Cub Cadet Big Country User Manual

Table of Contents

Table of Contents

Introduction.........................................................................................Section 1.............................Page

1

2

Safety.......................................................................................................... 1-1.....................................1-1

Model and Serial Numbers..........................................................................1-2.....................................1-1

Fasteners....................................................................................................1-3.....................................1-2

Special Tools..............................................................................................1-4...................................... 1-2

Consumable Parts.......................................................................................1-5.....................................1-3

Lubrication Chart.........................................................................................1-6.....................................1-4

Clutch, Transmission, Brakes, Linkages......................................... Section 2.............................Page

Shift Linkage Description............................................................................ 2-1.....................................2-1

Shift Linkage Removal and Replacement...................................................2-2.....................................2-1

Shift Linkage Adjustment............................................................................ 2-3.....................................2-3

Differential Lock, Checking Operation of.................................................... 2-4.....................................2-4

Differential Lock, Linkage Removal and Replacement............................... 2-5.....................................2-4

Differential Lock, Cable Adjustment............................................................2-6.....................................2-6

Brake System Description.......................................................................... 2-7.....................................2-6

Brake Cable Removal and Replacement....................................................2-8.....................................2-7

Brake Cable Adjustment............................................................................. 2-9.....................................2-10

Clutch Pulley Brake and Shift Interlock Cable Removal............................. 2-10...................................2-12

3

3

4

5

6

7

Clutch Pulley Brake and Shift Interlock Adjustment....................................2-11................................... 2-13

Shift Interlock Arm Removal and Replacement.......................................... 2-12...................................2-15

Clutch Pulley Brake Arm Removal and Replacement.................................2-13.................................. 2-17

Belt Removal and Replacement..................................................................2-14...................................2-19

Driven Clutch Pulley Removal and Replacement....................................... 2-15...................................2-20

Driving Clutch Pulley Removal and Replacement...................................... 2-16...................................2-20

Transmission Removal and Replacement.................................................. 2-17...................................2-21

Internal Transmission Service.................................................................... 2-18...................................2-25

Torque Table............................................................................................... 2-19...................................2-34

Table of Contents

Table of Contents

Drive Axle Service................................................................. .Section 3.............................Page

Lift the Big Country and Remove the Drive Wheels........................3-1....................................3-1

Chain Lubrication........................................................................... 3-2.....................................3-2

Chain Retention............................................................................. 3-3.....................................3-2

Chain Tension Adjustment (Fixed Chain Guides).......................... 3-4.....................................3-4

Chain Guide Removal and Replacement....................................... 3-5.................................... 3-5

Chain Removal and Replacement..................................................3-6.....................................3-6

Chain Tensioner Removal (Roller Tensioners)...............................3-7.................................... 3-7

Spring and Shock Assembly Removal .......................................... 3-8.....................................3-11

Front Drive Axle Removal and Replacement................................. 3-9.....................................3-13

Front Drive Sprocket...................................................................... 3-10...................................3-16

Universal Joint Removal and Replacement................................... 3-11...................................3-17

Universal Joint Service...................................................................3-12...................................3-18

Rear Drive Axle Removal and Replacement..................................3-13...................................3-22

Rear Sprocket Removal and Replacement.................................... 3-14...................................3-23

Axle Bushing Removal and Replacement......................................3-15...................................3-23

Axle Bearing Removal and Replacement...................................... 3-16...................................3-25

Torque Table.................................................................................. 3-17...................................3-26

Engine and Transmission Support Assembly.....................Section 4............................. Page

Engine and Transmission Support Assembly:

Removal and Replacement as a Unit.............................................4-1.....................................4-1

Engine Removal and Replacement............................................... 4-2.....................................4-9

Isolator Mounts (Rear) Removal and Replacement........................4-3....................................4-12

Isolator Mounts (Front) Removal and Replacement........................4-4....................................4-13

Torque Table...................................................................................4-5.....................................4-14

Fuel System........................................................................... Section 5............................. Page

Precautions.................................................................................... 5-1.....................................5-1

About the Fuel System.................................................................. 5-2.....................................5-2

Fuel Tank Removal and Replacement........................................... 5-3.....................................5-3

Fuel Pump Performance................................................................ 5-4.....................................5-5

Fuel Pump Removal and Replacement..........................................5-5.................................... 5-6

Plenum and Air Filter..................................................................... 5-6.....................................5-7

Choke Cable Removal and Replacement...................................... 5-7.................................... 5-8

Choke Cable Adjustment............................................................... 5-8.....................................5-9

Throttle Cable Removal and Replacement.................................... 5-9.....................................5-10

Table of Contents

Table of Contents

Front Suspension................................................................................Section 6............................ Page

Lifting the Big Country and Removing the Front Wheels............................ 6-1.....................................6-1

Front Suspension and Steering Component Inspection............................. 6-2.....................................6-2

Checking and Adjusting Front Wheel Alignment.........................................6-3.....................................6-5

Steering Wheel Removal and Replacement............................................... 6-4.....................................6-8

Wheel Bearing Removal and Replacement................................................ 6-5.....................................6-8

Tie Rod End Removal and Replacement................................................... 6-6.....................................6-9

Spring and Shock Unit Removal and Replacement....................................6-7.....................................6-10

Steering Knuckle Removal and Replacement............................................ 6-8.....................................6-11

Front Axle Assembly Removal and Replacement...................................... 6-9.....................................6-13

Steering Rack Removal and Replacement................................................. 6-10...................................6-15

Torque Table............................................................................................... 6-11...................................6-18

Electrical............................................................................................. Section 7............................. Page

Component Location...................................................................................7-1.....................................7-1

1

2

3

3

4

Big Country Starter Circuit.......................................................................... 7-2.....................................7-4

Big Country Run Circuit...............................................................................7-3.....................................7-5

Big Country Accessory Circuit.....................................................................7-4.....................................7-6

Big Country Complete Schematic................................................................7-5.....................................7-7

5

6

7

Table of Contents

Blank Page

Section 1: Introduction

Section 1: Introduction

1

1. Safety

1.1. Before servicing the Big Country, technicians

should be familiar with the vehicle and the Operator’s Manual that applies to it. There are important instructions that pertain to safe and correct

operation and service of the Big Country contained in the Operator’s Manual

1.2. The procedures in the Service Manual

ten with the safety of the technician and operator

as a primary consideration. Failure to follow

these procedures may create a dangerous condition.

1.3. There is no substitute for common sense.

2. Model and Serial Numbers

2.1. The engine and transmission are components

that Cub Cadet has purchased from outside

sources and incorporated into the Big Country

utility vehicle. The Chassis, engine, and transmission each have separate model and serial

numbers.

2.2. To make parts identification easier, and to

accommodate warranty administration, the

chassis numbers should be recorded in the

Operator’s Manual as well as the sales receipt.

