Page 1

DNC 60 G

Machine Parameters

CYBELEC SA Tel. ++ 41 24 447 02 00

RUE DES UTTINS 27 Fax ++ 41 24 447 02 01

CH - 1400 YVERDON-LES-BAINS E-Mail: info@cybelec.ch

SWITZERLAND

V-DOC-60G-EN

Page 2

Page 3

26.09.2008 V. 1.8d

CONTENTS

MACHINE PARAMETERS ............................................................................................................... 6

Safety, Copyright & License agreement .............................................................................. 6

Introduction .......................................................................................................................... 6

Specification of alphanumeric characters 8

Machine parameters definition ............................................................................................ 9

P29 Display Resolution 9

P30 Security distance (distance at low speed) 9

P31 Number of supplementary legs 10

P32 Leg distance 11

P33 Sheet present speed 11

P34 Type management axis 11

P35 Retraction distance 12

P36 Hold-downs Time 12

P37 Correction factor blade gap 13

P38 Treatment Jitter Error 13

P39 TDC Time 14

P40 None Synchro limit (Opened clamps / Closed clamps) 14

P41 Distance "Sheet present" <–> "Bottom of mechanical clamp" 14

P42 Distance "Sheet present" <–> "Bottom of electronic clamp" 14

P43 Clamp disengagement time 15

P44 Distance sheet index <–> blade 15

P49 Ejection time 15

P50 Maximum sheet width 16

P51 Distance stop X1 <–> Square 16

P52 Articulated arm length 16

P53 Maximum rotation arm angle 16

P54 Rake angle min and max 17

P55 Distance Í fixed point blade 17

P56 Cycle Option 17

P57 Access to EasyCut mode 17

P58 Distance Potentiometer 18

Material 18

Default thickness 18

P60 Transmission speed 18

P61 Transmission data 19

PM60G16_EN_V2.DOC CONTENTS PAGE 1

Page 4

P62 Stop bits 19

P63 Parity 19

P65 Protocol 19

P66 BCC 20

Tests of the serial port ........................................................................................................ 20

P67 None at product search in cassette 21

P68 Conversion Inch/mm 21

P69 Stop Q Product reached 21

Auxiliary functions parameters (AF) 22

P70 Function type 23

P71 Digital Mode 23

P72 Analogue mode 24

P73 Voltage mode 24

P74 LS distance 25

P75 Overrun distance 25

P76 Advanced stop 25

P77 Tolerance 26

P78 Reversal time 26

P79 Minimum range (D/A) 26

P80 Maximum range (D/A) 26

P81 Minimum range (progr) 27

P82 Maximum range (progr) 27

Cutting pressure parameters (AF6) 27

P83 Minimal Blade up pressure 27

P84 Rake angle adjust. pressure 27

P85a ELECTRICAL BLADE GAP 28

P85b Blade gap adjust. pressure 28

P86 Blade Up pressure 28

P87 Blade Up gain 28

P88 Acc. time Blade Down pressure 28

P89a Dec. time Blade Down pressure 28

P89b Dec. time manual pressure 29

P90 Acc. time Blade Up pressure 29

P91 Dec. time Blade Up pressure 29

P92 Decompression time 29

Calibration cutting pressure parameters (AF6) 29

P93 TDC max Sensor Distance 30

Extended blade gap parameters (8 segments) 30

X Backgauge foldaway parameters 31

P94 Park distance 31

PAGE 2 MACHINE PARAMETERS DNC 60 G

Page 5

P95 Crawl distance 31

P96 Hydraulic foldaway time 32

P97 LS/HS X Commutation 33

P98 Delay Reset out Hold-downs 33

P99 Pulsate TDC duration 33

P100 Easy Optimizer 33

P101 AFs Adjustment once out of … 34

P104 Cut on middle 34

Thickness measurement parameters (8 segments) 34

Sheet Support 35

Anti-Twist Parameters 36

P112 Sequentiel sending FAs 38

P113 Delay opening hold-downs 38

P114 Duration opening hold-downs 38

P117 Toggle Mode Level 3/2/3 38

P118 I/O Visualization in Run 39

P119 Nibbling Mode 39

P120 Uninterruptible Cut 39

P121 Show all Mach. Par. 39

P122 Print all Mach. Par. 39

P123 Key 0 Blocks Utilization 40

SPECIAL SHEAR FUNCTIONS ....................................................................................................... 41

Blade gap function (F1) ....................................................................................................... 41

Calibration of functions F1 / F5 42

Blade gap calculation 42

Rake angle (F2) and cutting length (F3) functions (with only one potentiometer) .............. 43

Calibration of the auxiliary function rake angle F2 44

Calibration of the auxiliary function cutting length F3 45

Rake angle calculation 46

Cutting length calculation 46

Cutting length function (F3) with fixed rake angle (no F2 rake angle function) .................. 47

Calibration of function F3 47

Cutting length calculation 48

Cutting length function (F3) without measuring potentiometer (Use of tempo) .................. 49

Calibration of function F3 49

Flying Cut Function (F4) ...................................................................................................... 50

Pressure ramps function (F6) .............................................................................................. 51

Calibration of function F6 51

CONTENTS PAGE 3

Page 6

Parametrizing of function F6 52

Function Pressure ON or OFF (F6) .................................................................................... 53

Blade Up or Down 53

SP or SN of the AF 53

Sheet thickness measurement function (F7) ...................................................................... 54

Calibration of function F7 54

Sheet Support ..................................................................................................................... 55

Configuration 56

Parameters 57

Screen Display (for the Operator) 57

Cycle of a 2-position Sheet Support 58

Cycle of a 3-position Sheet Support 61

Manual Mode 62

Anti-Twist Device ................................................................................................................ 63

Inputs/Outputs 63

Parameters 63

A-TW Device Cycle 64

Screen Display (for the Operator) 64

Mode manuel 64

FUNCTIONALITIES ......................................................................................................................... 65

Visualization of the Inputs/Outputs pages in cycle 65

Input clearance X 65

Backgauge foldaway X 65

Clearance of the backgauge X 67

Hydraulic foldaway of backgauge X 68

Input Set Pressure 69

Facilitated Up/Down manipulation of the blade 70

Internal backup (save) 71

Internal restoration of PMs and tools 73

Input/Output configuration 75

Configurable axes and functions ........................................................................................ 75

Axes 75

Functions 76

Definition of inputs/outputs by default ................................................................................. 77

INPUTS 77

OUTPUTS 78

Configuration of digital inputs/outputs ................................................................................ 80

PAGE 4 MACHINE PARAMETERS DNC 60 G

Page 7

Configuration of analogic inputs/outputs ............................................................................. 81

Management of the access levels by external key ............................................................. 82

Machine Messages ............................................................................................................. 83

INDEX .............................................................................................................................................. 85

CONTENTS PAGE 5

Page 8

MACHINE PARAMETERS

SAFETY, COPYRIGHT & LICENSE AGREEMENT

Please consult the safety instructions, copyright and license agreement on the

first pages of the manual.

INTRODUCTION

On the machine parameters page N° 01, you will find the following fields:

Softs:

PIC

Key:

Language

CONFIGURATION 8

I/O

GIXME: Version of the Master software contained

in the DNC.

ZIAMBA3: Version of the Master boot software

N2XMng: Version of the axes software

ZZAMBA3: Version of the axes boot software

N2XSA1: Version of the N2XSUP axes software.

Name of the pic software the DNC is equipped

with.

Enables to choose between a cabled key or a

password.

Field allowing a pre-selection of the various

resident languages (by means of the manual

displacement keys (

Field allowing to select the hardware

configuration.

).

PAGE 6 MACHINE PARAMETERS DNC 60 G

Page 9

MACHINE PARAMETERS -01- IGNORE

Softs: GIXMEG/ZIAMBA3 PIC:AA6

N2XMng/ZZAMBA3 N2XSA1 Key:0

Language: [GB] FR GB DE IT ES PT SE NL

CONFIGURATION 8 I/O: 1

X FRONT GAUGE: _ X3: X

00 Axis type __

01 Operating mode __

02 Encoder reso. (I/mm) ___.___

03 Tolerance 0.05

04 Advanced stop _.__

05 Overrun distance ___.__

06 Slow speed distance __.__

07 SP / SN time _.___

08 Acceleration time 0.300

09 Deceleration time 0.400

MACHINE PARAMETERS -02- IGNORE

X3: X

10 Positioning speed 30.00

11 Fin.approach speed __.__

12 Indexing speed ____.__

13 Manual slow speed ___.__

14 Manual high speed ____.__

15 A priori voltage __.___

16 Maximum voltage _.___

17 Minimum voltage _.___

18 Offset voltage __.___

19 Closed loop toler. 80%

20 Max. follow.error __.__

21 Surveillance time _.___

22 Proportional gain _____

23 Integral gain _____

With regard to the axis parameters (P00 –> P28), these are described in the

"N2X BOARD PARAMETERS" manual.

The name of the axes and auxiliary functions can be personalized. An axis or

auxiliary function's name may contain up to 4 characters.

MACHINE PARAMETERS PAGE 7

Page 10

SPECIFICATION OF ALPHANUMERIC CHARACTERS

1) With the aid of the manual displacement keys, run through the

character table until the required character appears in the display.

Note: The

characters.

The

character.

2) Press the

memorized.

3) Repeat operations 1 and 2 for the following characters.

or keys move forward or backward by 4

or keys move forward or backward by 1

or TEACH key (memorize). The first character is

PAGE 8 MACHINE PARAMETERS DNC 60 G

Page 11

MACHINE PARAMETERS DEFINITION

MACHINE PARAMETERS -03- IGNORE

X3: X

24 Differential gain _____

25 Index mode __

26 Index position ______.__

27 Min. limit - 0.00

28 Max. limit + 1000.00

29 Display resolut. _.__

30 Saf. Limit dist. _____.__

31 Supplement stops _

32 Dist.between legs _____.__

33 Sheet pres. speed ___.__

34 Type of axe funct.

35 Retraction distance 2.00

36 Hold-downs/retr.time 1.20

37 Blade gap corr.factor 0.90

P29 DISPLAY RESOLUTION

(Does not function in Inch mode, P68).

