Page 1

Avance

User’s Reference Manual

Software Revision 6.X

Page 2

Datex-Ohmeda, Inc., a General Electric Company, doing business as GE Healthcare.

User Responsibility

This Product will perform in conformity with the description thereof

contained in this User’s Reference manual and accompanying labels

and/or inserts, when assembled, operated, maintained, and repaired

in accordance with the instructions provided. This Product must be

checked periodically. A defective Product should not be used. Parts

that are broken, missing, plainly worn, distorted, or contaminated

should be replaced immediately. Should repair or replacement

become necessary, Datex-Ohmeda recommends that a telephonic or

written request for service advice be made to the nearest

Datex-Ohmeda Customer Service Center. This Product or any of its

parts should not be repaired other than in accordance with written

instructions provided by Datex-Ohmeda and by Datex-Ohmeda

trained personnel. The Product must not be altered without the prior

written approval of Datex-Ohmeda. The user of this Product shall

have the sole responsibility for any malfunction which results from

improper use, faulty maintenance, improper repair, damage, or

alteration by anyone other than Datex-Ohmeda.

CAUTION U.S. Federal law restricts this device to sale by or on the

order of a licensed medical practitioner. Outside the

U.S.A., check local laws for any restriction that may apply.

Datex-Ohmeda products have unit serial numbers with coded logic

which indicates a product group code, the year of manufacture, and a

sequential unit number for identification. The serial number can be in

one of two formats.

AAAX11111 AAAXX111111AA

The X represents an alpha

character indicating the year

the product was manufactured;

H = 2004, J = 2005, etc. I and

O are not used.

Avance, Advanced Breathing System, ComWheel, D-fend,

EZchange, Disposable Multi Absorber, Reusable Multi Absorber,

PSVPro, SmartVent, Tec 6 Plus, and Tec 7 are registered

trademarks of Datex-Ohmeda, Inc.

Other brand names or product names used in this manual are

trademarks or registered trademarks of their respective holders.

The XX represents a number

indicating the year the product

was manufactured; 04 = 2004,

05 = 2005, etc.

Page 3

1 Introduction

Intended use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Symbols used in the manual or on the equipment . . . . . . . . 1-4

Typeface conventions used . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

2 System Controls and Menus

System overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Advanced breathing system (ABS) components . . . . . . . . . 2-5

Table of Contents

Optional ABS components . . . . . . . . . . . . . . . . . . . . . . . 2-7

Non-circle circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-8

ACGO (optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-9

Scavenging the ACGO sample flow . . . . . . . . . . . . . . . . 2-9

Scavenging from an auxiliary manual breathing circuit 2-10

Scavenging a gas monitor sample flow . . . . . . . . . . . . 2-10

Vaporizer controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Display controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

Anesthesia system display . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

Waveform fields . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

Digit field . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

Using menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

M1145956 i

Page 4

Avance

3 Operation

Turning on the system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Start case (start gas flow) . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Using default settings . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Using customized settings . . . . . . . . . . . . . . . . . . . . . . . 3-4

Minimum Alveolar Concentration (MAC) . . . . . . . . . . . . 3-5

End case . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Ventilator setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Using quick keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Using Vent Setup menu . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Changing ventilator modes and settings . . . . . . . . . . . . 3-8

Gas setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Using quick keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Using Gas Setup menu . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Changing gas and settings . . . . . . . . . . . . . . . . . . . . . . 3-9

Changing circuit type . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

Spirometry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Setting loop type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

Scaling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

Spirometry setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

Setting patient and sensor type . . . . . . . . . . . . . . . . . . 3-14

Selecting a data source . . . . . . . . . . . . . . . . . . . . . . . . 3-15

Setting spirometry split screen . . . . . . . . . . . . . . . . . . . 3-15

Main Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

Trends . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

Cardiac bypass . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

Fresh gas usage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-19

Screen configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-20

Select page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-20

Screen setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-21

ii M1145956

Page 5

4 Preoperative Checkout

Table of Contents

Alarm setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-23

Setting alarm limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-23

Volume apnea . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-24

MV/TV alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-24

CO2 alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-24

Auto MV limit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-25

Alternate O2 control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-26

EZchange canister (optional) . . . . . . . . . . . . . . . . . . . . . . . 3-27

Condenser (optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-28

Passive AGSS (optional) . . . . . . . . . . . . . . . . . . . . . . . . . . 3-29

Active AGSS (optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-30

Connecting active AGSS with a flow indicator . . . . . . . 3-31

Connecting active adjustable AGSS . . . . . . . . . . . . . . 3-31

5 Preoperative Tests

Every day before your first patient . . . . . . . . . . . . . . . . . . . . 4-2

Before every patient . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Inspect the system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Vaporizer installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Flow and pressure calibration . . . . . . . . . . . . . . . . . . . . . . . 5-4

Circuit compliance compensation . . . . . . . . . . . . . . . . . . . . 5-4

Checkout menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Leak < 250 ml . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

No . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Yes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Machine check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Machine check - system . . . . . . . . . . . . . . . . . . . . . . . .5-6

Machine check - circuit . . . . . . . . . . . . . . . . . . . . . . . . .5-7

Machine check -circuit O2 . . . . . . . . . . . . . . . . . . . . . . . 5-7

Machine check - monitor . . . . . . . . . . . . . . . . . . . . . . . . 5-7

Individual checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

M1145956 iii

Page 6

Avance

6 Airway Modules

Circuit O2 cell . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

Low P leak . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

Low P leak (machines with ACGO) . . . . . . . . . . . . . . . . 5-9

Positive low pressure leak test (ACGO systems only) . . . . 5-10

Vaporizer back pressure test . . . . . . . . . . . . . . . . . . . . . . . 5-11

Airway modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Connection to a patient . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Parameters setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

Data source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

CO2 setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

O2 setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

Agent setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

Spirometry setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

Automatic agent identification . . . . . . . . . . . . . . . . . . . . . . . 6-6

Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

7 Alarms and Troubleshooting

Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

List of alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

Alarm ranges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-12

Alarm tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-14

Breathing system problems . . . . . . . . . . . . . . . . . . . . . . . . 7-16

Electrical problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-17

Alarm priorities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Silencing alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Display changes during alarms . . . . . . . . . . . . . . . . . . . 7-2

De-escalating alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

Battery indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

Internal failure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

Pneumatic problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-18

iv M1145956

Page 7

8 Setup and Connections

Table of Contents

Setup warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

Canister setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-4

When to change the absorbent . . . . . . . . . . . . . . . . . . . 8-5

Removing a canister . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-6

Removing an EZchange canister . . . . . . . . . . . . . . . . . . 8-6

Reusable Multi Absorber canister filling . . . . . . . . . . . . . 8-7

Electrical connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-9

Mains inlet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-9

Outlets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-9

Serial port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-10

Pneumatic connections . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-11

Pipeline inlets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-11

Scavenging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-11

9 User Maintenance

Sample gas return port . . . . . . . . . . . . . . . . . . . . . . . . 8-12

Vacuum suction regulator (optional) . . . . . . . . . . . . . . 8-12

Venturi suction regulator (optional) . . . . . . . . . . . . . . . 8-13

Auxiliary O2 flowmeter (optional) . . . . . . . . . . . . . . . . . 8-13

How to install gas cylinders . . . . . . . . . . . . . . . . . . . . . . . . 8-14

Pin indexed cylinder yokes . . . . . . . . . . . . . . . . . . . . .8-14

DIN cylinder connections . . . . . . . . . . . . . . . . . . . . . . . 8-14

High-pressure leak test . . . . . . . . . . . . . . . . . . . . . . . . 8-15

How to attach equipment to the top of the machine . . . . . . 8-16

Repair policy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-2

Maintenance summary and schedule . . . . . . . . . . . . . . . . . 9-2

Datex-Ohmeda approved service . . . . . . . . . . . . . . . . . 9-3

Circuit O2 cell replacement . . . . . . . . . . . . . . . . . . . . . . . . . 9-4

Calibration menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-5

Flow and pressure calibration . . . . . . . . . . . . . . . . . . . . . . . 9-5

Circuit O

cell calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-6

2

21% O

calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-6

2

Airway gas calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-6

M1145956 v

Page 8

Avance

10 Parts

Backlight test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-7

How to help prevent water buildup . . . . . . . . . . . . . . . . . . . . 9-7

Flow sensor module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-2

Breathing circuit module . . . . . . . . . . . . . . . . . . . . . . . . . . 10-3

Bellows . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-4

Complete Advanced Breathing System . . . . . . . . . . . . . . . 10-5

Absorber canister . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-6

Exhalation valve assembly . . . . . . . . . . . . . . . . . . . . . . . . . 10-7

AGSS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-8

EZchange canister system . . . . . . . . . . . . . . . . . . . . . . . . . 10-9

Condenser . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-10

Test tools and system parts . . . . . . . . . . . . . . . . . . . . . . . 10-11

11 Specifications and Theory of Operation

System pneumatic circuits . . . . . . . . . . . . . . . . . . . . . . . . . 11-2

Gas supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-4

O2 flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-4

Air and N2O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-4

Mixed gas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-4

EZchange canister . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-4

Condenser . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-5

Pneumatic specifications . . . . . . . . . . . . . . . . . . . . . . . . . . 11-5

Gas supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-5

ACGO Port relief . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-5

Non-circle circuit relief . . . . . . . . . . . . . . . . . . . . . . . . . 11-5

Electrical block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-6

Electrical power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-8

Power cord . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-8

Battery information . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-9

Flow specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-9

Breathing system specifications . . . . . . . . . . . . . . . . . . . . 11-10

Gas scavenging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-11

Physical specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-12

vi M1145956

Page 9

Table of Contents

Environmental requirements . . . . . . . . . . . . . . . . . . . . . . 11-12

Airway module specifications . . . . . . . . . . . . . . . . . . . . . . 11-13

Gas specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-13

Typical performance . . . . . . . . . . . . . . . . . . . . . . . . . 11-14

Suction regulators (optional) . . . . . . . . . . . . . . . . . . . . . . 11-15

Ventilator theory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-16

O2 monitoring theory of operation . . . . . . . . . . . . . . . 11-17

Ventilation modes . . . . . . . . . . . . . . . . . . . . . . . . . . .11-17

Ventilator operating specifications . . . . . . . . . . . . . . . . . . 11-25

Pneumatics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-25

Fresh gas compensation . . . . . . . . . . . . . . . . . . . . . . 11-25

Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-25

Volume . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-25

Oxygen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-25

Ventilator accuracy data . . . . . . . . . . . . . . . . . . . . . . . . . 11-26

Electromagnetic compatibility (EMC) . . . . . . . . . . . . . . . . 11-27

Guidance and manufacturer’s declaration -

electromagnetic emissions . . . . . . . . . . . . . . . . . . . . . 11-27

Guidance and manufacturer’s declaration -

electromagnetic immunity . . . . . . . . . . . . . . . . . . . . . 11-28

Power immunity . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-28

Radiated immunity . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-29

Recommended separation distances . . . . . . . . . . . . . 11-30

Electrical safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-31

IEC 60601-1 Classification . . . . . . . . . . . . . . . . . . . . . . . . 11-32

Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-32

System components . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-33

Integral . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-33

Not integral . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-33

M1145956 vii

Page 10

Avance

12 Super User Mode

Index

Install/Service menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-2

Using super user mode . . . . . . . . . . . . . . . . . . . . . . . . 12-3

Menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-4

Cumulative gas usage . . . . . . . . . . . . . . . . . . . . . . . . . 12-4

Volume apnea setup . . . . . . . . . . . . . . . . . . . . . . . . . . 12-5

Setting time and date . . . . . . . . . . . . . . . . . . . . . . . . . . 12-6

Trends setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-7

Setting colors and units . . . . . . . . . . . . . . . . . . . . . . . . 12-9

Parameter settings . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-10

Page Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-10

Configuring case defaults . . . . . . . . . . . . . . . . . . . . . 12-12

Warranty

viii M1145956

Page 11

1 Introduction

WARNING Read each component’s User’s Reference manual and

understand the following before using this system:

• All system connections.

• All warnings and cautions.

• How to use each system component.

• How to test each system component.

w Before using the system:

• Complete all of the tests in the “Preoperative Tests”

section.

• Test all other system components.

w If a test fails, do not use the equipment. Have a

Datex-Ohmeda trained service representative repair the

equipment.

