Page 1

R

CTK-750

(with price)

ELECTRONIC KEYBOARD

CTK-750

Page 2

CONTENTS

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Replacing the DSP (HG51A115A01FD) . . . . . . . . . . . . . . . . . . . . . 2

Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Circuit Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Major Waveforms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

PCB View and Major Check Points . . . . . . . . . . . . . . . . . . . . . . . 16

Schematic Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Exploded View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

IC and Transistor Lead Identification . . . . . . . . . . . . . . . . . . . . . 21

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

— 14 —

Page 3

SPECIFICATIONS

General

Number of Keys: 61

Polyphonic: 32-note

Preset Tones: 128

Tone Expander: Layer, Split

Keyboard Controls: Touch Response: On/Off

Touch Sensitivity: Light/Middle/Heavy

Key Transpose: Range from F# to F by a half-note increment

Auto-Rhythms: 128

Tempo Control: 40 to 255

Auto-Accompaniment: CASIO Chord/Fingered/Full-Range Chord

Controller: Variation, Fill-In, Intro/Ending

Magical Preset Variations: 128; BREAK BEAT 16 MELODYCOMP 8

SHADOW DRUM 4 FREE SESSION 32

TONE STACK 40 KEY SPLIT 12

HYPERACTIVE 16

Digital Effects: 16; Reverb-1, Reverb-2, Reverb-3, Chorus, Tremplp, Phase Shifter,

Organ SP, Enhancer, Flanger, EQ Loudness, Delay-1, Delay-2,

Analog Delay, Tap Delay, Chorus Reverb, Tremolo Reverb

Sound/Control Pads: 6

Pad Variations: 32; Phrases: 10, Drums: 10, SE/Percussion: 10, Controller: 2

Song Memories: 2; Tracks: 6

System: Real-time recording

Memory Capacity: Approx. 5,800 notes

Registration Memories: 10

Registration Items: Tone Number, Rhythm Number, Tempo, Accompaniment Mode,

Accompaniment Volume, Effects, Layer On/Off, Split On/Off,

Pad Variation, Assignable Jack, Auto-Accompaniment On/Off,

Auto-Accompaniment Controller, MIDI (Channel On/Off, GM On/Off,

Local Control On/Off, Bend Range)

Tuning Control: 440Hz ± 100 cents

Terminals: Headphone Jack [Output Impedance: 100 Ω, Output Voltage: 1.7 V(rms)

MAX], Assignable Jack, MIDI Jacks (IN, OUT), AC Adaptor Jack (12V)

Built-In Speakers: 12 cm dia. 1.1W Input Rating: 2 pcs.

Power Source: 2-way AC or DC source

AC: AC adaptor AD-12

DC: 6 D size dry batteries

Battery life: Approx. 5 hours by manganese batteries R20P(SUM-1)

Approx. 5 hours by alkaline batteries LR20(AM1)

Auto Power Off: Approximately 6 minutes after the last operation

Power Consumption: 18 W

Dimentions: 141 x 968 x 411 mm (HWD)

(5-11/16 x 38-1/16 x 16-5/16 inches) (HWD)

Weight: 7.0 kg (15.5 lbs) excluding batteries

Standard Accessory: Music stand

— 1 —

Page 4

Electrical

Current Drain with 12V DC:

No Sound Output 390 mA ± 20%

Maximum Volume 1700 mA ± 20%

with white keys D2 to D3 pressed in Synth-Bass-2 tone

and in Latin Fusion rhythm at initial setup tempo

Volume; maximum, Touch: maximum

Line Output Level (Vrms with 47 KΩ load each cannel):

with key D4 pressed in FSynth-Bass-2 tone on L-ch 850 mV ± 20%

with key G4 pressed in FSynth-Bass-2 tone on R-ch 800 mV ± 20%

Phone Output Level (Vrms with 8 Ω load each channel):

with key D4 pressed in FSynth-Bass-2 tone on L-ch 280 mV ± 20%

with key G4 pressed in FSynth-Bass-2 tone on R-ch 260 mV ± 20%

Speaker Input Level:

with key D4 pressed in FSynth-Bass-2 tone on L-ch 5200 mV ± 20%

with key G4 pressed in FSynth-Bass-2 tone on R-ch 5600 mV ± 20%

Minimum Operating Voltage: 5.5 V

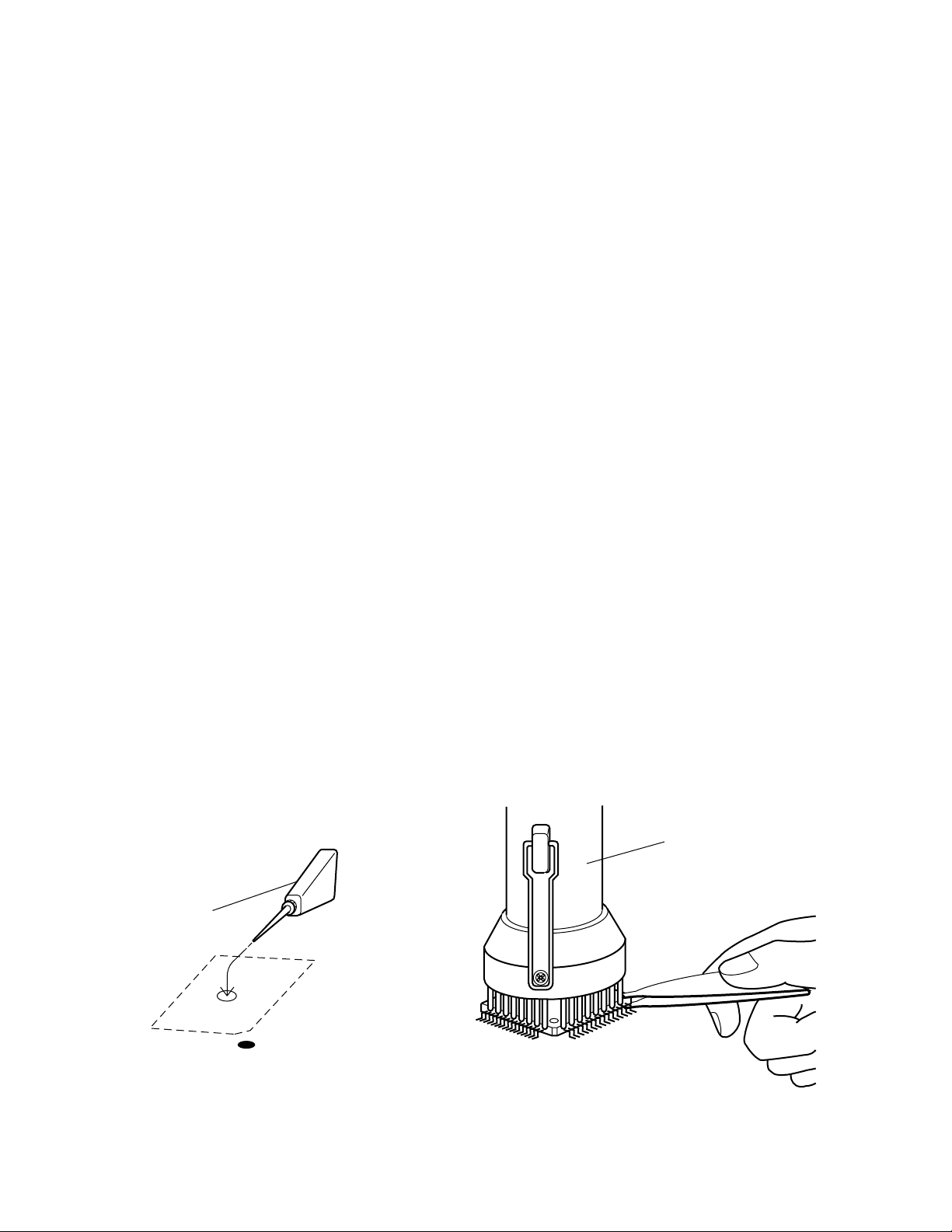

REPLACING THE DSP (HG51A115A01FD)

Note: To increase productivity ,the DSP HG51A115A01FD is sticked on the main PCB with a double-side

adhesive tape, then its leads are soldered.

Remove the DSP according to the following procedures.