2.3. Chassis Identification: The model and serial

number of the Big Country are located on a tag

on the bottom of the plate that driver’s seat is

mounted to. Tilt the seat forward to view the tag.

See Figure 2.3.

.

are writ-

2.4. If the tag comes off, or if the seat plate is

removed, the servicing dealer can get a new tag

issued by calling Cub Cadet.

2.5. The servicing dealer must be able to identify a

Big Country by model and serial number in order

to perform warranty service on that unit.

2.6. Engine Identification: The engine serial number

is located behind the starter motor.

See Figure 2.6.

Starter Motor Locating Dowels

(starter removed for clarity)

Serial Number

Figure 2.6

2.7. The engine serial number is easily visible from

under the Big Country without removing any

parts. See Figure 2.7.

Figure 2.3

Engine Numbers

Oil Drain Valve

Figure 2.7

1 - 1

Section 1: Introduction

2.8. The engine family and specification numbers are

located on a tag on the rear cylinder shroud of

the engine.

2.9. The transmission identification number is

located on a flat surface adjacent to the dipstick.

See Figure 2.9.

Transmission Number

Figure 2.9

4. Special Tools

NOTE: We are not in the tool business. Where

special tools will make a specific job easier for

the technician, we offer them.

4.1. Shock and Spring Unit Removal and Installa-

tion Tool: Part Number 703-05103 is designed

to hook into the upper spring and shock

absorber mount on the drive axles.

See Figure 4.1.

Shock and Spring Unit Tool

Part Number 703-05103

3. Fasteners

3.1. A combination of metric and SAE fasteners are

used to assemble the Big Country. If a metric

tool size is specified in this manual, the fastener

will be metric. If fractional inch tool size is specified in this manual, the fastener will be SAE.

3.2. When servicing a Big Country it is important to

replace locking hardware when it is worn. Lock

washers should be replaced if they show any

sign of flattening. Nylon insert lock nuts and

center-lock nuts should be replaced when they

get easy to turn. The bolts used in conjunction

with center-lock nuts are also subject to wear.

They should be replaced if the thread profile is

noticeably worn. Any hardware that shows signs

of wear, stripping, or stretch should be replaced

in the course of normal service. If locking hardware is not readily available, thread locking

compound such as Loctite 242 (blue) should be

used.

3.3. All torque specifications will be given in inchpounds or foot-pounds, whichever scale is

appropriate for a particular fastener. This

includes metric fasteners.

Figure 4.1

4.2. Use the dowel to hold the spacers in position on

each side of the top mounting point of the spring

and shock absorber unit during the removal and

installation process. See Figure 4.2.

703-05103

Dowel Pin

Spacers

Mounting

Bolt

Figure 4.2

1 - 2

NOTE: A 3/8” by 1 3/8” steel dowel pin can be

made or purchased locally.

Section 1: Introduction

4.3. Universal Joint Spacer Tool: See Figure 4.3.

Universal Joint Spacer Tool

Part Number 703-05104

Figure 4.3

4.4. Part Number 703-05104 is used to set the correct clearance between the end of the axle

assembly and the end of the universal joint on

the drive axles. See Figure 4.4.

4.5. Two 1/4” by 4 1/2” long dowel pins are used to

lock the roller-type chain Tensioner in the

released position. The can be made or purchased locally. See Figure 4.5.

Dowel pins used to lock chain tensioners

in the released position

Side of Frame

Between Drive Axles

Figure 4.5

1

Figure 4.4

Universal Joint

Spacer Tool

In Position

5. Consumable Parts:

Component Part Number

Oil Filter 15400-POH-

305PE

Air Filter 751-3027

Drive Belt 754-0646

Battery (Shipped Dry) 925-1707E

1 - 3

Section 1: Introduction

5.9 qt.

