Page 1

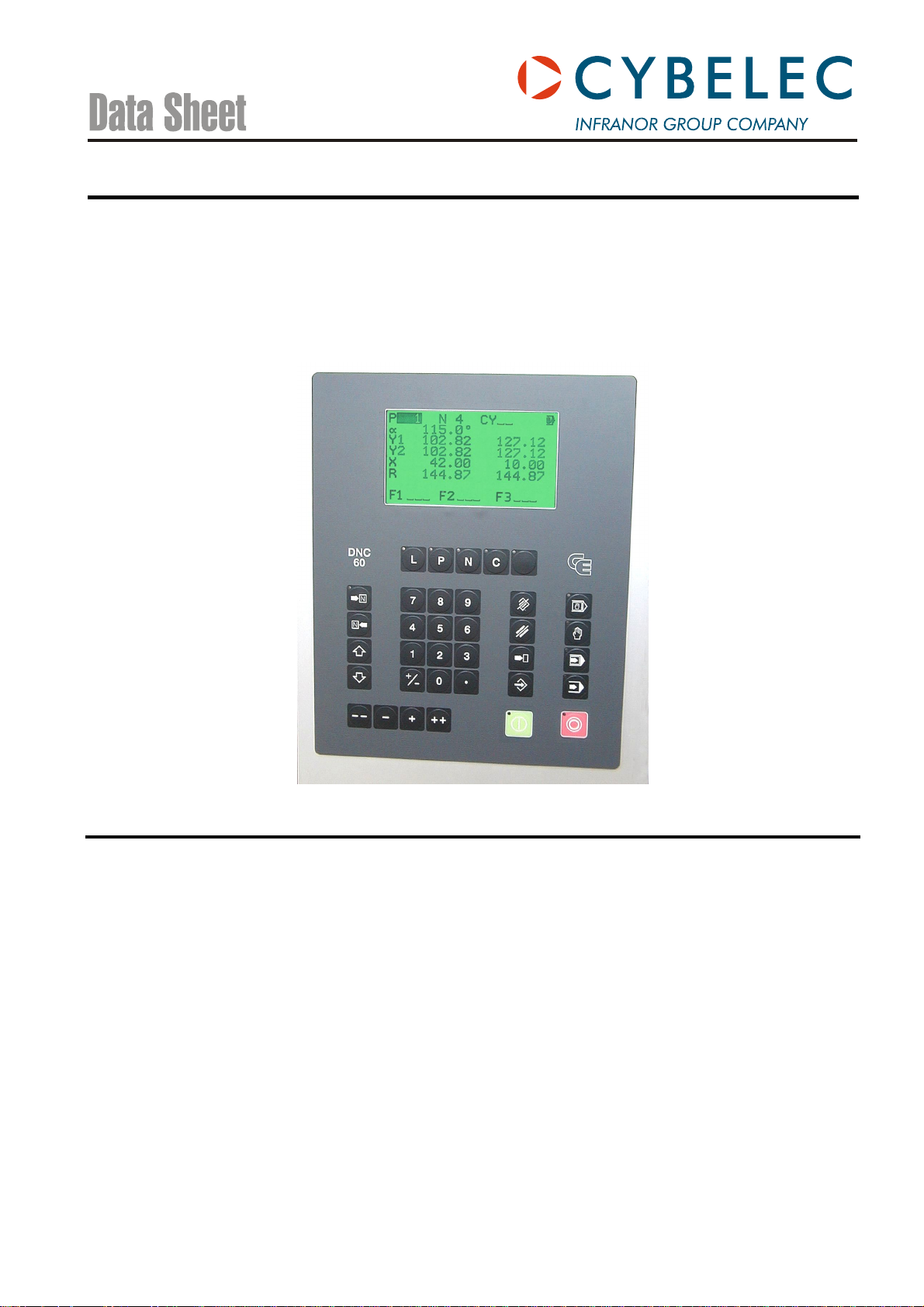

Numerical Control DNC 60

Numerical control DNC 60 specifically destined for sheetmetal working. Depending on the installed software, it can b e

used for synchronized or non-synchronized press-brakes, of up-stroking or down-stroking type, for shears, for tube

bending machines, for automatic machines, etc. (see list of versions below).

