Page 1

Engström Ventilator

Technical Reference Manual

Page 2

Engström Ventilator

Datex-Ohmeda products have unit serial numbers with coded logic which indicates a product

group code, the year of manufacture, and a sequential unit number for identification. The serial

number can be in one of two formats.

AAAX11111 AA AXX111111A A

The X represents an alpha character

indicating the year the product was

manufactured; J = 2004, K = 2005, etc.

IIII and O are not used.

The XX represents a number indicating

the year the product was manufactured;

04

= 2004, 05 = 2005, etc.

Engström Ventilator, ComWheel, D-fend and

EVair 03 are registered trademarks of

Datex-Ohmeda Inc.

Other brand names or product names used in this manual are trademarks or registered

trademarks of their respective holders.

10/04 1505-1018-000

Page 3

Technical Reference Manual

Engström Ventilator

This document is not to be reproduced in any manner, nor are the contents to be disclosed to

anyone, without the express authorization of the product service department, Datex-Ohmeda,

Ohmeda Drive, PO Box 7550, Madison, Wisconsin, 53707.

©

2004 Datex-Ohmeda Inc.

1505-1018-000 10/04

i

Page 4

Engström Ventilator

Important

The information contained in this Technical Reference manual pertains only to those models of

products which are marketed by Datex-Ohmeda as of the effective date of this manual or the

latest revision thereof. This Technical Reference manual was prepared for exclusive use by

Datex-Ohmeda service personnel in light of their training and experience as well as the

availability to them of parts, proper tools and test equipment. Consequently, Datex-Ohmeda

provides this Technical Reference manual to its customers purely as a business convenience

and for the customer's general information only without warranty of the results with respect to

any application of such information. Furthermore, because of the wide variety of circumstances

under which maintenance and repair activities may be performed and the unique nature of each

individual's own experience, capacity, and qualifications, the fact that customer has received

such information from Datex-Ohmeda does not imply in anyway that Datex-Ohmeda deems said

individual to be qualified to perform any such maintenance or repair service. Moreover, it should

not be assumed that every acceptable test and safety procedure or method, precaution, tool,

equipment or device is referred to within, or that abnormal or unusual circumstances, may not

warrant or suggest different or additional procedures or requirements.

This manual is subject to periodic review, update and revision. Customers are cautioned to

obtain and consult the latest revision before undertaking any service of the equipment.

Comments and suggestions on this manual are invited from our customers. Send your

comments and suggestions to the Manager of Technical Communications, Datex-Ohmeda,

Ohmeda Drive, PO Box 7550, Madison, Wisconsin 53707.

wwww CAUTION

Servicing of this product in accordance with this

be undertaken in the absence of proper tools, test equipment and the most recent

revision to this service manual which is clearly and thoroughly understood.

Technical Competence

The procedures described in this Technical Reference manual should be performed by trained

and authorized personnel only. Maintenance should only be undertaken by competent

individuals who have a general knowledge of and experience with devices of this nature. No

repairs should ever be undertaken or attempted by anyone not having such qualifications.

Datex-Ohmeda strongly recommends using only genuine replacement parts, manufactured or

sold by Datex-Ohmeda for all repair parts replacements.

Read completely through each step in every procedure before starting the procedure; any

exceptions may result in a failure to properly and safely complete the attempted procedure.

Technical Reference

manual should never

ii

10/04 1505-1018-000

Page 5

Table of Contents

Important . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .ii

Technical Competence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .ii

1 Introduction

1.1 What this manual includes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

1.2 User’s Reference manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

1.2 Conventions used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

1.3 What is an Engström Ventilator? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

1.4 Ventilator overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

1.5 Display controls and indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-6

1.6 Ventilator display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-7

1.6.1 Using menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-9

1.7 Symbols used in the manual or on the equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

1505-1018-000 10/04 1

Page 6

Engström Ventilator

2 Theory of Operation

3 Checkout Procedure

2.1 Pneumatic Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

2.1.1 Inspiratory circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

2.1.2 Expiratory circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-7

2.1.3 Associated circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-8

2.1.4 Electronic micropump nebulizer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-8

2.2 Electrical Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-9

2.2.1 Display Unit (DU) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-9

2.2.2 Communication channels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

2.2.3 Ventilator Control Board - VCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

2.2.4 Ventilator Monitoring Board - VMB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

2.2.5 Power Management Board – PMB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

2.2.6 Other Electronic Items . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

2.2.7 Motherboard (backplane) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

2.2.8 Monitoring Interface Board – Monitoring Module Bays . . . . . . . . . . . . . . . . . . . . 2-17

3.1 Inspect the system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

3.2 Automated Checkout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

3.3 Backlight test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

3.4 Power failure test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

3.5 Electrical safety tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

4 Installation and Service Menus

4.1 Service and Installation menu structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2

4.2 Install/Service Menu (Super User) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

4.2.1 Defaults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-4

4.2.2 Factory Defaults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-5

4.3 Calibration menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-6

4.4 Service menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-7

4.4.1 Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-8

4.4.2 Copy Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-9

4.4.3 Service Log menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

4.4.4 Software/Hardware version menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

2 10/04 1505-1018-000

Page 7

5 Service Tests and Calibration

5.1 Calibration (super-user) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-2

5.2 Service level tests and calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-4

Table of Contents

5.1.1 Calibration procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-3

5.2.1 Service application setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-4

5.2.2 Test setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-4

5.2.3 Vent engine debris clean-out . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-5

5.2.4 Vent engine leak test (low pressure) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-6

5.2.5 Vent engine leak test (high O2 pressure) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-8

5.2.6 Vent engine leak test (high Air pressure) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

5.2.7 Calibrate airway pressure transducer Zero and Span . . . . . . . . . . . . . . . . . . . . . 5-12

5.2.8 Verify operation of free- breathing valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-14

5.2.9 Verify operation of inspiratory effort valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-16

5.2.10 Verify operation of auxiliary pressure relief valve . . . . . . . . . . . . . . . . . . . . . . . . 5-18

5.2.11 Mechanical over-pressure valve test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-20

5.2.12 Verify regulator output pressure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-22

6 Maintenance

7 Troubleshooting

6.1 Engström Ventilator planned maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-2

6.1.1 Every twelve (12) months . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-2

6.1.2 Every forty-eight (48) months . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-2

6.2 Battery capacity test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-3

7.1 Troubleshooting Checkout Failures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-2

7.1.1 Paw Transducer Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-2

7.1.2 Barometric pressure test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-2

7.1.3 Low Pressure Leak and Compliance Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-3

7.1.4 Safety Valve Relief and Back Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-3

7.1.5 Exhalation Valve Calibration Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-4

7.1.6 Exhalation Flow Sensor Calibration Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-4

7.1.7 Measure Breathing Circuit Resistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-4

7.1.8 Air Inspiratory Flow Sensor Calibration Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-5

7.1.9 O2 Inspiratory Flow Sensor Calibration Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-5

7.1.10 O2 Sensor Test and Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-5

7.2 Troubleshooting Vent Engine Leaks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-6

7.3 Alarm message troubleshooting chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-10

7.4 Troubleshooting Service App messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-26

1505-1018-000 10/04 3

Page 8

Engström Ventilator

8 Service Diagnostics and Software Download

8.1 EV Service Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-2

8.1.1 Main Menu and System Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-2

8.1.2 Power Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-3

8.1.3 Power Controller Power Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-4

8.1.4 Display Unit Power Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-6

8.2 Display Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-7

8.3 Special Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-8

8.3.1 View Revision Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-9

8.3.2 View PC Card Install Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-9

8.4 Software Download . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-10

8.5 EV Service Application (PC based) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-12

8.5.1 Port Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-12

8.5.2 Main Menu and System Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-12

8.6 VCB Diagnostics and Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-13

8.6.1 Sensirion Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-13

8.6.2 VCB Input Signal Latch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-14

8.6.3 VCB Channel Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-15

8.6.4 VCB Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-16

8.6.5 Calibrations and Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-17

8.7 VMB Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-18

9 Repair Procedures

8.7.1 VMB Channel Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-19

8.7.2 VMB Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-20

8.7.3 VMB Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-20

8.7.4 Baro P Cal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-20

9.1 Circuit Board Replacement precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-3

9.1.1 Software download . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-3

9.1.2 Required calibrations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-3

9.2 How to bleed gas pressure from the machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-4

9.3 Accessing chassis components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-4

9.3.1 To remove the chassis from the housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-5

9.3.2 To remove the Vent Engine from the chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-5

9.3.3 To replace chassis mounted components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-6

9.3.4 To replace Vent Engine components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-6

4 10/04 1505-1018-000

Page 9

10 Illustrated Parts

Engström Ventilator

9.4 Servicing the Display Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-7

9.4.1 Remove the Display Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-7

9.4.2 Disassemble the Display Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-8

9.4.3 To replace the CPU board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-9

9.4.4 To replace the LCD display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-10

9.4.5 To replace the backlights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-11

9.4.6 To replace the Inverters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-12

9.4.7 To replace the front enclosure or components . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-13

9.5 Adjusting the display arm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-15

9.5.1 Adjust upper pivot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-15

9.5.2 Adjust lower pivot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-16

9.5.3 Adjust arm bearing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-16

9.6 Removing a compressor from the cart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-17

10.1 Service tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-2

10.1.1 Software tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-2

10.1.2 Manual shut-off valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-3

10.1.3 Special tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-3

10.1.4 Leak test devices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-4

10.1.5 Lubricants and Adhesives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-5

10.2 External components - front view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-6

Schematics and Diagrams

10.3 External components - rear view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-7

10.4 Display arm mounting hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-8

10.5 Display arm assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-10

10.6 Display Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-12

10.7 Main enclosure (external) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-14

10.8 Main enclosure (internal) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-16

10.9 Vent Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-18

10.10 Outlet manifold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-20

10.11 Inlet manifold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-22

10.12 AC power cords . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-23

10.13 AC Inlet/Outlet Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-24

10.14 Cart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-26

10.15 Module rack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-28

10.16 Compressor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-29

10.16 Exhalation valve assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-30

1505-1018-000 10/04 5

Page 10

Notes

6 10/04 1505-1018-000

Page 11

1 Introduction

In this section

This section provides a general overview of the Engström Ventilator.