In this section Intended use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Symbols used in the manual or on the equipment . . . . . . . . 1-4

Typeface conventions used . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

M1145956 1-1

Page 12

Avance

Intended use

The Avance anesthesia system combines our highly advanced

anesthesia delivery, the very best in patient monitoring, and care

information management. The contemporary, compact design

addresses many ergonomic considerations including an efficient

cable management solution and storage system and an extra large

work surface area. Optional, integrated features include auxiliary O2

and suction control. The Avance system offers improved usability

through integration of ventilation, gas delivery and gas monitoring (E

and M-Series respiratory gas module capable) on a full-color 12-inch

display. This system also features electronic gas mixing of up to three

gases.

The Avance system uses SmartVent ventilation technology offering

Volume Control Ventilation with tidal volume compensation and

electronic PEEP. The proven SmartVent technology also features

optional Pressure Control Ventilation, Pressure Support Ventilation

with an Apnea Backup (PSVPro) that is used for spontaneously

breathing patients, Synchronized Intermittent Mandatory Ventilation

(SIMV) modes, Pressure Control Ventilation-Volume Guarantee

(PCV-VG), and VCV cardiac bypass. These advanced features allow

for the ventilation of a broad patient range: from neonates and

compromised patients to routine cases.

The Avance system uses the Advanced Breathing System (ABS).

This integrated breathing system is easy to remove and disassemble,

is made of highly durable polymers, and is fully autoclavable. Its fully

integrated design enhances the system’s elegance while minimizing

tube connections, minimizing circuit volume, and increasing the work

surface area.

The anesthesia system is designed for expansion and upgrades, so it

is easy to add new technologies and ventilation capabilities without

investing in a new system.

This anesthesia system is not suitable for use in an MRI environment.

This system must only be operated by authorized medical personnel

well trained in the use of this product. It must be operated according

to the instructions in this User’s Reference manual.

WARNING Explosion Hazard. Do not use this system with flammable

anesthetic agents.

Note Configurations available for this product depend on local market and

standards requirements. Illustrations in this manual may not

represent all configurations of the product. This manual does not

cover the operation of every accessory. Refer to the accessory

documentation for further information.

1-2 M1145956

Page 13

1 Introduction

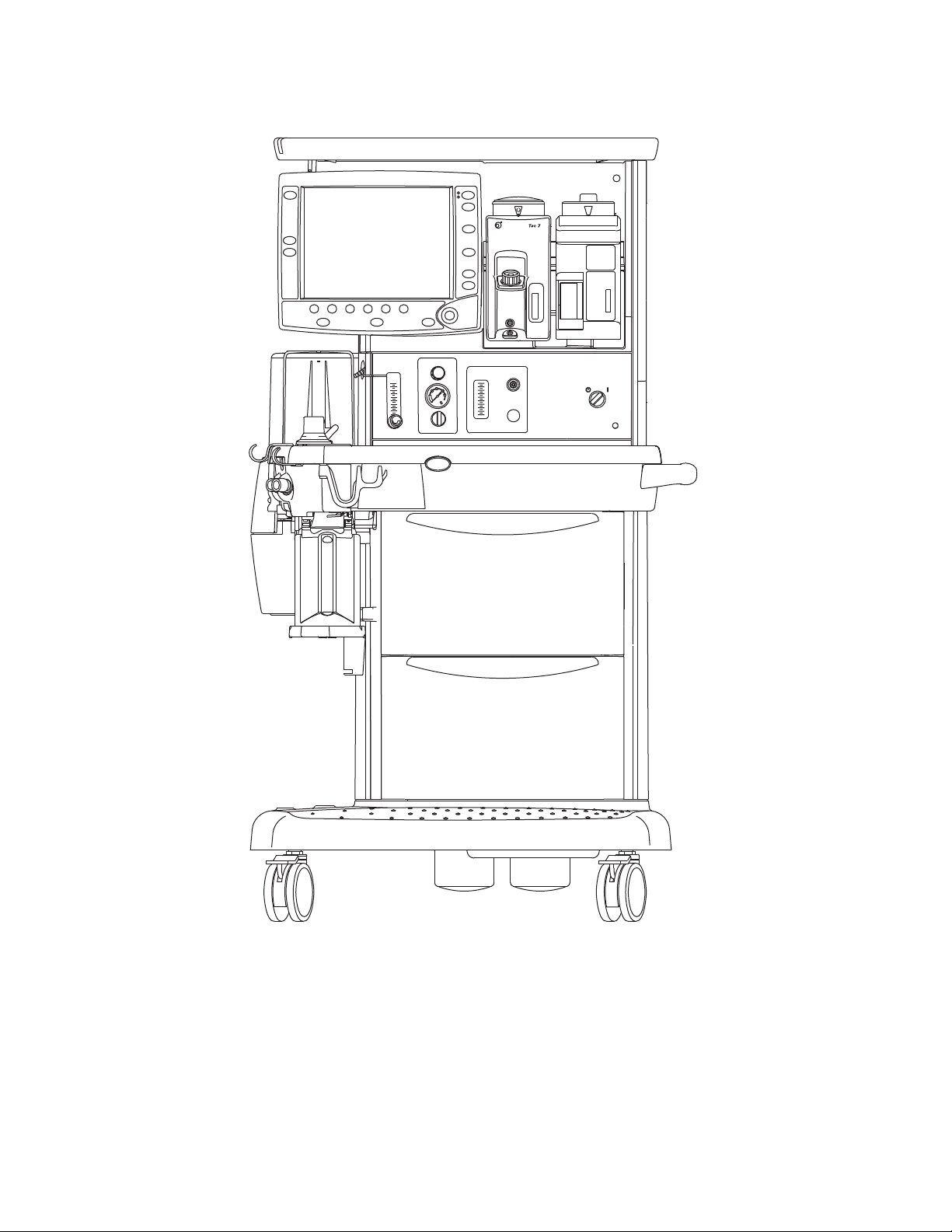

AB.91.108

Figure 1-1 • Front view

M1145956 1-3

Page 14

Avance

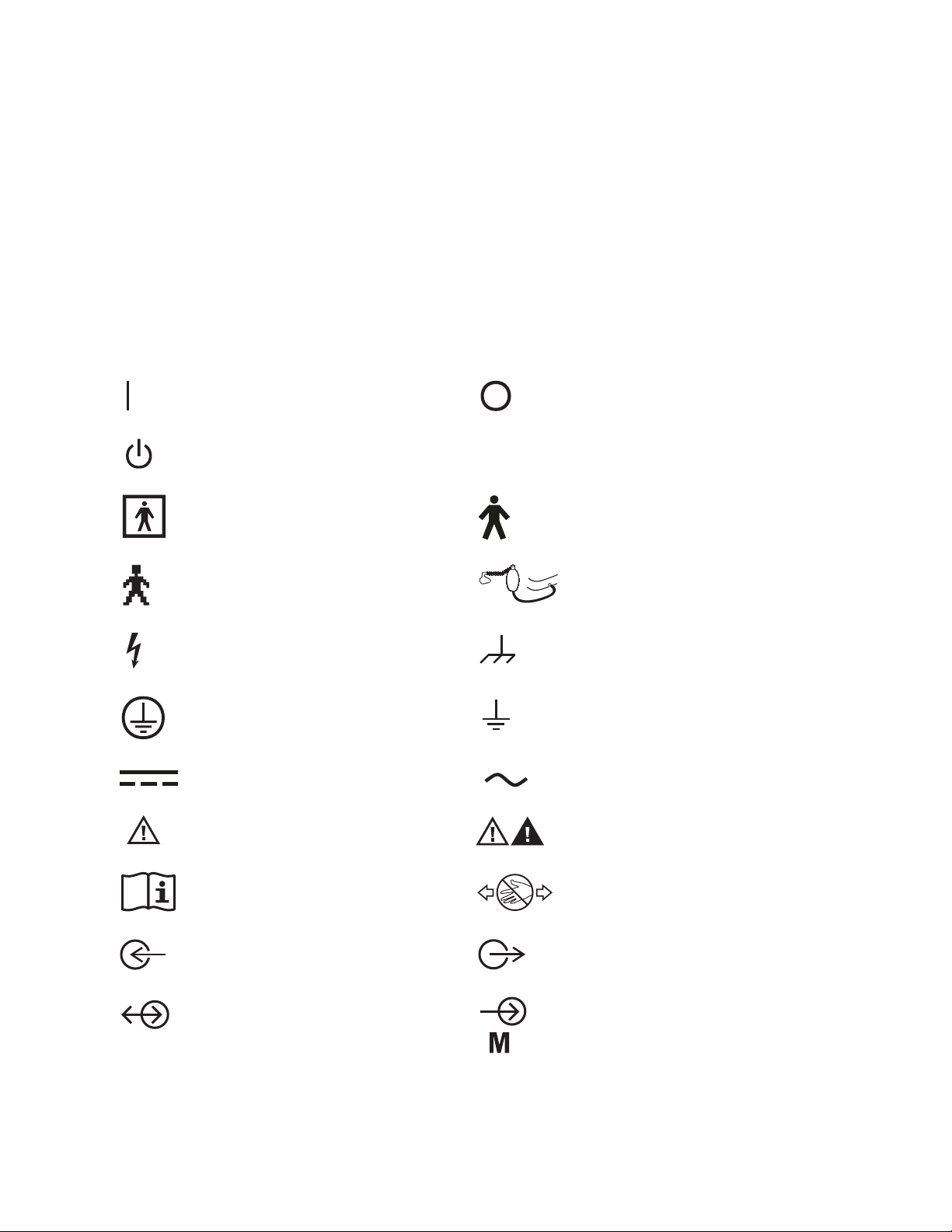

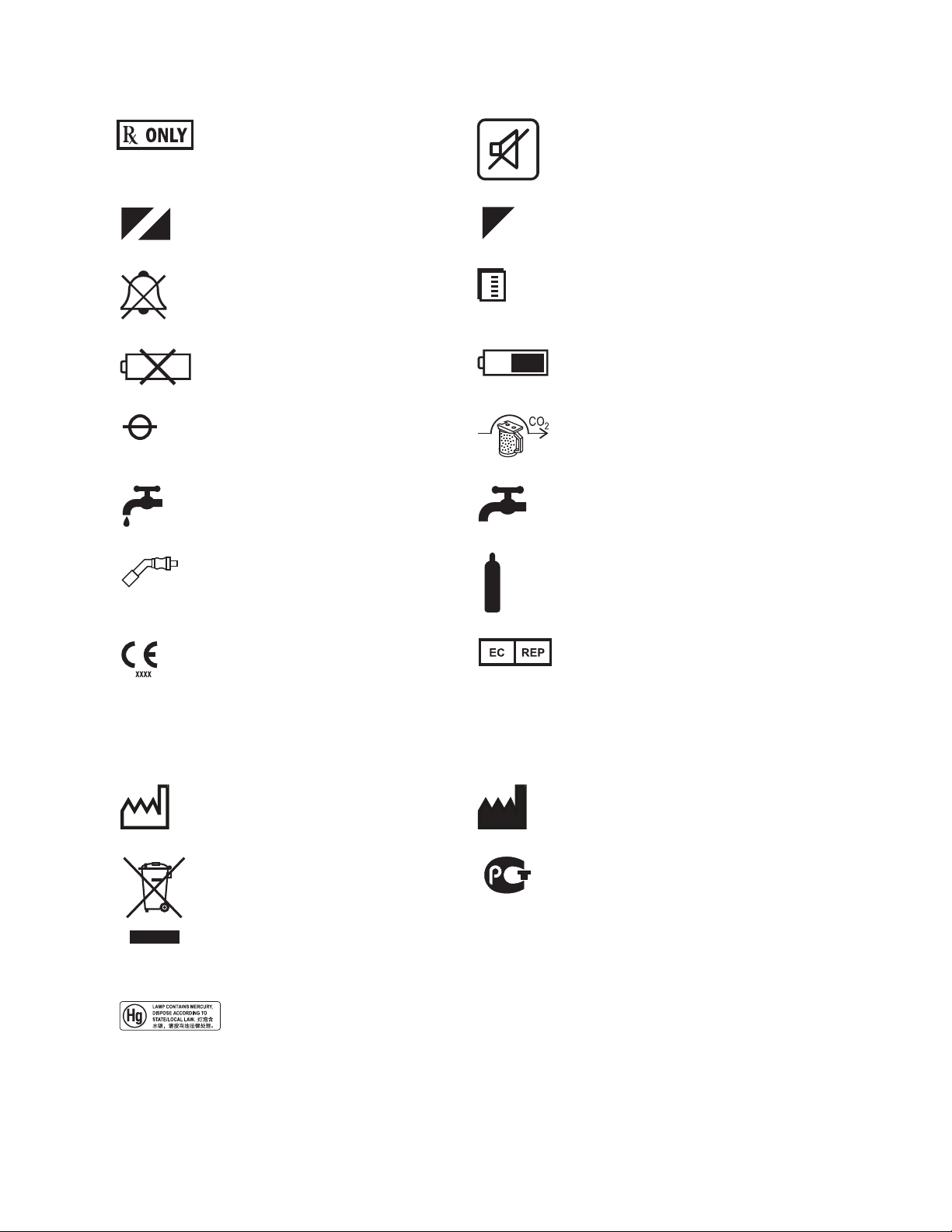

Symbols used in the manual or on the equipment

Symbols replace words on the equipment, on the display, or in

Datex-Ohmeda manuals.