The numerical control DNC 60 can control up to 4 axes, of which two are synchronized hydraulic axes, specifically

destined for press-brakes. It is fitted out with a monochrome screen and a simplified keyboard with large keys.

The software enables the machine manufacturer to configure the axes, the inputs/outputs and the auxiliary functions

according to his needs.

Versions

DNC 60 PS, PSS Numerical control for synchronized press-brakes. Configurable from version PS, the version

PSS is destined for single cylinder presses.

Max. configuration: Y1-Y2, X, R or X-X1, X1-X2, X, Z, etc.

DNC 60 PC Like DNC 60 PS, but for press-brakes with mechanical (or hydraulic) stops and beam control

by means of a linear encoder.

Max. configuration: Y0-Y, X, R or X-X1, X1-X2, X, Z, etc.

DNC 60 P Like DNC 60 PC, but without beam control by means of a linear encoder.

Max. configuration: Y, X, R, Z or other combinations.

DNC 60 GS For shears with max. 4 axes. The for this application specific software controls all the typical

functions for this machine, such as X3 backgauge, X1-X2 frontgauges, free axes (feeding,

evacuator, etc.), blade gap, rake angle, cutting depth, etc.

DNC 60 X Universal numerical control 1-4 axes for diverse applications.

1-4 numerical high speed axes, programmable cycles, delay functions, cams, etc.

Ideal for automatic machines with programmable axes.

DNC 60 C Numerical control for tube bending machines 1-4 axes.

DNC 60 PV Numerical control for straight side presses 1-4 axes.

60PS_E.DOC C-PUB-CDS60PS-EN V1.2e 26.06.2006

Page 2

Axes and auxiliary functions for press-brakes

The elements listed hereafter are available and can be configured in all numerical controls supplied with the

standard software (within the number of available axes and inputs/outputs).

Y1 – Y2

Synchronized axes for the beam (servo-valves, proportional valves).

Should current output be needed, this would require the MSV 400 accessory, an external amplifier

to be mounted inside the electrical cabinet (see data sheet of MSV 400).

Yo – Y

Press with mechanical stop: Yo = beam position measurement.

Y = management of the depth stop.

X, X1, X2

X1 ABS, X2 REL

R, R2

Z, Z2

Pressure

Crowning

F1 to F5

Languages

M1, M2 ***

X3, X4 ***

BM10 ***

Languages ***

24-32 I/O ***

Main backgauge axes.

Secondary gauge axes in absolute or relative mode.

Backgauge height adjustment axes.

Axes for left/right movement of backgauge.

Voltage output (0-10VDC) for pressure valve control.

Voltage output (0-10VDC) for adjustment of hydraulic crowning.

Should current output be needed, CYBELEC recommends the MVP 403 accessory, an external

amplifier to be mounted inside the electrical cabinet.

Configurable auxiliary functions (possibly, the number of AFs may be limited, depending on the

type of function and management). Voltage output (0-10VDC) or 24VDC digital outputs, with or

without position control by means of a potentiometrical position transducer.

Special controls for gauge fingers, bending aids, die movement.

11 languages are available in the DNC.

French, German, English, Italian, Spanish, Portuguese, Dutch, Swedish, Danish, Finnish,

Norwegian.

Axes for adjustment / movement of the die.

(Caution: the use of this option will cause certain other axes to become unavailable).

Frontgauge axes (caution: with this option the "Z" axes are no longer available).

Remote control unit BM10 with handwheel and display, allowing remote-controlled axis

movements.

Greek, or other languages (with extra charge).

Module to reach 24 inputs and 24 outputs or 32 inputs and 32 outputs.

*** Options to be ordered especially.

Axes and auxiliary functions for shears

The elements listed hereafter are available and can be configured in all numerical controls supplied with the standard

software (within the number of available axes and inputs/outputs).

X1, X2, X3, X4

Free axes

Backgauge or frontgauge axes.

Axes, whose function is freely attributable (feeding, evacuator, manipulator, etc.) dependent or

independent of the shear's cycle.

Special shears

• 3 special functions make it possible to handle automatically the blade gap, the rake angle and

the cutting length according to the programmed material and thickness.

