Page 1

Rue des Uttins 27 CH-1401 Yverdon Switzerland TEL:+ 41 24 447 02 00 FAX:+ 41 24 447 02 01 E-Mail: info@cybelec.ch

m

2

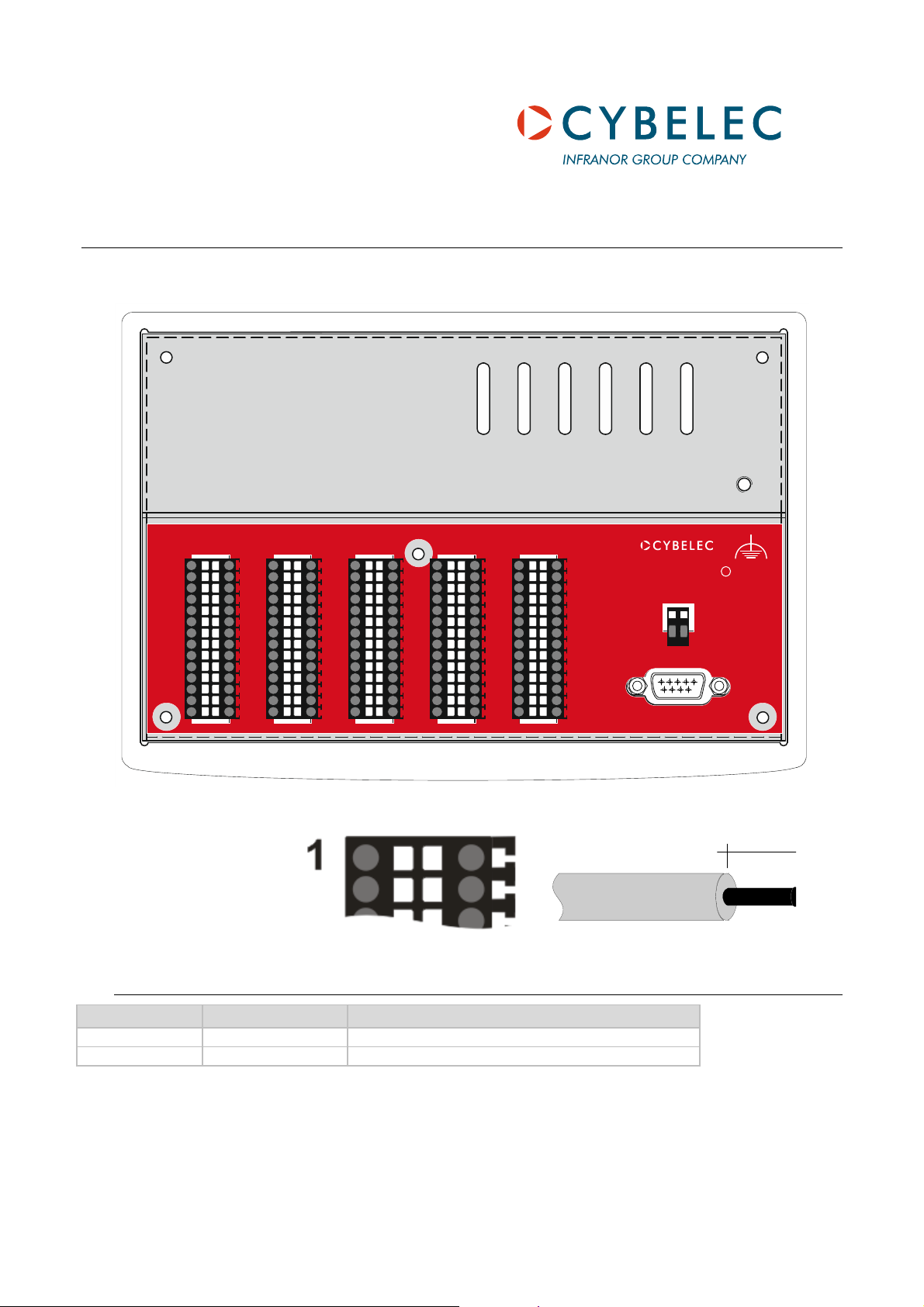

Input/Output List for CybTouch 8 (8/12io SBC-200A)

For all CybTouch SN xxxxxx/A1 and above

X2

1

4

7

8

11

14

24Vi/o

18

0Vi/o

21

22

25

28

X3

1

4

7

8

11

14

Connectors X2 to X5 =

Weidmüller

SN BK

L Max 4 A / connector pin.

B2L 3.5/28/180

X1 Power Connector

24Vi/o

18

0Vi/o

21

22

25

28

X4

Encoders

1

4

7

8

11

14

24Vi/o

18

0Vi/o

21

22

25

28

X5

1

4

7

8

11

14

15

18

21

22

25

28

X6

1

4

7

8

11

14

24Vi/o

18

0Vi/o

21

22

25

28

i

M4x6 m ax.