Warnings and Cautions tell you about dangerous conditions that can

occur if you do not follow all instructions in this manual.

Warnings tell about a condition that can cause injury to the operator

or the patient.

Cautions tell about a condition that can cause damage to the

equipment. Read and follow all warnings and cautions.

On (power) Off (power)

Standby

Type BF equipment Type B equipment

Airway module indicator ACGO active

Dangerous voltage Frame or chassis ground

Protective earth ground Earth ground

Direct current Alternating current

Caution/Warning Attention, refer to product instructions

Refer to product instructions Pinch hazard

O2+

O2 Flush button

Electrical input Electrical output

Electrical input/output Sample gas inlet to scavenging

1-4 M1145956

Page 15

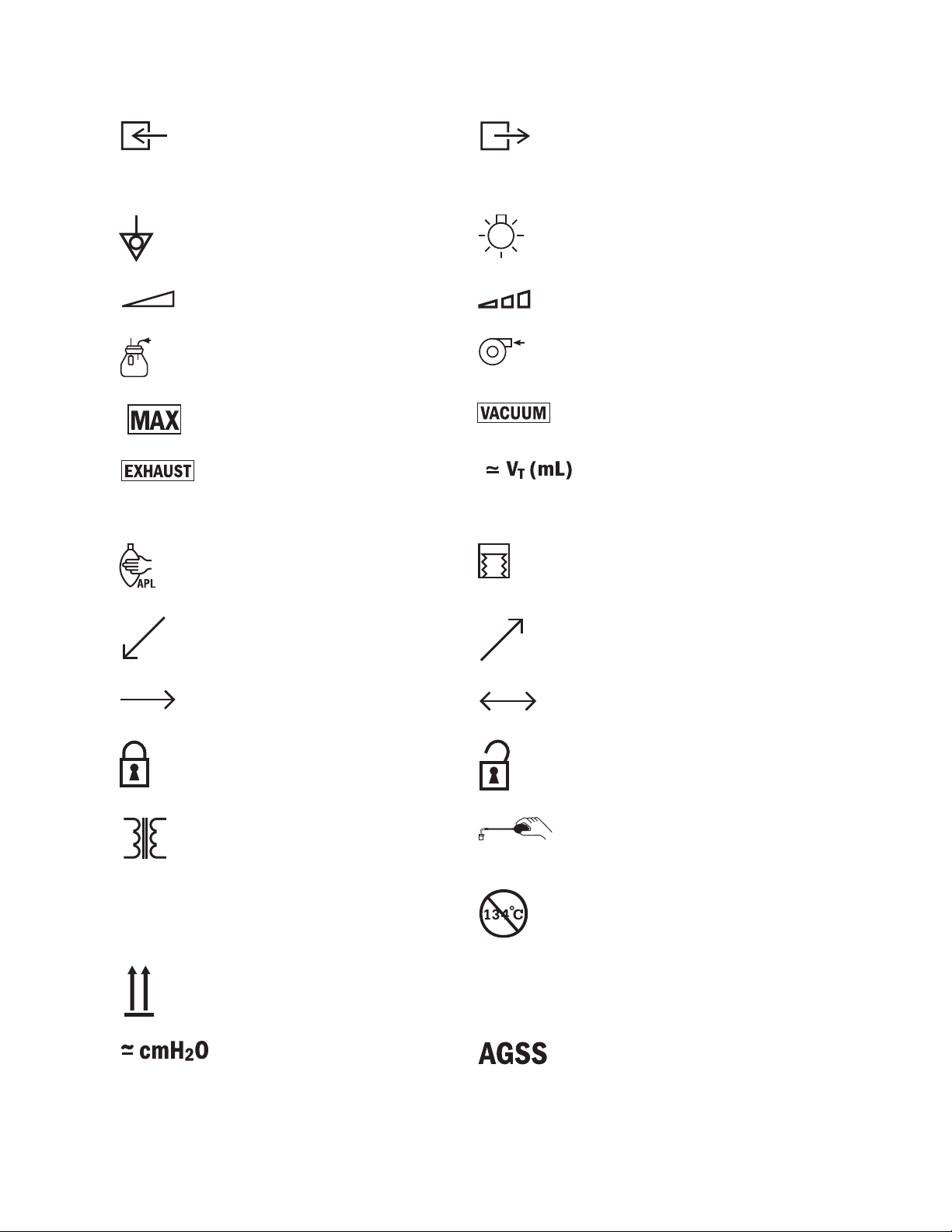

Pneumatic inlet Pneumatic outlet

1 Introduction

SN

+

Serial number

Equipotential Lamp, lighting, illumination

Variability Variability in steps

Suction bottle outlet Vacuum inlet

Maximum Vacuum

Exhaust Bellows volumes are approximate

Plus, positive polarity

Bag position/manual ventilation Mechanical ventilation

Inspiratory flow Expiratory flow

REF

-

Stock number

Minus, negative polarity

134°C

Movement in one direction Movement in two directions

Lock Unlock

Isolation transformer Low pressure leak test

Autoclavable Not autoclavable

This way up

APL settings are approximate Anesthetic Gas Scavenging System

O2%

O2 cell connection

M1145956 1-5

Page 16

Avance

Caution: federal law prohibits

dispensing without prescription.

O2% indicator on left and balance gas

indictor on right. Colors associated

with gas settings.

Alarm silence Submenu

No battery/battery failure Battery in use. Bar indicates amount of

Read to center of float EZchange canister (CO2 bypass)

Open drain (remove liquid) Close drain

Pipeline Cylinder

Alarm silence touch key (Tec 6 Plus)

Gas indicator. Color associated with gas

settings.

battery power remaining.

Systems with this mark agree with the

European Council Directive (93/42/

EEC) for Medical Devices when they

are used as specified in their User’s

Reference manuals. The xxxx is the

certification number of the Notified

Body used by Datex-Ohmeda’s

Quality Systems.

Date of manufacture Manufacturer

Indicates that the waste of electrical

and electronic equipment must not be

disposed as unsorted municipal waste

and must be collected separately.

Please contact an authorized

representative of the manufacturer for

information concerning the

decommissioning of equipment.

This product consists of devices that

may contain mercury, which must be

recycled or disposed of in accordance

with local, state, or country laws.

(Within this system, the backlight

lamps in the monitor display contain

mercury.

Authorized representative in the

European Community

GOST R Russian certification

1-6 M1145956

Page 17

Typeface conventions used

Names of hard keys on the display and modules are written in bold

typeface; for example,

Menu items are written in bold italic typeface; for example, Vent

Setup.

Messages that are displayed on the screen are enclosed in single

quotes; for example, ‘Check sample gas out.’

When referring to different sections and other documents, the names

are written in italic typeface and enclosed in double quotes; for

example, “System Controls and Menus.”

Abbreviations

Abbreviation Definition

A

AA Anesthetic agent

ABS Advanced breathing system

ACGO Auxiliary Common Gas Outlet

AGSS Anesthesia Gas Scavenging System

Alt O2 Alternate O2

APL Adjustable pressure-limiting

APN Apnea

1 Introduction

Normal Screen.

C

CGO Common Gas Outlet

CO2 Carbon dioxide

Compl Compliance

E

ET End-tidal concentration

EtCO2 End-tidal carbon dioxide

EtO2 End-tidal oxygen

Exp Expiratory

F

FI Fraction of inspired gas

FiCO2 Fraction of inspired carbon dioxide

FI-ET Difference between inspiratory and expiratory

concentrations

FiO2 Fraction of inspired oxygen

F-V Flow-volume loop

M1145956 1-7

Page 18

Avance

Abbreviation Definition

I

I:E Inspiratory-expiratory ratio

Insp Inspiratory

Insp Pause Inspriatory pause time

M

MAC Minimum Alveolar Concentration

MV Minute volume

MVexp Expired minute volume

MVinsp Inspired minute volume

N

N2O Nitrous oxide

O

O2 Oxygen

P

Pair Air supply pressure

Paux Auxiliary pressure

Paw Airway pressure

PCV Pressure controlled ventilation

PCV-VG Pressure controlled ventilation - volume guaranteed

PEEP Positive end expiratory pressure

PEEPe Extrinsic positive end expiratory pressure

Pexp Expiratory pressure

P-F Pressure-flow loop

Pinsp Inspiratory pressure

Plimit High pressure limit

Pmax Maximum pressure

Pmean Mean pressure

PO2 Oxygen supply pressure

Ppeak Peak pressure

Pplat Plateau pressure

Psupp Support pressure

PSV Pressure supported ventilation

PSVPro Pressure supported ventilation with apnea backup

P-V Pressure-volume loop

R

Rate Respiratory rate

Raw Airway resistance

RR Respiratory rate

1-8 M1145956

Page 19

1 Introduction

Abbreviation Definition

S

SIMV/PSV Synchronized intermittent mandatory ventilation with

pressure supported ventilation

SIMV-PC Synchronized intermittent mandatory ventilation -

pressure controlled

T

TV Tidal volume

TVexp Expired tidal volume

TVinsp Inspired tidal volume

V

VCO2 Carbon dioxide production

VCV Volume controlled ventilation

Vol Volume

M1145956 1-9

Page 20

Avance

1-10 M1145956

Page 21

2 System Controls and Menus

WARNING Do not use antistatic or electrically-conductive breathing

tubes or masks. They can cause burns if used near highfrequency surgical equipment.

w Explosion Hazard. Do not use this system with flammable

anesthetic agents.

In this section System overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Advanced breathing system (ABS) components . . . . . . . . . 2-5

Vaporizer controls. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Display controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

