Page 1

Datex-Ohmeda

AS/3 Compact Monitor, CS/3 Compact Monitor

Technical Reference Manual

Datex-Ohmeda Inc.

3 Highwood Drive

Tewksbury, MA 01876

Tel. (978) 640-0460 Fax (978) 640-0469

www.us.datex-ohmeda.com

All specifications are subject to change without notice.

Document No. 896623

February 2000

Datex-Ohmeda Division,

Instrumentarium Corp.

P.O. Box 900, FIN-00031

DATEX-OHMEDA, FINLAND

Tel. +358 10 394 11 Fax +358 9 146 3310

www.datex-ohmeda.com

Instrumentarium Corp. All rights reserved.

Page 2

NOTICE

Intended purposes

The Datex-Ohmeda AS/3 Compact Monitor is a multiparameter patient monitor intended for the

physiological monitoring of hospitalized patients. It is indicated for monitoring anesthetized patient’s

relaxation, hemodynamic, ventilation, gas exchange, regional perfusion and neurophysiological parameters.

The system is indicated for use by qualified medical personnel only.

The Datex-Ohmeda CS/3 Compact Monitor, CMC, is a multiparameter patient monitor intended for the

physiological monitoring of hospitalized patients. It is indicated for monitoring the patient’s hemodynamic,

ventilation, gas exchange, regional perfusion and central nervous system. The system is indicated for use by

qualified medical personnel only.

The Datex-Ohmeda CS/3 Compact Monitor with S-ICU99/A software is intended for multiparameter patient

monitoring. The monitor is indicated for monitoring of hemodynamic (including arrhythmia and ST-segment

analysis), respiratory, ventilatory, gastrointestinal/regional perfusion and neurophysiological status of all

hospital patients. The system is indicated for use by qualified medical personnel only.

Classifications

In accordance with IEC 60601-1:

Class I and internal powered equipment- the type of protection against electric shock.

Type BF or CF equipment. The degree of protection against electric shock is indicated by a symbol on the

parameter panel beside each connector.

Equipment is not suitable for use in the presence of a flammable anesthetic mixture with air or with oxygen or

nitrous oxide.

Continuous operation according to the mode of operation.

In accordance with IEC 60529:

Degree of protection against the harmful ingress of water as detailed in the IEC 60529: IPX1

In accordance with EU Medical Device Directive: IIb

Responsibility of the manufacturer

Datex-Ohmeda Division, Instrumentarium Corp. is responsible for the safety, reliability and performance of

the equipment only if:

− assembly, operations, extensions, readjustments, modifications, service and repairs are carried out

by personnel authorized by Datex-Ohmeda.

− electrical installation complies with appropriate requirements.

− the equipment is used in accordance with the User’s Guide and serviced and maintained in

accordance with the Technical Reference Manual.

Storage and Transport

For allowed storage and transport conditions refer to the documentation delivered with the monitor.

Trademarks

Datex®, Ohmeda®, and other trademarks AS/3, CS/3, D-lite, Pedi-lite, D-fend, D-fend+, MemCard,

ComWheel, EarSat, FingerSat, FlexSat, PatientO2, Patient Spirometry and Tonometrics are property of

Instrumentarium Corp. or its subsidiaries. All other product and company names are property of their

respective owners.

© Instrumentarium Corp. All rights reserved.

Page 3

Master table of contents

Datex-Ohmeda AS/3TM Compact Monitor and CS/3TM Compact Monitor

Technical Reference Manual, 896 623

#

Folder

Document No. Updated Updated Description

1(2), PART I, General Service Guide

896 623

896674

8001068

888737-2

895156-2

896 620-1

896 619

896 621

896 622-1

Introduction, System description, Installation, Interfacing, Functional check, General troubleshooting

Planned Maintenance Instructions

PART II, Product Service Guide

AS/3 CM Frames; F-CM, F-CMREC

CS/3 CMC Frames; F-CMC, F-CMCREC

CPU Boards; B-CMCPU4, B-CPU3, B-CPU2

Software cards and cartridges

Upinet Board,B-UPINET

MRI Shield, N-MRI

MRI Multiparameter NES Module, M-MRI

Folder #2(2), PART II, Product Service Guide (continues)

Hemodynamic Modules,

M-NE12STPR, M-NE12STR, M-NE12TPR, M-NESTPR, M-NESTR, M-NETPR, M-ESTPR, M-ESTR, M-ETPR

Compact Airway Modules, M-CAiOVX, M-CAiOV,M-CAiO, M-COVX, M-COV, M-CO, M-C

Tonometry Module, M-TONO

EEG Module, M-EEG and EEG Headbox, N-EEG

1

2

1

2

3

1

2

3

4

889 881-5

885 935-7

893 224-3

885 936-6

885 937-6

885 940-7

887 780-5

893 780-3

885 939-6

893 779-2

885 941-6

Cardiac Output Modules, M-COP and M-COPSv

Pressure Module, M-P, Pressure Temp Module, M-PT

Dual Pressure Module, M-PP

NIBP Module, M-NIBP

Recorder Module, M-REC

Nellcor Compatible Saturation Module, M-NSAT

NeuroMuscular Transmission Module, M-NMT

Anesthesia Keyboard, K-ARK, Keyboard Interface Board, B-ARK and ARK Barcode Reader, N-SCAN

Memory Module, M-MEM, Memory Board, B-CMMEM

Interface Module, M-INT

Network Board, B-NET

5

6

7

8

9

10

11

12

13

14

15

Document No. 896623

Page 4

Page 5

Table of contents

TABLE OF CONTENTS

AS/3 Compact Monitor, CS/3 Compact Monitor

TABLE OF CONTENTS i

TABLE OF FIGURES ii

1 INTRODUCTION 1

1.1 Notes to the reader ....................................................................................................................................2

1.1.1 Related Documentation.....................................................................................................................2

1.1.2 Conventions used..............................................................................................................................3

1.2 Safety Precautions.....................................................................................................................................6

1.2.1 Warnings ..........................................................................................................................................6

1.2.2 Cautions ...........................................................................................................................................7

2 SYSTEM DESCRIPTION 9

2.1 Introduction...............................................................................................................................................9

2.2 Bus structure .............................................................................................................................................9

2.3 Distributed processing .............................................................................................................................10

2.4 Module communication ...........................................................................................................................11

2.5 Software loading......................................................................................................................................12

2.6 Parameter modules .................................................................................................................................12

3 SYSTEM INSTALLATION 14

3.1 Unpacking instructions.............................................................................................................................14

3.2 Choosing location....................................................................................................................................14

3.3 Assembling the AS/3, CS/3 Compact Monitor Frame................................................................................14

3.3.1 Compact Monitor connections .........................................................................................................15

3.3.2 Rear panel connectors.....................................................................................................................16

3.3.3 Connection to mains........................................................................................................................17

3.3.4 Connection to Network ....................................................................................................................17

3.3.5 Inserting the parameter modules......................................................................................................17

3.3.6 Replacing the CPU Board, B-CMCPU4..............................................................................................18

3.3.7 Performing Factory Reset.................................................................................................................19

3.3.8 Replacing the Software Cartridge of B-CPU2/3.................................................................................20

3.3.9 Replacing the CPU Board, B-CPU2/3...............................................................................................21

3.4 AS/3 Memory Board, B-CMMEM Installation (w/ B-CPU2/3).....................................................................23

3.5 AS/3 Memory Board, B-CMMEM Installation (w/ B-CMCPU4)....................................................................26

3.6 Network Board, B-NET Installation (w/ B-CPU2/3) ....................................................................................29

3.7 Network Board, B-CMNET Installation (w/ B-CMCPU4) ..............................................................................32

3.8 AS/3 UPINET Board, B-UPINET Installation (w/ B-CPU2/3)........................................................................34

3.9 AS/3 UPINET Board, B-UPINET Installation (w/ B-CMCPU4).......................................................................37

3.10 Compact Airway Modules, M-XXXX..........................................................................................................39

3.10.1 Sample Gas Exhaust .....................................................................................................................39

3.10.2 Scavenging Through Reservoir .......................................................................................................40

3.10.3 Scavenging Through Direct Connection ..........................................................................................40

3.10.4 Returning Gas to Patient Circuit......................................................................................................41

3.11 AS/3 Anesthesia Keyboard, K-ARK.........................................................................................................41

3.12 Remote Controller, K-REMCO .................................................................................................................41

3.13 Bar Code Reader ...................................................................................................................................42

Document No. 896623

i

Page 6

Datex-Ohmeda AS/3 CM and CS/3 CMC

3.13.1 Connection to the Compact Monitor...............................................................................................42

3.13.2 Different Configurations ................................................................................................................42

3.14 Troubleshooting .................................................................................................................................... 44

4 INTERFACING 45

4.1 Interfacing Monitors via UPI Board, B-UPI .................................................................................................46

4.1.1 Interconnection Datex-Ohmeda Monitors .........................................................................................46

4.1.2 Setting the Interfacing Parameters................................................................................................... 47

4.1.3 Setting the Interfacing Parameters for the Compact Monitor.............................................................. 47

4.2 Interfacing with Datex-Ohmeda Monitors via UPINET Board, B-UPINET .......................................................47

4.3 Interfacing Monitors via M-INT..................................................................................................................48

4.3.1 Connection to Datex-Ohmeda Monitors............................................................................................48

4.3.2 Connection to Critikon Dinamap 1846SX, Abbott Oximetrix 3 and Baxter Explorer ..............................49

4.3.3 Connection to Baxter Vigilance ........................................................................................................49

4.3.4 Connection to Nellcor N-100 and N-1000........................................................................................49

4.3.5 Connection to Nellcor N-200 ...........................................................................................................49

4.4 Interfacing Datex-OhmedaAS/3 Anesthesia Delivery Unit.......................................................................... 49

4.5 Interfacing Dräger Cicero and Cato ...........................................................................................................50

4.6 Interfacing a printer .................................................................................................................................50

4.7 Interfacing a computer.............................................................................................................................50

4.8 UPI Board Output Signals.........................................................................................................................51

4.8.1 Digital Outputs................................................................................................................................ 51

4.8.2 Analog Outputs ...............................................................................................................................52

4.8.3 Setting the Analog Output Signals....................................................................................................53

4.9 Pressure Temp Module, M-PT Output Signals ............................................................................................54

4.9.1 Analog Outputs ...............................................................................................................................54

5 FUNCTIONAL CHECK 55

5.1 Recommended tools ...............................................................................................................................55

5.2 Visual inspection/preparation..................................................................................................................55

5.3 Functional Inspection ..............................................................................................................................58

6 GENERAL TROUBLESHOOTING 74

APPENDIX A 75

FUNCTIONAL CHECK FORM A-1

TABLE OF FIGURES

Figure 1 AS/3, CS/3 Compact Monitor ..................................................................................................................1

Figure 2 General Structure of AS/3 and CS/3 System.............................................................................................9

Figure 3 Distributed Processing in AS/3 and CS/3 System ...................................................................................10

Figure 4 Principle of UPI operation .......................................................................................................................11

Figure 5 Software loading....................................................................................................................................12

Figure 6 General structure of parameter modules .................................................................................................13

Figure 7 AS/3 Compact Monitor Connections....................................................................................................... 15

ii

Document No. 896623

Page 7

Table of contents

Figure 8 Rear Panel with Memory, CPU and UPINET Boards ...................................................................................16

Figure 9 Rear Panel with NET, CPU and UPI Boards. NET and UPI Boards can be replaced by UPINET board.............16

Figure 10- Datex-Ohmeda Compact Airway Module ..............................................................................................39

Figure 11 Scavenging through Ventilator Reservoir................................................................................................40

Figure 12 Connection Directly to a Scavenging System .........................................................................................40

Figure 13 Sample Gas Return to Patient Circuit in ADU..........................................................................................41

Figure 14 Bar Code Reader connected to the Compact Monitor .............................................................................42

Figure 15 Monitor General Troubleshooting Flowchart ...........................................................................................74

Document No. 896623

iii

Page 8

Datex-Ohmeda AS/3 CM and CS/3 CMC

iv

Document No. 896623

Page 9

1 INTRODUCTION

Datex-Ohmeda AS/3 Compact Monitor is a cardiac and respiratory monitoring device used during

anesthesia, recovery and short transports.

