Page 1

DNC 60 G16 Manuel d’utilisation

DNC 60 G16 User Guide

Anglais

Code CYB: V-DOC-60G16-EN

Fichier: 60G16_EN.DOC

Les informations sur cette page sont purement internes et n'apparaissent pas

sur la notice qui sera distribuée au client.

Évolution de la notice:

V. 1.1 20.02.2004 Création de la notice GCUT sur la base de la DNC 60 GS.

Nouveau: la fonction EASYCUT.

V. 1.2 10.02.2005 Mise à jour par D. Jaton.

Supprimé le PRELIMINARY, changé la photo de page de garde.

Suppression du chapitre "Page PRODUCTION".

Ajout sous "Page EASYCUT" du § "Page EasyCut en Mode Easy

Optimizer".

Ajout du chapitre "Fonctionnalités".

Diff. autres petites modif.

V. 1.3 21.04.2005 Nouvelle mise à jour par D. Jaton.

Modifs et ajouts sous chapitre "La page EASYCUT" + "Effacement

du buffer" (dans Programmation).

Ajouté dans les "Fonctionnalités" le chapitre "Décalage origine

tôle".

V. 1.4 14.09.2005 Nouvelle mise à jour par D. Jaton.

Modifs sous chapitre "La page EASYCUT" + "Entrée dégagement

X3".

Ajouté le chapitre "Dégagement de la butée arrière X3".

V. 1.5 13.10.2005 Nouvelle mise à jour par Ch. Ingold.

Ajouté deux schémas dans le chapitre "Escamotage de la butée

arrière X3".

Déplacé les chapitres "Visualisation des pages entrées/sorties en

cycle", "Entrée dégagement X3", "Escamotage de la butée arrière

X3", "Dégagement de la butée arrière X3", "Escamotage

hydraulique de la butée arrière X3", "Entrée Set Pression" et

"Manipulation Montée/Descente du couteau facilitée" dans la

notice PM60GCUT_FR.DOC.

V. 1.6 18.01.2007 Nouvelle mise à jour par Ch. Ingold

Complété le chapitre "Messages interactifs", Mis à jour versions de

soft, Ajouter chapitre Hyper Terminal, Mis à jour écrans DNC,

Modifié le chapitre EASYCUT, Ajouter le chapitre Restauration

interne

V 1.6b 25.01.2007 Modifier chapitre Protection niveau d’accès

V 1.6c 20.06.2007 Rajouter une introduction et les limitations dans chapitre

Page 2

EasyOptimizer

V 1.7 11.12.2007 Ajouté la section "Sheet Support" (Support tôle)

V1.8 11.04.08 Ajouté la section "Anti-Twist"

V1.8a

V1.9

25.09.08

05.05.11

Changé le titre "DNC 60 GCUT" en "DNC 60 G16"

Renommé le fichier 60GCUT_xx.DOC

Relecture Jamie

Page 3

DNC 60 G16

User Guide

CYBELEC SA Tel. ++ 41 24 447 02 00

RUE DES UTTINS 27 Fax ++ 41 24 447 02 01

CH - 1400 YVERDON-LES-BAINS E-Mail: info@cybelec.ch

SWITZERLAND

V-DOC-60G16-EN

Page 4

Information in this document is subject to change without notice, and does not represent

a commitment on the part of CYBELEC SA.

The software described in this document is furnished under a license agreement or nondisclosure

agreement. The software may be used or copied only in accordance with the terms of the agreement. It is

against the law to copy the software on any medium except as specifically allowed in the license or

nondisclosure agreement.

Copyright CYBELEC SA. 1991

All rights reserved.

Important:

This notice explains normal and standard programming operations for the numerical control.

In view of the fact that numerical controls can be equipped with configurable functions by the press

manufacturer for his own specific purposes, please refer to the manufacturer-supplied complementary

instructions regarding the programming of these functions.

AutoCAD

CYBELEC

is a registered trade mark of Autodesk Inc..

is a registered trademark of CYBELEC SA.

is a registered trade mark of Xerox Corporation. Ethernet

, PC/AT , PC Network , Token Ring Network

IBM

are registered trademarks of the International Business Machines Corporation.

is a registered trade mark of Microsoft Corporation. MS-DOS

MS-Windows is a registered trade mark of Microsoft Corporation.

is a registered trade mark of Novell, Incorporated. Novell Netware

Windows NT

is a registered trade mark of Microsoft Corporation.

Page 5

SAFETY AND MAINTENANCE INSTRUCTIONS

The operator must be trained for working with the

machine on which the numerical control is installed.

Improper use of the numerical control can cause

heavy damage on equipment and/or injuries to

people.

Modification of machine parameters can cause

important material damage or lead to irregular

product quality.

The rear panel may only be removed by a qualified

technician (danger of electrocution).

Do not expose the numerical control to excessive

humidity so as to avoid any risk of electrocution and

any deterioration of the equipment.

Make sure the numerical control is disconnected

from the mains power before carrying out any

cleaning. Do not use liquids based on alcohol or

ammoniac.

In case of malfunction of the numerical control, call a

technician.

Do not expose the numerical control to direct sun

rays or any other heat source.

Do not place the numerical control in the

neighbourhood of magnetic equipment such as

transformers, motors or devices which generate

interference (welding machines, etc.)

Replace fan filters at regular intervals so as to avoid

overheating.

SAFETY AND MAINTENANCE INSTRUCTIONS PAGE I

Page 6

This page has been left blank intentionally.

PAGE II USER GUIDE DNC 60 G16

Page 7

LICENSE AGREEMENT FOR CYBELEC SOFTWARE

GENERAL COPYRIGHT

The CYBELEC software is protected by Copyright, and all the copying rights are reserved.

The CYBELEC software may only be installed and used in authorized equipments (PC or DNC).

The user manuals are also covered by copyright, and all rights to use and to copy are reserved.

This document may not, in whole or in part, be copied, photocopied, reproduced, translated or reduced

without prior consent, in writing, from CYBELEC.

SPECIAL DISKETTE COPYRIGHT

The legal users of this software product are authorized only to copy the contents of the diskette into the

memory of the computer to run the program, and to make one backup copy of the original diskette for

safety purposes in case of loss of the original program.

Unauthorized copying, duplicating, selling or otherwise distributing this product is a violation of the law.

SPECIAL EPROM COPYRIGHT

The CYBELEC DNC and CNC units in which the original software made by CYBELEC has been

replaced by a copy not made by CYBELEC, and without written authorization of CYBELEC, will

immediately lose their warranty.

WARRANTY

CYBELEC does not warrant that its software products will function properly in every computer and

programming environment.

The limitations of use of a software product and its technical specifications are decided by CYBELEC

only; CYBELEC solely is entitled to decide upon conformity and performance of a given software.

The CYBELEC software does not compensate for incompatibilities in operating system revisions or

versions.

Running the CYBELEC software under various revisions or versions, or switching between different

versions or revisions may result in loss or alteration of data.

LICENSE AGREEMENT PAGE III

Page 8

SOFTWARE UPDATE SERVICE

Purchase of the CYBELEC software entitles the user, during one year, to delivery of software updates of

the "correction" type.

During the use of a revised or corrected version of the software it may occur that data (program,

parameters, etc.) is lost, or that the equipment or its connections need to be modified; these effects are not

always foreseeable and do not engage CYBELEC's responsibility.

TERMINATION

This agreement shall automatically terminate upon any act of bankruptcy by or against licensee, upon any

assignment for the benefit of creditors of the licensee, upon any attachment execution of judgement or

process against licensee or its assets that substantially inhibits its ability to do business, or upon

dissolution of licensee.

CYBELEC has the right to terminate this agreement immediately, should the licensee violate the

aforementioned conditions.

Within 30 days of termination of this agreement for any reason, licen see shall at his option, either:

return to CYBELEC or authorized dealer all existent copies of such software and related materials, or

furnish to CYBELEC evidence satisfactory that the original and all copies of the software, in whole

and in any form, have been destroyed.

LIMITATION OF LIABILITY

The foregoing warranty is instead of all other warranties, expressed or implied.

Licensee further agrees that CYBELEC shall not be liable for any lost profits, lost savings, loss of use, or

other incidental or consequential damages arising from the use or inability to use the software, or fo r any

claim or demand against licensee by any other party.

In no event shall CYBELEC be liable for consequential damages, even if CYBELEC has been advised of

the possibility of such damages.

CYBELEC does not warrant that the functions contained in the software will meet the licensee's

requirement or that the operation of the software will be totally error free.

Should the software prove defective, the licensee (and not CYBELEC or an authorized dealer or

representative) will assume the entire cost of all necessary service, repair or correction.

CYBELEC warrants the diskettes, EPROMS or other magnetic support or cassettes on which the

programs are supplied to be free of defects in material and workmanship under normal use for a period of

90 days from the date of shipment to the licensee as evidenced by a copy of the packing slip.

PAGE IV LICENSE AGREEMENT

Page 9

LIMITATION OF REMEDIES

CYBELEC's entire liability and the licensee's exclusive remedy shall be as follows:

The replacement of any diskettes or EPROMS or magnetic support media or cassettes not meeting

CYBELEC's limited warranty and which materials are returned to CYBELEC or an authorized

CYBELEC representative with a copy of the packing slip, or

If CYBELEC or its representative is unable to deliver replacement diskettes, magnetic support media,

EPROM or cassettes which are free of defects in materials or workmanship, the licensee may terminate

this agreement under the terms and conditions herein mentioned, and the purchaser's money will be

refunded.

GENERAL

The licensee acknowledges that he has read this agreement, understands it and agrees to be bound by its

terms and conditions.

The licensee agrees to hold CYBELEC harmless on all liability associated with licensee's breach of this

agreement including, but not limited to, all reasonable attorney's fees and court costs, if any.