Anesthesia system display . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

Using menus. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

M1145956 2-1

Page 22

Avance

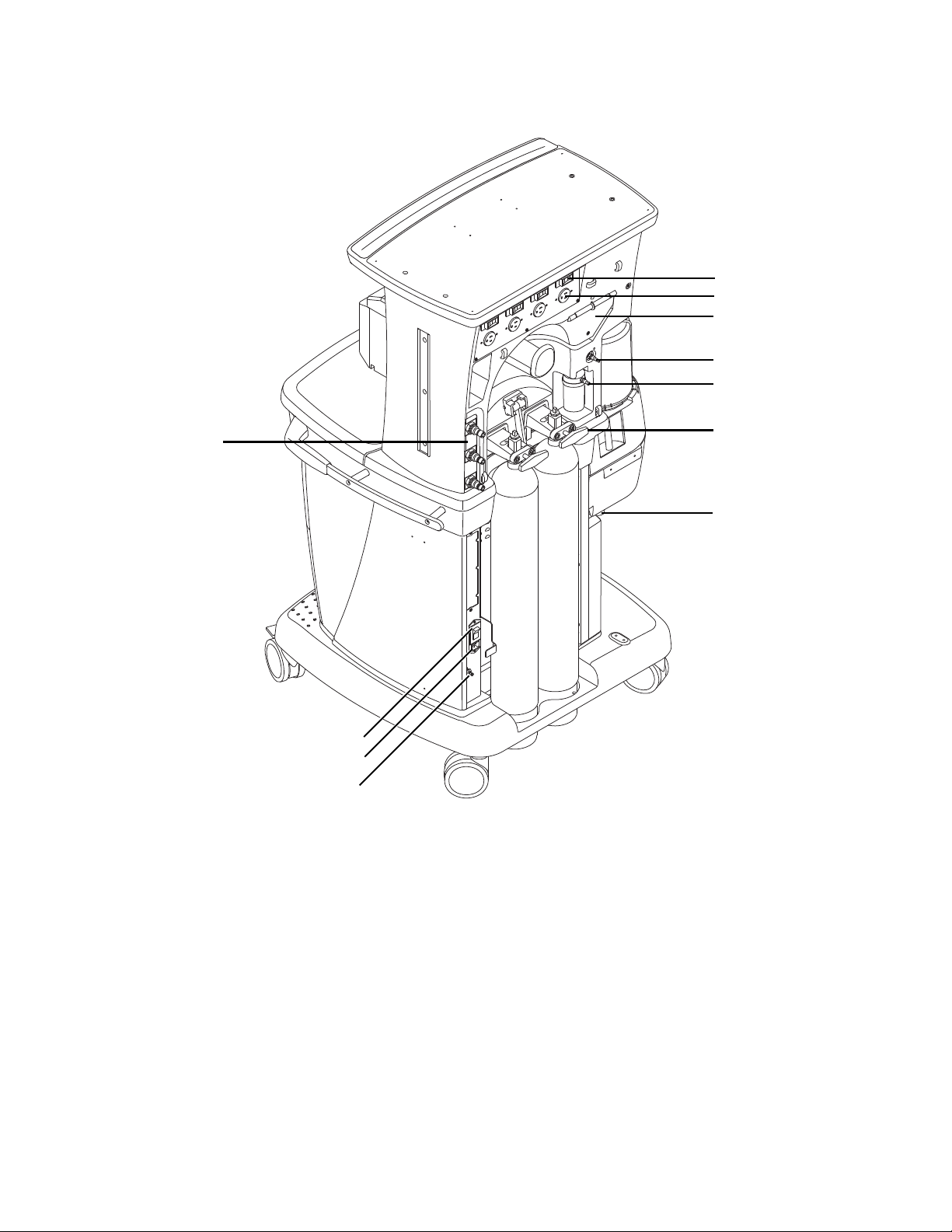

AB.91.111

1

2

3

4

5

6

7

8

9

10

12

11

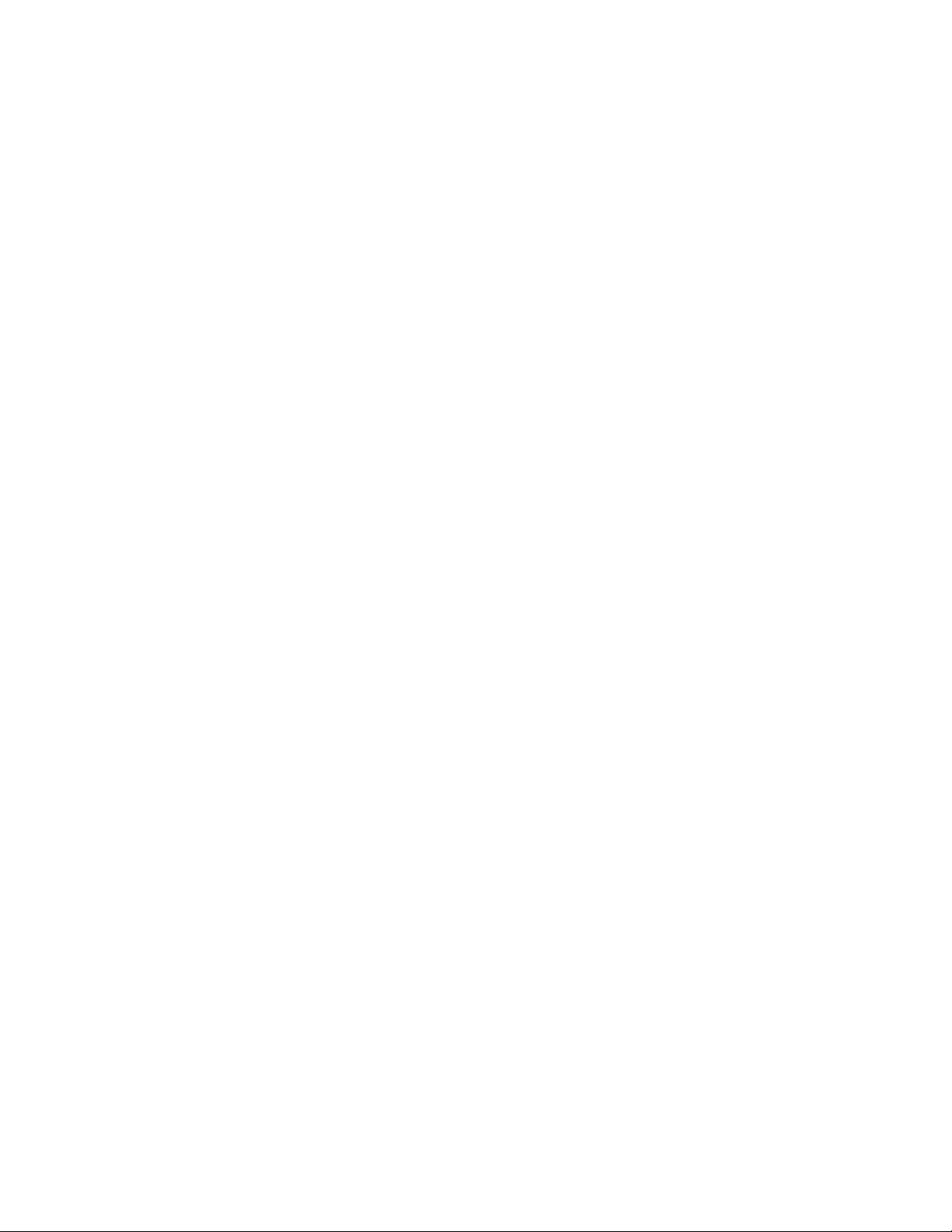

System overview

1. Light switch 7. Integrated suction (optional)

2. Dovetail 8. Brake

3. Vaporizer 9. O2 flush button

4. Alternate O2 control 10. Advanced breathing system

5. System switch 11. Auxiliary O2 flow control (optional)

6. Mains indicator 12. Anesthesia display

Figure 2-1 • Front view

2-2 M1145956

Page 23

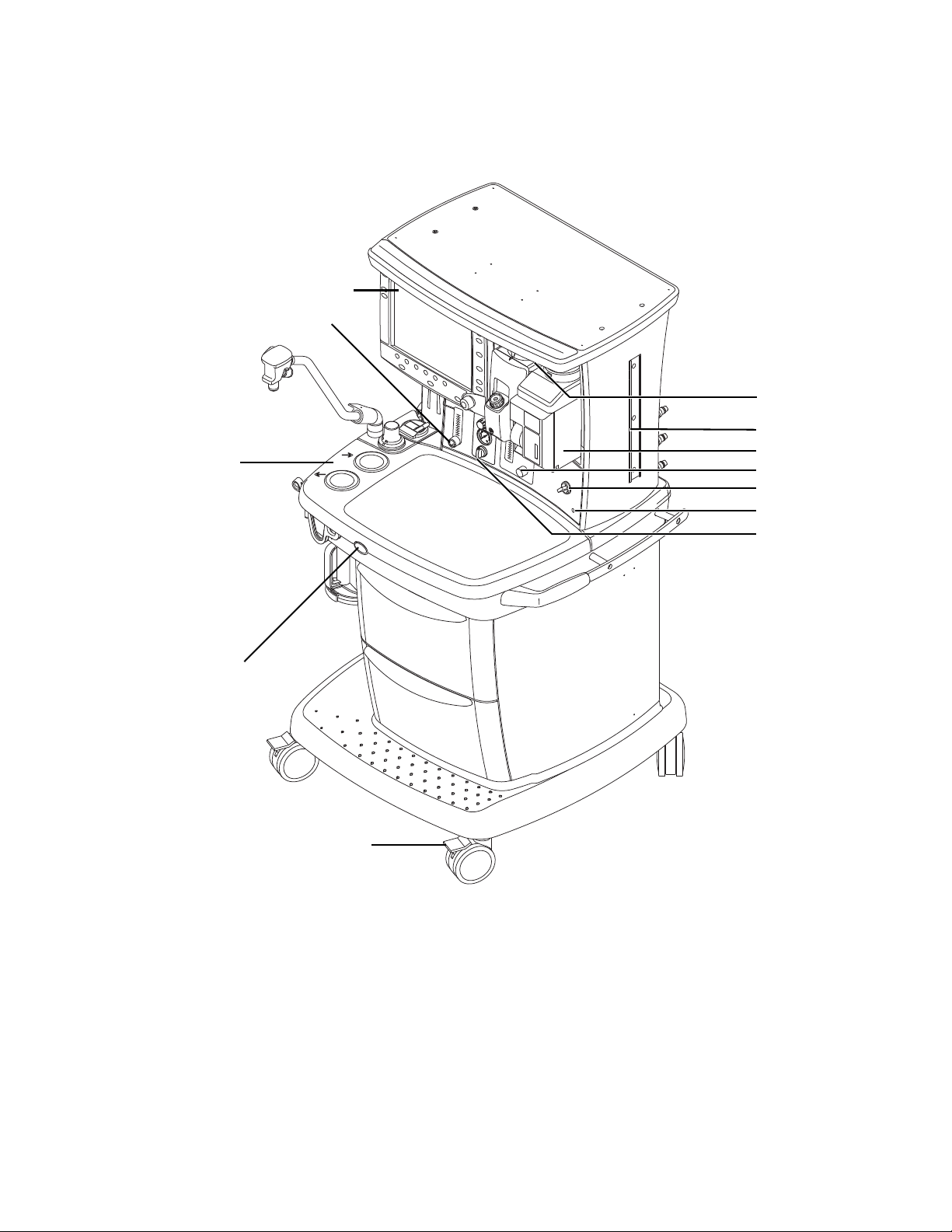

2 System Controls and Menus

Item, Figure 2-1 Description

4 Alternate O2 control Alternate O2 control activates automatically in the case of certain failures or errors. It

can also be activated manually by pushing the Alternate O2 control button if the display

fails. Turn the knob counterclockwise to increase the flow. Turn the knob clockwise to

decrease the flow. See “Alternate O2 control” in the Operation section.

5 System switch Set the switch to the On (|) position to permit gas flow and to turn on the system.

6 Mains indicator The mains indicator will come on when AC power is connected.

7 Integrated suction

(optional)

Turn the switch to MAX for full vacuum. Turn the switch to Off (0) for no vacuum. Turn

the switch to On (|) for adjustable vacuum. When in adjustable vacuum, turn the knob

clockwise to increase the vacuum and counterclockwise to decrease the vacuum.

8 Brake Push down to lock. Lift to release.

9 O2 flush button Push the O2 flush button to supply high flows of O2 to the breathing system.

11 Auxiliary O2 flow

control (optional)

Turn the knob counterclockwise to increase the flow. Turn the knob clockwise to

decrease the flow.