1.00

0.10

0.01

axis display to 1 mm accuracy

axis display to 1/10 mm accuracy

(or undefined) axis display to 1/100 mm accuracy

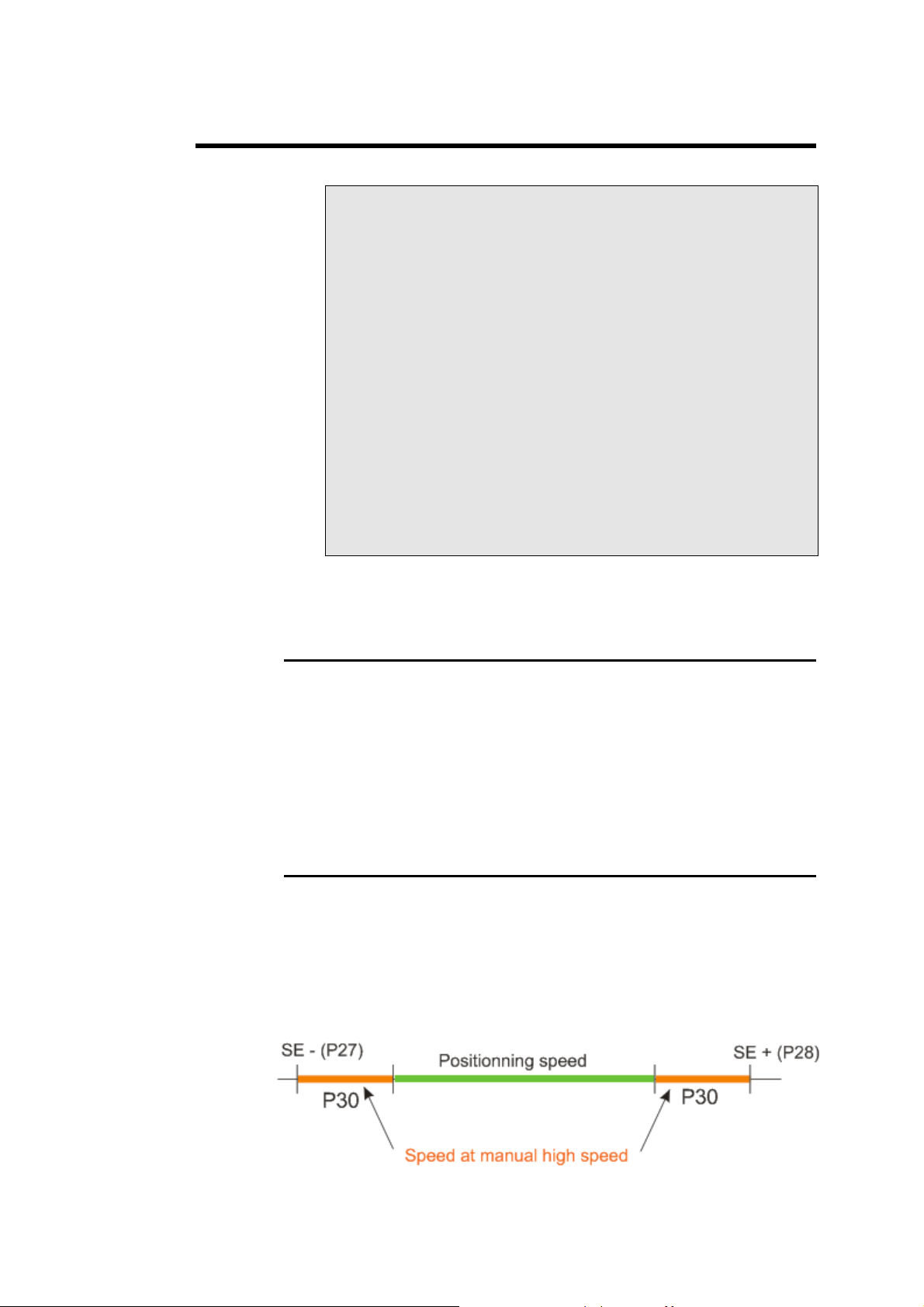

P30 SECURITY DISTANCE (DISTANCE AT LOW SPEED)

This is the safety distance from the stroke end (SE) at which the back gauge

switches from manual high speed (P14) to manual low speed (P13), or vice

versa.

This security distance provides extra security when approaching stroke end

and avoids vibrations at the end of the ball screw drives.

IMORTANT: P30 must be

< [(SE–) – (SE +)] / 2

MACHINE PARAMETERS PAGE 9

Page 12

P31 NUMBER OF SUPPLEMENTARY LEGS

In the case of an axis with several gauge arms, P31 defines the number of

supplementary arms (max. 7).

PAGE 10 MACHINE PARAMETERS DNC 60 G

Page 13

P32 LEG DISTANCE

P32 defines the separation between two consecutive arms. The separation

between 2 consecutive arms being always the same.

P33 SHEET PRESENT SPEED

In the case of a take sheet cycle, without square, the P33 defines the speed at

which the axis moves once the clamp has detected the sheet.

P34 TYPE MANAGEMENT AXIS

Remark: This field is accessible only on X4, X5, X6.

Definitions:

y The dependant axes will follow the cycle sequences.

y The independent axes will execute their own advance sequence with

their signal "Start Xn".

y The axes with automatic "Start" will have their positioning departure

synchronized with the departure of the shear axes (X1/X2/X3).

y The axes with an external "Start" will have their positioning departure

commanded by their signal "Start Xn".

Modes:

0 or __: Auxiliary axis dependant on the cycle with automatic "Start".

1 (D0): Auxiliary axis independent of the cycle with external "Start"

(masked time).

4 (D2): Auxiliary axis dependant on the cycle with external "Start". In this

mode, the axis' sequences follow the cycle sequences but the cycle

does not wait for the end of axis positioning to execute the advanced

sequence (masked time).

2 (D1): Only for X4, this mode indicates that X4 is used as a second

backgauge.

MACHINE PARAMETERS PAGE 11

Page 14

X1, X2: frontgauges

X3, X4: backgauges

Remark: P35, P36, P37 are accessible only on X1 and X3.

P35 RETRACTION DISTANCE

Sufficient distance for the axis retraction.

This retraction is made:

1) Before the cut for backgauges.

By cutting, the sheet spreads. The gauge must be retracted.

2) After the cut for frontgauges.

After the cut, the sheet holder moves upward. The sheet has to be

retracted in order to enable the raising of the blade without rubbing.

The cycle will only wait for the axis to reach its retraction value (in high

speed), then the axis will be stopped independently of the machine cycle.

P36 HOLD-DOWNS TIME

Negative value: This value is interpreted as a retraction delay time and

allows to wait for the hold-down to pressure up before

starting the retraction.

After receiving the HOLD-DOWN CLOSED signal

(0V) the DNC waits for the time programmed in this

parameter before starting the retraction.

Positive value:

The programmable range for this time is situated between -9,99 and +9,99

seconds.

This parameter (programmed positive) defines machine

functioning without the HOLD-DOWN input signal.

Effectively this signal is replaced by the programmed

time. As soon as the CUTTING AUTHORIZATION

signal is furnished, the DNC will wait for the

programmed time then start the retraction.

After this time has elapsed, the DNC considers that the

sheet is held down.

PAGE 12 MACHINE PARAMETERS DNC 60 G

Page 15

P37 CORRECTION FACTOR BLADE GAP

This parameter allows to correct the axis positioning value as a function of

the blade gap defined in the product.

The DNC applies a constant correction, to all the programmed positioning

values, as a function of the blade gap and this parameter.

Cv = Cp + P37 * Jc

Cv Axis positioning value (target value)

CP Programmed value

Jc Blade gap

P37 positive Back gauge cycle

P37 negative Front gauge cycle

At each STOP the DNC displays the real axis value (with the correction).

MACHINE PARAMETERS -04- IGNORE

38 Treatment jitter error _

39 TDC time 0.80s

Clamp: Opened Closed

40 Synchro limit ____.__ ____.__

41 Mech. sheet <-> clamp bottom ___.__

42 Elect. sheet <-> clamp bottom ___.__

43 Clamp disengagement time _.__s

44 Distance Index <-> Blade ___.__

49 Ejection time __.__s

50 Maximal sheet width 4000

51 Distance stop X1 <-> Square ___.__

52 Length of articulated arm ___.__

53 Max angle of articulated arm __._°

P38 TREATMENT JITTER ERROR

Management of encoder impulse errors.

0

2

Other values

MACHINE PARAMETERS PAGE 13

No error handling

Display of alarm messages in the interactive field, but

no machine stop.

Display of alarm messages in the interactive field, the

DNC goes into MANUAL mode, and the pressing of

the

key of the front panel is being simulated.

Page 16

P39 TDC TIME

This parameter is only used if for the RAKE ANGLE (AF2) and CUTTING

LENGTH (AF3) functions only one potentiometer is used.

This time is used to delay the adjustment of the RAKE ANGLE function

(AF2 P70 = 2 or 50) after reception of the TDC signal in order to wait for

the stabilization of the blade at the TDC.

Effectively, in this configuration it is only possible to adjust the rake angle if

the blade is completely stopped at the TDC.

P40 NONE SYNCHRO LIMIT (OPENED CLAMPS / CLOSED CLAMPS)

This double parameter defines the maximum separation authorized between

X1 and X2 with the clamps opened and closed.

This safety control is switched on as soon as an axis moves. If the limit is

reached, the axis is stopped and an error is signalled.

It also allows to deal with all mechanical backgauge configurations (eg.

gauges joined by a bar).

P41 DISTANCE "SHEET PRESENT" <–> "BOTTOM OF

MECHANICAL CLAMP"

This distance should be greater than the distance between the sheet detector

and the mechanical bottom of the clamp.

It is used in sheet taking cycles without square.

P42 DISTANCE "SHEET PRESENT" <–> "BOTTOM OF

ELECTRONIC CLAMP

This distance should be less than the distance between the sheet detector and

the mechanical bottom of the clamp. It is used in sheet taking cycles with

square or in "Square=2" mode.

It prevents the clamps from touching the sheet before they are closed.

"

PAGE 14 MACHINE PARAMETERS DNC 60 G

Page 17

P43 CLAMP DISENGAGEMENT TIME

Remark: The programming of this parameter determines the use or not of

clamps.

Undefined = machine without clamps

Defined = machine with clamps.

This delay is used to make a safety control on the disengagement of the sheet

from the clamps.

In the case of a cycle "without sheet", "without cutting", the clamps will open

then the axis will move backwards to disengage the clamps.