This license agreement shall be governed by Swiss law; place of jurisdiction is Lausanne, Switzerland.

MAINTENANCE

CYBELEC will provide one year of software maintenance. The extent of maintenance, and response time

for furnishing same, shall be at the sole discretion of CYBELEC. Maintenance shall normally include

correction of errors in code, correction of errors in supporting documentation, update versions of the

covered software which may be released by CYBELEC during the maintenance period.

In no event shall CYBELEC be obliged to provide technical support in attempting to resolve problems or

difficulties resulting from licensee's modification of the licensed software; any such modification by

licensee is entirely at licensee's own risk.

LICENSE AGREEMENT PAGE V

Page 10

This page has been left blank intentionally.

PAGE VI LICENSE AGREEMENT

Page 11

25.09.2008 V. 1.8a

TABLE OF CONTENTS

SAFETY AND MAINTENANCE INSTRUCTIONS ........................................................................... I

LICENSE AGREEMENT FOR CYBELEC SOFTWARE .................................................................. III

FOREWORD .................................................................................................................................... 5

EASY CUT ....................................................................................................................................... 7

Programming a cut 7

PROGRAMMING A PRODUCT ....................................................................................................... 9

Operating procedure ........................................................................................................... 9

Clearing the buffer ............................................................................................................... 9

Programming a sequence ................................................................................................... 9

Creating a second (or nth) sequence ................................................................................... 10

Searching for a sequence ................................................................................................... 10

Deleting a sequence ............................................................................................................ 10

Inserting a sequence ........................................................................................................... 11

Jumping a sequence ........................................................................................................... 11

Repeating a sequence ........................................................................................................ 11

Repeating a group of sequences ........................................................................................ 11

Saving and searching for programs in the internal memory ............................................... 12

Saving a product ................................................................................................................. 12

Recalling a product from the internal memory .................................................................... 12

Deletion of a product from the internal memory .................................................................. 13

Complete clearance of the internal memory ....................................................................... 13

Modifying a program in the internal memory ....................................................................... 13

DESCRIPTION OF THE NUMERICAL CONTROL DNC 60 G16 .................................................. 15

Physical and logical organization ........................................................................................ 15

The memories ..................................................................................................................... 16

Work memory (buffer memory) 16

DNC internal memory 16

The user interface ............................................................................................................... 17

The screen 17

The keyboard 17

Presentation of the screen pages ....................................................................................... 21

Cursor accessible fields 21

THE SCREEN PAGES ..................................................................................................................... 23

The MENU page .................................................................................................................. 23

The EASYCUT page ........................................................................................................... 24

List of products in the internal memory ............................................................................... 26

List of products according criteria ....................................................................................... 27

Data link RS232 page ......................................................................................................... 28

DNC <–> PC TRANSFER page 28

60G16_EN.DOC TABLE OF CONTENTS PAGE 1

Page 12

PRODUCT page (AF Information) ...................................................................................... 29

PRODUCT page ................................................................................................................. 30

Sequences list page ........................................................................................................... 32

SEQUENCE page (small characters) ................................................................................. 34

Definition of the work cycle 37

SEQUENCE page (large characters), Programming ......................................................... 38

SEQUENCE page (large characters), Operating ............................................................... 39

Corrections page ................................................................................................................ 40

Axes datum ......................................................................................................................... 40

Machine parameters ........................................................................................................... 41

FUNCTIONALITIES ......................................................................................................................... 43

Nibbling mode 43

Blade Up Output 43

Offset of sheet origin 44

Sheet Support 45

Screen Display (for the Operator) 46

Manual Mode 46

Anti-Twist Device 46

Screen Display (for the Operator) 46

Manual Mode 47

TRANSFER ..................................................................................................................................... 48

Testing the serial port ......................................................................................................... 49

CYBACK ............................................................................................................................. 50

PROTECTING ACCESS LEVELS .................................................................................................. 52

General Information ............................................................................................................ 52

The users ............................................................................................................................ 53

Access by password ........................................................................................................... 54

Access to levels superior to 3 ............................................................................................. 55

Change password ............................................................................................................... 56

MAINTENANCE .............................................................................................................................. 58

In case of failure ................................................................................................................. 58

Initial checks to be carried out 58

Possible memory pollution 58

The Initialization page 59

Before calling for technical help 60

Internal backup (save) 61

Internal restoration of PMs and tools 63

SAFETY AND INTERACTIVE MESSAGES .................................................................................... 66

The interactive messages ................................................................................................... 66

PAGE 2 TABLE OF CONTENTS

Page 13

PRINT SCREEN TO THE PRINTER (OR ASCII FILE) ................................................................... 74

HyperTerminal ..................................................................................................................... 75

Connection 75

Preparation 76

Entering the screens 80

EASY OPTIMIZER ........................................................................................................................... 82

Information 82

Install 83

First launch 84

INDEX .............................................................................................................................................. 93

TABLE OF CONTENTS PAGE 3

Page 14

Page 15

FOREWORD

This manual will familiarize you with the programming of the DNC 60 G16. It

provides the information needed for you to program products and tools.

It will also inform you on how to search for, copy, modify and save these data.

FOREWORD PAGE 5

Page 16

This page has been left blank intentionally.

PAGE 6 USER GUIDE DNC 60 G16

Page 17

EASY CUT

The EASY CUT page is accessible by pressing the key once. If the

menu page is displayed, press the

key again.

EASY CUT STOP PA

STL

2.00 1000

____

X _____.__

ACTUAL _____.__

EASY OPT:_

Q_____

This page allows you to quickly program a cut, and/or briefly stop

production to perform a single cut without modifying or losing data in the

production program.

PROGRAMMING A CUT

Enter the thickness and the material.

Enter the distance at which the X gauge is to be positioned.

Press the START button or the pedal and the axes will position to the

desired values.

Actuate the pedal to cut.

Once the blade returns you can enter new data or actuate the pedal for a

new cut.

PAGE EASY CUT PAGE 7

Page 18

This page has been left blank intentionally.

PAGE 8 USER GUIDE DNC 60 G16

Page 19

PROGRAMMING A PRODUCT

OPERATING PROCEDURE

Enter the data

Test the product

Correct the product (if necessary) using the COR. page

Store (optional) the product

Begin production

CLEARING THE BUFFER

To enter a new program into the buffer (work memory) it is best to clear

its contents before entering new data:

Press

Press

Place the cursor on N field using the

Enter the value 99.

Press

The DNC should now display the message FREE in the interactive field

at the top right of the screen.

In the Material field, the DNC should display the 1st material defined in

the machine parameters. In the Thickness field, the DNC should display

the default thickness.

to set the DNC in programming mode.

to select the sequence page.

to clear the buffer (work memory).

PROGRAMMING A SEQUENCE

or keys.

Press the or key to place the cursor on the next

programmable field.

Enter the desired value and press the

and move on to the next field.

PROGRAMMING A PRODUCT PAGE 9

or key to validate

Page 20

CREATING A SECOND (OR NTH) SEQUENCE

Press the key at the end of the program to add a sequence.

Note: when the

program.

The DNC displays the message COPIED and the number in the N field is

incremented by 1. The DNC has now created a sequence identical to the

previous one.

Enter the desired values for the new sequence.

Repeat the procedure to add a new a new sequence.

At this point you can test the product in

mode and make any necessary corrections.

The product has not as yet received a number; it will receive a number when

it is stored in the memory (see the Storage and recall of programs in the

internal memory paragraph below).

key lights up, this indicates the last sequence of the

SEARCHING FOR A SEQUENCE

Place the cursor on the N field.

Enter the number of the sequence to be found.

mode or directly in

Press the

DELETING A SEQUENCE

Place the cursor on the N field.

Enter the number of the sequence to be deleted.

Press the

Press the

This operation automatically restructures (renumbers) the remaining sequences

of the product.

key.

key.

key.

PAGE 10 USER GUIDE DNC 60 G16

Page 21

INSERTING A SEQUENCE

Inserting a sequence (with automatic re-numbering of the product

sequences):

Select the sequence after which you want to insert a new sequence

(

Place the cursor on the N field.

Press the

The DNC creates a copy of the selected sequence and places it just

after the selected sequence.

Enter the desired values for the new sequence.

Inserting a sequence by transferring an existing sequence.

Search for the sequence to be inserted.

Place the cursor on the N field.

Enter the number of the sequence where the new sequence is to be

inserted.

Press the

JUMPING A SEQUENCE

...).

key.

key.

Enter 0 in the CY field.

REPEATING A SEQUENCE

Enter the desired number of repetitions the CY field.

If the CY field is empty, the sequence is executed only once (identical to

CY = 1).

REPEATING A GROUP OF SEQUENCES

Select the last sequence of the group to be repeated.

In the JS field, enter the number of the first sequence of the group.

In the FOIS field, enter the number of repetitions minus one un it.

PROGRAMMING A PRODUCT PAGE 11

Page 22

SAVING AND SEARCHING FOR PROGRAMS IN THE

INTERNAL MEMORY

Searching, saving and deleting products can only be performed in the

mode.

The field concerned is the PRODUCT field found on the top left of most

pages.

When this field exists, products can be searched for, saved and deleted

directly from this field.

SAVING A PRODUCT

A created (and tested) product can be saved for future use.

Choose an unused product number.

Place the cursor on the PRODUCT field, enter the chosen number

and press the

The message STORED is displayed once the product is saved.

key.

If the message EXISTS appears, it means that the chosen number is

already used by another program. In this case you must choose another

number.

Note: The number under which the product is to be saved must be

programmed last in the PRODUCT field, just before pressing the

Otherwise, when the cursor leaves the field, the previous value is displayed.

All other data must be entered before saving the product.