M1145956 2-3

Page 24

Avance

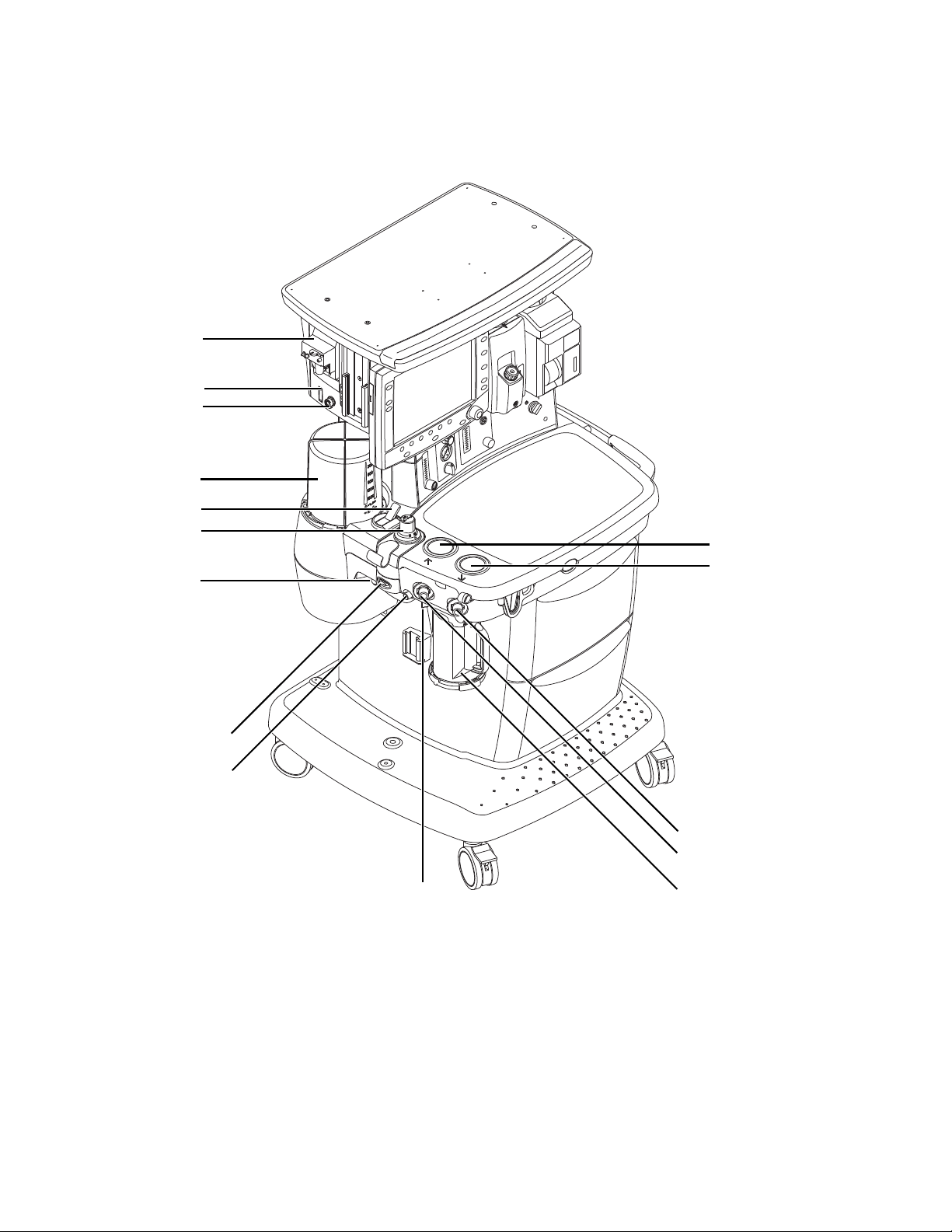

AB.91.029

1

2

3

4

5

6

7

8

9

10

11

1. Outlet circuit breaker 7. AGSS (Anesthesia Gas Scavenging System)

2. Isolated electrical outlet (optional) 8. Equipotential stud

3. Cable access door 9. Mains inlet

4. Vacuum connection 10. System circuit breaker

5. Collection bottle connection 11. Pipeline connections

6. Cylinder yoke

Figure 2-2 • Rear view

2-4 M1145956

Page 25

2 System Controls and Menus

AB.91.110

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

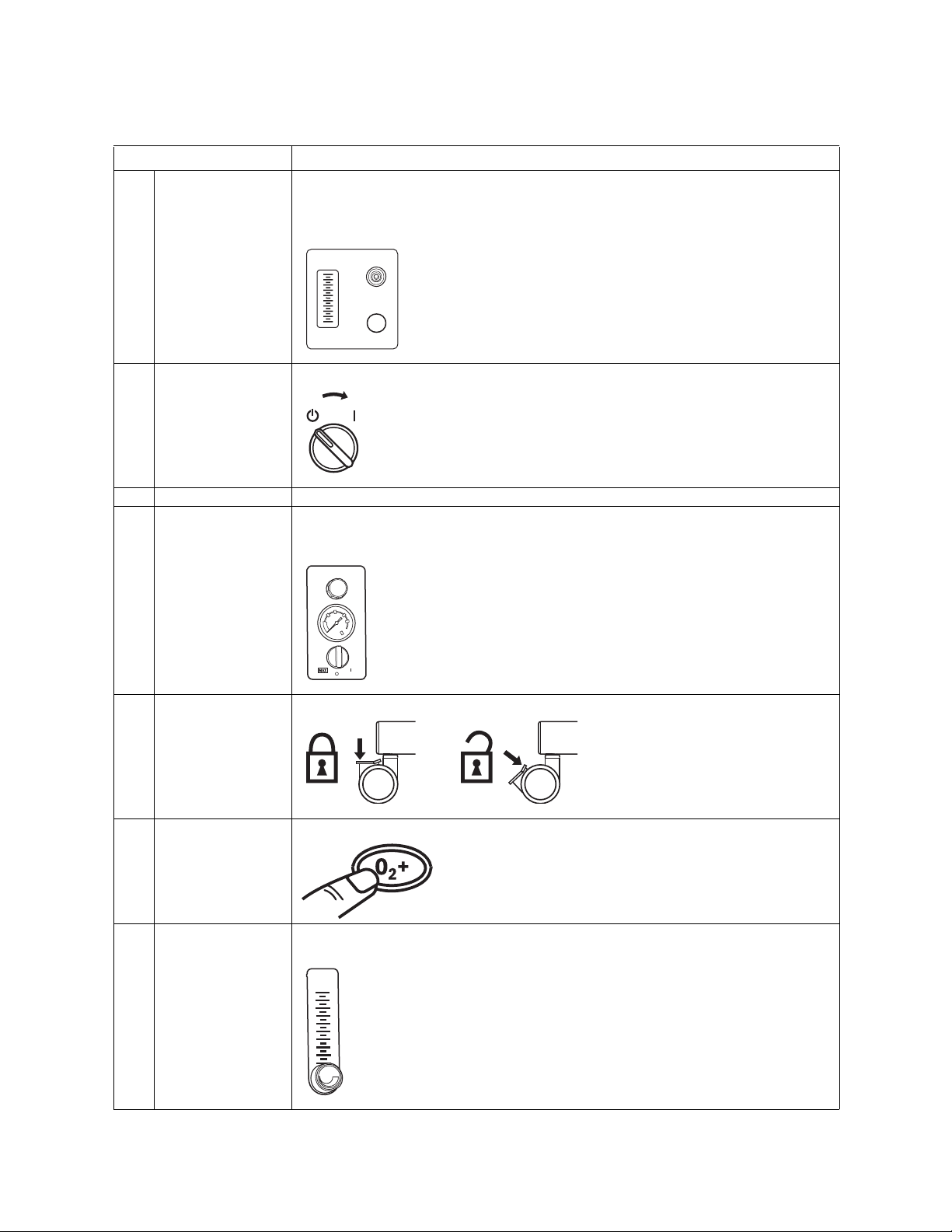

Advanced breathing system (ABS) components

1. Expiratory check valve 9. Manual bag port

2. Inspiratory check valve 10. Adjustable pressure-limiting (APL) valve

3. Inspiratory flow sensor 11. Bag/Vent switch

4. Expiratory flow sensor 12. Bellows assembly

5. Absorber canister 13. Sample gas return port

6. Absorber canister release 14. AGSS indicator (only on some AGSS versions)

7. Leak test plug 15. Airway module (optional)

8. Breathing system release

Figure 2-3 • Advanced breathing system

M1145956 2-5

Page 26

Avance

20

30

70

M

I

N

Item, Figure 2-3 Description

3, 4 Inspiratory flow sensor

Expiratory flow sensor

6 Absorber canister release Push to remove the canister. This causes the breathing system to vent to

Flow sensors provide volume measurements for some monitoring

functions and tidal volume delivery.

the room (unless the EZchange canister option is installed). Be sure to hold

the canister by the handle before releasing the canister.

10 Adjustable pressure-limiting

(APL) valve

Adjusts breathing system pressure limit during manual ventilation. The

scale shows approximate pressures. Above 30 cmH2O, the knob will click

as it turns.

11 Bag/Vent switch Selects between manual ventilation (bag) or mechanical ventilation

(ventilator).