Datex-Ohmeda CS/3 Compact Monitor is designed for monitoring in intensive care units.

The monitor consists of the CM frame and modules. There are single and double width modules

containing one or more parameters. The modules can be removed and inserted during operation.

The CM frame is equipped with a battery, and also a built-in recorder is available. AS/3 Anesthesia

Keyboard, K-ARK is available for AS/3 Compact Monitor.

General Service Guide

1

Figure 1 AS/3, CS/3 Compact Monitor

(1) CM Frame

(2) Printer

(3) Remote Controller, K-REMCO

2

3

Document No. 896 623

1

Page 10

Datex-Ohmeda AS/3 Compact Monitor, CS/3 Compact Monitor

1.1 Notes to the reader

This technical reference manual is intended for service personnel and engineers who will perform

service and maintenance procedures on Datex-OhmedaAS/3 Compact Monitor and DatexOhmeda CS/3 Compact Monitor.

This technical reference manual is divided into two parts:

• The Part I gives to the reader overview of the AS/3 Compact Monitor and CS/3 Compact

Monitor. This part of the manual contains also the information you need to unpack, install

and test the monitors. Read the manual through and make sure that you understand the

procedures described before installation of the monitor. To avoid risks concerning safety or

health, strictly observe the warning indications. If you need any assistance concerning the

installation, please do not hesitate to contact your authorized distributor.

• The Part II gives detailed descriptions of each component of Compact Monitor.

The manufacturer reserves the right to make changes in product specifications without prior notice.

The information in this manual is believed to be accurate and reliable; however, the manufacturer

assumes no responsibility for its use.

Datex-Ohmeda assumes no responsibility for the use or reliability of its software on equipment that

is not furnished by Datex-Ohmeda.

1.1.1 Related Documentation

AS/3 Compact Monitor

More information about the clinical aspects and technical background:

AS/3 Compact Monitor, User’s Guide

AS/3 Compact Monitor, User’s Reference Manual

Default configuration options: Default Configuration Worksheet

Circuit diagrams, component lay-out pictures, etc.: Schematic Diagrams

More information about other devices closely related to the Compact Monitor:

Information Center, User’s Reference Manual

AS/3 Record Keeper, User’s Reference Manual

CS/3 Compact Monitor

More information about the clinical aspects and technical background:

CS/3 Compact Monitor, User’s Guide

CS/3 Compact Monitor, User’s Reference Manual

Default configuration options: Default Configuration Worksheet

Circuit diagrams, component lay-out pictures, etc.: Schematic Diagrams

2

Document No. 896 623

More information about other devices closely related to the Compact Monitor:

Information Center, User’s Reference Manual

CS/3 Arrhythmia Workstation, User’s Reference Manual

Page 11

1.1.2 Conventions used

Throughout this manual, the following conventions are used to distinguish procedures or elements

of text:

General Service Guide

?

Sign the performed procedure in the check list.

To help you find and interpret information easily, the manual uses consistent text formats for

certain text types:

Hard Keys Names of the hard keys on the Remote Controller, Command Board and modules are written in the

following way:

Menu Items Menu items are written in bold italic typeface, for example Location.

‘Messages’ Messages (alarm messages, informative messages) displayed on the screen are written inside

single quotes, for example ‘Learning’.

Chapters When referring to different sections in this manual, section names are written in italic typeface and

enclosed in double quotes, for example “Cleaning and Care”.

WARNING Warnings are written in bold D-O Sans typeface. The font size is 13 points. The

word warning itself is written in capitals.

CAUTION The font size is 13 points. The word caution itself is written in capitals.

NOTE: Notes are written like this using Bodytext.

Symbols on transport packaging

Cancel.

The contents of the transport package are fragile and have to be handled with care.

This symbol indicates the correct upright position of the transport package.

The transport package must be kept in a dry environment.

This symbol is to indicate the temperature limitations within which the transport package should be

kept and handled.

Symbols on equipment

Ni-Cd

This battery contains Ni-Cd and in case of disposal, must be separated from other

waste according to local regulations.

3

Document No. 896 623

Page 12

Datex-Ohmeda AS/3 Compact Monitor, CS/3 Compact Monitor

This battery contains Ni-Cd and it can be recycled.

Ni-Cd

Dangerous voltage

When using the ARK Barcode Reader, N-SCAN, do not stare into beam. The N-SCAN

Barcode Reader is a Class 2 laser product.

Attention, consult accompanying documents.

When displayed beside the O

value, indicates that FiO2 low alarm limit is set below 21

2

%.

When displayed next to the HR value, indicates that the pacer is set on R or a wide QRS

is selected.

On the Interface Module M-INT, indicates that it is for connecting external devices. Do

not connect patient cables to the module.

On the rear panel of the monitor indicates the following warnings and cautions:

• Electric shock hazard. Do not open the cover or the back.

Refer servicing to qualified personnel.

For continued protection against fire hazard, replace only with same type

•

and rating of fuse.

• Disconnect power supply before servicing.

Type BF (IEC-601-1) protection against electric shock

Type BF (IEC-601-1) defibrillator-proof protection against electric shock

Type CF (IEC-601-1) protection against

electric shock

Type CF (IEC-601-1) defibrillator-proof protection against electric shock

Other Symbols

4

Document No. 896 623

Gas outlet (in airway gas models only)

Ethernet connectors

When displayed on the upper left corner of the screen, indicates that the alarms

are silenced. When in the menu or digit fields, indicates that the alarm source has

been turned off.

Equipotentiality. Monitor can be connected to potential equalization conductor.

Page 13

Alternating current

Fuse

General Service Guide

SN, S/N

Serial Number

Sub menu. Selecting an alternative with this symbol in a menu opens a new menu.

The monitor is connected to the Datex-Ohmeda Network.

Data card (green) and/or the Menu card (white) is inserted.

Indicates the beats detected.

Respiration rate is measured using impedance respiration measurement.

Document No. 896 623

5

Page 14

Datex-Ohmeda AS/3 Compact Monitor, CS/3 Compact Monitor

1.2 Safety Precautions

1.2.1 Warnings

WARNING A WARNING indicates a situation in which the user or the patient may be in

danger of injury or death

Power Connection

• Before connecting the power cord to the mains outlet, check that the local voltage and

frequency rating corresponds with the rating stated on the device plate on the rear panel of

monitor frame.

• Connect the monitor to a three-wire, grounded, hospital grade receptacle. Do not remove

the grounding prong from the power plug.

• Use intact power cord. Replace the cord if it is cracked, frayed, broken or otherwise

damaged.

• Do not apply tension to the power cord. The cord may get broken.

• Do not use extension cords or adapters of any type.

External Connection

• Do not connect any other external devices to the monitor than those specified by Datex-

Fuse Replacement

• Replace the fuse with a fuse of the same type and with the same rating.

Explosion Hazard

• Do not use the monitor in the presence of flammable anesthetics.

Patient Safety

• Do not perform any testing or maintenance on the monitor while it is being used on a

• Use only cables and accessories approved by Datex-Ohmeda. Do not modify them. Other

Ohmeda.

patient.

cables and accessories may damage the monitor or interfere with measurement.

6

Document No. 896 623

• PACEMAKER PATIENTS: The impedance respiration measurement may cause rate changes

in Minute Ventilation Rate Responsive Pacemakers. Set the pacemaker rate responsive

mode off or turn the impedance respiration measurement off on the monitor.

Page 15

General Service Guide

Cleaning and Service

• Only trained personnel with proper tools and test equipment should perform the tests and

repairs described in this manual. Unauthorized service may void the monitor warranty.

• Switch the power off and unplug the power cord before cleaning or service. Get rid of

moisture completely before reconnecting it to the mains outlet.

• Do not touch any exposed wire or conductive surface while covers are off and the monitor is

energized. The voltages present can cause injury or death.

• Perform electrical safety check and leakage current test to the monitor always after service.

1.2.2 Cautions

CAUTION A CAUTION indicates a condition that may lead to equipment damage or

malfunction.

Installation

• Leave space behind the monitor to allow proper ventilation.

Before Use

• Allow two minutes for warm-up and note any error messages or deviations from normal

operation.

• Clean side panel fan dust filter once a month or whenever necessary.

Autoclaving and Sterilizing

• Do not autoclave any part of the monitor.

• Do not gas sterilize the modules.

Cleaning and Service

• Do not use ammonia-, phenol-, or acetone-based cleaners. These cleaners may damage

the monitor surface.

• Do not immerse the monitor in any liquid. Do not allow liquid to enter the monitor or into

modules.

• Electrostatic discharge through the PC boards may damage the components. Before

replacing PC boards, wear a static control wrist strap. Handle all PC boards by their nonconductive edges and use anti-static containers when transporting them.

• Do not break or bypass the patient isolation barrier when testing PC boards.

7

Document No. 896 623

Page 16

Datex-Ohmeda AS/3 Compact Monitor, CS/3 Compact Monitor

Special Components

• There are special components used in this monitor which are vital to assure reliability and

safety. Datex-Ohmeda assumes no responsibility for damage if replacement components

not approved by Datex-Ohmeda are used.

• There is a lithium battery on the CPU board. Discard broken IC containing the battery according

to local regulations.

Batteries

The battery package of the power supply unit in this device contains NiCd which is hazardous to

environment and thus the battery needs to be disposed of carefully according to local regulations.

To replace the batteries safely, please refer to the instructions further on in this manual.

• Do not short-circuit the battery terminals, short-circuiting the battery may produce a very

high current, which damages the battery.

• Do not dispose of the battery into open flame, nor put the battery near fire, as it may

explode.

• Do not disassemble the battery. It contains electrolyte, which may damage clothing or

cause injury to skin or eyes. If exposed to electrolyte, wash the injured area with plenty of

water and contact a doctor.

See also the chapter “Symbols”.

Storage and Transport

Do not store or transport the monitor outside the specified temperature and pressure range:

Temperature -10...+50 °C /14...122 °F

Ambient pressure 660...1060 hPa/500...800 mmHg/

Humidity 0...85 % non-condensing

Discard

Discard the device and parts thereof according to local regulations. Do not discard to the nature.

The manufacturer accepts no responsibility for any modifications made to the monitor outside the

factory.