RECALLING A PRODUCT FROM THE INTERNAL

MEMORY

Place the cursor on the PRODUCT field

Enter the number of the product to be found and press the

The recalled program automatically replaces the program already in the

buffer.

The replaced program can only be recovered if it was saved beforehand.

key.

key.

PAGE 12 USER GUIDE DNC 60 G16

Page 23

DELETION OF A PRODUCT FROM THE INTERNAL

MEMORY

Place the cursor on the PRODUCT field.

Enter the number of the product to be deleted.

Press the

The interactive field displays DELETED.

If the product does not exist the message IGNORE is displayed.

key.

COMPLETE CLEARANCE OF THE INTERNAL MEMORY

Place the cursor on the PRODUCT field.

Enter the value 999.

Press the

The DNC displays DELETED.

key.

MODIFYING A PROGRAM IN THE INTERNAL MEMORY

Recall the program to be corrected as explained above.

Modify the program.

Delete the former program by placing the cursor on the PRODUCT

field and pressing the

Enter the new program by pressing the

key.

key.

PROGRAMMING A PRODUCT PAGE 13

Page 24

This page has been left blank intentionally.

PAGE 14 USER GUIDE DNC 60 G16

Page 25

DESCRIPTION OF THE NUMERICAL CONTROL

DNC

60 G16

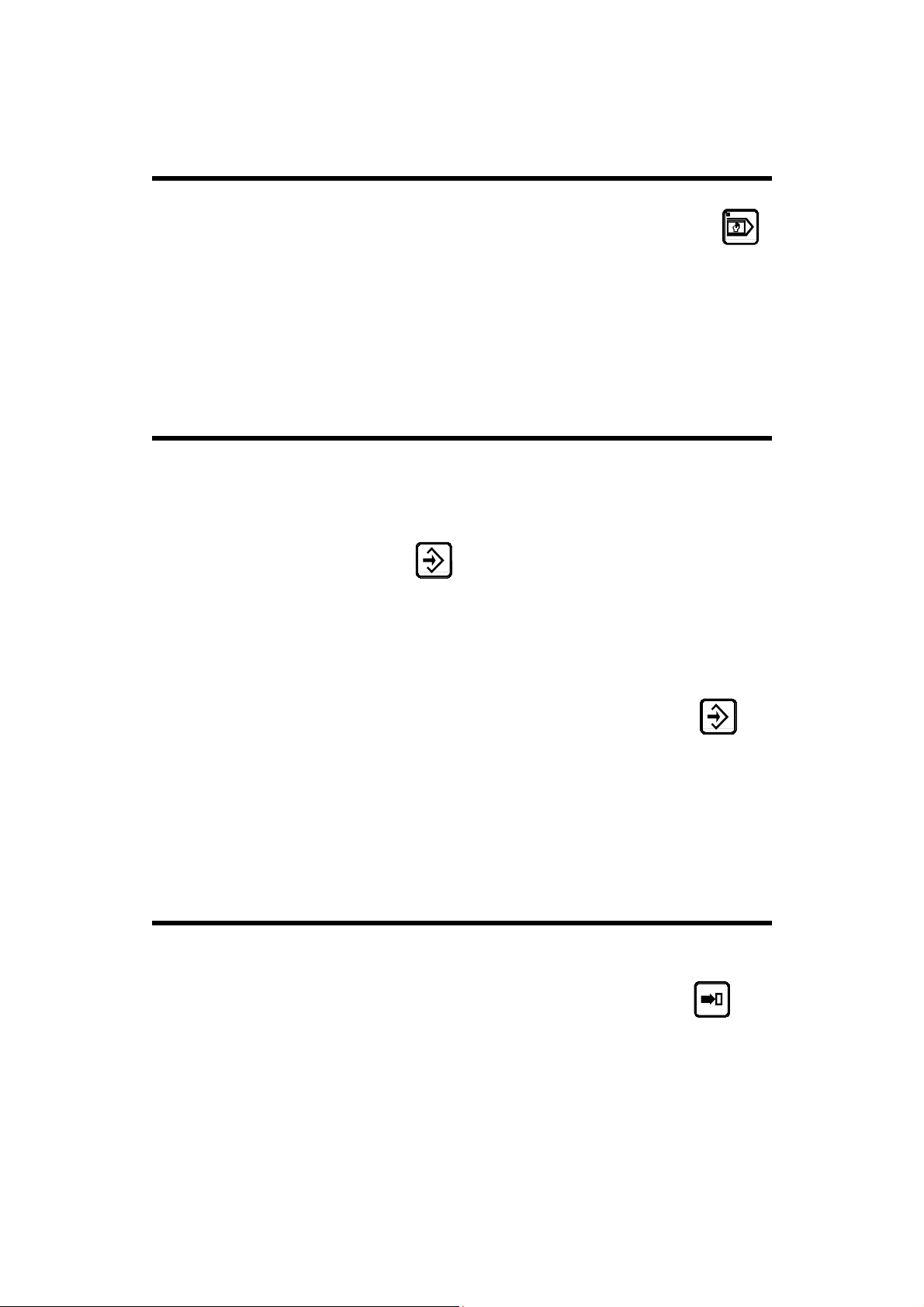

PHYSICAL AND LOGICAL ORGANIZATION

The following diagram is a schematic representation of the physical and logical organization of

the DNC 60.

RS232

Screen Keyboard

interface

Axes command and

surveillance

Motors

encoders

Microprocessors, memory

PCBs

Auxiliairy

functions

DESCRIPTION OF THE DNC 60 G16 PAGE 15

Page 26

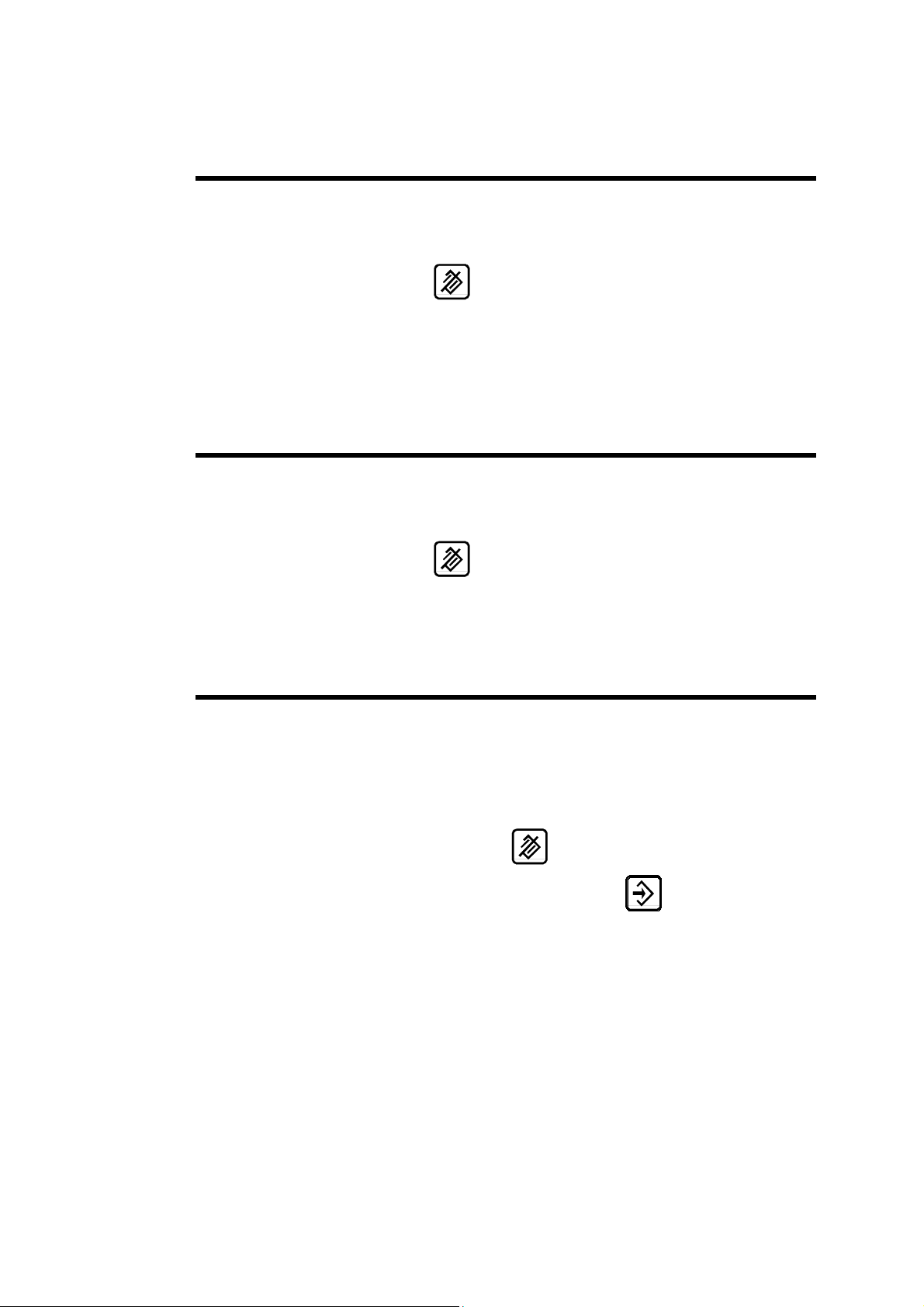

THE MEMORIES

The different memories of the DNC 60 can be represented schematically as

follows:

ROM

RAM

+

battery

The DNC 60 is equipped with a ROM memory containing the DNC 60

program and a RAM memory, which allows the programming and saving of

products and machine parameters.

The RAM is divided into several zones each having a different use.

Program

Work memory

Internal no n vola t i le memory

Products, production,

machine parameters,

axes position

WORK MEMORY (BUFFER MEMORY)

This is a static RAM used for programming, modifying and executing

products.

