801

Estonian M1141753

French 6600-0848-802

German 6600-0848-804

Italian 6600-0848-805

Language Manual Kit

Korean M1141804

Norwegian 6600-0848-818

Polish M1141761

Romanian M1141769

Russian M1141767

Spanish 6600-0848-803

Swedish 6600-0848-806

Turkish M1141751

User Responsibility

This Product will perform in conformity with the description thereof contained in this operating manual and

accompanying labels and/or inserts, when assembled, operated, maintained and repaired in accordance with

the instructions provided. This Product must be checked periodically. A defective Product should not be used.

Parts that are broken, missing, plainly worn, distorted or contaminated should be replaced immediately. Should

such repair or replacement become necessary, GE Healthcare recommends that a telephone or written request

for service advice be made to the nearest GE Healthcare Regional Service Center. This Product or any of its

parts should not be repaired other than in accordance with written instructions provided by GE Healthcare

and by GE Healthcare trained personnel. The Product must not be altered without GE Healthcare’s prior written

approval. The user of this Product shall have the sole responsibility for any malfunction that results from

improper use, faulty maintenance, improper repair, damage or alteration by anyone other than GE Healthcare..

Important

The information contained in this service manual pertains only to those models of products which are

marketed by GE Healthcare as of the eective date of this manual or the latest revision thereof. This service

manual was prepared for exclusive use by GE Healthcare service personnel in light of their training and

experience as well as the availability to them of parts, proper tools and test equipment. Consequently, GE

Healthcare provides this service manual to its customers purely as a business convenience and for the

customer’s general information only without warranty of the results with respect to any application of such

information.

xiv 6600-0356-000 103 © 2001 by Datex-Ohmeda, Inc.. All rights reserved.

Page 15

About this Manual

Furthermore, because of the wide variety of circumstances under which maintenance and repair activities

may be performed and the unique nature of each individual’s own experience, capacity, and qualications,

the fact that a customer has received such information from GE Healthcare does not imply in anyway that

GE Healthcare deems said individual to be qualied to perform any such maintenance or repair service.

Moreover, it should not be assumed that every acceptable test and safety procedure or method, precaution,

tool, equipment or device is referred to within, or that abnormal or unusual circumstances, may not warrant or

suggest dierent or additional procedures or requirements.

This manual is subject to periodic review, update and revision. Customers are cautioned to obtain and consult

the latest revision before undertaking any service of the equipment.

CAUTION:

Servicing of this product in accordance with this service manual should never be undertaken in the

absence of proper tools, test equipment and the most recent revision to this service manual which

is clearly and thoroughly understood.

Technical Competence

The procedures described in this service manual should be performed by trained and authorized personnel

only. Maintenance should only be undertaken by competent individuals who have a general knowledge of

and experience with devices of this nature. No repairs should ever be undertaken or attempted by anyone

not having such qualications. Genuine replacement parts manufactured or sold by GE Healthcare must be

used for all repairs. Read completely through each step in every procedure before starting the procedure; any

exceptions may result in a failure to properly and safely complete the attempted procedure.

© 2001 by Datex-Ohmeda, Inc.. All rights reserved. 6600-0356-000 103 xv

Page 16

About this Manual

xvi 6600-0356-000 103 © 2001 by Datex-Ohmeda, Inc.. All rights reserved.

Page 17

Warnings

WARNING:

Before using the Girae Incubator, read through the entire operator’s manual. As with all medical

equipment, attempting to use this device without a thorough understanding of its operation may

result in patient or user injury. This device should only be operated by personnel trained in its

operation under the direction of qualied medical personnel familiar with the risks and benets of

this type of device. Additional precautions specic to certain procedures are found in the text of this

manual.

WARNING:

Complete the “Pre-use Checkout“ chapter of the Operator’s manual before putting the unit into

operation. If the incubator fails any portion of the checkout procedure it must be removed from use

and repaired.

Important Safety Information

WARNING:

Do not use the incubator in the presence of ammable anesthetics; an explosion hazard exists

under these conditions.

WARNING:

Always disconnect the power before performing service or maintenance procedures detailed in this

manual. Apply power only if you are specically instructed to do so as part of the procedure.

WARNING:

Thoroughly air dry the incubator after cleaning it with ammable agents. Small amounts of

ammable agents, such as ether, alcohol or similar cleaning solvents left in the incubator can cause

a re.