1. Prepare isopropyl alcohol and a flat IC desoldering machine (Spot Heater HS-600).

2. Apply plenty of the alcohol to the adhesive tape from the reverse side of the main PCB. (Fig. 1)

There is a hole on the PCB just under the LSI, and the adhesive tape can be seen through the hole.

3. Leave it more than one minute so that the alcohol weaken adhesive power fully.

4. Using a proper size of nozzle, apply heat to leads of the LSI with the desoldering machine.

5. Grasp the LSI with tweezers, and using gentle force vibrate the tweezers to feel melting solder. (Fig.2)

6. Remove the LSI after meltingsolder at every leads wholly.

Spot Heater HS-600

Alcohl

HG51A115A

LSI-S

— 2 —

Fig.2Fig.1

Page 5

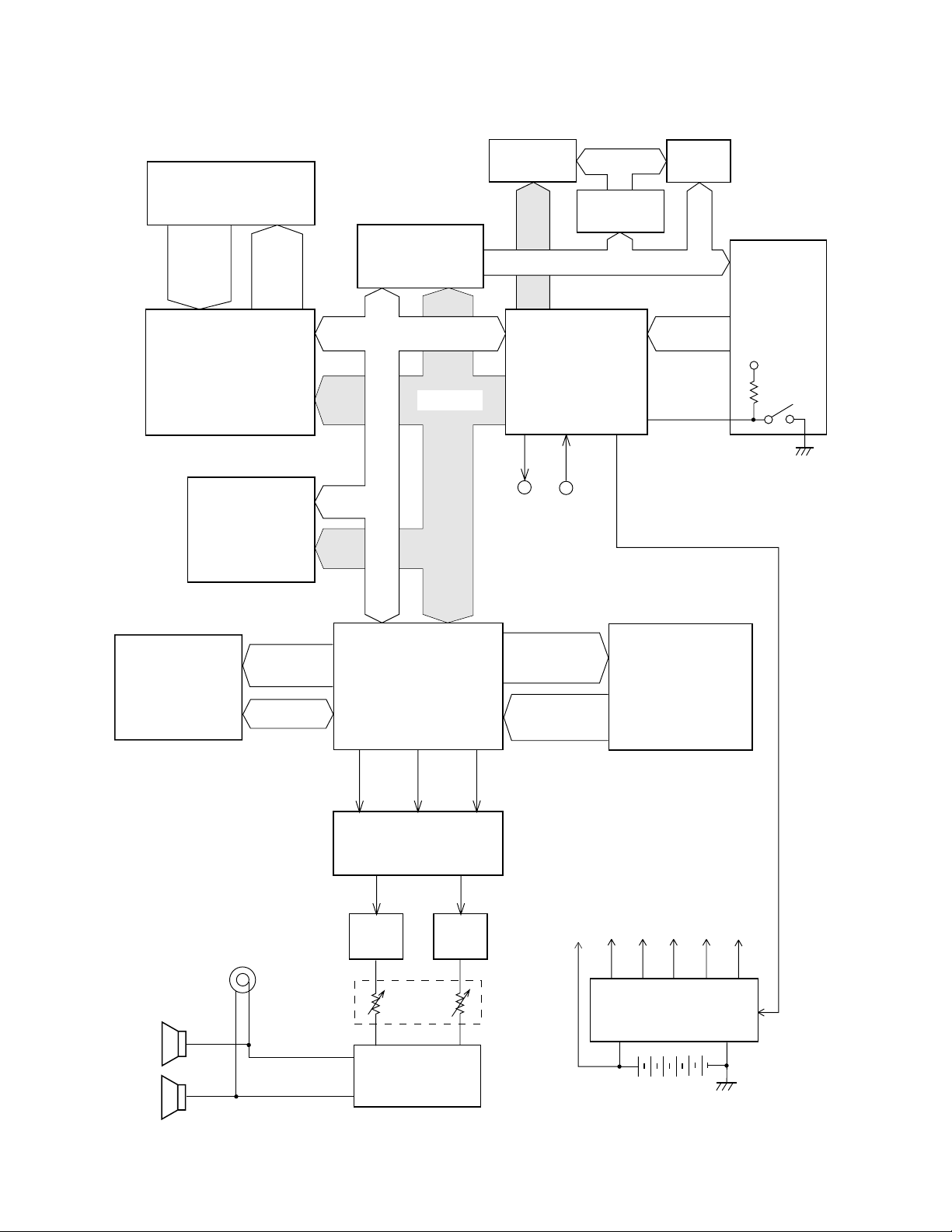

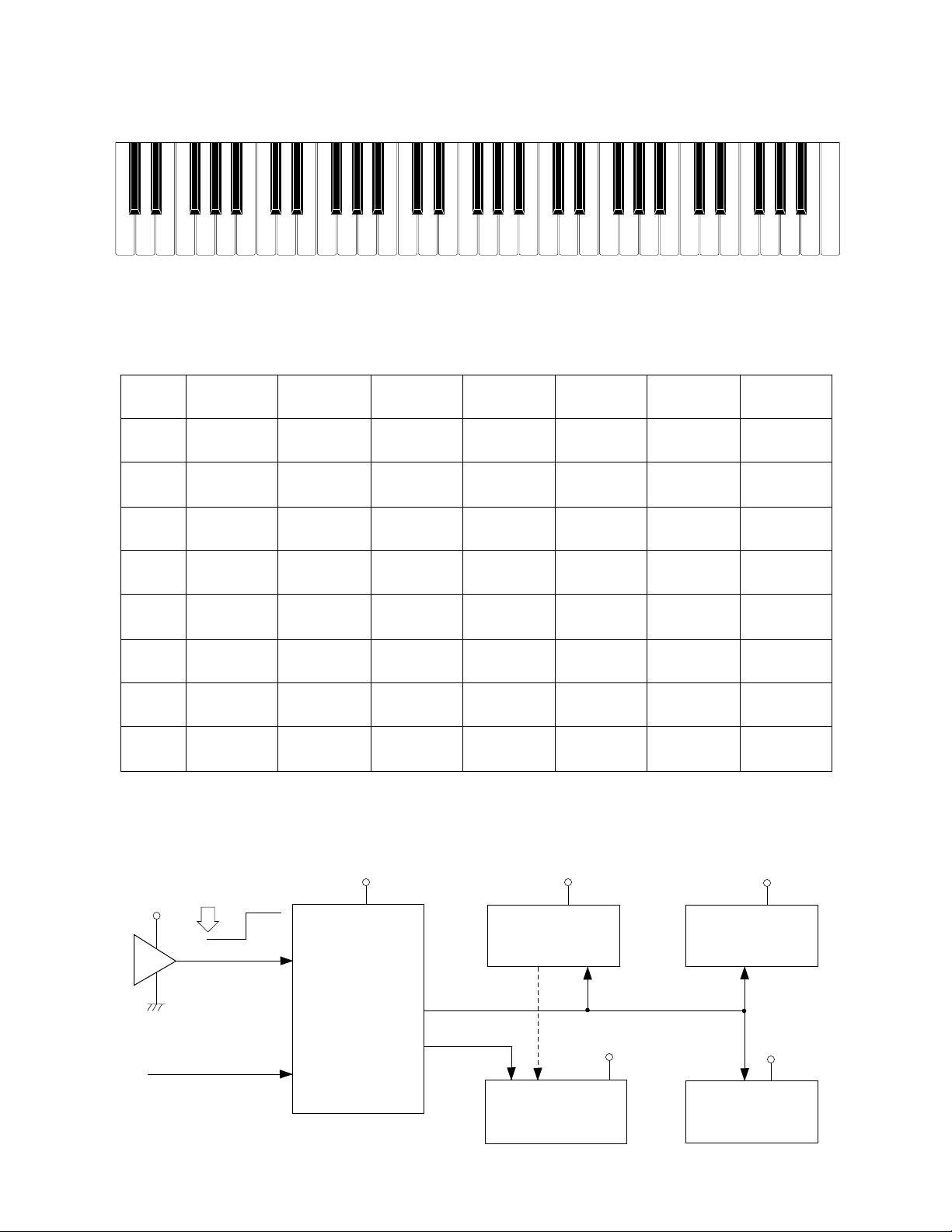

BLOCK DIAGRAM

Keyboard

FI0 ~ FI7

SI0 ~ SI7

Key Touch LSI

HG52E35P

Working Strage

Working Strage

RAM (256K-bit)