660...1060 mbar

8

Document No. 896 623

Page 17

2 SYSTEM DESCRIPTION

2.1 Introduction

Datex-OhmedaAS/3 and CS/3 monitors builds up to freely configurable modular system. The

architecture is designed to enable different module combinations so that the user is able to get the

desirable parameter and feature set. The modular approach makes it possible to add new features

when they are needed.

2.2 Bus structure

The operation of Datex-OhmedaAS/3 and CS/3 products is based on two communication

channels, the CPU bus and the module bus. All boards connected to the CPU bus as well as the

parameter modules attached to the module bus receive their power from the same power supply,

which is an integral part of the frame.

General Service Guide

UPI /

UPINET

CPU BUS

MODULE BUS

Figure 2 General Structure of AS/3 and CS/3 System

The CPU bus is a parallel communication channel used only for internal data transfer between the

boards connected to one frame. It is based on the ISA bus used in the IBM PC computers. Data is

transferred on this 16 bits wide bus using the CPU clock frequency.

The module bus is used to connect the parameter modules to the frame. It based on the widely

used industry standard RS-485, which uses differential serial method to transfer the data. This

type of bus is quite robust and it allows the modules to be attached or detached when the power is

on.

The RS-485 type serial communication supports so called multidrop or party line connections. This

means that all modules connected to module bus are using the same two physical wires for

communication purposes. The advantage is, that all the module bus connectors are identical and

the modules can be connected to any order and position.

CPU

Parameter

Module

Display

Controller

Parameter

Module

Power

Supply

Module bus is using 500 kbps data transfer rate and it can be used for longer distances than the

CPU bus, e.g. for external-frame connections.

Document No. 896 623

9

Page 18

Datex-Ohmeda AS/3 Compact Monitor, CS/3 Compact Monitor

2.3 Distributed processing

A system put together from AS/3 and CS/3 products is a multiprocessor system. All the modules

have their own microprocessor and they are doing the low-level functions such as module key

control, waveform filtering, pneumatic control, etc. At the same time the main CPU is doing higher

level tasks, e.g. trending and alarm control. While modules and CPU are doing their job, the UPI

processor takes care of all functions needed to transfer the data between modules and CPU. And

at the same time the processor on display control board is doing pixel calculations for graphics.

This kind of parallel processing gives one major advantage to centralized processing. Each time

new modules or boards are added to the system, the processing power is also increased. As a

result the system is not slowing down when new features are added.

Module

RAM

UPI or UPINET

Dual-port RAM

Display Control

Figure 3 Distributed Processing in AS/3 and CS/3 System

CPU

System memory

Board

Display memor y

10

Document No. 896 623

Page 19

2.4 Module communication

A

s

The communication master controlling the data transfer between CPU bus and module bus is

called UPI (Universal Peripheral Interface) board. It sends information or questions to each module

100 times per second, and if the module is present it replies to each question immediately by

sending a data package back to UPI board. This communication protocol ensures that each

module receives and sends information every 10 ms, the package length depends on the module

type. If the module does not respond, the UPI presumes that the module is not connected.

Each module type has a unique name, which UPI uses to address its messages. If there are two

modules of the same type, they both answer at the same time. This results an error and thus two

similar modules are not allowed in one frame.

General Service Guide

UPI Board

CPU Bus

Module Bus

Dual-port

RAM

Microcontroller

Figure 4 Principle of UPI operation

The microprocessor on the UPI board collects all information coming from the modules into a dualport RAM. This memory is located on UPI board and it is mapped directly to the address space of

the main CPU. The main CPU is thus reading information from it's own memory and UPI guarantees

that the data is up to date. This operation works also to the other direction, when CPU is filling the

dual port RAM with data and UPIs’ microprocessor is distributing it to the modules.

S/3 Bu

11

Document No. 896 623

Page 20

Datex-Ohmeda AS/3 Compact Monitor, CS/3 Compact Monitor

2.5 Software loading

The Software Cartridge attached to the B-CPU2/3 board contains the program for the CPU board

as well as for some other boards attached to the CPU bus. When the system is turned on, all

processors load their part of the software from the cartridge and after that start to execute their

program.

The CPU Board, B-CMCPU4 contains no external software cartridge. The softwares are always

loaded on the B-CMCPU4 boards already at the factory. For service procedures B-CMCPU4 boards

has a PC card drive, through which the software is loaded permanently on the board from the

software card.

w/ B-CPU2/3 or w/ B-CMCPU4

Software

Cartridge

UPI OR UPINET

Board

Program

Memory

CPU

Board

Program

Memory

Software

Card

Display

Controller

Board

Program

Memory

Figure 5 Software loading

2.6 Parameter modules

The detailed structure of the parameter modules depends on the specific needs for each individual

parameter. Some common parts can be found inside the modules, however. The electronics inside

the module is usually divided into isolated (floating) and non-isolated sections. Typically the nonisolated part consists only buffers needed to interface the module to module bus, the rest of the

electronics can be found from the isolated side. This includes the microcontroller together with

memory components, the front end analog electronics (amplifiers, etc.) and peripheral drivers to

control LEDs, sensors, valves and pumps.

CPU BUS

12

Document No. 896 623

Page 21

General Service Guide

Module

keys

Patient

Analog

electronics

Peripheral

drivers

A/D

converter

RAM

EEPROM

Figure 6 General structure of parameter modules

+5V

±12V

CPU

Isolation

transformer

P

a

t

i

e

n

t

i

s

o

l

a

t

i

o

n

Opto

isolation

Power

+15V

Reset

Data

RS485

drivers

M

o

d

u

l

e

B

u

s

13

Document No. 896 623

Page 22

Datex-Ohmeda AS/3 Compact Monitor, CS/3 Compact Monitor

3 SYSTEM INSTALLATION

3.1 Unpacking instructions

1. Confirm that the packing box is undamaged. If the box is damaged, contact the shipper.

2. Open the top of the box and carefully unpack all components.

3. Confirm that all components are undamaged. If any of the components is damaged,

contact the shipper.

4. Confirm that all components are included. If any of the components is excluded, contact

your Datex-Ohmeda distributor.

3.2 Choosing location

Consider the following aspects:

• Lighting

• Space

• Connections

• Electromagnetic and radio frequency interference

• Atmosphere

3.3 Assembling the AS/3, CS/3 Compact Monitor Frame

Mounting of the Compact Monitor to the Compact Monitor Bed Mount or Wall Mount is described in

a separate instruction sheet delivered with the mount.

14

Document No. 896 623

Page 23

3.3.1 Compact Monitor connections

1

2

General Service Guide

9

3

4

5

6

8

7

Figure 7 AS/3 Compact Monitor Connections

(1) Dust filter

(2) Recorder (optional)

(3) Connector for Remote Controller, Anesthesia Keyboard (K-ARK) and Bar Code Reader

(4) Potential equalization

(5) Mains power inlet

(6) Network connectors on B-NET/B-CMNET (optional)

(7) Device plate with voltage information

(8) Network connectors on B-UPINET/B-UPI (optional)

(9) Insertion slots for memory cards (optional)

15

Document No. 896 623

Page 24

Datex-Ohmeda AS/3 Compact Monitor, CS/3 Compact Monitor

3.3.2 Rear panel connectors

1

2

3

Figure 8 Rear Panel with Memory, CPU and UPINET Boards

(1) Software Cartridge, on CPU board, B-CPU2 or B-CPU3,

or Software Card drive and lid for back plate on B-CMCPU4,

connector on B-CMCPU4 is reserved for future use (not in figure).

(2) Network connector

(3) Network identification plug connector

(4) Serial communication connector

1

2

3

4

5

Figure 9 Rear Panel with NET, CPU and UPI Boards. NET and UPI Boards can be

replaced by UPINET board.

(1) Network identification plug connector

4

6

(2) Network connector

(3) Ethernet status LEDs

(4) Software Cartridge, on CPU board, B-CPU2 or B-CPU3,

or Software Card drive and lid for back plate on B-CMCPU4,

connector on B-CMCPU4 is reserved for future use (not in figure).

(5) Serial communication connector

(6) Parallel printer port, analogue & digital input/output connector

CAUTION Turn the power off before making any rear panel connections.

NOTE: Your monitor configuration may not include all circuit boards listed above.

16

Document No. 896 623

Page 25

General Service Guide

3.3.3 Connection to mains

Connect the power cord to the mains power inlet on the side of the monitor and to the wall socket.

WARNING The power cord may only be connected to a three-wire, grounded, hospital grade

receptacle.

3.3.4 Connection to Network

To connect your monitor to Datex-Ohmeda Network, make sure you have a network board B-NET or

B-UPINET installed.

Use the Monitor-Network cable to connect the monitor to the network.

1. Make sure that the power is turned off.

2. Connect the one of RJ-45 connectors to the connector and the Identification Plug to X2

connector on the network board.

3. Connect the other RJ-45 connector to the corresponding connector on the wallbox.

4. Turn on the power. Confirm that the network symbol and 'Connected to Network' message

are displayed on the upper part of the screen.

NOTE: The network symbol will not be displayed if the battery symbol is displayed on the upper part

of the screen.

3.3.5 Inserting the parameter modules

Insert each plug-in parameter module into a module slot. Firmly press the module in position.

NOTE: Do not use two or more modules with identical functions in the monitor. Take special care of

this when using the extension frame.

Modules with identical functions are:

• Haemodynamic multiparameter modules: M-ESTPR, M-ETPR, M-ESTR, M-NESTPR, M-

NETPR, M-NESTR, M-NE12STPR, M-NE12TPR and M-NE12STR

• Pressure Modules: M-P, Pressure Temp Module, M-PT

• Cardiac Output Modules: M-COP and M-COPSv

• NIBP Modules: M-NIBP, M-NESTPR, M-NETPR, M-NESTR, M-NE12STPR, M-NE12TPR and

M-NE12STR

• Airway Modules: M-C, M-CO, M-COV, M-CAiOV, M-CAiO and M-CAiOVx

• The Recorder Module, M-REC and the built-in recorders in F-CMREC or F-CMCREC may not

be used simultaneously.

17

Document No. 896 623

Page 26

Datex-Ohmeda AS/3 Compact Monitor, CS/3 Compact Monitor

3.3.6 Replacing the CPU Board, B-CMCPU4

In case of service procedures (empty B-CMCPU4 and service software on PCMCIA card) refer the

slot of CM Frame, CPUs and Softwares; Part II/1.

1. Make sure that the power is turned off on the Compact Monitor and unplug the power cord.

Press and hold the service reset button on the rear panel for at least five seconds until the

service reset indicator LED is switched off.

2. Unscrew the six screws holding the back plate in position and remove the plate.

WARNING The Compact Monitor is always energized by the internal battery. Do not touch

any exposured wiring or conductive surface with metallic object while the back

plate is off or electric failure may result.

CAUTION The Compact Monitor is always energized by the internal battery. A short circuit may

cause internal damage.

3. Before you can remove the B-CMCPU4 board you have to remove boards next to it (B-

UPI/B-UPINET and B-NET/B-CMMEM). Refer instructions in this same chapter.

4. Unscrew the screws holding the B-CMCPU4 board in position and remove the board.

18

Document No. 896 623

Page 27

General Service Guide

5. Remove the CPU board from the protective anti static packaging. Always hold the board by

the edges and wear a wrist grounding strap.

CAUTION The CPU Board comprises sensitive integrated circuits that can be damaged by an

electrostatic discharge. Careful handling of the board is therefore essential.