WARNING:

The user or service sta should dispose all the waste properly as per federal, state, and local waste

disposal regulations. Improper disposal could result in personal injury and environmental impact.

© 2001 by Datex-Ohmeda, Inc.. All rights reserved. 6600-0356-000 103 xvii

Page 18

About this Manual

Service Language Disclaimer

ПРЕДУПРЕЖДЕНИЕ

Това упътване за работа е налично само на английски език.

(BG)

(ZH-CN)

(ZH-HK)

• Ако доставчикът на услугата на клиента изиска друг език, задължение на клиента е да

осигури превод.

• Не използвайте оборудването, преди да сте се консултирали и разбрали упътването за

работа.

• Неспазването на това предупреждение може да доведе до нараняване на доставчика на

услугата, оператора или пациентa в резултат на токов удар, механична или друга опасност.

警告

本维修手册仅提供英文版本。

• 如果客户的维修服务人员需要非英文版本,则客户需自行提供翻译服务。

• 未详细阅读和完全理解本维修手册之前,不得进行维修。

• 忽略本警告可能对维修服务人员、操作人员或患者造成电击、机械伤害或其他形式的伤害。

警告

本服務手冊僅提供英文版本。

• 倘若客戶的服務供應商需要英文以外之服務手冊,客戶有責任提供翻譯服務。

• 除非已參閱本服務手冊及明白其內容,否則切勿嘗試維修設備。

• 不遵從本警告或會令服務供應商、網絡供應商或病人受到觸電、機械性或其他的危險。

警告

本維修手冊僅有英文版。

(ZH-TW)

• 若客戶的維修廠商需要英文版以外的語言,應由客戶自行提供翻譯服務。

• 請勿試圖維修本設備,除非您已查閱並瞭解本維修手冊。

• 若未留意本警告,可能導致維修廠商、操作員或病患因觸電、機械或其他危險而受傷。

UPOZORENJE

Ovaj servisni priručnik dostupan je na engleskom jeziku.

(HR)

• Ako davatelj usluge klijenta treba neki drugi jezik, klijent je dužan osigurati prijevod.

• Ne pokušavajte servisirati opremu ako niste u potpunosti pročitali i razumjeli ovaj servisni

priručnik.

• Zanemarite li ovo upozorenje, može doći do ozljede davatelja usluge, operatera ili pacijenta

uslijed strujnog udara, mehaničkih ili drugih rizika.

xviii 6600-0356-000 103 © 2001 by Datex-Ohmeda, Inc.. All rights reserved.

Page 19

VÝSTRAHA

Tento provozní návod existuje pouze v anglickém jazyce.

About this Manual

(CS)

(DA)

(NL)

• V případě, že externí služba zákazníkům potřebuje návod v jiném jazyce, je zajištění překladu do

odpovídajícího jazyka úkolem zákazníka.

• Nesnažte se o údržbu tohoto zařízení, aniž byste si přečetli tento provozní návod a pochopili

jeho obsah.

• V případě nedodržování této výstrahy může dojít k poranění pracovníka prodejního servisu,

obslužného personálu nebo pacientů vlivem elektrického proudu, respektive vlivem

mechanických či jiných rizik.

ADVARSEL

Denne servicemanual ndes kun på engelsk.

• Hvis en kundes tekniker har brug for et andet sprog end engelsk, er det kundens ansvar at

sørge for oversættelse.

• Forsøg ikke at servicere udstyret uden at læse og forstå denne servicemanual.

• Manglende overholdelse af denne advarsel kan medføre skade på grund af elektrisk stød,

mekanisk eller anden fare for teknikeren, operatøren eller patienten.

WAARSCHUWING

Deze onderhoudshandleiding is enkel in het Engels verkrijgbaar.

• Als het onderhoudspersoneel een andere taal vereist, dan is de klant verantwoordelijk voor de

vertaling ervan.

• Probeer de apparatuur niet te onderhouden alvorens deze onderhoudshandleiding werd

geraadpleegd en begrepen is.

• Indien deze waarschuwing niet wordt opgevolgd, zou het onderhoudspersoneel, de operator

of een patiënt gewond kunnen raken als gevolg van een elektrische schok, mechanische of

andere gevaren.

WARNING:

This service manual is available in English only.

(EN)

• If a customer’s service provider requires a language other than English, it is the customer’s

responsibility to provide translation services.