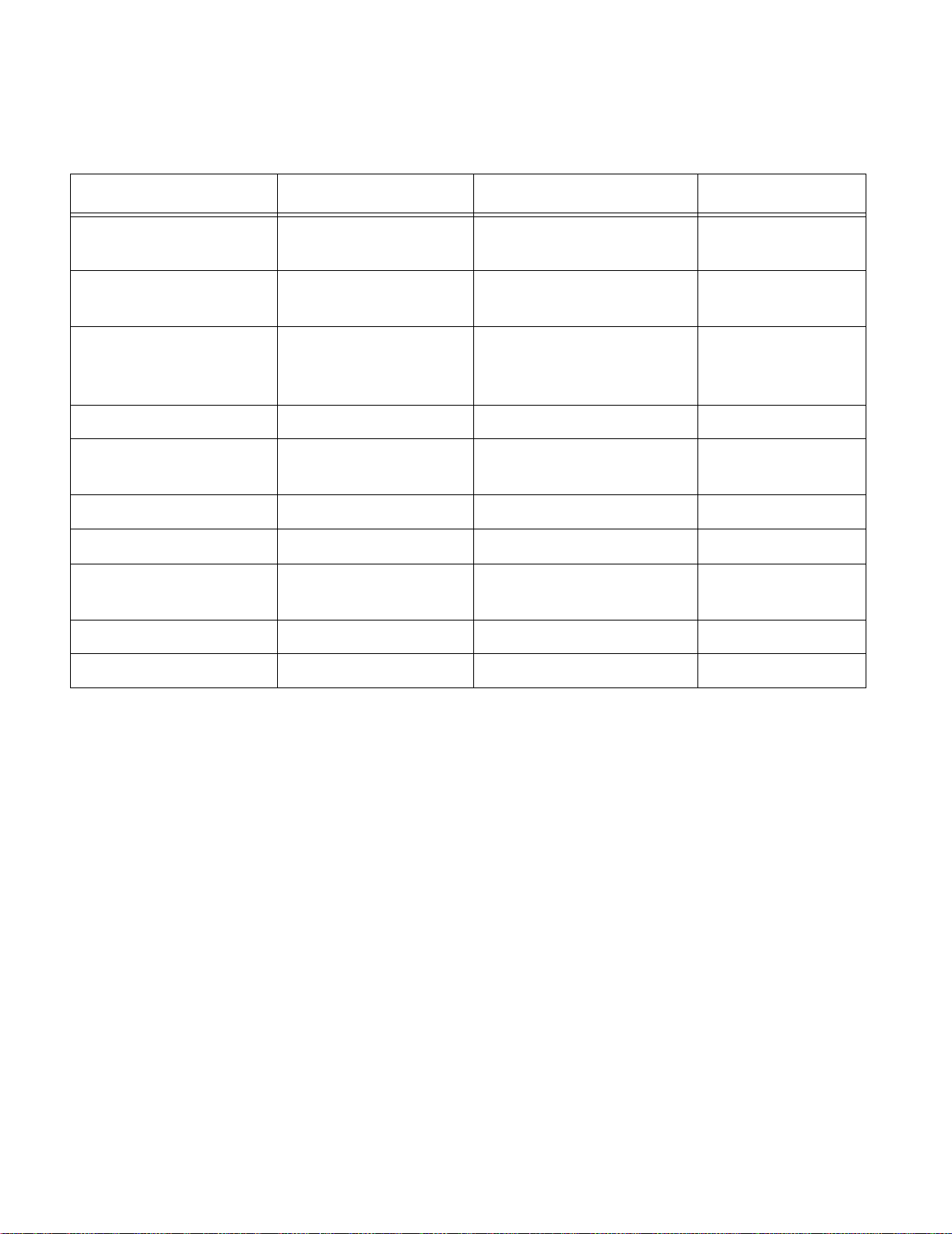

6. Lubrication Specifications.

Application Type Amount Part Number

Engine Oil

general use

Engine Oil

sub-freezing

Gear Lube Drive System Fluid

10W-30 API: SJ 1.16 qt.

1.48 qt. with / filter

5W-30 API: SJ 1.16 qt.

1.48 qt. with / filter

189 oz. 737-3120

737-3030A

Obtain Locally

Plus

Chain Lube Aerosol As Needed 737-3038

Chain Lube

Dusty Conditions

Dry Aerosol: PTFE or

Graphite Base

As Needed Obtain Locally

Penetrating Lube Spray As Needed 737-3037

Chassis Lube E.P. Chassis Lube As Needed 737-3034

Chassis Lube Alvania E.P. lead

As Needed 737-0168A

free ROO Grease

Chassis Lube Benalene 920 As Needed 737-0300

Anti-Sieze Compound As Needed Obtain Locally

1 - 4

Section 2: Clutch, Transmission, Brakes, Linkages

Section 2: Clutch, Transmission, Brakes, Linkages

1. Shift Linkage

NOTE: The shift linkage and brake linkage of the

Big Country are tied together by a shift interlock

mechanism that prevents the operator from

shifting gears while the vehicle is in motion. The

brake pedal must be depressed before the gearshift lever will move. The effect is the same

whether the brake is held down by the operator’s

foot or by the parking brake.

NOTE: A clutch pulley brake operates in unison

with the vehicle brakes inside the transmission.

The purpose of the clutch pulley brake is to

insure that the input shaft of the transmission is

not rotating when the operator shifts gears. This

prevents gear “crunch” on engagement, and

improves transmission life.

NOTE: The shift lever is the longer of the two

levers located between the seats. The shorter

lever is the differential lock. See Figure 1.0.

Reverse

Shift Lever

2. Shift Linkage Removal and Replacement

NOTE: If an operator has tried to shift gears

without using the brake or if the interlock

mechanism is out of adjustment, shift linkage

damage may occur.

2.1. Turn the engine off, remove the key, put the

transmission in neutral, and set the parking

brake.

2.2. Lift and secure the bed.

2.3. Fold both seats forward.

2.4. To reach the shift lever and the front of the shift

rod, remove the bolt that fastens the cup holder

between the seats using a 3/8” wrench.

See Figure 2.4.

Cup Holder (Bolt Removed)

Parcel Bin

2

Neutral

Differential Lock

Forward

Figure 1.0

NOTE: The shift lever has three positions to

select from. “Forward” is selected by pushing the

shift lever forward and down. “Reverse” is

selected by pulling the gearshift up and back.

“Neutral” is centered between “Forward” and

“Reverse”.

Figure 2.4

2.5. Remove the cup holder.

2.6. Remove the two bolts that fasten the parcel bin

into the recess beneath the passenger seat

using a 1/2” wrench.

2.7. Lift out the parcel bin and set it aside.

2- 1

Section 2: Clutch, Transmission, Brakes, Linkages

2.8. Inspect the shift interlock mechanism. If the

interlock mechanism does not work properly,

refer to the “Shift Interlock and Clutch Pulley

Brake Adjustment” section of this manual.

See Figure 2.8.

Interlock

Arm

I

Figure 2.8

2.10. To Remove the shift rod, remove the hairpin

clip and clevis pin that connect it to the transmission shift arm. See Figure 2.10.

Transmission Lever

Shift Rod

Clevis Pin

Hairpin Clip

Figure 2.10

2.11. To remove the shift lever, remove the red knob

from the end of the shift lever.

2.9. Remove the hairpin clip and flat washer that

secure the shift rod to the shift lever and disconnect the shift rod by pulling it out of the hole in

the lever. See Figure 2.9.

Shift Lever

Hairpin Clip

Shift Rod

Figure 2.9

NOTE: The knob and lever are threaded.

2.12. Remove the bolt that holds the pivot pin to the

frame. See Figure 2.12.

End of

Pivot Pin

Shift Lever

Shift Rod

Figure 2.12

2 - 2

Section 2: Clutch, Transmission, Brakes, Linkages

2.13. Withdraw the pivot pin. See Figure 2.13.

Pivot Pin

Figure 2.13

2.14. Remove the shift lever.

2.15. Reverse the removal procedures to install

the shift linkage components.

NOTE: Apply white lithium grease to all pivot

points on assembly.

NOTE: Check shift linkage adjustment before

returning the unit to service.

3. Shift Linkage Adjustment

3.1. Perform steps 1 through 7 of the “Shift Linkage

Removal” section of this manual.

3.2. Use a 9/16” wrench to loosen the jam nut that

locks the clevis on the end shift rod.

See Figure 3.2.

3.3. Remove the hairpin clip and clevis pin that connect the clevis to the transmission shift arm.

3.4. Rotate the clevis to thread it up or down the

length of the shift link. See Figure 3.4.

Transmission Lever

Clevis

Figure 3.4

3.5. Check the position of the hole in the transmission lever in relation to the hole in the clevis with

the transmission and shift lever in forward gear

and reverse gear.

NOTE: Forward and Reverse are at the two

extreme ends of the shift lever’s travel. If they

are both correct, neutral will be correct as well.

3.6. Connect the clevis to the transmission lever by

installing the clevis pin and hairpin clip.

3.7. Tighten the jam nut using a 9/16” wrench, locking the adjustment.

Jam Nut

Shift Rod

2

Clevis Pin

Clevis

Figure 3.2

Jam Nut

Shift rod

3.8. Test the function of the shift lever with the brake

pedal depressed.

NOTE: The lever should click firmly into each of

the three positions without hitting the end of its

travel.

NOTE: The travel of the shift lever should be

centered in the slot.

NOTE: If an extreme amount of adjustment is

necessary to center the gearshift lever, the linkage may be damaged.