2-6 M1145956

Page 27

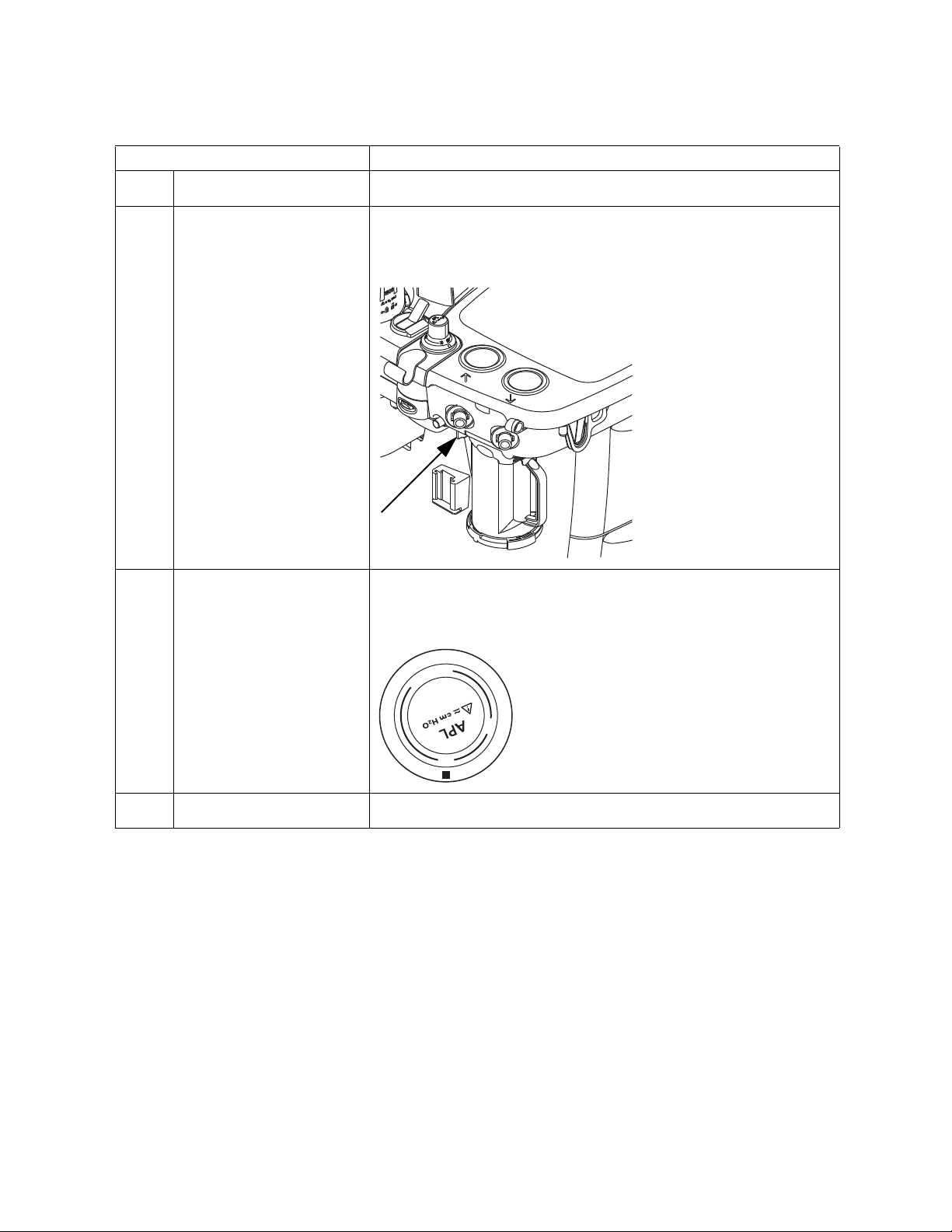

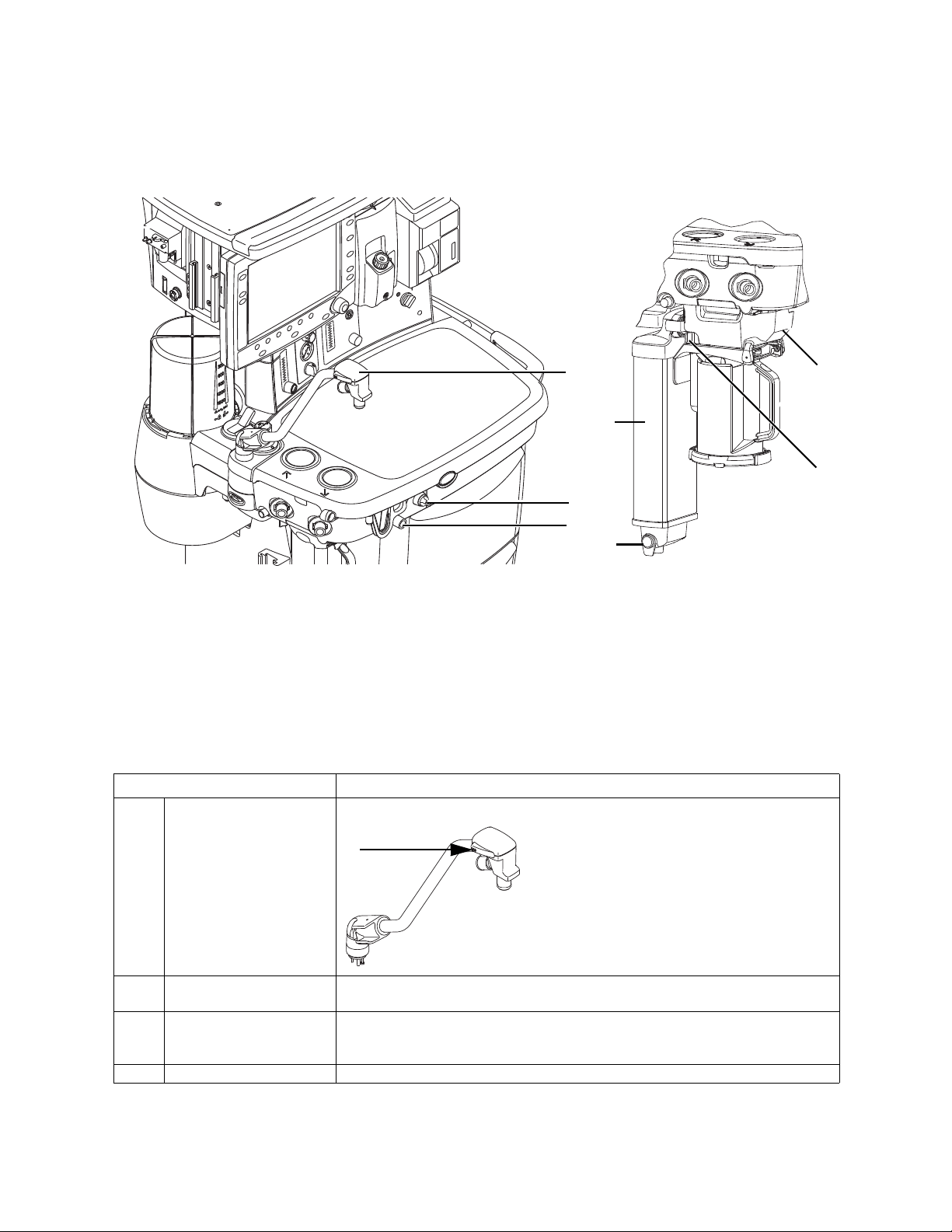

Optional ABS

AB.91.109

AB.82.043

1

2

3

4

5

6

7

components

2 System Controls and Menus

1. Bag support arm

2. Auxiliary Common Gas Outlet (ACGO) switch

3. ACGO port

4. EZchange canister module (CO2 bypass)

5. EZchange canister release

6. Condenser drain button

7. Condenser

Figure 2-4 • Breathing system options

Item, Figure 2-4 Description

1 Bag support arm Squeeze the button to raise or lower the arm.

2 Auxiliary Common Gas

Outlet (ACGO) switch

5 EZchange canister

release

6 Condenser drain button Push to drain water out of the condenser.

Set switch to ACGO position for fresh gas to flow through the ACGO port. The

ACGO may be used to provide fresh gas to an auxiliary manual breathing circuit.

Push to drop the canister to EZchange position. This seals the breathing circuit,

permitting continued ventilation and rebreathing of exhaled gases. Be sure to

hold the canister by the handle before releasing the canister.

M1145956 2-7

Page 28

Avance

Non-circle circuit Fresh gas flow is diverted around the inspiratory check valve and out

through the inspiratory port when non-circle ventilation is selected.

This fresh gas source may be used with circuits without CO2

absorbent capability (for example, Mapleson variants). Mechanical

ventilation is not available when using the non-circle circuit. Tidal

volume monitoring is not available.

O2 monitoring of fresh gas is available automatically when using the

non-circle circuit if the system has the airway module option or the O2

cell monitoring option.

Fresh gas oxygen concentration is displayed on the screen. Set the

alarm limits appropriately. Note that fresh gas oxygen concentration

may not reflect FiO2 when using these types of circuits. Use an

external O2 monitor when using a rebreathing circuit with the noncircle circuit.

Systems with both an airway module and an O2 cell will display the

circuit O2 value obtained from the airway module.

Do not use an external ventilator when using the non-circle circuit. Do

not use the non-circle circuit to drive external ventilators or for jet

ventilation.

WARNING The maximum pressure at the non-circle circuit can be up

to 27 kPa (4 psi). Use a breathing circuit with pressure

relief.

2-8 M1145956

Page 29

2 System Controls and Menus

ACGO (optional) Fresh gas flow is directed through the Auxiliary Common Gas Outlet

(ACGO) on the front of the machine when the ACGO switch is in the

ACGO position. Mechanical ventilation is not available when

operating an auxiliary manual breathing circuit with fresh gas from the

ACGO. The Bag/Vent switch, APL valve, and bag arm are not part of

the external circuit. Volume and pressure monitoring are not

available.

O2 monitoring of fresh gas is available automatically when the ACGO

is selected if the system has the airway module option or the O2 cell

monitoring option. A sample of the fresh gas is diverted to the O2 cell

in the breathing system. The sample flow to the O2 cell is dependent

on the pressure in the external circuit. The sample flow reduces the

fresh gas flow rate to the auxiliary breathing circuit equal to the

amount diverted to the O2 cell.

Fresh gas oxygen concentration is displayed on the screen. Set the

alarm limits appropriately. Note that fresh gas oxygen concentration

may not reflect FiO2 during spontaneous breathing or in rebreathing

circuits. Use an external O2 monitor if using a rebreathing circuit on

ACGO.

Systems with both an airway module and an O2 cell will display the

circuit O2 value obtained from the airway module.

Do not use an external ventilator on the ACGO. Do not use the ACGO

to drive external ventilators or for jet ventilation.

WARNING The maximum pressure at the ACGO can be up to 55 kPa

Scavenging the

ACGO sample flow

(8 psi). Use a breathing circuit with pressure relief.

A sample of the fresh gas is diverted to the airway module or the O2

cell in the breathing system to show the O2 numerics on the screen.

This sample flow should be scavenged when an auxiliary manual

breathing circuit is used with N2O or volatile anesthetics. If

scavenging is not connected, the sample flow is emptied into the

room. To connect the scavenging:

1. Attach a circle breathing circuit to the inspiratory and expiratory

ports.

2. Occlude the breathing circuit by connecting the Y-piece to the

leak test plug located behind the expiratory port.

3. Check for clinically correct settings.

4. Check the position of the Bag/Vent switch.

• If the Bag/Vent switch is set to mechanical ventilation mode,

the bellows fills slowly with the sample flow. When the

bellows is full, the sample flow goes to the AGSS.

(Mechanical ventilation does not start when the ACGO switch

is set to ACGO.)

• If the Bag/Vent switch is set to the bag mode, set the APL

valve to MIN, and attach a bag. The bag fills slowly with the

sample flow. When the bag is full, the sample flow goes to the

AGSS.

M1145956 2-9

Page 30

Avance

Scavenging from an

auxiliary manual

breathing circuit

Scavenging a gas

monitor sample flow

Scavenge the exhaust if an auxiliary manual breathing circuit is used

with N2O or volatile anesthetics.

An auxiliary inlet is available for active and passive AGSS units. It

provides a female connection with 30 mm - 30 mm male connector

(or a 30 mm -19 mm male connector) into the auxiliary port under the

breathing system. Do not use these connectors as an outlet for

exhaust flow.

The auxiliary inlet is a convenience inlet to the air brake of active

AGSS units. There is a reservoir to capture exhaust flows higher than

the extract flow.

A separate exhaust hose is needed from the auxiliary manual

breathing circuit to the disposal point for all AGSS units.

Sample gas from a gas monitor can be scavenged using the sample

gas return port or the AGSS.

• To scavenge from a gas monitor using the sample gas return

port, connect the tubing from the monitor to the sample gas return

port.

• To scavenge from a gas monitor using the AGSS, connect tubing

from the monitor to the male luer inlet on the bottom of the AGSS

underneath the breathing system.

2-10 M1145956

Page 31

Vaporizer controls

AB.80.009

AA.43.051

33

4

4

5

6

12

2 System Controls and Menus

Refer to the vaporizer User’s Reference manual for more detailed

information on the vaporizer.

1. Tec 6 Plus

2. Tec 7

3. Lock lever

4. Concentration control and release

5. Indicators (Tec 6 Plus)

6. Silence alarm touch key (Tec 6 Plus)

Figure 2-5 • Vaporizer controls

M1145956 2-11

Page 32

Avance

Åben

Item, Figure 2-5 Description

3 Lock lever Turn the lever fully clockwise to lock the vaporizer in position.

4 Concentration control and

release

Push the release and turn the concentration control to set the agent

concentration. The Tec 6 Plus concentration control does not turn as long

as the warm-up indicator is on.

5 Indicators (Tec 6 Plus) All indictors come on briefly at the start. The warm-up indicator goes off

after approximately 10 minutes and the operational indicator comes on.

Other indicators come on to advise the user of required action.

6 Silence alarm touch key

(Tec 6 Plus)

Push to silence alarms. Hold for 4 seconds to sound the speaker and light

all indicators (alarm test).

2-12 M1145956

Page 33

Display controls

AB.91.107

1

2

3

42

6

5

7

8

2 System Controls and Menus

1. Silence Alarms key Push to silence any active, silenceable high and medium priority alarms or to

suspend/acknowledge any non-active medium or high priority alarms. Alarm is

silenced for 120 seconds or alarm is suspended for 90 seconds.

2. Menu keys Push to show corresponding menu.

3. ComWheel Push to select a menu item or confirm a setting. Turn clockwise or counterclockwise

4. Normal Screen key Push to remove all menus from the screen.

5. Quick keys Push to change corresponding gas setting or ventilator setting. Turn the ComWheel

6. Timer keys Push to start or stop the timer. Push to reset the timer back to zero.

7. MV/TV Alarms key Push to turn off the MV and TV alarms. Push again to turn the MV and TV alarms on.

8. Alarm LEDs Turn on solid or flash to indicate alarm priority.

to scroll menu items or change settings.

to make a change. Push the ComWheel to activate the change.

Figure 2-6 • Display controls

M1145956 2-13

Page 34

Avance

Measured

l/min

Air

O2

Plug in power

cable. On

battery.

Paw

Agent

CO2

Fresh Gas: O2+Air PCV-VG: Ventilator On Exp Flow

O2

%

Total Flow

l/min

TV

ml

RR

/min

I:E PEEP

cmH2O

MV l/min

TVexp ml

Pmean

Ppeak

cmH2O

PEEP

RR /min

Et %

Fi %

MAC 40

FiO2 %EtO2 %

1

23

45 6

7

8

9101112

AB.91.125

Timer:

EtCO2 %s

FiCO2 %s

Off

Anesthesia system display

1. Split screen area showing electronic gas flow indicators

2. Alarm silence symbol and countdown

3. Alarm message fields

4. Waveform fields

5. General message field or timer field

6. Clock

7. Battery indicator field

8. Measured values field

9. Pipeline and cylinder supply or respiratory data or digit field

10. Ventilator settings

11. Ventilation mode

12. Gas settings

Figure 2-7 • Normal view

2-14 M1145956

Page 35

2 System Controls and Menus

Fresh Gas: O2+Air PCV-VG: Ventilator On Exp Flow

O2

%

Total Flow

l/min

TV

ml

RR

/min

I:E PEEP

cmH2O

MV l/min

TVexp ml

Pmean

Ppeak

cmH2O

PEEP

RR /min

Et %

Fi %

MAC 40

FiO2 %EtO2 %

AB.91.124

EtCO2 %s

FiCO2 %s

Off

Main Menu

Trends

System Status

Cardiac Bypass

Off

Fresh Gas Usage

Screen Setup

Parameters Setup

Calibration

Normal Screen

Show trends.

2

1

When a menu key is selected, the menu field overlays the gas flow

indicators and the waveform fields start at the right edge of the menu.