• Do not attempt to service the equipment unless this service manual has been consulted and is

understood.

• Failure to heed this warning may result in injury to the service provider, operator, or patient from

electric shock, mechanical hazards, or other hazards.

© 2001 by Datex-Ohmeda, Inc.. All rights reserved. 6600-0356-000 103 xix

Page 20

About this Manual

HOIATUS

See teenindusjuhend on saadaval ainult inglise keeles

(ET)

(FI)

(FR)

• Kui klienditeeninduse osutaja nõuab juhendit inglise keelest erinevas keeles, vastutab klient

tõlketeenuse osutamise eest.

• Ärge üritage seadmeid teenindada enne eelnevalt käesoleva teenindusjuhendiga tutvumist ja

sellest aru saamist.

• Käesoleva hoiatuse eiramine võib põhjustada teenuseosutaja, operaatori või patsiendi

vigastamist elektrilöögi, mehaanilise või muu ohu tagajärjel.

VAROITUS

Tämä huolto-ohje on saatavilla vain englanniksi.

• Jos asiakkaan huoltohenkilöstö vaatii muuta kuin englanninkielistä materiaalia, tarvittavan

käännöksen hankkiminen on asiakkaan vastuulla.

• Älä yritä korjata laitteistoa ennen kuin olet varmasti lukenut ja ymmärtänyt tämän huolto-

ohjeen.

• Mikäli tätä varoitusta ei noudateta, seurauksena voi olla huoltohenkilöstön, laitteiston käyttäjän

tai potilaan vahingoittuminen sähköiskun, mekaanisen vian tai muun vaaratilanteen vuoksi.

ATTENTION

Ce manuel d’installation et de maintenance est disponible uniquement en anglais.

• Si le technicien d’un client a besoin de ce manuel dans une langue autre que l’anglais, il

incombe au client de le faire traduire.

• Ne pas tenter d’intervenir sur les équipements tant que ce manuel d’installation et de

maintenance n’a pas été consulté et compris.

• Le non-respect de cet avertissement peut entraîner chez le technicien, l’opérateur ou le patient

des blessures dues à des dangers électriques, mécaniques ou autres.

WARNUNG

Diese Serviceanleitung existiert nur in englischer Sprache.

(DE)

• Falls ein fremder Kundendienst eine andere Sprache benötigt, ist es Aufgabe des Kunden für

eine entsprechende Übersetzung zu sorgen.

• Versuchen Sie nicht diese Anlage zu warten, ohne diese Serviceanleitung gelesen und

verstanden zu haben.

• Wird diese Warnung nicht beachtet, so kann es zu Verletzungen des Kundendiensttechnikers,

des Bedieners oder des Patienten durch Stromschläge, mechanische oder sonstige Gefahren

kommen.

xx 6600-0356-000 103 © 2001 by Datex-Ohmeda, Inc.. All rights reserved.

Page 21

ΠΡΟΕΙΔΟΠΟΙΗΣΗ

Το παρόν εγχειρίδιο σέρβις διατίθεται μόνο στα αγγλικά.

About this Manual

(EL)

(HU)

(IS)

• Εάν ο τεχνικός σέρβις ενός πελάτη απαιτεί το παρόν εγχειρίδιο σε γλώσσα εκτός των

αγγλικών, αποτελεί ευθύνη του πελάτη να παρέχει τις υπηρεσίες μετάφρασης.

• Μην επιχειρήσετε την εκτέλεση εργασιών σέρβις στον εξοπλισμό αν δεν έχετε συμβουλευτεί

και κατανοήσει το παρόν εγχειρίδιο σέρβις.

• Αν δεν προσέξετε την προειδοποίηση αυτή, ενδέχεται να προκληθεί τραυματισμός στον

τεχνικό σέρβις, στο χειριστή ή στον ασθενή από ηλεκτροπληξία, μηχανικούς ή άλλους

κινδύνους.

FIGYELMEZTETÉS

Ezen karbantartási kézikönyv kizárólag angol nyelven érhető el.

• Ha a vevő szolgáltatója angoltól eltérő nyelvre tart igényt, akkor a vevő felelőssége a fordítás

elkészíttetése.

• Ne próbálja elkezdeni használni a berendezést, amíg a karbantartási kézikönyvben leírtakat

nem értelmezték.

• Ezen gyelmeztetés gyelmen kívül hagyása a szolgáltató, működtető vagy a beteg áramütés,

mechanikai vagy egyéb veszélyhelyzet miatti sérülését eredményezheti.