The DNC will control only after the P43 time that the "sheet present" signal

has disappeared. If the sheet remains blocked in the clamps, the axes are

stopped and an error is signalled.

P44 DISTANCE SHEET INDEX <–> BLADE

This parameter indicates the distance between the sheet detection point and

the cutting line.

This parameter is used in the case where an indirect measure of the sheet is to

be made before it is cut.

This working mode is selected by programming the value 2 (D1) in the Take

sheet field.

P49 EJECTION TIME

This parameter should only be programmed in the case where the clamps are

equipped with ejectors.

In the case where the Ejection field has been defined (on the sequence

page) the ejection cycle is as follows:

P49 positive:

1) Set ejection signal

2) Ejection time (P49)

3) Clamp opening

4) Reset ejection signal

P49 negative:

1) Clamp opening

2) Set ejection signal

3) Ejection time (P49)

4) Reset ejection signal

MACHINE PARAMETERS PAGE 15

Page 18

P50 MAXIMUM SHEET WIDTH

This parameter should only be programmed in the event that the machine is

equipped with function (F3), measuring the length of the cut or function

(F2), measuring the rake angle. It defines the maximum cutting length of the

machine.

The three parameters which follow (P51, P52, P53) should be programmed

only for machines equipped with 2 frontgauge clamps (X1, X2) of which X1

(left leg) is fixed and X2 (right leg) is fitted with an articulated arm.

P51 DISTANCE STOP X1 <–> SQUARE

This parameter defines the distance between the left leg and the right end of

the blade (generally the square).

P52 ARTICULATED ARM LENGTH

This parameter defines the distance between the axis of the articulated arm

and the axis of the cylinder holding the sheet.

P53 MAXIMUM ROTATION ARM ANGLE

This parameter defines the maximum angle of rotation authorized for the

articulated arm.

PARAMETRES MACHINE -05- IGNORE

54 Angle MIN: 0.50° MAX (Nom): 5.00°

55 Dist <- fixed point blade 100.00

56 Cycle options __

57 EASYCUT mode at Power on 0

58 Distance Potentiometer 3800

RAKE ANGLE / BLADE GAP TABLES

/ PRESSURE

Material 1: ALU1 Def Thickn: __.__

Thickness Rake angle Bl.gap Pressure

min 0.20 0.10° 0.20 20

I1 2.00 0.50° 0.40 40

I2 3.00 1.50° 0.60 60

I3 4.00 2.10° 0.80 80

max 6.00 3.00° 1.00 100

The four parameters which follow (P54 –> P57) should be programmed only

for machines equipped with a function (AF2) for measuring the rake angle.

PAGE 16 MACHINE PARAMETERS DNC 60 G

Page 19

P54 RAKE ANGLE MIN AND MAX

Min and max rake angle authorized.

P55 DISTANCE Í FIXED POINT BLADE

Distance between the left extremity of the lower blade and the axis of the

rotation point of the upper blade. This rotation point being fixed (no vertical

variation) regardless of the rake angle. (See figure 4, page 43).

the case where this point does not exist the point with the least variation is

In

chosen.

N.B.: This point can be situated outside the cutting range (to the right).

In this case, P55 can be defined negative.

P56 CYCLE OPTION

This parameter is used to define the cyle options explained hereafter.

D0 = 0 The gauge axis starts its positioning when the blade arrives at

the TDC.

D0 = 1 The gauge axis starts its positioning when the blade arrives at

the TDC if the gauge approachs the blade. Positioning in SN

(negative sense).

The gauge axis starts its positioning when the blade arrives at

the BDC if the gauge moves away from the blade. Positioning

in SP (positive sense).

D1 = 1 The gauge axis starts its positioning when the blade arrives at

the BDC.

D2 = 1 The Retraction field is not displayed in key position 0 or 1.

D3 = 1 Activates the messaging of the cycle follow-up information.

P57 ACCESS TO EASYCUT MODE

This parameter allows you to choose the access to the EasyCut page.

0 Access to the MENU page at the start up of the soft

1 Access only to EASYCUT page.

2 No access to the EASYCUT page

Undef Access to the EASYCUT page at the start up of the soft

MACHINE PARAMETERS PAGE 17

Page 20

P58 DISTANCE POTENTIOMETER

Horizontal distance between the left edge of the lower blade and the

potentiometer position. This parameter must be greater than P55 and less

than or equal to P50 (P55 < P58 ≤ P50). If this parameter is not definied, it

will take the default value of P50.

MATERIAL

The name of the material is programmed in 4 characters in the fields located

on the line headed -MATERIAL-.

The name of the material is defined in alpha numerical using the manual

displacement keys. You will find a description of the use of the manual

displacement keys for defining the alpha numerical characters in the

paragraph concerning the auxiliary functions.

DEFAULT THICKNESS

For each material you can program a default thickness. When clearing the

buffer or selecting another material, if the default thickness is defined, then it

will be transferred in the Thickness field of the product.

MACHINE PARAMETERS -06- IGNORE

-- RS232 CHARACTERISTICS --

60 Transmission speed 38400

61 Transmission data 8

62 Stop bits 1.0

63 Parity (-:off, 0:even, 1:odd) _

65 Protocol 6

66 BCC 9

67 None at product search in cassette _

68 Conversion Inch/mm

69 Stop Q Product reached _

Cut Counter: 127

Counter 11h 42min

P60 TRANSMISSION SPEED

Programmable to 300, 600, 1200, 2400, 4800, 9600, 14400, 19200, 38400,

57600 baud.

PAGE 18 MACHINE PARAMETERS DNC 60 G

Page 21

P61 TRANSMISSION DATA

Number of data bits (usually 8) used for transmission.

P62 STOP BITS

Programmable, depending on the peripheral: 1.0, 1.5, 2.0

P63 PARITY

Parity checking.

P65 PROTOCOL

This parameter allows the selection of one of several transmission protocols.

0 / _

1 Identical to 0 or _, but without echo from PC.

2 Protocol for liaison with PUNCHER,

Cybelec standard for PC link with software via

CYBELEC protocol.

When the DNC is sending, the PC sends back a

control character after receiving each character

from the DNC.

When the DNC is receiving, no control

character is sent back to the PC.

READER.

CTS and DSR signal management for flow

control.

When the DNC is receiving, and if the DNC

wishes to halt transmission temporarily to

process the received data, the CTS line goes

low, indicating that only one more character

can be accommodated (if more arrive, they will

be lost).

With this protocol in force, the READER must

thus send only one more character when the

CTS line goes low.

On the other hand, when the DNC is sending,

and the READER forces the CTS line low, the

DNC stops sending characters immediately

(not even 1 more is sent).

3 Same as for protocol 2, but when the DNC

forces the CTS line low, it does not expect to

receive any more characters (not even 1).

Therefore, the READER must not send even 1

more character, the moment the CTS line goes

low.

MACHINE PARAMETERS PAGE 19

Page 22

P66 BCC

This parameter authorizes or inhibits the checksum test in reception mode.

_

1

with checksum

without checksum

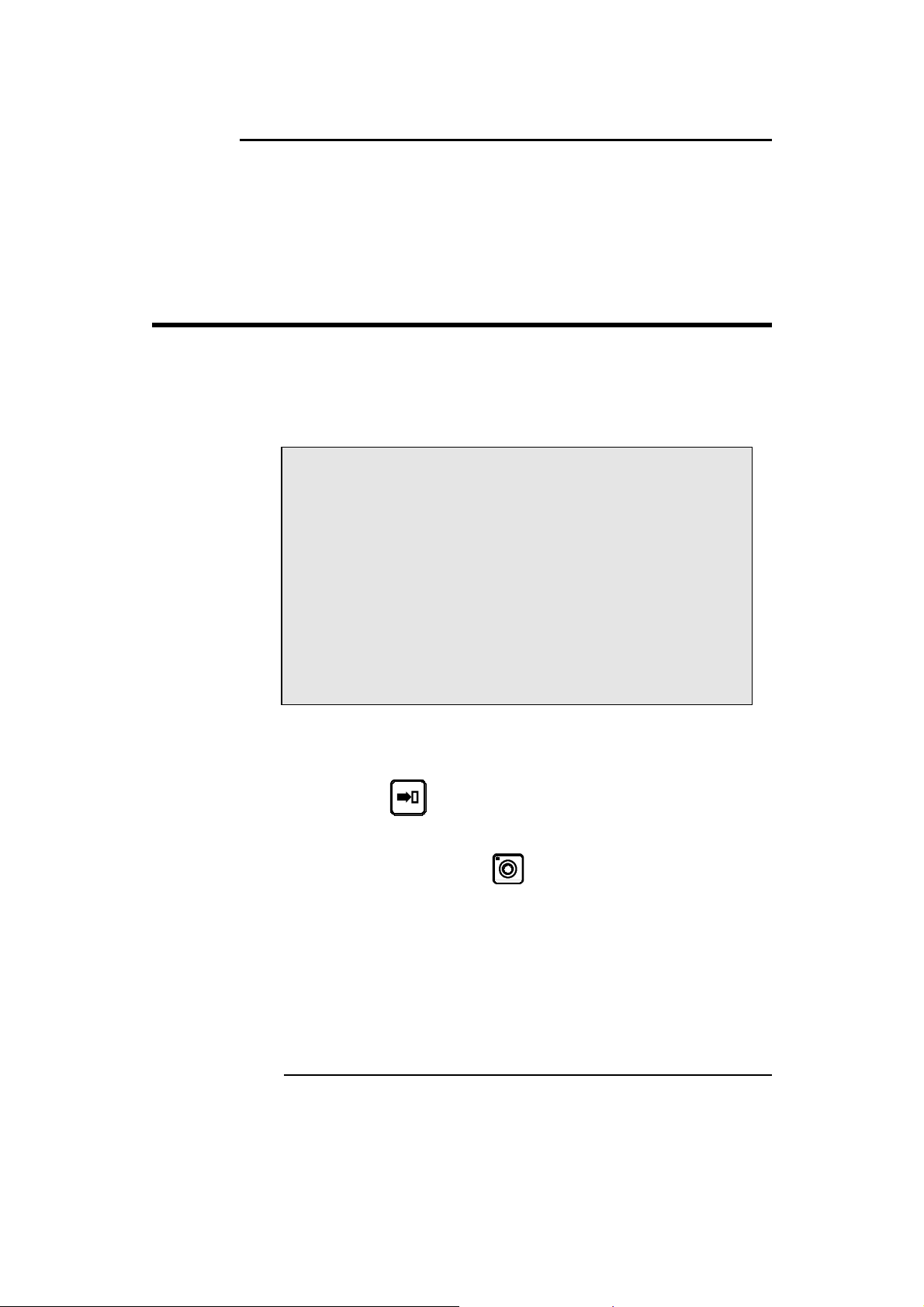

TESTS OF THE SERIAL PORT

The serial port of the DNC 60 is SUB-D 9P, plug J5.

y Introduce and verify that the transmission parameters are programmed

as follows:

PARAMETERS RS232 / DIVERS

. . .