1.1 What this manual includes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

1.2 User’s Reference manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

1.2 Conventions used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

1.3 What is an Engström Ventilator? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

1.4 Ventilator overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

1.5 Display controls and indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-6

1.6 Ventilator display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-7

1.6.1 Using menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-9

1.7 Symbols used in the manual or on the equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

1505-1018-000 10/04 1-1

Page 12

Engström Ventilator

1.1 What this manual includes

This manual covers the service information for the Engström Ventilator.

It covers the following components:

• Display Unit

• Integral electronics

• Gas delivery components

• Frame component

Other equipment

Other equipment may be attached to the system. Consult separate

documentation relative to these items for details.

1.2 User’s Reference manuals

Some sections of this manual refer you to the User’s Reference manual for the

Engström Ventilator. To expedite repairs, you must have, and be familiar with,

the User’s Reference manual for this product.

Refer to the Engström Ventilator User’s Reference manual if you need further

information about the operation of the system.

Conventions used

Hard keys

Menu selections

Names of the hard keys on the display and modules are written in bold

typeface, for example,

Menu selections are written in bold italic typeface, for example,

Setup

.

Normal Screen

.

Patient

Messages

Sections and headings

1-2 10/04 1505-1018-000

Messages that are displayed on the screen are enclosed in single quotes, for

example, ‘Check sample gas out.’

When referring to different sections or headings in the User’s Reference

manual, the name is written in italic typeface and is enclosed in double

quotes, for example,

“System Controls and Menus.”

Page 13

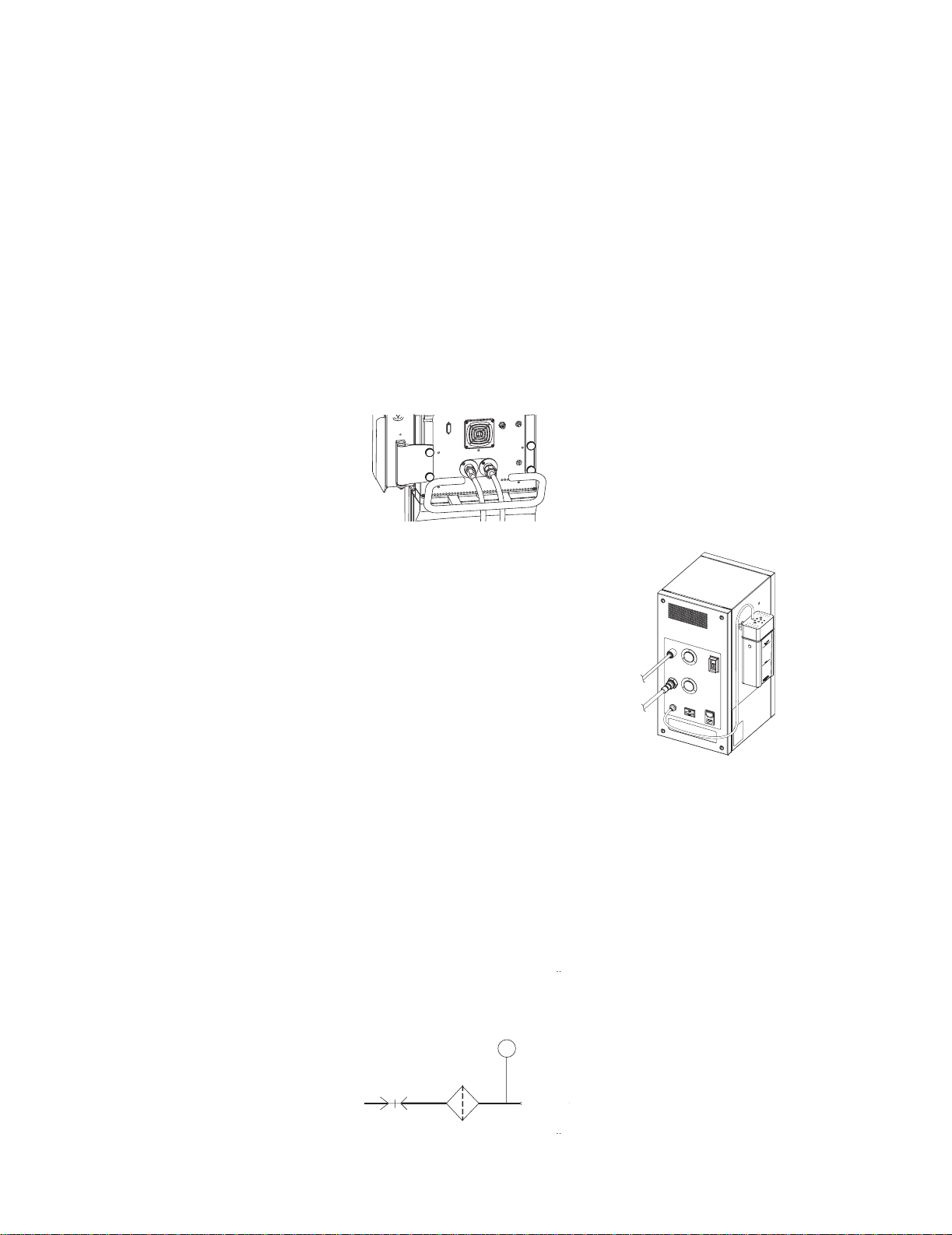

1.3 What is an Engström Ventilator?

The Engström Ventilator (EV) is a flexible, adaptable, and intuitive critical care

ventilator. A wide selection of performance options gives the user full control

of the system configuration.

The EV must only be operated by authorized medical personnel well trained in

the use of this product, for patient ventilation in the intensive care

environment. It must be operated according to the instructions in this User’s

Reference manual.

The ventilator is designed to be used with infant through adult patients with a

body weight of 5 kg or greater. The EV is designed to maintain lung ventilation

in the absence of spontaneous breathing effort as well as in support of the

patient’s existing spontaneous breathing effort.

The system is designed for facility use, including within-facility transport.

The ventilator consists of three main components: a display, a ventilator unit,

and an optional module bay. The display allows the user to interface with the

system and control settings. The ventilator unit controls electrical power,

nebulization, and pneumatic gas flow to and from the patient. The module bay

allows the integration of various patient monitoring modules with the

ventilator.

1 Introduction

Optional accessories include an air compressor, airway modules, module

bay, humidifier and water trap mounting brackets, and auxiliary electrical

outlets.

Figure 1-1 • Engström Ventilator (EV)