AÐVÖRUN

Þessi þjónustuhandbók er aðeins fáanleg á ensku.

• Ef að þjónustuveitandi viðskiptamanns þarfnast annas tungumáls en ensku, er það skylda

viðskiptamanns að skaa tungumálaþjónustu.

• Reynið ekki að afgreiða tækið nema að þessi þjónustuhandbók hefur verið skoðuð og skilin.

• Brot á sinna þessari aðvörun getur leitt til meiðsla á þjónustuveitanda, stjórnanda eða sjúklings

frá raosti, vélrænu eða öðrum áhættum.

AVVERTENZA

Il presente manuale di manutenzione è disponibile soltanto in lingua inglese.

(IT)

• Se un addetto alla manutenzione richiede il manuale in una lingua diversa, il cliente è tenuto a

provvedere direttamente alla traduzione.

• Procedere alla manutenzione dell’apparecchiatura solo dopo aver consultato il presente

manuale ed averne compreso il contenuto.

• Il mancato rispetto della presente avvertenza potrebbe causare lesioni all’addetto alla

manutenzione, all’operatore o ai pazienti provocate da scosse elettriche, urti meccanici o altri

rischi.

© 2001 by Datex-Ohmeda, Inc.. All rights reserved. 6600-0356-000 103 xxi

Page 22

About this Manual

このサービスマニュアルには英語版しかありません。

(JA)

(KO)

(LV)

• サービスを担当される業者が英語以外の言語を要求される場合、翻訳作業はその業者の責

任で行うものとさせていただきます。

• このサービスマニュアルを熟読し理解せずに、装置のサービスを行わないでください。

• この警告に従わない場合、サービスを担当される方、操作員あるいは患者さんが、感電や

機械的又はその他の危険により負傷する可能性があります。

경고

본 서비스 매뉴얼은 영어로만 이용하실 수 있습니다.

• 고객의 서비스 제공자가 영어 이외의 언어를 요구할 경우, 번역 서비스를 제공하는 것은

고객의 책임입니다.

• 본 서비스 매뉴얼을 참조하여 숙지하지 않은 이상 해당 장비를 수리하려고 시도하지

마십시오.

• 본 경고 사항에 유의하지 않으면 전기 쇼크, 기계적 위험, 또는 기타 위험으로 인해 서비스

제공자, 사용자 또는 환자에게 부상을 입힐 수 있습니다.

BRĪDINĀJUMS

Šī apkopes rokasgrāmata ir pieejama tikai angļu valodā.

• Ja klienta apkopes sniedzējam nepieciešama informācija citā valodā, klienta pienākums ir

nodrošināt tulkojumu.

• Neveiciet aprīkojuma apkopi bez apkopes rokasgrāmatas izlasīšanas un saprašanas.

• Šī brīdinājuma neievērošanas rezultātā var rasties elektriskās strāvas trieciena, mehānisku vai

citu faktoru izraisītu traumu risks apkopes sniedzējam, operatoram vai pacientam.

ĮSPĖJIMAS

Šis eksploatavimo vadovas yra tik anglų kalba.

(LT)

• Jei kliento paslaugų tiekėjas reikalauja vadovo kita kalba – ne anglų, suteikti vertimo paslaugas

privalo klientas.

• Nemėginkite atlikti įrangos techninės priežiūros, jei neperskaitėte ar nesupratote šio

eksploatavimo vadovo.

• Jei nepaisysite šio įspėjimo, galimi paslaugų tiekėjo, operatoriaus ar paciento sužalojimai dėl

elektros šoko, mechaninių ar kitų pavojų.

ADVARSEL

Denne servicehåndboken nnes bare på engelsk.

(NO)

• Hvis kundens serviceleverandør har bruk for et annet språk, er det kundens ansvar å sørge for

oversettelse.

• Ikke forsøk å reparere utstyret uten at denne servicehåndboken er lest og forstått.

• Manglende hensyn til denne advarselen kan føre til at serviceleverandøren, operatøren eller

pasienten skades på grunn av elektrisk støt, mekaniske eller andre farer.

xxii 6600-0356-000 103 © 2001 by Datex-Ohmeda, Inc.. All rights reserved.

Page 23

OSTRZEŻENIE

Niniejszy podręcznik serwisowy dostępny jest jedynie w języku angielskim.