RAM (256K-bit)

HM62256ALP-10

HM62256ALP-10

KC0 ~

KC7

A0 ~ A2

A0 ~ A14

Gate Array

UPD65005C-578

D0~D7

A0 ~ A15

7-Segment

LED

HD6433298A18P

OUT

MIDI

A0 ~ A3

LO0 ~ LO4

LED driver

BA612

KO0 ~ KO7

LD0 ~ LD7

CPU

IN

LEDs

Buttons

KI1 ~ KI7

VDD

POWER

Power Switch

APO

Effect RAM

(256K-bit)

HM62256ALP-10

Speakers

EA0 ~ EA14

ED0 ~ ED7

Output

DSP

HG51A115A01FD

WCK1 SLOP BCK

D/A Converter

UPD6376CX

Filter

Main

Volume

Power Amplifier

LA4620

Filter

RA0 ~ RA19

RD0 ~ RD15

VD

Sound Source ROM

(16M-bit)

TC5316200CP-C081

LVDD

VCC

AVDD

Power Supply Circuit

Q1 ~ Q7

DVDD

VDD

— 3 —

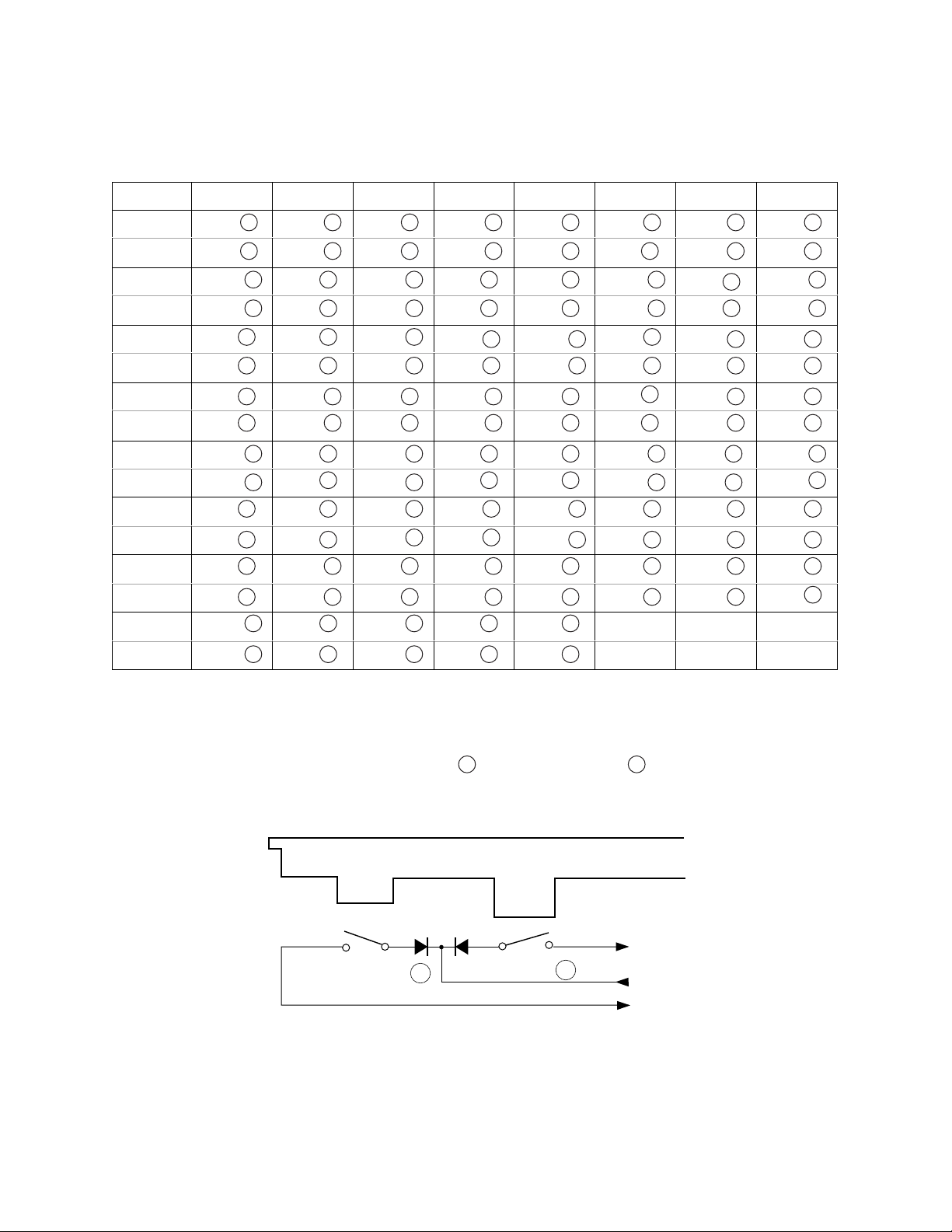

Page 6

CIRCUIT DESCRIPTION

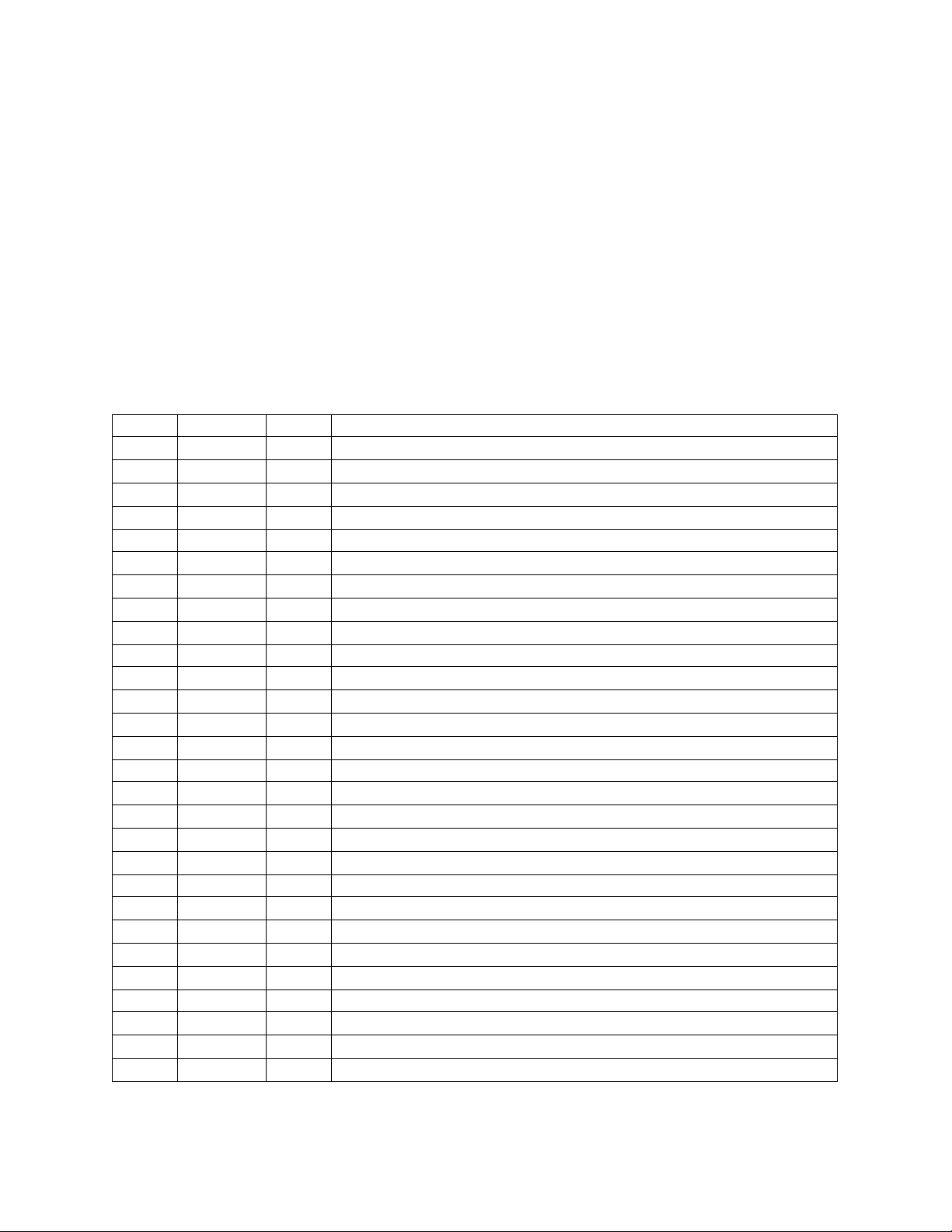

Key Matrix

KC0 KC1 KC2 KC3 KC4 KC5 KC6 KC7

FI0 C2 1 C#2 1 D2 1 D#2 1 E2 1 F2 1 F#2 1 G2 1

SI0 C2 2 C#2 2 D2 2 D#2 2 E2 2 F2 2 F#2 2 G2 2

FI1 G#2 1 A2 1 A#2 1 B2 1 C3 1 C#3 1 D3 1 D#3 1

SI1 G#2 2 A2 2 A#2 2 B2 2 C3 2 C#3 2 D3 2 D#3 2

FI2 E3 1 F3 1 F#3 1 G3 1 G#3 1 A3 1 A#3 1 B3 1

SI2 E3 2 F3 2 F#3 2 G3 2 G#3 2 A3 2 A#3 2 B3 2

FI3 C4 1 C#4 1 D4 1 D#4 1 E4 1 F4 1 F#4 1 G4 1

SI3 C4 2 C#4 2 D4 2 D#4 2 E4 2 F4 2 F#4 2 G4 2

FI4 G#4 1 A4 1 A#4 1 B4 1 C5 1 C#5 1 D5 1 D#5 1

SI4 G#4 2 A4 2 A#4 2 B4 2 C5 2 C#5 2 D5 2 D#5 2

FI5 E5 1 F5 1 F#5 1 G5 1 G#5 1 A5 1 A#5 1 B5 1

SI5 E5 2 F5 2 F#5 2 G5 2 G#5 2 A5 2 A#5 2 B5 2

FI6 C6 1 C#6 1 D6 1 D#6 1 E6 1 F6 1 F#6 1 G6 1

SI6 C6 2 C#6 2 D6 2 D#6 2 E6 2 F6 2 F#6 2 G6 2

FI7 G#6 1 A6 1 A#6 1 B6 1 C7 1

SI7 G#6 2 A6 2 A#6 2 B6 2 C7 2

Note: Each key has two contacts, the first conatct 1 and second contact 2 .

Key

FI

Second contact 2

First contact 1

KC

SI

— 4 —

Page 7

Nomenclature of Keys

C#2

C2 D2E2F2G2A2 B2 C3 D3

F#2D#2

C#3A#2G#2

F#3 G#3

D#3

E3

F3 G3 A3 B3 C4 D4 E4 F4 G4 A4 B4 C5 D5 E5 F5 G5 A5 B5

A#3 C#4 D#4

F#4 G#4

A#4

C#5

D#5

F#5 G#5

A#5

C#6

C6

Button Matrix

KI1 KI2 KI3 KI4 KI5 KI6 KI7

KO0 Split Layer Upper 1 Lower 1 Lower 2 Upper 2

KO1 Transpose Tune MIDI Jack Rhythm Tone Play Style

KO2

Track 4

Chord 1

KO3 3 6 9 Demo

Track 5

Chord 2

Track 6

Chord 3

Touch

Responce

Track 2