1505-1018-000 10/04 1-3

Page 14

Engström Ventilator

1.4 Ventilator overview

7

6

5

1

891011

2

3

12

13

AB.98.011

4

1. Module bay (optional)

2. Ventilator lock [locks Ventilator unit (item 6) to Cart (item 3)]

3. Cart

4. Caster

5. Dovetail rails

6. Ventilator unit

7. Display

8. Nebulizer connection

9. Exhalation valve housing

10. Expiratory inlet

11. Expiratory flow sensor

12. Gas exhaust port

13. Leak test plug

14. Exhalation valve housing latch

15. Water trap

16. Auxiliary pressure port

17. Inspiratory outlet

AB.98.007

1617

1415

Figure 1-2 • Front view of the EV

1-4 10/04 1505-1018-000

Page 15

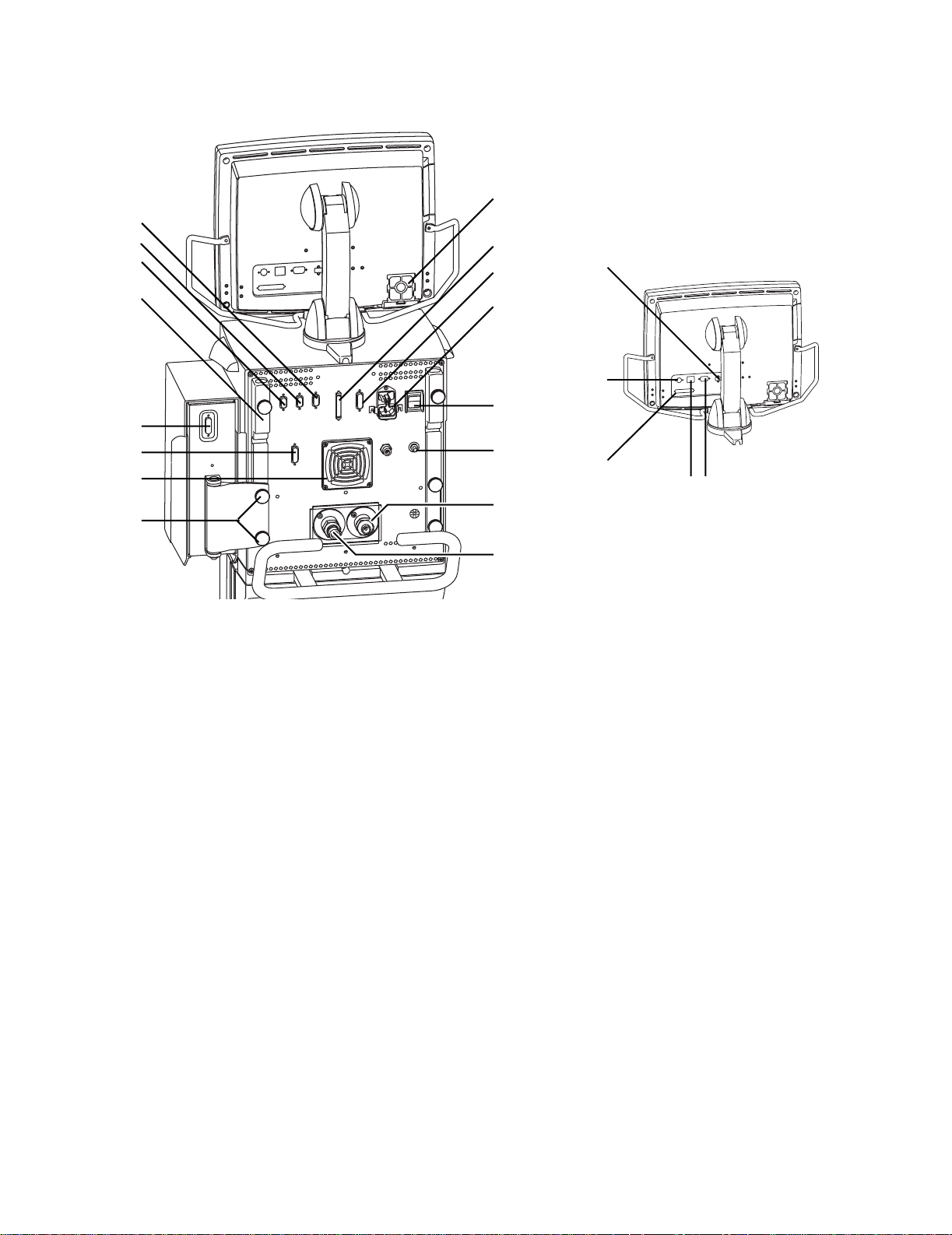

15

14

13

1 Introduction

1

2

3

19

12

4

18

5

3

11

6

2

10

7

9

8

AB.98.009

1. Display fan filter

2. Display connection

3. Module bay connection

4. AC mains inlet

5. System switch

6. Equipotential connector

7. Oxygen supply connection (pipeline)

8. Air supply connection (pipeline or compressor)

9. Module bay mounting thumbscrews

10. Ventilator unit fan filter

11. Serial communication port (RS 232 port)

12. Arm holder

13. RS 485 port (not currently supported)

14. RS 485 port (not currently supported)

15. RS 422 port (used to communicate with PC based Service Application — Refer to Section 8.5)

16. Network ID connection

17. Ethernet connection

18. DIS port (not currently supported)

19. USB port

AB.98.045

1617

Figure 1-3 • Back view of the E V

1505-1018-000 10/04 1-5

Page 16

Engström Ventilator

1.5 Display controls and indicators

8

3

1

2

3

7

6

3

1 Alarm LEDs The red and yellow LEDs indicate the priority of active alarms.

2 Alarm Silence key Push to silence any active, silenceable high and medium priority alarms or

to suspend any non-active medium priority alarms. Alarm audio is silenced

or suspended for 120 seconds. Push to clear resolved alarms.

3 Menu keys Push to show corresponding menu.

4 ComWheel Push to select a menu item or confirm a setting. Turn clockwise or

counterclockwise to scroll menu items or change settings.

5 Normal Screen key Push to remove all menus from the screen.

6AC mains indicator The green LED lights continuously when the EV is connected to an AC mains

source. The internal batteries are charging when the LED is lit.

7 Quick keys Push to change corresponding ventilator setting. Turn the ComWheel to

make a change. Push the Quick key or ComWheel to activate the change.

8100% O2 key Push to deliver 100% O

for 2 minutes.

2

5

4

AB.98.012

Figure 1-4 • Controls and indicators

1-6 10/04 1505-1018-000

Page 17

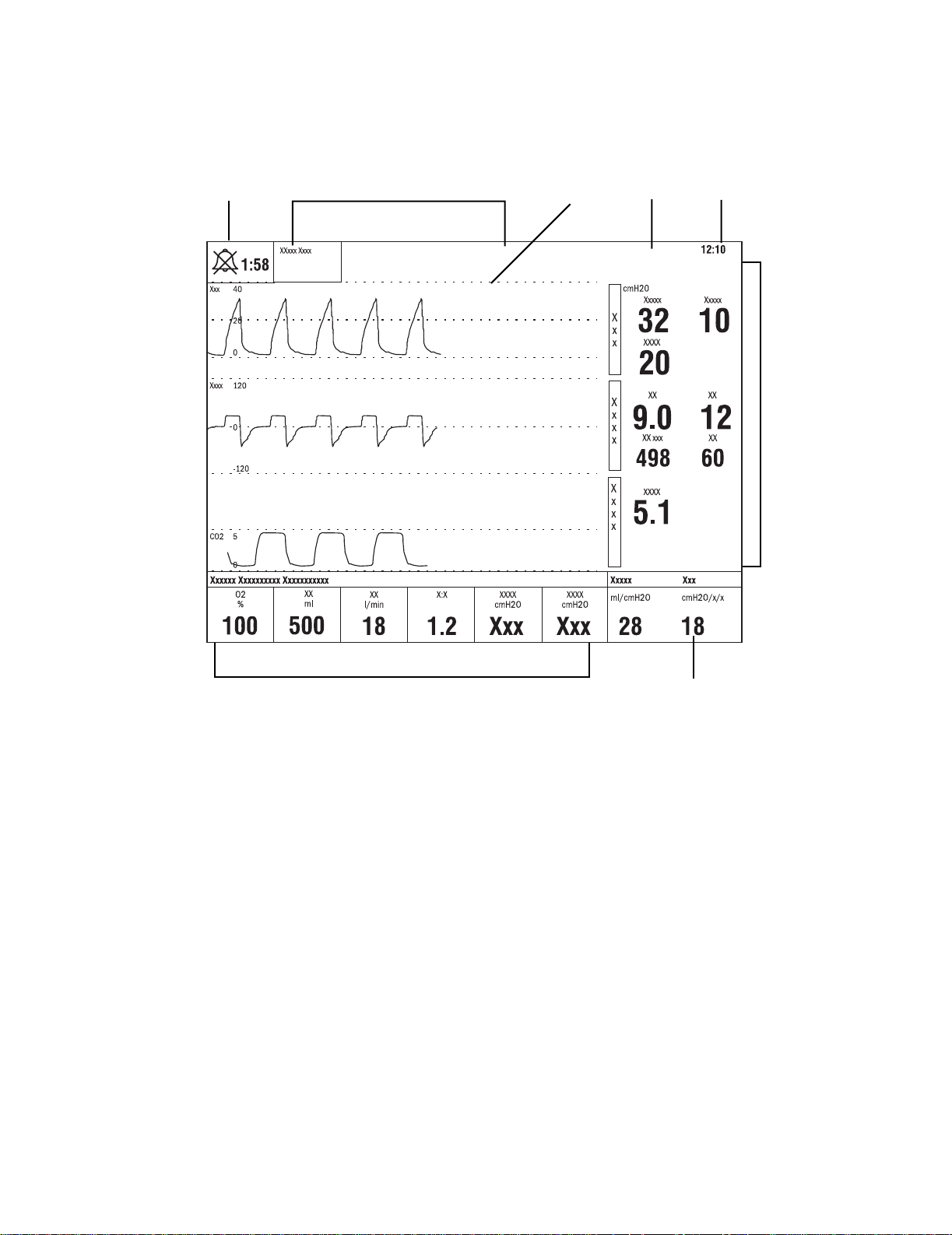

1.6 Ventilator display

1 Introduction

12 34

•

5

6

AB.98.013

8

1 Alarm silence symbol

and countdown

2 Alarm message fields Alarms will appear in order of priority. Refer to

3Waveform fields The top two waveforms are permanently set to Paw and Flow. The third waveform may be selected

4 General message field Displays informational messages.

5 Clock The time may be set in 12 or 24 hour format in the Time and Date menu.

6 Measured value fields Displays current measured values corresponding to the waveforms.

7 Digit field Displays information related to Volume, CO2, O2, Compliance or Spirometry.

8Ventilator settings Displays several of the settings for the current mode of ventilation.