1. Menu

2. Waveform fields

Figure 2-8 • Menu view

M1145956 2-15

Page 36

Avance

Waveform fields Up to three waveforms can be shown on the normal screen view.

Each waveform can be set to show specific information such as Paw,

agent, flow, or CO2 data. The corresponding numeric information

shows in the measured values field to the right of the waveform. If the

waveform is set to show the agent and no airway module is inserted,

that waveform and numeric areas are blank.

When one waveform is turned off, that waveform and the

corresponding numerics information are removed from the normal

screen view. The remaining waveforms and numerics increase in size

to fill the waveform area. When two waveforms are turned off, those

waveforms and the corresponding numerics information are removed

from the normal screen view. The remaining waveform increases in

size and is centered in the waveform area.

See “Screen configuration” in the “Operation” section for more

information.

Digit field The digit field can be set to show specific information such as gas

supply, flow, or agent. If the digit field is set to show agent and no

airway module is inserted, the area is blank.

Paw, O2, and either TVexp or CO2 must show on the display during a

case. If any of these parameters is not selected to show on the

display, the digit field information is replaced with the missing

parameter.

See “Screen configuration” in the “Operation” section for more

information.

2-16 M1145956

Page 37

Using menus

AB.91.126

Main Menu

Trends

System Status

Cardiac Bypass

Fresh Gas Usage

Screen Setup

Parameters Setup

Calibration

On

On

Off

On suspends the volume, apnea, low

agent, and low CO2 alarms.

Normal Screen

1

2

3

4

5

6

2 System Controls and Menus

Push a menu key to display the corresponding menu. Use the

ComWheel to navigate the menu.

1. Menu title

2. Current selection

3. Adjustment window

4. Submenu

5. Instructions or help information

6. Menu items

Figure 2-9 • Menu example

1. Push the menu key to display the corresponding menu.

2. Turn the ComWheel counterclockwise to highlight the next menu

item. Turn the ComWheel clockwise to highlight the previous

menu item.

3. Push the ComWheel to enter the adjustment window or a

submenu.

4. Turn the ComWheel clockwise or counterclockwise to highlight

the desired selection.

5. Push the ComWheel to confirm the selection.

6. Select Normal Screen or push the

Normal Screen key to exit

the menu and return to the normal monitoring display. (Select

Previous Menu to return to the last displayed menu, if available.)

M1145956 2-17

Page 38

Avance

2-18 M1145956

Page 39

3 Operation

WARNING Ventilator alarms indicate potential hazard conditions. All

alarms that occur should be investigated to help ensure

adequate patient safety.

w Maintain sufficient fresh gas flow when using sevoflurane.

w Desiccated (dehydrated) absorbent material may produce

dangerous chemical reactions when exposed to inhalation

anesthetics. Adequate precautions should be taken to

ensure that absorbent does not dry out. Turn off all gases

when finished using the system.

In this section Turning on the system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Start case (start gas flow) . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

End case. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Ventilator setup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Gas setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Spirometry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Spirometry setup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

Main Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

Screen configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-20

Alarm setup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-23

Alternate O2 control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-26

EZchange canister (optional) . . . . . . . . . . . . . . . . . . . . . . . 3-27

Condenser (optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-28

Passive AGSS (optional) . . . . . . . . . . . . . . . . . . . . . . . . . . 3-29

Active AGSS (optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-30

M1145956 3-1

Page 40

Avance

1

2

AB.91.044

Turning on the system

1. Plug the power cord into an electrical outlet. Make sure the

system circuit breaker is on.

• The mains indicator is lit when AC power is connected.

• Battery is charging if it is not already fully charged.

1. System switch

2. Mains indicator

Figure 3-1 • Mains indicator and system switch

2. Check that the breathing system is properly connected.

CAUTION Do not turn on the system with the right-hand (inspiratory)

port plugged.

3. Turn the System switch to On.

• The display shows the power-up screen.

• The system does a series of automated self tests.

4. Perform a Machine Check before the first case of the day.

5. Perform a preoperative checkout before each case. See the

“Preoperative Checkout” section.

Note The system must perform a power-up self test after 12 hours of

remaining on. If the system has been on longer than 12 hours without

a power-up self test, the ‘Turn power Off and On for self tests’ alarm

occurs. Turn the power off and then back on between cases to

resolve the alarm.

3-2 M1145956

Page 41

Start case (start gas flow)

Access the Start Case menu by pushing the Start/End Case key or

by selecting Start Case from the Checkout menu. Use the Start

Case menu to set the case data and to start the gas flow.

Default Settings

Set Vent By Weight

Start Case Now

The Default Settings has five selections. The first four selections are

case types. The fifth selection is Last Case. The case type in the first

slot shows as the default when the Start Case menu is opened.

Case types are configured in the Install/Service - Case Defaults

menu. The Install/Service menu is only accessible by a Super User

or a service person. See the “Super User Mode” section for more

information on the Start Case menu defaults.

3 Operation

Start Case

Patient Weight

Patient Age

Other Gas

CO2 Alarms

Volume Apnea

The values of Patient Weight, Patient Age, Other Gas, and Volume

Apnea are configured to the default case type by the Super User.

CO2 Alarms setting is set to ‘On’ when the Start Case menu is

opened.

Note Volume Apnea is not shown on the Start Case menu when the

Volume Apnea Selection is set to Disable in the Install/Service

menu.

The Set Vent By Weight menu item is accessible when the

ventilation mode is set to VCV or PCV-VG. Use this setting for breath

rate and tidal volume calculations based on the set patient weight.

The Default Settings selection shows ‘Weight’ when Set Vent By

Weight is selected.

M1145956 3-3

Page 42

Avance

Using default

settings

Using customized

settings

1. Set the Bag/Vent switch to Bag.

2. Push the

• The case defaults are shown on the menu.

•The Default Settings selection shows the preset case type.

3. Verify or change the settings on the Start Case menu.

4. Select Start Case Now. Gas flow starts.

The case type, ventilator settings, ventilation mode, alarm settings,

and gas settings can be changed before starting a case. Use the

Vent Setup menu, Alarm Setup menu, or Gas Setup menu to

change settings not shown on the Start Case menu before starting a

case. Return to the Start Case menu from these menus to make

additional adjustments or to start a case.

1. Set the Bag/Vent switch to Bag.

2. Push the

3. Verify or change the settings on the Start Case menu.

• Select a case type or Last Case from the Default Settings.

• Make adjustments to the other settings as appropriate for the

•The Default Settings selection changes to show ‘Preset’ if

4. To change the alarm settings:

• Push the

•Select Adjust Settings.

• Change the settings.

•Select Back.

• Make any other changes to the alarm setup.

•Select Previous Menu to return to the Start Case menu to

5. To change ventilator settings:

• Push the

•Select Adjust Settings.

• Change the settings.

•Select Exit to return to the Start Case menu.

6. To change the ventilation mode:

• Push the

• Select the desired mode.

•Select Confirm or adjust the settings and select Confirm to

Start/End Case key.

Start/End Case key.

case.

any changes to the settings are made.

Alarm Setup key.

make additional adjustments.

Vent Setup key.

Vent Setup key.

return to the Start Case menu.

3-4 M1145956

Page 43

3 Operation

7. To change the gas settings:

• Push the

•Select Adjust Settings.

• Change the settings.

•Select Exit to return to the Start Case menu.

8. To change the balance gas:

• Push the

• Select the balance gas to use with O2.

•Select Exit or adjust the settings and select Exit to return to

the Start Case menu.

9. To change the circuit type:

• Push the

• Select the circuit type.

•Select Confirm or adjust the settings and select Confirm to

return to the Start Case menu.

10. From the Start Case menu, select Start Case Now. Gas flow

starts.

Gas Setup key.

Gas Setup key.

Gas Setup key.

Minimum Alveolar

Concentration (MAC)

The adjusted Minimum Alveolar Concentration (MAC) is calculated

based on the patient age entered in the Start Case menu. The

default patient age of selected case type is used if no patient age is

entered.

The MAC value is calculated from the exhaled gas concentration and

the related affects based on the age of the patient. Typically, younger

patients have better liver function and can clear a drug faster,

resulting in a higher MAC value. The MAC calculation used is based

on the Eger formula. When two agents are detected, the MAC values

of each agent are added together. The MAC value range is 0.0 to 9.9.

The adjusted MAC value shows on several areas of the screen

including in the mini-trend, agent waveform numeric information,

gases digit field, and graphical trends page. MAC data shows as

dashes if there is not an airway module installed in the module bay.

M1145956 3-5

Page 44

Avance

End case

Use the End Case menu to stop gas flow and end the patient alarms.

End Case

End Case Now

Normal Screen

1. Set the Bag/Vent switch to Bag.

2. Push the

Start/End Case key.

3. Select End Case Now to put the system in standby (stops gas

flow and patient alarms).

3-6 M1145956

Page 45

Ventilator setup

3 Operation

Access the Vent Setup menu by pushing the Vent Setup key. The

system has up to six modes of mechanical ventilation:

• Volume Control Ventilation (VCV).

• Pressure Control Ventilation (PCV) (optional).

• Synchronized Intermittent Mandatory Ventilation/Pressure

Support (SIMV/PSV) (optional).

• Pressure Support Ventilation (PSVPro) (optional).

• Synchronized Intermittent Mandatory Ventilation-Pressure

Control (SIMV-PC) (optional).

• Pressure Control Ventilation-Volume Guarantee (PCV-VG)

(optional).

Ven t Setup

Adjust Settings

Mode:

VCV

PCV

Spirometry

Normal Screen

WARNING Most anesthetic agents will cause patients to have

reduced ventilatory responses to carbon dioxide and to

hypoxemia. Therefore, triggered modes of ventilation may

not produce adequate ventilation.

w The use of neuromuscular blocking agents will reduce the

patient’s breathing response, which will interfere with

triggering.

Important Refer to the “Specifications and Theory of Operation” section for

more information on ventilation modes.

Using quick keys The four main ventilator settings for each mode can easily be

changed using the ventilator quick keys.

1. Push a ventilator quick key to select the corresponding ventilator

setting.

2. Turn the ComWheel to make a change.

3. Push the ComWheel to activate (confirm) the change.

M1145956 3-7

Page 46

Avance

Using Vent Setup

menu

Changing ventilator modes and settings

1. Push the Vent Setup key.

• Adjust Settings is selected by default.

• An arrow to the right of the mode indicates the current mode.

2. Push the ComWheel to enter the adjustment window for the

selected mode.

3. Use the ComWheel to navigate the adjustment window and to

change a value.

4. Push the ComWheel to activate the change.

5. Push the

1. Push the Vent Setup key.

2. Select the mode and push the ComWheel to enter the adjustment

window.

3. Use the ComWheel to navigate the adjustment window and to

change a value.

4. Select Confirm to activate the mode.

Normal Screen key or select Exit.

3-8 M1145956

Page 47

Gas setup

3 Operation

Access the Gas Setup menu by pushing the Gas Setup key. Use

the Gas Setup menu to adjust the O2% and total flow, to change the

balance gas, and to change the circuit type.

Gas Setup

Adjust Settings

Gas:

N2O

Air

Circuit:

Circle

Non-Circle

Normal Screen

Using quick keys The O2% and total flow can easily be changed using the gas quick

keys.

1. Push a gas quick key to select the corresponding gas setting.

2. Turn the ComWheel to make a change.

3. Push the ComWheel to activate (confirm) the change.

Using Gas Setup

menu

Changing gas and

settings

1. Push the Gas Setup key.

• An arrow to the right of the balance gas indicates the gas

currently being used with O2.

• Adjust Settings is selected by default.

2. Push the ComWheel to enter the adjustment window.

3. Use the ComWheel to navigate the adjustment window and

change a value.

4. Push the ComWheel to activate the change.

5. Push the

1. Push the Gas Setup key.

2. Select the balance gas to use with O2 and push the ComWheel

to enter the adjustment window.

Normal Screen key or select Exit.

3. Use the ComWheel to navigate the adjustment window and

change a value.

4. Push the ComWheel to activate the change.

5. Push the

M1145956 3-9

Normal Screen key or select Exit.

Page 48

Avance

Changing circuit type 1. Push the Gas Setup key.

• Adjust Settings is selected by default.

• An arrow to the right of the circuit type indicates the circuit

currently in use.

2. Use the ComWheel to select Circle or Non-Circle and enter the

adjustment window.

3. Confirm or change and confirm the settings.

4. Push the

Normal Screen key or select Exit.

