Page 1

CybTouch 6 G-W

Shears

Machine Parameters Manual V.2.0

Page 2

Page left blank intentionally

Page 3

v2.0 Nov.12

TABLE OF CONTENTS

INTRODUCTION ..................................................................................................................................... 6

P01 MACHINE CONFIGURATION ......................................................................................................... 7

Menu Button 7

Toggle Pages Button 7

P01.01 Machine Type 7

P01.02 Start Pump Button 8

P01.03 Automatic Cut 8

P01.04 Quantity 8

P01.05 Material 9

P01.06 Blade Gap 9

P01.07 Second Blade Gap 9

P01.08 Axis 10

P02 MACHINE CONFIGURATION 2 ...................................................................................................... 11

P02.01 Sheet Support 11

P02.02 Return to Sender (RTS) 12

P03 MACHINE CONFIGURATION 3 ...................................................................................................... 13

P03.01 Auxilary Function 13

P03.02 Eco Mode 13

P03.03 Store/Delete Programs in Level 0 14

P03.04 HMI Locked in Level 0 14

P03.05 Toggle Pages 14

P03.06 Show Cycle Steps 14

P03.07 Retraction 15

P03.08 Analog Pressure 15

P03.09 Cutting Length Sensor 15

P04 MACHINE SETTINGS ..................................................................................................................... 16

Machine Settings Wizard 16

P04.01 Max Programmable Cutting Length 16

P04.02 Time Before Axis Start at BDC 16

P04.03 Default Time for Max Cutting Length 17

P04.04 Time to Close Hold-Downs 17

P04.05 Time to Close Hold-Downs if not TDC max 17

P04.06 Timing Valves 18

P04.07 AutoCut Minimum Waiting Time at TDC 18

P05 PREFERENCES .............................................................................................................................. 19

P05.01 Axes Start at 19

P05.02 Sheet Offset 19

PM_CybTouch6_ Shears_v2.0.doc page 3 of 55

Page 4

v2.0 Nov.12

P05.03 Angle Control at TDC Max 19

P05.04 Square Signal Low/High 19

P06 AXIS SETTINGS -X- ........................................................................................................................ 20

P06.00 Display Resolution 20

P06.01 Axis Type 20

P06.02 Closed Loop 20

P06.03 Encoder resolution 21

P06.04 Position Speed 21

P06.05 Position Tolerance 21

P06.06 One-Way Positioning 21

Advanced button 22

Axis Settings -X- Wizard 22

P06B ADVANCED AXIS REGULATOR X ............................................................................................. 25

P06b.01 Change Counting Direction 25

P06b.02 Manual Speed 25

P06b.03 Acceleration 25

P06b.04 Invert voltage & Speed at 10V 25

P06b.05 Closed Loop Frequency 25

P06b.06 Integrator factor 26

P06b.07 Offset Voltage 26

P06b.08 Supervisor Error 26

P06b.09 Supervisor Speed Level 26

P06b.10 Control Time Out 27

07 INDEXATION AXIS -X- ...................................................................................................................... 28

Indexation Axis -X- Wizard 28

P07.01 Index Type 29

P07.02 Index Zone in Reverse Logic 29

P07.03 Start Indexation in Negative Direction 29

P07.04 Indexation Speed 29

P07.05 Index Position 29

P07.06 Minimum Limit 29

P07.07 Maximum Limit 30

P07.10 Parking 30

P07.11 Parking Tolerance 30

08 AXIS FUNCTIONS -X- ....................................................................................................................... 31

P08.01 Blade Gap Factor 32

P08.02 Speed with input “Speed reduction” 32

P09 DIGITAL INPUT CONFIGURATION ............................................................................................... 33

P10 DIGITAL OUTPUT CONFIGURATION ........................................................................................... 35

P11 ANALOG I/O CONFIGURATION .................................................................................................... 37

PM_CybTouch6_ Shears_v2.0.doc page 4 of 55

Page 5

v2.0 Nov.12

P12 BLADE GAP .................................................................................................................................... 38

Blade Gap Wizard 38

P12.01 Inverted AD Input 39

P12.02 Tolerance 39

P12.03 Advanced Stop 39

P12.04 Overrun Distance 39

P12.05 SP/SN Time 39

P13 ANGLE & CUTTING LENGTH ........................................................................................................ 40

Angle & Cutting Length Wizard 40

P14 ANGLE AND CUTTING LENGTH 2 ................................................................................................ 41

P14.01 Inverted Input 41

P14.02 Resolution 41

P14.03 Minimum Limit 41

P 14.04 Distance Max TDC – Mechanical Stop 41

P14.05 TDC Time Before Angle Control 41

P14.06 Cutting Angle Tolerance 42

P14.07 Stop if Angle Sensor Max 42

P14.08 Advanced stop, angle down/up 42

P14.09 Advanced stop, cut down/up 42

P15 PRESSURE ..................................................................................................................................... 43

Pressure Wizard 43

P15.02 Minimum Pressure Beam Down 43

P15.03 Beam Up 44

P15.04 Final Approach Up (min pressure) 44

P15.05 Ramp / Final Approach Up 44

P15.06 Final Approach Speed Up 44

P15.07 Final Approach Gain 44

P15.08 Cutting Angle 44

P15.09 Blade Gap 44

P15.10 Ramp Cutting Pressure 44

CHANGING ACCESS LEVEL SECURITY PASSWORDS: ................................................................... 45

Default passwords 45

Changing passwords 45

CREATING BACKUPS AND RESTORING DATA ................................................................................. 47

Creating an Internal Backup of Machine Parameters 47

Restoring Creating an Internal Backup of Machine Parameters 47

ERROR AND WARNING MESSAGES IN CYBTOUCH 6 FOR SHEARS ............................................. 48

APPENDIX 1 – USING REMOTE CONTROL ........................................................................................ 54

Wiring Recommendation for Remote Control 55

PM_CybTouch6_ Shears_v2.0.doc page 5 of 55

Page 6

v2.0 Nov.12

INTRODUCTION

This manual is specifically written for qualified technicians.

Information contained herein will serve as a guide for all technicians setting up shear

machines with the Cybelec CybTouch 6 numerical control.

The following documents may also be useful to a technician for setting up and testing

a shear machine with the CybTouch 6:

CybTouch 6 for shears user manual:

CybTouch6_Shear_Usermanual_EN_vx.x.pdf

CybTouch 6 for shears technical manual:

CybTouch_6_G_1612io_Technical_manual_vx.x.pdf OR

CybTouch_6_W_88io_Technical_manual_vx.x.pdf

The present manual will describe all machine parameters of the CybTouch.

Please note that modifications to the machine parameters may imply additional inputs

or outputs to be configured (also done in the machine parameters), and will have a

direct effect on the HMI. Functions and/or buttons will be deactivated/hidden/made

available depending on the machine configuration.

This manual describes all features of CybTouch 6 X or G with software

version 2.0.0.

