Craftsman 247.77636 User Manual

Operator’s Manual

®

7.5 Horse Power

CHIPPER SHREDDER

Model No. 247.776360

CAUTION: Before using this product, read this manual and follow all safety rules and operating instructions.

•SAFETY

•ASSEMBLY

•OPERATION

•MAINTENANCE

•PARTS LIST

Sears, Roebuck and Co., Hoffman Estates, IL 60179, U.S.A.

Visit our web site: www.sears.com/craftsman |

FORM NO. 769-02543 |

|

05/24/2006 |

TABLE OF CONTENTS

Warranty Statement.................................. |

Page 2 |

Off-Season Storage.................................. |

Page 12 |

Safe Operation Practices.......................... |

Pages 3-4 |

Trouble Shooting....................................... |

Page 13 |

Assembly................................................... |

Page 6 |

Parts List................................................... |

Page 14-16 |

Operation................................................... |

Pages 7-9 |

Español...................................................... |

Page 17 |

Maintenance.............................................. |

Pages 10-11 |

Service Numbers....................................... |

Back Cover |

WARRANTY STATEMENT

One -Year Warranty on Craftsman Chipper Shredder

For one year from the date of purchase, when this Craftsman Chipper Shredder is maintained, lubricated and tuned up according to the instructions in the owner’s manual, Sears will repair, free of charge, any defect in material and workmanship. If this Craftsman chipper shredder is used for commercial or rental purposes, this warranty applies for only 30 days from the date of purchase.

This warranty does not cover:

•Expendable items which become worn during normal use, such as spark plug, blades and air cleaner.

•Repairs necessary because of operator abuse or negligence, including bent crankshafts and the failure to maintain the equipment according to the instructions contained in the owner’s manual.

WARRANTY SERVICE IS AVAILABLE BY RETURNING THE CRAFTSMAN CHIPPER SHREDDER TO THE NEAREST

SEARS PARTS & REPAIR CENTER IN THE UNITED STATES.

This warranty applies only while this product is in use in the United States.

TO LOCATE THE NEAREST SEARS PARTS & REPAIR CENTER OR TO SCHEDULE SERVICE,

SIMPLY CONTACT SEARS AT 1-800-4-MY-HOME®.

This warranty gives you specific legal rights and you may also have other rights which may vary from state to state.

SEARS, ROEBUCK AND CO., D/817WA, HOFFMAN ESTATES, IL 60179

Repair Protection Agreements

Congratulations on making a smart purchase. Your new Craftsman® product is designed and manufactured for years of dependable operation. But like all products, it may require repair from time to time. That’s when having a Repair Protection Agreement can save you money and aggravation.

Here’s what’s included in the Agreement:

•Expert service by our 12,000 professional repair specialists

•Unlimited service and no charge for parts and labor on all covered repairs

•Product replacement if your covered product can’t be fixed

•Discount of 10% from regular price of service and service-related parts not covered by the agreement; also, 10% off regular price of preventive maintenance check

•Fast help by phone – phone support from a Sears technician on products requiring in-home repair, plus convenient repair scheduling

Purchase a Repair Protection Agreement now and protect yourself from unexpected hassle and expense.

Once you purchase the Agreement, a simple phone call is all that it takes for you to schedule service. You can call anytime day or night, or schedule a service appointment online.

Sears has over 12,000 professional repair specialists, who have access to over 4.5 million quality parts and accessories. That’s the kind of

professionalism you can count on to help prolong the life of your new purchase for years to come. Purchase your Repair Protection Agreement today!

Some limitations and exclusions apply. For prices and additional information call 1-800-827-6655.

Sears Installation Service

For Sears professional installation of home appliances, garage door openers, water heaters, and other major home items, in the U.S.A. call 1-800-4-MY-HOME®

PRODUCT SPECIFICATIONS

Horse Power: |

7.5 Horse Power |

Engine Oil: |

SAE 30 |

Oil Capacity: |

20 Ounces |

Fuel: |

Unleaded Gasoline |

Spark Plug: |

Champion® RC-12YC |

Engine: |

Briggs and Stratton 150112-0408 |

MODEL NUMBER

Model Number..............................................................