6. Insert the new CPU Board into the empty slot and firmly press the board in position.

7. Replace PC boards removed earlier and secure the boards.

8. Attach the back plate removed earlier.

9. Reconnect the Power Cord and turn the power on.

10. Perform factory reset.

3.3.7 Performing Factory Reset

NOTE: The factory reset is necessary after replacing software and after replacing CPU board.

NOTE: The factory reset will restore all your customized defaults, including language selection, to

factory defaults.

1. Press the

2. Select Install/Service and password (16-4-34).

3. Select Service and password (26-23-8).

4. Select Set/ Test and perform factory reset.

Monitor Setup key.

19

Document No. 896 623

Page 28

Datex-Ohmeda AS/3 Compact Monitor, CS/3 Compact Monitor

3.3.8 Replacing the Software Cartridge of B-CPU2/3

NOTE: All user settings will be lost after replacing the software cartridge.

1. Make sure that the power is turned off on the Compact Monitor and unplug the power cord.

Press and hold the service reset button on the rear panel for at least five seconds until the

service reset indicator LED is switched off.

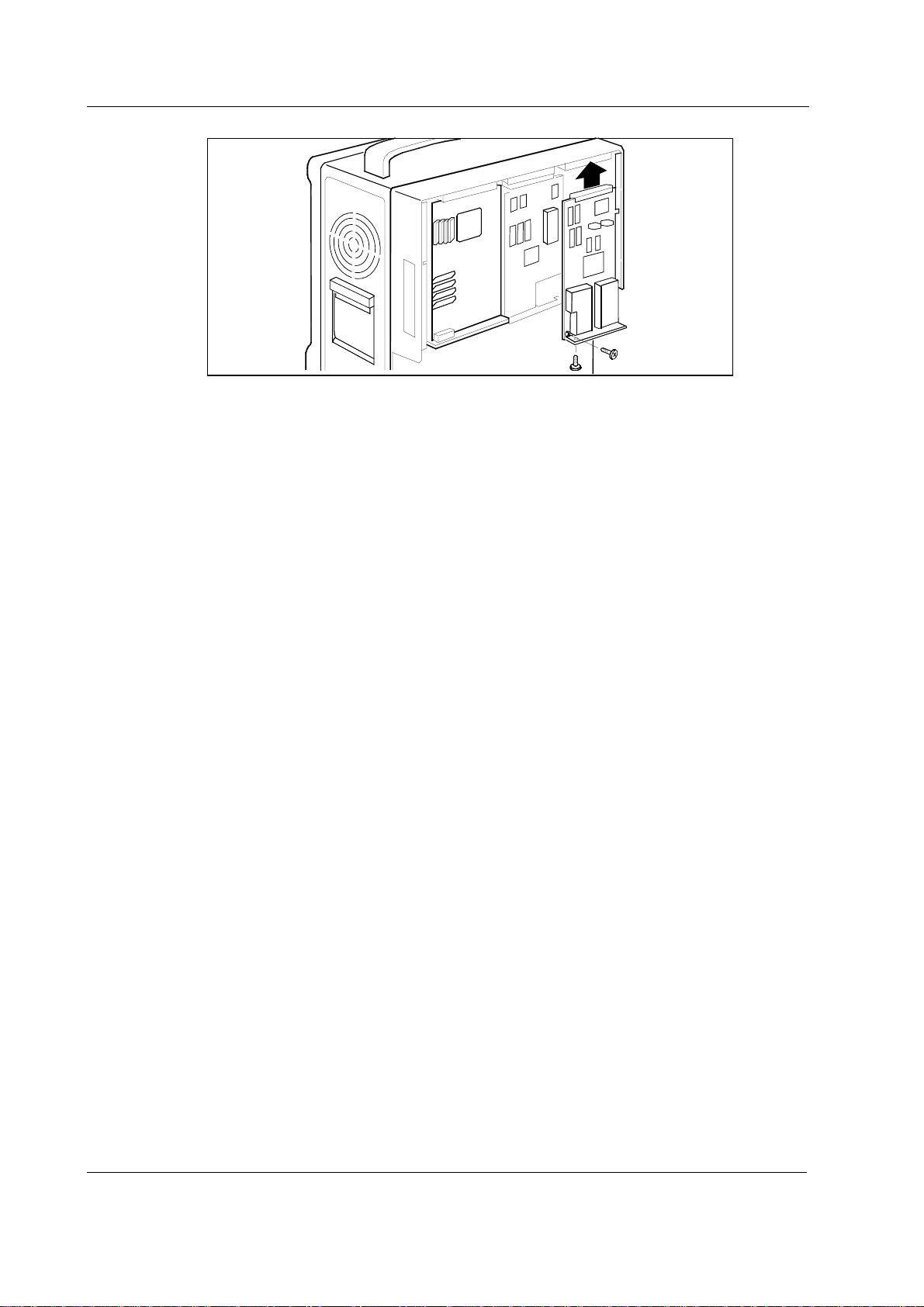

2. Unscrew the two screws holding the software cartridge in position and remove the cartridge.

20

Document No. 896 623

3. Insert the new software cartridge into the empty slot and firmly press the cartridge in

position. Secure the cartridge (two screws).

4. Reconnect the power cord.

5. Perform factory reset.

NOTE: After changing the software cartridge the start-up time is considerably longer when the

monitor is started for the first time.

Page 29

3.3.9 Replacing the CPU Board, B-CPU2/3

1. Make sure that the power is turned off on the Compact Monitor and unplug the power cord.

Press and hold the service reset button on the rear panel for at least five seconds until the

service reset indicator LED is switched off.

2. Unscrew the six screws holding the back plate in position and remove the plate.

General Service Guide

WARNING The Compact Monitor is always energized by the internal battery. Do not touch

any exposured wiring or conductive surface with metallic object while the back

plate is off or electric failure may result.

CAUTION The Compact Monitor is always energized by the internal battery. A short circuit may

cause internal damage.

21

Document No. 896 623

Page 30

Datex-Ohmeda AS/3 Compact Monitor, CS/3 Compact Monitor

3. Remove the software cartridge.

4. Unscrew the screw holding the CPU Board in position and remove the board.

5. Remove the CPU Board from the protective anti static packaging. Always hold the board by

the edges and wear a wrist grounding strap.

CAUTION The CPU Board comprises sensitive integrated circuits that can be damaged by an

electrostatic discharge. Careful handling of the board is therefore essential.

6. Remove the EMC plate from the CPU Board.

7. Insert the new CPU Board into the empty slot and firmly press the board in position. Secure

the new board.

8. Replace the Software Cartridge and secure the cartridge with the two screws removed from

the cartridge earlier.

9. Replace the back plate and secure the plate with the six screws removed from the plate

earlier.

10. Reconnect the Power Cord.

11. Perform Factory Reset.

22

Document No. 896 623

Page 31

General Service Guide

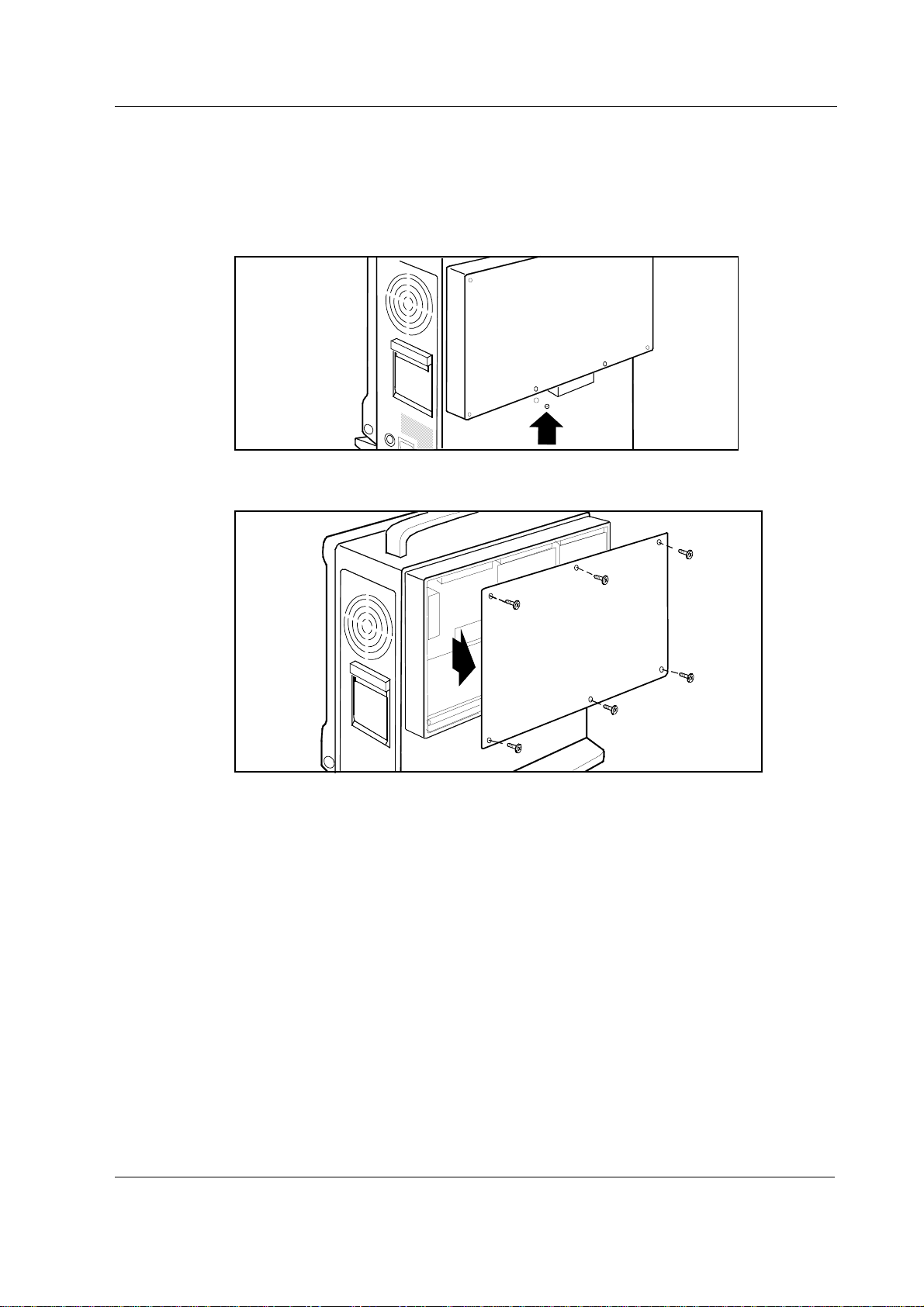

3.4 AS/3 Memory Board, B-CMMEM Installation (w/ B-CPU2/3)

1. Make sure that the power is turned off on the Compact Monitor and unplug the Power Cord.

Press and hold the Service Reset button on the rear panel for at least five seconds until the

service reset indicator LED is switched off.

2. Unscrew the six screws holding the back plate in position and remove the plate.

WARNING The Compact Monitor is always energized by the internal battery. Do not touch

any exposured wiring or conductive surface with metallic object while the back

plate is off or electric failure may result.

CAUTION The Compact Monitor is always energized by the internal battery. A short circuit may

cause internal damage.