-- COMPUTER LINK – 106 BAUD RATE 4800 STOP 1.0

PARITY ODD(1) EVEN(2) _ BITS 8

PROTOCOLE _ BCC ___

y Set a test loopback connector on the serial line connector RS232 to be

tested.

y Press the

The message RUN must flash.

y To stop the test, press the

If you wish as well to test the cable:

y Connect the transmission cable to the DNC and fit a short circuiting

loopback connector on the other end of the cable to be tested.

key to start the test.

(STOP) key.

Test loopback connector

Pin 2 (RXD) wired to pin 3 (TXD)

Pin 4 (DTR) wired to pin 6 (DSR)

Pin 7 (RTS) wired to pin 8 (CTS)

PAGE 20 MACHINE PARAMETERS DNC 60 G

Page 23

RS 232 transmission cable

Shield: connection on the metallic hood

Blindage: connexion sur le capot métallique

Abschirmung: Anschluss an Metallhülse

P67 NONE AT PRODUCT SEARCH IN CASSETTE

If P67 = 1 The DNC inhibits the various calculations

relative to functions F1, F2, F3 (blade gap, rake

angle, cutting length) whenever a product is

recalled from the product memory. Otherwise,

all the relevant calculations are performed at

each product recall.

If P67 = 2 The DNC inhibits the calculation of the TDC. The

blade upstroke will hence only take account of the

exterior TDC (24V contact of max TDC).

If P67 = 3 The above two conditions are in fare.

P68 CONVERSION INCH/MM

If P68 = 1 Conversion to inches of user data expressed in

mm.

If P68 = 0 or undefined User data expressed in mm.

P69 STOP Q PRODUCT REACHED

This parameter allows to stop the cycle execution in AUTOMATIC mode as

soon as the quantity of products has been reached.

This functionality is active by default (P69 = Undef). To inhibit it, you have

to program P69 = 0.

In page MP 12 (PARAMETRIZING OF THE MACHINE MESSAGES),

write Q PRODUCT REACHED in message 15.

When the quantity of products is reached, the STOP key is activated and the

DNC displays the MACHINE MESSAGES page with Q PRODUCT

REACHED. When releasing the STOP, the quantity of executed products is

reinitialized at 0.

MACHINE PARAMETERS PAGE 21

Page 24

AUXILIARY FUNCTIONS PARAMETERS (AF)

MACHINE PARAMETERS -07- IGNORE

--Auxiliary functions- F1:GAP F2:ANGL F3:BDC

70 Function type 2 2 2

71 Mode: Digital _ _ _

72 Analogue 1 1 0

73 Voltage _ _ _

74 LS distance __ __ __

75 Overrun dist. __ __ __

76 Advanced stop 2 2 2

77 Tolerance 2 2 2

78 Reversal time _.__ _.__ _.__

79 Min.range(D/A) 2 38 2

80 Max.range(D/A) 250 254 254

81 Min.range(prog) 5 34 0

82 Max.range(prog) 165 341 361

On the MACHINE PARAMETERS page N° 7 you will find a set of fields

under the heading:

Fn

Specification of alphanumeric characters

1) With the aid of the manual displacement keys, run through the

character table until the required character appears in the display.

Remark: The

4 characters.

The

1 character.

2) Press the

memorized.

3) Repeat operations 1 and 2 for the following characters.

The auxiliary function pages can only display 3 AF at the same time, whereas

the DNC can handle up to 8.

In order to visualize the other AF, position the cursor on any field pertaining

to parameters 70 to 78, and use the manual displacement keys.

In these fields you can enter the auxiliary

function identifier using 4 alphanumeric

characters (n=1 to 8).

On initialisation, these appear as F1, F2 .... F8.

:

or keys move forward or backward by

or keys move forward or backward by

or TEACH key (memorize). The first character is

PAGE 22 MACHINE PARAMETERS DNC 60 G

Page 25

P70 FUNCTION TYPE

Definitions:

y The dependent auxiliary functions follow the sequences of the cycle.

y The auxiliary functions with automatic START have their

management start synchronised with their axis start.

y The independent auxiliary functions execute their own advance

sequence and START with their signal START AFn.

y The auxiliary functions with external START have their management

start triggered by their START AFn signal.

Programming:

P70 = undefined

P70 = 0

P70 = 1 (D0)

P70 = 2 (D1)

P70 = 4 (D2)

AF dependent on the machine cycle with

automatic START.

The code 0 prohibits display of the function,

but allows to reserve the function outputs in

digital mode. The aim of this is to avoid a

difference of the auxiliary functions as a

function of the configuration of the machine

options. The wiring can be standardized.

Cycle-independent AF with independent

advance sequence and external START.

Special AF with internal calculations:

- for F1 and F5: blade gap

- for F2: cutting angle

- for F3: cutting length (BDC)

- for F4: timer for flying cut

- for F7: sheet thickness measurement

AF dependent on the cycle for the advance

sequence, but having its own management

start, supplied by its corresponding START

AFn signal.

P71 DIGITAL MODE

This parameter configures the AF in digital mode.

The programmed number (maximum 8) corresponds to the number of 24V

output wires (binary coded) for the chosen function. This number of outputs

is reserved.

Calibrating digital functions

The parameters P79 and P80 can be used to define a limit for the binary

codes attributed to the function.

Example: A digital function programmed with 3 wires accepts the digital

values from 0 to 7. These values are used by default if P79 and

P80 are not programmed. If you program P79 = 2 and P80 = 5,

the codes 0, 1, 6 and 7 are excluded.

MACHINE PARAMETERS PAGE 23

Page 26

P72 ANALOGUE MODE

This parameter configures the AF in analogue mode, so that it can be used as

an axis with analogue position measurement, or measurement of any other

physical attribute (temperature, pressure, etc.).

Mode 1: Reservation of 2 digital outputs (SP/SN) and a digital input

(potentiometer).

Mode 0: Reservation of just one analogue input (F3 in cutting length

mode).

Calibration of an analogue function

1) Move down the function until its minimum position is reached, by

placing the cursor on P79 and pressing the

2) Perform the TEACH of the minimum D/A value (P79 of the function),

by pressing the

will appear in the active field (value range between 1 and 254).

3) Program in P81 the physical value corresponding to this state (mm,

degrees, pressure, temperature, etc.).

4) Move up the function until its maximum position by placing the cursor

on P80 and pressing the

5) Perform the TEACH of the maximum D/A value (P80 of the function),

by pressing the

6) Program in P82 the physical value corresponding to this state (mm,

degrees, pressure, temperature, etc.).

key. The D/A value read on the potentiometer

key.

key (value less than 255).

key.

P73 VOLTAGE MODE

This parameter configures the AF in voltage mode. In this mode the DNC

supplies a voltage of between 0V and 10V.

Reserves an analogue output.

Calibration of a tension function

1) Program in parameter 79 the minimum D/A value, while aware that:

0 V corresponds to 0 D/A

+10 V corresponds to 254 D/A.

2) Program in P81 the physical value corresponding to this state (mm,

degrees, pressure, temperature, etc.).

3) Program in parameter P80 the maximal D/A value, while aware that:

0 V corresponds to 0 D/A

+10 V corresponds to 254 D/A.

4) Program in P82 the physical value corresponding to this state (mm,

degrees, pressure, temperature, etc.).

PAGE 24 MACHINE PARAMETERS DNC 60 G

Page 27

NB: The 1 to 3 steps can be realized by teaching, using the manual keys.

The manual keys will increase or decrease the P79 or P80 values

(according to the cursor position) meanwhile the voltage corresponding

to the reached digital value will be output on the analogue auxiliary

function.

The

1 to 10 units.

The

1 to 10 units.

For the 5 following parameters (P74 → P78), you will find a diagram explaining the positioning of an AC axis at 1 or 2 speeds in the notice "N2X BOARD

PARAMETERS" at figure 1. The only difference to take into account is that

the units of measurement are replaced by increments from the D/A unit.

or keys will increase respectively the D/A value of

or keys will respectively decrease the D/A value of

P74 LS DISTANCE

Switch on low speed signals "n" D/A units before the required position is

reached.

Default value = no low speed.

Type value = 10.

This distance must be sufficiently large to enable the axis to stabilise at the

required low speed.

Programming this parameter reserves an extra (HS) digital output.

P75 OVERRUN DISTANCE

Defines, in D/A units, the distance allowing for an overrun to catch up with

any play in the auxiliary axis.(unidirectional positioning).

Value type = 0 (without overrun).

The sign preceding the value determines the direction at the end of

positioning, namely:

Sign negative: the axis terminates positioning in SN.

Sign positive: the axis terminates positioning in SP.

P76 ADVANCED STOP

Distance in D/A units before the aimed-for position at which the movement

command is cut.

Value type = 1 (depending on axis inertia).

The inertia of the axis determines this distance.

MACHINE PARAMETERS PAGE 25

Page 28

P77 TOLERANCE

Maximum tolerance, in D/A units, authorized each side of the position value

without having to reposition with a new start.

Value type = 2.

Insensitive zone.

P78 REVERSAL TIME

This parameter corresponds to the waiting time before a change in the

positioning direction (directional change timeout).

P79 MINIMUM RANGE (D/A)

Digital value from the analogue-to-digital convertor for the minimum

position of the function.

This parameter functions as an electronic limit switch for the analogue AF.

To determine the required value, the cursor should be positioned on the

parameter and the axis moved to the desired limit switch position. Then,

)

press the TEACH key

potentiometer position will appear in this field, and effectively becomes the

minimum limit switch value not to be exceeded.

Attention: The value must be greater than zero, otherwise this indicates that

the axis has reached the electrical limit of the potentiometer.