2- 3

Section 2: Clutch, Transmission, Brakes, Linkages

NOTE: When the brake is released and a gear is

engaged, the pin that connects the clevis to the

transmission shift lever should be centered in a

slot in the interlock arm. If it is not, refer to the

“Shift Interlock and Clutch Brake Adjustment”

section of this manual.

NOTE: When the parking brake is set, the shift

lever should move between gears without catching or dragging against the interlock arm. If it

does not, refer to the “Shift Interlock Adjustment

and Clutch Brake Adjustment” section of this

manual.

4. Checking Operation of the Differential Lock Mechanism

4.1. Lift and safely support the drive wheels of the

Big Country according to the procedures listed in

the “Lifting the Big Country and Removing the

Drive Wheels” section of this manual.

NOTE: Operation of the differential lock mechanism may be tested by manually rotating the

drive wheels.

4.2. With the differential lock released both drive

wheels on eather side of the vehicle should spin

when either the front or rear drive wheel is

rotated by hand. The drive wheels on the other

side of the Big Country should remain stationary.

4.3. With the differential lock lever pulled-up roughly

half the length of the slot that it travels in, all four

wheels should rotate if any one wheel is turned

by hand.

4.4. The differential lock should engage within 90

degrees of front drive wheel rotation.

NOTE: Internal transmission damage, or collision damage may result if the differential lock

lever is not operated in accordance with the

instructions in the “Big Country Operator’s Manual”.

NOTE: It is normal for the steering abilities of

any six-wheeled vehicle to be greatly diminished

while the differential is locked.

NOTES

5. Differential Lock Linkage Removal and Replacement

5.1. To reach the differential lock cable, Perform

steps 1 through 7 of the “Shift Linkage Removal”

section of this manual.

5.2. To remove the cable, loosen the jam nuts that

hold the differential lock cable to the differential

lock bracket. See Figure 5.2.

Differential Lock Bracket

4.5. Once engaged, it will remain engaged even if

the lever is released, as long as there is a difference in the drive load between the left and right

sides of the vehicle.

NOTE: In service, differences in drive load

would result from greater traction on one side

than the other, attempting to turn the vehicle

while the differential lock is engaged, a dragging

brake on one side or the other, or grossly different air pressures in the tires from one side to the

other.

4.6. When the drive load is equalized from left to

right, the differential lock will automatically disengage if the lever has been released.

Jam Nuts

Differential Lock cable

Figure 5.2

NOTE: The differential lock bracket is located at

the right rear corner of the transmission, beneath

the air filter.

5.3. Pull the cable housing out of the bracket.

2 - 4

Section 2: Clutch, Transmission, Brakes, Linkages

5.4. Pivot the cable in the differential lock arm so that

the cable aligns with the slot in the arm. This will

allow the barrel at the end of the cable to be

remove from the arm. See Figure 5.4.

Slot

Differential Lock Arm

Figure 5.4

5.5. Trace the cable forward to the bracket on the

frame. See Figure 5.5.

5.8. Unhook the spring at the end of the cable from

the differential lock lever. See Figure 5.8.

Differential Lock Lever

2

Differential Lock Cable

Figure 5.8

5.9. To remove the differential lock lever, first

remove the cable.

5.10. Release the return spring that runs between the

differential lock lever and the frame.

See Figure 5.10.

Jam Nuts

Front Bracket

Differential Lock Cable

Figure 5.5

5.6. Loosen the jam nuts that hold the cable in the

bracket.

5.7. Slip the cable out of the bracket.

Return Spring

Differential Lock Lever

Figure 5.10

NOTE: This spring is most easily reached from

beneath the driver’s seat.

5.11. Remove the black knob from the end of the differential lock lever. It is threaded onto the lever.

5.12. Remove the bolt that holds the pivot pin into the

frame using a ½” wrench.

2- 5

Section 2: Clutch, Transmission, Brakes, Linkages

5.13. Withdraw the pivot pin far enough to clear the

differential lock lever, and remove the lever. See

Figure 5.13.

Partially Removed

Pivot Pin

Bolt Hole

Figure 5.13

5.14. Reverse the removal procedure to install the

differential lock lever.

5.15. Use the following procedure to install the differential lock cable.

5.16. Thread the first jam nut on the front (spring) end

of the cable housing all the way to the shoulder

of the threaded end.

5.19. Tighten the second jam nut against the bracket

to secure the cable.

5.20. Insert the barrel on the end of the cable through

the hole in the differential lock arm by aligning

the cable with the slot in the arm.

5.21. Thread the first jam nut on the back (barrel) end

of the cable housing all the way to the shoulder

of the threads.

5.22. Position the cable housing in the bracket

mounted to the transmission.

5.23. Thread the second jam nut up against the

bracket to secure the cable.

5.24. Check cable adjustment after replacement.

NOTES

6. Differential Lock Cable Adjustment

6.1. To reach the differential lock cable, Perform

steps 1 through 7 of the “Shift Linkage Removal”

section of this manual.

6.2. Operate the differential lock lever and observe

the motion of the cable and differential lock arm

on the transmission. See Figure 6.2.

5.17. Hook the spring onto the differential lock lever.

5.18. Position the cable housing in the bracket

attached to the frame. See Figure 5.18.

Figure 5.18

Engage

Differential Lock Lever

Figure 6.2

NOTE: To achieve full engagement, it may be

necessary to rotate the transmission clutch pulley until the differential lock pins align with their

holes within the differential. At this point, additional movement of the differential lock lever will

be noticeable.

2 - 6

Section 2: Clutch, Transmission, Brakes, Linkages

6.3. When the differential lock lever is released, there

should be slight slack in the cable.

6.4. When fully engaged, the differential lock arm

should move up at least 3/4” as measured along

the cable. See Figure 6.4.

NOTE: The differential lock bracket is located at

the right rear corner of the transmission, beneath

the air filter.

Differential Lock Bracket

Differential Lock Arm

3/4” to engagement

7. Brake System Description

7.1. There are two multi-disc wet brakes inside the

transmission. One brake assembly works on the

left out-put shaft, the other works on the right

out-put shaft.

7.2. The brakes are actuated by two heavy cables

that connect to the brake pedal.

7.3. A third cable connects to the brake pedal. The

third cable is used to operate the clutch pulley

brake and the shift interlock mechanism.

7.4. If the brakes are out of adjustment, the travel of

the cable that operates the clutch pulley brake

and shift interlock will be effected as well.

NOTES

8. Brake Cable Removal and Replacement

2

Figure 6.4

6.5. Loosen the jam nuts that hold the differential

lock cable to the differential lock bracket.

6.6. Trace the cable to the bracket that is mounted to

the frame.

NOTE: At both brackets, the inner jam nut

should be all the way up against the shoulder of

the threaded cable end.