X1

0V24V

12

X7

1

0.75 mm

max 8 m

X1 Signal Default I/0

1 24 V 24 VDC DNC

2 0V 0V DNC

CybTouch8_PS_812io_V2.1.doc / November 2013 Page 1 of 10

Page 2

Generalities

• All 0V_I/O pins are connected together.

• The 24V_I/O pins from connectors X2 and X3 are connected together.

• The 24V_I/O pins from connectors X4 and X6 are connected together

• All digital outputs are capable of driving a load (for example valves) up to 3 A maximum.

Digital outputs are short-circuit and overload protected.

• Inductive loads must be equipped with surge suppressors.

• See basic diagram.

CybTouch8_PS_812io_V2.1.doc Page 2 of 10

Page 3

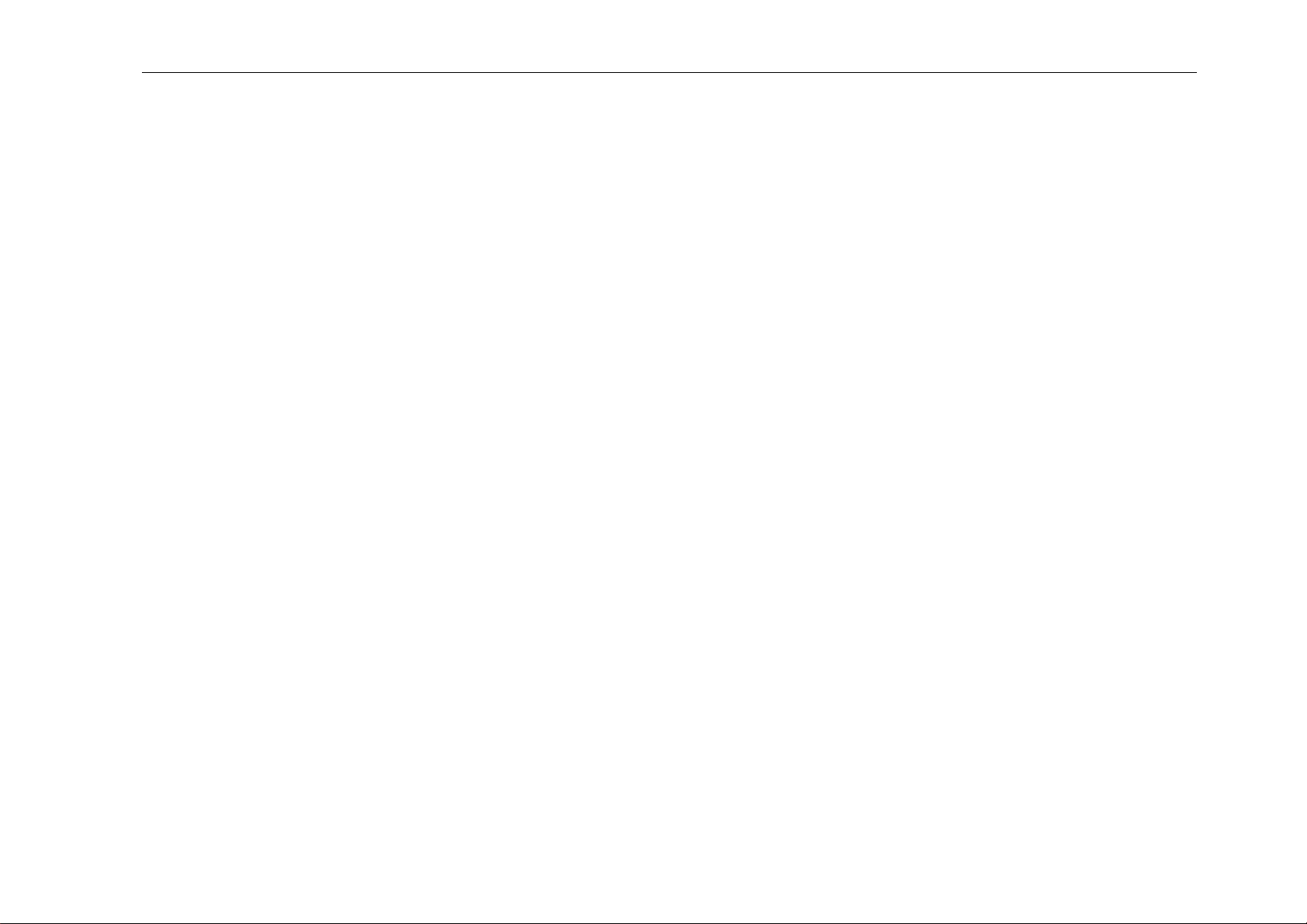

Crowning Wiring

Earth and 24 VDC Wiring

A 4 wires shielded cable must

be used for the potentiometer.