About this Manual

(PL)

(PT-BR)

(PT-PT)

• Jeśli serwisant klienta wymaga języka innego niż angielski, zapewnienie usługi tłumaczenia jest

obowiązkiem klienta.

• Nie próbować serwisować urządzenia bez zapoznania się z niniejszym podręcznikiem

serwisowym i zrozumienia go.

• Niezastosowanie się do tego ostrzeżenia może doprowadzić do obrażeń serwisanta, operatora

lub pacjenta w wyniku porażenia prądem elektrycznym, zagrożenia mechanicznego bądź

innego.

AVISO

Este manual de assistência técnica encontra-se disponível unicamente em inglês.

• Se outro serviço de assistência técnica solicitar a tradução deste manual, caberá ao cliente

fornecer os serviços de tradução.

• Não tente reparar o equipamento sem ter consultado e compreendido este manual de

assistência técnica.

• A não observância deste aviso pode ocasionar ferimentos no técnico, operador ou paciente

decorrentes de choques elétricos, mecânicos ou outros.

ATENÇÃO

Este manual de assistência técnica só se encontra disponível em inglês.

• Se qualquer outro serviço de assistência técnica solicitar este manual noutro idioma, é da

responsabilidade do cliente fornecer os serviços de tradução.

• Não tente reparar o equipamento sem ter consultado e compreendido este manual de

assistência técnica.

• O não cumprimento deste aviso pode colocar em perigo a segurança do técnico, do operador

ou do paciente devido a choques eléctricos, mecânicos ou outros.

ATENŢIE

Acest manual de service este disponibil doar în limba engleză.

(RO)

• Dacă un furnizor de servicii pentru clienţi necesită o altă limbă decât cea engleză, este de

datoria clientului să furnizeze o traducere.

• Nu încercaţi să reparaţi echipamentul decât ulterior consultării şi înţelegerii acestui manual de

service.

• Ignorarea acestui avertisment ar putea duce la rănirea depanatorului, operatorului sau

pacientului în urma pericolelor de electrocutare, mecanice sau de altă natură.

© 2001 by Datex-Ohmeda, Inc.. All rights reserved. 6600-0356-000 103 xxiii

Page 24

About this Manual

ОСТОРОЖНО!

Данное руководство по техническому обслуживанию представлено только на английском

(RU)

языке.

• Если сервисному персоналу клиента необходимо руководство не на английском, а на

каком-то другом языке, клиенту следует самостоятельно обеспечить перевод.

• Перед техническим обслуживанием оборудования обязательно обратитесь к данному

руководству и поймите изложенные в нем сведения.

• Несоблюдение требований данного предупреждения может привести к тому, что

специалист по техобслуживанию, оператор или пациент получит удар электрическим током,

механическую травму или другое повреждение.

UPOZORENJE

Ovo servisno uputstvo je dostupno samo na engleskom jeziku.

(SR)

(SK)

(ES)

• Ako klijentov serviser zahteva neki drugi jezik, klijent je dužan da obezbedi prevodilačke usluge.

• Ne pokušavajte da opravite uređaj ako niste pročitali i razumeli ovo servisno uputstvo.

• Zanemarivanje ovog upozorenja može dovesti do povređivanja servisera, rukovaoca ili

pacijenta usled strujnog udara ili mehaničkih i drugih opasnosti.

UPOZORNENIE

Tento návod na obsluhu je k dispozícii len v angličtine.

• Ak zákazníkov poskytovateľ služieb vyžaduje iný jazyk ako angličtinu, poskytnutie

prekladateľských služieb je zodpovednosťou zákazníka.

• Nepokúšajte sa o obsluhu zariadenia, kým si neprečítate návod na obluhu a neporozumiete mu.

• Zanedbanie tohto upozornenia môže spôsobiť zranenie poskytovateľa služieb, obsluhujúcej

osoby alebo pacienta elektrickým prúdom, mechanické alebo iné ohrozenie.

ATENCION

Este manual de servicio sólo existe en inglés.

• Si el encargado de mantenimiento de un cliente necesita un idioma que no sea el inglés, el

cliente deberá encargarse de la traducción del manual.

• No se deberá dar servicio técnico al equipo, sin haber consultado y comprendido este manual

de servicio.