PM_CybTouch6_ Shears_v2.0.doc page 6 of 55

Page 7

v2.0 Nov.12

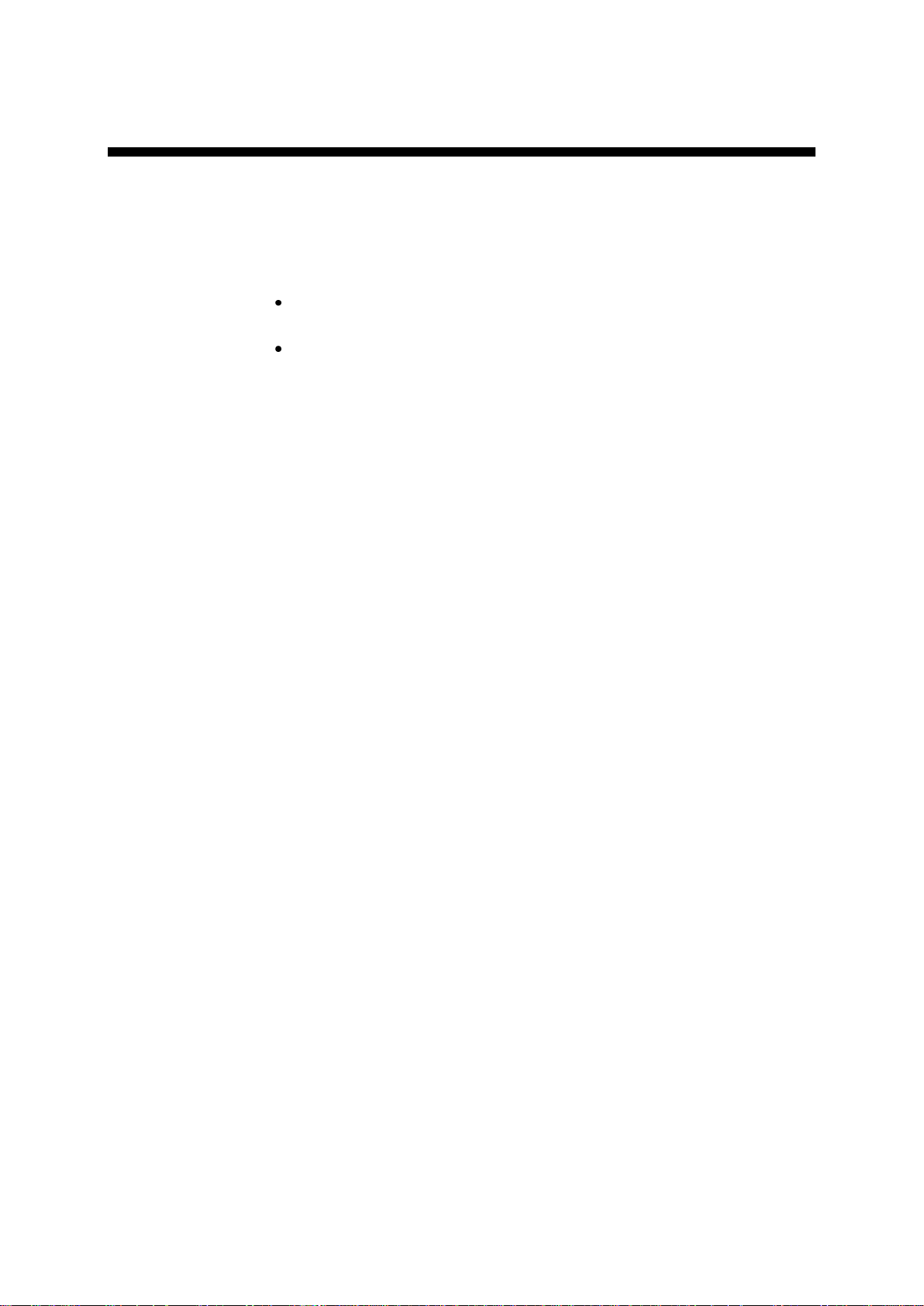

P01 MACHINE CONFIGURATION

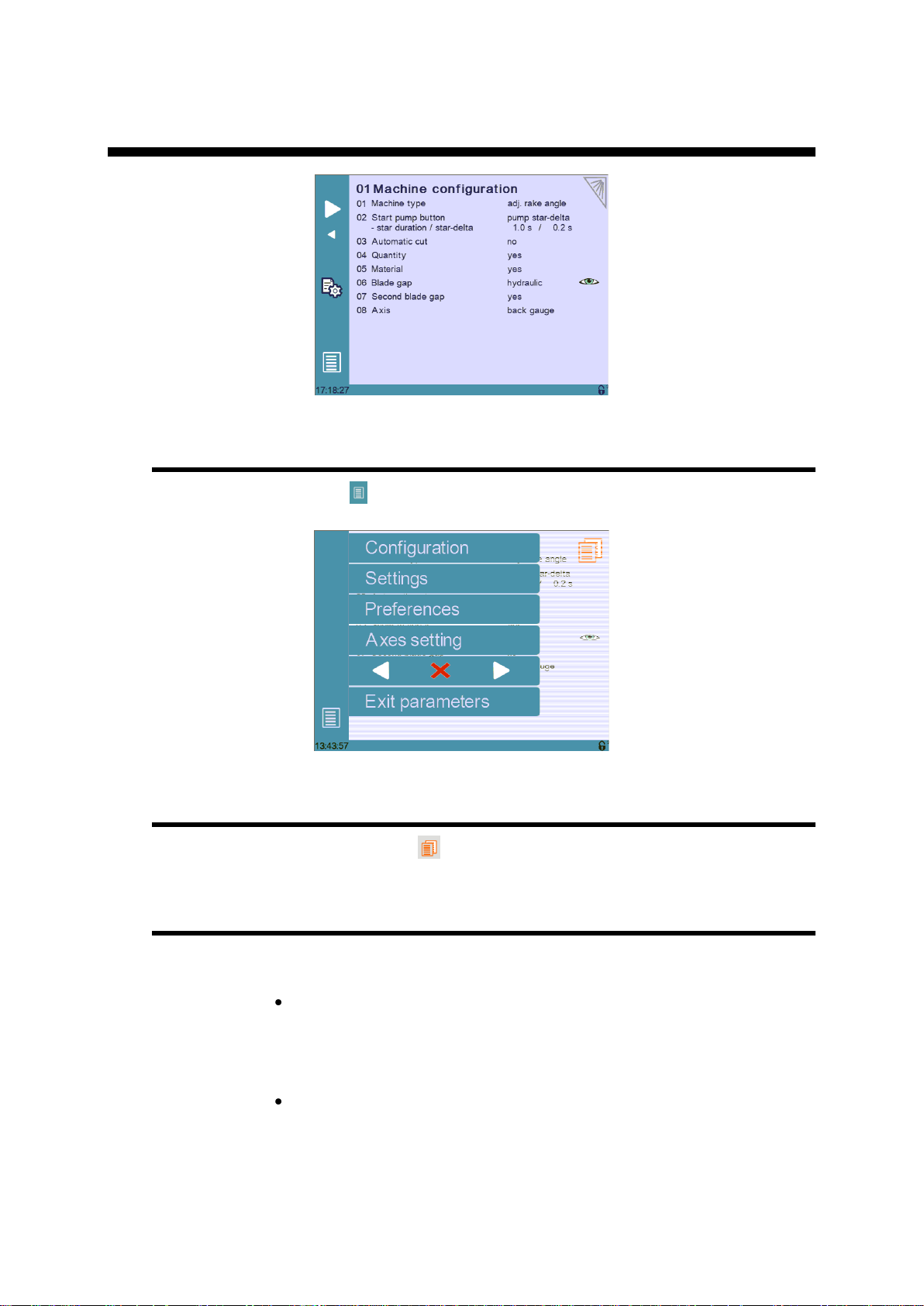

Menu Button

The Menu button allows you to exit the P01 Machine Configuration page or to

scroll through the other machine parameters pages:

Toggle Pages Button

The Toggle pages button

P01.01 Machine Type

Touch the Machine type field to choose the type of machine used with the

CybTouch:

Adjustable rake angle: Select this mode if your machine has a rake

angle managed by the CybTouch. Angle and cutting length are managed

by a sensor (potentiometer or linear encoder).

Selecting this option will give you access to dedicated machine

parameters for controlling this type of shears.

Swing: Select this mode if your machine has a fixed angle. The cutting

length is managed by a timer.

is described in section P03.05 Toggle Pages.

PM_CybTouch6_ Shears_v2.0.doc page 7 of 55

Page 8

v2.0 Nov.12

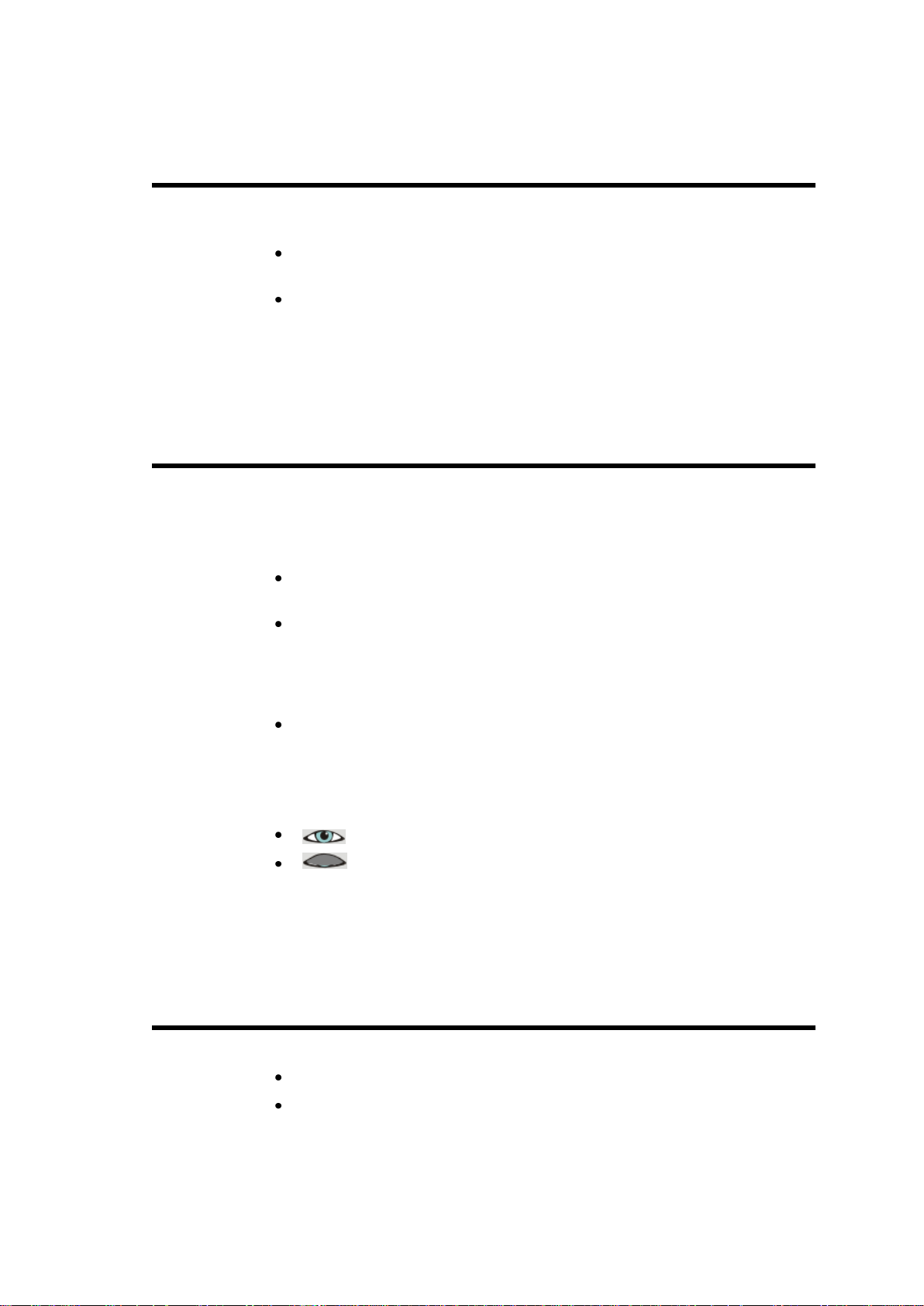

P01.02 Start Pump Button

Touch the Start Pump field to select:

No = Start Pump: start pump button is not available on screen.

Yes = Start Pump start pump button is available on screen.

1 output (Pump_on) is dedicated to this.

Pump star delta start pump button is available on screen.

3 outputs are dedicated to the star delta pump start.

1.0s = star duration.

0.2s = star to delta commutation time.

P01.03 Automatic Cut

The Automatic cut function is only available in EasyCut mode, and can be

configured as follows:

No: The Automatic cut function is disabled.

Yes, auto stop: The Automatic cut function is enabled but will be

deactivated when the operator releases the foot pedal. The operator then

has to press the Automatic cut button again to work in AutoCut mode.

Yes, no auto stop: The Automatic cut function is enabled and will

remain enabled, even after releasing the pedal. Usually, if this feature is

configured a key switch is wired to the machine to allow (or not) the

Automatic cut function.

Note: The Automatic cut input must be activated to enable the

Automatic cut icon ( ) on the screen.

P01.04 Quantity

When enabled, the Show quantity function allows the operator to enter a number

of times a program can be repeated (number of pieces to be produced).

No: The quantity counter is not displayed.

Yes: The quantity counter is displayed; the operator can enter a number

of pieces to be produced.

PM_CybTouch6_ Shears_v2.0.doc page 8 of 55

Page 9

v2.0 Nov.12

P01.05 Material

When enabled, the Show material function will display the material type used and

allow the operator to change the material type:

Yes: Material selection is displayed; the operator can select the material

type.

No: Material selection is not displayed. Blade gap is also not visible

- Minimum display Yes/No

When set to Yes, the working pages of the interface are simplified

(less icons) so that the CybTouch can be used as a positioner

control.

P01.06 Blade Gap

The blade gap is adjusted according to the selected material and thickness. These

values are set in the Material page by the machine manufacturer. Usually the blade

gap is not modified by the operator and is only shown to the operator.

Note: Blade gap feedback can only be provided by a potentiometer.

No: No blade gap management; blade gap icon and value are not

displayed and cannot be configured in machine parameters.