Serial Number...............................................................

Date of Purchase..........................................................

Record the model number, serial number

and date of purchase above

SAFE OPERATION PRACTICES

WARNING: Engine Exhaust, some of its constituents, and certain vehicle components contain or emit chemicals known to State of California to cause cancer and birth defects or other reproductive harm.

DANGER: This machine was built to be operated according to the rules for safe operation in this manual. As with any type of power equipment, carelessness or error on the part of the operator can result in serious injury. This machine is capable of amputating hands and feet and throwing objects. Failure to observe the following safety instructions could result in serious injury or death.

WARNING: This symbol points out important safety instructions which, if not followed, could endanger the personal safety and/or property of yourself and others. Read and follow all instructions in this manual before attempting to operate this machine. Failure to comply with these instructions may result in personal injury.

When you see this symbol. HEED ITS WARNING!

Training

1.Read, understand, and follow all instructions on the machine and in the manual(s) before attempting to assemble and operate. Keep this manual in a safe place for future and regular reference and for ordering replacement parts.

2.Be familiar with all controls and their proper operation. Know how to stop the machine and disengage them quickly.

3.Never allow children under 16 years old to operate this machine. Children 16 years old and over should read and understand the operation instructions and safety rules in this manual and should be trained and supervised by a parent.

4.Never allow adults to operate this machine without proper instruction.

5.Keep bystanders, helpers, pets, and children at least 75 feet from the machine while it is in operation. Stop machine if anyone enters the area.

6.Never run an engine indoors or in a poorly ventilated area. Engine exhaust contains carbon monoxide, an odorless and deadly gas.

7.Do not put hands and feet near rotating parts or in the feeding chambers and discharge opening. Contact with the rotating impeller can amputate fingers, hands, and feet.

8.Never attempt to unclog either the feed intake or discharge opening, remove or empty vacuum bag, or inspect and repair the machine while the engine is running. Shut the engine off and wait until all moving parts have come to a complete stop. Disconnect the spark plug wire and ground it against the engine.

Preparation

1.Thoroughly inspect the area where the equipment is to be used. Remove all rocks, bottles, cans, or other foreign objects which could be picked up or thrown and cause personal injury or damage to the machine.

2.Always wear safety glasses or safety goggles during operation or while performing an adjustment or repair, to protect eyes. Thrown objects which ricochet can cause serious injury to the eyes.

3.Wear sturdy, rough-soled work shoes and close-fitting slacks and shirts. Loose fitting clothes or jewelry can be caught in movable parts. Never operate this machine in bare feet or sandals. Wear leather work gloves when feeding material in the chipper chute.

4.Before starting, check all bolts and screws for proper tightness to be sure the machine is in safe working condition. Also, visually inspect machine for any damage at frequent intervals.

5.Maintain or replace safety and instructions labels, as necessary.

6.To avoid personal injury or property damage use extreme care in handling gasoline. Gasoline is extremely flammable and the vapors are explosive. Serious personal injury can occur when gasoline is spilled on yourself

or your clothes which can ignite. Wash your skin and change clothes immediately.

a.Use only an approved gasoline container.

b.Extinguish all cigarettes, cigars, pipes, and other sources of ignition.

c.Never fuel machine indoors.

d.Never remove gas cap or add fuel while the engine is hot or running.

e.Allow engine to cool at least two minutes before refueling.

f.Never over fill fuel tank. Fill tank to no more than 1/2 inch below bottom of filler neck to provide space for fuel expansion.

g.Replace gasoline cap and tighten securely.

h.If gasoline is spilled, wipe it off the engine and equipment. Move machine to another area. Wait 5 minutes before starting the engine.

i.Never store the machine or fuel container inside where there is an open flame, spark, or pilot light (e.g. furnace, water heater, space heater, clothes dryer, etc.).

j.To reduce a fire hazard, keep machine free of grass, leaves, or other debris build-up. Clean up oil or fuel spillage and remove any fuel soaked debris.

k.Allow machine to cool at least 5 minutes before storing.