(

. The D/A value corresponding to the

P80 MAXIMUM RANGE (D/A)

Digital value from the analogue-to-digital convertor for the maximum

position of the function.

This parameter functions as an electronic limit switch for the analogue AF.

To determine the required value, the cursor should be positioned on the

parameter and the axis moved to the desired limit switch position. Then,

)

press the TEACH key

potentiometer position will appear in this field, and effectively becomes the

maximum limit switch value not to be exceeded.

Attention : The value must be less than 255, otherwise this indicates that the

axis has reached the electrical limit of the potentiometer.

These 2 parameters (P79, P80) are generally determined by use of the

TEACH key for analogue functions.

(

. The D/A value corresponding to the

PAGE 26 MACHINE PARAMETERS DNC 60 G

Page 29

P81 MINIMUM RANGE (PROGR)

Programming value which corresponds to the minimum D/A (P79).

P82 MAXIMUM RANGE (PROGR)

Programming value which corresponds to the maximum D/A (P80).

This parameter determines the unit with which you want to work.

CUTTING PRESSURE PARAMETERS (AF6)

MACHINE PARAMETERS -13- IGNORE

-- PRESSURE PARAMETRIZING (AF6) --

83 MINIMAL BLADE UP PRESSURE: 10

84 RAKE ANGLE ADJUST. PRESSURE: 20

85 b ELECTRICAL BLADE GAP: _

a BLADE GAP ADJUST. PRESSURE: 20

86 BLADE UP PRESSURE: 80

87 BLADE UP GAIN: 200

88 ACC.TIME BLADE DOWN PRESSURE: 1.00

89 a DEC.TIME BLADE DOWN PRESSURE: 1.00

b DEC.TIME MANUAL PRESSURE: _.__

90 ACC.TIME BLADE UP PRESSURE: 1.00

91 DEC.TIME BLADE UP PRESSURE: 1.00

92 DECOMPRESSION TIME: 1.00

P83 MINIMAL BLADE UP PRESSURE

This parameter indicates the remaining minimum pressure at the raising of

the blade when it has reached the max. TDC.

P84 RAKE ANGLE ADJUST. PRESSURE

This parameter indicates the pressure used to carry out the angle adjustment.

Remark: If AF2 and AF3 are calibrated, the used pressure is the max.

pressure of parameters P84 and P85.

MACHINE PARAMETERS PAGE 27

Page 30

P85A ELECTRICAL BLADE GAP

This parameter indicates that the blade gape is adjusted with a electrical

motor and not with hydraulic pressure. (Value = _, 0 ou 1)

P85B BLADE GAP ADJUST. PRESSURE

This parameter indicates the pressure used to carry out the blade gap

adjustment

Remark: If AF2 and AF3 are calibrated, the used pressure is the max.

pressure of parameters P84 and P85.

P86 BLADE UP PRESSURE

This parameter indicates the pressure level used to carry out the raising of the

blade.

P87 BLADE UP GAIN

This parameter is used to soften the arrival at the TDC on the blade raising.

y Default value (if Undef) = 100.

y A too low value can limit too much the upstroke pressure of the blade

(the raising doesn't cushion).

y More the value is strong, more the softening comes late. On the other

hand it is more sloping.

P88 ACC. TIME BLADE DOWN PRESSURE

This parameter indicates the required time to reach the downstroke pressure

of the blade.

This parameter corresponds to a pressure acceleration ramp.

P89A DEC. TIME BLADE DOWN PRESSURE

This parameter indicates the required time to reach the zero pressure at the

end of the descent of the blade.

This parameter corresponds to a pressure deceleration ramp.

PAGE 28 MACHINE PARAMETERS DNC 60 G

Page 31

P89B DEC. TIME MANUAL PRESSURE

This parameter indicates the required time to reach the zero pressure at the

end of the manual movement of the blade.

This parameter corresponds to a pressure deceleration ramp. The default

value is 0,3 seconds (max. 0,3 seconds).

P90 ACC. TIME BLADE UP PRESSURE

This parameter indicates the required time to reach the upstroke pressure of

the blade.

This parameter corresponds to a pressure acceleration ramp.

P91 DEC. TIME BLADE UP PRESSURE

This parameter indicates the required time to reach the minimum upstroke

pressure (P83) at the end of the ascent of the blade.

This parameter corresponds to a pressure deceleration ramp.

P92 DECOMPRESSION TIME

This parameter indicates the waiting time after the cut before the blade

moves up again.

CALIBRATION CUTTING PRESSURE PARAMETERS (AF6)

MACHINE PARAMETERS -14- IGNORE

93 TDC MAX SENSOR DISTANCE IN MM: 20

IN U D/A: 14

-- PRESSURE CALIBRATION (AF6) --

AF6 AF6

U Pr U D/A

Min = P81 1 = P79 2

25% 64

50% 128

75% 192

Max = P82 100 = P80 254

MACHINE PARAMETERS PAGE 29

Page 32

P93 TDC MAX SENSOR DISTANCE

This parameter can be considered as an advanced stop which allows to avoid

a shock at the top of the machine when the blade is moving up.

ATTENTION: This parameter must be programmed in millimeter after the

calibration of AF2 and AF3, for after that it is converted and displayed (just

underneath) in U D/A as soon as you leave the field. This U D/A value is

then exploited by the software for the management of the angle adjustment

tolerance.

This parameter enables to improve the management of the angle adjustment

tolerance.

EXTENDED BLADE GAP PARAMETERS (8 SEGMENTS)

MACHINE PARAMETERS -15- IGNORE

-- BLADE GAP WITH 9 POINTS (8 SEGMENTS) --

AF1 AF1 (TEACH) AF5

U Pr U D/A U D/A

Min = P81 1 = P79 2 2

Int1 12 32 16

Int2 25 64 32

Int3 37 96 48

Int4 50 128 64

Int5 62 160 80

Int6 75 192 96

Int7 87 224 112

Max = P82 100 = P80 254 128

PAGE 30 MACHINE PARAMETERS DNC 60 G

Page 33

X BACKGAUGE FOLDAWAY PARAMETERS

MACHINE PARAMETERS -16- IGNORE

-- X BACKGAUGE FOLDAWAY --

P94 PARK DISTANCE: _____.__

PARK TARGET: +_____.__

P95 CRAWL DISTANCE: _____.__

CRAWL TARGET: +_____.__

P96 HYDRAULIC FOLDAWAY TIME:

a: IN: _.__ b: OUT: _.__

c: DELAY: _.__ d: PRESSURE: _.__

P97 LS/HS X3 COMMUTATION: _

P98 DELAY RESET OUT HOLD-DOWNS: _.__

P99 PULSATE TDC DURATION: _.__

P100 EASY OPTIMIZER _

P101 AFS ADJUSTMENT: 1 x / ___

P104 CUT ON MIDDLE _

P94 PARK DISTANCE

This parameter is used for the backgauge foldaway. It defines the safety

distance from the max. limit switch where the gauge is retracted.

The PARK TARGET (= LSW max – P94) is the absolute value from which

the gauge is completely retracted.

For more details, see User Guide, Ch. Functionalities, Backgauge foldaway.

P95 CRAWL DISTANCE

This parameter is used for the backgauge foldaway. It defines the transition

distance between the normal position of the backgauge and its retracted

position.

The CRAWL TARGET (= PARK TARGET – P95) is the absolute maximum

value of the backgauge for a normal use.

For more details, see User Guide, Functionalities, Backgauge foldaway.

MACHINE PARAMETERS PAGE 31

Page 34

P96 HYDRAULIC FOLDAWAY TIME

This parameter is used for the backgauge foldaway activated by a hydraulic

cylinder. It defines the dwell time of the hydraulic system of the gauge

foldaway.

L In order to activate this functionality, you have to program:

• P94 (PARK DISTANCE)

• P95 (CRAWL DISTANCE) =

a: In

Temporization while the pressure is active for the foldaway. (Max.

9.99seconds)

b: Out

Temporization while the backgauge goes at his normal height of use. (Max.

9.99seconds)

c: Delay

This parameter extends the time for the signal of the pressure up and down

command for the foldaway. (Max. 2.54seconds)

0

d: Pressure

Pressureof for the hydraulic foldaway rise. The value in this field is percent.

The minimum value (0%) corresponds to P81 Min. Range (prog) of the

AF6 and the maximum value (100%) at P82 Max. Range (prog) of the

AF6.

If the cursor is on this field, it’s possible move up or down the hydraulic

foldaway with the key

or .

PAGE 32 MACHINE PARAMETERS DNC 60 G

Page 35

P97 LS/HS X COMMUTATION

If this parameter P97 is configurated with value 1, then:

y at each entry of X in the retraction zone (= P94 + P95), the DNC

passes to LS on X.

y at each exit of X from the retraction zone (= P94 + P95), the DNC

passes to HS on X.

CAUTION: To use this functionality, it is recommended to not configure

the LSX input.

P98 DELAY RESET OUT HOLD-DOWNS

The independent management of the hold-downs can be done uniquely with

a two-level pedal. The 1

the downstroke of the blade.

Right from the beginning of the blade upstroke, the value of parameter P98

defines the delay (from 0 to 9,99 seconds) before disactivating the Hold-

downs output.

P98 = Undef is considered as a delay zero (0 sec).

st

level activates the hold-downs and the 2nd activates

P99 PULSATE TDC DURATION

When the Pulsate TDC output is configured, parameter P99 defines the

activation time (from 0 to 9,99 seconds) of this output, as soon as the blade

arrives at the TDC calculated by the DNC.

For P99 = Undef or P99 = 0, the Pulsate TDC output is not activated.

P100 EASY OPTIMIZER

This parameter is used for the Easy Optimizer mode.

If P100 = 1, the MODE EASY OPTIMIZER field appears in the

EASYCUT page.

To activate this functionality, the value 1 must furthermore be programmed

in the MODE EASY OPTIMIZER field of the EASYCUT page.

For more details, see: User Guide, The EASYCUT page, EasyCut page in

Easy Optimizer mode.

MACHINE PARAMETERS PAGE 33

Page 36

P101 AFS ADJUSTMENT ONCE OUT OF …

This parameter allows to increase the cutting cadence by not raising each

time up to the top of the machine (TDC max).