23

Document No. 896 623

Page 32

Datex-Ohmeda AS/3 Compact Monitor, CS/3 Compact Monitor

3. Unscrew the two nuts holding the side plates in position and remove the plates. Put the

memory card collar in the place of the side plates.

1

4. Unscrew the five screws holding the bottom plate in position and remove the plate.

5. Unscrew the screw holding the cover plate in position and remove the plate.

6. Remove the Memory Board, B-CMMEM, including the connection board and the memory

board, from the protective anti static packaging. Always hold the boards by the edges and

wear a wrist grounding strap.

2

CAUTION The Memory Board, B-CMMEM comprises sensitive integrated circuits that can be

damaged by an electrostatic discharge. Careful handling of the board is therefore

essential.

24

Document No. 896 623

Page 33

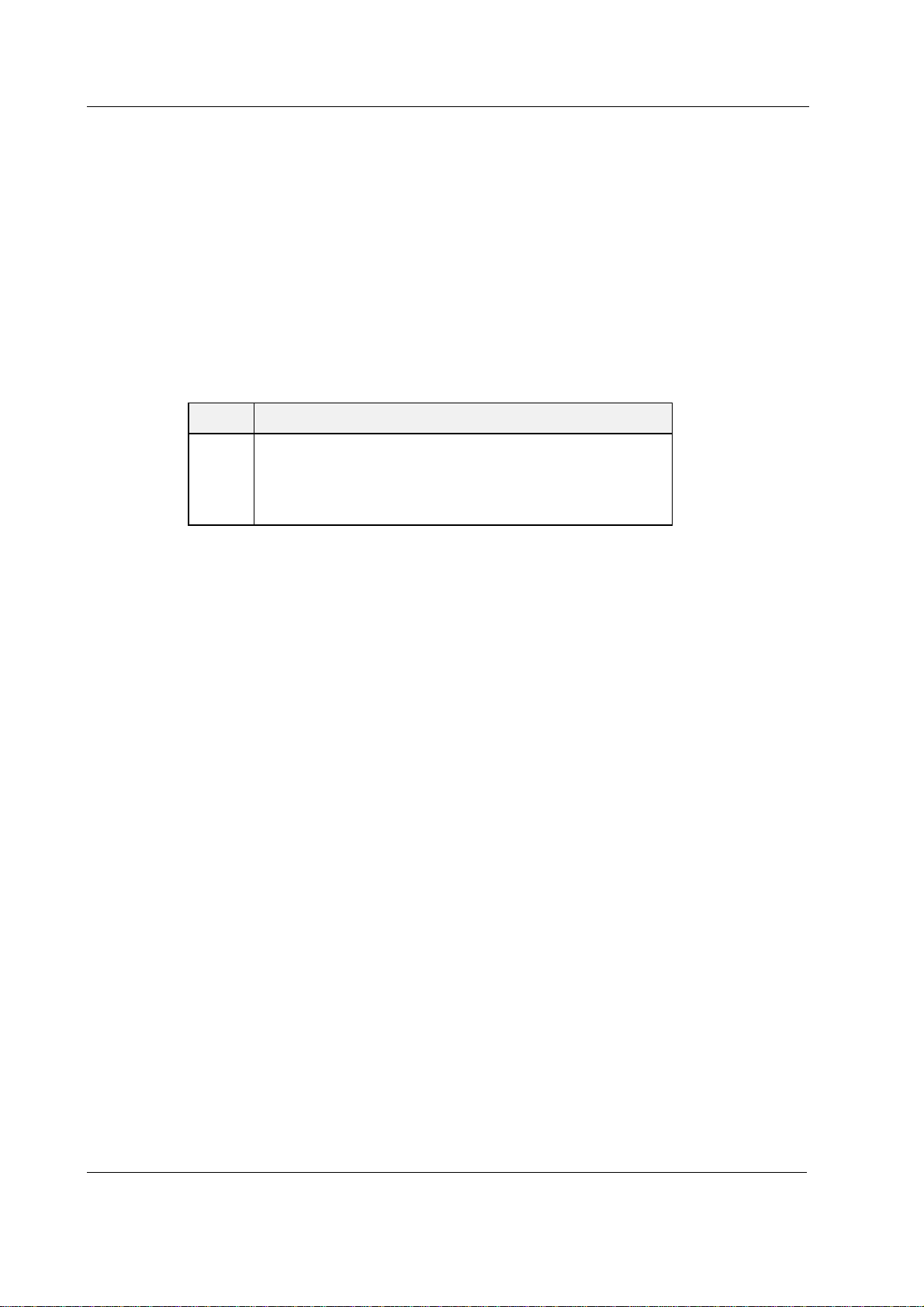

General Service Guide

7. Insert the connection board into the empty slot and firmly press the board in position.

8. Place the memory board, the bottom plate and the cover plate in position. First, secure the

memory board with the three screws in the sequence indicated. Then, secure the memory

board, the bottom plate and the cover plate with the two screws (M3x25). Finally, secure the

bottom plate (four screws).

2

1

3

9. Replace the back plate (six screws).

10. Reconnect the power cord.

25

Document No. 896 623

Page 34

Datex-Ohmeda AS/3 Compact Monitor, CS/3 Compact Monitor

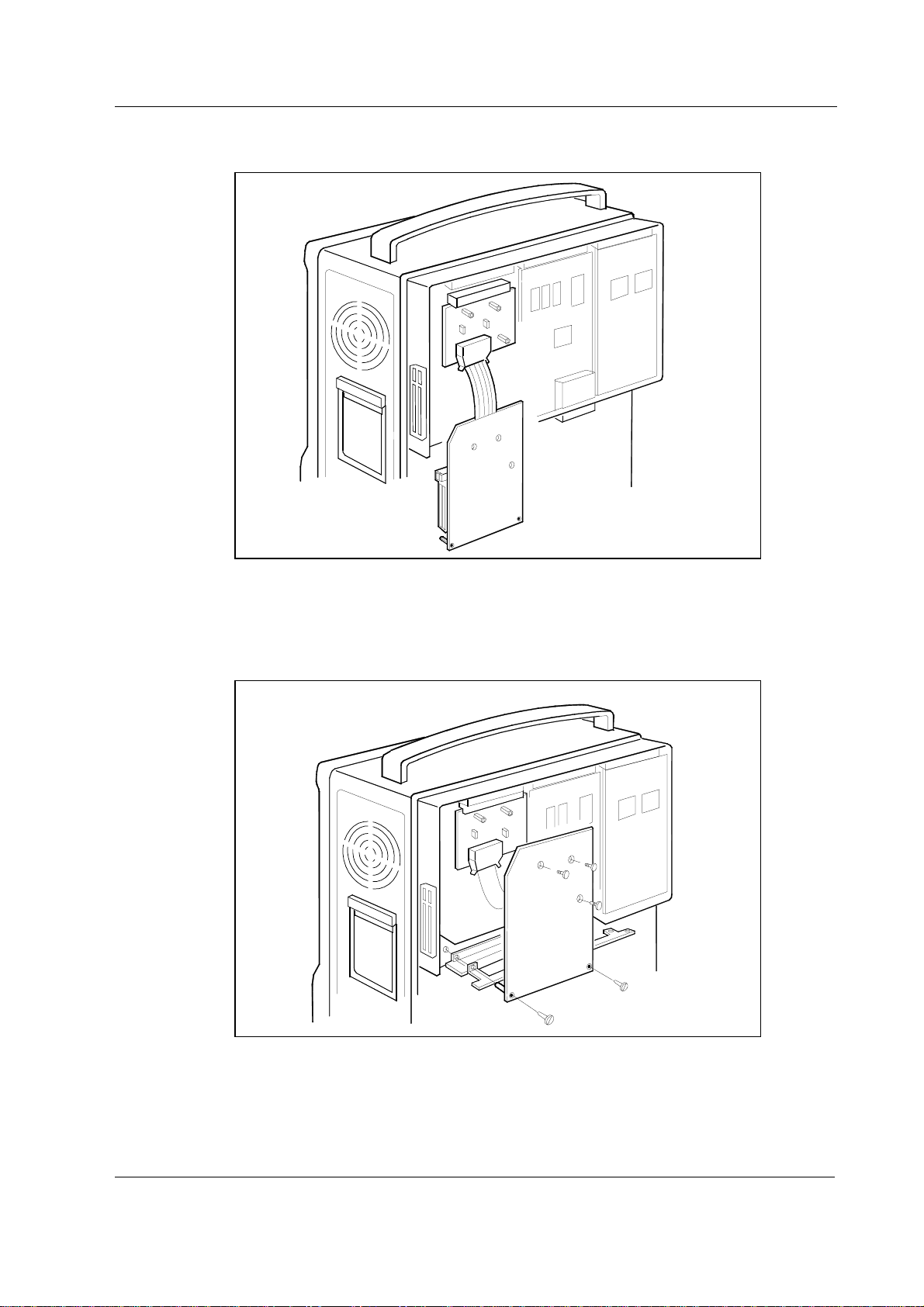

3.5 AS/3 Memory Board, B-CMMEM Installation (w/ B-CMCPU4)

1. Make sure that the power is turned off on the Compact Monitor and unplug the Power Cord.

Press and hold the Service Reset button on the rear panel for at least five seconds until the

service reset indicator LED is switched off.

2. Unscrew the six screws holding the back plate in position and remove the plate.

WARNING The Compact Monitor is always energized by the internal battery. Do not touch

any exposured wiring or conductive surface with metallic object while the back

plate is off or electric failure may result.

CAUTION The Compact Monitor is always energized by the internal battery. A short circuit may

cause internal damage.

26

Document No. 896 623

Page 35

General Service Guide

3. Unscrew the two nuts holding the side plates in position and remove the plates. Put the

memory card collar in the place of the side plates.

2

4. Unscrew the screws holding the bottom plate in position and remove the plate.

5. Remove the Memory Board, B-CMMEM, including the connection board and the memory

board, from the protective anti static packaging. Always hold the boards by the edges and

wear a wrist grounding strap.

CAUTION The Memory Board, B-CMMEM comprises sensitive integrated circuits that can be

damaged by an electrostatic discharge. Careful handling of the board is therefore

essential.

27

Document No. 896 623

Page 36

Datex-Ohmeda AS/3 Compact Monitor, CS/3 Compact Monitor

6. Insert the connection board into the empty slot and firmly press the board in position.

7. Place the memory board, the bottom plate and the cover plate in position. First, secure the

memory board with the three screws in the sequence indicated. Then, secure the memory

board, the bottom plate and the cover plate with the two screws (M3x25). Finally, secure the

bottom plate (four screws).

