Page 1

Transducers

T1-40 T1-40BF T1-40V

T1-38 T1-38BF T1-38V

Velocity transducers

B A L A N C I N G M A C H I N E S

Page 2

B A L A N C I N G M A C H I N E S

Principle of operation

A voltage proportional to the velocity of vibration is induced in a coil that moves in a field generated by a permanent magnet.

The coil is suspended seismically on the body of the transducer which is fixed to the measuring point.

Typical applications

The transducer is normally connected to a vibration monitoring unit. This creates a measuring chain able to detect the vibrations

of any rotating machine. The most frequent applications regard motors, pumps, fans, compressors, turboalternators, etc.

considered strategic in any manufacturing cycle. Various models are available according to the different fields of application;

the transducer should be chosen on the basis of the frequency response, direction of measurement, type of material of the

outer case, temperature range or application in a classified area. Each transducer is designed with characteristics to suit the

industrial environment and is provided with a connector to MIL standards or integral teflon cable, with high degree of protection

against atmospheric agents. Installation is very easy and can even be carried out under normal working conditions.

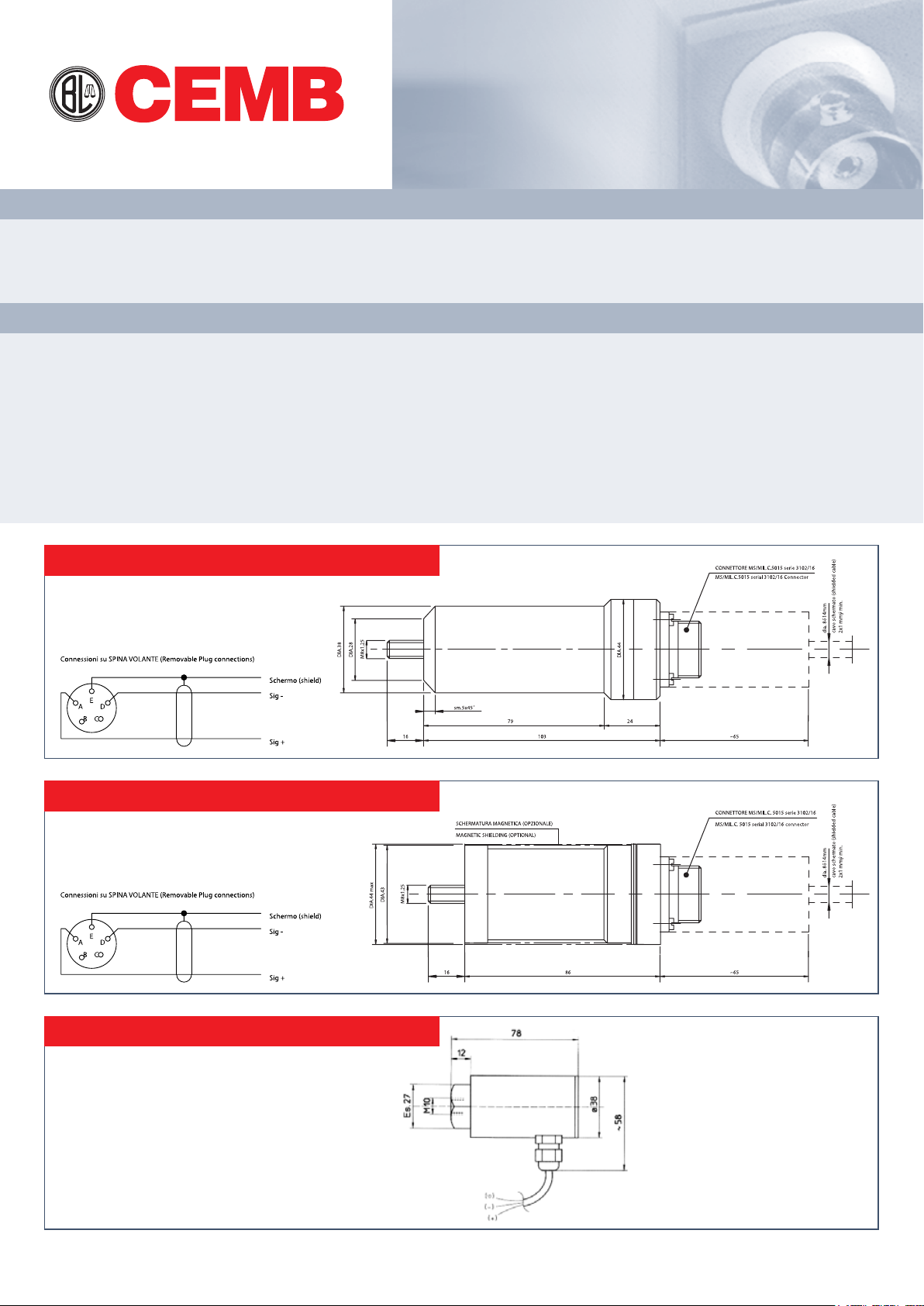

Overall dimensions drawing 1

Overall dimensions drawing 2

Overall dimensions drawing 3

The transducers of this series supply a signal proportional to the velocity of vibration of the point where they are fixed.

Page 3

T1-40/T1-40BF/T1-40V

VELOCITY TRANSDUCERS T1-40 T1-40BF T1-40V

Type of measurement absolute absolute absolute

Direction of measurement any horizontal vertical

Frequency range 10 ÷ 1000 Hz 3 ÷ 2000Hz 10 ÷2000 Hz

Maximum amplitude ± 1 mm ± 1 mm ± 1 mm

Nominal sensitivity 21.2 mV/mm/s 21.2 mV/mm/s 21.2 mV/mm/s

Resonant frequency 12 Hz 4.5 Hz 10 Hz

Transverse sensitivity < 7% < 3% < 3%

Output impedance ~ 1 K Ω at 25°C ~ 1 K Ω at 25°C ~ 1 K Ω at 25°C