3-10 M1145956

Page 49

Spirometry

3 Operation

There are three types of spirometry loops: Pressure-Volume (P-V),

Flow-Volume (F-V) and Pressure-Flow (P-F). View, save, and erase

spirometry loops and set the loop scaling in the Spirometry menu.

Access the Spirometry menu by pushing the

selecting Spirometry.

Use the Spirometry menu to:

• View a specific loop type; select Loop Type and set the loop

type.

• Adjust the loop scaling; select Scaling and set the scale type.

• Access the Spirometry Setup menu; select Spiro Setup.

• Store a loop to memory; select Save Loop. Up to six loops can

be saved.

• View a saved loop; select Reference Loop and the time at which

the loop was saved.

• Erase a saved loop; select Erase Loop and the time at which the

loop was saved.

Vent Setup key and

Spirometry

Loop Type P-V

Scaling

Spiro Setup

Save Loop

Reference Loop None

Erase Loop None

Previous Menu

M1145956 3-11

Page 50

Avance

AB.98.039

Setting loop type The spirometry loops show in the spirometry window and can be set

to show alongside the waveforms as the split screen.

1. Volume axis

2. Pressure axis

3. Real-time loop

4. Reference loop (appears on display in white)

Figure 3-2 • Example of a P-V loop

To set the loop type:

1. Push the

2. Select Spirometry - Loop Type and set the loop type.

•Set to P-F for Paw-Flow.

•Set to F-V for Flow-Volume.

•Set to P-V for Paw-Volume.

Note The loop type can also be set in the Spirometry Setup menu. Push

the

Main Menu key, and select Parameters Setup - Spirometry

Setup - Loop Type.

Vent Setup key.

3-12 M1145956

Page 51

3 Operation

Scaling The scales shown in the spirometry loop graph are set in the Scaling

menu. The available settings for the volume, Paw, and flow graph

axes are dependent on the set patient type of adult or pediatric.

The AUTO selection automatically adjusts the volume, Paw, and flow

axes of the loop graph based on the minimum and maximum breath

reading shown in the waveform.

The Linked selection links the adjustment of the volume, Paw, and

flow axes of the loop graph together. Change one of the scales and

the remaining two scales automatically change based on the one set

scale.

The Indep selection allows the axes of the loop graph to be changed

separately for the volume, Paw, and flow axes.

Scaling

Scaling AUTO

Vol Scale

Paw Scale

Flow Scale

Previous Menu

1. Push the

2. Select Spirometry - Scaling.

3. Set the scale type to AUTO, Linked, or Indep.

•If AUTO is selected, the scales are automatically set.

•If Linked is selected, set one of the scales volume, Paw, or

•If Indep is selected, set the volume scale, set the Paw scale,

Vent Setup key.

flow. The other two scales adjust based on the set scale.

and set the flow scale.

M1145956 3-13

Page 52

Avance

Spirometry setup

Push the Vent Setup key and select Spirometry - Spiro Setup to

access the Spirometry Setup menu. Use the Spirometry Setup

menu to:

• Set the patient and sensor type.

• Select a data source.

• Set the loop type.

• Change the volume shown on the spirometry split screen to

MVexp or TVexp.

• Set split-screen view.

• Access the Paw and MVexp alarm limits.

Note The Spirometry Setup menu is also accessible through

Setting patient and

sensor type

Main Menu

- Parameters Setup - Spirometry Setup.

Spirometry Setup

Patient and Sensor Type Adult

Data Source Vent

Loop Type P-V

TV or MV TV

Split Screen None

Paw Alarm

MVexp Alarm

Previous Menu

Patient and sensor type refer to the style of airway adapter used with

the airway module. If spirometry data is obtained from the airway

module, ensure that the sensor type matches the airway adapter

used.

If the sensor type is not set correctly, the information displayed may

not be accurate.

1. Push the

2. Select Spirometry.

Vent Setup key.

3. Select Spiro Setup - Patient and Sensor Type.

4. Select Adult or Pedi depending on the sensor used.

• Adult refers to the D-lite sensor.

• Pedi refers to the Pedi-lite sensor.

3-14 M1145956

Page 53

3 Operation

Selecting a data

source

Several monitoring parameters can be obtained from the ventilator or

the airway module.

When setting the airway module as the data source, make sure that a

D-lite or Pedi-lite sensor is properly connected on the airway module.

If the sensor is not properly connected, but the airway module is

installed, the waveform shows no flow. The gas monitor samples and

displays room air.

If information is not available through the airway module, information

comes from the internal ventilator sensors. If the internal ventilator

sensor readings disagree with the airway module sensor readings,

the associated alarm occurs.

Information that is retrieved from the airway module is identified with

the module data indicator. See the “Airway Modules” section for more

information.

Figure 3-3 • Airway module data indicator

Setting spirometry

split screen

1. Push the

2. Select Spirometry.

3. Select Spiro Setup - Data Source.

4. Select Patient or Vent as the primary source for information.

•If Patient is selected, the airway module will be the first

•If Vent is selected, the internal sensors of the ventilator will

5. Push the

Spirometry loops can be viewed alongside the waveforms on the

normal screen. To set up the spirometry split screen:

1. Push the

2. Select Spirometry.

3. Select Spiro Setup.

4. Select Split Screen - Spiro.

5. Push the

Vent Setup key.

source for information.

be the first source for information.

Normal Screen key or select Previous Menu.

Vent Setup key.

Normal Screen key.

M1145956 3-15

Page 54

Avance

Main Menu

Menus and settings available through the Main Menu include

Trends, System Status, Cardiac Bypass, Fresh Gas Usage,

Screen Setup, Parameters Setup, and Calibration.

System Status shows the status of gas supplies, electrical supplies,

and software settings.

See “Screen configuration” for information on the Screen Setup

menu item.

See “Parameters setup” in the “Airway Modules” section for more

information on the Parameters Setup menu item.

See the “User Maintenance” section for more information on

calibrations.

Main Menu

Trends

System Status

Cardiac Bypass Off

Fresh Gas Usage

Screen Setup

Parameters Setup

Calibration

Normal Screen

3-16 M1145956

Page 55

3 Operation

Trends There are three views for patient trends: measured (numerical),

settings, and graphical. Trend information is saved every 1 minute for

the most recent 24 hours.

Tre nds

Cursor

Next Page

View

Measured

Settings

Graphical

Time Scale

Previous Menu

1. Push the

Main Menu key.

2. Select Trends.

3. Select the desired view.

• An arrow indicates the current trend view.

4. Select Cursor to scroll through the current trend view.

5. Push the ComWheel to return the highlight to Cursor.

6. Select Next Page to view additional parameters.

7. Push the

Normal Screen key or select Previous Menu.

M1145956 3-17

Page 56

Avance

Cardiac bypass There are two types of cardiac bypass. Manual ventilation cardiac

bypass is standard. VCV cardiac bypass is optional.

Manual ventilation

cardiac bypass

WARNING Manual ventilation cardiac bypass and VCV cardiac

VCV cardiac bypass

(optional)

Manual ventilation cardiac bypass suspends alarms for patients on

cardiac bypass when the ventilator is not mechanically ventilating.

The volume, apnea, low agent, CO2, and respiratory rate alarms are

suspended. The alarms are enabled when cardiac bypass is turned

off or mechanical ventilation is started.

bypass modes should only be used when the patient is

receiving extra-corporeal oxygenation by means of a

heart-lung machine. These modes of ventilation are not

intended to provide metabolic levels of ventilation to the

patient.

1. Set the Bag/Vent switch to Bag.

2. Push the

3. Set Cardiac Bypass to On.

• The general message ‘Cardiac Bypass’ shows in the

Systems with VCV cardiac bypass enabled can mechanically

ventilate while in VCV mode. The VCV mode is the only ventilation

mode available while using VCV cardiac bypass. The volume, apnea,

low agent, CO2, low Paw, and respiratory rate alarms are suspended.

The alarms are enabled when VCV cardiac bypass is turned off or

mechanical ventilation is stopped.

Main Menu key.

waveforms and in the general message field when manual

ventilation cardiac bypass is active.

WARNING Manual ventilation cardiac bypass and VCV cardiac

bypass modes should only be used when the patient is

receiving extra-corporeal oxygenation by means of a

heart-lung machine. These modes of ventilation are not

intended to provide metabolic levels of ventilation to the

patient.

1. Start mechanical ventilation in VCV mode.

2. Push the

3. Set Cardiac Bypass to On.

• The PEEP is set to 5 cmH2O.

• TV settings of less than 170 ml prior to starting cardiac

• TV settings of more than 170 ml prior to starting cardiac

• PEEP and TV settings can be changed after entering cardiac

4. The general message ‘VCV Cardiac Bypass’ shows in the

waveforms and in the general message field when VCV cardiac

bypass is active.

Main Menu key.

bypass remain at the set TV.

bypass change to 170 ml.

bypass mode.

3-18 M1145956

Page 57

3 Operation

Fresh gas usage Use the Fresh Gas Usage selection to view the volume of O2, Air,

N2O, and agents used for the three most recent cases. Data only

shows for gases available on the system. Agent data shows the three

most recently used agents.

1. Push the

2. Select Fresh Gas Usage.

3. Select the patient case to view.

4. Push the

Main Menu key.

Normal Screen key or select Previous Menu.

M1145956 3-19

Page 58

Avance

Screen configuration

Select page Use the Select Page menu to quickly change or return the normal

Each case type selected on the Start Case menu has a

corresponding screen configuration for the normal screen. Four

additional normal screen views are available through the Select Page

menu. The case type screen configurations and the normal screen

views are set by the Super User in the Install/Service menu.

Areas of the normal screen can be customized to show specific

information. Use the Screen Setup menu to customize the normal

screen view.

screen view to a case type view.

Select Page

Page:

Default Screen

PAW TUBES

LOOPS

BIG WAVE

LOCAL

Normal Screen

1. From the normal screen with no menus showing, push the

ComWheel.

• An arrow to the right of the menu item indicates the page

view that is in use.

• A corresponding message shows in the general message

area.

• If no arrow shows on the Select Page menu, a customized

normal screen view is in use.

2. Select a view or select Normal Screen to leave the selections

unchanged.

3-20 M1145956

Page 59

3 Operation

Screen setup Waveform, digit field, fresh gas control style, split screen, sweep

speed, and brightness are adjusted in the Screen Setup menu.

Changes made to all settings (except Brightness) during a case are

not saved when the case is ended. The set Brightness remains until

it is changed again or until the system power is turned off.

Screen Setup

Waveform Field 1 Paw

Waveform Field 2 Flow

Waveform Field 3 CO2

Digit Field AA

Fresh Gas Controls O2%

Split Screen None

Sweep Speed Fast

Brightness 4

Install/Service

Previous Menu

Waveform fields The waveforms can be set to show agent, CO2, flow, Paw, or can be

set to off. Waveforms cannot be set to the same value (except for off).

If waveform is set to the same value as another waveform, the

previously set waveform changes to off and is removed from the

normal screen

1. Push the

2. Select Screen Setup.

Main Menu key.

3. Select the waveform field and make the change.

4. Push the

Normal Screen key or select Previous Menu.

Digit field The digit field can be set to show gas supply, flow, or agent.

1. Push the

2. Select Screen Setup - Digit Field.

3. Select the Supply, Flow, or AA.

•If AA is selected, an airway module must be inserted or the

4. Push the

Main Menu key.

digit field will be blank.

Normal Screen key or select Previous Menu.

M1145956 3-21

Page 60

Avance

Setting gas controls and

screen configuration

Split screen Gas and agent delivery, trends, spirometry loops, or a Paw gauge

There are two ways to configure gas controls: O2% with total flow or

individual gas flow. The Super User can set the gas control for the

facility. Or the Super User can set the gas control to allow the user to

select the setting.

Selecting O2% shows O2% as the first quick key and total flow l/min

as the second quick key. This gas control configuration adjusts the

balance automatically when either the O2% or the total flow is

changed.

Selecting Flow shows balance gas l/min as the one quick key and O2

l/min as the other quick key. This gas control/screen configuration

allows individual control of the gasses.

1. Push the

2. Select Screen Setup - Fresh Gas Controls.

3. Select the desired view.

4. Push the

can be shown as a split screen alongside the waveforms on the

normal screen. To change the normal screen to show a split screen:

1. Push the

2. Select Screen Setup - Split Screen.

3. Select the desired view.