Show only: Blade gap is not managed by the CybTouch (manual blade

gap) but the blade gap values must be entered in Material page.

When the P01.05 Material is set to Show only, icon and value are

displayed for reference only to the operator (P12 Blade gap page is

hidden).

Electric or Hydraulic: choose the type of blade gap (electric motor or

hydraulic cylinder). The icon and value are displayed and can be

configured in machine parameters (P12 Blade gap page).

Note: When Hydraulic is selected, Pressure output must be

configured.

: Blade gap value is visible on work pages.

: Blade gap value is not visible on work pages.

Note: If the operator needs to change the blade gap, it must be set as

visible and the programmable tolerances must be set in the Material

pages. See Materials section in CybTouch 6 user guide for more

details.

P01.07 Second Blade Gap

A second blade gap can be configured. See P12 Blade gap page for calibration.

No: Only 1 blade gap actuator.

Yes: If a second blade gap is needed.

Note: Blade gap feedback can only be provided by a potentiometer.

PM_CybTouch6_ Shears_v2.0.doc page 9 of 55

Page 10

v2.0 Nov.12

P01.08 Axis

Back gauge: The back gauge is configured and can be used.

Front gauge: The front gauge is configured and can be used.

P01.09 Clamp parameter becomes available.

None: The back gauge is disabled (screen and management). This

feature is commonly used at startup of the machine.

PM_CybTouch6_ Shears_v2.0.doc page 10 of 55

Page 11

v2.0 Nov.12

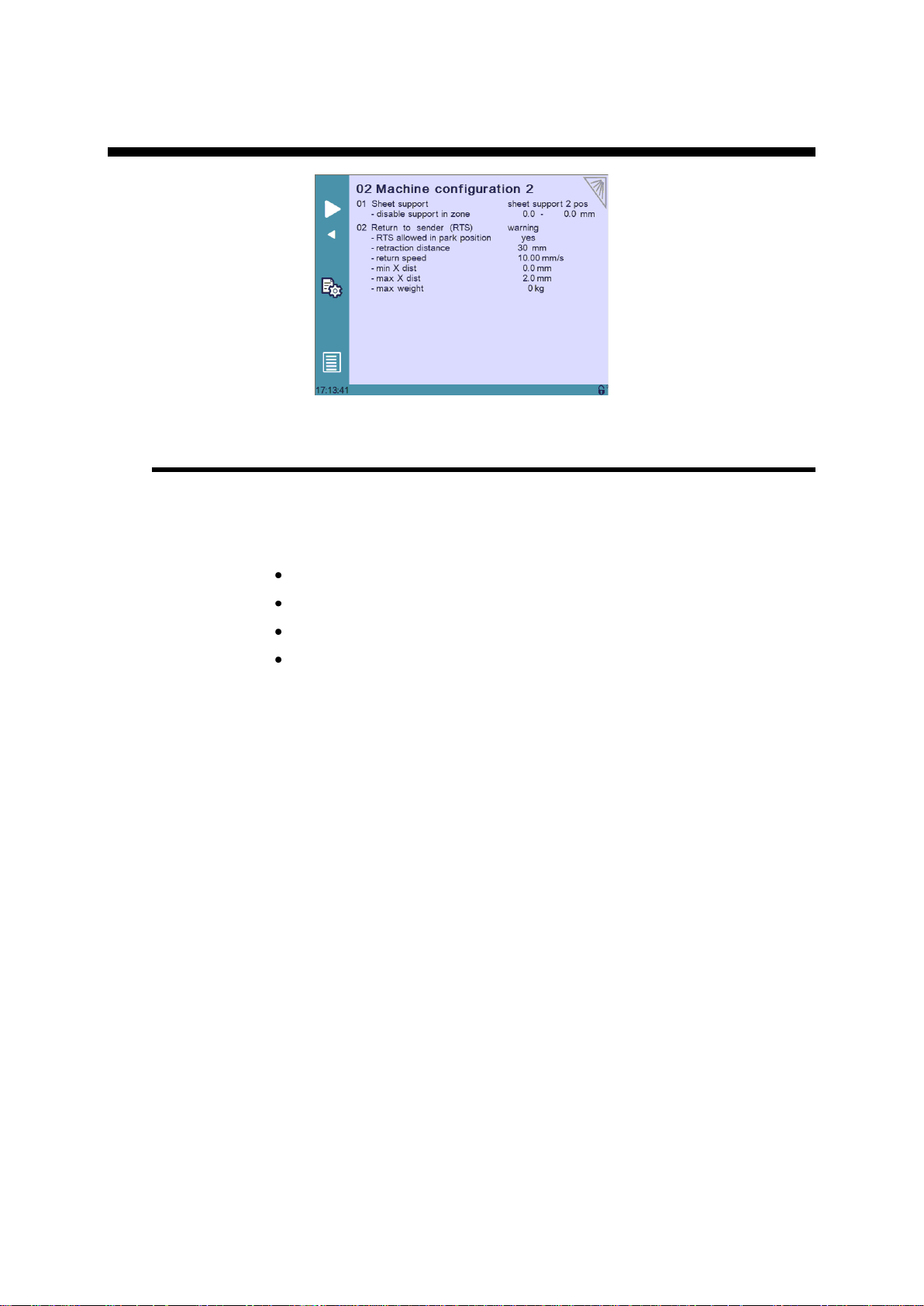

P02 MACHINE CONFIGURATION 2

P02.01 Sheet Support

The sheet support cycle must be managed by the electrical box.

The sheet support function activates 1 output for Sheet support 2 (with

2 positions) or 2 outputs for Sheet support 3 (with 3 positions).

The sheet support can be configured as follows:

No: No sheet support.

Sheet support 2 pos: Sheet support with 2 positions (1 output).

Sheet support 3 pos: Sheet support with 3 positions (2 outputs).

Disable support in zone: E.g. 0.0 – 300.0 mm values are

entered: for a part less than 300 mm in length, sheet support isn’t used.

Note: Once configured, the sheet support button is available in the

work pages for the operator to select.

PM_CybTouch6_ Shears_v2.0.doc page 11 of 55

Page 12

v2.0 Nov.12

P02.02 Return to Sender (RTS)

Sheet support must be configured to activate the RTS function. The RTS function can

be configured as follows:

No: RTS is not configured.

o Warning: RTS is configured and operator will see a warning popup

if max weight is exceeded. Operator can acknowledge the popup

and continue by pressing the foot pedal.

o Not allowed: RTS not available if max weight, min X dist, or

max X distance is exceeded.

RTS allowed in park position: RTS can be allowed or not when

the gauge is in parking position.

Retraction distance: RTS mode back gauge retraction distance is

usually greater than normal retraction.

Return speed: Speed at which the cut piece is pushed back to the

sender by the back gauge. The return is triggered by touching the RTS

button on the screen or using the RTS move input.

Min X dist: Minimum length of the part for which the RTS will be used,

depending on the choice made above.

Max X dist: Maximum length of the part for which the RTS will be used,

depending on the choice made above.

Max weight: Maximum weight of the part for using RTS function,

depending on the choice made above.

PM_CybTouch6_ Shears_v2.0.doc page 12 of 55

Page 13

v2.0 Nov.12

P03 MACHINE CONFIGURATION 3

P03.01 Auxilary Function

Several preset auxiliary functions can be configured: light, scrap, and ejector. And one

or two freely configurable auxiliary functions can be added: F1 or F1+F2.

None: No auxiliary function configured.

Light: Light is configured.

F1: 1 auxiliary function is configured and called F1.

F1+F2: 2 auxiliary functions are configured, called F1 and F2, and can

be used separately or at the same time.

Scrap: The scrap function is configured. The scrap feature is a

compartment that opens to receive scrap cuts.

Ejector: The ejector function is configured. The ejector function is used

usually with front gauge to push the remaining metal backwards.

When auxiliary functions are configured, the below parameter determines if they are to

be applied to the whole machine (on-off on operator use), saved in the complete

program for a specific part, or saved in a sequence in a part.

mode: machine/part/sequence.

P03.02 Eco Mode

The Eco mode parameter defines after how much time of operator or machine

inactivity the CybTouch will switch to economical mode.

When switching into Eco mode the Pump on output is turned off and the screen

becomes darker.

Current value is usually 5-15 min.

Setting the Eco Mode to 0.0 min deactivates Eco mode.

Note: If the Start Pump button is not configured on the screen, but

wired conventionally, the Eco mode off output can be used to

switch off the pump after the Eco mode time is reached. Please refer

to basic electrical diagrams in the CybTouch 6 technical manual.

PM_CybTouch6_ Shears_v2.0.doc page 13 of 55

Page 14

v2.0 Nov.12

P03.03 Store/Delete Programs in Level 0

Here you can choose whether or not operators with access level 0 can be authorized

to store or delete programs in the CybTouch.

P03.04 HMI Locked in Level 0

The Human Machine Interface can be locked in level 0. This is commonly used when

machines are left unattended on exhibitions to prevent visitors from changing

programs.

When set to Yes, the operator will need a code to access programming (level 2).

The HMI will be automatically locked every time:

The CybTouch is switched off.

The CybTouch switches to Eco mode.

The HMI can be locked manually by opening the menu and pressing the icon.

The unlocking code is “55". See section Changing Access Level Security Passwords.

Another option: EasyOK, means that the CybTouch is locked in the EasyCut page.

This option is to make the machine very simple.

P03.05 Toggle Pages

If activated, the toggle button allows you to switch directly from any parameter

page "back" to the last working page visited before accessing the parameters.

Once you are in the working pages, touching allows you to return to the last

accessed parameter page.

This functionality is very useful for technicians during the machine set-up.

Its vivid orange color just informs the technician that this toggle page mode is active

and acts as a reminder to deactivate this functionality before machine delivery.

The Toggle pages button will disappear automatically from operator pages (Toggle

page parameter set to no) after 24 hours of inactivity.

P03.06 Show Cycle Steps

Cycle steps messages at the top of the screen can be displayed or not by activating or

deactivating the Show Cycle Steps parameter.

Ex: .

By default this parameter is set to Yes. The operator immediately knows in which

phase the machine currently is. This feature and the Machine Status pages are very

helpful during the first service calls between the operator and the service technician.

PM_CybTouch6_ Shears_v2.0.doc page 14 of 55

Page 15

v2.0 Nov.12

P03.07 Retraction

Retraction of the back gauge can be set as follow:

No: The backgauge will not retract.

Always: The backgauge will always retract.

Selectable: The backgauge will retract or not, this is defined by

operator.

Retraction is only possible if AutoCut function is active.

Retraction distance: Backgauge retraction distance

Mandatory for thickness over: Retraction is mandatory if

material is thicker than this parameter value.