X2/27and X2/28 terminals

must be connected together

at one side of the potentiometer.

The cable shield must be connected to the

chassis of the CybTouch using the grounding

system.

If a twisted pair cable is used, use twisted pair

shown.

CybTouch8_PS_812io_V2.1.doc Page 3 of 10

Page 4

L All pin attributions below are programmable. The list below correspond to the default settings in machine parameters.

X2 I/O Connector

X2 Signal Default I/0 X2 Signal Default I/0

1

24V_I/O 24 VDC electrical box

15

L Max 4 A / connector pin.

2

3

4

5

6

7

8

9

10

11

12

13

14

L 24VDC_I/O (X4.1 - X4.15) & 0V_I/O (X4.10 – X4.25) must be connected.

OUT 1 Pump motor ON

OUT 2 Machine ready

0V_I/O 0 V electrical box

OUT 3 Beam SP

OUT 4 Beam SN

0V_I/O 0 V electrical box

OUT 5 Beam PV

OUT 6 TDC sequence

0V_I/O 0 V electrical box

AOUT 1 Y1 analog out

0Vanalog Y1 0V analog out

AOUT 2 Y2 analog out

0Vanalog Y2 0V analog out

* Crowning depends on the machine and can be set or not in machine parameters.

16

17

18

19

20

21

22

23

24

25

26

27

28

24V_I/O 24 VDC electrical box

L Max 4 A / connector pin.

IN 1 Permanent regulation

IN 2 Downward command

IN 3 Upward command

IN 4 Commutation HS-LS beam

0V_I/O 0 V electrical box

IN 5

IN 6 Stop

IN 7 X index zone

IN 8 R index zone

10Vref 10 VDC reference (max 25 mA)

AIN1 + Crowning potentiometer / cursor *

AIN1 - Crowning potentiometer / 0V

0Vanalog Crowning potentiometer / 0V

Refer to electrical box wiring diagram

X3 I/O Connector

X3 Signal Default I/0 X3 Signal Default I/0

1

24V_I/O 24 VDC electrical box

15

L Max 4 A / connector pin.

2

3

4

5

6

7

8

9

10

11

12

13

14

CybTouch8_PS_812io_V2.1.doc Page 4 of 10

OUT 7 Safety point

OUT 8 End of bend

0V_I/O 0 V electrical box

OUT 9 End of product

OUT 10

0V_I/O 0 V electrical box

OUT 11 X enable

OUT 12 R enable

0V_I/O 0 V electrical box

AOUT 3 X analog out

0Vanalog X 0V analog out

AOUT 4 R analog out

0Vanalog R 0V analog out

16

17

18

19

20

21

22

23

24

25

26

27

28

24V_I/O 24 VDC electrical box

L Max 4 A / connector pin.

NA

NA

NA

NA

0V_I/O 0 V electrical box

NA

NA

NA

NA

0Vanalog 0V analog out

AIN2 +

AIN2 -

0Vanalog 0V analog out

Page 5

X4 I/O Connector

X4 Signal Default I/0 X4 Signal Default I/0

1

24V_I/O 24 VDC electrical box

15

L Max 4 A / connector pin.

2

24V_I/O 24 VDC electrical box

16

L Max 4 A / connector pin.

3

4

5

6

7

8

9

10

11

12

13

14

L 24VDC_I/O (X4.1 - X4.15) & 0V_I/O (X4.8 – X4.22) must be connected.

NA

NA

0V_I/O 0 V electrical box

NA

NA

0V_I/O 0 V electrical box

NA

NA

0Vanalog

NA

NA

0Vanalog

17

18

19

20

21

22

23

24

25

26

27

28

24V_I/O 24 VDC electrical box

L Max 4 A / connector pin.

24V_I/O 24 VDC electrical box

L Max 4 A / connector pin.

NA

NA

0V_I/O 0 V electrical box

NA

NA

0V_I/O 0 V electrical box

NA

NA

0Vanalog

NA

NA

0Vanalog

CybTouch8_PS_812io_V2.1.doc Page 5 of 10

Page 6

X5 Encoder Connector

X5 Signal Assignation X5 Signal Assignation

1

2

3

4

5

6

7

8

9

10

11

12

13

14

L Use twisted pair cables for encoder signals.