• La no observancia del presente aviso puede dar lugar a que el proveedor de servicios, el

operador o el paciente sufran lesiones provocadas por causas eléctricas, mecánicas o de otra

naturaleza.

xxiv 6600-0356-000 103 © 2001 by Datex-Ohmeda, Inc.. All rights reserved.

Page 25

VARNING

Den här servicehandboken nns bara tillgänglig på engelska.

About this Manual

(SV)

(SL)

(TR)

• Om en kunds servicetekniker har behov av ett annat språk än engelska, ansvarar kunden för att

tillhandahålla översättningstjänster.

• Försök inte utföra service på utrustningen om du inte har läst och förstår den här

servicehandboken.

• Om du inte tar hänsyn till den här varningen kan det resultera i skador på serviceteknikern,

operatören eller patienten till följd av elektriska stötar, mekaniska faror eller andra faror.

OPOZORILO

Ta servisni priročnik je na voljo samo v angleškem jeziku.·

• Če ponudnik storitve stranke potrebuje priročnik v drugem jeziku, mora stranka zagotoviti

prevod.·

• Ne poskušajte servisirati opreme, če tega priročnika niste v celoti prebrali in razumeli.·

• Če tega opozorila ne upoštevate, se lahko zaradi električnega udara, mehanskih ali drugih

nevarnosti poškoduje ponudnik storitev, operater ali bolnik.

DİKKAT

Bu servis kılavuzunun sadece ingilizcesi mevcuttur.

• Eğer müşteri teknisyeni bu kılavuzu ingilizce dışında bir başka lisandan talep ederse, bunu

tercüme ettirmek müşteriye düşer.

• Servis kılavuzunu okuyup anlamadan ekipmanlara müdahale etmeyiniz.

• Bu uyarıya uyulmaması, elektrik, mekanik veya diğer tehlikelerden dolayı teknisyen, operatör

veya hastanın yaralanmasına yol açabilir.

Cautions

CAUTION:

Only competent individuals trained in the repair of this equipment should attempt to service it as

detailed in this manual.

CAUTION:

Detailed information for more extensive repairs is included in the service manual solely for

the convenience of users having proper knowledge, tools and test equipment, and for service

representatives trained by GE Healthcare.

© 2001 by Datex-Ohmeda, Inc.. All rights reserved. 6600-0356-000 103 xxv

Page 26

About this Manual

Temp alarm

Airflow curtain

Heater

Temp alarm

c

37

Airflow curtain

Fan

Heater

Temp alarm

c

37

Canopy up / down (used in conjunction with up/down arrows)

Environmental Probe

Airflow curtain

Fan

Heater

Temp alarm

c

37

Canopy up / down (used in conjunction with up/down arrows)

Environmental Probe

Scale

Airflow curtain

Fan

Heater

Temp alarm

c

37

Canopy up / down (used in conjunction with up/down arrows)

Environmental Probe

Scale

Patient O2

Airflow curtain

Fan

Heater

Temp alarm

c

37

Alarm Silence

Canopy up / down (used in conjunction with up/down arrows)

Environmental Probe

Scale

2

Patient O2

Airflow curtain

Fan

Heater

Temp alarm

c

37

Alarm Silence

Patient

Canopy up / down (used in conjunction with up/down arrows)

Environmental Probe

Scale

2

Patient O2

Airflow curtain

Fan

Heater

Temp alarm

c

Ground

Used on Giraffe Humidifier Reservoir

Ground

Used on all electrical equipment

Symbol Denitions

This section identies the symbols that are displayed on the Girae Incubator:

Symbol Description

Consult accompanying documents.

Lower the elevating base before mounting accessories.

37

Temperature Alarm

c

Airow Curtain

Fan

Environmental Probe

Scale

2

Patient Oxygen

Alarm Silence

Patient

Protective Ground

Opening Girae Humidier Reservoir

xxvi 6600-0356-000 103 © 2001 by Datex-Ohmeda, Inc.. All rights reserved.

Page 27

Symbol Description

Used on Giraffe Humidifier Reservoir

Max water level for humidifier

Ground

Used on all electrical equipment

Used on Giraffe Humidifier Reservoir

MAX

Max water level for humidifier

Power disconnect

Ground

Used on all electrical equipment

Used on Giraffe Humidifier Reservoir

MAX

Max water level for humidifier

Power disconnect

Maximum weight (of accessories on rail)

Ground

Used on all electrical equipment

22 Kg

MAX.