Rhythm

Digital

Effect

Resistration

G#6F#6D#6

A#6

Track 3

Bass

B6A6G6F6E6D6

C7

KO4 2 5 8 Track 1 1 4 7

KO5

KO6

Accomp.

Volume

Synchro/

Ending

KO7 Mode A C E

Song

Memory

Variation

/Fill-In

Accomp. Track 0 - +

Normal/

Fill-In

Intro F D B

Start/

Stop

Tempo

Down

Reset Circuit

-SRAM

VDD

HG51A115A01FD

VDD

VDD

Battery set

RESET

Reset IC

S8053ANO

POWER

VDD

CPU

HD6433298A18P

Gate Array

UPD65005C-578

-RESET

WR

Tempo

Up

DVDD

DSP

DVDD

From power switch

Working Strage RAM

HM62256ALP-10

— 5 —

Key Touch LSI

HG52E35

Page 8

Initial reset

When batteries are set or an AC adapter is connected, the reset IC provides a low pulse to the CPU.

The CPU then initializes its internal circuit and clears data in the working strage RAM.

Power ON reset

When the power switch is pressed, the CPU receives a low pulse of POWER signal. The CPU first raises

APO signal to +5V to generat DVDD voltage, then raises RESET signal to +5V. During this period the

gate array, the DSP and the key touch LSI initializes their internal circuit.

CPU (HD6433298A18P)

The 16-bit CPU contains a 32k-bit ROM, a 1k-bit RAM, seven 8-bit I/O ports, an A/D convertor and serial

interfaces. The CPU accesses to the working strage RAM, the DSP and the key touch LSI. The CPU also

controls buttons, LEDs, bender input and MIDI input/output.

Pin No. Terminal In/Out Function

1 P40 Out KO signal data output

2 P41 Out Clock for KO signal data

3 P42 Out APO (Auto Power Off) signal output. ON: High, OFF: Low

4 P43 Out Read enable signal output

5 P44 Out Write enable signal output

6 P45 Not used.

7 P46 Out 10MHz clock output

8 P47 In Wait signal input. Connected to +5V.

9 TXD Out MIDI signal output

10 RXD In MIDI signal input

11 P52 Out Reset signal output

12 -RESET In Reset signal input

13 -NMI In Power ON signal input.

14 VCC In +5V source

15 -STBY In Standby signal input. Connected to +5V.

16 VSS In Ground (0V) source

17 XTAL In 20MHz clock input

18 EXTAL In 20MHz clock input

19, 20 MD1, MD0 In Mode selection input. (Internal ROM mode --- MD1: Hight, MD0: Low)

