Page 1

SEISMIC VELOCITY TRANSDUCER T1-40

Measurement of Omnidirectional Absolute Vibrations

Certified according to ATEX 94/9/CE directive

OPERATION

Transducer T1-40 serves for seismic measurement of the absolute vibrations of the machinery through direct fixing

(omnidirectional) on the supports of the vibrating part in a dangerous area. It supplies an output signal directly

proportional to the vibration speed of the point to which it is fastened. Such signal is then processed in a safe zone by

a measuring channel of the “T” series.

The transducer, in its various models, is certified for applications in areas classified as:

ZONE 0 ZONE 1

- Ex II 1GD Ex ia IIC T6 Ex iaD 20 T85°C - Ex II 2GD Ex ia IIC T6 Ex iaD 21 T85°C

- Ex II 1GD Ex ia IIC T5 Ex iaD 20 T100°C - Ex II 2GD Ex ia IIC T5 Ex iaD 21 T100°C

- Ex II 1GD Ex ia IIC T4 Ex iaD 20 T135°C - Ex II 2GD Ex ia IIC T4 Ex iaD 21 T135°C

PRINCIPLE OF OPERATION

A voltage, proportional to the speed of vibration, is induced in a coil suspended seismically to the transducer body

and immersed in a field generated by a permanent magnet rigidly fastened to the transducer body.

Page 2

SPECIFICATIONS

Type of measurement : SEISMIC (absolute vibrations)

Field of application : AMPLITUDE = ± 1000 µm p.p.