2

1

3

28

Document No. 896 623

8. Replace the back plate (six screws).

9. Reconnect the power cord.

Page 37

General Service Guide

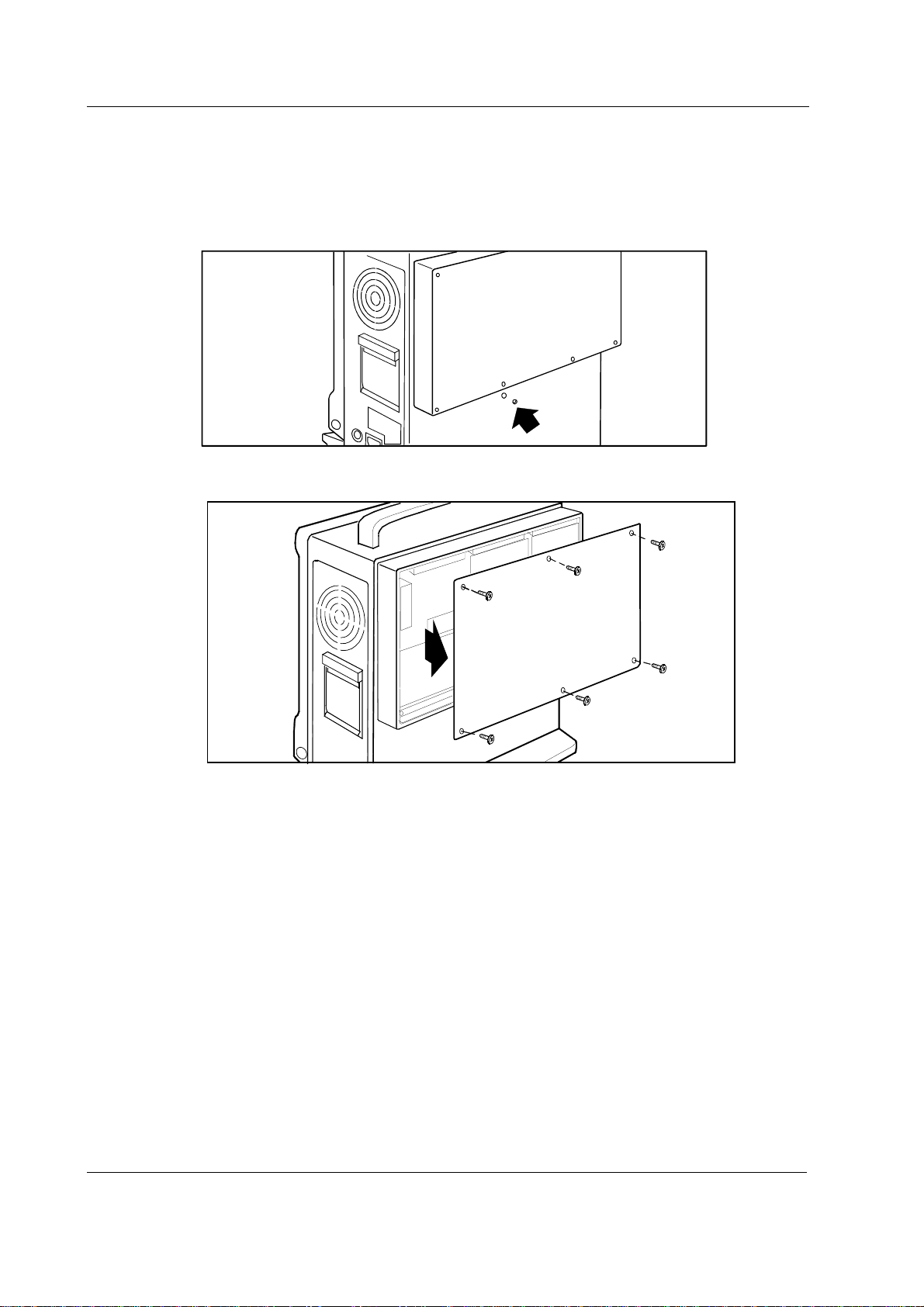

3.6 Network Board, B-NET Installation (w/ B-CPU2/3)

Insert the Network Board, B-NET according to following procedure.

1. Make sure that the power is turned off on the Compact Monitor is and unplug the Power

Cord. Press and hold the Service Reset button on the rear panel for at least five seconds

until the service reset indicator LED is switched off.

2. Unscrew the six screws holding the back plate in position and remove the plate.

WARNING The Compact Monitor is always energized by the internal battery. Do not touch

any exposured wiring or conductive surface with metallic object while the back

plate is off or electric failure may result.

CAUTION The Compact Monitor is always energized by the internal battery. A short circuit may

cause internal damage.

29

Document No. 896 623

Page 38

Datex-Ohmeda AS/3 Compact Monitor, CS/3 Compact Monitor

3. Unscrew the five screws holding the bottom plate in position and remove the plate.

4. Unscrew the screw holding the cover plate in position and remove the plate.

5. Remove the Network Board, B-NET from the protective anti static packaging. Always hold

the board by the edges and wear a wrist grounding strap.

CAUTION The Network Board, B-NET comprises sensitive integrated circuits that can be

damaged by an electrostatic discharge. Careful handling of the board is therefore

essential.

30

Document No. 896 623

Page 39

General Service Guide

6. Loosen the two screws holding the EMC plate in position, remove the plate and tighten the

screws.

7. Insert the Network Board, B-NET into the empty slot and firmly press the board in position.

Secure the board with the screw removed from the cover plate earlier.

8. Replace the bottom plate and secure the plate with the five screws removed from the plate

earlier.

9. Replace the back plate and secure the plate with the six screws removed from the plate

earlier.

10. Reconnect the Power Cord.

Document No. 896 623

31

Page 40

Datex-Ohmeda AS/3 Compact Monitor, CS/3 Compact Monitor

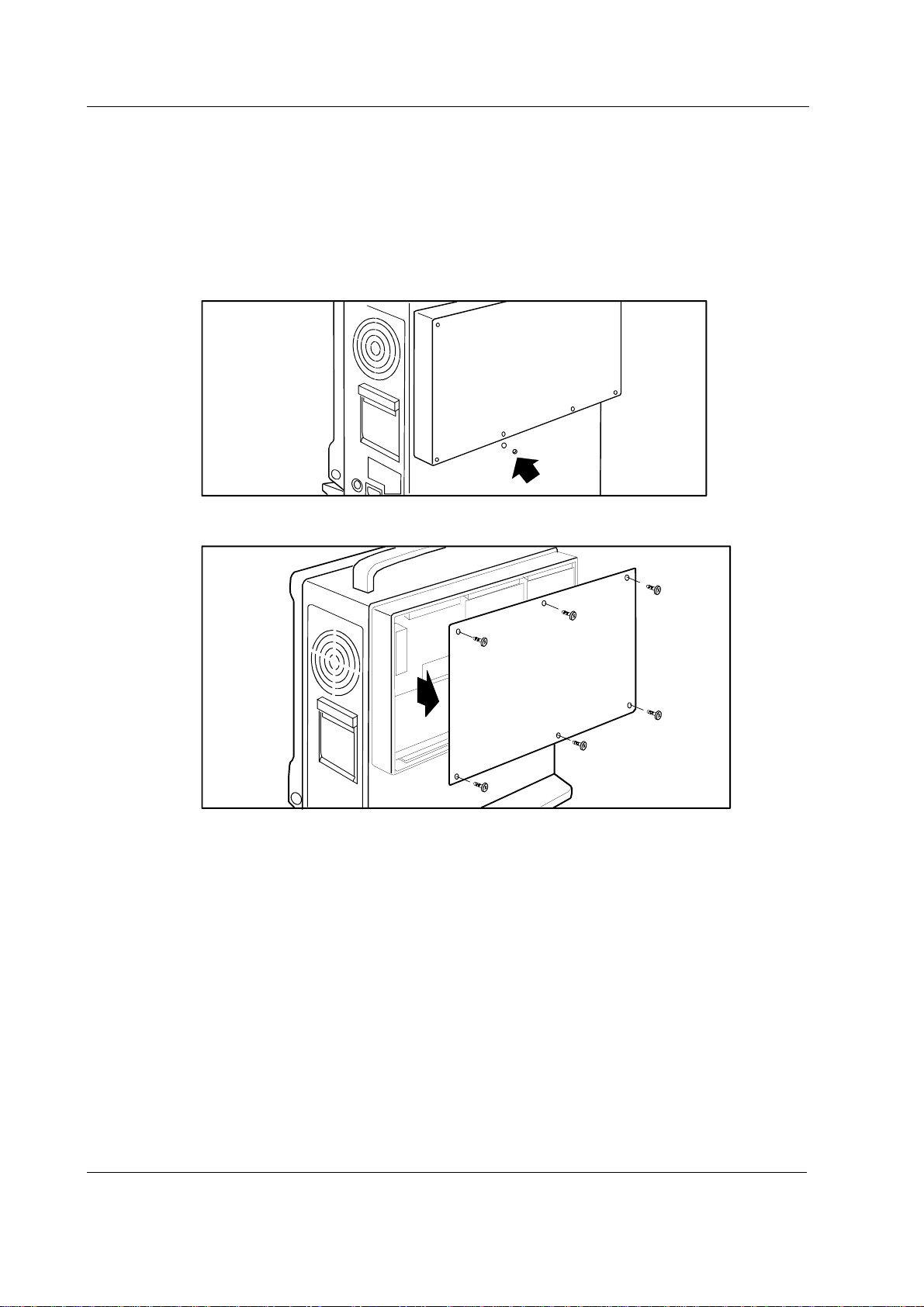

3.7 Network Board, B-CMNET Installation (w/ B-CMCPU4)

Insert the Network Board, B-CMNET (B-CMNET differs from B-NET with mechanical changes)

according to following procedure.

1. Make sure that the power is turned off on the Compact Monitor is and unplug the Power

Cord. Press and hold the Service Reset button on the rear panel for at least five seconds

until the service reset indicator LED is switched off.

2. Unscrew the six screws holding the back plate in position and remove the plate.

WARNING The Compact Monitor is always energized by the internal battery. Do not touch

any exposured wiring or conductive surface with metallic object while the back

plate is off or electric failure may result.

CAUTION The Compact Monitor is always energized by the internal battery. A short circuit may

cause internal damage.

32

Document No. 896 623

Page 41

General Service Guide

3. Unscrew the screws holding the bottom plate in position and remove the plate.

4. Remove the Network Board, B-CMNET from the protective anti static packaging. Always hold

the board by the edges and wear a wrist grounding strap.

CAUTION The Network Board, B-CMNET comprises sensitive integrated circuits that can be

damaged by an electrostatic discharge. Careful handling of the board is therefore

essential.

5. Insert the Network Board, B-CMNET into the empty slot and firmly press the board in

position. Secure the board with the screw removed from the cover plate earlier.

6. Replace the back plate and secure the plate with the six screws removed from the plate

earlier.

7. Reconnect the Power Cord

33

Document No. 896 623

Page 42

Datex-Ohmeda AS/3 Compact Monitor, CS/3 Compact Monitor

3.8 AS/3 UPINET Board, B-UPINET Installation (w/ B-CPU2/3)

Insert the B-UPINET Board according to following procedure.

1. Make sure that the power is turned off on the Compact Monitor and unplug the Power Cord.

Press and hold the Service Reset button on the rear panel for at least five seconds until the

service reset indicator LED is switched off.

2. Unscrew the six screws holding the back plate in position and remove the plate.

WARNING The Compact Monitor is always energized by the internal battery. Do not touch

any exposured wiring or conductive surface with metallic object while the back

plate is off or electric failure may result.

CAUTION The Compact Monitor is always energized by the internal battery. A short circuit may

cause internal damage.

34

Document No. 896 623

Page 43

General Service Guide

3. Unscrew the two screws holding the software cartridge in position and remove the cartridge.

4. Unscrew the three screws holding the UPI Board in position and remove the board.

5. Remove the UPINET Board, B-UPINET from the protective antistatic packaging. Always hold

the board by the edges and wear a wrist grounding strap.