21 AVSS In Ground (0V) source for internal DAC

22 AN0 In Analog input. Connected to the bender volume.

23 ~ 29 P71 ~ P77 In Button input signal input

30 AVCC In +5V source for internal DAC

31 ~ 38 P60 ~ P67 Out LED segment signal output

39 VCC In +5V source

40 ~ 56 P27 ~ P10 Out Address bus

48 VSS In Ground (0V) source

57 ~ 64 P30 ~ P37 Ijn/Out Data bus

— 6 —

Page 9

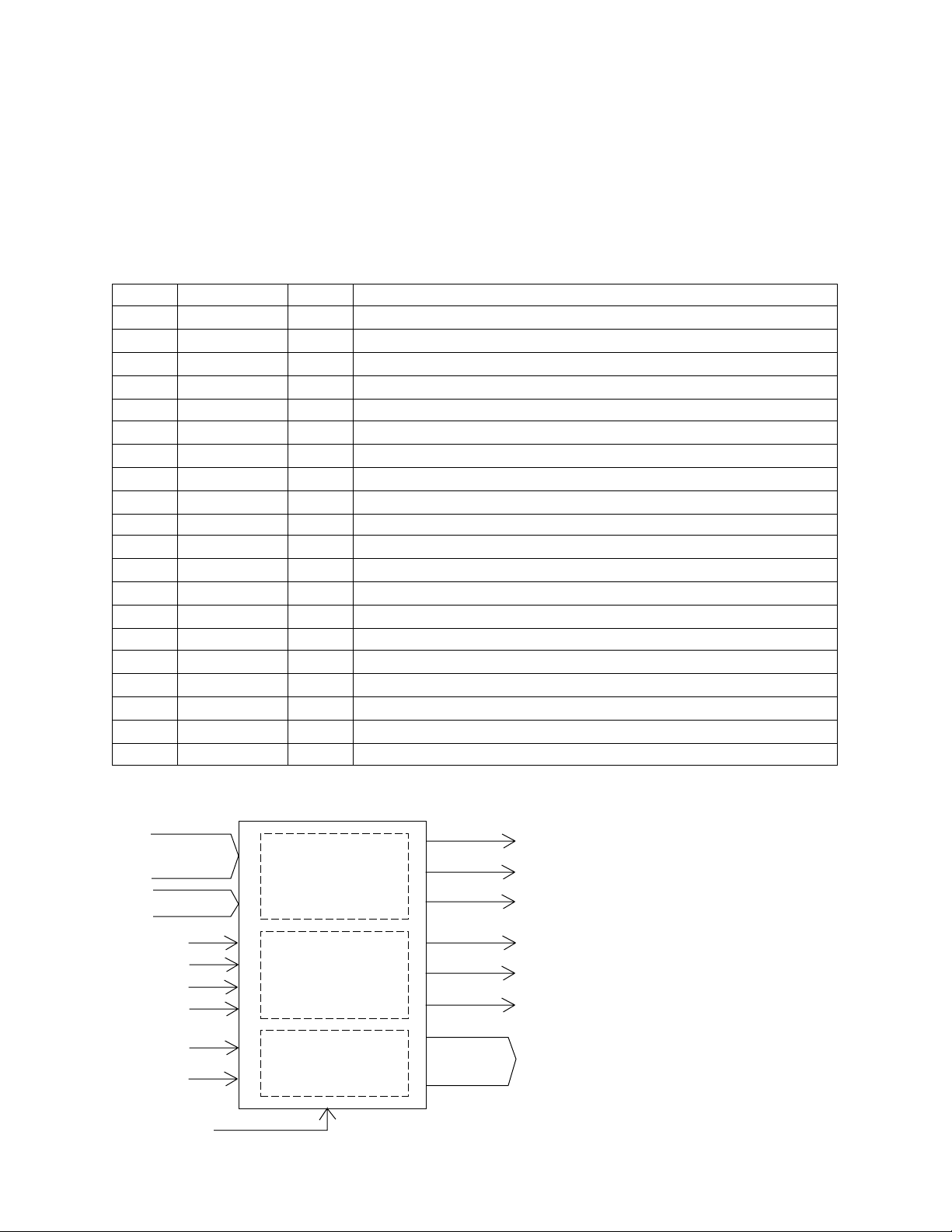

Gate Array (UPD65005C-578)

Functions of the gate array are;

(1) To decode chip select signals for the working strage RAM, the DSP and the key touch LSI.

(2) To hold the following signals on "Low" during power off.

Read/write enable signals for the DSP and the key touch LSI

10MHz clock for the key touch LSI

(3) To generate button scan / LED drive signals.

The following table shows the pin functions of the gate array.

Pin No. Terminal In/Out Function

1 -RESET In Reset signal input

2 -RDAPO Out Read enable signal output

3 -WRAPO Out Write enable signal output

4 -LSIS Out Chip select signal for the DSP

5 -HG Out Chip select signal for the key touch LSI

6 PHAPO Out 10MHz clock for the key touch LSI

7 -SRAM Out Chip select signal for the working strage RAM

8 ~ 9 KO8 ~ KO9 Not used.

10 ~ 17 KO7 ~ KO0 Out Button scan / LED drive signal output

18 ~ 20 Not used.

21 GND In Ground (0V) source

22 PHA In 10MHz clock input

23 -WR In Write enable signal input

24 -RD In Read enable signal input

25 -APO In APO (Auto Power Off) signal input

26 KOC In KO signal data input

27 KOD In Clock for KO signal data

28 ~ 39 A15 ~ A4 In Address bus

40, 41 D0, D1 In Data bus

42 VDD In +5V source

A4 ~ A15

D0, D1

RD

WR

PHA

APO

KOD

KOC

RESET

Address decoder

Controller

Shift register

LSIS

HG

SRAM

RDAPO

WRAPO

PHAPO

KO0 ~ KO7

— 7 —

(Chip select sigal for the DSP)

(Chip select signal for the key touch LSI)

(Chip select signal for the working strage RAM)

(Read enable signal controlled by APO)

(Write enable signal controlled by APO)

(10MHz clock for the key touchLSI.

Controlled by APO)

(Button scan / LED drive signal)

Page 10

Digital Signal Processor (HG51A115A01FD)

Upon receipt of note numbers and their velocities, the DSP reads sound and velocity data from the sound

source ROM in accordance with the selected tone; the DSP can read rhythm data simultaneously when a

rythm pattern is selected. Then it provides 16-bit serial signals containing data of the melody, chord, bass,

and percussion to the DAC. The DSP also adds the selected effect to the sound data using a 256k-bit

RAM.

The following table shows the pin functions of the DSP.

Pin No. Terminal In/Out Function

1 ~ 8 CD0 ~ CD7 In/Out Data bus

9, 10 Not used.

11 GND7 In Ground (0V) source

12 CK16 Out 16.384MHz clock output

13 VCC6 In +5V source

14 CK0 In Clock input. Connected to terminal CK16.

15 TCKB Not used.

16 VCC1 In +5V source

17 GND1 In Ground (0V) source

18, 19 XT0, XT1 In/Out 16.384MHz clock input/output. Connected to a crystal oscillator.

20 SGL In System control terminal. Single chip system: Open

21 CCSB In Chip select signal input

22 ~ 25 CA0 ~ CA3 In Addess bus

26 CE0 In Not used. Connected to ground.

27 CWRB In Write enable signal

28 CRDB In Read enable signal

29 ~ 32 Not used.

33 RESB In Reset signal input

34 TESB In Not used. Connected to +5V.

35 ~ 39 Not used.

40 ~ 49

52 ~ 57

RD0 ~ RD15 In Data bus for the sound source ROM

58 RA23 Out Not used.

59 RA22 Out Chip select signal for the sound source ROM

60, 61 RA20, RA21 Out Not used.

62 ~ 73

75 ~ 82

RA0 ~ RA19 Out Data bus for the sound source ROM

74 GND5 In Ground (0V) source

83 WOK2 Out Word clock output. Not used.

84 VCC3 In +5V source

85 GND3 In Ground (0V) source

86 WOK1 Out Word clock for the DAC

87 SOLM Out Serial data output. Not used.

88 SOLP Out Serial data output for the DAC

89 BOK Out Bit clock output for the DAC

90 ~ 92 Not used.

— 8 —

Page 11

Pin No. Terminal In/Out Function

93 VCC5 In +5V source

94, 95

97 ~ 105

107,109

EA0 ~ EA14 Out Address bus for the effect RAM

110, 112

96 EWEB Out Write enable signal output for the effect RAM

106 EOEB Out Read enable signal output for the effect RAM

108 VCC7 In +5V source

111 ECEB Out Chip select signal output for the effect RAM

113 ~ 117 Not used.

118 VCC4 In +5V source

119 GND4 In Ground (0V) source

120 ~ 122 Not sued.

123 ~ 130 ED0 ~ ED7 In/Out Data bus for the effect RAM

131 GND5 In Ground (0V) source

132 ~ 134 Not used. Connected to ground.

135, 136 Not used.

Block diagram of DSP and DAC circuit

Sound Source ROM

TC5316200CP-C081

CE

A0 ~ A19 D0 ~ D15

RA22

RA0 ~

RA19

D0 ~ D7

A0 ~ A3

HG51A115A01FD

LSIS

RDAPO

WRAPO

RESET

ECEB EOEB

OE

CS

PG

16.384MHz

RD0 ~

RD15

DSP

EWEB

WE

ED0 ~

ED15

D0 ~ D15

EA0 ~

EA14

A0 ~ A14

Effect RAM (256K-bit)

HM65256BLP

SOLP: Sound data

BOK: Bit clock

WOK1: Word clock

DAC

SOLP

BOK

WOK1

SI

CLK

LRCK

UPD6376CX

ROUT

LOUT

— 9 —

Page 12

DAC (UPD6376CX)

RESB

CCSB

CWRB

CRDB

CKI

CD0

CD7

CA0 ~ CA2

First contact

Second contact

KC0

KC7

FI0

FI7

SI0

SI7

Key input signal

Key scan signal

~

Data bus

Address bus

Reset signal from the CPU

Chip select signal from the gate array

Read enable signal from the gate array

Write enable signal from the gate array

Clock from the gate array

Key touch LSI

HG52E35P

Keyboard

FI

SI

KC

UPD6376CX is a two-channel 16-bit Digital to Analog Convertor consisting of resistor string, output

amplifier and zero offset circuit.