NOTE: The differential lock lever is able to apply

more movement to the cable than is necessary

to engage the differential lock. Looseness of the

cable will seldom be an issue.

6.7. If there is an issue with differential lock engagement or disengagement, inspect the cable, lever,

and differential lock arm on the transmission for

freedom of movement and correct mounting.

6.8. Lubricate or repair them as necessary. See “Differential Lock Linkage Removal and Replacement” section of this manual for linkage service

instructions.

NOTE: If adjustment and repair of the linkage

does not make the differential lock function properly, an internal transmission problem exists.

6.9. Install the cup holder and parcel bin by reversing

the removal procedure.

8.1. Remove cup holder and parcel bin according to

steps one through seven of the “Shift Linkage

Removal” section of this manual.

8.2. Remove the two bolts that hold the hood closed.

8.3. Open the hood.

8.4. Release the brake return spring by unhooking

the rear of the spring from the frame.

See Figure 8.4.

Brake cable

Cam Arm

Brake Return Spring

Frame

Figure 8.4

2- 7

Section 2: Clutch, Transmission, Brakes, Linkages

8.5. Remove the jam nut from the end of the brake

cable core using a deep ½” socket on an extension. See Figure 8.5.

(Grip here if necessary.)

Cable Core

Cable Housing

Large Jam Nuts

NOTE: Use a pair of slip joint pliers to hold the

cable, if necessary.

8.6. Loosen the large jam nuts that secure the cable

housing to the bracket on the frame using a pair

of 7/8” wrenches.

NOTE: The large jam nut to the rear of the

bracket is easily accessible from below.

Jam Nut

(Recessed in Cam Arm)

Figure 8.5

8.9. Slip the cable core through the slot in the

bracket.

8.10. Working from the front of the Big Country,

remove the hairpin clip and clevis pin that connect the brake cable clevises to the brake pedal.

See Figure 8.10.

Brake Pedal

Hairpin Clip

Clevis Pin

Clevis

(Right Brake Cable)

Clevis

(Interlock and

Clutch Brake Cable)

Figure 8.10

8.11. Slip the rubber boot off the end of the cable

housing, and remove the large jam nut that is

above the bracket using two 7/8” wrenches.

See Figure 8.11.

Clevis

(Left Brake Cable)

8.7. Slip the rubber boot off the end of the cable

housing and remove the large jam nut nearest

the end of the cable housing.

8.8. Pull the cable forward far enough for the cable

housing to clear the bracket. See Figure 8.8.

Bracket

Rubber Boot

Figure 8.8

Bracket

Figure 8.11

8.12. Pull the cable down far enough for the cable

housing to clear the bracket. The cable core will

fit through the slot in the bracket.

8.13. To install a new brake cable, position the jam

nut on the replacement cable ¼” from the end of

the threads.

2 - 8

Section 2: Clutch, Transmission, Brakes, Linkages

8.14. Slip the threaded end of the replacement cable

into the yoke of the cable to be replaced. The nut

should fit into the throat of the yoke, locking the

two cables together. See Figure 8.14.

Clevis End of Old Cable

Threaded End of New Cable

Figure 8.14

8.15. Wrap the joint in duct tape.

8.16. Pull the old cable out through the engine compartment, fishing the replacement cable through

the channel beneath the floor in the process.

See Figure 8.16.

8.18. Slip the boot off the end of the cable housing

and remove the large jam nut. See Figure 8.18.

2

Figure 8.18

8.19. Position the remaining jam nut on the new cable

housing about 1” from the end of the housing.

8.20. Install the jam nut on the cable about ¼” from

the shoulder of the threaded end.

8.21. Slip the cable core through the slot in the

bracket, and draw the end of the cable housing

into the bracket.

New Cable

Old cable

Figure 8.16

8.17. Unwrap the joint between the two cables, and

remove the old cable.

8.22. Start the large jam nut onto the threads on the

cable housing, and thread it up to the bracket.

8.23. Tighten both jam nuts using a pair of 7/8”

wrenches.

8.24. Insert the cable end through the pivot pin on the

brake cam lever. See Figure 8.18.

Pivot Pin

Figure 8.24

2- 9

Section 2: Clutch, Transmission, Brakes, Linkages

8.25. Working at the front of the Big Country, thread

the first jam nut all the way up the cable housing

end until it stops against the shoulder.

See Figure 8.25.

First Jam Nut

(Thread to Shoulder)

Rubber Boot

Figure 8.25

8.26. Slip the cable core through the slot in the

bracket, and draw the end of the cable housing

into the bracket.

8.27. Slip the rubber boot back onto the end of the

cable housing.

8.30. Apply a small amount of white E.P. chassis lube

grease to the clevis pin, and install it through the

brake pedal, the clevises of all three cables.

8.31. Secure the clevis pin with a hairpin clip.

8.32. Follow steps number five through number eight

of the “Brake Cable Adjustment” procedure, to

set the two jam nuts on the cable end.

NOTES

9. Brake Cable Adjustment

9.1. Safely lift and support the Big Country. Refer the

the “Lifting the Big Country and Removing the

Drive Wheels” section of this manual.

NOTE: It is not necessary to loosen the lug bolts

or remove the wheels.

9.2. Lift and secure the bed.

9.3. Release the brake return spring by unhooking

the rear of the spring from the frame.

See Figure 9.3.

8.28. Start the second large jam nut onto the threads

on the cable housing, and tighten against the

bracket.

8.29. Tighten both large jam nuts against the bracket

using a pair of 7/8” wrenches. See Figure 8.29.

Jam Nuts

Tightened

Figure 8.29

Brake Cable

Cam Arm

Figure 9.3

9.4. Loosen the jam nut at the cam arm end of the

brake cable core using a deep ½” socket on an

extension.

NOTE: Use a pair of slip joint pliers to hold the

cable, if necessary.

9.5. Thread the jam nut that is immediately forward

of the cam arm all the way forward, to the shoulder of the threaded cable core end.

Brake Return Spring

2 - 10

Section 2: Clutch, Transmission, Brakes, Linkages

9.6. Pull the threaded end of the cable core as far out

(back) as possible, while pushing the brake cam

arm forward until resistance is felt.

See Figure 9.6.

Pull Cam Arm

Pull Cable

Figure 9.6

NOTE: The resistance indicates the point where

the brakes are applied.

9.7. Adjust the jam nut nearest the shoulder of the

cable end one turn beyond the point where it

contacts the pivot pin with the cable taught and

the brake cam arm in the applied position.

9.12. Check the parking brake latch for correct operation. See Figure 9.12.

Parking Brake Switch

Parking Brake Latch

(Engaged)

Upper Notch

Lower Notch

Figure 9.12

NOTE: The latch mechanism is visible beneath

the dashboard.

NOTE: There are two notches in the parking

brake latch. The tab on the pedal should engage

the upper notch.