Displays the time remaining during an alarm silence or alarm suspend period.

“Alarms and Troubleshooting”

on alarm behavior.

as CO2, O2, Vol, Paux, or Off.

7

for more information

Figure 1-5 • Normal Screen view

1505-1018-000 10/04 1-7

Page 18

Engström Ventilator

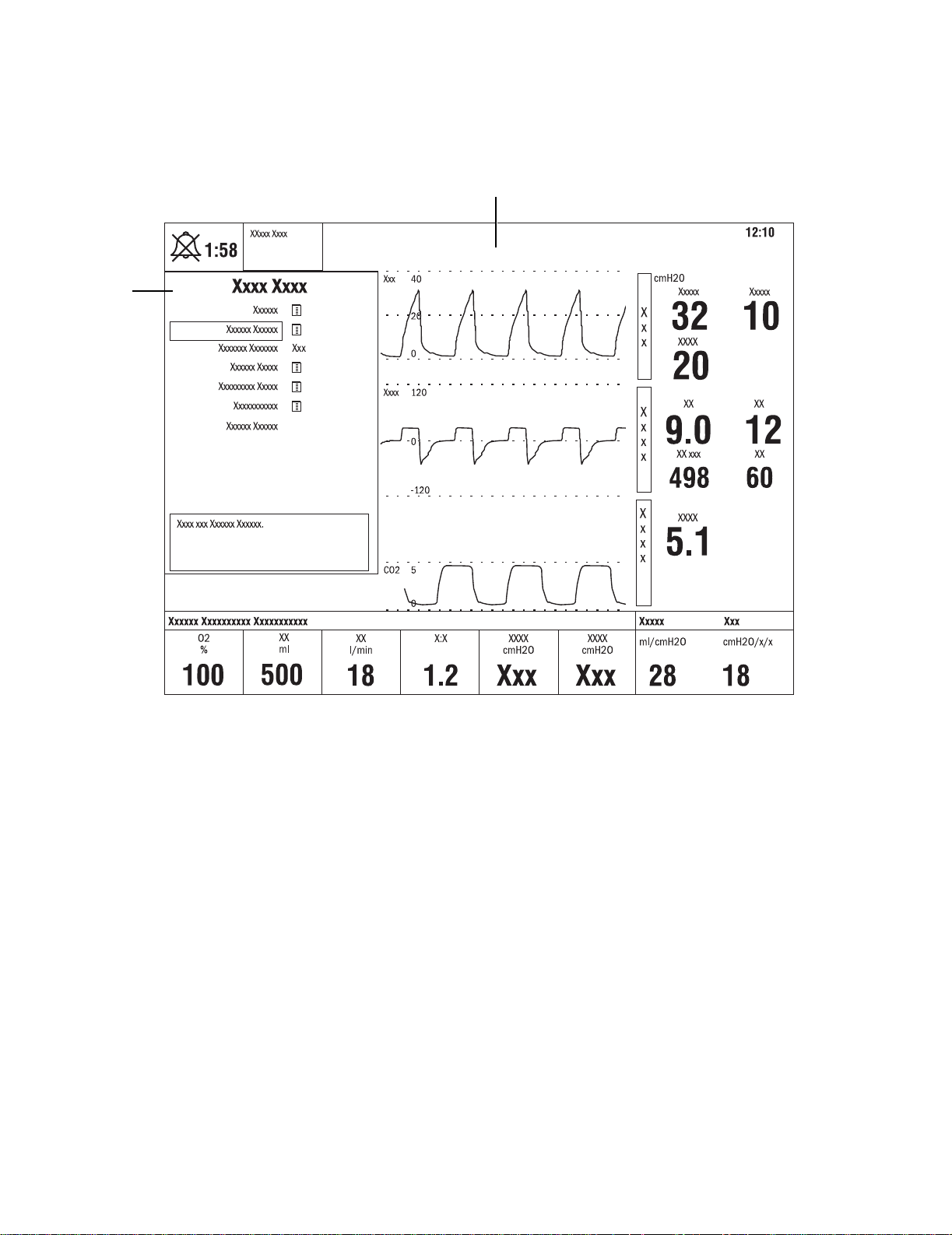

1

When a menu key is selected the waveform fields start at the right edge of the

menu. The entire waveform is always displayed.

2

1. Menu

2. Waveform fields

Figure 1-6 • Menu view

1-8 10/04 1505-1018-000

AB.98.014

Page 19

1 Introduction

1.6.1 Using menus

Push a menu key to display the corresponding menu. Use the ComWheel to

navigate through the menu.

1

2

3

6

4

Xxxxxx Xxxxxx

5

AB.91.007

1. Menu title

2. Present selection

3. Adjustment window

4. Indicates submenu

5. Short instructions

6. Menu selections

Figure 1-7 • Example menu

1. Push the menu key to display the corresponding menu.

2. Turn the ComWheel counterclockwise to highlight the next menu item.

(Turn the ComWheel clockwise to highlight the previous menu item.)

3. Push the ComWheel to enter the adjustment window or a submenu.

4. Turn the ComWheel clockwise or counterclockwise to highlight the

desired selection.

5. Push the ComWheel to confirm the selection.

6. Select

Normal Screen

or push the

Normal Screen

and return to the normal monitoring display. (Select

key to exit the menu

Previous Menu

to

return to the last displayed menu, if available.)

1505-1018-000 10/04 1-9

Page 20

Engström Ventilator

1.7 Symbols used in the manual or on the equipment

Symbols replace words on the equipment, on the display, or in

Datex-Ohmeda manuals.

Warnings and Cautions tell about the dangerous conditions that can occur if

the instructions in the manual are not followed.

Warnings tell about a condition that can cause injury to the operator or the

patient.

Cautions tell about a condition that can cause damage to the equipment.

Read and follow all warnings and cautions.

l

p

o

wW

REF

†

y

Y

z

t

On (power)

Off (power)

O

On for part of the equipment

Off for part of the equipment

œ

Standby

Attention, refer to product instructions

IEC 60601-1

Stock number

Direct current

m

w

SN

Type B protection against

electrical shock

Caution, ISO 7000-0434

Serial number

Alternating current

∏

Earth ground

Protective earth ground

x

Equipotential connector Fuse

Lock

Unlock

Z

Variability

Variability in steps

T

+

N

N

N

1-10 10/04 1505-1018-000

Plus, positive polarity

-

Movement in one direction

ˆ

This way up Warning, dangerous voltage

Minus, negative polarity

Movement in both directions

Page 21

1 Introduction

Pneumatic inlet Pneumatic outlet

Electrical input Electrical output

Inspiratory port Expiratory port

Electrical testing certification Inspiratory breath identifier

Serial port Module data indicator

Module bay port Electronic micropump nebulizer

Auxiliary pressure port Display signal input/output

No battery/battery failure Battery in use. Bar indicates

amount of battery power

remaining.

Silence alarms Submenu

Hourmeter Drain outlet

1505-1018-000 10/04 1-11

Page 22

Engström Ventilator

Air Pump

Heavy object USB port

134°C

Ethernet connection Network ID connection

Autoclavable

ID

X1

(Datex-Ohmeda proprietary port)

Not autoclavable

Í

Authorized representative in the

European Community

XXXX

Systems with this mark agree with

the European Council Directive

(93/42/EEC) for Medical Devices

when they are used as specified in

their User’s Reference Manuals.

The xxxx is the certification number

of the Notified Body used by

Datex-Ohmeda’s Quality Systems.