Pin No. Terminal In/Out Function

1 SEL In Mode selection terminal. Connected to ground.

2 D.GND In Ground (0V) source for internal digital circuit

3 NC Not used.

4 DVDD In +5V source for internal digital circuit

5 A.GND In Ground (0V) source for internal analog circuit

6 R.OUT Out Sound waveform output

7 A.VDD In +5V source for internal analog circuit

8 A.VDD In +5V source for internal analog circuit

9 R.REF In Reference voltage terminal. Connected to a capacitor.

10 L.REF In Reference voltage terminal. Connected to a capacitor.

11 L.OUT Out Left channel sound waveform output

12 A.GND In Ground (0V) source for internal analog circuit

13 LRCK In Word clock (L/R separation signal) input.

14 LRSEL In Not used. Connected to ground.

15 SI In Sound data input

16 CLK In Bit clock input

Key Touch LSI (HG52E35P)

By counting the time between first-key input signal FI and second-key SI from the keyboard unit, the key

touch LSI detects key velocity of 256-step. Then the LSI sends the CPU the note number and its velocity

data.

— 10 —

Page 13

The following table shows the pin functions of the key touch LSI.

Pin No. Terminal In/Out Function

1 REQB Out Interrupt request. Not used.

2, 3 FI10, SI10 In Key input signal

4 VCC In +5V source

5 CRDB In Read enable signal

6 CWRB In Write enable signal

7 CCBB In Chip select signal

8, 9 T, STBY In Not used. Connected to +5V.

10 RESB In Reset signal

11 W In Not used. Connected to +5V.

12 CKI In 10 MHz clock input

13, 14 TMD, TST In Not used. Connected to ground.

15 CKO Out Not used.

16 GND In Ground (0V) source

17 XIN In Not used. Connected to ground.

18 XOUT Out Not used.

19 TRES In Not used. Connected to ground.

20 ~ 23, 25 ~ 28 CD0 ~ CD7 In/Out Data bus

24 GND In Ground (0V) source

29 ~ 31 CR0 ~ CR2 In Address bus

32 VCC In +5V source

33 ~ 39, 41 ~ 43

53 ~ 55, 57 ~ 63

FI0 ~ FI9,

SI0 ~ SI9

In Key input signal

40 VCC In +5V source

44 ~ 47, 49 ~ 52 KC0 ~ KC7 Out Key scan signal

48, 56 GND In Ground (0V) source

64 VCC In +5V source

Filter Block

Since the sound signals from the DAC are stepped waveforms, the filter block is added to smooth the

waveforms.

10V22µ

To main volume

M5218APR

+

-

C104(H)

1K

C182(H)

AG

— 11 —

2SC1740SQ

1K 1K

C152(H)

AG

AVDD

1K

AG

AVEE

10K

10V22µ

From the DAC

Page 14

Power Amplifier (LA4620)

The power amplifier is a two-channel balanced amplifier with standby switch. The following figure shows

the internal diagram of the amplifier.

Internal Diagram of LA4620

Boot11

19

20

21

22

23

1

18

17

15

14

12

OUT11

PoGND1

OUT12

Boot21

VCC1

Boot21

OUT21

PoGND2

OUT22

Boot22

IN11+

IN11-

IN12-

PriGND

IN21+

IN21-

IN22-

3

5

4

6

9

7

8

+

Input

Amp.

-

Input

Amp.

+

Terminal

Protection

Circuit

+

Input

Amp.

-

Input

Amp.

+

Pre-drive

Amp.

RL Short

Protector

Pre-drive

Amp.

Ripple

Filter

Pre-drive

Amp.

RL Short

Protector

Pre-drive

Amp.

Power

Amp.

Power

Amp.

Pop Noise

Prevention

Circuit

Power

Amp.

Power

Amp.

16

NC DC MUTE VCC2 ADJ

2

10

11

13

Power Supply Circuit

The power supply circuit generates six voltages as shown in the following table. VDD voltage is always

generated. The others are controlled by APO signal from the CPU.

Name Voltage For operation of

VDD +5.1V CPU, Reset IC, Gate array, Working strage RAM

DVDD +5.3V DSP, Key touch LSI, Sound source ROM, Effect RAM, DAC

AVDD +5.2V DAC, Filter

LVDD +5.2V LED driver

VCC +12V Pilot lamp

VD +12V Power amplifier

— 12 —

Page 15

Bender

Volume

DVDD

JF3

JE5

JE4

JE3

JE2

JE1

DG

BENDER

JF2

JF1

AG

LMELO OUT

RMELO OUT

RMELO IN

LMELO IN

JG1

LG

JG1

JE5

JE4

JE3

JE2

JE1

WIRING DIAGRAM

M5712-CN1M

JG2

JG3

JG4

JG5

JG6

JG7

JG8

JG9

JG10

JG11

JG12

KO7

PWLD

JG2

JG3

KO6

JG4

KO5

KO4

KO3

KO2

JG5

JG6

JG7

JG8

M5172-MA2M

Main Volume

KO1

JG9

KO0

POWER

JG10

JG11

KI1

JG12

JG13

KI2

JG13

JH1

KI3

JH1

JH2

KI4

JH2

JH3

KI5

JH3

JH4

KI6

JH4

JH5

KI7

JH5

JH6

La

LbLcLd

JH6

JH7

JH7

JH8

JH8

Green

Yellow

JH9

JH9

CD1

CD2

CD3

CD4

CD5

CD6

CD7

CD8

CC1

CC2

CC3

CC4

CC5

CC6

CC7

CC8

JH10

JH11

LeLfLg

JH10

JH11

JH12

JH12

FI1

FI2

FI0

SI0

SI1

SI2

SI3

FI3

KC0

KC1

KC2

KC3

KC4

KC5

KC6

KC7

JH13

Lp

JH13

BK

KC0

CB1

KC1

CB2

KC2

FI7

Blue

Red

FI6

FI5

CB3

CB4

CB5

CB6

CB7

CB8

CA1

CA2

CA3

CA4

CA5

CA6

CA7

CA8

PR

SI7

SI6

W

BL

SI5

KC3

KC4

KC5

FI4

SI4

KC6

KC7

SI5

SI6

SI7

FI5

FI6

FI7

KC7

KC6

A5712-MA1M

PS

R

W

PR

O

FI3

SI3

SI2

SI1

SI0

FI0

FI2

FI1

KC7

KC6

KC5

KC4

KC3

KC2

KC1

KC0

SI4

FI4

KC5

KC4

KC3

KC2

KC1

KC0

CA8

CA7

CA6

CA5

CA4

M615T-KY1M

CA3

CA2

CA1

CB8

CB7

CB6

CB5

CB4

CB3

CB2

CB1

— 13 —

CC8

CC7

CC6

CC5

CC4

CC3

M615T-KY2M

CC2

CC1

CD8

CD7

CD6

CD5

CD4

CD3

CD2

CD1

Page 16

MAJOR WAVEFORMS

— 14 —

Page 17

— 15 —

Page 18

PCB VIEW and MAJOR CHECK POINTS

28 24 25 1922 23 20 18

21

1

— 16 —

9 10 1127 26 29 14 15 16 17 13 12 2 6 3 5 4 7 8

Page 19

Main PCB M5712-MA1M

11.6

0.0

0.0

10.9

0.7

11.6

11.6

0.0

11.4

10.9

5.2

5.9

5.3

5.3

2.6

24

25

2.6

2.6

2.6

2.6

5.2

2.6

2.6

3.2

5.2

2.6

SCHEMATIC DIAGRAMS

23

21

18

19

20

22

3.2

7

5

11.8

11.0

5.8

5.1

1

5.2

3.4

13

12

14 15

16 17

6

4

28

29

0.7

27

5.3

0.0

2

8 9 10 11

26

3

— 17 —

Page 20

Console PCB M5712-CN1M

— 18 —

Page 21

Keyboard PCBs M615T-KY1M, KY2M

— 19 —

Page 22

EXPLODED VIEW

— 20 —

Page 23

IC LEAD IDENTIFICATION AND INTERNAL DIAGRAM

UPD6376CX

VDD

VSS

LRCK

LRSEL/RSI

SI/LSI

CLK

4/8 fs SEL

D.GND

MAIN DAC

13

54

A.GND

SUB DAC

SUB DAC

MAIN DAC

712

A.VDD

14

15

TIMING

16

1

2

GENERATOR

3

N.C.