9.13. Check the parking brake switch for correct actuation. See Figure 9.13.

Brake Pedal

2

NOTE: If there is insufficient thread length to do

this, use the large jam nuts on the end of the

cable housing to make a coarse adjustment,

bringing the cable into range to make a fine

adjustment at the cable end.

9.8. Tighten the second jam nut up against the back

side of the pivot pin.

9.9. Hook the rear end of the brake return spring

back onto the frame.

9.10. Repeat the adjustment procedure on the second

brake cable.

9.11. Make a preliminary check of the brakes:

• Rotate the drive wheels by hand with the brakes

released. There should be no brake drag.

• Set the parking brake and attempt to rotate the

drive wheels again. They should not move.

Parking Brake Rod

Tab on Parking

Brake Latch

Adjustment Slot

in Switch Bracket

Figure 9.13

9.14. With the parking brake set, loosen the screws

that hold the parking brake switch to its bracket

using a phillips head screwdriver and an 11/32”

wrench.

2- 11

Section 2: Clutch, Transmission, Brakes, Linkages

9.15. Slide the switch forward until the plunger on the

switch makes an audible “click”, indicating the

closure of the contacts within the switch.

NOTE: The plunger need not be fully depressed.

9.16. Secure the switch in this position by tightening

the screws that hold it to the bracket.

9.17. Perform the “Clutch Pulley Brake and Shift Interlock Adjustment” section of this manual.

10. Clutch Pulley Brake and Shift Interlock Cable Removal and Replacement

NOTE: The ferrule is threaded onto the end of

the cable housing.

10.3. Push the ferrule down to release it from the lockout arm.

10.4. Disconnect the spring at the end of the cable

from the clutch pulley brake arm.

See Figure 10.4.

10.1. Remove the belt guard. Refer to the “Belt

Removal and Replacement” section of this manual. See Figure 10.1.

Clutch Pulley Brake Arm

Driven Clutch Pulley

Figure 10.1

10.2. Remove the hairpin clip and flat washer that hold

the ferrule to the interlock arm. See Figure 10.2.

Spring

(end of Cable)

Figure 10.4

10.5. Remove the two bolts that hold the hood closed

using a 1/2” wrench, and open the hood.

10.6. Remove the hairpin clip and clevis pin that hold

the brake cable yokes to the brake pedal.

See Figure 10.6.

Clevis Pin

Brake Pedal

Ferrule

Figure 10.2

Interlock Arm

Cable

(operates clutch

pulley brake and shift

interlock arm)

Hairpin

Clip

Shift Interlock

and Clutch Pulley

Brake Cable

Brake Cables

Figure 10.6

2 - 12

Section 2: Clutch, Transmission, Brakes, Linkages

10.7. Loosen the jam nuts that hold the clutch pulley

brake and shift interlock cable to the bracket

using a pair of 1/2” wrenches.

NOTE: A crowfoot socket may be helpful.

10.8. Slip the cable out of the bracket, and pull the

yoke on the end of the cable down through the

gap between the bracket and the frame.

10.9. To install the new cable, hook the spring on the

end of the replacement cable through the yoke

on the end of the cable being removed.

See Figure 10.9.

New Cable

Old Cable

10.17. Secure the pin with a hairpin clip.

10.18. Close the hood, and install the two bolts, rubber

washers, and flat washers that secure it using a

1/2” wrench.

10.19. Route the spring end of the cable under the

bracket that supports the shift lock-out arm and

the clutch pulley brake arm. See Figure 10.19.

2

Spring

Cable (routed under

bracket)

Figure 10.19

Figure 10.9

10.10. Secure the two cables together with a wrap of

duct tape.

10.11. Withdraw the old cable from the engine compartment, fishing the new cable into position in the

process.

NOTE: If the old cable is broken, the new cable

can be pushed through the channel beneath the

floor of the Big Country.

10.12. Remove the duct tape, and disconnect the two

cables.

10.13. Working at the front of the vehicle, thread the

first jam nut on the end of the cable housing all

the way up against the shoulder of the cable

housing end.

10.14. Slip the clevis up through the bracket and position the cable end in the bracket.

10.15. Tighten the jam nuts using a pair of ½”

wrenches.

10.16. Connect the yokes of the three cables to the

brake pedal by installing the long clevis pin.

10.20. Hook the spring onto the clutch pulley brake

arm.

10.21. Install the pin of the ferrule through the hole in

the shift lock-out arm, and secure it with a flat

washer and hairpin clip.

10.22. Perform the steps detailed in the “Clutch Pulley

Brake and Shift Interlock Adjustment” section of

this manual.

11. Clutch Pulley Brake and Shift Interlock Adjustment

11.1. If the parking brake is set, release it.

11.2. Remove the belt guard using the procedure

described in the “Belt Removal and Replacement” section of this manual.

11.3. Remove the hairpin clip and flat washer that

secure the ferrule on the threaded end of the

cable to the shift lock-out arm and disconnect

the ferrule from the arm.

11.4. While the cable is disconnected from the shift

lock-out arm, make sure that the arm and the

clutch pulley brake arm move freely.

2- 13

Section 2: Clutch, Transmission, Brakes, Linkages

11.5. If either arm binds or exhibits excessive play,

i n s p e c t t h e b u s h i n g s t h a t t h e a r m p i v o t s o n .

See Figure 11.5.

Ferrule

Stop Bolt

Clutch Pulley Brake Arm

Driven Clutch Pulley

Figure 11.5

11.6. Measure the gap between the closest point of

the pad to the pulley.

NOTE: Because the tension springs that apply

and return the clutch pulley brake arm are

mounted to the bottom of the arm the closest

point between the pad and the clutch pulley is

likely to be at the bottom edge of the pad.

11.7. Adjust the travel stop bolt using a 7/16” wrench

to loosen the jam nut and a 3/8” wrench to turn

the bolt. See Figure 11.7.

Adjust Here

Interlock Arm

11.9. Tighten the jam nut to lock the adjustment.

11.10. Loosen the jam nuts on either side of the ferrule

using a pair of 1/2” wrenches.

11.11. Thread the ferrule up or down the threaded end

of the cable housing to reach a point where the

pin on the ferrule slips easily through the hole in

the clutch pulley brake arm.

NOTE: The cable should be taught, but the

spring that connects the cable to the brake arm

should not be under enough tension to bring the

driven clutch pulley brake pad into contact with

the pulley when the ferrule is installed.

11.12. Secure the ferrule to the brake arm using a hairpin clip and flat washer.

11.13. Tighten the jam nuts against both sides of the

ferrule using a pair of ½” wrenches.

11.14. Operate the brake pedal and shift lever to insure

that they work correctly.

NOTE: If difficulty is encountered engaging

either gear while the parking brake is set, the

cable needs to be tightened slightly.