The UPINET Board, B-UPINET comprises sensitive integrated circuits that can be damaged by an

electrostatic discharge. Careful handling of the board is therefore essential.

35

Document No. 896 623

Page 44

Datex-Ohmeda AS/3 Compact Monitor, CS/3 Compact Monitor

6. Insert the UPINET Board, B-UPINET into the empty slot and firmly press the board in

position. Secure the board with the two screws removed from the UPI Board earlier.

7. Attach the EMC gasket to the EMC cases on the UPINET Board so that the adhesive part of

the gasket is against the cases. Place the right end of the gasket next to the back plate

screw hole in the lower right corner of the frame. Fit the gasket closely to the front plate.

8. Replace the Software Cartridge and secure the cartridge with the two screws removed from

the cartridge earlier.

9. Replace the back plate and secure the plate with the six screws removed from the plate

earlier.

10. Connect the B-NET connector cable to the network connector.

11. Reconnect the Power Cord.

NOTE: These instructions applies only for F-CM(REC) rev. 02 and rev. 03 and for F-CMC(REC) rev.

00 Compact Monitors. For earlier revisions also additional parts are required. Please contact your

authorized Datex-Ohmeda distributor.

36

Document No. 896 623

Page 45

General Service Guide

3.9 AS/3 UPINET Board, B-UPINET Installation (w/ B-CMCPU4)

Insert the B-UPINET Board according to following procedure.

1. Make sure that the power is turned off on the Compact Monitor and unplug the Power Cord.

Press and hold the Service Reset button on the rear panel for at least five seconds until the

service reset indicator LED is switched off.

2. Unscrew the six screws holding the back plate in position and remove the plate.

WARNING The Compact Monitor is always energized by the internal battery. Do not touch

any exposured wiring or conductive surface with metallic object while the back

plate is off or electric failure may result.

CAUTION The Compact Monitor is always energized by the internal battery. A short circuit may

cause internal damage.

37

Document No. 896 623

Page 46

Datex-Ohmeda AS/3 Compact Monitor, CS/3 Compact Monitor

3. Unscrew the three screws holding the UPI Board in position and remove the board.

4. Remove the UPINET Board, B-UPINET from the protective antistatic packaging. Always hold

the board by the edges and wear a wrist grounding strap.

CAUTION The UPINET Board, B-UPINET comprises sensitive integrated circuits that can be

damaged by an electrostatic discharge. Careful handling of the board is therefore

essential.

5. Insert the UPINET Board, B-UPINET into the empty slot and firmly press the board in

position. Secure the board with the two screws removed from the UPI Board earlier.

6. Replace the back plate and secure the plate with the six screws removed from the plate

earlier.

7. Connect the B-NET connector cable to the network connector.

38

Document No. 896 623

8. Reconnect the Power Cord.

NOTE: These instructions applies only for F-CM(REC) rev. 04 and F-CMC(REC) rev. 01 Compact

Monitors. For earlier revisions also additional parts are required. Please contact your authorized

Datex-Ohmeda distributor.

Page 47

3.10 Compact Airway Modules, M-XXXX

Airway modules of M-family (M-C etc.) are installed as any plug-in modules.

Figure 10- Datex-Ohmeda Compact Airway Module

General Service Guide

3.10.1 Sample Gas Exhaust

When N2O or volatile anesthetics are used, pollution of the operation room by these gases should

be prevented. Connect the sample gas outlet of the module to the scavenging system or return it to

the patient circle.

Connect the sample gas outlet of the module to the scavenging system either

− through the ventilator reservoir.

− directly to the scavenging tube using a T-fitting.

Connect sample gas outlet only to open scavenging system where gas is removed in room

pressure.

CAUTION Strong scavenging suction may change the operating pressure of the module and

cause inaccurate readings or internal damage.

39

Document No. 896 623

Page 48

Datex-Ohmeda AS/3 Compact Monitor, CS/3 Compact Monitor

3.10.2 Scavenging Through Reservoir

SAMPLE GAS O UT

Figure 11 Scavenging through Ventilator Reservoir

• Connect an exhaust line to the sample gas outlet on the module’s front panel.

• Attach the other end of the line to the ventilator reservoir. Make sure that the reservoir tube

diameter is at least 2-3 times larger than the exhaust line.

3.10.3 Scavenging Through Direct Connection

Figure 12 Connection Directly to a Scavenging System

• Connect a T-fitting between the monitor and the exhaust line.

• Attach the other end of the line to the scavenging tube.

SAMPLE GAS OUT

40

Document No. 896 623

Page 49

3.10.4 Returning Gas to Patient Circuit

The sampling gas can also be returned to the patient circuit. If you use the Datex-OhmedaAS/3

Anesthesia Delivery Unit (ADU), you need an optional adapter connected to the patient breathing

tubes.

General Service Guide

Figure 13 Sample Gas Return to Patient Circuit in ADU

3.11 AS/3 Anesthesia Keyboard, K-ARK

To connect AS/3 Anesthesia Keyboard, K-ARK to the Compact Monitor:

1. Make sure that the power is turned off on the Compact Monitor.

2. Connect the Keyboard-LCD Display Cable to the K-ARK connector on the display and to the

connector on the rear of the keyboard. Secure the connection with the thumb screw and slip

the cable beneath the fasteners.

3.12 Remote Controller, K-REMCO

To connect a Remote Controller, K-REMCO to your Compact Monitor you need a Remote ControllerCompact Monitor Cable. For further information, please contact your authorized Datex-Ohmeda

distributor.

41

Document No. 896 623

Page 50

Datex-Ohmeda AS/3 Compact Monitor, CS/3 Compact Monitor

3.13 Bar Code Reader

3.13.1 Connection to the Compact Monitor

The bar code reader can be connected to the K-ARK connector on the monitor.

Figure 14 Bar Code Reader connected to the Compact Monitor

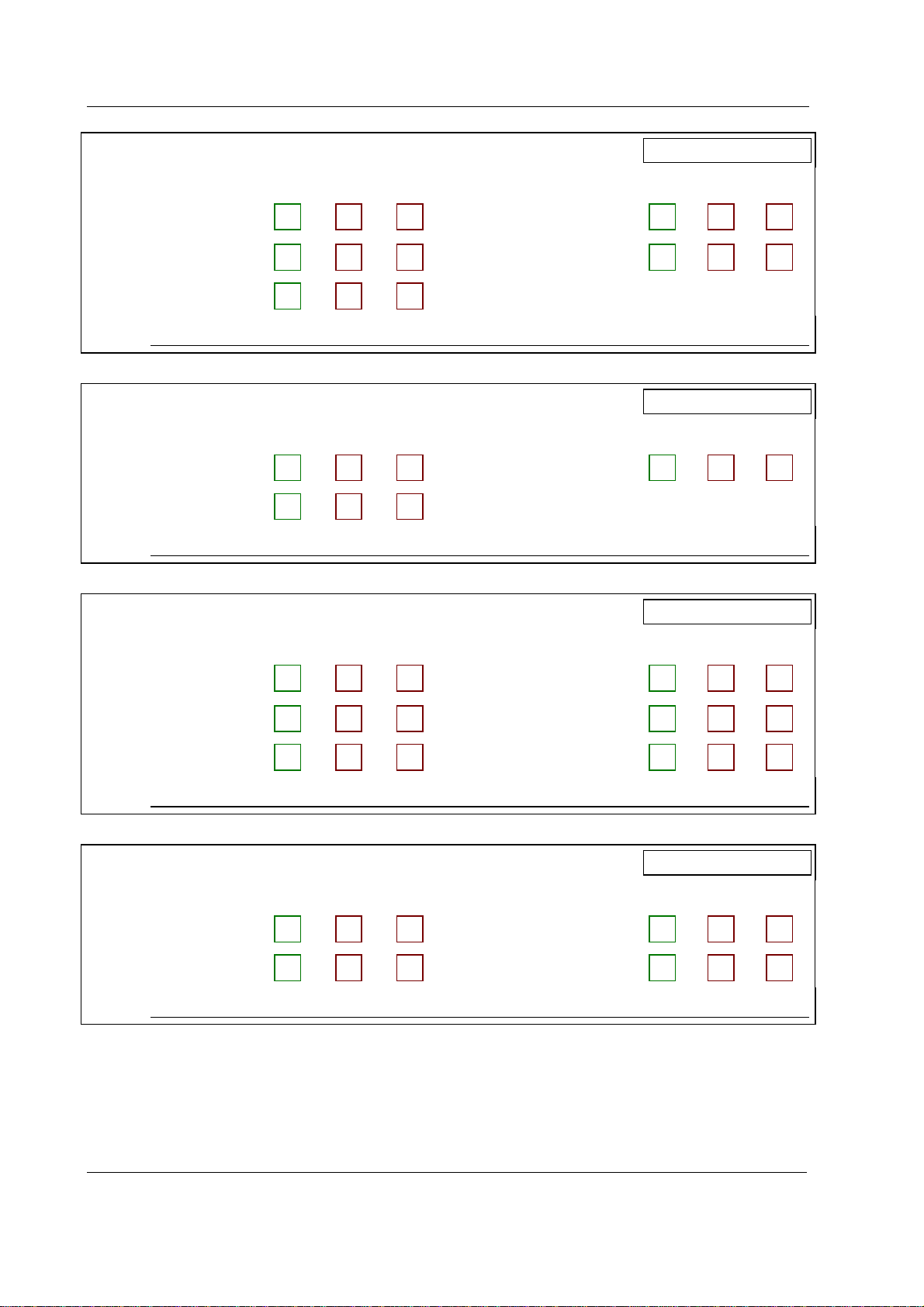

3.13.2 Different Configurations

The bar code reader comes from HP factory with factory default settings. These settings are slightly

modified at Datex-Ohmeda factory to match Datex-Ohmeda applications. The following table

shows the differences between the HP configuration and the Datex-Ohmeda configuration.

Option HP configuration Datex-Ohmeda configuration

Message components

Header [<<61>>] [hhh]

No-read [<<61>><<61>>] []

Keycodes

Key delay [1] ms [12] ms

The default settings can also be modified outside the factory by scanning special bar code labels

from the documentation that comes with the scanner. To do this the scanner should be connected

to the keyboard port of your PC.

42

Document No. 896 623

Page 51

General Service Guide

1. Start the configuration (Default Wedge Mode).

2. Begin with the header label (Header). Set the contents of the header to hhh.

3. End the header (End of Characters).

4. Clear the no-read message (No-Read Message is Empty).

5. Select the interkey delay (Interkey Delay). Set the interkey delay to 12 s.

The configuration of the bar code reader is shown by scanning the Show Configuration label.