P03.08 Analog Pressure

Analog pressure can be configured if a proportional pressure valve is used for the

system pressure of the machine. Output manages ramps and pressure levels

depending on programmed material.

When P03.09 Analog Pressure is set to Yes, P15 Pressure becomes available

in machine parameters.

P03.09 Cutting Length Sensor

CybTouch 6 G allows the choice between a linear encoder or a potentiometer for

angle and cutting length functions.

If 2 blade gaps are used, the angle and cutting length sensor must be an

encoder.

The sensor (potentiometer/linear encoder) must be positioned as far as possible to the

right of the machine in order to obtain maximum precision.

Encoder index must be positioned near to BDC (approx. 10 - 20 mm), before the

blades cross.

PM_CybTouch6_ Shears_v2.0.doc page 15 of 55

Page 16

v2.0 Nov.12

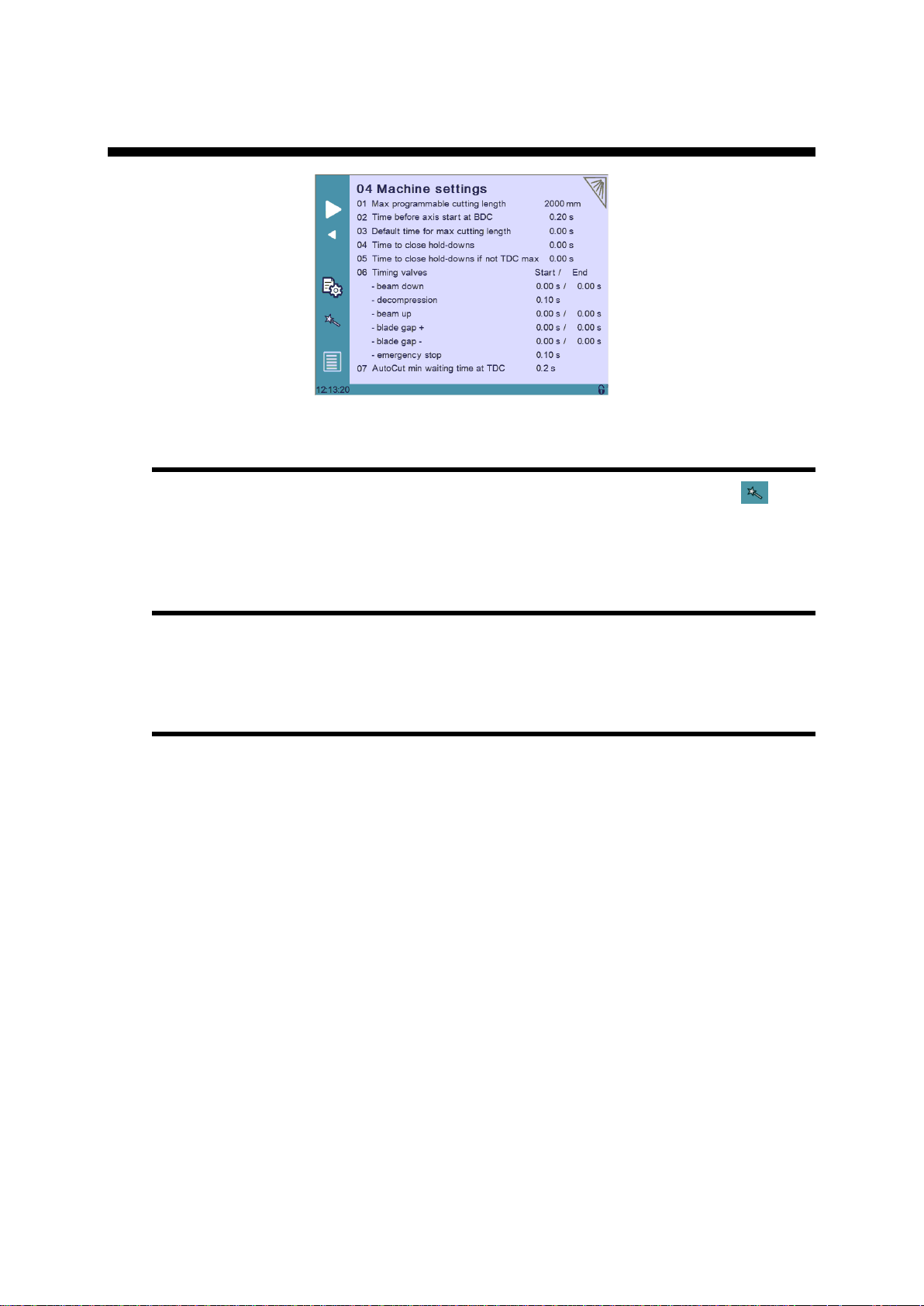

P04 MACHINE SETTINGS

Machine Settings Wizard

When a swing shear machine is used, a Wizard is available by touching the

button. This allows you to measure the default time for the maximum cutting length.

See section P04.04 Default Time for Max Cutting Length for more details.

P04.01 Max Programmable Cutting Length

This parameter is only available with swing shear machines. It is the maximum cutting

length, depending on the machine dimensions.

P04.02 Time Before Axis Start at BDC

After the beam begins to move up from BDC, this is an extra time that can be set

before axes (sheet support and back gauge begin to move. This parameter is only

active if P05.01 Axes Start At is set to BDC.

PM_CybTouch6_ Shears_v2.0.doc page 16 of 55

Page 17

v2.0 Nov.12

P04.03 Default Time for Max Cutting Length

This is the default time it takes to cut a piece with the previously set maximum cutting

length in P01 Maximum Cutting Length.

This is the value set by default when working in the EasyCut and Program page.

This is also the maximum time the operator can program.

This parameter is only available with swing shear machines.

This time can easily be measured using the Wizard:

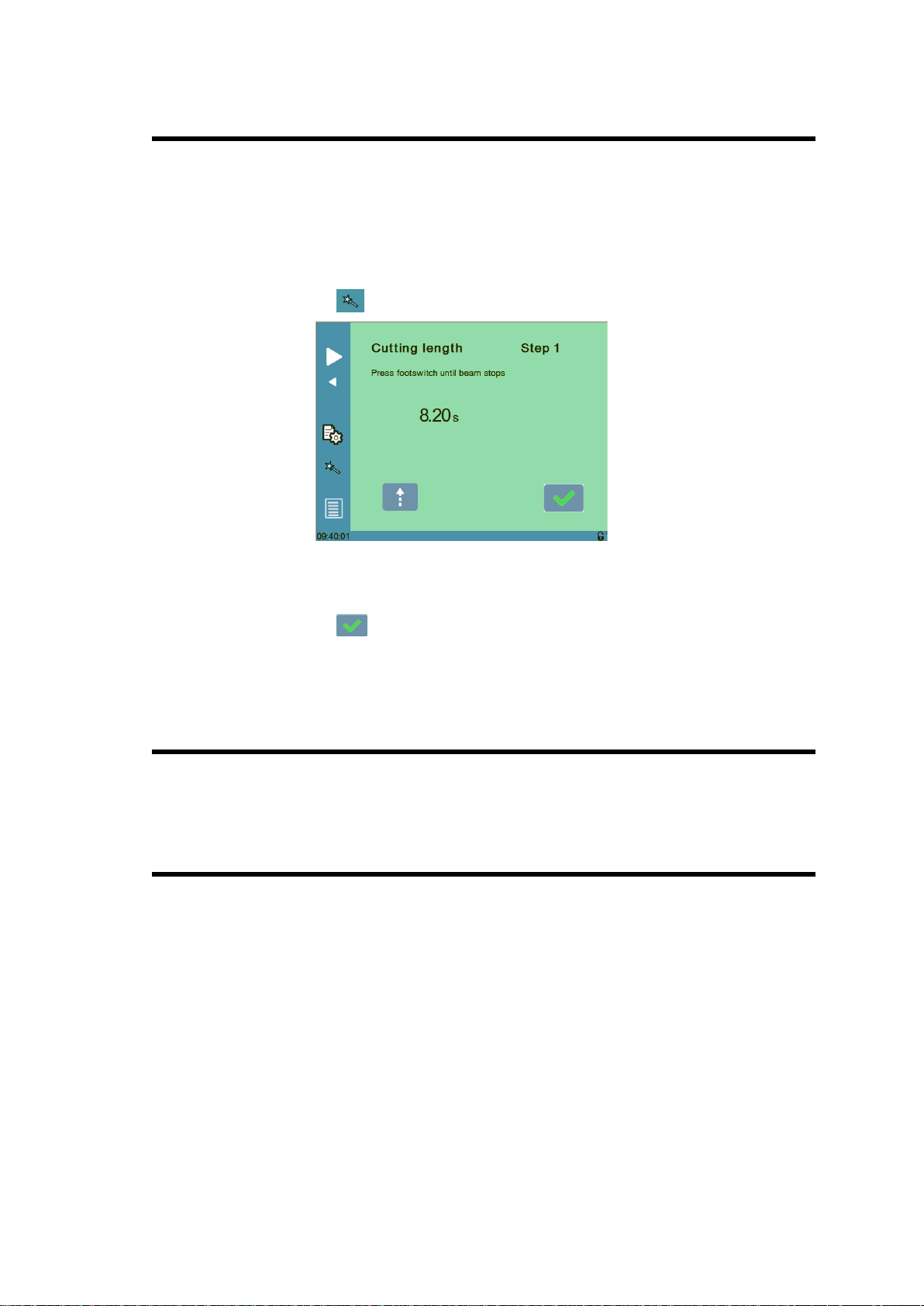

1. Touch the button, the below Wizard is displayed:

2. Press the foot pedal to lower the beam, the time it takes for the beam to go from

TDC position to BDC is measured (here 8.20 seconds).

3. Touch the button to exit the Wizard and return to the machine parameters

page.

4. The programmed cutting length value is now set.

P04.04 Time to Close Hold-Downs

This parameter determines the time before the output Time hold dn closed (for closing

the holdowns) is activated after the beam starts to descend from TDC max.

P04.05 Time to Close Hold-Downs if not TDC max

This parameter determines the time before the output Time hold dn closed (for closing

the holdowns) is activated after the beam starts to descend from a point below TDC

max, upon pressing foot pedal.

PM_CybTouch6_ Shears_v2.0.doc page 17 of 55

Page 18

v2.0 Nov.12

*Or beam up, blade gap +, blade gap -

P04.06 Timing Valves

This parameter is used to manage system pressure for hydraulic systems in the

machine by timing the opening and closing of valves according to the system

pressure:

E.g.: Beam down 0.20s / 0.30s

P04.07 AutoCut Minimum Waiting Time at TDC

This parameter determines the minimum time that the blade must stay at TDC

between cuts in automatic cut mode.