FREQUENCY = 10÷1000 Hz

DIRECT. OF VIBR. = ANY

Rated sensitivity : 21,2 mV/mm/sec (RMS) a 25°C

Typical frequency : 12 Hz

Damping coeff. : 0.7

Cross sensitivity : < 7%

Output impedance : 1 Kohm at 25°C

Power supply : None

Ambient operating range : Temperature = see certification

Humidity = 100% max

Ambient = IP65 EN 60529/10.91

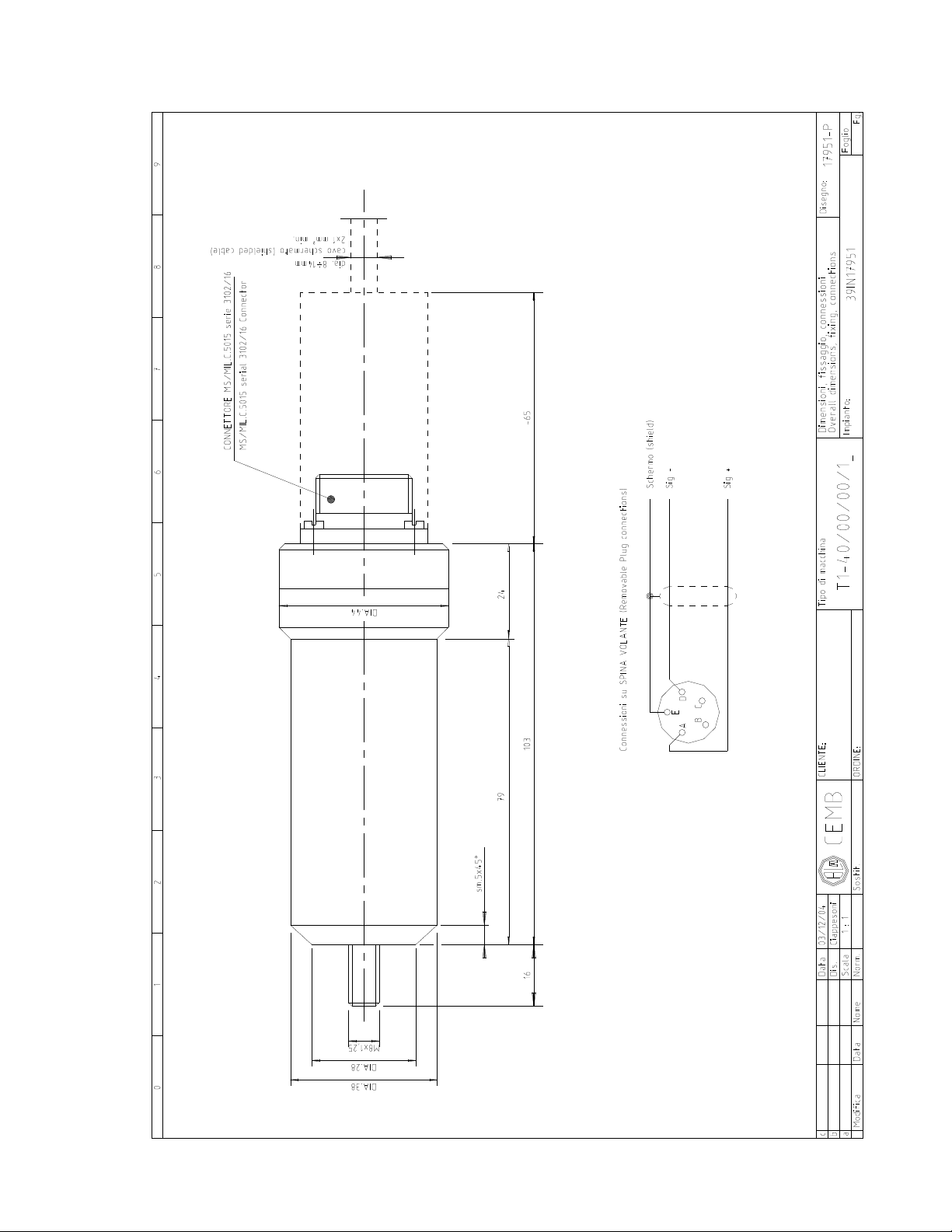

External connections : Connector MS/MIL-C-5015 series 3102/16, std. accessory

Outer casing material : Alluminium P.Al.Si 5.5 (Zone 1)

or

Stainless steel AISI 303 (Zone 0)

Weight of transducer : approx. 0.300 kg

Fastening : Screw, M8x1.25 – L=16 mm

Maintenance : None

Enclosed drawings : 17951 = Overall dimensions, layout and el. connections.

TRANSDUCER POSITIONING

Refer to drawing 17951.

N.B.: The operations should be performed possibly with the machine stationary and

taking the greatest care so as not to damage the internal mechanisms of the transducer.

1) On the support to be measured, drill a hole M8x1.25, 17 mm min. depth, making sure of its perpendicularity (if it is

not possible to reach the depth of 17 mm, provide spacers of suitable thickness between the support surface and

the transducer).

The surface on which the transducer rests should be flat and smooth. It is advisable to apply a layer of silicone

between the casing and the resting surface.

2) Screw the transducer in the M8x1.25 hole provided at point 1. Avoid knocks on the transducer. The use of a

thread compound is advisable during tightening.

3) Carry out the electrical connections of the transducer to the measuring instrument by using the free lead

connector (supplied as standard).

Notes regarding positioning:

- The wiring MUST be made with cables resistant to agents related to the workplace (oils, corrosive acids,

temperature, etc.).

- Shielded cables MUST be used. Make sure that the shield is connected to the frame earth (GND=ground) at just

one of the cable ends (the instrument side is advised).

- The electrical conductors must all have a minimum cross section of 1.0 mm², max. possible cross section = 2.5

mm² for a max. distance of approx. 800 metres.

T1-40-ATEX 04 gb 2

Page 3

Notes concerning certification:

1) The use of ATEX certified transducers is not allowed for different hazardous conditions or for those

exceeding the data specified on the nameplate affixed to the transducer.

2) The transducer does not require maintenance. Any work regarding performance checks or repair

should only be carried out in a laboratory duly authorized by CEMB SpA.

Notes for the identification :

The TRANSDUCER is manufactured in various versions in order to be correctly used according to :

1) the dangerous Zones where they will be used (zone 0 and 1)

2) the operating temperature (ambient t. and maximum t.)

3) the ambient operating characteristics (suitable or less suitable atmospheres for

the following materials : STAINLESS STEEL, ALUMINIUM, PLASTIC)

These characteristics must match in order to meet ALL the plant requirements. The CEMB codes with

which the main versions are identified and which meet requirements as per points 1 to 3 are as follows:

CEMB Code ZONE 0

9801145T4 TRANSDUCER T1-40/00/00/1C (-40÷+100°C) II 1GD Ex ia IIC T4 Ex iaD 20 T135°C

+135°C SURFACE, Zone 0, ATEX

9801145T5 TRANSDUCER T1-40/00/00/1B (-40÷+80°C) II 1GD Ex ia IIC T5 Ex iaD 20 T100°C

+100°C SURFACE, Zone 0, ATEX

9801145T6 TRANSDUCER T1-40/00/00/1A (-40÷+60°C) II 1GD Ex ia IIC T6 Ex iaD 20 T85°C

+85°C SURFACE, Zone 0, ATEX

CEMB Code ZONE 1

9831145T4 TRANSDUCER T1-40/00/00/1N (-40÷+100°C) II 2GD Ex ia IIC T4 Ex iaD 21 T135°C

+135°C SURFACE, Zone1,ATEX

9831145T5 TRANSDUCER T1-40/00/00/1M (-40÷+80°C) II 2GD Ex ia IIC T5 Ex iaD 21 T100°C

+100°C SURFACE, Zone1,ATEX

9831145T6 TRANSDUCER T1-40/00/00/1L (-40÷+60°C) II 2GD Ex ia IIC T6 Ex iaD 21 T85°C

+85°C SURFACE, Zone 1,ATEX

T1-40-ATEX 04 gb 3

Page 4

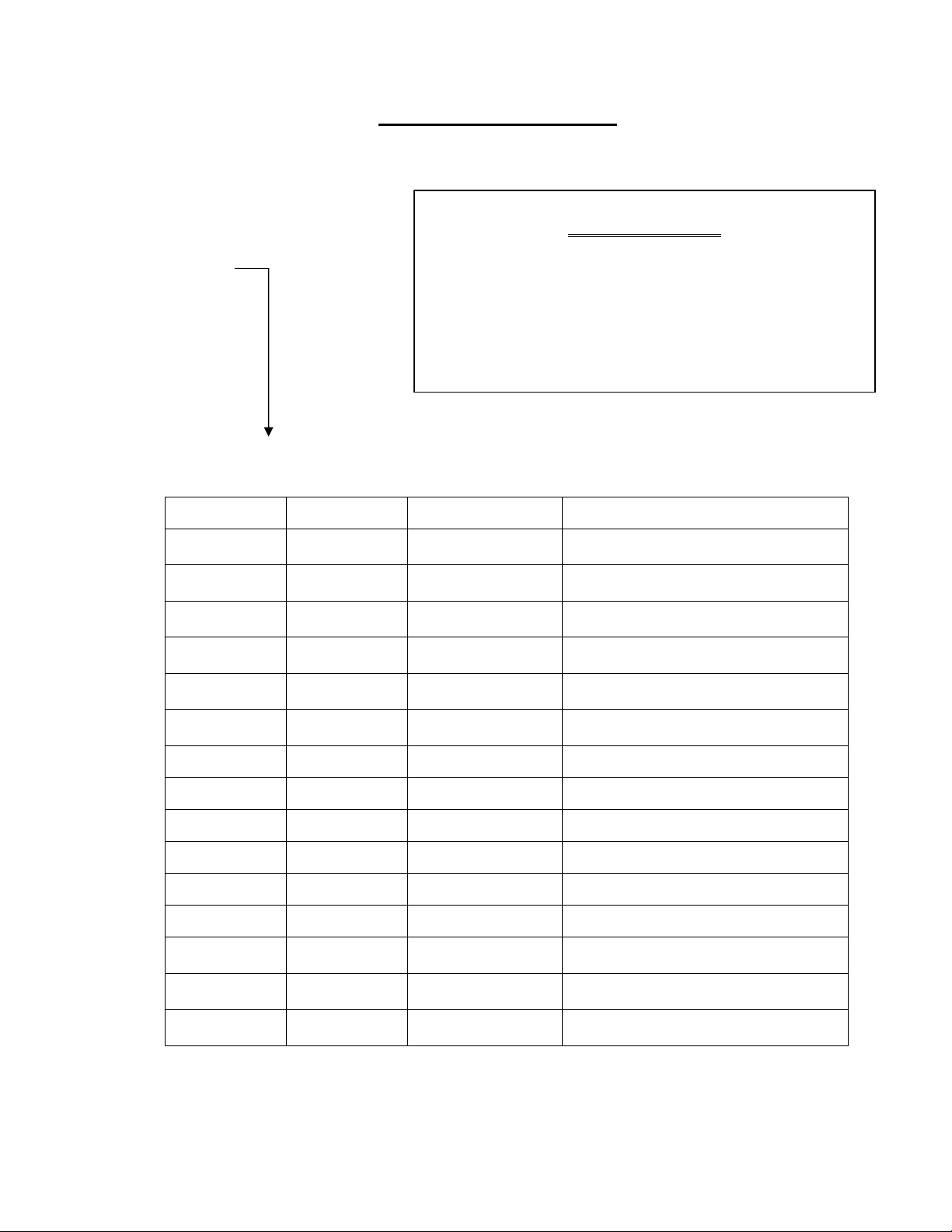

D

T1- 40 / 00 / 00 /

Where “D” =

D : Certification Code

“D” Code BODY CONNECTOR MARKING

/1A

/1B

/1C

/1D

/1E

/1F

/1G ALUMINIUM PLASTIC II 2GD Ex ia IIC T6 Ex iaD 21 T85°C

STAINLESS

STAINLESS

STAINLESS

STAINLESS

STAINLESS

STAINLESS

STEEL

STEEL

STEEL

STEEL

STEEL

STEEL

Information complete table

Example of order

T1-40/00/00/1A

1A = Certif. Atex II 1GD Ex ia IIC T6 Ex iaD 20 T85°C

FOR ZONE 0, WITH PLASTIC CONNECTOR AND

STAINLESS STEEL BODY