1-12 10/04 1505-1018-000

Page 23

2 Theory of Operation

In this section

2.1 Pneumatic Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

2.1.1 Inspiratory circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

2.1.2 Expiratory circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-7

2.1.3 Associated circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-8

2.1.4 Electronic micropump nebulizer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-8

2.2 Electrical Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-9

2.2.1 Display Unit (DU) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-9

2.2.2 Communication channels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

2.2.3 Ventilator Control Board - VCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

2.2.4 Ventilator Monitoring Board - VMB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

2.2.5 Power Management Board – PMB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

2.2.6 Other Electronic Items . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

2.2.7 Motherboard (backplane) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

2.2.8 Monitoring Interface Board – Monitoring Module Bays . . . . . . . . . . . . . . . . . . . . 2-17

1505-1018-000 10/04 2-1

Page 24

Engström Ventilator

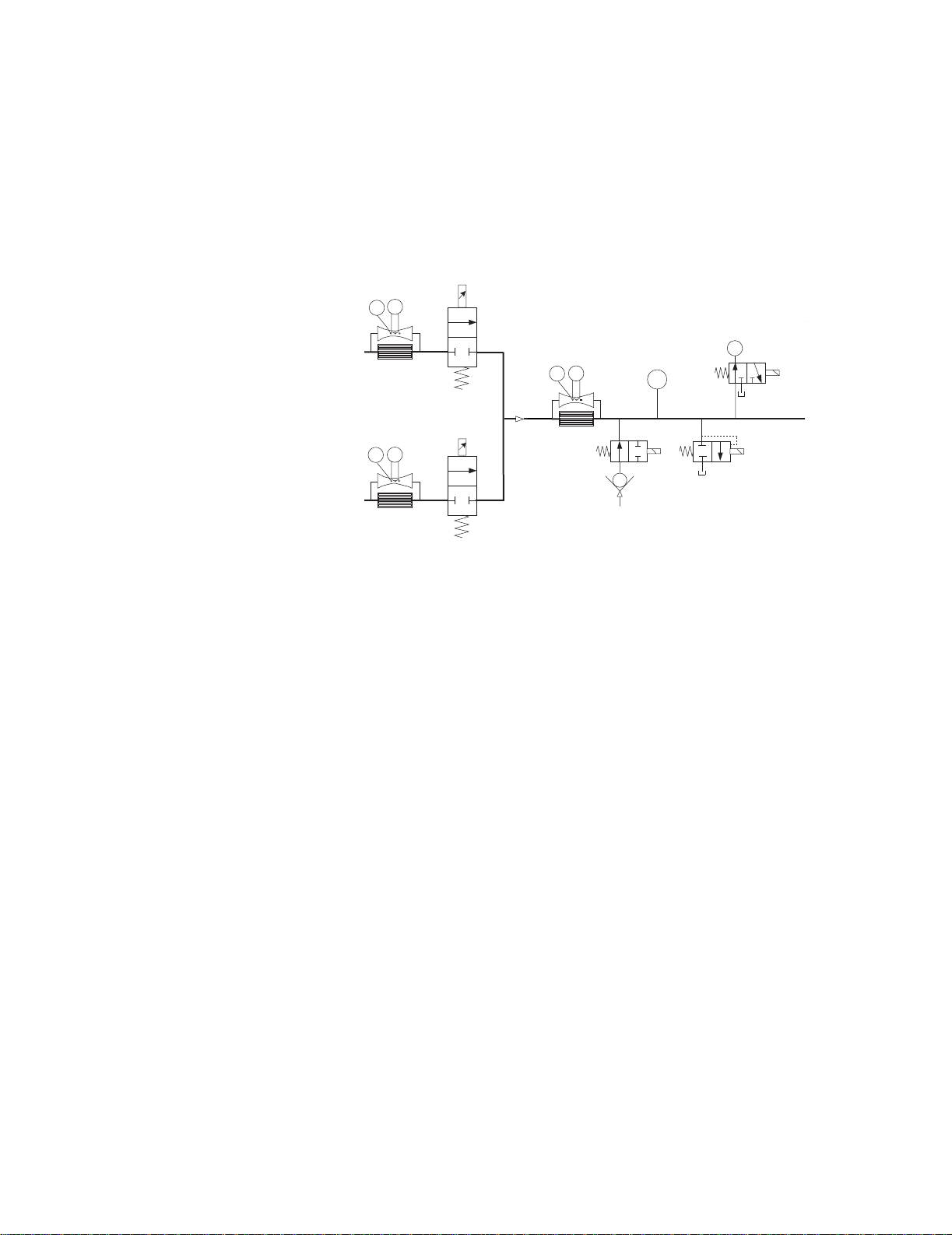

2.1 Pneumatic Operation

For a complete diagram of the pneumatic system, refer to Figure 11-2, "

Engine manifold flow diagram

" in Section11.

Vent

The EV requires a medical-grade oxygen (O2) and Air source ranging from 2.4

to 6.5 bar (35 to 94 psi).

The system includes two separate channels (O2 and Air) to provide dynamic

mixture control of the delivered O2 percentage.

The Air supply may include an optional compressor unit {1} for applications

where pipeline Air is not available or to provide a continued Air supply if the

pipeline supply goes down.

Air

O2

2.1.1 Inspiratory circuit

{1}

Air

Compressed gas enters the EV through an inlet fitting {2} that is particular to

the institution’s supply system. The gas is filtered through a 2-micron

particulate filter {3} as it enters the ventilator’s “pneumatic engine” manifold.

A high-pressure transducer {4} having a dynamic range of 0 to 8.3 bar

(0 to 120 psi) is tapped at the outlet of the filter. This transducer monitors the

adequacy of the supply pressure. Failures of supply gas, coupling hoses or an

occluded filter are identified by the supply pressure transducer.

{4}

High Pressure

Transducer

{2}

Primary

Inlet

{3}

Inlet

Filter

P

Check

Valve

2-2 10/04 1505-1018-000

Page 25

2 Theory of Operation

Next in the downstream path of flow is a check valve {5}. The check valve

prevents backflow from the EV that would possibly contaminate the supply

pressure lines. For example; if the O

the O2 channel will prevent Air from moving back into the O2 supply lines.

High Pressure

Transducer

P

Primary

Inlet

Inlet

Filter

Check

Valv e

{5}

Downstream from the check valve is a 172 kPa (25 psi) pressure regulator {6}.

(The regulator is a non-relieving type that does not bleed gas into the

ventilator’s enclosure.) The regulator ensures a constant pressure supply to

the flow valve {8}. The regulated supply is flow rate dependant, which is

compensated for in the flow valve’s on-site calibration.

supply were to be lost, the check valve in

2

{8}

Flow

Valv e

Primary

Inlet

Inlet

Filter

High Pressure

Transducer

P

Check

Valv e

{6}

Regulator

25 psi

172 kPa

{7}

Flow

Test

Port

Sensor

H

T

Between the regulator and the flow valves is the inspiratory flow sensor {7}.

The sensor is a thermal mass-flow type that injects heat into the flow stream

and monitors the associated temperature rise at a downstream location. The

temperature change is dependent on the mass flow of the flow stream and

the specific heat of the gas moving through the sensor. Since the composition

of gas in the sensor is known, a conversion of mass-flow rate to volumetric

flow at ambient conditions can be made using the ambient density of the gas.

The sensor uses a laminar (two channel) flow element to split a portion of the

flow through the sensor past the heat injection and temperature sensing

elements. The sensor is pre-calibrated and includes an electronic PCB that

produces direct digital output of mass flow through an RS-232 interface.

Individual flow sensors measure the volume of gas dispensed from the O

and

2

Air channels during inspiration and expiration. The relative proportion of gas

dispensed from each channel is continuously adjusted to precisely control the

percentage of O2 delivered to the patient.

1505-1018-000 10/04 2-3

Page 26

Engström Ventilator

Downstream of the flow sensor is a flow valve {8} that meters flows from

approximately 0.05 l/min (leakage level) to a full flow value of 160 l/min. The

valve is a normally- closed proportional solenoid that is powered by a current

feedback loop. When calibrated on-site, using data from the inspiratory flow

sensor, a precise volumetric flow versus input current profile is developed that

includes both the valve and regulator characteristics.

{8}

Valv e

Flow

Primary

Inlet

Inlet

Filter

High Pressure

Transducer

P

Check

Valv e

Regulator

25 psi

172 kPa

Flow

Sensor

Test

Port

H

T

Following the two individual flow valves is the total flow sensor {10}. This

sensor is the same type as the individual flow sensors and is used to measure

the combined inspiratory flow being dispensed from the system. Using the

known mixture composition along with atmospheric pressure and gas

temperature information, mass-flow data from the sensor is converted to

delivered volumetric flow towards the patient. During calibration, the sensor is

checked against the output of the O

and Air flow sensors to ensure proper

2

operation.

Flow

Flow

Sensor

H

T

Flow

Sensor

H

T

Valv e

Flow

Valv e

Air

Pneumatic

Resistor

{10}

Tot al Flow

H

T

Inspiratory

Effort

Valv e

Free Breathing

O

2

Check Valve

2-4 10/04 1505-1018-000

Page 27

2 Theory of Operation

Following the total flow sensor are the free-breathing check valve {11} and the

inspiratory effort valve {12}.

During normal operation, the inspiratory effort valve is open, allowing the

free-breathing check valve to admit flow if the patient draws a significant

amount of inspiratory pressure, causing the airway pressure to become more

negative than -0.5 cm H

to spontaneously breathe in case of a ventilation delivery failure.

On occasion, to assess the patient’s tolerance to be weaned from the

ventilator, clinicians can determine the amplitude of inspiratory effort that the

patient can create. During this “procedure”, the inspiratory effort valve is

closed, effectively locking out the free breathing valve from the patient circuit.

Flow

Flow

Sensor

H

T

Valv e

O. The free-breathing check valve allows the patient

2

Pneumatic

Resistor

P

Expiratory Press

Air

Tot al Flow

H

T

Flow

Sensor

H

T

Flow

Valv e

Inspiratory

Effort

Valv e

{12}

Free Breathing

O

2

Check Valve

{11}

{13}

O2 Sensor

O

2

Auxil

Next in the flow path is the O2 sensor {13}. The sensor is used to monitor the

O2 concentration produced by the combined O2 and Air flows.

