Page 1

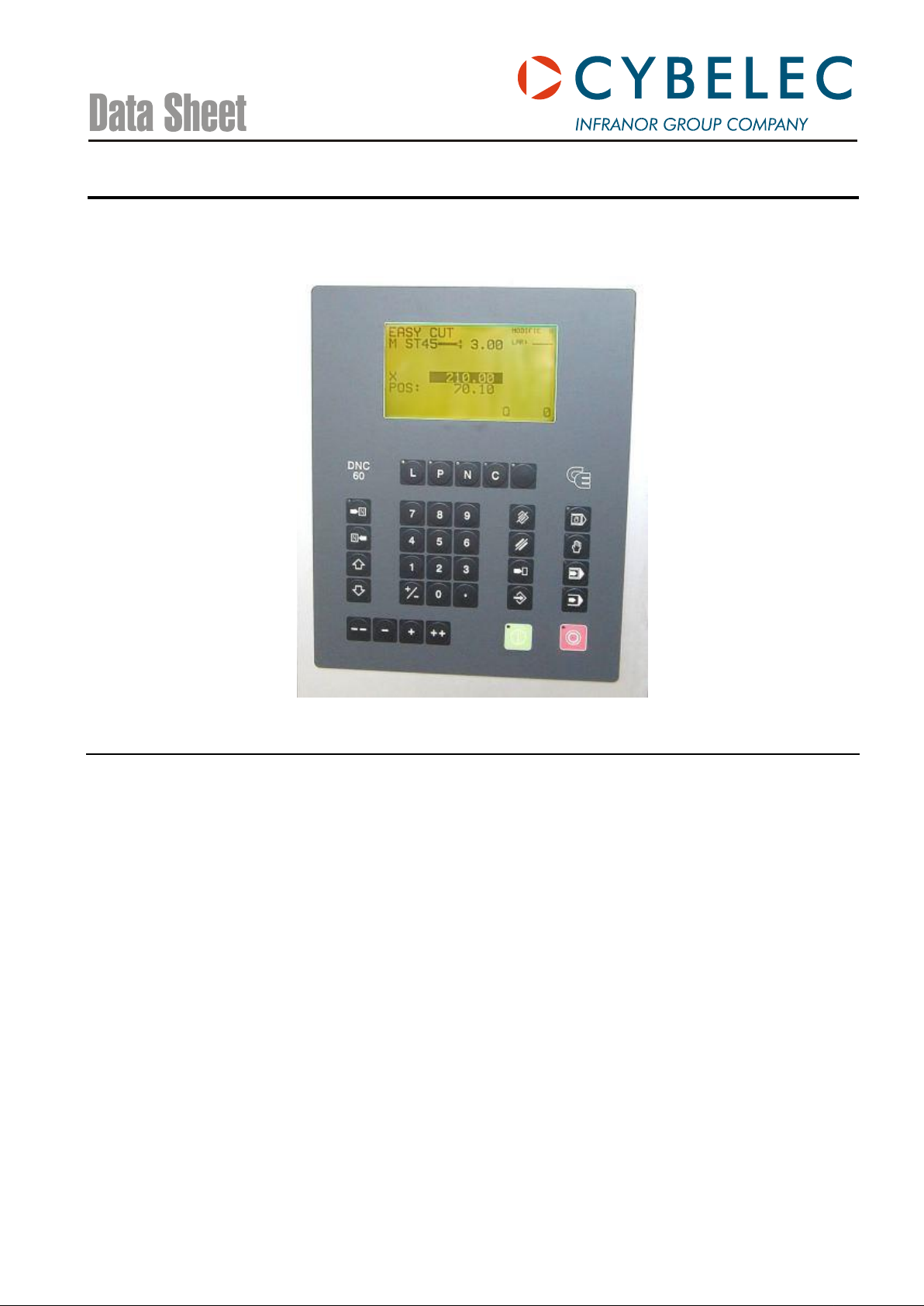

Numerical control DNC 60 G

The numerical control DNC 60 G is specifically intended and optimized for shears.

Its software simplifies the work of both the user and the integrator.

Advantages for the user:

A page entitled Easy-Cut is displayed when the machine turns on.

The user simply enters the desired position of the end stop and the thickness of the material.

The machine is adjusted automatically and the user can cut his sheet. He does not have to erase, memorize or change

mode. He simply activates the cut command.

It is as simple to use DNC 60 G as a positioner, but with the advantage of the automatic adjustments of a complex machine.

As with a normal numerical control, DNC 60 G also makes it possible to enter complicated cutting sequences (programs)

that can be memorized for consistent cutting work.