SAFE OPERATION PRACTICES

Operation

1.Do not put hands and feet near rotating parts or in the feeding chambers and discharge opening. Contact with the rotating impeller can amputate fingers, hands, and feet.

2.Before starting the machine, make sure the chipper chute, feed intake, and cutting chamber are empty and free of all debris.

3.Thoroughly inspect all material to be shredded and remove any metal, rocks, bottles, cans, or other foreign objects which could cause personal injury or damage to the machine.

4.If the impeller strikes a foreign object or if your machine should start making an unusual noise or vibration, immediately shut the engine off. Allow the impeller to come to a complete stop. Disconnect the spark plug wire, ground it against the engine and perform the following steps:

a.Inspect for damage.

b.Repair or replace any damaged parts.

c.Check for any loose parts and tighten to assure continued safe operation.

5.Do not allow an accumulation of processed material to build up in the discharge area. This can prevent proper discharge and result in kickback of material through the feed opening.

6.Do not attempt to shred or chip material larger than specified on the machine or in this manual. Personal injury or machine damage could result.

7.Never attempt to unclog either the feed intake or discharge opening while the engine is running. Shut the engine off, wait until all moving parts have stopped, disconnect the spark plug wire and ground it against the engine before clearing debris.

8.Never operate without vacuum bag and discharge chute properly attached to the machine. Never empty or change vacuum bag while the engine is running. Zippered end of vacuum bag must be kept closed at all times during operation.

9.Never operate without either the inlet nozzle or optional hose attachment properly attached to the machine. Never attempt to attach or change either attachment while the engine is running.

10.Keep all guards, deflectors and safety devices in place and operating properly.

11.Keep your face and body back and to the side of the chipper chute while feeding material into the machine to avoid accidental kickback injuries.

12.Never operate this machine without good visibility or light. Always be sure of your footing and keep a firm hold on the handles.

13.Do not operate this machine on a gravel surface.

14.Do not operate this machine while under the influence of alcohol or drugs.

15.Muffler and engine become hot and can cause a burn. Do not touch.

16.Never pick up or carry machine while the engine is running.

Maintenance & Storage

1.Never tamper with safety devices. Check their proper operation regularly.

2.Check bolts and screws for proper tightness at frequent intervals to keep the machine in safe working condition. Also, visually inspect machine for any damage and repair, if needed.

3.Before cleaning, repairing, or inspecting, stop the engine and make certain the impeller and all moving parts have stopped. Disconnect the spark plug wire and ground it against the engine to prevent unintended starting.

4.Do not change the engine governor settings or overspeed the engine. The governor controls the maximum safe operating speed of the engine.

5.Maintain or replace safety and instruction labels, as necessary.

6.Follow this manual for safe loading, unloading, transporting, and storage of this machine.

7.Never store the machine or fuel container inside where there is an open flame, spark or pilot light such as a water heater, furnace, clothes dryer, etc.

8.Always refer to the operator’s manual for proper instructions on off-season storage.

9.If the fuel tank has to be drained, do this outdoors.

10.Observe proper disposal laws and regulations for gas, oil, etc. to protect the environment.

Do not modify engine

To avoid serious injury or death, do not modify engine in any way. Tampering with the governor setting can lead to a runaway engine and cause it to operate at unsafe speeds. Never tamper with factory setting of engine governor.

Notice regarding Emissions

Engines which are certified to comply with California and federal EPA emission regulations for SORE (Small Off Road Equipment) are certified to operate on regular unleaded gasoline, and may include the following emission control systems: Engine Modification (EM) and Three Way Catalyst (TWC) if so equipped.

Your Responsibility

Restrict the use of this power machine to persons who read, understand and follow the warnings and instructions in this manual and on the machine.

Look For Relevant Emissions Durability Period and

Air Index Information On Your Engine Emissions Label

Engines that are certified to meet the California Air Resources Board (CARB) Tier 2 Emission Standards must display information regarding the Emissions Durability Period and the Air Index. Sears, Roebuck and Co., U.S.A. makes this information available to the consumer on our emission labels.