Caution: Hot surface

Used on Giraffe Humidifier Reservoir

MAX

Max water level for humidifier

Power disconnect

Maximum weight (of accessories on rail)

Ground

Used on all electrical equipment

Used on Giraffe OB heater head,

humidifier

Set up screen

About this Manual

MAX

22 Kg

MAX.

Maximum Water Level for Humidier

Power Disconnect

Maximum Weight

Caution: Hot Surface

Setup Screen

© 2001 by Datex-Ohmeda, Inc.. All rights reserved. 6600-0356-000 103 xxvii

Page 28

About this Manual

xxviii 6600-0356-000 103 © 2001 by Datex-Ohmeda, Inc.. All rights reserved.

Page 29

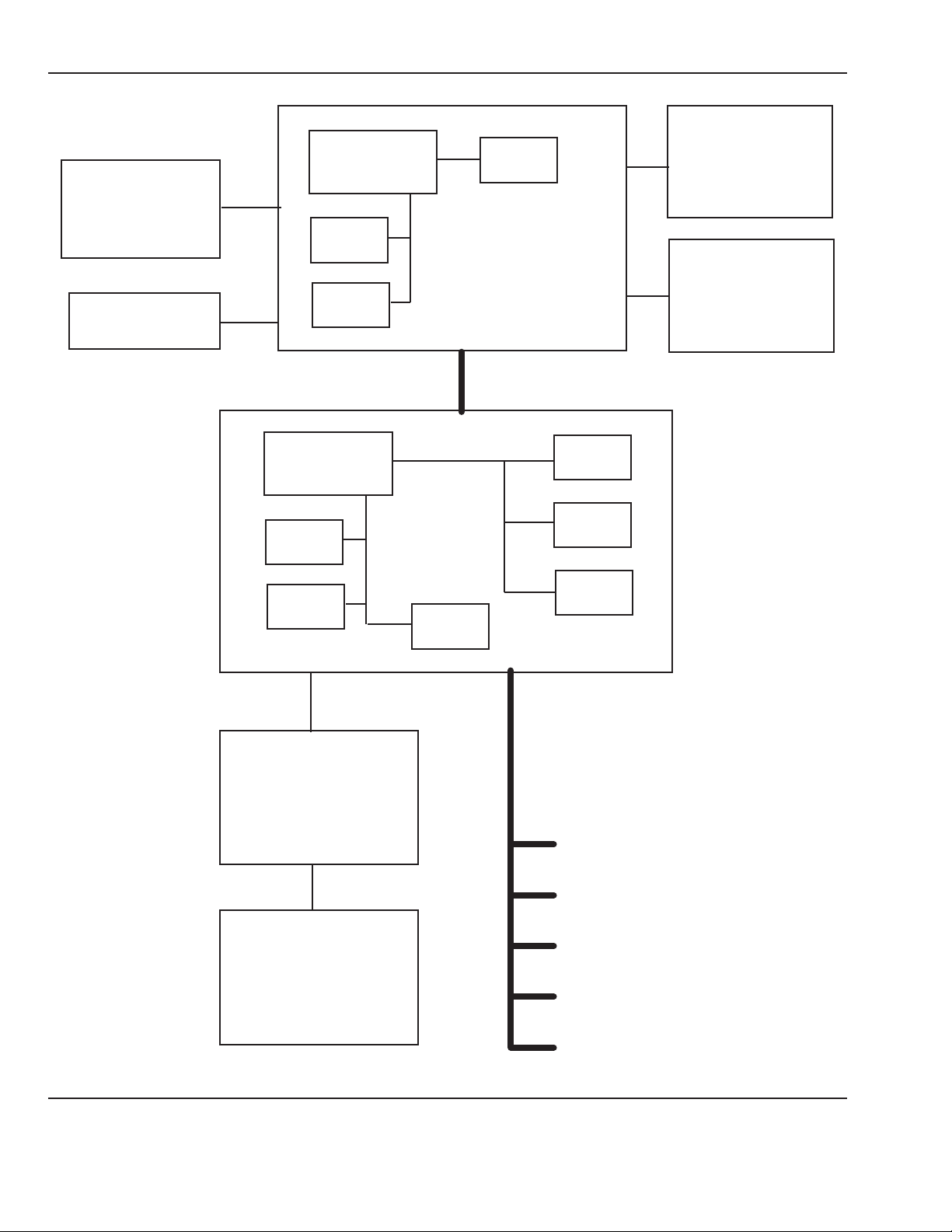

Chapter 1: Functional Description

This functional description is divided into four sections representing each of the four boards. The reader should

also reference the block diagram and wiring diagram when studying this section.