It is a temporary memory containing data which is deleted whenever another

product is called for.

The content of this memory is kept if the DNC power supply is cut, even if it

has not been previously saved in the internal memory.

DNC INTERNAL MEMORY

This non-volatile internal memory, of the static RAM type maintained by a

lithium battery, contains the products, axes positions and numbers

concerning the production and machine parameters.

No programming or modifications are made directly in this memory.

PAGE 16 USER GUIDE DNC 60 G16

Page 27

THE USER INTERFACE

THE SCREEN

The screen displays the products and machine parameters as well as all other

useful information for programming and machine work.

The keys located on the front of the DNC 60 are used for selecting the screen

pages and entering data.

A cursor indicates where the user can intervene.

THE KEYBOARD

The keyboard is divided into several zones:

a) Numerical keyboard

b) Screen page selection keys

c) Working mode selection keys

d) The control keys

e) The cursor keys

f) Other keys

a) Numerical keyboard:

The numerical keys as well as the

numbers or values into the different fields.

b) The screen page selection keys:

MENU key:

Double function key.

Pressing the key once opens the EASY CUT

page.

Pressing the key a second time displays the

MAIN MENU page.

PRODUCT LIST key:

Pressing this key displays the list of products

in the DNC memory.

PRODUCT key:

Visualization of the product data (sequence 0)

and shear functions.

SEQUENCE key:

Triple function key.

Pressing the key once displays all the values of

the current sequence.

Pressing the key a second time displays the

main values of the sequences and axes in large

characters.

Pressing a third time displays the main values

of the sequence with the secondary values of

the axes in large characters.

and keys are used to enter

DESCRIPTION OF THE DNC 60 G16 PAGE 17

Page 28

CORRECTION key:

This key displays the correction page which

allows corrections to be made to the current

sequence, as well as to the entire product.

c) The working modes

PROGRAMMING mode:

Allows you to enter, modify and read data.

Allows you to save, search for and transfer

programs.

Pressing the

button or pedal will

automatically switch the DNC to automatic

mode and start the axes and functions.

MANUAL mode:

Allows axis movement and auxiliary functions

using the

keys.

SEMI-AUTOMATIC mode:

Allows a machine cycle with the current

sequence values without automatic sequence

changes.

This mode is used to make adjustments while

producing the first product, as well as for

products with only one cut.

The sequence change is made using the

keys.

Note: The product counter Q does not

function in this mode.

AUTOMATIC mode:

Standard product production mode.

The DNC automatically changes sequence

after each cut.

Changing directly from "programming" mode

automatically forces the first sequence of the

program.

Changing from "programming" mode to "semiautomatic" mode, and then to "automatic"

mode, keeps the current sequence for

execution.

This allows you to pick up the production of a

product without having to make "empty"

cycles.

PAGE 18 USER GUIDE DNC 60 G16

Page 29

d) The controls

DELETE key:

Allows you to delete a sequence or a program

when the cursor is placed on the PRODUCT

or N fields.

Only possible in PROGRAMMING mode.

CLEAR key:

This key allows you to delete data selected by

the cursor.

Pressing this key twice, on most pages, deletes

all the data on the page.

SEARCH key:

According to the cursor position, this key

allows you to:

- search for a product

- search for a sequence

- search for a screen page

- execute a transfer

Only possible in PROGRAMMING mode.

STORE (save) key:

According to the cursor position, this key

allows you to:

- save the current program in the DNC

internal memory

- create (insert) a new sequence into an

existing program

- copy (teach) the value of an axis positioned

manually in the current sequence.

This key is only valid in programming

(saving and inserting) mode and in manual

(teach) mode.

DESCRIPTION OF THE DNC 60 G16 PAGE 19

Page 30

e) The cursor keys

NEXT SEQUENCE/PAGE key:

This key allows you to scroll trough pages of

the same type. It also allows you to display the

next page when a series of information is on

several pages.

E.g.: program sequence

production pages

parameter pages

In PROGRAMMING mode, this key also

allows you to create an identical sequence

(copy function) to the previous one as long as

the last sequence of the program is selected.

The incorporated LED indicates whether the

sequence is the last of the program.

PREVIOUS SEQUENCE/PAGE key:

Allows you to scroll back through pages of the

same type.

Works in all modes except in automatic mode.

f) Other keys

Cursor up, to the next accessible field.

Cursor down, to the next accessible field.

START key:

Controls:

The movement of the axis and auxiliary

functions.

During movement the LED lights up.

An indexation (optional, depending on the

configuration) of digital axes, when this key

is first pressed after switching on the DNC.

To indicate that an index is being taken the

LED remains on until the indexes are received.

Indexes can only be taken in

or

modes.

STOP key:

Depending on the selected work mode, this key

stops the axes or auxiliary functions that are in

movement.

The Stop LED will remain on until you press

it a second time.

NB: No axes (or auxiliary function) movement

will be authorized unless the stop LED is

off.

PAGE 20 USER GUIDE DNC 60 G16

In this group of other keys, you will also find

all the movement keys connected to the

MANUAL mode.

Page 31

PRESENTATION OF THE SCREEN PAGES

CURSOR ACCESSIBLE FIELDS

By default, the cursor is located on the programmable field on which it was

placed during the last intervention on that page.

The cursor can be moved to the previous or following fields by pressing the

or key.

Regardless of the cursor position on the page, pressing the

keys simultaneously moves the cursor to the first programmable field

on the page.

When the cursor is placed on a field, you can:

introduce a number or value using the numerical keyboard.

delete the contents using the

(Important: on certain pages, pressing the

programmable fields on the page).

key.

key twice can delete all the

and the

DESCRIPTION OF THE DNC 60 G16 PAGE 21

Page 32

This page has been left blank intentionally.

PAGE 22 USER GUIDE DNC 60 G16

Page 33

THE SCREEN PAGES

THE MENU PAGE

Press the key twice to access the Menu page..

CHOICE ? 7 STOPPED

1 DATA LINK RS232

2 DISPLAY AXES

3 DISPLAY AF

4 DISPLAY CY/JS/TI

5 MACHINE MESSAGES

6 PROGRAMMING AXES DATUM

7 PROGRAMMING MACHINE PARAMETERS

To select one of the pages listed on the screen, enter its corresponding

number in the margin. Your choice is displayed in the CHOICE?__ field.

Press the

All the pages can be displayed from any mode, but it is only possible to

program in the PROGRAMMING mode.

key to display the page.

THE SCREEN PAGES PAGE 23

Page 34

THE EASYCUT PAGE

When starting, you reach directly this page, if the value of PM57 is not 0.

To open this page, press the

key.

EASY CUT STOPPED

STL

____

2.00 1000

X _____.__

ACTUAL _____ __

EASY OPT:_

Q 0

This page allows to perform individual cuts with simplified

programming.

You can momentarily interrupt the execution of a series of

programmed products in order to make a quick cut from this page.

You can then pick up the series of programmed products where it was

stopped.

When you reach this page:

- the cutting width is not defined,

- the quantity of products is initialized at 0.

The

the machine and the sheet (its availability depends on the machine

type) (see Functionalities, Offset of sheet origin).

field represents the distance between the left edge of

PAGE 24 USER GUIDE DNC 60 G16

Page 35

Flying cut in EasyCut mode

A flying cut can be performed in the EasyCut mode. To do so, an external

switch on the electrical cabinet allows you to activate or deactivate the flying

cut mode (if configured by the manufacturer).

1. The Flying cut switch is in set to ON: the AF4 field is displayed

and its value is undefined.

This field must contain a value between 1 and 9 in order to activate

the flying cut.

This value corresponds to the time spent at the TDC before the blade

starts moving again.

2. The Flying cut switch is set to OFF: the AF4 field is not displayed

and the flying cut is not active.

Note:

For safety reasons, when releasing the foot pedal, the AF4 field is reinitialized with an undefined value and the flying cut is deactivated.

THE SCREEN PAGES PAGE 25

Page 36

LIST OF PRODUCTS IN THE INTERNAL MEMORY

Press the key to access the list of products page.

PRODUCT 4 NEXT PROD.___ N 1 STOPPED

CODE

SEQUENCES N: PROG: 16 FREE: 832

--LIST OF PRODUCTS--

1 2 3 4 ___ ___ ___ ___ ___ ___

___ ___ ___ ___ ___ ___ ___ ___ ___ ___

___ ___ ___ ___ ___ ___ ___ ___ ___ ___

___ ___ ___ ___ ___ ___ ___ ___ ___ ___

___ ___ ___ ___ ___ ___ ___ ___ ___ ___

___ ___ ___ ___ ___ ___ ___ ___ ___ ___

___ ___ ___ ___ ___ ___ ___ ___ ___ ___

This page is only used to display the internal memory contents and

mention the number of programmed sequences, as well as the number

of sequences still available.

If this page is full, another page is automatically created, which can

be displayed by pressing the

It is not possible to program in the list of products.

The PRODUCT__ and CODE__ fields are only there as reminders of

the number of the product currently in the work buffer.

To store the product currently in the product buffer, press the

key.

To recall a product saved in the internal memory; select the number

and enter it in the PRODUCT field, then press the

To delete a product in the internal memory, select the number and

enter it in the PRODUCT field, then press the

To clear the whole internal memory, enter the value 999 in the

key.

key.

key.

PRODUCT field, then press the

PAGE 26 USER GUIDE DNC 60 G16

key.

Page 37

LIST OF PRODUCTS ACCORDING CRITERIA

Press the key to search in the internal memory for a product number

according to one or more of the criteria mentioned.

PRODUCT 4 NEXT PROD.__ N 1 STOPPED

CODE

THICKNESS RAKE ANGLE

3.00 __.__°

-- LIST OF PRODUCTS ACCORDING CRITERIA - 1

2

3

4

___

___

___

___

___

___

Example: Searching for a product according to its code number.