SHIFT REGISTER

LATCH

D.VDD

11

L.OUT

10

L.REF

R.REF

9

6

R.OUT

8

S8053ANO

2

1

OUT

3

1 2 3

1A

1Y

2A 3

2Y

3A

3Y

GND

TC74HC04AP

1

2

4

5

6

7

14

12

11

10

M5218APR PC900V

VCC

VCC

6A13

8

VCC

67

5

6

-

+

-

6Y

+

GND

5A

12

34

12

5Y

9

4A

4Y

8

GND

45

NC

3

— 21 —

Page 24

Q2: 2SD1762E,F

Q4: 2SB1274

B C E

Q1/6: 2SB1240Q,R

E C B

B C E

Q3, Q5, Q7, Q11/12: 2SC1740SQ

Q13: 2SA933SQ

Q14~21: DTA114TS

E C B

— 22 —

Page 25

PARTS LIST

CTK-750

Notes: 1. Prices and specifications are subject to change with-

out prior notice.

2. As for spare parts order and supply, refer to the

"GUIDEBOOK for Spare parts Supply", published

separately.

3. The numbers in item column correspond to the same

numbers in drawing.

Page 26

FOB Japan

N Item Code No. Parts Name Specification Q M N.R.Yen R *

Unit Price

PCB Ass'y M5712-MA1M

2010 4928 LSI HM65256BLP-10 1 1 720 A H

2011 3325 LSI UPD6376CX 1 1 230 A C

2011 5194 LSI HG52E35P 1 1 600 A F

2011 5201 LSI HG51A115A01FD 1 1 2,820 A T

N 2011 5810 LSI UPD43256AC-85L,10L 1 1 620 A F

N 2011 6867 LSI UPD65005C-578 1 1 220 A C

N 2011 7196 LSI TC5316200CP-C081 1 1 1,230 A N

N 2011 7203 LSI HD6433298A18P 1 1 880 A J

2105 2219 IC S-8053ANO 1 1 60 A B

N 2105 3164 IC HD74HC04P 1 1 28 A A

2114 1421 Photo-coupler PC900V 1 1 210 A C

2114 1799 IC M5218APR 1 1 38 A A

2114 1883 IC LA4620 1 1 350 A D

2250 0441 Transistor 2SA1267Y-AT-T 1 10 9 A A

2251 0140 Transistor 2SB1240Q,R-TV6-T 2 10 10 A A

2251 0672 Transistor 2SB1548-P.CS 1 10 44 A A

2252 0497 Transistor 2SC3199Y-AT-T 5 10 9 A A

2253 0455 Transistor 2SD1762E,F 1 1 47 A A

2259 1883 Digital transistor DTA114TS-TP-T 8 10 10 A A

2360 1729 Zener diode MTZJ5.1AT-77-T 1 10 8 B A

2360 1946 Zener diode MTZJ5.6CT-77-T 1 10 8 B A

N 2360 2254 Zener diode HZS6B2LTD-T 1 10 9 B A

N 2360 2261 Zener diode RD5.1JSB3-T1-T 1 10 9 B A

2390 0371 Diode DSK10B-BT-T 3 10 11 C A

2390 1323 Diode RB100A-T32-T 1 10 29 C A

2390 1344 Diode 1SS133T-77-T 5 20 3 C A

2390 1463 Schottky diode SB20-03B 1 5 39 C A

2590 1519 Crystal oscillator HC-49U16384 1 1 100 B B

N 2590 1547 Ceramic oscillator EFO-EC2005C4 1 5 64 B B

2606 1141 Carbon film resistor R-20-1K-J-T23-T 16 20 2 C A

2606 1148 Carbon film resistor R-20-220-J-T23-T 4 20 2 C A

2606 1155 Carbon film resistor R-20-330-J-T23-T 1 20 2 C A

2606 1162 Carbon film resistor R-20-10-J-T23-T 5 20 2 C A

2606 1169 Carbon film resistor R-20-100-J-T23-T 33 20 2 C A

2606 1176 Carbon film resistor R-20-100K-J-T23-T 9 20 2 C A

2606 1183 Carbon film resistor R-20-10K-J-T23-T 7 20 2 C A

2606 1197 Carbon film resistor R-20-22-J-T23-T 8 20 2 C A

2606 1232 Carbon film resistor R-20-82-J-T23-T 2 20 2 C A

2606 1253 Carbon film resistor R-20-4.7K-J-T23-T 2 20 2 C A

2606 1302 Carbon film resistor R-20-270-J-T23-T 1 20 2 C A

2606 1309 Carbon film resistor R-20-470-J-T23-T 36 20 2 C A

2606 1323 Carbon film resistor R-20-56K-J-T23-T 22 20 2 C A

2606 1330 Carbon film resistor R-20-68K-J-T23-T 1 20 2 C A

2606 1337 Carbon film resistor R-20-1M-J-T23-T 1 20 2 C A

2606 1358 Carbon film resistor R-20-3.3K-J-T23-T 3 20 2 C A

2606 1372 Carbon film resistor R-20-33K-J-T23-T 11 20 2 C A

2606 1428 Carbon film resistor R-20-5.6K-J-T23-T 2 20 2 C A

2606 1435 Carbon film resistor R-20-560-J-T23-T 1 20 2 C A

2606 1491 Carbon film resistor R-20-6.8K-J-T23-T 1 20 2 C A

2606 1694 Carbon film resistor R-20-68-J-T23-T 2 20 2 C A

2606 1708 Carbon film resistor R-20-47-J-T23-T 4 20 2 C A

N 2606 1722 Carbon film resistor R-20-2.2-J-T23-T 4 20 2 C A

N 2606 1757 Carbon film resistor R-20-6.8-J-T23-T 4 20 2 C A

2800 9091 Electrolytic capacitor 25RE2-220-T2-T 1 10 33 C A

Notes: N – New parts

M – Minimum order/supply quantity

R – Rank

— 23 —

Page 27

FOB Japan

N Item Code No. Parts Name Specification Q M N.R.Yen R *

Unit Price

2802 9231 Electrolytic capacitor 25RE3-2200-S1 2 10 75 C A

N 2803 6743 Electrolytic capacitor 50RBP2-R22-T2-T 2 20 16 C A

N 2803 6750 Electrolytic capacitor 50RBP2-R33-T2-T 2 20 16 C A

N 2803 6757 Electrolytic capacitor 50RBP2-4R7-T2-T 2 20 18 C A

2805 3061 Electrolytic capacitor 6.3RE2-220-T2-T 1 10 26 C A

2805 3134 Electrolytic capacitor 10RE2-22-T2-T 10 20 14 C A

2805 3142 Electrolytic capacitor 16RE2-10-T2-T 2 20 14 C A

2807 1015 Electrolytic capacitor 16RE2-47-T2-T 2 10 20 C A

2807 1040 Electrolytic capacitor 6.3RE2-470-T2-T 3 10 27 C A

2807 1082 Electrolytic capacitor 16RE2-100-T2-T 8 10 27 C A

2807 1091 Electrolytic capacitor 6.3RE2-100-T2-T 6 20 18 C A

2813 1722 Semiconductive capacitor DD407SR104K16-T 2 20 9 C A

2813 2597 Ceramic capacitor RT-HE40TKCH080D-T 1 20 5 C A

2813 3283 Ceramic capacitor UP050F104Z-A-B 22 20 8 C A

N 2813 3381 Semiconductive capacitor DD404SR152K16-T 2 20 5 C A

N 2813 3388 Semiconductive capacitor DD404SR182K16-T 2 20 5 C A

2818 0446 Ceramic capacitor RT-HE40TKYB101K-T 22 20 4 C A

2818 3275 Ceramic capacitor RT-HE40TKCH220J-T 2 20 5 C A

2830 6229 Mylar capacitor AMZV-104K50-T 6 10 13 C A

2845 0168 Module capacitor CNB8X101K 3 5 58 C B

2845 3213 Three-polarity capacitor EXC-ECT223ZVT-T 2 10 14 C A

2845 3220 Ferrite beads EXC-ELDR35V-T 20 10 12 C A

3025 0826 EMI filter EXC-EMT222DT-T 3 10 21 C A

3501 4816 DIN jack YKF51-5051 1 1 110 C A

3501 5012 DC jack HEC2305-01-920 1 10 25 A A