Operating temperature range -40 ÷ +100°C -40 ÷ +100°C

(-40 ÷ +170°C)*

* on request

External connection MS3102A-16S-8S MS3102A-16S-8S MS3102A-16S-8S

-40 ÷ +100°C

(-40 ÷ +170°C)*

* on request

External case anodized aluminium anodized aluminium anodized aluminium

Transducer weight ~ 300 gr ~ 300 gr ~ 300 gr

Mounting Screw M8 screw M8 screw M8 screw

Protection class IP 65 IP 65 IP 65

Overall dimensions according to Dwg. 1 according to Dwg. 2 according to Dwg. 2

T1-40 T1-40BF / T1-38BF

Page 4

T1-38/T1-38BF/T1-38V

VELOCITY TRANSDUCERS T1-38 T1-38BF T1-38V

Type of measurement absolute absolute absolute

Direction of measurement any horizontal vertical

Frequency range 15 ÷ 2000 Hz 3 ÷ 2000Hz 10 ÷2000 Hz

Maximum amplitude ± 1 mm ± 1 mm ± 1 mm

Nominal sensitivity 100 mV/mm/s 21.2 mV/mm/s 21.2 mV/mm/s

Resonant frequency 15 Hz 4.5 Hz 10 Hz

Transverse sensitivity < 3% < 3% < 3%

Output impedance ~ 3.6 K Ω at 25°C ~ 1 K Ω at 25°C ~ 1 K Ω at 25°C

Operating temperature range -40 ÷ +100°C -40 ÷ +100°C

(-40 ÷ +170°C)*

* on request

External connection

through integral cable

(optional protection of cable

with flexible conduit)

through integral cable

(optional protection of cable

with flexible conduit)

-40 ÷ +100°C

(-40 ÷ +170°C)*

* on request

through integral cable

(optional protection of cable

with flexible conduit)

External case

Transducer weight 300 / 500 gr 300 / 500 gr 300 / 500 gr

Mounting Screw M10 screw M10 screw M10 screw

Protection class IP 66 IP 66 IP 66

Overall dimensions according to Dwg. 3 according to Dwg. 3 according to Dwg. 3

anodized aluminium

stainless steel

anodized aluminium

stainless steel

anodized aluminium

stainless steel

T1-40V / T1-38V T1-38

Page 5

Ordering data

A / B / C / D / E / F / G

T1 -

A : type of transducer

38 model 38

40 model 40

B : direction of measurement

00 in all directions

BF horizontal

VO vertical

C : temperature range

00 standard

HT 170° C

D : certified version

(only for model T1-40)