11.15. Install the belt guard using two 1/2” wrenches.

11.16. Lower, and secure the bed.

11.17. Lower the Big

11.18. country to the ground

11.19. Test drive the vehicle to check the following

functions:

• Effectiveness of parking brake on a 15 degree

grade. See Figure 11.19.

Measure Here

(1/8” - 3/16”)

Figure 11.7

11.8. Loosen the jam nut, adjust the bolt so that there

is 1/8” of clearance between the brake pad and

the clutch pulley,

Figure 11.19

2 - 14

Section 2: Clutch, Transmission, Brakes, Linkages

• Equal and effective application of both sets of

brakes (left and right).

• Complete engagement of shift lock-out mechanism when the brakes are released.

• Complete disengagement of shift lock-out mechanism when brakes are applied.

• Complete engagement of clutch pulley brake

when brakes are applied, and complete release

when the brakes are released.

NOTE: If the transmission clashes on engagement of forward or reverse, the clutch pulley

brake and shift interlock cable needs to be tightened slightly.

NOTE: If the brake pad drags on the clutch pulley with the brake pedal released, the clutch pulley and shift interlock cable needs to be

loosened slightly.

11.20. Install the plenum by reversing the steps used to

remove it.

NOTES

12.4. Remove the two bolts that fasten the plenum to

the frame using a pair of 9/16” wrenches.

12.5. Lift the plenum straight up, and remove it.

See Figure 12.5.

2

Figure 12.5

NOTE: There are two rubber washers that fit

between the plenum and the frame.

12. Shift Interlock Arm Removal and Replacement

NOTE: If the shift lock-out arm is being removed

in conjunction with other service to the brakes

and related linkages, the plenum removal

instructions may be redundant.

12.1. Lift and secure the bed.

12.2. Fold both seats forward.

12.6. Remove the hairpin clip and flat washer that hold

the ferrule into the lockout arm.

12.7. Push the ferrule down to release it from the lockout arm. See Figure 12.7.

Interlock Arm

Ferrule

Shift Rod

Clevis Pin

12.8. Remove the hairpin clip, flat washer, and clevis

pin that connect the clevis on the shift rod to the

shift arm on the transmission.

Clevis

Figure 12.7

12.3. Loosen the hose clamp at the plenum end of the

hose that connects the plenum to the air filter.

2- 15

Section 2: Clutch, Transmission, Brakes, Linkages

12.9. Remove the nut from the shoulder bolt that the

lock-out arm pivots on using a 9/16” wrench and

a ¾” wrench. See Figure 12.9.

Figure 12.9

12.10. Lift-up and pivot the arm to release the spring

that maintains tension between the lock-out arm

and the clutch pulley brake arm.

12.15. Hook the spring through the hole in the interlock

arm, and stretch the spring to allow the shoulder

bolt to reach the slot in the bracket.

See Figure 12.15.

Hook-up spring

Figure 12.15

NOTE: The end of the spring that hooks inward

connects to the lock-out arm.

12.11. Remove the interlock arm from the vehicle.

12.12. Inspect the arm and replace the bushings. See

Figure 12.12.

Shoulder Bolt

Heavy Flat Washer

Bushings

Bellville Washer

Center-locking Nut

Figure 12.12

12.13. Lubricate the shoulder bolt with dry PTFE-based

lubricant and insert it through the heavy flat

washer, the arm and the bushings.

12.14. Position the bellville washer over the slot in the

bracket that the lock-out arm mounts to.

12.16. Insert the shoulder bolt through the belleville

washer and the bracket, securing it with the center lock flange nut.

12.17. Install the clevis pin through the transmission

shift arm.

12.18. Position the lockout arm so that the clevis pin

that connects the shift link to the shift arm is centered in the appropriate notch in each of the

three positions. See Figure 12.18.

Transmission Shift Arm

Clevis Pin

Reverse

Neutral

Test Fit:

Pin Centered in notch

Figure 12.18

Forward

2 - 16

Section 2: Clutch, Transmission, Brakes, Linkages

NOTE: The mounting hole is slotted to allow

adjustment.

NOTE: If the lock-out link forces the shift arm to

one side or the other it will apply a constant load

to the shift collar inside the transmission, reducing service life.

NOTE: If the lock-out link is disabled it is possible to shift from one motion gear to the opposite

while the Big Country is in motion. This will

cause immediate and severe damage to the

transmission. Repair of damage caused by an

intentionally disabled interlock is not warrantable.

12.19. Lock the shoulder bolt in place by tightening the

nut. Use a 9/16” wrench and a ¾” wrench.

13. Clutch Pulley Brake Arm Removal and Replacement

13.1. Remove the belt guard using the procedure

described in the “Belt Removal” section of this

manual.

13.2. Remove the hairpin clip and flat washer that hold

the ferrule on the clutch pulley brake and shift

interlock cable into the interlock arm.

2

13.3. Push the ferrule down to release it from the lockout arm.

13.4. Unhook the spring that connects the clutch pulley brake arm to the cable.

13.5. Remove the hairpin clip, flat washer, and clevis

pin that connect the clevis on the shift rod to the

transmission lever. See Figure 13.5.

12.20. Insert the clevis pin through the clevis on the end

of the shift rod, and through the shift arm.

12.21. Secure the clevis pin with a hairpin clip and flat

washer.

12.22. Insert the pin of the ferrule (threaded onto the

cable end) through the hole in the interlock arm

and secure it with a flat washer and hairpin clip.

12.23. Install the plenum by reversing the steps used to

remove it.

NOTES

Spacer

Shift Rod Clevis

Interlock

Arm

Figure 13.5

NOTE: This will relieve tension on the return

spring that connects the lock-out arm with the

clutch pulley brake arm.

13.6. Remove the nut, bolt, flat washer and spacer

that hold the top to the interlock bracket to the

transmission using two 9/16” wrenches.

Interlock Bracket

Ferrule

13.7. Remove the nut and bolt that hold the bottom of

the interlock bracket to the transmission using

two 9/16” wrenches.

13.8. Maneuver the interlock assembly out from

between the transmission and the frame crossmember, and remove it from the Big Country.

2- 17

Section 2: Clutch, Transmission, Brakes, Linkages

13.9. On the bench, remove the nut from the shoulder

bolt that the clutch pulley brake arm pivots on

using a 9/16” wrench and a ¾” wrench.

See Figure 13.9.

Brake Arm

Shoulder Bolt

Figure 13.9

13.10. Pull the brake arm off of the interlock bracket,

and unhook the spring that connects it to the

interlock arm

13.11. Pry the bushings out of the hole that the shoulder bolt passes through. See Figure 13.11.

13.13. To install the clutch pulley brake arm, hook

the return spring through the hole in the interlock

arm, and position the brake arm on the bracket.