3501 7651 Connector S8B-PH-K-E 1 10 25 C A

3501 7658 Connector S8B-PH-K-M 1 10 25 C A

3501 7665 Connector S8B-PH-K-R 1 10 25 C A

3501 7672 Connector S8B-PH-K-Y 1 10 25 C A

3612 0711 Miniature jack YKB21-5101 1 5 90 B A

3612 0789 Jack YKB21-5010 1 5 60 B B

3719 2695 Heat sink OSH2742-L25-SP 1 1 150 C B

3719 4032 Heat sink UOT-10CS25-SPL 1 5 65 C B

3841 0539 Inductor ELE-V100KR-T 2 20 26 C A

3841 0819 Common mode coil PLT09H-2003R 1 1 140 C B

N 4317 4242 Blank PCB M5712-MA1M M211741B-1 1 1 700 C G

N 6922 4200 PCB ass'y M5712-MA1M M211743*1 1 1 11,110 B CC

PCB Ass'y M5712-MA2M

2765 1211 Slide volume EWA-MJCC20B23 1 1 110 A B

N JE 3719 4214 Ribbon cable M712B DF5H05070-8000M 1 20 16 C A

N 4317 4262 Blank PCB M5712-MA2M M211741B-2 1 5 8 C A

N 6922 4230 PCB ass'Y M5712-MA2M M312162*1 1 1 360 C D

PCB Ass'y M5712-CN1M

2114 3318 IC BA612 1 5 98 A B

2370 0343 LED LN28RPX-(TT) 15 20 16 C A

2370 0952 LED LB-603VP1 1 1 240 C C

2370 0959 LED LN882RPX-(TT) 2 20 27 C A

2390 1344 Diode 1SS133T-77-T 53 20 3 C A

N JH/JG 3719 4207 Ribbon cable M712A DF5H13130-8000M 2 10 36 C A

N 4317 4250 Blank PCB M5712-CN1M M211742-1 1 1 420 C D

N 6922 4220 PCB ass'y M5712-CN1M M211744*1 1 1 1,690 B P

PCB Ass'y M615T-KY1M

2301 0101 Diode M111224-1 64 1 8 C A

CA 3501 7588 8P connector MHTRASKA DS-8P-46-MHTRASKA 1 1 110 C B

CB 3501 7595 8P connector MHTRASKB DS-8P-46-MHTRASKB 1 1 130 C B

Notes: N – New parts

M – Minimum order/supply quantity

R – Rank

— 24 —

Page 28

FOB Japan

N Item Code No. Parts Name Specification Q M N.R.Yen R *

Unit Price

3637 5220 Ferrite core ZCAT2032-0930 1 1 170 C B

4317 3820 Blank PCB M615T-KY1M M111575-1 1 1 260 C C

6921 8590 PCB ass'y M615T-KY1M M111608*1 1 1 870 B I

6921 9460 Sponge 60x400 M412219-1 1 10 50 C A

PCB Ass'y M615T-KY2M

2301 0101 Diode 1S2473T-77-T 58 20 8 C A

CC 3501 7602 8P connector MHTRASKD DS-8P-48-MHTRASKC 1 1 110 C B

CD 3501 7609 8P connector MHTRASKD DS-8P-48-MHTRASKD 1 1 110 C B

3637 5220 Ferrite core ZCAT2032-0930 1 1 170 C B

4317 3830 Blank PCB M615T-KY2M M111576-1 1 1 210 C C

6921 8600 PCB ass'y M615T-KY2M M111609*1 1 1 850 B I

6921 9460 Sponge 60x400 M412219-1 1 10 50 C A

Keyboard

1 6920 7581 TR white key set CEGB M111223A-1 5 1 180 C C

2 6920 7591 TR white key set DFAS M111222A-1 1 1 180 C C

3 6920 7601 TR white key set DFA M111221A-1 4 1 160 C B

4 6920 7611 TR black key set 10P M111220A-1 2 1 230 C C

5 6920 7621 TR black key set 5P M111220A-2 1 1 150 C B

6 6920 7560 PET-TAC-TR29 M111224-1 1 1 350 C D

7 6920 7570 PET-TAC-TR32 M111225-1 1 1 370 C D

8 6921 8610 KB chassis HTRASK61GD M111547-1 1 1 650 C G

9 6921 8621 Upper stopper HTRASK M412168A-1 1 1 130 C B

10 6921 8631 Lower stopper HTRASK M412169A-1 1 1 110 C B

Bender

2765 1141 Volume RK1631110-50KB 1 1 190 C C

N 11 3719 4270 Ribbon cable M712D DF0H03390-35353535 1 10 29 C A

12 6909 2170 Bender knob M31488-2 1 10 47 C A

6911 5241 Bender chassis A M31487A-1 1 10 45 C A

6911 5250 Bender chassis B M41946-1 1 10 16 C A

6911 5260 Bender spring M41949-1 1 10 15 C A

6911 5390 Felt 152A M42037-1 1 10 8 C A

6921 0550 Felt 5X13 M412026-1 2 20 6 C A

N 6922 4760 Felt D M4382-4 1 20 6 C A

Upper Case

N 13 6922 4301 Upper case sub ass'y M111786A*1 1 1 2,710 C T

14 6921 5040 Slide volume knob 601 M311860-1 1 10 13 B A

N 15 6922 4270 Panel 712 M312134-1 1 1 120 C B

N 16 3831 0672 Speaker 12G30BFB 2 1 330 B D

N 17 6922 4310 Rubber button 712A M312131-1 1 1 130 B B

N 18 6922 4320 Rubber button 712B M312132-1 1 1 70 B B

19 6922 2660 Rubber button 710C M312088-1 1 1 97 B B

20 6922 2680 Rubber button 710D M312082-2 5 10 29 B A

21 6922 3830 Rubber button 711A M312122-1 1 10 31 B A

22 6922 3840 Rubber button 711B M312123-1 1 10 32 B A

23 6922 3860 Rubber button 711F M211727-1 1 1 130 B B

24 6922 3870 Rubber button 711D M312125-1 1 5 72 B B

25 6922 3880 Rubber button 711D M312125-2 1 5 73 B B

26 6922 3890 Rubber button 711E M312126-1 1 5 73 B B

N 3035 0315 Ferrite core BP59RB140070N0M 2 10 39 C A

3719 2422 Ribbon cable M288S DF5H02260-35353535 1 20 23 C A

3719 4046 Ribbon cable M584R DF0H02300-35353535 1 20 20 C A

N 6922 5420 Sponge 42X68 M411740-2 2 20 22 C A

6910 9170 Sponge 84 M41661-1 2 20 14 C A

Lower Case

N 27 6922 4281 Lower case sub ass'y M111787A*1 1 1 1,820 C Q

Notes: N – New parts

M – Minimum order/supply quantity

R – Rank

— 25 —

Page 29

FOB Japan

N Item Code No. Parts Name Specification Q M N.R.Yen R *

Unit Price

27-1 6902 6140 Battery spring 90 M41226-1 1 10 27 B A

27-2 6903 2150 Battery spring B M41330-1 1 10 18 B A

27-3 6919 3190 Key damper 61 M411615-1 1 5 55 B A

6917 9300 Rubber foot M41109-3 5 20 6 C A

6920 2290 Clip CS-3 2 20 9 C A

N 6921 5490 Sponge 425X54 M412141-1 1 10 44 C A

N 28 6922 4290 Packing 845X22 M412281-2 2 5 65 C B

N 29 6918 1634 Battery cover sub ass'y M311164D*1 1 1 200 B C

Screws

30 0009 2680 Screw 4 x 8 10 50 2 C A

31 0009 2682 Screw 2.6 x 8 20 50 2 C A

32 5111 2571 Screw 3 x 8 8 50 2 C A

33 0009 5791 Screw 3 x 20 15 50 2 C A

34 6919 0420 Screw 3 x 8 6 50 2 C A

35 0009 6417 Screw 4 x 10 20 50 2 C A

36 5111 2679 Screw 3 x 8 38 50 2 C A

37 0009 2698 Screw 3 x 14 16 50 2 C A

Accessory

6920 8691 Music stand 590 M311760A-1 1 1 130 C B

Notes: N – New parts

M – Minimum order/supply quantity

R – Rank

— 26 —

Page 30

MA0300941A

Loading...

Loading...