Place the cursor on the CODE__ field.

Enter the desired code number, and clear the other fields.

Press the SEARCH key

If the product exists, it is displayed in the PRODUCT column with its

code number.

If it does not exist, or the number or value is badly entered and or

incorrect, the DNC indicates IGNORE in the interactive field (top

right).

The search is performed according to the entered criteria, and

according to their values.

Any error in the entered data prevents the DNC from finding the

required product.

.

THE SCREEN PAGES PAGE 27

Page 38

DATA LINK RS232 PAGE

Choice 1 of the main menu.

The DNC 60 allows you to transfer data from or to a PC.

DNC <–> PC TRANSFER PAGE

This page allows data to be transferred to an IBM, XT, AT or compatible PC

from a RS 232 serial line.

You can transfer all the products, or just isolated products.

For a transfer to an IBM PC by serial line, the DNC 60 must be equipped

with a RS232 serial link, and the PC must be equipped with the CYBACK

type PC storage software or any other software complying with the

transmission protocol of the DNC.

DNC <-> PC STATUS STOP PA

TRANSFER 11 1 DNC --> PC

2 PC --> DNC

3,4 DATA LINK TEST 1 2

7 FLASH

8 EXT KEYBD

10 ARDIS CONNECTION

11 INTERNAL BACKUP

12 INTERNAL RESTORE

Quantity of free backup memory 93 %

-- RS232 PARAMETERS - Baud rate 57600 Stop 1.0

Parity odd (1) EVEN (0) _ Bits 8

The transmission procedure DNC <–> PC is described on page 45.

PAGE 28 USER GUIDE DNC 60 G16

Page 39

PRODUCT PAGE (AF INFORMATION)

Press the key to access the product page for auxiliary functions .

P 0 N 1 CY__

ALU1 2.00

STOPPED

____

0.74°

1000

TDC 54 0.24

BDC 39 PRESS 60

This page displays information relating to the auxiliary functions (AF)

specific to shears (blade gap, rake angle, cutting depth).

The information displayed is: - the material

- the thickness

- the width

Here you will find the following information (calculated using the

three values mentioned above).

- the blade gap

- the rake angle

- the TDC (top dead center)

- the BDC (bottom dead center)

- the downstroke pressure

The

machine and the sheet (see Functionalities, Offset of sheet origin).

THE SCREEN PAGES PAGE 29

field displays the distance between the left edge of the

Page 40

PRODUCT PAGE

Pres the key to access the product page.

PRODUCT 0 N 1 STOPPED

NEXT PRODUCT ___

CODE

Acceleration Factor X __%

SHEET: Length Width Thickness

Untreated _____.__ _____.__ 2.00

Material ALU1

NEXT PRODUCT

CODE

Acceleration factor X

SHEET

Length Width

Thickness

Untreated

Material

This field allows you to specify the next

product to be executed.

Code number for the current product.

Same with X (backgauge or dependant

auxiliary axis).

Geometrical dimensions of the sheet (they may

be used for calculating clean cut cycles).

This field is used for the calculation of the

blade gap, rake angle and possibly the blade

disengagement TDC functions. (Figure 3).

The corresponding dimensions of the sheet

before being loaded into the machine.

This field determines the blade gap calculation

constant (programmed machine parameters)

according to the material used. This field is

only displayed if the machine has a "blade gap"

function.

To select the material, use the manual keys.

Cutting width

PAGE 30 USER GUIDE DNC 60 G16

This field is only displayed if the machine is

equipped with a "cutting depth" function.

It is the width over which the upper and lower

blades cross.

Programming this field starts the calculation of

the BDC (cutting depth, figure 3).

Page 41

Blade gap (AF1)

Rake angle (AF2)

BDC (AF3)

TDC (AF3)

Gap between the cutting blades (in 1/100) for

the sheet thickness and material chosen.

Upper blade angle. It is calculated

automatically but can also be entered manually.

This field is only displayed if the machine has

a "Rake angle" function.

Cutting depth.

The value calculated for this field corresponds

to the distance (in mm) between the right end

of the upper blade and the lower blade.

This field is only displayed if the machine has

a "Cutting depth" function. Optimum Top

Dead Centre blade disengagement. It is

calculated automatically (if rake angle is

variable) but can also be entered manually.

THE SCREEN PAGES PAGE 31

Page 42

SEQUENCES LIST PAGE

a) Choice 2 of the main menu.

This page displays the data for the sequences concerning the main axis (X).

PRODUCT 4 NEXT PROD.__ N 1 STOPPED

CODE

N --X -- V%

1 _ 200.0 __

2 _ 200.0 __

3 _ 200.0 __

4 _ ______._ __

5 _ ______._ __

6 _ ______._ __

7 _ ______._ __

8 _ ______._ __

9 _ ______._ __

10 _ ______._ __

11 _ ______._ __

12 _ ______._ __

b) Choice 3 of the main menu.

This page displays the data for the sequences concerning the auxiliary

functions (AF1–>AF8).

PRODUCT 4 NEXT PROD.__ N 1 STOPPED

CODE

-- AUXILIARY FUNCTIONS - N GAP ANGL BDC

1 0.48 97 75

2 0.48 97 50

3 0.48 97 25

4 _.__ ___ ___

5 _.__ ___ ___

6 _.__ ___ ___

7 _.__ ___ ___

8 _.__ ___ ___

9 _.__ ___ ___

10 _.__ ___ ___

11 _.__ ___ ___

12 _.__ ___ ___

PAGE 32 USER GUIDE DNC 60 G16

Page 43

c) Choice 4 of the main menu.

This page displays the cycle data (CY, JS, sequence type, etc.) of the

sequences.

PRODUCT 4 NEXT PROD.__ N 1 STOPPED

CODE

N CY JS NCut

1 2 __x__ _

2 __ __x__ _

3 __ __x__ _

4 __ __x__ _

5 __ __x__ _

6 __ __x__ _

7 __ __x__ _

8 __ __x__ _

9 __ __x__ _

10 __ __x__ _

11 __ __x__ _

12 __ __x__ _

The maximum number of sequences provided for this type of machine is 36.

As the screen page can only display 12 sequences, the other sequences are

displayed on the following page, which can be displayed by pressing the

key.

To go back to the previous pages, simply press

.

THE SCREEN PAGES PAGE 33

Page 44

SEQUENCE PAGE (SMALL CHARACTERS)

Press the

This page is a recapitulative of the sequences information.

key.

PRODUCT 0 N 1 CY __/__pos STOPPED

M ALU1 Th. 2.00 Sheet Nr _______

-MEM- -POS- -SPE- -COR X _ 100.0 99.8 __% ___ __

Cut width 1000

JS __x__/__ Q prod. _____ / _____

Cycle:No cut_

Retr. _ Clean.Cut _

GAP ANGL BDC

0.24 50 39

N_

This is the sequence number. It is

automatically generated when creating a

product.

CY_

CY/POS

SHEET N°

Represents the number of times a sequence is

to be repeated before moving on to the next

sequence.

_ and 1 = no repetition (i.e. only one

sequence).

0 = the sequence is not carried out.

2 to 99 = number of repetition s desired.

The number displayed in this field corresponds

to the number of repetitions already made.

This 7 digit sheet metal number can be entered

for each sequence. It is transmitted by the RS

232 at each sequence change according to a

pre-defined protocol.

PAGE 34 USER GUIDE DNC 60 G16

Page 45

Xn

If the field immediately following the axis'

denomination is clear, the value of X -MEM- is

an absolute value to be reached.

If the field is set to 1, the X will move from the

last positioning value.

This movement will be made the number of

times programmed under CY_.

It is forbidden to program a relative value for

the X movement in the No 1 sequence (the

DNC signals an error).

If the field is programmed at 2, the axis will be

placed at 0,0 at the beginning of positioning

and it will then perform an absolute positioning

of the programmed value.

SPE

COR

Speed factor (0->99%, undef. = 100%)

This field indicates the sum of the corrections

(constant and variable) of the displayed

sequence.

JS__ J for Jump and S for Sequence.

This field allows the program to jump to a

sequence, from the next sequence, to the

sequence entered into the JS field.

TIMES/POS

The first field defines the number of times the

sequence jump (programmed in JS) is to be

performed.

The POS field defines the number of times the

jump has already been performed.

NB: Programming the JS field without

defining the number of times will result in

an unconditional jump of the planned

sequence. Generally a sequence previous

to the current sequence is programmed in

the JS field.

Similarly to the CY, which enables cycle

repetition, JS allows the repetition of a

group of sequences. This type of

programming can be very useful to carry

out a production with a minimum of

stock.

THE SCREEN PAGES PAGE 35

Page 46

Example: N JS TIMES

------------------------- 1 __ __

2 __ __

3 __ __

4 2 2

5 __ __

6 1 2

7 9 __

8 __ __

9 __ __

Cycle progression:

Note: In the above example, the sequence 8 is never effectuated

(unconditional jump).

Q__ The Q-MEM- is the number of products to be

made.

The product counter Q -POS- must be

validated by entering the value 0 or another

number corresponding to the number of

products already made.

Only then will the counter work.

To clear the counter, simply clear the Q-POS-

field.

A 24V signal is sent out as soon as Q -POS-

field value reaches the Q -MEM-value.