This is to ensure a smooth and less brutal change of direction/pressure in the system.

PM_CybTouch6_ Shears_v2.0.doc page 18 of 55

Page 19

v2.0 Nov.12

P05 PREFERENCES

P05.01 Axes Start at

The axes (back gauge) can be configured to start positioning at different moments,

depending on the position of the beam:

BDC if X SP:

o If the axes movement will be in positive direction, axes (back

gauge) will start once the beam reaches BDC.

o If the axes movement will be in negative direction, axes (back

gauge) will wait and start once the beam reaches TDC.

BDC: Back gauge starts moving when beam reaches BDC.

TDC: Back gauge starts moving when beam reaches TDC.

P05.02 Sheet Offset

Only available with adjustable rake angle machines.

If configured, allows the operator to set a series of cuts to be made in the center of the

machine without the beam having to return to TDC max for each cut. This function is

only available if the machine is capable of stopping in the middle of a return of stroke.

P05.03 Angle Control at TDC Max

Only available with adjustable rake angle machines.

The CybTouch can be configured to check the blade angle at TDC Max.

It can be configured to perform this check every X number of cuts (value between 1

and 999 cuts). More frequent controls are usually used for older machines or

machines with hydraulic systems with minor leakage.

Setting this parameter to 0 disables the angle check at TDC Max.

P05.04 Square Signal Low/High

The square signal is used to carry out tests on the machine. This signal is available on

one output Square signal and must be configured to be used.

PM_CybTouch6_ Shears_v2.0.doc page 19 of 55

Page 20

v2.0 Nov.12

P06 AXIS SETTINGS -X-

P06.00 Display Resolution

This value must be entered manually before using the Wizard.

Here you must set the displayed resolution for the selected axis to 0.01 mm,

0.1 mm or 1 mm.

P06.01 Axis Type

This value must be entered manually before using the Wizard.

Depending on the drive logic, you must select either:

For DC or AC brushless motor, select Enable +/-10V.

For frequency converter with asynchronous motor, select either

If a frequency converter is used, the offset must be 0.0 V.

En/SN 0/10V, or SP/SN 0/10V according to the drive logic.:

P06.02 Closed Loop

Must be programmed manually before using the Wizard.

If you are using a frequency converter this parameter must be set to No.

PM_CybTouch6_ Shears_v2.0.doc page 20 of 55

Page 21

v2.0 Nov.12

P06.03 Encoder resolution

The encoder resolution can be programmed if it is already known

It can also easily be determined using the axis Wizard .

P06.04 Position Speed

Must be programmed manually before using the Wizard.

Here you must enter an approximate realistic positioning speed for the back gauge.

The real maximum positioning speed will then be determined by the Wizard.

P06.05 Position Tolerance

Must be programmed manually before using the Wizard.

Here you must enter the position tolerance accepted by the machine for the axis.

P06.06 One-Way Positioning

Back gauge positioning can be configured here. Various configurations are possible;

here are some examples which display how to configure this parameter:

Bi-directional positioning without final approach:

Bi-directional positioning with final approach of 5 mm at 1 mm/s:

One-way positioning with overrun of 30 mm:

PM_CybTouch6_ Shears_v2.0.doc page 21 of 55

Page 22

v2.0 Nov.12

One-way positioning with overrun of 30 mm +final approach of 5 mm

and 1 mm/s:

Advanced button

Touching the Advanced button displays the P06b Advanced Axis Regulator

page.

These parameters are automatically generated by executing the Wizard described

below. See section P06b Advanced Axis Regulator X for more details.

Axis Settings -X- Wizard

Important: Before using the Wizard, a number of parameters must be set manually,

see section P06 Axis Settings –X-.

For this example of axis setting, we will enter the below values in the 06 Axis settings

X Page:

Axis type En/SN 0/10V

Closed loop no

Time before 0.0s

Encoder resolution xxxxx p/mm

Positioning speed 60,00 mm/s (*)

One way positioning: no.

(*) Make sure this speed is at least 30 to 40 % lower than the expected final

speed.

1. Touch the Wizard button to launch a Wizard to help you set the axis.

Simply follow the instructions in the Wizard for the following:

Axis movement direction:

2. Program the voltage to a value of minus 30-50%

(30% = auto-tuning will be made with max 3V output. 50% = auto-tuning done

with 5V output)

3. Simply follow instructions in the Wizard.

4. Proceed the same for the following steps:

Axis resolution.

Axis position test.

Note: if the mechanical position is not right when you measure it,

restart the wizard.

Axis limits.

PM_CybTouch6_ Shears_v2.0.doc page 22 of 55

Page 23

v2.0 Nov.12

Axis identification:

5. Set the direction (01 Direction) in which the axis should move. The axis will

move for its identification for a certain time as defined in the next steps. Choose

the axis direction where the most distance is available for the stroke.

6. Set a test voltage (02 Voltage) for axis movement, 2 to 5 V preferably.

Start tests with a small v at the beginning in order to observe axis reaction.

7. Set the duration (03 Time) for axis movement, 2 to 4 sec preferably (but

depending on the axis speed). Start with small value. Too small value will

results one error. Increase the time if error 56 is shown (see errors on page 48).

8. Touch Start,

a. Axis starts a movement with above values, oscillates, stops, and then

returns near to the start position.

b. The Positioning OK message appears and the 10 speed at

10V value is calculated.

Note: P06.04 Positioning speed = 10 Speed at 10 V – 15%.

The P06.04 Positioning Speed can be made lower but never higher.

If an identification error [ ] occurs:

i. Err 1 = No motion detected. Should not happen if you

started the Wizard from the beginning.

ii. Err 2 = Not enough oscillations.

Increase the above identification time.

iii. Err 3= Oscillation amplitude.

Increase the above identification voltage.

In all cases, make sure that the amplifier / frequency converter doesn't

have internal ramps.

If ramps are set, turn them off (or set them to 0).

Make sure that no tests are performed by the drive at start movement.

If tests are set, turn these tests off (such as the inductance or poles

tests).

PM_CybTouch6_ Shears_v2.0.doc page 23 of 55

Page 24

v2.0 Nov.12

9. Touch to move on to Axis Tuning.

Axis tuning:

1. Choose between closed loop and open loop. Select open loop if frequency

converter is used.

2. Reduce the 04 Positioning speed if needed, never make it higher.

3. Increase or decrease manual speed depending on machine behavior.

4. Increase or decrease acceleration speed depending on machine behavior.

5. Enter a position in the field above and touch START.

6. Verify that X axis went to the right position. Repeat with different values.

Adjust 03 Acceleration to your convenience.

And if necessary set a final approach distance and or the one-way positioning

mode (in P06.06 One-way positioning).

All tests and axis adjustments can easily be made in this page.

After executing the Wizard, the backgauge is set to run in normal operating conditions.

7. Touch to move on to Axis Tuning.

Axis tuning:

1. Choose between closed loop and open loop. Keep open loop if frequency

converter is used.

2. Reduce the 04 Positioning speed if needed, never make it higher.

3. Increase or decrease manual speed depending on machine behavior.

4. Increase or decrease acceleration speed depending on machine behavior.

5. Enter a position in the field above and touch START.

6. Verify that X axis went to the right position. Repeat with different values.

Adjust 03 Acceleration to your convenience.

And if necessary set a final approach distance and or the one-way positioning

mode (in P06.06 One-way positioning).

All tests and axis adjustments can easily be made in this page.

After executing the Wizard, the backgauge is set to run in normal operating conditions.

PM_CybTouch6_ Shears_v2.0.doc page 24 of 55

Page 25

v2.0 Nov.12

P06B ADVANCED AXIS REGULATOR X

All parameters in this chapter are automatically calculated by the Wizard.

This page is accessed by touching the advanced button on P06 Axis Setting.

P06b.01 Change Counting Direction

This parameter changes the counting direction for the axis movement/positioning.

P06b.02 Manual Speed

This parameter determines the manual movement speed for the axis in mm/sec.

P06b.03 Acceleration

This parameter determines the X axis default acceleration speed.

The bigger the value is, the faster the acceleration is.

P06b.04 Invert voltage & Speed at 10V

The theoretical maximum speed of the axis with 10V applied to the drive.

This value is set by the Wizard and should be handled manually with great care, or

simply left to be calculated by the Wizard.

The sign in front of the value (+ or -) shows inversion or not.

P06b.05 Closed Loop Frequency

This parameter determines the level of proportional gain. This value is set by the

Wizard and should be handled manually with great care, or simply left to be

calculated by the Wizard.

PM_CybTouch6_ Shears_v2.0.doc page 25 of 55

Page 26

v2.0 Nov.12

P06b.06 Integrator factor

Integral gain. This value is set by the Wizard.

Can be adjusted manually to increase positioning accuracy.

P06b.07 Offset Voltage

Offset voltage, 0 - 9.999V

P06b.08 Supervisor Error

Supervisor error 0 - 999.99 mm

999.99 = no test

Usually programmed:

10 - 30 mm with frequency converter and

5-10 mm with servo-drives.

This is the max allowed distance between the calculated and the real trajectory.

If during movement the value in P06b.08 Supervisor error is exceeded, the

CybTouch stops the movement and displays FW Err 32 Trajectory following

error.

If this occurs, try to slow down the positioning speed and or acceleration, or check

that the axis has no mechanical friction spots on its stroke.

Refer to the error description chapter for additional information.

P06b.09 Supervisor Speed Level

Speed supervisor level 100%.

0 = no test.

Usually programmed:

20-30% with frequency converter and

5-10 % with servo-drives.

This is the max. allowed speed difference between the calculated and the real

speed.

If during movement speed difference exceeds the value in P06b.09 Supervisor

speed level, the CybTouch stops the movement and displays FW Err 39

Speed following error.

If this occurs, try to slow down the positioning speed and/or acceleration, or check

for friction points on the axis stroke.

Refer to the error description chapter for additional information.

PM_CybTouch6_ Shears_v2.0.doc page 26 of 55

Page 27

v2.0 Nov.12

P06b.10 Control Time Out

Control time out 9.999s

0 = no test

Usually programmed

0.4 to 0.8s with frequency converter, and

0.2 -0.4s with servo-drives.

This is the max allowed time with regulator at max voltage.

If this error appears, it means the regulator had to provide 10V for at least the

duration programmed in this parameter.

If at start and during movement, the value in P06b.10 Control time out is

exceeded, the CybTouch stops the movement and displays FW Err 33 Maximum

voltage time exceeded.

Refer to the error description chapter for additional information.

PM_CybTouch6_ Shears_v2.0.doc page 27 of 55

Page 28

v2.0 Nov.12

07 INDEXATION AXIS -X-

Most of these parameters are set during the Wizard procedure. They can be

modified manually if necessary.