In AUTOMATIC or SEMI-AUTOMATIC mode:

y If P101 = 0, the blade never raises up to the top of the machine

(TDC max) during the whole cycle. The blade gap and the angle

adjustment is executed only once at the start-up of the cycle.

y If P101 = 1 or P101 = Undef, the blade raises each time up to the

top of the machine (TDC max) in order to execute the blade gap and

the angle adjustment.

y If P101 = n (2 ≤ n ≤ 999), the blade raises up to the top of the

machine each n

adjust-ment. For the other n-1 times, the blade raises up to the TDC

pot only.

th

time in order to execute the blade gap and the angle

P104 CUT ON MIDDLE

This parameter allows to active the function of offset of sheet origin

. This function allows the sheet cutting anywhere on the width of

the machine.

THICKNESS MEASUREMENT PARAMETERS (8 SEGMENTS)

MACHINE PARAMETERS -17- IGNORE

-THICKNESS MEASUREMENT 9 POINTS (8 SEGM.)-

AF7 AF7 (TEACH)

U Pr U D/A

Min = P81 0 = P79 2

Int1 10 32

Int2 15 64

Int3 20 96

Int4 40 128

Int5 60 160

Int6 80 192

Int7 100 224

Max = P82 120 = P80 254

PAGE 34 MACHINE PARAMETERS DNC 60 G

Page 37

SHEET SUPPORT

For more details on how to use the sheet support feature, please refer to

section Sheet Support, on page 55 of t

MACHINE PARAMETERS -18- STOPPED 3

P103 PIN SECURITY ZONE _.__

-- SHEET SUPPORT FUNCTION --

P115 SHEET SUPPORT START DELAY: _.__

P105 SHEET SUPPORT TIME UP: _.__

P102 SHEET SUPPORT TIM

P106 SHEET SUPPORT TIME DOWN: _.__

b : SECURITY DELAY DOWN: _.__

P107 RETURN SHEET SUPPORT AT TDC: _

-- A-TW FUNCTION --

P116 A-TW START DELAY: _.__

P108 A-TW TIME UP: _.__

P109 A-TW TIME: _.__

P110 A-TW TIME DOWN: _.__

P111 RETURN A-TW AT TDC: _

his manual.

P102 Sheet Support Time

This specified time starts when the blade is at BDC and the sheet support at a

low position, and ends when the support starts going up.

(Value range: from 0 to 9.99 seconds)

P105 Sheet Support Time Up

Estimation of the time needed for the sheet support to go up to the high

position.

(value range : from 0 to 9.99 seconds)

P106 Sheet Support Time Down

This parameter is an estimation of the time needed for the sheet support to go

down to the lower position.

(value range : from 0 to 9.99 seconds)

P106b Security Delay Down

This parameter is the specified time at the end of which the numerical control

checks whether the sensor on position 1 is activated or not.

MACHINE PARAMETERS PAGE 35

Page 38

(Value range: from 0.01 to 2.54 seconds, if no value is specified, no check is

performed)

P106b<P106

P107 Return Sheet Support at TDC

This parameter controls whether the sheet support goes back to position 1

(high) after the blade reaches TDC or whether it remains in the lower

position.

If the value for this parameter is 1, the sheet support goes to position 1 at the

end of the time specified in P102.

You may also use parameter P107 if you need to ensure that the sheet

support only goes up after blade, eg, to avoid collisions between the two.

P115 Sheet Support Start Delay

This parameter is the delay between the cutting authorization signal and the

start of the sheet support cycle.

(Value range : from 0.01 to 9.99 seconds, Default value = 1 second)

Reminder: in a work cycle without sheet support, parameter P36 is the

specified time between the cutting authorization and the moment where the

hold-downs are tightened, that is, when the blade can start going down.

When using a sheet support, you must enter a value for P36: this parameter

then acts as an additional security.

As a rule, the sheet support cycle must start after the metal is clamped: P115

must be greater than P36.

However, in special situations, the support cycle may need to start before the

metal is clamped. In this case, P115 must be less than P36.

Using a pressure sensor may shorten the duration of both P115 and P36.

ANTI-TWIST PARAMETERS

For more details on how to use the anti-twist feature, please refer to section

Sheet Support on page 63 of this manual.

P116 A-TW Start Delay

This parameter is the delay between the cutting authorization signal and the

start of the anti-twist device's cycle.

(Value range : from 0.01 to 9.99 seconds, Default value = 1 second)

Reminder: in a work cycle without sheet support, parameter P36 (Hold

Downs Time) is the specified time between the cutting authorization and the

moment where the hold-downs are tightened, that is, when the blade can start

going down.

PAGE 36 MACHINE PARAMETERS DNC 60 G

Page 39

When using a sheet support, you must enter a value for P36: this parameter

then acts as an additional security.

As a rule, the anti-twist device cycle must start after the metal is clamped:

P116 must be greater than P36.

However, in special situations, the anti-twist device cycle may need to start

before the metal is clamped. In this case, P116 must be less than P36.

Using a pressure sensor on the hold-downs may shorten the duration of both

P116 and P36.

P108 A-TW Time Up

Estimation of the time needed for the anti-twist device to go up to the high

position.

This parameter is similar to P105 for sheet support.

P109 A-TW Time

This specified time starts when the blade is at BDC and the anti-twist device

at a low position, and ends when the A-TW device starts going up.

(Value range: from 0 to 9.99 seconds)

P110 A-TW Time Down

This parameter is an estimation of the time needed for the sheet support to go

down to the lower position.

(value range : from 0 to 9.99 seconds)

P111 Return A-TW at TDC

If the value for this parameter is 1, the anti-twist device goes back up after

the blade reaches TDC and the time specified in P109 has elapsed.

Use this parameter if you need the anti-twist device to go back up after the

blade.

MACHINE PARAMETERS PAGE 37

Page 40

MACHINE PARAMETERS -19- 3

P112 SEQUENTIEL SENDING FAs: _

P113 DELAY OPENING HOLD-DOWNS : _.__

P114 DURATION OPENING HOLD-DOWNS : _.__

P117 TOGGLE MODE LEVEL 3/2/3 (1=YES)_

P118 I/O VISUALIZATION IN RUN (1=YES)_

P119 NIBBLING MODE (1=YES) _

P120 UNINTERRUPTIBLE CUT (1=YES) _

P121 SHOW ALL MACH. PAR. (1=YES) _

P122 PRINT ALL MACH. PAR. (1=YES) _

P123 KEY 0 BLOCKS UTILIZATION (1=YES)_

P112 SEQUENTIEL SENDING FAS

If this parameter is at 1, the auxiliary functions (1st blade gap, 2nd blade gap,

cutting angle) are adjusted one after the other.

P113 DELAY OPENING HOLD-DOWNS

In the hold-down hydraulic circuit, an opening valve is integreted. The

POuvSerT output drives this valve.

The activation of the POuvSerT output will be temporized by the parameter

Delay opening hold-downs and a potientiometer after the start of the

blade goes up. A potientiometer must be connected on 4

1 of connector J8).

This function is always active, except if the value of the potentiometer is

smaller than 20 units D/A.

See also parameter P114.

th

analogic input (Pin

P114 DURATION OPENING HOLD-DOWNS

This parameter allows to limit the duration of POuvSerT output activation.

P117 TOGGLE MODE LEVEL 3/2/3

When this parameter is active (set to 1), the operator can switch from 3 to 2

and conversely by holding down the key

PAGE 38 MACHINE PARAMETERS DNC 60 G

for a few seconds.

Page 41

This parameter won't let you toggle from level 0 to level 1. It is only intended

to help you start a machine quickly.

P118 I/O VISUALIZATION IN RUN

When this parameter is active (set to 1), the operator may view the status of

all inputs/ouputs while in cycle, by pressing either

or

P119 NIBBLING MODE

This parameter lets you activate or de-activate the nibbling mode (for more

details, please refer Nibbling Mode section of the DNC60G16 User Guide).

1 = actives

0 or undef = de-activated.

P120 UNINTERRUPTIBLE CUT

When this parameter is active (set to 1), the blade will go down to BDC

without stopping - even if you release the pedal. This applies only from the

moment the hold-down is down (tightened).

P121 SHOW ALL MACH. PAR.

.

When this parameter is active (set to 1), all machine parameters will display,

including unused parameters such as unassigned auxiliary functions.

If this parameter is set to 0 or undefined, parameters that are connected to

another (unset) parameter do not display.

Ex: P39 (TDC TIME) only displays if F2 is in "cutting angle" mode or if

P121 is set to 1.

P122 PRINT ALL MACH. PAR.

When this parameter is set to 1, you can print all machine parameters simply

by pressing

If this parameter is undefined, enter 1, then move the cursor out of the field,

and press

What is referred to as printing is the process of downloading the content of

all all Machine Parameter screens to the HyperTerminal utility (on a PC).

For more information on this operation, please refer to section

HyperTerminal in the DNC60G16 User Guide.

.

to print all machine parameters.

MACHINE PARAMETERS PAGE 39

Page 42

P123 KEY 0 BLOCKS UTILIZATION

This parameter is actually an additional security for the DNC.

When this parameter is set to 1 with the DNC is in key level 0 mode, the only

actions possible are to press or release the pedal or the Stop button.

To unblock the DNC, simply switch key levels.

PAGE 40 MACHINE PARAMETERS DNC 60 G

Page 43

SPECIAL SHEAR FUNCTIONS

AUXILIARY FUNCTIONS Type of management (P70)

F1/F5: Blade gap 2

F2: Cutting angle 2

F3: Cutting length 2

F4: Flying cut 2

F6: Pressure 2

F7: Sheet thickness measurement 2

BLADE GAP FUNCTION (F1)

FIELDS TO

PROGRAM

Material tables 0.01Î9.99

P70 F1 2

P72 F1 (par ex.) 1

P79 F1 1Î254

P80 F1 1Î254

P81 F1 0Î999

P82 F1 0Î999

On the sequence

page:

-

- select the

MATERIAL

with the manual

displacement

keys.

The BLADE GAP function can be adjusted using two motors placed at each

end of the machine. This configuration allows to simplify the adjustment

mechanism of the blade gap.

nd

AF used for this adjustment is AF5; it is programmed and calibrated

The 2

the same as AF1 (in BLADE GAP mode).In this mode, the AF5 does not

appear on the screen but is programmed automatically when a calculation is

made or a blade gap function is programmed. It is also moved simultaneously

with the AF1 in AUTOMATIC or MANUAL.

VALUES COMMENTS

Calculation constants for

blade gap according to

material and thickness.