0 standard

Certifications according to ATEX 94/9/CE

1

0722 II 1 GD EEx ia IIC T6 IP65 T85°C

0722 II 1 GD EEx ia IIC T5 IP65 T100°C

0722 II 1 GD EEx ia IIC T4 IP65 T135°C

0722 II 2 GD EEx ia IIC T6 IP65 T85°C

0722 II 2 GD EEx ia IIC T5 IP65 T100°C

0722 II 2 GD EEx ia IIC T4 IP65 T135°C

E : housing material

(only for model T1-38)

0 anodized aluminium

1 stainless steel

F : length of integral cable

(only for model T1-38)

0 5 meters

1 10 meters

2 20 meters

3 special to be defined

G : cable protection

(only for model T1-38)

0 without protection

1 with protection

Example of an order:

A / B / C / D / E / F / G

T1 -

3 8 B F 0 0 0 1 0 0

G : without protection

F : with 5 meters of cable

E : of stainless steel

D : not certified

C : standard temperature

B : for measuring in horizontal direction

A : model 38

Page 6

Technical data

Electrical connection

The connection cable should be shielded, bipolar type with

minimum cross section of 1 mm2, joined to the connector supplied

as standard with the transducer (model T1-40) or else directly fitted

to the transducer (model T1-38).

Mounting

The transducer should be fitted by tapping a hole at the point where

it has to be fixed. If this is not possible, apply a block with tapped

hole on the machine support. The use of adhesive is advisable

when tightening the transducer.

CEMB also manufactures

• Universal horizontal balancing machines with coupling and/or belt

drive for balancing rotors from 10 g to 100.000 Kg.

• Vertical balancing machines for balancing rotors from 50 g to 1500

Kg on 1 or 2 correction planes.

• Special purpose balancing machines for complete assemblies.

• Special purpose balancing machines including various types of

units for correcting unbalances semi-automatically or automatically.

• Portable equipments for measuring and analyzing vibrations as well

as balancing under service conditions.

• Fixed supervisory and testing equipment for continuous monitoring

of large scale plants with rotating machines (turbines, pumps,

compressors) including checking for vibrations, displacements,

deformations, eccentricity, etc.

and offers the following services:

• Balancing on a contract work basis

• Vibration analysis on a contract work basis

• Periodic maintenance data acquisition service

• Training courses in balancing and vibration technology at CEMB

or customer’s premises

• Specific technical booklets on balancing and vibration technology

are available upon request, free of charge:

Booklet N.2 - “Mechanical vibration technology”

Booklet N.3 - “Balancing technology”

Booklet N.8 - “Accuracy in balancing rigid rotors”

Booklet N.10 - “Balancing of flexible rotors”

Booklet N.11 - “Testing of balancing machines”

Booklet N.17 - “Theoretical principle of wheel balancing”

Booklet N.18 - “Wheel balancing”

Booklet N.19 - “Crankshaft balancing”

Booklet N.20 - “Balancing under service conditions”

Booklet N.23 - “Testing of vibrations in machines during service”

Booklet N.24 - “Machinery monitoring and

supervisory instrumentation”

Booklet N.26 - “Protection of balancing machines”

Safety precautions and devices for use

on balancing machines

Booklet N.27 - “Choice of a balancing machine”

B A L A N C I N G M A C H I N E S

CEMB S.p.A.

Via Risorgimento, 9

23826 Mandello del Lario (LC) Italy

www.cemb.com

Vibration analysis division:

phone +39 0341 706111

fax +39 0341 706299

stm@cemb.com

All the data and features mentioned in this catalogue are purely for information and do not

constitute any commitment on the part of our company, which reserves the right to make any and

all alterations it may consider suitable without notice.

AT5001420 06/08

Loading...

Loading...