• 5 pre-programmed types of material.

• Backgauge clearance during the cutting process (yes / no).

• Blade gap with one or two motors.

• Management of the cutting length by delay or by potentiometer.

• Automatic backgauge correction according to the blade gap.

• Sequence repetition, sub-programs, chaining of programs.

16-32 I/O ***

Module to reach 16 inputs and 16 outputs or 32 inputs and 32 outputs.

*** Options to be ordered especially.

60PS_E.DOC V1.2e

Page 3

Axes and auxiliary functions for DNC 60 X

The elements listed hereafter are available and can be configured in all numerical controls supplied with the standard

software (within the number of available axes and inputs/outputs).

X0, X1, X2, X3

Digital axes (position supplied by an incremental position encoder) for the control of a DC or AC

brushless motor, hydraulic or AC 1 or 2 speeds, with or without brake.

Programming possibilities in absolute mode, relative incremental mode, relative mode with

position being set to 0, relative mode specific to transmission, "cam" mode (enabling to carry out

an operation at a given position without stopping the axis), rotating mode.

Possibility of selecting a different speed for each sequence, and a particular acceleration /

deceleration for each product.

Change of target and/or speed per sequence (without travel interruption). Sequence repetition,

sub-programs, conditional or unconditional chaining of programs.

Possibility of masking certain fields, or to inhibit access to them. Delays can be programmed in

each sequence. Cycle counter. Constant or variable corrections.

F1 - F8

Auxiliary functions:

digital 0 or 24 VDC outputs

analog digital outputs controlling a movement whose position is controlled by a

potentiometer (axis with 1 or 2 speeds).

voltage voltage outputs from 0 to 10 VDC according to the programmed value.

16-32 I/O ***

Module to reach 16 inputs and 16 outputs or 32 inputs and 32 outputs.

*** Options to be ordered especially.

Other options

Housing

Others

External housing for mounting with pendant arm.

There are a great number of manufacturer-specific options.

Other options can be developed upon request.

Standard-characteristics

Multiprocessor design using ASIC and SMD components. This allows high integration and ensures

great reliability.

Keyboard with large keys.

Monochrome graphic LCD screen 75 x 130 mm (visible surface) 240 x 128 pixels with automatic

contrast correction.

Internal SRAM memory.

FLASH memory with, in option, updating possibility of the software via RS232.

2 RS232-ports (option).

N2X axes with high speed counting (250 Khz) with PID regulator and programmable resolution.

Conversion Inch/mm, TON/TONS, etc.

16 inputs (24 or 32 in option)

16 outputs (24 or 32 in option)

General technical characteristics

Power supplies DNC: + 24 VDC (min. 18 – max. 35 VDC) max. 1 A (DNC) 20 W.

Electrical cabinet: + 24 VDC ± 10% for the digital inputs/outputs.

Encoder inputs Line driver. L On this DNC, the inverted signals are compulsory.

Power supply for encoders 5 VDC (supplied by the DNC) max. 900 mA for all encoders.

Digital inputs Optocoupled inputs 24 VDC stabilized ± 3 %.

Analogic inputs According to configuration 0-5, 0-10, 0-24 VDC.

Digital outputs Optocoupled short circuit proof outputs.

Source 24 VDC max. 0.3 A / output.

Voltage outputs (axes, functions) 0-10 VDC output impedance Zout < 100 Ω, load Zl ≥ 10 kΩ.

Temperature, pollution level,

relative humidity, and

height during work

Min. 5° Celsius, max. 40° Celsius.

Pollution level 2. Relative humidity (10 to 85% non condensing).

Max. height 2000 m.

EC Directives

Directives Our numerical controls comply with the EC Directives

EN 61000-6-4

EN 61000-6-2

60PS_E.DOC V1.2e

Page 4

9

876

J15

J18

J9

J13

J12

Pin N°

1

20

J16

J17

J10 J11

1

2

34

56

J8

J6

J5

Maximum cutout : 284.0 x 228.0 * = option 24 or 32 outputs

J7

Sub 9 pins

Female

Sub 9 pins

Male

12345

6789

54321

Modification rights reserved

60PS_E.DOC V1.2e

Loading...

Loading...