Management type

Analogue mode

Value D/A min. (teach)

Value D/A max. (teach)

Min programming range

Max programming range

0.01Î99.99

ALU

(for ex.)

Sheet metal thickness

Sheet metal type

Note : F1 / F5 could be defined as analogue, voltage, or digital, by

defining parameters 71, 72 or 73 (see relevant text, page 23/24).

SPECIAL SHEAR FUNCTIONS PAGE 41

Page 44

CALIBRATION OF FUNCTIONS F1 / F5

1) Adjust the blade gap function to its minimum position, by placing the

cursor in the F1 column of row P79, and pressing the

2) Perform the TEACH for the minimum D/A value (row P79, column

F1) with

written in to the active field (value in range 1-254).

3) Program in P81 the measured distance (in 1/100 mm) between the

blades.

4) Adjust the blade gap function to its maximum position by placing the

cursor in the F1 column of row P80, and pressing the

5) Perform the TEACH for the maximum D/A value (row P80,

column F1) with

6) Program in P82 the measured distance (in 1/100 mm) between the

blades.

If F6 is defined in pressure mode (see function F6 Pressure), each pressing

on a manual key provokes the pressure rise to P85 (Blade gap adjustment

pressure). When releasing the key, the pressure will fall back to 0.

key. The D/A value read on the potentiometer will be

key (value less than 255).

key.

key.

BLADE GAP CALCULATION

The calculation of the blade gap is performed each time the sheet metal

thickness or sheet metal type fields are programmed (according to the table

of materials explained earlier).

The value of blade gap calculated on the sequence page corresponds to an

accuracy of 1/100 mm.

Manual programming of the blade gap (in 1/100 mm) on the (

page remains possible.

) function

PAGE 42 MACHINE PARAMETERS DNC 60 G

Page 45

g

RAKE ANGLE (F2) AND CUTTING LENGTH (F3)

FUNCTIONS

(WITH ONLY ONE POTENTIOMETER)

FIELDS TO

PROGRAM

P70 F2 2

P72 F2 1

P79 F2 1Î254

P80 F2 1Î254

P81 F2 (b-a) mm

P82 F2 (c-a) mm

P70 F3 2

P72 F3 0

P79 F3 1Î254

P80 F3 1Î254

P81 F3 0 mm

P82 F3 (c) mm

P50 1Î99999

Table of materials 0.01Î9.99

P55 0.01Î999.99

On sequence page :

-

- choose the

MATERIAL using

the manual

displacement keys.

-

VALUES COMMENTS

Type of management

AF2 analog

Min D/A value (teach)

Max D/A value (teach)

Minimum programming range.

(See figure 4, page 43)

Maximum programming

range. (See figure 4, page 43)

Type of management

AF3 analog

Min. D/A value (teach)

Max D/A value (teach)

Minimum programming range

Maximum programming range

(see figure 4, page 43).

Maximum cutting length

Rake angle according to

material and thickness

Dist. between left edge and

fixed point blade

0.01Î99.99

ALU

1Î99999

(e.g.)

Sheet metal thickness

Sheet metal type

Sequence cutting length

Rake angle and cutting depth

measuring potentiometer

Measurin

point

Fixed

rotation point

max

<min

c

b

Lower blade

P 55

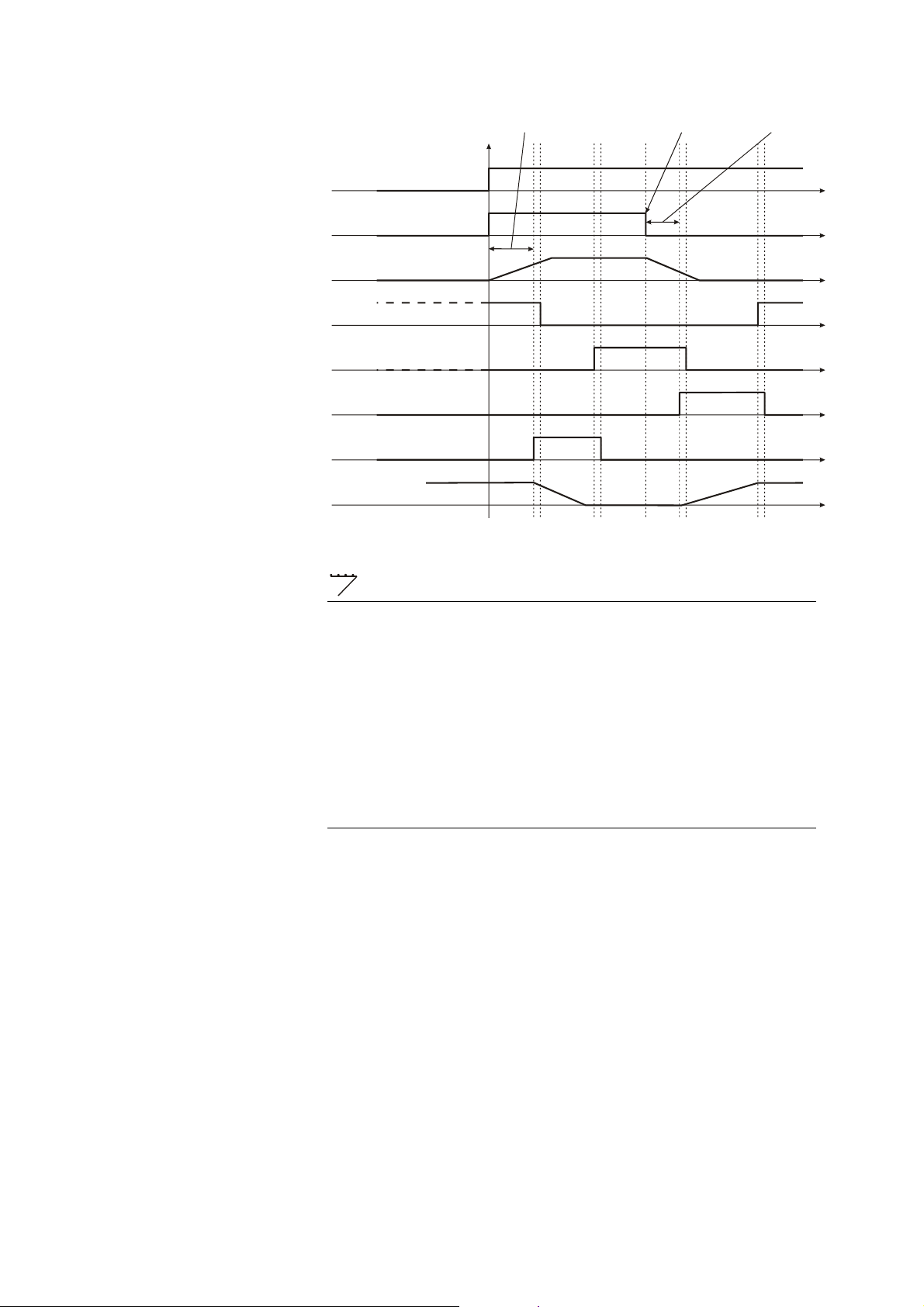

Figure 4

SPECIAL SHEAR FUNCTIONS PAGE 43

Page 46

p

CALIBRATION OF THE AUXILIARY FUNCTION RAKE

ANGLE F2

Rake angle and cutting depth

measuring potentiometer

Fixed

rotation

oint

P54 max.

P54 min.

+

_

Dmax.

P81

P82

Lower blade

P55

P58

P50

1) Program in P50 the maximum cutting width of the machine.

2) Program in P54 the max. angle and the min. angle of the blade.

3) Program in P55 the horizontal distance between the left edge of the

lower blade and the axis of the rotation point of the upper blade.

4) Program in P58 the horizontal distance between the left edge of the

lower blade and the potentiometer position.

5) Move the blade up to the max. TDC (Dmax distance) by setting the

cursor in P80 of F3 and pressing the

6) Move the blade up to its min. angle by setting the cursor in P79 of F2

and pressing the

7) Perform the TEACH of the min. D/A value (P79 of F2). The (in mm)

calculated vertical distance between the fixed rotation point and the

upper blade, at the point where the potentiometer is found, is transferred

in P81 of F2.

8) Move the blade up to its max. angle by setting the cursor in P80 of F2

and pressing the

key (by keeping the Dmax distance).

key.

key.

PAGE 44 MACHINE PARAMETERS DNC 60 G

Page 47

p

9) Perform the TEACH of the max. D/A value (P80 of F2). The (in mm)

calculated vertical distance between the fixed rotation point and the

upper blade, at the point where the potentiometer is found, is transferred

in P82 of F2.

If F6 is defined in pressure mode (see function F6 Pressure), each pressing

on a manual key provokes the pressure rise to P84 (Rake angle adjustment

pressure). When releasing the key, the pressure will fall back to 0.

CALIBRATION OF THE AUXILIARY FUNCTION CUTTING

LENGTH F3

Rake angle and cutting depth

measuring potentiometer

+

_

Fixed

rotation

oint

P54 max.

P82

P81 = 0

Lower blade

P55

P58

Remark: The upstroke / downstroke of the blade can also be carried out by

P50

the pedal. In this case, if the elapsed time between two pedal

pressings is less than 2 seconds, the blade will move in the same

direction as previously, otherwise it changes the direction.

After having carried out the above described steps 1 to 9, the calibration of

the auxiliary function F3 is the following:

10) Place the cursor in P80 of F3 and make the TEACH of the max. D/A

value (P80 of F3).

11) Measure the distance between the upper and the lower blade at the right

extremity of the machine and transfer this value (in mm) in P82 of F3.

12) Bring down the upper blade until the right-hand edges of the blades

cross, by setting the cursor in P79 of F3 and pressing the

Stop the blade in this position.

SPECIAL SHEAR FUNCTIONS PAGE 45

key.

Page 48

13) Perform the TEACH of the min. D/A value (P79 of F3).

14) Program in P81 of F3 the value 0.

If F6 is defined in pressure mode (see function F6 Pressure), each pressing

on a manual key provokes the pressure rise to P86 (Blade up pressure).

When releasing the key, the pressure will fall back to 0.

RAKE ANGLE CALCULATION

The rake angle calculation is performed on each occasion the sheet metal

thickness or name fields are programmed.

The calculated value, in 1/100

page.