This machine parameters page can display parameters for more than one axis.

Simply touch –X– or –Y– in the page title to switch from one axis to the other.

Indexation Axis -X- Wizard

Touch the indexation Wizard button to launch the axis indexation Wizard and

follow instructions. Make sure you select the type of index before launching the

Wizard.

PM_CybTouch6_ Shears_v2.0.doc page 28 of 55

Page 29

v2.0 Nov.12

P07.01 Index Type

None: No indexation.

Index and zone:

Axis enters the index zone (24V input),

Reverses direction and exits the zone, and then

The first 5V encoder index = index is taken.

Index only:

At first 5V encoder index = index is taken.

Index zone only:

Axis enters the index zone (24V input),

Reverses direction and exits the zone.

The axis indexes when leaving the index zone.

Mechanical stop:

There is no index zone switch or index.

The axis move in index speed until it is stopped mechanically at

end of the stroke.

The mechanic axis stop = index.

This indexing mode requires precise and constant mechanic stop

and a slow indexing speed.

Mechanical and index:

Same as above, but the mechanical stop acts as an indexing zone.

The axis stops on the mechanical stop (can be a rubber stop to

reduce strength on the axis)

Axis reverses direction and exits the zone.

At first 5V encoder index = index is taken.

P07.02 Index Zone in Reverse Logic

Inverts the input signal function. 24V or 0V active depending on selection.

P07.03 Start Indexation in Negative Direction

Indexation starts in positive or negative direction. This parameter is used in

conjunction with above P07.02. IndexZone in Reverse Logic.

P07.04 Indexation Speed

Defines the axis indexation speed.

P07.05 Index Position

Defines the index position. This value is set using the Wizard.

P07.06 Minimum Limit

Defines the minimum limit position. This value is set using the Wizard.

PM_CybTouch6_ Shears_v2.0.doc page 29 of 55

Page 30

v2.0 Nov.12

When the operator touches the back gauge icon, it changes

to the foldaway icon and value is hidden. The backgauge

automatically moves to its parking position.

If a foldaway system is used, enter the ramp start value and

speed on ramp value.

If no ramp, set the ramp start at smaller value than parking

position and program speed on ramp at same value as

positioning speed.

P07.07 Maximum Limit

Defines the maximum limit position. This value is set with the Wizard.

P07.10 Parking

Note: Parking position must be smaller than P07.07 Maximum limit parameter

value.

P07.11 Parking Tolerance

This parameter determines the tolerance for the gauge’s parking position.

Recommended Parking Tolerance is 10.0 to 20.0 mm.

PM_CybTouch6_ Shears_v2.0.doc page 30 of 55

Page 31

v2.0 Nov.12

08 AXIS FUNCTIONS -X-

If there are several axes, touch the axis name –X– or –Y– on top of the page to

switch from one axis to the other.

PM_CybTouch6_ Shears_v2.0.doc page 31 of 55

Page 32

v2.0 Nov.12

Blade gap

fracture width

Sample values (mm):

- blade gap = 1.00

- fracture width = 0.40

- cut length = 100.00

needed correction 0.60

P37 = 0.6

1.00

99.000.40

0.40

0.00 100.00

needed correction -0.4

P37 = - 0.4

1.00

100.000.40

0.40

0.00

100.00

needed correction - 1.00

P37 = 0.6

1.00

101.00

0.40

0.00100.00

P08.01 Blade Gap Factor

The blade gap factor is used to correct the x axis value with regards to the blade gap

value and the backgauge fixing point or if front gauge.

P08.02 Speed with input “Speed reduction”

The Speed reduction input allows you to reduce the positioning speed of the axis.

Enter here the speed when the input is active.

PM_CybTouch6_ Shears_v2.0.doc page 32 of 55

Page 33

v2.0 Nov.12

P09 DIGITAL INPUT CONFIGURATION

The inputs can be modified according to the machine requirements.

Simply touch a field and select the output to configure:

Note: Use the arrows to scroll through the available inputs.

Doubling inputs will result in error (configuration error) while leaving machine

parameters.

PM_CybTouch6_ Shears_v2.0.doc page 33 of 55

Page 34

v2.0 Nov.12

INPUT

RECEIVED SIGNAL

Safety system down

Inform the CybTouch that the safety system is

deactivated

Pedal

Down Pedal is pressed

Automatic cut

AutoCut function is enabled (external switch)

TDC max

Beam has reached the max beam position switch

(TDC = Top Dead Center)

BDC min

Beam has reached min beam position switch

(BDC = Bottom Dead Center)

X index zone

X axis is in the index zone (index zone active)

Speed reduction X

When active, X axis runs at reduced speed (P08.02)

External stop

When activated, stops all movement of the CybTouch.

Must be deactivated to let the CybTouch start again.

RTS ready

If configured, this signal inform the CybTouch that the

RTS (return to sender) system is in its final up position

and operator can use the “return” button to move the

plate back to him. If not in position, the “return” button will

not be active

RTS move

The RTS return button on the CybTouch may not be

convenient for the operator to move the plate backward to

him. On external switch may be mounted in a more

convenient place for this operation. Configure this input

and connect the external switch. Both buttons (switch and

screen) can be activated.

Beam up

Beam moving up by remote control (*1).

Blade gap 1 select

Selects blade gap1 using remote control (*1).

Blade gap 2 select

Selects blade gap 2 using remote control (*1).

Blade gap +

Blade gap made larger using control. (*1)

Blade gap -

Blade gap made smaller control using remote control (*1).

(*1) Please refer to Appendix 1 –Using Remote Control for more information.

Available digital inputs for configuration:

PM_CybTouch6_ Shears_v2.0.doc page 34 of 55

Page 35

v2.0 Nov.12

P10 DIGITAL OUTPUT CONFIGURATION

The outputs can be modified according to the machine requirements.

Simply touch a field and select the output to configure.

Note: Use the arrows to scroll through the available outputs.

Some outputs can doubled for more power. Simply configure the output twice to

double it. Only the outputs marked with a * can be doubled.

Doubling an output that isn’t marked with a * will result in an error (configuration

error) occurring when you leave the machine parameters page.

PM_CybTouch6_ Shears_v2.0.doc page 35 of 55

Page 36

v2.0 Nov.12

OUTPUT

SENT SIGNAL

Enable X axis

Allows the machine to move.

SN X axis

Pump on

See parameter P01.02

Pump star

See parameter P01.02

Pump delta

See parameter P01.02

System pressure

Activates the ON-OFF system pressure valve (if applies).

Blade down

Moves blade down

Blade up

Moves blade up

Blade gap +

Makes blade gap larger

Blade gap -

Makes blade gap smaller

Blade gap2 +

Makes second blade gap larger.

Blade gap2 -

Makes second blade gap smaller.

Sheet support 2

Informs the electrical box that the operator selected the

Sheet support 2 positions. Management of sheet support

cycle must be done by the electrical box

Sheet support 3

Informs the electrical box that the operator selected the

Sheet support 3 positions. Management of sheet support

cycle must be done by the electrical box

Square signal

Can be used to make some automatic tests

Safety system reset

Once the operator presses the button on the warning

display, this output gives a 24VDC impulse (can be used

to reset a system)

Aux funct F1

Turns on the light or activates configured aux function F1

Eco mode off

This output gives a 24VDC impulse when the CybTouch

goes into Eco mode. It can be used to stop the main

pump (and other device). See P03.02 and electrical

diagram samples.

Cutting angle -

Makes cutting angle smaller.

Cutting angle +

Makes cutting angle larger.

RTS on

Inform the electrical box that the RTS function is active.

Time hold dn closed

Output activated to close holdowns (at end of P04.04 /

P04.05 Time to Close Hold Downs), it remains active until

beam returns to TDC (while pedal is pressed).

RTS active

Return To Sender is ready to be used

Mach ready

Machine is ready.

Mach indexed

Machine is indexed.

Available digital outputs for configuration:

PM_CybTouch6_ Shears_v2.0.doc page 36 of 55

Page 37

v2.0 Nov.12

INPUT

RECEIVED SIGNAL

Blade gap

Input of the Blade gap potentiometer

Blade gap2

Input of the second Blade gap potentiometer (if

configured)

Cutting length

Input of the Cutting length potentiometer

OUTPUT

RECEIVED SIGNAL

X axis

+/- 10 V analog output for the X axis drive

Pressure

0-10 V analog output for Pressure proportional valve

10V ref.

+ 10V reference output for potentiometers

10V ref. 2

+ 10V reference output for potentiometers

X axis

X axis encoder input (see input/output list)

Cutting length

Encoder input for Angle & Cutting length if configured as

encoder

P11 ANALOG I/O CONFIGURATION

The analog inputs or outputs may be modified according to the machine requirements.

Simply touch a field and select the input or output to configure.

Available analog outputs for configuration:

Available analog inputs for configuration:

Encoder signals:

PM_CybTouch6_ Shears_v2.0.doc page 37 of 55

Page 38

v2.0 Nov.12

If configured (in P01.07) the second blade gap can be adjusted in the second machine

parameter page. Press the (1) or (2) to switch between blade gap pages.

Touch the V (Voltage) box and press

the teach button to copy the current

potentiometer value into the blade gap

table.

P12 BLADE GAP

It is recommended to use the blade gap Wizard to setup the range (min-max) of

the blade gap stroke. For more info, simply follow the Wizard on the CybTouch:

If the stroke is not linear (eccentric) it is possible to compensate this adding some

points (up to 6 more):

Touch a column header (2 to 7).

Move the blade gap ( ) until it reaches the thickness gauge you

selected (eg. 0.15).

Touch the mm box in the column and enter the gauge value (0.15)

Move the blade gap until it reaches the thickness gauge.

If the parameters are changed after the Material tables are programmed, you MUST

check and adapt the minimum and maximum of all tables in the Material pages.

Blade Gap Wizard

Touch the Wizard button to launch the blade gap Wizard.

Follow the instructions on screen and touch . The Wizard will help you to define

PM_CybTouch6_ Shears_v2.0.doc page 38 of 55

Page 39

v2.0 Nov.12

the minimum and the maximum stroke values, the P12.03 Advanced stop and the

P12.04 Overrun distance.

P12.01 Inverted AD Input

Allows the blade gap sensor signal to be inverted.

P12.02 Tolerance

Tolerance for blade gap positioning.

To avoid problems, the tolerance value must be bigger than the P12.03 advanced

stop parameter.

If there is a programmed P12.04 Overrun distance, the tolerance value may be

programmed at smaller value than the advance stop.

P12.03 Advanced Stop

Compensates the time required for the blade gap motor to stop. This value is

automatically found during the Wizard procedure.