The Emissions Durability Period describes the number of hours of actual running time for which the engine is certified to be emissions compliant, assuming proper maintenance in accordance with the Operating & Maintenance Instructions. The following categories are used:

Moderate: Engine is certified to be emission compliant for 125 hours of actual engine running time. Intermediate: Engine is certified to be emission compliant for 250 hours of actual engine running time. Extended: Engine is certified to be emission compliant for 500 hours of actual engine running time.

For example, a typical walk-behind lawn mower is used 20 to 25 hours per year. Therefore, the Emissions Durability Period of an engine with an intermediate rating would equate to 10 to 12 years.

The Air Index is a calculated number describing the relative level of emissions for a specific engine family. The lower the Air Index, the cleaner the engine. This information is displayed in graphical form on the emissions label.

After July 1, 2000, Look For Emissions Compliance Period

On Engine Emissions Compliance Label

After July 1, 2000 certain Sears, Roebuck and Co., U.S.A. engines will be certified to meet the United States Environmental Protection Agency (USEPA) Phase 2 emission standards. For Phase 2 certified engines, the Emissions Compliance Period referred to on the Emissions Compliance label indicates the number of operating hours for which the engine has been shown to meet Federal emission requirements.

For engines less than 225 cc displacement, Category C = 125 hours, B = 250 hours and A = 500 hours. For engines of 225 cc or more, Category C = 250 hours, B = 500 hours and A = 1000 hours.

The displacement engines of Model Series 150112 is 249 cc.

This is a generic representation of the emission label typically found on a certified engine.

ASSEMBLY

IMPORTANT: This unit is shipped without gasoline or oil in the engine. After assembly, see OPERATION section of this manual for proper fuel and engine oil fill-up.

This Chipper Shredder has been completely assembled at the factory, except for the debris collection bag, which is stowed in the chipper chute for shipping.

Removing Unit From Carton

1.Remove staples, break glue on top flaps or cut tape at carton end and peel along top flap to open carton.

2.Remove any loose parts.

3.Cut down along carton edges and lay carton down flat.

4.Remove packing material, if present. Lift unit from the rear and discard bottom pad, if present. Roll unit out of carton. Check carton thoroughly for loose

parts.

Loose Parts In Carton

a.One Debris Collection Bag

b.One Pair of Safety Glasses

c.One 20 oz. Bottle of Engine Oil

d.One Operator’s Manual

Attaching The Debris

Collection Bag

2.To attach the bag:

a.Place the opening of the bag completely over the chute deflector.

b.Position the bag so that the wing knobs which secure the chute deflector to the impeller housing are completely covered.

c.Pull on the drawstrap until the bag is tight around chute deflector opening. See Figure 1.

Figure 1

OPERATIONWARNING: The operation of any chipper shredder can result in foreign objects being thrown. Always wear the safety glasses provided with this unit or eye shields before chipping or shredding and while performing any adjustments or repairs.Engine ControlsSee the Briggs & Stratton Owner/Operator manual packed with your unit for the location and function of the controls on the engine.Reduction ChamberChuteDeflectorHopperHandleChipper Chute

Figure 2Chipper ChuteBranches up to 2” in diameter may be fe

OPERATION

WARNING: The operation of any chipper shredder can result in foreign objects being thrown into the eyes, which can damage your eyes severely. Always wear the safety glasses provided with this unit or eye shields before chipping or shredding and while performing any adjustments or repairs.

Gas and Oil Fill-Up

Service the engine with gasoline and oil as instructed in the separate Briggs & Stratton engine manual packed with your chipper shredder. Read instructions carefully.

WARNING: Never fill fuel tank indoors with engine running or until the engine has been allowed to cool for at least two minutes after running.

Starting Engine

1. Move choke control lever to CHOKE position. See Figure 5.

NOTE: A warm engine may not require choking.

2.Move throttle control lever to FAST (rabbit) position. See Figure 5.

3.Grasp starter handle and pull rope out slowly until engine reaches start of compression cycle (rope will pull slightly harder at this point).