PAGE 36 USER GUIDE DNC 60 G16

Page 47

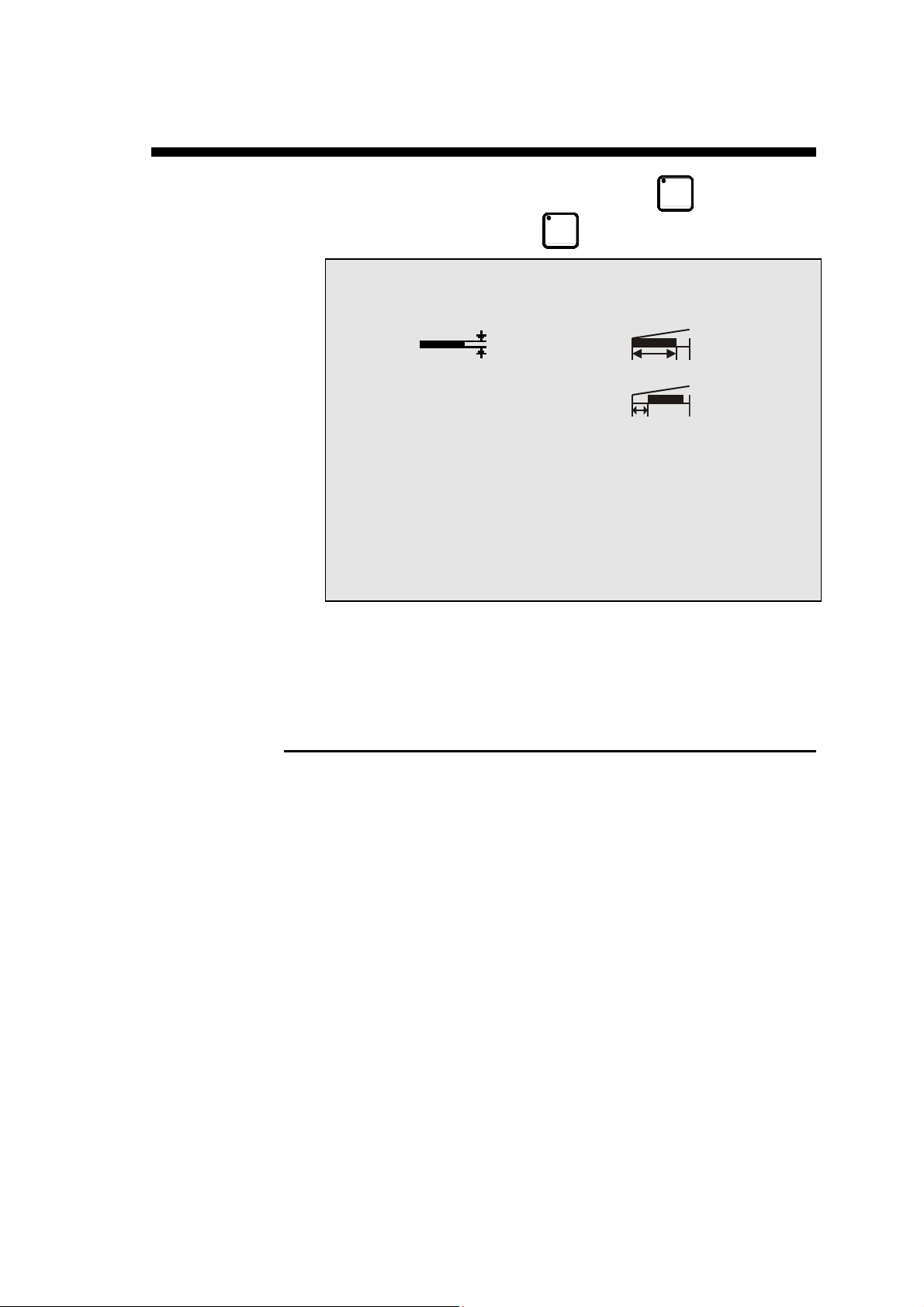

DEFINITION OF THE WORK CYCLE

The following fields define the type of work cycle to be chosen for the

current sequence.

Without cutting_

Retract_

Clean cut

Cutting width

Blade gap (AF1)

Cut (AF2)

Work cycle without any cutting.

By default (field is empty), the cycle will

retract. If the value of the field is 0, the cycle

will not retract. In all other cases the cycle will

retract.

Programming this field sends out a 24V signal

at the beginning of the sequence, in order to

open the scrap evacuation flap.

This field is only displayed if the machine is

equipped with a "cutting depth" function.

Width over which the upper and lower blades

cross.

Programming this field starts the calculation of

the BDC (cutting depth, figure 3).

If this field is left empty, the cut is made on the

total width of the machine.

Gap between the cutting blades (in 1/100) for

the chosen sheet thickness and material.

Function corresponding to the rake angle.

The value calculated in this field corresponds

to the vertical separation (in mm) between the

two ends of the upper blades. (Figure 3).

BDC (AF3)

Co

TDC

BDC

upper

blade

cutting

Cutting

engthl

Cutting depth.

The value calculated for this field corresponds

to the distance (in mm) between the right end

of the upper blade and the lower blade.

TDC

rake angle

sheet

lower

blade

BDC

Figure 3

THE SCREEN PAGES PAGE 37

Page 48

SEQUENCE PAGE (LARGE CHARACTERS), PROGRAMMING

Press the

P 0 N 1

ALU1 2.00

key to display the large characters sequence page.

STOPPED

1000

X _ 100.0

Actual 140.0

CY: 10/ 0

JS: __x__/ 0 Q _____

Cycle: No cut _

Retr. _ Clean.Cut _

This page is designed to facilitate product programming to the maximum.

Choice P (Product N°)

If applicable CY (number of repetitions)

Choice materiel

Choice thickness

Choice length

Choice speed

Choice cutting length

If applicable JS__x__ (jump and number of jump repetitions)

Choice quantity

If applicable: - No cut

- Retraction

- Clean cut

PAGE 38 USER GUIDE DNC 60 G16

Page 49

SEQUENCE PAGE (LARGE CHARACTERS), OPERATING

Press the key to display the large characters sequence page.

P 0 N 1 CY__

STOPPED

M ALU1 2.00

X

_ 100.0

99.8

1000

JS__x__/__

Q _____/_____

This page appears as soon as the work cycle begins.

It shows the state of the machine while it is working.

On this page you find:

The correct axis position underneath the programmed value.

CY: the number of repetitions already effectuated.

JS__x__: the number of jump repetitions already effectuated.

Q: the number of products already effectuated.

THE SCREEN PAGES PAGE 39

Page 50

CORRECTIONS PAGE

Press the key to open the corrections page.

PRODUCT 4 N 1 STOPPED

CODE

--CORRECTIONS--

CONSTANT VARIABLE --MEM--

X _ __._ __._ 200.0

CONSTANT

CORRECTIONS

VARIABLE

CORRECTIONS

NB: The resulting positioning value is displayed under the column -MEM-.

AXES DATUM

Choice 6 of the main menu.

This page is used to introduce or modify the origin of the main axis (X).

PRODUCT 4 STOPPED

SET MAIN AXES

X 100.0

100.0

Corrections to be applied to all sequences.

Corrections to be applied only to the specified

sequences.

Place the cursor on the desired axis field.

Enter the chosen value.

Remove the cursor from the field (

entered value.

The value is entered into the corresponding -POS- field.

The

PAGE 40 USER GUIDE DNC 60 G16

or ) to validate the

key allows you to display the auxiliary axes (X4/X5/X6).

Page 51

MACHINE PARAMETERS

Choice 7 of the main menu.

These pages display the operating parameters of the machine. They are

programmed when the machine is installed.

MACHINE PARAMETERS -02 X :X

10 Positioning speed ____.__

11 Fin approach speed __.__

12 Indexing speed ____.__

13 Manual slow speed ___.__

14 Manual high speed ____.__

15 A priori voltage __.___

16 Maximum voltage _.___

17 Minimum voltage _.___

18 Offset voltage __.___

19 SP/SN ratio __

20 Max. follow.eror __.__

21 Surveillance time _.___

22 Proportional gain _____

Displaying these pages from the menu page only allows you to see the

parameters, but not to modify them.

It is strongly recommended that you do not modify these values, unless

directed to do so by the CYBELEC company or one of its agents.

We also recommend that you keep a written copy of this data so that

technician can re-program the original values if necessary.

THE SCREEN PAGES PAGE 41

Page 52

This page has been left blank intentionally.

PAGE 42 USER GUIDE DNC 60 G16

Page 53

FUNCTIONALITIES

NIBBLING MODE

The nibbling mode allows you to cut by successive approaches, without

blade up stroking. This is typically for the cutting of wedges with a

rectangular form or disk sectors.

The nibbling mode is only active in semi-automatic mode, starting from key

1 and with the cursor placed on the CUTTING WIDTH field of the

SEQUENCE or EASYCUT pages.

When the pedal is released, the Cutting Authorization output is

deactivated (and also the pressure if AF6 is in pressure mode), the blade

stops and the message NIBBLING appears. As soon as the pedal is activated

again, the Cutting Authorization output is reactivated and the blade

continues its downstroke, and so on.

As soon as the BDC is reached, the blade moves normally upwards again. At

this moment you leave the nibbling mode and the message NIBBLING

disappears.

To rise the blade up again before the arrival on the BDC, just press one of the

manual keys

At this moment you leave the nibbling mode and the message NIBBLING

disappears.

or .

BLADE UP OUTPUT

This output is not configured by default. To be used, it must be configured by

the user. The idea is to be able to remove the cabled logic which is nor mally

found in the electrical cabinet for the upward movement of the blade.

This output is activated:

At each START or each time the pedal is pressed, if the blade is not at

the TDC Max.

Each time the blade has already moved down and has to be raised

again, that is to say:

– In normal use at the cutting end,

– At a STOP during the downstroking of the blade,

– At an incident in the course of the cycle.

This output is deactivated as soon as the blade has risen again, that is to say

at the ascending front of the TDC Max input.

FUNCTIONALITIES PAGE 43

Page 54

OFFSET OF SHEET ORIGIN

This functionality allows the sheet to be cut anywhere on the wid th of the

machine.