The O2 sensor uses the paramagnetic principle (oxygen molecules are

attracted in magnetic fields) to measure the oxygen concentration. The sensor

includes two nitrogen-filled glass spheres mounted on a suspension

containing a conductive coil that is located in a non-uniform magnetic field.

When the system is disturbed by an impulse of current, the suspension begins

to oscillate, inducing an EMF into the coil. The oscillation period of the

induced EMF is dependent on the partial pressure of oxygen surrounding the

suspension.

As sample gas fills the sensor, oxygen that is present in the sample is

attracted into the strongest part of the magnetic field. This congregation of O

molecules alters the natural oscillation frequency of the suspension.

Calculations based on the difference between the oscillation period for an

oxygen sample and that for nitrogen, and readings from the absolute pressure

transducer, determine the measured O

1505-1018-000 10/04 2-5

percentage.

2

2

Page 28

Engström Ventilator

n

Expirat

As a safety measure, a relief valve {14}, located downstream from the O2

sensor, can be energized to vent the full flow rate of the inspiratory delivery

side of the system. If an overpressure condition is detected, the valve can be

opened by either of the EV’s two control processors. To provide redundant

safety (independent of the electronic circuits), the valve begins to

mechanically relieve pressure at a nominal 115 cm H

Flow

Flow

Sensor

H

T

Valv e

Air

Pneumatic

Resistor

Tot al Flow

T

Expiratory Pressure

H

O2 Sensor

O.

2

ory Zero

Valv e

P

Exhalatio

Valv e

{15}

Inspiratory Pressure

P

Inspiratory Zero

Valv e

O

2

Flow

Sensor

H

T

Flow

Valv e

Inspiratory

Effort

Valv e

Safety

Free Breathing

O

2

Check Valve

Relief Valve

{14}

Auxiliary Pressure

Relief

The inspiratory airway pressure transducer {15}, along with its associated

zeroing valve, is located just prior to the inspiratory outlet port. This

transducer has a range of –20 to 120 cm H2O and serves as one of three

airway pressure measuring devices in the EV.

2-6 10/04 1505-1018-000

Page 29

2 Theory of Operation

2.1.2 Expiratory circuit At the expiratory side of the ventilator, a solenoid powered exhalation valve

{16} controls exhaust from the breathing circuit. The valve contains an

elastomer diaphragm that is held against a rigid seat by a solenoid (voice coil)

driven piston. The valve achieves a balance between the pressure generated

within its 21-mm diameter seat area and the force applied by the piston,

releasing exhalation flow as necessary to maintain balance. The proportional

solenoid controls the exhalation sealing pressure within a range of 0 to 100

cm H

O. Software control provides continuous oscillatory movement

2

(dithering) of the exhalation valve to minimize static friction effects.

{20}

H

30 mm Male Cone

Exhalation

Flow Sensor

{19}

EXP

22 / 15 mm

Male / Female

INSP

22 / 15 mm

Male / Female

From

Patient

To

Micropump

Nebulizer

Patient

Air

Pneumatic

Resistor

Tot al Flow

T

H

Inspiratory

Effort

Valv e

Pneumatic

Resistor

{18}

Expiratory Zero

P

Expiratory Pressure

Valv e

{16}

Exhalation

Valv e

{17}

Inspiratory Pressure

P

Inspiratory Zero

O2 Sensor

O

2

Safety

Valv e

Immediately upstream of the exhalation valve is a tap for the expiratory

pressure transducer {17} and its associated zeroing valve. The expiratory

pressure tap is continuously purged with 35 ml/min of air to ensure that

exhaled condensate does not occlude the tap. The air flow is established from

the regulated Air supply using a fixed orifice (pneumatic resistor) {18}.

Downstream of the exhalation valve is the expiratory flow transducer {19}. In

principle, the transducer is similar to a hot-wire anemometer. A wire having a

large “temperature to electrical resistance” relationship is placed in the

flowstream. The wire is kept at a constant temperature using a Wheatstone

bridge circuit. The current necessary to maintain the resistance of the sensor

portion of the bridge is a function of the flow through the sensor.

At the output of the flow sensor is a flapper type check valve {20} that

prevents gas from being drawn in through the expiratory valve and minimizes

patient rebreathing in the event of a ventilator failure.

1505-1018-000 10/04 2-7

Page 30

Engström Ventilator

2.1.3 Associated circuits Associated with the inspiratory and expiratory pressure transducers are two

“zeroing” solenoid valves {21} and {22}. These valves are used to disconnect

the pressure transducers from circuit pressure and vent them to atmosphere

during zero bias calibration. This zeroing procedure is conducted routinely

(every 12 hours) under the control of the Vent Engine software.

Pneumatic

High Pressure

Transducer

P

Inlet

Filter

Primary

Inlet

Air

High Pressure

Transducer

Inlet

Filter

Primary

Inlet

O

2

Regulator

25 psi

172 kPa

Check

Valve

Regulator

25 psi

P

172 kPa

Check

Valve

Sensor

Test

Port

T

Sensor

Test

Port

T

Flow

Valve

Flow

H

Flow

Flow

Valve

H

{25}

Pneumatic

Resistor

T

Tota l Flow

Inspiratory

Effort

Valve

H

Free Breathing

Check Valve

Auxiliary Pressure

Resistor

{24}

Purge Valve

P

Expiratory Pressure

O2 Sensor

O

2

Auxiliary Pressure

Relief Valve

{23}

Transducer

P

{22}

Expiratory Zero

Valve

Inspiratory Pressure

Safety

P

{26}

{21}

Inspiratory Zero

Relief

Valve

Valve

Exhalation

Valve

30 mm Male Cone

Exhalation

Flow Sensor

H

EXP

22 / 15 mm

Male / Female

P

a

tie

n

t

INSP

22 / 15 mm

Male / Female

Micropump

Nebulizer

{27}

Paux

1/8,3/16, 1/4 inch Stepped Hose Barb

A third (auxiliary) pressure channel {23} is used to measure additional patient

“airway” pressures at the discretion of the clinician. This port could be used to

measure circuit pressure directly at the airway, laryngeal cuff pressures or

pressures lower in the airway tract. The transducer circuit includes a valve {24}

to provide a 35 ml/min purge flow as required by the particular clinical

application. For example, in measuring airway pressure at the endotracheal

tube the purge would most likely be turned on, but for measuring laryngeal

cuff pressures (closed system) the purge would be turned off. The purge flow

is established from the regulated Air supply using a fixed orifice (pneumatic

resistor) {25}. The relief valve {26} limits pressure in the auxiliary channel to

less than 230 cm H

O.

2

2.1.4 Electronic

micropump nebulizer

The Aeroneb Professional Nebulizer System (Aeroneb Pro) by Aerogen, Inc.

{27} is integrated into the EV. This nebulizer is electrically connected to the EV

and uses proprietary technology to produce a fine-droplet, low-velocity

aerosolized drug delivered into the breathing circuit.

The Aeroneb Pro is designed to operate in-line with standard ventilator

circuits and mechanical ventilators. It operates without changing the patient

ventilator parameters.

2-8 10/04 1505-1018-000

Page 31

2 Theory of Operation

2.2 Electrical Operation

For a complete diagram of the electrical system, refer to Figure 11-4,

"Electrical architecture" in Section11.

The EV includes 4 major processor control boards:

• the Display Unit (DU),

• the Ventilator Control Board (VCB),

• the Ventilation Monitoring Board (VMB),

• and the Power Management Board (PMB).

Two analog boards — the motherboard (backplane) and the monitoring

module power supply board — round out the electronic architecture.

2.2.1 Display Unit (DU) The DU is physically separate from the ventilator chassis (connected through

a single cable running through the display arm). The DU contains a CPU board

based on the Elan SC520 processor. A small daughter board (DU Interface

board), provides a communications interface between the DU’s CPU

and the remainder of the EV system. A second daughter board (DU Connector

board), provides hardware connector interfaces for the USB ,

ID

Network ID , Ethernet , and DIS (Display Interface Solution) ports.

X1

The CPU board includes a PCMCIA (PC Card) interface.

The DU’s CPU board provides power and signals for operating the main audio

speaker and a 12 inch (30 cm) backlit color LCD display, providing an

interactive video interface. Membrane keys from three front-panel keypads

and a rotary encoder (ComWheel) complete the loop for acquiring user inputs.

The DU housing contains a continuously operating fan for temperature

reduction.

Display Unit

PC Card

Keypad

Knob

UARTs

DU Infc Bd

LCD Display

Display Unit

CPU Board

CPU Elan

SC520

Speaker

DU Conn Bd

DIS

Ethernet USB

1505-1018-000 10/04 2-9

Net

ID

Page 32

Engström Ventilator

2.2.2 Communication

channels

The DU communicates to the remainder of the EV system through the

motherboard using 5 digital channels.

[1] A 500 Kbaud, RS-485 interface (Mod Bus: Datex-Ohmeda proprietary

module communication protocol), to external monitoring modules. This

link runs through the Monitoring Module Power supply board which forms

the physical interface to the M-Gas (and ultimately other) monitoring

modules.

Additionally, the Mod Bus interfaces with the PSM (Patient Side Module)

support circuitry (future expansion).