NOTE: A “clanking” noise may be heard when pulling the starter rope. It is completely normal and does NOT indicate a malfunction of any kind.

4.Pull rope with a rapid, continuous, full arm stroke. Keep a firm grip on starter handle. Let rope rewind slowly.

5.Repeat the previous steps until engine starts. When engine starts, move choke control gradually to RUN position until the engine is running smoothly.

WARNING: Never run the engine indoors or in a poorly ventilated area. Engine exhaust contains carbon monoxide, an odorless and deadly gas.

Stopping Engine

1. Move throttle control lever to STOP position. See Figure 6.

NOTE: See your engine manual packed with your unit for more detailed instructions.

CAUTION: Never stop the engine by moving the choke lever into the CHOKE position. Backfire, fire or engine damage could result.

STOP

Figure 5

STOP

Figure 6

OPERATION

Shredding

Yard waste such as leaves and pine needles can be placed in the hopper for shredding. After material has been processed by the shredder blade and flails, it will be forced out of the chute deflector, and, if attached, into a debris collection bag.

Observe the following guidelines when shredding yard debris:

1.Never attempt to shred material other than normal yard debris (leaves, twigs, pine cones, etc.).

2.Avoid shredding fibrous plants such as tomato vines until they are thoroughly dried out. Fresh vines do not shred well and tend to wrap themselves around the impeller and flails.

3.Place reasonable amounts of debris into the hopper at a time. Do not overload the hopper.

4.Allow the material in the hopper to be drawn into the blades and shredded before adding additional debris to the hopper. Failure to due so may result in a clogged hopper, clogged chute deflector or a stalled engine.

5.Avoid placing twigs longer than 24 inches into the hopper. Twigs longer than 24 inches may result in a clogged hopper.

6.Never place branches with a diameter greater than 1/2-inch in the hopper. Doing so can result in serious damage to the unit’s shredder blade, flails or impeller.

Clearing the Hopper

Should the hopper become clogged with debris during operation, proceed as follows:

1.Grasp the handle with both hands and gently agitate the chipper shredder to help loosen debris, drawing it into the impeller.

If the clog does not clear, proceed as follows:

1.Stop engine.

2.Use your hands to remove any debris found near the top of the hopper.

3.Use a branch (or other available device, i.e. broomstick) to dislodge debris located toward the base of the hopper.

4.Restart engine.

NOTE: If you’re unable to pull the starter rope as a result of accumulated debris near the impeller, follow instructions under the heading Cleaning the Reduction Chamber in the “Maintaining Your Chipper Shredder” section of this manual.

Chipping

WARNING: Never operate the chipper shredder without chipper chute lowered into the operating position.

Branches up to 2” in diameter can be fed into the chipper chute. Observe the following guidelines when chipping branches:

1.Keep both hands firmly on the branch as you feed it into the chipper chute.

2.Never feed more than one branch into the chipper chute at a time.

3.Never feed anything other than branches (or wood) into the chipper chute.

4.Apply intermittent pressure (force, in short pulses) while feeding larger (2-inch diameter) branches into the chipper chute, to avoid bogging or stalling the engine.

IMPORTANT: Never feed branches with a diameter greater than two (2) inches into the chipper chute. Doing so can result in serious damage to your unit’s chipper blades, flails or impeller.

NOTE: For best performance, always operate the unit with sharp chipper blades. If a noticeable loss in performance is encountered while chipping branches, the chipper blades should be replaced.

Emptying the Debris Collection Bag

1.Stop engine.

2.Squeeze the locking buckle release the bag’s drawstrap before loosening it from the chute deflector. See Figure 7.

3.Empty the bag and reattach to the chute deflector opening. Refer to Figure 2.

Figure 7

MAINTENENCE

WARNING: Always stop engine, disconnect spark plug, and ground against engine before cleaning, lubricating or doing any kind of maintenance on your machine.

Lubrication

1.Lubricate the chipper chute hinge a with light oil once a season.

2.Lubricate the pivot points on the chute deflector with light oil once a season.