NOTE: The end of the spring that hooks outward

connects to the clutch pulley brake arm.

13.14. lubricate the shoulder of the bolt with dry PTFE

or graphite based lubricant and insert it through

the heavy flat washer, the arm and the bushings.

13.15. Install the nut on the shoulder bolt.

13.16. Position the interlock assembly in the Big Country and secure it with the lower nut and bolt,

installed finger tight.

13.17. Install the spacer, bolt, washer, and nut in the

upper mounting holes in the bracket and transmission.

13.18. Install the clevis pin through the yoke on the shift

link and the transmission shift arm and secure it

with a flat washer and hairpin clip.

13.19. Insert the pin on the ferrule through the hole in

the lock-out link and secure it with a flat washer

and a hairpin clip.

13.20. Check the adjustment and operation of the

clutch pulley brake and shift interlock. Refer to

the “Shift Interlock and Clutch Pulley Brake

Adjustment” section of this manual.

Bushings

Figure 13.11

13.12. Inspect the arm and bracket, and replace the

bushings.

13.21. Install the belt guard and plenum by reversing

the steps used to remove them.

NOTES

2 - 18

Section 2: Clutch, Transmission, Brakes, Linkages

14. Belt Removal and Replacement

14.1. The Belt should be checked for wear every 40

hours.

This is a visual inspection, and does not

necessarily involve belt removal.

NOTE: The belt is the primary wear item in the

drive system. If drive system performance

begins to degrade, inspect or replace the belt.

NOTE: The driving clutch should engage the

belt at 2,100 R.P.M. Check the engagement

speed before and after changing the belt. If

engagement speed is high before changing the

belt, but remains high with the new belt, there

may be an issue with the driving clutch.

NOTE: If drive system operation seems labored,

or if the belt wears prematurely, insure that the

brakes are not dragging.

14.2. To remove the belt, remove the belt guard

using the following procedure:

• Lift and secure the bed.

• Fold both seats forward.

• Loosen the hose clamp at the plenum end of the

hose that connects the plenum to the air filter.

• Remove the two bolts that fasten the plenum to

the frame using a pair of 9/16” wrenches.

• Lift the plenum straight up, and remove it.

14.4. Roll the belt off of the driven clutch pulley.

See Figure 14.4.

2

Driving Clutch Pulley

Driven Clutch Pulley

Figure 14.4

14.5. Turn the belt in-side-out.

NOTE: Clearance between the driving clutch

pulley and the frame may be extremely tight.

Turning the belt inside-out will help avoid scarring the belt during removal and installation.

14.6. Roll the belt off of the driving clutch pulley.

See Figure 14.6.

NOTE: There are rubber flat washers between

the plenum and the frame.

• Disconnect the barbed cable tie from the belt

guard.

• Remove the two horizontal bolts that hold the

belt guard to the frame using a ½” wrench.

• Remove the nuts from the bottom of the two vertical bolts that hold the belt guard to the frame,

using a pair of ½” wrenches.

• Lift the belt guard straight up and removed it.

14.3. Remove the clutch pulley brake arm according

to the instruction in the “Removal and Installation

of the Clutch Pulley Brake Arm” section of this

manual.

Engine Support

Frame

Figure 14.6

14.7. Inspect the clutch pulleys for signs of wear or

damage.

14.8. Reverse the removal procedure to install the

belt.

Driving Clutch

2- 19

Section 2: Clutch, Transmission, Brakes, Linkages

15. Driven Clutch Pulley Removal and Replacement

15.1. Set the parking brake

15.2. Place the shift lever in forward gear.

15.3. Loosen the bolt that secures the driven clutch

pulley to the input shaft of the transmission using

a 17 mm wrench.

15.4. Remove the drive belt from the driven clutch pulley as described in the “Drive Belt Removal and

Replacement” section of this manual.

See Figure 15.4.

NOTES

16. Driving Clutch Pulley Removal and Replacement

16.1. If equipped with fixed chain guides, remove the

upper chain guide using a 9/16” wrench as

described in the “Chain Tension Adjustment”

section of this manual.

16.2. If equipped with rotary chain tensioners,

retract the tensioner and lock it into position with

a pin, as described in the “Rotary Chain Tensioner” section of this manual.

Bolt (loosened)

Figure 15.4

15.5. Completely remove the bolt and flat washer that

secure the driven clutch pulley to the input shaft

of the transmission.

15.6. Slip the pulley off of the shaft.

15.7. To install the driven clutch pulley, reverse the

removal procedure.

NOTE: Apply a small amount of anti-seize compound to the splines that drive of the driven

clutch pulley prior to installing it on the Big Country.

NOTE: Apply Loctite 242 or an equivalent

thread locking compound to the threads of the

bolt that holds the pulley to the input shaft.

NOTE: Torque the bolt to 35-40 ft-lb.

Driven Clutch Pulley

(belt removed)

16.3. Remove the belt as described in the “Belt

Removal and Replacement” section of this manual.

16.4. Lock the driven clutch into position using a pry

bar between the head of one of the bolts that

holds the cover on the clutch and the washer

under the head of the bolt that holds the clutch to

the crankshaft. See Figure 16.4.

9/16” wrench

Pry Bar

Figure 16.4

16.5. Remove the bolt that holds the clutch to the

crankshaft using a 9/16” wrench.

2 - 20

Section 2: Clutch, Transmission, Brakes, Linkages

16.6. Slip the clutch off the end of the crankshaft. See

Figure 16.6.

Figure 16.6

NOTE: It will be necessary to partially remove

the key that rides between the clutch and the

crankshaft as the clutch is removed.

16.7. To install the driving clutch pulley on the Big

Country, reverse the removal procedure.

NOTE: Apply a small amount of anti-seize compound to the bore of the driving clutch pulley

prior to installing it on the Big Country.

NOTE: Apply Loctite 242 or an equivalent

thread locking compound to the bolt that holds

the pulley to the crankshaft.

NOTE: Torque the bolt to 20-30 ft-lb.

NOTES

17. Transmission Removal and Replacement

17.1. Remove the two bolts, flat washers, and rubber

washers that secure the hood using a 9/16”

wrench.

17.2. Disconnect the negative battery cable using a

7/16” wrench. See Figure 17.2.

2

Negative Battery Cable

Figure 17.2

17.3. Remove the driven clutch pulley as described in

the “Driven Clutch Pulley Removal and Replacement” section of this manual.

17.4. Lift the Big Country and remove the wheels as

described in the “Lifting the Big Country and

Removing the Wheels” section of this manual.

17.5. Position a drain pan (minimum capacity: one gallon) under the transmission drain plug.

See Figure 17.5.

2- 21

Transmission Drain Plug

Figure 17.5

Loading...

Loading...