[2] A 38.4 Kbaud, RS-422 interface relays setting and alarm annunciation

information from the VMB, and receives alarm commands and data.

[3] A 38.4 Kbaud, RS-422 interface relays setting and alarm annunciation

information from the VCB, and receives sensor data for presentation to the

user as well as alarm commands. As described later, the VMB also

communicates directly to the VCB, thus there exists a triangle of bidirectional communication paths between the DU, VCB and VMB.

[4] An RS-232 Serial port that routes to an external connector directly on the

motherboard. This link ports data from the DU to other compatible

equipment via the Ohmeda Com 1 protocol.

[5] A 38.4 Kbaud, RS-232 link to the PMB. Aside from providing battery and

power information to the DU, this link is used to confirm a “hard” power

down of the EV with user inputs to the DU being relayed to the PMB for

power down action.

2-10 10/04 1505-1018-000

Page 33

Display Unit

2 Theory of Operation

Module Bay

M-Gas

Intel 196

Processor

External I/O:

PCMCIA (2)

External I/O:

DIS

Ethernet

Net ID

USB

Mod Bus,

DU Controls

Atmel

ATmega 16

Processor

RS-485

500 Kbaud

Serial

9.6 Kbaud

Display Unit CPU

AMD Elan SC520

Processor

C&T 69000

Display Processsor

Color LCD

EV Chassis

RS-232

38.4 Kbaud

RS-232 Serial

External I/O

RS-422

38.4 Kbaud

RS-422

38.4 Kbaud

ISA

DU - UPI

Hitachi H8

Bus

Processor

Mod Bus,

RS-485

500 Kbaud

[1]

RS 485

RS 485

RS 422

RS 232

PSM

Future

Expansion

Future

Expansion

External

I/O Serial

RS-485

19.2 Kbaud

RS-422

19.2 Kbaud

VCB

Vent Control

Board

Motorola

Coldfire V4

Processor

PMB

Power

Management

Board

Atmel A Tmega

128 Processor

RS-422

921.6 Kbaud

RS-422

38.4 Kbaud

RS-232

38.4 Kbaud

VMB

Vent Monitor

Board

Atmel A Tmega

128 Processor

RS-422

38.4 Kbaud

[2]

[3]

[4]

[5]

AB.98.064

1505-1018-000 10/04 2-11

Page 34

Engström Ventilator

2.2.3 Ventilator

Control Board -

VCB

The VCB is a Motorola Coldfire V4 CPU powered assembly that:

• collects information from all EV system sensors (some indirectly from the VMB),

• and controls all actuators necessary to effect ventilation delivery.

The VCB computes and supplies all ventilation sensor monitoring data for display on

the DU. If there are alarms to be generated based on this monitoring data, the VCB

notifies the DU to post the appropriate alarm message and audio sequence. The VCB

observes the DU’s response to ensure that the alarm is adequately presented.

To control ventilation, the VCB accepts ventilation parameters from the DU. Measured

data (waveform and numeric) is also sent to the DU from the VCB. This data flow occurs

on the 38.4 Kbaud, RS-422 communications link (VCB - DU Data I/O).

The VCB also communicates directly with the VMB every 1 ms, receiving expiratory flow,

expiratory pressure and O

Sensor Data I/O). Barometric pressure data is also received from the VMB, but at a

lower data rate.

The following sensor information is acquired directly by the VCB:

• Air Flow/Temp sensor through the RS-232 cable interface @ 200 Hz,

• O2 Flow/Temp sensor through the RS-232 cable interface @ 200 Hz,

• Total Flow/Temp sensor through the RS-232 cable interface @ 200 Hz,

• Inspiratory Pressure sensor via a differential analog signal – 12 bits @ 1000 Hz.

• Auxiliary Pressure sensor via a differential analog signal – 12 bits @ 1000 Hz.

sensor data on the 921.6 Kbaud, RS-422 interface (VMB

2

The VCB contains actuator drive circuits for the following:

• the Air and O2 Flow Valves,

• the Exhalation Valve,

• the Inspiratory Pressure Sensor zeroing valve

• and the Auxiliary Pressure Sensor purge flow valve.

All valve actuators are driven using current drive circuits and feedback controlled using

current sense resistors. The VCB contains digital control signals for activating the

inspiratory effort and safety relief valves (through the VMB) and the Piezo-Electric

Nebulizer.

The VCB receives 12.5 Vdc from the PMB, which it regulates down to various voltages

for use by the board’s digital circuits and analog drivers. These voltage levels are selftested on the VCB.

An additional 12.5 Vdc power line is separately connected to an auxiliary buzzer on the

VCB that provides a backup audio alarm source. The buzzer is normally on and must be

kept silent by both the VCB and through a dedicated digital line coming from the VMB.

A reset or failure of either the VCB or VMB is regarded as a system fault and the buzzer

is activated.

The VCB includes 1 MB of SRAM and 8 MB of Flash memory. The CPU is connected to a

digital watchdog circuit to monitor continuous and properly sequenced execution of

software code.

As the core processor unit for the EV, the VCB includes two external serial I/O channels:

one 19.2 Kbaud RS-422 channel (Expansion Port I/O #1 to External Connector 3) and

one 500 Kbaud RS-485 channel (Expansion Port I/O #2 to External Connector 2).

2-12 10/04 1505-1018-000

Page 35

2 Theory of Operation

For further details, refer to Figure 11-9, "VCB block diagram" in Section11.

VCB

Vent Control Board

Circuit Power

VMB Sensor

Data I/O

Expansion Port I/O #1

Expansion Port I/O #2

Insp Effort Valve

Exh Valve Closed

Safety Valve On/Off

Exh Valve On/Off

RS-422

38.4Kb

VCB - DU Data I/O

Power for Buzzer

Buzzer Control

Buzzer Sense

Current Lmt Control

Expansion Signals

Coldfire

V4 CPU

Power

12 Bit

16 CH

Backup

Buzzer

Regs

ADC

MUX

1 MB

SRAM

8 MB

Flash

V Checks

Watchdog

Exhal Valve

Drive w/ V & I

Sense

Air Valve Drive

w/ I Sense

O2 Valve Drive

w/ I Sense

8 UARTS

Serial

XCVRs

RS-232

RS-232

RS-232

AB.98.076

Piezo-Electric

Neb Board

Air

Flow Valve

O2

Flow Valve

Exhal Valve

Total Flow/

Air Flow/

Temp

O2 Flow/

Temp

Temp

Insp P

Insp P Zero

Valve

Nebulizer

Aux P

Aux P Purge

Valve

1505-1018-000 10/04 2-13

Page 36

Engström Ventilator

2.2.4 Ventilator

Monitoring Board - VMB

The VMB is based on an Atmel Atmega 128 CPU. The VMB performs as an

independent monitoring system that provides computational and oversight

redundancy to the DU and VCB.

The VMB independently acquires sensor data relating to the ventilator’s three

safety parameters:

• airway pressure (expiratory),

• delivered O

percentage,

2

• and exhaled minute/tidal volume.

In addition, the VMB monitors the air and oxygen supply pressures:

• Air High Pressure Supply via analog cable –10 bits @ 11 Hz,

• O2 High Pressure Supply via analog cable – 10 bits @ 11 Hz,

• Expiratory flow sensor data via an I

•O

Concentration via a serial cable @ 5 Hz,

2

2

C cable interface @ 200 Hz,

• Expiratory Airway Pressure via analog signal – 12 bits @ 1000 Hz,

• Barometric Pressure onboard VMB – 10 bits @ 11 Hz.

The VMB controls a safety valve actuator that enables it to unilaterally relieve

pressure in the breathing circuit. This allows the barotrauma hazard with its

50 ms reaction time to be independently controlled by either action of the

VCB or VMB. The hazards associated with O

concentration (improper mixture)

2

and low exhaled minute volume (hypoventilation) have much slower reaction

times (on the order of minutes) and are controlled under fault conditions by

the VMB’s ability to unilaterally activate the backup buzzer.

The VMB receives 12.5 Vdc from the PMB, which it regulates down to various

voltages for use by the board’s digital circuits and analog drivers. These

voltage levels are self-tested on the VMB.

The VMB communicates directly to the DU via the bi-directional 38.4 Kbaud

RS-422 channel (VCD - DU Data I/O). A separate 921.6 Kb RS-422 link (VMB

Sensor Data I/O) is used to transmit the VMB’s sensor data to the VCB.

2-14 10/04 1505-1018-000

Page 37

Circuit Power

Insp Effort Valve Control

Exh Valve Closed

Safety Valve On/Off

Exh Valve On/Off

RS-422

38.4 Kb

RS-422

921.6 Kb

VMB - DU Data I/O

VMB Sensor

Buzzer Control

Buzzer Sense

Data I/O

2 Theory of Operation

For further details, refer to Figure 11-8, "VMB block diagram" in Section11.