5V encoder 5V out for encoder Y1

0V encoder 0V out for encoder Y1

A1+ A signal of encoder Y1

A1 - A - signal of encoder Y1

0V encoder

5V encoder 5V out for encoder Y2

0V encoder 0V out for encoder Y2

A2+ A signal of encoder Y2

A2 - A - signal of encoder Y2

0V encoder

5V encoder 5V out for encoder X

0V encoder 0V out for encoder X

A3+ A signal of encoder X

A3 - A - signal of encoder X

15

16

17

18

19

20

21

22

23

24

25

26

27

28

Z1+ Index encoder Y1

Z1 - Index - encoder Y1

B1+ B signal of encoder Y1

B1 - B - signal of encoder Y1

0V encoder

Z2+ Index encoder Y2

Z2 - Index - encoder Y2

B2+ B signal of encoder Y2

B2 - B - signal of encoder Y2

0V encoder

Z3+ Index encoder X

Z3 - Index - encoder X

B3+ B signal of encoder X

B3 - B - signal of encoder X

L Do not invert index signals (normal and inverted, Z+ and Z-).

It will result in a bad indexation procedure (loss of precision), difficult to trace or no indexation at all. If this

happens try to invert index signals.

Z+ Z-

9 Use twisted pair cables for encoder signals.

9 Encoder inputs support 12VDC and 24VDC signals. In this case e ncoder must be powered externally with its own power supply. 0V encoder must

be common. See page 8 of this document for more details.

9 Encoder inputs support encoders without inverted signals.

CybTouch8_PS_812io_V2.1.doc Page 6 of 10

Page 7

X6 Encoder Connector

X6 Signal Assignation X6 Signal Assignation

1

2

3

4

5

6

7

8

9

10

11

12

13

14

* Crowning depends on the machine. Can be set in machine parameters depnding on the ma chine.

24V_I/O 24 VDC electrical box

24V_I/O 24 VDC electrical box

NA NA

NA NA

0V_I/O

NA NA

0V_I/O

5V encoder 5V out for encoder R

0V encoder 0V out for encoder R

A4 + A signal of encoder R

A4 - A - signal of encoder R

0Vanalog

AOUT 5 Pressure

0Vanalog 0V Pressure

15

16

17

18

19

20

21

22

23

24

25

26

27

28

24V_I/O 24 VDC electrical box

24V_I/O 24 VDC electrical box

NA NA

NA NA

0V encoder

NA NA

0V_I/O

Z4 + Index encoder R

Z4 - Index - encoder R

B4 + B signal of encoder R

B4 - B - signal of encoder R

0Vanalog

AOUT 6 Crowning*

0Vanalog 0V Crowning

L Do not invert index signals (normal and inverted, Z+ and Z-).

It will result in a bad indexation procedure (loss of precision), difficult to trace or no indexation at all. If this

happens try to invert index signals.

Z+ Z-

9 Use twisted pair cables for encoder signals.

9 Encoder inputs support 12VDC and 24VDC signals. In this case e ncoder must be powered externally with its own power supply. 0V encoder must

be common. See page 8 of this document for more details.

9 Encoder inputs support encoders without inverted signals.

CybTouch8_PS_812io_V2.1.doc Page 7 of 10

Page 8

X7 Serial Port Connector

X7 Signal

1 /

2 IN RXD

3 OUT TXD

4 OUT DTR

5 0V encoder

6 IN DSR

7 OUT RTS

8 IN CTS

9 /

USB - Micro A/B Memory stick

L Micro USB A/B port for memory sticks only.

Not operational for keyboard or mouse.

CybTouch8_PS_812io_V2.1.doc Page 8 of 10

Page 9

12 / 24 V Single Ended (Unipolar) Encoders

Encoder inputs support 12VDC and 24VDC signals. In this case encoder m ust be powered externally with its own

power supply. 0V encoder must be common.

Encoder inputs support encoders without inverted signals.

Emitter follower encoder outputs must be connected to

A+ B+ inputs on the CybTouch.

the

Any unused inputs must be left disconnected.

5V single ended encoders may take their 5V power

supply from the CybTouch.

L Open collector encoder outputs must be

connected to the

Any unused inputs must be left disconnected.

5V single ended encoders may take their 5V power

supply from the CybTouch.

Push-pull encoder outputs must be connected to

A+ B+ inputs on the CybTouch.

the

Any unused inputs must be left disconnected.

5V single ended encoders may take their 5V power

supply from the CybTouch.

A – B – inputs on the CybTouch

5 V Differential Encoders / Emulated Encoders

Differential encoders (TTL / 422 / 485) are usually 5V

powered. All channels must be connected.

Usually, the 5V of emulated encoders (servodrives) output must NOT be connected to the 5V

encoder of the CybTouch.

This may be dangerous for the drive or the CybTouch.

But some drives are fully opto-coupled and 5V encoder

must be provided like for a normal encoder.

Please refer to the drive datasheet.

External Encoder

When wiring an

external encoder, it is

important that the power

supplies be connected

as explained here.

CybTouch8_PS_812io_V2.1.doc Page 9 of 10

Page 10

Default Configuration for Press Brakes

CybTouch8_PS_812io_V2.1.doc Page 10 of 10

Loading...

Loading...