CONFIGURATION DISPLAY

--- Version 14.3 -------------------------- (c) Hewlett-Packard 1986-1992

| CODE |READ |CHECK CHAR | LENGTH | CODE ID | OTHER CONFIG. SETTINGS |

|________|_____|verif_xmit_|min__max|xmit:[off]|--------------------------|

|Code 39 |[yes]|[no] | yes |[1] [32]| [a] |Extended: [no] |

|Int. 2/5|[yes]|[no] | yes |[4] [32]| [b] |Length: [variable] |

|Codabar |[yes]|[no] | yes |[1] [32]| [d] |Include start/stop: [yes] |

|Code 128|[yes]| yes | no |[1] [32]| [e] | |

|Code 11 |[yes]| [1] | yes |[2] [32]| [f] | |

|MSI Code|[yes]| yes | yes |[3] [32]| [g] | |

|Code 93 |[yes]| yes | no |[1] [32]| [h] | |

|UPC/EAN |[yes]| yes |[yes]| fixed | [c] |[+ none] |

| E:[0] |||| | |EAN:[yes] ID chars:[off]|

|----------- MESSAGE COMPONENTS ------------------------------------------|

| Ctrl character=^+letter ®nn¯ = Extended Key index |

|Header:[hhh] |

|Trailer:[^M] |

|No-Read:[] |

|--- KEYCODES --------- OPERATOR FEEDBACK ----------- GENERAL ------------|

|Key Delay:[10] ms |Ready Signal:[on] |[Wedge] (using keyboard) |

|[U.S. English] |Menu Scan Responses:[on] |No-Read Recognition:[off] |

|Code Set:[auto]->2|Good Read LED:[flashes] |Family:[auto]->PC/AT,PS/2 |

|ALT Sequence:[off]|LED Active:[high] |Ctrl Chars:[ASCII] |

-------------------------------------------------------------------------

43

Document No. 896 623

Page 52

Datex-Ohmeda AS/3 Compact Monitor, CS/3 Compact Monitor

3.14 Troubleshooting

If a problem occurs during the functional examination, check the components of the monitor

according to the following troubleshooting chart. If the problem persists, please refer to the part II.

TROUBLE TREATMENT

Nothing functions Unplug and replug Remote Controller Cable. Also confirm that the cable is intact.

Unplug and replug the Power Cord. Also confirm that the cable is intact.

Confirm that the fuses are intact.

A plug-in module does

not function

The airway module does

not function

Remove and replace the module.

Confirm that the desired parameters are configured to be displayed.

Confirm that “Occlusion” or “Calibrating Gas Sensor” messages are not displayed.

Confirm that a D-fend water trap and a sample tube are attached.

Confirm that the desired parameters are configured to be displayed.

Remove and replace the module.

44

Document No. 896 623

Page 53

4 INTERFACING

You can interface external devices to the AS/3 and CS/3 monitor via B-UPI or B-UPINET Board and

Interface Module (M-INT). For interfacing an intra-aortic balloon pump, ECG and pressure signals

are available from the M-PT module.

Via B-UPI or B-UPINET board you can interface:

• Datex-Ohmeda monitors

• AS/3 Anesthesia Delivery Unit

• printers

Via M-INT you can interface:

• Datex-Ohmeda monitors

• some monitors of other manufacturers

• some anesthesia machines

General Service Guide

45

Document No. 896 623

Page 54

Datex-Ohmeda AS/3 Compact Monitor, CS/3 Compact Monitor

4.1 Interfacing Monitors via UPI Board, B-UPI

The parameters transferred to the Compact Monitor are summarized in table 4-1.

4.1.1 Interconnection Datex-Ohmeda Monitors

Use the UPI-Monitor Cable to connect Compact Monitor to Datex-Ohmeda monitors.

1. Make sure that the power to both devices is turned off.

2. Connect the 9 pin D-shaped connector to the X3 connector and the 44 pin D-shaped

connector to the X2 connector on the UPI Board. Tighten the finger screws.

3. Connect the 25 pin D-shaped connector to the corresponding connector on the rear of the

other monitor. Tighten the finger screws.

Table 1 Transference of Parameters, Datex-Ohmeda Monitors

Device Waveforms (analog) Numerics Alarms

Cardiocap CO

Capnomac

CO

Capnomac II

2

2

Et&Fi Airway gases, Respiration

rate, SpO

, Pulse rate

2

Et&Fi Airway gases, Respiration

rate.

Capnomac Ultima CO2, Pleth Et&Fi Airway gases, Respiration

rate, Spirometry, Sp

, Pulse

O2

rate, Pleth amplitude

Normocap 200

Normocap 200

CO

2

Et&Fi Airway gases, Respiration

rate.

OXY

Oscar

Oscar II

Oscar OXY

Satlite

Satlite II

CO2, Pleth Et&Fi Airway gases, Respiration

rate, SpO

, Pulse rate, Pleth

2

amplitude

Pleth SpO2, Pulse rate, Pleth

amplitude

Satlite Plus

Satlite Trans None SpO2,, Pulse rate, Pleth

amplitude

None

None

CO

, O2, Anesthesia agent,

2

respiration rate, Apnea, occlusion,

, pulse rate.

SpO

2

None

None

None

None

46

Document No. 896 623

Page 55

General Service Guide

4.1.2 Setting the Interfacing Parameters

Set the serial output mode of Datex-Ohmeda monitors: Capnomac Ultima, Satlite Trans and

Normocap to numeric. This setting can be stored into permanent memory through the startup

menu. See the monitors’ manual for further information.

4.1.3 Setting the Interfacing Parameters for the Compact Monitor

1. Press the Monitor Setup key.

2. Select Install/Service password (16-4-34).

3. Select Interfacing and combine a required parameter with an external monitor. Two letters,

al, denote alarm integration. The selection will be automatically stored in permanent

memory.

4. Press the Normal Screen key.

4.2 Interfacing with Datex-Ohmeda Monitors via UPINET Board, B-UPINET

It is possible to interface Datex-Ohmeda monitors to the Compact Monitor via the UPINET Board, BUPINET. The parameters transferred to the Compact Monitor are summarized in table 4-1.

NOTE: Because the analog inputs are missing, waveforms are not transferred to the Compact

Monitor if the UPINET Board, B-UPINET is used.

Interconnection

Use the B-INT-External Device Cable to connect the Compact Monitor to Datex- Ohmeda monitors.

1. Make sure that the power is turned off on both devices.

2. Connect the 9 pin D-shaped connector to the corresponding connector on the UPINET

Board, B-UPINET.

3. Connect the remaining 25 pin D-shaped connector to the corresponding connector on the

rear of the other monitor. Tighten the finger screws.

Setting the Interfacing Parameters for Datex-Ohmeda Monitors

Set the interfacing parameters for the Datex-Ohmeda monitors according to previously described

procedure.

Setting the Interfacing Parameters for Compact Monitor

Set the interfacing parameters for the Compact Monitor according to previously described

procedure.

Document No. 896 623

47

Page 56

Datex-Ohmeda AS/3 Compact Monitor, CS/3 Compact Monitor

4.3 Interfacing Monitors via M-INT

It is possible to interface Datex-Ohmeda monitors, Critikon Dinamap 1846SX, Abbott Oximetrix 3,

Baxter Explorer and Vigilance, Nellcor N-100, N-200 and N-1000 to the Compact Monitor via the

Interface Module, M-INT. Interface Module, M-INT, has two serial and analog connectors (X7 and

X8). The parameters transferred are summarized in tables 4-1 and 4-2.

NOTE: Using the Interface Module , M-INT disables interfacing with Datex-Ohmeda monitors via the

UPI/UPINET Board.

WARNING Always make sure that the combination complies with the international safety

standard IEC 60601-1-1 for medical electrical systems and with the

requirements of local authorities.

Table 2 Transference of Parameters, Other Monitors

Device Waveforms Numerics Alarms

Critikon

Dinamap 1846SX

Abbott

Oximetrix 3

Baxter

Explorer

Baxter

Vigilance

Nellcor

N-100

N-200

N-1000

None NIBP None

None SvO2/SaO2, CO None

None C.O., SvO2, REF, Tblood None

None C.O., SvO2, C.C.O.,

Pleth (analog) SpO2, Pulse rate None

4.3.1 Connection to Datex-Ohmeda Monitors

Use the INT-External Device Cable.

1. Make sure that the power to both devices is turned off.

2. Connect the 9 pin D-shaped connector to one of the connectors on the Interface Module,

M-INT. Tighten the finger screws.

None

Tblood

48

Document No. 896 623

3. Connect the 25 pin D-shaped connector to the corresponding connector on the other

monitor. Tighten the finger screws.

Page 57

General Service Guide

4.3.2 Connection to Critikon Dinamap 1846SX, Abbott Oximetrix 3 and Baxter Explorer

Use the INT-External Device Cable.

1. Make sure that the power to both devices is turned off.

2. Connect the 9 pin D-shaped connector to one of the connectors on the Interface Module,

M-INT. Tighten the finger screws.

3. Connect the remaining 25 pin D-shaped connector to the connector on the other monitor.

Tighten the finger screws.

4.3.3 Connection to Baxter Vigilance

Use the INT-Baxter Vigilance Cable.

1. Make sure that the power to both devices is turned off.

2. Connect one of the connectors to the corresponding connector on the Interface Module, M-

INT. Tighten the finger screws.

3. Connect the other 9 pin D-shaped connector to the on the other monitor. Tighten the finger

screws.

4.3.4 Connection to Nellcor N-100 and N-1000

Use the Monitor-Nellcor Cable.

1. Make sure that the power to both devices is turned off.

2. Connect the 9 pin D-shaped connector to on of the connectors on the Interface Module, M-

INT. Tighten the finger screws.

3. Connect the mono connectors to the corresponding connectors on the other monitor.

4.3.5 Connection to Nellcor N-200

Use the Monitor-Nellcor Cable.

1. Make sure that the power to both devices is turned off.

2. Connect one of the connectors to the corresponding connector on the Interface Module, M-

INT. Tighten the finger screws.

3. Connect the other connector to the corresponding connector on the other monitor. Tighten

the finger screws.

4. Connect the mono connectors to the corresponding connectors on the other monitor.

4.4 Interfacing Datex-OhmedaAS/3 Anesthesia Delivery Unit

It is possible to interface Datex-Ohmeda Anesthesia Delivery Unit to the Compact Monitor via the

UPI Board.

For further information, please contact your authorized Datex-Ohmeda distributor.

49

Document No. 896 623

Page 58

Datex-Ohmeda AS/3 Compact Monitor, CS/3 Compact Monitor

4.5 Interfacing Dräger Cicero and Cato

It is possible to interface Dräger Cicero and Cato to the Compact Monitor via the Interface Module,

M-INT.

For further information, please contact your authorized Datex-Ohmeda distributor.

WARNING Always make sure that the combination complies with the international safety

standard IEC 60601-1-1 for medical electrical systems and with the

requirements of local authorities.

4.6 Interfacing a printer

It is possible to interface a laser printer (either serial or parallel) to the Compact Monitor via the UPI

Board. Only serial printer can also be interfaced via the UPINET board. The printer must be PCL5

compatible.

WARNING Always make sure that the combination complies with the international safety

standard IEC 60601-1-1 for medical electrical systems and with the

requirements of local authorities.

WARNING Connecting the power supply cord of the printer to the wall socket may cause

the printer leakage current to exceed the limit specified for medical equipment.

Always connect the printer to an appropriate separating transformer.

4.7 Interfacing a computer

It is possible to interface a computer to Compact Monitor. For further information, please contact

your authorized Datex-Ohmeda distributor.

WARNING Always make sure that the combination complies with the international safety

standard IEC 60601-1-1 for medical electrical systems and with the

requirements of local authorities.

WARNING Connecting the power supply cord of the computer to the wall socket may cause

the computer leakage current to exceed the limit specified for medical