VMB

Vent Monitor Board

Atmel

ATmega128

CPU

UARTS

Watchdog

V Checks

ADC /

MUX

Insp Maneuver

Valve Drive

Safety Valve

Drive

Baro P

I2C

RS-232

Insp Effort

Valve

Safety

Relief Valve

Air Pipeline P

O2 Pipeline P

Exp Flow

Sensor Bd

O2 Sensor

Exp P

Exp Flow

Infc Bd

Exp Flow

Sensor

Circuit Power

Expansion Signals

Exp P Zero

Valve

AB.98.077

1505-1018-000 10/04 2-15

Page 38

Engström Ventilator

2.2.5 Power

Management Board –

PMB

The PMB is based on an Atmel Atmega 128 CPU. The PMB performs power

selection between power sources in the following order:

• AC power mains,

• External battery,

• Internal battery.

The PMB regulates the 24 Vdc power supply output down to raw 16 V and 12.5

V power rails that are used throughout the system (all boards locally regulate

from these power rails).

The PMB controls the charging operation of the internal battery, selecting

trickle, bulk, or float charge status.

The PMB communicates with the DU through the 9.6 Kbaud, RS-232 link

(PMB Data I/O). It sends status commands to the DU concerning the charge

status of the internal 24 V battery.

The PMB uses this link as a communication interlock to handle the unit

shutdown sequence. Once a signal is received by the PMB from the

mechanical On/Standby switch, the PMB prompts the DU for a confirmation

signal that shutdown is appropriate (unit is not in a ventilation therapy state).

Once the DU relays this confirmation to the PMB, the power-off sequence is

initiated.

The PMB supports the operation of the EV chassis fan and the fan on the PMB

heatsink.

2.2.6 Other Electronic

Items

Power Panel

Connectors

Ext Bat

24V

Ext Bat

Connector

On/Standby

Safety Switch

and

The EV/5 employs a separate AC to DC switching power supply for the

providing a nominal 24v voltage level to the PMB. The power supply is capable

of regulating 150 W of power output. A power entry module contains fuses

and filters for Mains AC input cables. Finally, two internal 12v batteries are

connected in series to provide an internal backup 24v power source for the

system.

For further details, refer to Figure 11-7, "PMB block diagram" in Section11.

PMB

Power Entry

Module

150W Mains

Power Supply

PMB

Fan

Vent

Engine

Fan

Power Management

Atmel

ATmega

128 CPU

UARTS

V Checks

Mains/Bat

Select

Fan Cntlrs

Backup

Audio Power

16V

Reg

12.5V

Reg

Bat Charge

Cntlr

Battery I &

V Monitor

Board

PMB Data I/O

Chassis Gnd

2 - 12 V

4AHr

Batteries

2-16 10/04 1505-1018-000

Page 39

2 Theory of Operation

2.2.7 Motherboard

(backplane)

The EV motherboard provides backplane connectivity for the VCB, VMB and

PMB assemblies in the EV chassis.

Analog circuits on the board provide current limiting for external peripheral

connections to ensure that the EV’s primary ventilation and monitoring

functions are not compromised by excessive power draw. In addition, 10VA

energy limit circuitry is provided for power connections within 20 cm of O

2

exhaust outlets, in order to mitigate the risk of an oxygen enriched fire.

The board features 6 external connectors that exit through a rear sheet metal

interface:

• Patient Side Module (PSM) support connector (future expansion)

• RS-485 Serial (future expansion) connector

• RS-422 Serial (future expansion) connector

• External Serial I/O connector

2.2.8 Monitoring

Interface Board –

Monitoring Module Bays

Bay 1

NESTPR

Module

Bay 2

Bay 3

M-CAiOVX

Module

Bay 4

• Main DU connector (communication channel between DU and EV)

• Monitoring Module, Mod Bus connector

The EV accommodates an optional four-bay module assembly that supports

compatible Datex-Ohmeda M-series modules.

The assembly includes a Monitoring Interface Board (MIB) that communicates

with the DU through the Mod Bus connector. The MIB includes circuitry that

regulates the raw16 V power down to +15 V (unregulated), ±15 V (regulated),

and +5 V levels required by the M series monitoring modules.

I/O Panel Connectors

Ext Serial

I/O

RS-422

#1

RS-485

#1

Mod Bus

PSM

Filtering

Filtering

Filtering

Filtering

Filtering

Expansion Port I/O #1

12.5V

Expansion Port I/O #2

12.5V

16V

16V

PSM

16V

Monitor

Interface

Board

+15VD

-15V

+15V

+5V

RS 232

RS 422

RS 485

RS 485

1505-1018-000 10/04 2-17

Page 40

Notes

2-18 10/04 1505-1018-000

Page 41

3 Checkout Procedure

In this section 3.1 Inspect the system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

3.2 Automated Checkout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

3.3 Backlight test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

3.4 Power failure test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

3.5 Electrical safety tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

wwwwWARNINGS After any repair or service of the Engström Ventilator, complete all tests in this

section.

Before you do the tests in this section:

• Complete all necessary calibrations and subassembly tests. Refer to the

individual procedures for a list of necessary calibrations.

• Completely reassemble the system.

If a test failure occurs, make appropriate repairs and test for correct operation.

1505-1018-000 10/04 3-1

Page 42

Engström Ventilator

3.1 Inspect the system

3.2 Automated Checkout

Before testing the system, ensure that:

• The equipment is not damaged.

• Components are correctly attached.

• Pipeline gas supplies are connected.

• The casters are not loose and the brakes are set and prevent movement.

• The power cord is connected to a wall outlet. The mains indicator comes

on when AC Power is connected.

The EV is equipped with an automated checkout.

When in Standby, the Patient Setup menu is displayed on the normal screen.

1. Select Checkout.

2. Attach the patient circuit.

3. Occlude the patient wye.

4. Select Start Check.

• The results appear next to each check as they are completed. When

the entire checkout is finished ‘Checkout complete’ will appear and

the highlight will move to Delete Trends.

• If one or more checks fail, select Check Help for troubleshooting

tips.

5. Select Previous Menu.

Checkout includes the following checks:

• Paw Transducer Check

• Barometric Pressure Check

• Relief Valve Check

• Exhalation Valve Check

• Expiratory Flow Sensor Check

• Air Flow Sensor Check

• O2 Flow Sensor Check

• O2 Concentration Sensor Check

• Circuit Leak, Compliance, and Resistance

Note If any of the Checks fail, refer to Section 7.1, “Troubleshooting Checkout

Failures”, to troubleshoot a specific failure.

3-2 10/04 1505-1018-000

Page 43

3.3 Backlight test

3 Checkout Procedure

1. Access the Calibration menu.

3.4 Power failure test

• In the standby mode, push the

• On the System Setup menu, select Install/Service (23-17-21).

• On the Install/Service menu, select Calibration.

2. On the Calibration menu, select Backlight Test.

3. Select Start Test.

4. The display will show the test running on light 1 and then on light 2. If the

display goes completely blank or flickers during the test, one of the lights

has failed.

1. Connect the power cord to a wall outlet. The mains indicator on the front

panel of the Display Unit comes on when AC Power is connected.

2. Set the system switch to On and Start a case.

3. Unplug the power cord with the system turned on.

4. Make sure that the power failure alarm comes on.

5. Make sure the following message is displayed:

System Setup key.

6. Connect the power cable again.

7. Make sure the alarm cancels.

3.5 Electrical safety tests

wwwwWARNING Make sure the system is completely assembled and that the power

cords are connected as illustrated in Section 10.12. Make sure all

accessory devices are connected to electrical outlets.

1. Connect an approved test device (for example: UL, CSA, or AAMI) and verify

2. Make sure that the resistance to ground is less than 0.2Ω between the

• ‘On battery’

that the leakage current is less than:

Voltage Max. Leakage Current

120/100 Vac 300 µAmps

220/240 Vac 500 µAmps

equipotential stud and the ground pin on the power cord.

1505-1018-000 10/04 3-3

Page 44

Notes

3-4 10/04 1505-1018-000

Page 45

4 Installation and Service Menus

In this section 4.1 Service and Installation menu structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2

4.2 Install/Service Menu (Super User) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

4.2.1 Defaults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-4

4.2.2 Factory Defaults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-5

4.3 Calibration menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-6

4.4 Service menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-7

4.4.1 Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-8

4.4.2 Copy Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-9

4.4.3 Service Log menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

4.4.4 Software/Hardware version menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

1505-1018-000 10/04 4-1

Page 46

Engström Ventilator

4.1 Service and Installation menu structure

This section describes the Service level functions that are part of the main

software installed in the ventilator.

Section 8, “Service Diagnostics and Software Download,” covers a separate

service application that loads from a PCMCIA card and is used to download

system software and run service diagnostics and other service tests.

Menu structure The Service menu structure has two levels which are password protected:

• Install/Service (super-user)

• Service

The Install/Service level (with super-user password) supports standard

hospital preferences such as colors, units, ventilator settings and alarm

defaults, and access to the Calibration and Service menus.

The Service level (with service password) supports system configuration and

provides access to the Service Log menu.

Follow the menu structure to access the various service screens:

• on the front panel of the Display Unit, press the System Setup key to access

the System Setup menu.

• on the System Setup menu, select Install/Service to access (with super-

user password) the Install/Service menu;

- select Calibration to access the Calibration menu.

- select Service to access (with service password) the Service menus.