PLASTIC II 1GD Ex ia IIC T6 Ex iaD 20 T85°C

PLASTIC II 1GD Ex ia IIC T5 Ex iaD 20 T100°C

PLASTIC II 1GD Ex ia IIC T4 Ex iaD 20 T135°C

ALUMINIUM II 2GD Ex ia IIC T6 Ex iaD 21 T85°C

ALUMINIUM II 2GD Ex ia IIC T5 Ex iaD 21 T100°C

ALUMINIUM II 2GD Ex ia IIC T4 Ex iaD 21 T135°C

/1H ALUMINIUM PLASTIC II 2GD Ex ia IIC T5 Ex iaD 21 T100°C

/1I ALUMINIUM PLASTIC II 2GD Ex ia IIC T4 Ex iaD 21 T135°C

/1L ALUMINIUM ALUMINIUM II 2GD Ex ia IIC T6 Ex iaD 21 T85°C

/1M ALUMINIUM ALUMINIUM II 2GD Ex ia IIC T5 Ex iaD 21 T100°C

/1N ALUMINIUM ALUMINIUM II 2GD Ex ia IIC T4 Ex iaD 21 T135°C

/1P

/1Q

/1R

T1-40-ATEX 04 gb 4

STAINLESS

STEEL

STAINLESS

STEEL

STAINLESS

STEEL

PLASTIC II 2GD Ex ia IIC T6 Ex iaD 21 T85°C

PLASTIC II 2GD Ex ia IIC T5 Ex iaD 21 T100°C

PLASTIC II 2GD Ex ia IIC T4 Ex iaD 21 T135°C

Page 5

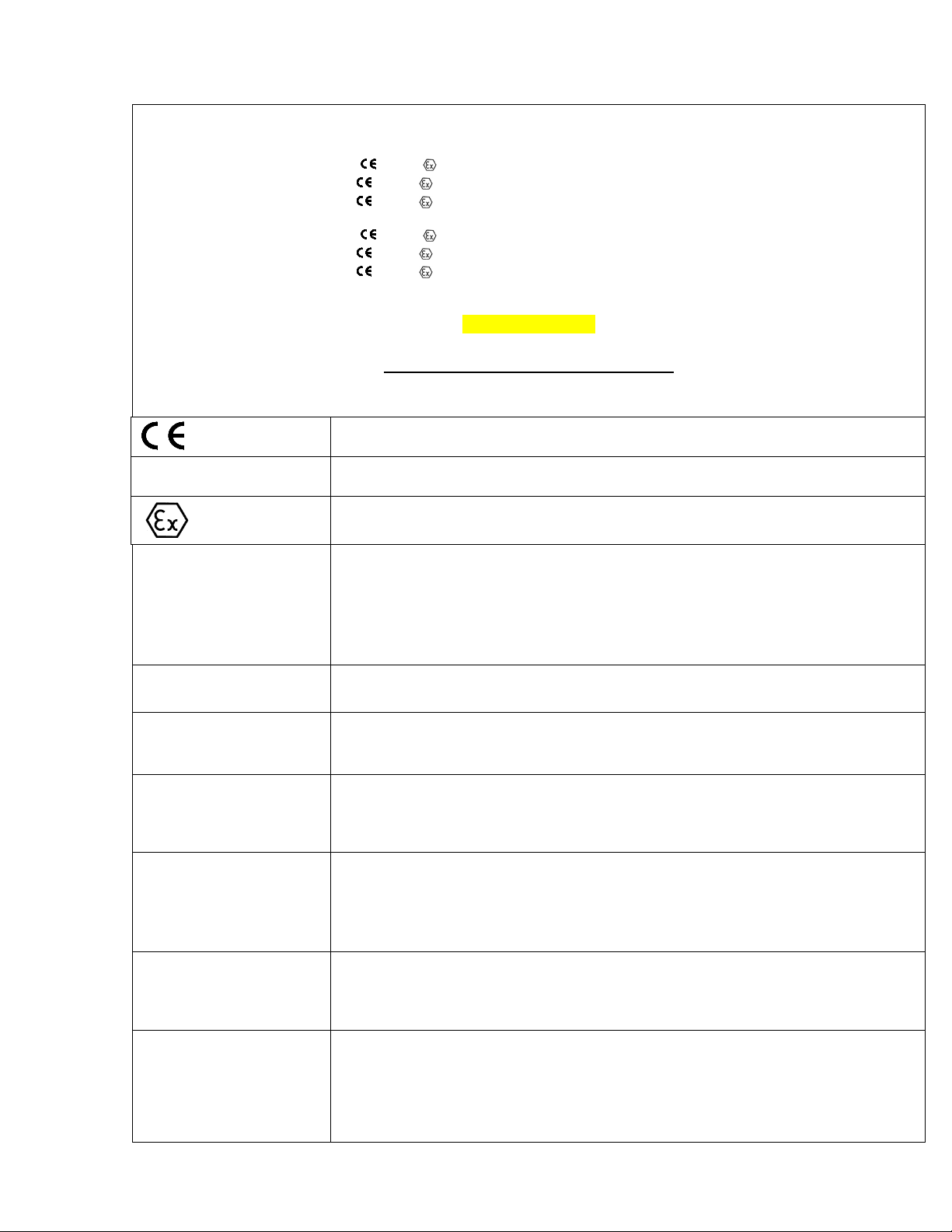

Certifications according to ATEX 94/9/CE

0722 II 1GD Ex ia IIC T6 Ex iaD 20 T85°C

0722 II 1GD Ex ia IIC T5 Ex iaD 20 T100°C

0722 II 1GD Ex ia IIC T4 Ex iaD 20 T135°C

0722 II 2GD Ex ia IIC T6 Ex iaD 21 T85°C

0722 II 2GD Ex ia IIC T5 Ex iaD 21 T100°C

0722 II 2GD Ex ia IIC T4 Ex iaD 21 T135°C

CESI 01 ATEX 050

Legend of nameplate safety data

Marking of compliance with the applicable European directives