The OFFS field, located on the P and EASYCUT pages, represents the

distance between the left edge of the machine and the sheet.

The TDC and BDC are recalculated according to the OFFS value.

Formula used:

Formula used:

OFFS

BDC = (P50 – Cutlen – OFFS) · tg

TDC = (P50 – OFFS) * tg + E

Cutlen

P50

TDC

BDC

PAGE 44 USER GUIDE DNC 60 G16

Page 55

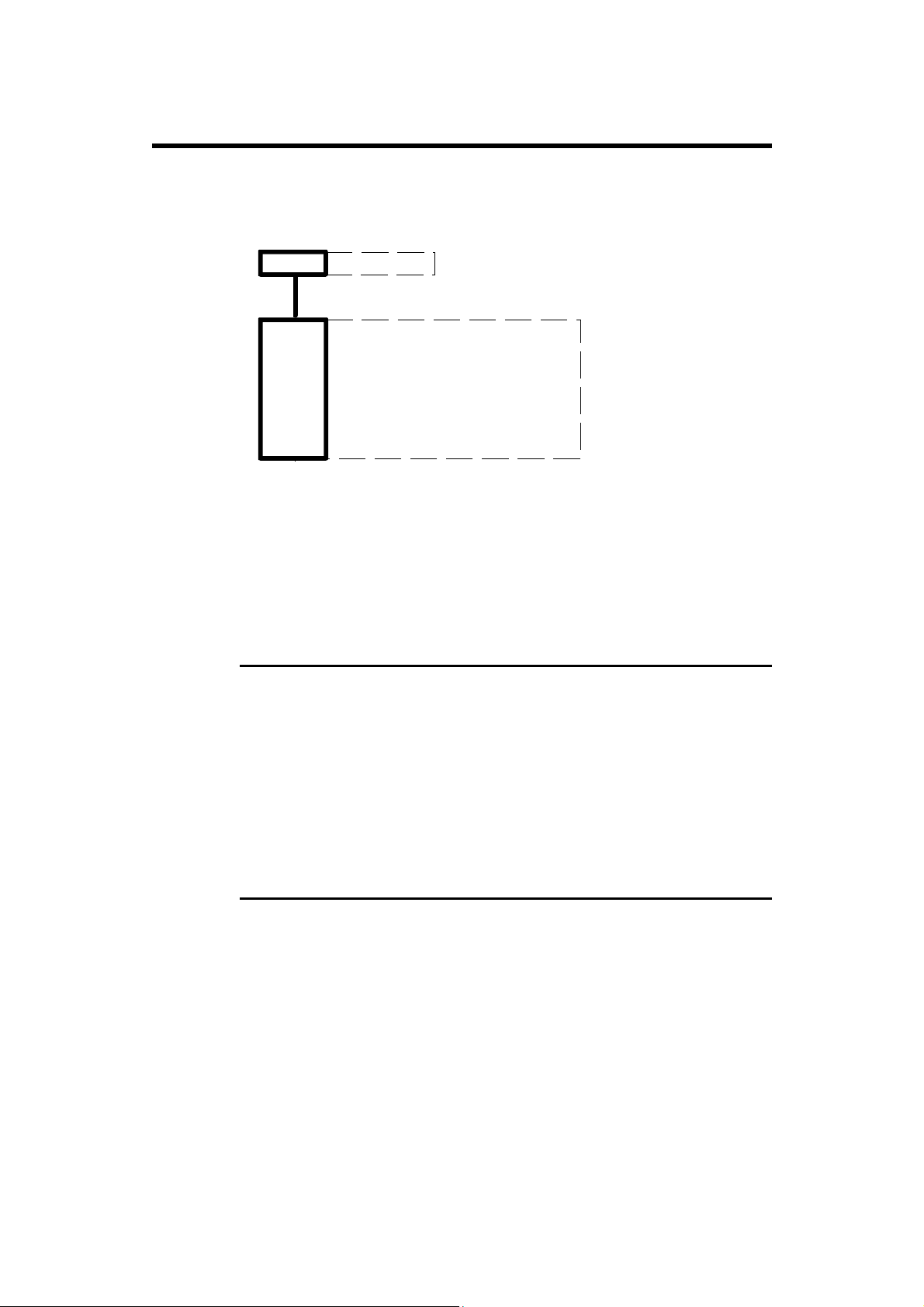

SHEET SUPPORT

Sheet supports are used to support the metal sheets before the hold-downs are

clamped (before shearing). They also help the sheared parts to slide down

onto a tray or stacker once they are cut.

Sheet supports can have 2 positions (1 high and 1 low) or 3 positions (1 high,

1 intermediate and 1 low).

The cycle of a sheet support starts after the hold-downs are tightened and

ends after they have been released (after the blade has reached the bottom

dead center).

(C1SupTol)

SW1

(C1SupTol)

SW2

(C2SupTol)

SW1

(C3SupTol)

SW2

(C2SupTol)

SW3

Position 1

Position 1

o

i

it

s

o

P

2

n

Positio

Posi

n

2

n

io

t

3

SHEET SUPPORT PAGE 45

Page 56

SCREEN DISPLAY (FOR THE OPERATOR)

This icon appears on the operator screen whenever the SupTol

field is available, i.e. whenever a sheet support is configured

on your DNC.

The value in this field only applies to the current sequence and

may change at every sequence.

To activate the sheet support for a given sequence, enter the

value 1 in this field. To de-activate it, enter the value 0 or leave

the field empty.

Whenever it is activated in a sequence, the sheet support rises to the upper

position at the beginning of the sequence.

If it isn't activated, the sheet support goes down to the lower position at the

beginning of the sequence and stays down for the entire duration of the

sequence.

MANUAL MODE

When the cursor is on the SupTol field, pressing on one of the following

keys

To stop the support at any time, simply release the key.

When the cursor is placed on the Cut width field, pressing on

down. However, pressing on

sheet support.

or on will cause both the blade and the sheet support to go

ANTI-TWIST DEVICE

An anti-twist device is a piece of equipment that will prevent the sheet from

twisting when cutting long pieces of metal.

When you start cutting, the device is in high position and holds up the metal

sheet. It is then lowered to support the sheet during cutting.

will cause the sheet support to go up or down.

or on won’t have any effect on the

SCREEN DISPLAY (FOR THE OPERATOR)

The 'A-TW' field appears on the sequence and EASY CUT pages whenever

the anti-twist feature is activated

To set the anti-twist feature, enter the value 1 in the field.

PAGE 46 USER GUIDE DNC 60 G16

Page 57

MANUAL MODE

Pressing one of the following keys

placed on the A-TW field will cause the anti-twist device to go up or down.

To stop the device at any time, simply release the key.

with the cursor

TRANSMISSION PAGE 47

Page 58

TRANSFER

To transfer data to an IBM PC by serial line, the DNC 60 must be equipped

with the RS232option.

Backup The PC must be equipped with the CYBACK storage software.

CYBACK allows you to make a backup of the data in the DNC without any

incidence on the data on the PC's level.

Updating Easy, practical and very rapid, this possibility facilitates (if necessary) the

updating of the DNC software in the FLASH memory.

The PC must be equipped with the updating software.

From the main menu page, open the TRANSFER DNC <–> PC

page.

DNC <-> PC STATUS STOP PA

TRANSFER 11 1 DNC --> PC

2 PC --> DNC

3,4 DATA LINK TEST 1 2

7 FLASH

8 EXT KEYBD

10 ARDIS CONNECTION

11 INTERNAL BACKUP

12 INTERNAL RESTORE

Quantity of free backup memory 93 %

-- RS232 PARAMETERS - Baud rate 57600 Stop 1.0

Parity odd (1) EVEN (0) _ Bits 8

Who controls ? This page will only be used to initialize the transfer type. It is not possible to

start the transfer from the DNC, this will always be done from the PC.

TRANSFER Allows you to select the type of transmission.

DNC PC Initializes the transmission PC-DNC. Mode 1 or

2 can be selected indifferently.

DATA LINK TEST Selects the test mode of the serial ports.

See the following chapter.

FLASH Prepares the DNC for the update.

EXT KEYBD Puts the DNC in external terminal mode.

See the concerned chapter.

ARDIS CONNECTION Sends the necessary values for cutting to the

DNC via RS232.

CHOICE This field allows you to select the objects to be

transferred.

In the case of option 6, PRODUCTS N°, the

last fields of the page must contain the numbers

of the products to be transferred.

PAGE 48 USER GUIDE DNC 60 G16

Page 59

TESTING THE SERIAL PORT

The serial port of the DNC 60 is the SUB-D 9P, plug J5.

Make sure that the transfer parameters are entered as follows:

PARAMETERS RS232 / DIVERS

. . .

-- COMPUTER LINK – 106 BAUD RATE 4800 STOP 1.0

PARITY ODD(1) EVEN(2) _ BITS 8

PROTOCOLE _ BCC ___

Set a test loopback connector on the serial line connector RS232 to be

tested.

Press the

The message RUN should flash.

To stop the test, press the

You can also test the transfer cable:

Connect the transfer cable to the DNC and fit a short circuiting

loopback connector on the other end of the cable to be tested.

key to start the test.

(STOP) key.

Test loopback connector

Pin 2 (RXD) wired to pin 3 (TXD)

Pin 4 (DTR) wired to pin 6 (DSR)

Pin 7 (RTS) wired to pin 8 (CTS)

TRANSMISSION PAGE 49

Page 60

CYBACK

RS 232 transmission cable

Shield: connection on the metallic hood

For this program, the RS cable must be connected to the RS232 port of the J5

plug.

The transfer parameters must be entered into the DNC, make sure that you

enter the same parameters as in the previous section (see above).

The same parameters must also be entered into the PC.