3.Refer to the Briggs & Stratton Owner/Operator manual packed with your unit for engine lubrication instructions.

Engine Care

Refer to the Maintenance section of the Briggs & Stratton Owner/Operator manual packed with your unit. Read and follow instructions carefully.

1.Check engine oil level before each use as instructed in the separate engine manual.

2.Clean air cleaner’s precleaner every 25 hours under normal conditions. Clean every few hours under extremely dusty conditions. Replace the air cleaner cartridge once a season. To service the air cleaner, refer to the separate engine manual.

3.The spark plug should be cleaned and the gap reset once a season. Refer to the separate engine manual for correct plug type and gap specifications.

C

A

B

Figure 8

4.When the area is cleaned, pivot the shredder screen downward and re-secure with the clevis pin and hairpin clip removed earlier.

5.Reattach the debris collection bag to the chute deflector, if desired.

Chipper Shredder Care

Before each use, visually inspect your chipper shredder for loose (or missing) nuts and bolts. Securely tighten (or replace) all hardware before operating the chipper shredder.

Cleaning The Reduction Chamber

WARNING: The impeller’s shredder blade and chipper blades are sharp. Wear leather work gloves to protect your hands when cleaning out the reduction chamber.

If the reduction chamber becomes clogged with debris, the shredder screen can be pivoted upward so that you can clean the surrounding area. To do so, proceed as follows:

1.Stop engine, disconnect spark plug, and make certain the chipper shredder has come to a complete stop.

WARNING: The muffler and surrounding area will be hot if the engine has been running. Use caution and protect your hands if working near the muffler.

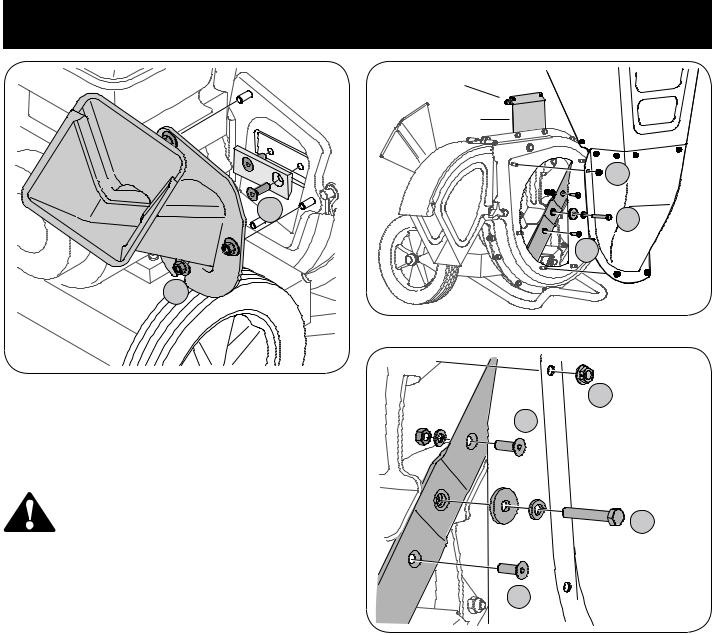

2.a. If attached, remove debris bag. Remove the two wing knobs on either side of the chute deflector and pivot the chute deflector upward. See Figure 8.

b.Remove the hairpin clip from the clevis pin which extends through the housing and shredder screen. See Figure 8. Remove clevis pin.

c.Pivot the shredder screen upward and clean the surrounding area by scraping away debris.

3.Confirm that the spark plug wire is disconnected and away from spark plug. Pull on the starter rope two-to-three times to purge any remaining debris from the reduction chamber

Sharpening Or Replacing Chipper Blades

WARNING: The impeller’s chipper blades are sharp. Wear leather work gloves to protect your hands.

1.Stop engine, disconnect spark plug, and make certain the chipper shredder has come to a complete stop.

2.Pivot the shredder screen upward as instructed under the heading Cleaning the Reduction Chamber.

3.a. Remove the chipper chute by removing three hex nuts and washers which secure it to the impeller housing. See Figure 9.