1.1 Control Board

The Intel 80C188EC microcontroller is an enhanced X86 processor with many on-board peripheral features,

such as a interrupt controller, DMA controller, peripheral chip select driver, programmable timers, etc. The

two programmable timers are used to control the bed heaters. The input to these timers is line frequency.

This allows the control signal to be synchronized with the line frequency to better control the zerocrossing

solid state relays. The on-board interrupt controller has several interrupts: analog-to-digital converter (ADC)

conversion ready signal, overtemperature comparator output, watchdog output, power fail signal, and module

interrupt signal from the system data bus. The microcontroller external bus is a multiplexed address and data

bus.

The system memory consists of a programmable read-only memory (PROM) and static random access memory

(SRAM). The EEPROM is used for calibration and biomedical conguration values. This memory holds the data

even after power is turned o.

The RS-485 integrated circuit converts the RS-232 TTL signals from the microcontroller to RS-485 signals for

the bus. This bus is the main communications bus from the control board to the display board, scale, and servo

oxygen board.

There are two isolation transceivers used to isolate the circuits powered by +5V and the circuits powered by

+5VSTBY (battery backup).

The board contains a 16 channel multiplexer. There are seven temperature measurement channels. These

channels measure the two patient probes and the compartment probe (with two thermistors each), and the

heat sink sensor used to measure the heat sink temperature. Additional channels include the humidity sensor

(RHIN), LINE COMP & LINE COMP2, 5 Volts, Motor current, Vthref, VDAC, and 1.2Vind.

Attached to the compartment probe connection is the relative humidity signal conditioning circuitry. The 1V

reference that is used for the analog circuitry is also the maximum input voltage and the oset voltage for the

ADC. This yields a purely ratiometric system.

The overtemperature circuit compares the air temperature to a reference level, generates an interrupt, and

turns o the heat if the air temperature is higher than the reference level. The overtemperature circuit requires

varying its voltage levels to accommodate various thermistor measurements. This is because the calibration is

digital (no potentiometer).

© 2001 by Datex-Ohmeda, Inc.. All rights reserved. 6600-0356-000 103 1

Page 30

Chapter 1: Functional Description

Figure 1-1 Block Diagram

2 6600-0356-000 103 © 2001 by Datex-Ohmeda, Inc.. All rights reserved.

Page 31

Chapter 1: Functional Description

The watchdog circuitry monitors the 80C188 microprocessor, and monitors the +5V and +5VSTBY voltages.

It generates the interrupt signal and power failure signal to the 80C188 microprocessors. The audio circuit

includes a 8752 microcontroller that reads a wavetable located in a PROM and sends the table to a digital

audio circuit and amplier. The high priority (HP) and other alarm signal lines select an output at the correct

frequencies.

Three OR gates are combined to generate the error signal. The inputs to the circuit are overtemperature, power

failure, and system failure. This circuit generates an error signal that turns o the heater and sounds the HP

alarm. This circuit is independent of the microcontroller.

1.2 Relay Board

The Relay Board includes 2 safety relays, which close to supply mains power to the heater and motor circuits.

Safety relay 1 is wired in series with the primary coil of the isolation transformer for the incubator heater. Safety

relay 2 closes the mains supply to the humidier isolation transformer and the transformer for the e-base

motor. Control signals for the two relays originate on the Control Board.

The Relay Board interfaces the DC Control signal to the chassis mounted solid-state relay (SSR), which controls

the incubator heater. The Control signals for the heater SSR originates on the Control Board.

The Relay Board includes a SSR for the humidier. The SSR output is wired in series with the humidier heater.

The humidier SSR control signal originates on the Control Board.

There is one current sense circuit for the incubator and an additional one for the humidier heater. These

circuits consist of a small signal transformer that produces a current proportional to the current through the

heater circuits. The current is rectied and measured. The subsequent comparator then generates a digital

level based on a specied current level. This results in a signal to the Control Board representing the state of the

heater (on or o).

The line compensation circuit consists of a signal transformer connected to the mains voltage. The secondary

of this transformer feeds a full wave rectier and capacitor. The resulting DC voltage is proportional to mains

voltage, and it is measured on the Control Board.