0722

II 1GD / II 2GD

Ex ia

II C

T6-T5-T4

Ex iaD T85°C

Ex iaD T100°C

Ex iaD T135°C

Number of the Notified Body carrying out the surveillance (CESI)

Marking of compliance with 94/9/CE Directive and relevant technical

standards

II 1 GD Equipment intended for use in areas in which Ex atmosphere

caused by gases and dust, suitable for Zone 0 and 20

II 2 GD Equipment intended for use in areas in which Ex atmosphere

caused by gases and dust, suitable for Zone 1 and 21

Not suitable for mines

Equipment belonging to category "ia" with intrinsic safety

Suitable for substances (gas) of group IIC, also suitable for groups IIA

and IIB

T6 temperature class (surface temperature: 85°C)

T5 temperature class (surface temperature: 100°C)

T4 temperature class (surface temperature: 135°C)

Protection for Dust

For T6 class, ambient temperature : -40 ÷ 60 °C

T. amb.

For T5 class, ambient temperature : -40 ÷ 80 °C

For T4 class, ambient temperature: -40 ÷ 100 °C

Certificate identification :

• Name of the laboratory issuing the CE-type-examination certificate

CESI 01 ATEX 050

• 01 = year of certificate issue

• 050 = certificate number

T1-40-ATEX 04 gb 5

Page 6

ASTD90420

T1-40-ATEX 04 gb 6

Loading...

Loading...