Clear messages on security measures or external dysfunctions are naturally displayed if necessary.

DNC 60 G is supplied with its backup software CYBACK_Win.

DNC 60 G can be connected to the powerful cutting optimizing software ARDIS via RS232. In this way the user can in real

time see on the PC screen the cutting plan and the current cut. For each cut, the DNC 60 G receives the new value.

DNC 60 G numerical control has many functions. A full page luminous LCD screen as well as a simplified keyboard with

large keys give a comfort of use comparable with that of a high-level numerical control.

There are generally 8 languages available directly in the DNC. With this numerical control, the CYBELEC experience offers

very fast programming that is much appreciated by users.

The FLASH memory makes it possible to update the software over an RS232 line.

Each DNC 60 G is supplied with the CYBACK software so that the contents of the numerical control, be it parameters

and/or the memorized parts, can be backed up.

60G_en.DOC C-PUB-CDS61GC-EN V1.1b 26.06.2006

Page 2

Advantages for the manufacturer:

The elements listed hereafter are available and can be configured in all numerical controls supplied with the standard

software (within the number of available axes and inputs/outputs).

Axis

Backgauge axis.

The DNC 60 G controls:

- the gauge retreat during the cutting process

- the retraction of the gauge, whether in mechanical way or hydraulic (with valves)

Shear functions

Easy_Cut page for an easy use like that of a positioner.

Management of the system pressure with ramp and pressure proportional valve.

Management of delays between the pressure valve (ON-OFF) and the direction valves.

Automatic management of:

- the blade gap (with one or two actuators and linearisation of the curve)

- the cutting angle

- the cutting length

according to the programmed material and thickness.

5 pre-programmable types of material.

Backgauge clearance during the cutting process (yes / no).

Blade gap with one or two motors.

Management of the cutting length by delay or by potentiometer.

Automatic backgauge correction according to the blade gap.

Sequence repetition, sub-programs, chaining of programs.

Nibbling function, allowing to bring down the blade by little phases.

Flying Cut function.

DNC 60 G is equipped with 8 inputs and 16 outputs 2.5A which make it possible to directly operate valves without passing

through relays.

The numerical control cycle directly controls the blade movements, the blade gap, the cutting angle and/or the cutting

length and the pressure.

No need for automats or numerous relays. The electrical wiring is thus greatly simplified and the size of the cabinet

consequently reduced, which results in a significant reduction in material, wiring and start-up costs.

The parameters are memorized and the CYBACK software loaded via an RS232 linkup.

The flexibility of the software makes it possible for the manufacturer to configure the axes, the inputs-outputs and auxiliary

functions according to his needs.

DNC 60 G is designed to be easily integrated into a control panel or electrical equipment cabinet. Its case, which is

ingeniously designed, serves as a mechanical and electrical protection and a fixing element.

The DNC 60 G is of modern design and all its electronics are concentrated on a single board, most of which is assembled

in SMD.

Simple connection technology and a single 24VDC power supply unit considerably reduce the material and wiring costs.

Axis and shear functions

60G_en.DOC V1.1b

Page 3

Technical characteristics

Multiprocessor design using ASIC and SMD components. This allows high integration and ensures great reliability.

Keyboard

Keyboard with large keys.

Screen

Monochrome graphic LCD screen 75 x 130 mm (visible surface)

240 x 128 pixels with automatic contrast correction.

Work memory

SRAM

"Data" memory

FLASH with updating possibility of the software via RS232.

Port

1 RS232-port.

Axis

N2X axes with high speed counting (250 Khz).

Unit of length

Conversion Inch/mm, TON/TONS, etc.

Power supplies

DNC: + 24 VDC (min. 18 – max. 35 VDC) max. 1 A (DNC) 20 W.

Electrical cabinet: + 24 VDC ± 10% for the digital inputs/outputs.

Encoder X3 inputs

Line driver. Attention: the inverted signals are compulsory on all encoder

inputs.

Power supply for encoders X3

5 VDC (supplied by the DNC) max. 900 mA for all encoders.

Digital inputs

8 optocoupled inputs 24 VDC stabilized 3 %.

Analogic inputs

According to configuration 0-5, 0-10, 0-24 VDC.

Digital outputs

16 optocoupled short circuit proof outputs

(whereof 2 intended to axis X sp/sn).

Source 24 VDC max. 2,4 A / output.

Possibility to define 2 outputs for doubling the current.

Voltage outputs (axes, functions)

0-10 VDC output impedance Zout < 100 , load Zl 10 k .

Temperature, pollution level,

relative humidity, and

height during work

Min. 5° Celsius, max. 40° Celsius.

Pollution level 2. Relative humidity (10 to 85% non condensing).