P12.04 Overrun Distance

Overrun distance for the blade gap. Value is proposed by the Wizard.

0.00 mm= no overrun.

P12.05 SP/SN Time

This parameter determines the stop time between changing from a positive movement

to negative movement or vice versa. This is specifically used during the overrun

distance.

0 s = not in use.

PM_CybTouch6_ Shears_v2.0.doc page 39 of 55

Page 40

v2.0 Nov.12

P13 ANGLE & CUTTING LENGTH

Make sure you select the correct sensor (potentiometer or encoder) in P03.10.

Enter the machine dimensions (the three lower fields in the above screen).

Enter the minimum and maximum cutting angle.

Angle & Cutting Length Wizard

1. Touch the Wizard button to launch the Wizard.

2. Follow the instructions on the screen and touch .

The Wizard will set all parameters for the angle and cutting length function:

PM_CybTouch6_ Shears_v2.0.doc page 40 of 55

Page 41

v2.0 Nov.12

P14 ANGLE AND CUTTING LENGTH 2

P14.01 Inverted Input

Inverts the sensor signal (valid for potentiometer or encoder).

Automatically calculated using the Wizard.

P14.02 Resolution

This parameter defines the resolution (degree of precision) of the cutting length

sensor. If the sensor is a linear encoder, usually the resolution is 200.000.

If you know the resolution, enter the value when Wizard asks for it.

If the sensor is a potentiometer, let the Wizard determine the resolution for you.

P14.03 Minimum Limit

Minimum beam position (measured at right of the machine). Usually a negative value.

Automatically calculated during the Wizard.

P 14.04 Distance Max TDC – Mechanical Stop

Distance between the TDC switch and the mechanical TDC stop.

Automatically calculated during the Wizard.

P14.05 TDC Time Before Angle Control

Time spent at TDC before angle control is performed (this is to allow the beam to

stabilize). Must be programmed.

PM_CybTouch6_ Shears_v2.0.doc page 41 of 55

Page 42

v2.0 Nov.12

P14.06 Cutting Angle Tolerance

Accepted margin of positioning error for the cutting angle (in degrees or mm).

To avoid problems, the tolerance value must be bigger than the P14.08 Advanced

stop parameter.

P14.07 Stop if Angle Sensor Max

If the max TDC switch (left side) is reached before the sensor (right side) reaches its

TDC, this means the beam angle has changed.

In this case CybTouch can have 2 reactions:

Stop and display a message (Yes).

Correct automatically (No = default).

CybTouch will adjust angle automatically.

P14.08 Advanced stop, angle down/up

Advanced stop values for the angle movements.

P14.09 Advanced stop, cut down/up

Advanced stop values for the beam cutting movements (up/down).

PM_CybTouch6_ Shears_v2.0.doc page 42 of 55

Page 43

v2.0 Nov.12

P15 PRESSURE

This feature manages a proportional pressure valve for the system pressure.

Only displayed if the P03.09 Analog pressure parameter is set to Yes.

The technician can teach pressures by entering values in the linearization table.

To enter a value, touch the header of the column where the value should be entered.

Make sure the values are consistent (increasing from left to right).

Beam upwards stroke parameters:

Pressure Wizard

Touch the Wizard button to launch the pressure Wizard then follow the

instructions in the Wizard.

P15.02 Minimum Pressure Beam Down

This is the minimum pressure required for the beam to move down.

PM_CybTouch6_ Shears_v2.0.doc page 43 of 55

Page 44

v2.0 Nov.12

P15.03 Beam Up

This is the pressure required for the beam to move up at a certain speed.

P15.04 Final Approach Up (min pressure)

This is the minimum pressure the beam needs to move up slowly. This parameter is

used in the final approach P15.05.

P15.05 Ramp / Final Approach Up

This is the ramp position (speed change position) and the final approach distance

when positioning to TDC.

P15.06 Final Approach Speed Up

Expected speed of the beam during final approach up.

P15.07 Final Approach Gain

Correction factor of the speed in the ramp to final approach up. (Higher value = more

correction).

P15.08 Cutting Angle

Pressure applied when adjusting the cutting angle.

P15.09 Blade Gap

Pressure applied when adjusting the blade gap.

P15.10 Ramp Cutting Pressure

This is the time required for pressure to build up before cut/down movement.

PM_CybTouch6_ Shears_v2.0.doc page 44 of 55

Page 45

v2.0 Nov.12

Access

level

Description

Default

Notes

0

Unlock touchscreen when

locked in level 0.

55

If machine parameter P03.04 HMI

locked in level 0 is set to Yes

1

Access to programs

111

Only if the machine parameter

P03.03 Store/Delete programs

in level 0 is set to Yes

2

Access Service

222 3

Access Machine parameters

333

4

Supervisor access level

*

Supervisor level of access allows the

access levels 1, 2 and or 3 to be

modified. It cannot be modified.

5

Reset the HMI password (for

blocking the touchscreen)

*

This password resets the HMI

password to the default password.

Only works If machine parameter

P03.04 HMI locked in level 0 is

set to Yes

Internal

backup

Create an internal backup for

data

*

Internal backup is created in a specific

area of CybTouch memory

Restore

Restore using internal backup

*

Restores data from the internal backup

on CybTouch memory

CHANGING ACCESS LEVEL SECURITY PASSWORDS:

Default passwords

For each access level there is a default password:

* Please ask for level 4 and 5 passwords by phone or email to support@cybelec.ch.

Changing passwords

Access level 4 is required to modify all access level passwords:

1. Go to the machine parameters and enter the password level 4.

2. Now touch the Menu button and scroll through the pages using or

until the below page appears with Passwords:

Important: Once a password is modified it is no longer possible to

return to the default password, except the HMI lock (touchscreen

locked in level 0 access).

If a password is forgotten / lost the only way to continue is to modify

the password again in Supervisor mode.

PM_CybTouch6_ Shears_v2.0.doc page 45 of 55

Page 46

v2.0 Nov.12

3. Touch Passwords and select the password you wish to change:

4. Enter the new password with the numerical keypad and validate. Enter the new

password again to confirm. The message Password accepted is displayed

in the interactive message line if the password was changed successfully.

Note: The new passwords must all be unique and must not be the same as the default

passwords described above.

PM_CybTouch6_ Shears_v2.0.doc page 46 of 55

Page 47

v2.0 Nov.12

CREATING BACKUPS AND RESTORING DATA

Creating an Internal Backup of Machine Parameters

After setting up the machine, the tachnician must create an in internal backup in the

CybTouch for the machine parameters. This is used if there is a problem with the

CybTouch to reset the machine paremeters. Code level 3 and the backup code are

required for this (817).

This is done via the Maintenance page, in the Service Menu:

1. Touch the Menu button

2. Touch Services.

3. Touch Services again.

4. Touch Maintenance.

5. Touch Internal backup.

6. Enter password level 3.

7. Touch Backup.

8. Enter the backup password (817).

9. Touch Internal backup again.

10. Touch Backup again.

11. Validate to create the backup.

Restoring Creating an Internal Backup of Machine Parameters

The end user will request the assistance of a technician to restor machine parameters

if there is a problem with the CbTouch. This is why code level 2 (not 3) and the restore

code 718 (inverted 817 password) are required foer this.

This is done via the Maintenance page, in the Service Menu:

12. Touch the Menu button

13. Touch Services.

14. Touch Services again.

15. Touch Maintenance.

16. Touch Internal backup.

17. Enter password level 2.

18. Touch Restore.

19. Enter the backup password (718).

20. Touch Internal backup again.

21. Touch Restore again.

22. Validate to restore machine parameters.

PM_CybTouch6_ Shears_v2.0.doc page 47 of 55

Page 48

v2.0 Nov.12

WARNING MESSAGES

10 //Cycle in progress

The operator touched the screen while a cycle is running (the

screen is inactive except the STOP button).

15 //"automatic cut" input is not

active

The automatic cut input is configured but not active. It must be

active to enable the AutoCut function in the EasyCut page.

Usually a switch or key switch is used to enable this function.

18 //Empty field

Operator did not enter a value.

19 //24V I/O power on

24V to the inputs/outputs is now available.

29 //End of list

End of list reached. Scroll backwards.

32 //Data entry in progress

Operation impossible: data entry in progress.

35 //Access not allowed

Operator needs to enter a different password.

37 //Moving direction has been

inverted

Wizard msg.: Rotary direction of the motor has been changed.

38 //Counting direction has been

inverted

Wizard msg.: Counting direction of the axis has been changed.

39 //Moving and counting direction

have been inverted

Wizard msg.: Both the rotary direction of the motor and the

counting direction have been changed

42 //No movement executed

Wizard msg.: Operator pressed but the requested movement

was not made.

43 //Waiting input "RTS ready"

A switch makes sure the sheet support is in the correct position

for the operator to move the backgauge to retrieve the cut part.

Check the RTS switch on the sheet support.

44 //Min. BDC limit reached

Minimum BDC limit has been reached, down stroke has been

stopped. This may occur in manual mode. If this message

appears often In normal cutting operation, the machine

parameters need to be readjusted.

ERROR MESSAGES

03 //Buffer Full

The part-program memory is full, you cannot add another

sequence.

04 //Code refused

The password to access the selected page is not correct. Enter

the correct password.

05 //File not compatible

The loaded part-program is incompatible with the CybTouch.

This part should be deleted.

ERROR AND WARNING MESSAGES IN CYBTOUCH 6

FOR SHEARS

Below is a list of warning and error messages which may be displayed in the

interactive message line on the CybTouch. Each message is explained and possible

solutions are provided:

Warning messages are on a green background, and are information or

instructions that will disappear automatically.

Error messages (machine or CybTouch errors) are on a red background. They

inform the user of an error occurring on the machine or CybTouch, and

sometimes require intervention by the end user or a technician.

PM_CybTouch6_ Shears_v2.0.doc page 48 of 55

Page 49

v2.0 Nov.12

06 //Machine parameter file

problem

This file is corrupt and cannot be saved. Try to restart the

CybTouch. If the problem persists, format the memory.

07 //Machine parameters not

compatible, please format data

If a software update has been made over a much older version,

the parameters are perhaps no longer compatible. Or if

uploaded parameters (with RFlink) are much older or newer than

the current software version, they may also not be compatible. A

new start up of the machine must be made.

Please contact a Cybelec technician for more information.

08 //Lismisc File not compatible

Information message, it will disappear upon next CybTouch

restart.

09 //Save program problem

This file is corrupt and cannot be saved. Try to restart the

CybTouch. If the problem persists, format the memory.

11 //Write to file problem

This file is corrupt and cannot be saved. Try to restart the

CybTouch. If the problem persists, format the memory.

12 //X smaller than minimum limit

The operator entered a value under the limit or a memorized

value in the program is under the limit. Change value.