If the transfer runs at 4800 baud, you can try to increase the transmission rate

to 9600 baud.

The RS 232 norm imposes that the transfer distance be no more be then 15m

. If the distance is longer, this may affect the quality of the transfer and you

will have to decrease the transfer rate.

Reminder: The transfer command can only be given from the side of the PC.

To perform the serial transmission with CYBACK:

Set to programming mode.

Display the TRANSFER DNC <–> PC page.

Enter the value 2 into the TRANSFER field.

Press the

The display indicates STATUS RS232.

Programming mode The DNC can now receive data sent from the PC, provided that the DNC is

in programming mode.

In the other modes (auto, semi-auto or manual), the DNC doesn't respond and

the transmission is therefore not accepted.

During the transmission, the operator can leave the DNC on any page. It is

not necessary to display the transfer page.

The transfer mode remains memorized, even if the DNC is disconnected

from the power supply. It has to be re-programmed however if the mode is

changed (for instance to FLASH).

key.

PAGE 50 USER GUIDE DNC 60 G16

Page 61

This page has been left blank intentionally.

TRANSMISSION PAGE 51

Page 62

PROTECTING ACCESS LEVELS

GENERAL INFORMATION

The DNC 60 has four access levels.

Depending on the version, the DNC 60 can or cannot be equipped with a

4-position key switch.

If the DNC 60 is not equipped with a switch key, the access is protected by

password.

IMPORTANT

initialization of the machine parameters (817 on INIT page and Choice Init

Mach Par = 1).

In this manual we always will speak of a (virtual) key position, e.g.: "Key in

position 3".

Levels There are 4 access levels, 0 to 3:

0 = Programming is prohibited.

1 = Creation, correction, modification, saving, deleting, transfer of one

2 = Creation, correction, modification, saving, deleting, transfer of the

3 = Programming, modification and transfer of the machine parameters.

Access These levels are accessed by pressing the

A pop-up is displayed.

Press the

The key position is displayed as a number on the upper right part of the

screen (after the interactive field).

When passing to a higher access level, a new password will be requested.

When the password has been entered, you can access levels inferior or equal

to the authorized one, without reentering the password.

Passing to level 0 resets the password validity.

: passwords will be reset to the default values at each

(or more) product(s).

tools.

or keys to enter your password.

(STOP) key for two seconds.

Users A number of different users are predefined. A user is not a particular

individual, but can for example correspond to all the operators having the

authorization to work on the machine.

Each predefined user has a password and a maximum level which can be

reached. See the Table of users, access and passwords section.

Password Certain users can modify their own password. For the others, the password

can only be changed by a user having a superior access level.

Loss of the password If the password is lost, a user of a superior access level has to reprogram the

password.

PAGE 52 USER GUIDE DNC 60 G16

Page 63

THE USERS

Table of users, access and passwords.

Level Names of

predefined

users

1

2

3

4 WSSUPER OK OK 3 Workshop supervisor

5 MACHMAN NO OK 3 Machine manufacturer's

6 MACHMAN0 OK OK 3 Machine manufacturer’s

A predefined user is just a role.

Many physical persons can have the same role. E.g., many physical operators can be a EUL1 (level 1).

After installing the machine it is recommended that the password by default of level 4 (WSSUPER =

Workshop supervisor) and of level 3 (EUL3 = Operators with authorization level 3) be modified, simply

because the passwords are in this manual.

EUL1 NO NO

EUL2 NO NO

EUL3 NO NO

Changing of

the personal

password

Changing of

passwords of

the

subordinates

Level

virtual key

1

2

3

Password

by default

111 Operators with access

222 Operators with access

Operators with access

User generally attributed to:

authorization to level 1

authorization to level 2

authorization to level 3

Service technicians

technician manager.

PROTECTION OF ACCESS LEVELS PAGE 53

Page 64

ACCESS BY PASSWORD

Upon starting the software, the virtual key is always positioned at 0.

Press the

Choose the level to access by pressing the

keys.

The message VALUE ? appears.

Enter the password and press the

The message OK and the selected level are displayed if the password

is accepted, or KO if it is refused.

Once the authorization is granted, the operator can change levels according

to his accessibility, without entering a new password.. For instance, a user

with access on level 3 can navigate between levels 1, 2 and 3 without having

to enter the password again.

If level 0 is activated, a password will be required to access any other level.

This password will also be requested when the user passes to a superior level

(from 0 to 1, from 1 to 2, from 2 to 3, etc.) and does not have access with the

current password.

Advice If you have access to level 3, access level 0 after your intervention. This will

avoid making unwanted changes by mistake.

key for two seconds.

, or

key to validate the password.

PAGE 54 USER GUIDE DNC 60 G16

Page 65

ACCESS TO LEVELS SUPERIOR TO 3

Certain users can access levels superior to 3. This allows them, among other

things, to modify passwords.

To find out more about the various authorizations, see Table of users, access

and passwords.

Press the

A pop-up is displayed.

The message LEVEL ? appears.

Type the access level you want to access.

The message VALUE ? appears.

Enter the password corresponding to the requested access level and

validate with the

The DNC passes to level 1. The operator can "navigate" between

levels 1 and 3 without reintroducing his password.

At the end of the intervention, don't forget to pass to level 0 in order

to leave the current access level.

key for two seconds.

key. Press the

key.

PROTECTION OF ACCESS LEVELS PAGE 55

Page 66

CHANGE PASSWORD

This allows some users to modify the passwords attributed by default.

Certain users can do it for themselves, others cannot. In order to know the

authorizations, see Table of users, access and passwords.

To change a password:

Press the

A pop-up is displayed.

Press the

The message LEVEL ? appears.

Type the access level number you want to access.

The message VALUE ? appears.

Enter the password corresponding to the requested level and validate

with the

Press the

A pop-up is displayed.

Press the

The message LEVEL ? appears.

Program the access level for which you want to modify the password.

The message IGNORE appears if the requested level is superior to the

accessed level. If not, the message VALUE ? appears.

key for 2 seconds.

key.

key.

keys for two seconds.

key.

Enter the desired new password and validate with the

The message CONFIRM appears.

Enter the new password again and validate with the

If the two registered passwords are identical, the message OK is

displayed.

If the two registered passwords are different, the user is invited to

introduce the 2 passwords again, the message VALUE is displayed.

At the end of the procedure, don't forget to pass to level 0 in order to

leave the current level.

PAGE 56 USER GUIDE DNC 60 G16

key.

key.

Page 67

This page has been left blank intentionally.

PROTECTION OF ACCESS LEVELS PAGE 57

Page 68

MAINTENANCE

IN CASE OF FAILURE

INITIAL CHECKS TO BE CARRIED OUT

Switch the machine off then on again.

Check the program (safety factors).

Check that the axes can be moved in manual mode.

Compare the machine parameters to those on the written list made

during the installation.

Check the power supply voltages (to do this please refer to the

technical manual).

Check that the keyboard responds.

Check that the front panel lamps light up.

POSSIBLE MEMORY POLLUTION

After performing the initial checks above, it is then likely that you have a

memory pollution problem. To locate the fault, proceed as follows:

Switch off the DNC.

Switch on the DNC.

Follow the instructions in the next chapter The Initialization page.

PAGE 58 USER GUIDE DNC 60 G16

Page 69

THE INITIALIZATION PAGE

This page appears if a calculation is impossible, due to unprogrammed data

or an incorrect value.

It can also appear as a result of pollution of one of the memory zones which

will also result in impossible calculations.

INITIALIZATION DNC 60 G

---------

--MEMORY ZONE--

_ Clear variables zone

_ Clear machine parameters zone

_ Clear transmission RS232 zone

EXECUTION CODE ___

It may be necessary to use this page intentionally in order completely clear

the data on the DNC and to re-start the programming on a "clean" basis.

To display the Initialization page, press the

If the Initialization page appears unexpectedly, proceed as follows:

Note: If point 1 does not re-establish a normal situation, go on to the next

point and so on. The following operations clear successively all the data in

the selected memories. It is therefore recommended to re-introduce the data.

1) Press the

2) Enter:

- value

- value

Press the

Press the

1 in the Clear variables zone field

817 in the EXECUTION CODE.field

key twice.

key.

key twice.

and keys.

3) Enter:

- value

- value

- value

MAINTENANCE PAGE 59

1 in the Clear variables zone field,

1 in the Clear machine parameters zone field

817 in the EXECUTION CODE field.

Page 70

Press the

Press the

4) Enter:

value

1 in the field Clear variables zone,

1 in the field Clear machine parameters zone,

value

1 in the field Clear transmission RS232 zone

value

and value

Press the

Press the

Clearing the machine parameters also deletes all the input / output

configuration defined by the operator.

We therefore recommend that the DNC 60 be re-configured before next use.

Important: If you use an external system for re-entering data (CYBACK

via RS232) and the problem persists, then the information re-entered by this

system have to checked again.

The best thing to do in this case is to again delete the who le contents of the

DNC and to re-program the DNC manually via the keyboard (not the RS232

line).

key.

key twice.

817 in the field EXECUTION CODE.

key.

key twice.

BEFORE CALLING FOR TECHNICAL HELP

Please have ready the following information:

Type of numerical control.

Serial Nr of the DNC.

DNC and axes (N2X) software numbers.

Name of the machine tool's manufacturer.

List of machine parameters (have on hand when the technician

comes).

The state of the numerical control:

- which LEDs are on?

- which message is on the screen ?

Details of what caused or is causing the problem.

PAGE 60 USER GUIDE DNC 60 G16

Page 71

INTERNAL BACKUP (SAVE)

A machine parameter and tools backup is available in the internal memory. A

restoration can also be performed from this same internal memory.

This functionality is exclusively used by the manufacturer to memorize the

parameters and tools state, at the time of the delivery of the machine.