Max. height 2000 m.

Dimensions

Height: 290 mm / Width: 239 mm / Depth 80 / 140 (with jacks) mm.

EC Directives

Our numerical controls comply with the EC Directives

89/336/EEC and 73/23/EEC.

60G_en.DOC V1.1b

Page 4

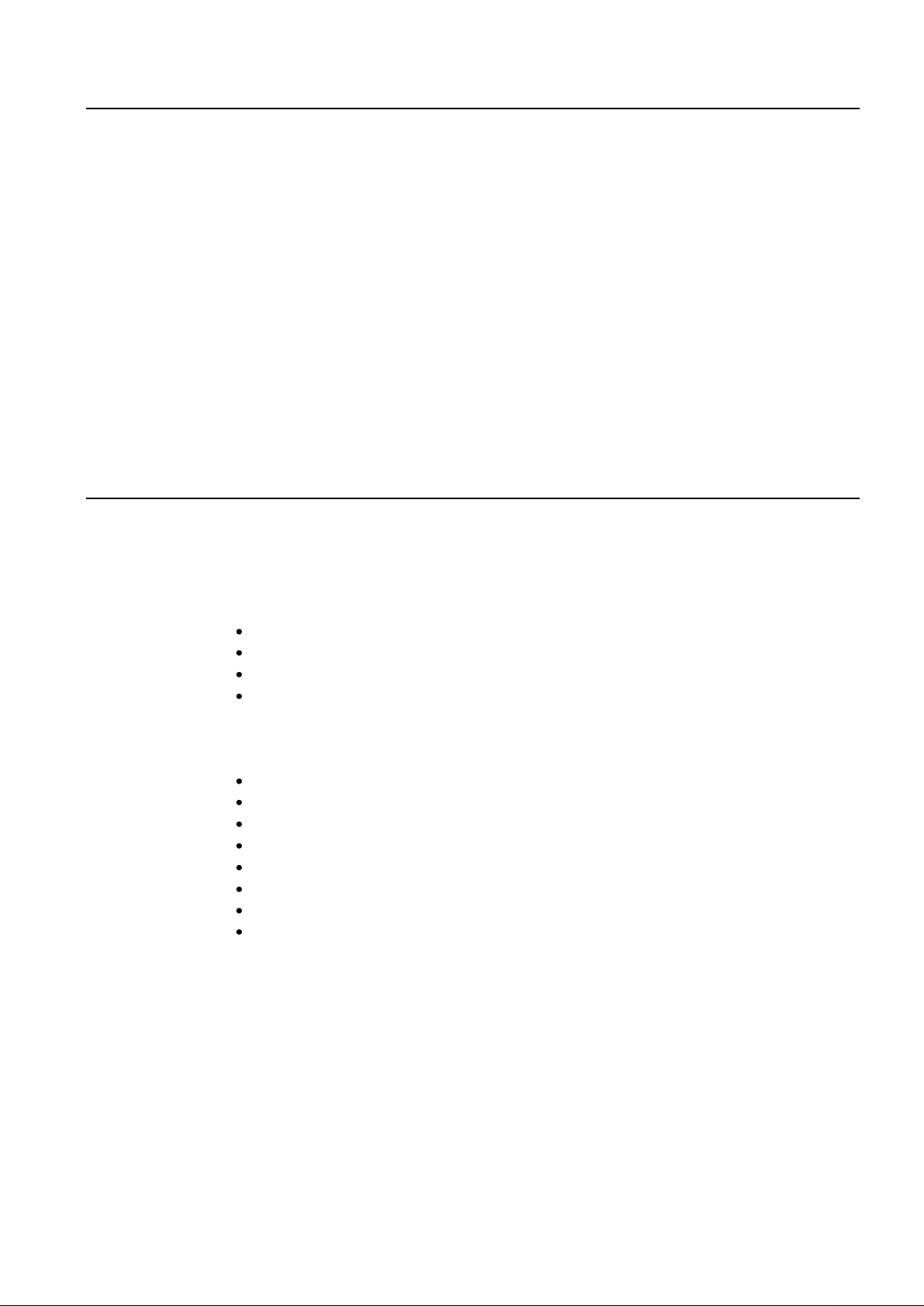

5 6

3 4

1

2

J16

J5

J7

J6

J8

J9

J13

J12

J17

J10 J11

J15

J18

1

Pin N°

20

12345

6789

Sub 9 pins

Female

54321

Sub 9 pins

Male

Modification rights reserved

Maximum cutout: 284.0 x 228.0 * = option 24 or 32 outputs

60G_en.DOC V1.1b

Loading...

Loading...