The calculation will be carried out from the tables which define the rake

angle according to the thickness and the material.

ths

of a degree, is displayed on the function

CUTTING LENGTH CALCULATION

The DNC calculates the BDC and TDC each time the sheet metal thickness,

material sigma or sequence cutting length fields are programmed.

The calculated and displayed BDC value corresponds to the geometric

position (in mm) of the measurement point (figure 4, page 43), relative to the

lower blade at the end-of-cut.

ula used:

Form

Cutlen: Sequence cutting length

: Rake angle

The calculated and displayed TDC value corresponds to the geometric

position (in mm) of the measurement point (figure 4, page 43), relative to the

ower blade at sheet disengagement position.

l

Formula used:

E: Material thickness

BDC = tg *(P50- Cutlen)

TDC = (tg *P50)+E

PAGE 46 MACHINE PARAMETERS DNC 60 G

Page 49

CUTTING LENGTH FUNCTION (F3) WITH FIXED RAKE

ANGLE

(NO F2 RAKE ANGLE FUNCTION)

The potentiometer position (right or left) is immaterial, but a positive

displacement (increasing voltage) must correspond to the upward movement

of the blade.

FIELDS TO

PROGRAM

P54 0,11Î9,99

P70 F3 2

P72 F3 0

P79 F3 1Î254

P80 F3 1Î254

P81 F3 1Î999

P82 F3 1Î999

P50 1Î99999

On sequence page:

-

VALUES COMMENTS

For TDC calculation

Type of management

Analog AF3

Min. D/A value (teach)

Max. D/A value (teach)

Min. programming range

Max. programming range.

Max. cutting length.

1Î99999

Cutting length for the

sequence

CALIBRATION OF FUNCTION F3

Remark: The upstroke / downstroke of the blade can also be carried out by

the pedal. In this case, if the elapsed time between two pedal

pressings is less than 2 seconds, the blade will move in the same

direction as previously, otherwise it changes the direction.

1) Lower the blade to the point where its right extremity crosses the lower

blade.

Make a TEACH of the min D/A value (P79 of F3) while maintaining

the blade at this position.

2) Program in P81 the value 0.

3) Rise the upper blade until its maximum position.

Perform the TEACH of the minimum D/A value (P79 of F3) while

maintaining the blade in this position.

4) Maintaining the position of point 3, program in P82 the value of the

maximum programming range corresponding to the distance measured

between the two right extremities of the blades (value "c" of figure 4).

If F6 is defined in pressure mode (see function F6 Pressure), each pressing

on a manual key provokes the pressure rise to P86 (Blade up pressure).

When releasing the key, the pressure will fall back to 0.

SPECIAL SHEAR FUNCTIONS PAGE 47

Page 50

CUTTING LENGTH CALCULATION

Calculation of the BDC is performed each time the sequence cutting length

field is programmed.

Formula used:

BDC = (P50 – Cutlen) · tan(P54)

TDC

BDC

P54

Cutlen

P50

The TDC is only calculated if P54 (nominal angle) is programmed at the

value of the fixed angle.

In any case, the TDC can always be programmed manually.

Notes on functions F1 and F2:

The procedures described above allow to set up only the analogue functions.

It will subsequently be necessary to adjust the position parameters (P74,

P75, P76, P77, P78) for functions F1 and F2.

PAGE 48 MACHINE PARAMETERS DNC 60 G

Page 51

CUTTING LENGTH FUNCTION (F3) WITHOUT

MEASURING POTENTIOMETER

In this configuration, a time-out value is used to manage the blade descent.

The length of the time-out period is calculated as a function of the cutting

length.

FIELDS TO

PROGRAM

P54 0,1Î9,99

P70 F3 2

P79 F3 1Î254

P80 F3 1Î254

P81 F3 0mm.

P82 F3 (c)mm.

P50 1Î99999

On the sequence page:

-

VALUES COMMENTS

1Î99999

(USE OF TEMPO)

Calculation of TDC

Type of management

Generally = 0

Descent time 1/10 of a second

for the maximum cutting

length

Minimum Prgramming range.

Minimum descent time for

max. cutting length

Maximum cutting length

Sequence cutting length.

CALIBRATION OF FUNCTION F3

Use the calibration method with the variable or fixed angle (depending on the

configuration of the machine) with the exception of the P79 and P80

parameters of AF3.

1) Usually the value P79 = 0 is programmed.

You can also program, if necessary, on this parameter a time offset in

1/10 of seconds corresponding to the starting time of the blade.

2) Program in P80 the time in 1/10 of seconds necessary to cut across

the whole length of the machine (with max angle).

SPECIAL SHEAR FUNCTIONS PAGE 49

Page 52

FLYING CUT FUNCTION (F4)

The Flying Cut input (at 24V) allows to automatically link several cuts

without having to release and press again the foot pedal in order to obtain the

subsequent cut. The Cutting Authorization is issued as soon as the TDC is

reached and the axes are in position.

In order to allow sufficient time to the operator for putting the sheet against

the backgauge, it is possible to introduce a time-out between the end of the

axes positioning (and the return to TDC) and the output of the Cutting

Authorization signal.

This time-out can be programmed, per sequence, in AF4 which will have

been defined in the Flying Cut mode beforehand.

FIELDS TO

PROGRAM

VALUES COMMENTS

P70 F4 2

P71 F4

P72 F4

P73 F4

P79 F4 0Î254

Function type = flying cut

Undefined

Undefined

Undefined

Min. time-out in 1/10 of

seconds

P80 F4 0Î254

Max. time-out in 1/10 of

seconds

P81 F4 0Î254

P82 F4 0Î254

Min. programming range

Max. programming range

Here are two examples where the user can program this time-out either in

seconds or in tenths of seconds:

Example 1: (time-out programmable in seconds)

P79 = 0 =

P80 = 120 =

> 0 10

> 120 10

ths

of sec. = 0 sec. min.

ths

of sec. = 12 sec. max.

P81 = 1 => min. 1 sec.

P82 = 12 => max 12 sec.

When programming FA4 = 8, this corresponds, for the current sequence, to a

delay of 8 seconds before cutting.

Example 2: (time-out programmable in 1/10

P79 = 0 =

P80 = 50 =

> 0 10

> 50 10

ths

of sec. = 0.0 sec. min.

ths

of sec. = 5 sec. max.

ths

of seconds)

P81 = 0 => min. 0.0 sec.

P82 = 50 => max 5 sec.

When programming FA4 = 30, this corresponds, for the current sequence, to

a delay of 3 seconds before cutting.

Note: If AF4 is not programmed, the time-out is not active.

PAGE 50 MACHINE PARAMETERS DNC 60 G

Page 53

PRESSURE RAMPS FUNCTION (F6)

An analog output enables to adjust the pressure of the upward and downward

system of the blade in order to have pressure ramps instead of an all or

nothing (On/Off) pressure.

FIELDS TO

PROGRAM

VALUES COMMENTS

P70 F6 2

P73 F6 1

Type of management

AF6 voltage

CALIBRATION OF FUNCTION F6

The calibration of function F6 is carried out in the MACHINE

PARAMETERS 14 page with the manual keys.

y Pressing the

of 1 unit and outputs the corresponding voltage on the analog output.

y Pressing the

of 10 units and outputs the corresponding voltage on the analog

output.

At each releasing of one of these keys, the voltage on the analog output

returns to 0 Volt.

1) With the cursor on the Min U D/A field, increase with the manual keys

progressively the value until the desired Min pressure is reached.

Note down this value = Min pressure.

or key increases or decreases the D/A value

or key increases or decreases the D/A value

2) With the cursor on the Max U D/A field, increase with the manual keys

progressively the value until the desired Max pressure is reached.

Note down this value = Max pressure.

3) For each of the 3 remaining intermediate points (in X %), increase with

the manual keys progressively the value until the desired pressure, that

is to say:

Pressure = Min Pressure + X % * (Max pressure – Min pressure).

SPECIAL SHEAR FUNCTIONS PAGE 51

Page 54

PARAMETRIZING OF FUNCTION F6

The parametrizing of function F6 is carried out in the MACHINE

PARAMETERS 13 page with the manual keys.

Define first the time of the pressure ramps for the upstroke and the

downstroke of the blade (P88 to P91) as well as the decompression time

(P92).

On each of the fields P83 (Minimal Blade Up Pressure), P84 (Rake Angle

Adjustment Pressure), P85 (Blade Gap Adjustment Pressure) and 86 (Blade

Up Pressure) first program a value, then:

1) When pressing a manual key:

y The pressure rises up to this programmed value.

y The corresponding digital output (Blade Up, Cutting Authorization,

SP, SN) is activated (24V).

2) When releasing the key:

y The activated digital output (Blade Up, Cutting Authorization, SP,

SN) is disactivated (0V).

y The pressure falls back to 0.

PAGE 52 MACHINE PARAMETERS DNC 60 G

Page 55

FUNCTION PRESSURE ON OR OFF (F6)

The output System Pressure must be configured to be able to use this

function.

FIELDS TO

PROGRAMME

VALUES COMMENTS

P70 F6 2

P88 0Î254

P89 0Î254

P90 0Î254

P91 0Î254

Type of management

Tempo in 1/10 of second

Tempo in 1/10 of second

Tempo in 1/10 of second

Tempo in 1/10 of second

BLADE UP OR DOWN

The management of the outputs used for the displacement of the blade is as

follows:

1. Starting:

Output SP/SN is activated. After a waiting period (defined by P88 if

the blade goes down or P90 if the blade goes up), the output System

Pressure is activated.

2. Stop:

The output System Pressure is desactived. After a waiting period

(defined by P89 if the blade goes down or P91 if the blade goes up),

the output SP/SN is desactivated.

SP OR SN OF THE AF

The management of the outputs used for SP/SN of the AF is as follows:

1. Starting:

2. Stop:

Output SP/SN is activated. After a waiting period defined by P88,

the output System Pressure is activated.

The output System Pressure is desactived. After a waiting period

defined by P89, the output SP/SN is desactivated.

SPECIAL SHEAR FUNCTIONS PAGE 53

Page 56

SHEET THICKNESS MEASUREMENT FUNCTION (F7)

With an analog sensor 0 – 10V connected to an analog input of the DNC, it is

possible to automatically measure the sheet metal thickness.

FIELDS TO

PROGRAM

VALUES COMMENTS

P70 F7 2

P72 F7 0

P79 F7 1Î254

P80 F7 1Î254

P81 F7 1Î999

P82 F7 1Î999