•Rotate the impeller by hand until one of the two chipper blades is visible through the impeller housing opening.

b.Remove the blade by removing the internal hex screws, lock washers and hex nuts which secure it to the impeller.

NOTE: Use a 3/16” hex key (Allen) wrench on the outside of the blade and a 1/2” box (or socket) wrench on the inside of the impeller. Hold the Allen wrench stationary and rotate the box (or socket) wrench to loosen the nut.

4.Install a replacement (or sharpened) blade (Part No. 742-0544A) with the hardware removed earlier.

IMPORTANT: If sharpening the blade, protect hands by using gloves. Follow the original angle of grind and make sure to remove an equal amount from each blade.

5.To replace the other blade, rotate the impeller to expose the second blade and repeat the steps above.

10

MAINTENENCE

B

A

Figure 9

NOTE: Make certain blades are reassembled with the sharp edge outward (toward the chipper chute). Torque hardware to between 20 ft.-lbs and 25 ft.-lbs.

Sharpening Or Replacing the Shredder Blade

WARNING: The shredder blade is sharp. Wear leather work gloves to protect your hands.

1.Stop engine,disconnect spark plug, and make certain that all moving parts have come to a complete stop.

2.Remove the two flange nuts (and hex bolts) which secure the hopper support bracket to the impeller housing. Retain the hardware. See Figure 10.

3.Pivot the shredder screen upward as instructed under the heading

Cleaning the Reduction Chamber.

4.a. Remove six flange nuts which secure hopper inlet guide to impeller housing. See Figure 11.

•Carefully separate the hopper assembly from the impeller housing and set it aside.

•Insert a piece of wood into the chute deflector opening to stabilize the impeller and prevent it from rotating when removing the shredder blade.

b.Remove the two internal hex screws, hex lock nuts, and lock washers which secure the shredder blade to the impeller. See Figure 11.

NOTE: Use a 3/16” hex key (Allen) wrench on the outside of the shredder blade and a 1/2” box (or socket) wrench on the inside of the shredder blade. Hold the Allen wrench stationary and rotate the box (or socket) wrench to loosen the nut.

c.Remove the hex bolt, lock washer, and flat washer to completely free shredder blade. See Figure 11.

Flange Nut

Support

Bracket

A

C

B

Figure 10

A

B

C

B

Figure 11

IMPORTANT: If sharpening the blade for reuse, follow the original angle of grind as a guide. Make certain each cutting edge receives an equal amount of grinding to prevent an unbalanced blade. Remove metal from the heavy side until it is balanced evenly.

IMPORTANT: When reassembling the blade, tighten center bolt to between 45 ft.-lbs and 60 ft.-lbs and the two out bolts to between 20 ft.-lbs and 25 ft.-lbs.

Storing Your Chipper Shredder

1.Clean the equipment thoroughly.

2.Wipe equipment with an oiled rag to prevent rust.

3.Refer to engine manual for correct engine storage instructions

4.Store unit in a clean, dry area. Do not store next to corrosive materials such as fertilizer.

11

OFF-SEASON STORAGE

Prepare your Craftsman Chipper Shredder for storage at the end of the season or if the unit will not be used for 30 days or longer. A yearly check-up by your local Sears Parts & Repair Center is a good way to ensure that the unit runs properly next season.

Chipper Shredder

•Clean the equipment thoroughly.

•Wipe equipment with an oiled rag to prevent rust. Use a light oil or silicone to wipe.

•Store unit in a clean, dry area. Do not store next to corrosive materials such as fertilizer.

Engine

•Service the engine as instructed in the separate Briggs & Stratton engine manual packed with your chipper shredder.

Other

•Do not store gasoline from one season to another.

•Replace the gasoline can if it starts to rust. Rust and/or dirt in the gasoline will cause problems.

•Store unit in a clean, dry area. Do not store next to corrosive materials, such as fertilizer.

NOTE: If storing in an unventilated or metal storage shed, be certain to rustproof the equipment by coating with a light oil or silicone.

12

Loading...

Loading...