13 //X over maximum limit

Operator entered a value over the limit or a memorized value in

the program is over the limit. Change value.

14 //Fw SetVar Error

May occur when a feature is configured, but a dedicated in–

output is not configured. Usually this is solved by loading the

default in-outputs configuration.

15 //"BDC min" input is active

Min BDC has been reached, cannot descend more.

17 //Programming error

Machine parameters incorrectly configured, the page with the

error is displayed.

19 //Sheet support X safety

A safety zone is defined while using the sheet support. The

sheet support can't be used while X is programmed in that zone.

20 //Cycle repeat = 0

Cannot start cycle because the repeat cycle function is set to

“0”.

21 //No material defined (define

one or more in Materials page)

No materials programmed in the Material pages (in User

preferences). A material must be selected to perform

calculations.

25 //No FAST task running [ ]

Switch OFF the machine for 1 min and restart it.

28 //No I/O 24V or overload (output

in safety off)

Inputs/outputs 24V power supply is no longer present or an

output is overloaded. Reset any safety device on the machine,

and check that protection grids and rear guards are closed, etc.

If problem persists, switch machine OFF for 3 min and restart

again. If problem still persists check the machine manual and/or

contact a Cybelec technician for more information.

30 //Touch Screen error, code [ ]

Please contact a Cybelec technician for more information

regarding this specific code and details.

31 //Retraction mandatory for the

selected thickness

Cannot disable retraction because the selected material is too

thick.

32 //Pedal released before end of

cycle

Cutting length is programmed and operator released the foot

pedal before the cutting length was reached.

In such case, the cut is considered as not finished. In a program,

the CybTouch doesn't jump to next step. Keep pedal pressed

until the beam automatically returns.

33 //Syntax error in XML file

This file is corrupt and cannot be used. Try to restart the

CybTouch. If the file is a part-program, try to delete it.

PM_CybTouch6_ Shears_v2.0.doc page 49 of 55

Page 50

v2.0 Nov.12

34 //Memory allocation problem

(xml)

Usually displayed when loading an element (part-program,

parameter, etc.) and memory is almost full.

35 //Endless loop on process task

Process error. Please restart the CybTouch. If the problem

persists please contact a Cybelec technician.

39 //"Pedal" input refused

Pressing the pedal is not accepted in this page/situation.

40 //Error calculating resolution

Wizard msg. in machine parameters while setting the axis. Start

the wizard again, measure and enter values with care.

41 //Cutting angle < min angle

When a movement is attempted, the cutting angle is smaller

than the minimum machine limits. Check the Material page.

42 //Cutting angle > max angle

When a movement is attempted, the cutting angle is larger than

the minimum machine limits. Check the Material page.

43 //Configuration error

I/O incorrectly configured in machine parameters, the error I/O

page is displayed.

44 //"External stop" input is active

An external stop may be caused by safety devices, emergency

buttons, rear protection guards, etc. Check machine instructions.

45 //"Blade gap" analog input not

configured

While configuring (setting up) the CybTouch, dedicated input or

output are not configured but are requested to run properly.

46 //"Pressure" analog output not

configured

While configuring (setting up) the CybTouch, dedicated input or

output are not configured but are requested to run properly.

47 //Error calculating cutting angle

Wizard msg in machine parameters while setting up the angle.

Start the wizard again, measure and enter values with care.

48 //Error calculating cutting length

Wizard msg in machine parameters while setting up the angle.

Start the wizard again, measure and enter values with care.

49 //Max pressure moving to TDC

While beam was returning to TDC, the CybTouch provided

maximum pressure output, perhaps due to friction point or

setting point. This case should not occur.

52 //"Blade gap2" analog input not

configured

While configuring (setting up) the CybTouch, dedicated input or

output are not configured but are requested to run properly.

53 //"TDC Max" digital input not

configured

While configuring (setting up) the CybTouch, dedicated input or

output are not configured but are requested to run properly.

54 //"BDC Min" digital input not

configured

While configuring (setting up) the CybTouch, dedicated input or

output are not configured but are requested to run properly.

55 //Identification Error 1 (No

motion detected)

No motion detected. Should not happen if you started the

Wizard from the beginning. If the error remains, check limit

switches, drive, wiring, etc.

56 //Identification Error 2 (Not

enough oscillations)

Not enough oscillation. Increase the identification time. See

machine parameters manual.

57 //Identification Error 3

(Amplitude of the oscillation)

Oscillation amplitude.

Increase the identification voltage. See machine parameters

manual.

PM_CybTouch6_ Shears_v2.0.doc page 50 of 55

Page 51

v2.0 Nov.12

58 //Fw Axes Error 32 [Trajectory

tracking error]

This is a regulator error. The axis could not follow its trajectory.

This may be due to high friction, resistance or an obstacle on the

axis movement. This may also be a drive problem.

The parameter P06b.08 Supervisor error monitors whether the

axis can follow the trajectory.

If the error between the theoretical (requested) trajectory and the

real trajectory (position of the axis) is more than xx mm, the

CybTouch stops and displays FW Axes Error 32.

Try adjusting speed and acceleration (generally by reduce

P06.04 Positioning speed and P06b03 Acceleration.).

Usually this parameter can be set to 10 mm. It can be increased

if needed, but the correct way is to adjust the axis and reduce

acceleration and speed.

Tip: To adjust the speed, we recommend that you use the axis

Wizard:

While using a frequency converter

Please check that in parameter P06b.07 the offset value = 0.0V.

Offset must always be 0.0V when using frequency converters.

With software version V1.2.x (shears) and V1.2.x (Press) The

offset identification is automatically disabled if SP/SN 0-10V or

En/SN 0-10V is configured and offset value is set to 0.0V. So

the above step is not necessary

If the speed found by the Wizard is too high, it can safely be

reduced, but must never be increased.

59 //Fw Axes Error 311 [MaxSpeed

too high !]

Max speed or encoder resolution too high.

60 //Fw Axes Error 312 [MaxSpeed

too small !]

Max speed or encoder resolution too low

61 //Fw Axes Error 313

[Acceleration too small or

MaxSpeed too high !]

Acceleration too small (mm/s²) or max speed too high. This

needs to be corrected. Please note that acceleration is not a

ramp distance.

62 //Fw Axes Error 314

[Acceleration too high or

MaxSpeed too small !]

Acceleration too high (mm/s²) or max speed too low. This needs

to be corrected.

63 //"Cutting length" analog input

not configured

While configuring (setting up) the CybTouch, dedicated input or

output are not configured but are requested to run properly.

64 //"Cutting length" encoder not

configured

While configuring (setting up) the CybTouch, dedicated input or

output are not configured but are requested to run properly.

65 //X axis is not configured

RTS is configured in machine parameters, while X axis is not

configured. X axis must be configured for RTS function to be

available.

PM_CybTouch6_ Shears_v2.0.doc page 51 of 55

Page 52

v2.0 Nov.12

66 //Fw Axes Error 33 [Maximum

voltage time exceeded (10V)]

This is a regulator error. The axis could not follow its trajectory.

May be due to higher friction, resistance or an obstacle on the

axis movement. May also be a drive problem.

The parameter P06b.10 Control time out is the maximum time

that the regulator is allowed to give the maximum voltage. In this

example, the parameter is set to 0.1 s. This means if the

regulator gives 10V for more than 0.1 sec, the CybTouch will

stop and display FW Axes Error 33.

This error means the axis cannot follow the trajectory

programmed in the machine parameters (acceleration and

speed). So the regulator gives 10V to try to make the axis

follow. Try to reduce the Positioning speed P06.04 and or

reduce the Acceleration P06b.03. To avoid excessive errors

program this parameter to 0.2 / 0.3 sec, or even 0.5 sec.

Tip: To adjust speed, we recommend you use the axis Wizard.

If the speed found by the Wizard is too high, it can safely be

reduced, but must never be programmed higher.

67 //Fw Axes Error 39 [Speed

tracking error]

This is a regulator error. The axis could not follow its trajectory.

May be due to higher friction, resistance or an obstacle on the

axis movement. May also be a drive problem.

The parameter P06b.09 Supervisor speed level monitors

whether the axis can follow the programmed speed. If the speed

is less or more than xx% of the P06.04 Positioning speed, the

CybTouch stops and displays FW Axes Error 39 .

This means the axis could not follow the programmed speed.

Try to adjust speed correctly (by reducing P06.04 Positioning

speed).

Usually this parameter can be set to 20%. It can be increased if

needed, but the correct way is to adjust the axis correctly and

reduce the speed.

Tip: To adjust the speed, we recommend you use the axis

Wizard. If the speed found by the Wizard is too high, it can safely

be reduced, but must never be programmed higher.

69 //The machine is not indexed!

No limit

Before the machine is indexed, the CybTouch doesn’t know

where the axes are.

In manual page, movements are authorized but the electronic

stroke limits are not activated. Operator is responsible for

stopping axis movement before mechanical limit is reached.

70 //Blade gap out of limit

When a movement is attempted, the blade gap is out is out of

machine limits. Check the Material page.

PM_CybTouch6_ Shears_v2.0.doc page 52 of 55

Page 53

v2.0 Nov.12

Error 115

Error 115 is a "parasite" problem. This error can occur if:

the frame of the CybTouch is not connected to the

ground.

the 0VDC_IO is not well connected.

the 0VDC_IO is wired in serial when it should be wired

in star.

See wiring recommendation in the technical manual:

This error may be also caused by spikes coming from

unprotected valves or if the 0V_analog is connected to the

0VDC_IO or CybTouch frame or machine ground.

PM_CybTouch6_ Shears_v2.0.doc page 53 of 55

Page 54

v2.0 Nov.12

APPENDIX 1 – USING REMOTE CONTROL

A remote control can be used by the technician to facilitate adjusting the up and down

movements of the blade, as well as the blade gap positive and negative movements.

This remote control is very useful as jobs that required two technicians (one beneath

the shear blade, and one near the electrical box) can now be performed by only one

technician, using the remote control directly linked to the electrical box:

Specific inputs are available for controlling the electrical box with the remote control:

Beam up,

Blade gap 1 select,

Blade gap 2 select,

Blade gap +,

Blade gap -.

Please refer to the P10 Digital Output Configuration section for more details.

PM_CybTouch6_ Shears_v2.0.doc page 54 of 55

Page 55

v2.0 Nov.12

Blade Gap 1 select

0 1 0

1

Blade Gap 2 select

0 0 1

1

No movement

Blade Gap 1

Blade Gap 2

Blade Gap 1+2

Wiring Recommendation for Remote Control

PM_CybTouch6_ Shears_v2.0.doc page 55 of 55

Loading...

Loading...